Page 1

Walk Behind Lawn Mower

Owner/Operator & Parts Manual

Model

907254 - LM21SW

01185100 12/99

Printed in USA

Page 2

Page 3

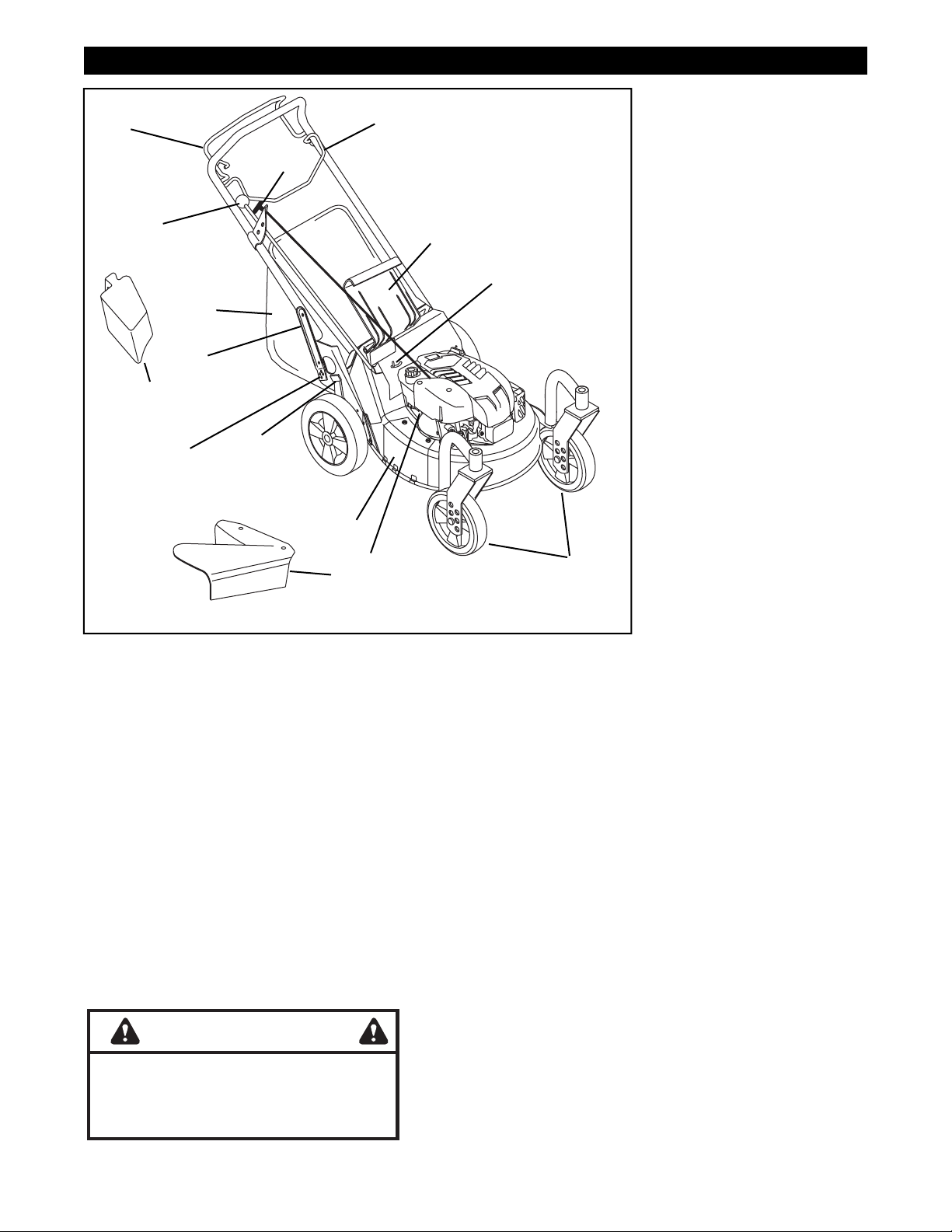

CONTROLS AND FEATURES

FRANÇAIS

11

12

1

10

2

9

8

13

6

4

3

5

7

14

15

OM0690

Figure 1

ENGLISH

1. Engine Control

2. Speed Selector (Selfpropelled)

3. Primer (Briggs Engine)

4. Side Discharge Cover

5. Side Discharge Deflector

6. Cutting Height Levers (2

Rear Wheel Adjusters, 2

Front Wheel Adjusters)

7. Rear Door

8. Adjustable and Folding

Handlebars

9. Grass Bag

10. Recoil

11. Wheel Drive Control

12. Mulch Plug

13. Handlebar Adjustment

Holes

14. Speed Indicator (Selfpropelled)

1. Commande moteur

2. Sélecteur de vitesse

3. Poire d’amorçage

4. Plaque de fermeture

latétale

5. Déflecteur de décharge

latérale

6. Leviers de hauteur de

coupe (réglage par les

roues)

7. Trappe arrière

8. Guidon réglable et pliable

9. Sac à herbe

10. Poignée du démarreur

manuel

11. Commande de

l’entraînement des roues

12. Déflecteur à paillis Mulch

13. Trous de réglage du

guidon

14. Indicateur de vitesse

ESPAÑOL

1. Control del motor

2. Selector de velocidad

3. Cebador

4. Cubierta de la descarga

lateral

5. Deflector de la descarga

lateral

6. Palancas de la altura de

corte (ajustadores de la

rueda)

7. Puerta trasera

8. Manillares ajustables y

plegables

9. Bolsa de recolección del

césped

10. Manilla de arranque de

retroceso

11. Control de la transmisión

de la rueda

12. Tapón Mulch

13. Agujeros para el ajuste

del manillar

14. Indicador de velocidad

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

OL4030

3

Page 4

4 5

Page 5

E

TABLE OF CONTENTS

NGLISH

Controls and Features. . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION

THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

All reference to left, right, front, or rear are given from

the operation position, facing the direction of forward

travel.

SERVICE AND REPLACEMENT PARTS

When ordering replacement parts or making service

inquiries, know the Model and Serial numbers of your

unit and engine.

Numbers are located on the product registration form

in the unit literature package. They are also printed on

a serial number label, located on the frame of your unit

(Figure 2).

• Record Unit Model and Serial numbers here.

• Record Engine Model and Serial numbers here.

Service and Adjustments . . . . . . . . . . . . . . . . 18

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 21

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PRODUCT REGISTRATION

A warranty card must be filled out, signed, and returned

at time of purchase. This card activates the warranty.

Claims meeting requirements during limited warranty

period will be honored.

UNAUTHORIZED REPLACEMENT PARTS

Use only Ariens replacement parts. The replacement of

any part on this vehicle with anything other than an

Ariens authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Scotts and Ariens disclaim

liability for any claims or damages, whether warranty,

property damage, personal injury or death arising out of

the use of unauthorized replacement parts.

DELIVERY

Customer Note: If you have purchased this product

without complete assembly and instruction by your

retailer, it is your responsibility to:

• Read and understand all assembly instructions in

this manual. If you do not understand or have

difficulty following the instructions, contact your

nearest Ariens Dealer for assistance. To locate

your nearest Ariens Dealer, call 1-877-466-0812.

Serial Number

Label

Figure 2

OM0650

WARNING: Improper assembly or

adjustments can cause serious injury.

• Do not operate the unit unless all controls

function as described in this manual. Before

attempting to operate your unit:

1. Make sure all assembly has been properly

completed.

2. Understand all Safety Precautions provided in

the manuals.

3. Review control functions and operation of the

unit.

4. Review recommended lubrications,

maintenance and adjustments.

5. Review Limited Warranty Policy.

6. Fill out Original Purchaser Registration Card

and return the card to Ariens Company.

Page 6

DISCLAIMER

This product has been manufactured by Ariens. Scotts

and Ariens reserve the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligation. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

SAFETY

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper oper-

ation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

6

Page 7

OL3030

OL4530

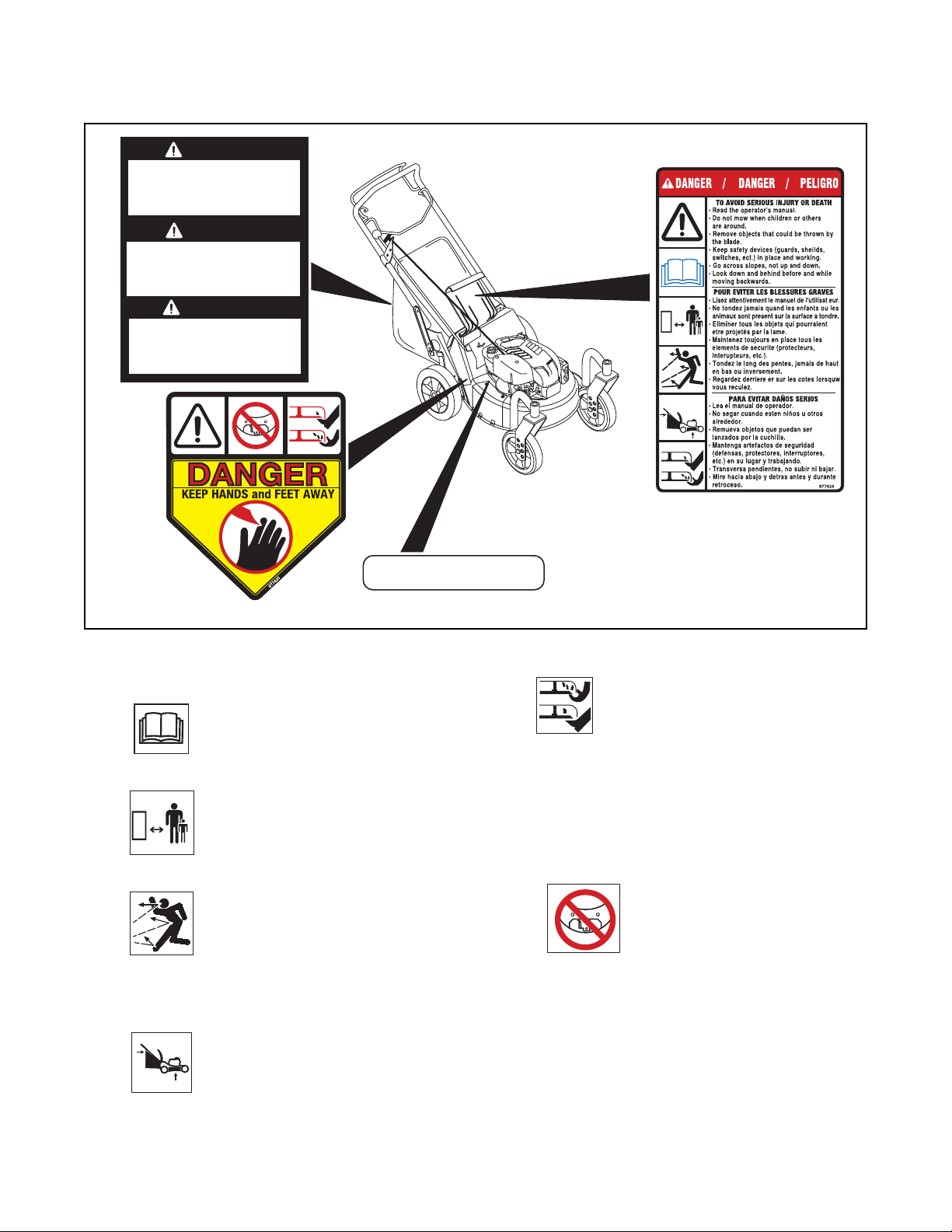

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals.

Refer to Figure 3 for Safety Decal locations.

CAUTION

BAG IS SUBJECT TO WEAR AND

•

DETERIORATION.

CHECK BAG FEQUENTLY, REPLACE WHEN

•

NECESSARY.

USE ORIGINAL BAG TO COMPLY WITH SAFETY

•

SPECIFICATIONS.

PRECAUCION

LA BOLSA ESTA SUJETA A DESGASTE Y

•

DETERIORO.

REVISAR LA BOLSA FREQUENTAMENTE,

•

Y REEPLAZARLA SI ES NECESARIO.

USAR BOLSAS ORIGINAL PARA CUMPLIR CON

•

LAS ESPECIFICACIONES DE SEGURIDAD.

ATTENTION

LE SAC EST SOUMIS À L’USURE ET A LÀ

•

DÉTÉRIORATION.

VÉRIFIER LE SAC FRÉQUEMMENT. LE

•

REMPLACER AU BESOIN.

UTILISER UN BAC D’ORIGINE CONFORME

•

AUX NORME DE SECURITE.

3

1

1. DANGER

TO AVOID SERIOUS INJURY OR DEATH

OL1801

OL4370

OL0910

OL4540

2

MEETS C.P.S.C. BLADE

SAFETY REQUIREMENTS

Before operating unit, completely read

and understand all manuals provided.

Keep people and pets away when

operating unit. Keep children out of

the work area and under the watchful

care of a responsible adult.

Always stand clear of discharge area.

DO NOT direct discharge toward

other people. Remove objects that

could be thrown by the blade. DO

NOT operate mower over gravel and

hard surfaces.

DO NOT operate mower unless

guards are in operating position.

Figure 3

OM0660

ROTATING BLADE! Keep hands and

feet away.

• Go across slopes, not up and down.

• Look down and behind before and while moving

backwards.

2. DANGER

KEEP HANDS AND FEET AWAY

• Do not operate mower unless

guards are in operating position.

3. CAUTION!

• Bag is subject to wear and deterioration.

• Check bag frequently, replace when necessary.

