Page 1

Installation Manual

InRow® Direct Expansion Air Conditioners

InRow RD DX

ACRD600, ACRD601, ACRD602,

ACRD600P, ACRD601P, ACRD602P

990-5711C-001

Publication Date: April 2017

Page 2

Schneider Electric IT Corporation Legal Disclaimer

The information presented in this manual is not warranted by the Schneider Electric IT Corporation to be

authoritative, error free, or complete. This publication is not meant to be a substitute for a detailed operational

and site specific development plan. Therefore, Schneider Electric IT Corporation assumes no liability for

damages, violations of codes, improper installation, system failures, or any other problems that could arise

based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of

evaluating data center design and construction. This Publication has been compiled in good faith by Schneider

Electric IT Corporation. However, no representation is made or warranty given, either express or implied, as to

the completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL SCHNEIDER ELECTRIC IT CORPORATION, OR ANY PARENT, AFFILIATE OR

SUBSIDIARY COMPANY OF SCHNEIDER ELECTRIC IT CORPORATION OR THEIR RESPECTIVE

OFFICERS, DIRECTORS, OR EMPLOYEES BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL,

PUNITIVE, SPECIAL, OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS, CONTRACT, REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION)

RESULTING FROM, ARISING OUT, OR IN CONNECTION WITH THE USE OF, OR INABILITY TO USE THIS

PUBLICATION OR THE CONTENT, EVEN IF SCHNEIDER ELECTRIC IT CORPORATION HAS BEEN

EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SCHNEIDER ELECTRIC IT

CORPORATION RESERVES THE RIGHT TO MAKE CHANGES OR UPDATES WITH RESPECT TO OR IN

THE CONTENT OF THE PUBLICATION OR THE FORMAT THEREOF AT ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software, audio,

video, text, and photographs) rests with Schneider Electric IT Corporation or its licensors. All rights in the

content not expressly granted herein are reserved. No rights of any kind are licensed or assigned or shall

otherwise pass to persons accessing this information.

This Publication shall not be for resale in whole or in part.

Page 3

Table of Contents

Safety.................................................................................1

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Considerations While Installing This Equipment . . . . . . . . . . . . . 2

General Information...........................................................3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Save these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Symbols used in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Waste Electrical and Electronic Equipment (WEEE) disposal . 3

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Filing a claim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storing the Equipment Before Installation . . . . . . . . . . . . . . . . . . . . . . . 3

Moving the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install kit inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Exterior components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Interior components (ACRD60x) . . . . . . . . . . . . . . . . . . . . . . . . 7

Interior components (ACRD60xP) . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigeration piping diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connections overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Piping connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communication connections . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Room Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Incoming power supply requirement . . . . . . . . . . . . . . . . . . . . 16

Service access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

InRow RD Installation Manual i

Page 4

Access Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Top piping and power access locations—top view, looking down (ACRD600/P series) 19

Bottom piping and power access locations—bottom view, looking up (ACRD600/P series)

20

Equipment Guidelines......................................................21

Working Conditions and Environmental Limits . . . . . . . . . . . . . . . . . . 21

Installation........................................................................22

Removing the Doors and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removing the front and rear doors . . . . . . . . . . . . . . . . . . . . . 23

Removing and installing the side panel . . . . . . . . . . . . . . . . . . 24

Removing the electrical panel cover . . . . . . . . . . . . . . . . . . . . 25

Joining the Equipment to Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Joining to NetShelter™ SX enclosures . . . . . . . . . . . . . . . . . . 26

Joining to NetShelter VX and VS enclosures . . . . . . . . . . . . . 26

Leveling the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mechanical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Refrigeration piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connect refrigerant lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Flooded receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Humidifier (ACRD60xP only) . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Condensate pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Condensate overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Leak sensor (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adding a holding charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adding compressor oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Customer interface connections . . . . . . . . . . . . . . . . . . . . . . . 37

Form C alarm contacts and shutdown input . . . . . . . . . . . . . . 39

Rack temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Communication connections . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Network port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Wiring configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Top routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Bottom routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Strain relief (ACRD602/602P only) . . . . . . . . . . . . . . . . . . . . . 45

Connect flooded receiver heater . . . . . . . . . . . . . . . . . . . . . . . 46

Voltage selections—ACRD60x units . . . . . . . . . . . . . . . . . . . . 46

Voltage selections – ACRD60xP units . . . . . . . . . . . . . . . . . . 47

ii

InRow RD Installation Manual

Page 5

Charging with Refrigerant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calculating R410A charge . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Charging the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Compressor Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Oil charging procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Accessories .....................................................................54

Low Temperature Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install kit inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Bulb location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Heater connection location . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

iiiInRow RD Installation Manual

Page 6

Page 7

Safety

Important Safety Information

Read the instructions carefully to become familiar with the equipment before trying to install, operate, service,

or maintain it. The following special messages may appear throughout this manual or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death

or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor

or moderate injury.

