Page 1

CS60

INTRODUCTION

This service manual co vers the ins tallation,

operatio n, maintenance and serv ice of this ice

machine.

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

FOR THE INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

FOR THE PLUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

INITIAL START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

HOW IT WORKS: COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . Page 7

COMPONENT LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

HOW IT WORKS: WATER . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

HOW IT WORKS: REFRIGERATION . . . . . . . . . . . . . . . . . . . . . . Page 10

HOW IT WORKS: REFRIGERATION . . . . . . . . . . . . . . . . . . . . . . Page 11

OPERATION & ADJUSTMENT: OPERATING CHARACTERISTICS . . . . . . . . . . Page 12

SANITIZING AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

SERVICE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

SERVICE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 15

REMOVAL AND REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . Page 16

REMOVAL AND REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Service Parts lists and Wiring diagrams are located in the center of this manual, printed on

yellow paper.

This manual was printed on recycle d paper.

Keep this manual for future reference.

Note the Warning symbo l, it marks a possib le haza rd.

January 1995

Page 1

Page 2

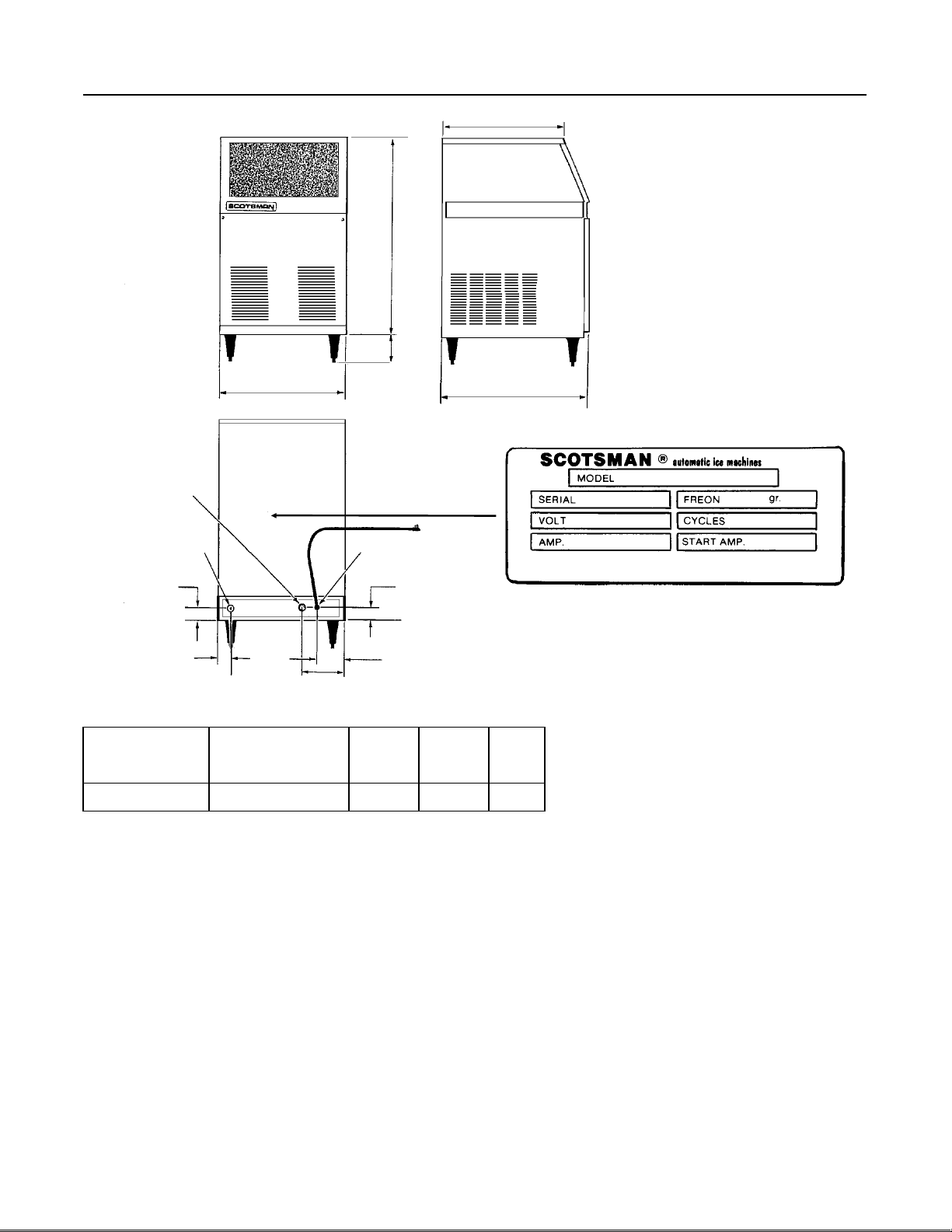

2 .2"

CS60

SPECIFICATIONS

17 9/16"

28.42"

5.5"

18"

3/4" HOSE COUPLI NG

THREAD

25/32"

1 .76"

5

.4"

POWER

3.83"

SPECIFICATIONS

Model Number Dimension s

H" X W" X D"

CS60MAS-1A 28.42 X 18 X 20.6 Medium 115/60/1

Cube

Size

The finish is stainle ss st eel. Minimu m circu it

ampacity is used to determin e wire size per

national elec tric code. Refrig eran t ty pe is R-22.

2 .2"

Basic

Electrical

20.6"

NAMEPLATE LOCATION

Max.

Fuse

Size

15

Refrigerant Charge is 12 oz of R-22.

Always go by the namepate.

