Page 1

Service Manual for

Cuber Model CS0415

Page 2

Introduction

CS0415

Service Manual

This is the service manual for the CS0415 ice

machine.

Basic installation information is provided, however

the installation manual is separate.

Note and heed any warning symbols where they

appear.

Table of Contents

Specifications .......................................... Page 3

Installation: ........................................... Page 4

Test Mode - Ice Thickness Adjustment ............................. Page 5

Technical Charts: ........................................ Page 6

Operational Modes: ....................................... Page 7

Harvest Mode .......................................... Page 8

Component Location ...................................... Page 9

Component Location ...................................... Page 10

Diagnostic Mode ........................................ Page 11

Error Displays .......................................... Page 12

Component Testing ....................................... Page 13

Component Testing ....................................... Page 14

Flow Chart - Overall Operation ................................. Page 15

Flow Chart - Freeze Mode Details ............................... Page 16

Service Diagnosis ........................................ Page 17

Service Diagnosis ........................................ Page 18

Removal and Replacement - Thermistor ............................ Page 19

Removal and Replacement ................................... Page 20

Removal and Replacement - Controller ............................. Page 21

Removal and Replacement ................................... Page 22

Removal and Replacement - Evaporator ............................ Page 23

July 2007

Page 2

Page 3

Specifications

CS0415

Service Manual

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of agencies like NSF and UL..

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

hat have been altered in any way, including the use

of any part and/or other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

AC Power Supply:

104 to 127 VAC (rated 115 VAC), 60 Hz

•

Amperage:

6.5 Amps (max)

•

Storage Capacity (Approximate)

24 lbs. (10.9 kg)

•

Exterior Dimensions (WxDxH)

15" x 24" x 34" (381 or 457.2 x 609.6 x 863.6

•

mm)

Exterior Finish:

Painted Steel

•

Net Weight:

94 lb. (42.6 kg)

•

Cube Thickness Control:

Thermistor under Evaporator & Control

•

Board Setting

Harvest Control:

Minimum Circuit Capacity:

•

15 Amps

Ice Production per 24 hours (Approximate)

•

70oF (27oC) 46 lbs (21 kg)

•

80oF (27oC) 47 lbs (21 kg)

•

90oF (32oC) 40 lbs (18 kg)

•

100oF (38oC) 40 lbs (18 kg)

Ice Shape:

•

3/4" x 3/4" Square

Ice Thickness @ Normal Setting (Approximate)

•

0.32" or 5/16" (8.1 mm)

Ice Thickness @ Thin Setting (Approximate)

•

0.28" or 9/32" (7.0 mm)

Ice Thickness @ Thick Setting (Approximate)

•

Thermistor under Evaporator & Control

Board Setting

Bin Ice Level Control:

•

Thermistor on side of Bin

Refrigerant:

•

R-134a (6.2 oz). Weigh into high side only.

Ambient Temperature Operation Range:

•

55 to 100

Water Pressure Operating Range

•

20 to 120 psig

Water Consumption (Dependent On Water

Pressure)

•

6 to 10 gallons per 4 hours

o

F

•

0.39" or 3/8" (9.9 mm)

July 2007

Page 3

Page 4

Installation:

The ice machine is designed to be installed

indoors, in a controlled environment. Do not place

where the temperature limits for air or water are

exceeded.

The water supply must be cold, potable water. A

drain must be nearby or a drain pump model used

or a gravity drain model must be converted to use a

drain pump.

The ice machine must be on its own electrical

power circuit. The machine must be grounded. Do

not connect to an extension cord. Do not cut off the

ground prong off the power cord plug. Do not

bypass the ground prong.

The cabinet is designed to be either free standing

or built in. In either case the area in front of the

kickplate must be free of obstruction. Blocking this

area will cause low ice capacity and likely damage

the machine. Such damage is considered mis-use

and is not covered by warranty.

CS0415

Service Manual

When building into a cabinet, be sure the power

supply, water and drain are all available within the

built in area.