NOTICE

NOTICE addresses practices not related to physical injury including certain environmental

hazards, potential damage or loss of data.

1InRow RD Installation Manual

Page 8

Safety Considerations While Installing This Equipment

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. See NFPA 70E or CSA Z462.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the equipment for

foreign objects before closing the doors and starting the equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF EQUIPMENT FALLING OVER

• Use two or more persons at all times to move or turn this equipment.

• Always push, pull, or turn while facing the front and rear of this equipment. Never push,

pull, or turn while facing the sides of this equipment.

• Slowly move this equipment across uneven surfaces or door thresholds.

• Lower leveling feet to floor when this equipment is at rest.

• Lower leveling feet and attach joining brackets to adjacent racks when this equipment is

in final position.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

InRow RD Installation Manual2

Page 9

General Information

Overview

Save these instructions

This manual contains important instructions that must be followed during the installation of this equipment.

Symbols used in this manual

Indicates that more information is available in another location.

Equipment Disposal

Waste Electrical and Electronic Equipment (WEEE) disposal

Schneider Electric products comply with international directives on the Restriction of

Hazardous Substances (RoHS) in electronic and electrical equipment and the disposal of

Waste Electrical and Electronic Equipment (WEEE). Dispose of any waste electronic or

electrical equipment with the appropriate recycling center. Contact Schneider Electric for

assistance.

Inspecting the Equipment

Your InRow air conditioner has been tested and inspected for quality assurance before shipment from

Schneider Electric. Carefully inspect both the exterior and interior of the equipment immediately upon receipt to

ensure that the equipment has not been damaged during transit.

Verify that all parts ordered were received as specified and that the equipment is the correct type, size, and

voltage.

Filing a claim

If damage is identified on receipt of the equipment, note the damage on the bill of lading and file a damage

claim with the shipping company. Contact Schneider Electric Worldwide Customer Support for information on

how to file a claim with the shipping company. The shipping claim must be filed at the receiving end of the

delivery.

NOTE: In case of shipping damage, do not operate the equipment. Keep all packaging for inspection by the

shipping company and contact Schneider Electric.

Storing the Equipment Before Installation

If the equipment will not be installed immediately, store it in a safe place, protected from the weather.

NOTICE

HAZARD TO EQUIPMENT

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

3InRow RD Installation Manual

Page 10

Moving the Equipment

The recommended tools for moving the equipment while it is still on the pallet include the following:

Pallet Jack Forklift

NOTE: The equipment can be rolled to its final location using its casters if the floor is smooth and clean.

Model Identification

Standard unit

The model number can be found on the outside of the shipping crate and on the nameplate located inside the

equipment as shown. Use the table below to verify that the equipment is the correct size and voltage.

Model Configuration Voltage Frequency Reheat Humidifier Air Pattern

ACRD600

ACRD601

ACRD602

ACRD600P

ACRD601P

ACRD602P

Air-cooled 200-240 50-60 Hz N/A N/A Back to front

Air-cooled 460-480 60 Hz N/A N/A Back to front

Air-cooled 380-415 50-60 Hz N/A N/A Back to front

Air-cooled 200-240

Air-cooled 460-480

Air-cooled 380-415

50-60 Hz Electric

60 Hz Electric

50-60 Hz Electric

NAMEPLATE

Steam canister

(replaceable)

Steam canister

(replaceable)

Steam canister

(replaceable)

Back to front

Back to front

Back to front

na5809a

InRow RD Installation Manual4

Page 11

Component Identification

Install kit inventory

na2505b

Item Description Quantity Item Description Quantity

Threaded ring seal straight fitting,

female, 1 1/4-in. to 3/4-in.* I.D.

Humidifier inlet water connection,

shutoff

• 1/4-in. NPT*** and 1/4-in. BSPT**

4

1 ea

M6 x 16-mm TORX screw with

washer

Strain relief, metal (ACRD602 and

602P only)

5

2

(ACRD600P)

• 1/4-in. NPT*** (ACRD601P)

• 1/4-in. BSPT** (ACRD602P)

Condensate drain outlet, shutoff, 3/8-in.

1

1

1

Wire clip 9

BSPT**

Condensate overflow hose adapter

2

Tie wrap, 200 mm (8 in.) 10

clamp, double snap

Threaded ring seal male straight -

2

Tie wrap, 390 mm (15.3 in.) 3

3/4-in.* I.D.

Gas shutoff valve, 3/4-in. I.D. 2

Temperature sensor 3

Rotalock gasket, 1 1/4-in. 4

Resistor, 150 Ohm 1

Cable tie 10

Condensate overflow hose

1

adapter

M5 x 10-mm TORX® screw with washer

5

Reducer, 3/8-in. to 1/2-in. BSPT** 1

(spare parts)

M6 x 12-mm TORX screw with washer

5

Reducer, 3/8-in. to 1/2-in. NPT*** 1

(spare parts)

M6 x 10-mm self-tapping TORX screw

5

Voltage jumper ****

(spare parts)

*Standard wall thickness

**British Standard Pipe Thread

***National Pipe Thread

****Quantity and wire connections vary depending

on model number. See “Voltage selections—

ACRD60x units” on page 46.

