Modicon TM5

EIO0000000889 09/2020

Modicon TM5

Safety Logic Controller SLC100/200 FS

Hardware Guide

Original instructions

09/2020

EIO0000000889.08

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000000889 09/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Functional Safety Information. . . . . . . . . . . . . . . . . . . . . 13

IEC 61508 and Safety Integrity Level (SIL) . . . . . . . . . . . . . . . . . . . . .

Functional Safety Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 TM5CSLC100FS and TM5CSLC200FS . . . . . . . . . . . . . 21

General Information on Safety Logic Controllers. . . . . . . . . . . . . . . . .

Safety Logic Controller Presentation. . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Logic Controller Characteristics . . . . . . . . . . . . . . . . . . . . . . . .

Safety Logic Controller Memory Key. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Operating and Connection Elements . . . . . . . . . . . . . . . 35

Safety Logic Controller Description . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Processor LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Processor Selection Switch and Confirmation Button . . . . . . . .

Safety Terminal Block Presentation . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sercos III Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

15

19

22

23

25

28

36

38

42

44

47

49

55

57

EIO0000000889 09/2020 3

4 EIO0000000889 09/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000000889 09/2020 5

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

QUALIFICATION OF PERSONNEL

Only appropriately trained persons who are familiar with and understand the contents of this

manual and all other pertinent product documentation are authorized to work on and with this

product.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying parameter values and generally from mechanical, electrical, or electronic equipment.

The qualified person must be familiar with the standards, provisions, and regulations for the

prevention of industrial accidents, which they must observe when designing and implementing the

system.

INTENDED USE

The products described or affected by this document, together with software, accessories, and

options, are programmable logic controllers (referred to herein as “logic controllers”), intended for

industrial use according to the instructions, directions, examples, and safety information contained

in the present document and other supporting documentation.

The product may only be used in compliance with all applicable safety regulations and directives,

the specified requirements, and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application.

Based on the results, the appropriate safety-related measures must be implemented.

Since the product is used as a component in an overall machine or process, you must ensure the

safety of persons by means of the design of this overall system.

Operate the product only with the specified cables and accessories. Use only genuine accessories

and spare parts.

Any use other than the use explicitly permitted is prohibited and can result in unanticipated

hazards.

6 EIO0000000889 09/2020

About the Book

At a Glance

Document Scope

This manual describes the Safety Logic Controllers SLC100 Sercos III (TM5CSLC100FS) and

SLC200 Sercos III (TM5CSLC200FS). These controllers help you to achieve the safety

requirements codified in the IEC 61508 standard. The present document also provides part

descriptions, specifications and wiring diagrams.

Schneider Electric takes no responsibility for the solutions adopted by you or any customer

concerning the circuits, the electrical schematics, and the chosen configuration parameters of the

application. The implemented circuits and electrical diagrams and the choice of the system

configuration parameter values, including those of TM5CSLC100FS and TM5CSLC200FS, are

fully under your control and responsibility.

Validity Note

This document has been updated for the release of EcoStruxure

The technical characteristics of the devices described in the present document also appear online.

To access the information online, go to the Schneider Electric home page at

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

TM

Machine Expert V1.2.5.

www.se.com

.

Related Documents

Document title Reference

Modicon TM5/TM7 I/O Safety Modules Hardware

Guide

PacDrive TM5 / TM7 Safety Flexible System, System

Planning and Installation Guide

Modicon M262 Logic/Motion Controller, Programming

Guide

EIO0000000889 09/2020 7

EIO0000000861 (ENG)

EIO0000000862 (GER)

EIO0000001064 (ENG)

EIO0000001066 (GER)

EIO0000003651 (ENG)

EIO0000003652 (FRE)

EIO0000003653 (GER)

EIO0000003654 (SPA)

EIO0000003655 (ITA)

EIO0000003656 (CHS)

EIO0000003657 (POR)

EIO0000003658 (TUR)

Document title Reference

How to Configure the Firewall for PacDrive LMC

Controllers, User Guide

EcoStruxure Machine Expert, CommonToolbox,

Library Guide

You can download these technical publications and other technical information from our website

www.schneider-electric.com/en/download

at

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

EIO0000004198 (ENG)

EIO0000004199 (GER)

EIO0000004219 (ENG)

.

DANGER

DANGER

POTENTIAL FOR EXPLOSION

Only use this equipment in non-hazardous locations, or in locations that comply with Class I,

Division 2, Groups A, B, C and D.

Do not substitute components which would impair compliance to Class I, Division 2.

Do not connect or disconnect equipment unless power has been removed or the location is

known to be non-hazardous.

Do not use the USB port(s), if so equipped, unless the location is known to be non-hazardous.

Failure to follow these instructions will result in death or serious injury.

8 EIO0000000889 09/2020

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

1

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The Safety Logic Controller system is built to the following safety integrity levels: SIL 3 according

to EN/IEC 61508, SILcl 3 according to EN/IEC 62061, in accordance with the applicable

standards. However, the definitive SIL and PL of the application depends on the number of safety

components, their parameters, and the connections that are made, as per the risk analysis.

The module must be configured in accordance with the application-specific risk analysis and all the

applicable standards.

Pay particular attention in conforming to any safety information, different electrical requirements,

and normative standards that would apply to your adaptation.

EIO0000000889 09/2020 9

UNINTENDED EQUIPMENT OPERATION

Perform an in-depth risk analysis to determine the appropriate safety integrity level for your

specific application, based on all the applicable standards.

Do not exceed SIL 3 ratings in the application of this product.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

For reasons of Internet security, TCP/IP forwarding is disabled by default. Therefore, you must

manually enable TCP/IP forwarding. However, doing so may expose your network to possible

cyberattacks if you do not take additional measures to protect your enterprise. In addition, you may

be subject to laws and regulations concerning cybersecurity.

UNAUTHENTICATED ACCESS AND SUBSEQUENT NETWORK INTRUSION

Observe and respect any an all pertinent national, regional and local cybersecurity and/or

personal data laws and regulations when enabling TCP/IP forwarding on an industrial network.

Isolate your industrial network from other networks inside your company.

Protect any network against unintended access by using firewalls, VPN, or other, proven

security measures.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

WARNING

WARNING

,

, etc.

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

General principles for design.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

Part 1: General requirements and tests.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

