Page 1

Remote Terminal Unit

W@de range

W310 (Brio)

Telemetry remote autonomous system

User's manual

W310

ade

w

Page 2

Page 3

W310 (Brio)

Contents

Safety information 4

Safety 4

Disclaimer 4

W310 security alert 4

Overview 6

Purpose 6

Main features 6

Self-sufficiency 7

Operating principles 7

Operating modes 8

Function indicator lights 8

Installation 9

Prerequisites 9

Internal view of W310 9

Inserting SIM card 9

Connectors 10

Commissioning 12

Preliminary checkings 12

Types of configuration 12

Wake up W310 and local activation of the dialogue 13

Activating a diagnostic SMS send 14

Local configuration of W310 (Kervisu) 16

Configuration using Kervisu 16

Configuration screen 17

Channels (1 to 8) screen 20

Counters screen 24

System screen 25

System error table 25

GSM screen 26

Modbus settings screen 27

Retrieval/Downloading of the configuration 28

Remote configuration of W310 (Kerweb) 29

Configuring the Supervisor (Kerwin) 30

Self-configuration: case of a W310 unit site 30

Manual creation of a W310 unit site 30

Testing the installation 31

Frequently asked questions 33

NT00196-EN-03

Appendices 35

Detailed technical features 35

Factory predefined cable 36

Setting up the infrared/USB interface 37

Setting up the W310 peripheral with Kervisu 39

Local data retrieval 41

Calculating the battery's lifespan 41

Tips for opening your GSM account 42

Codes and spare parts 42

W310 (Brio) hardware/software version history 43

Notes 44

3

Page 4

W310 (Brio)

NOTICE:

Safety informations

Safety

Read these instructions carefully, and look at the equipment to become

familiar with the device before trying to install, operate or maintain it.

The following special messages may appear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to

information that clarifi es or simplifi es a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that

an electrical hazard exists, which will result in personal injury if the instructions

are not complied with.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

or DANGER

DANGER indicates an imminently hazardous situation, which, if not prevented,

will result in death or serious injury.

NOTICE:

or WARNING

WARNING indicates a potentially hazardous situation, which, if not prevented,

can result in death, serious injury or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not prevented,

can result in injury or equipment damage.

Disclaimer

Electrical equipment should be installed, operated, serviced and maintained

only by qualifi ed personnel.

Schneider Electric may not be held liable for any consequences arising out

of the use of this equipment.

© 2012 Schneider Electric. All rights reserved

W310 security alert

WARNING

MOUNTING OF W310 (UL COMPLIANCE)

The W310 must be mounted vertically in order to offer the best protection against

the spread of fi re.

The W310 shall be installed and used on distance greater than 20 cm from

human body.

WARNING

ONLY QUALIFIED PERSON TO OPEN THE EQUIPMENT

It’s forbidden to open the equipment by an operator:

Battery or SIM card installation must be obligatorily carried out by the offi ce,

factory or a qualifi ed person.

Failure to follow these instructions can result in serious injury or equipment

damage.

4

NT00196-EN-03

Page 5

W310 (Brio)

Safety informations

CAUTION

PIN CODES INFORMATION

Before the insertion of the SIM card, you must check the correspondence between

PIN codes or inhibit the PIN code of the card to be used.

Failure to follow these instructions can result in invalidate the SIM card.

Then you will need to request the PUK code from the operator!

CAUTION

INSERTION OF SIM CARD

Never insert or extract a SIM card when W310 is in communication

(indicator lit on or blinking).

Failure to follow these instructions can result in equipment destruction.

WARNING

BATTERY REPLACEMENT AND RESPECT THE POLARITY

The W310 operates exclusively on a Lithium Thionyl Chloride battery

(VITZROCELL SW-D02 or SAFT LSH20).

Replace only with the same model or an equivalent model proposed by

the manufacturer.

The battery must be positioned correctly while respecting polarity inside the socket.

Failure to follow these instructions can result in serious injury or equipment

damage and the W310 will have to be repaired in the manufacturer.

WARNING

ELECTRICAL SHOCK RISK

All wiring must be carried out in accordance with industry standards.

NEVER ALLOW BARE WIRES TO COME INTO CONTACT WITH EACH OTHER.

The sensors or the power used with the W310 must answer specifi cations SELV

(Safety Extra Low Voltage). They must be obligatorily installed by qualifi ed

personnel.

Failure to follow these instructions can result in death, serious injury or

equipment damage.

CAUTION

RECOMMENDATION ON SENSORS CONNECTION

The total length wiring must not exceed 3 meters. The wiring must be twisted pair

armed type to connect the sensor.

Failure to follow these instructions can result in equipment measurement

failure.

DANGER

SENSORS INSTALLATION

This manual covers only W310. The installation of the sensors and the external

elements is not the subject of this document. Imperatively contact the manufacturer

as of these supplies to know the limitations of uses of their products.

Please refer to the applicable safety requirements on their use.

Failure to follow these instructions can result in death, serious injury

or equipment damage.

NT00196-EN-03

5

Page 6

W310 (Brio)

Overview

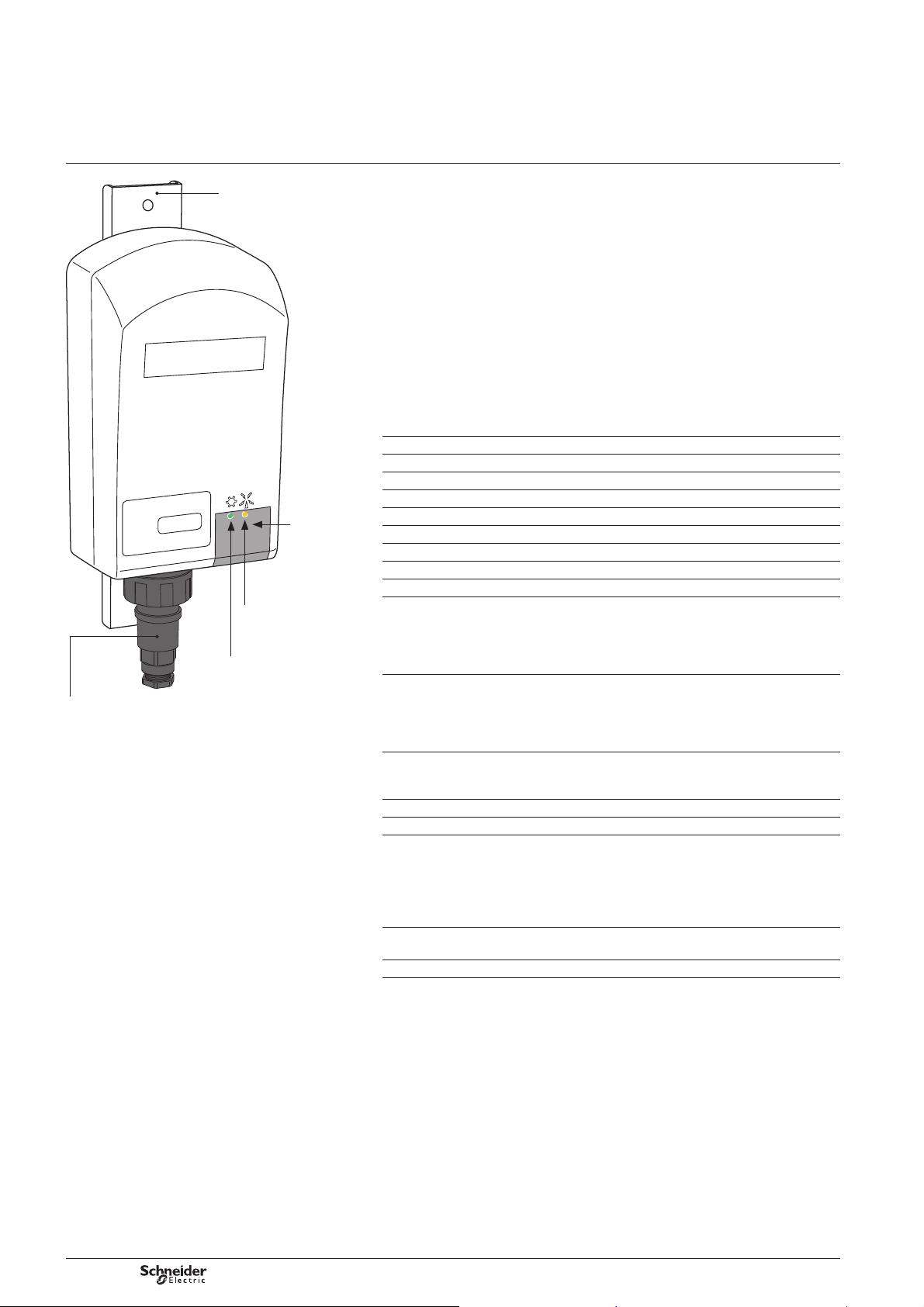

DE59642

Bulgin connector:

Sensors input measurement,

Sensor output 15 Vdc power.

Unistrut™ rail adaptor

(not provided)

Infrared

communication

area

Status indicator lights

Yellow: GSM

SMS transmission

function

Green: RUN

operating function

Purpose

This document is the user manual for the W310 wireless local telemetry unit.

W310 refers to the same product. In the following, only W310 will be used.

Presentation

W310 belongs to a generation of ultra-low power consumption data acquisition and

transmission products that use the GSM network.

W310 is battery-powered, making it completely self-suffi cient and extremely quick

and simple to install.

W310 comes in a robust polycarbonate box which is highly resistant to adverse

weather conditions and is connected to the signals it is monitoring by means of

a waterproof connector. It has two indicator lights which indicate the device's

operating status.

Main features

Operating temperature Between –25°C and +60°C, between 0 and 90% humidity

Protection class IP56 (IP40 for UL)

Dimensions 194.4 x 107.7 x 65.7 mm

Power supply Lithium-thionyl-Chloride 3.6 V (size D) cell

Battery life Up to 10 years depending on type of use

Connection IP68 waterproof connector

Local link IrDA infrared (9600 bauds no-parity 8 bits)

GSM Quadri-band (850, 900, 1800, 1900 MHz)

GSM antenna Internal

Digital inputs b 4 digital inputs usable as pulse counting (32 bits, 50 Hz,

minimum pulse width: 10 ms)

b Flow calculation, close contact time calculation

b Measuring voltage: ~ 3.3 V

b Reading current: ~ 3 A

Analogue inputs 4 universal analogue inputs:

b 0-100 mV, 0-1 V, ±10 V, ±10 Vpp

b 0-20 mA, 4-20 mA (W310 is able to power sensors

(supply voltage = 15 V))

b Resistor (0-2000 ), PT1000, PT100 (2 and 3 wire)

Other link Modbus Master RS485 (1200 – 38400 bauds)

W310 is able to power Modbus sensors

(supply voltage = 15 V)

Measurement resolution 16 bits

Accuracy < 0.1% (see features in detail)

Security b SIM card PIN number management

b Confi guration backed up in non volatile EEPROM

memory and non-volatile RAM

b “Watchdog timer”

b Overvoltage protection and polarity reversal protection

on input

Conformity b CE

b UL61010-1

RoHS Compliant

6

NT00196-EN-03

Page 7

W310 (Brio)

Overview

Self-suffi ciency

W310 has been developed using ultra-low power consumption technology which

enables it to be selfpowered for up to 10 years.

