Page 1

Altivar 71

User's manual

Retain for future use

Modbus/Uni-Telway card

Modbus protocol

VW3 A3 303

Page 2

Contents

1. Before you begin___________________________________________________________________________________________ 3

2. Documentation structure_____________________________________________________________________________________ 4

3. Introduction_______________________________________________________________________________________________ 5

3. 1. Presentation _____________________________________________________________________________________ ____ 5

3. 2. Notation ______________________________________________ ______________________________________________ 5

4. Hardware setup ___________________________________________________________________________________________ 6

4. 1. Receipt _________________________________________________________________________________________ ____ 6

4. 2. Hardware description __________________________________________________________________________________ 6

4. 3. Installing the card in the drive____________________________________________________________________________ 6

4. 4. Switch coding ________________________________________________________________________________________ 7

5. Connecting to the bus__________________________________________________________________ _____________________ 9

5. 1. Wiring recommendations _______________________________________________________________________________ 9

5. 2. Modbus RS485 standard __________________________________________________ _____________________________ 9

5. 3. Connection via RJ45 wiring system ______________________________________________________________________ 10

5. 4. Connection via junction boxes __________________________________________________________________________ 12

6. Configuration ____________________________________________________________________________________________ 14

6. 1. Communication parameters ____________________________________________________________________________ 14

6. 2. Control - Command __________________________________________________________________________________ 15

6. 3. Communication scanner_______________________________________________________________________________ 18

6. 4. Communication faults_________________________________________________________________________________ 19

6. 5. Monitored parameters________________________________ _________________________________________________ 20

7. Diagnostics______________________________________________________________________________________________ 21

7. 1. Checking the address_________________________________________________________________________________ 21

7. 2. LEDs______________________________________________________________________________________________ 21

7. 3. Control - Command __________________________________________________________________________________ 22

7. 4. Communication scanner_______________________________________________________________________________ 23

7. 5. Communication fault__________________________________________________________________________________ 24

7. 6. Card fault __________________________________________________________________________________________ 24

8. Modbus protocol__________________________________________________________________________________________ 25

8. 1. Principle __________________________________________________ _________________________________________ 25

8. 2. Modes_____________________________________________________________________________________________ 26

8. 3. Modbus functions available _______________________________ _____________________________________________ 27

8. 4. Read Holding/Input Registers (3/4) ______________________________________________________________________ 27

8. 5. Write Single Register (6)________________________________________________________________________ _______ 28

8. 6. Diagnostics (8) ______________________________________________________________________________________ 29

8. 7. Get Comm Event Counter (11 = 16#0B) __________________________________________________________________ 30

8. 8. Write Multiple Registers (16 = 16#10) ____________________________________________________________________ 30

8. 9. Read/Write Multiple Registers (23 = 16#17)____________________________________ ____________________________ 31

8. 10. Read Device Identification (43 = 16#2B) _________________________________________ ________________________ 32

8. 11. Communication scanner______________________________________________________________________________ 34

8. 12. Exception responses ________________________________________________________________________________ 37

8. 13. Read non-existent or protected parameters_______________________________________________________________ 38

9. Appendix________________________________________________________________________________________________ 39

9. 1. RS485 standard _____________________________________________________________________________________ 39

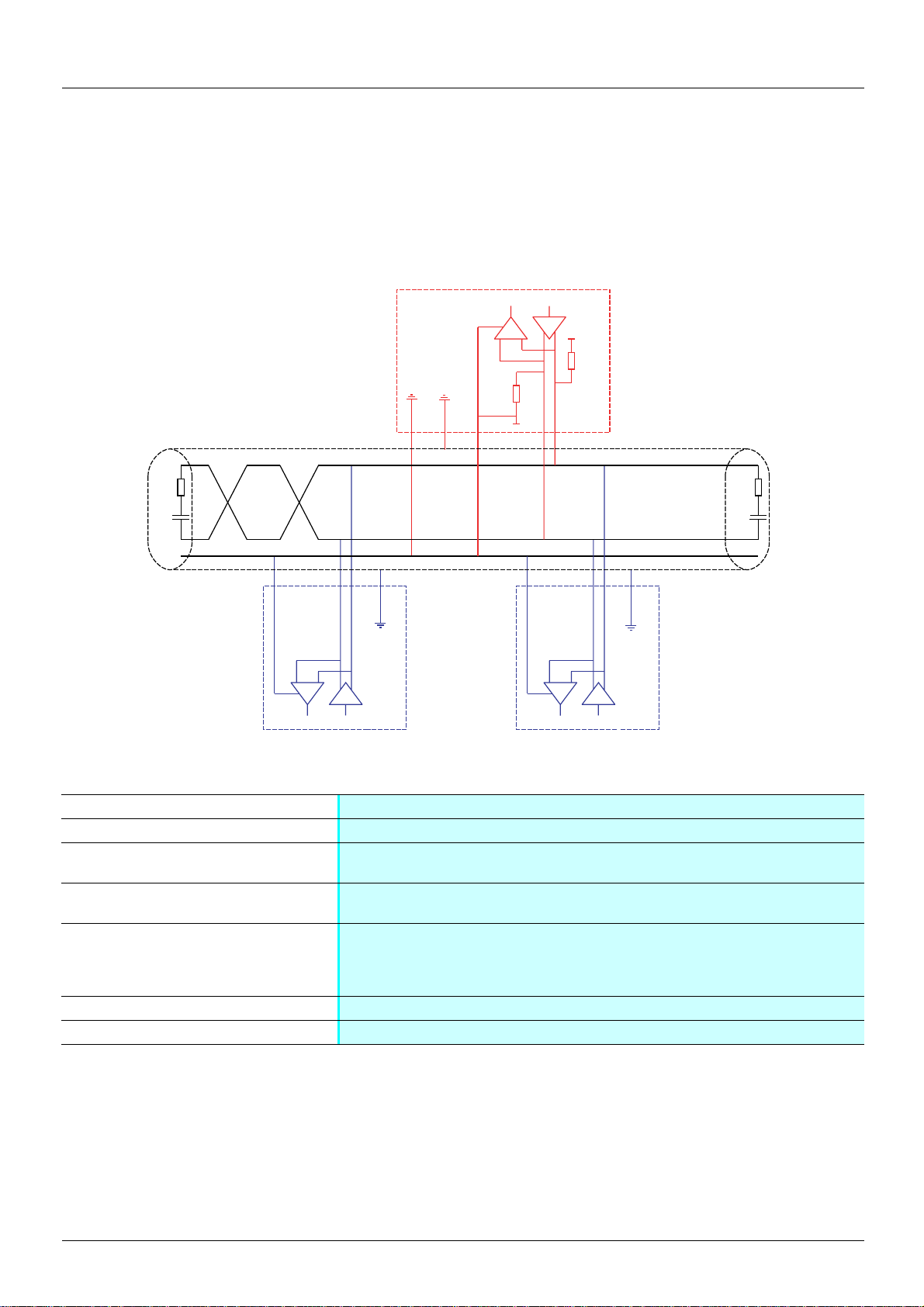

9. 2. Modbus 2-wire standard schematic ______________________________________________________________________ 40

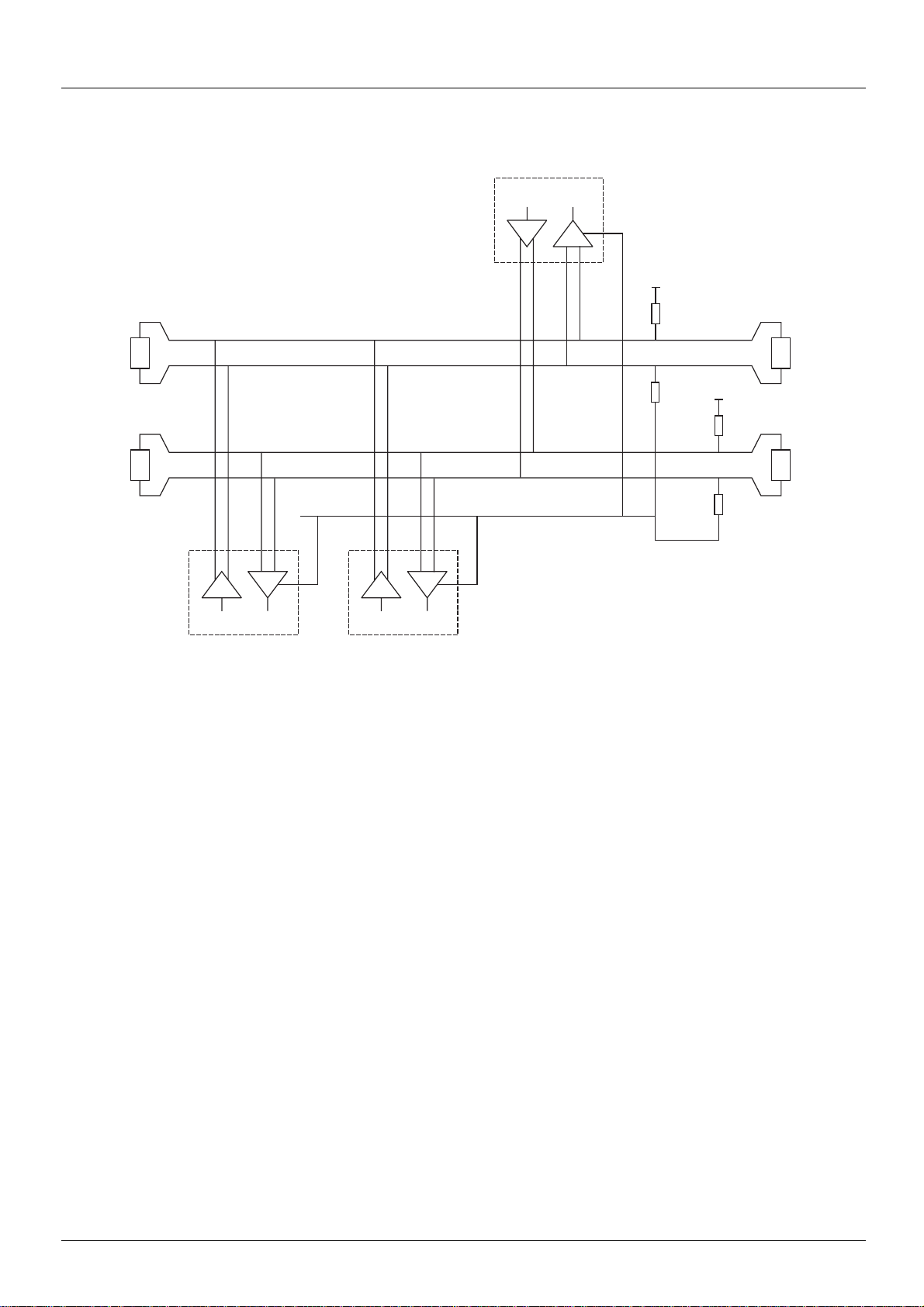

9. 3. Modbus 4-wire standard schematic ______________________________________________________________________ 41

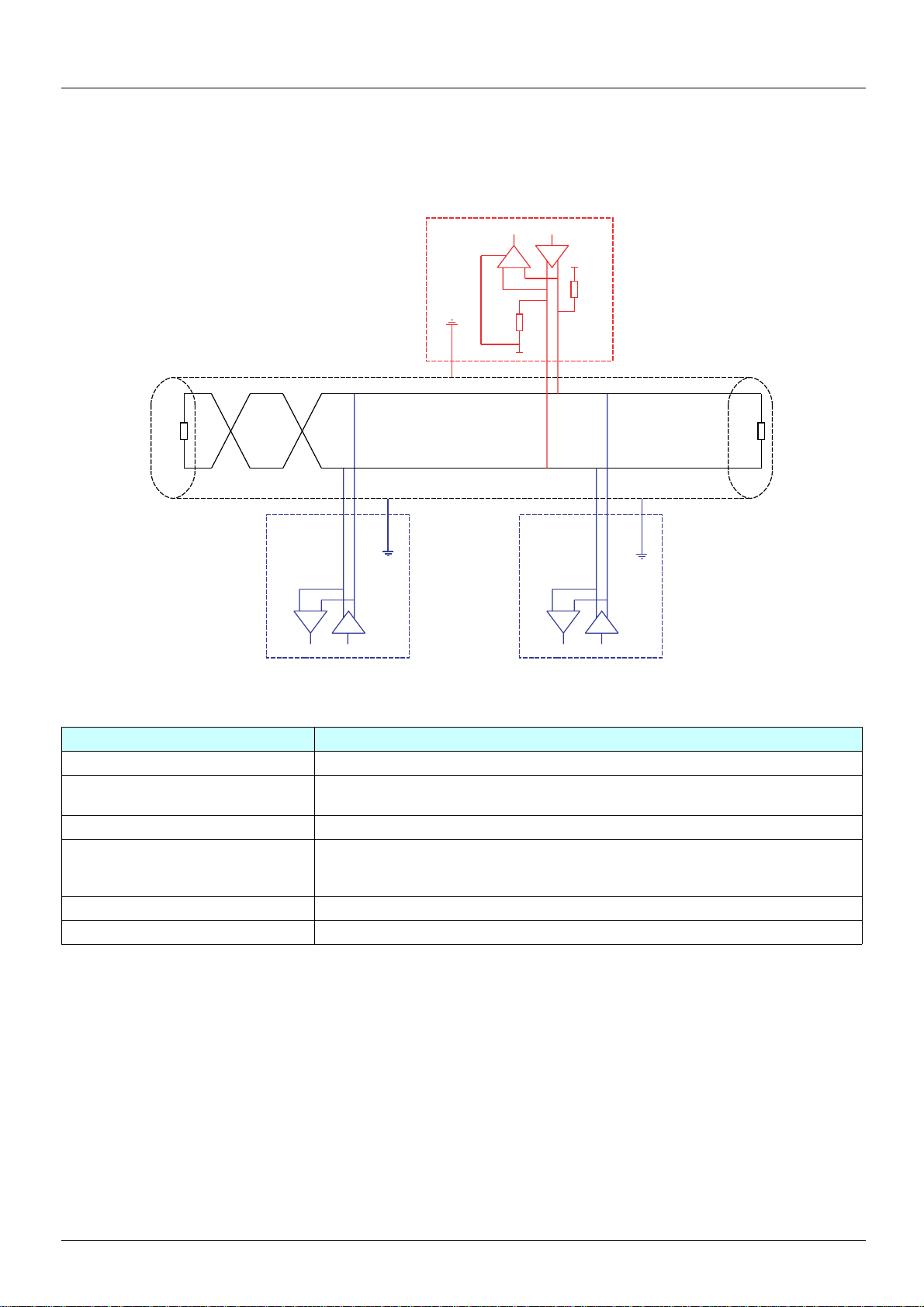

9. 4. Uni-Telway schematic_______________________ __________________________________________________________ 42

9. 5. 2-wire Jbus schematic ________________________________________________________________________________ 43

9. 6. Creating a Modbus bus using non-standard equipment_______________________________________________________ 44

9. 7. RS485 schematic for the card __________________________________________________________________________ 46

9. 8. Card connector pinout ________________________________________________________________________________ 46

While every precaution has been taken in the preparation of this document, Schneider

Electric SA assumes no liability for any omissions or errors it may contain, nor for any

damages resulting from the application or use of the information herein.

The products and options d escribed i n this document may be changed or modi fied at

any time, either from a technical point of view or in the way they are operated. Thei r

description can in no way be considered contractual.

2

Page 3

1. Before you begin

Read and understand these instructions before performing any procedure with thi s drive.

DANGER

HAZARDOUS VOLTAGE

• Read and understand the Installation Ma nual before inst alling or op erating the Al tivar 71 drive. Installati on, adjustme nt,

repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts of this variable speed drive, including the printed circuit board s, operate at the line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage prese nt.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Install and close all covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive

- Disconnect all power.

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect.

- Lock the disconnect in the open position.

• Disconnect all power including external control power that may be present before servicing the drive. WAIT 15

MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement procedure given

in the installation manual to verify that the DC volta ge is less than 45 VDC. The drive LEDs are not accura te indi cators

of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

CAUTION

EQUIPMENT DAMAGE

Do not operate or install any drive that appears damaged.

Failure to follow these instructions can result in equipment damage.

3

Page 4

2. Documentation structure

The following Altivar 71 technical documents are availa ble on the Telemecanique website (www.telemecanique.com) as we ll as on the CDROM supplied with the drive.

b Installation Manual

This manual describes:

• How to assemble the drive

• How to connect the drive

b Programming Manual

This manual describes:

• The functions

• The parameters

• How to use the drive display terminal (integrated display terminal and graphic display terminal)

b Communication Parameters Manual

This manual describes:

• The drive parameters with specific information (addresses, formats, etc.) for use via a bus or communication network

• The operating modes specific to communication (state chart)

• The interaction between communication and local control

b Modbus, CANopen, Ethernet, Profibus, INTERBUS, Uni-Telway, DeviceNet, Modbus Plus and

FIPIO manuals

These manuals describe:

• Connection to the bus or network

• Configuration of the communication-specific parameters via the integrated display terminal or the graphic display terminal

• Diagnostics

• Software setup

• The communication services specific to the protocol

b Altivar 58/58F Migration Manual

This manual describes the differences between the Altivar 71 and the Altivar 58/58F.

It explains how to replace an Altivar 58 or 58F, including how to replace drives communicating on a bus or network.

4

Page 5

3. Introduction

3. 1. Presentation

The communication card (catalog number VW3 A8 303) is used to connect an Altivar 71 drive to a Uni-Telway or Modbus bus.

This manual only describes how to use the Modbus protocol. For Uni-Telway, please refer to the Uni-Telway protocol manual.

The data exchanges permit access to all Altivar 71 functions:

• Configuration

• Adjustment

• Control and command

• Monitoring

• Diagnostics

The card has a female 9-way SUB-D connector for connection to the Modbus bus.