10 EIO0000000889 09/2020

reduction

Standard Description

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

EIO0000000889 09/2020 11

12 EIO0000000889 09/2020

Modicon TM5

Functional Safety Informat ion

EIO0000000889 09/2020

Functional Safety Informat ion

Chapter 1

Functional Safety Information

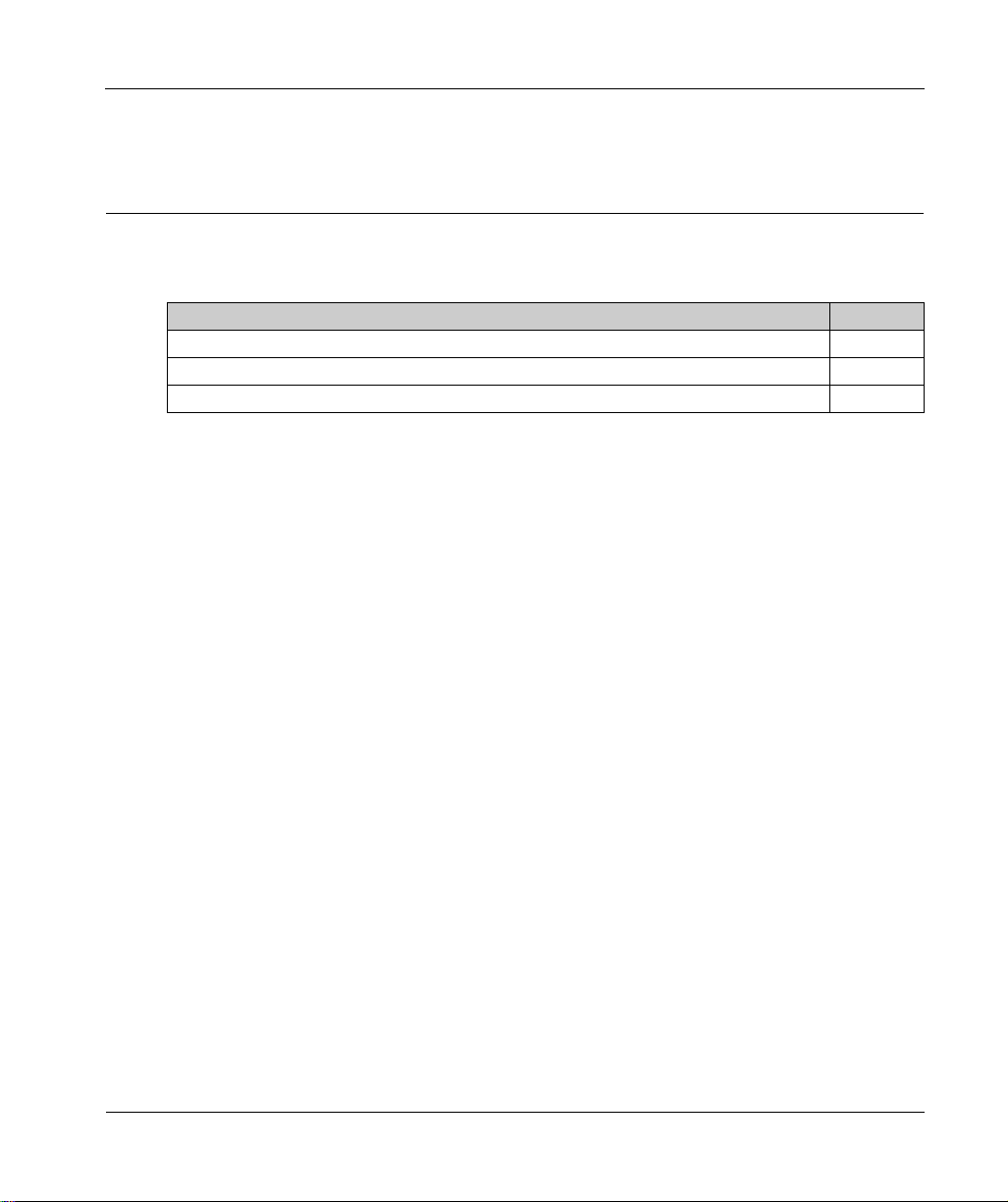

What Is in This Chapter?

This chapter contains the following topics:

IEC 61508 and Safety Integrity Level (SIL) 14

Functional Safety Certification 15

Training 19

Topic Page

EIO0000000889 09/2020 13

Functional Safety Information

IEC 61508 and Safety Integrity Level (SIL)

Introduction

The TM5CSLC100FS and TM5CSLC200FS Safety Logic Controllers are part of a Safety-Related

System certified according to IEC 61508 by TÜV NORD.

IEC 61508 Description

The IEC 61508 is a technical standard concerning the functional safety of electrical, electronic or

programmable electronic safety-related systems.

A safety-related system is a system that is required to perform one or more specific functions to

ensure that risks are kept at or below an acceptable level. Such functions are defined as safety

functions.

A system is defined “functionally safe” when random, systematic, and common cause equipment

or machine failures do not lead to malfunctioning of the system and do not result in injury or death

of humans, spills to the environment, and loss of equipment and production.

Description of the Safety Integrity Level (SIL)

Safety-related functions are executed to help achieve and maintain the defined safe state of a

system. The IEC 61508 specifies four levels of safety performance for a safety-related function.

These are called Safety Integrity Levels (SIL), ranging from 1 (the lowest) to 4 (the highest). The

TM5CSLC100FS and TM5CSLC200FS Safety Logic Controllers are certified for use in SIL 3

applications in which the de-energized state is the defined safe state.

14

EIO0000000889 09/2020

Functional Safety Certification

Introduction

The TM5CSLC100FS and TM5CSLC200FS Safety Logic Controllers are certified

by TÜV NORD

for use in applications up to and including SIL 3 according to IEC 61508 and IEC 62061.

This certification verifies that the Safety Logic Controllers are compliant with the following

standards:

IEC 61508: Functional safety of electrical/electronic/programmable electronic safety-related

systems, Parts 1 to 4, 2010, up to SIL 3

ISO 13849-1: Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design, 2015, up to PL e (Category 4)

IEC 62061: Safety of machinery - Functional safety of safety-related electrical, electronic, and

programmable electronic control systems, 2005 (A1:2013), up to SILcl 3

NOTE: Using Safety Logic Controller equipment is a necessary but insufficient precondition for the

certification of a SIL 3 application. A SIL 3 application must also fulfill the requirements of the

IEC 61508, IEC 61511, IEC 61131-2, and other application standards.

Functional Safety Parameters

The Functional Safety parameters according to EN ISO 13849 are as follows:

Performance Level for

SDI (safety-related digital input) to SDO (safety-related digital output): up to PL e

SAI (safety-related analog input) to SAO (safety-related analog output): up to PL e

Category: up to 4

Functional Safety Information

Classification of the Schneider Electric Products

The Safety Logic Controllers are dedicated to perform safety-related functions. The Safety Logic

Controller system consist of the controller supporting the Sercos III fieldbus network. The controller

then interfaces with the Sercos III Bus Interface, TM5/TM7 Safety-Related I/O modules, and other

safety-related devices such as drives and third-party devices. However, it also supports other

modules, enabling you to add non-safety-related parts to your SIL 3 project.

Therefore, the Schneider Electric products must be distinguished into:

safety-related modules and

non-safety-related modules

In contrast to the safety-related modules, non-safety-related modules are not used to perform

safety-related functions. They are certified as non-interfering modules for use with the Safety Logic

Controller. A detected error in one of these modules does not interfere with the execution of the

safety-related functions.