W310's self-powered lifespan is closely connected to the conditions in which it is

used, especially transmission frequency. Schneider Electric Telecontrol can assess

the probable lifespan of the battery according to the type of use to which it will be put.

The table below indicates probable lifespans for several typical hypothetical scenarios:

SMS transmission

frequency

1 / month* 3 Hz 10 years

1 / week 3 Hz 8 years

1 / day 3 Hz 5 years

3.6 V Supply voltage Consumption Activities carried out by W310

Sleep mode <30 A At 25°C, Clock running,

Read mode <30 mA Reading analogue channels

GSM transmission mode 400 mA Sending the SMS(s) (*)

(*) Real-life measurements have shown that the system can transmit more than 12000 SMS

messages without a change of battery (the consumption in this test is essentially due to the

communication).

Please note that by nature 4-20mA sensors cause a high level of consumption

when supplied by the W310. The longer it takes for the sensor to stabilise,

the higher the consumption will be.

Count frequency Lifespan (average)

1 Hz counting on on-off inputs.

(Except 4/20 mA and Modbus sensors)

Operating principles

W310 is based on simple operating principles:

b Programmable frequency acquisition and logging of various physical

measurements (metering, voltages, 4-20 mA sensing probes, temperatures, etc.).

Note that W310 is able to supply power to 4-20mA sensing probes. After taking

readings, the W310 then implements its alarm detection function.

b Programmable frequency transmission (in SMS form) of the data logged.

Data reception is provided by a master station such as Kerwin supervisor of

Schneider Electric Telecontrol.

Note that in the event of an alarm, a transmission will be sent as soon as the alarm

status is detected during a logging. To facilitate diagnostic of whichever element

is in alarm status, the W310 transmits all data in the memory at the same time

as it transmits the alarm.

b In sleep mode

v Real time “Detection” of changes in status of the digital inputs, with transfer to

“Read” mode

v Pulse counting (50 Hz max.) on all digital inputs.

b Programmable frequency diagnostic of operating settings (Battery voltage,

GSM signal strength, etc.): these settings are intended for monitoring and preventive

maintenance of the equipment.

Note: to be able to receive SMS messages sent by W310, the master station must

be equipped with a GSM modem in reception mode (cf. “Confi guration of the Kerwin

master station”).

NT00196-EN-03

7

Page 8

W310 (Brio)

Overview

Operating modes

W310 essentially operates in two modes, “Sleep” mode and “Awake” mode.

It is important to note that as W310 is an ultra-low power consumption product,

it is in “sleep” mode most of the time.

Its functions are activated under the following conditions:

b When it is the time programmed for acquisition or transmission

b When the activating magnet is used (A suffi ciently powerful magnet or the magnet

located in the infrared interface)

b When a change occurs on the status of one digital input (depending on the settings

of the digital inputs).

In particular, the system cannot be activated by a GSM call, as this would involve a

“standby” level of power consumption that would not be compatible with the lifespan

of the battery. These energy saving principles have been adopted in order to obtain

a maximal battery lifetime.

When the W310 is not in operation, for example when in transit, it can be set to

“transport”mode. While this mode is activated, W310 doesn't perform any

acquisition nor data transmission.

Function indicator lights

Two indicator lights are used to indicate the device's operating modes:

Light Colour Function Notes

RUN Green

GSM Yellow

Indicates the processor's activity:

b In “sleep” mode, a very short fl ash

every second.

b In “transport” mode, one fl ash every two

seconds.

b Quick blink when the magnet is detected

(local mode activation W310).

b ON during acquisition and transmission

periods.

b During dialogue with Kervisu, fl ashes

at each query during IrDA connection.

Indicates activity of the GSM function:

b Short fl ash (1/10 s) each second

during GSM communication.

b "Long" signal (1s x 1) to indicate SMS

successfully sent ending communication.

b Variable length signal to indicate GSM

reception strength (only when reading GSM

signal strength).

In sleep mode, the fl ash each

second is only noticeable

in semi-darkness; it is more

visible on each minute.

During data transmission,

the number of fl ashes

corresponds to the time

taken to transmit the SMS(s).

8

NT00196-EN-03

Page 9

W310 (Brio)

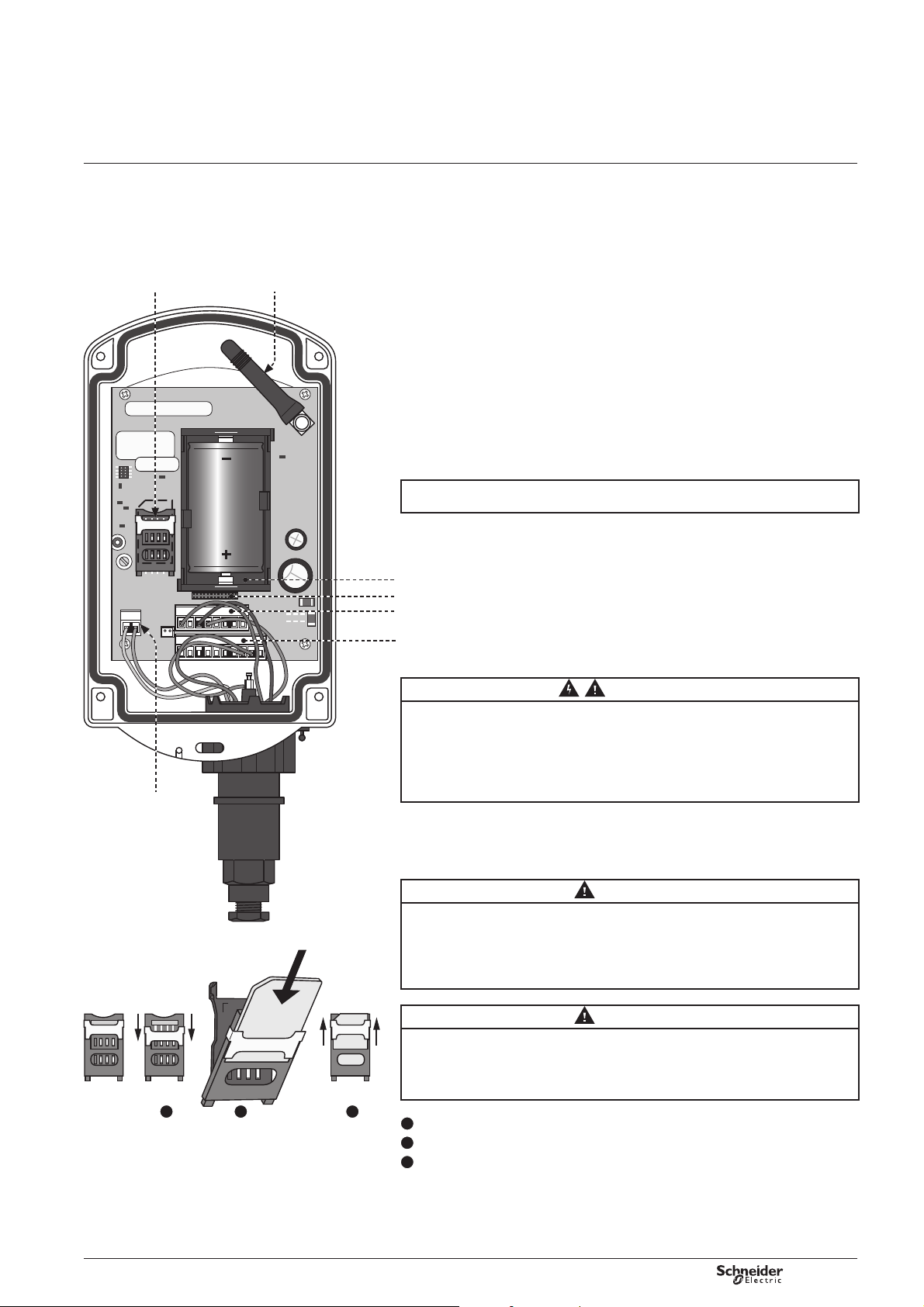

DE59635

Installation

Prerequisites

Please refer to the W310 Installation Guide for the details of the installation steps.

In order to operate the W310, you will need:

b Kervisu software version 1.9.4.1 or higher with the confi guration fi le for W310

used by Kervisu (Ref.: KvBRIO_6_Fr.CFG on the CD-ROM delivered with the product).

AntennaSIM card slot

b A Kervin master station, version 4.1.X or higher (applying a 3.6.2 patch to Kerwin

version 3.6 will also allow SMS messages from W310 version 5 or higher to be received).

b An activated SIM card with SMS capability.

b A USB/IrDA interface supplied by Schneider Electric Telecontrol

(Ref.: 0BRIOKIRDA-USB) for which the drivers are loaded onto the PC in accordance

with the instructions in chapter “Setting up the infrared / USB interface” and a magnet

(integrated in the IrDA interface).

Internal view of W310

The waterproof box is screwed down using four head screws: after loosening

the four screws completely, the cover can be removed by inserting a screwdriver

into the attachment hole at the top.

Take care to keep the cover parallel with the box when removing, so that it can be

removed easily and without damaging it.

RS485 connector

DE59639

1 2 3

Battery holder

For factory test

Analogue input terminal block

Digital input terminal block

WARNING

ONLY QUALIFIED PERSON TO OPEN THE EQUIPMENT

It's forbidden to open the equipment by an operator:

Battery or SIM card replacement must be necessarily carried out by returning

the product to the factory or by a qualifi ed person.

Failure to follow these instructions can result in serious injury or equipment

damage.

Insertion of SIM card

CAUTION

PIN CODE INFORMATION

Before the insertion of the SIM card, you must check the correspondence between

PIN codes or inhibit the PIN code of the card to be used.

Failure to follow these instructions can result in invalidate the SIM card.

Then you will need to request the PUK code from the operator!

CAUTION

INSERTION OF SIM CARD

Never insert or extract a SIM card when W310 is in communication

(indicator lit on or blinking).

Failure to follow these instructions can result in equipment destruction.

1

Unlock the SIM card slot by moving down the metal part to the bottom.

2

Insert the SIM card inside the shutter.

3

Pull down the SIM card shutter toward the support and lock it by moving up

the metal part.

NT00196-EN-03

9

Page 10

W310 (Brio)

WARNING

ELECTRICAL SHOCK RISK

All wiring must be carried out in accordance with

industry standards. NEVER ALLOW BARE WIRES

TO COME INTO CONTACT WITH EACH OTHER.