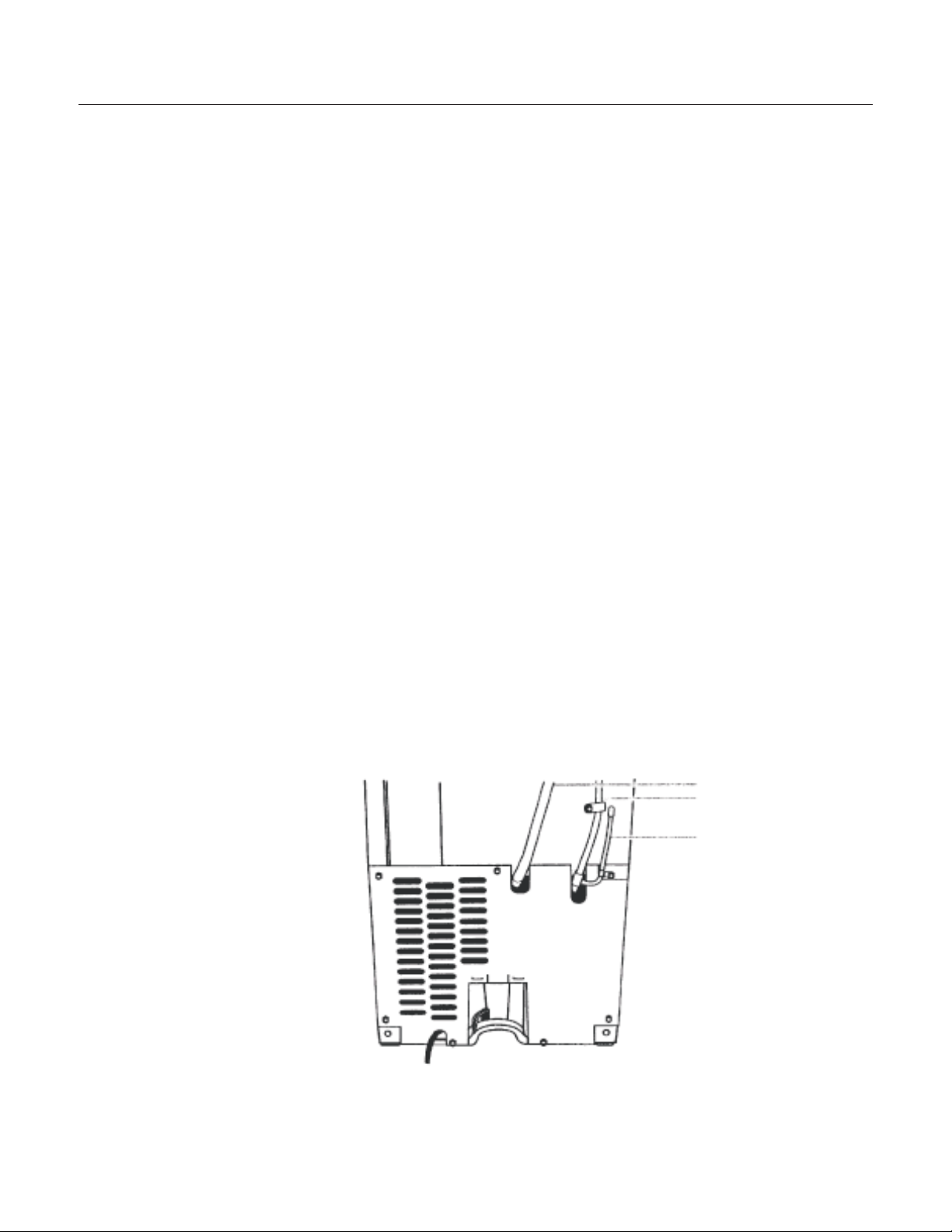

Drain Hose*

Vent Hose*

Water Inlet

Back View

July 2007

Page 4

* Drain Pump Models

Page 5

Test Mode - Ice Thickness Adjustment

CS0415

Service Manual

The CS0415 has three push button switches: ON,

OFF and CLEAN. These can be used to switch the

machine on, off and to start the cleaning process.

They can also be used to test the unit's

components.

To test and/or to adjust ice thickness:

1. Unplug or disconnect the unit from the power

supply.

Note: Unit must be On (make ice mode) when

power is disconnected.

2. Reconnect power to the unit.

3. Immediately, within ten seconds of power

re-connection, push and hold the On and Clean

buttons until the three indicator lights begin to blink.

4. Push and release the Off button to cycle through

testing the various components.

Test 9, no component tested.

Test 10, displaying the ice thickness setting.

Ice Thickness Adjustment.

The Off light is the indicator.

If it blinks 2 times and repeats, the ice

•

thickness is set at thin

If it blinks 4 times and repeats, the ice

•

thickness is set at normal.

If it blinks 6 times and repeats, the ice

•

thickness is set at thick

Pushing and releasing the Clean button between

flashes adjusts the thickness setting to the next

one.

.

.

Note: 10 push-and-releases will switch the

controller to ice thickness adjustment mode.

Pre-Test Mode: All 3 lights are on steady.

Test 1, testing the bin thermistor. The On light is

the indicator, if it is on steady, it is OK. If it blinks

twice and repeats, it is open. If it blinks 4 times and

repeats, it is shorted.

Test 2, testing the evaporator thermistor. The

Clean light is the indicator, if it is on steady, it is

OK. If it blinks twice and repeats, it is open. If it

blinks 4 times and repeats, it is shorted.

Test 3, testing the inlet water valve. Four minute

test.

Test 4, testing the water level sensor.

Test 5, testing the water pump.

Test 6, Testing the reservoir drain pump.

Test 7, testing the compressor and condenser fan

motor.

Test 8, testing the compressor and hot gas valve.