EIO0000000889 09/2020 15

Functional Safety Information

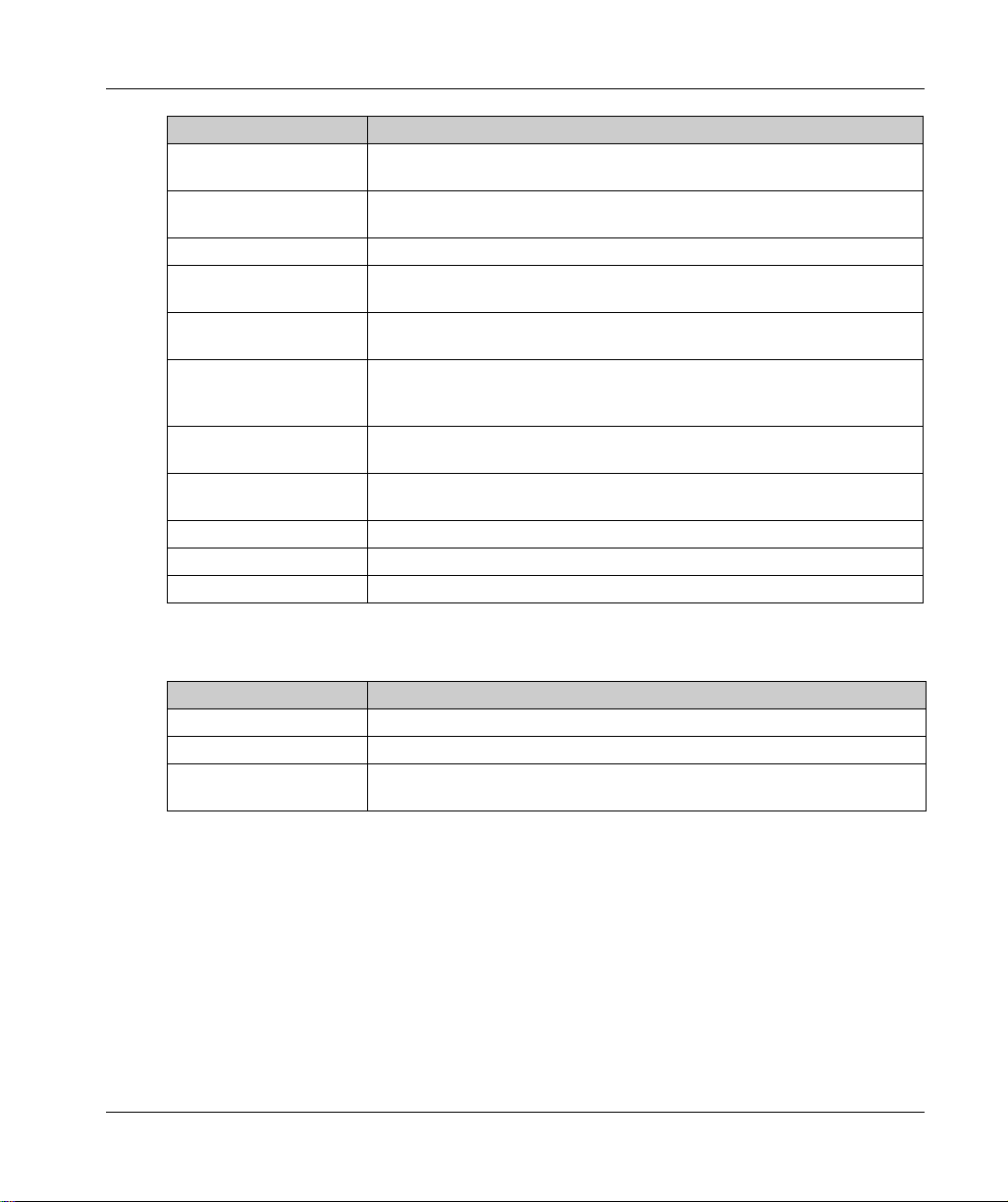

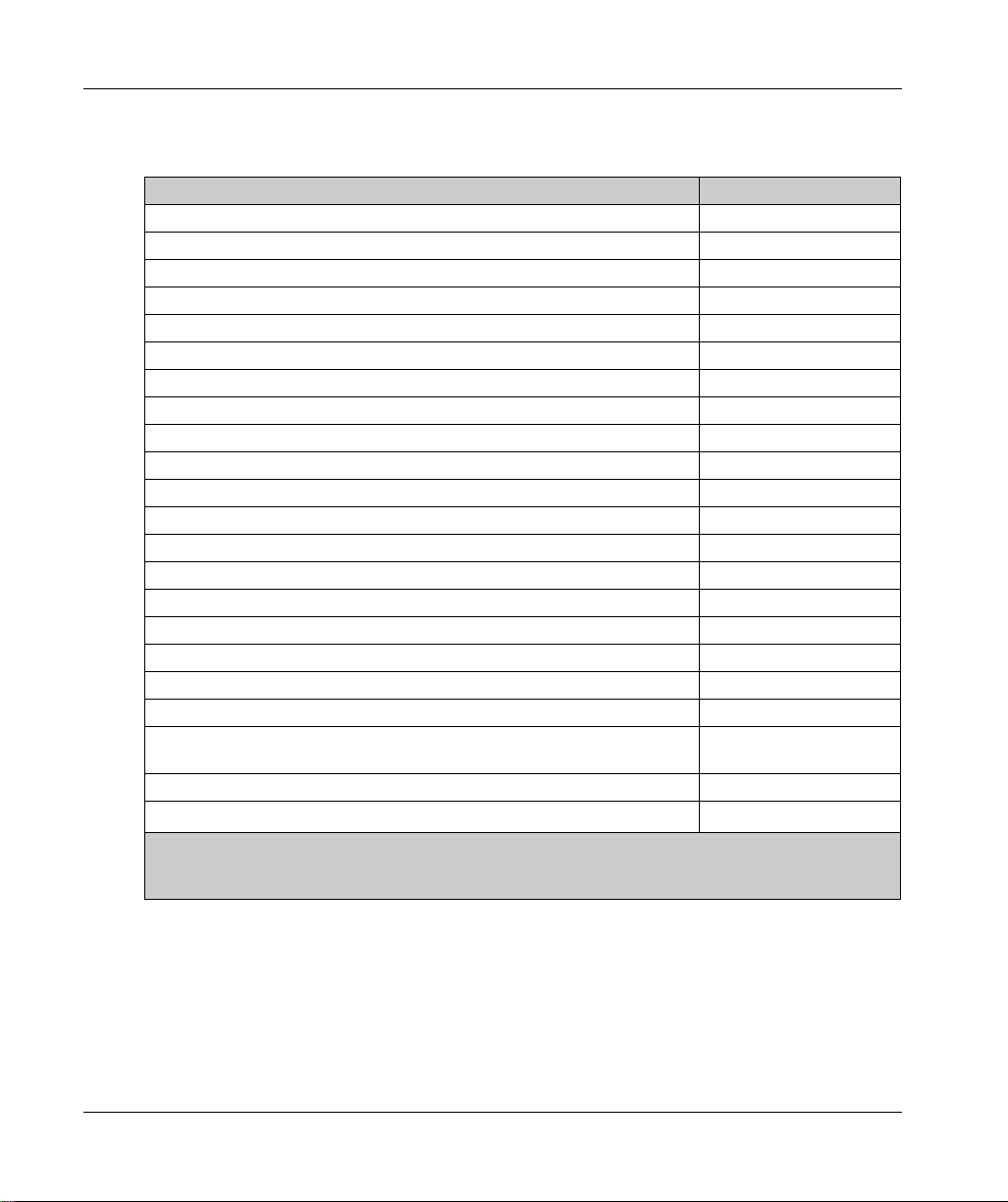

Safety-Related Products of the Safety Logic Controller System

The Safety Logic Controller system is comprised of the following safety-related products:

Type Module Reference

Safety Logic Controller, SLC 100 Sercos III, 24 Vdc TM5CSLC100FS

Safety Logic Controller, SLC 200 Sercos III, 24 Vdc TM5CSLC200FS

Safety-related Module 2DI 24 Vdc Sink TM5SDI2DFS

Safety-related Module 4DI 24 Vdc Sink TM5SDI4DFS

Safety-related Module 20DI 24 Vdc Sink TM5SDI20DFS

Safety-related Module 2DO 24 Vdc, 0.5 A TM5SDO2TFS

Safety-related Module 2DO 24 Vdc, 2 A TM5SDO2TAFS

Safety-related Module 4DO 24 Vdc, 0.5 A TM5SDO4TFS

Safety-related Module 2DO TM5SDO2TRFS

Safety-related Module 4DO 24 Vdc, 2 A TM5SDO4TAFS

Safety-related Module 6DO 24 Vdc, 0.2 A TM5SDO6TBFS

Safety-related Module 2DI (2 test (pulse) outputs), 2DO 24 Vdc, 6 A TM5SDM4DTRFS

Safety-related Module 6DI, 2DO 24 Vdc TM5SDM8TBFS

Safety-related Module 2x2AI 4-20 mA 24 bits TM5SAI4AFS

Safety-related Module 2x2AI Thermocouple J/K/N/S/R/C/T TM5STI4ATCFS

Safety-related Counter Module DC1 7 kHz 24 Vdc Sink TM5SDC1FS

Safety-related Power Distribution Module PS 1DO 24 Vdc TM5SPS10FS

IP67 Block, 8 DI, 24 Vdc TM7SDI8DFS

IP67 Block, 8 DI, 4 DO, 2 A TM7SDM12DTFS

TM5 Bus Base for safety-related Electronic modules, safety coded, internal I/O

supply interconnected

Safety-related Terminal Block, 12-pin, safety coded TM5ACTB52FS

Memory Key, 8 MB

(1) A memory key is required for operation of the Safety Logic Controller, and is sold separately. For more

information concerning the role of the memory key in the Safety Logic Controller system, refer to Safety Logic

Controller Memory Key

(1)

(see page 28)

.

TM5ACBM3FS

TM5ACSLCM8FS

16

Only modules certified as safety-related modules are allowed to perform safety functions. Make

certain that neither inputs nor outputs of non-safety-related modules are used for safety-related

inputs or outputs.

EIO0000000889 09/2020

IMPROPERLY CONFIGURED SAFETY-RELATED SYSTEM

Use only safety-certified products for use in a safety-related system.

Use only Schneider Electric authorized products in a Safety Logic Controller system.