The sensors or the power used with the W310 must

answer specifi cations SELV (Safety Extra Low Voltage).

They must be obligatorily installed by qualifi ed

personnel.

Failure to follow these instructions can result

in death, in serious injury or equipment damage.

CAUTION

RECOMMENDATION ON SENSORS CONNECTION

The total length wiring must not exceed 3 meters.

The wiring must be twisted pair armed type to connect

the sensor.

Failure to follow these instructions can result

in equipment measurement failure.

(*) BUCCANER connector ref.: PX0745/S, Manufacturer:

BULGIN (UK).

This connector is supplied as standard with the W310

but can also be ordered directly from Schneider Electric

Telecontrol or via the electronic distribution system.

Installation

Connectors

Connectors

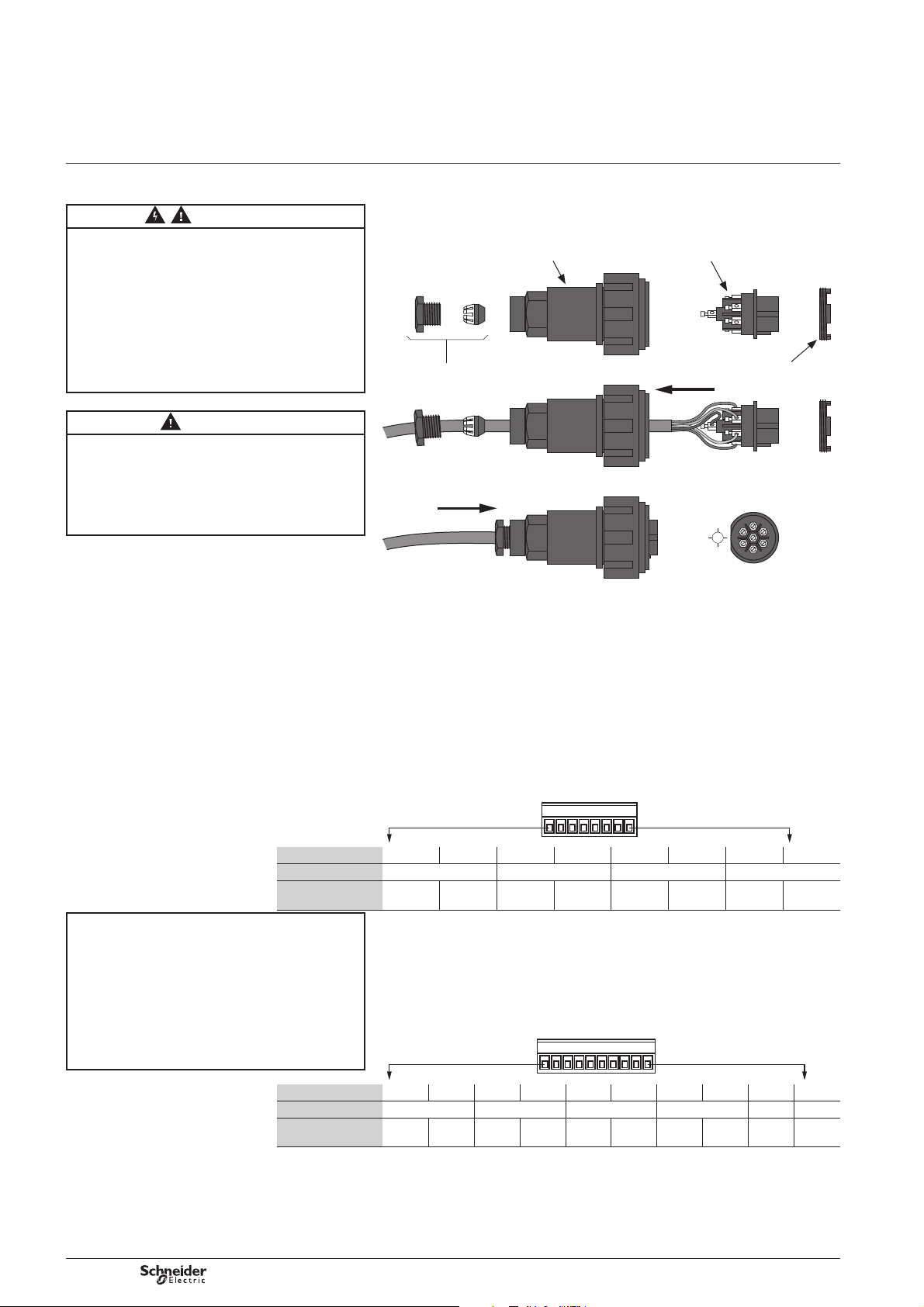

The W310 is equipped with a 7-point IP68 fi xed female connector (*) which can be

screwed directly onto the ends of the cables, with no welding or crimping.

The connector can be detached using a screw-off (anti-clockwise) threaded bolt.

Flex body moulding Contact insert

DE59646

Gland nut Insert retaining ring

2

1

7

6

The 7 pins, which have their numbers printed in relief on the connecting piece,

are for connecting to the signals that are to be read.

The 7 pins are connected to wires inside the box which are coloured according to

the international code and can be wired to the terminal blocks when required.

Schneider Electric Telecontrol delivers the W310 pre-wired according to various

different standard schemes (The different schemes are described in the Appendices).

3

4

5

Terminal no. 1 2 3 4 5 6 7 8

Printed ref. A1(*) A2 A3 A4

Corresponding

reading

NB: please take note of the polarity of the signals,

especially for sensors supplied by the W310

(two-wire sensors should be connected between

the supply signal and the relative input, the sensor's +

to the power, the sensor's – to the signal terminal of

the channel in question).

NB: please take note of the correspondence between

the physical signals and the software channels

confi guration. (See the channels confi guration screens

on Local confi guration of W310 (Kervisu) chapter).

Terminal no. 1 2 3 4 5 6 7 8 9 10

Printed ref. DI1 DI2 DI3 DI4 15V(*) 15V(*)

Corresponding

reading

Analogue input internal terminal block

The detachable terminal block has 8 terminals. Each of the analogue channels

corresponds to two terminals (signal and reference). The 4 analogue channels all

have the same reference.

Reference screen-printed on the electronic card: ANALOG INPUT

Ana 1

signal

(*) A1: Analogue Input 1

AGND Ana 2

signal

AGND Ana 3

signal

AGND Ana 4

signal

AGND

Digital input internal terminal block

The detachable terminal block has 10 terminals. Each of the inputs corresponds to

two terminals (signal and reference). The 4 digital channels all have the same

reference. It also has 2 terminals that can supply power to a 4-20mA sensing probe.

Reference screen-printed on the electronic card: DIGITAL INPUT

EL/Cpt 1GND EL/Cpt 2GND EL/Cpt 3GND EL/Cpt 4GND Sensor

(*) For 4-20 mA and Modbus sensors.

power

Sensor

power

10

NT00196-EN-03

Page 11

W310 (Brio)

Installation

Connectors

Connections for the various types of sensor

Digital Input or Counting

NB: the digital inputs are fi ltered by an RC/Hysteresis device, but they are high

impedance in order to limit the power consumption; the reading voltage is

approximately 3.3 V and the reading current is 3 A.

The connected contact must therefore be potential-free and leakage-free.

Wire between DI (1 to 4) and GND internal block DIGITAL INPUT

4-20 mA Analogue Input

2-wire passive: sensor block Internal W310 block

+ +15V (terminal 9 or 10, Digital Input block)

– Ai (i = 1 to 4) (terminal 1, 3, 5, 7 on Analog Input block)

Active sensor block Internal W310 block

+ Ai (i = 1 to 4) (terminal 1, 3, 5, 7 on Analog Input block)

– AGND (terminal 2, 4, 6, 8 on Analog Input block)

Voltage, Resistance, Platinium sensor analogue inputs

Voltage sensor block Internal W310 block

+ Ai (i = 1 to 4) (terminal 1, 3, 5, 7 on Analog Input block)

– AGND (terminal 2, 4, 6, 8 on Analog Input block)

Resistance, Platinium sensor block Internal W310 block

Terminal 1 (*) Ai (i = 1 to 4) (terminal 1, 3, 5, 7 on Analog Input block)

Terminal 2 (*) AGND (terminal 2, 4, 6, 8 on Analog Input block)

(*): any polarity

Modbus sensor

Modbus sensor block Internal W310 block

Power + +15V (terminal 9 or 10 on Digital Input block)

Power – GND (terminal 2, 4, 6, 8 on Digital Input block)

RS485 + RS+ (RS485 block 2 terminal)

RS485 – RS- (RS485 block 2 terminal)

PT100 sensor – 3 wires:

GND

A

i + 1

R

A

i

NT00196-EN-03

11

Page 12

W310 (Brio)

Commissioning

Types of configuration

Checks before starting

For your activation to run smoothly, you are strongly advised to check that

the following conditions have been met:

Please note that the checks below are not required if the product has been factory

pre-confi gured (the fi nal quality control sheet will certify that the settings have been

checked).

b The battery installed should be brand new and not used at all (this can be quickly

verifi ed using a multimeter, which should give a reading between 3.6 V and 3.7 V).

You are strongly advised to attach a label with the date on which the battery is fi rst used.

b The analogue signals that are to be connected are compatible with the inputs used

(you should pay particular attention to the connection direction when connecting

4-20 mA sensors when these are being supplied by the W310).

b The digital signals connected are completely potential free: zero voltage should

be recorded at the start for each pair (before connection)..

b The SIM card should be correctly inserted in its holder, which should be locked

in place.

In order for the confi guration and test to be carried out smoothly, ensure that:

b The device is fi tted with a SIM card for which the account has been activated

(this can easily be checked by sending an SMS with the SIM card inserted in a

mobile phone).

b On the supervisor, a site has been created with a phone number corresponding to

the one of the SIM card inserted in the tested W310 (this is the condition which

determines that the data sent by W310 is registered). The number is usually provided

by the network operator when the card is delivered. If you are unsure of the number,

it will be displayed when an SMS sent from the SIM card is received.

NB: Kerwin versions 4.1 and higher allow autoconfi guration of a W310 site

(in that case, the site is automatically created in Kerwin Supervisor with W310

phone number as soon as a SMS coming from that W310 is received).

Types of confi guration

W310 has been designed to be set up very simply. There are two different

confi guration possibilities:

Factory pre-confi guration

In this instance, commissioning on-site consists of connecting the signals, fi xing

the item in place and running a diagnostic transmission. The same method will be

used for repeat installations where all the operating settings are pre-confi gured in

advance (see details of the procedure in paragraph “Activating a diagnostic SMS

send” of this chapter).

User confi guration

This solution is more fl exible and allows all the operating settings to be confi gured

on-site. It requires use of a PC equipped with Kervisu software (Version 1.9.4.1 or

higher). Details of the procedure and the different possibilities for confi guration are

given below.

d In both case, W310 must be activated.

