Page 1

Introduction

CSW45

This manual includes:

Installation Information

•

Use And Care

•

Service Diagnosis

•

and Repair Information

•

Table of Contents

Introduction ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 1

Specifications ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 2

Installing The Ice Maker ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 3

Electrical & Leveling ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 4

To Adjust The Rear Wheel Height,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 5

Connecting the Ice Maker to a Water Source ,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 6

Water Connection - continued ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 7

Connecting The Drain ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 8

A Service Parts Section is also included in the center

of the manual.

Drain Pump Kit ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 9

Reversing the Door Swing,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 10

Using The Ice Maker ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 11

Caring For Your Ice Maker ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 12

Cleaning the Condenser,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 13

Cleaning the Interior Components,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 14

Cleaning Interior - continued ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 15

Vacation and Moving Care ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 16

Before Calling for Service ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 17

Technical Service Diagnosis ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 18

Technical Service Diagnosis ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 19

Technical Information ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 20

Electrical Sequence ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 21

Repair Information ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 22

Repair Information ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 23

Repair Information ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,Page 24

July 1999

Page 1

Page 2

CSW45

Specifications

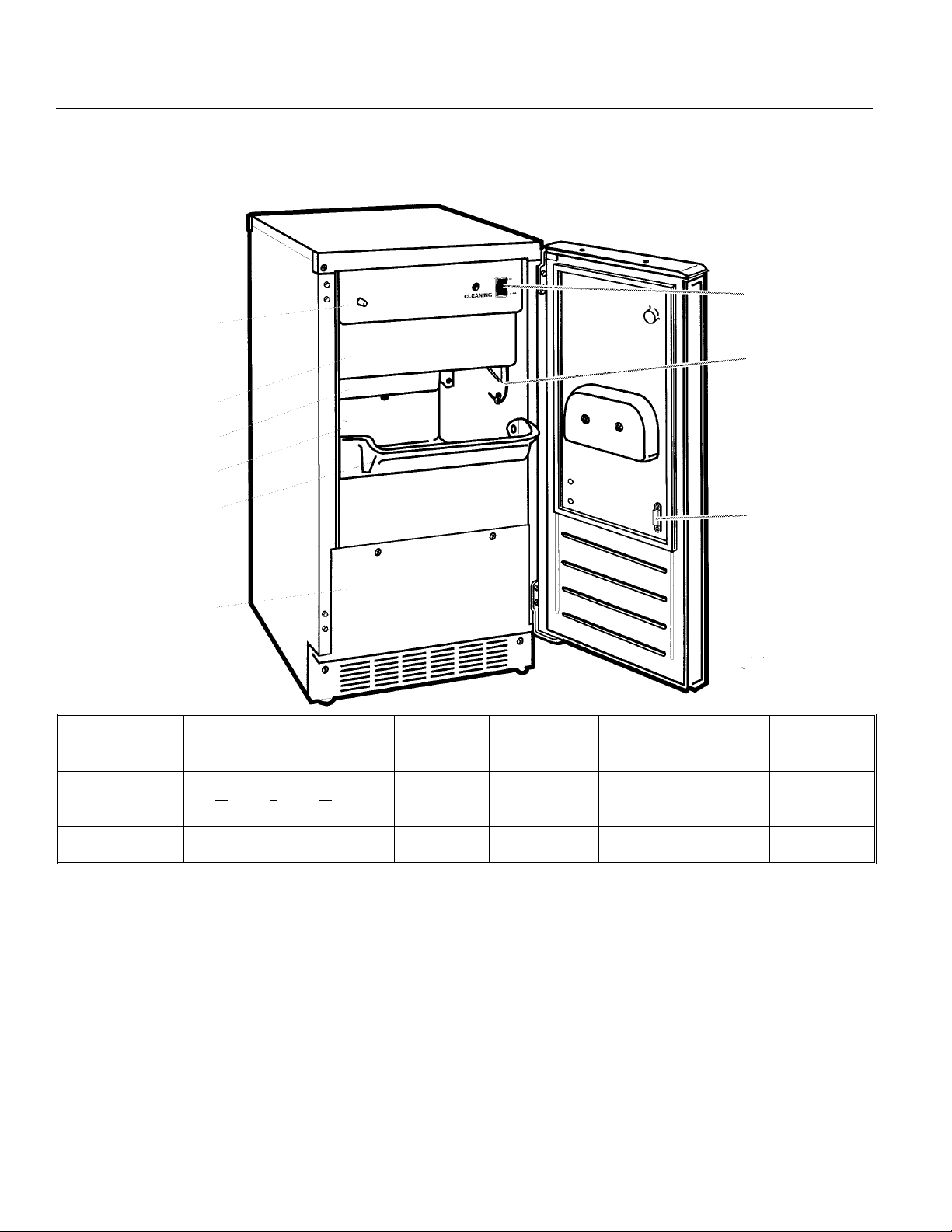

Light Switch

Cutter Grid Cover

Water Pan

Model Serial

Number Label

Ice Retainer Baffle

Control Panel

Ice Level Sensor

Magnetic Door

Catch

Lower Access Panel

Model Cabinet Size, w” x d” x h”

14

CSW45A-1B

CSW45PA-1B same same Drain Pump same same

All units are white enamel.

Optional Kits: Trim Kit: KCSWTRIM, Filler Kit for 18” spaces: KCSWFILL, Drain Pump: A37649-001

Scotsman Ice Systems are designed and manufactured with the highest regard for safety and performance.

They meet or exceed the standards of UL, NSF, and CSA.

Scotsman assumes no liability or responsibility of any kind for products manufactured by Scotsman that

have been altered in any way, including the use of any part and/or other components not specifically

approved by Scotsman.

x21 x33

Basic

Electrical

115/60/1 Gravity

Drain Type Power

Cord Supplied, uses

15 amp circuit

Refrigerant

Charge

6.5 oz

R-134a

Scotsman reserves the right to make design changes and/or improvements at any time. Specifications and

design are subject to change without notice.

July 2001

Page 2

Page 3

Installing The Ice Maker

Unpacking

Excessive Weight Hazard

Installation of the ice maker requires a cold

•

water supply inlet of

1

“ (6mm) OD soft copper

4

tubing with a shut-off valve and either a

gravity-drain system or condensate pump to

carry the water to an existing drain.

CSW45

Use two or more people to move and install ice

maker.

Failure to do so can result in back or other injury.

Removing packaging materials

IMPORTANT: Do not remove any permanent

instruction labels inside your ice maker or the Tech

Sheet that is fastened behind the lower access

panel.

• Remove tape and any labels from your ice

maker before using (except the model and serial

number label).

To remove any remaining tape or glue, rub the area

briskly with your thumb. Tape or glue residue can

also be easily removed by rubbing a small amount of

liquid dish soap over the adhesive with your fingers.

Wipe with warm water and dry.

•

Do not use sharp instruments, rubbing alcohol,

flammable fluids, or abrasive cleaners to remove

tape or glue. These products can damage the

surface of your ice maker. For more information,

see the “Important Safety Instructions” section.

Choose a well ventilated area with

•

temperatures above 55°F (13°C) and below

100°F (38°C). Best results are obtained

between 70°F (21°C) and 90°F (32°C). This unit

MUST be installed in an area protected from the

elements, such as wind, rain, water spray, or

drip.