• Use original bag to comply with safety

specifications.

7

Page 8

SAFETY RULES

Operational

Inspect unit and work area before operation.

Clear work area of objects which might be picked up

and thrown. Remove all stones, sticks, wires, and other

foreign objects. Tall grass can hide obstacles.

Only Trained Adults may operate unit. Training includes

actual operation.

Keep equipment in good condition.

ALWAYS keep discharge cover in place.

NEVER operate the engine with the Rear Door open

unless the Grass Bag is in place.

When mulching, the Side Discharge Opening Cover

must be installed and the Rear Door fully closed

whenever the engine is operating.

DO NOT pull mower backwards unless absolutely

necessary. Look down and back before and while

moving backwards.

DO NOT start the engine or operate mower unless

either the Side Discharge Opening Cover or the Side

Discharge Deflector is installed.

Keep the area of operation clear of all persons, children

and pets.

ALWAYS clear area before operation to avoid thrown

objects.

Stop mower if anyone enters the area.

Keep safety devices or guards in place and functioning

properly. NEVER modify or remove safety devices.

ALWAYS keep hands away from all rotating parts

during operation.

Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening and mower pan at

all times. NEVER open the Rear Door without the

Grass Bag in place when the engine is operating.

ALWAYS keep feet and hands away from all rotating

parts during operation. Rotating parts can cut off body

parts.

DO NOT mow at too fast a rate. DO NOT change

engine governor setting or over-speed the engine.

ALWAYS operate unit when there is good visibility and

light.

Use extra care when approaching blind corners,

shrubs, trees, or other objects which may obscure

vision.

ALWAYS be sure of your footing.

Do not operate mower in wet grass. Always be sure of

your footing. Keep a firm hold on handlebar. Walk,

never run.

If equipment vibrates abnormally, stop engine at once,

wait for moving parts to stop and remove wire from

spark plug. Repair any damage before restarting unit.

Avoid uneven work areas and any rough terrain.

Be familiar with area of operation. Stay alert for holes,

rocks, roots, and hidden hazards in area of operation.

Keep away from drop-offs, ditches or embankments.

Operator could lose footing or balance.

DO NOT operate on steep slopes.

NEVER leave unit unattended on a slope. Chock

wheels if parking on a slope.

Mow across the face of slopes, never up and down. Be

especially cautious when changing direction on slopes.

Remove the key when parking.

Take all possible precautions when leaving unit

unattended.

ALWAYS shut off engine and remove spark plug wire to

prevent accidental starting or unauthorized use.

Personal

Keep children out of work area and under the watchful

care of an adult.

NEVER allow children to operate mower.

Turn the mower off if children enter the area.

NEVER direct discharge toward bystanders. The

operator is responsible for the safety of bystanders.

Wear adequate safety gear, protective gloves and

footwear.

Wear sturdy footwear. DO NOT operate mower

barefoot or when wearing open sandals or canvas

shoes.

Always wear safety goggles or safety glasses with side

shields when operating mower.

NEVER wear loose clothing, jewelry or long hair that

may get caught in rotating parts. Protect eyes, face and

head from objects that may be thrown from unit.

NEVER operate after or during the use of medication,

drugs or alcohol. Complete and unimpaired attention is

required when operating unit.

ALWAYS stand clear of discharge when operating unit.

Do not operate mower on gravel or on loose material

such as sand. Stop mower when crossing gravel

drives, walks, or roads. Objects may be picked up and

thrown, causing damage or injury.

DO NOT touch parts which are hot. Allow parts to cool.

Moving parts can cut or amputate fingers or a hand.

Wrap blade(s) or wear gloves to service.

ALWAYS keep hands away from all pinch points.

Fumes from the engine exhaust can cause death or

serious injury. DO NOT run engine in an enclosed

area.

8

Page 9

Service and Adjustments

NEVER attempt to make any adjustments to unit while

engine is running. Stop engine and wait for all moving

parts to stop before servicing (except where

specifically recommended).

DO NOT make cutting height wheel adjustments while

the engine is running.

On self-propelled models, the wheel drive control will

cause the forward movement of the mower to stop. If

this feature fails to operate, disconnect spark plug wire

and repair before using unit. Wheel drive must be

disengaged when starting engine.

Fuel is highly flammable and its vapors can explode.

ONLY use approved fuel containers.

• NO Smoking!

• NO Sparks!

• NO Flames!

• Allow engine to cool before filling fuel tank.

Check fuel supply before starting engine.

DO NOT fill gasoline tank indoors, when engine is

running, or while engine is still hot.

Allow engine to cool several minutes before removing

fuel cap.

Replace gasoline tank cap securely and clean up any

spilled fuel before starting engine.

Stop engine, wait for moving parts to stop, remove

ignition wire and secure away from spark plug before

attempting to: unclog, repair, adjust, inspect or clean

unit.

To reduce fire hazard and overheating, keep equipment

free of grass, leaves, debris or excessive lubricants.

Maintenance

Follow engine manufacturer’s safety instructions when

servicing engine.

Keep all nuts, bolts, and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals, especially blade

attachment bolts.

Use only replacement parts designed for your unit. See

your Ariens Dealer.

Worn out mufflers are more than just a noise nuisance

and should be replaced immediately. Continued use

could result in fire or explosion.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Check grass bag for wear, damage, and/or

deterioration. Replace only with Ariens original

equipment replacement part for safety.

Storage

Allow engine to cool before storing in any enclosure.

Refer to Storage Section of this Owner’s Manual for

important instructions if unit is to be stored for

extended periods.

ALWAYS clean unit before extended storage. See

engine manual for proper storage.

DO NOT store unit inside a building with fuel in the fuel

tank where any ignition sources are present.

Safety Interlock System

Engine/Blade Control feature on mower will cause

engine and blade to stop whenever operator releases

control on handlebar. If feature fails to operate,

disconnect spark plug wire and adjust or have it

repaired before using unit.

Accessories

Use only accessories which have been approved by

Ariens and are properly installed.

Spark Arrestor

This product is equipped with an internal combustion

engine. DO NOT use on or near any unimproved, forest

or brush covered land unless the exhaust system is

equipped with a spark arrestor meeting applicable

local, state or federal laws. A spark arrestor, if used,

must be maintained in effective working order by the

operator. See your Ariens Dealer or engine

manufacturer’s service center.