Failure to follow these instructions will result in death or serious injury.

NOTE: The Sercos III Bus Interface, required for communication with TM5 Safety-related modules,

is considered a non-interfering module and does not contribute nor detract from the safety function

of the controller. The safety layer part of the Sercos III communication is managed inside the

Safety-related modules and not in the Sercos III Bus Interface.

Available Bus Interface

The following Schneider Electric bus interface is available:

Module Type Module Reference

Sercos III Bus Interface TM5NS31

NOTE: The Sercos III Bus Interface, required for communication with the safety-related expansion

modules, is considered a non-interfering module and does not contribute nor detract from the

safety-related function of the controller. The safety layer part of the Sercos III communication is

managed inside the safety-related modules and not in the Sercos III Bus Interface.

For more information on safety-related product architectures, refer to TM5 / TM7 Safety-Related

System I/O Architecture

Installation Guide)

Functional Safety Information

DANGER

(see PacDrive TM5 / TM7 Safety Flexible System, System Planning and

.

DANGER

IMPROPER SAFETY-RELATED SYSTEM

Use only modules designated as safety-related modules to perform safety-related functions.

Make sure that neither inputs nor outputs of non-safety-related modules are used for safety-

related outputs.

Failure to follow these instructions will result in death or serious injury.

Probabilities of Failure

For SIL 3 applications, IEC 61508 defines the following probabilities of failure on demand (PFD)

and probabilities of failure per hour (PFH) depending on the mode of operation:

PFD ≥ 10

PFH ≥ 10

EIO0000000889 09/2020 17

-4

to < 10-3 for low demand mode of operation

-8

to < 10-7 for high demand mode of operation

Functional Safety Information

Defined Safe State and Life Span

For more information on the defined safe state of modules in the case of detected errors as well

as on the life span, refer to Defined Safe State and Life Span

Modules, Hardware Guide)

(see Modicon TM5/TM7, I/O Safety

.

18

EIO0000000889 09/2020

Training

Introduction

As stated in the IEC 61508, Part 1, App. B, all persons involved in a Safety Lifecycle activity must

have the appropriate training, technical knowledge, experience, and qualifications relevant apply

the products specified in the present document. Training, technical knowledge, experience, and

qualifications should be assessed in relation to each particular application.

NOTE: Make sure you possess all information and skills required to install, run, and maintain

Safety-Related Systems correctly.

Functional Safety Information

EIO0000000889 09/2020 19

Functional Safety Information

20

EIO0000000889 09/2020

Modicon TM5

SLC 100 Sercos III and SL C 200 Sercos III

EIO0000000889 09/2020

TM5CSLC100FS and TM 5CSLC200FS

Chapter 2

TM5CSLC100FS and TM5CSLC200FS

What Is in This Chapter?

This chapter contains the following topics:

General Information on Safety Logic Controllers 22

Safety Logic Controller Presentation 23

Safety Logic Controller Characteristics 25

Safety Logic Controller Memory Key 28

Topic Page

EIO0000000889 09/2020 21

SLC 100 Sercos III and SLC 200 Sercos III

General Information on Safety Logic Controllers

General Overview

Safety Logic Controllers manage the tasks within a safety-related application and provide the

following functionalities:

configuration management

parameter management

execution of the safety-related application program

NOTE: The safety-related modules must be connected through a Sercos III Bus Interface.

Configuration Management

The configuration management monitors the safety-related configuration of the application in the

Safety Logic Controller and provides the following functions:

Helps ensure a consistent, safety-related configuration.

Verifies the module types, as well as the hardware and firmware versions, with those specified

in the Safety Logic Controller application.

Verifies the configuration at startup and periodically during operation.

Parameter Management

When replacements are needed, the parameter management system helps to ensure that newly

installed modules are assigned correct parameters that apply to the application in the Safety Logic

Controller.

The parameter management provides the following functions:

Helps to ensure consistent parameters on the safety-related I/O modules.

Verifies the parameters with those specified in the Safety Logic Controller application.

Independently performs complete parameter downloads.

Memory Key

The memory key on the Safety Logic Controller supports the following features:

holds the safety-related application that is loaded at boot-up.

storage medium for the application, configuration, and parameters.

application transfer of safety-related functions to another Safety Logic Controller.

NOTE: A memory key is required for operation of the Safety Logic Controller. For more information

concerning the role of the memory key in the Safety Logic Controller system, refer to Safety Logic

Controller Memory Key

22

(see page 28)

.

EIO0000000889 09/2020

Safety Logic Controller Presentation

Features

The table below describes the features of TM5CSLC100FS and TM5CSLC200FS :

Feature TM5CSLC100FS TM5CSLC200FS

System module Safety CPU Standard Safety CPU Plus

Maximum I/O modules

via Sercos III interface

Interfaces Sercos III, controlled node, integrated 2x switch

Application memory exchangeable application memory: memory key

Dimensions (W x H x D) 87.5 x 99 x 75 mm (3.44 x 3.89 x 2.92 inches)

Ordering Information

The figure below presents TM5CSLC100FS and TM5CSLC200FS in combination with the required

accessories:

20 safety-related modules 100 safety-related modules

SLC 100 Sercos III and SLC 200 Sercos III

EIO0000000889 09/2020 23

SLC 100 Sercos III and SLC 200 Sercos III

The table below presents the references for the Safety Logic Controllers and the terminal block:

Number Reference Description Color

1 TM5CSLC100FS SLC 100 Sercos III red

TM5CSLC200FS SLC 200 Sercos III

2 TM5ACTB52FS

(see page 44)

3

(1) Included in delivery of TM5CSLC100FS/TM5CSLC200FS

TM5ACLPR10

(1)

(1)

NOTE: A memory key is required for operation of the Safety Logic Controller, and is sold

separately. For more information concerning the role of the memory key in the Safety Logic

Controller system, refer to Safety Logic Controller Memory Key

TM5 terminal block, 12-pin, safety coded red

TM5 Locking plate white

(see page 28)

.

24

EIO0000000889 09/2020

Safety Logic Controller Characteristics

Introduction

This section describes the characteristics of TM5CSLC100FS and TM5CSLC200FS:

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the power supplies.

Failure to follow these instructions will result in death or serious injury.

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the characteristics tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

General Characteristics

The table below provides general characteristics of TM5CSLC100FS and TM5CSLC200FS :

SLC 100 Sercos III and SLC 200 Sercos III

DANGER

WARNING

General Characteristics

Status indicators

Diagnostics Diagnostics for controller functions, Sercos III and memory key

Cooling convection

Power consumption 5.1 W

Certifications and standards

EIO0000000889 09/2020 25

Controller state

Sercos III

Memory key

are indicated by status LED.

CE

CSA, Class I., Div. 2

cULus

EN 62061

EN ISO 13849-1

IEC 61508

SLC 100 Sercos III and SLC 200 Sercos III

Operating Conditions

The table below lists the operating conditions for TM5CSLC100FS and TM5CSLC200FS:

Operating Conditions

Mounting orientation horizontal or vertical

Operating temperature horizontal installation 0...+55 °C (+32...131°F)

Relative humidity 5...95%

Installation at altitudes above sea level: Up to 2000 m (up to 6561 ft) no derating

EN 60529 Protection IP20

Storage and Transport Conditions

The table below lists the storage and transport conditions for TM5CSLC100FS and

TM5CSLC200FS:

Storage and Transport Conditions

Temperature -25...+70 °C (-13...+158 °F)

Relative humidity 5...95%

vertical installation 0...+45 °C (+32...113 °F)

> 2000 m (>6561 ft) reduction of ambient temperature

by 0.5 °C per 100 m (32.9 °F per

328 ft)

Controller Characteristics

The table below lists the controller characteristics for TM5CSLC100FS and TM5CSLC200FS:

Controller

Fastest task class cycle time 2 ms

Memory Key slot 1x

Real-time clock

Modular interface slots none

Processor Intel XSCALE 266 MHz

Fieldbus Characteristics

The table below lists the fieldbus characteristics for TM5CSLC100FS and TM5CSLC200FS:

Fieldbus

Type Sercos III

26

non-volatile memory

resolution 1 second

EIO0000000889 09/2020

Fieldbus

Design internal 2x switch

Cable length maximum 100 m (328 ft) between two stations (segment length)

Transfer rate 100 MBit/s Full Duplex

Power Supply Characteristics

The table below lists the power supply characteristics for TM5CSLC100FS and TM5CSLC200FS:

Power supply

Rated voltage + 24 V (-15% / +20%)

Reverse polarity reaction yes

Fuse integrated, cannot be exchanged

Functionality Characteristics

The table below lists the functionality characteristics for TM5CSLC100FS and TM5CSLC200FS:

Functionality TM5CSLC100FS TM5CSLC200FS

Number of supported safety-related I/O

devices

SLC 100 Sercos III and SLC 200 Sercos III

2x shielded RJ45 port

maximum 20 maximum 100

Safety-Related Characteristics

The table below lists the safety-related characteristics for TM5CSLC100FS and TM5CSLC200FS:

Characteristic Value

Category according to EN ISO 13849 CAT 4

Maximum performance level according to EN ISO 13849 PL e

Maximum safety integrity level according to IEC 62061 SIL 3

Maximum safety integrity level according to IEC 61508 SIL 3

PFH

PFD

-9

<1*10

<1*10

<2*10

-5

at a proof test interval of 10 years

-5

at a proof test interval of 20 years

PT maximum 20 years

DC >90%

SFF >90%

MTTFd >100 years

Life time

(see Modicon TM5/TM7, I/O Safety Modules,

20 years

Hardware Guide)

EIO0000000889 09/2020 27

SLC 100 Sercos III and SLC 200 Sercos III

Safety Logic Controller Memory Key

Presentation

A memory key is required for operation of the Safety Logic Controller, and is sold separately.

The table below presents the reference for the memory key:

Reference Description Color

TM5ACSLCM8FS Safety Logic Controller memory key, 8 Mb Gray and red

Functions of the Memory Key

The memory key is required to load the program, parameters and configuration into the Safety

Logic Controller when it boots up. In addition, you can use the key to store the program, the

parameters, and the system configuration and transfer the data to another Safety Logic Controller.

The memory key is equipped with a mechanical locking mechanism to help prevent removal during

operation:

Locking mechanism

Unlocked memory key: Locked memory key:

First Insertion and Confirmation of the Memory Key

Before applying power to the Safety Logic Controller for the first time, you have to insert the

memory key.

To confirm the first insertion of a memory key, proceed as follows:

Step Action Result

1 Ensure that the Safety Logic Controller is not

under power.

2 Insert the memory key in the Safety Logic

Controller and apply power to the Safety Logic

Controller.

28

-

The FW-ACKN LED illuminates.

EIO0000000889 09/2020

SLC 100 Sercos III and SLC 200 Sercos III

Step Action Result

3 Move the selection switch to SK-XCHG and

press the confirmation button.

4 Engage the mechanical locking mechanism. -

5 Open EcoStruxure Machine Expert - Safety,

connect to the Safety Logic Controller and set a

new password for the Safety Logic Controller

(refer to EcoStruxure Machine Expert - Safety

User Guide).

The ENTER LED illuminates. The memory key

insertion is confirmed.

NOTE: To allow the connection between

EcoStruxure Machine Expert - Safety and the

Safety Logic Controller via the Sercos bus,

appropriate Ethernet settings have to be

applied on the standard controller. Refer to the

M262 Programming Guide

Services

(see Modicon M262 Logic/Motion Controller,

Programming Guide)

refer to the User Guide

Firewall for PacDrive LMC Controllers

(see How to Configure the Firewall for

PacDrive LMC Controllers, User Guide)

CommonToolbox Library Guide

(see EcoStruxure Machine Expert,

CommonToolbox, Library Guide)

information on related IEC application

functions.

6 Download your valid safety-related application

on the Safety Logic Controller (refer to

EcoStruxure Machine Expert - Safety User

Guide).

7 Execute a complete validation of the Safety

Logic Controller functional safety system.

-

-

, chapter

for information on IP forwarding

settings. For PacDrive,

Ethernet

How to Configure the

provides

. The

WARNING

UNINTENDED EQUIPMENT OPERATION

Ensure that the Safety Logic Controller is stopped before attempting to insert or remove the

memory key.

Each time the memory key is used (inserted/replaced), carefully verify that the loaded safety

application is the one that was intended for the particular system.

Conduct a complete functional test of the system, composed of the Safety Logic Controller

plus all input and output hardware connected to it, after using the memory key to overwrite your

safety-related application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000000889 09/2020 29

SLC 100 Sercos III and SLC 200 Sercos III

NOTE: You can verify your safety-related application by examining the project CRC and the date

that were saved with the application on the memory key. For more information, refer to the

EcoStruxure Machine Expert - Safety User Guide.

Removing a Memory Key

Removing a memory key results in a boot status change (the LED indicators F, I and L illuminate)

and a disabling of the safety-related functions. In addition, removing the memory key during

operation can corrupt the data on the memory key.

INTERRUPTION OF SAFETY-RELATED FUNCTION AND POSSIBLE LOSS OF MEMORY

KEY DATA

Do not remove the memory key when the Safety Logic Controller is in a RUN state.

Engage the locking mechanism while the key is inserted in the Safety Logic Controller.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

To remove the memory key, proceed as follows:

Step Action

1 Ensure that the Safety Logic Controller is STOPPED or that power has been removed.

2 Disengage the mechanical locking mechanism.

3 Pull the memory key out of the Safety Logic Controller.

NOTE: The Safety Logic Controller requires a valid memory key to operate.

WARNING

Copying to a Memory Key

Copying to a memory key is a function that allows you to copy the configuration data from the

Safety Logic Controller to another memory key. The application and parameters are not copied to

the memory key.

Pre-requisite 1: The Safety Logic Controller is operational, therefore, with an existing memory key.

Pre-requisite 2: You have another memory key, already containing an application valid for the

present Safety Logic Controller.

30

EIO0000000889 09/2020

SLC 100 Sercos III and SLC 200 Sercos III

To transfer the configuration data to another memory key, proceed as follows:

Step Action Result/Comment

1 Set the selection switch to SK-COPY position

and press the confirmation button.

NOTE: Refer to Logic Processor Selection

Switch and Confirmation Button

(see page 42)

2 Dis-engage the mechanical locking

mechanism and replace the existing memory

key by the other memory key.

.

(1)

NOTE: Do not move the selection switch. It

remains on the position SK-COPY.

3

Press the confirmation button

4 Move the selection switch to SK-XCHG and

press the confirmation button.

5 Engage the mechanical locking mechanism. 6 Execute a complete validation of the Safety

Logic Controller functional safety system.

(1) If no memory key is inserted after 30 seconds, the Safety Logic Controller switches to boot status (the

LED indicators F, I and L illuminate).

(2) If the other memory key is not acknowledged after 30 seconds, the function ends, that is, in case the

function is triggered inadvertently, the copy function ends automatically after 30 seconds.

(2)

.

Result: The ENTER LED illuminates and the

SKEY LED flashes. The existing memory key

configuration data is saved to an internal,

temporary file on the Safety Logic Controller to

be later transferred to the other memory key, and

the FW-ACKN LED flashes when the action is

completed.

A maximum of 30-second delay is provided for

this step. The FW-ACKN LED flash frequency

increases after 20 seconds to signal the end of

that delay.

The internal, temporarily saved configuration file

is transferred to the memory key.

Result: The ENTER LED illuminates. The

memory key replacement is confirmed

(see page 32)

-

.

WARNING

UNINTENDED EQUIPMENT OPERATION

Ensure that the Safety Logic Controller is stopped before attempting to insert or remove the

memory key.

Each time the memory key is used (inserted/replaced), carefully verify that the loaded safety

application is the one that was intended for the particular system.

Conduct a complete functional test of the system, composed of the Safety Logic Controller

plus all input and output hardware connected to it, after using the memory key to overwrite your

safety-related application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000000889 09/2020 31

SLC 100 Sercos III and SLC 200 Sercos III

NOTE: You can verify your safety-related application by examining the project CRC and the date

that were saved with the application on the memory key. For more information, refer to the

EcoStruxure Machine Expert - Safety User Guide.

