Page 1

i2/b3 865/866/885-V Controller

Retrofit Guide

P1

(LO)

P2

(HI)

(LOW)

AIR FLOW

INPUT

(HIGH)

IN11

2

IN2

3

RET

UNIVERSAL

INPUTS

4

IN3

5

IN4

6

RET

7

SPWR

SMART

8

RET

SENSOR

9

IN5

USE COPPER CONDUCTORS ONLY

24VAC

10

INPUT:

24VAC , 0.42A, 10 VA, 50/60HZ

11

8xx-V

CAUTION

MORE THAN ONE DISCONNECT SWITCH

MAY BE REQUIRED TO DE-ENERGIZE THIS

EQUIPMENT BEFORE SERVICING.

This equipment complies with part 15 of the FCC rules.

Operation is subject to the following two conditions.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

CLASS 2 POWER ONLY

RS-485

ANALOG

OUTPUTS

0-10 VDC

DIGITAL

OUTPUTS

24VAC ,

PORT

0.5A

COM

COM

SHIELD

TRIAC REF

OUT5

OUT4

OUT3

21

20

19

A07

18

RET

17

AO6

16

15

14

13

12

Page 2

© 2018, Schneider Electric

All Rights Reserved

No part of this publication may be reproduced, read or stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying, recording,

or otherwise, without prior written permission of Schneider Electric.

This document is produced in the United States of America.

Product Names are trademarks of Schneider Electric. All other trademarks are the property of their respective owners.

Title: i2/b3 865/866/885-V Controller Retrofit Guide

Revision: D

Date: December, 2010

Schneider Electric part number: 30-3001-988

i2/b3 865/866/885-V Controller

Infinet Controller Firmware Version 3.3

BACnet Controller Firmware Version 4.5

The information in this document is furnished for informational purposes only, is subject

to change without notice, and should not be construed as a commitment by Schneider Electric. Schneider Electric assumes no liability for any errors or inaccuracies that may appear

in this document.

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider

Electric. This document reflects the visual identity of Schenider Electric. However, there

remain references to TAC as a corporate brand throughout the Andover Continuum software. In those instances, the documentation text still refers to TAC - only to portray the

user interface accurately. As the software is updated, these documentation references will

be changed to reflect appropriate brand and software changes. All brand names, trademarks, and registered marks are the property of their respective owners.

Schneider Electric

Page 3

i2/b3 865/866/885-V Controller

Retrofit Guide

30-3001-988

Revision D.1

July, 2018

Page 4

Page 5

Contents

Regulatory Notices................................................................ 7

Radio Interference - Federal Communications Commission .... 7

Industry Canada ......................................................................... 7

CE - Compliance to European Union (EU) ................................ 8

Australian Communications Authority (ACA) .......................... 8

WEEE - Directive of the European Union (EU) ........................ 8

About this Manual ................................................................. 9

What’s in this Manual .................................................................... 9

Related Documentation .................................................................. 10

Symbols Used .................................................................................. 10

Chapter 1 Mechanical Installation ........................................................ 11

Mechanical Installation .................................................................. 12

Removing the Old Controller ........................................................ 12

Installing the New “-V” Controller ............................................... 13

Chapter 2 Connections .......................................................................... 17

Power Connections .......................................................................... 18

Universal Input Connections .......................................................... 19

Smart Sensor Connections ............................................................. 21

Digital Output Connections ............................................................ 22

How to Wire Digital Outputs .......................................................... 23

Rewiring Digital Outputs for an Old i2/b3 8xx-VAV Controller 26

Rewiring Digital Outputs for a TCX Controller .......................... 27

Analog Output Connections ............................................................ 29

Airflow Connections ........................................................................ 30

i2/b2 865/866/885-VAV Controller Retrofit Guide 5

Page 6

Contents

6 Schneider Electric

Page 7

Regulatory Notices

Note: The following regulatory notices are for the new i2/b3 865, 866

and 885-V Controllers, not for the older controllers they are

replacing.

Radio Interference - Federal Communications Commission

FCC Rules and Regulations CFR 47, Part 15, Class A

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Caution: The user that changes or makes modifications not expressly

approved by Schneider Electric for compliance could void the user's

authority to operate the equipment.

Industry Canada

ICES-003

This is a Class A digital device that meets all requirements of the

Canadian Interference Causing Equipment Regulations.

i2/b2 865/866/885-V Controller Retrofit Guide 7

Page 8

Regulatory Notices

CE - Compliance to European Union (EU)

89/336/EEC - EMC Directive

This equipment complies with the rules of the Official Journal

of the European Communities specified in the EMC directive

89/336/EEC governing the Self Declaration of the CE Marking

for the European Union..

Australian Communications Authority (ACA)

AS/NZS 3548

This equipment carries the C-Tick label and complies with

EMC and radio communications regulations of the

Australian Communications Authority (ACA), governing

the Australian and New Zealand communities.

WEEE - Directive of the European Union (EU)

2002/96/EC

This equipment and its packaging carry the waste electrical

and electronic equipment (WEEE) label, in compliance with

European Union (EU) Directive 2002/96/EC, governing the

disposal and recycling of electrical and electronic equipment in

the European community.

8 Schneider Electric

CAUTION

All pertinent state, regional, and local safety regulations must be

observed when installing and using this product.

For reasons of safety and to assure compliance with documented product information,

repairs to components should be performed only by the manufacturer or an authorized

dealer.

Failure to observe this precaution can result in injury or equipment

damage.

Page 9

What’s in this Manual

The new Andover Continuum i2/b3 865/866/885-V controllers can

replace the previous generation i2/b3 865/866/885 VAV controllers, as

well as the older generation of TCX 865/866 VAV controllers.

This manual highlights the mounting and connecting differences

between the new and older controllers and what you should consider

when replacing a unit. It consists of the following chapters:

About this Manual

z Chapter 1: Mechanical Installation

z Chapter 2: Connections

Note: This manual is not a replacement for the installation

instructions supplied with each controller, or the information

and descriptions supplied in the i2 and b3 Controller Technical

Reference manuals.

i2/b3 865/866/885-V Controller Retrofit Guide 9

Page 10

About this Manual

Related Documentation

For additional or related information, refer to these documents.