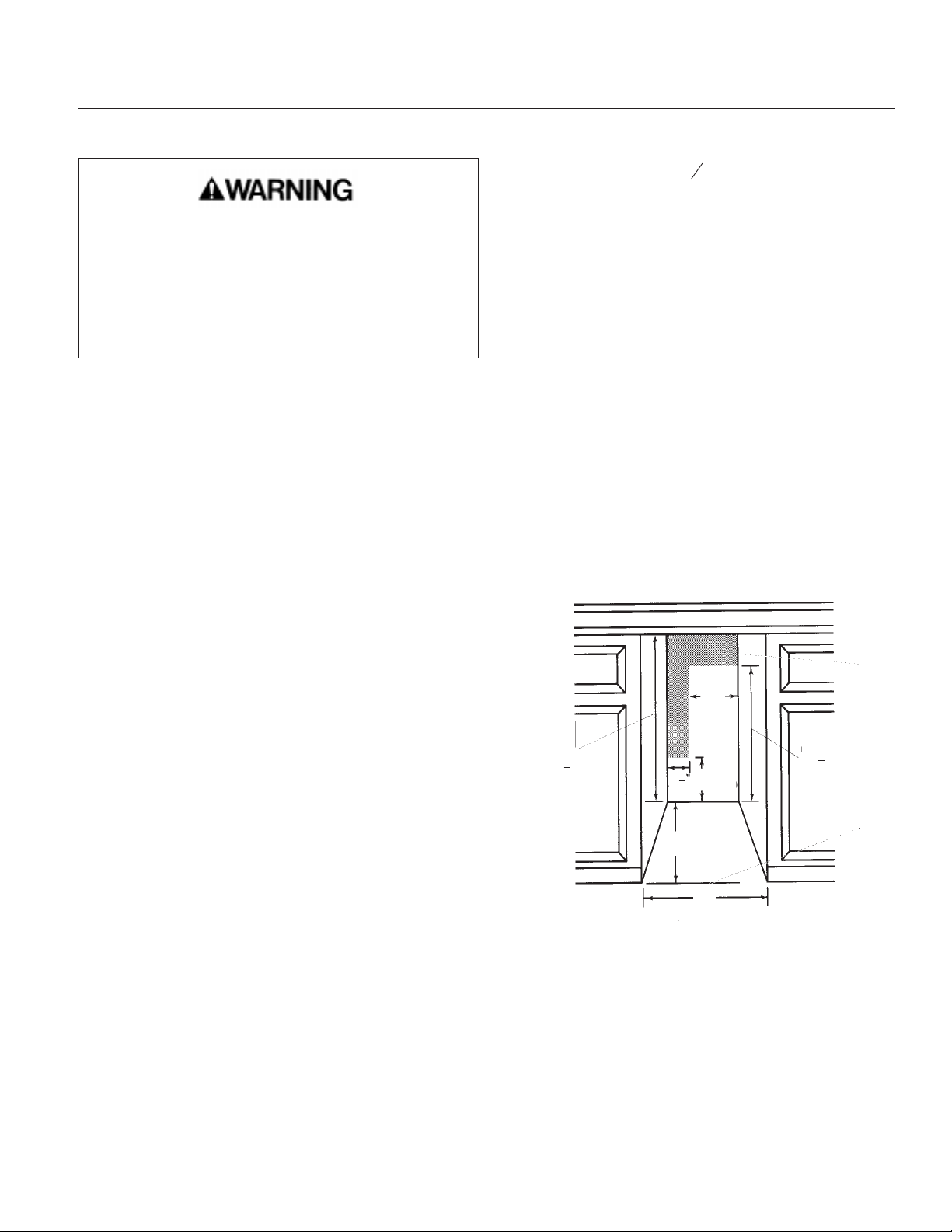

When installing the ice maker under a counter,

•

follow the recommended opening dimensions

shown. Do not place electrical or plumbing

fixtures in the clear zone as indicated by the

gray shaded area.

NOTE: Do not kink or pinch the power supply cord

between the ice maker and cabinet.

1

11

”

2

34”

min

34

max

1

”

2

1

3

9”

2

28

1

”

2

Cleaning before use

After you remove all of the packaging materials,

clean the inside of your ice maker before using it.

See the cleaning instructions in the “Caring for Your

Ice Maker” section.

Space Requirements

•

To ensure proper ventilation for your ice maker,

the front side must be completely unobstructed.

The unit may be closed-in on the top and three

sides, but the installation should allow the ice

maker to be pulled forward for servicing if

necessary.

July 1999

Page 3

24”

15”

1. Clear Zone

2. Floor Level

n You should choose a location where the floor is

even. It is important for the ice maker to be level in

order to work properly. If needed, you can adjust the

height of the ice maker by changing the position of

the rear wheels. See the “Leveling the Ice Maker”

section.

Page 4

CSW45

Electrical & Leveling

Electrical Shock Hazard

Plug into a grounded 3

prong outlet.

Failure to follow these

instructions can result in

death, fire, or electrical

shock.

Do not use an extension

cord.

Do not use an adapter.

Do not remove ground

prong.

Before you move your ice maker into its final

location, it is important to make sure you have the

proper electrical connection:

A 115 Volt, 60 Hz., AC only 15 ampere electrical

supply, properly grounded in accordance with the

National Electrical Code and local codes and

ordinances, is required.

It is recommended that a separate circuit, serving

only your ice maker, be provided. Use a receptacle

which cannot be turned off by a switch or pull chain.

Recommended Grounding Method

For your personal safety, this appliance must be

grounded. This appliance is equipped with a power

supply cord having a 3 prong grounding plug. To

minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type wall

receptacle, grounded in accordance with the

National Electrical Code and local codes and

ordinances. If a mating wall receptacle is not

available, it is the personal responsibility of the

customer to have a properly grounded, 3 prong wall

receptacle installed by a qualified electrician.

Leveling the Ice Maker

It is important for the ice maker to be level in order to

work properly. Depending upon where you install the

ice maker, you may need to make several

adjustments to level it.

Tools required

Carpenter’s level

•

Adjustable wrench

•

1

" socket wrench

•

4

Undercounter Installation

If you are installing the ice maker under a

countertop, then you may need to adjust the height

of the ice maker. The adjustable rear wheels are

preset to position 1 for a cabinet opening height of

34" (86.4 cm).

1

2

3

4

1. For cutout height of 34" (86.4 cm)

2. For cutout height of 34

3. For cutout height of 34

4. For cutout height of 34

1

" (86.7 cm)

8

5

" (87.2 cm)

16

1

" (87.6 cm)

2

July 1999

Page 4

Page 5

To Adjust The Rear Wheel Height

CSW45

Electrical Shock Hazard

Failure to follow these

instructions can result in

death, fire, or electrical

shock.

Disconnect power before

servicing.

Replace all panels before

operating.