Confirming Memory Key Insertion

The following procedure authorizes the safety-related application stored on the memory key to be

used with the Safety Logic Controller. In addition, after confirmation, the application on the memory

key is compared with that in execution memory, and if they are different, the application on the

memory key is transferred to the Safety Logic Controller.

To confirm the insertion of a memory key, proceed as follows:

Step Action Result

1 Ensure that the Safety Logic Controller is

STOPPED.

2 Insert the memory key in the Safety Logic

Controller.

NOTE: The Safety Logic Controller requires a

valid memory key to operate.

3 Move the selection switch to SK-XCHG and

press the confirmation button.

4 Engage the mechanical locking mechanism. -

5 Execute a complete validation of the Safety

Logic Controller functional safety system.

-

The FW-ACKN LED illuminates.

The ENTER LED illuminates. The memory key

replacement is confirmed

-

(see page 32)

.

32

WARNING

UNINTENDED EQUIPMENT OPERATION

Ensure that the Safety Logic Controller is stopped before attempting to insert or remove the

memory key.

Each time the memory key is used (inserted/replaced), carefully verify that the loaded safety

application is the one that was intended for the particular system.

Conduct a complete functional test of the system, composed of the Safety Logic Controller

plus all input and output hardware connected to it, after using the memory key to overwrite your

safety-related application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTE: You can verify your safety-related application by examining the project CRC and the date

that were saved with the application on the memory key. For more information, refer to the

EcoStruxure Machine Expert - Safety User Guide.

EIO0000000889 09/2020

Creating a Memory Key Backup

The procedure described in Copying to a Memory Key

memory key backup by using a second memory key with an identical safety-related application.

After executing the procedures, two identical memory keys are available.

Formatting the Memory Key

The following procedure allows you to format the memory key. Only use this procedure if your

firmware update was not successful or the memory has a detected error.

A formatting of the memory key deletes the current memory key data, including your password.

LOSS OF MEMORY KEY DATA

Create a memory key backup before formatting the memory key.

Connect to the EcoStruxure Machine Expert - Safety software to assign a new password.

Failure to follow these instructions can result in equipment damage.

To format the memory key, proceed as follows:

Step Action Comment / Result

1 Ensure that the Safety Logic Controller is

stopped.

2 Move the selection switch to the unlabeled

position between SK-XCHG and FW-ACKN.

(see page 30)

NOTICE

SLC 100 Sercos III and SLC 200 Sercos III

can also be used to create a

-

3 Press the confirmation button for a minimum of

20 to 30 s to receive a confirmation.

EIO0000000889 09/2020 33

After 20 s, the ENTER LED illuminates.

NOTE:

When you have released the confirmation

button, the ENTER LED remains illuminated

for another second.

When you press the confirmation button for

less than 20 s, it has no effect.

When you press the confirmation button for

longer than 30 s, the ENTER LED flashes

for 5 s to display a detected error.

Result: The LED will indicate that there is no

valid application on the key

SLC 100 Sercos III and SLC 200 Sercos III

Step Action Comment / Result

4 Follow the procedures necessary to add a valid

application to the key.

-

34

EIO0000000889 09/2020

Modicon TM5

Operating and Connectio n Elements

EIO0000000889 09/2020

Operating and Connectio n Elements

Chapter 3

Operating and Connection Elements

Information

This chapter provides information on operating and connection elements, as well as the LED

indicators of the Safety Logic Controller.

What Is in This Chapter?

This chapter contains the following topics:

Safety Logic Controller Description 36

Logic Processor LED Indicators 38

Logic Processor Selection Switch and Confirmation Button 42

Safety Terminal Block Presentation 44

Integrated Power Supply 47

Sercos III Interface 49

Topic Page

EIO0000000889 09/2020 35

Operating and Connection Elements

Safety Logic Controller Description

Description

The LED indicators, buttons and switches are integrated to operate the Safety Logic Controller.

The following figure presents the operating and connection elements:

36

N° Description Refer to

1 Confirmation button Confirming a Function

2 Selection switch Description of the Selection Switch Functions

(see page 43)

(see page 42)

3 Logic processor Logic Processor LED indicators

4 Sercos III interface Sercos III interface

5 Integrated power supply Integrated Power Supply

6 Sercos address switches Sercos Address

7 Terminal block for Safety Logic Controller

power supply

Safety-Related Terminal Block Presentation

(see page 44)

(see page 49)

(see page 51)

(see page 38)

(see page 47)

EIO0000000889 09/2020

Operating and Connection Elements

N° Description Refer to

8 Sercos III connection with 2 x RJ45 Sercos III RJ45 Ports

9 Memory key slot / slot cover Safety Logic Controller Memory Key

(seepage52)

(see page 28)

These components enable you to perform the following operations:

module replacement

firmware update

memory key replacement, including a possible transfer of module configuration from the

previous memory key

support for the replacement of Safety Logic Controller

EIO0000000889 09/2020 37

Operating and Connection Elements

Logic Processor LED Indicators

Description of the LED Indicators for the Logic Processor

The figure and table present the LED indicators for the logic processor of the TM5CSLC100FS and

TM5CSLC200FS:

LED

indicator

R/E N/A off Boot phase -

ENTER

(1) When a module scan is being executed, the ENTER, MXCHG, and FW-ACKN LED indicators are flashing.

(2) When the controller is in error state, the states of the other L ED indicator s ( R/E, ENTER, MXCHG, and FW-ACKN)

are not updated.

LED color LED status Description Instructions / information for

the user

green on Application found and executed

flashing Application exists but is not being

processed

orange on EcoStruxure Machine Expert -

Safety software is in RUN

(Debug) state

flashing EcoStruxure Machine Expert -

fast flashing No application found on the

(1)

green on Waiting for confirmation -

1x flash every 0.8 s Confirmation of correct entry

flashes (1 Hz) for 5sOperator error detected

Safety software is in STOP

(Debug) state or HALT (Debug)

state, application stopped

memory key

38

EIO0000000889 09/2020

Operating and Connection Elements

LED

indicator

MXCHG

LED color LED status Description Instructions / information for

the user

(1)

orange off Valid module configuration -

Replacement of one module

detected

Select the position 1 on the

selection switch and press the

confirmation button ENTER.

Replacement of two modules

detected

Select the position 2 on the

selection switch and press the

confirmation button ENTER.

Replacement of three modules

detected

Select the position 3 on the

selection switch and press the

confirmation button ENTER.

Replacement of four modules

detected

Select the position 4 on the

selection switch and press the

confirmation button ENTER.

Replacement of more than four

modules detected

Select the position n on the

selection switch and press the

confirmation button ENTER.

Missing module detected -

FWACKN

orange off Valid firmware configuration -

(1)

flashing Firmware update successful Select the position FW-ACKN

on the selection switch and

press the confirmation button

ENTER.

on Memory key was exchanged Select the position SK-XCHG

on the selection switch and

press the confirmation button

ENTER.

(1) When a module scan is being executed, the ENTER, MXCHG, and FW-ACKN LED indicators are flashing.

(2) When the controller is in error state, the states of the other LED ind ica tor s (R/E, ENTER, MXCHG, and FW-ACKN)

are not updated.

EIO0000000889 09/2020 39

Operating and Connection Elements

LED

indicator

F

A

I

L

LED color LED status Description Instructions / information for

the user

red FAI LThese four LEDs indicate first the

boot status, then, when the

system is running, the general

state of the controller.

x- xx

Boot phase

Loading of the firmware

Memory key is missing

Project CRC (Cyclic

Redundancy Check) is wrong

or not defined

Safety Logic Controller cycle

time is exceeded

If the LED status persists:

Refer to the Safe logger for

additional diagnostic

information on the error.

Verify if the memory key is

plugged correctly.

Re-download the

corresponding project, and

verify the project CRC.

