Page 1

Selection Guide

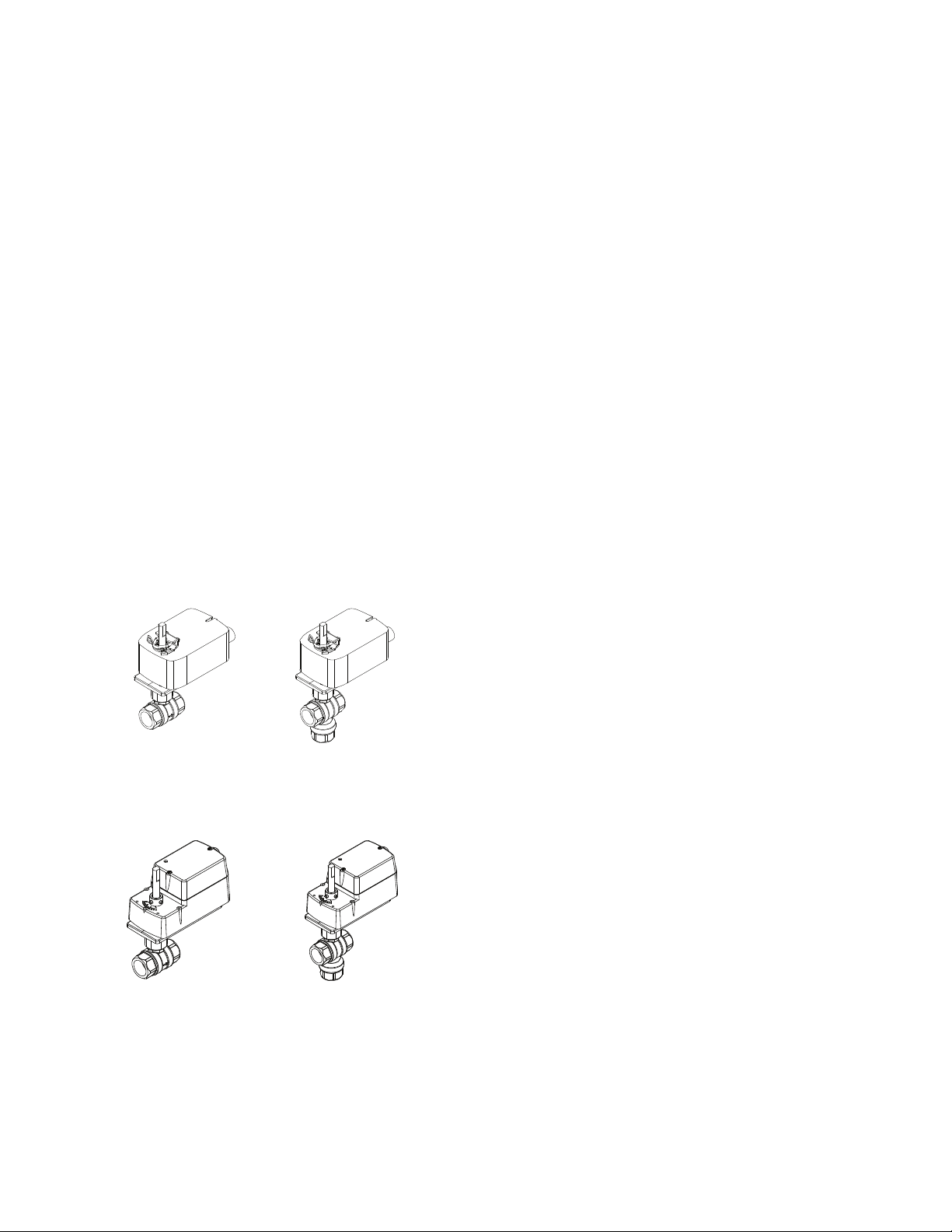

Ball Valve Assemblies with SmartX

Actuators

Selection Guide

The Schneider Electric VA, VF, and VS-2xx3-xxx-9-xx series

Ball Valve Assemblies are complete actuator/valve assemblies that accept two-position, floating, or proportional control

signals from a DDC system or a thermostat, for control of hot

or chilled water, or solutions of up to 50% glycol. They consist

of direct-coupled, SmartX, spring return or non-spring return

actuators mounted on 2-way (1/2” to 3”) and 3-way (1/2” to 2”)

ball valve bodies. Typical applications include reheat on VAV

boxes, fan coil units, hot and chilled water coils in air handling

units, and unit ventilators.

Ball Valve Assemblies with SmartX

Actuators

Vx-2xx3-5xx-9-xx series ball valve assemblies are available

with either spring return or non-spring return SmartX

tors.

Vx-22x3-5xx-9-xx

2-Way Assembly with

Spring Return Actuator

Vx-2313-5xx-9-xx

3-Way Assembly with

Spring Return Actuator

Vx-2xx3-8xx-9-xx Spring return valve assemblies equipped

with Mx4D-x0x3 SmartX Actuators, respectively.

®

Actua-

Contents

Ball Valve Assemblies with SmartX Actuators. ...................................1

Ball Valve Body/Linkage Assemblies.

Features and Benefits

Ball Valve Assembly Selection Procedure

Applicable Literature.

Part Numbering System.

Ball Valve Assemblies Using SmartX 5xx Actuators

Ball Valve Assemblies Using SmartX 8xx Actuators

Port Codes.

2-Way Ball Valve Assemblies with SmartX Actuators

3-Way Ball Valve Assemblies with SmartX Actuators

Ball Valve Specifications.

Valve/Actuator Combinations..............................................................9

2-Way Ball Valve Assemblies Using SmartX Actuators

3-Way Mixing Assemblies Using SmartX Actuators

2-Way Ball Valve Assemblies Using SmartX Actuators

3-Way Mixing Assemblies Using SmartX Actuators

Actuator Specs and Valve Assembly Mounting Dimensions.

Assemblies with MF/MS41-6043/83 NSR SmartX Actuators

Assemblies with Mx40-704x SR SmartX Actuators

Installation Considerations.

Mounting Angle of Valve Assembly

Piping

Water System Maintenance

Sizing and Selection

Two-position Control

Flow Characterization: Proportional/Floating Control

3-Way Mixing Valves

Cavitation Limitations on Valve Pressure Drop

Using Pipe Reducers with 2-Way Ball Valve Assemblies

Using Pipe Reducers with 3-Way Ball Valve Assemblies

.........................................................................................6

...........................................................................................23

....................................................................2

.........................................................................3

....................................................................4

....................................................................8

..............................................................23

....................................................................24

....................................................................24

....................................................................25

................................................2

.....................................3

......................4

......................5

....................6

....................7

.................9

...................10

...............11

....................12

...........13

.......13

.....................16

............................................23

.........................................................24

..................25

............................26

............27

............30

Vx-22x3-8xx-9-xx

2-Way Assembly with

Mx4D Series Actuator

Vx-2313-8xx-9-xx

3-Way Assembly with

Mx4D Series Actuator

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 2

Selection Guide

Ball Valve Body/Linkage Assemblies

Ball valve body/linkage assemblies allow field mounting of SmartX actuators.

Features and Benefits

Feature Benefit

Close-offs of 40 to 130 psi. Accommodates most close-off requirements.

Available in full range of line sizes, 1/2 in. to 3 in. for 2-way valves

and 1/2 in. to 2 in. for 3-way valves.

Cvs from 0.33 to 266. Permits optimal valve sizing, minimizing the need for pipe reducers.

Flow characterizing insert, made of glass-filled Noryl™. Provides equal percentage flow characteristic so that the heat output of

Available in both spring return and non-spring return models. Allows power loss mode requirement to be met for any given application.

Utilizes SmartX Actuators with two-position, floating, and proportional control.

All models equipped with pigtail leads. Eases installation. Reduced electrician costs.

Low-friction seals and o-rings. Allows the use of lower-torque actuators, reducing cost.

Valve body made of forged brass ASTM B283-06. Rated for static pressure of 360 psi at fluid temperatures of 20 to 250 °F

ANSI Class IV (0.01% of Cv) shutoff with 2-way valves. Allows accurate control, saves energy.

Choices of spring return direction. Provides Normally Closed or Normally Open spring return.

Thermally isolated mounting plate. Protects the actuator from excess cold or heat from chilled or hot water

Ball Valve Body/Linkage Assemblies are available separately. They

include anti-rotation clips for SmartX Actuators.

Satisfies a wide range of applications.

the coil is linear with respect to valve position.

Models to fit a wide range of applications.

(-7 to 121 °C).

passing through the valve. Discourages condensation.