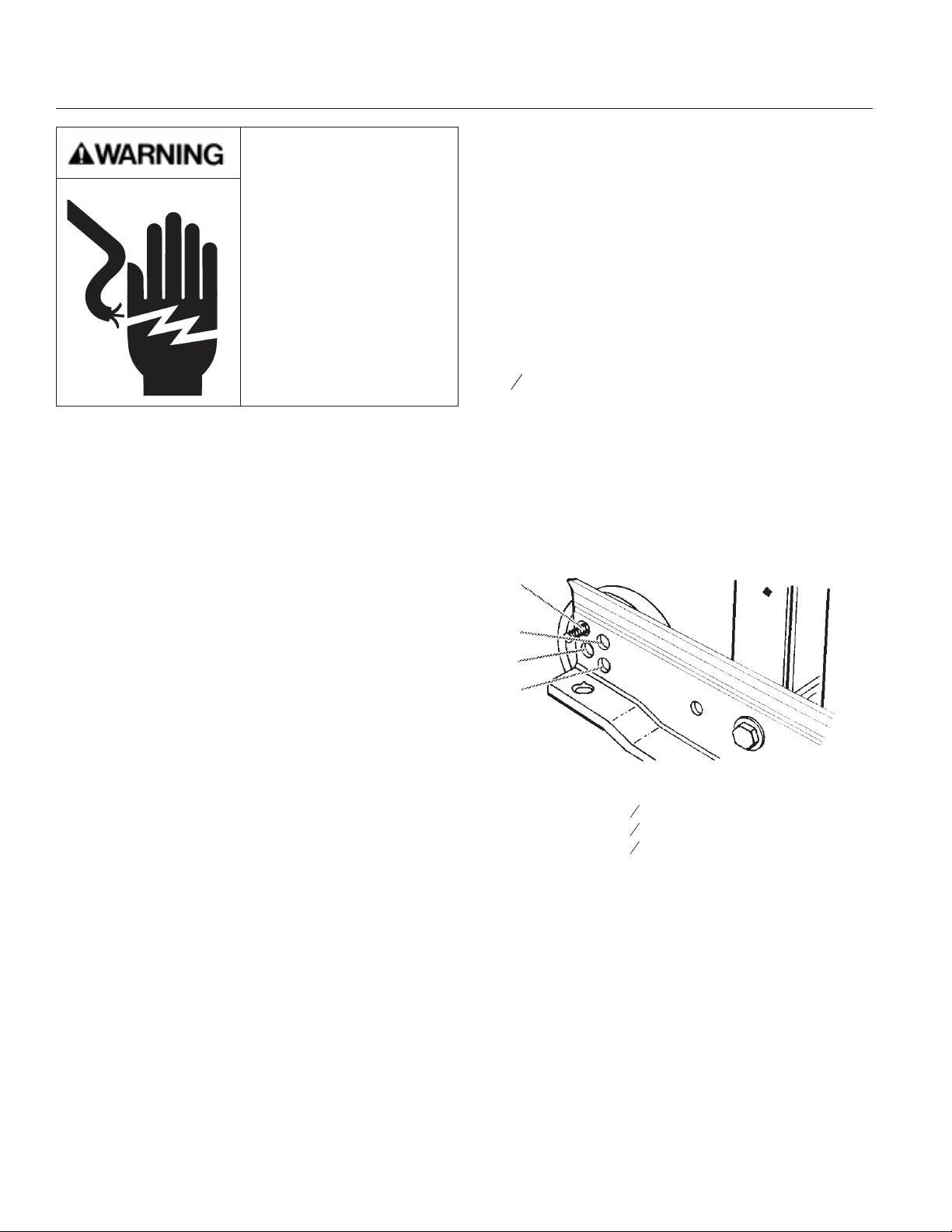

1. Using a

1

“ socket wrench, remove the seven

4

screws from the rear access panel and carefully pull

the panel away from the drain hose.

2. Using a

3

“ or adjustable wrench, remove the

8

screw that holds the rear wheel.

NOTE: Pushing up against the top back of the ice

maker takes some of the weight off of the wheels.

This makes it easier to remove the screws.

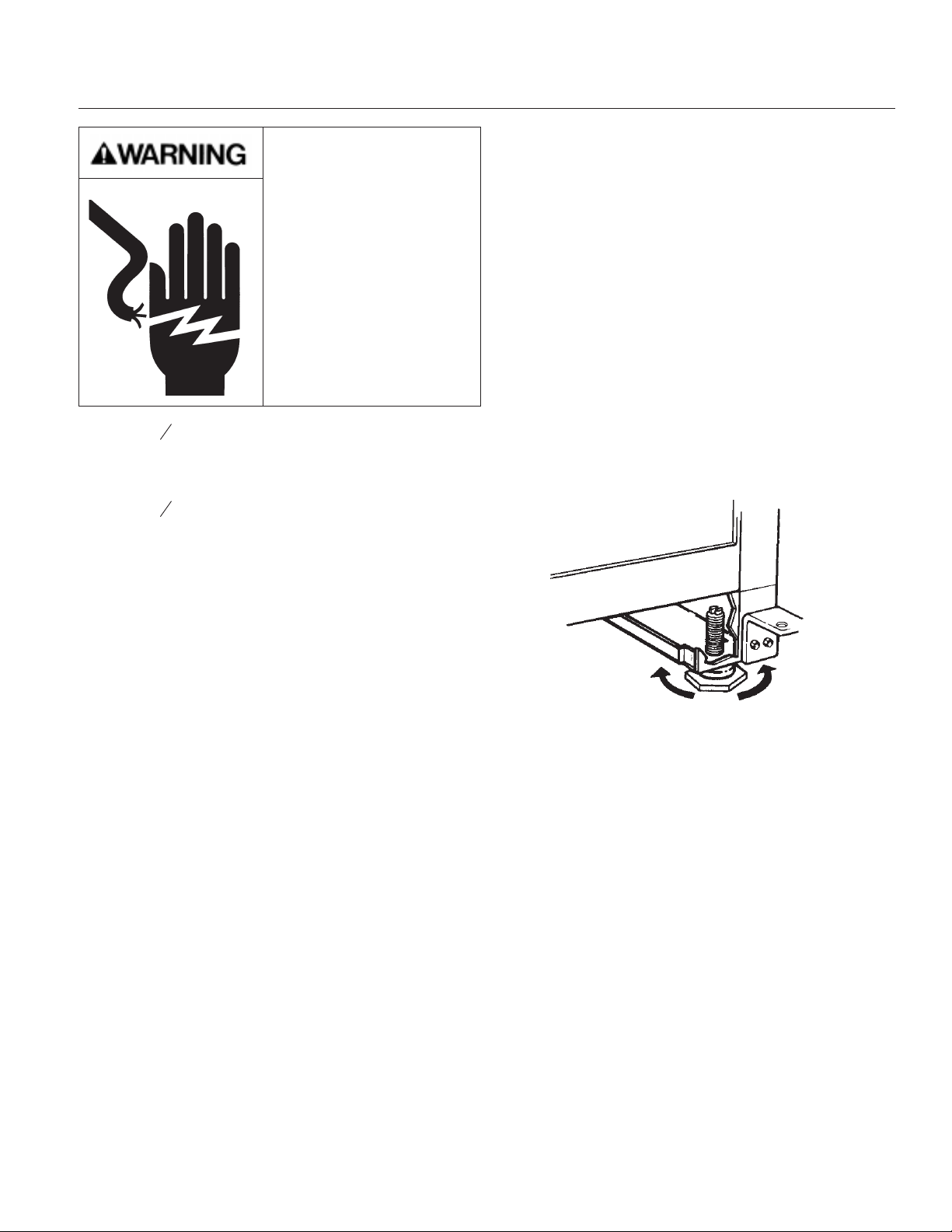

2. Push up on the top front of the ice maker, and

then locate the leveling screws that are on the

bottom front of the product.

3. Using an adjustable wrench, change the height of

the legs as follows:

Turn the leveling leg to the right to lower that

•

side of the ice maker.

Turn the leveling leg to the left to raise that side

•

of the ice maker.

NOTE: The ice maker should not wobble. Use shims

to add stability when needed.

3. Move the rear wheel and screw to a new position

as needed for your cabinet opening height. Tighten

the screw completely.

4. Repeat Steps 3 and 4 to change the position of

the wheel on the other side.

5. Replace the rear panel and screws. Be sure that

the drain tube is positioned in the opening provided.

6. Use the front leveling legs to make sure the

product is level.

To adjust the front leveling legs

Your ice maker has two adjustable leveling legs to

help you steady the product and make sure it is

level.

SUGGESTION: It is easier to adjust the leveling legs

if you have another person to assist you.

1. Place a carpenter’s level on top of the product to

see if the ice maker is level from front to back and

side to side.

4. Use a carpenter’s level to re-check the ice maker

to see that it is even from front to back and side to

side. If the ice maker is not level, repeat Steps2&3.

If the ice maker is level, go to the “Connecting the

Ice Maker to a Water Source” section.

Freestanding Installation

If you are not installing your ice maker under a

countertop, you will probably not need to adjust the

rear wheel height. Follow the steps outlined in “To

adjust the front leveling legs” earlier in this section.