OPERATING REQ UIRE MENT S:

MINIMUM MAXIMUM

0

Air Temperature 50

Wate r Temperatu re 40

F. 1000 F.

0

F. 1000 F.

Water Pressure 20 PSIG 100 PSIG

Voltage 103.5V 126.5V

Scotsman Ice Systems are designed and

manufactu re d with the high es t regard fo r sa fety

and performance. They meet or exceed the

standards o f UL and NSF.

Scotsman assu mes no liability or resp onsibilit y

of any kind for products manufactured by

Scotsman tha t have been altered in any way,

including the use of any parts and/or other

components not specifically approved by

Scotsman.

Scotsman reserve s th e right to make design

changes and/or improvements at an y time.

Specification s and designs are subject to

change without notice.

January 1995

Page 2

Page 3

FOR THE INSTALLER

CS60

Location:

Prior consideration for the location shall inc lud e:

••Indoors, with a minimum room tempe ratu re of

0

F. and a maximum room temperature of

50

0

F.

100

••Water tempera tu re to the machin e sh ou ld be

betwee n 40

0

F. and 1000F.

•• Service Access. Allow enough space at the

back of the cabinet for the utilit ies to be

connected. Allow enough space for the

machine to be pulled out from its ins talled

location. Do not build a floor in front of the

machine that would preve nt its remov al.

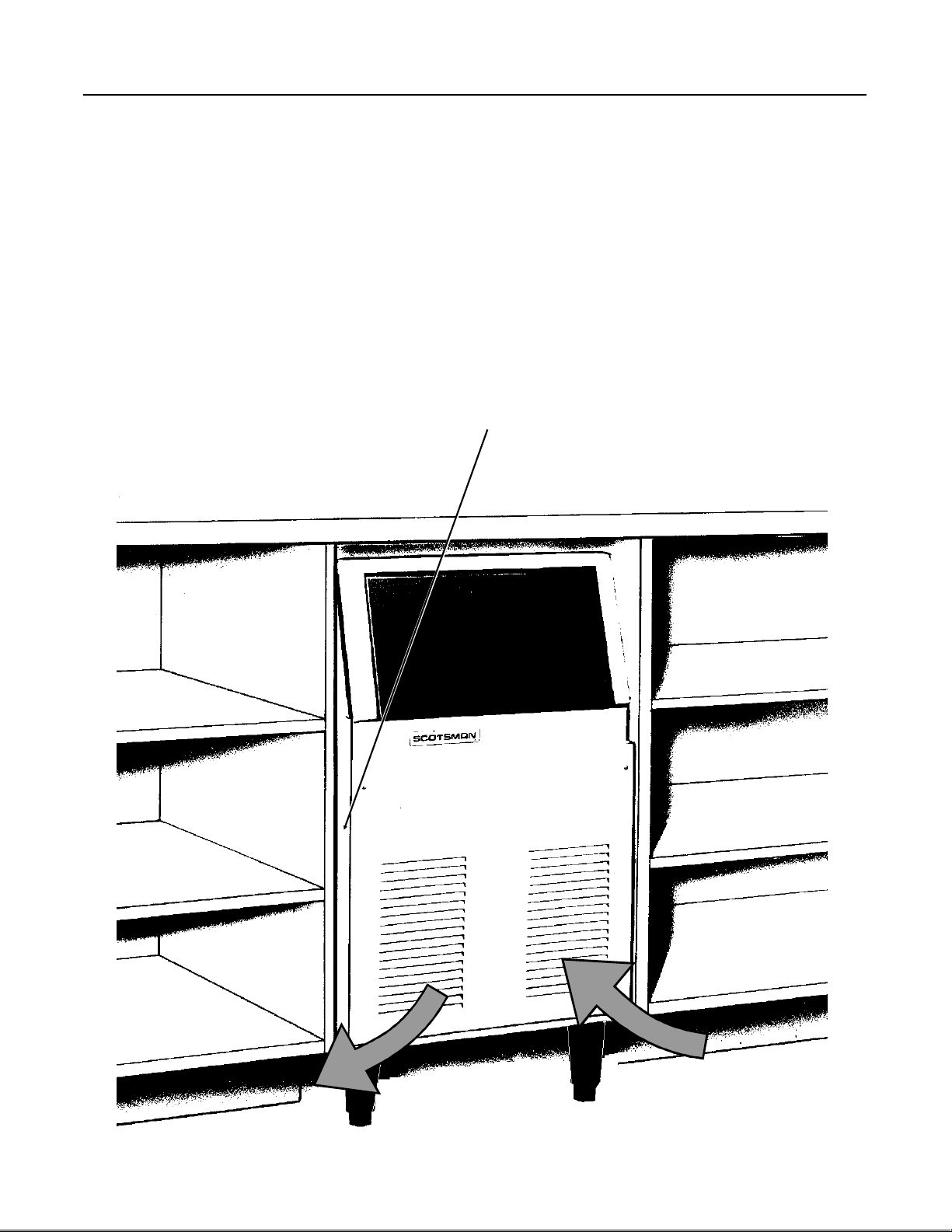

••Air circulation: The front pane l MUST remain

unobstruct ed . Do not blo ck with any type of

door or curtain .

If the unit is built in, it will pull air in from the right

side of the front panel, and exhaust it out the left

side of the front panel. If the left side of the

machine is left open, warm air will be

discharged from th e left sid e panel.