The connection cables and accessories should be ordered separately.

The drive address should be configured using the switches on the card.

The graphic display terminal or the integrated display terminal offer numerous functions for communication diagnosti cs.

Note: The Modbus card supports the following services in addition to those provided by the drive’s integrated ports:

- 2-wire and 4-wire RS485

- Choice of line polarization

- RTU and ASCII modes

- More diagnostic subcodes

- More Modbus functions (04: Read Input Registers and 11: Get Comm Event Counter)

3. 2. Notation

Drive terminal displays

The graphic display terminal menus are shown in square brackets.

Example: [1.9 COMMUNICATION]

The integrated 7-segment display terminal menus are shown in round brackets.

Example: (COM-)

Parameter names displayed on the graphic display terminal are shown in square brackets.

Example: [Fallback speed]

Parameter codes displayed on the integrated 7-segment display terminal are shown in round brackets.

Example: (LFF)

Formats

Hexadecimal values are written as follows: 16#

Binary values are written as follows: 2#

Abbreviations

Hi: High order

Lo: Low order

5

Page 6

4. Hardware setup

4. 1. Receipt

Check that the card catalog number marked on the label is the same as that on the delivery note corresponding to the purchase order.

Remove the option card from its packaging and check that it has not been damaged in transit.

4. 2. Hardware description

LEDs

Female 9-way SUB-D connector

Polarization switches

4. 3. Installing the card in the drive

See the Installation Manual.

Address switches

6

Page 7

4. Hardware setup

4. 4. Switch coding

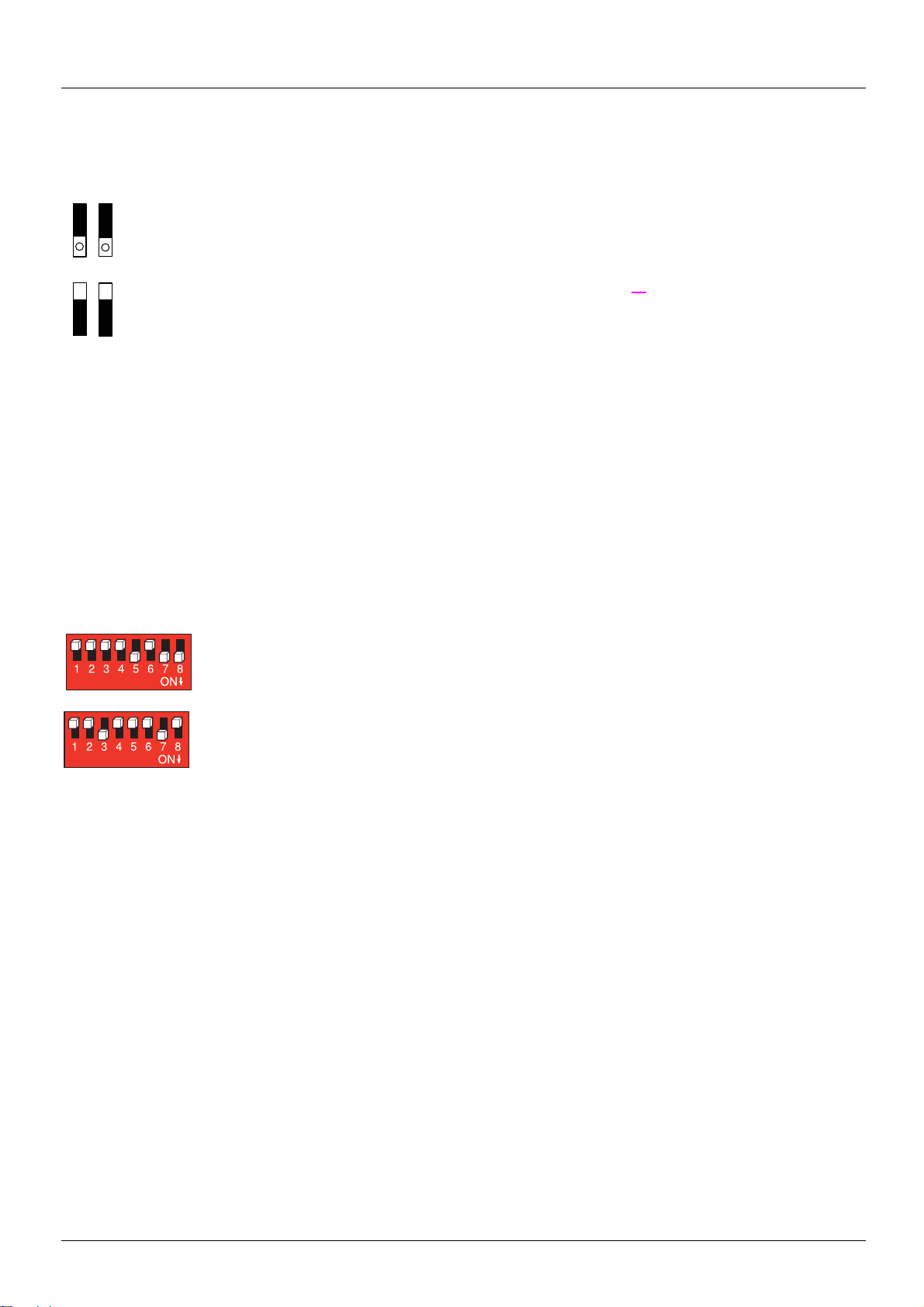

b Choosing polarization

Normal setting for a Modbus bus:

• No polarization at drive level

Special setting (see "Creating a Modbus bus using non-standard equipment" on page 44

Ω RS485 line polarization at drive level

• 4.7 k

b Coding the address

The address switches are used to encode the address (1 to 247) of the drive on the bus.

The switch settings can only be changed when the drive is turned off.

The correspondence between the value and the position of the switch is as follows:

• 0 = OFF = Switch in upper position

• 1 = ON = Switch in lower position

The address is binary-coded.

Examples:

Address 11 = 2#0000 1011

Address 34 = 2#0010 0010

):

7

Page 8

4. Hardware setup

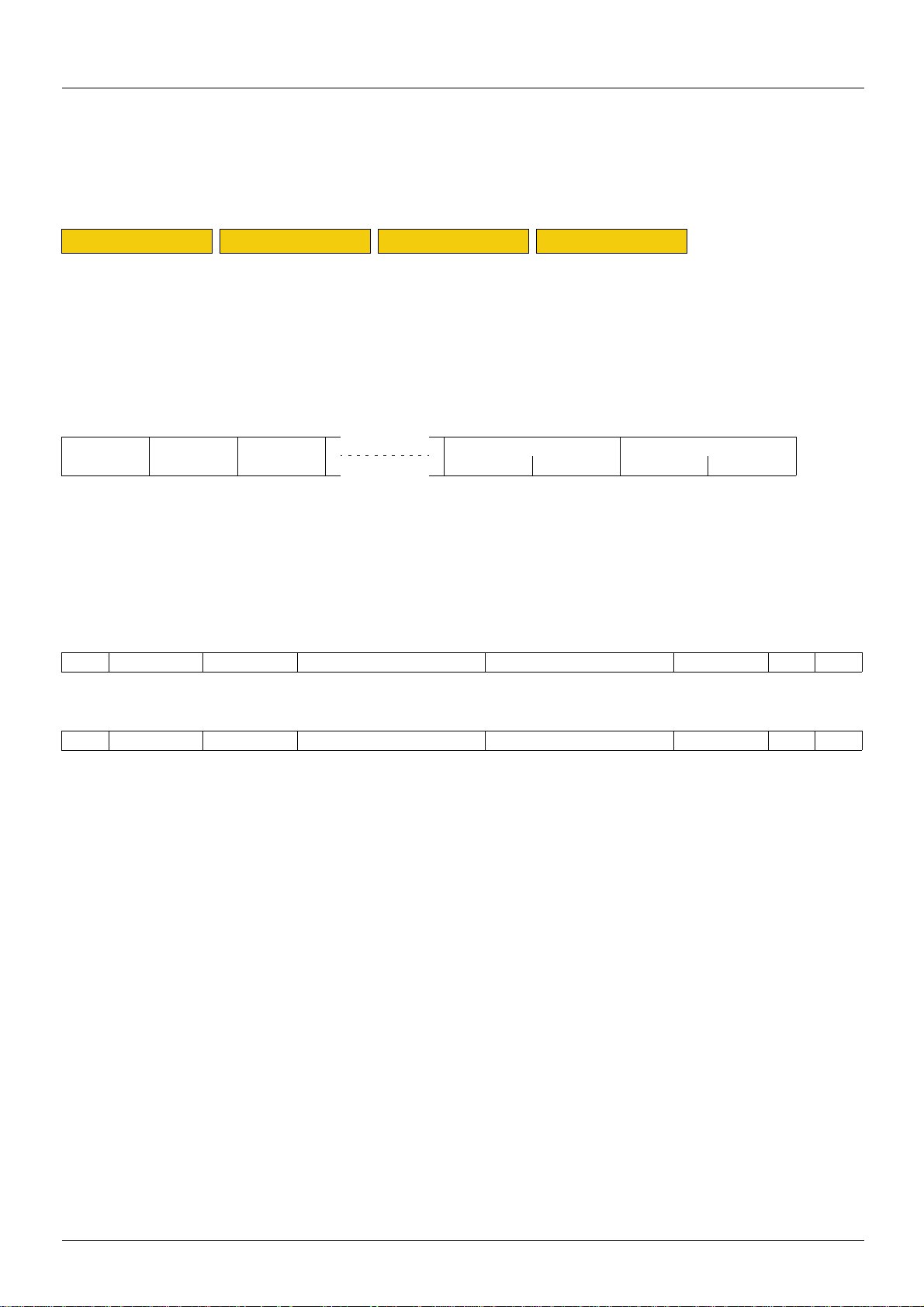

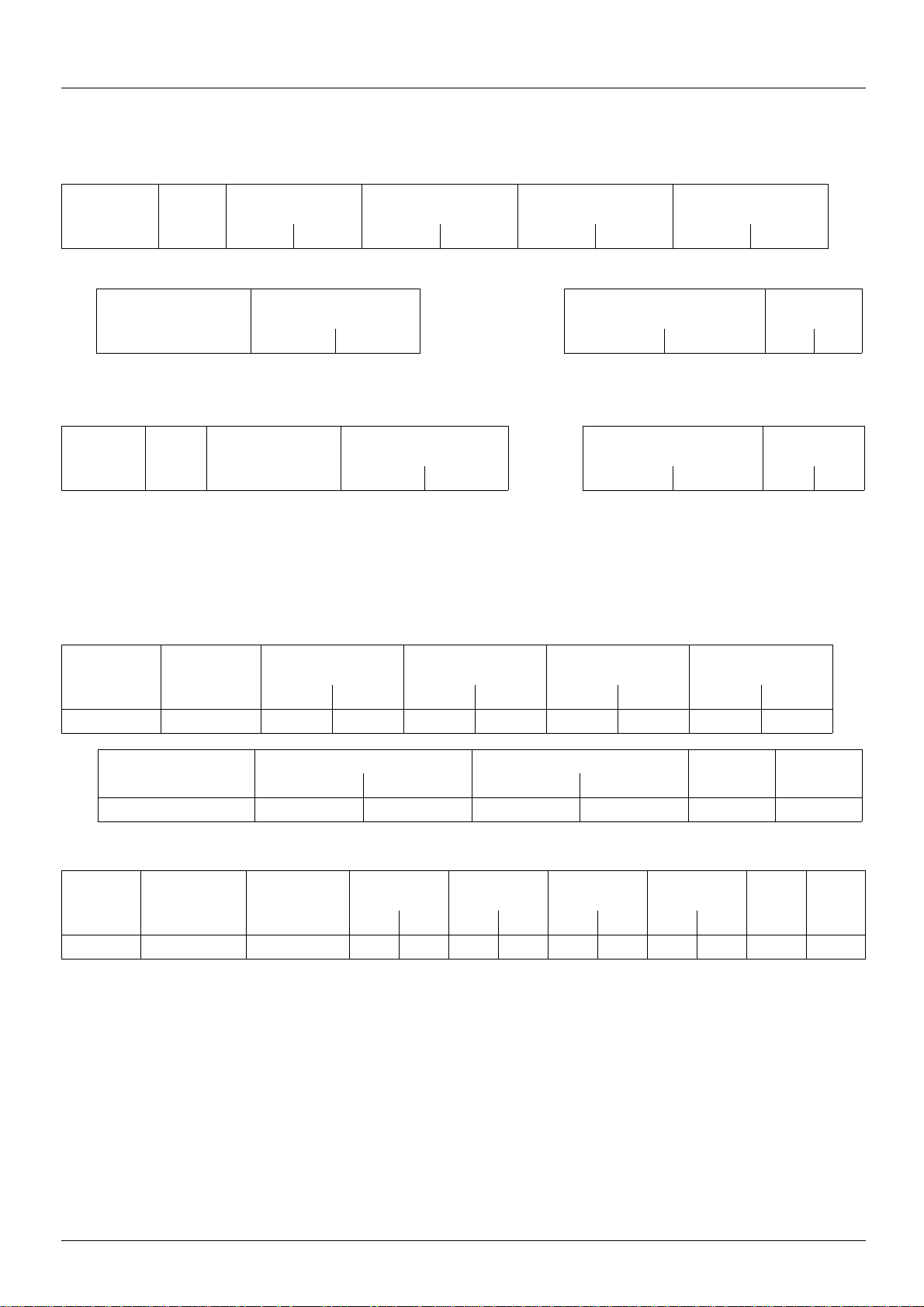

The table below indicates the positions of the 8 switches for all configurable addresses:

Address Switches

1234 5678

0 0000 0000 052 0011 0100 104 0110 1000 156 1001 1100 208 1101 0000

001 0000 0001 053 0011 0101 105 0110 1001 157 1001 1101 209 1101 0001

002 0000 0010 054 0011 0110 106 0110 1010 158 1001 1110 210 1101 0010

003 0000 0011 055 0011 0111 107 0110 1011 159 1001 1111 211 1101 0011

004 0000 0100 056 0011 1000 108 0110 1100 160 1010 0000 212 1101 0100

005 0000 0101 057 0011 1001 109 0110 1101 161 1010 0001 213 1101 0101

006 0000 0110 058 0011 1010 110 0110 1110 162 1010 0010 214 1101 0110

007 0000 0111 059 0011 1011 111 0110 1111 163 1010 0011 215 1101 0111

008 0000 1000 060 0011 1100 112 0111 0000 164 1010 0100 216 1101 1000

009 0000 1001 061 0011 1101 113 0111 0001 165 1010 0101 217 1101 1001

010 0000 1010 062 0011 1110 114 0111 0010 166 1010 0110 218 1101 1010

011 0000 1011 063 0011 1111 115 0111 0011 167 1010 0111 219 1101 1011

012 0000 1100 064 0100 0000 116 0111 0100 168 1010 1000 220 1101 1100

013 0000 1101 065 0100 0001 117 0111 0101 169 1010 1001 221 1101 1101

014 0000 1110 066 0100 0010 118 0111 0110 170 1010 1010 222 1101 1110

015 0000 1111 067 0100 0011 119 0111 0111 171 1010 1011 223 1101 1111

016 0001 0000 068 0100 0100 120 0111 1000 172 1010 1100 224 1110 0000

017 0001 0001 069 0100 0101 121 0111 1001 173 1010 1101 225 1110 0001

018 0001 0010 070 0100 0110 122 0111 1010 174 1010 1110 226 1110 0010

019 0001 0011 071 0100 0111 123 0111 1011 175 1010 1111 227 1110 0011

020 0001 0100 072 0100 1000 124 0111 1100 176 1011 0000 228 1110 0100

021 0001 0101 073 0100 1001 125 0111 1101 177 1011 0001 229 1110 0101

022 0001 0110 074 0100 1010 126 0111 1110 178 1011 0010 230 1110 0110

023 0001 0111 075 0100 1011 127 0111 1111 179 1011 0011 231 1110 0111

024 0001 1000 076 0100 1100 128 1000 0000 180 1011 0100 232 1110 1000

025 0001 1001

026 0001 1010 078 0100 1110 130 1000 0010 182 1011 0110 234 1110 1010

027 0001 1011 079 0100 1111 131 1000 0011 183 1011 0111 235 1110 1011

028 0001 1100 080 0101 0000 132 1000 0100 184 1011 1000 236 1110 1100

029 0001 1101 081 0101 0001 133 1000 0101 185 1011 1001 237 1110 1101

030 0001 1110 082 0101 0010 134 1000 0110 186 1011 1010 238 1110 1110

031 0001 1111 083 0101 0011 135 1000 0111 187 1011 1011 239 1110 1111

032 0010 0000 084 0101 0100 136 1000 1000 188 1011 1100 240 1111 0000

033 0010 0001 085 0101 0101 137 1000 1001 189 1011 1101 241 1111 0001

034 0010 0010 086 0101 0110 138 1000 1010 190 1011 1110 242 1111 0010

035 0010 0011 087 0101 0111 139 1000 1011 191 1011 1111 243 1111 0011

036 0010 0100 088 0101 1000 140 1000 1100 192 1100 0000 244 1111 0100

037 0010 0101 089 0101 1001 141 1000 1101 193 1100 0001 245 1111 0101

038 0010 0110 090 0101 1010 142 1000 1110 194 1100 0010 246 1111 0110

039 0010 0111 091 0101 1011 143 1000 1111 195 1100 0011

040 0010 1000 092 0101 1100 144 1001 0000 196 1100 0100 1111 1000

041 0010 1001 093 0101 1101 145 1001 0001 197 1100 0101 1111 1001

042 0010 1010 094 0101 1110 146 1001 0010 198 1100 0110 1111 1010

043 0010 1011 095 0101 1111 147 1001 0011 199 1100 0111 1111 1011

044 0010 1100 096 0110 0000 148 1001 0100 200 1100 1000 1111 1100

045 0010 1101 097 0110 0001 149 1001 0101 201 1100 1001 1111 1101

046 0010 1110 098 0110 0010 150 1001 0110 202 1100 1010 1111 1110

047 0010 1111 099 0110 0011 151 1001 0111 203 1100 1011 1111 1111

048 0011 0000 100 0110 0100 152 1001 1000 204 1100 1100

049 0011 0001 101 0110 0101 153 1001 1001 205 1100 1101

050 0011 0010 102 0110 0110 154 1001 1010 206 1100 1110

051 0011 0011 103 0110 0111 155 1001 1011 207 1100 1111

Address Switches

1234 5678

077 0100 1101 129 1000 0001 181 1011 0101 233 1110 1001

Address Switches

1234 5678

Address Switches

1234 5678

Address Switches

1234 5678

1111 0111

247

Note: Address 0 is not valid.