W310 is delivered in the “transport” mode to prevent any energy consumption

before commissioning. In this mode (one weak fl ash every 2 seconds), neither data

capture nor SMS transmission is activated.

The operation described hereafter switches the W310 from the transport mode

to the active mode and allows local communication.

12

NT00196-EN-03

Page 13

W310 (Brio)

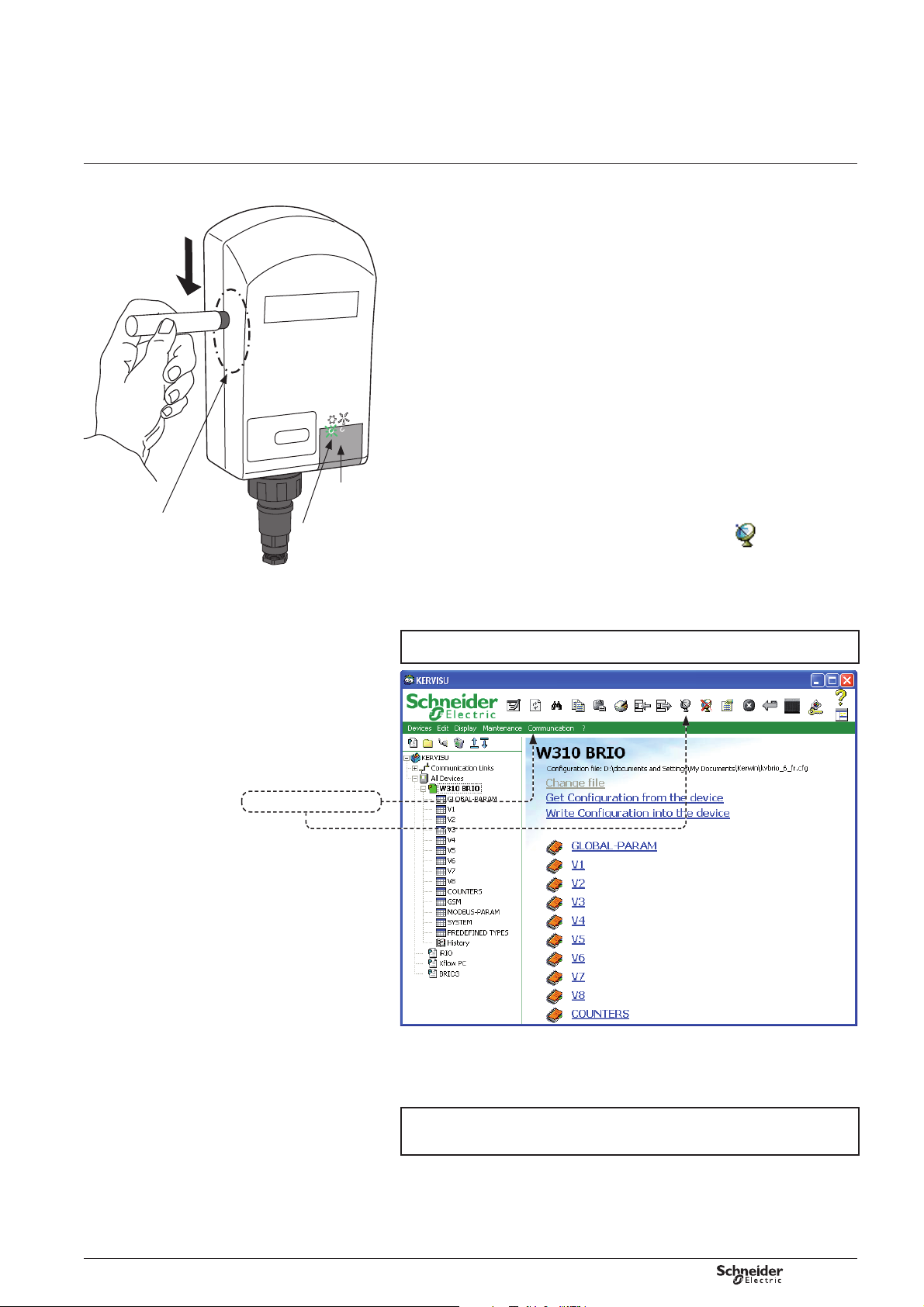

DE59643

Detection area

Infrared

communication

area

Green

indicator

Commissioning

Wake up W310 and local activation

of the dialogue

Wake up W310 and local activation of the dialogue

The W310 is always in sleep mode except during acquisition and transmission

phases, therefore it is necessary to activate it before being able to initiate a dialogue.

The port is activated by holding a magnet (located in the infrared interface supplied

by Schneider Electric Telecontrol) against the left side of the device for a few seconds

(5 s), as shown in the photo above. When the W310 is activated, the green indicator

light will go on.

When the green light is on, the W310 is ready to dialogue with Kervisu,

and you can then proceed with confi guration according to the instructions

in Chapter “Local confi guration of W310 (Kervisu)”.

Please note that once it has been activated, the W310 will be in communication

standby mode for 2 minutes. If there is no dialogue during that time, it will automatically

revert to sleep mode. It will then need to be activated again in order to start the dialogue.

When the green indicator light (on the left) is fl ashing, this shows that communication

is in progress. The light changes status at each data exchange.

The infrared port is located near the two indicator lights to the right of the “W310” mark.

It uses the IrDA protocol.

Schneider Electric Telecontrol provides a USB/IrDA cable as standard, which can be

used on any PC that has a USB port. As with all USB devices, it requires drivers,

which need to be installed as per the procedure described in appendix.

The Kervisu connection is carried out either by clicking on the

“connect” from the “communication” menu, as shown in the screen shot below.

The icon should then change colour and you will be able to choose one of the pages

suggested: “confi guration”, “channel 1” , etc. If the connection icon (dish aerial) does

not change colour, it means the infrared cable is not connected or Kervisu has not

been correctly confi gured (see chapter Appendices).

NB: from version 1.10.0.0 of Kervisu, the IrDA link must be positioned in order

to communicate with the W310 awake to allow the connection.

, or by selecting

Connecting to the W310

The following indicates that communication between Kervisu and the W310

has been successful:

b The values on the various screens are refreshed and appear in bold.

b The green light on the W310 fl ashes simultaneously with the data exchange.

Note: the link will only be established if the pre-requisites mentioned in page 9

have been met, especially setting up the infrared interface on the PC, and

registering the W310 in the Kervisu confi gurator (cf. Appendices).

NT00196-EN-03

13

Page 14

W310 (Brio)

Note: diagnostic values OP, RT, CB

and CI are valid from W310 fi rmware

version 6.20 and higher.

Commissioning

Activating a diagnostic SMS send

Activating a diagnostic SMS send

NB: since it is coded, a diagnostic SMS can only be sent to a suitable supervisor

(Kerwin type); it is no sense to send a diagnostic SMS to a cellular phone

(except for tests).

Defi nition of a diagnostic SMS

A diagnostic SMS can be sent automatically at a programmable frequency or

on demand.

Diagnostic data are intended for monitoring and preventive maintenance

of the W310 equipment.

A diagnostic SMS includes:

b The current values of the confi gured variables

b The diagnostic values (system data available on every W310).

In the SMS, diagnostic values are identifi ed with a 2 letters mnemonic.

Kerwin supervisor matches these mnemonics with comprehensive labels

(those labels identify the W310 system variables on Kerwin supervisor side).

Each label has a default value but can be changed as the user wants.

The relation between the mnemonic and the label is specifi ed in the KERWIN32.CFG

fi le (which stands in the Kerwin32 installation directory) in the [Brio diagnostic] section.

Mnemo Corresponding label

RL Radio Level GSM received signal strength (in dBm)

BL Battery Level Minimum voltage reading of the battery during the previous data

SV Software Version Numeric value for the software version (e.g.: 510 => 5.1.0)

SA Send Attempts Number of attempts at sending SMS

SS SMS Sent Number of SMS actually sent to the GSM network

MC Gaz Consumption Calculation of the total amount of energy consumed from the delivery

SE System Error Numeric value of the last system error (See system error table)

ST Session Time Total number of seconds the W310 modem has been taking

LC Last Confi guration Date of last change in the W310 confi guration

NV Number of Variables Maximum number of variables (usually 8)

SN Serial Number Serial number

AV Application Version Numeric value corresponding to the confi guration loaded in the W310

SR SMS Received W310 received SMS counter

OP OPerator ID Operator ID number

RT Registration Time This fi eld represents time in seconds encountered between the modem

CB Current Bands This fi eld represents the frequencies band or the group of two

CI Cell I

in Kerwin supervisor

dentifi cation Cell ID number. This information is transmitted in a decimal format

Description

transmission phase (in Volts)

of the W310 (x 100 A)

to send SMS

before the delivery

b MCC: fi rst 3 digits (Mobile Country Code)

b MNC: 2 last digits (Mobile Network Code)

The information sent within a diagnostic SMS concerns the operator

to which the W310 is registered when the SMS is sent. This operator

code is memorized on the W310 and is displayed on Kervisu GSM page

start (beginning of the SMS session) and the registration on a network

frequencies bands chosen by the modem to register on the network.

This fi eld is transmitted on a numerical format and matches a fi eld

of bits defi ning the different frequencies which are compatible with

the modem.

1 : 0000 0001 GSM 900 MHz

2 : 0000 0010 GSM 1800 MHz

4 : 0000 0100 GSM 1900 MHz

(unsigned 4 bytes (2 words)):

b 1st word : LAC: Location Area Code.

In each network, cells are grouped by geographical regions which are

attached to a LAC. These regions can be more or less big depending

on the density of the covered surface, on average some dozens of

kilometers.

b 2nd word: CI: Cell ID

Inside a LAC, each cell owns a unique ID (CI). Information transmitted

on a diagnostic SMS matches the cell where the W310 is registered

at the moment when the SMS is sent.