9

Page 10

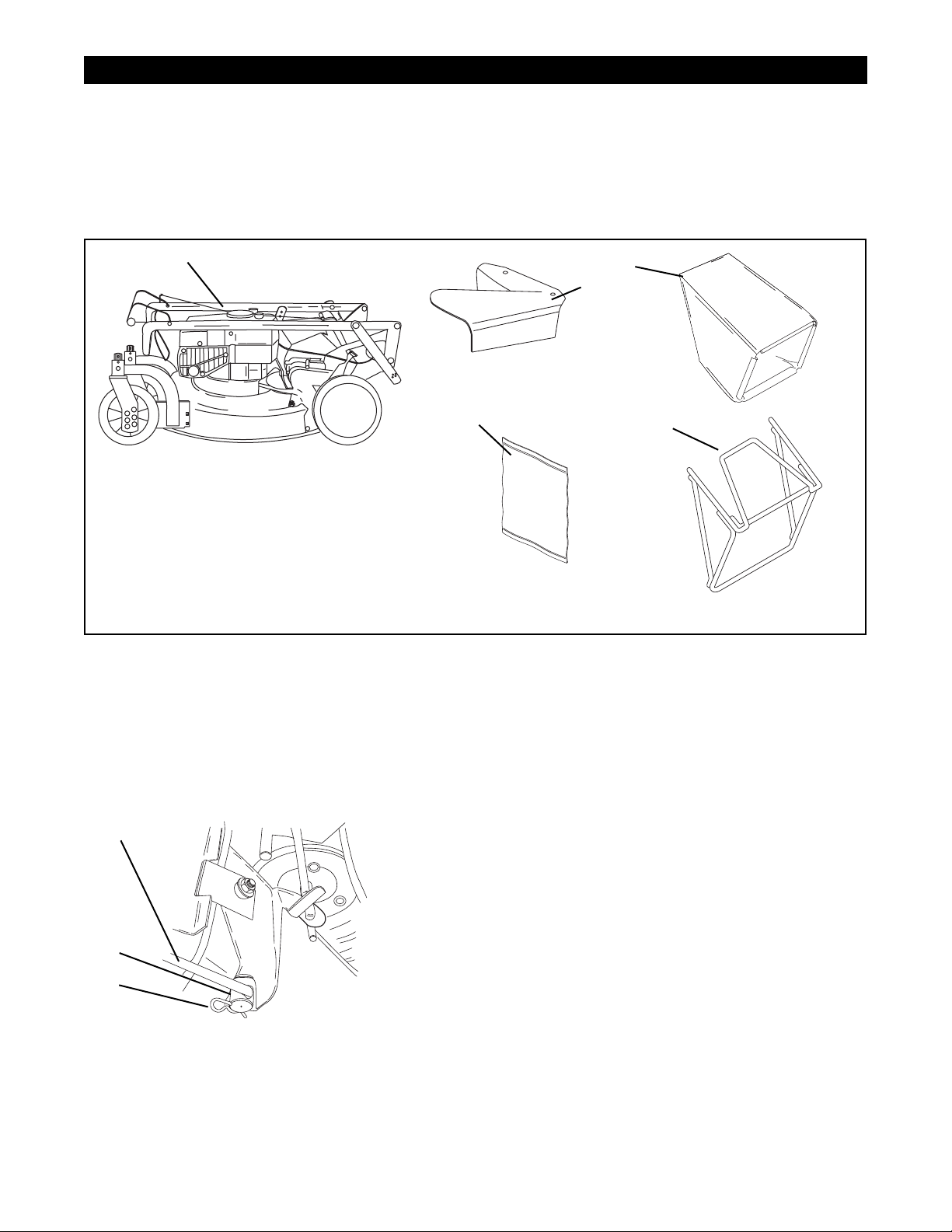

TO REMOVE UNIT FROM CARTON

1. Cut off top of carton.

2. Remove front and rear inserts and literature pack.

3. Cut out back of carton and roll unit out.

4. Remove protective packaging materials.

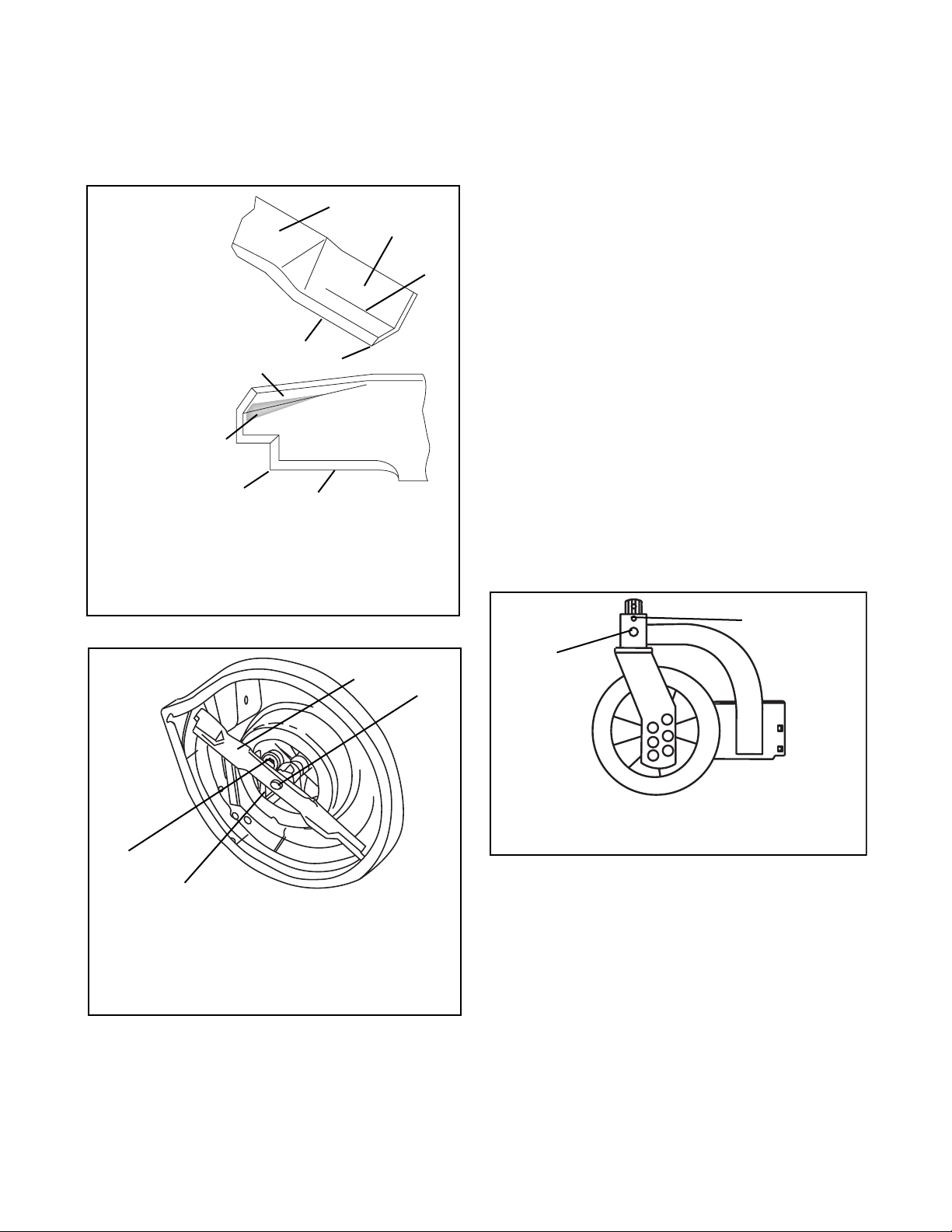

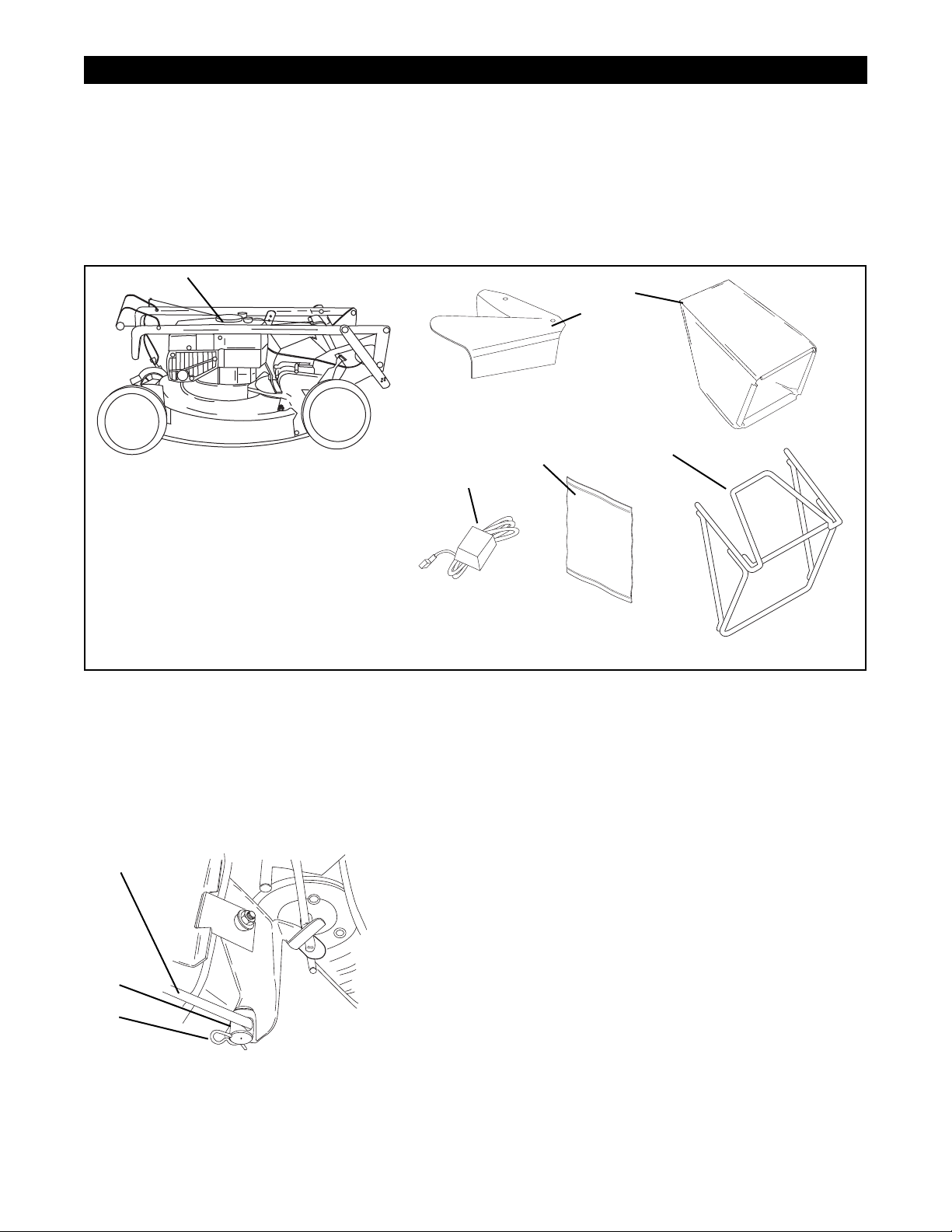

ASSEMBLY

1

OM0700

1. Mower Unit

2. Discharge Chute

3. Grass Bag

4. Grass Bag Frame

5. Literature Pack

ASSEMBLY

1. Unfold and adjust handlebar.

2. The Speed Selector rod is shipped on the

handlebar with hardware in position. Remove hair

pin, insert bent end of rod through hole in swivel

of speed control bell crank, and retain with hair

pin.

5

Figure 4

3

2

OM0340

OM0320

4

Literature

Pack

OM0350

OM0330

3. Assemble grass bag onto bag frame.

4. Configure mower for bagging, side discharge or

mulching. See Mower Configurations in

Operation Section.

5. Check the Engine/Blade Control feature. Engine

and blade must stop within 3 seconds whenever

control handlebar is released.

6. Fill fuel tank. See Operation Section.

1

3

2

1. Speed Selector Rod

2. Hair pin

3. Speed Control Bell

Crank

OM0300

Figure 5

10

Page 11

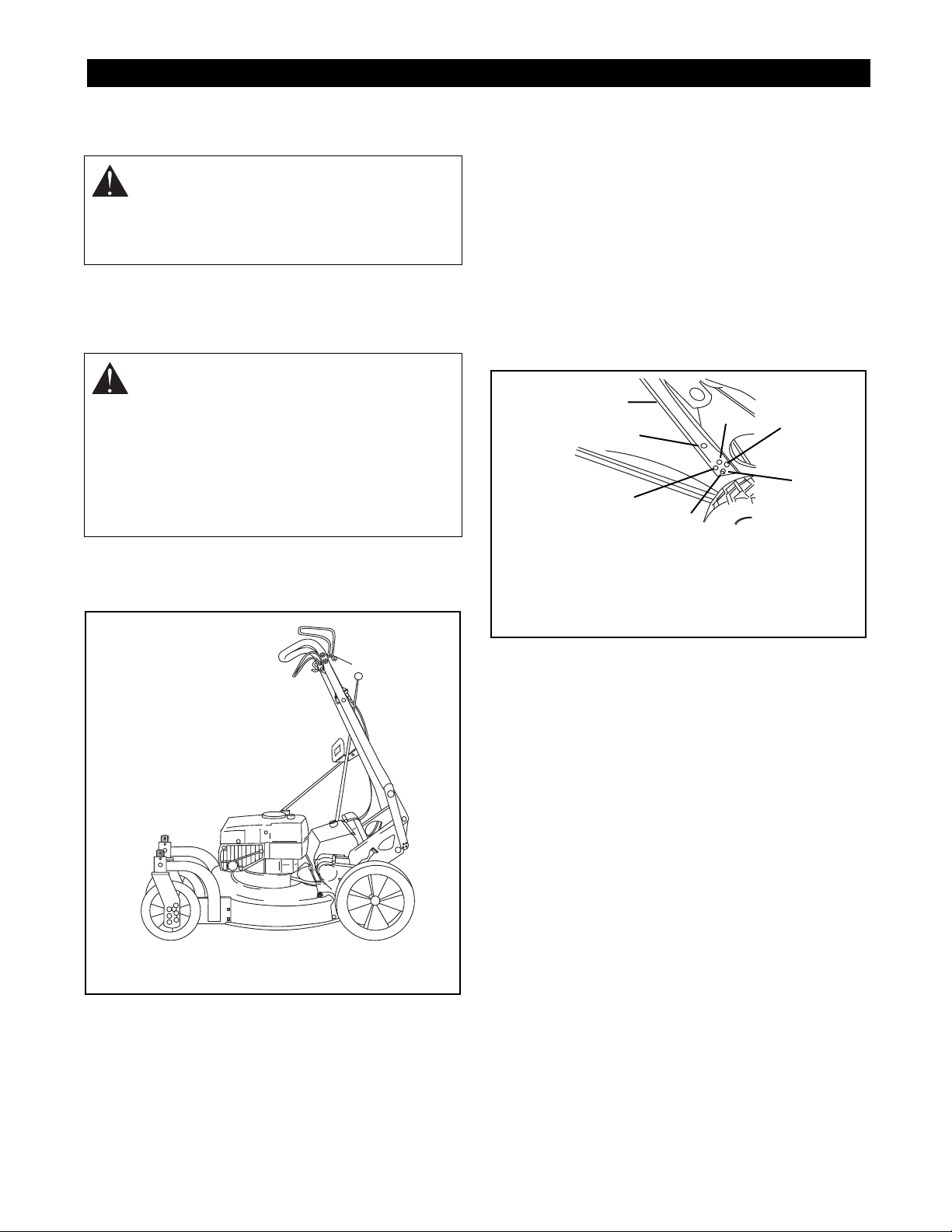

OPERATION

CONTROLS AND FEATURES

See Figures 1 and 6 for Controls and Features.

Engine/Blade Control

WARNING: DO NOT attempt to start your

engine at this time. Familiarize yourself with

controls to see what they do and how they

work. Thoroughly read and understand entire

Operators Manual first.

CAUTION: Check function of Engine/Blade

Control regularly. Improper function of control

could cause injury.

The Engine Control must be held

against the handlebar in order to start

the engine as well as during mowing

operations to keep the engine running.

Releasing the control during operation stops the

engine and blade.

Handlebar

Handlebar adjusts to four positions by selecting holes

in braces. Select a safe, comfortable height and place

pin through hole in brace that is closest to that height.

Refer to Adjustment Section for instructions.

Recoil Starter Handle

When pulled, handle will turn engine over.