5InRow RD Installation Manual

Page 12

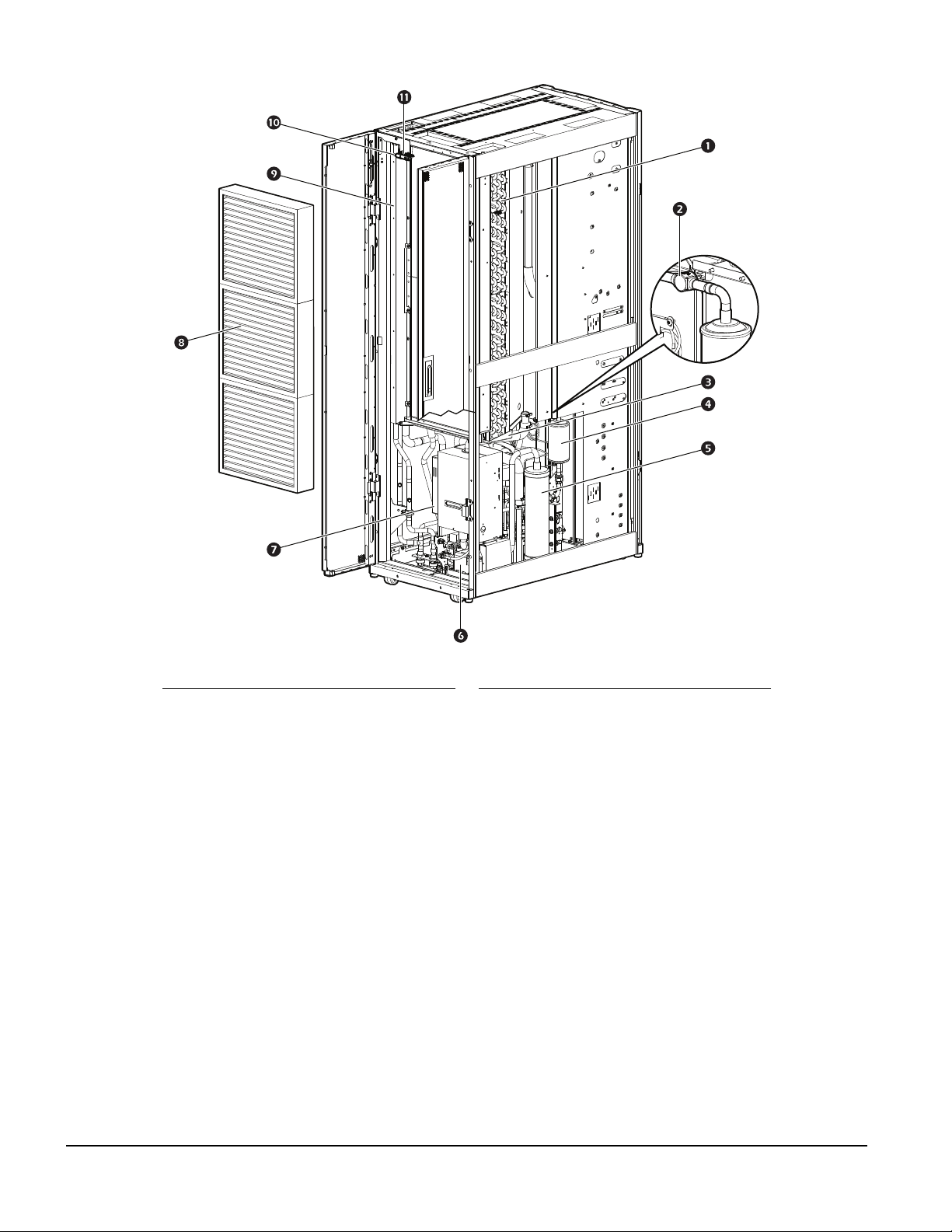

Exterior components

Item Description Item Description

Removable rear doors

Side panel lock

Removable side panel

Adjustable leveling foot

Caster

Door handle and lock

Display interface

Removable front door

na5807a

InRow RD Installation Manual6

Page 13

Interior components (ACRD60x)

Front

Item Description Item Description

Condensate drain pan

Electronic expansion valve

Compressor

Variable frequency drive (for

compressor)

Supply air temperature sensor

Main circuit breaker

Fan (2)

Fan guard (2)

Electrical panel

Communication and external device

connectors

Ground lug

Humidity sensor

na5823a

7InRow RD Installation Manual

Page 14

Rear

Item Description Item Description

Evaporator coil

Sight glass

Condensate drain pan

Filter drier

Oil separator

Condensate pump

Air filters

Pipe chase

Return air temperature sensor

na5824a

InRow RD Installation Manual8

Page 15

Interior components (ACRD60xP)