8

Page 9

5. Connecting to the bus

5. 1. Wiring recommendations

• Use Telemecanique-approved cables and wiring accessories to ensure good transmission quality (matched impedance, immunity,

shielding connection, etc.).

• Keep the Modbus cable away from the power cables (30 cm minimum).

• Be sure to cross the Modbus cable and the power cables at right angles.

• Whenever possible, connect the bus cable shiel ding to the protective ground, e.g., to th e ground of each device if this ground is connected

to the protective ground.

• Install a line terminator at both ends of the line.

• Ensure the correct line polarization.

• Connect the common polarity ("Common" signal) to the protective ground at one or more points on the bus.

For more information, please refer to the TSX DG KBL E guide: "Electromagnetic compatibility of industrial networks and fieldbuses".

5. 2. Modbus RS485 standard

The characteristics and accessories mentioned in this section ("5. Connecting to the bus") comply with the Modbus standard.

Other non-Modbus-standard RS485 wiring diagrams are possible. Please see the Appendix for further information.

The latest generation of Telemecanique equipment conforms to Modbus (2-wire RS485).

Main characteristics:

Maximum length of bus 1000 m at 19,200 bps

Maximum number of stations 32 stations, i.e., 31 slaves (without repeater)

9

Page 10

5. Connecting to the bus

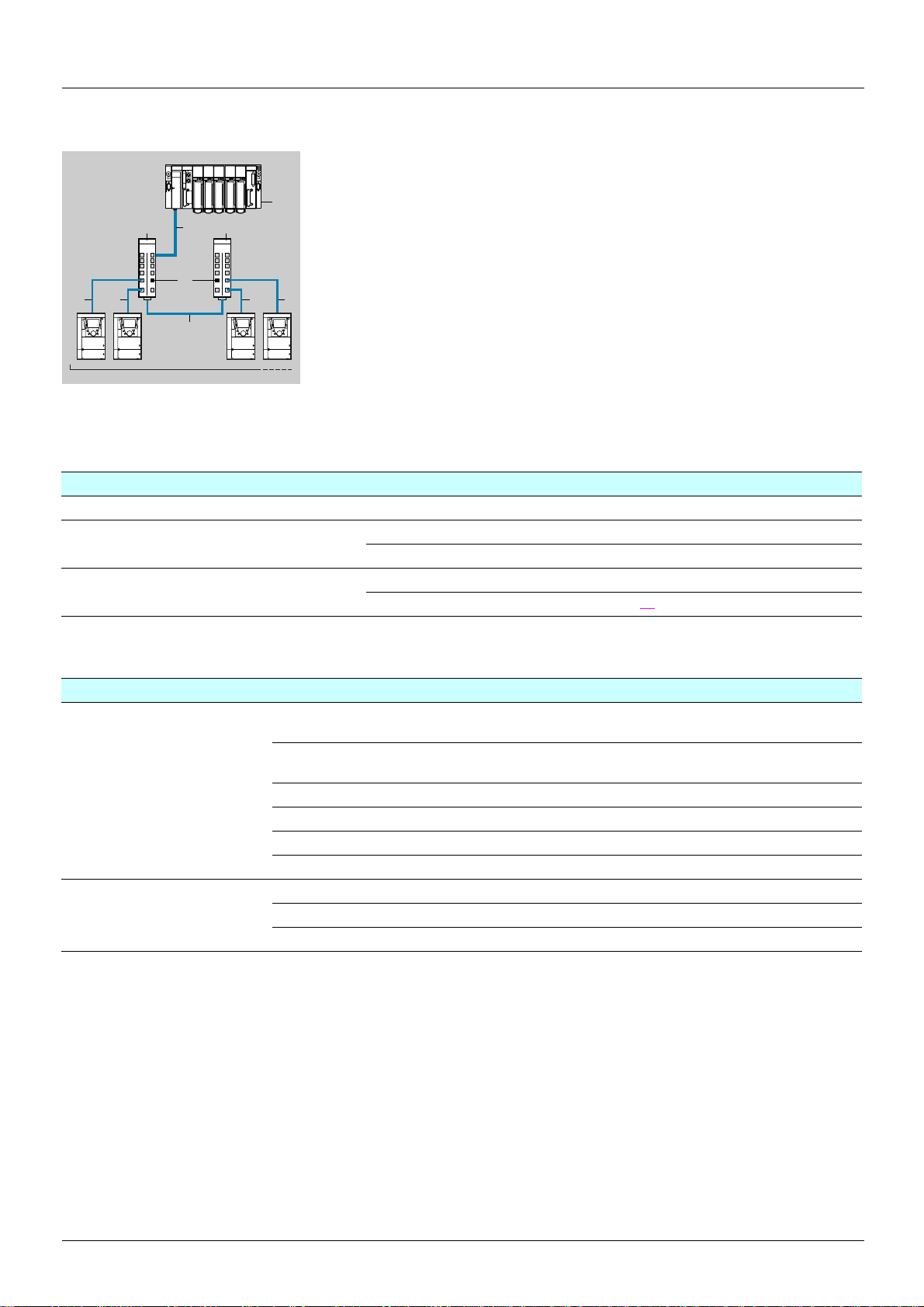

5. 3. Connection via RJ45 wiring system

1. Master (PLC, PC or communication module)

2. Cable depending on the type of master (see table)

3. Splitter block LU9 GC3

4. Drop cable VW3 A58 306 Rpp

5. Line terminators VW3A8306RC

44

6. Modbus cable TSX CSA p00

A TV 71

1

3

44

3

2

5

6

b Connection accessories

Description Ref. Catalog number

Modbus splitter block 10 RJ45 connectors and 1 screw terminal block 3 LU9 GC3

Modbus T-junction boxes With integrated cable (0.3 m) VW3 A8 306 TF03

With integrated cable (1 m) VW3 A8 306 TF10

Line terminators

For RJ45 connector

R = 120 Ω, C = 1 nF 5 VW3 A8 306 RC

R = 150 Ω (specific to "Jbus schematic" page 43

)5 VW3A8306R

b Connection cables

Description Length (m) Connectors Ref. Catalog number

Cables for Modbus bus 1 1 RJ45 connector and

1 male 9-way SUB-D connector

3 1 RJ45 connector and

1 male 9-way SUB-D connector

3 1 RJ45 connector and 1 stripped end VW3 A8 306 D30

0.3 2 RJ45 connectors VW3 A8 306 R03

1 2 RJ45 connectors VW3 A8 306 R10

3 2 RJ45 connectors VW3 A8 306 R30

RS485 double shielded twisted

pair cables

100 Supplied without connector 6 TSXCSA 100

200 Supplied without connector 6 TSXCSA 200

500 Supplied without connector 6 TSXCSA 500

4 VW3 A58 306 R10

4 VW3 A58 306 R30

10

Page 11

5. Connecting to the bus

b Connection cables for the master

Type of master Master interface Description Catalog number

Twido PLC Adaptor or mini-DIN

RS485 interface module

Adaptor or screw

terminal RS485

interface module

TSX Micro PLC Mini-DIN RS485

connector port

PCMCIA card

(TSX SCP114)

TSX Premium PLC TSX SCY 11601 or

TSX SCY 21601

module

(25-way SUB-D socket)

PCMCIA card

(TSX SCP114)

Ethernet bridge

(174 CEV 300 20)

Profibus DP gateway

(LA9P307)

Fipio (LUFP1) or

Profibus DP (LUFP7) or

DeviceNet (LUFP9)

gateway

Serial port PC Male 9-way SUB-D

Screw terminal RS485 3 m cable equipped with an RJ45 connector and stripped at

RJ45 RS485 1 m cable equipped with 2 RJ45 connectors VW3 P07 306 R10

RJ45 RS485 0.3 m cable equipped with 2 RJ45 connectors or

RS232 serial port PC

3 m cable equipped with a mini-DIN connect or and an RJ45

connector

3 m cable equipped with an RJ45 connector and stripped at

the other end

3 m cable equipped with a mini-DIN connect or and an RJ45

connector

Stripped cable TSX SCP CM 4030

Cable equipped with a 25-way SUB-D connector and

stripped at the other end (for connection to the screw

terminals of the LU9GC3 splitter block)

Stripped cable TSX SCP CM 4030

the other end

1 m cable equipped with 2 RJ45 connectors or

3 m cable equipped with 2 RJ45 connectors

RS232/RS485 converter and 3 m cable equipped with an

RJ45 connector and stripped at the other end (for

connection to the screw terminals of the LU9GC3 splitter

block)

TWD XCA RJ030

VW3 A8 306 D30

TWD XCA RJ030

TSX SCY CM 6030

VW3 A8 306 D30

VW3 A8 306 R03 or

VW3 A8 306 R10 or

VW3 A8 306 R30

TSX SCA 72 and

VW3 A8 306 D30

11

Page 12

5. Connecting to the bus

5. 4. Connection via junction boxes

1. Master (PLC, PC or communication module)

2. Modbus cable depending on the type of master (see table)

1

32

44

3. Modbus cable TSX CSAp00

4. Subscriber sockets TSX SCA 62

5. Modbus drop cable VW3A83062

A TV 71

6

6

b Connection accessories

Description Ref. Catalog

number

Subscriber socket

2 female 15-way SUB-D connectors, 2 screw terminals, and an RC line terminator,

to be connected using cable VW3 A8 306 or VW3 A8 306 D30

4 TSX SCA 62

b Connection cables

Description Length (m) Connectors Ref. Catalog

number

Cables for Modbus bus 3 1 9-way SUB-D connector and

1 male 15-way SUB-D connector

for TSX SCA 62

RS485 double shielded twisted pair

cables

100 Supplied without connector 3 TSX CSA 100

200 Supplied without connector 3 TSX CSA 200

500 Supplied without connector 3 TSX CSA 500

6 VW3 A8 306 2

12

Page 13

5. Connecting to the bus

b Connection cables for the master

Type of master Master interface Description Catal og number

Twido PLC Adaptor or screw terminal

RS485 interface module

TSX Micro PLC Mini-DIN RS485

connector port

PCMCIA card (TSX SCP114) Cable equipped with a special connector and

TSX Premium PLC TSX SCY 11601 or

TSX SCY 21601 module

(25-way SUB-D socket)

PCMCIA card (TSX SCP114) Cable equipped with a special connector and

Ethernet bridge

(174 CEV 300 10)

Profibus DP gateway

(LA9P307)

Fipio (LUFP1) or

Profibus DP (LUFP7) or

DeviceNet (LUFP9) gateway

Serial port PC Male 9-way SUB-D RS232

Screw terminal RS485 Modbus cable TSX CSA100 or

RJ45 RS485 3 m cable equipped with an RJ45 connector

RJ45 RS485 3 m cable equipped with an RJ45 connector

serial port PC

Modbus cable TSX CSA100 or

TSX CSA200 or

TSX CSA500

Tap junction TSX P ACC 01

TSX SCP CM 4030

stripped at the other end

Cable equipped with a 25-way SUB-D

connector and stripped at the other end

stripped at the other end

and stripped at the other end

and stripped at the other end

RS232/RS485 converter and

Modbus cable

TSX SCY CM 6030

TSX SCP CM 4030

TSX CSA200 or

TSX CSA500

VW3 A8 306 D30

VW3 A8 306 D30

TSX SCA 72 and

TSX CSA100 or

TSX CSA200 or

TSX CSA500

13

Page 14

6. Configuration

6. 1. Communication parameters

Configure the following parameters in the [1.9 - COMMUNICATION] (COM-) menu, [Uni-Telway/Modbus] (UtL-) submenu:

[Protocol] (PrO), [Bit rate] (bdr) and [Format] (FOr).

These parameters can only be modified when the motor is stopped. Modifications can only be taken into account by the drive following a

power break.