NOTE: The ice maker should not wobble. Use shims

to add stability when needed.

July 1999

Page 5

Page 6

CSW45

Connecting the Ice Maker to a Water Source

Read all directions carefully before you begin.

IMPORTANT:

All installations must be in accordance with local

•

plumbing codes requirements.

Use copper tubing and check for leaks.

•

Install copper tubing only in areas where

•

temperatures will remain above freezing.

7. Place the free end of the tubing into a container or

sink, and turn on main water supply and flush out

tubing until water is clear. Turn off shut-off valve on

the water pipe.

Slip compression sleeve and compression nut

•

on copper tubing as shown. Insert end of tubing

into outlet end squarely as far as it will go.

Screw compression nut onto outlet end with

adjustable wrench. Do not over tighten.

Before purchasing, make sure a saddle-type valve

complies with your local plumbing codes. Do not

use a piercing-type or 3/16” saddle valve which

reduces water flow and clogs more easily.

Connecting the water line:

1. Unplug ice maker or disconnect power.

2. Turn off main water supply. Turn on nearest

faucet long enough to clear line of water.

3. Find a

1

"to

2

1

" vertical cold water pipe near the

1

4

ice maker.

NOTE: Horizontal pipe will work, but the following

procedure must be followed: Drill on the top side of

the pipe, not the bottom. This will help keep water

away from the drill. This also keeps normal sediment

from collecting in the valve.

4. Using a grounded drill, drill a

1

" (6 mm) hole in the

4

cold water pipe you have selected.

NOTE: Always drain the water line before making

the final connection to the inlet of the water valve to

prevent possible water valve malfunction.

8. Remove the two screws in the lower access panel

and the two screws in the base grille area of the front

panel support. Pull forward to remove the lower

access panel.

9. Position the tubing so it can enter one of the two

access holes located at the right-hand rear of the

cabinet as shown. The tubing should extend beyond

the cabinet front when the cabinet is pushed back

into position. Move the ice machine into position.

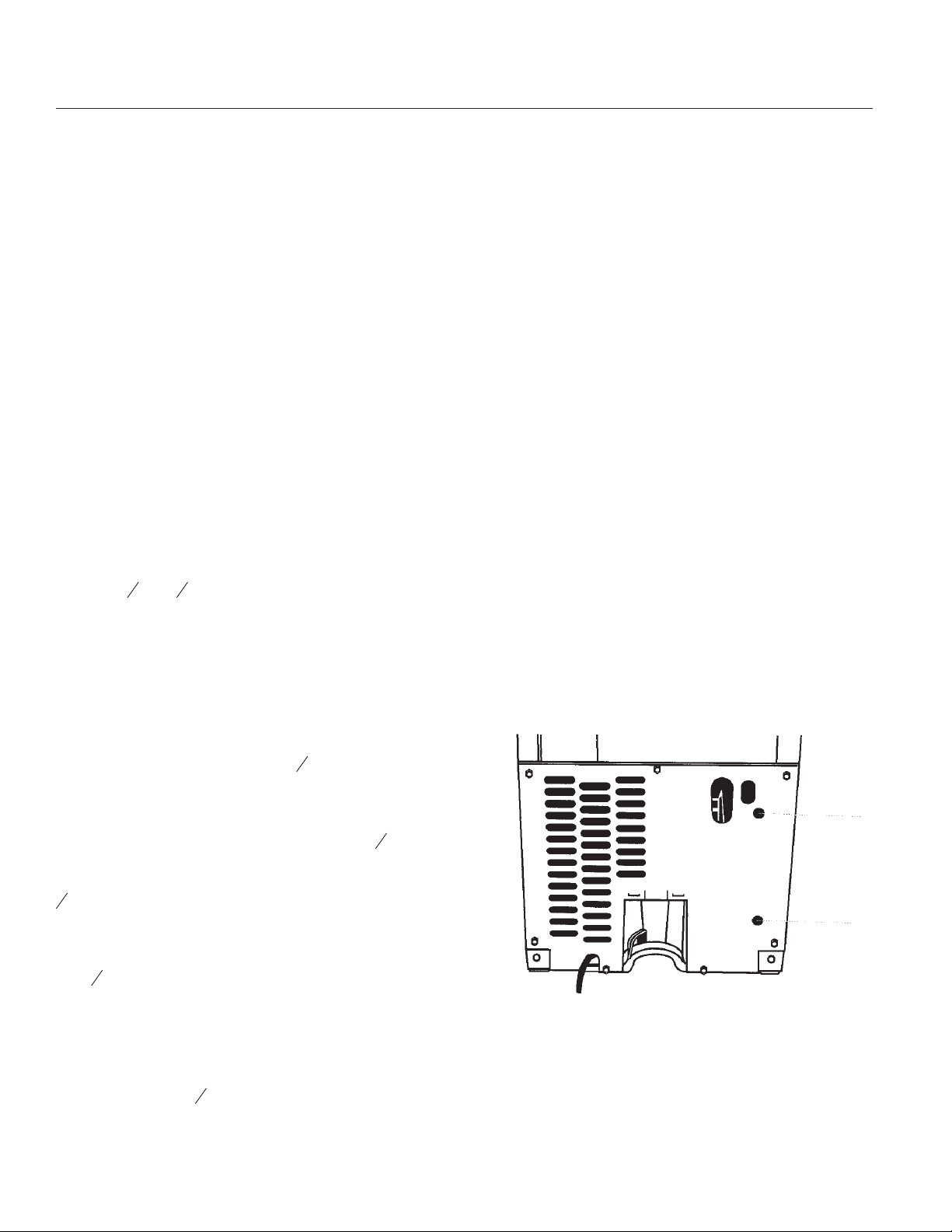

REAR VIEW

1. Upper Water Line Access Hole

2. Lower Water Line Access Hole

5. Fasten shut-off valve to cold water pipe with pipe

clamp. Be sure outlet end is solidly in the

1

-inch

4

drilled hole in the water pipe and that washer is

under the pipe clamp. Do not use a piercing-type or

3

" saddle-type valve which reduces water flow and

16

clogs more easily.

6. Now you are ready to connect the copper tubing.

1

Use

" (6mm) OD soft copper tubing for the cold

4

water supply.

•

Measure from the connection at the front of the

ice maker to the cold water pipe. Add 3 feet to

ensure that you have the proper length. This is

the length of

1

" (6mm) OD soft copper tubing

4

you need for the job. Be sure both ends of the

copper tubing are cut square.

1

2

10. Bend the copper tubing to meet the water valve

inlet on the water valve which is located in the front

of the ice maker cabinet as shown.

July 1999

Page 6

Page 7

Water Connection - continued

CSW45

11. Unscrew the water valve inlet cover, and attach

the copper tubing with the compression sleeve and

nut.

NOTE: To prevent rattling, be sure the copper tubing

does not touch the cabinet’s side wall or other parts

inside the cabinet.

