Page 1

Altivar® 61 / 71

User's manual

30072-452-37

Retain for future use

Modbus® TCP/IP Daisy Chain Ethernet Card

VW3A3310d

Page 2

Page 3

Table of contents

Important Information _________________________________________________________________________________________ 5

Before you begin_____________________________________________________________________________________________ 6

Documentation structure_______________________________________________________________________________________ 7

Introduction_________________________________________________________________________________________________ 8

Presentation _____________________________________________________________________________________________ 8

Notation ________________________________________________________________________________________________ 8

Hardware setup _____________________________________________________________________________________________ 9

Receipt _________________________________________________________________________________________________ 9

Hardware description ______________________________________________________________________________________ 9

Installing the card in the drive________________________________________________________________________________ 9

Connecting to the Ethernet network _____________________________________________________________________________ 10

Card RJ45 connector pinout________________________________________________________________________________ 10

Example of connection to an Ethernet network _________________________________________________________________ 10

Ethernet network connection elements________________________________________________________________________ 11

Ethernet menu _____________________________________________________________________________________________ 12

Access to Ethernet menu via graphic display terminal ____________________________________________________________ 12

Access to Ethernet menu via the integrated display terminal_______________________________________________________ 12

Ethernet menu parameters_________________________________________________________________________________ 13

Configuration ______________________________________________________________________________________________ 16

List of functions to be configured ____________________________________________________________________________ 16

Configuring IP addresses __________________________________________________________________________________ 17

Reserving control ________________________________________________________________________________________ 19

Configuring IO Scanning___________________________________________________________________________________ 19

Configuring the control ____________________________________________________________________________________ 20

Configuring the fault management ___________________________________________________________________________ 23

Configuring monitored parameters ___________________________________________________________________________ 25

Diagnostics ________________________________________________________________________________________________ 26

Signalling LEDs _________________________________________________________________________________________ 26

Available information _____________________________________________________________________________________ 27

Monitoring the control _____________________________________________________________________________________ 27

Troubleshooting communication interruptions __________________________________________________________________ 28

Troubleshooting the card __________________________________________________________________________________ 29

Software setup _____________________________________________________________________________________________ 30

List of services supported__________________________________________________________________________________ 30

TCP connections ________________________________________________________________________________________ 30

Modbus TCP server _________________________________________________________________________________________ 31

Modbus TCP frames______________________________________________________________________________________ 31

Drive Modbus servers_____________________________________________________________________________________ 31

Ethernet card parameters__________________________________________________________________________________ 32

List of Modbus functions supported __________________________________________________________________________ 35

“Read Holding Registers” (3) function ________________________________________________________________________ 35

“Write Single Register” (6) function___________________________________________________________________________ 36

“Write Multiple Registers” (16 = 16#10) function ________________________________________________________________ 37

“Read/Write Multiple Registers” (23 = 16#17) function____________________________________________________________ 38

“Read Device Identification” (43 = 16#2B) function ______________________________________________________________ 39

IO Scanning service _________________________________________________________________________________________ 40

Presentation ____________________________________________________________________________________________ 40

Periodic variables ________________________________________________________________________________________ 40

Address table ___________________________________________________________________________________________ 41

FDR service _______________________________________________________________________________________________ 42

Presentation ____________________________________________________________________________________________ 42

Local configuration _______________________________________________________________________________________ 43

Downloaded configuration _________________________________________________________________________________ 44

Periodic saving __________________________________________________________________________________________ 46

Other commands ________________________________________________________________________________________ 46

Configuration file_________________________________________________________________________________________ 46

3

Page 4

Table of contents

Standard Web server ________________________________________________________________________________________ 47

Web server functions _____________________________________________________________________________________ 47

Applets ________________________________________________________________________________________________ 48

Access to the Web server__________________________________________________________________________________ 49

Web server user interface__________________________________________________________________________________ 50

“Home” menu ___________________________________________________________________________________________ 50

“Monitoring” menu________________________________________________________________________________________ 50

“Altivar Viewer” page _____________________________________________________________________________________ 51

“Data Viewer” page_______________________________________________________________________________________ 52

“Altivar Chart” page_______________________________________________________________________________________ 53

“Diagnostics” menu_______________________________________________________________________________________ 53

“Ethernet Statistics” page __________________________________________________________________________________ 54

“Setup” menu ___________________________________________________________________________________________ 54

“HTTP password” and “Data write password pages” _____________________________________________________________ 55

“FDR Agent” page________________________________________________________________________________________ 56

“IO Scanner” page _______________________________________________________________________________________ 58

"E-mail" page ___________________________________________________________________________________________ 61

“Documentation” menu ____________________________________________________________________________________ 62

FTP server ________________________________________________________________________________________________ 63

Downloading from the Web server ______________________________________________________________________________ 65

SNMP agent _______________________________________________________________________________________________ 68

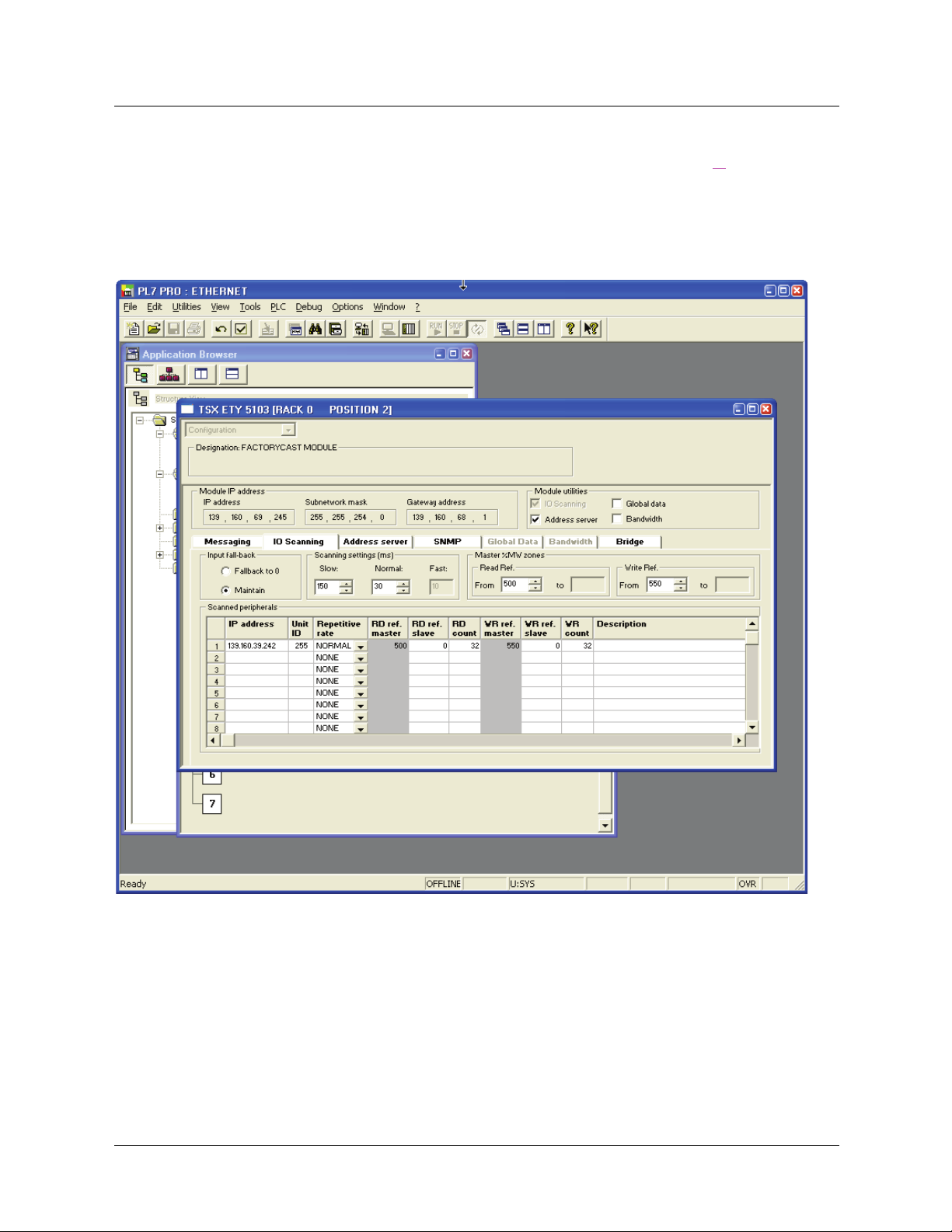

Setup using PL7 ____________________________________________________________________________________________ 70

Setup using Concept ________________________________________________________________________________________ 76

Setup using ProWORX NxT ___________________________________________________________________________________ 77

4

Page 5

1. Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying to install, operate, or maintain

it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death, serious injury, or

equipment damage.

WARNING

Warning indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment

damage.

PLEASE NOTE:

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by

Schneider Electric for any consequences arising out of the use of this material.

© 2008 Schneider Electric. All Rights Reserved.

5

Page 6

2. Before you begin

Read and understand these instructions before performing any procedure with this drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the Altivar 61 (ATV61) or Altivar 71 (ATV71) drive

controller. Installation, adjustment, repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with respect to

grounding of all equipment.

• Many parts of this drive controller, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use

only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Before servicing the drive controller

- Disconnect all power, including external control power that may be present.

- Place a “DO NOT TURN ON” label on all power disconnects.

- Lock all power disconnects in the open position.

- WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement

procedure given in the Installation Manual to verify that the DC voltage is less than 42 V. The drive LED is not an

indicator of the absence of DC bus voltage.

• Install and close all covers before applying power or starting and stopping the drive controller.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED EQUIPMENT

Do not install or operate any drive or drive accessory that appears damaged.The relays, inputs, or outputs of a damaged

drive may not operate in a normal manner, leading to unintended equipment operation.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential failure modes of control paths and, for certain critical

control functions, provide a means to achieve a safe state during and after a path failure. Examples of critical control

functions are emergency stop and overtravel stop.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths may include communication links. Consideration must be given to the implications of unanticipated

transmission delays or failures of the link.*

• Each implementation of an Altivar 71 Modbus TCP/IP Ethernet card must be individually and thoroughly tested for proper

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

* For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for

Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

6

Page 7

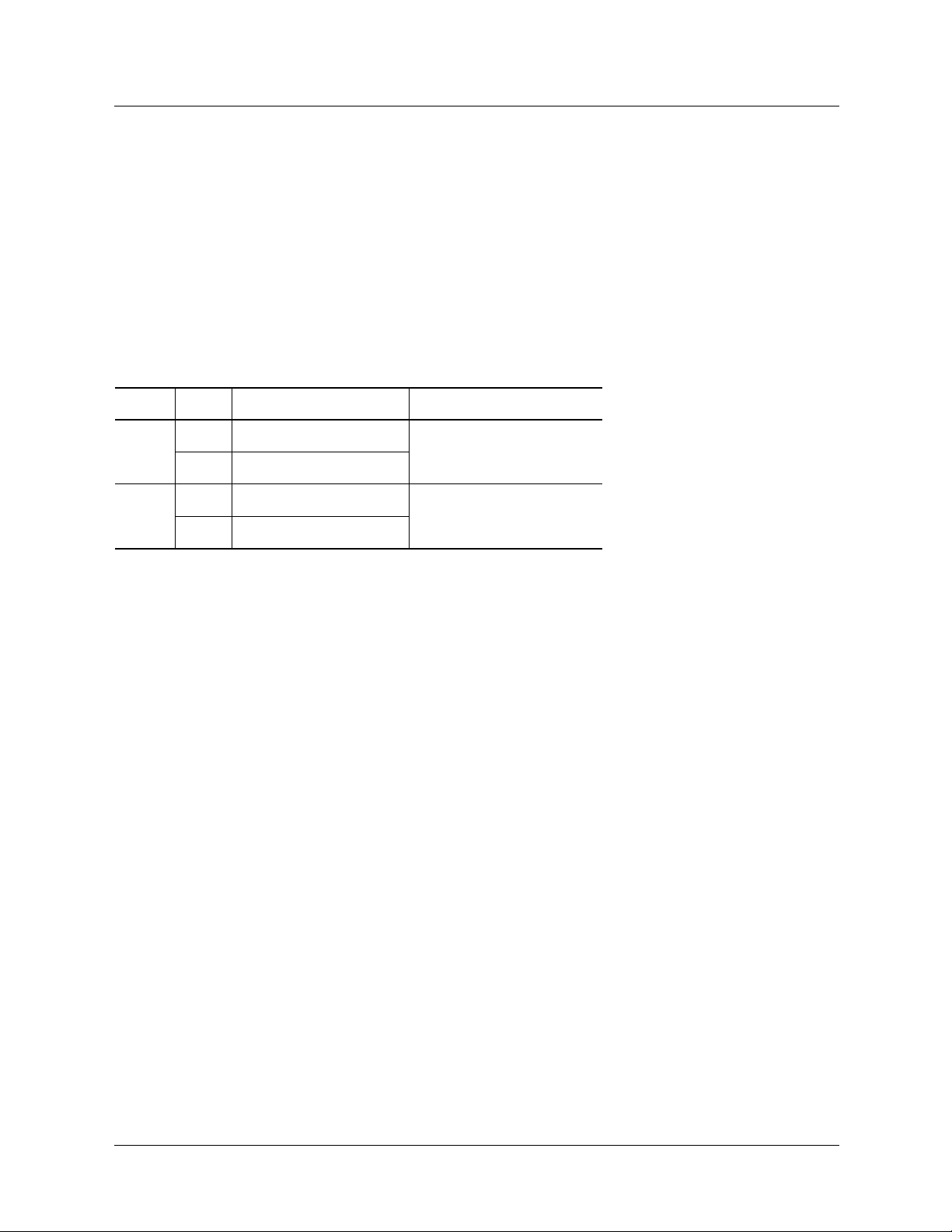

3. Documentation structure

The following Altivar 61 and Altivar 71 technical documents are available on the web site www.us.Telemecanique.com and on the CD ROM

delivered with each drive controller.

b Installation Manual

This manual describes:

• How to assemble the drive controller

• How to connect the drive controller

b Programming Manual

This manual describes:

• The drive controller functions

• The drive controller parameters

• How to use the drive display terminal (integrated display terminal and graphic display terminal)

Installation and Programming Manuals

Drive

Family

ATV61 0.5–100 1760643

ATV71 0.5–100 1755843

Range

(hp)

75–800 1760655

75–700 1755849

Installation Manual

Module No.

(atv61s_installation_manual)

(atv61e_installation_manual)

(atv71s_installation_manual)

(atv71e_installation_manual)

Programming Manual

Module No.