Increases flexibility and minimizes inventory.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 3

Page 4

Selection Guide

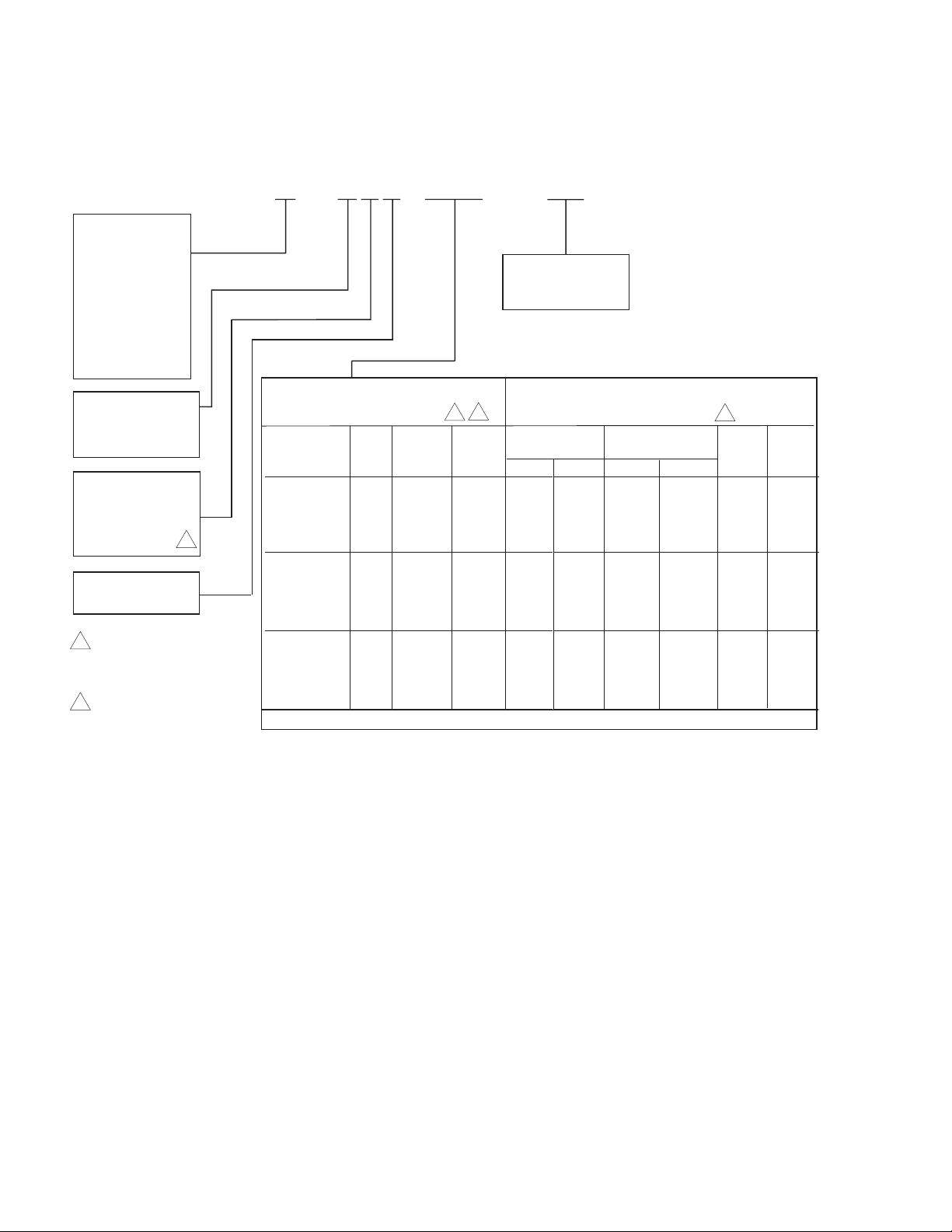

V x - 2 x x 3 - 5 x x - 9 - x x

Part Numbering System

Ball Valve Assemblies Using SmartX 5xx Actuators

Control

Signal Type

A = Two Position

F = Floating

S = Proportional

B = Valve Body &

Linkage

(less actuator)

a

Port Code

Refer to separate

Port Code table

Configuration

2 = 2 Way

3 = 3 Way Mixing

Material

1 = Nickel/Chromium

Plated Brass

5 = Stainless Steel

Connection

3 = Threaded NPT

1 Normal position for 3 way

spring return ball valve

assemblies refers to A to AB

ports.

3 Stainless steel ball is

available only on 2 way

versions.

3

2

Actuator Code Valves Used On

1

3

1-1/2" 1-1/2"

Normal 1/2 to 1" 1-1/4" to 3" to 2"

Model Code Position Voltage 2-way 3-way 2-way 3-Way 2-Way 3-way

Two-Position

MA40 7040 522 SR Close 120 Vac X X X X X X

MA40 7040 532 SR Open 120 Vac X X X X X X

MA40 7043 526 SR Close 24 Vac X X X X X X

MA40 7043 536 SR Open 24 Vac X X X X X X

Floating

MF41 6043 505 NSR 24 Vac X X X X

MF41 6083 506 NSR 24 Vac X X

MF40 7043 526 SR Close 24 Vac X X X X X X

MF40 7043 536 SR Open 24 Va c X X X X X X

Proportional

MS41 6043 505 NSR 24 Vac X X X X

MS41 6083 506 NSR 24 Vac X X

MS40 7043 526 SR Close 24 Va c X X X X X X

MS40 7043 536 SR Open 24 Vac X X X X X X

Valve Body/Linkage Assembly

SR = Spring Return

NSR = Non Spring Return

a

Includes valve body, linkage, and anti rotation clips for spring return and non spring return SmartX

actuators, listed above. Ordered separately.

Note: Not all model configurations are available as factory assemblies. You can purchase the the actuator

and a VB 22x3 500 9 xx valve body and linkage separately for field assembly.

a

VB-22x3-500-9-xx, VB-2313-500-9-xx

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 5

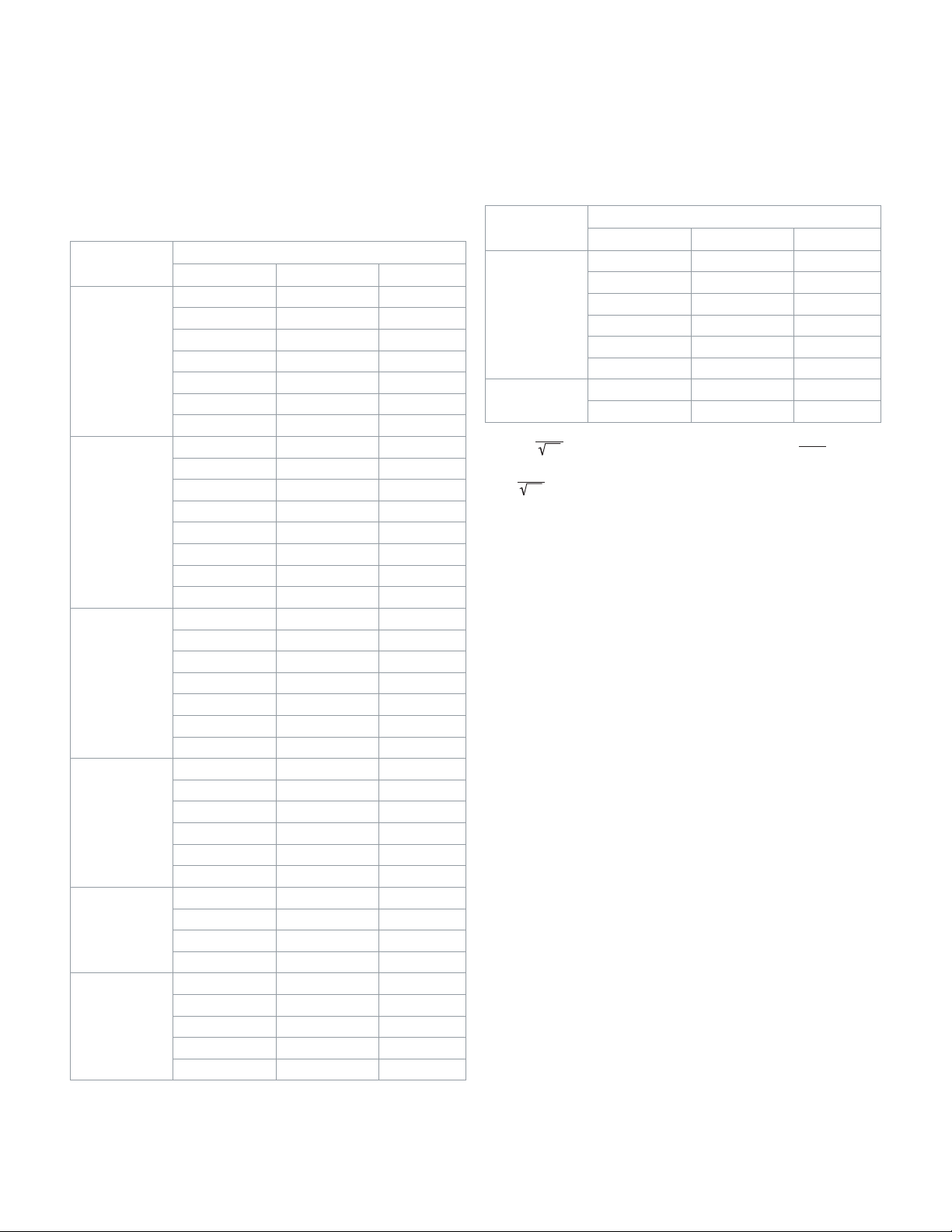

Ball Valve Assemblies Using SmartX 8xx Actuators

V x - 2 x x 3 - 8 x x - 9 - x x

Control

Signal Type

A = Two Position

F = Floating

S = Proportional

B = Valve Body &

Linkage

(less actuator)

c

Configuration

2 = 2 Way

3 = 3 Way Mixing

Material

1 = Nickel/Chromium

Plated Brass

5 = Stainless Steel

3

Connection

3 = Threaded NPT

1 Normal position for 3 way spring

return ball valve assemblies refers to

A to AB ports.

3 Stainless steel ball is available only

on 2 way versions.