14

NT00196-EN-03

Page 15

W310 (Brio)

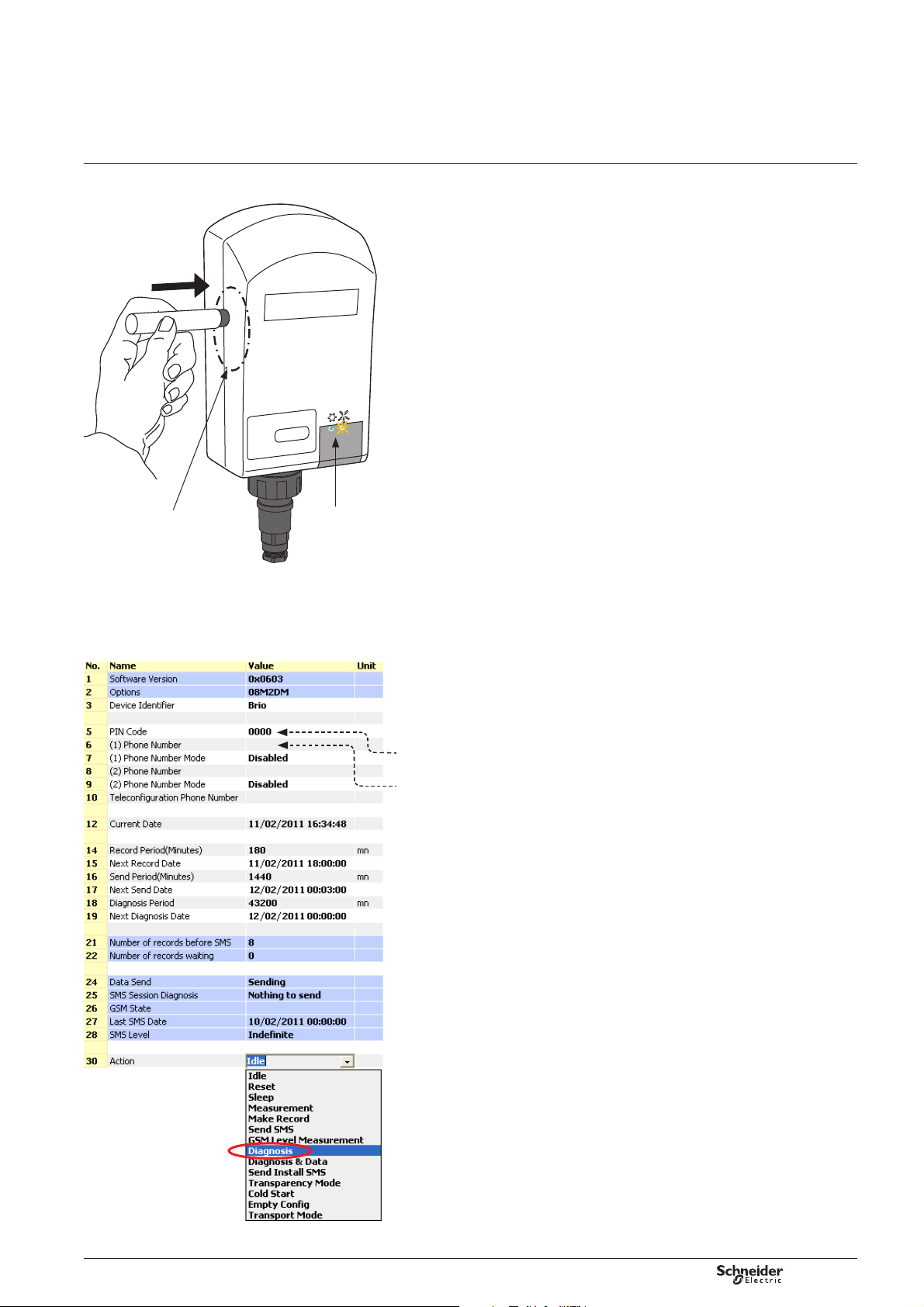

DE59644

Maintain

during 10 s

Detection area

Indicator

lights

Commissioning

Activating a diagnostic SMS send

When the W310 has been factory pre-confi gured

A factory pre-confi guration means that Schneider Electric Telecontrol will have

all the confi guration data relating to the site for which the W310 is to be used:

b What signals are to be connected to the W310 (which determines which channels

will be registered, along with their type)

b The frequency with which the data acquisitions are to be carried out

b The frequency with which the readings will be transmitted by SMS

b The SIM card’s PIN number

b The receiving telephone number(s) for the SMS messages.

The customer will also have provided Schneider Electric Telecontrol with the SIM card

and requested its activation in order for Schneider Electric Telecontrol to insert it

at the factory before delivery.

If all the above conditions have been met, you simply need to hold the activating

magnet in position for at least 10 seconds in order to activate the following actions:

b Acquisition via the registered channels

b Sending a diagnostic SMS

b Sending a diagnostic SMS including:

v values of the confi gured channels

v values of the diagnostic parameters.

When the green LED fl ashes (5 Hz), this shows that W310 has detected the presence

of the magnet.

One fl ash per second of the yellow LED indicates that the request for a diagnostic

SMS has been registered and is being transmitted.

If the SMS transmission is successful, the fi nal fl ash lasts for a whole second.

If however the transmission is not successful, the W310 will retry for a further

2 minutes, after which it will abandon the attempt. It will only retry again if:

b The current date is a logging date.

b The diagnostic procedure is reactivated (you must wait until W310 has returned

to sleep mode – one fl ash per second on the green LED).

When the W310 has not been factory pre-confi gured

In this case, before being able to carry out a test SMS transmission, you will need

to make the local connection (with Kervisu) (see chapter “Wake up W310 and/or

local activation of the dialogue”), so as to confi gure the settings which until will

enable an SMS to be transmitted:

b Be sure that at least one measurement channel is confi gured (see Channels 1 to 8

screen)

b The SIM card’s PIN code

b The phone number to call for the Kerwin supervisor (if there is no mobile phone

number)

b Enter the PIN code

b Enter the Kerwin receiving number for the SMS, along with its mode

(Data or Data + Alarms)

b In the “Action” fi eld, select the command “Diagnostic”

b An SMS will be prepared and sent; you can track the send status in the “GSM action”

and “Session diagnostic” fi elds.

NT00196-EN-03

15

Page 16

W310 (Brio)

Local configuration of W310

(Kervisu)

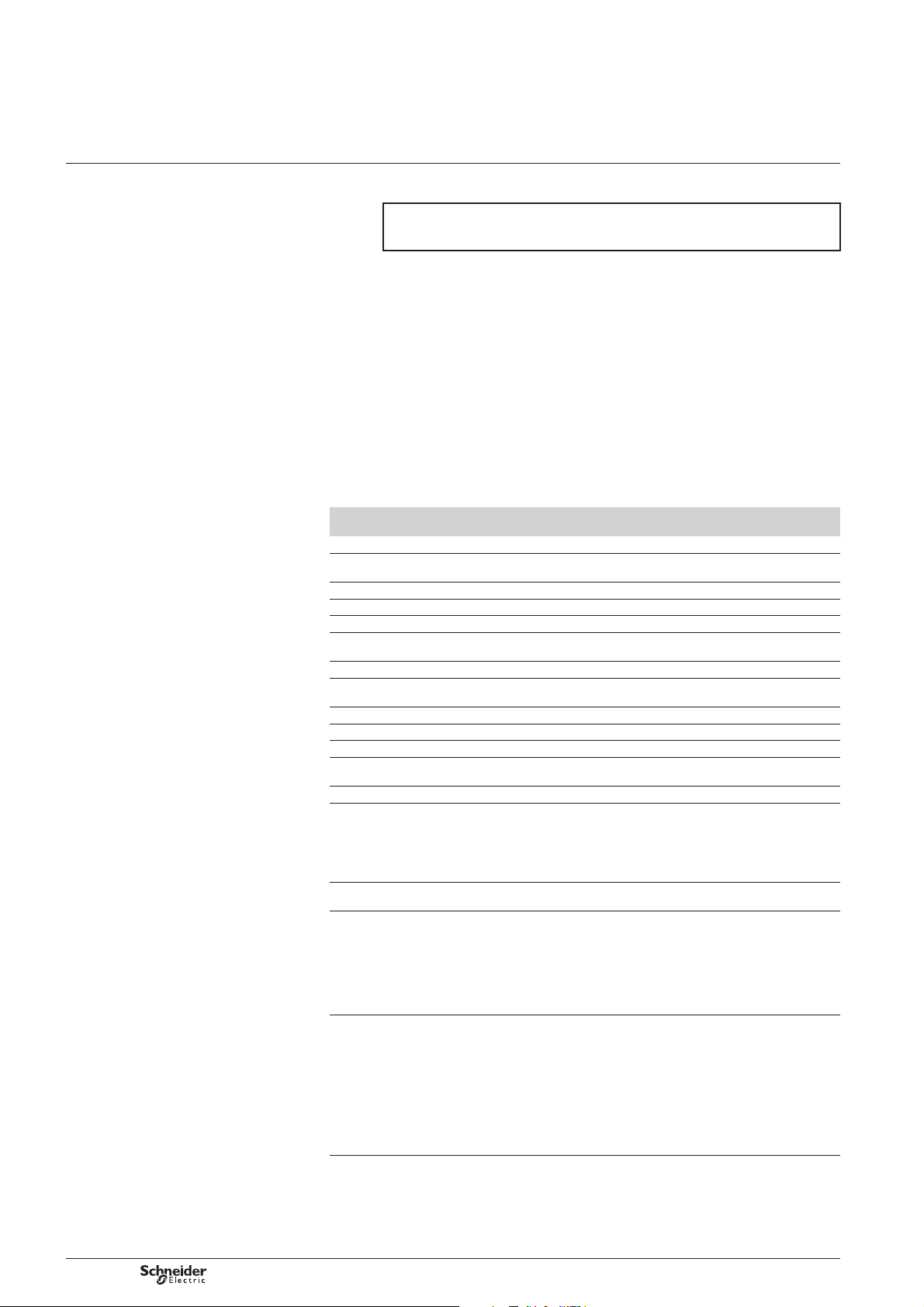

Confi guring using Kervisu

The W310 is confi gured using Kervisu, on a PC equipped with the infrared interface

cable.

This guide gives details of:

b The installation procedure for the infrared interface, chapter Appendices.

b The procedure for registering W310, chapter Appendices.

b The procedure for activating W310’s to communicate with Kervisu, chapter

“Commissioning”.

All the actions needed for confi guration are carried out under 4 section headings,

which correspond to the four screens described below:

Confi guration screen

This is where all the general operating settings are defi ned (names, logging and

transmission frequency, telephone number, etc.).

Channels (1 to 8) screen

This is where the variables to be logged are defi ned: their names, types, slope, shift,

modes and alarm thresholds.

System screen

For the system control (traceability) and system settings.

Counters screen

Where the indexes for the digital input counters (DI1 to DI4) can be pre-loaded,

whether they are used for pulse counting or time counting.

Various commands can also be run from these screens, such as SMS send, reading

GSM reception signal strength.

Just to remind you…

Kervisu is the confi guration tool for W310 products.

All the device’s operating settings can be displayed in Kervisu. This paragraph

is intended for users who have not used it before:

Communication can only take place if Kervisu is in connected mode

(click on the corresponding icon

and local activation of the dialogue).

, see chapter Commissioning V Wake up W310

16

NT00196-EN-03

Page 17

W310 (Brio)

NB: all the modifi able fi elds need to have values

entered which are consistent with one other, even if

they are not going to be used. You are advised to use

short titles, as these are the titles which will be

transmitted in the SMS messages.

Local configuration of W310

(Kervisu)

Configuration screen

Name Modifi able Description

Software version No Version number of the W310 application software. This number should match

Options No Character string defi ning the various software options.

Device identifi er Yes 7-character serial number for identifying the W310.