OM0450

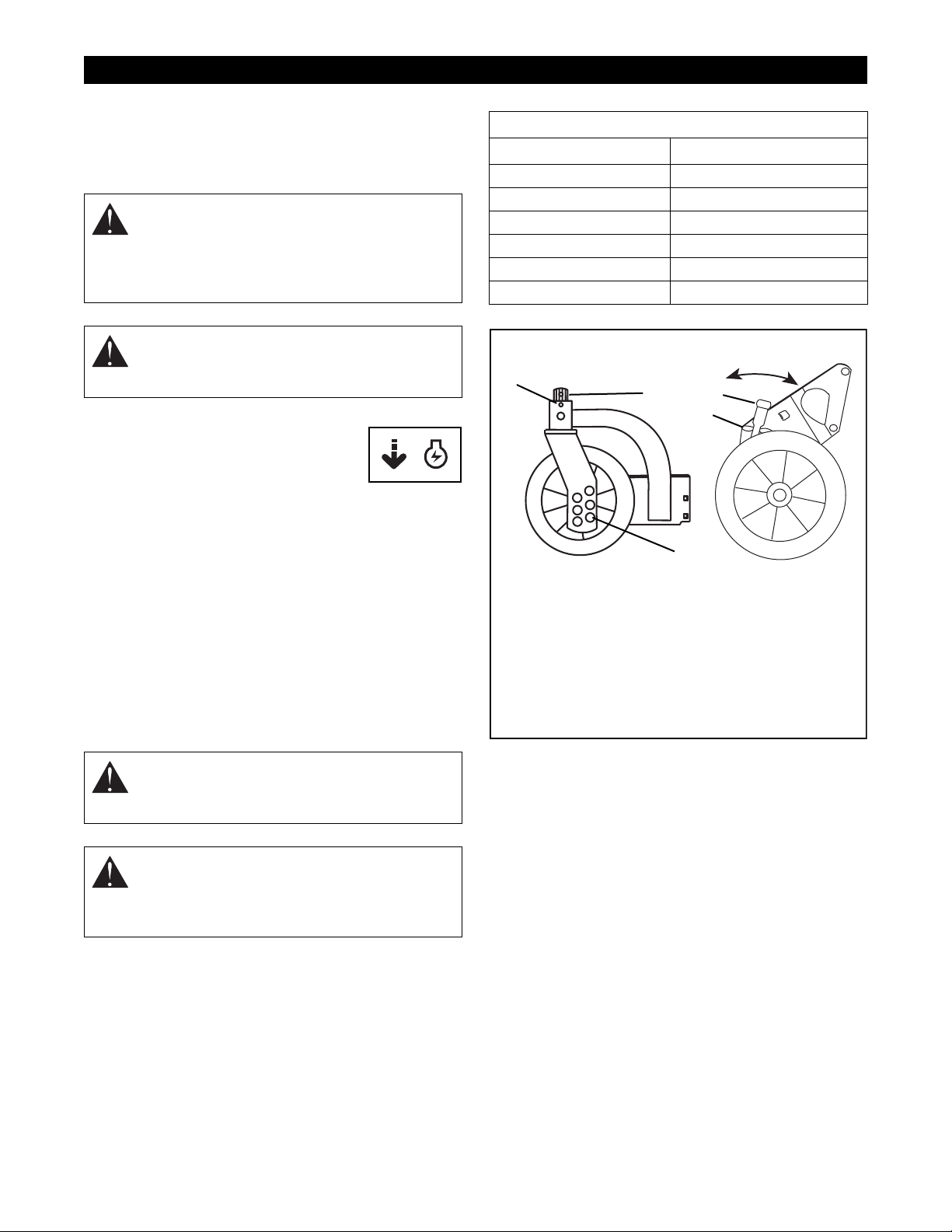

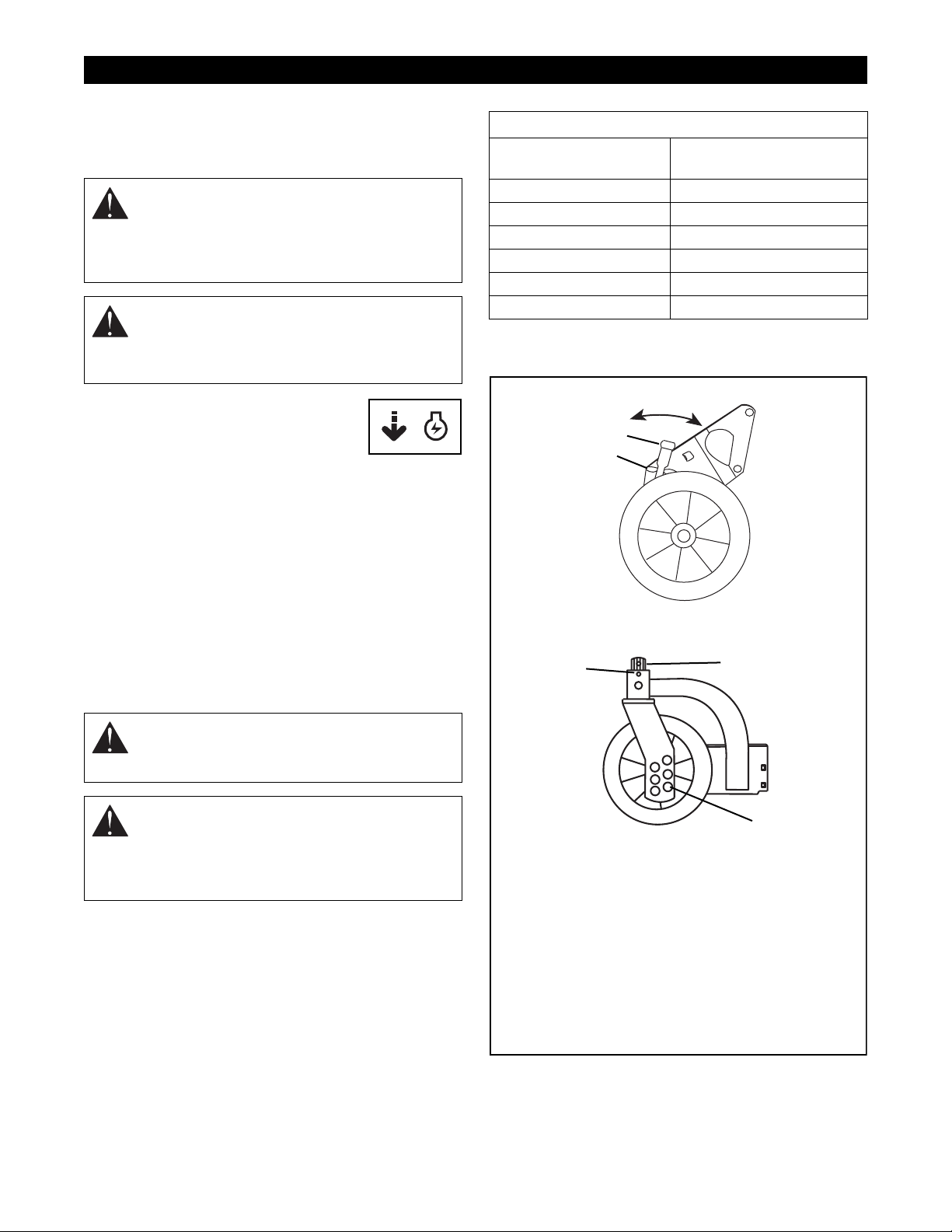

Cutting Height Settings Chart

Notch Cut grass length

LOW

2

3

4

5

HIGH

4

5

3

Front Swivel

OM0180

1. Cutting Height Lever

2. Notches

3. Clevis Pin & Swivel Height Adjustment Holes

4. Swivel Lock Hole (Swivel Locked)

5. Linchpin Storage Hole (Free)

1" (25 mm)

1-3/8" (35 mm)

1-3/4" (45 mm)

2-1/4" (57 mm)

2-3/4" (70 mm)

3-1/4" (83 mm)

Low

1

2

High

Rear

OM0190

Cutting Height – Standard Models

DANGER: To avoid inadvertent blade contact,

NEVER attempt to make any cutting height

adjustment while engine is running.

CAUTION: On self-propelled models, both

rear wheels must be positioned at same

height or traction drive may not clutch or

operate properly.

To change cutting height, move cutting height levers

one notch at a time on each wheel until desired height

of cut is obtained. (Figure 6)

NOTE: Each Wheel on mower must be set at the same

height for a level cut.

Figure 6

11

Page 12

OPTIONAL CONTROLS

See Figures 1 and 6.

Cutting Height – Swivel Models

CAUTION: On swivel wheel models, when

mowing on slopes it is recommended that the

linchpin be positioned through the swivel lock

hole. If wheels are in the swivel position and

control handles are released the mower may

“free roll” downhill. Never mow on steep

slopes.

To change front wheel cutting height, insert clevis pin

into the holes that correspond to the desired cutting

height. (Figure 6).

To change rear wheel cutting height, move cutting

height levers one notch at a time until the desired

cutting height is obtained. (Figure 6).

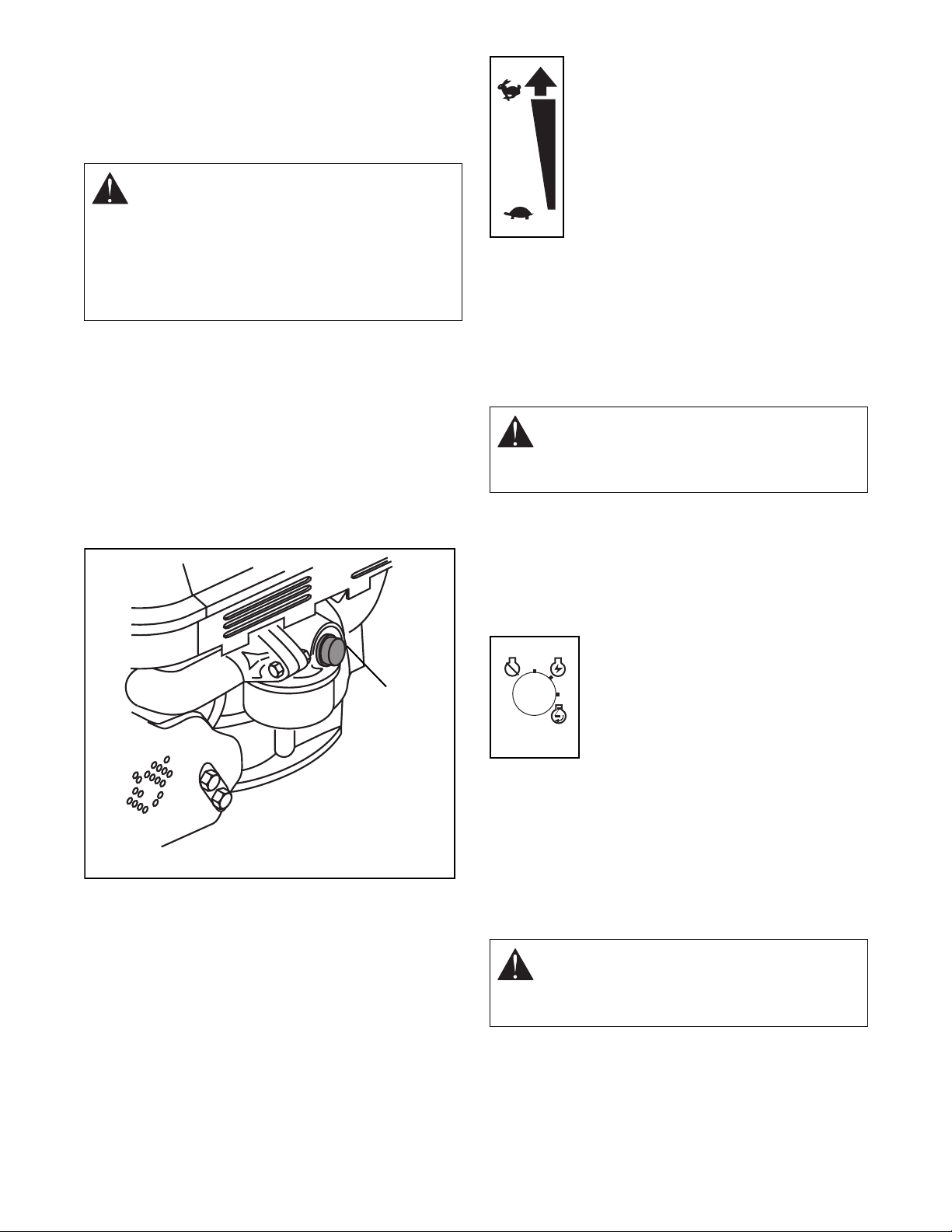

Primer Bulb (Briggs & Stratton Engine)

Push the Primer Bulb in to add fuel for easier engine

start.

With Speed Selector set at a slow travel speed and

engine running, engage Wheel Drive Control. Increase

speed with Speed Selector to a safe, comfortable

walking pace. Once speed has been selected, Speed

Selector should remain in this position. If not, adjust

speed control bell crank spring tension. (See

Adjustments ).

Wheel Drive Control

CAUTION: Holding Wheel Drive control of

self-propelled models against handlebar,

when attempting to start mower, will propel

mower forward.

With engine running, slowly squeeze and hold Wheel

Drive Control against handlebar to propel mower

forward. Release Wheel Drive Control to stop forward

motion.

PRE-START

CAUTION: Make sure all hardware is tight, all

safety devices in place and all adjustments

made correctly.

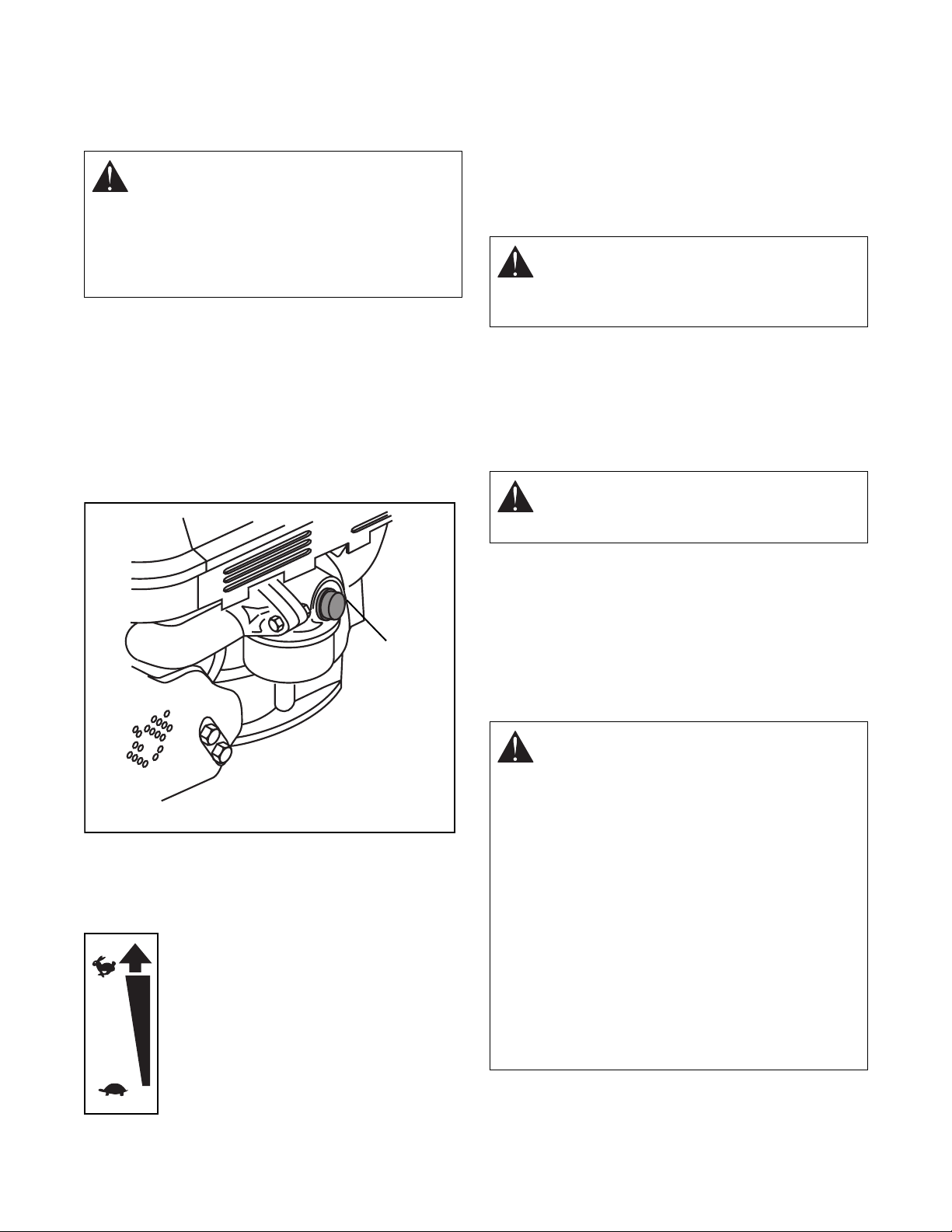

Primer Bulb

OM0200

Figure 7

Speed Selector

Speed Selector is used to select variable forward travel

speeds of mower.

High –Push selector all the way forward.

Low –Pull selector all the way rearward.

OM0480

1. Check that engine crankcase oil is at proper level.

Fill or change engine oil as required.