Document Document

For new replacement controllers:

i2/b3 865/866/885-V Installation Instructions 30-3001-985

i2 Controller Technical Reference 30-3001-861

b3 and b4920 Controller Technical Reference 30-3001-862

For older controllers being replaced:

i2/b3 865/866 VAV Controller Installation Sheet 30-3001-810

i2/b3 885 VAV Controller Installation Sheet 30-3001-848

TCX 865/866 VAV Installation Guide 30-3001-497

Symbols Used

Number

10 Schneider Electric

The Notes, Warnings and Cautions that may be used in this manual

are listed below.

Note: Contains additional information of interest to the user.

CAUTION or WARNING

Type of hazard

How to avoid hazard.

Failure to observe this precaution can result in injury or equipment

damage.

DANGER

ELECTRIC SHOCK HAZARD

How to avoid hazard.

Failure to observe these instructions will result in death or serious

injury.

Page 11

Chapter 1

Mechanical Installation

This chapter explains how to mechanically replace an older i2/b3

865/866/885 VAV or TCX 865/866 VAV controller with the new i2/b3

865, 866 or 885-V controller.

The new controllers have been redesigned with a new actuator

component. Other small changes have been made, but the controllers

are essentially the same, allowing the new “-V” models to replace older

models with only minor changes to mounting the unit, securing the

shaft of the VAV unit, and making the correct input, output, power,

airflow, and communication connections.

This chapter discusses the physical removal of the older unit and the

mounting of the replacement controllers. Chapter 2 discusses the

connections you must make to complete the installation.

i2/b3 865/866/885-V Controller Retrofit Guide 11

Page 12

Chapter 1: Mechanical Installation

I

U

:

C

SS

O

W

O

LYLL

2

4

V

AC , 0.

VV

4

2

A,

0

V

A, 5

VV

0

/

6

0

HZ

USECO

PP

ERC

O

ND

U

C

T

O

RS

O

N

L

Y

M

O

R

E

T

H

A

N

O

D

I

S

O

N

N

E

S

H

M

A

Y

B

E

R

EQ

U

IR

E

D

T

O

DE

-

E

N

E

R

G

IZ

E

T

HI

S

E

Q

U

M

E

N

T

B

E

F

O

R

E

E

R

V

I

N

G

.

C

U

O

N

T

his

equipment

com

p

lie

s

i

h

p

a

t

1

5o

f

he

FC

C

r

le

s

.

Oper

a

ti

i

s

qp

qp

u

bject

t

t

h

f

ll

o

wing

p

t

w

di

t

i

s

.

(1)

p

p

T

p

p

his d

e

ic

e

m

a

y

n

t

u

se

ha

r

mful

g

g

i

r

f

e

r

e

n

ce

.

(2)

T

hi

d

e

ic

e

t

a

c

cept

a

n

y

i

r

f

erence

re

c

i

v

d

,

i

l

di

g

i

r

f

eren

c

e

t

h

a

t

m

a

yc

a

de

s

i

e

d

operation

g

.

2

4

VA

C

RETRETRE

T

I

N

5

I

N

4

I

N

3

I

N

2

I

N

1

1

2

1

2

0

191

8

O

U

T

4

O

U

T

5

TRIA

C

RE

F

A

O

6

RE

T

A

7

S

L

D

1

2

O

U

T

3

2

3

4

5

6

7

8

9

101

1

(

H

)

(

W

)

AI

R

FLO

W

IN

P

U

T

UN

I

VER

SA

L

IN

P

UT

S

R

S

48

5

P

O

R

T

A

N

A

L

O

G

O

U

T

P

UT

S

0

-

1

0

V

DC

D

I

G

I

TA

L

O

U

T

P

UT

S

2

4

V

A

C

,

0

.

5

A

SM

AR

T

SE

N

SO

R

C

M

CO

M

8

6

6

-

V

P1

(

)

P2

(

)