1760649

(atv61_programming_manual)

1755855

(atv71_programming_manual)

7

Page 8

4. Introduction

4. 1. Presentation

The Ethernet card (catalog number VW3A3310d) is used to connect an Altivar 61 / 71 drive to an Ethernet network using the Modbus

TCP/IP protocol and Transparent Ready services.

The VW3A3310d card is equipped with two shielded RJ45 Ethernet connectors.

The accessories for connection to the Ethernet network must be ordered separately.

The data exchanges permit the following drive functionality:

• Configuration

• Adjustment

• Control

• Monitoring

• Diagnostics

The standard web server (English only) provides access to the following pages:

• Altivar Viewer

• Data Viewer

• Ethernet

• Security

The standard web server can be adapted or replaced by a customized server depending on the requirements of the application.

The graphic display terminal or the integrated display terminal can be used to access numerous functions for communication diagnostics.

4. 2. Notation

Drive terminal displays

The graphic display terminal menus are shown in square brackets.

Example: [1.9 COMMUNICATION].

The integrated 7-segment display terminal menus are shown in parentheses.

Example: (COM-).

The parameter names displayed on the graphic display terminal are shown in parentheses.

Example: [Fallback speed].

The parameter codes displayed on the integrated 7-segment display terminal are shown in round brackets.

Example: (LFF).

Formats

Hexadecimal values are written as follows: 16#

Binary values are written as follows: 2#

8

Page 9

5. Hardware setup

5. 1. Receipt

• Check that the card catalog number marked on the label is the same as that on the delivery note corresponding to the purchase order.

• Remove the option card from its packaging and check that it has not been damaged in transit.

CAUTION

STATIC SENSITIVE COMPONENTS

Avoid damage to the Modbus TCP/IP card by electrostatic discharge. Observe the electrostatic precautions below when handling

controller circuit boards or when testing components.

Failure to follow these instructions can result in injury or equipment damage.

Observe the following precautions for handling static-sensitive components:

• Keep static-producing material such as plastic, upholstery, and carpeting out of the immediate work area.

• Store the Modbus TCP/IP card in its electrostatic protective packaging when it is not installed in the drive controller.

• When handling the Modbus TCP/IP card, wear a conductive wrist strap connected to the card through a minimum of 1 megohm

resistance.

• Avoid touching exposed conductors and component leads with skin or clothing.

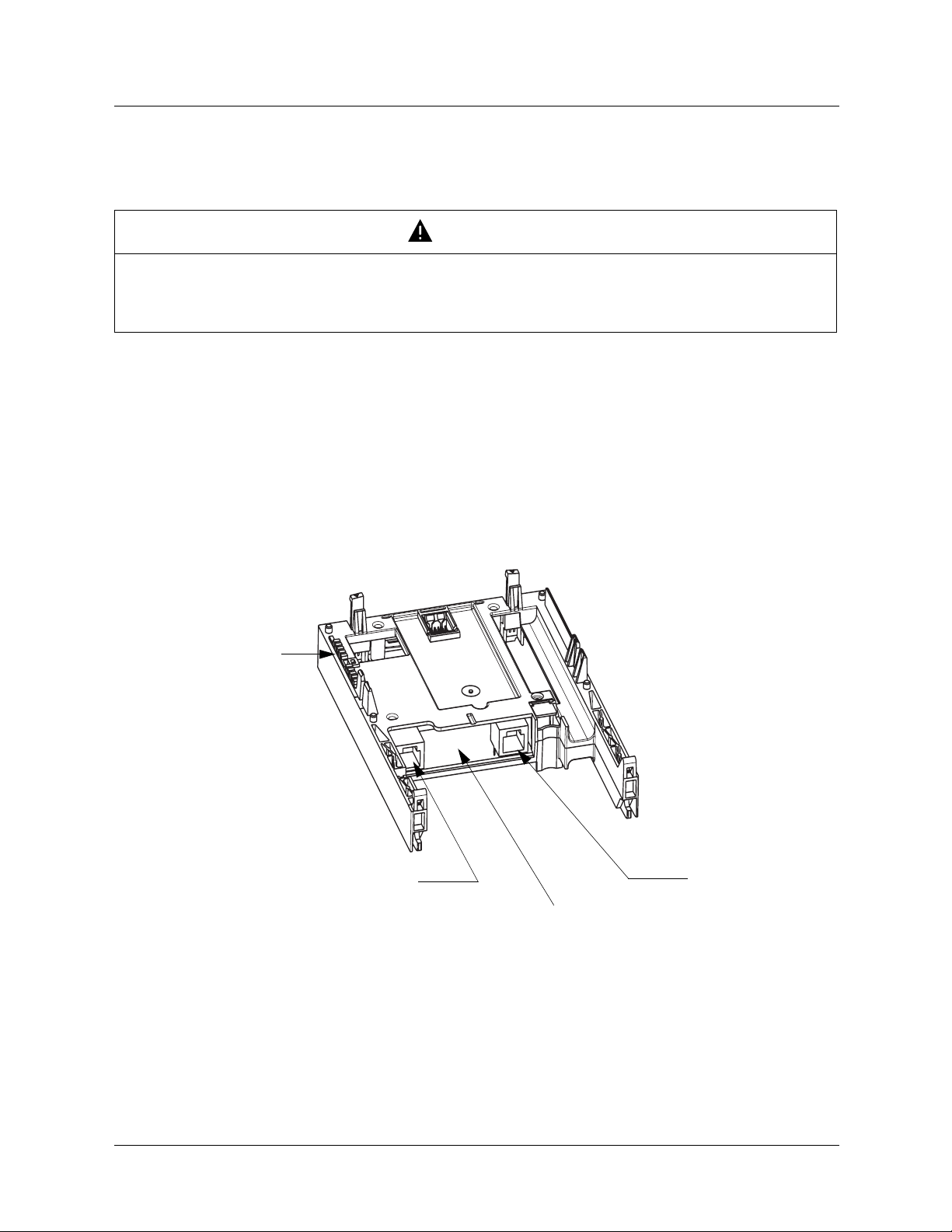

5. 2. Hardware description

LEDs

Shielded female RJ45

Ethernet connector

(Port 2)

5. 3. Installing the card in the drive

See the ATV61 or ATV71 Installation Manual.

MAC address label

on the Ethernet card

Shielded female RJ45

Ethernet connector

(Port 1)

9

Page 10

6. Connecting to the Ethernet network

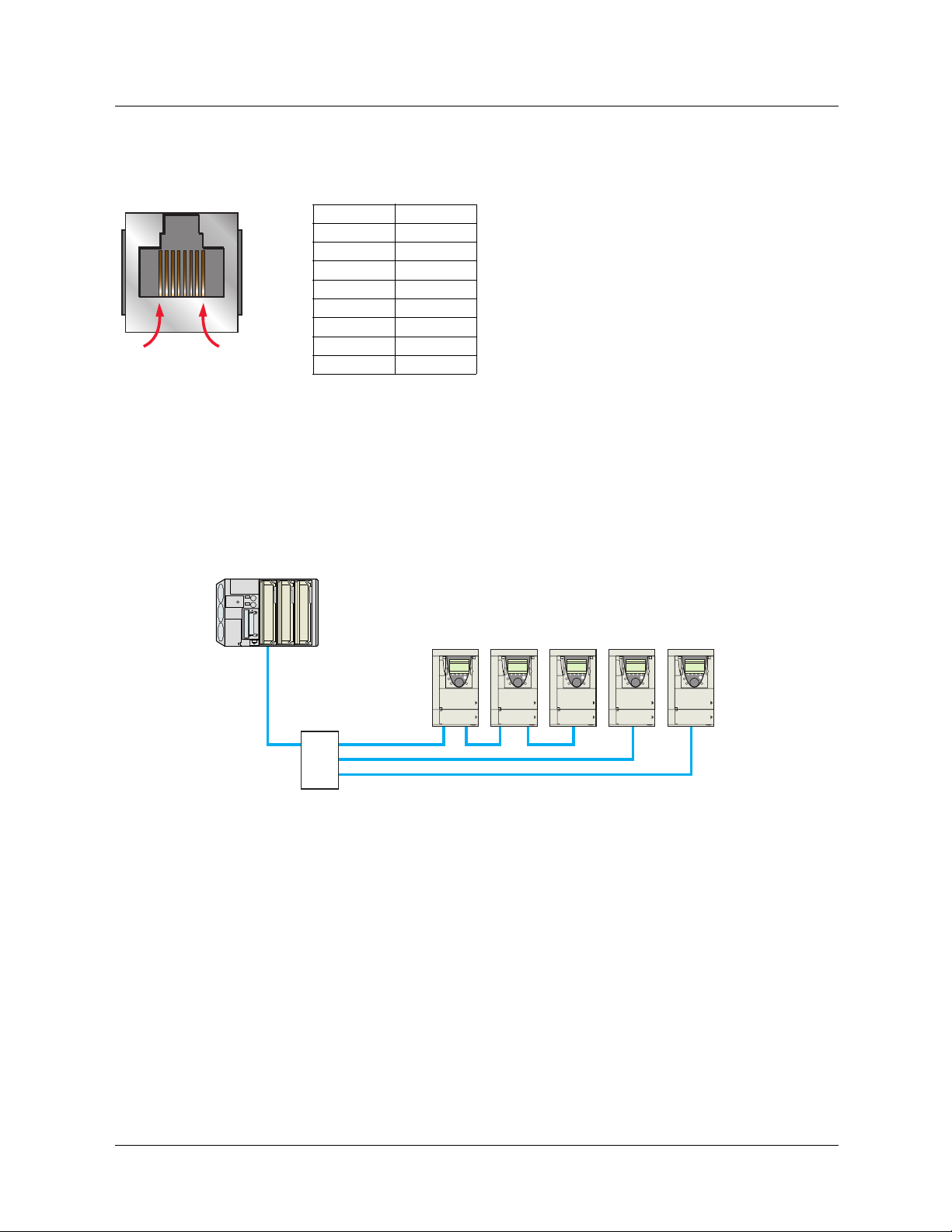

6. 1. Card RJ45 connector pinout

The Ethernet card is equipped with a shielded RJ45 connector. The shielding is connected to the drive ground.

Use STP (shielded twisted pair) Ethernet cable.

Pin Signal

1TD+

2TD-

3 RD+

4

5

6 RD-

8........................1

The transmission speed is detected automatically by the card (10 Mbps or 100 Mbps).

The card can operate in half duplex or full duplex mode, whether connected to a hub or switch, regardless of the transmission speed

(10 Mbps or 100 Mbps).

The card supports the ETHERNET 2 frame format (IEEE 802-3 not supported).

6. 2. Example of connection to an Ethernet network

7

8

PLC

Daisy chain and/or star topology (1)

ATV61/71 ATV61/71 ATV61/71 ATV61/71 ATV61/71

Ethernet switch

(1)When the topology is a daisy chain, if one drive is turned off, the other drive(s) stop in response to a communication network fault (CNF).

Redundancy can be added by connecting the first and last drive in the daisy chain to a hub or switch to create a loop.