Front

Item Description Item Description

Electric heater

Condensate drain pan

Electronic expansion valve

Humidifier

Compressor

Main circuit breaker

Fan (2)

Fan guard (2)

Electrical panel

Communication and external device

connectors

Variable frequency drive (for compressor)

Supply air temperature sensor

Ground lug

Humidity sensor

na5821a

9InRow RD Installation Manual

Page 16

Rear

Item Description Item Description

Evaporator coil

Sight glass

Condensate drain pan

Filter drier

Oil separator

Condensate pump

Humidifier

Air filters

Pipe chase

Humidity sensor

Return air temperature sensor

na5822a

InRow RD Installation Manual10

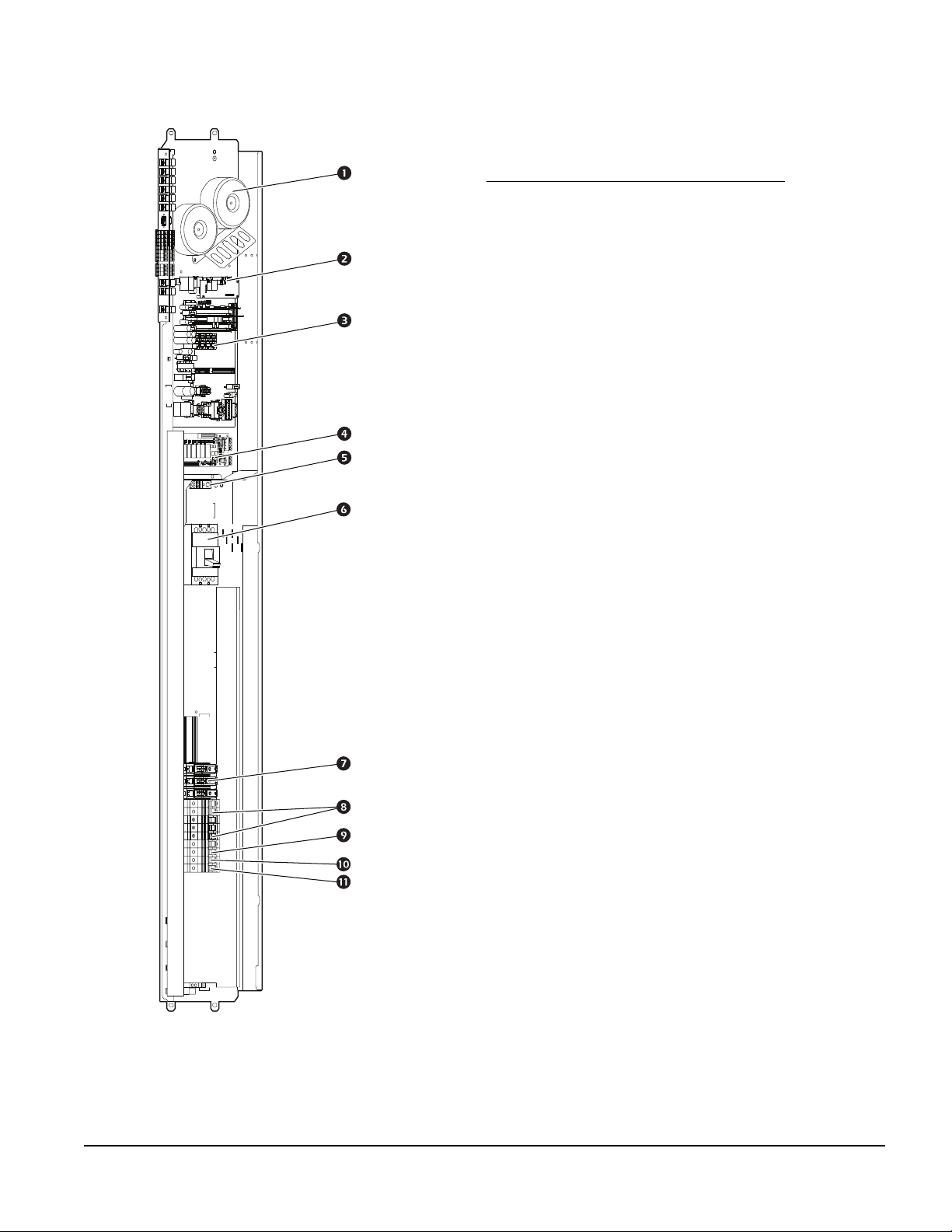

Page 17

Electrical panel

ACRD600, ACRD601, ACRD602

Item Description

Transformers

Display interface connectors

Main controller board

Relay board

Ground lug

Main circuit breaker

Compressor fuse block

(ACRD600, ACRD601)

Compressor circuit breaker

(ACRD602)

Fan circuit breakers

Fuse not populated

Transformer A fuse

Transformer C/MB fuse

na2724b

11InRow RD Installation Manual

Page 18

ACRD600P, ACRD601P, ACRD602P

Item Description

Transformers

Display interface connectors

Main controller board

Relay board

Ground lug

Main circuit breaker

Compressor fuse block

(ACRD600P, ACRD601P)