2. Check air cleaner for dirt. Clean as required.

3. Check hardware and safety devices.

FILLING FUEL TANK

WARNING: EXPLOSIVE VAPORS and

FLAMMABLE FUEL can result in serious

injury or death. Handle fuel with care.

ALWAYS use an approved fuel container.

No Smoking! No Lighted Materials!

No Open Flame!

Allow engine to cool before maintenance.

Gasoline is highly flammable and must be

handled with care. Allow engine to cool

several minutes before removing fuel tank

cap. Never fill tank when engine is running or

is hot from operation. DO NOT allow open

flame, matches, or smoking in area. DO NOT

overfill. Allow about 1/4" of tank space for fuel

expansion. Wipe up any spills and allow

vapors to dissipate before starting engine.

Use approved (Red) gasoline container.

To add fuel to Fuel Tank:

1. Put unit in open or well-ventilated area.

2. Stop engine and allow to cool.

12

Page 13

3. Clean Fuel Cap and surrounding area to prevent

dust, dirt and debris from entering Fuel Tank.

4. Remove Cap.

IMPORTANT: DO NOT use gasohol or gasoline

containing alcohol because alcohol will cause internal

parts to deteriorate. See Engine Manual for correct

type and grade of fuel.

5. Fill fuel tank. (See Specifications for tank

capacity.)

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

Mower Configurations

CAUTION: DO NOT operate mower unless

either side discharge opening cover or side

discharge deflector is installed. Objects may

be picked up and thrown causing damage or

personal injury. Never operate engine with

rear door open unless grass bag is in place.

To configure your mower for bagging, side discharge or

mulching, proceed as follows:

Bagging: Lift rear door, place bar of grass bag frame

on lip of mounting flange and lower rear door. If

necessary, lift rear of grass bag frame to lock in

position.

Be sure there are no openings between bag and

mounting surface after installing bag. If necessary clear

bag mounting surface of debris.

To remove grass bag, lift rear door. Then with handle,

lift bag up off mounting flange and close rear door.

CAUTION: Objects may be thrown. Check

grass bag frequently for wear or deterioration.

Replace worn or damaged bag with Ariens

original equipment replacement bag only.

Mulching: Remove grass bag and install side

discharge opening cover. Open rear door and insert

Mulchmaster Plug with the beveled face to the left.

Rear door should close flush.

STOPPING IN AN EMERGENCY

To stop the mower in an emergency situation, release

both the engine/blade control bail and the wheel drive

control bail from the handlebar. Allow all moving parts

to stop before leaving operator’s position.

STARTING AND SHUT OFF

See Figures 1, 4 and 5 for all Controls and Features.

NOTE: Start engine on a hard level surface that is free

of debris.

Manual Start

1. For engines with a primer, push primer bulb 2 or 3

times for a cold engine.

2. With engine/blade control held against the

handlebar, grasp starter handle and pull rope out

slowly until it pulls harder. This is the compression

stroke. Let rope rewind slowly. Then pull rope with

rapid continuous full arm stroke to start engine.

Allow rope to rewind slowly.

IMPORTANT: DO NOT let starter handle snap against

engine.

3. Repeat until engine starts. (If engine does not

start, refer to Troubleshooting .)

Shut Off

1. On self-propelled models, release wheel drive

control and allow unit to come to a complete stop.

2. Release engine/blade control, and allow engine

to cool.

Side Discharge: With grass bag removed, remove two

lock nuts and washers that secure side discharge

opening cover to mower. Lift cover to free tabs from

slots and remove cover from mower.

Position holes in side discharge deflector over studs on

mower. Place tab on rear edge of deflector onto edge

of discharge opening. Secure deflector with cover

hardware.

WARNING: NEVER direct discharge of

material toward bystanders. Do not allow

anyone near equipment while unit is in

operation.

13

Page 14

Mowing Tips

CAUTION: On swivel wheel models, when

mowing on slopes it is recommended that the

linchpin be positioned through the swivel lock

hole. If wheels are in the swivel position and

control handles are released the mower may

“free roll” downhill. Never mow on steep

slopes.

CAUTION: If clog or obstruction prevents

grass flow, release Engine/Blade Control and

disconnect spark plug wire before attempting

to clear away any clogs.

The following tips will help you to mow safely, achieve

maximum performance from your mower and maintain

the appearance of your lawn.

When bagging, be sure to release Engine/Blade

Control to stop engine and blade before attempting to

remove and empty grass bag. Empty bag before it

becomes overloaded and clogs mower.

Restarting engine will be easier if mower is allowed to

completely discharge clippings before stopping engine.

NOTE: Be sure to empty grass bag and clean mower

pan after each use. DO NOT allow grass clumps or a

coating of grass and debris to collect inside of grass

bag or mower pan.

NOTE: Avoid operating over bare ground with only

patches of grass. This causes dirt and grass to collect

under pan surface and in grass bag.

Prevent debris buildup and allow proper air circulation.

Remove grass bag from mower, wash bag with hose

and allow to dry.

Mulching Tips

For best mulching performance, set mower height to 3

inches. If grass is very tall, do not cut more than 1 inch

of grass per cutting.

Cut grass only when dry, not when it is wet from dew,

rain, or watering. Wet grass tends to pack inside the

mower pan. If cut grass does not disperse evenly, it is

probably because too much grass is being removed

per cutting, the grass is too wet, or the travel speed is

too fast.

14

Page 15

MAINTENANCE

Ariens Dealers will provide any service, parts or

adjustments which may be required to keep your unit

operating at peak efficiency. Should engine service be

required, contact an Ariens dealer or an authorized

engine manufacturer's service center.

MAINTENANCE SCHEDULE

The chart shows the recommended maintenance

schedule that should be performed on a regular basis.

More frequent service may be required due to working

conditions (heavy loads, high ambient temperatures,

dusty conditions, or airborne debris).

See Engine Manual for further maintenance and

troubleshooting information.

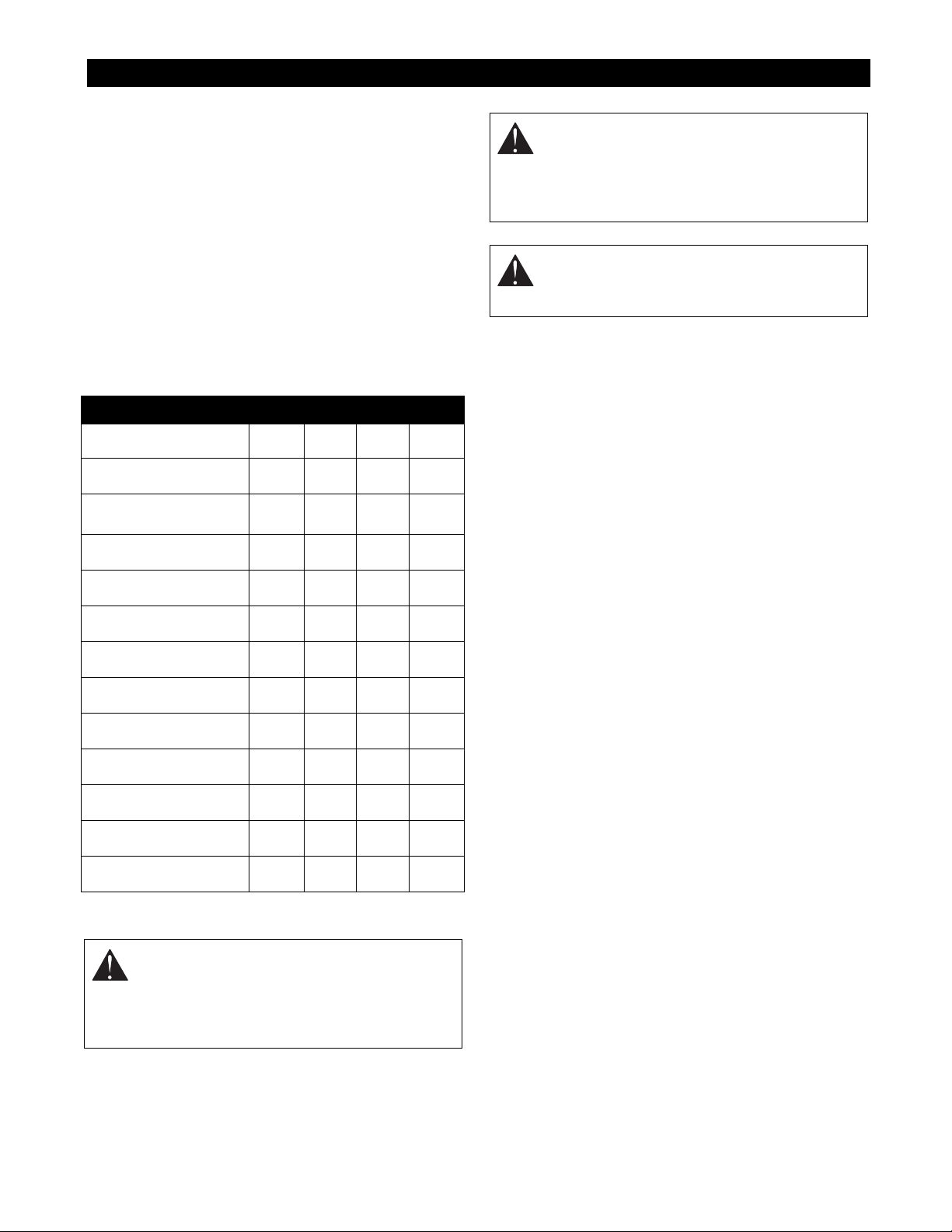

MAINTENANCE SCHEDULE

Service Performed

Check Air Cleaner

Check Engine Oil

Check Mower Blade

Check Drive Belt

Check Engine/Blade

Control

Check Grass Bag

Check Drive Control

Daily 25 50 100

•

•

*

•

•

•

•

•

•

WARNING: Stop engine, wait for moving

parts to stop, and remove wire from spark

plug (keep wire away from plug to prevent

accidental starting) before attempting any

lubrication or maintenance procedures.

CAUTION: DO NOT touch engine parts which

are hot from operation. Allow parts to cool

before servicing.

CHECK AIR CLEANER (Briggs & Stratton

Engine)

See engine manual for specific information.

CHECK ENGINE OIL

IMPORTANT: Change engine crankcase oil after first

two (2) hours of operation. Thereafter, change oil every

twenty five hours of operation (more often in dusty, dirty

conditions). Refer to Engine Manual for oil type and

grade and detailed instructions.

Engine Oil Check and Change

The engine crankcase oil should be checked daily or

every five (5) hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result.

IMPORTANT: DO NOT overfill. Be sure engine is level

when adding oil.

See Engine Manual for detailed instructions.

General Lubrication

Check Fasteners

Check Spark Plug

Check Engine Cooling

Check Muffler

After first 2 Hours of operation

*

WARNING: ROTATING PARTS can cut off

body parts. Keep hands and feet away. Loose

clothing, long hair or scarves can get caught

in rotating parts and cause death or serious

injury.

•

•

•

•

•

CHECK MOWER BLADE

See figures 10 and 11.

Regularly check mower blades for wear and that lock

washer is fully compressed by cap screw (requires

25-30 ft. lbs. of torque on cap screw).

When blade needs sharpening:

1. Block blade to prevent rotation.

2. Remove cap screw, lock washer and blade from

shaft.

3. Sharpen both ends of blade at original angle

(25°), removing equal amounts of material from

each end to maintain proper blade balance. New

blades are balanced to within 1.3 in. oz. at

factory. DO NOT grind around corner at tip of

blade. If cutting edge of blade cannot be

sharpened in a straight line to within 1/8 of an

inch of its end, replace blade with Ariens

replacement blade only.

15

Page 16

4. Install blade, lock washer and tighten cap screw

until lock washer is fully compressed (requires

25-30 ft. lbs. of torque on nuts).

IMPORTANT: If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded.

5

4

CHECK ENGINE/BLADE CONTROL

The engine/blade control must stop the engine and

blade within 3 seconds after the bail is released. If the

engine or blade continues to run, adjust or repair

control immediately. See Adjustments.

CHECK GRASS BAG

Check bag for wear or damage. Keep bag clean and

dry. Replace only with Ariens original equipment

replacement bag.

Mulching Blade

4

Standard Blade

3

2

1. Cutting Edge

2. Square Corner

3. Air Lift Erosion

4. Air Lift

Figure 10

CHECK DRIVE BELT

1

2

1

5. Reverse Lift

1

3

OM0230

OM0240

2

CHECK DRIVE CONTROL

Check operation of drive control. The drive must

disengage completely when the bail handle is

released. Adjust bail travel if necessary. See

Adjustments.

GENERAL LUBRICATION

Mower does not require any lubrication. Wheel

assemblies are designed for long life without additional

lubrication.

Swivel Lubrication (swivel units)

See Figure 12.

NOTE: Linchpin must be in the swivel lock hole while

lubricating.

2

1

4

3

1. Blade

2. Cap Screw, Lock Washer & Flat Washer

3. Drive Belt

4. Idler

OM0250

Figure 11

Check drive belt for wear or damage. Replace belt if

worn or damaged. See Service and Adjustments.

OM0180

1. Grease Fitting 2. Swivel Lock Hole

Figure 12

CHECK FASTENERS

Check all fasteners for proper tightness. Pay special

attention to blade hardware and all guards, shields and

safety devices.

CHECK SPARK PLUG

Spark plug should be cleaned (or replaced) if

necessary and gap reset to .030" every 100 hours of

operation or yearly, whichever comes first.

To clean:

1. Remove debris from area around spark plug

base.