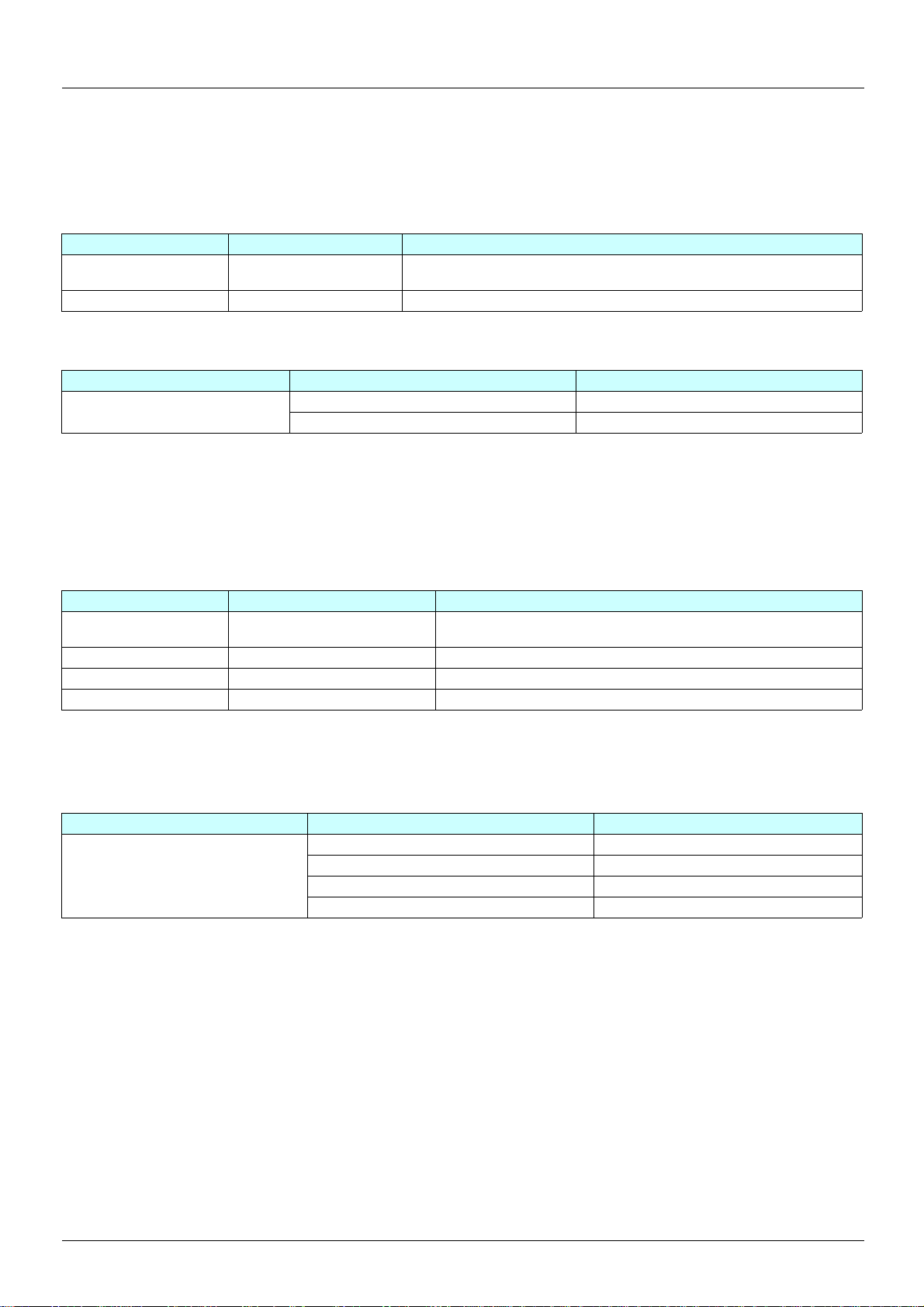

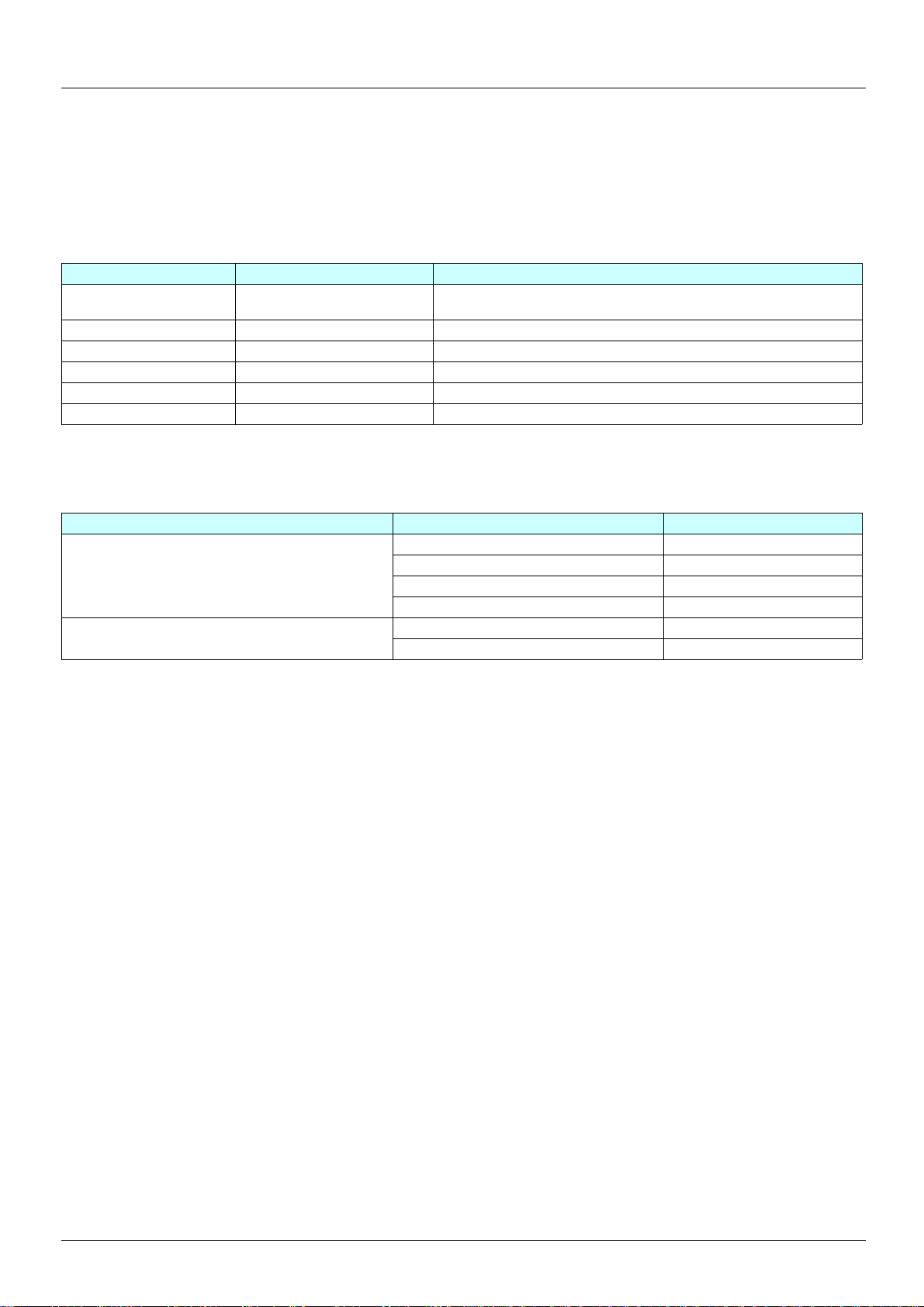

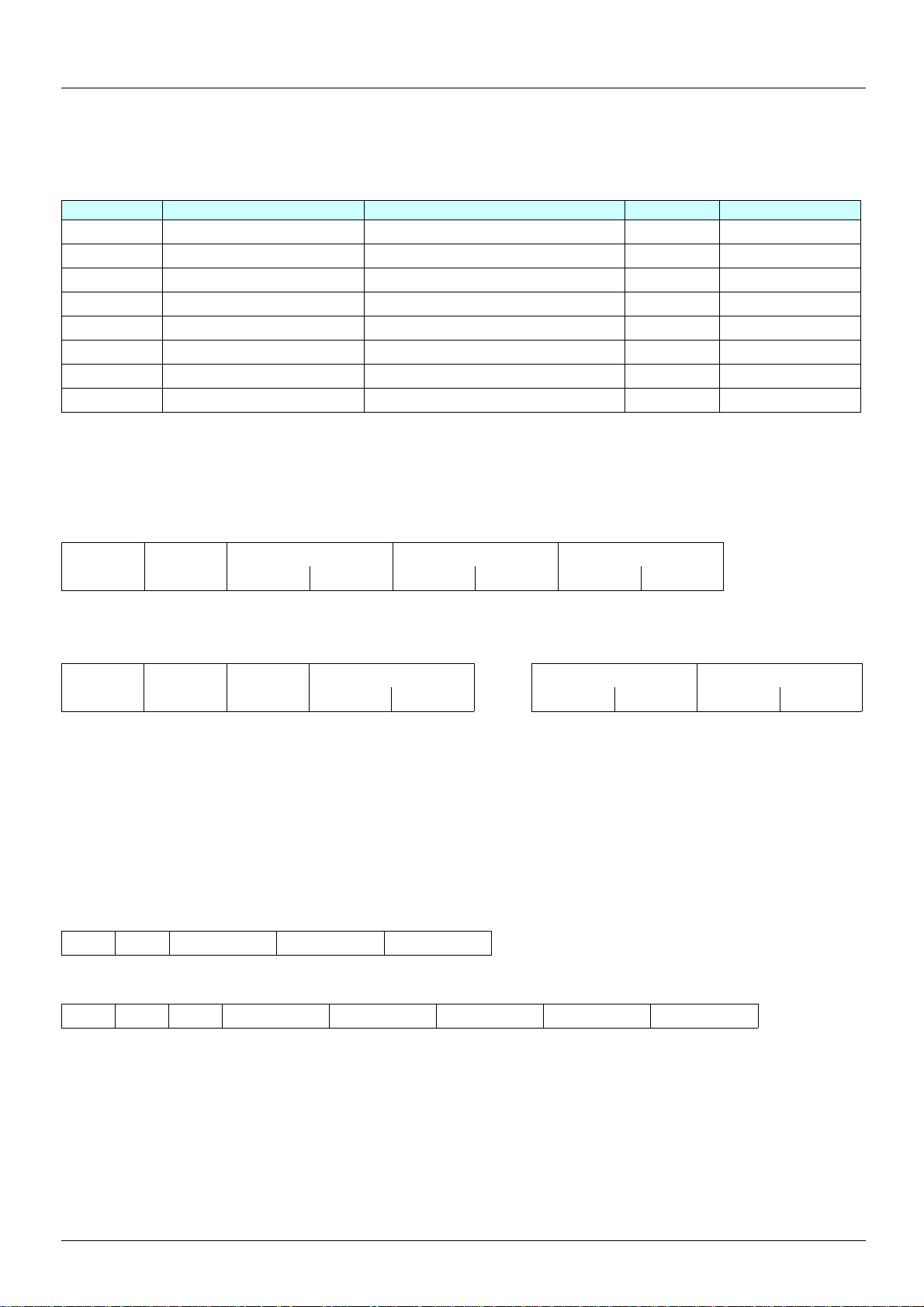

Parameter Possible values Terminal display Default value

[Protocol]

(PrO)

[Address]

(AdrC)

[Bit rate]

(Bdr)

[Format]

(FOr)

Uni-Telway

Modbus/RTU

Modbus/ASCII

0 to 247 [0] (0) to [247] (247) Value taken from the address switches

4800 bps

9600 bps

19,200 bps

In RTU mode only:

8 data bits, odd parity, 1 stop bit

8 data bits, even parity, 1 stop bit

8 data bits, no parity, 1 stop bit

8 data bits, no parity, 2 stop bits

In RTU and ASCII modes:

7 data bits, odd parity, 1 stop bit

7 data bits, even parity, 1 stop bit

7 data bits, odd parity, 2 stop bits

7 data bits, even parity, 2 stop bits

[Unitelway] (UtE)

[Modbus RTU] (rtU)

[Modbus ASCII] (ASC)

[4800 Bd] (

[9600 Bd] (

[19200 Bd] (

[8-O-1] (8o1)

[8-E-1] (8E1)

[8-N-1] (8n1)

[8-N-2] (8n2)

[7-O-1] (7o1)

[7-E-1] (7E1)

[7-O-2] (7o2)

[7-E-2] (7E2)

48)

96)

19 2)

[Unitelway] (UtE)

[19.2 Kbps] (

[8-O-1] (8o1)

19 2)

14

Page 15

6. Configuration

6. 2. Control - Command

Numerous configurations are possible. For more information, refer to the Programming Manual and th e Parameters Manual.

The following configurations are just some of the possibili ties available.

b Control via Modbus in I/O profile

The command and reference come from Modbus.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile The run command is simply obtained by bit 0 of the control word.

Reference 1 configuration Network card The reference comes from Modbus.

Command 1 configuration Network card The command comes from Modbus.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile]

(CHCF) [I/O profile] (IO)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (Cd1) [Com. card]

(nEt)

b Control via Modbus or the terminals in I/O profile

Both the command and reference come from Modbus or the terminals. Input LI5 at the terminals is used to switch between Modbus and the

terminals.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile The run command is simply obtained by bit 0 of the control word.

Reference 1 configuration Network card Reference 1 comes from Modbus.

Reference 1B configuration Analog input 1 on the termi nals Reference 1B comes from input AI1 on the terminals.

Reference switching Input LI5 Input LI5 switches the reference (1

Command 1 configuration Network card Command 1 comes from Modbus.

Command 2 configuration Terminals Command 2 comes from the terminals.

Command switching Input LI5 Input LI5 switches the command.

Note: Reference 1B is directly connected to the drive reference limit. If switching is performed, the functions that affect the reference

(summing, PID, etc) are inhibited.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[1.7 APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH.]

[Ref.1 channel]

[Cmd channel 1]

[Cmd channel 2] (Cd2) [Terminals] (tEr)

[Cmd switching] (CCS) [LI5] (LI5)

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

(Fr1) [Com. card] (nEt)

(Cd1) [Com. card] (nEt)

↔1B).

15

Page 16

6. Configuration

b Control via Modbus in Drivecom profile

The command and reference come from Modbus.

The command is in Drivecom profile.

Configure the following parameters:

Parameter Value Comment

Profile Drivecom profile not

separate

Reference 1 configuration Network card The command comes from Modbus.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM) (factory setting)

[Ref. 1] (Fr1) [Com. card] (nEt)

b Control via Modbus or the terminals in Drivecom profile

Both the command and reference come from Modbus or the terminals. Input LI5 at the terminals is used to switch between Modbus and the

terminals.

The command is in Drivecom profile.

The run commands are in Drivecom profile, the command and the reference

come from the same channel.

Configure the following parameters:

Parameter Value Comment

Profile Drivecom profile not separate The run commands follow the Drivecom profile, and the command and

Reference 1 configuration Network card Reference 1 comes from Modbus.

Reference 2 configuration Analog input 1 on the terminals Reference 2 comes from input AI1 on the terminals.

Reference switching Input LI5 Input LI5 switches the reference (1

Caution: Reference 2 is directly connected to the drive reference limit. If switching is performed, the functions that affect the reference

(summing, PID, etc) are inhibited.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Ref.2 channel] (Fr2) [Ref. AI1] (AI1)

[Ref. 2 switching] (rFC) [LI5] (LI5)

reference come from the same channel.

↔ 2) and the command.

16

Page 17

6. Configuration

b Control in Drivecom profile via Modbus and reference switching at the terminals

The command comes from Modbus.

The command comes either from Modbus or from the terminals. Input LI5 at the t erminals is used to switch the referenc e between Modbus

and the terminals.

The command is in Drivecom profile.

Configure the following parameters:

Parameter Value Comment

Profile Separate Drivecom profile The run commands follow the Drivecom profile, and the command and

Reference 1 configuration Network card Reference 1 comes from Modbus.

Reference 1B configuration Analog input 1 on the terminals Reference 1B comes from input AI1 on the terminals.

Reference switching Input LI5 Input LI5 switches the reference (1

Command 1 configuration Network card Command 1 comes from Modbus.

Command switching Channel 1 Channel 1 is the command channel.

Note: Reference 1B is directly connected to the drive reference limit. If switching is performed, the functions that affect the reference

(summing, PID, etc) are inhibited.

Configuration via the graphic display terminal or the integrated display terminal:

reference can come from different channels.

↔1B).

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (Cd1) [Com. card] (nEt)

[Cmd switching] (CCS) [ch1 active] (Cd1)

[1.7 APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH.]

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

17

Page 18

6. Configuration

6. 3. Communication scanner

The communication scanner enables all the applicatio n-relevant parameters to be grouped in 2 co nsecutive word tables so that singl e read

and write operations may be performed. It is even possible to perform a si ngle transact ion usi ng the "Rea d/Write Multi ple Re gist ers" (23 =

16#17) function.

The 8 output variables are assigned using the 8 [Scan.Outp address] (nCAp) parameters. They are configured using the graphic display

terminal via the [1.9 - COMMUNICATION] (COM-) menu, [COM. SCANNER OUTPUT] (OCS-) submenu.

The 8 input variables are assigned using the 8 [Scan. INp address] (nMAp) parameters. They are configured using the graphic display

terminal via the [1.9 - COMMUNICATION] (COM-) menu, [COM. SCANNER INPUT] (ICS-) submenu.

Enter the logic address of the parameter (see the Parameters Manual).

If a [Scan.Outp address] (nCAp) or [Scan. INp address] (nMAp) parameter equals zero, the corresponding variable is not used by the

drive.

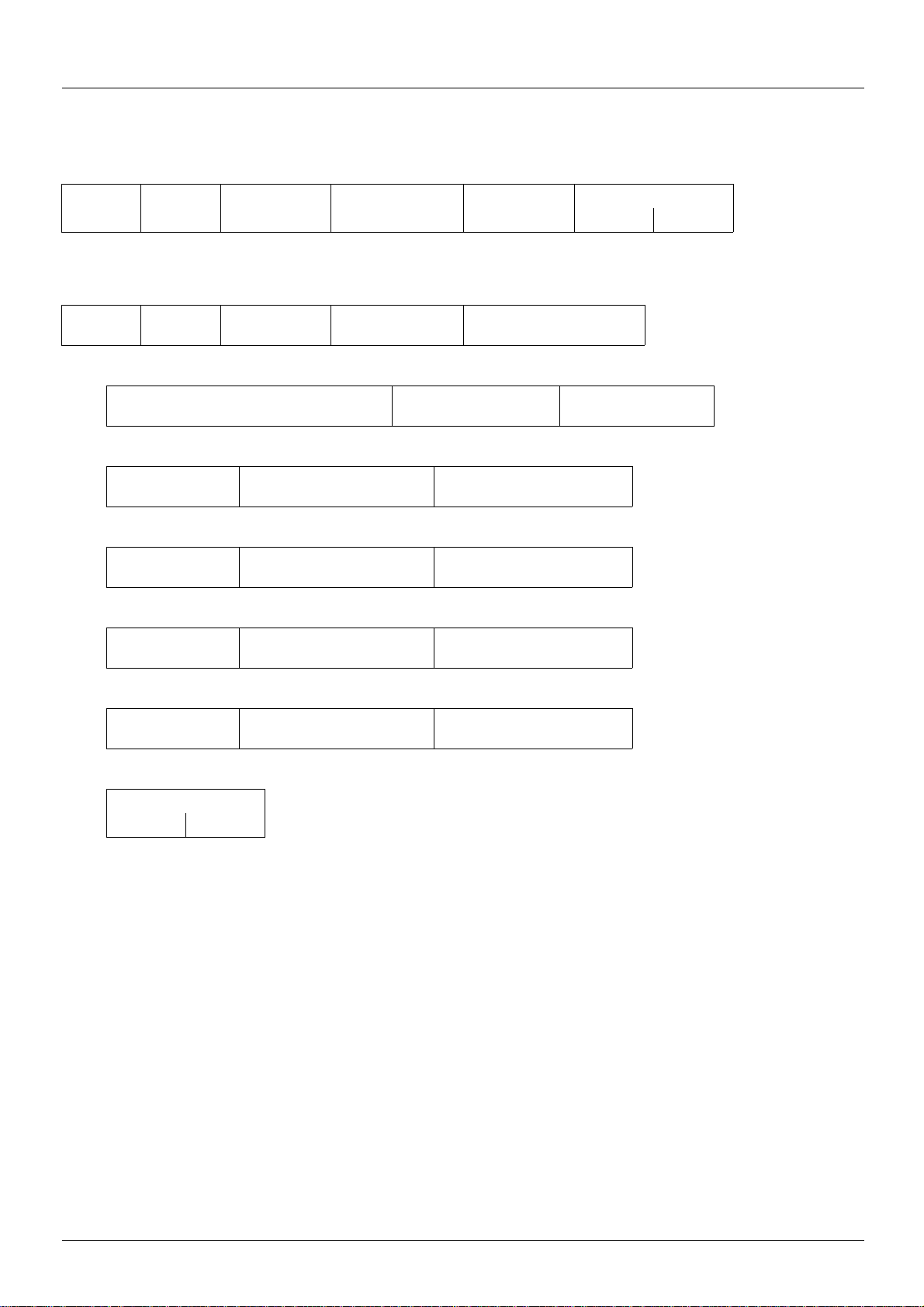

These 16 assignment parameters are described in the tables below:

Configuration parameter name Default assignment of the output variable

[Scan. Out1 address] (nCA1) Control word (CMd)

[Scan. Out2 address] (nCA2) Speed reference (LFrd)

[Scan. Out3 address] (nCA3) Not used

[Scan. Out4 address] (nCA4) Not used

[Scan. Out5 address] (nCA5) Not used

[Scan. Out6 address] (nCA6) Not used

[Scan. Out7 address] (nCA7) Not used

[Scan. Out8 address] (nCA8) Not used

Configuration parameter name Default assignment of the input variable

[Scan. IN1 address] (nMA1) Status word (EtA)

[Scan. IN2 address] (nMA2) Output speed (rFrd)