Actuator Code Valves Used On

1-1/4” 1-1/4”

Normal 1/2” to 1” to 3” to 2”

a

Code Position Voltage Type 2-way 3-way 2-way 3-way

Model

Two-Position

MA4D 7030 000 815 SR Open 120 Va c X X

MA4D 8030 000 817 SR Closed 120 Vac X X

MA4D 7033 100 821 SR Open 24 Vac X X

MA4D 8033 100 831 SR Closed 24 Vac X X

Floating

MF4D 7033 100 821 SR Open 24 Vac X X

MF4D 8033 100 831 SR Closed 24 Va c X X

MF4D 6083 100 N/Ab NSR 24 Vac X X X X

Proportional

MS4D 7033 100 821 SR Open 24 Vac 2 10 Vdc X X

MS4D 7033 120 N/Ab SR Open 24 Va c 0 3 Vdc X X

MS4D 7033 130 N/Ab SR Open 24 Vac 6 9 Vdc X X

MS4D 7033 150 N/Ab SR Open 24 Vac 0 10 Vdc X X

MS4D 7033 160 N/Ab SR Open 24 Vac 4 20 mA X X

MS4D 8033 100 831 SR Closed 24 Vac 2 10 Vdc X X

MS4D 8033 120 N/Ab SR Closed 24 Vac 0 3 Vdc X X

MS4D 8033 130 N/Ab SR Closed 24 Vac 6 9 Vdc X X

MS4D 8033 150 N/Ab SR Closed 24 Vac 0 10 Vdc X X

MS4D 8033 160 N/Ab SR Closed 24 Vac 4 20 mA X X

Valve Body/Linkage Assemblyc VB-22x3-500-9-xx, VB-2313-500-9-xx

SR = Spring Return NSR = Non Spring Return

a “ 000” models have appliance cables. “ 1X0” models have plenum cables.

b Factory assemblies not available. Purchase actuator and valve body separately and field

assemble.

c Includes valve body, linkage, and anti rotation clips for spring return and non spring return

SmartX actuators, listed above. Ordered separately.

Selection Guide

Port Code

Refer to separate

Port Code table

1

3

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 6

Selection Guide

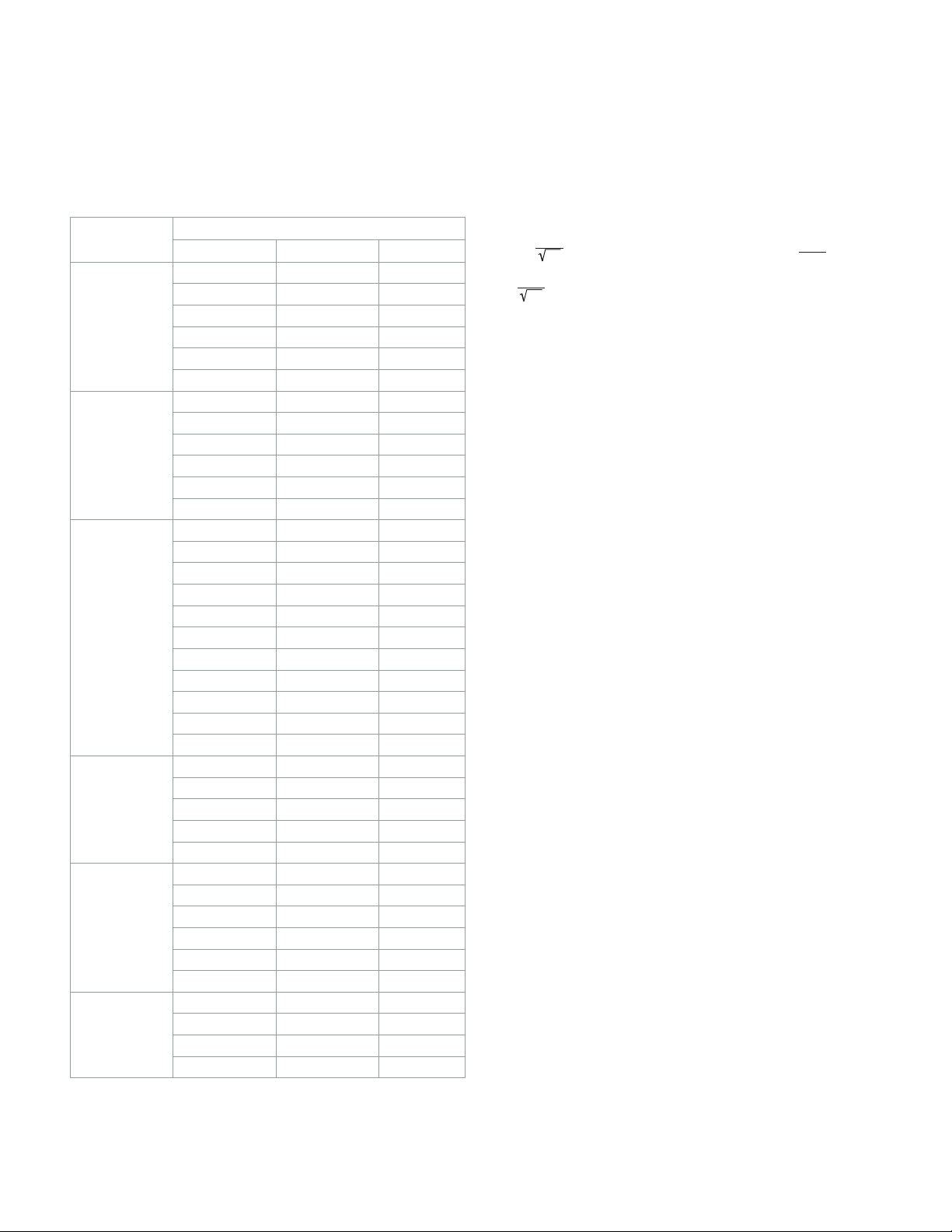

Cv =

gpm

∆P

Cv

1.156

kvs

kvs =

m3/h

∆P

Port Codes

2-Way Ball Valve Assemblies with SmartX Actuators

Table-1. 2-Way Ball Valve Assemblies - Sizes, Port Codes, and

Cvs.

Size

in.

1/2

¾

1

1¼

1½

2

Port Code Cv

01 0.38 0.33

02 0.68 0.59

03 1.3 1.1

04 2.6 2.2

05 4.7 4.1

06 8.0 6.9

07 11.7

11 0.31 0.27

12 0.63 0.54

13 1.2 1.0

14 2.5 2.2

15 4.3 3.7

16 10.1 8.7

17 14.7

18 28.6

21 4.4 3.8

22 9.0 7.8

23 15.3 13.2

24 26.1 22.6

25 28.4

26 43.9

27 54.2

41 4.4 3.8

42 8.3 7.2

43 14.9 12.9

44 36.5 31.6

45 41.1

46 102.3

51 22.8 19.7

52 41.3 35.7

53 73.9

54 171.7

61 41.7 36.1

63 71.1 61.5

65 108

66 210 181.7

67 266

2-Way

a

b

b

b

b

b

b

b

b

b

b

Kvs

10.1

12.7

24.7

24.6

38.0

46.9

35.6

b

b

88.5

63.9

148.5

93.4

230.1

a

Size

in.

Port Code Cv

2-Way

a

71 45 38.9

72 55 47.6

2½

73 72.3 62.5

74 101 87.4

75 162 140.1

76 202

3

a -

b - Denotes a full port valve, without the characterized insert.

(where DP is measured in psi)

(where DP is measured in bar; 1 bar = 100 kPa)

82 63 54.5

85 145

b

b

=

Kvs

174.7

125.4

a

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 7

Cv =

gpm

∆

Cv

1.156

kvs

kvs =

m3/h

∆P

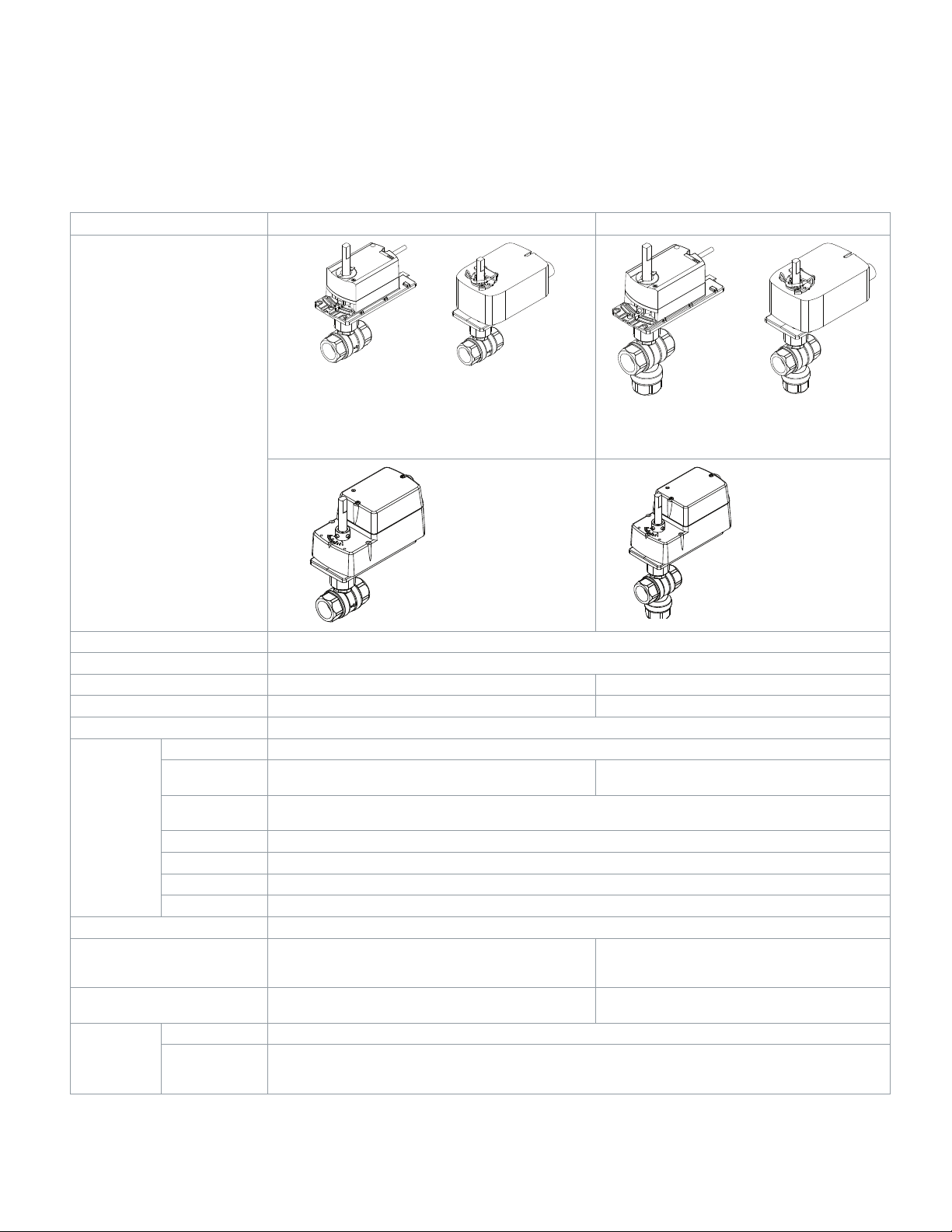

3-Way Ball Valve Assemblies with SmartX Actuators

Table-2. 3-Way Ball Valve Assemblies - Sizes, Port Codes, and Cvs

Selection Guide

Size

in.