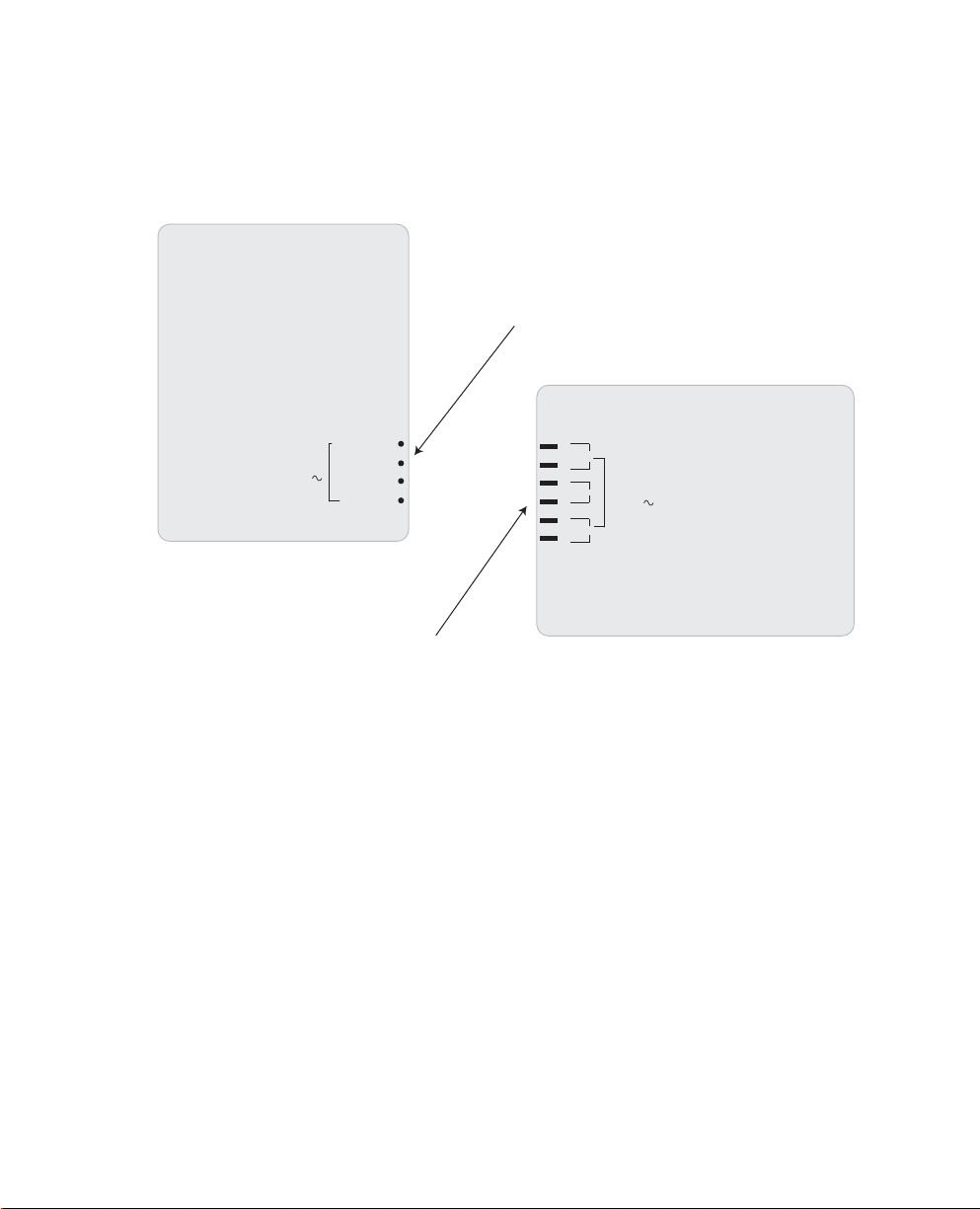

Mechanical Installation

Removing an old i2/b3 865/866/885 model or TCX 865/866 model VAV

controller and replacing it with the new “-V” model consists of two

procedures.

z Removing the old controller

z Installing the new “-V” controller

Remove Replace

(LO)

(HI)

LO

P1

P2

HI

10

11

8

34567

9

2

(HIGH)

(LOW)

HIG

LO

CAUTION

24VAC

RET

RET

RET

IN5

IN4

IN3

IN2

IN11

AIR FLOW

INPUT

UNIVERSAL

INPUTS

INPUT

24VAC , 0.42A, 10VA, 50/60HZ

SMART

SENSOR

USECOPPERCONDUCTORS ONLY

NP

Thisequipmentcomplies with part 15 of the FCC rules.

Operation is subjecttothe following two conditions.

(1)This devicemaynot cause harmful interference.

(2)This devicemust acceptany interference received,

including interference that may cause undesired

operation.

MORETHANONE DISCONNECTSWITCH

MAYBEREQUIRED TODE-ENERGIZETHIS

EQUIPMENTBEFORESERVICING.

T

:

A

nc

CLASS 2 POWER ONLY

s

IP

u

LA

on

n

v

v

TI

s

nte

2 P

mus

1

NE

o

o

ca

ER

e

w

o

t

S

C

N

nte

r

CI

useun

CT

nte

ocon

t

866-V

WITC

e

r

on

u

e

0-10VDC

24VAC ,

OUTPUTS

OUTPUTS

ANALOG

DIGITAL

RS-485

PORT

0.5A

-

TRIACREF

COM

COM

SHIELD

O

HIE

OUT4

OUT3

OUT5

AO6

RET

A07

0

20

161514

12

191817

13

21

i2/b3 865/866/885 or

TCX 865/866 VAV Controller

Removing the Old Controller

To remove the older unit, perform the following steps:

Step 1: Remove the mounting screw located by the input and output

terminals.

Step 2: Disconnect the airflow input and output tubing.

Step 3: Disconnect all the inputs and outputs, including the Infinet or

BACnet, power, digital output, analog output, smart sensor

and universal input connections

Step 4: Unscrew the nuts on the U-bolt clamp to loosen the grip on the

VAV shaft and remove the entire unit.

12 Schneider Electric

i2/b3 865/866/885-V Controller

Page 13

Installing the New “-V” Controller

To install the new “-V” model controller, perform the following steps:

Chapter 1: Mechanical Installation

Alternative Damper Shaft

Mounting Screw Position

Damper Shaft

Hex Mounting Screws

Alternative Damper Shaft

Mounting Screw Position

Damper Shaft

Damper Shaft Collar

Cover Release

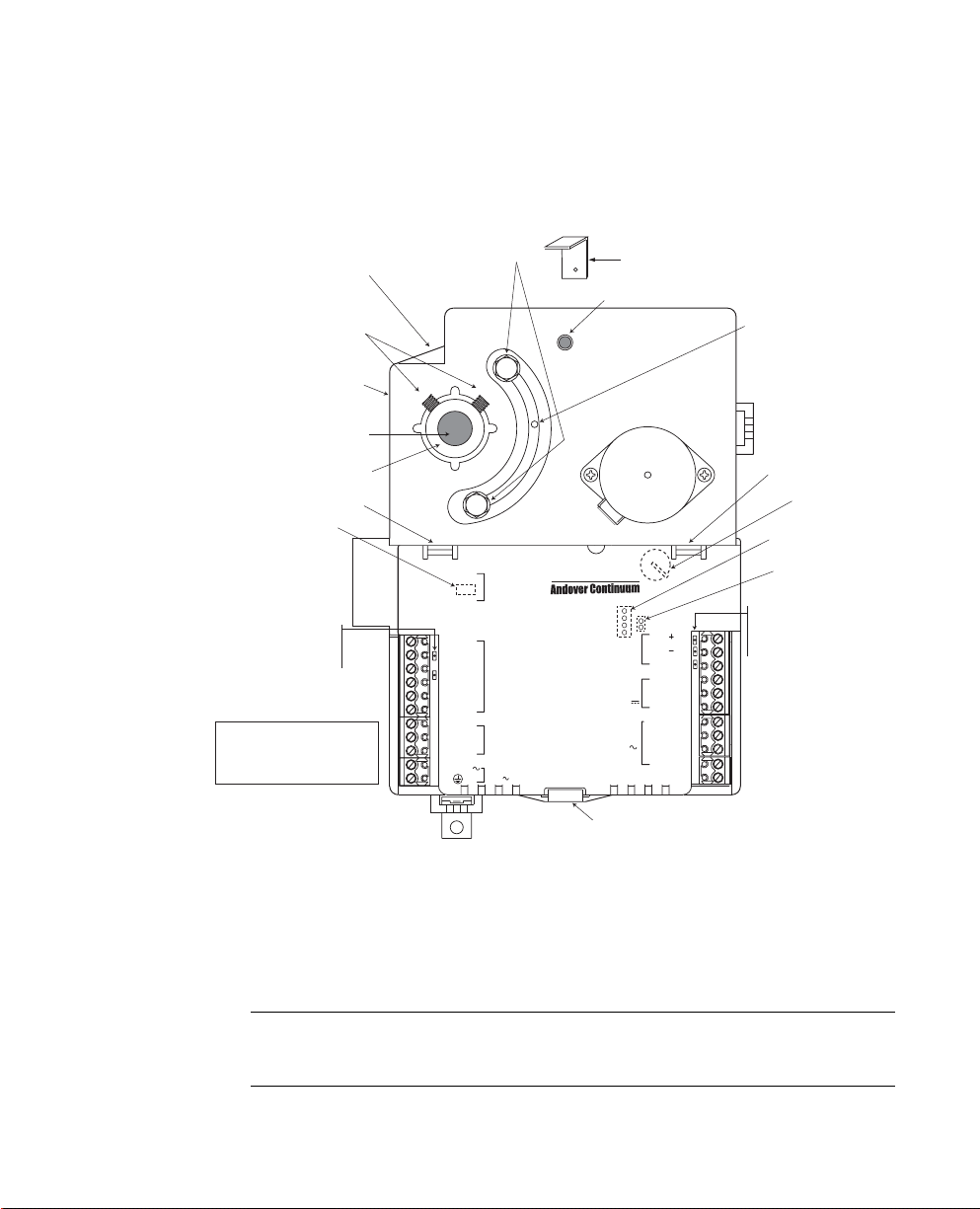

4-Position Dipswitch

Velocity Sensor

Inputs

(Barbed fittings)

Two CPU LEDs

Green = b3 controller

Yellow = i2 controller

Note: Input, Output, and

Smart Sensor connections will

vary per controller model.

Mounting Bracket

(LO)

(HI)

Adjustable Stops

Mounting Clip

Actuator Clutch Release

Damper Position Indicator

Alternate

Mounting Bracket

Cover Release

Battery Location

(Remove cover)

Service Port Location

P1

P2

(LOW)

AIR FLOW

INPUT

(HIGH)

IN11

2

IN2

3

RET

UNIVERSAL

INPUTS

4

IN3

5

IN4

6

RET

7

SPWR

SMART

8

RET

SENSOR

9

IN5

USE COPPER CONDUCTORS ONLY

24VAC

10

INPUT

24VAC , 0.42A, 10VA, 50/ 60HZ

11

866-V

CAUTION

MORE THAN ONE DISCONNECT SWITCH

MAY BE REQUIRED TO DE-ENERGIZE THIS

EQUIPMENT BEFORE SERVICING.

This equipment complies with part 15 of the FCC rules.

Operation is subject to the following two conditions.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

: CLASS 2 POWER ONLY

ANALOG

OUTPUTS

0-10VDC

DIGITAL

OUTPUTS

24VAC ,

RS-485

PORT

COM

21

COM

20

SHIELD

19

A07

18

RET

17

AO6

16

TRIAC REF

15

OUT5

14

OUT4

13

0.5A

OUT3

12

(Remove cover)

Jumper for Actuator

Direction

TD LED = Yellow

RD LED = Green

Wireless LED = Red

Cover Release

Step 1: Check the mounting location for the Andover Continuum i2 or

b3 865/866/885-V controller. The unit is typically mounted

with the controller extending down or to the right from the

damper shaft. However, the controller can be operated in any

position within the vertical plane.

Note: Installing the controller to the right (with the barbed fittings

pointing down) will help to prevent condensate from migrating

into the on-board velocity sensor.

i2/b3 865/866/885-V Controller Retrofit Guide 13

Page 14

Chapter 1: Mechanical Installation

With a downward extension, the available area around the

damper shaft must measure 6” (160 mm) down from the lower

edge of the shaft, 4.5” (120 mm) to the right, 1.5” (40 mm) to

the left and 1.75” (45 mm) above the shaft. Ensure the location

allows enough clearance for servicing.

The actuator is designed to mount over a

1

/2” (12.7 mm)

diameter shaft with a minimum of 2.5” (63.5 mm) of exposed

1

shaft. If the damper shaft diameter is less than

/2” (12.7 mm)

an adapter is required. An adapter (p/n AM-135) is available

3

from Schneider Electric to allow mounting on

/8” (9.5 mm)

damper shaft. The 865/866/885-V controller will not work with

larger damper shaft diameters.

Step 2: If the exposed damper shaft is less than 2” (51 mm) but at

least 1” (25.4 mm) long, move the two damper shaft mounting

screws to the alternate lower damper shaft positions (see

Figure 1).

Step 3: Select the mounting bracket location that will provide the

most stability for the operation of the actuator. Position the

mounting clip in the desired mounting bracket. Do not insert

the clip more than half-way into the bracket. This will allow

the clip and the back of the actuator to properly align with the

VAV box (see Figure 1).

Step 4: Rotate the VAV damper shaft by hand to the fully closed

position. Note whether the damper is rotated clockwise (CW)

or counter-clockwise (CCW) to close.

Step 5: Slip the controller over the damper shaft. Position the actuator

and, using a self tapping sheet metal screw, secure the

mounting clip to the VAV box.

14 Schneider Electric

Step 6: Press the actuator toward the box until the actuator comes

into contact with the VAV box, or the mounting clip snaps into

the bracket, or the back of the actuator comes into contact with

the VAV box.

tep 7: Press and hold the green actuator clutch release (see Figure 1)

S

and rotate the actuator collar to a nearly closed position, the 5°

index mark, if the damper shaft was rotated counter-clockwise

to close (Step 5). Rotate the actuator collar to the 85° index

Page 15

Chapter 1: Mechanical Installation

mark if the damper shaft was rotated clockwise to close

(Step 5).

Step 8: Tighten the two damper shaft hex mounting screws, using a

1

/8-inch Allen wrench. The minimum torque required to secure

the controller to the damper shaft depends on the shaft

material. The maximum torque for the socket screws is 30

inch-pounds (3.4 Nm).

Note: The damper should rotate freely when the clutch is released. If it

does not, the actuator may not be properly aligned with the

damper shaft – it may be necessary to repeat Steps 4 through 9

using a new orientation.

Step 9: If the damper does not provide a mechanical stop in the open

direction, or it is not desirable to use the damper’s open stop,

set the adjustable stops on the i2/b3 865/866/885-V controller

to the desired position. Use a

1

/4-inch hex driver to adjust the

screw stop on the controller.

Note: For the 866-V model only, the damper position feedback

reporting option can be enabled by changing the Andover

Continuum attribute, LCDState, from DISABLED to

ENABLED. The attribute, OverrideValue, indicates the

damper position as a fractional value from 0 (at the closed stop)

to 1 (at the open stop).