[Scan. IN3 address] (nMA3) Not used

[Scan. IN4 address] (nMA4) Not used

[Scan. IN5 address] (nMA5) Not used

[Scan. IN6 address] (nMA6) Not used

[Scan. IN7 address] (nMA7) Not used

[Scan. IN8 address] (nMA8) Not used

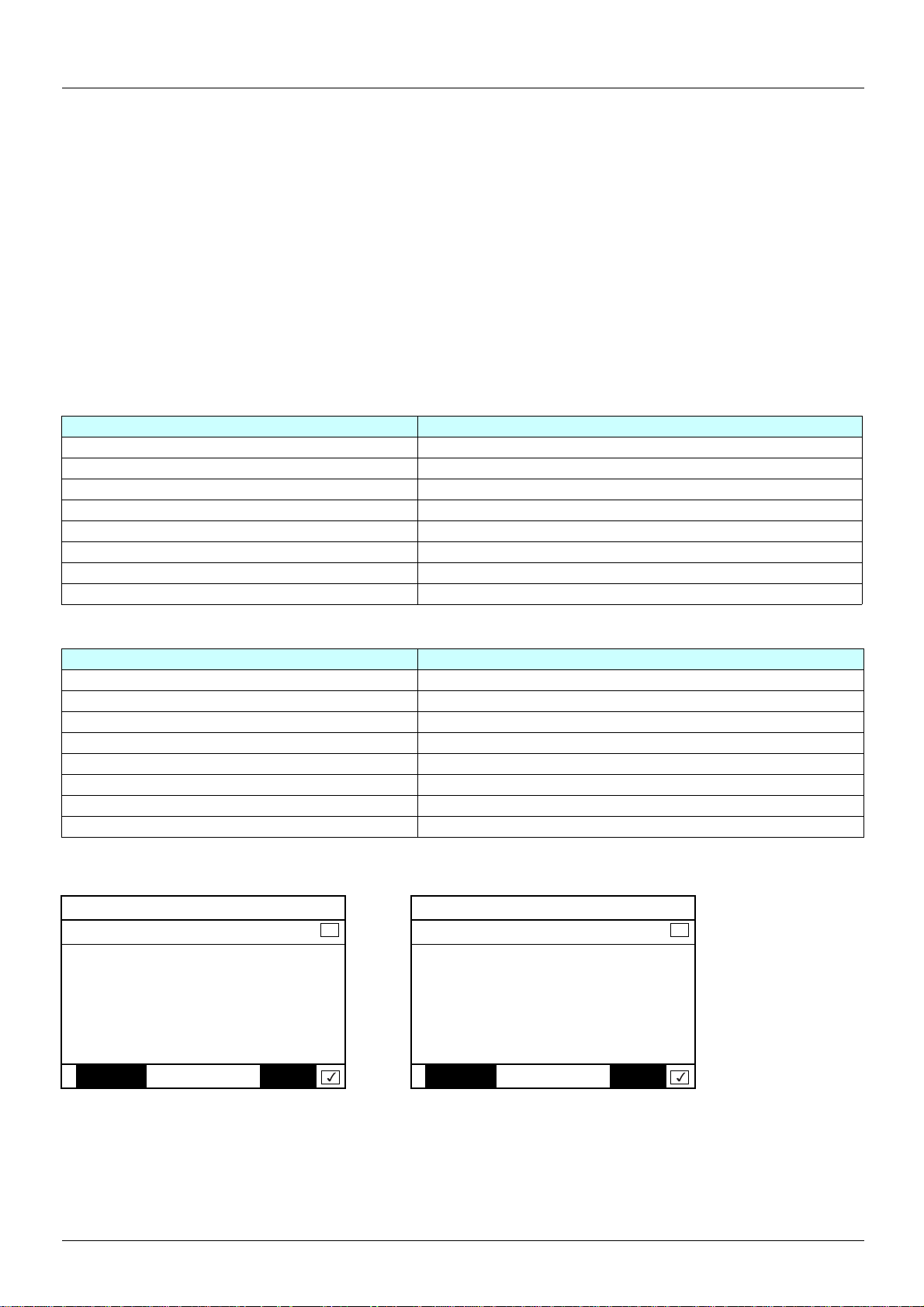

Example of configuration via the graphic display terminal:

RDY NET +0.00Hz 0A RDY NET +0.00Hz 0A

COM. SCANNER INPUT COM. SCANNER OUTPUT

Scan. IN1 address : 3201 Scan. Out1 address : 8501

Scan. IN2 address : 8604 Scan. Out2 address : 8602

Scan. IN3 address : 0 Scan. Out3 address : 0

Scan. IN4 address : 0 Scan. Out4 address : 0

Scan. IN5 address : 0 Scan. Out5 address : 0

Code Quick Code Quick

Scan. IN6 address : 0 Scan. Out6 address : 0

Scan. IN7 address : 0 Scan. Out7 address : 0

Scan. IN8 address : 0 Scan. Out8 address : 0

Note:

Any modification to parameters [Scan.Outp address] (nCAp) or [Scan. INp address] (nMAp) must be made with the motor stopped. The

master PLC program should be updated to take account of this modification.

18

Page 19

6. Configuration

6. 4. Communication faults

A Modbus fault is triggered if the Modbus card does not receive any Modbus requests at its address within a predefined time period (time

out). All Modbus request types are taken into account (read, write, etc.). The time out is fixed at 10 s (non-modifiable).

The response of the drive in the event of a Modbus communication fault can be configured.

RDY NET +0.00Hz 0A

COM. FAULT MANAGEMENT

Configuration can be performed using the graphic display terminal or

integrated display terminal using the [Network fault mgt] (CLL)

parameter in the [1.8 FAULT MANAGEMENT] (FLt-) menu, [COM.

FAULT MANAGEMENT] (CLL-) submenu.

The values of the [Network fault mgt] (CLL) parameter, which trigger a [Com. network] (CnF) drive fault, are:

Value Meaning

[Freewheel] (YES) Freewheel stop (factory setting)

[Ramp stop] (rMP) Stop on ramp

[Fast stop] (FSt) Fast stop

[DC injection]

(dCI) DC injection stop

Network fault mgt : Freewheel

CANopen fault mgt : Freewheel

Modbus fault mgt : Freewheel

Code Quick

The values of the [Network fault mgt] (CLL) parameter, which do not trigger a drive fault, are:

Value Meaning

[Ignore] (nO) Fault ignored

[Per STT] (Stt) Stop according to configuration of [Type of stop]

[fallback spd] (LFF) Switch to f allback speed, maintain ed as long as the faul t is present and the run command is not disabled.

[Spd maint.]

The fallback speed can be configured via the [Fallback speed]

(rLS)

The drive maintains the speed at the time the fault occurred, as long as the fault persists and the run

command has not been removed.

(LFF) parameter in the [1.8 – FAULT MANAGEMENT] (FLt-) menu.

(Stt).

19

Page 20

6. Configuration

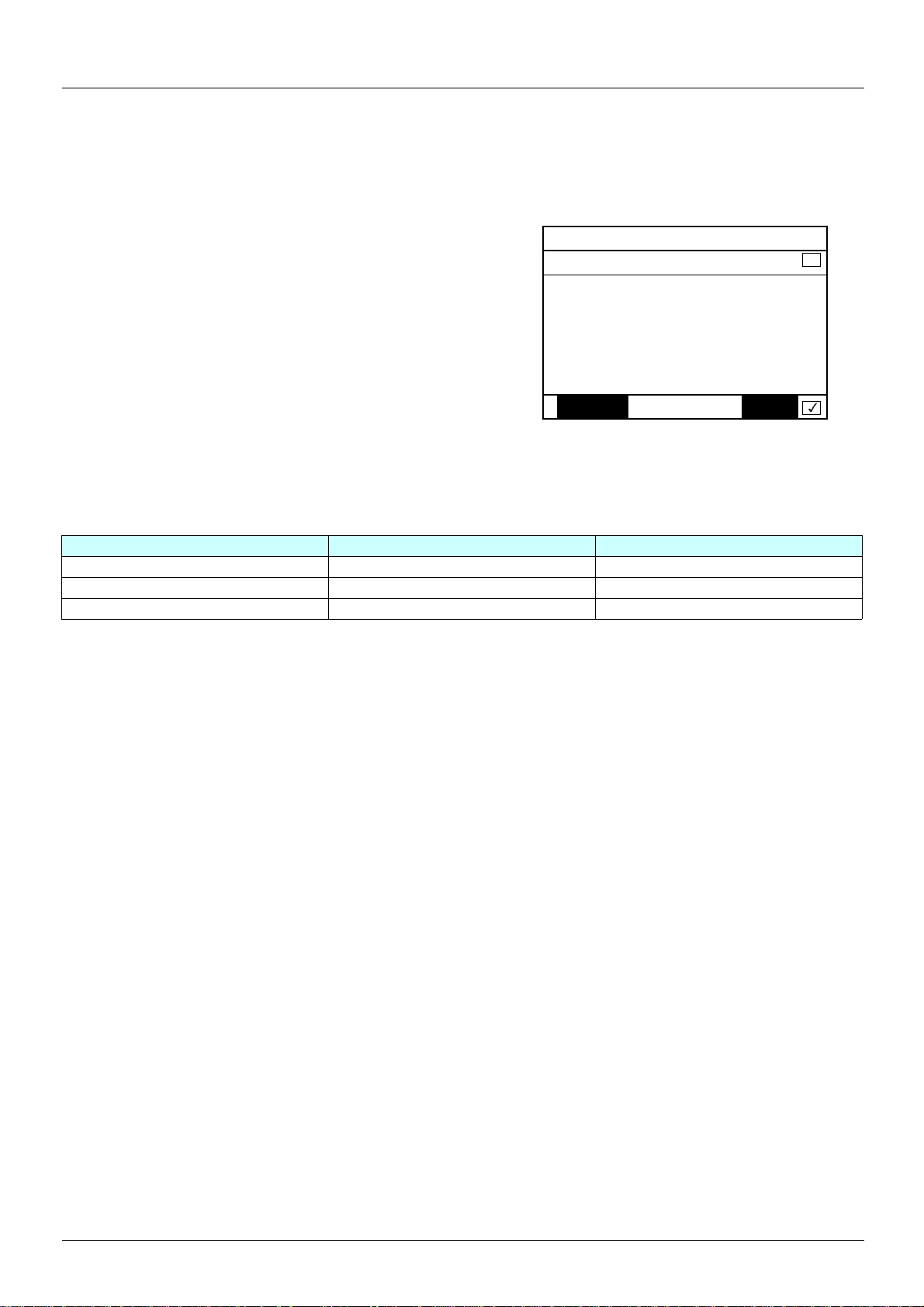

6. 5. Monitored parameters

It is possible to select up to 4 parameters to display their values in the [1.2 - MONITORING] menu ([COMMUNICATION MAP] submenu)

on the graphic display terminal.

The selection is made via the [6 – MONITOR CONFIG.] menu ([6.3 - CONFIG. COMM. MAP] submenu).

Each parameter [Address 1 select] ... [Address 4 selec t] can be used to

choose the logic address of the parameter. Select an address of zero

to disable the function.

In the example given here, the monitored words are:

• Parameter 1 = Motor current (LCr): logic address 3204;

signed decimal format

• Parameter 2 = Motor torque (Otr): logic address 3205; signed

decimal format

• Parameter 3 = Last fault occurred (LFt): logic address 7121;

hexadecimal format

• Disabled parameter: address 0; default format: hexadecimal format

RDY NET +0.00Hz 0A

6.3 CONFIG. COMM. MAP.

Address 1 select : 3204

FORMAT 1 : Signed

Address 2 select : 3205

FORMAT 2 : Signed

Address 3 select : 7121

Code Quick

FORMAT 3 : Hex

Address 4 select : 0

FORMAT 4 : Hex

One of the three display formats below can be assigned to each monitored word:

Format Range Terminal display

Hexadecimal 0000 ... FFFF [Hex]

Signed decimal -32,767 ... 32,767 [Signed]

Unsigned decimal 0 ... 65,535 [Unsigned]

20

Page 21

7. Diagnostics

2.1

2.2

7. 1. Checking the address

On the graphic display terminal or integrated dis play te rmi na l, chec k th e add ress t hat has been code d on the switches usi ng t he [Address]

(AdrC) parameter in the [1.9 COMMUNICATION] (COM-) menu, [Uni-Telway / Modbus] (UtL-) submenu.

This parameter cannot be modified.

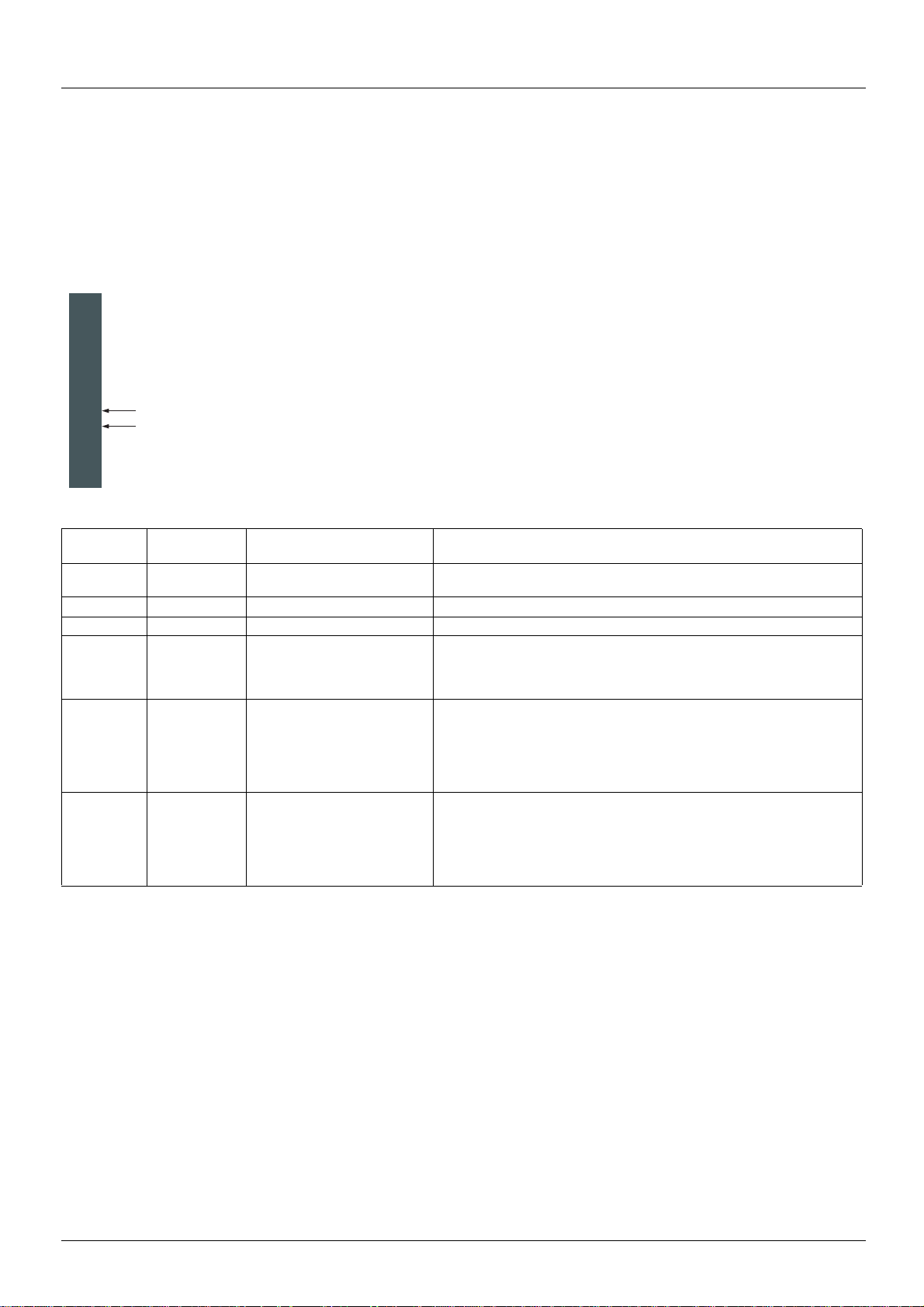

7. 2. LEDs

The Modbus card has 2 LEDs, RUN and ERR, which are visible through the drive cover.

1.1

1.2

1.3

1.4

1.5

RUN (green)

2.3

2.4

2.5

ERR (red)

Green RUN

LED

Off Off

On On Drive starting

On Off Normal operation

Off On

Off Flashing Error on character received

Flashing Off

Red ERR

LED

Meaning Corrective action

Drive not operating

or turned off

Communication fault

on the bus

Card fault

[internal com. link] (ILF)

Check the power supply.

• Check the environment (electromagnetic compatibility).

• Check the wiring.

• Check that the master is communicating within the time out period

(= 10 s).

• Check the environment (electromagnetic compatibility).

• Check the communication parameter configuration (protocol, speed,

format).

• Do not forget that the communication parameter configuration is only

taken into account by the drive following a power break.

• Check that the slave address is unique.

• Check the environment (electromagnetic compatibility).

• Check the card/drive connection.

• Check that only one communication card has been installed.

• Check that no more than two option cards have been installed.

• Replace the communication card.

• Inspect or repair the drive.

21

Page 22

7. Diagnostics

7. 3. Control - Command

On the graphic display terminal only, the [1.2 - MONITORING] menu ([COMMUNICATION MAP] submenu) can be used to display cont rolsignal diagnostic information between the drive and the master:

Active command channel

Value of control word used

Value of frequency reference

(unit 0.1 Hz) used to control the drive

Values of the four monitored words selected by the user.

The address and display format of these parameters

[6 - MONITORING CONFIG.] menu,

[6.3 - COM. MAP CONFIG.]

submenu (see "Configuration" section on page 20

The value of a monitored word is equal to "-----" if:

- Monitoring is not activated

(address equal to 0)

- The parameter is protected

- The parameter is not known (e.g., 3200)

Communication

scanner

Control word from Modbus

[COM. card cmd.] (CMd3)

Frequency reference from Modbus

to control the drive

(hexadecimal format)

Active reference channel

Value of status word

(hexadecimal format)

can be configured in the

Value of input variables

Value of output variables

[Com. card ref.] (LFr3)

RUN NET +50.00Hz 80A

COMMUNICATION MAP

Command Channel : Com. card

Cmd value : 000F

Active ref. channel : Com. card

Frequency ref. : 500.0

Status word : 8627

Code Quick

).