10

Page 11

6. Connecting to the Ethernet network

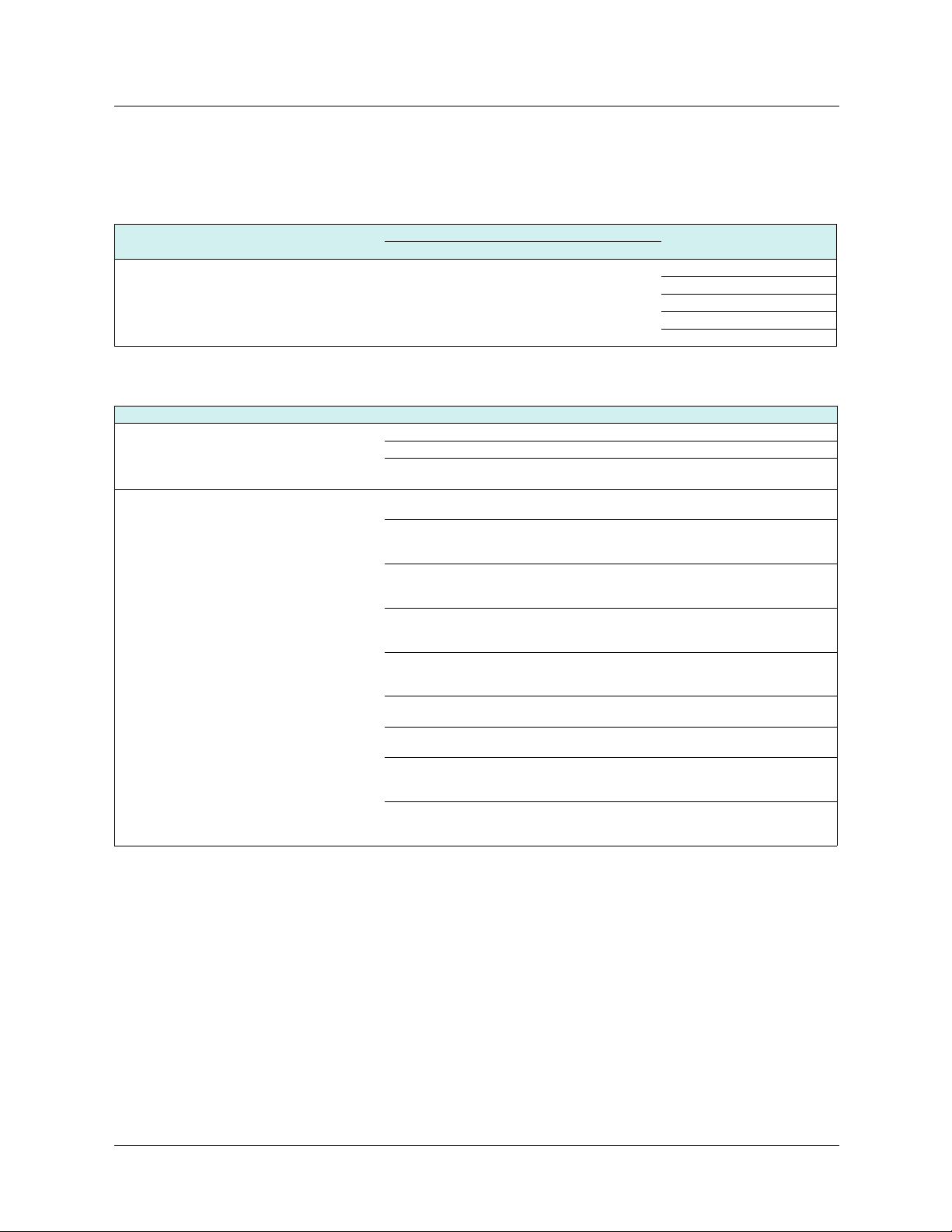

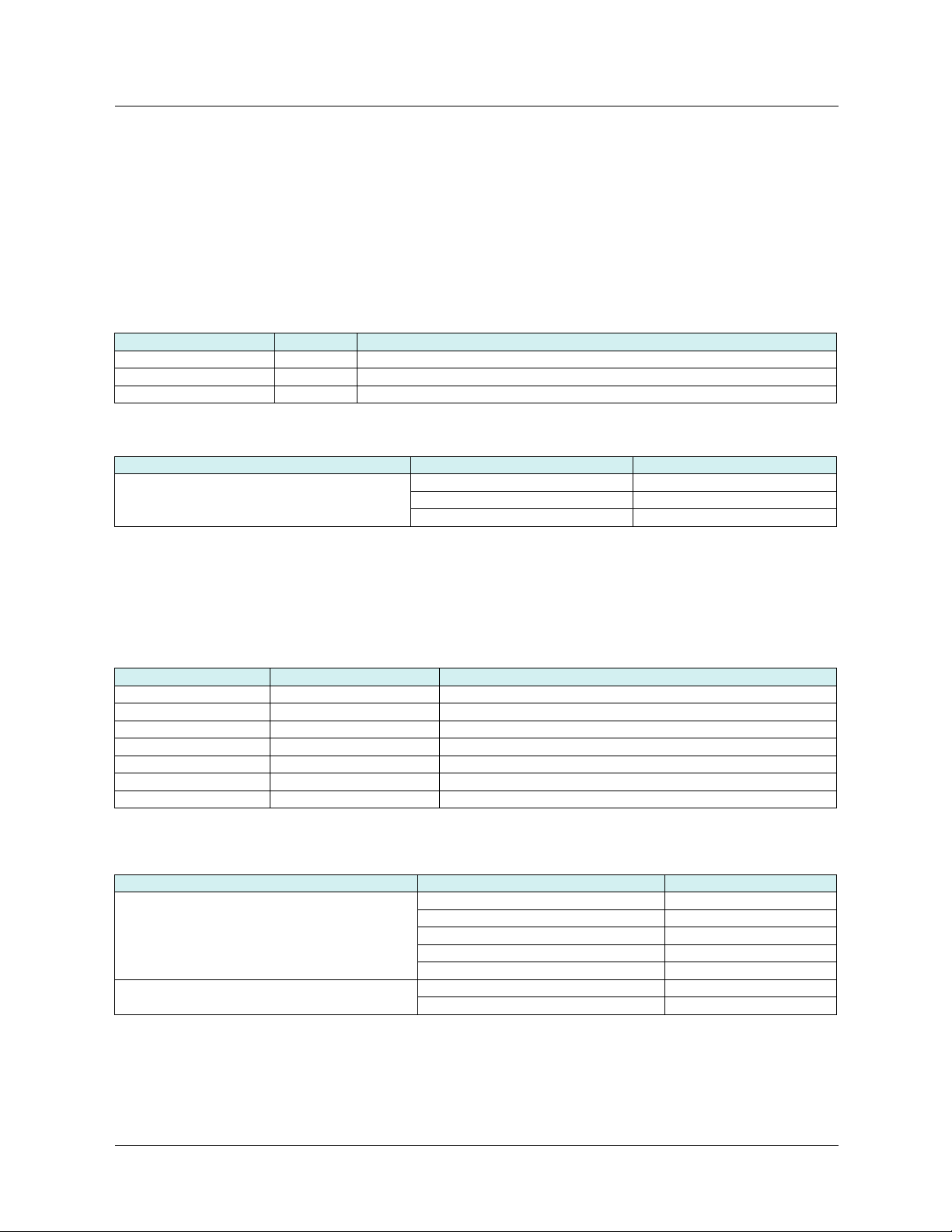

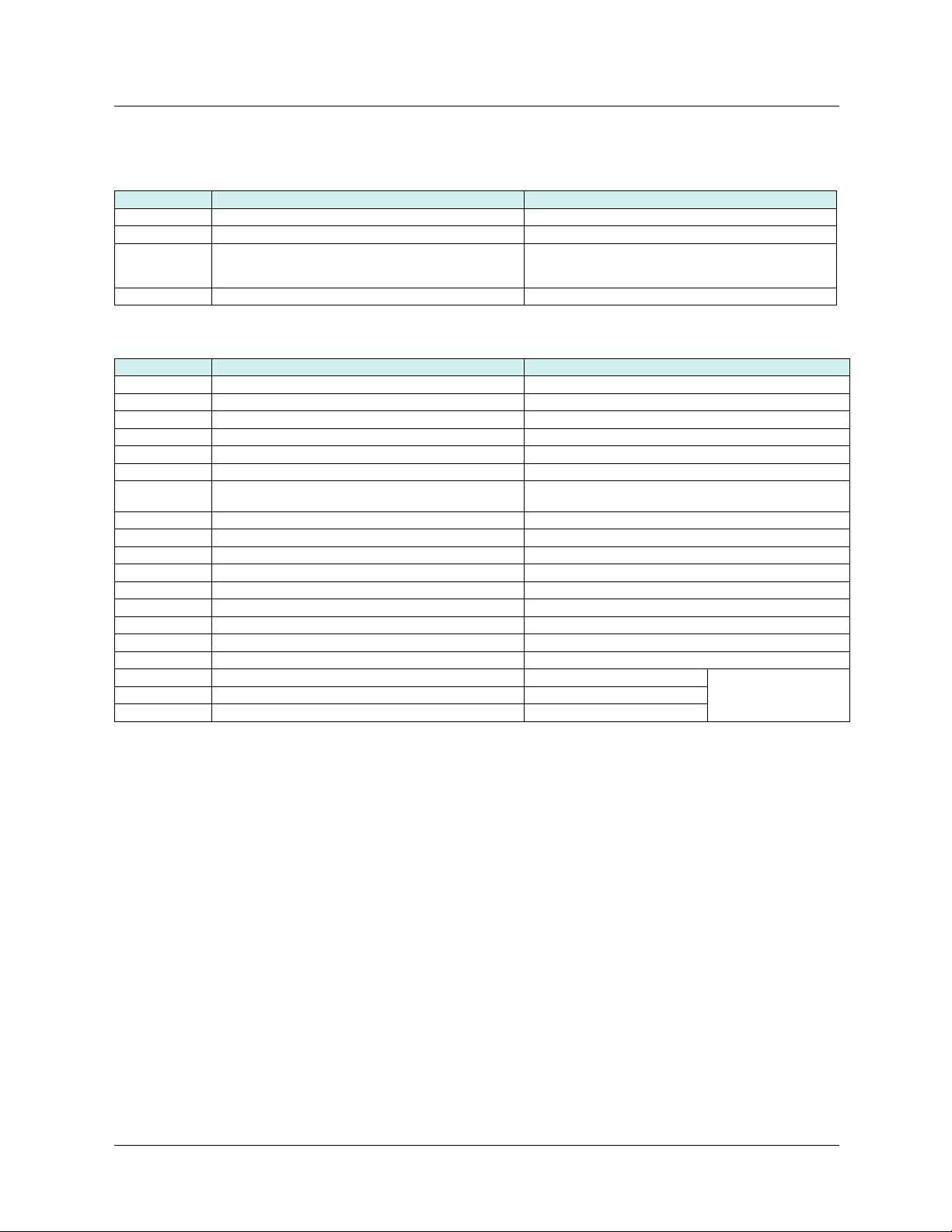

6. 3. Ethernet network connection elements

Please consult our catalog “Ethernet TCP/IP and the Web” (available on the web site www.telemecanique.com).

Connecting cables

Description Use Length Catalog number

From To m

Straight shielded twisted pair cables

2 RJ45 connectors

Hubs and switches

Description Characteristics Catalog number

Hubs 4 × 10BASE-T ports 499 NEH 104 10

Switches 5 × 10BASE-T/100BASE-TX ports

ATV71

(+ VW3A3310d card)

4 × 100BASE-TX ports 499 NEH 141 10

3 × 10BASE-T ports

2 × 10BASE-FL ports, multimode fiber, ST (BFOC) connectors

Unmanaged basic

4 × 10BASE-T/100BASE-TX ports

1 × 100BASE-FX port, multimode fiber, SC connectors

Unmanaged

3 × 10BASE-T/100BASE-TX ports

2 × 100BASE-FX port, multimode fiber, SC connectors

Unmanaged

4 × 10BASE-T/100BASE-TX ports

1 × 100BASE-FX port, monomode fiber, SC connectors

Unmanaged

3 × 10BASE-T/100BASE-TX ports

2 × 100BASE-FX port, monomode fiber, SC connectors

Unmanaged

8 × 10BASE-T/100BASE-TX ports

Unmanaged

7 × 10BASE-T/100BASE-TX ports

Managed

5 × 10BASE-T/100BASE-TX ports

2 × 100BASE-FX port, multimode fiber, SC connectors

Managed

5 × 10BASE-T/100BASE-TX ports

2 × 100BASE-FX port, monomode fiber, SC connectors

Managed

Hubs

499 N

pH 1pp 10

Switches

pS 171 00

499 N

2 490 NTW 000 02

5 490 NTW 000 05

12 490 NTW 000 12

40 490 NTW 000 40

80 490 NTW 000 80

499 NOH 105 10

499 NES 251 00

499 NMS 251 01

499 NMS 251 02

499 NSS 251 01

499 NSS 251 02

499 NES 181 00

499 NES 271 00

499 NOS 271 00

499 NSS 271 00

11

Page 12

7. Ethernet menu

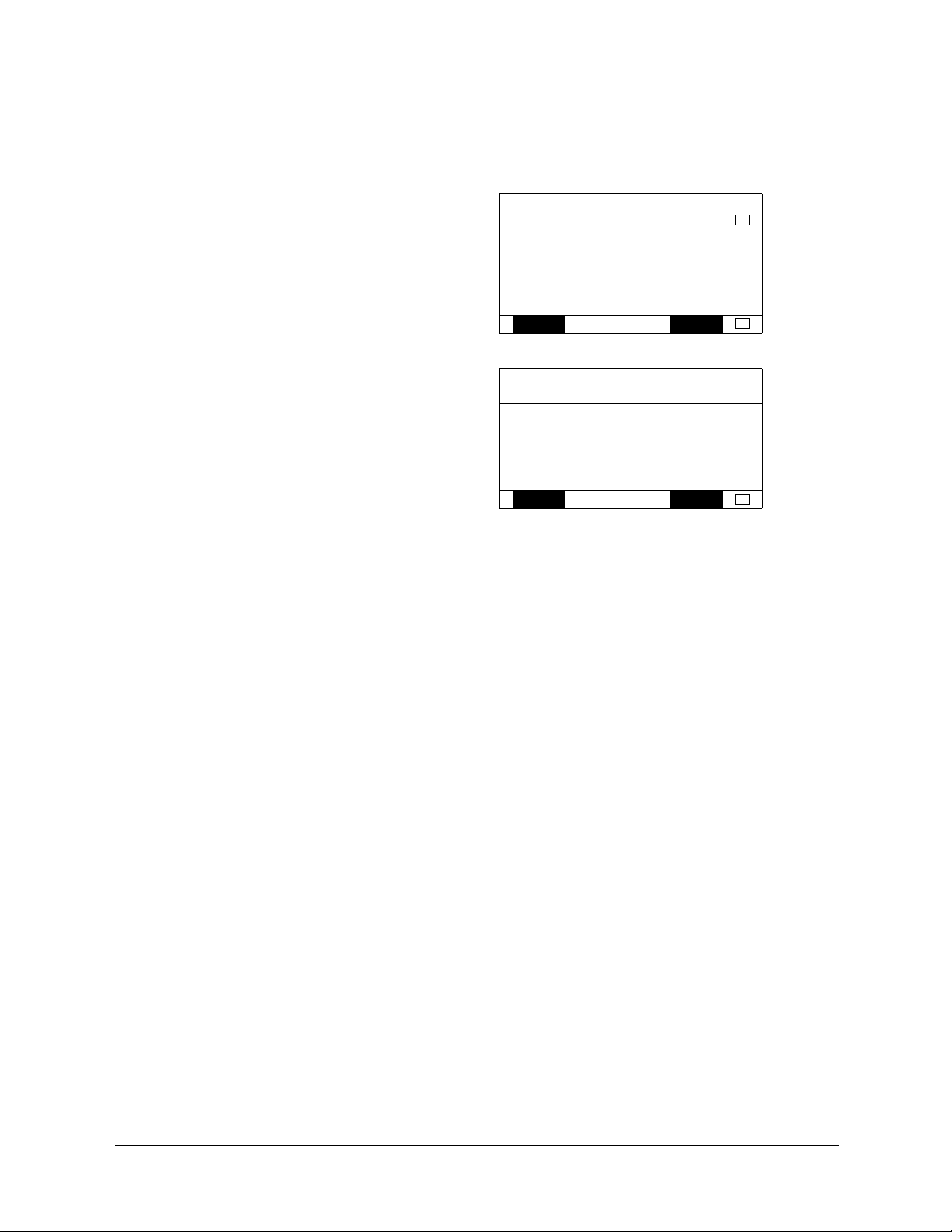

7. 1. Access to Ethernet menu via graphic display terminal

The [ETHERNET] submenu is used to configure and display the Ethernet card parameters and can be accessed via the

[1.9 - COMMUNICATION] menu.

If you are using the FDR (Faulty Device Replacement) function, you must also configure the device name in the [7. DISPLAY CONFIG.]

menu, [7.1 USER PARAMETERS] submenu, [DEVICE NAME] submenu.

This menu is only accessible in expert mode: In the [2 ACCESS LEVEL] (LAC-) menu, set the level to [expert] (EPr).

RDY NET +0.00 Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

RDY NET +0.00 Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

ENT

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS/OUTPUTS CFG

Code << >> Quick

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 PROGRAMMABLE CARD

ENT

RUN NET +50.00 Hz 80A

1.9 COMMUNICATION

COM. SCANNER OUTPUT

MODBUS HMI

MODBUS NETWORK

CANopen

ETHERNET

Code << >> Quick

7. 2. Access to Ethernet menu via the integrated display terminal

The (EtH-) submenu is used to configure and display the Ethernet card parameters. It can be accessed via the (COM-) menu.

Note: The device name required for the FDR (Faulty Device Replacement) function cannot be configured via the integrated display terminal.