PIN code Yes The W310 is capable of managing the PIN code, which is a 4-character code.

(1) Phone number Yes Telephone number (maximum of 12 digits, without spaces)

(1) Phone number mode Yes Transmission mode for 1st number, between:

(2) Phone number Yes Telephone number for a second recipient of data transmission if required.

(2) Phone number mode Yes Transmission mode for 2nd number

Teleconfi guration phone number Yes This is the master station from which the remote confi guration operations are carried out.

Current date Yes Enter in the format dd/mm/yy hh:mm:ss (*)

Record period Yes Number of minutes between each logging of the variables being measured

Next record date Yes Enter in the format dd/mm/yy hh:mm:ss (*)

the version of the confi guration fi le used (KvBRIO_6_En.CFG)

It is ESSENTIAL that the code corresponds to the code belonging to the card that is being used

b None: no transmission

b Data: transmission of data to the (Kerwin) master station

b Data + Alarms: transmission of data and alarms to the (Kerwin) master station

b Text alarms: transmission of alarms in SMS form to a mobile phone.

Note that Kerwin does not read SMS text messages.

W310 answers to Teleconfi guration SMS:

b Either to the phone number mentionned in this fi eld

b Or to the sender of the teleconfi guration SMS.

The Teleconfi guration tool, can specify in the SMS it sends to the W310 which telephone number

should receive the answer of the W310 (the one specifi ed in this fi eld (default) or another one

specifi ed in the Teleconfi guration SMS).

(Programme between 1 and 10080, equivalent to 7 days max.).

NB: when the logging interval is changed, the logging memory is cleared; when this happens,

you are therefore advised to run a send if you do not wish to lose any data.

This enables the date for the fi rst logging to be set.

After a logging, or when the logging interval is changed, W310 automatically

updates the date.

NT00196-EN-03

17

Page 18

W310 (Brio)

Local configuration of W310

(Kervisu)

Configuration screen

Name Modifi able Description

Send period Yes Number of minutes between 2 regular transmissions.

Next send date Yes This variable tells the user the date of the next SMS message(s) transmission.

Diagnostic interval Yes Number of minutes between 2 diagnostic transmissions

Date of next diagnostic Yes Date and time of next diagnostic; the date entered must correspond to a scheduled

Number of logs before

sending the SMS

Number of logs ready to send No Number of logs present in the system memory which have not yet been sent.

GSM action No Indicates the status of the GMS function, which will be either:

GSM diagnostic No Gives the result of a transmission request (automatic or manual):

SMS state No Shows the status of the SMS transmission dialer.

Date of last SMS transmission No Shows the date when the last SMS was sent.

GSM level No Shows the reception strength at the transmission of the last SMS or in real time during the test

Command Yes This refers to a menu which allows you to send various commands to the device.

No This refers to the relationship between the transmission interval and the logging interval.

This number should be a multiple of the logging interval.

W310 automatically limits the number if the value entered is too high for W310’s storage capacity.

This date is especially useful for synchronising the transmission date to a precise schedule.

It will be repeated for each transmission, except if there is an alarm or the fi le is full.

The date should coincide with a logging date.

E.g.: if a logging interval of 60 mins is specifi ed, with a transmission interval of 1440 mins (1 day)

and a transmission time of 05h00, the transmission will take place every day at 5am.

(see chapter Overview V Operating principles)

transmission date.

In other words, the number of logs sent with each transmission (when there is no alarm situation).

b Data not sent

b Send in progress

b GSM standby mode: wait during a confi gurable temporization (precede the reading of

received SMS)

b SMS search: look for the SMS stored in the SIM card or in the modem.

b SMS processing: SMS processing and deletion

b Complete session: the device has terminated the last command to be sent to the GSM

network. The result is shown under the section “GSM Diagnostic”.

b GSM signal strength: the device is reading the GSM reception signal strength.

b -------- : Diagnostic not yet determined

b Nothing to send: no recipient confi gured or no variable declared

b SIM card problem: SIM card not present or not detected

b Wrong PIN code: failure when writing the PIN code

b PIN code problem: there is less than 3 tries left for entering the PIN code, as a result SMS

sending is locked (to unlock the W310 PIN code protection and allow again SMS sending

see chapter Local confi guration of W310 V

b Wrong tel. number: no telephone number or bad format

b Send failure: the SMS sending is interrupted by the W310 after 3 minutes

b SMS sent: the last SMS requested was transmitted to the network

b Too many failures: after 4 successive sessions of SMS sending having failed, the sending

of SMS is blocked (the number of failure is set to zero every day at 12am and 12pm).

However it is possible to force the sending of SMS at any moment by using the commands

(Send SMS, Diagnostic,...).

GSM strength command. The reception quality is shown as one of the following:

Very good; Good; Medium; Weak; Very weak; Too weak

The objective measurement in decibels (dBm) is also given for the memory.,

This varies between – 51 dBm (very strong signal) and – 110 dBm (very weak signal).

The dBm is the usual unit of measurement of electromagnetic fi eld strength.

It is equivalent to 10*LOG(P) where P is the power received expressed in milliwatts.

To do this, click on the fi eld, select the command you require and wait for it to run before using

another command.

The most frequently used commands are:

Read channels; Test GSM strength; Send SMS; Sleep; Etc.

Details of these commands are given in the command table below

(*) : Depending on the date format selected (Kervisu: Devices – Options – Time and Date format,

Format type).

GSM screen)

18

d IMPORTANT

Some special characters must not be used for the titles, otherwise the SMS messages may not

be sent.

The following characters can be used: @ _ - : ‘ / =

Do not use the following characters: # 2 & \ ? % + ( ) ‘’

NT00196-EN-03

Page 19

W310 (Brio)

Local configuration of W310

(Kervisu)

Configuration screen

Table of commands

Name Description

Idle No command running

Sleep Tells the device to return to sleep mode (if there is no transmission or measurement in progress);

Measurement The W310 gets the data from the channels; each time this command is run,

Send SMS The device sends the waiting data to the master station. This command should be run when

GSM level measurement The device reads the GSM signal strength for approximately 2 minutes.

Empty confi guration All the settings return to their “Factory” confi guration.

Transport mode Places the W310 in sleep mode. It can only be activated using the magnet, as outlined

Diagnostic Initiates send of a diagnostic SMS (diagnostic data + variable current value)

Diagnostic & Data Initiates send of a diagnostic SMS and data to send

Send install SMS Send diagnostic data + install data (software version, options,…) + variable current value

Transparent mode Used during maintenance for direct dialogue with the GSM module

Reset Used during maintenance, in particular when loading a new software version

The fi eld assumes this value as soon as a command has been processed.

it will return to awake mode:

b When activated (See chapter Commissioning V Wake up W310 and local activation of the

dialogue)

b If the current date is a logging date

b When activated by a magnet.

the values for the different channels will be displayed in the value fi eld on each channel screen.

This command can be used to check the wiring and that the sensors are functioning properly.

you wish to transmit data that is ready to the master station.

If a “send SMS” command is run when there are no logs waiting to be sent, W310 will not

d

send any data, but will send a Diagnostic SMS.

This command can be used to unblock a blocked GSM transmission

(diagnostic: too many failures)

The value appears in the “GSM strength” fi eld.

It can also be seen from the GSM indicator light, which lights up in proportion to the signal

strength (the longer the light is on, the better the signal quality).

NB: it is essential that this command is run after inserting a battery if the device has been

without a battery for several minutes, especially when fi rst activating, if the battery is delivered

separately.

(see chapter Commissioning V Wake up W310).

This mode is used to reduce power consumption and to prevent any transmission attempt.

NT00196-EN-03

19

Page 20

W310 (Brio)

NB: the titles entered on this screen are restricted

to 7 characters, so as to avoid lengthy SMS

transmissions; a longer, more explanatory title

can be entered in the Kerwin master station.

Local configuration of W310

(Kervisu)

Channels (1 to 8) screen

Name Modifi able Description

Current Date No Date and time on W310’s real time clock

Action (Command) Yes See the table of commands previous page

Var. Name Yes Channel title, maximum 7 characters long.

Unit Yes Unit used for display (5 characters maximum) and during transmission of an alarm in SMS text

Var. Type Yes This refers to the type of channel, selected from the list of available types

Value Yes Value of the variable at the last reading. The value as displayed takes into account the type,

Status No Indicates any anomalies encountered during acquisition of the variable

Slope Yes Coeffi cient to be applied to the value to bring it in line with the required units.

Shift (Lag. Offset) Yes Lag to be applied to the value.

Data format Yes Indicates the format in which the values for this channel will be sent (during transmission

This title is transmitted in full to the master station; therefore you are advised to choose very

short titles.

format.

which is described in chapter following page.

NB: if this fi eld is set to “None”, it means that this channel is not in use by W310

(no readings or transmissions associated with the channel).

slope and lag.

(e.g. Modbus timeout for digital sensors).

The default slope value is 1.

The slope is used particularly for 4-20 mA sensors, as it enables the sensor’s scale to be defi ned.

For 4-20 mA types, the value is given between 0 (4 mA) and 1 (20 mA). For example, if you are

using a 600 bar pressure sensor, a slope of 600 will provide the value directly in bars.

The lag is usually nil and allows sensor errors to be corrected.

of the readings history (to the supervisor) or of alarms (to the supervisor or to a mobile phone

as an SMS text message).

The choices available are:

0.: whole number

0.0: fl oating point number with one decimal place

0.00: fl oating point number with two decimal places

0.000: fl oating point number with three decimal places.

20

NT00196-EN-03

Page 21

W310 (Brio)

Local configuration of W310

(Kervisu)

Channels (1 to 8) screen

Name Modifi able Description

Stabilization time Yes Supply time of the sensor in 1/10 s (+15V) before acquisition

Type of alarm Yes Choose from the 4 possibilities:

Hysteresis Yes Hysteresis value registered when returning to normal. The hysteresis is defi ned in the same

Upper threshold Yes Value recognised for the top threshold, whose signifi cance determines the type of alarm.

Lower threshold Yes Value recognised for the bottom threshold, whose signifi cance determines the type of alarm.

Upper critical level Yes This value is optional and is relayed to the master station to allow the alarms to be routed

Lower critical level Yes This value is optional and has the same role as the upper critical level

Send critical level Yes YES/NO fi eld to authorise sending of the critical level (*)

Upper limit class Yes Optional string of characters for identifying the alarms at the reception end

Lower limit class Yes Same as Upper limit class

Send class Yes YES/NO fi eld to authorise sending of the “class” (*)

Alarm date No Date on which the last alarm was recorded

Value in alarm No Value of the variable when the last alarm occurred (whose date of detection will be indicated

Predefi ned Type Yes Selection of a predefi ned type in the listbox to confi gure the whole parameters of the variable.