February 2008

Page 5

Page 6

Service Manual

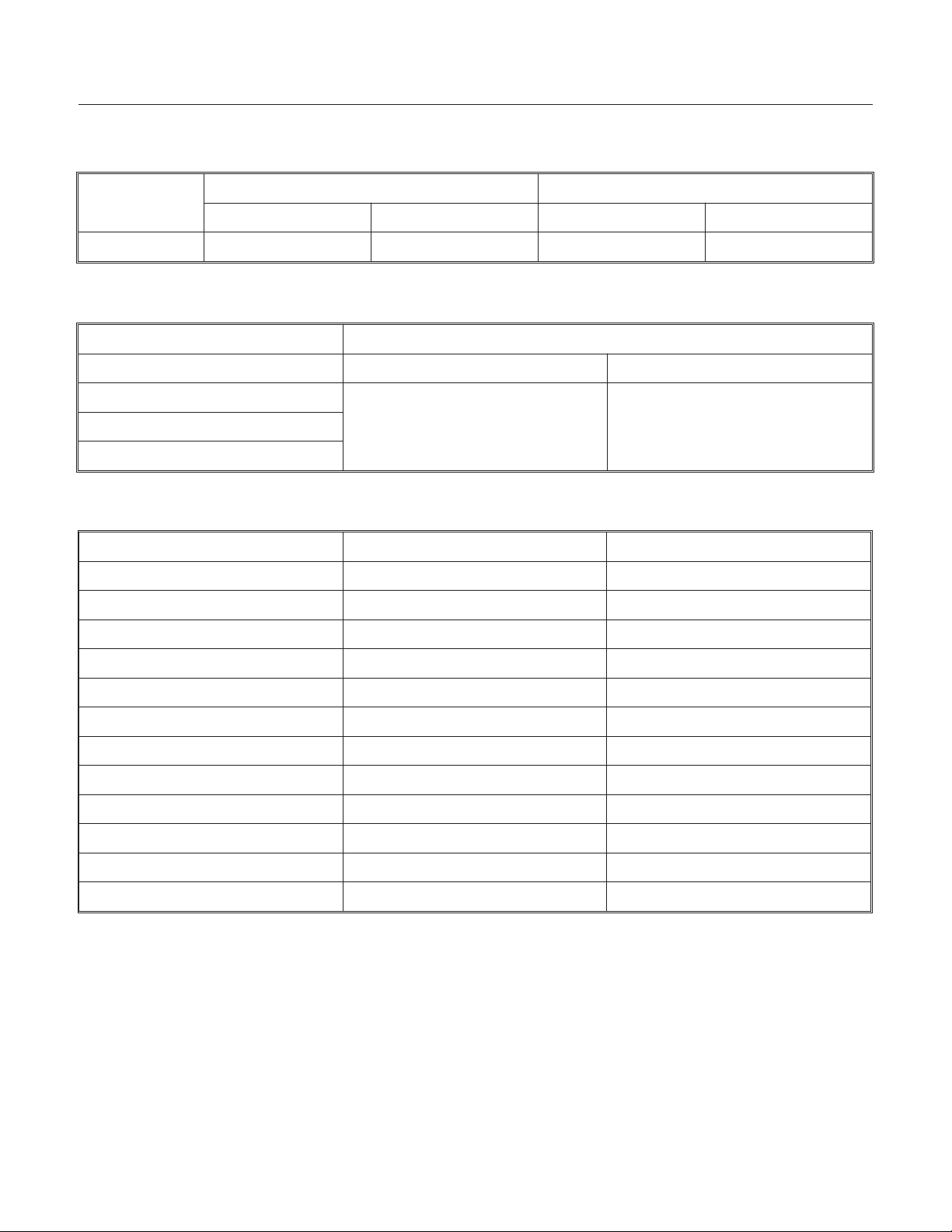

Technical Charts:

Bin Thermistor

Cut-In Cut-Out

Temperature Resistance Temperature Resistance

o

Bin 40

Evaporator Thermistor

Ice Thickness Temperature Resistance

Normal

Thin

F. +/- 1oF. 25.9k ohms +/- 3 % 35oF +/- 1oF. 29.8k ohms +/- 3 %

End Harvest Readings

o

F. +/- 3% 18.7k ohms +/-1%Thick

52

CS0415

Other Technical Information

Wattage @ 120 V Resistance

Compressor 244

Run 1 - 5

Start 3 - 11

Water pump 7.5 3.6

Reservoir drain pump 4.5 3.6

Water valve 20

Hot gas valve 7 - 9 385

Bin thermistor 10k @ 77

Evap thermistor 10k @ 77

Transformer 73

Fan motor 5.1 - 7.1 185

Cutter grid 20

o

F.

o

F.

July 2007

Page 6

Page 7

Operational Modes:

CS0415

Service Manual

There are four main operational modes for the ice

maker:

Freeze

•

Harvest

•

Clean

•

Service (Diagnostics)

•

Ice Making Cycle

In addition, there are three possible “Off” cycles for

the ice maker. They occur when:

1. The bin is full of ice and the LED is illuminated

“ON/OFF” (Idle mode).

2. The “On/OFF” control switch has been held for

three seconds. The ON/OFF LED will go out.

Electrical System

Line Voltage is supplied to the electrical control

switches and the primary side of the step-down

dual transformer. The dual transformer reduces

120 VAC to 8.75 VAC for the cutter grid and the

bin light and 12 VAC for the drain and

recirculating pumps. The electronic control board

directs 12 VAC to the water recirculating and

reservoir drain pumps, and 120 VAC to the hot gas

solenoid, condenser fan motor, and compressor.

The measured fill water valve will always have 120

VAC on the BK and WH wires and 14 VDC on the

OR/WH and BK/RD wires.

An evaporator thermistor supplies temperature

information to the electronic control to determine

when to terminate the harvest cycle.

Refrigeration System

The hot gas refrigerant, under high pressure, is

forced through the condenser, where it changes

into a liquid, and flows through the drier and

capillary tube into the evaporator. Under low

pressure in the evaporator, the liquid refrigerant

absorbs heat from the water flowing over the

evaporator as the refrigerant evaporates into a gas.

As a low pressure gas, the refrigerant flows back

through the suction line of the heat exchanger, to

the compressor.

During the Freeze mode, some of the hot gas that

is in the condenser accumulating tube, condenses

to a liquid, and remains in the accumulating tube.

During the later stages of the Freeze mode, as the

ice slab forms on the evaporator freezing plate,

some of the refrigerant passing through the

evaporator will not evaporate into a gas, but will

remain a liquid. This liquid refrigerant will settle in

the accumulator, while the refrigerant vapor is

sucked off through the suction tube at the top of the

accumulator. This accumulated liquid refrigerant

will eventually be directed to the evaporator to

quickly warm the evaporator plate during the

Harvest mode.

Note: It is very important that the accumulator is

not tilted out of a horizontal position. If moved, it

could cause compressor failure.

Water System

The water recirculating pump moves the water from

the reservoir pan up to the distributor, where it

flows out over the evaporator freezing plate.

Water that does not freeze on the evaporator plate

runs off the front edge, and falls back into the

reservoir, where it is recirculated back to the water

distributor.

As the ice slab forms, the minerals in the water are

on the surface of the ice. The water flowing over

the top of the ice slab washes these minerals back

into the water reservoir pan. The water continues to

recirculate until the water level in the reservoir

drops to the bottom of the water level sensor.