Verify the cycle time and

increase it if necessary.

x x x x Hardware test (max. approx. 5 s) -

x X x X Initialization and start-up of the

firmware

---X Pre-operational state

- - - - Operational state

xxxx

Controller in error state

(2)

x = illuminated

X= brightly illuminated

- = off

alternating flashing

of FI and AL

EcoStruxure Machine Expert Safety software is connected and

in RUN (Debug) state

SKEY orange off No access to the memory key -

flashing Access to the memory key

(1) When a module scan is being executed, the ENTER, MXCHG, and FW-ACKN LED indicators are flashing.

(2) When the controller is in error state, the states of the other L ED indicator s ( R/E, ENTER, MXCHG, and FW-ACKN)

are not updated.

Testing the LED Indicators for the Logic Processor

Follow this procedure to test the LED indicators:

Step Action

1 Position the selection switch to TEST.

40

EIO0000000889 09/2020

Step Action

2 Press the confirmation button.

Result: All LED indicators on the logic processor illuminates for as long as you press the

confirmation button.

Operating and Connection Elements

EIO0000000889 09/2020 41

Operating and Connection Elements

Logic Processor Selection Switch and Confirmation Button

Overview

Whenever you make a change in the configuration (module or memory key replacement, or

firmware update), you need to acknowledge the change on the Safety Logic Controller using the

selection switch and the confirmation button.

The following figure presents the selection switch and the confirmation button:

Description of the Selection Switch Functions

The following table describes the selectable functions:

Selection switch position Function Description

FW-ACKN Firmware update To acknowledge the firmware update on one or more

modules

SK-XCHG Memory key replacement

To confirm the memory key replacement

(see page 30)

SK-COPY Memory key copy

To copy of the configuration data from the memory key

(see page 30)

SCAN Scan To perform a module scan

TEST Test

1, 2, 3, 4, n Module(s) replacement To confirm the replacement of 1, 2, 3, 4 or more than 4

(1) Triggers an automatic restart.

(see page 40)

To perform a LED indicator test

module(s)

(1)

(1)

(1)

42

EIO0000000889 09/2020

Confirming a Function

To confirm a configuration change, proceed as follows:

Step Action

1 Select the desired function by means of the selection switch.

NOTE: If you do not place the selection switch properly, the LED ENTER flashes for 5 s to

display a detected error.

Example: To replace one specific module, place the selection switch on 1. If the selection switch

is not set to 1 when only one module was replaced, an error is detected and the LED ENTER

flashes for 5 s.

2 Press the confirmation button for 0.5 to 5 s to receive a confirmation.

Result: After 0.5 s, the LED ENTER is illuminated.

3 Release the confirmation button.

Result: The LED ENTER remains illuminated for additional 0.8 s.

NOTE: If you release the confirmation button before 0.5 s, it has no effect. If you press the confirmation

button longer than 5 s, the LED ENTER flashes for 5 s to display a detected error.

Operating and Connection Elements

EIO0000000889 09/2020 43

Operating and Connection Elements

Safety Terminal Block Presentation

TM5ACTB52FS Features

The safety-related modules and the Safety Logic Controllers are wired by means of the

TM5ACTB52FS Safety terminal block:

Features

Type of terminal block 12-pin, safety coded terminal block

Features

Ordering Information

The following figure presents the TM5ACTB52FS Safety terminal block:

tool-free wiring with push-in technology

simple wire release using lever

allows labeling of each terminal

allows plain text labeling

test access for standard probes

potential for customer coding

44

The following table presents the reference for the Safety terminal block:

Reference Description Color

TM5ACTB52FS 24 Vdc / 230 Vac, 12-pin terminal block for

safety-related modules and Safety Logic

Controllers, safety coded

red

EIO0000000889 09/2020

INCOMPATIBLE COMPONENTS CAUSE ELECTRIC SHOCK OR ARC FLASH

Do not associate components of a slice that have different colors.

Verify that correct terminal blocks (minimally, matching colors and correct number of

terminals) are installed on the appropriate electronic modules.

Failure to follow these instructions will result in death or serious injury.

Characteristics

This section describes the characteristics of the TM5ACTB52FS Safety terminal block, you can

also refer to TM5 Environmental Characteristics

Hardware Guide)

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the I/O channels and

power supplies.

For relay output (2 A) wiring, use conductors of at least 0.5 mm

rating of at least 80 °C (176 °F).

For common conductors of relay output wiring (4 A), or relay output wiring greater than 2 A,

use conductors of at least 1.0 mm

(176 °F).

Failure to follow these instructions will result in death or serious injury.

Operating and Connection Elements

DANGER

(see Modicon TM5/TM7, I/O Safety Modules,

.

DANGER

2

(AWG 20) with a temperature

2

(AWG 16) with a temperature rating of at least 80 °C

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not connect wires to unused terminals and/or terminals indicated as “No Connection (N.C.)”.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the characteristics tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000000889 09/2020 45

Operating and Connection Elements

The following table lists the characteristics of the TM5ACTB52FS:

Characteristics

Type of terminal block Push-in terminal block

Distance between

contacts

Contact resistance ≤ 5 mΩ

Maximum current carrying capacity of the

connector

Connection cross

section

Cable type Copper wires only

LOOSE WIRING CAUSES ELECTRIC SHOCK

Do not insert more than one wire per connector of the spring terminal blocks unless using a

double wire cable end (ferrule).

Failure to follow these instructions will result in death or serious injury.

left - right 4.2 mm / 0.16 in

above - below 10.96 mm / 0.43 in

10 A / contact

NOTE: The electrical characteristics of the individual

modules must be respected.

solid wire

multi-wire

with wire cable ends

-

0.08 mm

0.25 mm

0.25 mm2 ... 1.5 mm2 / AWG 24 ... 16

Up to 2x 0.75 mm

wire cable ends

2

... 2.5 mm2 / AWG 28 ... 14

2

... 2.5 mm2/ AWG 24 ... 14

DANGER

2

(AWG 2 x 24 ... 2 x 18) with double

46

EIO0000000889 09/2020

Integrated Power Supply

Presentation

A power supply is integrated in the Safety Logic Controller TM5CSLC100FS and TM5CSLC200FS.

LED indicators

The following figure presents the status LED indicators for integrated power supply:

The following table describes the LED status for the integrated power supply:

LED indicator LED color LED status State description

DCOK green on Power applied to the controller

Operating and Connection Elements

off No power applied to the controller

Wiring Diagram

DANGER

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the power supplies.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OVERHEATING AND FIRE

Do not connect the modules directly to line voltage.

Use only isolating PELV systems according to IEC 61140 to supply power to the modules.

Connect the 0 Vdc of the external power supplies to FE (Functional Earth/ground).

Failure to follow these instructions will result in death or serious injury.

EIO0000000889 09/2020 47

Operating and Connection Elements

The following figure presents the wiring diagram of the power supply for the Safety Logic

Controller:

1 Internal electronics

2 PS1: External isolated power supply 24 Vdc (-15% / +20%)

3 External fuse, Type T slow-blow, 1 A, 250 V

48

EIO0000000889 09/2020

Sercos III Interface

LED Indicators for the Sercos III Interface

The following figure presents the LED indicators for the Sercos III interface of the TM5CSLC100FS

and TM5CSLC200FS:

The following LED indicators are provided:

State

S3

S3 P1

S3 P2

Operating and Connection Elements

State LED Indicator

The State LED is a green (status) / red (error) dual LED indicator:

The following table describes the State LED indicator:

LED color LED status State description

- off No supply voltage applied or device is inoperable.

green on No detected error, bus interface is initialized and ready for operation.

green flashing (12.5 Hz) Initialization phase (booting of the I/O modules or setting up the I/O

green flashing (4 Hz) Recoverable error detected, such as missing I/O module (this LED

green flashing (0.66 Hz) New or modified configuration data (I/O modules or bus interface) have

red flashing (8 Hz) Unrecoverable error detected (for example, lack of resources, error

functional groups).

indicator is reset when the error state is corrected).

been received but not yet stored in the flash memory.

detected in the firmware data flow).

NOTE: After applying power to the bus interface, several red flashing signals are displayed. These

signals are not error indications, but indication of the initialization process.