Power-up

Displays the drive state

XXX

ENT

ESC

SIM-

ESC

FLt-

ESC

ESC

CON-

FCS-

ENT

ESC

EtH-

ESC

LAC-

12

Page 13

7. Ethernet menu

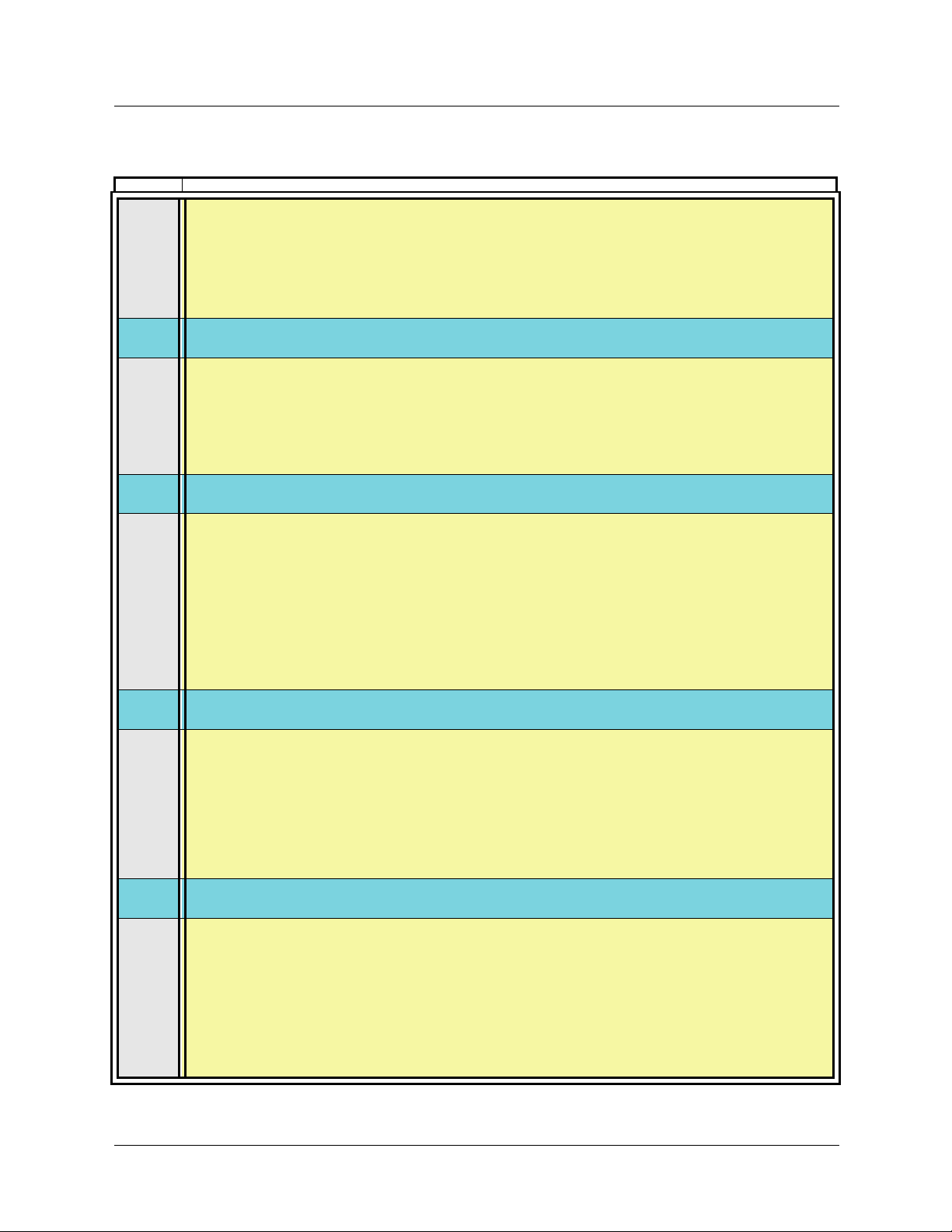

7. 3. Ethernet menu parameters

Code Description

(bdr) M [Bit rate]

(PAn-)

(IPC-)

(IPC1)

(IPC2)

(IPC3)

(IPC4)

Transmission speed detected on the network by the Ethernet card

Type: Display (read-only)

Possible

values:

Default value: [0 Mbps] (0M)

b [DEVICE NAME]

Device name used by FDR service. Accessible with an ATV71 from V1.2 and a ATV61 from V1.3 version.

Use the navigation selector button to increment the character (alphabetical order) and << and >> (F2 and F3) to switch

to the next or previous character respectively. Use F1 to change to ABC, abc, 123, *[-.

Type: Configuration (read and write)

Possible values: 16 characters on 1 or 2 lines.

Default value: [0]

b [IP card]

M [139.160.069.241] (139) (160) (069) (241)

Ethernet card IP address

Type: Configuration (read and write)

Possible

values:

Default value: [0.0.0.0] (0) (0) (0) (0)

[0 Mbps] (0M): Automatic detection of the Ethernet network speed

[10 Mbps] (10M): 10 Mbps

[100 Mbps] (100M): 100 Mbps

Display (read-only)

Display (read-only) if the address has been supplied by a BOOTP or DHCP server

• 0 to 255 for each of fields IPC1, IPC2, IPC3 and IPC4.

• If the value is [0.0.0.0] (0) (0) (0) (0), the Ethernet card waits for an address from a BOOTP

or DHCP server.

Note: If you enter a value other than [0.0.0.0] (0) (0) (0) (0), dynamic addressing by a BOOTP

or DHCP server is disabled.

Note: After dynamic addressing by a BOOTP or DHCP server, the value [0.0.0.0] (0)(0)(0)(0)

is replaced by the address supplied.

(IPM-)

(IPM1)

(IPM2)

(IPM3)

(IPM4)

(IPG-)

(IPG1)

(IPG2)

(IPG3)

(IPG4)

b [IP Mask]

M [255.255.254.0] (255) (255) (254) (0)

Subnet mask

Type: Configuration (read and write)

Possible

values:

Default value: [0.0.0.0] (0) (0) (0) (0)

Display (read-only) if the address has been supplied by a BOOTP or DHCP server

• 0 to 255 for each of fields IPM1, IPM2, IPM3 and IPM4.

• If the value of the IP address [IP card] is [0.0.0.0] (0) (0) (0) (0), the Ethernet card waits for

a mask from a BOOTP or DHCP server.

Note: After dynamic addressing by a BOOTP or DHCP server, the current value is replaced by the

address supplied.

b [IP Gate]

M [0.0.0.0] (0) (0) (0) (0)

Gateway IP address

Type: Configuration (read and write)

Possible

values:

Default value: [0.0.0.0] (0) (0) (0) (0)

Display (read-only) if the address has been supplied by a BOOTP or DHCP server

• 0 to 255 for each of fields IPG1, IPG2, IPG3 and IPG4.

• If the value of the IP address [IP card] is [0.0.0.0] (0) (0) (0) (0), the Ethernet card waits for

a mask from a BOOTP or DHCP server.

Note: After dynamic addressing by a BOOTP or DHCP server, the current value is replaced by the

address supplied.

13

Page 14

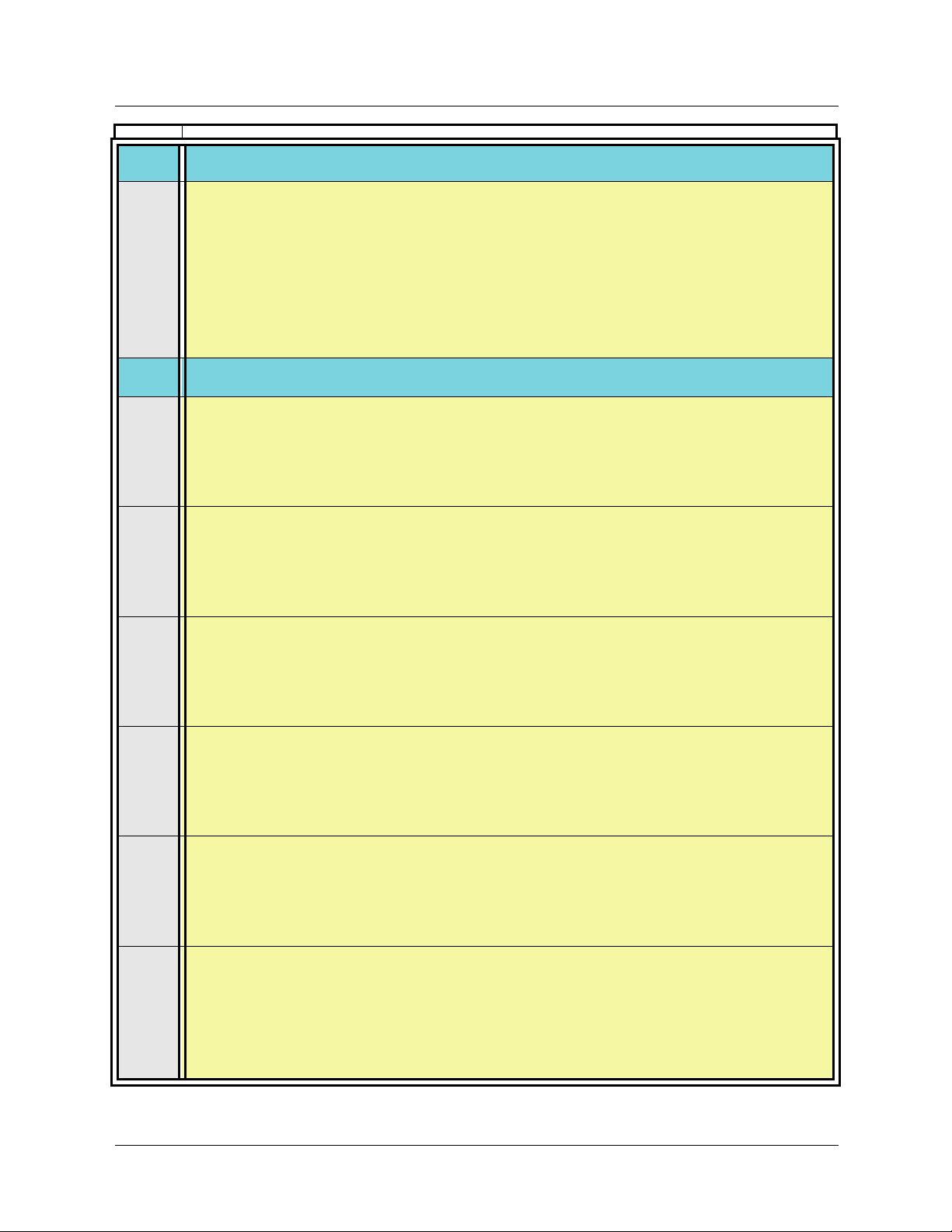

7. Ethernet menu

Code Description

(IPP-)

(IPP1)

(IPP2)

(IPP3)

(IPP4)

(IPF-)

(IPF1)

(IPF2)

(IPF3)

(IPF4)

(ISA) M [IO Scan.activ.]

(tOUt) M [time out]

b [IP Master]

M [0.0.0.0] (0) (0) (0) (0)

IP address of the device that retains control

Type: Configuration (read and write)

Possible

values:

Default value: [0.0.0.0] (0) (0) (0) (0)

b [IP FDR]

M [0.0.0.0] (0) (0) (0) (0)

IP address of the FDR server

Type: Display (read-only)

Possible

values:

Default value: [0.0.0.0] (0) (0) (0) (0)

Enable IO Scanner

Type: Configuration (read and write)

Possible

values:

Default value: [Yes] (YES)

Display (read-only) if the address is supplied by a DHCP server

• 0 to 255 for each of fields IPP1, IPP2, IPP3 and IPP4.

• If the value is [0.0.0.0] (0) (0) (0) (0), writing of the control word (CMd) is accepted

by the Ethernet card regardless of which device has sent it.

• If the value is other than [0.0.0.0] (0) (0) (0) (0) only the device which has the IP address

[IP Master] is authorized to write the control word (CMd).

Note: This configuration also affects the type of communication monitoring.

• 0 to 255 for each of fields IPF1, IPF2, IPF3 and IPF4.

• If the value is [0.0.0.0] (0) (0) (0) (0), there is no server.

• [No] (nO): IO Scanner disabled.

• [Yes] (YES): IO Scanner enabled.

Ethernet communication monitoring time out

Type: Configuration (read and write)

Possible

values:

Default value: [2.0 s] (2.0)

(FdrU) M [FDR validation]

Enable FDR service

Type: Configuration (read and write)

Possible

values:

Default value: [Yes] (YES)

(LCFG) M [FDR Local Config.]

Selection of local or server configuration

Type: Configuration (read and write)

Possible

values:

Default value: [No] (nO)

(FdrF) M [FDR Error Mgt.]

Enable FDR file error detection

Type: Configuration (read and write)

Possible

values:

Default value: [Yes] (YES)

• [0] (0): Monitoring disabled.

• [0.5 s] (0.5) to [60.0 s] (60.0): Time out value (unit: 0.1 s).

• [No] (nO): FDR service disabled.

• [Yes] (YES): FDR service enabled.

• [No] (nO): The drive configuration is downloaded from an FDR server.

• [Yes] (YES): The drive configuration is local and saved in a FDR server.

In the event of a problem with the FDR file (missing or invalid):

• [No] (nO): The Ethernet card does not trigger an [FDR fault] (Fdrd).

• [Yes] (YES): The Ethernet card triggers an [FDR fault] (Fdrd).

14

Page 15

7. Ethernet menu

Code Description

(FdrA) M [FDR Action]

FDR service command

Type: Command (read and write)

Possible

values:

Default value: [IDLE] (IdLE)

(FdrS) M [FDR autosave]

Enable periodic saving of the FDR service

Type: Configuration (read and write)

Possible

values:

Default value: [No] (nO)

(Fdrt) M [FDR t.autosave]

Interval for periodic saving of the FDR service

Type: Configuration (read and write)

Possible

values:

Default value: [10] (10)

(FdrE) M [FDR state]

• [IDLE] (IdLE): No command.

• [SAVE] (SAUE): Command: save.

• [REST] (rESt): Command: download.

• [DEL] (dEL): Command: delete.

The command remains displayed during the action then reverts to the value [IDLE] (IdLE).

• [No] (nO): Automatic saving disabled.

• [Yes] (YES): Automatic saving enabled.

• [2] (2) to [9999] (9999): 2 min to 9999 min.

FDR service state

Type: Display (read-only)

Possible

values:

Default value: [IDLE] (IdLE)

(Fdrd) M [FDR Error Code]

FDR service status code

Type: Display (read-only)

Possible

values:

Default value: [0] (0)

• [IDLE] (IdLE): “Idle”.

• [INIT] (INIt): Initialization.

• [CONF] (CONF): Configuration.

• [RDY] (rdY): Ready.

• [GET] (GEt): Download the current configuration.

• [SET] (SEt): Save the current configuration.

• [APP] (APP): Write the FDR server configuration to the drive.

• [OPE] (OPE): Operational.