Compressor circuit breaker

(ACRD602P)

Fan circuit breakers

Controller fuse

Heater circuit breaker

Humidifier circuit fuse

Heater contactors

Humidifier contactor

na2032b

InRow RD Installation Manual12

Page 19

Refrigeration piping diagram

BOTTOM PIPING TOP PIPING

CONDENSER

HOT GAS

HOT GAS

LIQUID

RD

RECEIVER

RD

Item Description Item Description

Pitch in direction of refrigerant flow Pressure relief valve

Reduction of piping diameter for

P-trap

vertical piping run (if necessary)

Shutoff valves S-trap

CONDENSER

LIQUID

na2543a

RECEIVER

Head pressure control valve Inverted P-trap

Check valve

NOTE: All lines are Type L ACR hard-drawn copper pipes.

NOTE: Shutoff valves shown nearest to the condenser are provided in receiver kit.

NOTE: Pitch all lines in the direction of refrigerant flow: 4 mm per m (1/2 in. per 10 ft).

NOTE: Route piping through the top or bottom of the InRow RD cooling unit.

NOTE: Trap the vertical discharge line every 6 m (20 ft) to ensure proper oil return.

NOTE: The maximum piping run is 91 m (300 ft) equivalent length. Size the piping pursuant to accepted

refrigeration practice.

NOTE: Condenser can be placed up to 4.5 m (15 ft) below the indoor cooling unit for equivalent line lengths of

8 m (25 ft) or less.

For Condensers Mounted Below the Level of the Indoor Unit

Piping Equivalent Length – m (ft)

91 (300) 76 (250) 61 (200) 46 (150) 30 (100) 15 (50) 8 (25)

Allowable Distance From Bottom

of Condenser to Bottom of

0.3 (1) 1.5 (5) 2.1 (7) 2.7 (9) 3.3 (11) 3.9 (13) 4.5 (15)

Indoor Unit* – m (ft)

*When condenser is installed below unit level, use 7/8 in. pipe for liquid line.

Note: Condenser can be placed higher than indoor cooling unit but height shall be no more than 27 m (90 ft), regardless

of piping length.

13InRow RD Installation Manual

Page 20

Connections overview

All connections to and from the equipment can be made through either the top or the bottom of the equipment.

Once the corresponding connectors are sweated or soldered into place, the equipment can be disconnected

without additional soldering, welding, or gluing. See the following tables for information about the sizes and

types of connectors.

Power connections

Minimum

Circuit

Ampacity

Model Voltage

ACRD600 200-240 V,

50/60 Hz

ACRD601 460-480 V,

60 Hz

ACRD602 380-415 V,

50/60 Hz

ACRD600P 200-240 V,

50/60 Hz

ACRD601P 460-480 V,

60 Hz

ACRD602P 380-415 V,

50/60 Hz

*Consult local and national codes for wire size, conduit requirements, and overload protection.

(MCA)

51.6 80 - 29.7* 36.6 14.6

24.0 40 - 28.1* 16.6 14.6

30.7 50 25.2 28.1* 16.6 14.6

77.6 110 - 29.7* 36.6 23.5

36.5 50 - 28.1* 16.6 23.5

45.4 65 34.2 28.1* 16.6 23.5

Maximum

Overload

Protection

(MOP)

Full Load

Amperes

(FLA)

Locked Rotor

Amperes (LRA)

Piping connections

Connection Type

ACRD600

ACRD600P

ACRD601

ACRD601P

Compressor

Compressor

Rated Load

Amperes (RLA)

Power

(kW)

ACRD602

ACRD602P

Refrigerant discharge

Refrigerant liquid

Humidifier water supply

(ACRD600P, ACRD601P,

ACRD602P only)

Condensate drain Quick coupling

* Use a new Teflon gasket (supplied) to prevent leakage. Tighten Rotalock nut to 90 Nm (66 ft-lb).

1 1/4-in. Rotalock*

1 1/4-in. Rotalock*

Quick coupling 1/4-in. NPT or

3/4-in. ID 3/4-in. ID 3/4-in. ID

3/4-in. ID 3/4-in. ID 3/4-in. ID

1/4-in. NPT 1/4-in. BSPT

1/4-in. BSPT

1/2-in. female NPT or

1/2-in. female BSPT

1/2-in. female NPT or

1/2-in. female BSPT

1/2-in. female NPT or

1/2-in. female BSPT

InRow RD Installation Manual14

Page 21

Communication connections

Wire Size

Torque

Connection Type

Rack temperature 1 RJ-45 - - -

Rack temperature 2 RJ-45 - - -

Rack temperature 3 RJ-45 - - -

A-Link IN RJ-45 - - -

A-Link OUT RJ-45 - - -

Network port RJ-45 - - -

Customer output, Normally Closed (NC) Screw connector AWG 24 (0.2 mm2) AWG 18

Customer output, Common (COM) Screw connector AWG 24 (0.2 mm2) AWG 18

Customer output, Normally Open (NO) Screw connector AWG 24 (0.2 mm2) AWG 18

Supply GND Screw connector AWG 24 (0.2 mm2) AWG 18

Supply 12 Vdc Screw connector AWG 24 (0.2 mm2) AWG 18

Supply 24 Vdc Screw connector AWG 24 (0.2 mm2) AWG 18

Customer input + Screw connector AWG 24 (0.2 mm2) AWG 18

Customer input – Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus D1 Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus D0 Screw connector AWG 24 (0.2 mm2) AWG 18