W3204 : 53

W3205 : 725

W7132 : 0000

W0 : ----COM. SCANNER INPUT MAP

COM SCAN OUTPUT MAP

CMD. WORD IMAGE

FREQ. REF. WORD MAP

MODBUS NETWORK DIAG

MODBUS HMI DIAG

CANopen MAP

PROG. CARD SCANNER

Hex

Hz

Hex

Hex

Hex

22

Page 23

7. Diagnostics

7. 4. Communication scanner

On the graphic display terminal, in the [1.2 - MONITORING] (SUP-) menu ([COMMUNICATION MAP] (CMM-) submenu):

- The [COM. SCANNER INPUT MAP] (ISA-) submenu is used to display the value of the 8 communication scanner input variables

[Com Scan Inp val.] (NMp).

- The [COM SCAN OUTPUT MAP] (OSA-) submenu is used to display the value of the 8 communication scanner output variables

[Com Scan Outp val.] (NCp).

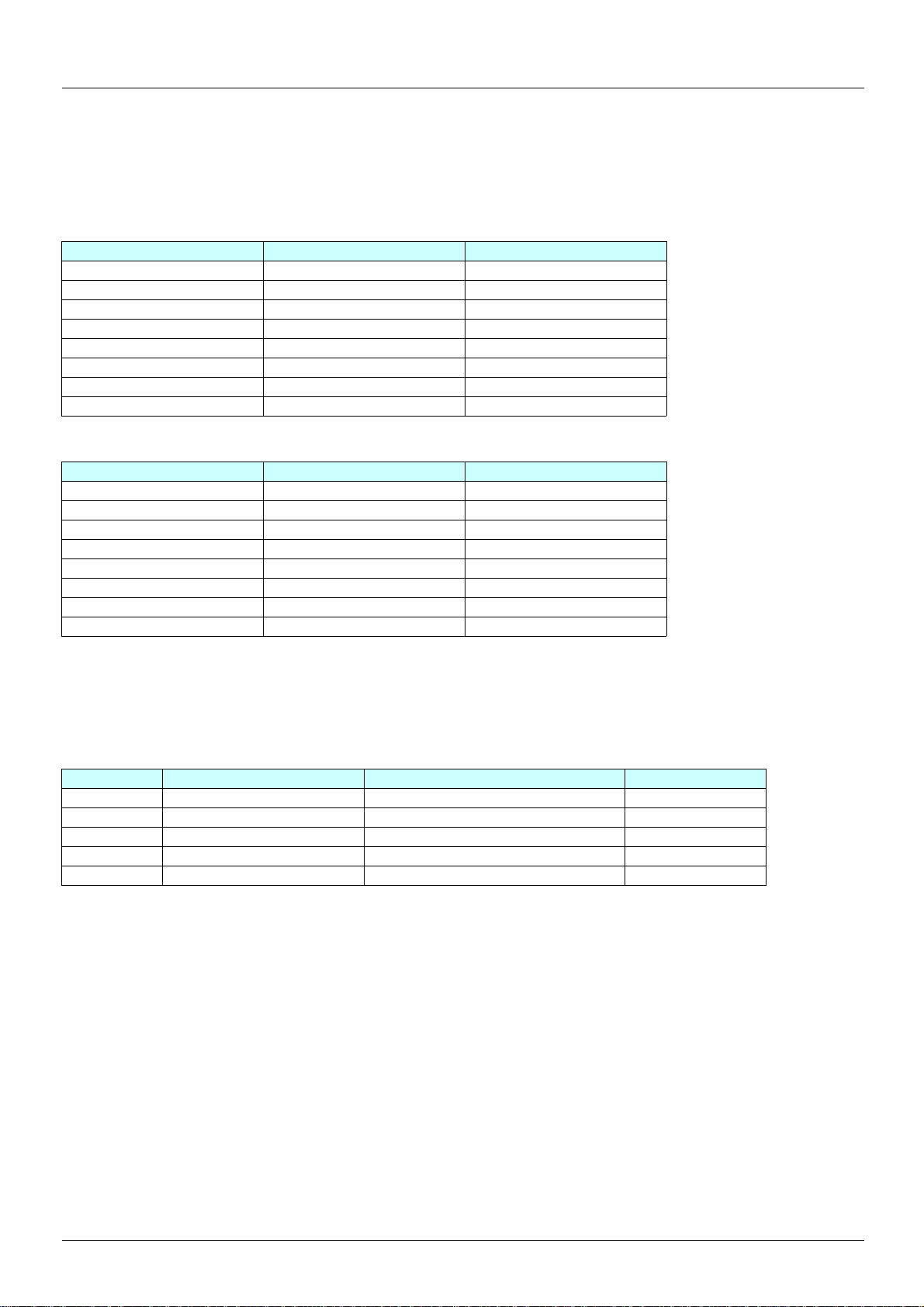

Input variable Scanner parameter Output variable Scanner parameter

No. 1 [Com Scan In1 val.] (NM1) No. 1 [Com Scan Out1 val.] (NC1)

No. 2 [Com Scan In2 val.] (NM2) No. 2 [Com Scan Out2 val.] (NC2)

No. 3 [Com Scan In3 val.] (NM3) No. 3 [Com Scan Out3 val.] (NC3)

No. 4 [Com Scan In4 val.] (NM4) No. 4 [Com Scan Out4 val.] (NC4)

No. 5 [Com Scan In5 val.] (NM5) No. 5 [Com Scan Out5 val.] (NC5)

No. 6 [Com Scan In6 val.] (NM6) No. 6 [Com Scan Out6 val.] (NC6)

No. 7 [Com Scan In7 val.] (NM7) No. 7 [Com Scan Out7 val.] (NC7)

No. 8 [Com Scan In8 val.] (NM8) No. 8 [Com Scan Out8 val.] (NC8)

Configuration of these variables is described in the "Configuration" section.

Example of communication scanner display on the graphic display terminal:

RUN NET +50.00Hz 80A RUN NET +50.00Hz 80A

COM. SCANNER INPUT MAP COM SCAN OUTPUT MAP

Com Scan In1 val. : 34359 Com Scan Out1 val. : 15

Com Scan In2 val. : 600 Com Scan Out2 val. : 598

Com Scan In3 val. : 0 Com Scan Out3 val. : 0

Com Scan In4 val. : 0 Com Scan Out4 val. : 0

Com Scan In5 val. : 0 Com Scan Out5 val. : 0

Code Quick Code Quick

Com Scan In6 val. : 0 Com Scan Out6 val. : 0

Com Scan In7 val. : 0 Com Scan Out7 val. : 0

Com Scan In8 val. : 0 Com Scan Out8 val. : 0

In this example, only the first two variables have been configured (default assignment).

[Com Scan In1 val.] = [34343] Status word = 34359 = 16#8637 V Drivecom "Operation enabled" state,

[Com Scan In2 val.] = [600] Output speed = 600 V 600 rpm

[Com Scan Out1 val.] = [15] Control word = 15 = 16#000F V "Enable operation" (Run) command

[Com Scan Out2 val.] = [598] Speed reference = 600 V 598 rpm

reverse operation, speed reached

23

Page 24

7. Diagnostics

7. 5. Communication fault

Modbus communication faults are indicated by the red ERR LED on the Modbus card .

In the factory configuration, a communication fault will trigger a resettable [Com. network] (CnF) drive fault and initiate a freewheel stop.

It is possible to change the response of the drive in the event of a Modbus communication fault (see the Configuration section).

- [Com. network] (CnF) drive fault (freewheel stop, stop on ramp, fast stop or DC injection braking stop)

- No drive fault (stop, maintain, fallback)

The Parameters Manual contains a detailed description of how to manage communication faults (see the "Communication monitoring"

section).

• Following initialization (power-up), the drive checks that at least one command or referenc e parameter has been wri tten for the first time

by Modbus.

• Then, if a communication fault occurs on Modbus, the drive will react according to the configuration (fault, maintain, fallback, etc.).

7. 6. Card fault

The [internal com. link] (ILF) fault appears when the following serious problems occur:

- Hardware fault on the Modbus card

- Dialog fault between the Modbus card and the drive

The response of the drive in the event of an [internal com. link] (ILF) fault cannot be configured, and the drive trips with a freewhee l stop.

This fault cannot be reset.

Two diagnostic parameters can be used to obtain more detailed information about the origin of the [internal com. link] (ILF) fault:

- [Internal link fault 1] (ILF1) if the fault has occurred on option card no. 1 (installed directly on the drive)

- [Internal link fault 2] (ILF2) if the fault has occurred on option card no. 2 (installed on option card no. 1)

The Modbus card can be in position 1 or 2.

The [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters can only be accessed on the graphic display terminal in

the [1.10 DIAGNOSTICS] (DGt-) menu, [MORE FAULT INFO] (AFI-) submenu.

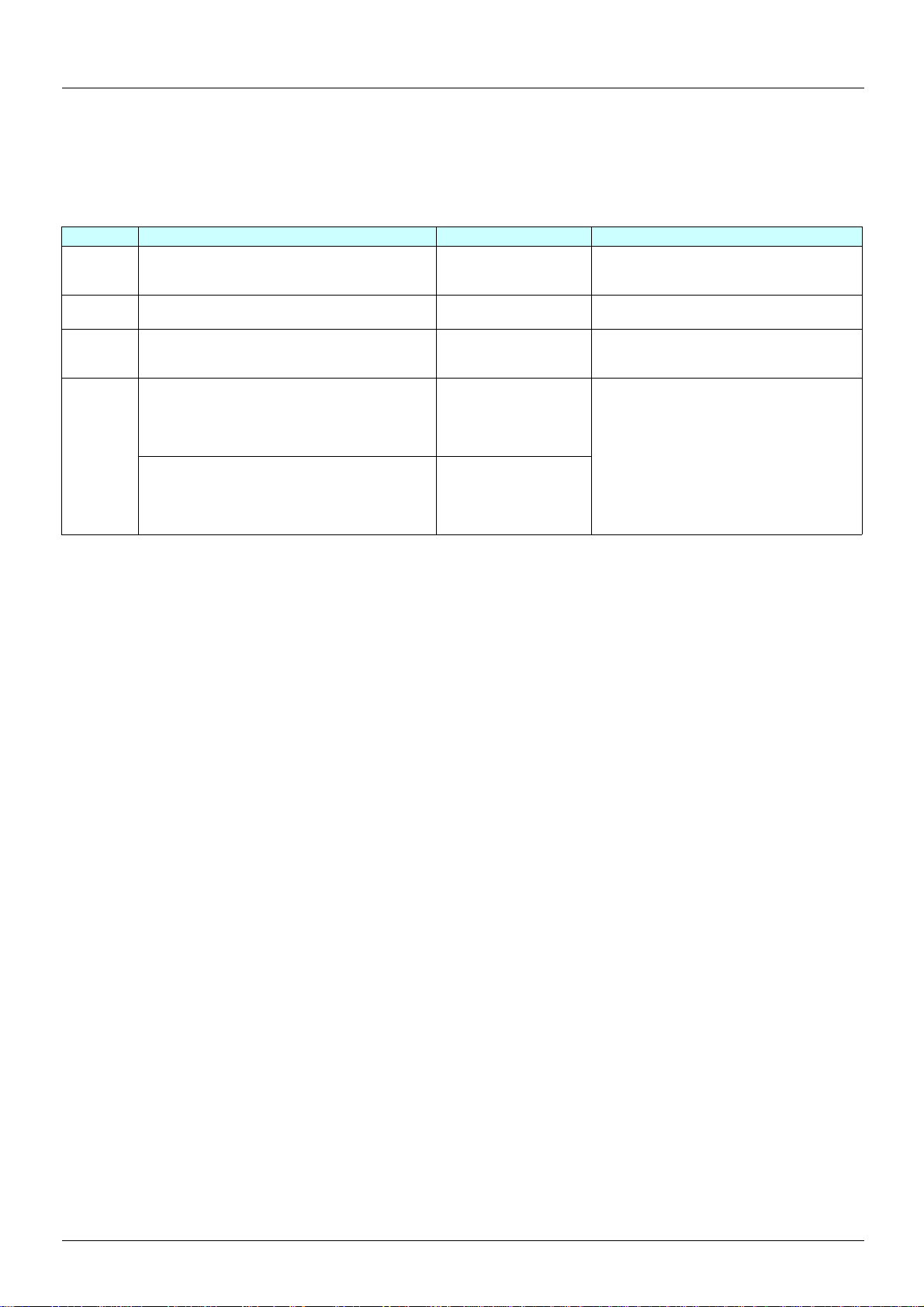

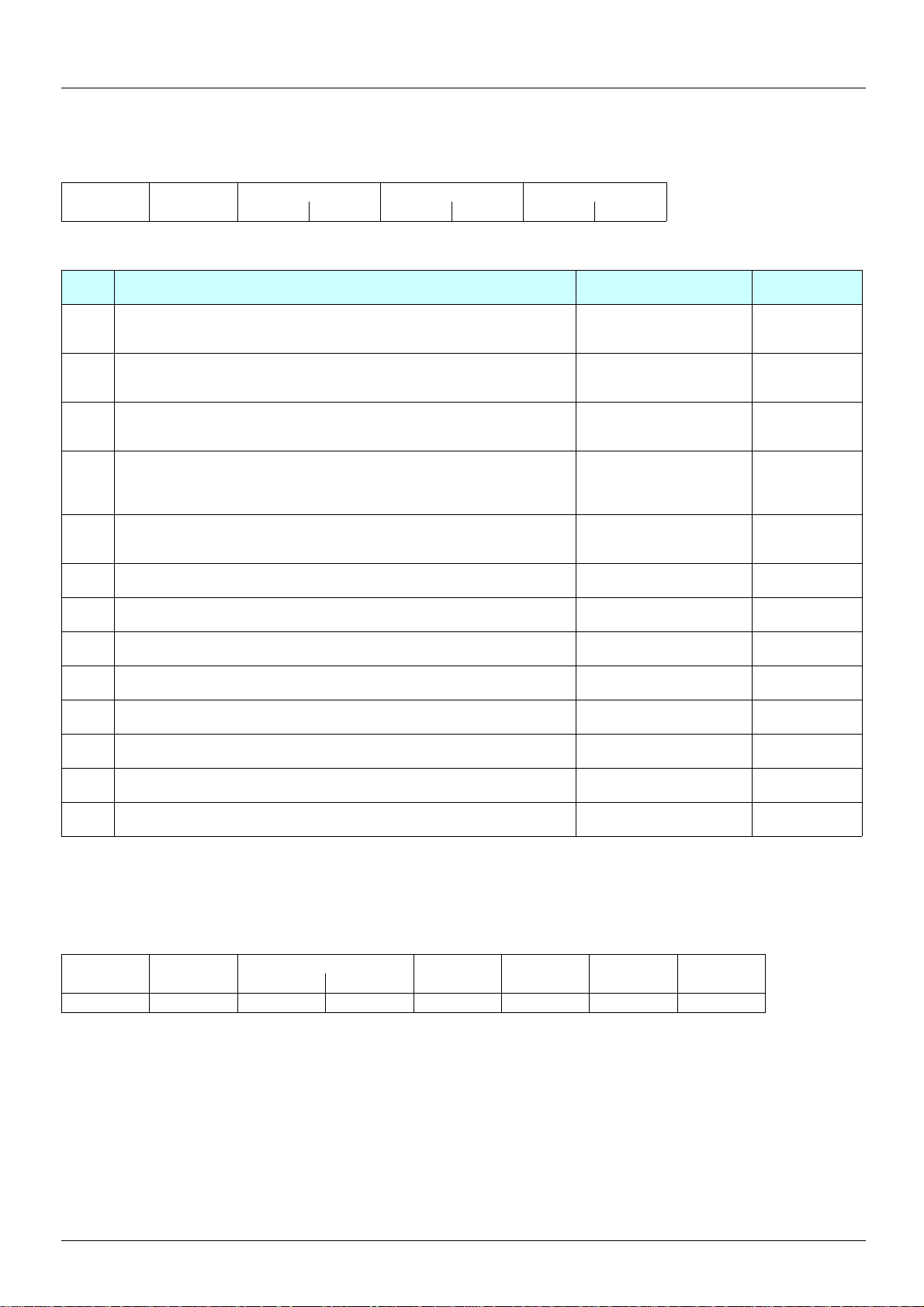

Value Description of the values of the [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters

0 No fault

1 Loss of internal communication with the drive

2 Hardware fault detected

3 Error in the EEPROM checksum

4 Faulty EEPROM

5 Faulty Flash memory

6 Faulty RAM memory

7 Faulty NVRAM memory

8 Faulty analog input

9 Faulty analog output

10 Faulty logic input

11 Faulty logic output

101 Unknown card

102 Exchange problem on the drive internal bus

103 Time out on the drive internal bus (500 ms)

24

Page 25

8. Modbus protocol

8. 1. Principle

The Modbus protocol is a master-slave protocol.

Only one device can transmit on the line at any one time.

The master manages the exchanges and only it can take the initiative.

It interrogates each of the slaves in succession.

Master

No slave can send a message unless it is invited to do so.

In the event of an error during data exchange, the master repeats the question and declares the interrogated

slave absent if no response is received within a given time period.

If a slave does not understand a message, it sends an exception response to the master.

The master may or may not repeat the request.

Slave i

Direct slave-to-slave communications are not possible.

For slave-to-slave communication, the master’s application software must therefore be designed to interrogate one slave and send back

data received to the other slave.

Two types of dialog are possible between master and slaves:

• The master sends a request to a slave and waits for it to respond.

• The master sends a request to all slaves without waiting for them to respond (broadcasting principle).

Note: The Modbus server on the "Controller Inside" card cannot be accessed via the Modbus card.

Slave j

Slave k

25

Page 26

8. Modbus protocol

8. 2. Modes

b RTU mode

The Modbus RTU frame contains no message header byte, nor end of message bytes.

It is defined as follows:

Slave address Function code Data CRC16

The data is transmitted in binary code.

CRC16: Cyclic redundancy check parameter.