1/2

¾

1

1¼

1½

2

3-Way

Port Code A Port Cv

01 0.33 0.28

02 0.59 0.51

03 1 0.86

04 2.4 2.1

05 4.3 3.7

06 8.0

11 0.40 0.35

12 0.66 0.57

13 1.3 1.1

14 2.4 2.1

15 3.8 3.3

16 11

21 0.40 0.35

22 0.65 0.56

23 1.3 1.1

24 2.3 2.0

25 3.5 3.0

26 4.5 3.9

27 8.6 7.4

28 10 8.6

29 14.9 12.9

30 22.3

31 30.8

41 4.1 3.5

43 8.7 7.5

44 12.7 11.0

45 19.4

46 34.1

51 4 3.5

52 8.3 7.2

53 13.4 11.6

54 23.5 20.3

55 32

56 61.1

61 23.9 20.7

62 38.2 33.0

63 56.7

64 108.5

a b

c

c

c

c

c

c

c

c

c

c

Kvs

6.9

9.5

19.3

26.6

16.8

29.5

27.7

52.8

49.0

93.8

a

a -

b - B port Cv is 80% of A por t Cv.

c - Denotes a full port valve, without the characterized insert.

(where DP is measured in psi)

P

(where DP is measured in bar; 1 bar = 100 kPa)

=

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 8

Selection Guide

Ball Valve Specifications

Table-3. Specifications for Ball Valve Assemblies

Valve Assembly Series 2-Way 3-Way Mixing

Ball Valve Assemblies using

SmartX Actuators

Non-Spring Return

Vx-22x3-505-9-P

Vx-22x3-506-9-P

Spring Return

Vx-22x3-5xx-9-P

Non-Spring Return

Vx-2313-505-9-P

Vx-2313-506-9-P

Spring Return

Vx-22x3-81x-9-P

Vx-22x3-82x-9-P

Vx-22x3-83x-9-P

Applications Chilled or Hot Water, up to 50% Glycol Solution

Type of End Fitting NPT Screwed

Size 1/2 in. through 3 in. 1/2 in. through 2 in.

Valve Assembly Series Vx-22x3-xxx-9-P Vx-2313-xxx-9-P

Flow Type Equal Percentage

Body Forged Brass (ASTM B283-06)

Ball 1 = Nickel/Chromium-Plated Brass

Characterizing

Material

Maximum Static Pressure 360 psig (25 bar) at 250 °F (121 °C)

Maximum Operating Differential

Pressure

Seat Leakage ANSI Class IV (0.01% of Cv) ANSI Class IV (0.01% of Cv),

Fluid (water)

Temperature

Insert

Stem Stainless Steel

Ball Seals Reinforced Teflon® Seals with EPDM O-Rings

Stem Seals EPDM O-Rings

Mounting Plate Glass-filled Polymer

Same as close-off pressures shown in Table-4 or

Table-6. Refer to “Cavitation Limitations on Valve

Minimum 20 °F (-7 °C)

Maximum 250 °F (121 °C)

5 = Stainless Steel

Glass-filled Noryl

Same as close-off pressures shown in Table-5 or

Table-7. Refer to “Cavitation Limitations on Valve

Pressure Drop” on page 26.

Nickel/Chromium-Plated Brass

Pressure Drop” on page 26.

piped coil-side outlet to A only

Spring Return

Vx-2313-5xx-9-P

Spring Return

Vx-2313-81x-9-P

Vx-2313-82x-9-P

Vx-2313-83x-9-P

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 9

Page 10

Page 11

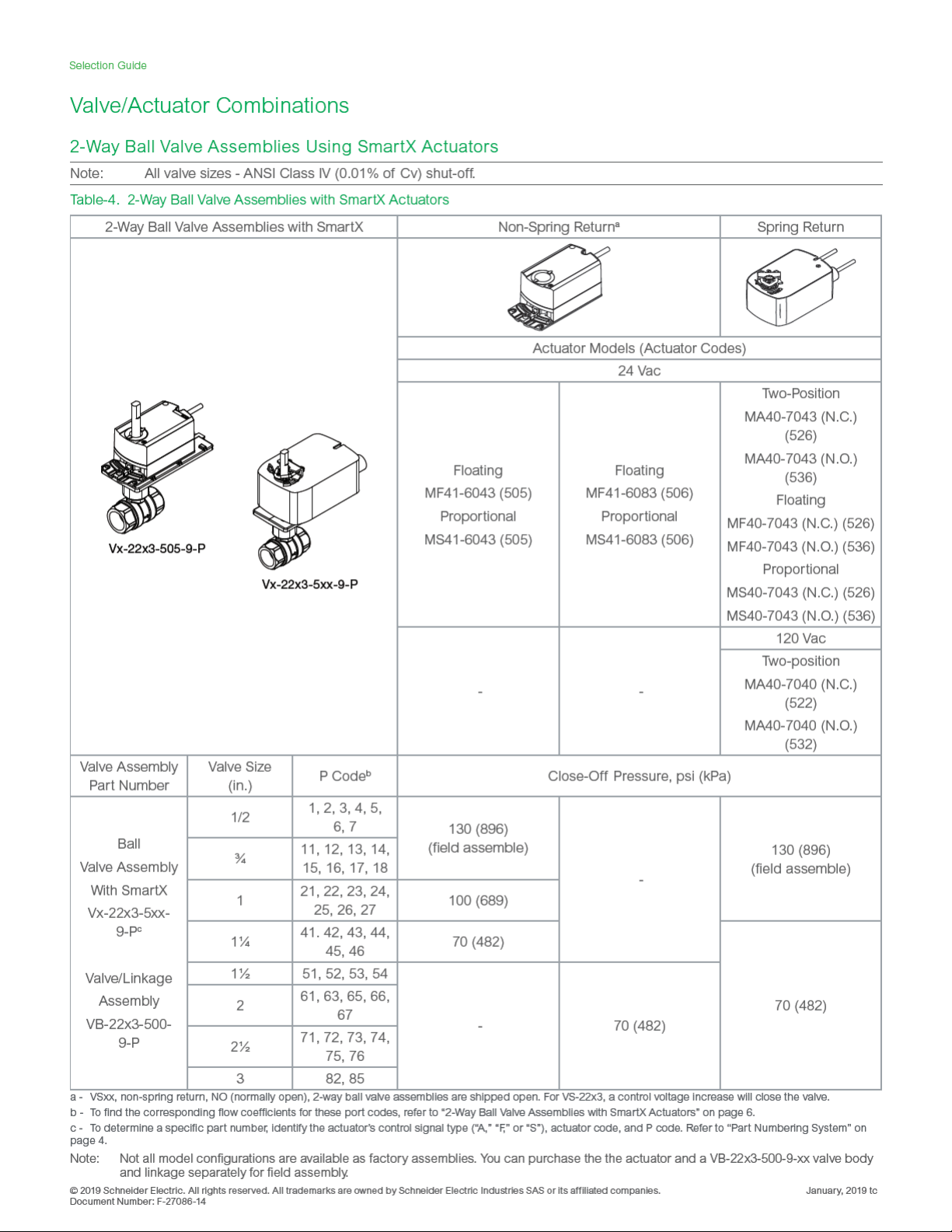

2-Way Ball Valve Assemblies Using SmartX Actuators

Note: All valve sizes - ANSI Class IV (0.01% of Cv) shut-off.

Table-6. 2-Way Ball Valve Assemblies with SmartX Actuators

2-Way Ball Valve Assemblies with SmartX Spring Return

Actuator Models (Actuator Codes)

24 Vac

Two-Position

MA4D-7033-100 (N.O.) (821)

MA4D-8033-100 (N.C.) (831)

Floating

MF4D-7033-100 (N.O.) (821)

Spring Return

Vx-22x3-81x-9-P

Vx-22x3-82x-9-P

Vx-22x3-83x-9-P

Valve Assembly

Part Number

Ball

Valve Assembly

with SmartX

Vx-22x3-5xx-9-P

Valve Size

c

(in.)

P Code

b

1/2 1, 2, 3, 4, 5, 6, 7 130 (896)

¾

11, 12, 13, 14, 15, 16, 17,

18

1 21, 22, 23, 24, 25, 26, 27 100 (689)

1¼ 41. 42, 43, 44, 45, 46

1½ 51, 52, 53, 54

Valve/Linkage

Assembly

VB-22x3-500-9-P

b - To find the corresponding flow coefficients for these port codes, refer to “2-Way Ball Valve Assembly Dimensions” on page 21.

c - To determine a specific part number, identify the actuator’s control signal type (“A,” “F,” or “S”), actuator code, and P code. Refer to “Part Numbering System” on

page 4.