Modbus GND Screw connector AWG 24 (0.2 mm2) AWG 18

Minimum Maximum

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

0.6 Nm

(0.75 mm2)

15InRow RD Installation Manual

Page 22

Room Preparation

During the design of the data center, consider ease of entry for the equipment, floor loading factors, and

accessibility to piping and wiring. In addition, the room temperature and humidity combination should conform

to the environmental operating envelope as defined in the following graphics.

90

80

70

60

50

40

30

20

10

0

10 15 20 25 30 35 40 45 50

RELATIVE HUMIDITY (% RH)

ACCEPTABLE

OPERATING

RANGE

AMBIENT TEMPERATURE (°C) AMBIENT TEMPERATURE (°F)

UNACCEPTABLE

OPERATING LIMITS

90

80

70

60

50

40

30

20

10

ACCEPTABLE

OPERATING

RANGE

0

60 65 70 75 80 85 90 95 100 105 110 115

UNACCEPTABLE

OPERATING LIMITS

RELATIVE HUMIDITY (% RH)

Seal the room with a vapor barrier to minimize moisture infiltration. Polyethylene film is recommended for

ceiling and wall applications. Apply rubber- or plastic-based paints to concrete walls and floors.

Insulate the room to minimize the influence of exterior heat loads. Reduce fresh air to the minimum required by

local and national codes and regulations. Fresh air imposes extreme load variation on the cooling equipment

from summer to winter and causes increased system operating costs.

Air distribution

The equipment distributes air in a back-to-front discharge pattern, removing hot air from a hot aisle and

discharging cooled air into a cold aisle.

NOTE: The equipment is designed for free air discharge or for use with the Rack Air Containment System or

EcoAisle Containment System. The equipment is not intended to be connected to a duct system.

na2544a

Incoming power supply requirement

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

InRow RD Installation Manual16

Page 23

Service access

A minimum of 900 mm (36 in.) of clear floor space in front of and behind the equipment is recommended for

service. All required normal maintenance is performed from the front and rear of the equipment.

Most of the cooling components in the equipment can be replaced while the unit is installed in row and without

the use of heavy lift equipment or a welding torch. However, if it is necessary to remove the unit for repair, use

the casters on the equipment to remove it from the row. An area of minimum 1200 mm (48 in.) of clear floor

space in front of or behind the equipment is recommended to roll out the equipment.

NOTE: Check local and national codes and regulations for further service access requirements.

na5810a

900 (36.00)

SERVICE ACCESS REQUIRED

WHEN EQUIPMENT IS INSIDE

THE ROW

Dimensions are shown in mm (in.).

900 (36.00)

1200 (48.00)

1200 (48.00)

FREE SPACE NEEDED TO

MOVE EQUIPMENT

OUTSIDE THE ROW

17InRow RD Installation Manual

Page 24

Weights and Dimensions

1070 (42.1)

2156

(84.9)

879 (34.6)

Dimensions are shown in mm (in.).

Model Net Weight – kg (lb) Shipping Weight – kg (lb)

ACRD600

ACRD601

ACRD602

ACRD600P 413 (911) 458 (1,010)

ACRD601P 402 (886) 447 (986)

ACRD602P 402 (886) 447 (986)

1137 (44.8)

402 (886) 447 (986)

391 (862) 436 (961)

391 (862 ) 436 (961)

600 (23.6)

1991

(78.4)

na5811a

InRow RD Installation Manual18

Page 25

Access Locations

Top piping and power access locations—top view, looking down (ACRD600/P series)

REAR—HOT AISLE

547 (21.54)

558 (21.97)

75 (2.95)

123 (4.84)

325 (12.78)

380 (14.94)

73 (2.86)

105 (4.12)

40 (1.58)

738 (29.04)

47 (1.85)

FRONT—COLD AISLE

Item Description

Refrigerant discharge line

Refrigerant liquid line

Trough for communication cables

Power connections

Humidifier water supply (ACRD600P series only)

Condensate drain

na2071a

NOTE: Dimensions are shown in mm (in.).

19InRow RD Installation Manual

Page 26

Bottom piping and power access locations—bottom view, looking up (ACRD600/P series)

REAR—HOT AISLE

480 (18.90)

345 (13.58)

404 (15.91)

115 (4.53)

420 (16.54)

57 (2.25)

184 (7.24)

199 (7.84)

796 (31.34)

893 (35.16)

na5837a

FRONT—COLD AISLE

Item Description

Humidifier water supply (ACRD600P series only)

Condensate drain

Power connections

Communication connections—27.80 mm (1.09 in.)

