Page 1

Application

The AV-29x linkages are used to field assemble

Schneider Electric gear train hazardous location

actuators to VB-7xxx series or select VB-9xxx series

valve bodies.

Features

• Die cast aluminum mounting bracket.

• Valve position indication provided as standard.

AV-291, AV-293, AV-295, and

AV-296

Valve Linkage for

Hazardous Location Gear Train Actuators

General Instructions

Applicable Literature

• EN-56-2 Apparatus for Use in Hazardous Locations,

F-

18451

• MAx-305 & MAx-318 Series MAx-405 through

MAx-

419 Series, Two-Position Actuators Genera

Instruc

tions, F-06491

• MC-351, 421, 431, MC-4311 Three-Wire, Two

Position

• MP-3xx and MP-4xx Series Reversible and

Proportional Electric

• Valve Products Catalog, F-27384

• EN-205 Water System Guidelines, F-26080

Actuators General Instructions, F-08366

Actuators, F-15479

l

Printed in U.S.A. 4/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-27441-2

Page 2

SPECIFICATIONS

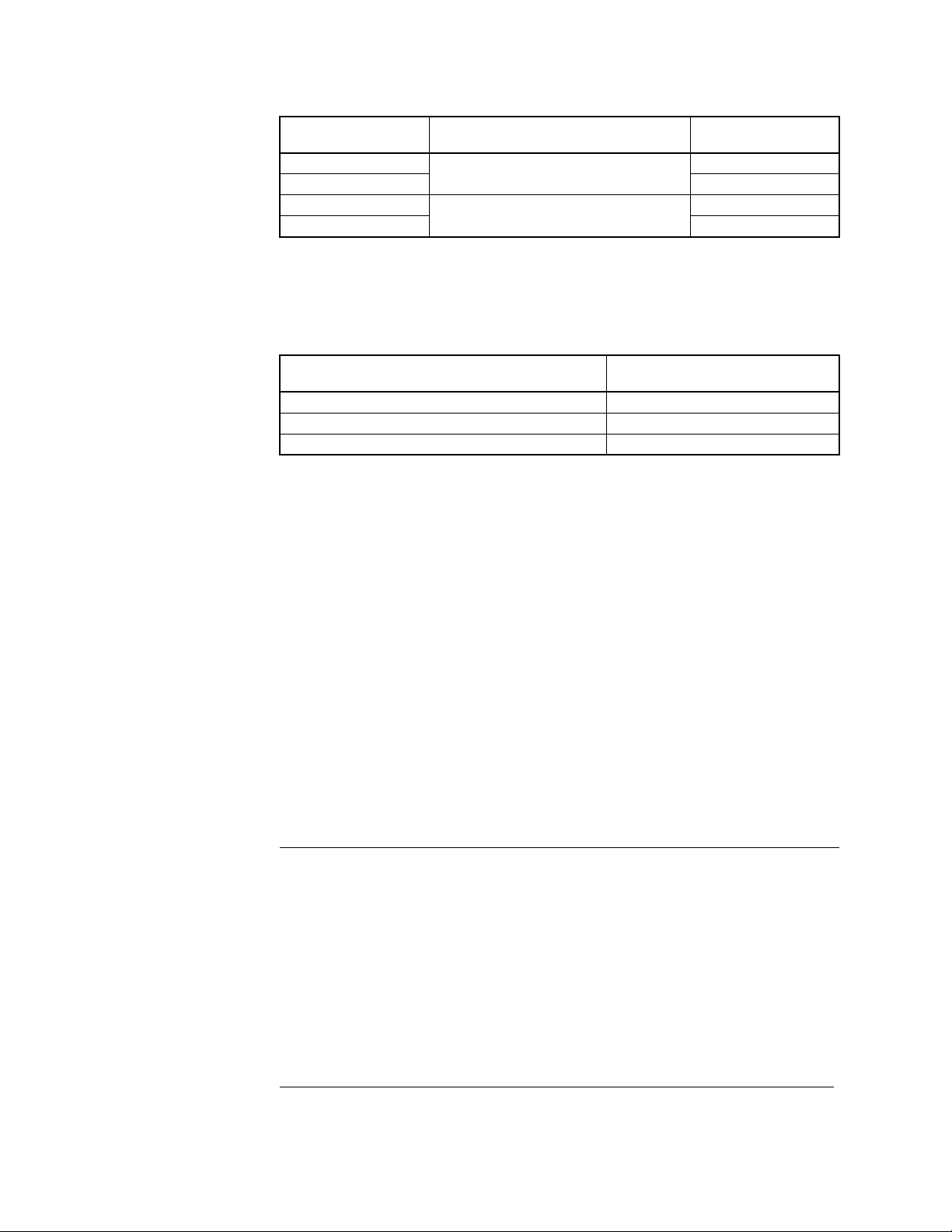

Table-1 Model Chart.