EIO0000000889 09/2020 49

Operating and Connection Elements

NOTE: If the firmware update is unsuccessful (corrupted file, interruption of the update, etc.), the

bus interface restarts with the previous version of the firmware.

S3 (Sercos III) LED Indicator

The following table describes the S3 LED indicator:

LED color LED status State description Instructions

- off Power is removed or there is no

green on Active Sercos III connection without

green flashing (4 Hz,

125 ms)

red on Sercos III diagnostic class error has

red/green flashing (4 Hz,

125 ms)

(1) IdentifyDevice is a parameter in EcoStruxure Machine Expert.

communication due to a connection

interruption.

a detected error in the

Communication Phase 4 (CP4).

The device is in Loopback mode.

Loopback describes the situation in

which the Sercos III telegrams have

to be sent back on the same port on

which they were received.

Possible causes:

line topology

Sercos III ring break

been detected on port 1 and/or

Sercos III communication is no

longer possible on the ports (for

example due to an encoder error).

Detected communication error.

Possible causes:

improper functioning of the

telegram

detected CRC (Cyclic

Redundancy Check) error

Apply power or verify physical

connections

n.a.

Close the ring.

Reset condition

clear the detected device

errors

acknowledge the detected

error in the menu

switch from CP2 to CP3

alternatively.

NOTE: Diagnostic

messages pending in the

system are not

acknowledged by this.

Reset condition

The configuration indicates

the detected error

acknowledge the detected

error.

switch from CP2 to CP3

alternatively.

NOTE: Diagnostic

messages pending in the

system are not

acknowledged by this.

50

EIO0000000889 09/2020

LED color LED status State description Instructions

orange on The device is in a communication

orange flashing (4 Hz,

125 ms)

(1) IdentifyDevice is a parameter in EcoStruxure Machine Expert.

S3 P1/S3 P2 LED Indicators

The following table describes the S3 P1 (Port 1) and S3 P2 (Port 2) LED indicators:

LED color LED status State description

- off no cable connected

green flashing active Sercos III communication

green on link, but no telegrams / communication (for example controller is

Sercos Address

The Sercos address is set by two switches. Positioning the switches at 0 triggers the autoaddressing feature.

NOTE: Only Sercos addresses between 1 and 255 are allowed.

The following figure presents the Sercos address switches:

Operating and Connection Elements

n.a.

phase CP0 up to and including CP3.

Sercos III telegrams are received.

Device identification Triggered by using the

parameter IdentifyDevice

or the DriveAssistant tool.

booting)

(1)

NOTE: The Sercos address is in hexadecimal notation. Set the address (1...255 dec) manually by

the two Sercos address switches.

EIO0000000889 09/2020 51

Operating and Connection Elements

The following table describes the Sercos address, set with the 2 hexadecimal switches:

Sercos address Description

0 dec (0 hex) Auto-addressing (not a valid address)

1-255 dec (1-FF hex) Manual addressing

(1) IdentificationMode is a parameter in EcoStruxure Machine Expert.

Example:

In order to set the Sercos address 190 (dec) / BE (hex), set the two hexadecimal switches as

follows:

Switch x1 = E

Switch x16 = B

For PacDrive LMC controllers, the setting 0 is recognized when the

value SerialNumberController or TopologyAddress or

ApplicationType is selected for the parameter

(1)

IdentificationMode

For Modicon TM262M• controllers, the setting 0 is recognized, when

.

the value Topology mode is selected for the parameter

IdentificationMode

For PacDrive LMC controllers, this setting is recognized when the

(1)

.

value SercosAddress is selected for the parameter

IdentificationMode

For Modicon TM262M• controllers, this setting is recognized when

(1)

.

the value Sercos mode is selected for the parameter

IdentificationMode

(1)

.

Sercos III Ports

The following figure presents the RJ45 connectors of the Safety Logic Controller:

1 Sercos III PORT A (P1)

2 Sercos III PORT B (P2)

52

EIO0000000889 09/2020

Operating and Connection Elements

The following table lists the pin assignments for the RJ45 connectors:

Pin Assignment

1 RXD (Receive Data)

2RXD\

3 TXD (Transmit Data)

4 Termination

5 Termination

6TXD\

7 Termination

8 Termination

For more information about the Sercos III ports, refer to Fieldbus Characteristics

(see page 26)

.

EIO0000000889 09/2020 53

Operating and Connection Elements

54

EIO0000000889 09/2020

bus base

DC

Modicon TM5

Glossary

EIO0000000889 09/2020

Glossary

B

A bus base is a mounting device that is designed to seat an electronic module on a DIN rail and

connect it to the TM5 bus for Safe Logic Controllers. Each bus base extends the TM5 data and the

power buses and the 24 Vdc I/O power segment. The electronic modules are added to the TM5

system through their insertion on the base bus. The bus base also supplies the articulation point

for the terminal blocks.

D

diagnostic coverage

Fractional decrease in the probability of dangerous hardware failures resulting from the operation

of the automatic diagnostic tests

(definition IEC 61508)

The fraction of the possible dangerous failures λ

diagnostics and failures which remain undetected.

λ

D=λDD+λDU

The diagnostic coverage (DC) defines the fraction of the dangerous failures which are detected.

• DC

λ

DD=λD

• (1-DC)

λ

DU=λD

The definition may also be represented in terms of the following equation, where DC is the

diagnostic coverage, λ

is the probability of detected dangerous failures and λD total is the

DD

probability of total dangerous failures:

is divided into failures which are detected by

D

M

MTTFd

mean time to failure - dangerous

EIO0000000889 09/2020 55

Glossary

PFD

PFH

P

probability of failure on demand

(definition IEC 61508)

For a single channel system the average probability of a failure on demand is calculated as follows:

For a dual channel system the average probability of a failure on demand is calculated as follows:

For a dual channel system, also the Common Cause effect (CC) must be considered. The common

cause effect ranges from 1% to 10% of PFD

probability of dangerous failure per hour

(definition IEC 61508)

and PFD

CH1

(=1/RRF).

CH2

PT

SFF

56

proof test interval

S

safe failure fraction

EIO0000000889 09/2020

Modicon TM5

Index

EIO0000000889 09/2020

Index

C

certification

TM5ACBM3FS,

characteristics

TM5ACBM3FS,

TM5CSLC100FS,

TM5CSLC200FS,

confirmation button

TM5CSLC100FS,

TM5CSLC200FS,

connection elements

TM5CSLC200FS,

connection elements

TM5CSLC100FS,

44

44

25

25

42

42

36

36

I

IEC 61508

defined safe state,

Emergency Shutdown (ESD),

ESD (Emergency Shutdown),

Safety Integrity Level (SIL),

SIL (Safety Integrity Level),

IEC61508

functional safety,

integrated power supply

TM5CSLC100FS,

TM5CSLC200FS,

intended use,

6

14

14

47

47

14

14

14

14

M

memory key

TM5ACSLCM2FS,

TM5ACSLCM8FS,

memory key

TM5ACSLCM2FS,

TM5ACSLCM8FS,

23

23

28

28

O

operating conditions

TM5ACBM3FS,

operating elements

TM5CSLC200FS,

operating elements

TM5CSLC100FS,

ordering information

TM5CSLC100FS,

TM5CSLC200FS,

44

36

36

23

23

P

PFD (probability of failure on demand,

PFH (probability of failure per hour),

power consumption

TM5ACBM3FS,

probability of failure on demand (PFD),

probability of failure per hour (PFH),

44

17

17

17

17

L

LED

TM5CSLC100FS,

LED indicators

TM5CSLC100FS,

TM5CSLC200FS, 23,

EIO0000000889 09/2020 57

38

23

38

qualification of personnel,

S

selection switch

TM5CSLC200FS,

selection switch

TM5CSLC100FS,

42

42

6

Q

Index

Sercos III interface

TM5CSLC200FS,

Sercos III interface switch

TM5CSLC100FS,

storage conditions

TM5ACBM3FS,

49

49

44

T

TM5ACTB52FS,

safety terminal block,

transport conditions

TM5ACBM3FS,

23

44

44

58

EIO0000000889 09/2020

Loading...

Loading...