Condensate overflow—50.00 mm (1.97 in.)

Refrigerant discharge line

Refrigerant liquid line

NOTE: Dimensions are shown in mm (in.).

140 (5.51)

178 (7.00)

InRow RD Installation Manual20

Page 27

Equipment Guidelines

Working Conditions and Environmental Limits

InRow DX units have a minimum heat load to ensure proper operation. Failure to operate the unit with at least

the minimum load will result in one or more of the following conditions:

• Decreased operating efficiency

• Equipment on/off cycling

• Inadequate dehumidification

• Increased wear and tear caused by frequent on/off cycles

• Decreased group control effectiveness

• Potential increase in cost of ownership

Limit Working Conditions

Models ACRD600/P ACRD601/P ACRD602/P

Power Supply

Minimum Recommended Load

200–240 V

3-Phase

50/60 Hz

460–480 V

3-Phase

60 Hz

8 kW (27,296 BTU/hr)

380–415 V

3-Phase

50/60 Hz

21InRow RD Installation Manual

Page 28

Installation

Removing the Doors and Panels

WARNING

MOVING PARTS HAZARD

All doors and side panels must be locked during normal operation. Do not open the side

panels while the fans are operating.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

EQUIPMENT DAMAGE

Do not lean the doors against a wall with the side panel latches facing the wall. This can

deform the latches and prevent them from properly working.

Failure to follow these instructions can result in equipment damage.

InRow RD Installation Manual22

Page 29

Removing the front and rear doors

1. Unlock and open the door 90

degrees.

2. Unplug the ground wires.

3. Lift the door up and off the

hinges.

na5812a

23InRow RD Installation Manual

Page 30

Removing and installing the side panel

REMOVING THE SIDE PANEL

INSTALLING THE SIDE PANEL

na5720b

InRow RD Installation Manual24

Page 31

Removing the electrical panel cover

WARNING

ELECTRICAL HAZARD

Ensure all wiring is not energized before routing cables into this equipment. Only qualified

service and maintenance personnel should work on this equipment.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

Remove the electrical panel cover to install the main power cable.

1. Remove the five M4 screws securing the cover.

2. Remove the cover by opening it and sliding it toward the front of the equipment.

25InRow RD Installation Manual

na2194a

Page 32

Joining the Equipment to Enclosures

Joining to NetShelter™ SX enclosures

The equipment comes with four joining brackets (two for the front and two for the rear).

1. Remove the front and rear doors.

See “Removing the front and rear

doors”.

2. Locate the four joining brackets.

Rotate each bracket ninety degrees

toward the adjoining enclosure so

the bracket is parallel to the floor and

install using the screws provided

with the enclosure.

ns0618a

For more information, see the Unpacking, Installation, and Customization manual for the NetShelter

SX Enclosure.

Joining to NetShelter VX and VS enclosures

For information on joining the equipment to NetShelter VX and VS enclosures, see the installation

sheet NetShelter™ SX to VX or VS External Joining Kit—AR7601, AR7602.

InRow RD Installation Manual26

Page 33

Leveling the Equipment

NOTICE

WIRING HAZARD

After re-installing the front door, reconnect all wires previously disconnected.

Failure to follow these instructions can result in equipment damage.

NOTE: The leveling feet at the corners of the equipment provide a stable base if the floor is uneven, but they

cannot compensate for a badly sloped surface.

1. Remove the front and rear doors.

NOTE: Before removing the front door, unplug the ground wires and any other wire connections that

may interfere with the removal of the doors.

2. For each leveling foot, insert a Phillips PH2 or standard

screwdriver into the screw above the leveling foot. Turn

the screw to the right to extend the leveling foot until it

makes firm contact with the floor.

NOTE: Use a 13-mm open-ended wrench to level the

equipment without removing the doors.

3. Re-install the front and rear doors.

na1572b

27InRow RD Installation Manual

Page 34

Mechanical Connections

Refrigeration piping

The equipment must be connected to a condenser— either a remote outdoor condenser or an indoor centrifugal

condenser. Systems with remote outdoor or indoor centrifugal condensers must have discharge and liquid lines

from the equipment to the condenser. Install all refrigerant lines in accordance with applicable industry

guidelines as well as local and national codes and regulations.

Calculate an equivalent length based on the actual linear length of the run, including valves and fittings.

NOTE: All fittings should be long-radius to minimize pressure drop.

NOTE: Change the size of the pipe after the P-trap. See “Refrigeration piping diagram” on page 13.

Make all refrigerant lines as short and direct as possible. Horizontal discharge lines must be pitched downward

at a minimum of 4 mm per m (1/2 in. per 10 ft) in the direction of flow to aid in oil return. Trap vertical discharge

lines approximately every 6 m (20 ft) to ensure proper oil return. Traps are normally not necessary at the base

of discharge lines; however, the line should be looped toward the floor before running it vertically to prevent the

drainage of oil back to the compressor during shutdown periods.