Required Components

Valve Linkage

Model Number

AV-291

AV-293 300

AV-295

AV-296 300

VB-9313 2

Description

Complete Linkages

VB-7xxx 1/2” to 2”

VB-9xxx 2-1/2” to 3” bronze

-1/2” to 4” cast iron flanged

Stem Force

(lb.)

150

150

Temperature Restrictions

Verify that the fluid temperature of the media in the valve versus the ambient temperature at

the actuator does not exceed the ratings shown in Table-2.

Table-2 Restrictions on Maximum Ambient Te m pe r ature for Actuators.

Maximum Temperature of Media in the Valve

(Check Rating of Valve) °F (°C)

260 (126) 136 (57)

281 (138) 125 (52)

300 to 366 (149 to 185) 100 (37)

Maximum Ambient for Actuator

°F (°C)

Close-off Pressure Rating

Close-off pressure ratings are listed in Table-3. Check the appropriate table to verify that the

selected valve, valve linkage,

application.

The actuator with hazardous location housing, valve, and valve linkage should be purchased

separately. See Table-3 for selections.

and actuator provide adequate close-off pressure for your

INSTALLATION

Inspection Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage. Return

damaged products.

Requirements • Tools (not provided):

– Appropriate wrenches for stem extensions, lock nuts, packing nuts, and brackets

– Appropriate screwdriver for actuator mounting screws

– TOOL-37, 1-5/8" open-ended wrench with a ma

• Training: Installer must be a qualified, experienced technician

Caution:

• Install the unit in accordance with the National Electric Code Article 500 and all

applicable local codes.

• Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

• Install all two-way valves so that they close against the flow. An arrow on the valve body

or a tag indicates the proper flow direction.

• Always install three-way mixing valves with two inlets and one outlet.

• Always install three-way diverting valves with one inlet and two outlets.

• The actuators can be mounted in any position above the centerline of the valve body.

For steam applications where the ambient temperature approaches the limit of the

actuator, the valve stem should be mounted 45° from vertical. When selecting a

location, allow sufficient room for accessories and for service of the product.

ximum thickness of 3/16"