Note: Not all model configurations are available as factory assemblies. You can purchase the the actuator and a VB-22x3-500-9-xx valve body

and linkage separately for field assembly.

2 61, 63, 65, 66, 67

2½ 71, 72, 73, 74, 75, 76

3 82, 85

MF4D-8033-100 (N.C.) (831)

Proportional

MS4D-7033-100 (N.O.) (821) to (829)

MS4D-8033-100 (N.C.) (831) to (839)

120 Vac

Two-position

MA4D-7030-100 (N.O.) (815)

MA4D-8030 (N.C.) (817)

230 Vac

Two-Position

MA4D-7031-100 (N.O.) (816)

MA4D-8031-100 (N.C.) (818)

Close-Off Pressure, psi (kPa)

130 (896)

-

Selection Guide

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 12

Selection Guide

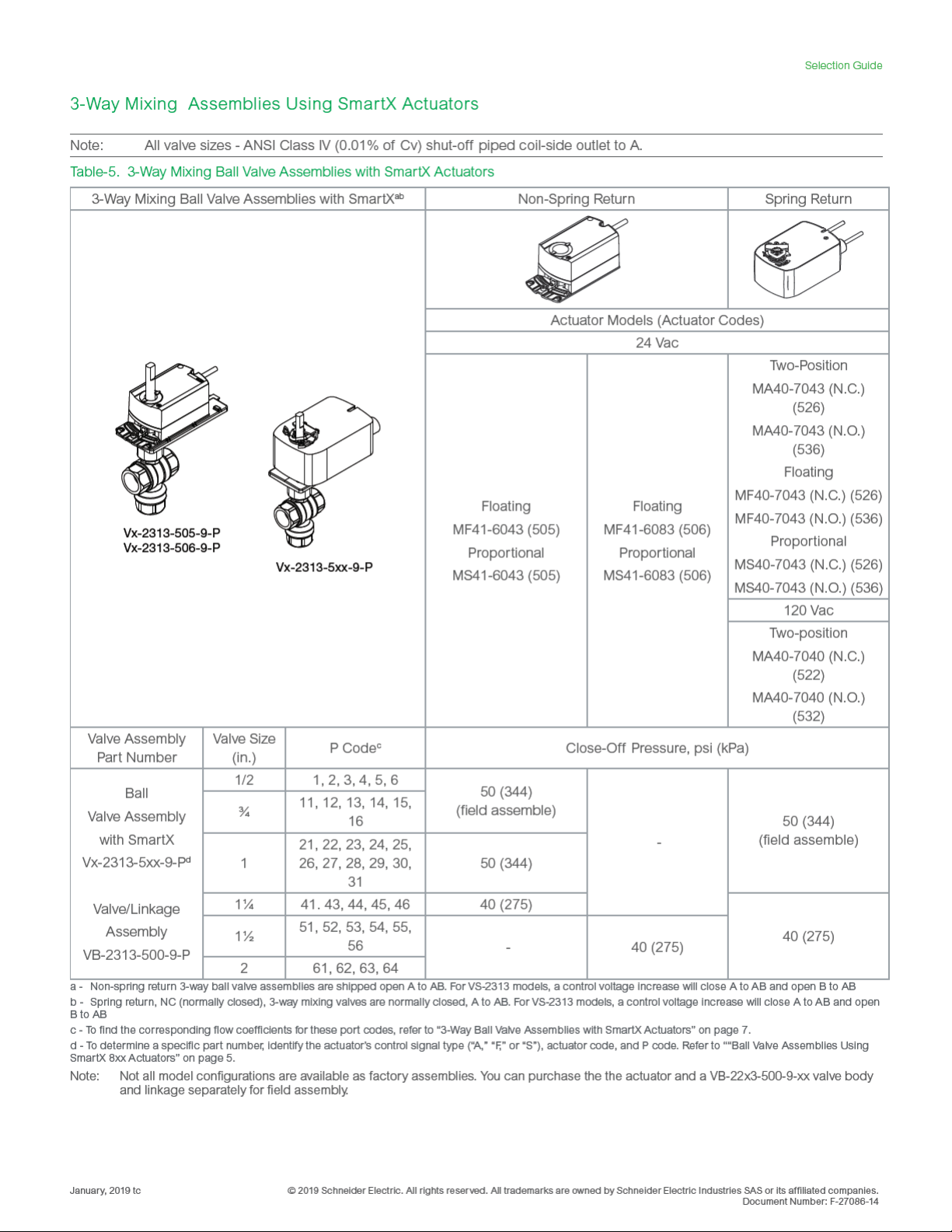

3-Way Mixing Assemblies Using SmartX Actuators

Note: All valve sizes - ANSI Class IV (0.01% of Cv shut-off piped coil-side outlet to A.

Table-7. 3-Way Mixing Ball Valve Assemblies with SmartX Actuators

Valve Assembly

Part Number

Ball

Valve Assembly

with SmartX

Vx-2313-8xx-9-P

Valve/Linkage

Assembly

VB-2313-500-9-P

3-Way Mixing Ball Valve Assemblies

with SmartX

Valve Size

(in.)

b

Spring Return

Vx-2313-81x-9-P

Vx-2313-82x-9-P

Vx-2313-83x-9-P

P Code

1/2 1, 2, 3, 4, 5, 6

¾ 11, 12, 13, 14, 15, 16

d

1

21, 22, 23, 24, 25, 26, 27, 28, 29,

30, 31

1¼ 41. 43, 44, 45, 46

1½ 51, 52, 53, 54, 55, 56

2 61, 62, 63, 64

Spring Return

Actuator Models (Actuator Codes)

24 Vac

Two-Position

MA4D-7033-100 (N.O.) (821)

MA4D-8033-100 (N.C.) (831)

Floating

MF4D-7033-100 (N.O.) (821)

MF4D-8033-100 (N.C.)(831)

Proportional

Two-Position

MA4D-7030-100 (N.O.)

(815)

MA4D-8030-100 (N.C.)

(817)

MS4D-7033-100 (N.O.)(821)

MS4D-8033-100 (N.C.)(831)

c

Close-Off Pressure, psi (kPa)

50 (344)

-

b - Spring retur n, NC (normally closed), 3-way mixing valves are normally A to AB closed. For VS-2313, a control voltage increase will open A to AB and close B to AB

c - To find the corresponding flow coefficients for these port codes, refer to “3-Way Ball Valve Assemblies with SmartX Actuators” on page 7.

d - To determine a specific part number, identify the actuator’s control signal type (“A,” “F,” or “S”), actuator code, and P code. Refer to ““Ball Valve Assemblies Using

SmartX 8xx Actuators” on page 5.

Note: Not all model configurations are available as factory assemblies. You can purchase the the actuator and a VB-22x3-500-9-xx valve body

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

and linkage separately for field assembly.

Page 13

Actuator Specs and Valve Assembly Mounting Dimensions

Assemblies with MF/MS41-6043/83 NSR SmartX Actuators

Table-8. Actuator Specifications

Inputs

MF41-6043 and MF41-6083: Floating three-position control, 24 Vac.

MS41-6043 and MS41-6083: Proportional, 0 to 10 Vdc; input resistance 100K ohms.

Control Signal

Power Requirements

Connections 3 ft. (0.9 m) long, 18 AWG plenum-rated leads.

Motor Type Synchronous

Outputs

Electrical

Control signal adjustment available with MS41-6043-520 and MS41-6043-522:

Start point (offset) - Between 0 and 5 Vdc (factory setting = 0 Vdc)

Span - 2 to 30 Vdc

All 24 Vac circuits are Class 2.

Part Number

MF41-6043 and MF41-6083

MS41-6043 and MS41-6083

Feedback potentiometer available for MF41-6043/6083-510: 0 to 1000 ohms < 10 mA

Position feedback voltage for MS41-6043/6083: 0 to 10 Vdc, 1 mA

Auxiliary Switches: Dual auxiliary switches available with MF41-6043/6083-502, MS41-6043/6083-502, and

MS41-6083-522 when these actuators are ordered as separate units. Auxiliary switches are not offered with

factory ball valve assemblies.

AC Rating: 24 Vac, 4 A resistive, 2 A inductive Switch hysteresis: 3° rotation

DC Rating: 12 to 30 Vdc, DC 2 A

Timing:

Part Num-

ber

MF41-6043

MS41-6043

MF41-6083

MS41-6083

90° Timing in Sec.

At 60 Hz At 50 Hz

90 108

125 150

Voltage Running VA Holding VA Watts

24 Vac +20/-

15%

Power Input @ 50/60 Hz

2.3 - 2.0

3.3 1.2 3.0

Switch Range:

Switch A - 0 to 90° range in 5° intervals

Recommended range usage - 0 to 45°

Factory setting - 5°

Switch B - 0 to 90° range in 5° intervals

Recommended range usage - 45 to 90°

Factory setting - 85°

Selection Guide

Output torque rating: 44 lb-in. (5 N-m) for Mx41-6043; 88 lb-in. (10 N-m) for Mx41-6083

Stroke: Normal angle of rotation is 90°, limited to a maximum of 95°. Field adjustable to limit travel on either

Mechanical

Environment

Temperature Limits

Humidity 5 to 95% RH, non-condensing.

Locations NEMA Type 2 (IEC IP54).

Agency Listings (Actuator)

UL UL-873, Underwriters Laboratories.

cUL Canadian Standards C22.2 No. 24-93.

European Community EMC Directive (89/336/EEC). Emissions (EN50081-1). Immunity (EN50081-2).

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

end of stroke.

Position indicator: Adjustable pointer is provided for position indication.