Note: The new 8xx-V controllers all use the same actuator jumper

settings to control the direction of the actuator motor. These

Tri-State settings are as follows:

Jumper Connected:

+ (On) = Clockwise (CW)

- (-On) = Counter Clockwise (CCW)

Off

Jumper Disconnected:

+ (On) = Counter Clockwise (CCW)

- (-On) = Clockwise (CW)

Off

i2/b3 865/866/885-V Controller Retrofit Guide 15

Page 16

Chapter 1: Mechanical Installation

Refer to the i2/b3 865/866/885-V Controller Installation Instructions

for additional information regarding the installation of your new “-V”

controller.

CAUTION

Connections

To complete the installation, you will need to make the correct power, input,

output and airflow connections. Although the location of the connections are

different between older and newer models, the only significant difference

is in the wiring required for the digital triac outputs. Continue to

Chapter 2 for more information and refer to the installation instructions

supplied with your controller.

Failure to observe this precaution can result in injury or equipment

damage.

16 Schneider Electric

Page 17

Chapter 2

Connections

This chapter describes the differences between the older generation

i2/b3 865/866/885 and TCX 865/866 VAV controllers and the newer

i2/b3 865/866/885-V controller’s connections.

Topics include:

z Power connections

z Universal Input connections

z Smart Sensor connections

z Digital Output connections

z Analog Output connections

z Airflow connections

Note: In addition to the information provided in these topics, please

refer to the i2/b3 865/866/885-V Controller Installation

Instructions when installing your new controller.

i2/b3 865/866/885-V Controller Retrofit Guide 17

Page 18

Chapter 2: Connections

I

:

CLASS

P

O

L

Y

V

AC , 0.

1

0

V

A, 5

0/6

0

S

Y

E

D

T

equipment

comeswith

art

ati

s

t

o

wing

t

w

p

p

e

vice

ayo

useha

gg

eece

)

T

e

vic

e

usta

c

ceptay

f

erenceceived

c

etata

c

a

d

operation

g

5

3

2

0

9

8

6

5

T

4

5

TRIA

RE

6

A0

E

3

2

3

5

6

890

W

O

T

5

T

0

0

T

,

0.5

A

O

1

)

2

)

Power Connections

Although the power connections for the older and newer controllers are

located in different places, they are clearly labelled and are all 24 VAC

connections.

The New i2/b3 8xx-V

Previous Generation

i2/b3 865/866 VAV

Power

P

P1

LO

(LO)

LO

(LOW)

P

P2

HIG

(HIGH)

HI

(HI)

IN11

2

IN2

2

3

RET

4

IN3

5

IN4

6

RET

7

8

RET

9

IN5

VA

24VAC

10

11

FL

AIRFLOW

INPUT

A

TIO

CAUTION

RTA

N

C

MORETHAN ONEDISCONNECT SWITCH

MAYBE REQUIREDTO DE-ENERGIZETHIS

EQUIPMENTBEFORE SERVICING.

UIPNTBOS

s

Thisequipment complies with part 15of the FCC rules.

on is

ot

efoll

Operation issubject to the following two conditions.

t ca

(1)Thisdevice may not cause harmful interference.

2

m

nter

(2)Thisdevice must accept any interference received,

includingnterferen

includinginterference that may cause undesired

operation.

UNIVERSAL

N

VER

A

INPUTS

SMART

SENSOR

E

USE COERCUTR

USE COPPERCONDUCTORS ONLY

NPUT

2

WER ON

INPUT

:

CLASS 2 POWER ONLY

A,

24VAC , 0.42A, 10VA, 50/60 HZ

866-V

ECTSWIT

VICIN

C

COM

21

oftheCes.

o conditions

nter

RS-485

-48

CO

COM

20

y

se undesre

PORT

HI

SHIELD

19

A07

18

ANALOG

RET

17

OUTPUTS

0-10VDC

O

AO6

16

TRIACREF

15

DIGITAL

O

OUT5

14

OUTPUTS

24VAC ,

OUT4

13

3

0.5A

OUT3

2

12

i2/b3 885 VAV

885

1

24VAC

0.42A,10VA

L

2

Power

Power

50/60HZ

USECOPPER

CONDUCTORSONLY

+

3

INFINET

-

4

PORT

5

SHIELD

6

3

OUT

DIGITAL

OUTPUTS

7

4

OUT

,0.5A

24VAC

8

GND

9

IN1

UNIVERSAL

10

RET

INPUTS

11

IN2

MODEL

S/N

DATE

INSTALLATION

For detailed instructions reviewdocument 30-3001-849 date

SERVICE

PORT

GND

+

-

MOTOR DIRECTION

Previous Generation

TCX 865/866 VAV

Power

18 Schneider Electric

Page 19

Chapter 2: Connections

New 8xx-V

Term inal

Locations

The power and ground connections for the i2/b3 8xx-V controllers are

located on the following terminals, which are labelled on each

controller.