2. Remove spark plug from engine.

16

Page 17

3. Scrape and wash spark plug with a commercial

solvent. DO NOT blast clean.

4. Replace spark plug.

NOTE: Sparking can occur if wire terminal does not fit

firmly on spark plug. Replace terminal if damaged.

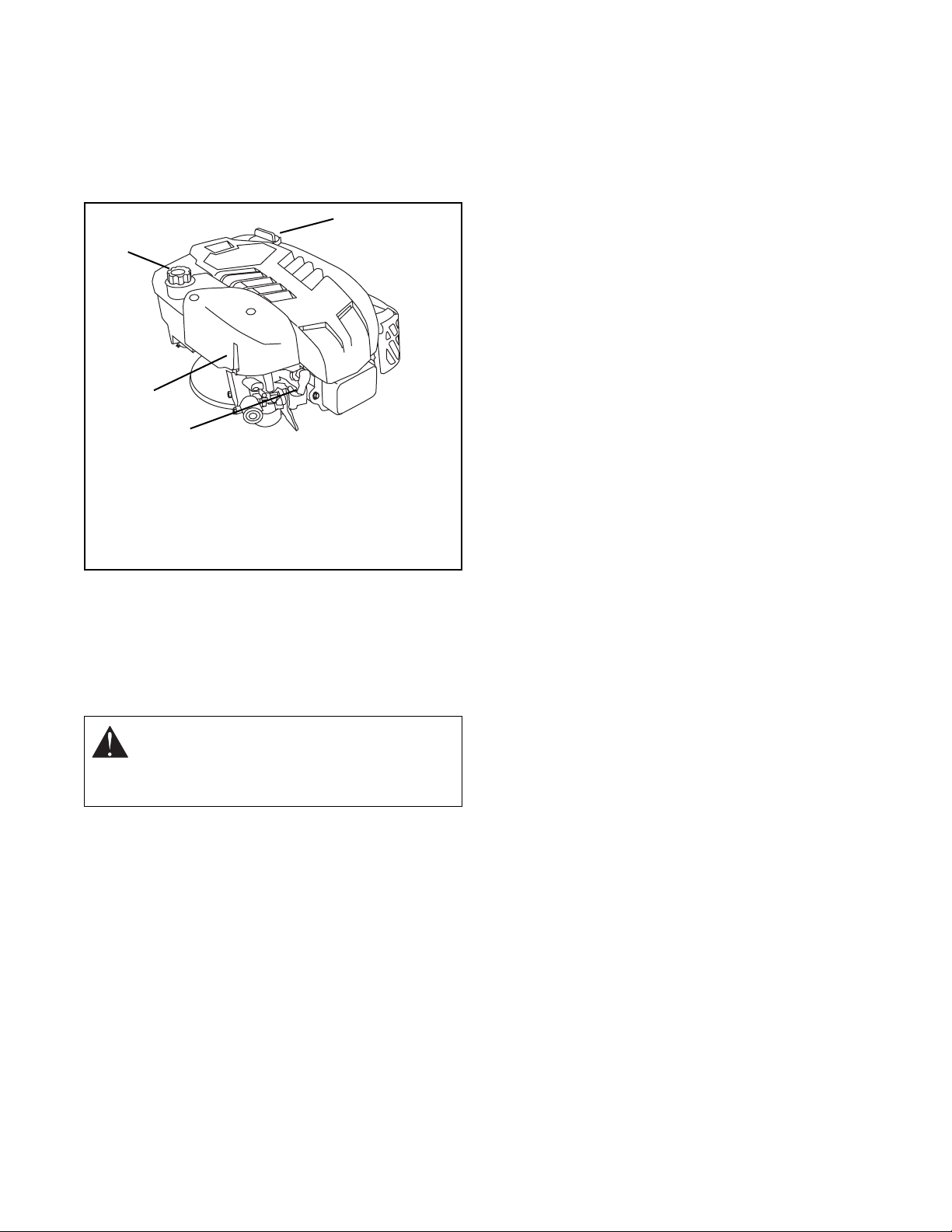

1

4

2

3

OM0680

Briggs & Stratton Intek OHV

1. Oil Fill Cap & Dipstick

2. Air Cleaner

3. Spark Plug & Wire

4. Fuel Cap & Tank

Figure 13

CHECK ENGINE COOLING

Engine is air cooled. Air must circulate freely around

engine from Air Intake to cooling fins on cylinder head

and block to prevent overheating.

WARNING: HOT SURFACES can cause

death or serious injury. DO NOT TOUCH parts

which are hot from operation. ALWAYS allow

parts to cool.

Every 100 hours of operation or yearly (more often if

conditions require) remove cooling shrouds and clean

cooling fins. Clean external surfaces of engine of dust,

dirt and oil deposits which can contribute to improper

cooling.

IMPORTANT: DO NOT operate engine with blower

housing removed or engine overheating damage will

result.

CHECK MUFFLER

Check muffler for cracks, wear, or other damage. Worn

out mufflers should be replaced immediately.

Continued use could result in fire or explosion.

17

Page 18

1. Hole No. 1

2. Hole No. 2

3. Hole No. 3

4. Hole No. 4

5. Pin

6. Brace

7. Storage Position

Figure 15

4

1

2

3

5

6

7

OM0271

SERVICE AND ADJUSTMENTS

SERVICE POSITION

WARNING: ACCIDENTAL ENGINE START

UP can cause death or serious injury.

ALWAYS stop engine, wait for moving parts to

stop and remove wire from spark plug before

adjusting or servicing.

Place unit on a flat level surface. ALWAYS stop engine.

Assure unit is secure and will not tip over. Strap and

clamp onto bench if needed.

CAUTION: Before unit is tipped up, remove

enough fuel so that no spills will occur. A

piece of plastic bag may be used to seal fuel

tank opening when tipping mower. To seal,

remove fuel tank cap, cover fuel tank opening

with plastic, replace and tighten cap securely

before attempting to tip mower. Be sure to

remove plastic before attempting to operate

mower.

A handlebar service position is provided for tipping the

unit for cleaning and service (Figure 14). See

Adjustments.

IMPORTANT: If engine becomes “flooded” due to

tipping, clean air cleaner (See Maintenance) and

remove spark plug, put one teaspoon of oil in cylinder,

turn engine over a few times and reinstall spark plug.

HANDLEBAR

To adjust handlebar height (Figure 15):

1. Place a hole (1-4) at the bottom of the braces

over the pins.

2. For service position, remove braces from pins,

rotate handlebar forward and place pins into

holes of braces.

Figure 14

IMPORTANT: When tipping to service engine or unit,

use the following service position:

OM0670

Briggs & Stratton Intek Engines: place handlebar

into handlebar service position and tip the machine to

the left, opposite the discharge opening.

18

Page 19

ENGINE/BLADE CONTROL

Engine Control must stop engine ignition, at 3/4”

to 1-1/4” from handlebar as control is released.

To check (Figure 16):

1. Start engine and slowly release Control until

engine stops firing.

2. Measure distance between handlebar and control

at the point that engine stopped firing.

3. Turn cable nuts at handlebar mount clockwise if

measurement is more than 1-1/4” or

counter-clockwise if measurement is less than

3/4”.

4. Turn nuts against mount to lock in position.

3/4" - 1 1/4 "

2

1

4. Check idler for free rotation of pulley and

movement of pivot.

5. Reinstall drive belt in reverse order. Be sure that

belt seats in pulley grooves with idler positioned

on back (flat) side of belt.

DRIVE WHEEL

See Figure 17.

When the Wheel Drive Control is squeezed toward the

handlebar the extension spring, located at the bottom

end of the traction cable, must start to extend when the

control is between 1-1/2" and 2" (3.8 and 5 cm) away

from the handlebar. To check:

1. Squeeze the Wheel Drive Control toward the

handlebar until the spring starts to open.

2. Measure the distance between the Wheel Drive

Control and handlebar at the handlebar

indentation.

3. To obtain the proper adjustment, turn the cable

nuts. Turn clockwise if the measurement is more

than 2"; counterclockwise if the measurement is

less than 1-1/2". Tighten the nuts against the

bracket to lock in position. If there is not enough

thread length for adjustment, the opposite end of

the cable can be adjusted.

4

3

1. Engine Control

2. Handlebar

3. Cable Nuts

4. Mount

Figure 16

DRIVE BELT (Self propelled units)

To remove drive belt:

1. Position right hand rear wheel Height Adjustment

lever in first notch and left hand rear wheel Height

Adjustment lever in third notch. This provides

clearance between friction wheel and drive disk.

2. Remove belt from idler, drive disk and engine

pulley.

3. Pull belt through opening under mower pan and

over blade.

OM0280

1-1/2" to 2"

2

3

1. Traction Cable

2. Handlebar Indentation

Figure 17

4

1

OM0290

3. Cable Nuts

4. Wheel Drive Control

19

Page 20

Speed Control Bell Crank

The speed control bell crank holds the speed selector

rod in position after a speed has been set. The spring

washers may become loose with normal wear. If the

speed selector rod does not stay firmly in position,

adjust the speed control bell crank. See Figure 18.

To adjust:

1. Remove cover, fully compress the helical spring

lockwashers with lock nut and then back lock nut

off, one half turn.

2. If the speed selector rod is still too loose, tighten

lock nut by small increments until it holds its

position. Tightening the lock nut too much will not

allow the speed selector rod to move at all.

3. Align notch in left hand side of cover with bolt and

secure with knob.

2

4

5

1. Lock Nut

2. Helical Spring

Lockwashers

3. Speed Control Bell

Crank

1

3

6

OM0300

4. Speed Selector Rod

5. Hair Pin

6. Swivel

Figure 18

STORAGE

WARNING: FLAMMABLE FUEL and its

EXPLOSIVE VAPORS can cause death or

serious injury. DO NOT store unit with fuel in

the fuel tank inside a building where any

ignition sources are present. Drain fuel

outdoors away from any ignition source. Allow

engine to cool before storing in any enclosure.

Only use approved fuel containers.

IMPORTANT: NEVER spray unit with water or store

unit outdoors. Water can seep into sealed bearings,

which are sealed against dirt and debris only, causing

reduced component life. Store mower in a cool, dry,

protected location.

Cleaning

Clean unit thoroughly. Brush dirt and debris off with a

brush. Apply paint or spray lubricant to exposed metal

joints and surfaces. Do not use abrasives, solvents, or

harsh cleaners.

Inspection

Inspect mower for signs of wear or damage. Order any

parts required and make necessary repairs to avoid

delays when beginning use again.

Keep all nuts, bolts and screws tight and know unit is in

safe working condition. Check all hardware at regular

intervals.

Grass Bag

Remove Grass Bag and clean out all debris before

storage. Grass Bag may be stored in position on

mower. Keep Grass Bag dry during storage.

Engine

When storing unit for extended periods of time, remove

all fuel from tank and carburetor (run dry). Refer to

Engine Manual.

20

Page 21

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTION

Engine will

not start

1. Fuel tank empty or low.

2. Spark plug wire loose or off.

3. Engine/brake control cable

detached, broken, or not adjusted

properly.

Self-propelled

drive does not

engage.

1. Traction drive bail not engaged.

2. Drive belt out of position.

3. Drive belt worn or damaged.

4. Rear wheels in different cutting

height positions.

5. Friction wheel engagement not

adjusted properly or damaged.

6. Idler and idler spring installed

incorrectly.

7. Traction drive cable detached or

broken.

8. Bearings damaged.

9. Debris in gear set.

SPECIFICATIONS

Model Number 907254

Description LM21SW

Length - in (cm) 61.5 (156)

Height - in (cm) 38 (96,5)

Width - in (cm) 23 (58,4)

Actual Weight - lbs (kg) 105 (47,6)

Cutting Width 21 (53,3)

Cutting Height - in. (cm) 6 Positions: 1.00 - 3.25

Engine, 4 cycle Briggs & Stratton Intek OHV

Engine Power Max - HP (kw)

Max Rotation Speed

of Cutting Edge - RPM (min

Governed RPM 3000 +/- 100

Displacement Cu. In. (cc) 11.57 (190)

Cylinder Bore Aluminum

Engine Oil Type SAE 30

Crank Case Capacity - Oz. (Liter) 22 (0,65)

Oil System

Spark Plug Gap - in (mm) 0.030 (0,76)

-1

)

(2,5 - 8,3)

4.37 (3,26)

3100

Splash

1. Check fuel level. Fill tank if necessary.

2. Check connection.

3. Check engine/brake control cable. Adjust,

repair or replace as necessary.

1. Engage traction drive bail.

2. Check drive belt. Adjust as necessary.

3. Replace belt.

4. Adjust rear wheel cutting position so that

cutting height is the same on both sides.

5. Adjust or replace friction wheel.

6. Check idler and spring. Adjust as

necessary.

7. Check drive cable. Adjust, repair or replace

as required.

8. Replace bearings.Contact your Dealer.

9. Remove debris. Contact your Dealer.

SPECIFICATIONS

Fuel Type Unleaded

Fuel Tank Capacity - qt (Liter)

Primer Bulb Standard

Air Cleaner Paper Element

Starting Recoil

Differential Standard

Variable Speeds - MPH (km/hr) 0-4 (0-6,4)

Mower Deck 14 Gauge - Stamped Steel

Adjustable Handlebar Four Position

Front Wheel Dia - in (cm) 7.5 (19,1)

Rear Wheel Dia - in (cm) 10.5 (26,7)

1.6 (1,5)

21

Page 22

2 Year Limited Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Ariens Company will be free from defects in material and workmanship for a period

of two (2) years after the date of purchase, and will repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

1-877-466-0812

Fax 920-756-2407

www.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

• The warranty registration card must be completed and

returned to Ariens Company.