The end of the frame is detected on a silence greater than or equal to 3.5 characters.

The format used for the frames in the rest of this document is RTU mode.

b ASCII mode

The structure of the Modbus ASCII frame is as follows:

Header

":"

Header: By default, ":" = 16#3A. Two other characters are possible: "CR" = 16#0D and "LF" = 16#0A.

LRC: The 2's-complement of the modulo 256 sum (in hexadecimal format) of the frame (excluding the header and end characters) before

ASCII coding.

Example: Write a value of 10 to logic address word 9001 (16#2329) on slave 2

Identical request and response:

In hexadecimal format

3A 30 32 30 36 32 33 32 39 30 30 30 41 41 32 0D 0A

In ASCII format

:02062329000AA2CRLF

Slave

address

Function

code

Data LRC End

Hi Lo "CR" "LF"

26

Page 27

8. Modbus protocol

8. 3. Modbus functions available

The following table indicates which Modbus functions are managed by t he Altivar 71 and specifies their limits.

The "read" and "write" functions are defined from the point of view of the master.

Code Modbus name Description Broadcast Size of data

3 = 16#03

4 = 16#04

6 = 16#06

8 = 16#08

11 = 16#0B

16 = 16#10

23 = 16#17

43 = 16#2B

8. 4. Read Holding/Input Registers (3/4)

Functions 3 and 4 access all the drive registers that make no distinction between the "Holding" or "Input" types.

Read Holding Registers Read N output words

Read Input Registers Read N input words

Write Single Register Write one output word

Diagnostics Diagnostics

Get Comm Event Counter Read counter

Write Multiple Registers Write N output words

Read/Write Multiple Registers Read/write N words

Read Device Identification Identification

NO

NO

YES

NO

NO

YES

NO

NO

63 words, max.

63 words, max.

61 words, max.

20/20 words max.

Request:

Slave no. 03/04 No. of first word Number of words CRC16

Hi Lo Hi Lo Lo Hi

1 byte 1 byte 2 bytes 2 bytes 2 bytes

Response:

Slave no. 03/04 Number of

bytes read

1 byte 1 byte 1 byte 2 bytes 2 bytes 2 bytes

Example: Use function 3 to read 4logic address words 3102 to 3105 (16#0C1E to 16#0C21) on slave 2, where:

• SFr = Switching frequency = 4 kHz (logic address 3102 = 16#0028)

• tFr = Maximum output frequency = 60 Hz (logic address 3103 = 16#0258)

• HSP = High speed = 50 Hz (logic address 3104 = 16#01F4)

• LSP = Low speed = 0 Hz (logic address 3105 = 16#0000)

Request:

02 03 0C1E 0004 276C

First word value ------- Last word value CRC16

Hi Lo Hi Lo Lo Hi

Response:

02 03 08 0028 0258 01F4 0000 52B0

Value of: 3102 3103 3104 3105

Parameter code: SFr tFr HSP LSP

27

Page 28

8. Modbus protocol

8. 5. Write Single Register (6)

Request and response:

Slave no. 06 Word number Value of word CRC16

Hi Lo Hi Lo Lo Hi

1 byte 1 byte 2 bytes 2 bytes 2 bytes

Example: Write value 16#000D to logic address word 9001 (16#2329) on slave2 (ACC = 13 s)

Request and response:

02 06 2329 000D 9270

28

Page 29

8. Modbus protocol

8. 6. Diagnostics (8)

Request and response:

Slave no. 08 Sub-code Data CRC16

Hi Lo Hi Lo Hi Lo

1 byte 1 byte 2 bytes 2 bytes 2 bytes

Sub

Function Request

code

00 Echo

This function asks the slave to return the request sent by the master. The size

of the data is limited to 2 bytes.

01 Reinitialize channel

This function is used to reinitialize slave communication and, in particular, to

make it exit listen only mode (LOM).

03 Change ASCII delimiter

In ASCII mode, messages are delimited by the line feed character

(LF = H'0A). This function is used to change this character.

04 Change to LOM mode

This function is used to force a slave to listen only mode (LOM). In this mode,

the slave does not handle messages which are add ressed to it, nor does i t send

any responses, except when the channel is reinitialized.

0A Counter reset

This function resets all the counters responsible for monitoring slave

exchanges.

0B Read the number of correct messages on the line without checksum error 00 00 Value of

0C Read the number of incorrect messages on the line with checksum error 00 00 Value of

0D Read the number of exception responses sent by the slave 00 00 Value of

0E Read the number of messages addressed to the slave excluding

broadcast messages regardless of type

0F Read the number of broadcast messages on the line regardless of type 00 00 Value of

10 Read the number of NAK exception responses

The value read is always 0.

11 Read the number of slave not ready responses

The value read is always 0.

12 Read the number of message s received with character overrun 00 00 Value of

data

XX YY XX YY

16#00 00

or

16#FF 00

XX 00

XX = new delimiter

00 00 00 00

00 00 00 00

00 00 Value of

00 00 00 00

00 00 00 00

Response

16#00 00

16#FF 00

counter

counter

counter

counter

counter

counter

data

or

XX 00

The counters are unsigned words.

Example: Values 16#31 and 16#32 echoed by slave 4

Request and response:

Slave no. Code Subcode Value of

Hi Lo Lo Hi

04 08 00 00 31 32 74 1B

st

byte

1

Value of

2nd byte

CRC CRC

29

Page 30

8. Modbus protocol

8. 7. Get Comm Event Counter (11 = 16#0B)

Question:

Slave no. 0B CRC16

1 byte 1 byte 2 bytes

Response:

Slave no. 0B 00 00 Value of counter CRC16

Hi Lo Lo Hi

1 byte 1 byte 2 bytes 2 bytes 2 bytes

8. 8. Write Multiple Registers (16 = 16#10)

Request:

Slave no. 10 No. of first word Number of words Number of bytes Value of first word ------- CRC16

Hi Lo Hi Lo Hi Lo Lo Hi

1 byte 1 byte 2 bytes 2 bytes 1 byte 2 bytes 2 bytes

Response:

Slave no. 10 No. of first word Number of words CRC16

Hi Lo Hi Lo Lo Hi

1 byte 1 byte 2 bytes 2 bytes 2 bytes

Example: Write values 20 and 30 t o logic address words 9001 and 9002 on sl ave 2 (acceleration time = 20 s and deceler ation time = 30 s)

Request:

Slave no. Request

code

02 10 23 29 00 02 04 00 14 00 1E 73 A4

Response:

Slave no. Response code No. of first word Number of words CRC16

02 10 23 29 00 02 9B B7

No. of first word Number of

words

Hi Lo Hi Lo Hi Lo Hi Lo Lo Hi

Hi Lo Hi Lo Lo Hi

Number of

bytes

Value of first word Value of second

word

CRC16

30

Page 31

8. Modbus protocol

8. 9. Read/Write Multiple Registers (23 = 16#17)

Request:

Slave no. 17 No. of 1

st

word to be

read

Number of words to be

read

No. of 1st word to be

written

Number of words to be

written

---

Hi Lo Hi Lo Hi Lo Hi Lo ---

1byte 1byte 2bytes 2bytes 2bytes 2bytes

--- Number of bytes to be

written

Value of 1

st

word to be

written

Value of last word to be written CRC16

--- Hi Lo ----------------------------- Hi Lo Lo Hi

1 byte 2 bytes 2 bytes 2 bytes

Response:

st

Slave no. 17 Number of bytes

Value of 1

word read Value of last word read CRC16

read

Hi Lo -------------- Hi Lo Lo Hi

1 byte 1 byte 1 byte 2 bytes 2 bytes 2 bytes

Example: This example combines the two examples for functions 3 and 16. With function 23, the line is less busy than with these two

functions. However, the number of words that can be read and written is restricted.

• Write the values 20 (16#14) and 30 (16#1E) respectively to the 2 logic address words 9001 and 9002 on slave 2.

• Read the 4 logic address words 3102 to 3105 on the same slave (values read = 16#0028, 16#0258, 16#01F4, and 16#0000).

Request:

Slave no. Request code No. of 1

word to be

read

No. of words to be

read

No. of 1st word to be

written

No. of words to be

written

---

st

Hi Lo Hi Lo Hi Lo Hi Lo ---

02 17 0C 1E 00 04 23 29 00 02 ---

--- No. of bytes to be written Value of 1

st

word to be written Value of 2nd word to be written CRC CRC

--- HiLoHiLoLoHi

--- 04 00 14 00 1E D2 F5

Response:

Slave no. Response code No. of bytes

read

Value of 1

word read

st

Value of 2

word read

Hi Lo Hi Lo Hi Lo Hi Lo Lo Hi

nd

Value of 3

word read

rd

Value of 4

word read

th

CRC CRC

02 17 08 00 28 02 58 01 F4 00 00 12 F0

31

Page 32

8. Modbus protocol

8. 10. Read Device Identification (43 = 16#2B)

Request:

Slave no. 2B

1 byte 1 byte 1 byte 1 byte 1 byte 2 bytes

Response:

Slave no. 2B

1 byte 1 byte 1 byte 1 byte 1 byte

------- Number of additional frames

------- Id of object no. 1

00+

1 byte 1 byte 13 bytes

------- Id of object no. 2

01

1 byte 1 byte 11 bytes

------- Id of object no. 3

02

1byte 1byte 04bytes

Type of MEI

0E

Type of MEI

0E

00

1byte 1byte 1byte

Length of object no. 1

Length of object no. 2

Length of object no. 3

ReadDeviceId

ReadDeviceId

0D

0B

04

01

01

Object Id

Degree of conformity

Next object Id

00

Value of object no. 1

“Telemecanique”

Value of object no. 2

“ATV71HU15M3”

Value of object no. 3

00

“0201”

Lo Hi

02

Number of objects04-------

CRC16

-------

-------

-------

-------

------- Id of object no. 4

06

1byte 1byte 09bytes

------- CRC16

Lo Hi

1byte 1byte

The total response size given in this example equals 55 bytes.

The response contains the following four objects:

• Object no. 1: Manufacturer name (always "Telemecanique", i.e., 13 bytes).

• Object no. 2: Device catalog number (ASCII string; for example: “ATV71HU15M3”, i.e., 11 bytes).

The length of this object varies accordin g to drive type. Use the “Length of object no. 2” field to det ermine the length.

• Object no. 3: Device version, in "MMmm" format where "MM" represents the determinant and "mm" the subdeterminant (4-byte

ASCII string; for example: "0201" for version 2.1).

• Object no. 4: Device name (ASCII string; for example: "MACHINE 4", i.e., 9 bytes).

The length of this object varies according to the device name assigned to the drive (the latter being configured by

the user): [7. DISPLAY CONFIG.] menu, [7.1 USER PARAMETERS] submenu, [DEVICE NAME] parameter.

This menu can only be accessed in Expert mode.

Maximum size 16 bytes.

Length of object no. 4

09

Value of object no. 4

“MACHINE 4”

-------

32

Page 33

8. Modbus protocol

Negative response specifically related to the identification function:

Slave no. 2B + 80

AB

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte

Error code: 16#00 = No error

16#01 = The "Request code" (16#2B), the "Type of MEI" (16#0E) or the "ReadDeviceId" (16#01) contained in the

16#02 = The "Object Id" (16#00) contained in the request is incorrect.

Example of positive response:

• Address = 2

• Manufacturer name = “Telemecanique”

• Device name = “ATV71HU15M3”

• Device version = “0201”

• Device name = “MACHINE 4”

Request:

Slave no. Request code Type of MEI ReadDeviceld Object Id

02 2B 0E 01 00 34 77

Response:

Type of MEI

0E

request is incorrect.

Error code

00 to 02

CRC16

Lo Hi

CRC

Lo

CRC

Hi

Slave no. Response

02 2B 0E 01 02 00 00 04

----- Id of

object no.

----- ’T’ ’e’ ’l’ ’e’ ’m’ ’e’ ’c’ ’a’ ’n’ ’i’ ’q’ ’u’ ’e’

---- Id of

---- ’A’ ’T’ ’V’ ’7’ ’1’ ’H’ ’U’ ’1’ ’5’ ’M’ ’3’

---- Id of

---- ’0’ ’2’ ’0’ ’1’

---- Id of

---- ’M’ ’A’ ’C’ ’H’ ’I’ ’N’ ’E’ ’ ’ ’4’ Lo Hi

1

00 0D 54 65 6C 65 6D 65 63 61 6E 69 71 75 65

object no.

2

01 0B 41 54 56 37 31 48 55 31 35 4D 33

object no.

02 04 30 32 30 31

object no.

4

06 09 4D 41 43 48 49 4E 45 20 34 6F 50

code

Length of

object no. 1

Length of

object no. 2

Length of

object no. 3

Length of

object no. 4

Type of

MEI

Value of object no. 3

ReadDeviceld

Value of object no. 4 CRC CRC

Degree of

conformity

Value of object no. 1

Value of object no. 2

No. of additional

frames

Next object Id

----

----

Object no.

-------

-------

-----

-----

33

Page 34

8. Modbus protocol

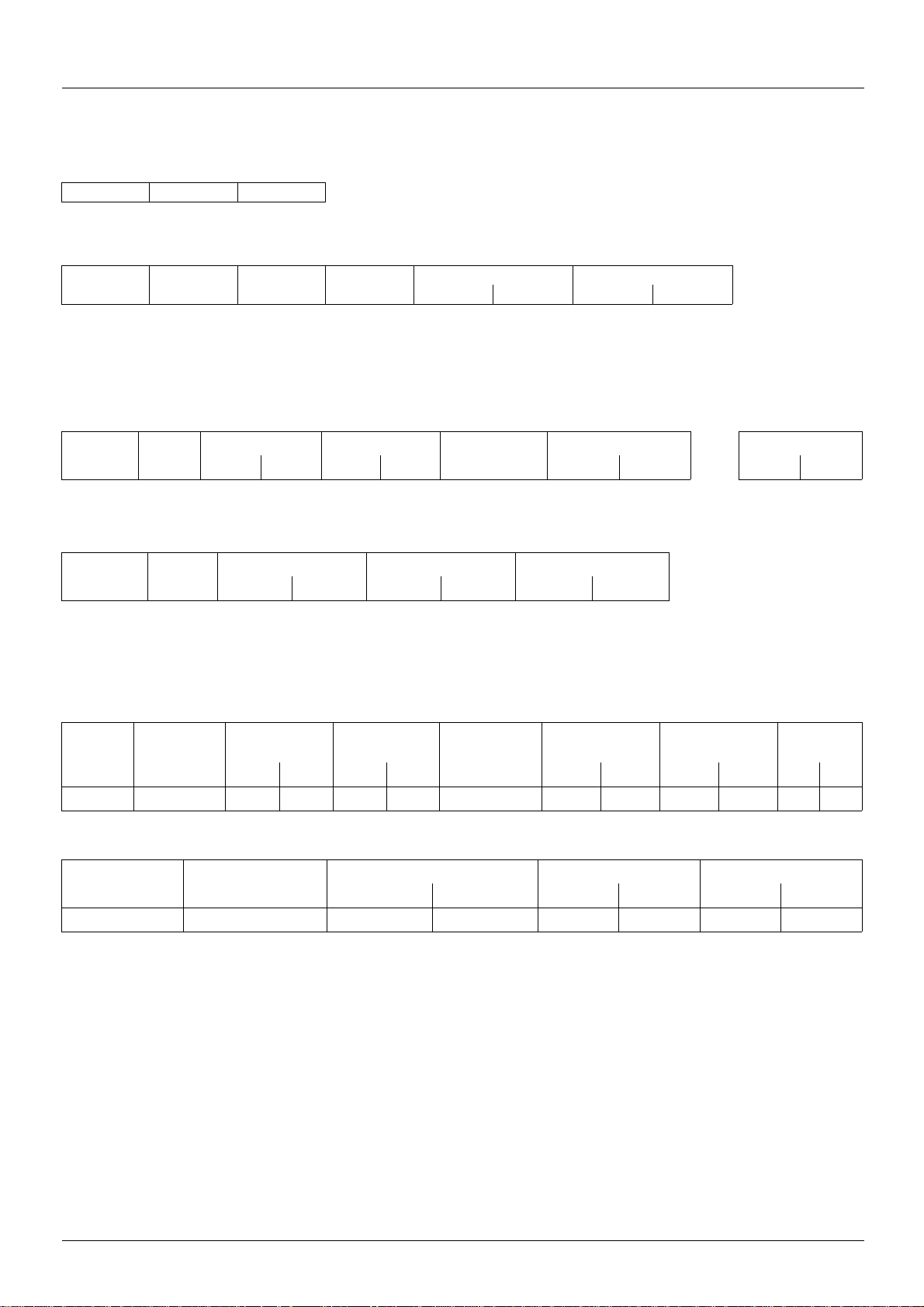

8. 11. Communication scanner

The communication scanner can be used to enhance application performance. The drive automa tically cop ies non-cont iguous paramet ers

to an input table and an output table. Thus, the copy of several non-contiguous parameters can be read or written in a single request (an

operation which would normally have required several Modbus requests).

The input table and the output table each contain 8 variables.