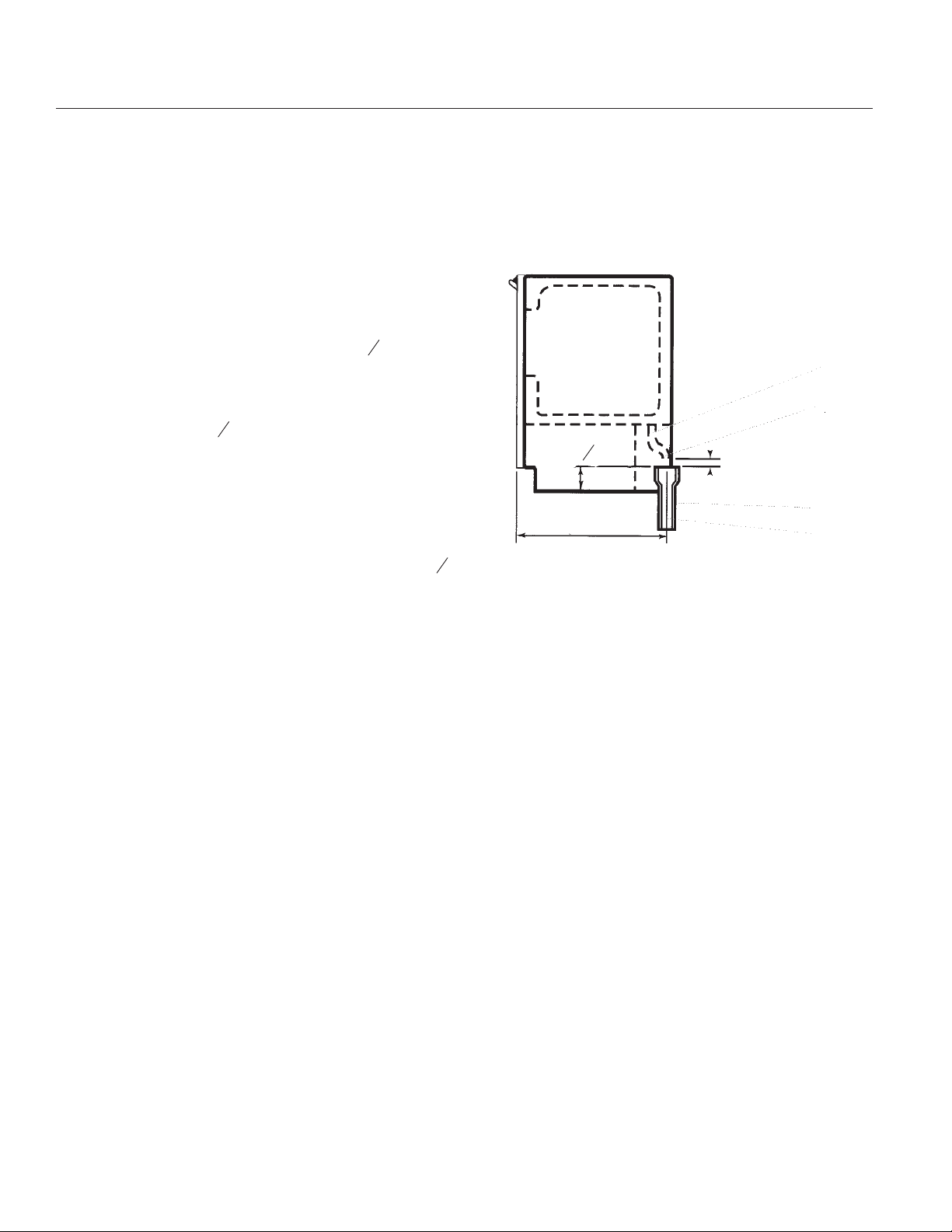

FRONT VIEW

1

12. Turn shut-off valve on. Check for leaks.

Tighten any connections (including connections at

the valve) or nuts that leak. The ice maker is

equipped with a built-in water strainer. If local water

conditions require periodic cleaning or a well is your

source of water supply, a second water strainer

should be installed. Obtain a water strainer from your

nearest appliance dealer and install it at either tube

connection.

13. Replace the lower access panel and screws.

3

12

16

5

7

“

16

2

1. Water Pan Drain

2. Water Valve

11

5

16

Custom Panel (for kit KCSWTRIM):

Customer supplied wood panel must be

•

” thick x

31

•

29

“ high x

64

33

•

14

“ wide

64

and be trimmed as shown in the diagram.

Route Approx

”

3

5

“

8

3

“

8

15

1

“

32

July 1999

Page 7

” Thick Panel

Page 8

CSW45

Connecting The Drain

Gravity drain system

Connect the drain pump hose (provided with the

product) to your drain in accordance with all state

and local codes and ordinances. If the ice maker is

provided with a gravity drain system, follow these

guidelines when installing drain lines: (This will

prevent water from flowing back into the ice maker

storage bin and potentially flowing onto the floor

causing water damage.)

Drain lines must have a minimum of

•

5

" (1.6 cm)

8

inside diameter.

Drain lines must have a 1" (2.5 cm) drop per 48”

•

(122 cm) of run (

1

" per foot [6mm per 30.5cm])

4

and must not have low points where water can

settle.

The floor drains must be large enough to

•

accommodate drainage from all drains.

• The ideal installation has a standpipe with a 1

to 2" PVC drain reducer installed directly below

the outlet of the drain tube as shown. You must

maintain a 1" air gap between the drain pump

hose and the standpipe.

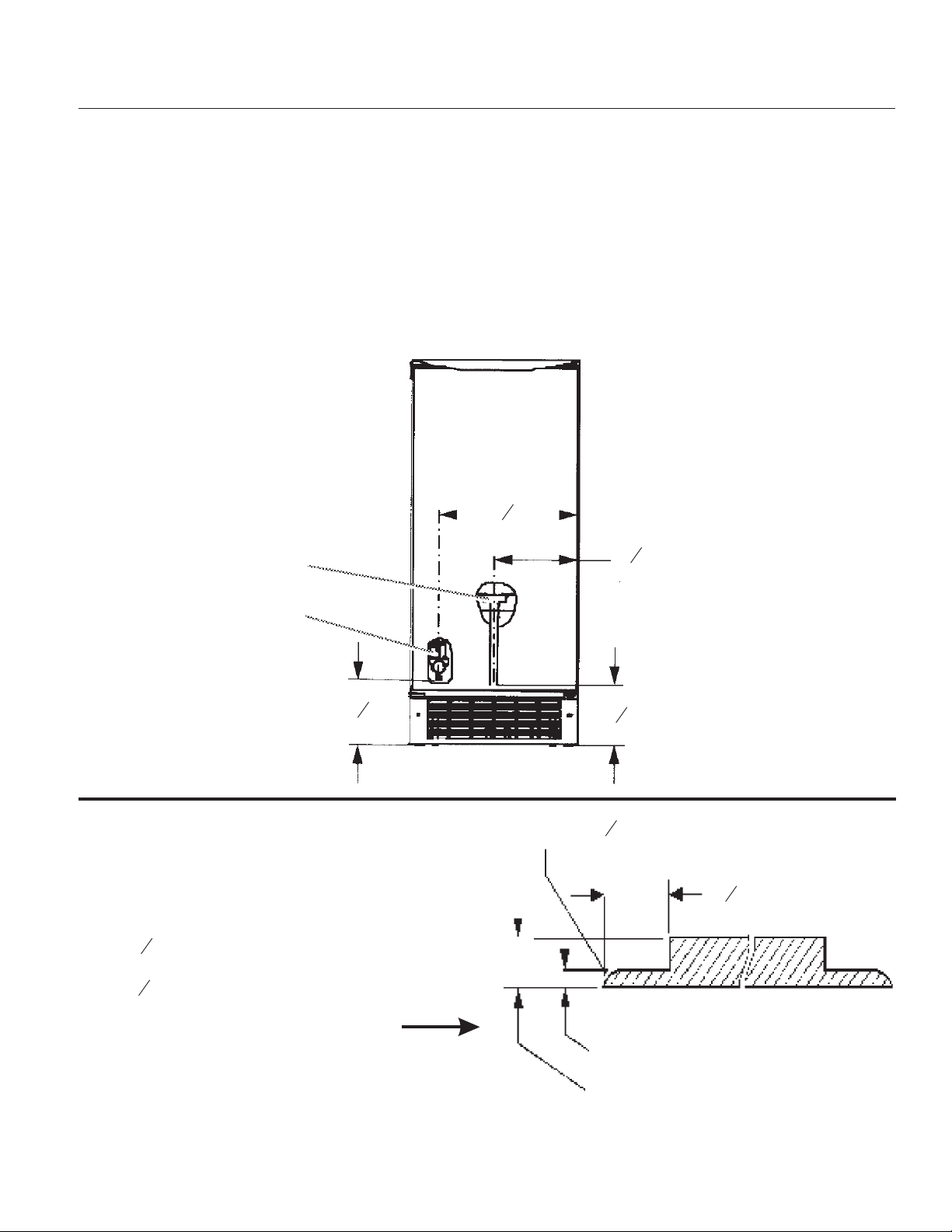

SIDE VIEW

1

"

2

1

2

5

“

4

8

1”

3

23”

4

2”

•

It may be desirable to insulate the drain line

thoroughly up to the drain inlet.