IF BUILT IN, THIS SIDE

SHOULD BE TIGHT AGAINST

THE CABINET T O PREVENT

AIR RECIRCULATION

WARM AIR DISCHARGE

COOL AIR INTAKE

January 1995

Page 3

Page 4

CS60

FOR THE PLUMBER

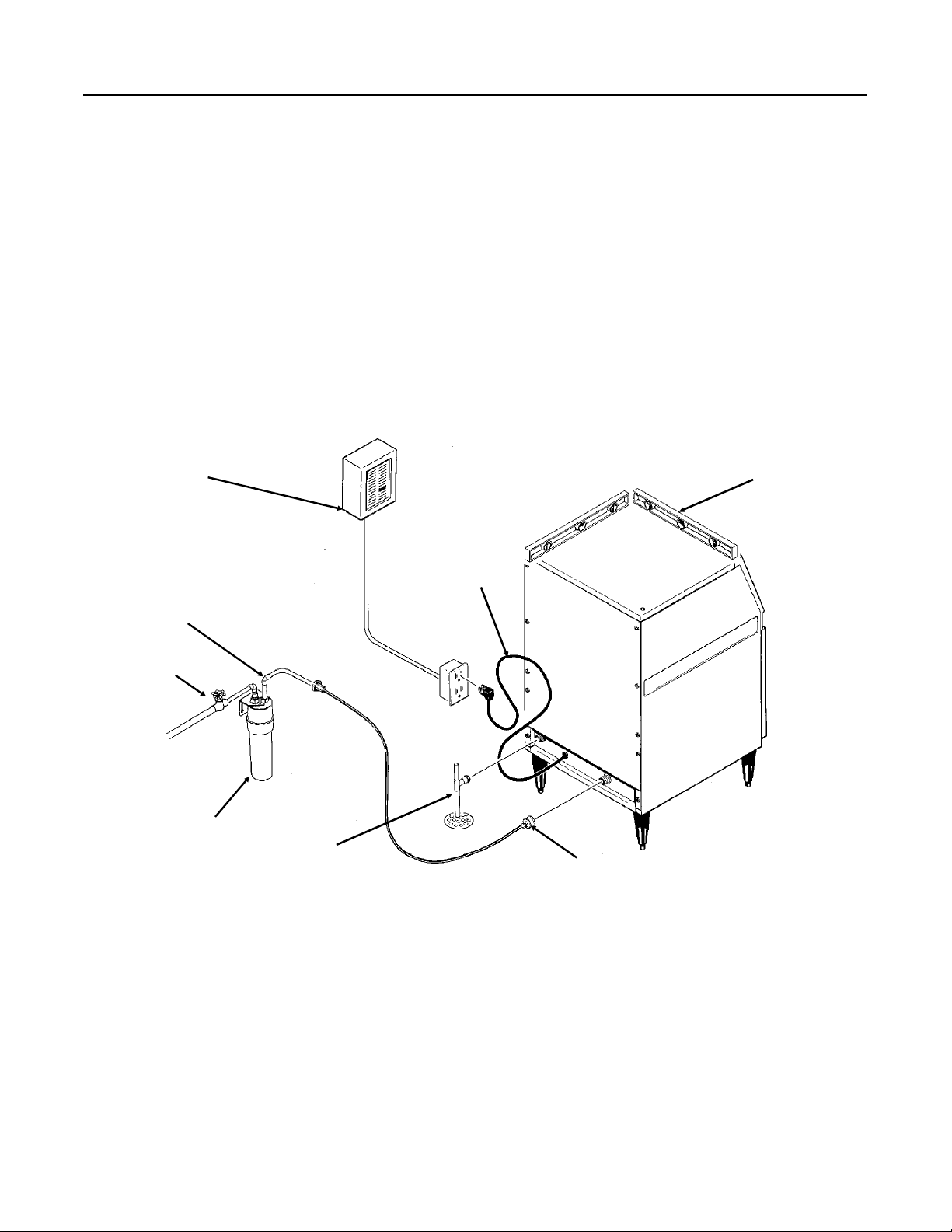

Wat er sup ply an d dra in conne ct ions.

1.The recomme nd ed water supp ly line is a 1/4"

o.d. coppe r tube , th e water pressure must have

a minimum incoming pressu re of 20 psig.

2.Con ne ct th e tubin g to the 3/4 " hose cou plin g

thread water inlet fitting at the back of the ice

maker. An optional adapter to go from the 3/4"

hose coupling thread to 1/4" compression fitting

is available fro m your de ale r under p art numbe r

0533238.

Or a similar adapter can be purchased from a

hardware store.

POWER

SUPPLY

3.Install a shut off valve in the incoming water

line near the ice maker so that the water can be

shut off for service.

4.Con nect a gra vity drain line to the dra in

connection at the ice ma ker. A minimum slope

of 1/4" fall per foot of horizontal run is

recommended. Install th e drain s per the loc al

codes.

A vent is reco mmended on the highest poin t of

the drain tube , and th e drain tubing mu st be

rigid pipe. Do NOT use flexible tubing.

LEVEL THE

UNIT

POWER

CORD

WATER

SUPPLY

SHUT

OFF

WATER FILTER

(FIELD SUPPLIED)

DRAIN

ELECTRICAL

1.Locat e th e namep lat e on the lower re ar pane l

and check tha t the locat ion sou rc e volt age an d

capacity are correct for this unit . The unit is

equipped with a grounded plug connection .

Under no circumstan ces must the gro und post

be altered or removed.

Extensio n cords are not pe rmitt ed.

ADAPTER

(FIELD SUPPLIED)

Be certain that the ice make r is conn ect ed to its

own electrical circuit and is individu ally fused.

The maximum allowable volt age varia tio n

should not exceed ten percent of the nameplate

rating.