When the water level in the reservoir drops below

the sensor, the control terminates the freeze mode

and initiates the harvest mode.

The control signals the measured fill valve to fill to

the selected water level setting. The measured fill

valve uses a flow meter to accurately fill to the

correct volume.

•

Thin Ice uses 32 ounces (954cc),

•

Normal Ice 37 ounces (1106cc), and

•

Thick Ice 42.5 ounces (1258cc).

July 2007

Page 7

Page 8

Harvest Mode

CS0415

Service Manual

Electrical System

When the water level in the reservoir drops below

the water level sensor it signals the electronic

control to terminate power to the condenser fan,

and then the water recirculating pump. The

reservoir drain pump is activated to fully drain the

reservoir. Power is then supplied to the hot gas

valve and a fill request is sent to the measured fill

valve. The fill valve fills to the requested volume

while the hot gas valve is energized for the balance

of the harvest mode.

If the evaporator thermistor is unplugged, the

evaporator defaults to a timed 4 minute harvest.

If the water level sensor is disconnected or open,

the control defaults to 25 minutes of freeze time.

The cleaning indicator LED feature will not function

if the water level sensor is disconnected.

Refrigeration System

The electronic control board operates the various

components and systems in the ice maker for each

of the Freeze and Harvest modes.

Clean Mode

Electrical System

The electronic control board operates the various

components and systems during the Clean mode.

Water System

When the service control switch is in the “Clean”

position, the water pump circulates the cleaning

solution that has been added to the reservoir, up to

the water distributor, across the evaporator, and

back into the reservoir, where it is recirculated. The

compressor and hot gas valve operate to heat the

evaporator.

The hot gas valve opens, allowing high pressure

refrigerant gas to bypass the condenser, and flow

through the condenser accumulating tube. The hot

gas pushes the liquid refrigerant that has

accumulated in the accumulator tube up into the

evaporator. The hot liquid refrigerant evenly heats

the evaporator plate so that the ice slab releases

quickly and evenly.

The ice slab, when released, slides off of the

evaporator plate onto the cutter grid.

Water System

The electronic control board sends a signal to the

water valve. The signal tells the water valve how

much water to be filled, allowing water to flow into

the water reservoir pan. The water fill volume is

determined by the ice thickness setting.

As a result of the hot gas flow and the ice sliding off

the evaporator plate, the evaporator temperature

begins to rise. When the evaporator thermistor

reaches the set temperature (52°F), the unit

switches to the Freeze mode. This cycling between

Freeze and Harvest, continues until the ice bin is

full.