After ensuring that the drain system is adequate,

follow these steps to properly place the ice maker:

1. Plug ice maker into a grounded 3 prong outlet.

2. Re-check the ice maker to be sure that it is level.

See the “Leveling the Ice Maker” section.

3. Push the ice maker into position so that the ice

maker drain tube is positioned over the PVC drain

reducer.

1. Drain Hose

2. 1" Air Gap

3. PVC Drain Reducer

4. Center of drain should be 23” (58.4 cm) from front of door

(with or without the C\v” (1.9 cm) panel on the door).

4. If it is required by your local sanitation code, seal

the cabinet to the floor with an approved caulking

compound after all water and electrical connections

have been made.

5. Plug in ice maker or reconnect power.

Drain pump system (on some models)

Connect the drain pump hose (provided with the

product) to your drain in accordance with all state

and local codes and ordinances.

July 1999

Page 8

Page 9

Drain Pump Kit

1. Remove rear cover.

2. Remove old drain tube.

3. Install new drain tube to bin (use old clamp).

CSW45

Pump, View from

Front of Cabinet

4. Install drain pump into machine. Carefully slide in

aligning the tab on the pump to the rectangular slot

in the unit base.

5. Attach bin drain tube from bin to pump.

6. Connect vent tube to vent connection on pump.

Route vent up through the rear cover. Secure vent

tube to back of ice machine using three clamps and

screws from the kit.

7. Route pump outlet tube to household drain.

8. Power cord from ice machine must be plugged

into pump. Coil up and tape power cord together,

insert between compressor and drain pump. Plug the

power cord into the pump.

9. Line up the two screws at the rear of the pump

and secure the pump using two screws from the kit.

Pump

Mounting Tab

Vent Tube

10. Install rear cover.

11. Connect power cord (pump’s) into the electrical

power supply. This must be a grounded circuit that

conforms to the National Electrical Code and all local

codes and ordinances.

July 1999

Page 9

Discharge

Hose

Pump

Mounting

Screws

Page 10

CSW45

Reversing the Door Swing

TOOLS NEEDED:

5

" wrench,

16

1

" wrench, flat putty

4

knife,

To remove door from hinges:

1. Unplug ice maker or

disconnect power.

2. Remove the handle screws and

handle (on some models). Keep

the parts together and set

them aside.

3. Remove the hinge pin from the

top hinge.

4. Remove the door from the

hinges and screw the top hinge

pin back into the top hinge.

5. Reverse the door endcaps as follows:

• Remove both the screws and endcaps (top and

bottom).

the hinge pin points down. Place the hinge on the top

opposite side of the ice maker and tighten the

screws.

6. Remove the top hinge pin.

To replace door on hinges:

1. Place plastic hinge pin sleeve in the top hinge hole

on the door. Align the door with the top hinge hole

and replace the top hinge pin.

2. Replace the handle and handle screws.

Top Hinge

1. Hinge Pin

2. Hinge Pin Sleeve

3. Hinge

4. Hex Head Hinge

Screw

1

2

3

• Place the top endcap on the bottom of the

opposite side of the door with the long flat side

facing the door front.

•

Place the bottom endcap on the top of the

opposite side of the door with the long flat side

facing the door front.

6. Set the door aside.

To reverse the hinges:

1. Unscrew and remove the top hinge. Replace the

screws in the empty hinge holes.

2. Remove the screws from the bottom of the

opposite side of the ice maker cabinet. Turn the top

hinge upside down so that the hinge pin points up.

Place the hinge on the bottom opposite side of the

ice maker and tighten screws.

3. Remove the plastic hinge pin sleeve from the “old”

bottom hinge and replace it on the new bottom hinge

pin.

4. Remove the “old” bottom hinge screws and hinge.

Replace the screws in the empty hinge holes. the ice

maker cabinet. Turn the hinge upside down so that

4

Bottom Hinge

1. Hex Head Hinge

Screw

2. Hinge Pin Sleeve

3. Hinge

4. Hinge Pin

1

2

3

4

To reverse the door

catch:

1. Remove the hole plugs from the opposite side of

the door and set aside.

2. Remove the screws from the magnetic door catch

and replace it on the opposite side of the door.

3. Push the hole plugs into place on the opposite

side of the door.

July 1999

Page 10

Page 11

Using The Ice Maker

CSW45

Understanding How Your Ice Maker Works

When you first start your ice maker, the water pan

will fill and the system will rinse itself before starting

to make ice. The rinsing process takes about five

minutes.

Under normal operating conditions, the ice maker will

cycle at preset temperatures. The ice level sensor

located in the ice storage bin will monitor the ice

levels.

IMPORTANT

If the water supply to the ice maker is turned off,

•

be sure to set the ice maker control to OFF.

The ice maker is designed to make clear ice

•

from the majority of water sources on a daily

basis. If your results are unsatisfactory, your

water may need to be filtered or treated.

Making Ice

1. Water is constantly circulated over a freezing

plate. As the water freezes into ice, the minerals in

the water are rejected. This produces a clear sheet

of ice with a low mineral content.

3. The water containing the rejected minerals is

drained after each freezing cycle.

4. Fresh water enters the machine for the next ice

making cycle.

5. Cubes fall into the storage bin. When the bin is

full, the ice maker shuts off automatically and

restarts when more ice is needed. The ice bin is not

refrigerated and some melting will occur. The

amount of melting varies with room temperature.

NOTE: As the room and water temperatures vary, so

will the amount of ice produced and stored. This

means that higher operating temperatures result in

reduced ice production.

Setting the Controls

2. When the desired thickness is reached, the ice

sheet is released and slides onto a cutter grid. The

grid divides the sheet into individual cubes.

1. To start the normal ice making cycle, select ON.

2. To stop ice maker operation, select OFF.

NOTE: The CLEAN setting is used whenever

solutions are circulated through the ice maker for

cleaning. Only the water pump and compressor

operate at this setting. See the “Cleaning the Ice

Maker System” section.

July 1999

Page 11

Page 12

CSW45

Caring For Your Ice Maker

Periodically inspect and clean the ice maker to keep

it operating at peak efficiency and to prevent

premature failure of system components.

Both the ice making system and the air cooled

condenser need to be cleaned regularly.

The minerals rejected from the circulating water

during the freezing cycle will eventually form a hard

scaly deposit in the water system which prevents a

rapid release of the ice from the freezing plate.

Clean the ice and water system periodically to

remove mineral scale buildup. Frequency of cleaning

depends on water hardness. With hard water (15 to

20 grains/gal. [4 to 5 grains/liter]), cleaning may be

required as frequently as every 6 months.

Cleaning Exterior Surfaces

Wash the exterior enamel surfaces and gaskets with

warm water and mild soap or detergent. Wipe and

dry. Regular use of a good household appliance

cleaner and wax will help protect the finish.

5. Push the selector switch to CLEAN. (See the

“Setting the Controls” section.) The light will turn on,

indicating that the cleaning cycle is in process. When

the indicator light turns off (approximately 45

minutes), the cleaning cycle is complete. During the

cleaning cycle, the system will both clean and rinse

itself.