Output shaft setscrew: Tightening torque 55 to 60 lb-in. (6.3 to 6.8 N-m).

Shipping and storage: -40 to 158 °F (-40 to 70 °C) ambient.

Operating: -25 to 130 °F (-32 to 55 °C) ambient.

NOTE: Check the valve operating temperature limit. The minimum valve temperature limit is 20 °F (6.7 °C)

Page 14

Selection Guide

3 (76)

B

2-Way Ball Valve Assembly Dimensions

Table-9. 2-Way Ball Valve Assembly Dimensions

Valve Assembly

Part Number

Valve Size

in.

1/2

¾

P Code

a

1, 2, 3, 4, 5, 7 2-3/8 (60) 7 (178) 8¼ (210) 3-1/8 (79)

6 2-5/8 (67) 7 (178) 8½ (216) 3-3/8 (86)

11, 12, 13,

14, 15, 17

Valve Dimensions in inches (mm) Refer to Figure 1

A B C D

2-7/16 (62) 7 (178) 8¼ (210) 3¼ (83)

16, 18 2¾ (70) 7 (178) 8½ (216) 3-3/8 (86)

21, 23 3-1/16 (78) 7 (178) 8-7/8 (225) 3-5/8 (92)

2-Way

1

VF-22x3-505-9-P

VF-22x3-506-9-P

VS-22x3-505-9-P

VS-22x3-506-9-P

1¼

1½

2

2½

3 82, 85 5-11/16 (144) 8-1/8 (206)

a - To find the corresponding flow coefficients for these port codes, refer to “2-Way Ball Valve Assemblies with SmartX Actuators” on page 6.

22, 25 2¾ (70) 7 (178) 8½ (216) 3-3/8 (86)

24, 26 4½ (114) 7-3/8 (187) 9-3/8 (238) 3-7/8 (98)

27 3 (76) 7 (178) 8-7/8 (225) 3-5/8 (92)

41, 42, 43, 45 3 (76) 7 (178) 8-7/8 (225) 3-5/8 (92)

44, 46 3-5/8 (92) 7-1/8 (181) 9-3/8 (238) 3-¾ (95)

51, 53 3-7/16 (87) 7-1/8 (181) 9-3/8 (238) 3-¾ (95)

52, 54 4-1/16 (103) 7¼ (184) 9-7/8 (251) 4-1/16 (103)

61, 65 3-15/16 (100) 7¼ (184) 9-7/8 (251) 4 (102)

63, 66, 67 4-15/16 (125) 7-¾ (197) 10½ (267) 4-7/16 (113)

71, 72, 76,

73, 74, 75

5-3/8 (137) 8 (203) 10-¾ (273) 4½ (114)

10-11/16

(271)

4¼ (108)

C

A

Figure 1. Mx41-6043 or Mx41-6083 with 2-Way Ball Valve.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

D

Page 15

3 (76)

3-Way Mixing Ball Valve Assembly Dimensions

Table-10. 3-Way Ball Valve Assembly Dimensions

Selection Guide

Valve Assembly

Part Number

Valve Size

in.

P Code

a

Valve Dimensions in inches (mm) Refer to Figure 2

A B C D E

1/2 1, 2, 3, 4, 5, 6 2-5/8 (67) 7 (178) 9-¾ (248) 3-5/16 (84) 2 (51)

3-Way

VF-2313-505-9-P

VF-2313-506-9-P

VS-2313-505-9-P

VS-2313-506-9-P

¾

1

1¼

1½

11, 12, 13,

14, 15, 16

21, 22, 23,

24, 25, 28

27, 30 4¼ (108) 7-3/8 (187) 11-5/8 (295) 3-5/8 (92) 3-1/16 (78)

26, 29, 31 4¼ (108) 7½ (191) 11½ (292) 3½ (89) 3-1/8 (79)

45 3 (76) 7 (178) 10-5/8 (270) 3-5/8 (92) 2-3/8 (60)

41, 43, 44, 46 3-5/8 (92) 7-1/8 (181) 10-7/8 (276) 3½ (89) 2¾ (70)

51, 52, 53, 55 3-5/8 (92) 7-1/8 (181) 10-7/8 (276) 3-5/8 (92) 2¾ (70)

54 4 (102) 7¼ (184) 11-¾ (298) 4 (102) 3¼ (83)

2¾ (70) 7 (178) 9-¾ (248) 3¼ (83) 2 (51)

2¾ (70) 7 (178) 9-13/16 (249) 3¼ (83) 2-1/8 (54)

56 4 (102) 7-¾ (197) 11-¾ (298) 4 (102) 3¼ (83)

61, 63 3-15/16 (100) 7¼ (184) 11-¾ (298) 3-7/8 (98) 3-1/16 (78)

2

a - To find the corresponding flow coefficients for these port codes, refer to “3-Way Ball Valve Assemblies with SmartX Actuators” on page 7.

62, 64 4-7/8 (124) 7-¾ (197)

12-11/16

(322)

4½ (114) 3-7/8 (98)

C

D

E

A

B

Figure 2. Mx41-6043 or Mx41-6083 with 3-Way Ball Valve.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 16

Selection Guide

Assemblies with Mx40-704x SR SmartX Actuators

Table-11. Actuator Specifications

Inputs

MA40-704x: ON/OFF SPST control contacts or Triacs (500 mA rated).

Control Signal

Power Requirements

Connections

Motor Type

Outputs

Electrical

Mechanical

Environment

Temperature Limits

Humidity 5 to 95% RH, non-condensing.

Locations NEMA 2, UL Type 2 (IEC IP54)

Agency Listings (Actuator)

UL UL 873, Underwriters Laboratories (File #9429 Category Temperature-Indicating and Regulating Equipment).

cUL Canadian Standards C22.2 No. 24-93.

European Community EMC Directive (89/336/EEC). Low Voltage Directive (72/23/EEC).

Australia

* Not available as an assembly.

MS40-7043: Proportional, 2 to 10Vdc or 4 to 20 mAdc with 500 ohm resistor.

MS40-7043 MP/MP5: Proportional 6 to 9 Vdc.

MF40-7043: Floating point control, 24 Vac.

All 24 Vac circuits are Class 2

Part Number

MA40-7043

MS40-7043 5.6 4.2 5.6 4.2 2.4 2.4

MF40-7043 5.9 4.4 5.9 4.4 2.9 2.9

MS40-7043-MP

MS40-7043-MP5*

MA40-7040*

MA40-704x and MA40-704x-501: 3 ft. (0.9 m) long, appliance cable, 1/2 in. conduit connector. For M20 Metric

conduit, use AM-756 adaptor.

MF40-7043 and MF40-7043-501, MS40-7043 and MS40-7043-501: 3 ft. (0.9 m) long, plenum rated cable, 1/2 in.

conduit connector. For M20 Metric conduit, use AM-756 adaptor..

MA40-704x: Brush DC.

MF40-7043, MS40-7043: Brushless DC.

Auxiliary Switches: Available when actuators are ordered as separate units. Auxiliary switches are not offered

with factory ball valve assemblies.

Mx40-7043-501 and MS40-7043-MP5:

One auxiliary switch available. SPDT 6 A resistive @ 24

Vac, adjustable 0 to 95° (0 to 1 scale). Switch meets

VDE requirements for 6 (1.5) A, 24 Vac.

Position Feedback Voltage: For 2 to 10 Vdc proportional actuators, the feedback signal is the same voltage

range as the input signal. The feedback signal can supply up to 0.5 mA to operate up to four additional slave

actuators.

Control Mode: Switch provided for selection of direct acting or reverse acting control mode on proportional

models.

Timing: MA-704x - Approx. 50 sec.; MF- and MS-7043 - Approx. 130 sec.

Auxiliary Power Supply: MS40-7043-MP and MS40-7043-MP5 - +20 Vdc @ 25 mA (max.).

Stroke: Angle of rotation is limited to a maximum of 95°, with mechanical stop.

Output torque rating: Mx40-704x - 44 lb-in (5 N-m).

Position indicator: Visual scale numbered from 0 to 90°, provided for position indication.

Shipping and storage: -40 to 160 °F (-40 to 71 °C) ambient.

Operating: -22 to 140 °F (-30 to 60 °C) ambient.

NOTE: Check the valve operating temperature limit. The minimum valve temperature limit is 20 °F (6.7 °C)

This product meets requirements to bear the RCM mark according to the terms specified by the Communications Authority under the Radiocommunications Act 1992.

Voltage 50/60 HzVoltage

Vdc

24 Vac ± 20% 22 to 30

120 Vac ±

10%

- 6.4 3.8 4.3 3.4 1.6 1.2

50 Hz 60 Hz 50 Hz 60 Hz

VA W VA W W W

4.4 2.9 4.4 2.9 0.8 0.8

6.9 5.0 6.6 5.0 3.2 3.2

Running Holding

MA40-7040-501:

One auxiliary switch available. SPDT 6 A resistive @

250 Vac, adjustable 0 to 95° (0 to 1 scale). Switch

meets VDE requirements for 6 (1.5) A, 250 Vac.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 17

4 (102)

2-Way Ball Valve Assembly Dimensions

Table-12. 2-Way Ball Valve Assembly Dimensions

Selection Guide

Valve Assembly Part

Number

Valve Size

in.