All external wirin g shou ld co nform to the

National, State, and local electrical code

requirements. Usually an electrical permit and

the services of a licensed electricia n will be

required to install the receptacle.

January 1995

Page 4

Page 5

INSTALLATION

CS60

FINAL CHECK

1.Is th e Cab ine t level?

2.Have all the electrical and piping connections

been made?

3.Has th e voltage been teste d and ch eck ed

against the nameplate rating?

4.Is th e unit plu gg ed into a sep arat e ele ct ric al

circuit?

5.Is the wat er sup ply line shut of f valv e inst alle d

and is the water turned on?

POWER?

6.Have the bin interior, and the cabinet exterior

been wiped clean?

7.Are all int ern al pa rt s in pla ce, including the

spray platf orm a nd curtain?

8.Have the internal refrigerant lines been

checked for rubbing and chaffing?

9.Has th e machine been installed where it is

indoors, in a cont rolled env ironme nt , with

adequate air circulation around the machine,

and where it can be serv iced ?

LEVEL?

DRAINS?

WATER?

January 1995

Page 5

Page 6

CS60

INITIAL START UP

1.Open water supply valve.

2.Move electrical breaker or switch to the on

position.

3.Remo ve fro nt panel.

4.Che ck th e cube size control sh af t, it shou ld be

in a preset cube size posit ion . If not, turn it

clockwise until the unit comes on. Note: cube

size adjust men ts may be required . St art with the

shaft in the "mid" posit ion.

5. The machine will go thru a "dry" cycle, this will

take about 10 minutes. Th en the water f ill and

harvest cycle will begin.

6. Observe the water fill cycle:

••The water inlet valve opens .

••Incoming wate r flows from th e valve th rou gh

the tubing to the top of the ice maker.

••Water flows around the inverted ice cube

cups an d drains through holes into the

reservoir.

•• The reservoir begins to fill up with water.

••Water continues to enter the machine and

overflows a stan dpipe in the reservo i r and

dow n the dr ain.

1

This will take about 3

freeze cycle will begin.

7.Che ck th e operat ion of the fre ezin g cyc le:

⁄2 minutes. Af te r th at th e

If the cu bes are overfilled, adjust the machine to

make smaller ice cubes by turnin g the cube size

control counter-clockwise.

In both cases , th e ne xt cyc le of cube s harv ested

must be observed, and further corrections may

be needed.

If the ice cubes are cloudy, an extreme water

condition may exist. Confirm that they are

cloudy by pla cing them in a glass of co ld water.

If, in the water, they remain cloudy, you may

want to have the water tested by a water

treatment specia list.

If the ice cubes are cloudy only on the bottom or

in the center, the machine ma y be running out of

water before the end of the fre ezin g cyc le.

10. Test the bin full shu t of f. To test this, ho ld

some ice on the bin thermo sta t bra cke t (t he

stainless steel tube on the left side of the ice

storage bin ). The ice maker sho uld stop within a

few minutes of having ice on that tu be.

1 1 . Fill out the W a rra nty Re gis trat ion and

Customer Evaluation form, and mail both to

Scotsman.

12. Make sure the user unders tand s the

operatio n and mainte na nce requ i remen ts for the

ice maker. Leave the service manual and the

name of the local Scotsma n service agen cy with

the us er.

••Compressor is running.

••Water pump is spraying water through the

spray nozzles.

••Ice making begins, the wat er gets very co ld,

and ice begins to form in the cube molds.

8.Che ck th at the plast ic curt ain asse mbly ha ngs

down evenly in the openin g and that no larg e

streams of water are pa ssin g throug h.

Note: Some wate r will drip from the reservo i r as

the machine runs. This is normal.

9.Afte r about 20 minut es the machin e will begin

to release the ice , th is is called the harve st cy cle.

Observe the first cube harvest:

••Check the size of the ice cubes.

Note: The normal size of the ice cube has a 1/4"

depressio n in the wide end.

If the cu bes are not filled out, adjust the machine

to make larger ice cu bes by tu rning the cube

size control shaft cloc kwise .

January 1995

Page 6

Page 7

HOW IT WORKS:

CS60

COMPONENT DESCRIP TI ON

Cube Size Control

The cube size control is loca te d in front of the

control box, behind the fron t pa ne l. Th e se nsing

capillary tube of the cube size control is routed

out of the control box int o its bulb ho lde r on the

evaporator coil. It is a reverse acting

temperat ure cont rol with doub le throw con ta ct s.

Turn ing its knob all the way coun terc lock wise

also shuts off the ice maker.

The control det ermine s th e len gth of the

freezing cyc le and corres pond ing ly the size of

the cube. A lo wer settin g will produce a smaller

cube, and a higher setting will make a large r

cube. The cube size control changes its

contact s whe n th e eva po rat or reaches its preset

temperature, starting the harvest cycle. When

the sensing tu be of the cu be siz e control

reaches th e hig h pres et temp erature, the

contact s cha nge again, restarting the freez e

cycle.

Compressor Toggle Switch.

The compressor toggle switch is located on the

side of the control box. When move d to the ON

position, it make s a circuit to the compres sor.

When moved to the OFF posit ion , th e other

components will still operate.

Water Pump

The water pump operates during the fre ez ing

cycle only, pumping water thro ug h the spra y

nozzles int o the inve rte d spra y cups.

Inlet Water Solenoid V al ve

The water sole no id valv e, locat ed in the bac k

panel of the unit, is energized only durin g the

harvest or cleaning cycle s. When energized it

allows a metered amou nt of wat er to flow int o

the machine (.21 g.p.m.) This water flows to the

top of the evaporator and then down into the

reservoir.