• [UCFG] (UCFG): Not configured.

• [0] (0): No communication interruption

• [2] (2): The FDR configuration file is not compatible with the drive type

(example: the drive is not the same rating as that defined in the FDR file).

• [3] (3): Error reading the FDR configuration file on the server.

• [4] (4): Error writing the FDR configuration file to the server.

• [7] (7): Time-out for receipt of the FDR configuration file from the server.

• [9] (9): Duplication of IP address.

• [12] (12): The FDR configuration file is missing.

15

Page 16

8. Configuration

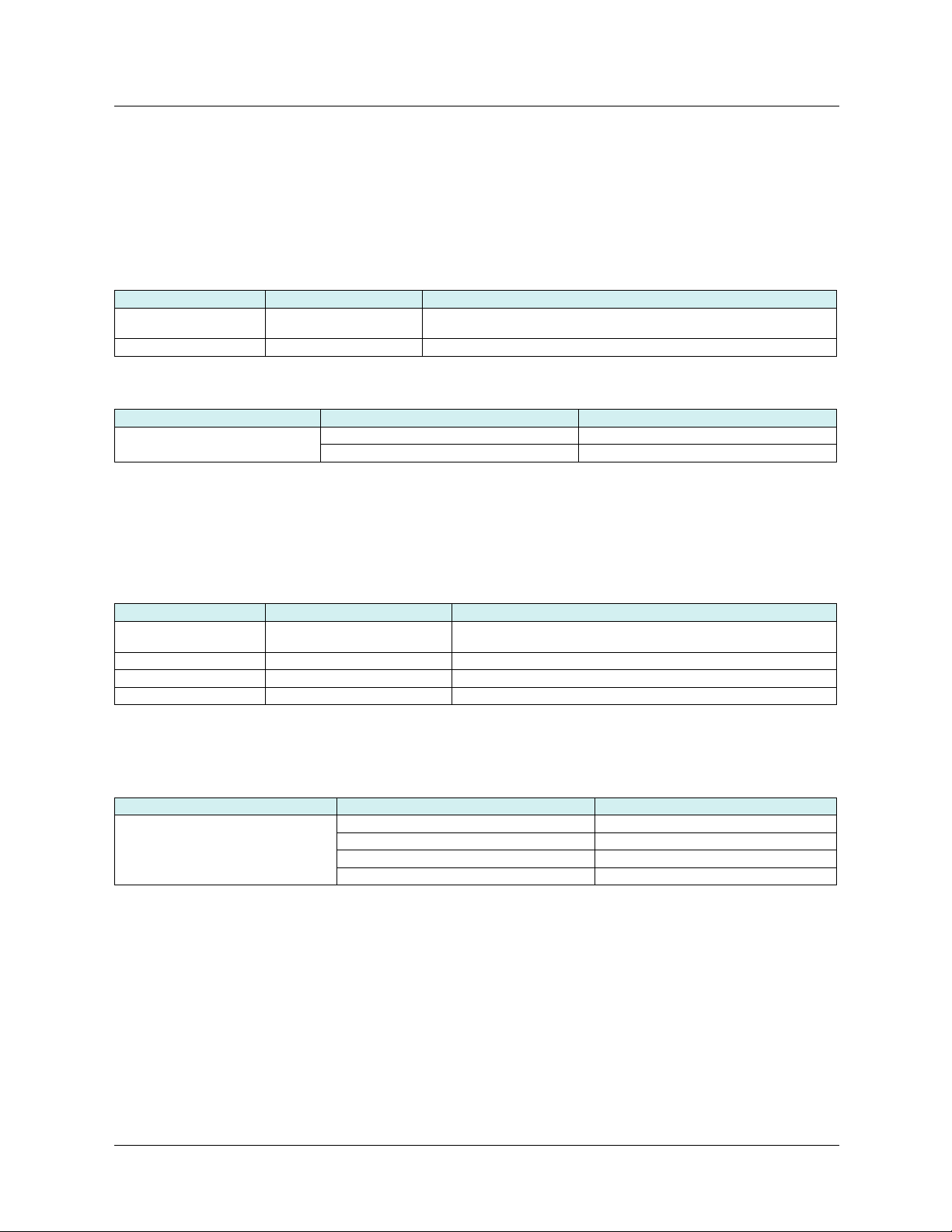

8. 1. List of functions to be configured

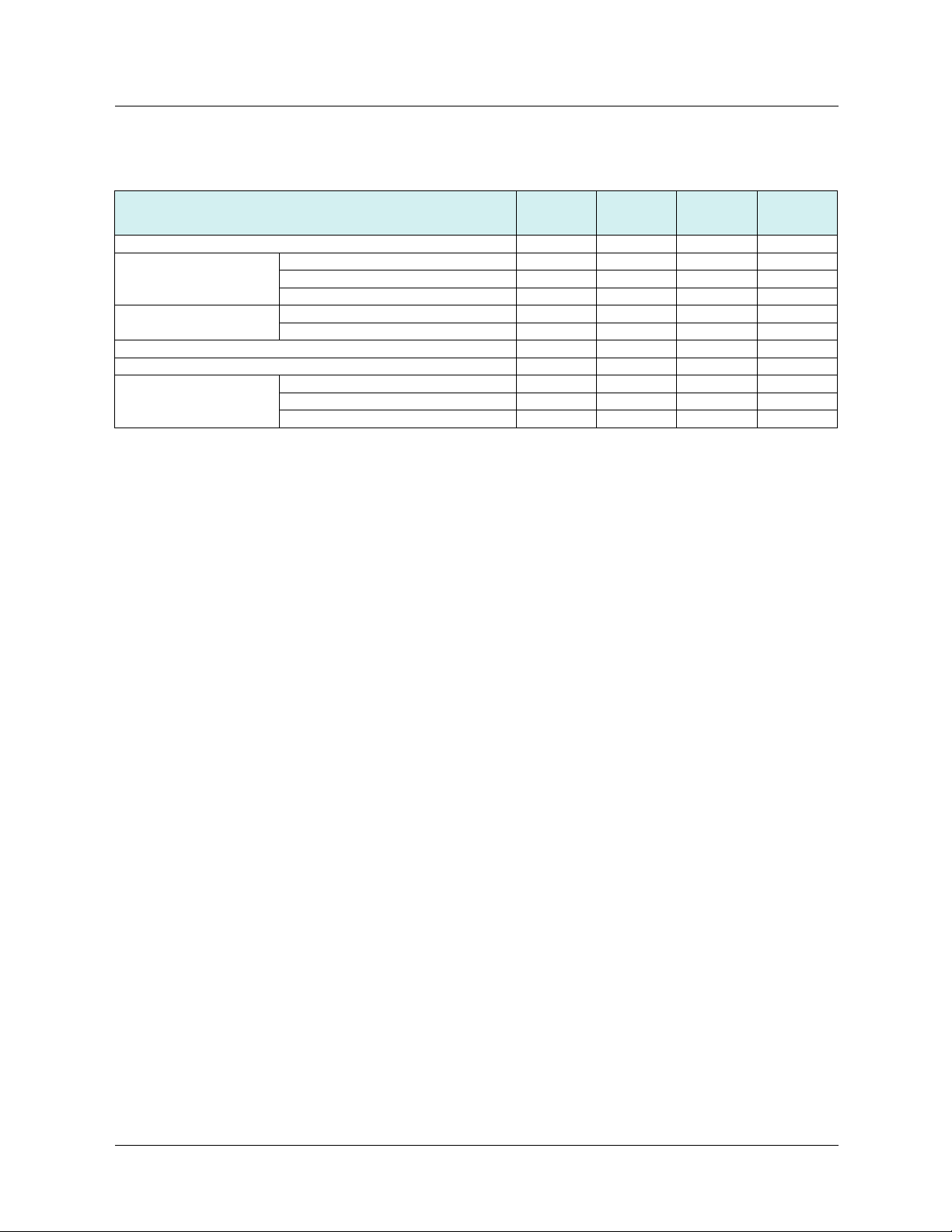

The table below gives the list of configuration functions and how they can be accessed:

Functions

Entering the IP addresses ppp

FDR

(Faulty Device Replacement)

IO Scanning

Reserving control (IP master) pppp

Communication monitoring pppp

Security of access

to the standard web server

Configuration using the drive graphic display terminal or the integrated display terminal is explained in the “Configuration” section.

Configuration using the standard web server is explained in the “Standard web server” section.

For configuration using the PowerSuite software workshop, refer to the PowerSuite online help.

Notes:

• The Ethernet card saves its configuration (IP address, mask, gateway, etc.) to the EEPROM each time the configuration is modified.

• For performance reasons, Schneider Electric recommends using the Ethernet IO Scanner, not the drive communication scanner.

• Configuration must be performed with the motor stopped.

Entering the device name pp

Configuration (time delay, etc.) pppp

Commands (save, etc.) pp p

Enable IO Scanner pppp

Configuring the IO Scanner variables pp

Changing the “username” p

Changing the “HTTP password” p

Changing the “Write password” pp

Graphic

display

terminal

Integrated

display

terminal

PowerSuite

software

workshop

Standard

web

server

16

Page 17

8. Configuration

8. 2. Configuring IP addresses

b Assigning IP addresses

The drive needs 3 IP addresses:

• The drive IP address.

• The subnet mask.

• The gateway IP address (not always required).

®

Note: Some controllers, such as Prosoft

address must be set in menu 1.9 of the drive, as well as in the software for the master device.

These IP addresses can be entered:

• Using the integrated display terminal.

• Using the graphic display terminal.

• Using the PowerSuite software workshop.

They can be provided by:

• A BOOTP server (correspondence between the MAC address and the IP addresses).

• A DHCP server (correspondence between Device Name [DEVICE NAME] and the IP addresses).

If an IP address other than 0.0.0.0 has been entered using the display terminal or the PowerSuite software workshop, assignment using

a server is disabled.

The BOOTP service is enabled:

• When no IP address other than 0.0.0.0 has been entered and

• The FDR service has not been enabled ([FDR validation] parameter = [No] or a [DEVICE NAME] has not been entered).

and DeltaV® modules, require a Modbus address to be set in addition to the IP address. This

The DHCP service is enabled:

• When no IP address other than 0.0.0.0 has been entered and

• The FDR service has been enabled ([FDR validation] parameter = [Yes] and a [DEVICE NAME] has been entered).

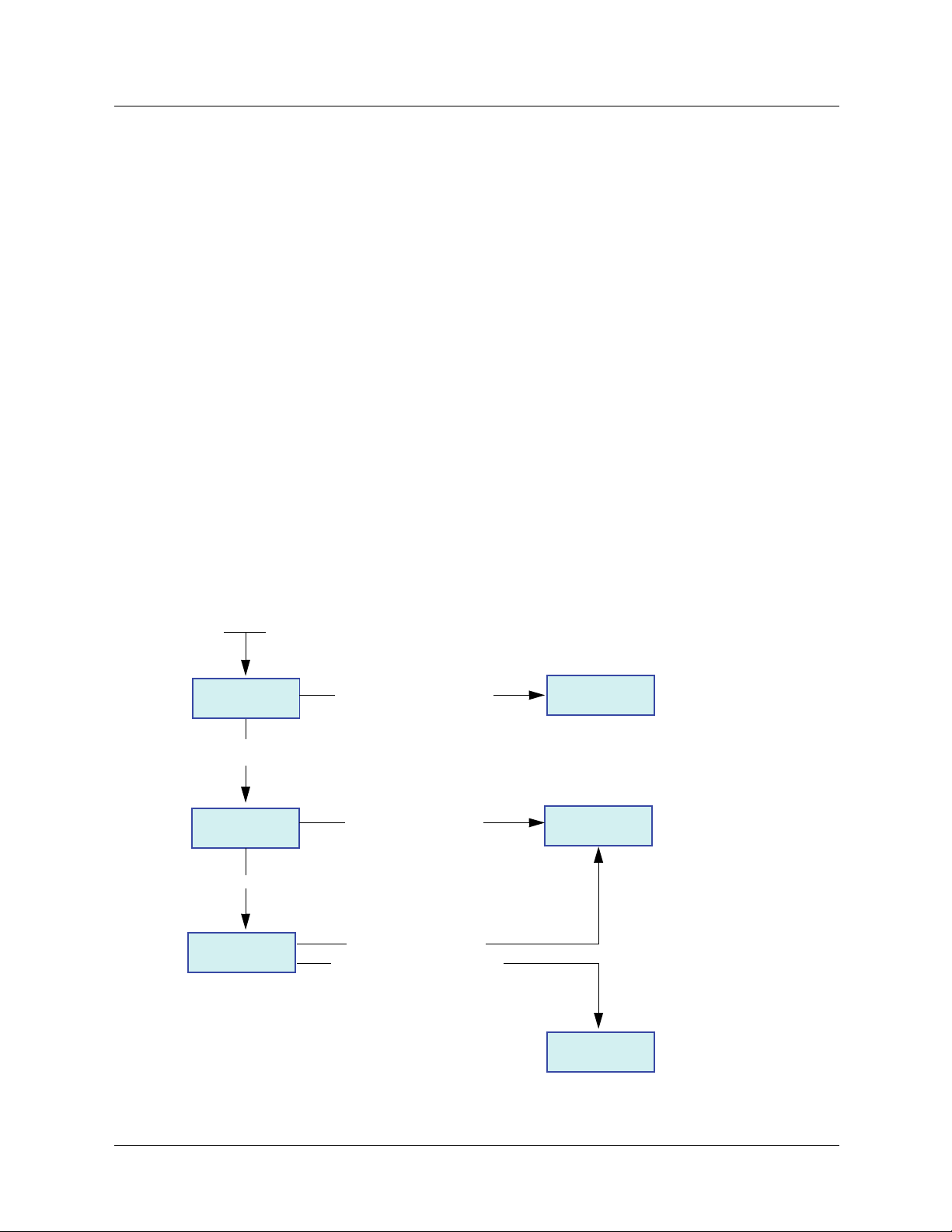

Power-up

Initialization

No address has been entered

[IP card] = 0.0.0.0

Dynamic

addressing

[FDR validation] = [Yes]

FDR

An address has been entered

[IP card] <> 0.0.0.0

[FDR validation] = [No]

[DEVICE NAME] blank

[DEVICE NAME] has been

entered

Static

addressing

BOOTP

DHCP

17

Page 18

8. Configuration

b Entering IP addresses in the terminal

In the [1.9 - COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-) submenu, enter the following IP addresses:

- [IP card] (IPC1) (IPC2) (IPC3) (IPC4).

- [IP Mask] (IPM1) (IPM2) (IPM3) (IPM4).

- [IP Gate] (IPG1) (IPG2) (IPG3) (IPG4) (not always required).