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-27441-2

Page 3

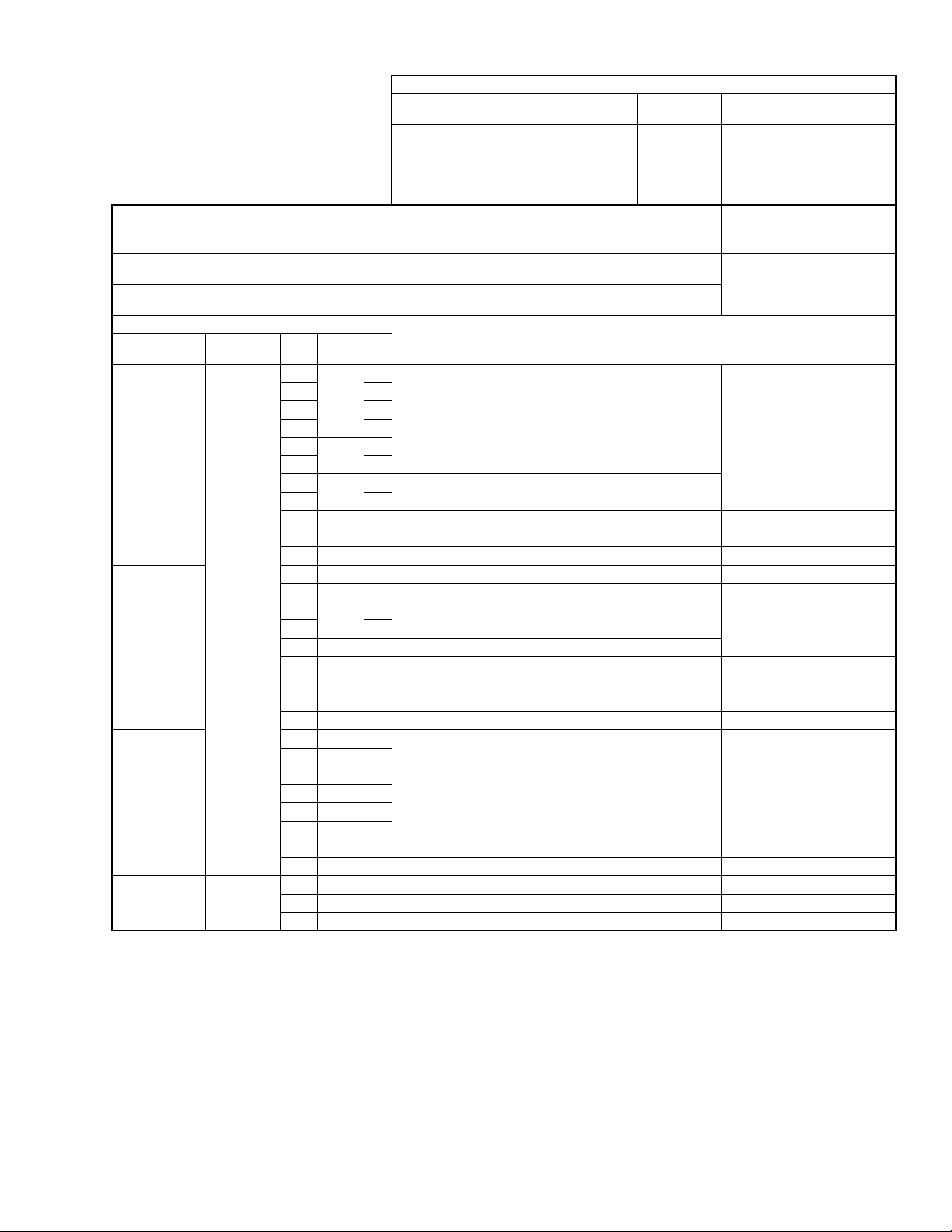

Table-3 Linkage Selection and Valve Close-Off Pressure Ratings for VB-7x xx and VB-9x1x Valve Bodies.

TYPICAL ACTUATOR PART NUMBERS

Spring Return No Normal

MA8-318, MA8-318-500

MA8-418, MA8-418-500

MP6-361, MP6-367

MP6-371, MP6-377, MP6-379,

MP6-465 MP7-4651

MP6-470, MP6-475, MP7-4751

Minimum Torque/Travel Required

Linkage for 1/2" to 2” VB-7xxx Series Valves AV-291 AV-293

Linkage for 2-1/2" to 3" VB-9xxx Series Bronze Body

Linkage for 2-1/2" to 4" VB-9313 Cast Iron Body

VALVE BODY INFORMATION CLOSE-OFF PRESSURE PSI (kPa)

Valve Body

t Number

Par

VB-7213-0-4-P

VB-7214-0-4-P

VB-7215-0-4-P

VB-7253-0-4-P

VB-7273-0-4-P

VB-9213-0-4-P

VB-9215-0-4-P

VB-7313-0-4-P

VB-7314-0-4-P

VB-7315-0-4-P

VB-7323-0-4-P

VB-9313-0-4-P

VB-9315-0-4-P

VB-9313-0-5-P

a

See Table-4 to set stem and cam position.

Description P

2-Way

3-Way

3-Way

125 lb

F

langed

Code

1

2 1.3

3 2.2

4 4.4

5

6 7.5

7

8 14

9 1-1/4" 20 90 (621) 200 (1379)

10 1-1/2" 28 65 (448) 140 (965)

11 2" 40 35 (241) 80 (552)

12 2-1/2" 65 20 (137) 50 (345)

13 3" 85 12 (83) 34 (234)

2

6 3/4" 7.5 220 (1517)

8 1" 14 150 (1034) 250 (1724)

9 1-1/4" 20 100 (689)

10 1-1/2" 28 60 (414) 140 (965)

11 2" 41 33 (228) 80 (552)

10 1-1/2” 28

11 2” 40

12 2-1/2" 67 20 (137) 50 (345)

13 3" 91 12 (83) 34 (234)

12 2-1/2" 74 20 (137) 50 (345)

.

13 3" 101 12 (83) 34 (234)

14 4" 170

4 1/2” 4.4

6 3/4” 7.5

8 1” 15

9 1-1/4” 20

lves

Va

Va

lves

Size Cv

0.4

1/2"

5.5

3/4"

10

1"

2.2

1/2"

50 lb.-in., 180° Rotation,

Plunger

150 lb.