Bin Thermostat Control

The bin thermo st at control bo dy is loca te d in

front of the control box just beside the cube

size control. The thermos ta t se nsin g tub e is

located in the ice storage bi n on the lef t side wall

where is automa tic ally sh uts the ice make r of f

when the bin is full and rest arts when ice is

removed. Factory settings are 1 degree C (36

degrees F) cut out and 4 degrees C (39 degrees

F) cut in. It can be adjusted by turning the

adjustment screw visible through the contro l box

cover.

Hot Gas V alve Assem bly

The hot gas valve assembly is comprise d of two

parts, the valve body and the coil. These p arts

are located on the discharge line of the

compressor and are activated by the cube size

control (harvest cyc le). When the coil of the hot

gas valve is energized, it magn etically lifts the

plunger in the hot ga s valve body. This allows

hot refrigerant gas to by-pass th e co nden ser

and go directly to the evaporator.

Spray Pla t form and Chute

The spray syst em use d on this unit is of the

station ary typ e. The water is forced by the

water pump into the pla tf orm chambe r and

spraye d int o the inve rte d cup mo lds throu gh a

set of six spray nozzles.

Fan Motor

The fan motor is electrically connec ted through

the cube size control and runs only durin g th e

freezing cyc le.

Hermetic Motor Compressor

The compress or is a vapor pump , fo rcing

refrigera nt gas throu gh ou t the refrigeration

system.

January 1995

Page 7

Page 8

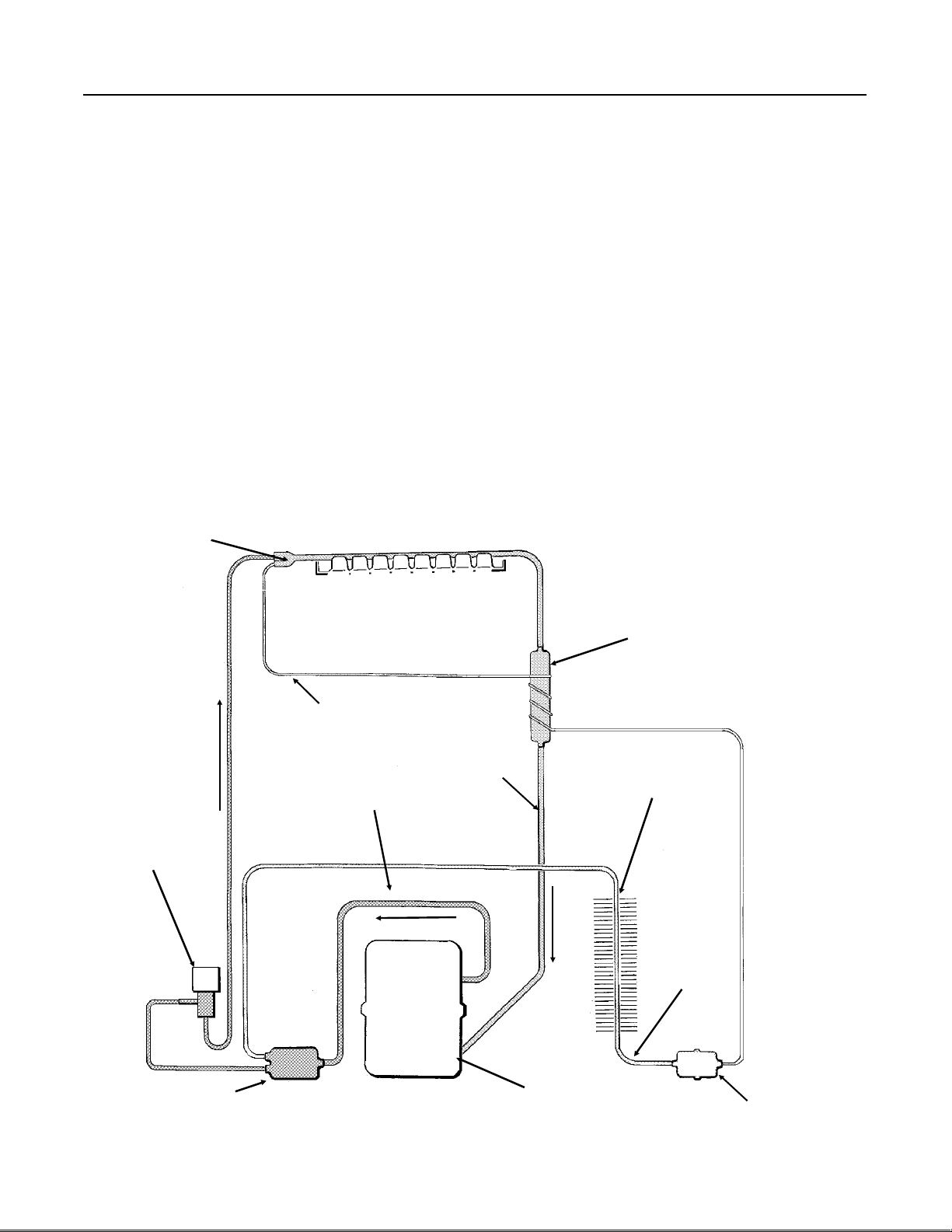

WATER

PUMP

HOT GAS

VALVE

CUBE SIZE

&

ON/OFF

CS60

COMPONENT LOCA T IO N

SPRAY PLATFORM

EVAPORATOR

RESERVOIR

FILL TU BE

WATER RESERVOIR

BIN LE VEL

CONTROL

TUBE

BIN DRAIN

BIN

THERMOSTAT

CONTROL

BOX

WATER

INLET

VALVE

COMPRESS OR

CLEANING

SWITC H

January 1995

Page 8

Page 9

HOW IT WORKS:

CS60

WATER

Freezing cycl e

The refrigerat ion proce ss crea te s cold

temperatures within the evaporator coils and

removes heat from the wat er spra yed up into

the inverted ice cube cup s. When enough heat

is removed, the wat er cha nges into ice, and

forms where it is the coldest: in the ic e cube

cups.