• The purchaser must perform maintenance and minor

adjustments explained in the owner’s manual.

• The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

This warranty is subject to the following limitations:

• The purchaser must transport the product to and from the

place of warranty service.

• Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative, contact Ariens Company at the number or

address above.)

• Batteries are warranted only for a period of twelve (12)

months after date of purchase, on a prorated basis. For the

first ninety (90) days of the warranty period, a defective

battery will be replaced free of charge. If the applicable

warranty period is more than 90 days, Ariens Company will

cover the prorated cost of any defective battery, for up to

twelve(12) months after the date of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The two year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. If the product is put to any

business, commercial, or industrial use such as, but not limited to, commercial landscaping,

mowing or snow removal services, or golf course or park maintenance, or agricultural

or farmstead use, then the duration of this warranty is ninety (90) days after the date

of purchase, or one (1) year after the date of purchase if the product is labeled as a

Professional/Commercial Product. If any product is rented or leased, then the duration

of this warranty is ninety (90) days after the date of purchase.

The following items are not covered by this warranty:

• Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

• If the product is equipped with a Peerless gearbox and/or

transmission, the gearbox and/or transmission are covered

only by the warranty made by Peerless, and are not covered

by this warranty.

• Parts that are not genuine Ariens service parts are not

covered by this warranty.

• Shoes, runners, scraper blades, shear bolts, mower blades,

mower vanes, headlights, light bulbs, are not covered by this

warranty.

• Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident, is not

covered by this warranty.

• Products which were not purchased in the United States,

Puerto Rico, or Canada are not covered by this warranty.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company’s liability under this warranty, and under any

implied warranty that may exist, is limited to repair of any

defect in workmanship, and repair or replacement of any

defective part. Ariens Company shall not be liable for incidental,

special, or consequential damages (including lost profits).

Some states do not allow the exclusion of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied

warranty is limited to the duration of this

warranty. Some states do not allow limitations

on low long an implied warranty lasts, so the

above limitation may not apply to you.

Form: SLW2-111299

22

Page 23

TABLE DES MATIÈRES

Commandes et caractéristiques . . . . . . . . . . . . . . . 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Montage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INTRODUCTION

LE MANUEL

Avant d’utiliser cette machine, lire entièrement et

attentivement les manuels qui l’accompagnent. Le contenu

de ces manuels permet de comprendre les commandes et

les consignes de sécurité lors de l'utilisation et de

l'entretien courant.

Les indications de côté, droit, gauche, avant et arrière

s’entendent par rapport au sens de marche avant.

ENTRETIEN ET PIÈCES DE RECHANGE

Lors de la commande de pièces de rechange ou au cours

de la recherche de renseignements concernant l’entretien,

fournir le modèle et les numéros de série de la machine et

du moteur.

Ces numéros se trouvent sur le formulaire d’enregistrement

du produit accompagnant les documents fournis avec la

machine. Ils sont également inscrits sur la plaque du

numéro de série située sur le châssis de la machine

(Figure 2).

• Noter le numéro du modèle et le numéro de série de la

machine dans l’encadré ci-dessous.

• Noter le numéro du modèle et le numéro de série du

moteur dans l’encadré ci-dessous.

Entretien et réglages. . . . . . . . . . . . . . . . . . . . . . . . 36

Remisage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dépannage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pièces de Rechange . . . . . . . . . . . . . . . . . . . . . . . . 59

ENREGISTREMENT DU PRODUIT

Une carte d’enregistrement de la garantie doit être remplie,

signée et renvoyée au moment de l’achat. Cette carte

active la garantie. Les réclamations faites pendant la

période couverte par la garantie limitée seront honorées.

PIÈCES DE RECHANGE NON

AUTORISÉES

Utiliser uniquement les pièces de rechange Ariens. Le

remplacement de toute pièce sur cette machine par une

pièce autre que les pièces de rechange autorisées par

Ariens peut affecter les performances, la durée de vie ou la

sécurité de cette machine et peut annuler la garantie.

Scotts et Ariens se dégagent de toute responsabilité

concernant toute réclamation ou dégât affectant les biens,

ou provoquant des blessures ou le décès qui seraient le

résultat de l’utilisation d’une pièce de rechange non

autorisée.

LIVRAISON

Note au client : Si vous avez acheté ce produit sans le

montage et les instruction du marchand, il vous incombe

de:

• Lire et comprendre toutes les instructions de

montage de ce manuel.

compréhension ou de difficultés à suivre les

instructions, contacter le concessionnaire Ariens

le plus proche pour assistance.

concessionnaire Ariens le plus proche, appeler

1-877-466-0812.

.

En cas de non

Pour le

F

RANÇAIS

Étiquette du

numéro de série

Figure 2

OM0650

WARNING: Un montage ou un réglage

incorrect risque de provoquer des blessures

graves.

• Vérifier le fonctionnement de toutes les

commandes avant la mise en marche du moteur.

Avant d’utiliser cette machine:

1. Le montage a été correctement effectué.

2. Toutes les consignes de sécurité des manuels ont été

comprises.

3. Les fonctions et le fonctionnement de la machine ont

été revus.

4. Le graissage, l’entretien et les réglages

recommandés ont été effectués.

5. La police de Garantie Limitée a été revue.

6. Remplir la carte d’enregistrement de l’acheteur

original et la renvoyer à Ariens.

23

Page 24

DÉNI DE RESPONSABILITÉ

Ce produit est fabriqué par Ariens. Scotts et Ariens se

réservent le droit de discontinuer, d’effectuer des

modifications ou des améliorations à ses produits à tout

moment et ce sans aucune obligation de préavis. Les

descriptions et les caractéristiques contenues dans ce

manuel sont en vigueur à la date d’impression.

L’équipement décrit dans ce manuel peut être en option.

SÉCURITÉ

CONSIGNES DE SÉCURITÉ

Rechercher ces symboles accompagnant

des précautions importantes pour la

sécurité. Ils signifient :

Attention !

Votre sécurité est en jeu !

Être en état d'alerte !

Obéir au message !

Ils apparaissent sur les autocollants de sécurité apposés

sur la machine et accompagnent la marche à suivre et le

fonctionnement corrects décrits dans le manuel. Bien

comprendre le message de sécurité. Celui-ci contient

des informations importantes concernant la sécurité de

l’utilisateur avec ou près de la machine.

Certaines illustrations peuvent ne pas s’appliquer à votre

machine.

USAGE ET LOIS

Respecter les précautions d’usage, pour la sécurité de

tous. Comprendre et respecter tous les messages de

sécurité. Être conscient des circonstances comportant un

danger et un risque de blessures légères, moyennes ou

graves, voire mortelles. Se familiariser avec toutes les

réglementations et lois locales.

FORMATION REQUISE DE L’UTILISATEUR

Le revendeur a informé l’acheteur original sur l’utilisation

correcte de cette machine selon le respect des règles de

sécurité. Si cette machine est utilisée par un autre individu

ou si elle est prêtée, louée ou vendue, TOUJOURS fournir

le manuel ainsi que la formation sur la sécurité nécessaire

avant l’utilisation.

DANGER :

DANGEREUSE ! Si elle n’est pas évitée, PEUT

ENTRAÎNER la mort ou des blessures graves.

AVERTISSEMENT :

POTENTIELLEMENT DANGEREUSE ! Si le

danger n'est pas écarté, IL Y A RISQUE de mort

ou de blessures graves.

PRUDENCE :

POTENTIELLEMENT DANGEREUSE ! Si le

danger n’est pas écarté, IL Y A RISQUE de

blessures légères ou moyennement graves.

Peut aussi signaler des gestes dangereux.

SITUATION EXTRÊMEMENT

SITUATION

SITUATION

REMARQUES

REMARQUE :

bon fonctionnement et l’entretien régulier de la machine.

IMPORTANT :

spécifiques nécessaires pour ne pas endommager la

machine ou un accessoire.

Renseignements généraux pour assurer le

Procédures ou renseignements

24

Page 25

OL3030

OL4530

AUTOCOLLANTS DE SÉCURITÉ ET

EMPLACEMENTS

TOUJOURS remplacer les autocollants de sécurité

manquants ou abîmés. Se reporter à la Figure 3 pour les

emplacements de ces autocollants.

CAUTION

BAG IS SUBJECT TO WEAR AND

•

DETERIORATION.

CHECK BAG FEQUENTLY, REPLACE WHEN

•

NECESSARY.

USE ORIGINAL BAG TO COMPLY WITH SAFETY

•

SPECIFICATIONS.

PRECAUCION

LA BOLSA ESTA SUJETA A DESGASTE Y

•

DETERIORO.

REVISAR LA BOLSA FREQUENTAMENTE,

•

Y REEPLAZARLA SI ES NECESARIO.

USAR BOLSAS ORIGINAL PARA CUMPLIR CON

•

LAS ESPECIFICACIONES DE SEGURIDAD.

ATTENTION

LE SAC EST SOUMIS À L’USURE ET A LÀ

•

DÉTÉRIORATION.

VÉRIFIER LE SAC FRÉQUEMMENT. LE

•

REMPLACER AU BESOIN.

UTILISER UN BAC D’ORIGINE CONFORME

•

AUX NORME DE SECURITE.

3

1

2

1. DANGER

POUR ÉVITER DES BLESSURES GRAVES,

VOIRE MORTELLES

Avant d’utiliser la machine, lire

complètement et comprendre tous les

manuels fournis.

OL1801

Éloigner les enfants et les animaux lors

de l’utilisation de la machine.

Rassembler les enfants à l'extérieur de

la zone de travail et les laisser sous la

OL4370

surveillance d'un adulte responsable.

Ne pas s’approcher de l’aire

d’évacuation. NE PAS diriger

l’évacuation vers les tierces personnes.

Retirer les objets pouvant être projetés

OL0910

par la lame. NE PAS utiliser la tondeuse

sur du gravier ou une surface dure.

NE PAS utiliser la tondeuse sans garant.

MEETS C.P.S.C. BLADE

SAFETY REQUIREMENTS

Figure 3

• Se déplacer en travers d'une pente et non pas de

• Regarder en bas et en arrière, avant et pendant toute

2. DANGER

3. PRUDENCE !

• Le sac est sujet à l’usure et aux détériorations.

• Le vérifier fréquemment, le remplacer si nécessaire.

• Utiliser un sac d’origine conforme aux normes de

OM0660

LAME ROTATIVE ! Éloigner les mains et

les pieds.

haut en bas.

manœuvre de recul.

ÉLOIGNER LES MAINS ET LES PIEDS

• Ne pas utiliser la tondeuse sans

garant.

sécurité.

OL4540

25

Page 26

CONSIGNES DE SÉCURITÉ

Utilisation

Inspecter la machine et la zone de travail avant l’utilisation

pour éviter la projection d’objets.

Nettoyer la zone de travail de tout objet pouvant être

ramassé et jeté. Retirer tous les cailloux, bâtons, câbles et

autre objet indésirable. L’herbe haute peut cacher des

obstacles.

Seuls les adultes ayant reçu la formation nécessaire

peuvent utiliser la machine. La formation comprend

l’utilisation de la machine.

Maintenir les accessoires en bon état.

TOUJOURS laisser la plaque d’évacuation en place.

NE JAMAIS utiliser la machine avec la trappe arrière

ouverte sauf si le sac à herbe est en place.

Pour le paillis, la plaque d’évacuation latérale ouvrable doit

être posée et la trappe arrière complètement ouverte

quand le moteur tourne.

NE PAS déplacer la tondeuse en marche arrière, sauf en

cas de nécessité absolue. Regarder en bas et en arrière,

avant et pendant toute manœuvre de recul.

NE PAS mettre le moteur en marche ou utiliser la tondeuse

si la plaque d’évacuation latérale ouvrable ou le déflecteur

d’évacuation latéral sont déposés.

Garder toute personne, enfant et animal domestique

éloigné de la zone de travail.

TOUJOURS dégager la zone de travail avant l’utilisation.

Arrêter la tondeuse si quelqu’un pénètre dans la zone.

Laisser en place les garants et les dispositifs de sécurité et

s’assurer qu’ils fonctionnent correctement. NE JAMAIS

modifier ou déposer les dispositifs de sécurité.

TOUJOURS éloigner les mains des pièces en rotation.

Ne pas approcher ou placer les mains ou les pieds en

dessous des pièces en rotation. Se tenir à l’écart des

orifices d’évacuation et du carter de la tondeuse en toute

circonstance. NE JAMAIS ouvrir trappe arrière quand le

moteur tourne si le sac à herbe est déposé.

TOUJOURS tenir les mains et les pieds à l’écart des pièces

en rotation. Les pièces en rotation peuvent sectionner un

membre.

NE PAS tondre trop rapidement. NE PAS modifier le

réglage du régulateur de vitesse ou faire tourner le moteur

à un régime trop élevé.

Utiliser la tondeuse UNIQUEMENT lorsque la visibilité et

l’éclairage sont satisfaisants.

Être extrêmement prudent à l’approche de tournants sans

visibilité, de buissons, d’arbres ou d’autres obstacles qui

réduisent la visibilité.

TOUJOURS être bien en équilibre.

Ne pas tondre d’herbe humide. TOUJOURS être bien en

équilibre. Tenir fermement le guidon. Marcher, ne jamais

courir.

