Installation

Smart-UPS® VT

in Parallel

10-40 kVA

380/400/415 V

208/220 V

200/208 V

Contents

Safety ............................................................................... 1

IMPORTANT SAFETY INSTRUCTIONS

- SAVE THESE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Prepare for Floor-Anchoring (optional) . . . . . . . . . . . . . . . . . . . . . . .2

System arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hole positions for a stand-alone UPS enclosure with L-shaped

anchoring brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Hole positions for up to four UPS units in parallel with U-shaped

anchoring brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Prepare for Parallel Communication Cables ................ 5

Three different ways of routing cables . . . . . . . . . . . . . . . . . . . . . . . 5

Schematic overview of the PBus cables layout . . . . . . . . . . . . . . . . 5

Remove the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remove the top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remove the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install the interconnection plates (optional) . . . . . . . . . . . . . . . . . . 7

Run the Cables.............................................................. 10

UPSs apart without Conduits and Interconnection . . . . . . . . . . . . . 10

UPSs bayed together without Conduits . . . . . . . . . . . . . . . . . . . . . . 12

UPSs apart or bayed together with Conduits. . . . . . . . . . . . . . . . . . 13

Final Mechanical Assembly ......................................... 15

Level the Enclosures (L-shaped Floor Anchoring Brackets)

and Install Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Level the enclosures with the leveling feet . . . . . . . . . . . . . . . . . . 15

Install battery-securing and floor-anchoring brackets . . . . . . . . . 16

Reinstall the top cover and the front panel . . . . . . . . . . . . . . . . . . 16

Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V

i

Power Connections (Overview). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

380/400/415 V input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Breaker sizes 380/400/415 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

200/208/220 V input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Breaker sizes 200/208/220 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ii

Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V

Safety

IMPORTANT SAFETY INSTRUCTIONS

-

SAVE THESE INSTRUCTIONS

Warning: ALL safety instructions in the Safety Sheet (990-2822) must be read,

understood and followed prior to installation. Failure to do so could result in equipment

damage, serious injury, or death.

Warning: Parallel operation is not available when the system is set up for 3-wire

operation, which only applies to Japanese systems.

Caution: All electrical power and power control wiring must be installed by a qualified

electrician, and must comply with local and national regulations for maximum power rating.

Note: The cables must be routed by the electrician but not attached. The field service

engineer from APC by Schneider Electric will install the parallel communication box and

attach all cables to the UPSs.

Note: Up to four UPS units can run in parallel.

See also:

For information on UPS specifications on the Smart-UPS VT series, see part nos. (available

from the document storage in the UPS):

-1986 — Installation 380/400/415 V

• 990

-1598 — Installation 208/220 V

• 990

• 990

-2360 — Installation 200/208 V

1Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V Installation in Parallel

Prepare for Floor-Anchoring (optional)

XRXR XR XRUPS XRXR XR XRUPS XRXR XR XRUPS XRXR XR XRUPS

XR XR XRXR XRXR XR XRUPSUPS

UPS UPS UPSUPS

Note: If floor anchoring and battery securing is required, read this section. If not, see “Prepare

for Parallel Communication Cables” on page 5.

Note: Allow for enough working space behind the enclosure for electrical work to be carried

out (e.g. if you want to install a conduit box or if you want to connect an XR Battery Enclosure

at a later stage). Minimum rear clearance is 100 mm (3.93 in) and must comply with applicable

national and local codes. 600 mm (23.6 in) is recommended.

Note: The L-shaped floor anchoring brackets that secured the enclosure to the pallet during

shipment may be used for a stand-alone UPS enclosure to enhance stability. See this chapter for

hole positions and see also “Level the Enclosures (L-shaped Floor Anchoring Brackets) and

Install Batteries” on page 15. The L-shaped floor anchoring brackets are not necessary when

baying enclosures together. Instead, the three U-shaped floor anchoring brackets from the

baying kit are used.

Note: Hole positions are only intended as a guide.