Minerals contain ed in the supply wat er will not

freeze and are drained away. Mostly pure water

will be frozen into the ice cubes.

During the freezing cycle , the compres sor, fan

motor, and water pump are operatin g. Wa te r is

continuou sly free zing or being sprayed and

recirculated. When evapora tor temperature is

lowered to th e cold temp era tu re set tin g of the

cube size control, it ends the freezin g cyc le an d

starts the harvest cycle.

Harvest cycle

The hot gas valve opens an d hot

refrigera nt gas is disc ha rged into the

evaporat or.

The inlet water valve opens an d a fresh

supp l y o f wa ter flows t o th e top of the

evaporat or and th en drains into the

reservoir.

WATER

SPRAY

WATER

PUMP, ON

DURING

FREEZE

The cube size control th ermo stat senses the

warmer temperat ures of the harv est cycle , an d

at a preset temperature, opens the circuit t o the

hot gas and inlet wat er valve s. Bot h valves th en

close.

The harvest cycle is comple te , and the free zin g

cycle restarts .

The automatic ic e making pro ces s con tin ues

until the bin is full of ice, and the bin thermostat

senses a cold er te mpe ra tu re.

The bin thermostat then opens the circuit to all

components and the automatic ice making

process stops.

WATER TO

EVAPORAT OR

The ice cubes hav e been releas ed

from the inverted cube cups in the

evaporator by th e warming eff ec t of the

hot refrig era nt gas co nd ensing in the

evaporator tu bin g, plus the inc omin g

water flowing aroun d the inv erted cups.

The release d ice cu be s drop ont o the

spray platf orm a nd thro ug h the curt ain

assembly int o th e ice st orag e bin .

INLET

WATER

VALVE, OPEN

DURING

HARVEST

DRAINS

January 1995

Page 9

Page 10

CS60

HOW IT WORKS:

FREEZE CYCLE

REFRIGERATION

The ice cubes are forme d in an inve rt ed mold

that is refrigerated.

The refrigerat ion proce ss be gin s at the

compress or. The re, ref rige rant vap or is

compressed and flows from the compressor

throug h the discharge line as a high

temperature, high pressure g as. In the

discharge line th ere is a stra ine r with two

outlets , on e lea ds to the cond enser, and one to

a solenoid valve . Be cause the solenoid valve is

closed, the gas flows to the condenser, where

heat is transferred from the ref rigera nt to the air

passing throu gh the con de nse r. The refrigerant

then condenses into a high pressure liquid.

EVAPORAT OR

From the condenser, the liquid refrigerant flows

throug h the liquid line , and the liqu id line

filter-drier. Af ter t he filter drier, the liquid

refrigerant enters the metering device, a

capillary tube. Af te r pas sing the restriction of

the capillar y tube, the refrigerant enters an area

of relative low pre ssu re, th e ev ap orator. In the

tubing of the ev aporator, the liquid refrigerant

expands and evaporates, absorbing heat from

the evaporat or tu bing and anything in contact

with it such as water sprayed against it.

The refrigeran t, now a low pressure, low

temperat ure va por, flows into the accumul ator,

which traps exc ess liquid refrigerant. The vapor,

now primarily a gas, goes through the suction

CAPILLARY TUBE

DISCHARGE

LINE

SUCTION

LINE

ACCUMULATOR

CONDENSER

LIQUID

LINE

STRAINER

Refrigeration System Schematic

January 1995

Page 10

COMPRESSOR

FILTER-DRIER

Page 11

HOW IT WORKS:

CS60

REFRIGERATION

HARVEST CYCLE

(When the cubes are released)

The ice cubes hav e be en formed in an inv erte d

mold that was refrigerated.

Now the refrigeratio n system will c hange to

warm the cube mold and release the cubes.

The process begins at the comp ressor. There,

refrigerant vapor is compress e d and flows from

the compressor through the di scharge line as a

high temperature, high pressure gas. Before

the gas gets to the con de nse r,it goes throu gh a

strainer, the strainer outlet is connected to two

tubes, one of which lead s to an electric va lve,

the hot gas sol eno id. When this valve opens,

the refrigerant gas follows the path of least

resistance and flows through the tu bing from the

EVAPORATOR

hot gas valve to the evapora tor, where the ice

cubes are frozen.

At th e evap orat or, th e high te mperature gases

are cooled by the cold te mpe rat ures of the cube

mold, and cond ense int o liqu id, transfer rin g heat

to the mold which warms up and releases the

cubes.

The refrigeran t, now a low pressure, low

temperat ure va por, flows into the accumul ator,

which traps exc ess liquid refrigerant. The vapor,

now primarily a gas, goes through the suction

line tub e to the compressor where the cycle is

repeated.