6. After the cleaning cycle is complete, remove the

drain cap from the water pan to see if any cleaning

solution is left in the water pan. If cleaning solution

drains from the water pan, you should run the clean

cycle again.

NOTE: Severe scale buildup may require repeated

cleaning with a fresh quantity of cleaning solution.

7. Push the selector switch to ON to resume ice

production.

Do not use abrasive cleaners on enamel surfaces as

they may scratch the finish.

Cleaning the Ice Maker System

1. Push the selector switch to OFF.

2. Wait 5 to 10 minutes for the ice to fall into the

storage bin. Remove all ice from the storage bin.

3. Unscrew the drain cap from the bottom of the

water pan located inside the storage bin as shown.

Allow the water to drain completely.

4. Replace the drain cap. Pour 16 ounces of

Scotsman Clear 1 scale remover into the water pan.

Fill the bottle twice with tap water and pour it into the

water pan.

September 2007

Page 12

Page 13

Cleaning the Condenser

CSW45

A dirty or clogged condenser:

Prevents proper airflow.

•

Reduces ice making capacity.

•

Causes higher than recommended operating

•

temperatures which may lead to component

failure.

Electrical Shock Hazard

Failure to follow these

instructions can result in

death, fire, or electrical

shock.

Disconnect power before

servicing.

Replace all panels before

operating.

1. Unplug ice maker or disconnect power.

2. Remove the two screws in the lower access panel

and the two screws from the base grille area of the

front panel support. Pull forward to remove the lower

access panel.

4. Remove dirt and lint from the condenser fins and

the unit compartment with a brush attachment on a

vacuum cleaner.

5. Replace the lower access panel using the four

screws.

6. Plug in ice maker or reconnect power.

3. Pull the bottom forward and then pull down to

remove the lower access panel.

July 1999

Page 13

Page 14

CSW45

Cleaning the Interior Components

1. Unplug ice maker or disconnect power.

Electrical Shock Hazard

Failure to follow these

instructions can result in

death, fire, or electrical

shock.

Disconnect power before

servicing.

Replace all panels before

operating.

2. Open the storage bin door and remove any ice

that is in the bin.

3. Remove the drain cap from the water pan and

drain thoroughly. Replace the drain cap.

4. Remove the three screws that hold the cutter grid

cover in place.

NOTE: Make sure the plastic spacer from the

right-hand side of the cutter grid bracket stays with

the cutter grid.

1

2

3

1. Cutter Grid Harness

2. Screw

3. Cutter Grid

4. Ice Level Sensor Harness

5. Plastic Spacer

6. Screw

4

5

6

5. Unplug the wiring harness from the left side of the

cutter grid.

1

2

1. Cutter Grid Cover

2. Screws

6. Unplug the ice level sensor from the right side of

the cutter grid. Pull the ice level sensor down and

forward away from the cutter grid.

7. Remove the right-hand screw and loosen the

left-hand screw. Lift the cutter grid up and out and

over the left-hand screw.

July 1999

Page 14

Page 15

Cleaning Interior - continued

CSW45

8. Remove the two screws that hold the water pan in

place. Push down with one hand on the front of the

pan while pulling forward on the bottom back side.

9. Wash the interior components (cutter grid, exterior

of hoses, and water pan) and the storage bin, door

gasket, and ice scoop with mild soap or detergent

and warm water. Rinse in clean water. Then clean

the same parts with a solution of 1 tablespoon (15

mL) of household bleach in 1 gallon (3.8 L) warm

water. Rinse again thoroughly in clean water.

NOTE: Do not remove hoses. Do not wash plastic

parts in dishwasher. They cannot withstand

temperatures above 145°F (63°C).

Changing the Light Bulb

The ice maker has a light bulb in the top of the

storage bin.

To replace it, open the bin door and follow these

instructions:

1. Unplug ice maker or disconnect power.

2. Remove the three screws that hold the cutter grid

cover in place. Reach behind the control panel and

pull the light bulb down from the ceiling.

3. Replace with a 12-volt wedge base-type bulb

(automotive #917). Locate the light bulb receptacle in

the ceiling behind the control panel. Align the flat

edge of the light bulb with the receptacle and snap

the bulb into place.

10. Replace water pan by pushing back on the

bottom with one hand while pushing up and back on

the top. Secure the water pan by replacing both

screws.

11. Check the following:

•

Drain cap from the water pan is in place.

•

Hose from water pan is inserted into storage bin

drain opening.

12. Slide the cutter grid back into place and secure it

by replacing the right-hand screw and plastic spacer.

Then tighten the left-hand screw. Reconnect the

cutter grid and ice level sensor harnesses.

4. Replace the cutter grid cover with three screws.

5. Plug in ice maker or reconnect power.

July 1999

Page 15

Page 16

CSW45

Vacation and Moving Care

To shut down the ice maker:

1. Unplug ice maker or disconnect power.

2. Remove all ice from storage bin.

3. Shut off the water supply.

4. Remove the two screws in the lower access panel

and the two screws from the base grille area of the

front panel support. Pull forward to remove the lower

access panel.

5. Disconnect the inlet and outlet lines to water

valve. Allow these lines to drain and then reconnect

to the valve.

6. Replace lower access panel and screws. Drain

water from water pan by removing the drain cap.

Also, remove water from drain line.

7. Before using again, clean the ice maker and

storage bin.

8. Plug in ice maker or reconnect power.

NOTE: All components of the ice maker are

permanently lubricated at the factory. They should

not require any additional oiling throughout the

normal life of the machine.

WA so can result in death or

electrical shock.

July 1999

Page 16

Page 17

Before Calling for Service

CSW45

Try the solutions suggested here first in order to

avoid the cost of an unnecessary service call.

Unit does not run

n Is the control set to ON?

Be sure that the control is set to ON.

n Is the power cord plugged in?

Firmly plug the cord into a live outlet with proper

voltage.

n Has a household fuse or circuit breaker

tripped?

Replace the fuse or reset the circuit.

n Is the room temperature cooler than normal?

Room temperature must be above 55°F (13°C).

Otherwise, bin thermostat may sense cold room

temperature and shut off even though bin is not full

of ice. Also, unit may not restart once it does shut off.

Unit runs but produces no ice

If there is white scale buildup in the ice maker’s

water or freezing system, you should clean the ice

maker. See the “Cleaning the Ice Maker System”

and the “Cleaning the Interior Components” sections.

Grid is not cutting ice sheets

n Is the cutter grid securely in place?

Unplug the ice maker or disconnect power. Remove

the cutter grid cover and check the cutter grid

harness plug to make sure the connection is secure.

Taste in ice cubes

n Is there unusually high mineral content in the

water supply?

The water may need to be filtered or treated.

n Are there food items stored in the ice bin?

Do not store any foods in the ice bin.

n Were all the packaging materials removed?

Make sure that all packaging materials were

removed at the time of installation. Service Diagnosis

n Is the control set to ON?

Be sure that the control is set to ON.

n Is the water supply connected?

Make sure the water supply is properly connected

and turned on.

Unit runs but produces very little ice

n Is the room temperature hotter than normal?

Room temperatures of more than 90°F (32°C) will

normally reduce ice production.

n Is the condenser dirty?

Dirt or lint may be blocking the airflow through the

condenser. See the “Cleaning the Condenser”

section.

n Is there scale buildup in the ice maker?

July 1999

Page 17

Page 18

CSW45

Technical Service Diagnosis

Symptom Possible Cause Probable Correction

Plug unit it

Unit Off

No power to unit

Unit switched off Check control switch

Ice level control keeping unit off

Transformer Open Check/replace transformer

Control board failed

No water to unit

Pump does not run

Reset circuit breaker or replace

fuse

Room colder than 55

heat

Ice on sensor tube - remove it

Switch unit to Clean, note if all

valves and motors are switched

on for 5 seconds each one after

another. If not, replace the board.