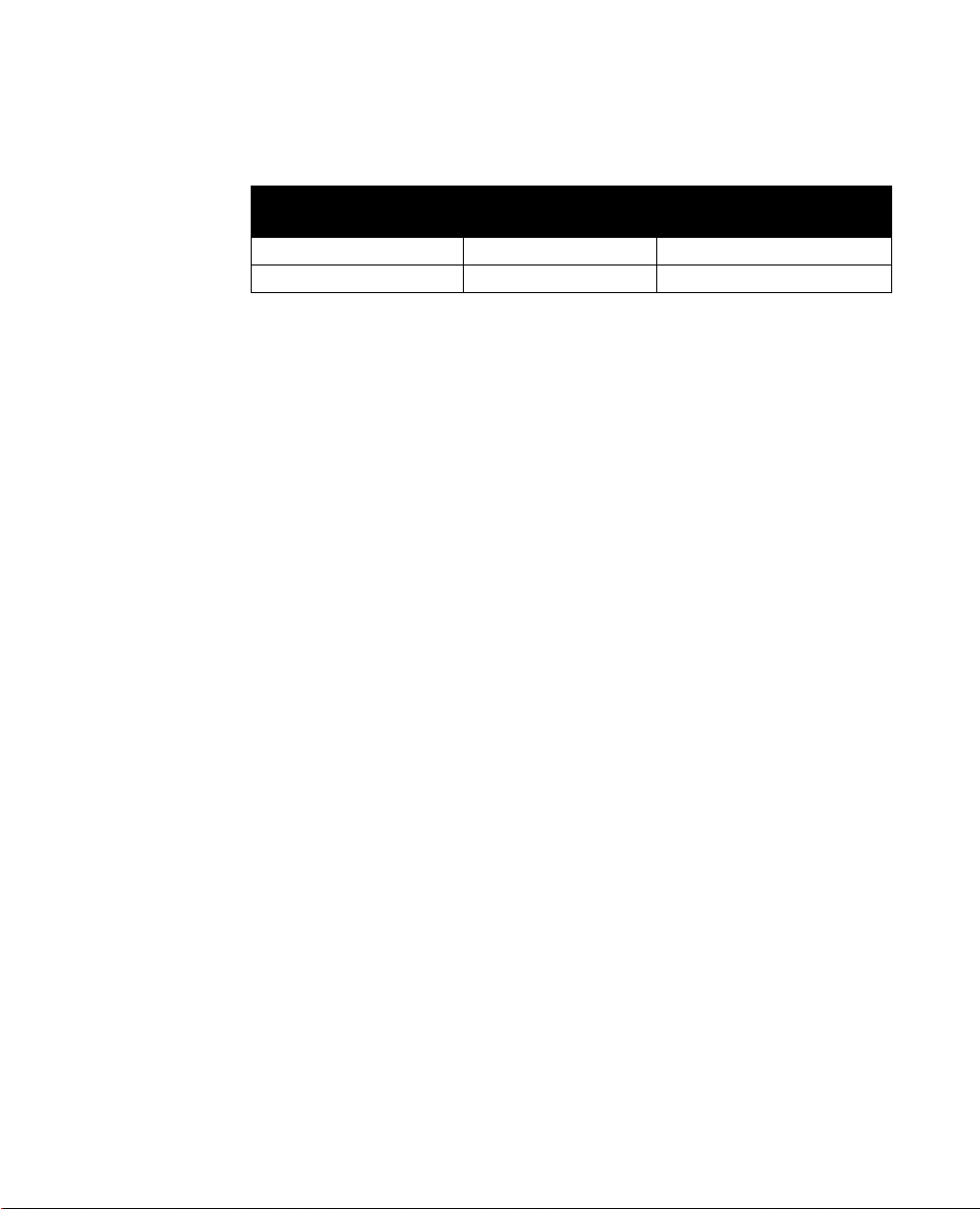

Controller Power Terminal Ground Terminal

i2/b3 865/866-V 10 11

i2/b3 885-V 4 5

Universal Input Connections

The differences in the number of universal inputs and returns between

the older generation and the new “-V” controllers are listed in the table

below.

Controller Universal Inputs Returns

i2/b3 865/866-V 4 2

i2/b3 885-V 2 1

i2/b3 865/866 VAV 4 3

i2/b3 885 VAV 2 1

TCX 865 2 2 Returns and 1 Shield

TCX 866 3 2 Returns and 1 Shield

The i2/b3 865/866-V has a 4-position dipswitch with one switch per input and four

universal inputs. This switch enables and disables input pullup resistors.

Note:

You need to be aware of the differences between the old controller you

are replacing and the new one. For example, if you are replacing a TCX

865 with a new i2/b3 865-V controller, you have two additional input

connections available. If you are replacing an old i2/b3 865 VAV with

the new i2/b3 865-V, you only have two returns, instead of three, to

complete the circuits for the four universal inputs.

i2/b3 865/866/885-V Controller Retrofit Guide 19

Page 20

Chapter 2: Connections

New 8xx-V

Terminal

Locations

The universal input connections for the i2/b3 8xx-V controllers are

located on the following terminals:

Controller Universal Input

Terminal

i2/b3 865/866-V 1, 2, 4, 5 3, 6

i2/b3 885-V 3 1, 2

Return Terminals

Refer to the label on the controllers to identify the terminals.

20 Schneider Electric

Page 21

Smart Sensor Connections

The Andover Continuum Smart Sensor provides a display and a

multi-button programmable keypad that enables operators and

occupants to change setpoints, balance VAV boxes, monitor occupancy

status, and turn equipment on and off.

The controllers that have Smart Sensor inputs are listed in the table

below.

Chapter 2: Connections

New 8xx-V

Term inal

Locations

Controller Smart Sensor

Input

i2/b3 865/866-V 1 1 Return and 1 SPWR

i2/b3 885-V None

i2/b3 865/866 VAV 1 1 Return and 1 SPWR

i2/b3 885 VAV None

TCX 865 None

TCX 866 1 1 Return and 1 SPWR

Return and SPWR*

Connections

*Note: SPWR stands for Smart Power and refers to an Andover

Continuum Smart Sensor connection.

The Smart Sensor connections for the i2/b3 8xx-V controllers are

located on the following terminals:

Controller Smart Sensor

Input Terminal

i2/b3 865/866-V 9 8 - Return

i2/b3 885-V Not Available Not Available

Return and SPWR

Terminals

7 - SPWR

Refer to the label on the controllers to identify the terminals.

i2/b3 865/866/885-V Controller Retrofit Guide 21

Page 22

Chapter 2: Connections

Digital Output Connections

The differences in the number of digital outputs and returns between

the older generation and new “-V” controllers are listed in the table

below.

Controller Digital Outputs Triac Ref

i2/b3 865/866-V 3 1 Triac Ref

i2/b3 885-V 2 1 Triac Ref

i2/b3 865/866 VAV 3 Internally referenced to

i2/b3 885 VAV 2 Internally referenced to

TCX 865/866 3 (Isolated Floating

Outputs)

GND

GND

3 Isolated Returns

(NO - Normally Open)

New 8xx-V

Terminal

Locations

Note: The previous generation i2/b3 865/866/885 VAV controllers were

internally referenced to ground. The external GND terminals in

the Digital Output area are grounds for optional 24 VAC power

sources.

The digital output connections for the i2/b3 8xx-V controllers are

located on the following terminals:

Controller Digital Output

Terminals

i2/b3 865/865-V 12, 13, 14 15

i2/b3 885-V 6, 7 9

Triac Reference

Terminal

Refer to the label on the controllers to identify the terminals.

22 Schneider Electric

Page 23

How to Wire Digital Outputs

T

T

C

T

3

T

S

2VA

The one significant difference between the new and old controllers is

how the digital output connections need to be wired.