HOT GAS

SOLENOID

(OPEN)

CAPILLARY TUBE

DISCHARGE LINE

SUCTION

LINE

ACCUMULATOR

CONDENSER

LIQUID

LINE

STRAINER

COMPRESSOR

FILTER-DRIER

January 1995

Page 11

Page 12

CS60

OPERATI ON & ADJ UST MENT : OP ERA TI NG CHA RACT E RIS T ICS

The informat ion sho wn below cov ers a wide range of air and water temperatures. It is intended as a

guideline only, and is based on data compile d from NE W CLE AN un its . Allo w a varia tio n fro m eac h end

of the range given .

A. Refrigeration system pressures:

High Side (discharge)

End of Freeze cycle 150 - 160 psig

Harvest cycle 100 - 125 psig

Low side (suction)

End of Freeze cycle 10 - 11 psig

Harvest cycle (ma ximu m )90 psig

ADJUSTMENT OF THE CUBE SIZE :

Adjust only when cubes are too big or small.

(See the illustration at the right.)

1. Remove fron t pane l, loc at e kno b.

2. To increase th e size, turn knob 1/8 turn

clockwise. To make the cubes smaller, turn the

knob 1/8 turn counterclockwise.

B. Freeze cycle time 20 minutes

C. Defrost cycle time 2- 3 minutes

D. Compressor amp s

Freeze cycle 4 to 3.4

Harvest cycle 3.8 to 4.1

3. Observe the size of the cube s in th e next two

harvest cycles, if more adjust men t is neede d,

continue adjustments until the correct size is

obtained.

ADJUSTMENT OF THE BIN THE RMOS TA T

CONTROL

Adjust the bin thermostat when the ice maker

turns off too soon (ice level low) or when it turns

off too late (ice storage bin overfills.)

To increase the ice lev el in th e sto rag e bin :

Rotate the bin thermostat adjustment screw

(located under front panel on control bo x cov er)

clockwise one eight turn at a time until the ice

level that the machin e main ta ins is correct.

To decrease the ice level in the storage bin:

Rotate the bin thermostat adjustment screw

counterclock wise one eight turn at a time until

the ice level is correct.

CORRECT SIZE

TOO SMALL, L ITT LE OR NO

ICE IN THE CENTER OF THE

TOO BIG, THICK BULG E OF

SOLID ICE ON THE END.

January 1995

Page 12

Page 13

CS60

SANITIZ ING AND CLE A NING

A Scotsman Ice Syst em represents a sizable investment of time and money in any comp any’s

business . In order to rece ive th e best return for that invest men t, it MUS T rece ive pe riod ic maint en ance.

It is the USER’S RESPONS IB IL ITY to see that the unit is properly maint ain ed. The followin g is a list of

recommended main tena nce that will help keep the machin e running with a minimum of pro ble ms.

Maintenance and Clea ning should be schedule d at a minimum of twice per year.

General

The periods and pr ocedures for maintenance

and cleaning are given as a guide. Cleaning will

vary depending upon local water con dit ions and

the amount of ice used. Each ice maker must

be maintained individually, in accordance with its

own requirements.

Icemaker In Place Cleaning

1.Remo ve th e ice from the bin.

2. Remove front pa nel.

3. Rotate control knob counter clockwise to the

Off position.

4.Remo ve curtain by pulling forward on the left

end, and then pulling the curtain to the left and

out of the machine.

5.Lif t up spray platf orm, locate stand pipe to the

right of the opening, and pull it out to drain th e

reservoir. Replace the standpipe, s pray

platform, an d curtain.

1

6. Mix approximately 3 ounces (

Scotsman Ice Machin e Clea ne r with 1.5 quarts

(1.5 liter) of warm (95 -115

pour this solution into the reservoir at th e curt ain

base.

o

⁄10 liter) of

F.) potable water, and

Scotsman Ic e

Machine Cleaner

contains ac ids.

These comp ou nd s

may cause burns. If

swallowed, DO NO T

induce vomiting.

Give large amoun ts of

water or milk. Call

Physician

immediately. In case

of extern al contact,

flush with water.

8. Then switch the cleanin g togg le swit ch to the

"cleaning" po sitio n for abo ut three min utes to

release all the ice cubes from their cups.

9. Switch the cleanin g toggle switch to the

"operation " p osit ion , an d allo w the ma ch ine to

run for 30 minutes, or until the next batch of ice

is rele a sed into the bin.

10. Pour hot water into the bin to melt the ice

produced during cleaning, an d to clean ou t the

drain. Wipe the interior of the bin with mild soap

and hot water, rinse with cold water .

To sanitize, mix a locally ap proved sanitizer

solution and repeat steps 3-10, except

substitute the sanitizer solution for the ice

machine clean er so lut ion . A possible sanitize r

solution may be obtaine d by mixing 1 ounce of

household bleach with 2 gallons of warm

(95-115

Caution: Do not use the ice produced during

cleaning , as it may have a stron g ac id content.

11. Replace th e front panel.

Ice maker Maintenance

1.Shut off wat er sup ply to the ice mak er.

2.Disconnect the water inlet tu be from the

connect ion at the back of the ice make r, and

check the screen at that point. If very dirty,

carefully pull the screen out and clean it.

Reassemble water line to ice maker.

3.Open the water shut off valve.

4.Unplug the power cord to disconnect electrical

power to the ice maker.

5.Remo ve th e fro nt panel.

6.Clea n the air-coo led con dense r fins us ing a

vacuum, whisk broo m, brush, or if needed, coil

cleaner. The ice making cap ac ity o f thi s

machine is reduced by a dirty condenser coil.

o

F) water.

7. Rotate the control kn ob to the "norma l "

position . Operate the machine for 20 min ut es .

January 1995

Page 13

Page 14

CS60

SERVICE DIAGNOSIS

SYMPTOM POSSIBLE CAUSE SUGGESTED CORRECTION

Unit will not run Blown fuse or breaker Replace fuse & check for cause

of blown fuse, reset breaker.