July 2007

Page 8

Page 9

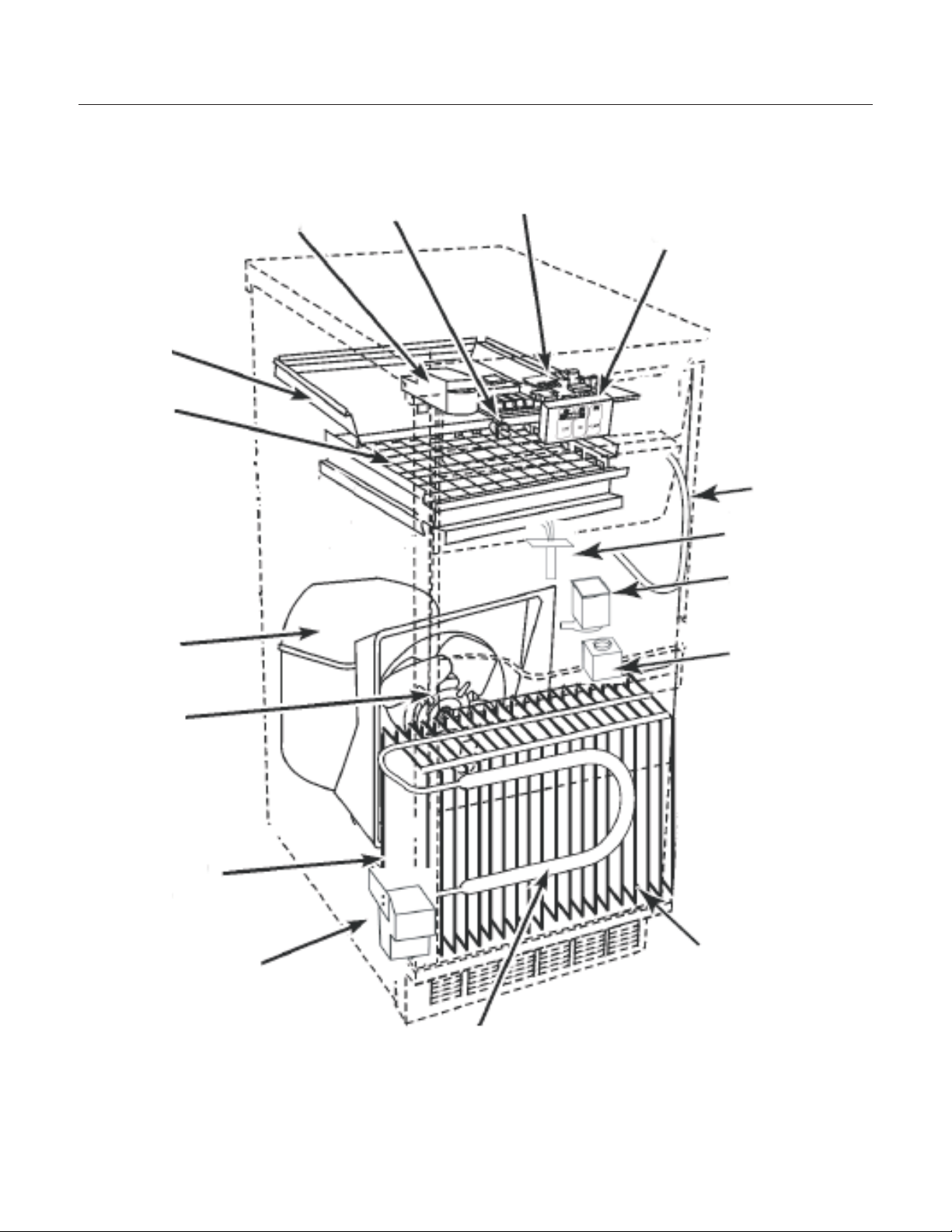

Component Location

CS0415

Service Manual

Evaporator

Cutter Grid

Compressor

Transformer

Light Switch

Controller

Push Button Switches

Bin

Thermistor

Water Level Sensor

Water Pump

Reservoir Drain

Pump

Fan Motor

Hot Gas Valve

Measured Fill Inlet

Water Solenoid Valve

Condenser

Condenser Accumulator Tube

July 2007

Page 9

Page 10

Component Location

Evaporator

Water Return

Tube

CS0415

Service Manual

Water

Distributor

Water Level

Sensor

Manual Drain

Water Valve

Outlet Tube

Measured Fill

Valve

Water Pump

Resevoir

Reservoir

Drain Pump

Bin

Drain

July 2007

Page 10

Page 11

CS0415

Service Manual

Diagnostic Mode

Do not continue with the diagnosis of the ice maker if a fuse is blown, a circuit breaker is tripped, or if

there is less than a 120 volt power supply at the wall outlet. Units that failed during the first few days of

use should be checked for loose connections or miswiring.

Entering and Navigating — Manual Diagnostics

Turn the product to On. Within 10 seconds of Power On, press and hold the On and the Clean buttons.

Release both buttons when all user interface LEDs begin to flash.

Within 5 seconds of all LEDs flashing, push any other button (On, Off, or Clean). This begins manual

diagnostics. If no button is pressed within 5 seconds, the product goes into an automatic diagnostic

mode. Each component is cycled for 5 seconds.

The Off button is used to advance through each step. To exit manual diagnostics, press the On button.

After pressing any button to enter manual diagnostics all LEDs will illuminate for 5 seconds. The controls

will then automatically move to the first component.

Order

1 Entry into Test Mode ON ON ON

2

3

4a

4b Water Level Sensor OFF

5 Water Pump ON ON ON

6 Reservoir Drain Pump ON OFF OFF

7

Component

Bin Thermistor

Evaporator Thermistor OFF OFF

Water Valve 4 min time

out Off button press will

advance to step 6

Compressor and

Condenser Fan Motor

On LED Off LED Clean LED

ON Solid—OK. 2

blinks—Open. 4

blinks—Shorted.

OFF

ON Solid while

cooling

OFF OFF

ON Solid—OK

2blinks—Open

4blinks—Short

ON Solid—reservoir full

Blinking—reservoir empty

ON Solid—reservoir full

Blinking—reservoir empty

Blinking when evap

thermistor reaches 4.5ºF;

full frost pattern should be

visible

ON

ON

ON

8

9 None Off Off On is normal*

10 Ice Thickness OFF

Compressor and Hot

Gas Valve

ON Solid while

heating

July 2007

Page 11

ON Solid while heating

Blinking when evap

thermistor reaches 52ºF

2 Blinks—Thin. 4 Blinks

—Normal. 6 Blinks —Thick.

Press Clean button to cycle

between settings

ON Solid while

heating

OFF

Page 12

CS0415

Service Manual

Error Displays

These errors will occur at any time during normal operation if a thermistor fails.

2 Blinks - Off Light is blinking twice in repeating intervals – This signals a bin thermistor failure.

•

Check that the bin thermistor is plugged in to the control box. Check that the bin thermistor is not

open or shorted. Replace the thermistor if it is open or shorted.

3 Blinks- Off Light is blinking three times in repeating intervals – This signals a harvest failure.

•

Check that the evaporator thermistor is connected to the sealed system tubing. If the thermistor is

plugged in, ensure that it is fully connected to the control box. (The ice maker will operate on a

timed cycle if the evaporator thermistor is unplugged.) Check the resistance of the thermistor. If

the thermistor checks good, then look for a frost pattern on the evaporator plate. The unit may be

low on refrigerant.

Note: The lights will continue to blink after correction until the unit is shut off and then switched back on.

The power cord on the internal drain pump is connected to a 120 VAC wall outlet. The ice maker is then

connected to the 120 VAC outlet on the drain pump. If the drain pump fails, or if the drain becomes

blocked, power is shut off to the 120 VAC outlet on the drain pump.

When the unit is first plugged in, the drain pump will run for 20 seconds. The power can be

disconnected and reconnected to verify that the pump is operating properly.

Water from the ice maker reservoir, or melting ice from the bin, drains down the bin drain tube into the

pump inlet, and then into the drain pump chamber. As the water level rises, it bridges the “full” contacts,

and the pump starts to run. The pump discharges the water through the outlet and the check valve.

When the “full” connection is removed, the pump runs for an additional 12 seconds to empty the tank.

If the water level in the drain pump continues to rise, due to a slow or blocked drain, or a blocked vent

hose, and touches the “overfill" contact, power will be turned off to the drain pump’s 120 VAC outlet,

causing the ice maker to turn off.

July 2007

Page 12

Page 13

Service Manual

Component Testing

Before testing any of the components, perform the following checks:

Control failure can be the result of corrosion on connectors. Therefore, disconnecting and

•

reconnecting wires will be necessary throughout test procedures.

All tests/checks should be made with a VOM or DVM having a sensitivity of 20,000 ohms per- volt

•

DC, or greater.