Note: Some controllers, such as Prosoft

address must be set in menu 1.9 of the drive, as well as in the software for the master device.

Turn the drive off and then back on again (control voltage if a separate power supply is being used), otherwise the IP addresses are not

taken into account.

Note: Before entry begins, the IP address displayed is the active IP address.

If this address is modified, the new IP address entered is displayed. This IP address will be effective the next time the drive is turned on.

b Configuring BOOTP

The BOOTP service is used to assign IP addresses from the MAC address. The MAC address consisting of 6 octets (00-80-F4-80-xx-yy)

must be entered in the BOOTP server. The MAC address appears on the label attached to the Ethernet card.

In the [1.9 - COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-) submenu:

• Leave the IP address [IP card] (IPC1) (IPC2) (IPC3) (IPC4) at the value [0.0.0.0] (0) (0) (0) (0).

• Do not enable the FDR service: [FDR validation] (FdrU) = [No] (nO).

b Configuring FDR

The FDR service (based on DHCP) is used to assign the IP addresses and other parameters from the device name that must be entered

in the drive and in the FDR server (DHCP).

®

and DeltaV® modules, require a Modbus address to be set in addition to the IP address. This

In the [1.9 - COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-) submenu:

• Leave the IP address [IP card] (IPC1) (IPC2) (IPC3) (IPC4) at the value [0.0.0.0] (0) (0) (0) (0).

• Enable the FDR service: [FDR validation] (FdrU) = [Yes] (YES).

For the FDR function, select the drive configuration as either:

• Local: [FDR Local Config.] (LCFG) = [Yes] (YES).

• Downloaded. In this case, it is essential to consult the “FDR Service” section.

Enter the device name, [DEVICE NAME], in the [7. DISPLAY CONFIG.] menu, [7.1 USER PARAMETERS] submenu.

This menu is only accessible in expert mode: In the [2 ACCESS LEVEL] (LAC-) menu, set the level to [expert] (EPr).

Turn the drive off and then back on again (control voltage if a separate power supply is being used), otherwise the device name is not taken

into account.

Note: The FDR function cannot be fully configured using the integrated display terminal as it does not provide access to the device name.

18

Page 19

8. Configuration

8. 3. Reserving control

It is strongly recommended that control should be reserved for a single master device.

If control were not to be reserved for a master device (for example a PLC):

• Any other Modbus TCP Ethernet client could send unwanted commands.

• Other clients could use the 8 available TCP connections and prevent the master from having control.

DANGER

UNINTENDED EQUIPMENT OPERATION

Ensure that a valid address for the IP master device has been specified.

Failure to follow this instruction will result in death, serious injury, or equipment damage.

Use the [IP Master] (IPP) menu option to configure a network master device. If a valid IP address for a master device is not specified

using this option, other Ethernet clients can saturate the TCP connections or send incorrect commands leading to unintended operation.

To configure this reservation, enter an IP address other than [0.0.0.0] (0) (0) (0) (0) in the [1.9 COMMUNICATION] (COM-) menu,

[ETHERNET] (EtH-) submenu, [IP Master] submenu.

• If control has been reserved:

Only the control word (CMd) written by the master with control will be accepted via IO Scanning or via Modbus TCP messaging.

2 TCP connections are reserved for this device. In this way, you avoid other TCP clients using all the available connections

(8 maximum) and the control master no longer being able to access the drive Modbus TCP server.

Other parameters written from other IP addresses are accepted (for example, adjustments or writing a setpoint).

When control has been reserved and another device attempts to write the control word (CMd):

- via IO Scanning: The Modbus TCP connection for this client is immediately reinitialized.

- via Modbus TCP messaging: Control is denied.

• If control has not been reserved ([IP Master] = [0.0.0.0] (0) (0) (0) (0)), control can come from any IP address.

8. 4. Configuring IO Scanning

Refer to the “IO Scanning Service” section.

The drive IO Scanning service can be enabled or disabled in the [1.9 - COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-)

submenu via parameter [IO Scan.activ.] (IOSA).

It is not possible to modify the assignment of the IO Scanning periodic variables using the display terminal (integrated or graphic).

To configure IO Scanning, use the standard web server or the PowerSuite software workshop.

19

Page 20

8. Configuration

8. 5. Configuring the control

Numerous configurations are possible. For more information, refer to the Programming Manual and the Communication parameters

Manual.

The following configurations are just some of the possibilities available.

b Control via Ethernet in I/O profile

The command and setpoint come from Ethernet.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile The run command is simply obtained by bit 0 of the control word.

Setpoint 1 configuration Network card The setpoint comes from Ethernet.

Command 1 configuration Network card The command comes from Ethernet.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (Cd1) [Com. opt card] (nEt)

b Control via Ethernet or the terminals in I/O profile

Both the command and setpoint come from Ethernet or the terminals. Input LI5 at the terminals is used to switch between Ethernet

and the terminals.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile The run command is simply obtained by bit 0 of the control word.

Setpoint 1 configuration Network card Setpoint 1 comes from Ethernet.

Setpoint 1B configuration Analog input 1 on the terminals Setpoint 1B comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the setpoint (1

Command 1 configuration Network card Command 1 comes from Ethernet.

Command 2 configuration Terminals Command 2 comes from the terminals.

Command switching Input LI5 Input LI5 switches the command.

Note: Setpoint 1B is connected to the functions (summing, PID, etc.), which remain active, even after switching.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (Cd1) [Com. card] (nEt)

[Cmd channel 2] (Cd2) [Terminals] (tEr)

[Cmd switching] (CCS) [LI5] (LI5)

[1.7 APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH.]

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

↔1B).

20

Page 21

8. Configuration

b Control via Ethernet in CiA402 (Drivecom) profile

The command and setpoint come from Ethernet.

The command is in CiA402 profile.

Note: The term Drivecom has been in use since 1991. Recently, the term has changed to DSP402, and currently is CiA402. This profile

requires a specific sequence of commands to control the drive. The profile is a standard that is available for use by many brands and

products to facilitate interchangeability of similar products from different manufacturers. Refer to the Communications Parameters and

Programming guides for additional details.

Configure the following parameters:

Parameter Value Comment

Profile Not separate The run commands are in CiA402 profile, the command and the setpoint come

Setpoint 1 configuration Network card The command comes from Ethernet.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM) (factory setting)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

b Control via Ethernet or the terminals in CiA402 profile

Both the command and setpoint come from Ethernet or the terminals. Input LI5 at the terminals is used to switch between Ethernet

and the terminals.

The command is in CiA402 profile.

from the same channel.

Configure the following parameters:

Parameter Value Comment

Profile Not separate The run commands are in CiA402 profile, the command and the setpoint

Setpoint 1 configuration Network card Setpoint 1 comes from Ethernet.

Setpoint 2 configuration Analog input 1 on the terminals Setpoint 2 comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the setpoint (1

Note: Setpoint 2 is directly connected to the drive setpoint limit. If switching is performed, the functions that affect the setpoint (summing,

PID, etc.) are disabled.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Ref.2 chan] (Fr2) [Ref. AI1] (AI1)

[Ref. 2 switching] (rFC) [LI5] (LI5)

come from the same channel.

↔ 2) and the command.

21

Page 22

8. Configuration

b Command in CiA402 (Drivecom) profile via Ethernet and setpoint switching at the terminals

The command comes from Ethernet.

The setpoint comes either from Ethernet or from the terminals. Input LI5 at the terminals is used to switch the setpoint between Ethernet

and the terminals.

The command is in CiA402 profile.

Configure the following parameters:

Parameter Value Comment

Profile Separate The run commands are in CiA402 profile, the command and the setpoint

Setpoint 1 configuration Network card Setpoint 1 comes from Ethernet.

Setpoint 1B configuration Analog input 1 on the terminals Setpoint 1B comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the setpoint (1

Command 1 configuration Network card Command 1 comes from Ethernet.

Command switching Channel 1 Channel 1 is the command channel.

Note: Setpoint 1B is connected to the functions (summing, PID, etc.), which remain active, even after switching.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

[1.7 APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH.]

can come from different channels.

↔1B).

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (Cd1) [Com. card] (nEt)

[Cmd switching] (CCS) [Ch1 active] (Cd1)

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

22

Page 23

8. Configuration

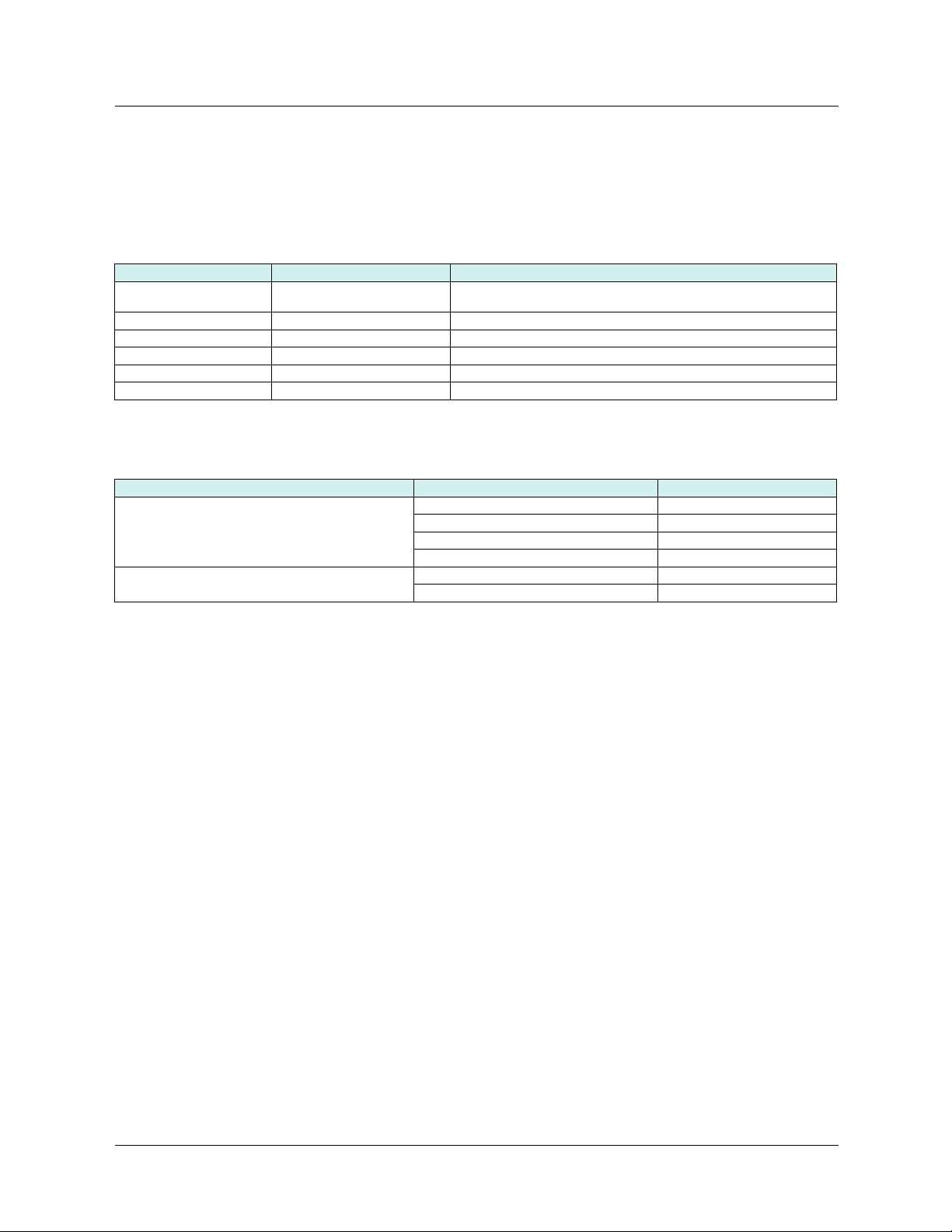

8. 6. Configuring communication interruption management

b Communication monitoring

The Ethernet card can detect 2 types of communication interruptions:

- Network management (server missing, duplication of IP address, etc.).

- Communication (time out on the master traffic, etc.).

The associated information is:

Ethernet interruption type

Network management Communication

Associated drive parameter Code:

Configuring the communication

interruption or file error detection

settings

Configuring the drive’s

response

[External fault com.] (EPF2)

Parameter:

[FDR Error Mgt.] (FdrF)

Menu:

[1.9 COMMUNICATION] (COM-)

Submenu:

[ETHERNET] (EtH-)

Parameter:

[External fault mgt] (EPL)

Menu:

[1.8 FAULT MANAGEMENT] (FLt-)

Submenu:

[EXTERNAL FAULT] (EtF-)

b Network management

The IP address duplication management detection cannot be configured.

Code:

[Com. network] (CnF)

Parameter:

[time Out] (tOUt)

Menu:

[1.9 COMMUNICATION] (COM-)

Submenu:

[ETHERNET] (EtH-)

Parameter:

[COM. fault mgt] (CLL)

Menu:

[1.8 FAULT MANAGEMENT] (FLt-)

Submenu:

[COM. FAULT MANAGEMENT] (CLL-)

If the FDR (Faulty Device Replacement) service has been configured, the FDR communication interruption detection can be disabled via

the [FDR Error Mgt.] (FdrF) parameter, which can be accessed via the [1.9 COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-)

submenu.

In factory settings mode, a network management interruption will trigger a resettable drive stop condition [External fault com.] (EPF2) and

initiate a freewheel stop.

b Communication

It is strongly recommended that control should be reserved for a single master device.

Monitoring begins when the first control word is received.

DANGER

UNINTENDED EQUIPMENT OPERATION

Ensure that a valid address for the IP master device has been specified.

Failure to follow this instruction will result in death, serious injury, or equipment damage.

Use the [IP MASTER] (IPP) menu option to configure a network master device. If a valid IP address for a master device is not specified

using this option, other Ethernet clients can saturate the TCP connections or send incorrect commands leading to unintended equipment

operation.

• If control has been reserved:

A communication interruption is triggered if the Ethernet card does not receive a Modbus TCP request within a predefined period

of time (time out).

Any type of Modbus request from the master device [IP Master] is taken into account (write operation, read operation, etc.).

• If control has not been reserved:

A communication interruption is triggered if the Ethernet card does not receive a control word write request (CMd) within a predefined

period of time (time out).

Receipt of the command (CMd) is taken into account regardless of the sender’s IP address.

The “time out” can be set to between 0.5 and 60 s via the graphic display terminal or integrated display terminal in the

[1.9 COMMUNICATION] (COM-) menu, [ETHERNET] (EtH-) submenu via the [time Out] (tOUt) parameter. The default value is 2 s.