1/2

¾

P Code

a

1, 2, 3, 4, 5, 7 2-3/8 (60) 7-3/8 (187) 8¼ (210) 3-1/8 (79)

6 2-5/8 (67) 7-3/8 (187) 8½ (216) 3-3/8 (86)

11, 12, 13,

14, 15, 17

Valve Dimensions in inches (mm) Refer to Figure 5

A B C D

2-7/16 (62) 7-3/8 (187) 8¼ (210) 3¼ (83)

16, 18 2¾ (70) 7-3/8 (187) 8½ (216) 3-3/8 (86)

2-Way

VA-22x3-522-9-P

VA-22x3-526-9-P

1

VA-22x3-532-9-P

VA-22x3-536-9-P

VF-22x3-526-9-P

VF-22x3-536-9-P

VS-22x3-526-9-P

VS-22x3-536-9-P

1¼

1½

2

2½

3 82, 85 5-11/16 (144) 8-¾ (222)

a - To find the corresponding flow coefficients for these port codes, refer to “2-Way Ball Valve Assemblies with SmartX Actuators” on page 6.

21, 23 3-1/16 (78) 7-3/8 (187) 8-7/8 (225) 3-5/8 (92)

22, 25 2¾ (70) 7-3/8 (187) 8½ (216) 3-3/8 (86)

24, 26 4½ (114) 8 (203) 9-3/8 (238) 3-7/8 (98)

27 3 (76) 7-3/8 (187) 8-7/8 (225) 3-5/8 (92)

41, 42, 43, 45 3 (76) 7-3/8 (187) 8-7/8 (225) 3-5/8 (92)

44, 46 3-5/8 (92) 7-¾ (197) 9-3/8 (238) 3-¾ (95)

51, 53 3-7/16 (87) 7-¾ (197) 9-3/8 (238) 3-¾ (95)

52, 54 4-1/16 (103) 7-7/8 (200) 9-7/8 (251) 4-1/16 (103)

61, 65 3-15/16 (100) 7-7/8 (200) 9-7/8 (251) 4 (102)

63, 66, 67 4-15/16 (125) 8-3/8 (123) 10½ (267) 4-7/16 (113)

71, 72, 76,

73, 74, 75

5-3/8 (137) 8-5/8 (219) 10-¾ (273) 4½ (114)

10-11/16

(271)

4¼ (108)

C

D

A

B

Figure 3. Mx40-704x with 2-Way Ball Valve.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 18

Selection Guide

4 (102)

3-Way Mixing Ball Valve Assembly Dimensions

Table-13. 3-Way Ball Valve Assembly Dimensions

Valve Assembly Part

Number

Valve Size

in.

P Code

a

Valve Dimensions in inches (mm) Refer to Figure 6

A B C D E

1/2 1, 2, 3, 4, 5, 6 2-5/8 (67) 7-3/8 (187) 9-¾ (248) 3-5/16 (84) 2 (51)

3-Way

VA-2313-526-9-P

VA-2313-536-9-P

VF-2313-526-9-P

VF-2313-536-9-P

VS-2313-526-9-P

VS-2313-536-9-P

¾

1

1¼

1½

11, 12, 13,

14, 15, 16

21, 22, 23,

24, 25, 28

27, 30 4¼ (108) 8 (203) 11-5/8 (295) 3-5/8 (92) 3-1/16 (78)

26, 29, 31 4¼ (108) 8-1/8 (206) 11½ (292) 3½ (89) 3-1/8 (79)

45 3 (76) 7-3/8 (187) 10-5/8 (270) 3-5/8 (92) 2-3/8 (60)

41, 43, 44, 46 3-5/8 (92) 7-¾ (197) 10-7/8 (276) 3½ (89) 2¾ (70)

51, 52, 53, 55 3-5/8 (92) 7-¾ (197) 10-7/8 (276) 3-5/8 (92) 2¾ (70)

54 4 (102) 7-7/8 (200) 11-¾ (298) 4 (102) 3¼ (83)

2¾ (70) 7-3/8 (187) 9-¾ (248) 3¼ (83) 2 (51)

2¾ (70) 7-3/8 (187) 9-13/16 (249) 3¼ (83) 2-1/8 (54)

56 4 (102) 8-3/8 (213) 11-¾ (298) 4 (102) 3¼ (83)

61, 63 3-15/16 (100) 7-7/8 (200) 11-¾ (298) 3-7/8 (98) 3-1/16 (78)

2

a - To find the corresponding flow coefficients for these port codes, refer to “3-Way Ball Valve Assemblies with SmartX Actuators” on page 7.

62, 64 4-7/8 (124) 8-3/8 (213)

12-11/16

(322)

4½ (114) 3-7/8 (98)

C

D

A

B

Figure 4. Mx40-704x with 3-Way Ball Valve.

E

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 19

Table-14. Actuator Specifications

Inputs

Part Number

for Mx4D-703x-

xxx

Mx4D-803x-

Control

Signal

Voltage

xxx

Control Signal

and

Power Requirements

Connections

MA4D-

x033-100

MF4D-

x033-100

MS4D-

x033-100

MS4D-

x033-120

MS4D-

x033-130

MS4D-

x033-150

MS4D-

x033-160

a. 4 to 20 mAdc with field-installed 500 W resistor.

Mx4D-703x-1x0 and Mx4D-803x-1x0: 10 ft. (3.05 m) long, plenum cable, 1/2 in. (13 mm) conduit

2-position

Floating 6.8 4.2 0.15 1.9

2 to 10 Vdc

Proportional

0 to 3 Vdc

Proportional

6 to 9 Vdc

a

24 Vac

±20%

or

20 to 30

Vdc

Proportional

0 to 10 Vdc

Proportional

4 to 20 mAdc

Proportional

connector. For M20 Metric conduit, use AM-756 adaptor.

Motor Type Brush DC

Outputs

Timing:

Part Number Approximate Timing in Sec. @ 70 °F (21 °C)

Powered Spring Return

MA4D-7033-100 56 26 -

Electrical

MF4D-7033-100

MS4D-7033-100

MA4D-8033-100 56 - 26

MF4D-8033-100

MS4D-8033-1x0

a. Timing was measured with no load applied to actuator.

b. CCW or CW as viewed from cover side of actuator.

85 21 -

85 - 21

Position Feedback Voltage: For 0 to 3 Vdc, 0 to 9 Vdc, 2 to 10Vdc, and 0 to 10 Vdc proportional

actuators, the feedback signal is the same voltage range as the input signal. The 4 to 20 mA pro-

portional actuators and floating actuators have a 2 to 10 Vdc feedback signal. The feedback signal

can supply up to 0.5 mA to operate up to four additional slave actuators.

Stroke: 93° nominal.

Manual override: Allows positioning of valve shaft, using a manual crank..

Mechanical

Output torque rating: 30 lb-in (3.4 N-m).

RA/DA Jumper (Proportional Models): Permits selection of reverse acting or direct acting control.

Position indicator: Visual indicator.

Actuator Power Input

Running Holding

50/60 Hz

VA W W

DC Amps

50/60 Hz

5.1 3.6 0.14 1.3

6.1 3.4 0.12 1.4

a

CCW

b

CW

b

Selection Guide

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 20

Selection Guide

Continued

Inputs

Environment

Shipping and storage: -40 to 160 °F (-40 to 71 °C) ambient.

Temperature Limits

NOTE: Check the valve operating temperature limit. The minimum valve temperature limit is 20 °F

Humidity 15 to 95% RH, non-condensing.

Locations

NEMA 1. NEMA 2, UL Type 2 (IEC IP54) with customer-supplied watertight conduit connectors.

Agency Listings (Actuator)

UL

UL 873, Underwriters Laboratories (File #9429 Category Temperature-Indicating and Regulating

cUL Canadian Standards C22.2 No. 24-93.

European Community

Australia

EMC Directive (89/336/EEC). Low Voltage Directive (72/23/EEC). This product fits into Installation

This product meets requirements to bear the RCM mark according to the terms specified by the

Communications Authority under the Radiocommunications Act 1992.

Operating: -22 to 140 °F (-30 to 60 °C) ambient.

(6.7 °C)

Enclosure is air plenum rated.

Equipment). Plenum rated..

Category (Overvoltage Category) II per EN 61010-1.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 21

3 1/2 (89)

2-Way Ball Valve Assembly Dimensions

Table-15. 2-Way Ball Valve Assembly Dimensions

Selection Guide

Valve Assembly Part

Number

2-Way

VA-22x3-815-9-P

VA-22x3-817-9-P

VA-22x3-821-9-P

VA-22x3-831-9-P

Valve Size

in.

1/2

¾

P Code

a

1, 2, 3, 4, 5, 7 2-3/8 (60) 8¼ (210) 8¼ (210) 3-1/8 (79)

6 2-5/8 (67) 8¼ (210) 8½ (216) 3-3/8 (86)

11, 12, 13,

14, 15, 17

16, 18 2¾ (70) 8¼ (210) 8½ (216) 3-3/8 (86)

Valve Dimensions in inches (mm) Refer to Figure 7

A B C D

2-7/16 (62) 8¼ (210) 8¼ (210) 3¼ (83)

21, 23 3-1/16 (78) 8¼ (210) 8-7/8 (225) 3-5/8 (92)

VF-22x3-821-9-P

VF-22x3-831-9-P

VS-22x3-821-9-P

1

22, 25 2¾ (70) 8¼ (210) 8½ (216) 3-3/8 (86)

24, 26 4½ (114) 8-7/8 (225) 9-3/8 (238) 3-7/8 (98)

27 3 (76) 8¼ (210) 8-7/8 (225) 3-5/8 (92)

VS-22x3-831-9-P

a - To find the corresponding flow coefficients for these port codes, refer to “2-Way Ball Valve Assemblies with SmartX Actuators” on page 6.

C

D

A

B

Figure 5. MA4D-7033, MF4D-7033, MS4D-7033, MA4D-8033, MF4D-8033, or MS4D-8033 with 2-Way Ball Valve.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 22

Selection Guide

3-1/2 (89)

3-Way Mixing Ball Valve Assembly Dimensions

Table-16. 3-Way Ball Valve Assembly Dimensions

Valve Assembly Part

Number

3-Way

VA-2313-815-9-P

VA-2313-817-9-P

VA-2313-821-9-P

VA-2313-831-9-P

Valve Size

in.