Compressor cycles intermittently Low voltage Check voltage at the supply to

the building.

Check circuit for overloading.

Dirty condenser Clean the condenser

Air circulation blocke d around

unit

Non condensable gas in system Evacuate and recharge with

Cubes too small Cube size control set too warm Check and adjust for prope r

Partially restricted cap tube Blow charge, evacu ate with new

Moisture in system Same as above

Overcharged Same as above

Undercharged Same as above , look for a leak.

Cloudy cubes Spray nozzles plu gged Clean

Needs cleaning Clean with Scotsman Ice

Irregular size cubes, some

cloudy

Cubes too large Cube size control set improp erly Check and adjust fo r proper

Decreased ice capacit y Inefficien t comp ress or Re pla ce

Low Ice Capacity Leaky inlet water Replace valve

Some jets plugged Clean jets

Shortage of water Check wat er supply

Non-conde ns ab le gas in the

system

High Head Pressure Dirty condenser,

High air temp Relocate machine or water line.

Overcharge Repla ce th e ref rig era nt

Restricted syste m Replace the drier and refrigerant

Allow sufficien t air arou nd unit

nameplat e charge

operation

drier, weigh in nameplate charge

Machine Clea ner

operation

Replace refrigerant

Worn fan motor,

High air tempera ture

High water temperature

January 1995

Page 14

Page 15

CS60

SERVICE DIAGNOSIS

SYMPTOM POSSIBLE CAUSE SUGGESTED CORRECTION

Poor harvest Too short defrost Replace cu be siz e contro l

Not enough water Check water supply

Hot gas valve does not work Replace

Inlet wat er valve plugg ed Clean or replace

Air and water temp too low Try to change locatio n

No harvest Cube size control do es not work Replace

Hot gas valve does not work Replace

Water inlet valv e does not work Replace

Excessive wat er in ice st orage

bin

Drain plugged Clean drain

January 1995

Page 15

Page 16

CS60

REMOVAL AND RE P LACE M ENT

Electrical Shock Hazard.

Disconnect electrical

power before beginning.

Bin Thermostat

Cube Size Control

1.Unplug the ice maker to disconnect electrical

power.

2.Remo ve screws and cabine t top, front , and

rear panels.

3.Pull knob from cube size control shaf t.

Remove screws and control box cover to gain

access to th e cube size con tro l b ody. Remove

screws and dismount cube size control fro m

control box. Disconne ct ele ct ric al wi res from

cube size control.

1.Unplug the ice maker to disconnect electrical

power.

2.Remo ve scre ws and cabinet front panel.

3.Remo ve scre ws and con trol box cov er,

disconnect electrical wires fro m bin th ermos ta t

cont rol.

4.Dismou nt bin thermo sta t fro m the control bo x

5.Remo ve rea r pane l.

6.Pull bin th ermos tat capillary line from tube in

ice storage bin. Remove complete control from

ice machine.

7.Rep lace wit h new control in reverse order of

removal.

Cube Size Control Tube. Locate

and Secure in its Original

Position

4.At the top of the mach ine , un clip cube size

thermosta t tube hold er from ev aporat or, (retain

clips and tube assembly.) Pull cube size control

capillary tube from the tube, and remove

complete cube size co ntrol from th e ice maker.

5.Insert capilla ry tube on new thermo sta t int o

tube holder, be sure that the end cap s are in

place.

6.Reve rse th e remo val pro ced ure s to rein sta ll

the cube size control. Ad jus t as ne eded.

Refrigerati on Sy stem

Any time the refrigeratio n sys te m is opened, the

drier must be replac ed, the syst em ev acu ated

and th e exact charg e me a sured into th e s y s tem.

Any other procedure is NOT CORRECT, and will

result in subst an dard pe rforma nce .

January 1995

Page 16

Cube Size

Control

Page 17

INLET WATER

VALVE

REMOVAL AND RE P LACE M ENT

Electrical Shock Hazard.

Disconnect electrical

power before beginning.

CS60

Water Inlet Valve

1.Unplug the ice maker to disconnect electrical

power.

2.Shut off wat er sup ply to ice maker.

3.Remo ve th e lowe r back panel, pull out to

expose inlet wat er valve.

4.Disconnect electrical wires from inlet water

valve.

Spray Platform

1.Open ice bin door.

2.Pu ll out on the lef t side and remove curtain

assembl y.

3.Lif t th e spra y plat fo rm up and pu ll out to get to

the water hose at the base of the platform.

4.Pull hose off of conn ection to spray platform,

and pull platform from ice maker.

5.To replace, reve rs e the remov al procedures.

CURTAIN

5.Disco nnect water lines to and from wat er

valve.

6.Remo ve va lve fro m ice make r.

7.Reve rse remo val procedure to repla ce .

Water Pump

1.Disconnect ice maker from electrical power.

2.Remo ve to p panel.

3.Open ice bin door pull up through top and

remove.

4.Remove curtain by pulling forward and out on

the left end.

5. Remove 2 screws holding pump bracket t o

right side panel.

6. Disconnect 2 electrical leads and 1 ground

wire from pump.

7.Pull out spray platf orm, lift pump and

disconn ect hose.

8.Pull water pump up and out of ice maker.

9.Dismount water pump from cover assembly

(retaining the bra cke ts), and remoun t the

replacemen t pu mp in its place .

10. Reverse the bala nce of the st ep s to

reassemble .

January 1995

Page 17

Loading...

Loading...