Si l’accessoire vibre de manière anormale, arrêter

immédiatement le moteur, attendre que les pièces en

rotation s’immobilisent et débrancher le fil de la bougie.

Effectuer les réparations nécessaires avant de remettre la

tondeuse en marche.

Éviter les zones irrégulières et les terrains accidentés.

Bien repérer la zone de travail. Faire attention aux trous,

rocs, racines et autre dangers cachés sur la zone de travail.

Se tenir à l’écart des dénivellations abruptes, fossés ou

remblais. L’utilisateur risque de perdre l’équilibre.

NE PAS utiliser la machine sur de fortes pentes.

NE JAMAIS laisser la machine en pente sans surveillance.

En cas de stationnement en pente, caler les roues.

Tondre en travers de la pente, jamais de haut en bas. Être

extrêmement prudent lors de changement de direction en

pente.

Retirer la clé une fois la machine garée.

Prendre toutes les précautions possibles avant de laisser la

machine sans surveillance.

TOUJOURS arrêter le moteur, retirer la clé et débrancher le

fil de la bougie pour éviter un démarrage accidentel ou une

utilisation non-autorisée.

Personne

Éloigner les enfants de la zone de travail et s’assurer qu’ils

sont surveillés par un adulte.

NE JAMAIS laisser un enfant utiliser la tondeuse.

Arrêter la tondeuse si des enfants pénètrent dans la zone

de travail.

NE JAMAIS diriger l’évacuation vers les personnes

présentes. L’utilisateur est responsable de la sécurité des

tierces personnes.

Porter les vêtements de sécurité appropriés, des gants et

des chaussures de protection.

Porter des chaussures résistantes. NE PAS tondre piedsnus, en sandales ou en espadrilles.

Toujours porter des lunettes de sécurité comportant des

montants de protection latéraux pour utiliser la tondeuse.

NE JAMAIS porter de vêtements larges, de bijoux ou de

cheveux longs pouvant être happés par les pièces en

rotation. Se protéger les yeux, le visage et la tête des

objets pouvant être projetés par la machine.

NE JAMAIS utiliser la machine après avoir consommé des

médicaments, des drogues ou de l’alcool. Une attention

totale est requise pendant l’utilisation de la machine.

NE JAMAIS s’approcher de la goulotte d’évacuation lors de

l’utilisation de la tondeuse.

Ne pas utiliser la tondeuse sur du gravier ou des matériaux

fluides tel que le sable. Arrêter la tondeuse pour traverser

une allée en gravier, une promenade ou une route. Des

objets risquent d’être happés et projetés, provoquant

dommage ou blessure.

NE PAS toucher les pièces chaudes. Laisser les pièces

refroidir.

Les pièces en mouvement peuvent couper ou amputer des

doigts, voire une main. Entourer la ou les lames de chiffons

ou porter des gants pour effectuer l’entretien.

NE PAS approcher les mains des points de pincement.

Les gaz d’échappement du moteur peuvent provoquer la

mort ou de graves blessures. NE PAS faire tourner le

moteur à l’intérieur d’une pièce ou d’un bâtiment.

Entretien et réglages

NE JAMAIS essayer de régler la machine tant que le

moteur est en marche. Avant d’entreprendre l’entretien,

arrêter le moteur, retirer la clé de contact et attendre l’arrêt

de toutes les pièces (sauf instruction contraire).

26

Page 27

NE PAS régler la hauteur de coupe par les roues tant que

le moteur est en marche.

Sur les modèles autotractés, la commande de traction

bloque la marche avant de la tondeuse. Si cette fonction est

en panne, débrancher le fil de la bougie et réparer avant de

réutiliser la tondeuse. La commande de traction doit être

désenclenchée lors de la mise en marche du moteur.

Le carburant est une substance hautement inflammable et

ses vapeurs peuvent exploser. Utiliser UNIQUEMENT des

récipients agréés.

• NE PAS fumer !

• NE PAS faire d'étincelles !

• NE PAS approcher de flammes !

• Laisser refroidir le moteur avant de faire le plein de

carburant.

Vérifier le niveau de carburant avant de mettre le moteur en

marche.

NE PAS faire le plein à l’intérieur quand le moteur est en

marche ou tant qu’il est encore chaud.

Laisser le moteur refroidir quelques minutes avant de

retirer le bouchon du réservoir.

Remettre le bouchon du réservoir correctement en place et

nettoyer le carburant renversé avant de mettre le moteur en

marche.

Arrêter le moteur, débrancher le câble d’allumage et le

ranger à l’écart de la bougie avant d’essayer de débourrer,

réparer, régler ou nettoyer la machine.

Pour réduire les risques d’incendie et de surchauffe,

nettoyer l’herbe, les feuilles, les débris ou l’excès de

graisse de la tondeuse.

Batterie

Éviter les décharges électriques. NE PAS débrancher le fil

de la bougie lorsque le moteur est en marche. Ne pas

mettre la batterie au feu ou la détruire.

Gaz Explosifs ! L’acide sulfurique contenu dans la batterie

est toxique. Il provoque de graves brûlures au contact de la

peau, des yeux ou des vêtements.

Ne pas approcher de flamme, d’étincelle ou fumer à

proximité de la batterie.

TOUJOURS porter des lunettes et des vêtements de

protection à proximité de la batterie.

TOUJOURS ENTREPOSER LES BATTERIES HORS DE

LA PORTÉE des enfants.

Les silencieux usagés représentent plus qu’une nuisance

sonore et doivent être remplacés immédiatement. Un

silencieux usé peut provoquer des incendies ou des

explosions.

TOUJOURS caler les roues et s’assurer que les chandelles

sont assez résistantes pour soutenir le poids de la machine

pendant l’entretien.

Vérifier l’état du sac à herbe. Remplacer uniquement par

un sac de rechange d’origine pour des raisons de sécurité.

Remisage

Laisser refroidir le moteur avant de remiser la machine

dans un local clos.

Consulter la section Remisage dans ce manuel pour les

consignes importantes concernant le remisage à long

terme.

TOUJOURS nettoyer la machine avant un remisage

prolongé. Voir le manuel du moteur pour la procédure de

remisage correcte.

NE PAS remiser la machine avec un réservoir contenant du

carburant dans un bâtiment où il y a risque d’incendie.

Circuits de sécurité

La commande moteur/lame permet d’arrêter le moteur et la

lame quand l’utilisateur relâche la commande sur le guidon.

Si cette fonction est en panne, débrancher le fil de la

bougie et régler ou la faire réparer avant de réutiliser la

tondeuse.

Accessoires

Utiliser uniquement les accessoires agréés par et

correctement posés.

Pare-étincelles

Ce produit est équipé d’un moteur à explosion. NE PAS

l’utiliser sur ou à proximité de terrains non aménagés,

boisés ou couvert de buissons à moins que l’échappement

ne soit équipé d’un pare-étincelles conforme aux

réglementations locales et régionales en vigueur. S’il est

utilisé, le pare-étincelles doit être maintenu en bon état de

fonctionnement par l’opérateur. Voir le concessionnaire ou

le centre d’entretien du fabriquant du moteur.

Entretien

Suivre les consignes de sécurité du fabriquant concernant

l’entretien du moteur.

S'assurer que tous les écrous et les vis sont bien serrés et

que la machine est en bon état de fonctionnement. Vérifier

toute la visserie à intervalles réguliers, en particulier les vis

de fixation de la lame.

Utiliser uniquement les pièces de rechange conçues pour

la machine. Voir le concessionnaire.

27

Page 28

MONTAGE

OUTILS NÉCESSAIRES

• Clé ouverte de 7/16 in.

DÉBALLAGE DE LA MACHINE

1. Couper le haut du carton.

1

1. Unité de coupe

2. Goulotte d'évacuation

3. Sac à herbe

4. Cadre du sac à herbe

5. Documentation

6. Chargeur de batterie (démarreur électrique)

OM0311

6

Figure 4

2. Retirer les inserts, avant et arrière, et la

documentation.

3. Couper l’arrière du carton et faire rouler la machine

pour la sortir.

4. Retirer l’emballage de protection.

3

2

OM0340

OM0320

5

Literature

Pack

OM0560

OM0350

4

OM0330

MONTAGE

1. Déplier et régler le guidon.

2. La tige du sélecteur de vitesse est livrée avec le

guidon, la visserie en place. Retirer la goupille et la

rondelle, insérer l’extrémité courbée de la tige du

sélecteur de vitesse dans le trou de pivot de la

manivelle de commande de vitesse.

1

3

2

1. Tige du sélecteur

de vitesse

2. Rondelle et goupille

3. Levier de la

commande de

vitesse

OM0300

3. Poser le sac à herbe sur son cadre.

4. Configurer la tondeuse pour l’ensachage,

l’évacuation latérale ou le paillis. Voir

de la tondeuse

dans la section Fonctionnement .

5. Charger la batterie à fond. Voir

Configurations

Entretien et réglages.

6. Vérifier le fonctionnement des commandes du

moteur et de la lame. Le moteur et la lame doivent

s’arrêter dans les trois secondes qui suivent le

relâchement des commandes au guidon.

7. Remplir le réservoir. Voir la section

Fonctionnement .

Figure 5

28

Page 29

Low

High

Arrière

3

4

5

1

2

OM0190

OM0180

1. Levier de hauteur de coupe

2. Crans

3. Trous de réglage de la chape et de l’émerillon

4. Trou de blocage de l’émerillon (émerillon

verrouillé)

5. Trou de remisage de la goupille à anneau (libre)

Pivot avant

Bas

Haut

Figure 6

FONCTIONNEMENT

COMMANDES ET CARACTÉRISTIQUES

Voir Figures 1 et 6 pour les commandes.

Commande moteur/lame

AVERTISSEMENT :

le moteur en marche à ce stade. Se familiariser

avec les commandes pour maîtriser leur

fonctionnement. Avant tout, lire attentivement

et comprendre le manuel de l’utilisateur.

PRUDENCE :

commande moteur/lame. Un mauvais

fonctionnement peut entraîner des blessures.

Pour pouvoir mettre le moteur en marche,

serrer la commande moteur/lame contre le

guidon.

Le relâchement de la commande arrête le

moteur et la lame.

NE PAS tenter de mettre

Vérifier régulièrement la

OM0450

Réglage de la hauteur de coupe

Cran Longueur de l’herbe

BAS 25 mm (1 in.)

2 35 mm (1-3/8 in.)

3 45 mm (1-3/4 in.)

4 57 mm (2-1/4 in.)

5 70 mm (2-3/4 in.)

HAUT 83 mm (3-1/4 in.)

Guidon

Le guidon possède 4 positions suivant le trou sélectionné

sur le support. Choisir une hauteur sûre et confortable puis

insérer la broche dans le trou du support se rapprochant le

plus proche de cette hauteur. Voir la section Réglage pour

les instructions.

Poignée du démarreur à cordon

Tirer sur la poignée pour faire tourner le moteur.

Hauteur de coupe – Modèles Standard

DANGER :

avec la lame, NE JAMAIS essayer de régler la

hauteur de coupe tant que le moteur est en

marche.

PRUDENCE :

les deux roues arrière doivent être réglées à la

même hauteur pour assurer le fonctionnement

correct de l’embrayage de traction.

Pour régler la hauteur de coupe, déplacer les leviers

progressivement d’un cran jusqu’à obtention de la hauteur

voulue. (Figure 6)

REMARQUE :

roues à la même hauteur.

Pour éviter tout contact accidentel

Sur les machines autotractées,

Pour assurer une tonte régulière, régler les

29

Page 30

STOP

RUN

START

COMMANDES EN OPTION

Voir figures 1 et 6.

Hauteur de coupe – Modèles à pivot

PRUDENCE :

recommandé d’insérer une goupille à anneau

dans le trou de blocage du pivot pour les

déplacements en pente. Si les roues sont en

position pivotante et les poignées de commande

sont relâchées, la tondeuse risque de descendre

la pente en roue libre. Ne jamais tondre dans des

pentes raides.

Pour régler la hauteur de coupe par les roues avant, insérer

la broche de la chape correspondant à la hauteur de coupe

voulue. (Figure 6).

Pour régler la hauteur de coupe par les roues arrière,

déplacer le levier d’un cran à l’autre jusqu’à obtention de la

hauteur voulue. (Figure 6).

Poire d’amorçage (moteur Briggs & Stratton)

Presser la poire d’amorçage pour ajouter du carburant

dans le carburateur et faciliter la mise en marche.

Sur les modèles à pivot, il est

Sélecteur de vitesses sur vitesse lente et moteur en

marche, enclencher la commande de traction des roues.

Augmenter la vitesse à l’aide du sélecteur pour obtenir une

vitesse de marche sûre et confortable. Une fois la vitesse

sélectionnée, le sélecteur doit rester dans cette position.

Dans le cas contraire, régler la tension du ressort du levier

de commande de vitesses. (Voir

Réglages ).

Commande de traction

PRUDENCE :

roues des modèles autotractés sont serrées

contre le guidon au moment de la mise en

marche du moteur, la tondeuse avance.

Moteur en marche, serrer lentement et maintenir la

commande de traction contre le guidon pour faire avancer

la tondeuse. Relâcher la commande pour l’arrêter.

Commutateur d’allumage

Le contacteur d’allumage est actionné à

l’aide d’une clé amovible. Pour mettre

la machine en marche, tourner le

commutateur dans le sens horaire de

la position « ARRÊT » à la position

« DÉMARRAGE ». La clé retourne

automatiquement sur « MARCHE ».

Position « ARRÊT » : Le démarreur est arrêté.