Type Name No Label of the last predefi ned type applied to the variable

Predefi ned Time Status No Status of the last predefi ned type applied:

b None: no alarm has been transmitted

b Min: W310 recognises two bottom thresholds: the upper and the lower (lowest)

b Max: W310 recognises two top thresholds: the upper (highest) and the lower

b Min-Max: W310 only recognises one top (the upper) and one bottom threshold (the lower).

units as the variable itself.

This threshold should be higher than or equal to the bottom threshold and should be defi ned

in the same units as the variable itself.

This threshold should be lower than or equal to the top threshold and should be defi ned in the

same units as the variable itself.

according to certain conditions.

as above)

(as a result, all parameters are erased)

To use this fonctionality, predefi ned types must have been uploaded earlier in factory

b Original: no parameters have been changed after the selection of the predefi ned type

b Modifi ed: at least one parameters have been changed.

(*) As these optional data items take up space in the SMS messages sent, you are advised

to disable their sending when they are not relevant.

Table of channel types

Channel type Full scale value Default format Comments

None Used to avoid sending unnecessary data when a channel is not in use

Counter 0. Sum of pulses at a digital input

Flow 0. Difference in the pulse count between two acquisitions.

Digital input 0: Open

Digital input

with wake-up

Contact closed

duration

1 V 1.0 V 0.000

+/- 10 V 10 V 0.00

10 Vpp 10 V 0.00 Peak to peak voltage calculation of an alternative signal (by detecting minimum and maximum

0-20 mA 1 0.000 Used for 0-20 mA analogue sensors. When this type is used, the terminal supplies a voltage

4-20 mA 1 0.000 Used for 4-20 mA analogue sensors. When this type is used, there is a voltage of 15 V

2000 2000 0. For a resistive sensor; value read with a current of 0.4 mA

PT100 0.0 In °C, with 2-wire wiring

3-wire PT100 0.0 In °C, with 3-wire wiring

PT1000 0.0 In °C, with 2-wire wiring

Modbus sensor 0.000 Value of a Modbus register read on a peripheral device

3V supply For maintenance only

4V supply For maintenance only

Sensor supply For maintenance only

1: Closed

0: Open

1: Closed

0.

0. The W310 is automatically woken up (to transmit an alarm or to revert to normal) if the status

0. Period in seconds during which the contact is closed

By choosing a suitable slope setting, it is possible to obtain the fl ow in minutes or in seconds.

changes.

When reverting to awake mode at a change in the on-off status, W310 carries out a reading

of all the channels (but without logging them) in order to detect any events, then sends alarm

SMS messages / returns to normal as applicable.

=> There must be an alarm associated with all channels of this type.

voltage over a 1 second period)

of 15 V and W310 waits for a certain time (confi gurable) before taking a reading.

at the terminal and W310 waits for a certain time (confi gurable) before taking a reading.

NT00196-EN-03

21

Page 22

W310 (Brio)

Local configuration of W310

(Kervisu)

Channels (1 to 8) screen

Correspondence between physical and software Channels

W310 usually enables to set up to 8 channels.

Up to 4 physical digital inputs and up to 4 physical analogue inputs can be connected.

Physical signals cannot be set on any software channels.

The relationship between physical and software channels is the following:

Physical signal

(Terminal block reference)

DI1 (Digital Input) 1, 5 Digital Input

DI2 (Digital Input) 2, 6

DI3 (Digital Input) 3, 7

DI4 (Digital Input) 4, 7

A1 (Analogue Input) 1, 5 100 mV, 1 V, ± 10 V, ± 10 Vpp

A2 (Analogue Input) 2, 6

A3 (Analogue Input) 3, 7

A4 (Analogue Input) 4, 8

RS+, RS- (RS485, JP7) Any channel Modbus sensor

Examples:

b Application with one digital input (for counting) and two 4-20 mA sensors

First possibility Second possibility

Physical signal

(Terminal block

reference)

DI1 (Digital Input) 1 Counter A1 (Analogue Input) 1 4-20 mA

A2 (Analogue Input) 2 4-20 mA A2 (Analogue Input) 2 4-20 mA

A3 (Analogue Input) 3 4-20 mA DI1 (Digital Input) 5 Counter

Channel

in Kervisu

1-8

b Application with one digital input (for counting and fl ow calculation) and

one 4-20 mA sensor

Physical signal

(Terminal block

reference)

DI1 (Digital Input) 1 Counter

A2 (Analogue Input) 2 4-20 mA

DI1 (Digital Input) 5 Flow

Channel

in Kervisu

1-8

In this specifi c case, it is not possible to use physical Analogue signal 1 (channels 1

and 5 are already confi gured in Kervisu because of digital signals wiring).

You have to wire the 4-20 sensor on A2, A3 or A4.

Possible channels

in Kervisu

With type Physical signal

(Terminal block

reference)

With type

With type

Counter

Flow

Contact close duration

0-20 mA, 4-20 mA

R 2000 , PT100, PT1000

Channel

in Kervisu

1-8

With type

22

NT00196-EN-03

Page 23

W310 (Brio)

Local configuration of W310

(Kervisu)

Channels (1 to 8) screen

Operation of alarms

W310 handles:

b 3 types of alarm: Min, Max and Min-Max

b 2 thresholds: Top and Bottom

Both thresholds can be used for each type. The top threshold must always be

higher than the bottom threshold.

For the Min-Max type, the top threshold corresponds to the upper top threshold and

the bottom threshold to the lower bottom threshold.

For the Min and Max types the top and bottom thresholds have 2 Min thresholds or

2 Max thresholds respectively. The advantage of 2 thresholds is that different

procedures can be triggered for each at the master station.

E.g.: for a level reading, the upper bottom threshold triggers a simple notifi cation at

the master station, whereas the lower bottom threshold (therefore very low) triggers

a more critical alert procedure.

How the hysteresis operates

Alarm

DE59649EN

Top

hysteresis

Bottom

Back to

normal state

The graph above illustrates how the alarm operates in the case of a Min-Max alarm.

The variable is shown in green when it is within the normal range and in red when

it is in the alarm range. In this case a non-zero hysteresis is used, which avoids

“interference” when the value is oscillating between the two thresholds.

The hysteresis is only recognised on return to normal, i.e.the alarm is triggered

as soon as the value goes over the threshold; return to normal is when the + (lower)

hysteresis threshold or – (upper) hysteresis threshold is crossed.

NB: in order for the detection of alarms to be effective, at least one of the telephone

numbers needs to be using one of the alarm transmission modes (Data + Alarms or

Text Alarms).

The occurrence of the fault and the return to normal are routinely transmitted

whatever of the type of recipient (Supervisor or Mobile phone).

hysteresis

t

Alarms on On-Off status inputs

The channel on which you wish to register the alarm should be programmed as

a STATUS type or STATUS with wake up.

The value read is 1 for a closed (Off) contact and 0 for an open (On) contact.

This means that the alarms need to be programmed as follows:

b For an alarm on contact open (i.e. contact usually closed):

v Type of alarm: MIN

v Top threshold: 0

v Bottom threshold: 0

b For an alarm on contact closed (i.e. contact usually open):

v Type of alarm: MAX

v Top threshold: 1

v Bottom threshold: 1

Note that for digital inputs which by defi nition can only have two different statuses,

it is essential that both thresholds be programmed to the same value, otherwise

there can be no detection of the alarm or return to normal.

NT00196-EN-03

23

Page 24

W310 (Brio)

Local configuration of W310

(Kervisu)

Counters screen

System screen

Counters screen

This screen is used for controlling and pre-loading counters. Please not that the values

will change in real time when the pulses are sent.

Two types of counter can be pre-loaded:

b Pulses counters (pulses counted on digital channels 1 to 4)

b Time interval counters (equivalent to the time the contact is closed on digital

channels 1 to 4).

Pre-loading pulse counters

The counters indicate directly the number of pulses, before the slope is taken into

account. If you want to align the value indicated by a counter that sends pulses

(Energy, water, etc.), the counter’s “pulse weighting” needs to be taken into account

to convert the pulse reading.

The same “pulse weighting” will also be used to programme the slope for the variable

in question and to convert the W310 and counter readings to the same units.

For example:

For a water meter supplying pulses calibrated at 10L/pulse and displaying a value

3

in m

b 1) If you wanted the W310 to transmit the value in m3, you would need to

programme a slope of 0.01 (since one pulse is equivalent to 10 litres, or 0.01 m3).

b 2) If you wanted to align W310 with the value read on the counter, for example

3

31415 m

(100 pulses per 1 m3). You would then enter this value (3141500) on the counter

screen to obtain the desired value of 31415 m3.

, you would convert this value into pulses, giving 3141500 pulses

System screen

This screen is used for analysing W310’s internal data.

24

NT00196-EN-03

Page 25

W310 (Brio)

Local configuration of W310

(Kervisu)

System screen

Name Modifi able Description

Current date No Date and time on W310’s real-time clock

Action/Command Yes See the commands table on the pages “Confi guration screen”

Board No Name of the card (Hardware)

Serial no. (batch) No Batch number for traceability

Serial no. (index) No Card number within the batch (traceability)

Software version No Software version number

Options No Character string indicating the software version options

Last modifi cation date No Date and time of last security backup (especially when changing battery)

Saved date No Date on which one of the settings was last changed; this date is transmitted during diagnostics

Card capacity No Available memory space on the system memory stack; this value must not be zero (> 10 typically)

System error No Value of the last system error detected by W310. This fi eld usually shows the value OK.

Battery voltage No Minimum voltage reading of the battery (in millivolts) during a data transmission phase

Battery alarm threshold Yes Threshold (in mV) below which a low battery alarm will be transmitted during a SMS transmission.

Number of RESET’s No No. of times the processor has been reset. The number of RESETs should remain low

Number of SMS attempts No Number of attempts at sending an SMS; this number is increased when an attempt is being made.

Number of successful SMS attempts No Number of SMS messages actually sent to the GSM network.

Number of received SMS No Number of SMS read by the W310 (command SMS or spam)

Session total duration Yes Sum of SMS sessions duration

Number of SMS errors Yes Number of failed sessions logged since:

SMS time-out No Maximum duration of SMS sessions; the default value is set at 2 minutes.

Local Time/UTC Yes Offset between the local time and UTC (GMT) (in 1/2 hour).

Digital wake-up Time Yes Time (in seconds) for detecting a change of status in the digital inputs (taken on the terminal)

Reception SMS Time Yes Time (in seconds) to wait after a successful SMS session in order to receive SMS.

and allows a change in confi guration to be detected.

See system error table.

(i.e. time of maximum consumption).

This value will not be calculated until a SMS is sent (default value after a Reset and before

the fi rst SMS is sent = 4400 mV).

It is recalculated at each attempted SMS send.

NB: the alarm will be sent at once a day maximum

and constant; a high number is a sign that there is a malfunction

Note that there will be no attempts if the SIM card is absent, the PIN code is rejected,

or the network is not found.