In factory settings mode, if Ethernet is involved in the command or setpoint, a communication interruption will trigger a resettable stop

condition [Com. network] (CnF) and initiate a freewheel stop.

23

Page 24

8. Configuration

b Drive response

The drive response to an Ethernet communication interruption can be configured via the graphic display terminal or the integrated display

terminal from the [1.8 FAULT MANAGEMENT] (FLt-) menu:

RDY NET +0.00Hz 0A

For communication faults

in the [COM. FAULT MANAGEMENT] (CLL-) submenu

via parameter [COM. fault mgt] (CLL)

For network management faults

in the [EXTERNAL FAULT] (EtF-) submenu

via the [External fault mgt] (EPL) parameter

Network fault mgt : Freewheel

CANopen fault mgt : Freewheel

Modbus fault mgt : Freewheel

External fault mgt : Freewheel

COM. FAULT MANAGEMENT

Code Quick

RDY NET +0.00Hz 0A

EXTERNAL FAULT

Code Quick

The values of parameters: [COM. fault mgt] (CLL) that will trigger a stop response from the drive [Com. network] (CnF)

and [External fault mgt] (EPL) that will trigger a stop response from the drive [External fault com.] (EPF2) are:

[Freewheel] (YES): Freewheel stop (factory setting).

[Ramp stop] (rMP): Stop on ramp.

[Fast stop] (FSt): Fast stop.

[DC injection] (dCI): DC injection stop.

The values of parameters [COM. fault mgt] (CLL) and [External fault management] (EPL) which will not trigger a stop response from the

drive are:

[Ignore] (nO): Communication interruption detection is disabled.

[Per STT] (Stt): Stop according to configuration of [Stop type] (Stt).

[fallback spd] (LFF): Change to fallback speed, maintained as long as the communication interruption persists and the run command has

not been removed.

[Spd maint.]

and the run command has not been removed.

The fallback speed can be configured in the [1.8 - FAULT MANAGEMENT] (FLt-) menu via the [Fallback speed] (LLF) parameter.

(rLS): The drive maintains the speed at the time the communication interruption occurred, as long as the interruption persists

24

Page 25

8. Configuration

8. 7. Configuring monitored parameters

It is possible to select up to 4 parameters to display their values in the [1.2 - MONITORING] menu on the graphic display terminal.

The selection is made via the [6 - MONITORING CONFIG.] menu, [6.3 - COM. MAP CONFIG.] submenu.

Each parameter in the range [Address 1 select.] … [Address 4 select.]

is used to select the parameter logic address. Select an address of zero

to disable the function.

In the example given here, the monitored words are:

• Parameter 1 = Motor current (LCR): logic address 3204;

signed decimal format.

• Parameter 2 = Motor torque (OTR): logic address 3205;

signed decimal format.

• Parameter 3 = Last fault occurred (LFT): logic address 7121;

hexadecimal format.

• Disabled parameter: address 0; default format: hexadecimal format.

One of the three display formats below can be assigned to each monitored word:

Format Range Terminal display

Hexadecimal 0000 … FFFF [Hex]

Signed decimal -32,767 … 32,767 [Signed]

Unsigned decimal 0 … 65,535 [Unsigned]

RDY NET +0.00Hz 0A

6.3 COM. MAP CONFIG.

Word 1 add. select. : 3204

Format word 1 : Signed

Word 2 add. select. : 3205

Format word 2 : Signed

Word 3 add. select. : 7121

Code Quick

Format word 3 : Hex

Word 4 add. select. : 0

Format word 4 : Hex

25

Page 26

9. Diagnostics

9. 1. Signalling LEDs

The VW3A3310d Ethernet card features 5 LEDs, which are visible through the Altivar 61 / 71 cover.

1.1

1.2

1.3

1.4

1.5

Port 1 activity

2.1

Port 2 activity

2.2

Link status

2.3

2.4

NS “Network status”

2.5

MS “Module status”

The first 2 LEDS are respectively dedicated to each Ethernet port.

The third LED is relative to the IP level.

The last 2 LEDs are specific to EtherNet/IP and CIP communication protocol.

LED Color/ state Description

2.1 Off No link

Flashing Green/yellow Power up testing.

Green ON Link at 100 Mbps.

Yellow ON Link at 10 Mbps.

Green BLINK Activity at 100 Mbps.

Yellow BLINK Activity at 10 Mbps.

2.2 Off No link

Flashing Green/yellow Power up testing.

Green ON Link at 100 Mbps.

Yellow ON Link at 10 Mbps.

Green BLINK Activity at 100 Mbps.

Yellow BLINK Activity at 10 Mbps.

2.3 Off Physical connections unplugged - No IP address obtained

Flashing Green/red Power up testing.

Green ON At least one port is connected and an IP address has been obtained.

Green flashing 3 times All ports are unplugged, but the card has an IP address.

Green flashing 4 times Error: Duplicated IP address (1)

Green flashing 5 times The card is performing a BOOTP or DHCP sequence

2.4

“NS”

2.5

“MS”

(1)The Ethernet card detects IP address duplication each time it connects to the network (power-up or connection to the network).

Off The device does not have an IP address or powered off.

Flashing Green/red Power up testing.

Green ON The device has at least one established Modbus connection (even to the Message Router).

Green flashing The device has not established Modbus connections, but has obtained an IP address.

Off No power is supplied to the device

Flashing Green/red Power Up testing.

Green ON The device is ready.

Green flashing The device is not ready (waiting for cable connection, ...).

Red flashing The device has detected a [Network fault] (CnF).

Red ON The device has detected a [internal com. link] (ILF) communication interruption.

If the card detects that another device is using the same IP address as itself, it abandons the use of the IP address and triggers the

status: [External fault com.] (EPF2).

If a device with an IP address identical to that of the drive is connected to the network during operation, the condition will not be detected

by the drive (it is the new station that has to disconnect).

26

Page 27

9. Diagnostics

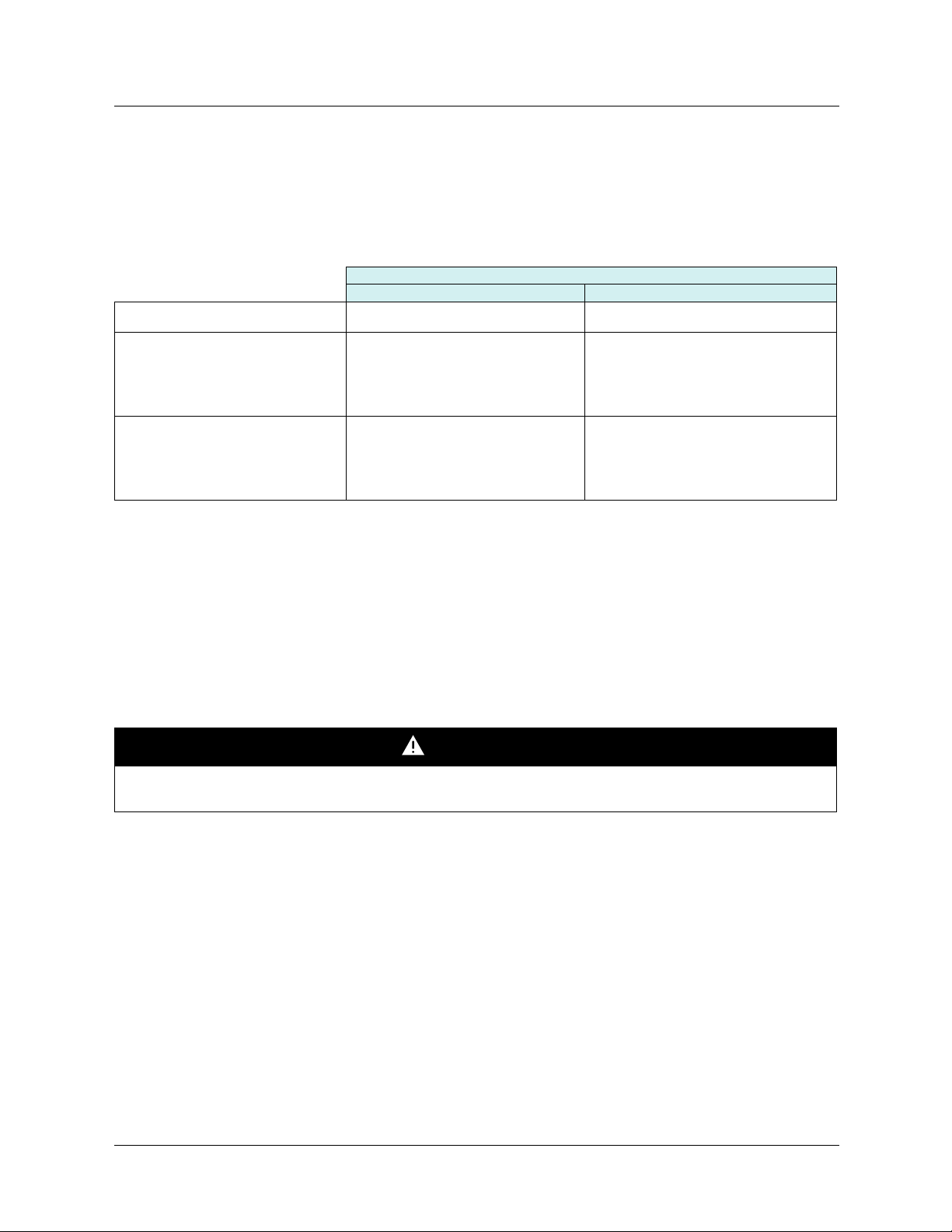

9. 2. Available information

In addition to the LEDs, the table below summarizes the diagnostic information available by various means.

Functions Graphic display

Control-signal diagnostics

• Control word

• Setpoint

• Active channel

•Etc.

Communication diagnostics

• Transmission counter

• Reception counter

• Collision counter

•Etc.

terminal

p

Integrated display

terminal

PowerSuite software

workshop

Standard

web server

ppp

pp

9. 3. Monitoring the control

On the graphic display terminal only, the [1.2 - MONITORING] menu, [COMMUNICATION MAP] submenu can be used to display control

signal diagnostic information between the drive and the Ethernet PLC:

Active command channel

Value of control word used

to send a command to the drive

(unit 0.1 Hz) used to control the drive

Values of the four monitored words selected by the user.

The address and display format of these parameters

can be configured in the [6 - MONITORING CONFIG.] menu,

[6.3 - COM. MAP CONFIG.] submenu

(see “Configuration” section on page 16

The value of a monitored word is equal to “-----” if:

- Monitoring has not been activated

(address equal to W0)

- The parameter is protected

- The parameter is not known (e.g., W3200)

Use not recommended for Ethernet

Frequency setpoint from Ethernet

(hexadecimal format)

Active setpoint channel

Value of frequency setpoint

Value of status word

(hexadecimal format)

Communication scanner:

for performance reasons

Control word from Ethernet

[COM. card cmd.] (CMd3)

[Com. card ref.] (LFr3)

RUN NET +50.00 Hz 80A

COMMUNICATION MAP

Command Channel : Com. card

Cmd value : 000F

Channel ref. active : Com. card

Frequency ref. : 500.0

Status word : 8627

Code Quick

).

W3204 : 53

W3205 : 725

W7132 : 0000

W0 : -----

COM. SCANNER INPUT MAP

COM SCAN OUTPUT MAP

CMD. WORD IMAGE

FREQ. REF. WORD MAP

MODBUS NETWORK DIAG

MODBUS HMI DIAG

CANopen MAP

SCANNER CARD PROG.

Hex

Hz

Hex

Hex

Hex

27

Page 28

9. Diagnostics

9. 4. Troubleshooting communication interruptions

b Communication monitoring

Ethernet faults are indicated by the drive display and the Module Status LED on the Ethernet card.

The Ethernet card can detect 2 types of communication interruptions:

- Network management (server missing, duplication of IP address, etc.).

- Communication (time out on the master traffic, etc.).

In factory settings mode, a network management interruption will trigger a resettable drive stop response [External fault com.] (EPF2)

and initiate a freewheel stop.

In factory settings mode, if Ethernet is involved in the command or setpoint, a communication interruption will trigger a resettable drive stop

response [Com. network] (CnF) and initiate a freewheel stop.

The drive’s response in the event of an Ethernet communication interruption can be changed. Refer to the Configuration section beginning

on page 17.

The associated information is:

Ethernet communication interruption type

Network management Communication

Associated drive parameter Code:

Extended communication interruption

code

[External fault com.] (EPF2)

[FDR fault] (Fdrd)

Menu:

[1.9 COMMUNICATION] (COM-)

Submenu:

[ETHERNET] (EtH-)

Code:

[Com. network] (CnF)

[Network fault] (CnF)

Menu:

[1.10 DIAGNOSTICS] (dGt-)

Submenu:

[MORE FAULT INFO] (AFI-)

Parameter [Network fault] (CnF) is used to obtain more detailed information about the origin of the last communication interruption

[Com. network] (CnF). It can be accessed on the graphic display terminal only, in the [1.10 DIAGNOSTICS] (dGt-) menu,

[MORE FAULT INFO] (AFI-) submenu.

Value Description of the values of the [Network fault] (CnF) parameter

0 No communication interruption

1 Modbus TCP time out

10 Network overload

11 Loss of Ethernet carrier

The [FDR fault] (Fdrd) Ethernet communication interruption status is used to obtain more detailed information about the origin of the last

fault [External fault com.] (EPF2). It can be accessed on the graphic display terminal only, in the [1.9 COMMUNICATION] (COM-)

menu, [ETHERNET] (EtH-) submenu.

Value Description of the values of the [FDR fault] (Fdrd) Ethernet communication interruption code parameter

0 No communication interruption

2 The FDR configuration file is not compatible with the drive type (example: the drive is not the correct rating).

3 Error reading the FDR configuration file on the server.

4 Error writing the FDR configuration file to the server.

7 Time-out for receipt of the FDR configuration file from the server.

9 Duplication of IP address (1).

12 FDR configuration file missing.

203 Inconsistent hardware configuration

(1)The Ethernet card detects IP address duplication each time it connects to the network (power-up or connection to the network).

If the card detects that another device is using the same IP address as itself, it abandons the use of the IP address and triggers the

status: [External fault com.] (EPF2).

If a device with an IP address identical to that of the drive is connected to the network during operation, the condition will not be detected

by the drive (it is the new station that has to disconnect).

28

Page 29

9. Diagnostics

9. 5. Troubleshooting the card

The [internal com. link] (ILF) status appears when the following conditions occur:

- Hardware becomes inoperative on the Ethernet card.

- Dialog interruption between the Ethernet card and the drive.

The drive’s response in the event of an [internal com. link] (ILF) status cannot be configured, and the drive stops with a freewheel stop.

This event cannot be reset.