AV-295 AV-296

–

250 (1724)

150 (1034)

250 (1724)

250 (1724) 250 (1724)

6 (41) 17 (117)

Posi

tion

MP6-421 MC6-351

a

No Normal Position

MC6-421

MC6-431

MP6-381

MP6-485

MC7-4311

175/220 lb.-in., 180° Rotation,

300 lb. Plunger

250 (1724)

250 (1724) 4 4.4

200 (1379)

F-27441-2 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

ASSEMBLY PROCEDURE

Indicator Screw

BYRF-105

Front Cover

ADDA-880-1

Nylon Bushing

AYRD-405

Mxx-xxx Hazardous Location Actuator

Mounting Screws (3)

BYRF-2286

Mounting Bracket

NYBA-61

Valve Body

Plunger Assembly

Connecting Pin

ADFA-20-1

Stem Extension

NYBA-37

Stem Locknut

YBA-519-1

Packing Nut

Mounting Nut

Cover Screws (2)

BYRF-695

Indicator

ADDA-9-2

Plunger Cam

NYBA-77

1

1

1

1 Not included in AV kits.

2 ADDA-104-002 (150 lb.)

FYBA-53-9 (300 lb.)

2

1

AV-291 and AV -293 Note: Position the bracket on the valve in such a way as to make it convenient to wire the

actuator.

Valve Linkage for 1/2" to 2" VB-7xxx

1. Mount the bracket on the valve body by screwing the mounting nut into the mounting

bracket. Tighten the hex mounting nut, using a 1-5/8" open-ended wrench with a

maximum thickness of 3/16" (TOOL-37). See

Valve Linkage Common Procedure on page 6.

Figure-1. Proceed to step 2 in AV29x

Figure-1 Valve Linkages for 1/2" to 2" VB-7xxx.

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-27441-2

Page 5

A V-295 and AV-296 on Valve Bodies

Valve Linkage for Current 2-1/2” to 4” VB-9x1x

1. Mount the bracket onto the valve body by removing the bracket nut, placing the bracket

on the valve body, and replacing and tightening the valve bracket nut. See Figure-2.

Proceed to step 2 in AV29x Valve Linkage Common Procedure on page 6.

Indicator

ADDA-9-2

Indicator Screw

BYRF-105

Cover Screws (2)

BYRF-695

Front Cover

ADDA-880-1

Nylon Bushing

Plunger Assembly

Plunger Cam

AYRC-44-2

Connecting Pin

ADFA-20-1

Mxx-xxx Hazardous Location Actuator

1

AYRD-405

2

Mounting Bracket

NYBA-68

Stem Extension

NYBA-37

Mounting Screws (3)

BYRF-2286

Threaded VB-9xxx Valve Body

2-1/2" and 3"

Figure-2 Valve Linkages for Current 2-1/2" to 4" VB-9313 Cast Iron Flanged,

Stem Locknut

DYRF-11

Packing Nut

Bracket Nut

1

and VB-9xxx

1

1

2-1/2” to 4”

Flanged VB-9313 V

alve Body

1

2-1/2” and 3” Threaded Bronze Valve Bodies.

1 Not included in AV kits.

2 ADDA-104-002 (150 lb.)

FYBA-53-9 (300 lb.)

F-27441-2 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Page 6

AV29x Valve Linkage

Full CW Position

Full CCW Position

Short Tooth on

Actuator Shaft

at 9:00

Short Tooth on

Actuator Shaft

at 3:00

Common Procedure

The following steps are common to all AV-29x valve linkages. Perform step 1 on page 4 or

5 before proceeding to step 2.

2. Thread the stem lock nut and stem extension down fully onto the valve stem.

3. Place the actuator onto the mounting bracket. Fasten the actuator to the mounting

bracket with the three mounting screws, BYRF-2286. Do not tighten the screws.

4. Place the nylon bushing onto the actuator shaft.

5. Position the actuator to the 3:00 (CW) or 9:00

up or down as required. Use Figure-3 and Table-4.

Table-4 Actuator Shaft and Cam Position.

Actuator

Shaft

Position

Valve Position Cam/Valve Position Valve Position Cam/Valve Position

(CCW) position so that the cam is pointing

Figure-3 Actuator Shaft Position (Front View).