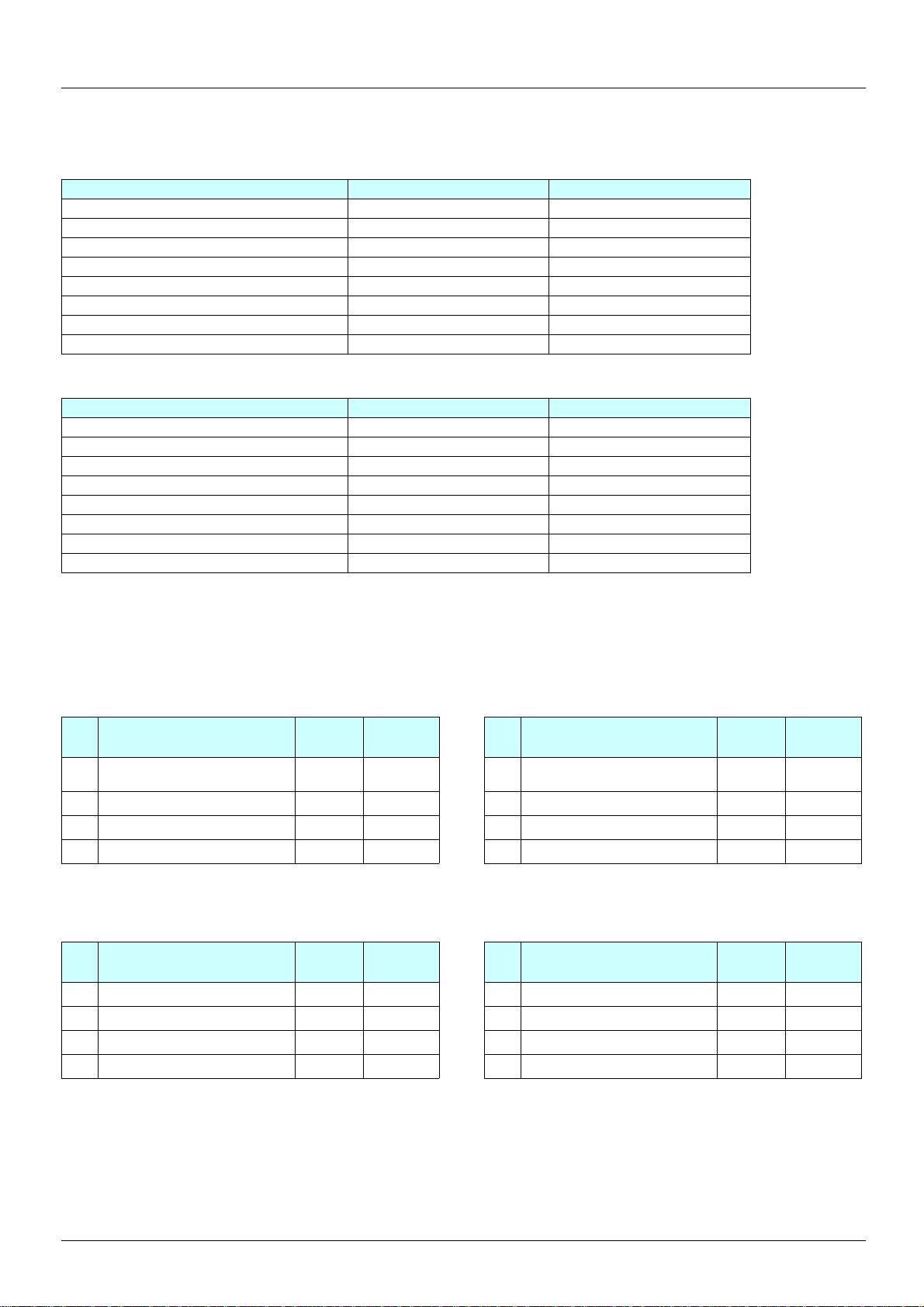

Output variables Logic address Default assignment

[Com Scan Out1 val.] (nC1) 12 761 = 16#31D9 Control word (CMd)

[Com Scan Out2 val.] (nC2) 12 762 = 16#31DA Speed reference (LFrd)

[Com Scan Out3 val.] (nC3) 12 763 = 16#31DB Not used

[Com Scan Out4 val.] (nC4) 12 764 = 16#31DC Not used

[Com Scan Out5 val.] (nC5) 12 765 = 16#31DD Not used

[Com Scan Out6 val.] (nC6) 12 766 = 16#31DE Not used

[Com Scan Out7 val.] (nC7) 12 767 = 16#31DF Not used

[Com Scan Out8 val.] (nC8) 12 768 = 16#31E0 Not used

Input variables Logic address Default assignment

[Com Scan In1 val.] (nM1) 12 741 = 16#31C5 Status word (EtA)

[Com Scan In2 val.] (nM2) 12 742 = 16#31C6 Output speed (rFrd)

[Com Scan In3 val.] (nM3) 12 743 = 16#31C7 Not used

[Com Scan In4 val.] (nM4) 12 744 = 16#31C8 Not used

[Com Scan In5 val.] (nM5) 12 745 = 16#31C9 Not used

[Com Scan In6 val.] (nM6) 12 746 = 16#31CA Not used

[Com Scan In7 val.] (nM7) 12 747 = 16#31CB Not used

[Com Scan In8 val.] (nM8) 12 748 = 16#31CC Not used

The values of these communication scanner variables can be displayed on the graphic display terminal using the

[1.2-MONITORING] menu, [COMMUNICATION MAP] (CMM) submenu (see section "7. Diagnostics - 7.4 Communication scanner").

These parameters can be accessed via all the read and write requests supported by the drive.

There is a marked improvement in performance for the following functions:

Code Modbus name Description Size of data

3 = 16#03 Read Holding Registers Read N output words 63 words, max.

4 = 16#04 Read Input Registers Read N input words 63 words, max.

16 = 16#10 Write Multiple Registers Write N output words 61 words, max.

23 = 16#17 Read/Write Multiple Registers Read/write N words 20/20 words max.

43 = 16#2B Read Device Identification Identification

34

Page 35

8. Modbus protocol

The link between the drive parameters and the communication scanner variables can be made:

- Via the display terminal (see section "6. Configuration - 6.2 Communication scanner")

- Via Modbus: Before starting the application, the PLC must first write the address tables described below.

Output variable address Logic address Default value

[Scan.Out1 address] (nCA1) 12 721 = 16#31B1 8501 = 16#2135

[Scan.Out2 address] (nCA2) 12 722 = 16#31B2 8602 = 16#219A

[Scan.Out3 address] (nCA3) 12 723 = 16#31B3 0

[Scan.Out4 address] (nCA4) 12 724 = 16#31B4 0

[Scan.Out5 address] (nCA5) 12 725 = 16#31B5 0

[Scan.Out6 address] (nCA6) 12 726 = 16#31B6 0

[Scan.Out7 address] (nCA7) 12 727 = 16#31B7 0

[Scan.Out8 address] (nCA8) 12 728 = 16#31B8 0

Input variable address Logic address Default value

[Scan. IN1 address] (nMA1) 12 701 = 16#319D 3201 = 16#0C8B

[Scan. IN2 address] (nMA2) 12 702 = 16#319E 8604 = 16#219C

[Scan. IN3 address] (nMA3) 12 703 = 16#319F 0

[Scan. IN4 address] (nMA4) 12 704 = 16#31A0 0

[Scan. IN5 address] (nMA5) 12 705 = 16#31A1 0

[Scan. IN6 address] (nMA6) 12 706 = 16#31A2 0

[Scan. IN7 address] (nMA7) 12 707 = 16#31A3 0

[Scan. IN8 address] (nMA8) 12 708 = 16#31A4 0

Example

• Use of the "Read/Write Multiple Registers" function (request code: 23 = 16#17)

• Transmission of the request to a drive located at address 20 (16#14)

• Reading all 8 scanner input variables

• List of source parameters:

Parameter

No.

Status word (EtA)

1

Output speed (rFrd)

2

Motor current (LCr)

3

Output torque (Otr)

4

• Writing the first 6 scanner output variables

• List of target parameters:

Parameter

No.

Control word (CMd)

1

Speed reference (LFrd)

2

High speed (HSP)

3

Low speed (LSP):

4

Logic

address

3201 16#0007 5

8604 16#1388 6

3204 16#0064 7

3205 16#0045 8

Logic

address

8501 16#000F 5

8602 16#1388 6

3104 16#1F40 7

3105 16#01F4 8

Read

value

Value to

be written

No.

No.

Parameter

Power section AC supply voltage

(ULn)

Drive thermal state (tHd)

Motor thermal state (tHr)

Altivar fault code (LFt)

Parameter

[Acceleration] (ACC)

[Deceleration] (dEC)

-

-

Logic

address

3207 16#00F0

3209 16#0065

9630 16#0032

7121 16#0000

Logic

address

9001 16#04B0

9002 16#0258

0 16#0000

0 16#0000

Read

value

Value to

be written

35

Page 36

8. Modbus protocol

The communication scanner is configured via the display terminal as follows:

Output (control):

Configuration parameter Value

Parameter assigned

[Scan. Out1 address] (nCA1) 8501 Control word (CMd)

[Scan. Out2 address] (nCA2) 8602 Speed reference (LFrd)

[Scan. Out3 address] (nCA3) 3104 [High speed] (HSP)

[Scan.Out4 address] (nCA4) 3105 [Low speed] (LSP):

[Scan. Out5 address] (nCA5) 9001 [Acceleration] (ACC)

[Scan. Out6 address] (nCA6) 9002 [Deceleration] (dEC)

[Scan. Out7 address] (nCA7) 0 Not used

[Scan. Out8 address] (nCA8) 0 Not used

Input (monitoring):

Configuration parameter Value Parameter assigned

[Scan. IN1 address] (nNA1) 3201 Status word (EtA)

[Scan. IN2 address] (nNA2) 8604 Output speed (rFrd)

[Scan. IN3 address] (nNA3) 3204 [Motor current] (LCr)

[Scan. IN4 address] (nNA4) 3205 [Output torque] (Otr)

[Scan. IN5 address] (nNA5) 3207 [Power section AC supply voltage] (ULn)

[Scan. IN6 address] (nNA6) 3209 [Drive thermal state] (tHd)

[Scan. IN7 address] (nNA7) 9630 [Motor thermal state] (tHr)

[Scan. IN8 address] (nNA8) 7121 Altivar fault code (LFt)

Request:

Slave no. Request code No. of 1

to be read

word

No. of words to

be read

No. of 1st word to

be written

No. of words to be

written

No. of bytes to be

written

st

Hi Lo Hi Lo Hi Lo Hi Lo ---

14 17 31 C5 00 08 31 D9 00 06 0C ---

--- Value of 1

word to be

written

st

Value of 2

word to be

written

nd

Value of 3

word to be

written

rd

Value of 4

word to be

written

th

Value of 5

word to be

written

th

Value of 6

word to be

th

CRC CRC

written

--- Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo Lo Hi

--- 00 0F 13 88 1F 40 01 F4 04 B0 02 58 56 3D

Response:

read

st

word

Value of 2nd word

read

Value of 3rd word

read

Value of 4th word

read

Slave no. Response code No. of bytes

read

Value of 1

Hi Lo Hi Lo Hi Lo Hi Lo ---

14 17 10 00 07 13 88 00 64 00 45 ---

--- Value of 5

th

word read Value of 6th word read Value of 7th word read Value of 8th word read CRC CRC

---HiLoHiLoHiLoHiLo Lo Hi

---00F0006500320000 E4 90

---

---

36

Page 37

8. Modbus protocol

8. 12. Exception responses

An exception response is returned by a slave when it is unable to perform the request which is addresse d to it.

Format of an exception response:

Slave

no.

1 byte 1 byte 1 byte 2 bytes

Response

code:

Error code: 1 = The function requested is not recognized by the slave.

Example: Writing the value 1 to the status word (EtA) = logic address 3201 (which cannot be written, because in “read-only" mode) on

slave 4

Request:

Slave no. Request

4 100C8100010200018AD1

Response:

Response

code

request code + H’80.

2 = The addresses indicated in the request do not exist in the slave.

3 = The values indicated in the request are not permitted on the slave.

4 = The slave has started to execute the request but cannot continue to process it completely.

6 = The requested write operation has been refused because the drive is in "Forced local" mode.

7 = The requested write operation has been refused because the motor is running (configuration parameters).

code

Error

code

st

No. of 1

Hi Lo Hi Lo Hi Lo Lo Hi

word No. of words No. of

CRC16

Lo Hi

Value of 1st word CRC CRC

bytes

Slave no. Response

code

490005C01

Error code CRC

Lo

CRC

Hi

37

Page 38

8. Modbus protocol

8. 13. Read non-existent or protected parameters

If a set of parameters is read using a Modbus function, the value returned for non-exi stent and protected parameters is equal to 16#8000.

If the same Modbus function is used to read parameters, all of which are non-existent or protected, the drive sends back an exception

response with an error code equal to 2.

Example of non-existent or protected parameters being read:

In this example, the same request to read a non-exi stent parameter followed by 2 existing parameters is used s everal times in a row in order

to demonstrate the effects of parameter protection.

The "Read Holding Registers" request (3) is addressed to a drive with a Modbus address of 12 (16#0C). The read operation is performed

for 3 consecutive words, starting with address 8400.

Logic address Parameter Value

8400 = 16#20FA Non-existent 8401 = 16#20D1 [Profile] (CHCF) 3

8402 = 16#20D2 [Copy channel 1

Request:

Slave no. Request code No. of 1st word No. of words CRC16

0C 03 20 D0 00 03 0E EF

↔ 2] (COP) 2

Hi Lo Hi Lo Lo Hi

Response:

Scenario no. 1: Parameters CHCF (8401) and COP (8402) not protected

to 16#8000 for the non-existent parameter located at address 8400.

Slave no. Response code No. of bytes read

0C 03 06

Scenario no. 2: Parameter CHCF (8401) protected and COP (8402) not protected

16#8000 for the non-existent parameter located at address 8400 and for parameter CHCF.

Slave no. Response code No. of bytes read

0C 03 06

Scenario no. 3: Parameters CHCF (8401) and COP (8402) protected

all the parameters read are either non-existent, or protecte d; error code equal to 2 (the word addresses in dicated in the request do not exist

in the slave).

Slave no. Response code Error code CRC16

0C 80+03 = 83 02 51 32

Value 8400 Value 8401 Value 8402 CRC16

Hi Lo Hi Lo Hi Lo Lo Hi

80 00 00 03 00 02 17 E4

Value 8400 Value 8401 Value 8402 CRC16

Hi Lo Hi Lo Hi Lo Lo Hi

80 00 80 00 00 02 CE 24

Lo Hi

V Successful reading of these two parameters and value equal

V Successful reading of COP and value equal to

V Exception response (response code = 16#80 + request code), as

38

Page 39

9. Appendix

9. 1. RS485 standard

The RS485 standard (ANSI/TIA/EIA-485-A-1998) allows variants of certain characteristics:

• Polarization

• Line termination

• Distribution of a reference potential

• Number of slaves

• Length of bus

It does not specify the connector type or pinout.

The Modbus specification published on www.modbus.org in 2002 contains precise details of all these characteristics. They are also

summarized in the next sections (Modbus 2-wire and 4-wire standard schematics). The latest generation Telemecanique devices

(Altivar 31, Altivar 71, etc.) conform to this specification.

Older devices comply with earlier specifications. The two most widespread are described in the following sections:

• "Uni-Telway schematic" page 42

• "Jbus schematic" page 43

Requirements enabling different types of protocol to coexist are given in the following section in this appendix:

• "Creating a Modbus bus using non-standard equipment" on page 45

39

Page 40

9. Appendix

9. 2. Modbus 2-wire standard schematic

The standard schematic corresponds to the Modbus specification published in 2002 on www.modbus.org

(Modbus_over_serial_line_V1.pdf, Nov 2002) and, in particular, to the 2-wire multipoint serial bus schematic.

The Modbus card (VW3 A3 303) conforms to this specification.

Schematic diagram:

Master

G

R

650 Ω

D1

5 V

650 Ω

0 V

120 Ω

1n F

Type of trunk cable

Maximum length of bus

Maximum number of stations (without

repeater)

Maximum length of tap links

Bus polarization

Line termination

Common polarity

120 Ω

1n F

R

Slave 1

G

D0

Common

R

Slave n

G

Shielded cable with 1 twisted pair and at least a 3rd conductor

1000 m at 19200 bps with the Telemecanique TSX CSAp00 cable

32 stations, i.e., 31 slaves

• 20 m for one tap link

• 40 m divided by the number of tap links on a multiple junction box

• One 450 to 650 Ω pull-up resistor to the 5 V (650 Ω or thereabouts recommended)

• One 450 to 650

Ω pull-down resistor to the Common (650 Ω or thereabouts

recommended)

This polarization is recommended for the master.

One 120 Ω 0.25 W resistor in series with a 1nF 10 V capacitor

Yes (Common), connected to the protective ground at one or more points on the bus

40

Page 41

9. Appendix

9. 3. Modbus 4-wire standard schematic

Master

G

R

5 V

TXD1

LT

TXD0

RXD1

LT

RXD0

Slave pair

Master pair

Rp

Rp

LT

5 V

Rp

LT

Rp

Common

R

G

R

G

Slave 1 Slave n

41

Page 42

9. Appendix

9. 4. Uni-Telway schematic

The Uni-Telway bus schematic was used by Telemecanique for older-generation drives and soft starters (ATV58, ATV28, ATS48, etc.)

marketed before the Modbus specifications were published on www.modbus.org.

Schematic diagram:

Master

G

R

4.7 kΩ

D(B)

5 V

4.7 kΩ

0 V

120 Ω

1 nF

D(A)

0VL

5 V

4.7 kΩ

0 V 0 V

R

4.7 kΩ

G

Slave 1

4.7 kΩ

R

Slave n

5 V

4.7 kΩ

G

120 Ω

1 nF

Type of trunk cable Cable with 2 twisted pairs shielded in pairs

Maximum length of bus 1000 m at 19200 bps

Maximum number of stations (without

29 stations, i.e., 28 slaves

repeater)

Maximum length of tap links

•20 m

• 40 m divided by the number of tap links on a multiple junction box

Bus polarization For the master and each slave:

• One 4.7 kΩ pull-up resistor to the 5 V

• One 4.7 kΩ pull-down resistor to the 0 VL

Line termination One 120 Ω 0.25 W resistor in series with a 1 nF 10 V capacitor

Common polarity Yes (0 VL) and high impedance placed between 0 VL and the ground in each station

42

Page 43

9. Appendix