Check all connections before replacing components, looking for broken or loose wires, failed

•

terminals, or wires not pressed into connectors far enough.

Resistance checks must be made with power cord unplugged from outlet, and with wiring harness

•

or connectors disconnected.

Transformer

1. Unplug ice maker or disconnect power.

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

Thermistor

Sensor Temperature °F

32 29,000 to 31,000

Resistance Range W

2. Set the ohmmeter to the appropriate scale.

3. Touch the ohmmeter test leads to the primary

black and white leads of the dual transformer. The

meter should indicate between 3.5 and 4.5 ohms.

4. Touch the ohmmeter test leads to the secondary

yellow and yellow leads of the dual transformer.

The meter should indicate between 0.11 and 0.14

ohms.

CS0415

75 9,500 to 10,500

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. For the most accurate measurement, immerse

the thermistor in ice water for 5 minutes, then use

the 32°F reading in the chart.

4. Touch the ohmmeter test leads to the two

evaporator thermistor connectors. The meter

should indicate as shown in the chart.

Cutter Grid

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. Touch the ohmmeter test leads to the pins of the

cutter grid 2-wire connector. The meter should

indicate 4 to 5 ohms

5. Touch the ohmmeter test leads to the secondary

red and red leads of the dual transformer. The

meter should indicate between 0.14 and 0.18

ohms.

Water Pump

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. Touch the ohmmeter test leads to the outside

water pump wire connector pins. The meter should

indicate approximately 3.6 ohms.

Reservoir Drain Pump

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. Touch the ohmmeter test leads to the outside

reservoir drain pump wire connector pins. The

meter should indicate approximately 3.6 ohms.

July 2007

Page 13

Page 14

Component Testing

CS0415

Service Manual

Water Level Sensor

1. Run the diagnostic tests and check for the

proper operation of the water level sensor in step

4b.

2. With the water level sensor immersed in water

the Service LED should stay on solid.

3. With the water level sensor out of the water the

Service LED should blink.

Measured Water Fill Valve

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

d) Turn the relay over so that the coil faces up, as

shown below.

e) With the tip of the ohmmeter test leads at the

Start (S) and Run (M) pin sockets, the meter

should indicate a closed circuit (0 ohms).

1. Unplug ice maker or disconnect power.

2. Unsnap and remove the cover from the

measured fill water valve.

3. Set the ohmmeter to the appropriate scale.

4. Touch the ohmmeter test leads to the measured

fill water valve solenoid terminals. The meter

should indicate between 240 and 280 ohms.

Compressor Start Relay

Position the relay with the coil facing down, as

shown below.

b) Insert the tip on one of the ohmmeter test leads

into the Run (M) pin socket, and touch the other

ohmmeter lead to the spade terminal. The meter

should indicate a closed circuit (0 ohms).

c) Move the tip of the ohmmeter test lead from the

spade terminal into the Start (S) pin socket. Leave

the other ohmmeter lead at the Run (M) location.

The meter should indicate an open circuit (infinite).

July 2007

Page 14

Page 15

Flow Chart - Overall Operation

Switch On

Flush Mode

Begins

Freeze Mode

Begins

Harvest Mode

Begins, water

drains and refills

Water Level

Drops Below

Sensor?

25 min. of

freeze time?

Yes

No

Yes

Compressor and

Hot Gas Valve on

for 1 minute

Bin Full?Yes

Compressor and

Hot Gas Valve on

for 1 minute

No

Evaporator

more than

52

o

F.?

Compressor and

Hot Gas Valve on

for 3 minutes.

No

Freeze ModeIdle Mode

Yes

Evaporator

more than

52

o

F.?

Yes

Evaporator

more than

52

o

F.?

No

Yes

Yes

Evap

Thermistor

Unplugged?

No

Yes Yes

No

Continued Harvest

Mode

Evaporator

more than

52

o

F.?

16 minutes

max harvest

time?

No

Failure ModeYes

Bin Full? Yes

Yes

No

No

CS0415

Service Manual

July 2007

Page 15

Page 16

Flow Chart - Freeze Mode Details

Freeze Mode

Water Level

Sensor

Detected?

Comp., fan motor,

spray pump are on

Water level

drops below

sensor?

Comp., fan motor,

spray pump are on

for 25 minutes

maximum

Comp., fan motor,

spray pump are on

Yes No

Harvest Mode

Hung Slab Noted

Yes

No

Water level

drops below

sensor?

Yes

20 minutes up?

No

YesNo

5 minutes up?

Yes

No

CS0415

Service Manual

July 2007

Page 16

Page 17

Service Diagnosis

Symptom Possible Cause Probable Correction

No power at wall outlet Check circuit breaker/fuses

CS0415

Service Manual

No ice, not operating

No ice. Will not make ice. Water

reservoir is empty. Evaporator is

cold with thin or no ice slab.

No power at auxiliary drain

pump power outlet

Check for kinked drain hose,

blocked screen or blocked vent

outlet or hose.

Disconnected selector switch

Room temperature below 55

o

C)

(13

o

Reconnect and check for proper

operation.

F.

Bin thermistor has unit shut off

Ice touching bin thermistor Normal operation

Water supply turned off Turn on water supply

Loose or missing reservoir cap Tighten or replace

Water slide return tube out of

reservoir

Inlet tube out of position and

missing reservoir

Water inlet tube frozen near

evaporator

Reposition tube

Reposition tube

Thaw and reposition tube

Defective inlet water valve Test and repair or replace

An ice slab only partially

released from evaporator and

water was bridged down into the

bin

Look for interference with cutter

grid and clean the evaporator

plate

Will not make ice. Water

reservoir is empty. Evaporator is

cold with 3/4" thick or larger ice

slab

Off LED on.