Two diagnostic parameters are used to obtain more detailed information about the origin of the [internal com. link] (ILF) status:

- [Internal link fault 1] (ILF1) if the interruption has occurred on option card no. 1 (installed directly on the drive).

- [Internal link fault 2] (ILF2) if the interruption has occurred on option card no. 2 (installed on option card no. 1).

The Ethernet card can be in position 1 or 2.

The [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters can only be accessed on the graphic display terminal

in the [1.10 DIAGNOSTICS] (dGt-) menu, [MORE FAULT INFO] (AFI-) submenu.

Value Description of the values of the [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters

0 No communication interruption

1 Loss of internal communication with the drive

3 Error in the EEPROM checksum

101 Unknown card

102 Exchange problem on the drive internal bus

103 Time out on the drive internal bus (500 ms)

29

Page 30

10. Software setup

10. 1. List of services supported

• Modbus TCP server, with the support of the “IO Scanning” periodic service.

• IP protocol (version 4).

• TCP and UDP protocol.

• HTTP server for configuring, adjusting and monitoring the drive.

• ICMP client for supporting certain IP services, such as the “ping” command.

• BOOTP client for assignment of an IP address by an address server.

• FTP protocol for file transfer.

• DHCP client for dynamic assignment of IP addresses by an address server.

• FDR service for replacement of a faulty device.

• SNMP protocol for network management.

• ARP protocol for detecting a competing IP address (IP address already in use).

10. 2. TCP connections

Number of simultaneous connections limited to 8 maximum (port 502).

The table below gives the number of connections consumed for each service:

Client Service Number of connections

Controller (PLC)

Web browser

Example:

If the “Altivar Viewer” page is viewed in two different windows of a web browser, on the same PC, four connections are consumed.

If the drive is controlled by a PLC, two connections are consumed by IO Scanning and Modbus messaging, so the total number

of connections consumed is then six.

Two connections are still available, since the maximum number of simultaneous connections is eight.

If control is reserved for a device ([IP Master] (IPP-) configured), 2 connections are reserved for this device, even if it is not present

on the network.

If the maximum number of connections has been exceeded, any new connection attempt will be rejected by the Ethernet card.

IO Scanning 1

Modbus messaging 1

“Home” page 0

“Monitoring\Altivar Viewer” page 2

“Monitoring\Data Viewer” page 1

“Monitoring\Altivar chart” page 1

“Diagnostics\Ethernet Statistics” page 1

“Setup\Security\HTTP password” page 0

“Setup\Security\Data write password” page 0

“Setup\FDR agent” page 1

“Setup\IO Scanner” page 1

30

Page 31

11. Modbus TCP server

11. 1. Modbus TCP frames

Modbus TCP frames consist of a header and a Modbus request.

Header format:

Byte Description Comments

0

Transaction identifier

1 low order

2

Protocol identifier

3 low order

4

Length of data

5 low order

6 Destination identifier (Unit ID)

7 Modbus request function code

The frame header returned by the Altivar 71 server is identical to that of the frame sent by the client.

11. 2. Drive Modbus servers

The destination identifier (Unit ID) is used to access 4 drive Modbus TCP servers:

Unit ID Modbus TCP server Accessible parameters

0 Variable speed drive See the Altivar 71 Communication parameters Manual.

251, AMOC Ethernet card See the “Ethernet card parameters” section.

252, AMOA Controller Inside card 2048 words (%MW0 to %MW2047).

255 IO Scanner See the “IO Scanner” section.

high order

high order

high order

This identifier always equals 0.

Number of bytes in the Modbus request +1. The frame length is always less than

256 bytes, the value of the significant byte therefore equals 0.

31

Page 32

11. Modbus TCP server

11. 3. Ethernet card parameters

Comments:

• Parameters on 2 words are double words (low order in address word n, high order in address word n+1).

• Parameters 60 019 to 60 043 and 60 066 to 60 068 can be accessed in both read and write mode. They can be reset using

a write operation.

• The current IP addresses (60006 to 60017) are the ones displayed on the terminal.

The EEPROM IP addresses (60075 to 60079) are the ones used by the card.

Address Size

(in words)

60 000 6 MAC address R 00-80-F4-80-xx-yy

60 006 4 Current value of IP Address

60 010 4 Current value of Subnet mask

60 014 4 Current value of Gateway Address

60 018 1 Transmission speed

60 019 2 OK transmission counter R/W

60 021 1 Store-and-forward transmission counter R/W

60 022 1 Late collision counter R/W

60 023 1 Buffer (Tx) error counter R/W

60 024 2 OK reception counter R/W

60 026 1 CRC error counter R/W

60 027 1 Frame error counter R/W

60 028 1 Buffer (Rx) error counter R/W

60 029 1 Collision counter R/W

60 030 1 Multiple collision counter R/W

60 031 1 OverRun counter R/W

60 032 2 Sent Modbus TCP message counter R/W IO Scanning messages not included

60 034 2 Received Modbus TCP message counter R/W IO Scanning messages not included

60 036 1 Modbus TCP message error counter R/W IO Scanning messages not included

60 037 2 Sent IO Scanning message counter R/W

60 039 2 Received IO Scanning message counter R/W

60 041 1 IO Scanning message error counter R/W

60 042 1 Active traffic (msg/s) R/W

60 043 1 Max. traffic (msg/s) R/W

60 044 1 Number of active TCP connections R 8 maximum

Description Access Possible values, comments

00: 60 000

80: 60 001

F4: 60 002

80: 60 003

xx: 60 004

yy: 60 005

[IP card] (IPC-)

[IP Mask] (IPM-)

[IP Gate] (IPG-)

[Bit rate] (bdr)

R/W IPC1.IPC2.IPC3.IPC4

R/W IPM1.IPM2.IPM3.IPM4

R/W IPG1.IPG2.IPG3.IPG4

R= 0:

IPC1: 60 006

IPC2: 60 007

IPC3: 60 008

IPC4: 60 009

IPM1: 60 010

IPM2: 60 011

IPM3: 60 012

IPM4: 60 013

IPG1: 60 014

IPG2: 60 015

IPG3: 60 016

IPG4: 60 017

Speed not defined

= 10:

10 Mbps

= 100:

100 Mbps

32

Page 33

11. Modbus TCP server

Address Size

(in words)

60 045 1 Communication monitoring

60 046 1 Drive type R = 2 ATV71

60 047 1 Reserved R = 0

60 048 1 Enable IO Scanner

60 049 1 Reserved R = 0

60 050 4 IP address of Master [IP Master] (IPP-) R/W IPP1.IPP2.IPP3.IPP4

60 054 4 IP address of DHCP-FDR server

60 058 1 Enable FDR service

60 059 1 Select local configuration

60 060 1 Enable FDR file error detection

60 061 1 FDR service command

60 062 1 FDR service state

60 063 1 Ethernet communication interruption

Description Access Possible values, comments

time out [time out] (tOUt)

[IO Scan. activ.] (IOSA)

[IP FDR] (IPF-)

[FDR validation] (FdrU)

[FDR Local Config.] (LCFG)

[FDR Error Mgt.] (FdrF)

[FDR Action] (FDrA)

[FDR state] (FDrE)

[FDR fault] (Fdrd)

R/W Unit: 0.1 s; min. = 5 (0.5 s); max. = 600 (60.0 s)

R/W = 0 [No] (nO) : IO Scanning disabled.

= 1 [Yes] (YES) : IO Scanning enabled.

IPP1 = 60 050

IPP2 = 60 051

IPP3 = 60 052

IPP4 = 60 053

R IPF1.IPF2.IPF3.IPF4

R/W 0 = [No] (nO) : FDR service disabled

R/W 0 = [No] (nO) : The drive configuration is

R/W In the event of a problem with the FDR file (missing or invalid)

R/W 0 =

R0 =

R When an Ethernet communication interruption is present, this

IPF1 = 60 054

IPF2 = 60 055

IPF3 = 60 056

IPF4 = 60 057

1 = [Yes] (YES) : FDR service enabled

1 = [Yes] (YES) : The drive configuration is local

0 = [No] (nO) : The Ethernet card does not trigger

1 = [Yes] (YES) : The Ethernet card triggers an

[IDLE] (IdLE)

20 =

[SAVE] (SAUE)

21 =

[REST] (rESt)

22 =

[DEL] (dEL)

[IDLE] (IdLE)

1 =

[INIT] (INIt)

2 =

[CONF] (CONF)

3 =

[RDY] (rDY)

4 =

[GET] (GEt)

5 =

[SET] (SEt)

6 =

[APP] (APP

7 =

[OPE] (OPE)

8 =

[UCFG] (UCFG)

parameter is used to determine the cause.

The code remains saved after the disappearance of the

condition.

2 = The FDR configuration file is not compatible with the

drive type

(example: the drive is not the correct rating)

3 = Error reading the FDR configuration file on the server

4 = Error writing the FDR configuration file to the server

7 = Time out for receipt of the FDR configuration file from the

server

9 = Duplication of IP address

12 = The FDR configuration file is missing

downloaded from an FDR server

an Ethernet communication

interruption

Ethernet communication

interruption

: No command

: Command: save

: Command: download

: Command: delete

: “Idle”

: Initialization

: Configuration

: Ready

: Downloading the current

configuration

: Saving the current configuration

)

: Writing the FDR server

configuration to the drive

: Operational

: Not configured

33

Page 34

11. Modbus TCP server

Address Size

(in words)

60 064 1 Enable periodic saving

60 065 1 Interval for saving

60 066 1 Number of FDR save

60 067 1 Number of FDR restore

60 068 1 Number of FDR deletions R/W

60 069 1 FDR file checksum R

60 070 5 Reserved R

60 075 4 IP address

60 079 4 Subnet mask

60 083 4 Gateway

60 087 20 Reserved R

60 107 1 Method of assigning IP

60 108 4 Adresse IP serveur

60112 1 E-mail activation R/W Bit 0: Error detected by drive actuation (ETA.3)

60113 1 E-mail status (of the

60114 1 E-mails number

60115 1 Number of errors R/W

60116 1 Last error code R

60117 85 E-mail address of the

60202 85 E-mail address of the

Description Access Possible values, comments

of the FDR service

[FDR autosave]

(FdrS)

the FDR service

[FDR t. autosave]

(Fdrt)

operations

operations

(EEPROM value)

(EEPROM value)

(EEPROM value)

addresses

E-mail

option board)

successfully sent

destination

sender

R/W 0 = [No] (nO) : Periodic saving is disabled

1 = [Yes] (YES) : Periodic saving is enabled

R/W 2 to 9999, unit: min

R/W

R/W

R IPC1.IPC2.IPC3.IPC4

IPC1 = 60 075

IPC2 = 60 076

IPC3 = 60 077

IPC4 = 60 078

R IPM1.IPM2.IPM3.IPM4

IPM1 = 60 079

IPM2 = 60 080

IPM3 = 60 081

IPM4 = 60 082

R IPG1.IPG2.IPG3.IPG4

IPG1 = 60 083

IPG2 = 60 084

IPG3 = 60 085

IPG4 = 60 086

R 0 = Configuration via the display terminal or PowerSuite

1 = Configuration via BOOTP

2 = Configuration via DHCP

R/W

Bit 1: Drive alarm activation (ETA.7)

Bit 2: Ethernet error activation

Bit 3: Controller Inside message activation

R

R/W

R/W

R/W

34

Page 35

11. Modbus TCP server

11. 4. List of Modbus functions supported

Code

(decimal)

3 = 16#03 Read Holding Registers Read N output words 63 words max.

6 = 16#06 Write Single Register Write one output word -

16 = 16#10 Write Multiple Registers Write N output words 61 words max.

23 = 16#17 Read/Write Multiple Registers Read/write N words 20/20 words max.

43 = 16#2B Read Device Identification Identification -

Modbus name Description Size of data

11. 5. “Read Holding Registers” (3) function

This Modbus request is used to read the values of a number (No. of Points) of adjacent words starting at the address indicated (Starting

Address). The values read are restored one after another, at the end of the response (First Point Data

Request format:

Byte Meaning

0 Function Code = 16#03

1 Starting Address Hi

2 Starting Address Lo

3 No. of Points Hi (0)

4 No. of Points Lo (1 - 125)

Response format:

Byte Meaning

0 Function Code = 16#03

1 Byte Count (B = 2 × No. of Points)

2 First Point Data Hi

3 First Point Data Lo

… ………………………

B Last Point Data Hi

B+1 Last Point Data Lo

→ Last Point Data).

Exception response format:

Byte Meaning With the VW3A3310d Ethernet card

0 Function Code = 16#83

01 (Illegal Function)

1 Exception Code

02 (Illegal Data Address)

03 (Illegal Data Value)

04 (Illegal Response Length)

35

Page 36

11. Modbus TCP server

11. 6. “Write Single Register” (6) function

This Modbus request is used to write a given value (Preset Data) to the address supplied (Register Address).

Request format:

Byte Meaning

0 Function Code = 16#06

1 Register Address Hi

2 Register Address Lo

3 Preset Data Hi

4 Preset Data Lo

Response format:

Byte Meaning

0 Function Code = 16#06

1 Register Address Hi

2 Register Address Lo

3 Preset Data Hi

4 Preset Data Lo

Exception response format:

Byte Meaning With the VW3A3310d Ethernet card

0 Function Code = 16#86

01 (Illegal Function)

1 Exception Code

02 (Illegal Data Address)

03 (Illegal Data Value)

04 (Illegal Response Length)

36

Page 37

11. Modbus TCP server

11. 7. “Write Multiple Registers” (16 = 16#10) function

This Modbus request is used to write a number (No. of Registers) of adjacent words starting at a given address (Starting Address).

The values to be written are supplied one after another (First Register Data

Request format:

Byte Meaning

0 Function Code = 16#10

1 Starting Address Hi

2 Starting Address Lo

3 No. of Registers Hi (0)

4 No. of Registers Lo (1 - 100)

5 Byte Count (B = 2 × No. of Registers)

6 First Register Data (Hi)

7 First Register Data (Lo)

… ……………

B+4 Last Register Data (Hi)

B+5 Last Register Data (Lo)

Response format:

Byte Meaning

0 Function Code = 16#10

1 Starting Address Hi

2 Starting Address Lo

3 No. of Registers Hi (0)

4 No. of Registers Lo (1 - 100)

V Last Register Data).

Exception response format:

Byte Meaning With the VW3A3310d Ethernet card

0 Function Code = 16#90

01 (Illegal Function)

1 Exception Code

02 (Illegal Data Address)

03 (Illegal Data Value)

04 (Illegal Response Length)

37

Page 38

11. Modbus TCP server

11. 8. “Read/Write Multiple Registers” (23 = 16#17) function