CW

Short tooth on

shaft

actuator

at 9:00

CCW

Short tooth on

shaft

actuator

at 3:00

VB-7213 (closed)

VB-7313 (B closed)

VB-7323 (B to A open)

VB-921x (closed)

VB-931x (B closed)

VB-7213 (open)

VB-7313 (A closed)

VB-7323 (B to AB open)

VB-921x (open)

VB-931x (A closed)

6. Consult Table-5 for the proper cam. Place the cam in the plunger and slip the plunger

VB-7213 (open)

VB-7313 (A closed)

VB-7323 (B to AB open)

VB-921x (open)

VB-931x (A closed)

Cam Down

Cam Up

VB-7213 (closed)

VB-7313 (B closed)

VB-7323 (B to A open)

VB-921x (closed)

VB-931x (B closed)

cam onto the actuator shaft with the cam po

Cam Up

Cam Down

inting to the required position.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-27441-2

Page 7

Table-5 Cam Selection.

Use Cam

Marked

77 AV-291 and AV-293 1/2" to 2" VB-7xxx 1/2"

44-2 AV-295 and AV-296 2-1/2" to 4" VB-9xxx 1"

Included in Linkage Kits For These Valve Bodies

With

minal

No

Stroke

7. Push the valve stem completely down.

8. Screw the stem extension until the hol

es in the stem extension and plunger line up.

9. Turn the stem extension upward, counterclockwise, into the plunger 2 full turns.

10. Raise the actuator up until the connecting pin can be inserted through the holes in the

plunger and stem extension.

1 1 . Tighten the actuator mounting screws.

12. Tighten the stem lock nut agai

nst the stem extension.

13. Place the front cover over the plunger assembly and fasten it to the actuator with two

cover screws, BYRF-695.

14. Install the position indicator to the end of the actuator shaft. See Table-4 for the correct

position.

F-27441-2 © Copyright 2010 Schneider Electric All Rights Reserved. 7

Page 8

CHECKOUT

Check to assure correct plunger spring compression. The length of the stem extension

should be adjusted so that the valve disc seats before the actuator reaches the end of the

stroke. The balance of the actuator stroke is taken up in the plunger spring compression,

which should be approximately 1/16 inch (1.6 mm). This applies pressure on the disc in the

closed position(s) and compensates for disc and seat wear. Refer to Figure-5 for VB-7213

(stem down closed). For three way applica

tions (VB-73x3 or VB-9313) refer to Figure-4

andFigure-5.

VB-7213 Example 1. Drive the actuator so the valve stem is fully down.

2. Observe the plunger spring compression as in Figure-5.

VB-7313 Example 1. Drive the actuator so the valve stem is fully up.

2. Observe the plunger spring compression as in Figure-4.

3. Drive the actuator so the valve stem is fully down.

4. Observe the plunger spring compression as in Figure-5.

Plunger Spring

Housing

Spring Compression

Approximately 1/16” (1.6 mm)

Spring Compression

Connecting Pin

Stem Extension

Stem Locknut

Plunger Spring

Housing

Connecting Pin

Stem Extension

Valve Seat Contact

Valve Stem

Figure-4 Valve Compression Stem Up.

Spring Compression

Approximately 1/16” (1.6 mm)

Valve Seat Contact

Valve Seat Compression

Stem Locknut

Valve Stem

Figure-5 Valve Compression Stem Down.

8 © Copyright 2010 Schneider Electric All Rights Reserved. F-27441-2

Page 9

MAINTENANCE

Allow 12” (300) minimum service clearance above the housing top.

O

P

E

N

C

L

O

S

E

D

8-1/4 (209)

4-1/8 (105)

4-1/2

(114)

7

(178)

9

(228)

Coupling Line

for Actuator

1/4

(6)

1-1/4 – 16 Threads

(AV-291 and

A

V-293 only)

Dimensions shown

are in inches (mm).

4-1/4 (108)

Coupling Line

for Valve Body

5-7/16

(139)

7-7/8 (200)

DIMENSIONAL DATA

Regular maintenance of the total system is recommended to assure sustained optimum

performance.

Figure-6 Front Dimensions.

F-27441-2 © Copyright 2010 Schneider Electric All Rights Reserved. 9

Page 10

On October 1st, 2009, TAC became the Buildings business of its parent company Schneider Electric. This document reflects the visual i denti ty of Schn eider Elec tric,

ho wever there rem ains r eferences to TAC as a corpor a te br and in the body copy. As each document is updated, the body copy will be c han ged to reflect appropriate

4-1/2

(114)

2-15/16

(51)

2-1/8

(54)

3/4 (19) Pipe Tap

On Each Side

9

(229)

10-13/16

(275)

1/8

(3)

1-1/4 (32)

5/8 (16)

Dimensions shown

are in inches (mm).

Figure-7 Side Dimensions.

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-27441-2

Loading...

Loading...