Chapter 2: Connections

New 8xx-V

Digital Outputs

AC Line

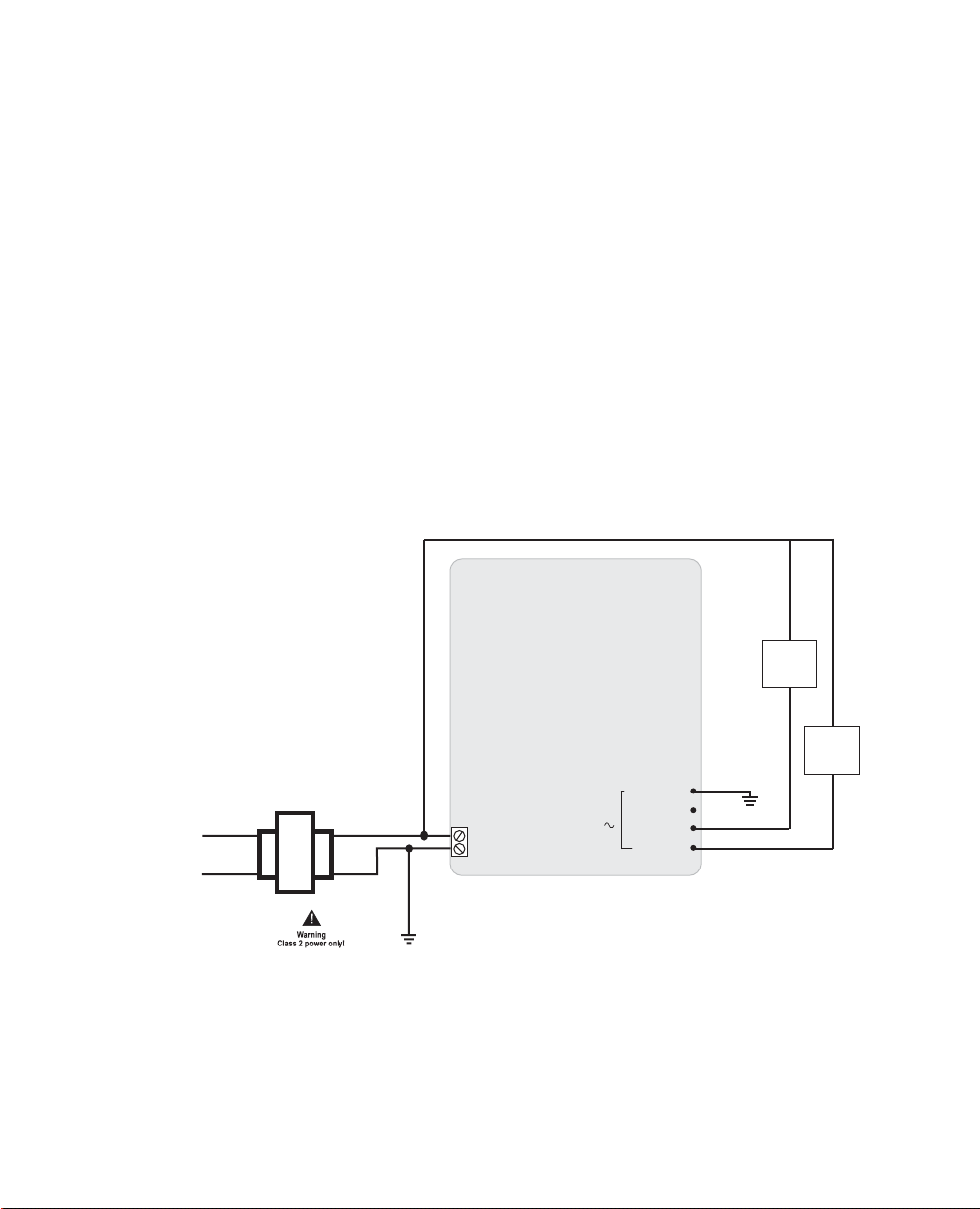

The new i2/b3 865/866-V controllers use three Form A triac output

terminals with a single triac reference. This configuration gives you the

flexibility to wire the single triac reference as either a hot or ground

connection. On these new controllers, all three outputs must be wired

the same, as either hot or ground switch applications.

To make a hot switch connection, connect one of the output terminals

(OUTX, where X = 3, 4, or 5) to a load, and connect the Triac Reference

to the incoming 24 VAC power.

Switching Option - Triac “Form A” Hot Connection

i2/b3 865/866-V Controller

24 VAC Step-Down

Power

Transformer

X1

X2

24 VAC

GND

DIGITAL

IGTAL

PUT

OUTPUTS

24VAC ,

0.5A

RIA

TRIAC REF

O

OUT5

OUT4

OUT3

15

5

14

T

13

12

Note: i2/b3 885-V Controller only has two digital outputs

i2/b3 865/866/885-V Controller Retrofit Guide 23

Page 24

Chapter 2: Connections

T

T

C

3

G

2VA

AC Line

Power

To make a ground switch connection, connect one of the output

terminals (OUTX, where X = 3, 4, or 5) to a load in series with the 24

VAC incoming power, and connect the Triac Reference to ground.

Switching Option - Triac “Form A” Ground Connection

i2/b3 865/866-V Controller

24 VAC Step-Down

Transformer

X1

X2

24 VAC

GND

Note: i2/b3 885-V Controller only has two digital outputs

DIGITAL

DI

TPUTS

OUTPUTS

24VAC ,

0

0.5A

RIA

TRIAC REF

OUT5

OUT4

OUT3

15

15

14

13

13

12

The new i2/b3 885-V controller, which only has two output terminal

connections, works the same, allowing for either two hot or ground

switch applications.

Old i2/b3

8xx-VAV Digital

Outputs

The previous generation of i2/b3 865/866-VAV controllers also used

three triac output terminals, but were internally referenced to ground

and cannot be wired as hot. All outputs are ground switch applications.

The old i2/b2 885-VAV controller used two output terminals that were

also internally referenced to ground and cannot be wired as hot.

Note: On the old i2/b3 865/866/885-VAV controllers, the external GND

terminals in the Digital Output area are grounds for optional 24

VAC power sources.

24 Schneider Electric

Page 25

Chapter 2: Connections

TCX 865/866

Digital Outputs

Form K Triac

Connections

Two product generations ago, the TCX 865/866 controllers also used

three triac output terminals, but allowed you to pair each output with

one of three isolated returns. This combination allowed you to create

either a hot or ground switch application for each individual output

load. The TCX controller could accommodate a combination of both hot

and grounded connections simultaneously.