Slab will not release during

harvest due to scale build up

Defective or disconnected hot

gas valve

Room temperature over 100

o

C)

(38

Open or disconnected bin or

evaporator thermistor or

thermistor wiring

July 2007

Page 17

Clean the evaporator plate

Test and repair or replace

o

F

Move machine or reduce heat

Test thermistor & wiring harness

or reconnect

Page 18

Service Manual

Service Diagnosis

Symptom Possible Cause Probable Correction

CS0415

Will not make ice. Water

reservoir is full. Evaporator is

cold with thin/partial/irregular or

no ice slab

Will not make ice. Water

reservoir is full. Evaporator is

warm.

Low capacity

Seeping water valve. Condenser

is hot

Partial refrigerant leak or

restriction (U-shaped slab)

Defective recirculating pump

Replace water valve

Check for leak/restriction and

repair or replace defective

component

Repair or replace the pump

motor assembly

Partially blocked water distributor Clean distributor and evaporator

Compressor is not running

Blocked condenser or stalled fan

motor

Test compressor, relay and

overload

Clean condenser, repair or

replace motor

Unit is in the startup mode Wait 5 minutes and recheck

Room temperature below 55

o

C)

(13

o

Seeping water valve. Condenser

is hot

Slow or defective drain or drain

pump causing water to back up

into the bin

Bin thermistor has unit shut off.

F

Advise user.

Replace water valve

Repair or replace drain or drain

pump

Airflow blocked Remove blockage

Go to manual test 9, if clean light

Control in extended cycle mode

is blinking, push Clean button

once.

Too much ice in bin Defective bin thermistor Test and replace thermistor

Banging sound

The slab dropping off the plate

and ice dropping from the cutter

grid into an empty bin are normal

sounds

The reservoir is empty. Look for

a partially released slab,

Noise

Grinding, cavitating sound.

interference with cutter grid etc

and clean the evaporator plate.

Grinding, cavitating sound from

recirculating pump

If the reservoir is full replace the

pump

Noisy drain pump Repair or replace

Ice freezing together in the bin Normal if little ice is used. Use more ice.

July 2007

Page 18

Page 19

Removal and Replacement - Thermistor

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

Bin Thermistor and / Or Cutter Grid

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Cover or remove the ice from the storage bin.

4. Place a cloth in the drain hole to avoid hardware

from falling inside.

CS0415

Service Manual

Slide the cutter grid forward and out of the unit and

place it on a work surface.

Be careful not to scratch the ice maker liner.

d) Remove the spacer from the right cutter grid

bracket tab.

Unsnap the two ice guides from the cutter grid

tabs. There should be a slight outward tilt after the

guides are installed. Bend the metal tabs outward if

necessary.

Control Housing

5. Remove the two hex-head screws from the

cutter grid cover and remove the cover.

Cutter Grid

6. To remove the bin thermistor:

a) Disconnect the bin thermistor connector from the

bottom of the control housing.

b) Pull the bin thermistor out of the retaining clamp

and remove it.

7. To remove the cutter grid:

Bin Thermostat

Connector

Cutter Grid

Connector

Cutter Grid

Screws

a) Disconnect the cutter grid and bin thermistor

connectors from the bottom of the control housing.

b) Remove the two hex-head screws from both

sides of the cutter grid. The longer screw and white

spacer are on the right side.

July 2007

Page 19

Page 20

Removal and Replacement

CS0415

Service Manual

To remove the evaporator thermistor:

Evaporator

Thermistor

a) Remove the cutter grid from the unit

b) Disconnect the evaporator thermistor connector

from the bottom of the control housing.

c) Remove the two hex-head mounting screws

from the water trough and pull the

trough from the unit.

To remove the water distributor:

a) Remove the cutter grid from the unit

b) Pull out on the left and right water distributor

retainers, and remove the tabs from the slots in the

evaporator. Pull the distributor forward and remove

the water hose.

Tab

Reach behind the accumulator,

and unclip the evaporator

thermistor from the evaporator

tubing and remove it.

Water Hose

Water Distributor

July 2007

Page 20

Page 21

Removal and Replacement - Controller

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Cover or remove the ice from the storage bin.

CS0415

Service Manual

7. To remove the electronic control board:

a) Disconnect the six harness connectors from the

board terminals.

b) Remove the two mounting screws.

Screw

4. Remove the cutter grid cover and the cutter grid.

5. Disconnect the remaining two connectors (bin

and evaporator thermistors) from the bottom of the

control housing.

6. Remove the four hex-head screws from the

control housing and lower the housing so that you

can access the components.

Water Pump

Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Remove the ice from the storage bin.

4. Unscrew the drain cap from the reservoir, drain

the water, and replace the cap tightly.

5. Place a cloth in the drain hole to avoid hardware

from falling inside.

6. Remove the hex-head screw from the water

recirculation pump shield and remove the shield

(see the photo below).

NOTE: The control housing components consist of:

• (1) Electronic control board

• (2) Dual transformer

• (3) Light switch

• (4) Push-button switch assembly

July 2007

Page 21

Water Reservoir

Drain Cap

Reservoir

Drain Pump

Page 22

Removal and Replacement

CS0415

Service Manual

3. Unscrew the drain cap from the reservoir, drain

the water, and replace the cap tightly.

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

7. Disconnect the water fill tube from the pump

mounting bracket.

8. Disconnect the two wire pump connectors from

the harness block.

9. Remove the two thumbscrews from the reservoir

and remove the reservoir from the ice maker.

10. Remove the pump outlet tube.

11. Remove three hex-headed screws from the

pump mounting bracket and remove pump

assembly.

4. Remove the recirculating pump cover hexhead

screw.