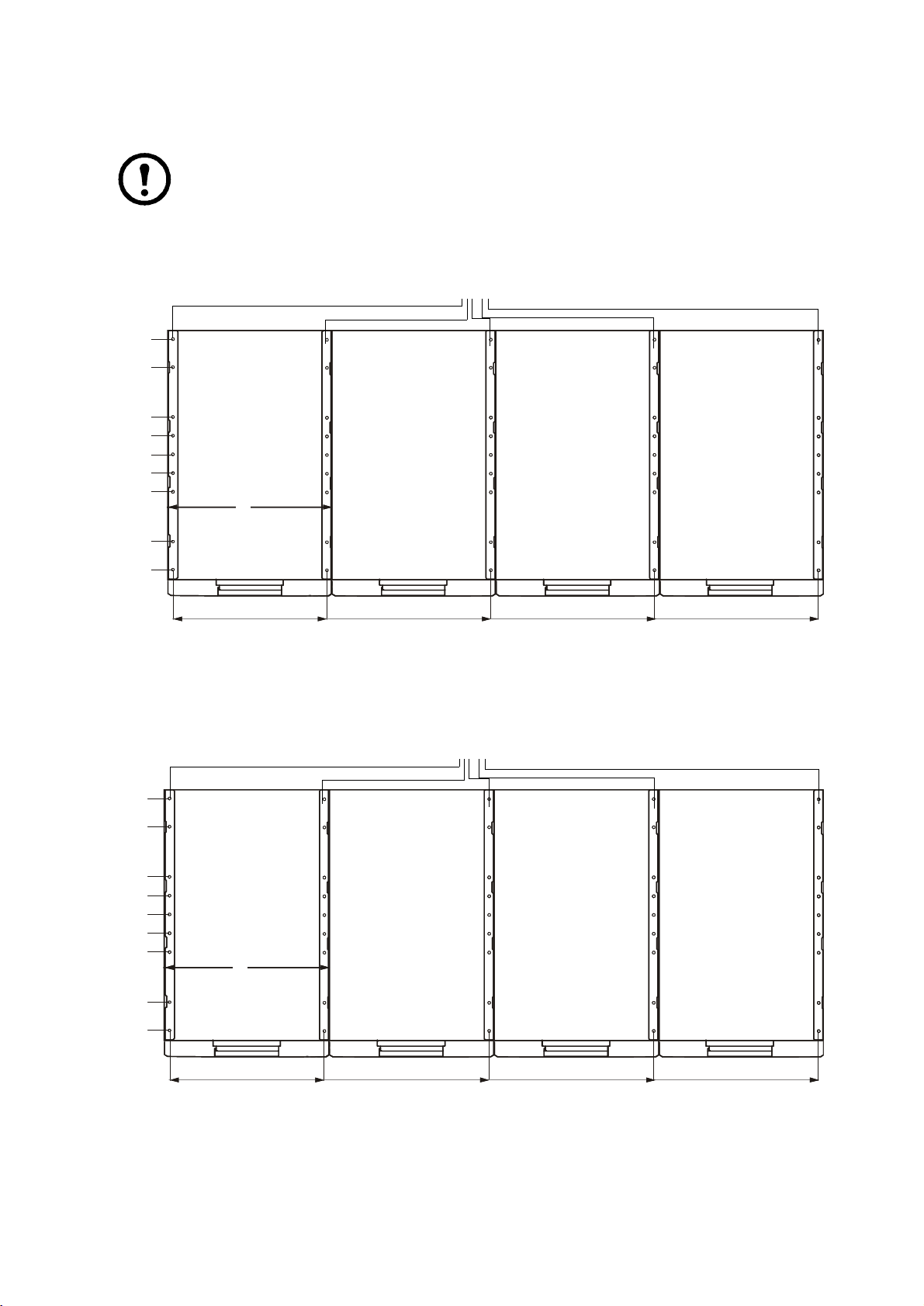

System arrangements

APC recommends the following arrangements of UPS units and XR Battery Enclosures (XR) in parallel.

Examples with two parallel systems using baying kits.

Note: UPS units and their respective XR Battery Enclosure must be bayed together. XR

Battery Enclosures must never be shared in a parallel UPS system.

Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V Installation in Parallel2

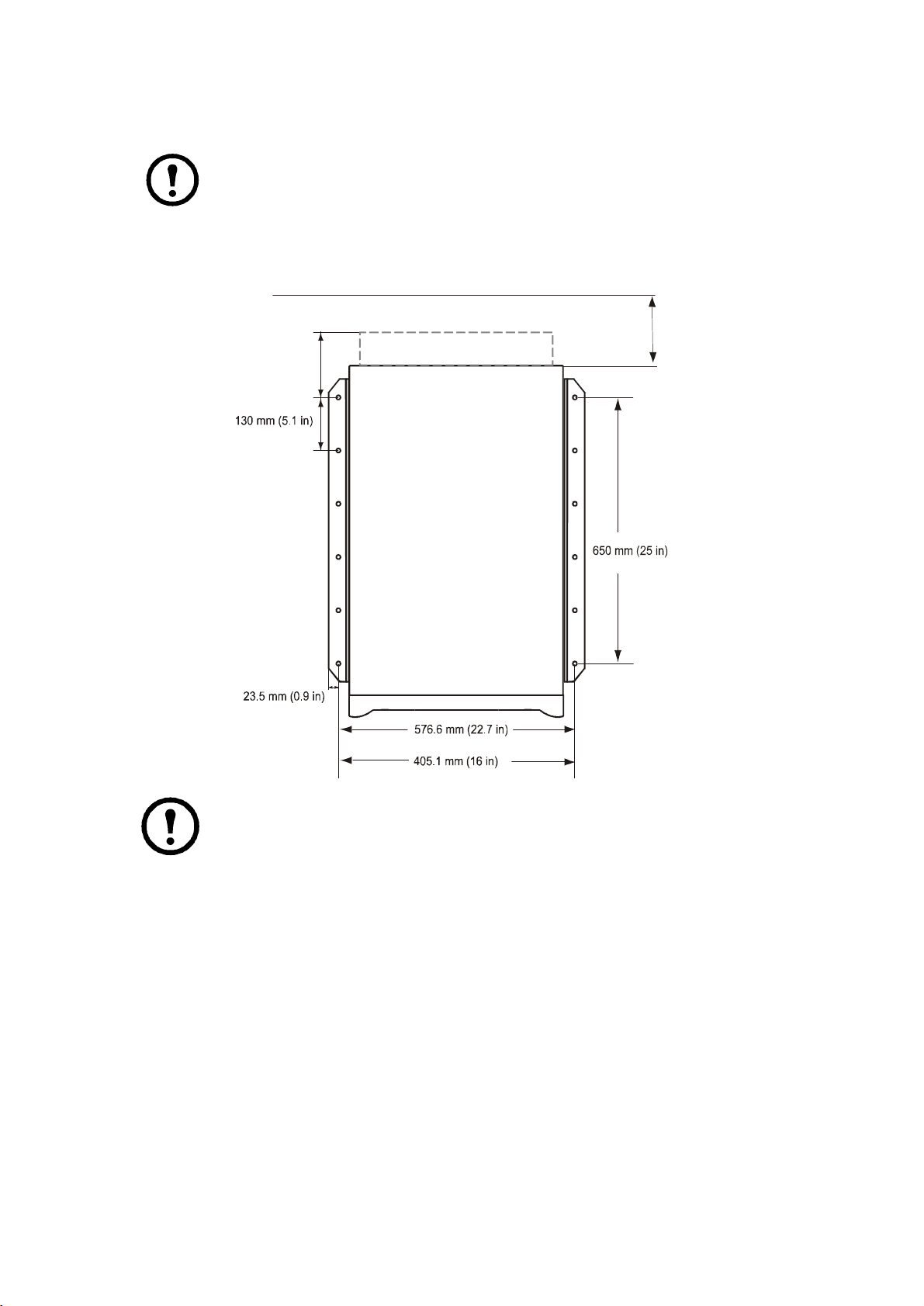

Hole positions for a stand-alone UPS enclosure with L-shaped anchoring brackets

Conduit box (if applicable)

Floor anchoring hole

Minimum rear

clearance:

100 mm (3.93 in)

Note: Recommended minimum number of screws per enclosure for the L-shaped brackets is

four; one in each corner. Recommended floor bolt size: M8.

Model width: 352 mm (13.85 in) and 523 mm (20.59 in).

Note: Rear service clearance must comply with applicable national and local codes. 600 mm

(23.6 in) is recommended.

3Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V Installation in Parallel

Hole positions for up to four UPS units in parallel with U-shaped anchoring brackets.

Top view

90 mm (3.54 in)

160 mm (6.29 in)

60 mm (2.36 in)

60 mm (2.36 in)

60 mm (2.36 in)

60 mm (2.36 in)

160 mm (6.29 in)

90 mm (3.54 in)

352 mm (13.85 in)

0

323 mm

(12.71 in)

675 mm

(26.56 in)

1027 mm

(40.41 in)

1379 mm

(54.26 in)

Floor anchoring brackets

Top view

90 mm (3.54 in)

160 mm (6.29 in)

60 mm (2.36 in)

60 mm (2.36 in)

60 mm (2.36 in)

60 mm (2.36 in)

160 mm (6.29 in)

90 mm (3.54 in)

523 mm (20.59 in)

0

494.5 mm

(19.46 in)

1017.5 mm

(40.05 in)

1540.5 mm

(60.46 in)

2063.5 mm

(81.23 in)

Floor anchoring brackets

Note: Recommended minimum number of floor screws for the below two

configurations is 10.

Model width: 352 mm (13.85 in).

Model width: 523 mm (20.59 in).

Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V Installation in Parallel4

Prepare for Parallel Communication Cables

Three different ways of routing cables

Note: The enclosures in a parallel system can be kept apart, or they can be assembled with

interconnection plates (SUVTOPT011 APC Smart-UPS VT Parallel Operation Baying Kit). If

the enclosures are kept apart the communication cables can be run in conduits (if applicable).

The routing of cables between the UPSs can be done in three different ways:

1. UPSs apart (without conduits and without interconnection plates)

2. UPSs bayed together (without conduits and with interconnection plates)

3. UPSs apart or bayed together (with conduits and optional interconnection plates).

Schematic overview of the PBus cables layout

Note: The cables must be run by the electrician but not attached. The Field Service Engineer

from APC by Schneider Electric will attach all cables to the UPS(s) and install the parallel

communication box.

Note: The PBus cables run from UPS 1 to UPS 2 to UPS 3 to UPS 4 if your configuration

consists of 4 UPSs.

Note: The PBus cables are labelled PBus 1 and PBus 2.

Note: PBus 1 cables must be kept together and PBus 2 cables must be kept together. If you by

mistake run a cable between a PBUS1 terminal and a PBUS2 terminal you will be notified by

the display.

Note: If the configuration consists of only two UPS units, the terminators must be installed in

UPS 1 & 2. With three UPS units the terminators must be installed in UPS 1 & 3.

5Smart-UPS® VT 10-40 kVA 380/400/415 V - 208/220 V - 200/208 V Installation in Parallel

Loading...

Loading...