All of the controllers, past and present, offer the ability to wire two of

the Form A outputs to create one Form K Tri-State output.

To create a Form K triac connection on the new i2/b3 865/866-V

controllers, make the individual connections from terminals 12 and 13

(OUT3 and OUT4), or use terminals 13 and 14 (OUT4 and OUT5), with

a common ground reference to terminal 15 (TRIAC REF).

Switching Option - Triac “Form K” Ground Connection

i2/b3 865/866-V Controller

OUT4

Load

AC Line

Power

OUT3

24 VAC Step-Down

Transformer

TRIAC REF

DIGITAL

X1

X2

24 VAC

GND

Note: i2/b3 885-V Controller only has two digital outputs

OUTPUTS

24VAC ,

0.5A

OUT5

OUT4

OUT3

15

14

13

12

Load

To maintain Form K triac connections on the new i2/b3 885-V

controller, make the individual connections from terminals 6 and 7

(OUT3 and OUT4) with a common ground reference to terminal 9

(TRIAC REF). Terminal 8 is not used on the 885-V controller.

i2/b3 865/866/885-V Controller Retrofit Guide 25

Page 26

Chapter 2: Connections

Rewiring Digital Outputs for an Old i2/b3 8xx-VAV Controller

Note: Since each generation of controller used a different internal

design for triac outputs and references, you need to pay close

attention to how the old controller you are replacing was wired.

If you are replacing a previous generation of i2/b3 8xx-VAV controller,

all the digital outputs for that generation of controller were referenced

to ground.

i2/b3 865/866 VAV Controller

i2/b3 885 VAV Controller

885

1

24VAC

0.42A,10VA

L

2

50/60HZ

USECOPPER

CONDUCTORSONLY

24VAC

MODEL

S/N

DATE

INSTALLATION

For detailed instructions reviewdocument 30-3001-849 date

SERVICE

+

3

PORT

INFINET

-

GND

4

+

PORT

-

5

SHIELD

6

3

OUT

DIGITAL

OUTPUTS

7

4

OUT

,0.5A

8

GND

9

IN1

UNIVERSAL

10

RET

INPUTS

11

IN2

MOTOR DIRECTION

Therefore, the simplest installation would be to make the following

ground switching connections when replacing the unit.

From the old i2/b3 865/866-VAV controller To the new i2/b3 865/866-V controller

OUT 3 (terminal 7) OUT3 (terminal 12)

OUT 4 (terminal 8) OUT4 (terminal 13)

OUT 5 (terminal 9) OUT5 (terminal 14)

GND (terminal 10 and 11) - Should not be

associated with Triac connections

From the old i2/b3 885-VAV controller To the new i2/b3 885-V controller

OUT 3 (terminal 6) OUT3 (terminal 6)

OUT 4 (terminal 7) OUT4 (terminal 7)

GND (terminal 8) - Should not be associated with

Triac connections

TRIAC REF (terminal 15)

TRIAC REF (terminal 9)

26 Schneider Electric

Page 27

Since the new i2/b3 8xx-V controllers are capable of both hot or ground

switching applications, you do have the option of rewiring all your

digital output connections to accomodate a hot switching application,

but this may cause problems with your existing circuits and loads.

For more information, refer to the hot switching diagram earlier in this

section, as well as the i2/b3 865/866/885-V Controller Installation

Instructions that came with the new controller.

Rewiring Digital Outputs for a TCX Controller

Chapter 2: Connections

Note: Since each generation of controller used a different internal

If you are replacing a previous generation TCX 865/866 controller, the

digital outputs and returns for that generation of controller were

individually isolated and permitted both hot and ground switching

application connections.

design for triac outputs and references, you need to pay close

attention to how the old controller you are replacing was wired.

TCX 865/866 VAV

Therefore, before replacing the unit and reconnecting the outputs, you

must understand how each output was wired. Since the replacement

i2/b3 8xx-V controller requires either all hot or all ground switch

connections, you may need to revise how some loads are wired to

complete the replacement installation.

i2/b3 865/866/885-V Controller Retrofit Guide 27

Page 28

Chapter 2: Connections

i2/b3 865/866-V Controller

The following illustration points out the differences in digital output

terminals for each controller.

Replacement

Three output terminals and one triac reference terminal

TCX 865/866 VAV Controller

TRIAC REF

DIGITAL

OUTPUTS

24VAC ,

0.5A

OUT5

OUT4

OUT3

15

14

13

12

OUT3

OUT4

OUT5

DIGITAL

OUTPUTS

24VA C ,

0.5 A

28 Schneider Electric

Three isolated output terminals and three isolated returns

for each connection

For more information refer to the hot and ground switching diagrams

earlier in this section, as well as the i2/b3 865/866/885-V Controller

Installation Instructions that came with the new controller.

Page 29

Analog Output Connections

The differences in the number of analog outputs and returns between

the older generation and the new “-V” controllers are listed in the table

below.

Controller Analog Outputs Returns

i2/b3 865-V None

i2/b3 866-V 2 1 Return

i2/b3 885-V None

i2/b3 865 VAV None

i2/b3 866 VAV 2 1 Return

i2/b3 885 VAV None

TCX 865 None

TCX 866 2 2 Return and 1 Shield

Chapter 2: Connections

New 8xx-V

Term inal

Locations

The analog output connections for the i2/b3 8xx-V controllers are

located on the following terminals:

Controller Analog Output

Terminals

i2/b3 865-V Not Available Not Available

i2/b3 866-V 16 and 18 17

i2/b3 885-V Not Available Not Available

Return Terminal

Refer to the label on the controllers to identify the terminals.

i2/b3 865/866/885-V Controller Retrofit Guide 29

Page 30

Chapter 2: Connections

Airflow Connections

The airflow sensors on both the old generation and the new “-V”

controllers have very similar connections, which include HI and LO

ports to match the HI and LO connections of the velocity sensor.

Airflow

Inputs

30 Schneider Electric

Note: Previous controllers required a micron filter component attached

to the HI hose connection. This is no longer required for the

i2/b3 8xx-V controllers.

Page 31

Page 32

i2/b3 865/866/885-V Controller Retrofit Guide

Document Number 30-3001-988

Revision D.1

Loading...

Loading...