Check/restore water supply

Check water valve

Check connection from control

box to pump

Check/replace pump

o

F., increase

Check for dirty condenser

Unit overheating

Unit runs, makes no ice

Compressor does not run

Low on refrigerant

Hot gas valve leaking thru Check/replace hot gas valve

* If the system has been running in a vacuum AND the leak is found to be on the LOW side, repair the leak

AND replace the compressor.

Check fan blade and motor

Air flow blocked, check for air

obstruction

Check compressor relay

Check compressor windings

Install service ports, weigh out

charge, If low, locate and repair

leak, replace drier evacuate to

300 microns and weigh in

nameplate charge*

July 1999

Page 18

Page 19

Technical Service Diagnosis

Symptom Probable Cause Possible Correction

Dirty air cooled condenser Clean condenser coil

Dirty fan blade Clean fan blade

CSW45

Water valve does not shut off

Low ice making capacity

Unit will not shut off Ice level control failure

Ice size incorrect Evaporator thermistor failure

Ice formation uneven

tightly

Scale on the evaporator surface

Unit in a very warm room

Water distributor restricted

Cutter grid failure Replace grid

Components contacting

Check/replace inlet water valve

Clean the ice machine’s water

system

Less ice will be made in

temperatures over 90

Check to see if it is unplugged

from the control box, if its

plugged in, check resistance

levels given on next page

Check to see if it is unplugged

from the control box, if its

plugged in, check resistance

levels given on next page

Clean the ice machine’s water

system

Check & adjust position of tubes

and panels

o

F.

Makes excessive noise

Water in bin

Ice melted together Low amount of ice used Remove ice

Fan blade bent Check & replace fan blade

Fan or pump motor bearing

failure

Drain plugged Clean out drain

Drain pump failed Check/replace pump

July 1999

Page 19

Locate noise, unplug motor to

confirm. Replace worn

component.

Page 20

CSW45

Technical Information

Performance Data

Temperature

o

Air 70

Air 90

Air 100

Air 70

Air 90

Air 100

F. Water 60oF. 1-4 65-80 18-22

o

F. Water 60oF. 2-5 85-100 22-27

o

F. Water 60oF. 2-6 85-105 28-35

o

F. Water 80oF. 1-4 65-80 20-25

o

F. Water 80oF. 2-5 85-100 23-30

o

F. Water 80oF. 2 - 6 85- 105 30 - 38

Ice Bin Thermistor

Bin Shut Off

Evaporator Thermistor

Suction Pressure at End

of Freeze Cycle

Head Pressure at End of

Freeze Cycle

Cycle Time in Minutes

Temperature Resistance Temperature Resistance

40

o

F.±1

o

25.9kW±3%

35

o

F.±1

o

29.8kW±3%

Cut-IN Cut-OUT Water valve off (harvest)

Ice

Thickness

Normal

Thick

Thin

Temperature Resistance Temperature Resistance Temperature Resistance

52.5

52.5

52.5

o

F.±.3

o

F.±.3

o

F.±.3

o

18.7kW±1%

o

18.7kW±1%

o

18.7kW±1%

Components

•

Compressor: Embraco, 244 watts .2 HP

•

Cutter Grid: 8.7 volts

•

Light: 8.7 volts

6.5

4.5

8.5

o

F.±.3

o

F.±.3

o

F.±.3

o

69.5kW±1%

o

73.9kW±1%

o

65.3kW±1%

40

40

40

o

F.±.3

o

F.±.3

o

F.±.3

o

o

o

25.9kW±1%

25.9kW±1%

25.9kW±1%

October 2005

Page 20

Page 21

Electrical Sequence

The CSW45’s operation is controlled by an electronic

board. This board takes in data from two thermistors:

The Ice Bin Thermistor and the Evaporator

Thermistor. The two resistances the thermistors

supply, along with the position of the control switch,

determine the cycles of the ice machine.

Start Up

The inlet water valve opens for about two minutes to

fill the reservoir.

The water pump starts and stays on for about a

minute, then shuts off.

Then the inlet water valve opens again for two

minutes. After it closes, the compressor, pump and

fan motor start.

Freeze

CSW45

The compressor, fan motor and water pump are all

operating and stay in a Freeze cycle until the

evaporator thermistor reaches 6.5

o

F. That signals

the control board to place the unit into a harvest

cycle.

Harvest

The compressor and hot gas valve are both powered

during the harvest cycle. The fan and pump are OFF.

The machine stays in the harvest cycle until the

evaporator thermistor senses 52

o

F. If the bin is not

full, the unit goes into another freeze cycle.

Bin Full

The unit will shut down when the ice level sensor

senses a temperature of less than 35

when the thermistor’s temperature increases to 41

o

F. It will restart

o

F.

Clean

The Clean Cycle lasts about 47 minutes. During the

first minute all motors and valves will be switched on

in sequence for 5 seconds each. This includes the

inlet water valve, condenser fan, hot gas solenoid

valve, water spray pump and the compressor. This

early portion of the Clean Cycle doubles as a

diagnostic cycle. The last 46 minutes of the clean the

compressor, water spray pump and hot gas valve will

be on.

July 1999

Page 21

Page 22

CSW45

Repair Information

Cutting Grid

The cutting grid rests on two shelves molded into the

bin liner. It is also secured to the liner with two

screws.

1. Remove the three screws holding the cutter grid

cover to the grid.

Remove 3 Screws

2. Disconnect the three wiring harness plugs from

the control box.

3. Remove the screw holding the grid to the right

side of the liner.

Remove This

Loosen This

Screw

4. Loosen, but don’t remove the screw holding the

grid to the left side of the liner.

Lift the front of the grid until the slot in the grid clears

the screw, the pull the grid forward and out of the

cabinet.

Control Box

The control box is located above the cutting grid. It is

suspended from the top panel by 4 screws. Its wiring

harness routes out the back of the control box

through a molded channel.

Screw

Wire Harness Plugs

July 1999

Page 22

Page 23

Repair Information

CSW45

Water Slide

The water slide is mounted to the front of the

evaporator and diverts water to the reservoir. It is

connected to the evaporator by two screws. Remove

the cutter grid first to get access to it.

Reservoir

The reservoir is located below the evaporator, and is

mounted to the bin liner with two screws.

Water Pump

The water pump is located below the evaporator. It is

mounted to the bin liner with three screws. It also

has a quick-connect electrical plug.

Evaporator Thermistor

This thermistor is a set of two red wires that connect

to the control box. There is a molded portion in one

of the wires with a clip on it. That portion clips onto

the part of the suction line under the middle of the

evaporator that runs front to back.

Fan Motor

The fan motor and/or blade is only accessible after

the cabinet has been tilted up.

Component Compartment Access

Note: Chassis does NOT pull out.

Unplug the unit from the power supply. If built in, pull

it out from the counter. Note: The water and drain

lines may have to be disconnected.

Compressor

The terminals for the compressor are accessible only

from the back of the unit. Compressor replacement

requires lifting up of the cabinet at the front.

Screws

Screws

Leveling Leg

1 Remove the front panel.

2. Remove the leveling legs from the cabinet.

3. Remove two screws at the front holding chassis

base to cabinet.

4. Tilt the entire ice maker back far enough to gain

access to the compartment.

July 1999

Page 23

Page 24

CSW45

Repair Information

When tilting the cabinet, be sure it is secure to avoid

any possibility that it will tip too far back or fall

forward.

Illustration of Cabinet in Service Position

Fan Motor,

viewed from

the back.

July 1999

Page 24

Loading...

Loading...