P Code

a

1/2 1, 2, 3, 4, 5, 6 2-5/8 (67) 8½ (216) 9-¾ (248) 3-5/16 (84) 2 (51)

¾

11, 12, 13,

14, 15, 16

21, 22, 23,

24, 25, 28

2¾ (70) 8½ (216) 9-¾ (248) 3¼ (83) 2 (51)

2¾ (70) 8½ (216) 9-13/16 (249) 3¼ (83) 2-1/8 (54)

Valve Dimensions in inches (mm) Refer to Figure 8

A B C D E

27, 30 4¼ (108) 8-7/8 (225) 11-5/8 (295) 3-5/8 (92) 3-1/16 (78)

VF-2313-821-9-P

1

VF-2313-831-9-P

26, 29, 31 4¼ (108) 9 (229) 11½ (292) 3½ (89) 3-1/8 (79)

VS-2313-821-9-P

VS-2313-831-9-P

a - To find the corresponding flow coefficients for these port codes, refer to “3-Way Ball Valve Assemblies with SmartX Actuators” on page 7.

C

D

E

A

Figure 6. MA4D-7033, MF4D-7033, MS4D-7033, MA4D-8033, MF4D-8033, or MS4D-8033 with 3-Way Ball Valve.

B

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 23

Page 24

Selection Guide

Cv =

gpm

∆P

kvs =

m3/h

∆P

Cv

1.156

kvs

Insulation of Ball Valve Assembly

The ball valve should be completely insulated to minimize the effect of heat transfer and condensation at the actuator.

Caution: The actuator itself must not be insulated. Doing so can result in excess heat or condensation within the actuator.

Temperature Limits for Ball Valve Assembly

When installing the ball valve assembly, observe the minimum and maximum temperature limits. Refer to the valve and actuator

specifications..

Water System Maintenance

All heating and cooling systems are susceptible to valve and system problems caused by improper water treatment and system

storage procedures. Durability of valve stems and packings is dependent on maintaining non-damaging water conditions. Inadequate water treatment or filtration, not in accordance with chemical supplier or ASHRAE handbook recommendations, can result

in corrosion, scale, and abrasive particle formation. Scale and particulates can cause scratches in the stem and packing, and

can adversely affect packing life and other parts of the hydronic system. Consult EN-205, Water System Guidelines Engineering

Information, F-26080, for futher details.

Sizing and Selection

Flow Coefficient (Cv)

When sizing a valve, you must select a flow coefficient (Cv), which is defined as the flow rate in gallons per minute (GPM) of 60 °F

water that will pass through the fully open valve with a 1 psi pressure drop (DP). It is calculated according to this formula:

where DP is measured in psi.

Since the flow rate through the heat exchanger is usually specified, the only variable normally available in sizing a valve is the

pressure drop. The following information in this section can be used to determine what pressure drop to use in calculating a valve

Cv. Once you have calculated the Cv, consult Table-1 and Table-2 to select the valve body having the nearest available Cv.

NOTE: Metric equivalent

The metric measure of flow coefficient is kvs, which is calculated according to the formula:

(where DP is measured in bar; 1 bar = 100 kPa).

If the Cv is already known, it may be converted directly to its kvs equivalent:

=

Two-position Control

Two-position control valves are normally selected “line size” to keep pressure drop at a minimum. If it is desirable to reduce the

valve below line size, then 10% of “available pressure” (that is, the pump pressure differential available between supply and

return mains, with design flow at the valve location) is normally used to select the valve.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 25

Page 26

Page 27

Page 28

Selection Guide

Estimated Effective Cv con’t

Valve

Size

in.

1

1¼

1½

2

P

Code

C

v

Pipe Size - inches (NPT)

1/2 ¾ 1 1¼ 1½ 2 2½ 3 4 5

Estimated Effective Cv (Kvs)

21 4.4

4.4 (3.8) 4.4 (3.8) 4.4 (3.8) 4.4 (3.8)

22 9.0 9.0 (7.8) 8.9 (7.4) 8.8 (7.6) 8.7 (7.5)

23 15.3

24 26.1

25 28.4

26 43.9

27 54.2

41 4.4

15.3

(13.2)

26.1

(22.5)

a

28.4

(24.6)

a

43.9

(38.0)

a

54.2

(46.8)

14.9

(12.9)

24.4

(21.1)

26.2

(22.7)

36.8

(31.8)

42.3

(36.6)

14.4

(12.5)

22.4

(19.4)

23.8

(20.6)

31.0

(26.8)

34.1

(29.5)

13.8

(11.9)

20.3

(17.5)

21.4

(18.5)

26.1

(22.6)

27.9

(24.1)

4.4 (3.8) 4.4 (3.8) 4.4 (3.8) 4.4 (3.8)

42 8.3 8.3 (7.2) 8.3 (7.2) 8.2 (7.1) 8.2 (7.1)

43 14.9

44 36.5

45 41.1

46 102.3

51 22.8

52 41.3

53 73.9

54 171.7

61 41.7

63 71.1

65 108.0

66 210.0

67 266.0

14.9

(12.9)

36.5

(31.6)

a

- -

a

41.1

(35.5)

102.3

(88.1)

-

a

a

-

a

a

14.8

(12.8)

35.0

(30.3)

39.0

(33.7)

79.1

(68.4)

22.8

(19.7)

41.3

(35.7)

73.9

(63.9)

171.7

(148.5)

-

14.5

(12.5)

31.5

(27.2)

34.3

(29.7)

53.3

(46.1)

22.4

(19.4)

39.3

(33.9)

63.7

(55.1)

101.2

(87.5)

41.7

(36.1)

71.1

(61.4)

108.0

(93.4)

210.0

(181.7)

266.0

(229.7)

14.3

(12.3)

29.6

(25.6)

31.9

(27.5)

45.5

(39.3)

22.0

(19.0)

37.2

(32.1)

55.9

(48.4)

76.6

(66.3)

41.2

(35.6)

68.8

(59.5)

100.3

(86.8)

165.9

(143.5)

189.7

(164.1)

-

-

21.8

(18.9)

36.0

(31.1)

52.0

(45.0)

67.2

(58.0)

40.6

(35.1)

65.9

(57.0)

92.0

(79.6)

134.6

(116.4)

146.4

(126.6)

-

-

39.7

(34.3)

62.4

(53.9)

83.0

(71.8)

110.5

(95.6)

116.7

(100.8)

a - Denotes a full port valve, without the characterized insert.

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 29

Selection Guide

Valve

Size

in.

P

Code

C

v

1/2 ¾ 1 1¼ 1½ 2 2½ 3 4 5

71 45.0

72 55.0

73 72.3

2½

74 101.0

75 162.0

76 202.0

a

82 63.0

3

85 145.0

a - Denotes a full port valve, without the characterized insert.

a

Estimated Effective Cv (Kvs)

Pipe Size - inches (NPT)

-

45.0

(38.9)

55.0

(47.5)

72.3

(62.5)

101.0

(87.4)

162.0

(140.0)

202.0

(174.4)

-

43.6

(37.7)

52.5

(45.3)

66.6

(57.6)

87.5

(75.7)

119.0

(102.9)

132.4

(114.5)

63.0

(54.4)

145.0

(125.2)

42.5

(36.8)

50.6

(43.7)

63.0

(54.5)

79.7

(68.9)

101.3

(87.6)

109.3

(94.5)

56.7

(49.0)

96.8

(83.7)

42.0

(36.3)

49.7

(42.9)

61.2

(52.9)

76.2

(65.9)

94.3

(81.6)

100.6

(87.0)

55.5

(47.9)

90.6

(78.4)

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Page 30

Page 31

Selection Guide

Valve

Size

in.

1¼

1½

2

P

Code

Cv

Pipe Size - inches (NPT)

1/2 ¾ 1 1¼ 1½ 2 2½

Estimated Effective Cv (kvs)

41 4.1

4.1 (3.5) 4.0 (3.5) 4.0 (3.5) 4.0 (3.5)

43 8.7 8.7 (7.5) 8.6 (7.4) 8.6 (7.4) 8.5 (7.4)

44 12.7

45 19.4 a

46 34.1 a

51 4.0

12.7

(11.0)

19.4

(16.8)

34.1

(29.4)

12.6

(10.9)

19.2

(16.6)

32.9

(28.4)

12.4

(10.7)

18.5

(16.0)

29.9

(25.9)

12.3

(10.6)

18.1

(15.7)

28.3

(24.4)

4.0 (3.5) 4.0 (3.5) 4.0 (3.5)

52 8.3 8.3 (7.2) 8.2 (7.1) 8.2 (7.1)

53 13.4

54 23.5

55 32.0

56 61.1

61 23.9

62 38.2

63 56.7

64 108.5

13.4

(11.6)

-

23.5

(20.3)

a

32.0

(27.7)

a

-

61.1

(52.8)

-

a

a

13.3

(11.5)

23.1

(19.9)

31.0

(26.8)

54.9

(47.5)

23.9

(20.7)

38.2

(33.0)

56.7

(49.0)

108.5

(93.9)

13.2

(11.4)

22.7

(19.6)

30.0

(25.9)

49.7

(43.0)

23.5

(20.3)

37.8

(32.7)

55.5

(47.9)

100.7

(87.1)

a - Denotes a full port valve, without the characterized insert.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies. Januar y, 2019 tc

Docume nt Numbe r: F-270 86-14

Page 32

Selection Guide

Januar y, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tr ademarks are o wned by S chneid er Elect ric Ind ustri es SAS or its af filiat ed companies.

Document Number: F-27086-14

Loading...

Loading...