If reception conditions are in order, this number should be very close to the previous one.

b Either the last successful transmission

b or 0h00 on today’s date.

When this number is greater than 4, transmission is disabled until 12h00 (midday) or 0h00

(midnight) (4 consecutive fails -1/2 day).

Parameter used to write the local time in text SMS.

System error table

Value displayed Meaning Comments

OK No error

ERR RAM Data lost in RAM Displayed following a battery change (the status can be re-initialised using the Reset command)

ERR RTC Clock anomaly detected

LOW BAT Battery voltage too low to guarantee

transmission

ERR I2C Anomaly in external EEPROM

memory access

ERR EEPROM Inconsistency detected in internal

memory

ERR COMPIL Inconsistency in the programme Invalid software version loaded

LENGTH SMS Error in compiling SMS If this error message appears, the SMS sent may be incorrect (may be incomplete).

The GSM transmission phase is the period of maximum power consumption.

If the voltage drops below a pre-defi ned threshold during this phase, the W310 will interrupt

the communication in order to avoid an overall lack of power.

In this case, the low battery error message will be displayed.

A problem in accessing this memory will translate as a loss of the data history

This error is possible if the memory is new or following a change in the W310 programme version.

(Error unlikely to occur when in operation)

NT00196-EN-03

25

Page 26

W310 (Brio)

This screen resumes part of the parameters

bound to the sending of SMS.

Local configuration of W310

(Kervisu)

GSM screen

Name Modifi able Description

Current date No Date and time on W310’s real-time clock

Action/Command Yes See the commands table on the pages “Confi guration screen”

Number of SMS attempts No See “System screen” pages

Number of successful SMS attempts No

GSM action No See “Confi guration screen” pages

GSM diagnostic No

SMS state No

Date of last SMS transmission No

GSM level No

GSM Buffer No To check Hayes commands sent to the modem

Number of remaining PIN attempts No Number of remaining PIN attempts during the last SMS session.

Force PIN code Yes Allows to force the writing of the PIN code in the modem during the next SMS session

SMS text language Yes Language used in the text SMS

Language n°1 No Language n°1 pre-loaded in the W310 for the text SMS

Language n°2 No Language n°2 pre-loaded in the W310 for the text SMS

Kerwin Token Yes Token inserted at the beginning of the SMS sent to the Kerwin

Mobile Phone Token Yes Token inserted at the beginning of the text SMS

Teleconfi guration Token Yes Token inserted at the beginning of the SMS sent in response of a teleconfi guration SMS

If the number of attempts is lower than 3, SMS are no longer sent to prevent a SIM card locking.

PIN code protection

If there was a failure when the PIN code has been entered during the previous SMS

session (diagnostic of session: “Error PIN”), the next sessions will be automatically

stopped not to enter again a bad PIN code and thus risk to lock the SIM card).

To unlock the W310 PIN code protection and allow again to send SMS, it is necessary

having corrected the PIN code in the page GLOBAL-PARAM. Then you have to

activate the fi eld “Force the PIN code”. Thus, during the next SMS attempt the

W310 will try again to enter the PIN code in the modem. As soon as the PIN code

is validated, the sending of the SMS is unlocked.

It is important to note that if we place a SIM card for the fi rst time in a W310 and

if a bad PIN code was already entered in the SIM card, the sending of SMS will

be locked (no matter the PIN code confi gured in the W310 is correct or bad).

To unlock the sending of SMS you can do what is described in the previous

paragraph or just put the SIM card in a phone to enter the correct PIN code.

26

NT00196-EN-03

Page 27

W310 (Brio)

Local configuration of W310

(Kervisu)

Modbus settings screen

Name Modifi able Description

Current date No Date and time on W310’s real time clock

Action/Command Yes See the commands table on the pages “Confi guration screen”

Starting time/Stabilisation time Yes Anticipated time (in 1/10s) between switching on the 15 V power supply and the fi rst Modbus

reading. This time will be zero if the peripheral is powered by a different source other than

the W310. This time interval has a direct impact on W310's power consumption.

Response time Yes Maximum time anticipated by the W310 to obtain a response.

After this time has elapsed, the status of the variable displayed will be “Modbus time-out”.

Parity Vx Yes Parity used for the Modbus connection

Baud rate Vx Yes Speed of the Modbus connection

Mask Vx Yes Used to isolate the digital statuses within words (from version 5.20 and higher).

The value should be kept at 0 x FFFF if it is not in use.

Only valid for types Byte, Word or Word [i].

Slave address Vx Yes Modbus address of the (slave) peripheral in which the variable in question is read

Function Yes Modbus function used to read the variable in the Modbus (3 or 4) peripheral

Address Yes Address (hexadecimal) of the variable in question in the Modbus peripheral

Type Type of variable read at the address specifi ed above.

The type can be:

byte ; word ; int16 ; dword ; int 32 ; ieee ; word [i] ; int 16 [i] ; dword [i] ; int 32 [i] ; ieee [i]

NT00196-EN-03

27

Page 28

W310 (Brio)

Local configuration of W310

(Kervisu)

Retrieval/Downloading

of the configuration

Retrieval/Downloading of the confi guration

The retrieval and the downloading of a W310 confi guration via Kervisu are available

in the version 1.10.0.0 and higher.

Download a W310 confi guration with a version of Kervisu previous to the 1.10.0.0

d

may involve a confi guration corruption.

To activate this functionality, be sure that the peripheral is declared with the connection

type W310 (Properties – Parameters - Connection – W310 (Brio))

See Appendices “Setting up the W310 peripheral with Kervisu”

When the connection to the peripheral is established, the commands of retrieval

and downloading of the confi guration are active.

The W310’s confi guration

is saved in a XML fi le on

the computer

The confi guration stored

in a XML fi le is downloaded

to the W310

28

NT00196-EN-03

Page 29

W310 (Brio)

Remote configuration of W310

(Kerweb)

The Web module (Kerweb) of Kerwin Supervisor allows you to remotely read or write

any of the W310 parameters described in the previous chapter.

The Remote confi guration Web page of a W310 is available as soon as it has been

created in Kerwin supervisor (see next chapter).

Once the W310 site is selected in the Kerwin Web interface, the Remote

confi guration web page is available from the “ Management ” menu.

All reading or writing demands are synthesized in the second part of the web page:

“Selected actions”.

These actions are performed as soon as the user clicks on “Validate pending actions”

button. Then Kerwin generates the corresponding SMS and sends them to the W310.

Notice

d

W310 retrieves the SMS from Kerwin only once it is awakened to send data SMS.

For example, if the W310 is confi gured to send its measurements once a day

at midnight, the reading/writing demands from Kerwin will be taken into account

at that time. In this case, it might have a delay of 24 hours between the Kerwin

demands and the W310 responses.

NT00196-EN-03

29

Page 30

W310 (Brio)

Configuring the Supervisor

(Kerwin)

Setting up a site in Kerwin consists of

registering the new site with its properties,

in particular its phone number, in the form

in which it will be received by Kerwin.

NB: up to version 4.0.0 inclusive of the Kerwin

Scada, there is no self-confi guration.

In this case, the data (only history fi les) will be

updated in Kerwin as of the fi rst call from W310,

once the W310 site has been manually confi gured

in Kerwin.

Data coming from W310 can be received by Kerwin

versions 3.6.2 and higher.

Self-confi guration: case of a W310 unit site

Kerwin supervisor version 4.1.0 and higher manages self-confi guration for W310

(Brio) type units (for Kerwin earlier versions until 4.0.0 included, see W310 (Brio)

sites manual confi guration in the next paragraph).

Kerwin creates automatically a new W310 site when it receives a SMS from a W310

unit for the very fi rst time (based on W310 telephone number).

The self-confi guration of a W310 site in Kerwin consists in:

b Adding automatically a new W310 site

b Creating automatically all application and system variables attached to this W310

b Creating automatically all fi les attached to the W310 (one fi le per application

variable, one fi le logging all system variables); System variables are transmitted

within diagnostic SMS.

If a W310 site with this telephone number already exists in Kerwin sites database,

no new W310 site is added.

The name of a W310 site that has been automatically created has the following format:

b Always began with characters: “<>”.

b The name confi gured in the W310 (See Confi guration screen, fi eld Device

Identifi er)

b The phone number detected (international form).

This name can then be changed at your convenience.

Manual creation of a W310 unit site

From Main Menu of Kerwin Scada, go to “Confi guration/Sites”.

General tab

Enter the following information below:

b Name: the name given to the site (for example its location, e.g. “33 Main Street”)

b RTU Type: you must choose W310 (Brio)

b Site group: optional facility for dividing the units into sectors (geographical) -

cf. general documentation on Kerwin.

Confi guring a site manually: “General” tab

Confi guring a site manually: “Detail” tab

Detail tab

Enter the following information below:

b Address: precise geographic location of the site (optional)

b Vocal GSM number: number received by Kerwin when it receives an SMS

message from the site: it usually includes the prefi x (+33 for France), followed by

the 9 last digits of the telephone number belonging to the sending SIM card (usually

its calling number). This setting is essential as it is the default setting enabling

the sender of the information to be recognised.

b Cyclical calls: tick the “periodic call” fi eld to monitor whether W310’s regular calls

are functioning smoothly, specifying the date of the next call and the interval between

calls.

Note: these confi guration operations on Kerwin supervisor are also available from

its Web interface(Kerweb).

30

NT00196-EN-03

Page 31

W310 (Brio)

Testing the installation

The tests described below require a local

connection between the W310 and a PC

equipped with Kervisu, via an IrDA link.

Checking the reading values

In order to check the readings and wiring, you are strongly advised to check the

values read for each sensor after the initial installation.

To do this:

b On one of the channel confi guration screens, activate an acquisition of

all the channels by running the “Read channels” command.

b The value will appear a few seconds later in the “value” area.

Transmission test

In the same way, you are strongly advised to carry out a test transmission:

the test transmission can be done:

b Either directly to the master station, if you have access to it

b Or to a mobile phone (you will need to enter its number in the “confi guration” screen).

v 1) Check that at least one telephone number and transmission mode are confi gured

v 2) Check that the card’s PIN number has been entered

v 3) Open the list on the right of the “Command” page and select “Diagnostic”.

As soon as the command is registered (immediately), the GSM indicator light

will fl ash on and off (see “Function indicator lights” chapter) for around 30 seconds

if the transmission is running smoothly.

The GSM indicator light will then go on for a fi nal full second. During this transmission

phase, it is possible to follow the progress of the transmission in real time by consulting

the sections:

b SMS progress: indicates in real time the status of the SMS send dialer.

b SMS Diagnostic: indicates the various situations detected by the SMS send

dialer.

b Data sending: indicates the data sending status.

If the transmission is not running smoothly, the GSM indicator light will fl ash on

and off for 2 minutes before the modem goes off.

The table below indicates the various values that these indicators can have.

Section Possible values Comments