5. To remove reservoir drain pump:

a) Disconnect the reservoir drain pump electrical

connection.

b) Remove the pump retaining screw and bracket.

c) Rotate the pump 1/4 turn and pull it down and

out of reservoir.

6. To remove the water level sensor:

a) Disconnect the water level sensor electrical

connection.

Water Fill

Tube

Pump Outlet

Tube

12. Separate the recirculation pump from the

bracket.

Reservoir Drain Pump and /or Water Level Sensor

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

Water Level

Sensor

b) Remove the retaining clips, if present.

c) Pull the sensor up and out of the bracket.

July 2007

Page 22

Page 23

Removal and Replacement - Evaporator

Electrical Shock Hazard

Electrical shock can

cause personal injury.

Disconnect electrical

power before proceeding.

Evaporator

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Remove the ice from the storage bin.

CS0415

Service Manual

Channel

Cover

4. Remove the cutter grid and the evaporator

thermistor from the unit.

5. Disconnect the bin thermistor connector from the

bottom of the control housing.

6. Remove the top door screw from the ice maker

door, and pull the door off the bottom hinge.

7. Remove the two 5/16” hex-head screws from the

top hinge and remove the hinge.

8. Remove the two front and two rear screws from

the cabinet top.

Lift the cabinet top and position it forward on top of

the unit.

From the rear of the unit, remove the six hex-head

screws from the channel cover and remove the

cover.

12. Remove the four screws from the unit

compartment cover and remove the cover.

13. Cut the tie wrap from around the tubing and

wire harness inside the channel.

Unit

Compartment

Cover

July 2007

Page 23

Page 24

CS0415

Service Manual

14. Remove the two screws from the reservoir

water trough and remove the trough.

Water Trough

Remove the hex-head screw from the water

pump shield and remove the shield.

Water Pump Shield

17. Pull out on the left

and right water

distributor retainers

and remove the tabs

from the slots in the

evaporator, disconnect

it from the hose, and

remove it.

16. Remove the water fill tube from the notch in

the water pump bracket, and pull the free end of

the water line up, out of the unit.

18. Remove the four screws from the evaporator,

then carefully lift the evaporator just high enough to

remove the two right spacers.

Remove the Permagum from the liner channel.

20. Lift the cabinet top off the unit and stand it on

the floor near the rear of the unit.

Fill Tube

July 2007

Page 24

Page 25

CS0415

Service Manual

21. Lift the evaporator and its connecting tubing

high enough from the unit to access the tubing

underneath.

Access the sealed system and discharge the

refrigerant into an approved recovery system.

IMPORTANT: Refrigerant lines must be connected

by a licensed, EPA certified refrigerant technician

in accordance with established procedures.

REASSEMBLY NOTES:

When installing the new evaporator, use a

generous amount of thermal heat trap paste

between the hot gas valve, and the evaporator

tubing joint to protect the hot gas valve when

brazing.

23. Unbraze (and cut) the evaporator from the

tubing at the following locations:

•

Suction line at the compressor.

•

Hot gas line at the hot gas valve.

•

Cut capillary tube at the drier fi lt

• Be sure to reinstall the Permagum in the liner

channel of the cabinet around the wire sheath and

tubing, so that there are no air leaks after the

cabinet top is installed

July 2007

Page 25

Page 26

CS0415 Cleaning Indicator Issue:

Symptoms: Cleaning light red after less than 2 weeks of usage.

Problem : hung slabs or simulated hung slabs ( run with no water for 48 hours) is the cause for

various reasons.

Observation : Customer sees red clean light on

To re-set the clean light : Customer/ Tech will have to let the clean cycle run all the way. 70 minutes

the light will go from blinking green ( during cleaning ) to solid green. But 70 minutes is a long time for a

tech to wait.

Following could cause faster/more frequent hung slabs:

1. Low or no fill on water

a. line pressure low,

b. fill tube alignment ( pointing down the standpipe drain )

c. RO water system capacity,

d. kinked lines to or inside product

e. leaking lines inside or outside the product

f. check fill level in reservoir ( should be within 1/2" of standpipe)

.

2. Leaking reservoir

a. drain cap

b. reservoir drain pump gasket

c. Goose neck drain tube fully seated and in vertical orientation ( slow siphoning of water during

recirculation would be observed)

d. reservoir level ( less probable)

3. Obstructed Cutter grid

a. foreign object on grid

b. thermistor wire blocking grid

c. ice guide missing or loose ( blocking slab as it travels)

d. cutter grid unplugged

4. Water quality causing stacking slabs

a.

Through control diagnostics change to delay harvest mode ( high mineral content water

makes ice difficult to cut )

b. verify in diagnostics on control. Will get blinking clean light in step #8.

5. Unlevel product

6. Evaporator

a. dirty , especially the front of side walls ( make slab hang on plate)

b. weld slag on back corners of the evap plate

c. toed in evap plate

1. front should be wider than the back

2. top should be wider than the bottom

d. verify alignment between evap side walls and water return into the iceguides.

Page 27

7. Leak in the recirculation system

a. return tube in reservoir

b. leak in tubing or distributor causing water to spray into the bin , not flowing down the evap plate

c. tube fully seated at motor and distributor

d. distributor attached to the evap , not loose causing water spray.

8. Hot gas valve

a. plugged in

b. verify in diagnostics run frost pattern less than 8 minutes, switch to mock harvest should

remove heavy frost in under 2 minutes.

c. sealed system leak or restriction in hot gas tubing ( harvest cycle)

9. Water level sensor

a. fully seated in the bracket

b. check functionality in diagnostics

Page 28

SCOTSMAN ICE SYSTEMS

775 Corporate Woods Parkway, Vernon Hills, IL 60061

800-533-6006

www.scotsman-ice.com

17-3187-01

Loading...

Loading...