Isolate piping from structural surfaces using vibration clamps.

NOTE: Install all piping in accordance with applicable industry guidelines as well as local and national codes

and regulations.

The following table provides ASHRAE standards for equivalent piping lengths of fittings and valves.

Type of Fitting or Valve—Equivalent Length of Pipe in m (ft)

Nominal Pipe

Size

3/4 in. 7/8 in. 0.27 (0.9) 2.74 (9) 6.71 (22) 0.61 (2.0) 0.30 (1.0) 1.22 (4) 0.43 (1.4)

1 in. 1 1/8 in. 0.30 (1.0) 3.66 (12) 8.84 (29) 0.79 (2.6) 0.37 (1.2) 1.52 (5) 0.52 (1.7)

1 1/4 in. 1 3/8 in. 0.46 (1.5) 4.57 (15) 11.58 (38) 1.01 (3.3) 0.55 (1.8) 2.13 (7) 0.70 (2.3)

ACR

Tubing

Size

Gate

Valve

Angle

Valve

Globe

Valve

Standard

Elbow 90°

Contraction

1/2 Tee Branch Tee Straight

InRow RD Installation Manual28

Page 35

Recommended Line Sizes

Equivalent Length [Le] m (ft) Line Type Length Details Pipe Size

Discharge line

0 (0) to 18 (60)

(Horizontal/Vertical)

Liquid line All lengths 5/8 in.*

Discharge line (Horizontal) All lengths 1 1/8 in.

Less than 9 m (30 ft) 7/8 in.

18 (60) to 46 (150)

Discharge line (Vertical)

More than 9 m (30 ft) 1 1/8 in.

Liquid line All lengths 7/8 in.

Discharge line (Horizontal) All lengths 1 1/8 in.

Less than 3 m (10 ft) 7/8 in.

46 (150) to 61 (200)

Discharge line (Vertical)

More than 3 m (10 ft) 1 1/8 in.

Liquid line All lengths 7/8 in.

Discharge line (Horizontal) All lengths 1 1/8 in

61 (200) to 91 (300)

Discharge line (Vertical) All lengths 1 1/8 in.

Liquid line All lengths 7/8 in.

* When a condenser is installed below unit level, use 7/8 in. pipe for liquid line.

NOTE: Actual vertical height of the condenser cannot exceed 90 ft.

All lengths 7/8 in.

29InRow RD Installation Manual

Page 36

Connect refrigerant lines

Be sure to use only clean, air conditioning/refrigeration (ACR) pipe and follow standard procedures for pipe size

selection for air-cooled equipment. All refrigerant piping must be Type L ACR hard-drawn copper pipes (soft/

annealed coper is unacceptable) and must be 700 psig UL rated or equivalent. The maximum allowable

equivalent length between the evaporator and condenser is 90 equivalent m (300 equivalent ft). Vertical runs

(hot gas) require a trap every 6 m (20 ft) of rise.

NOTE: When brazing field-installed copper refrigeration lines, use a nitrogen purge to minimize contamination

of the refrigeration system during the brazing process.

The air-cooled equipment has been dehydrated at the factory and is shipped with a holding charge of nitrogen.

Test refrigerant connections for leaks before replacing the holding charge.

NOTE: Remove the nitrogen holding charge tag from the lines after nitrogen removal and product startup.

Connect both refrigerant lines to the equipment, using all fittings as shown. See “Install kit

inventory” on page 5.

Item Description

3/4-in. copper tubing (field supplied and installed)

Ball valve (supplied)

3/4-in. female Rotalock connector (supplied)

Gasket (supplied)

3/4-in. male connector (supplied)

3/4-in. male connector (factory installed inside the equipment)

Condenser

Install and pipe the condenser in accordance with the provided instructions.

NOTE: If no receiver kit is being installed, a field-supplied pressure relief valve must be

installed.

Flooded receiver

Install the flooded receiver in accordance with the instructions included with the kit.

na2537a

InRow RD Installation Manual30

Page 37

Humidifier (ACRD60xP only)

The humidifier water supply line is routed to the unit in flexible tubing (or alternative tubing

approved by local building codes) that will allow the humidifier water supply line connector

to be moved approximately 25 mm (1 in.) away from the equipment. This facilitates

removing the equipment from a row.

A factory-installed quick-connector for connecting the tubing to the equipment is supplied.

The quick connector has a male 1/4-in. NPT or male 1/4-in. BSPT to connect to a

compression fitting. The quick-connector has a shut-off function, so no separate shut-off

valve is necessary.

The humidifier water supply line can be

connected through either the top or the

bottom of the equipment as shown. Male

quick-connectors are positioned in both

the top and the bottom of the equipment.

Water pressure should be between 100

and 800 kPa (15 and 115 psi) for proper

humidifier operation. Dirty water must be

filtered before it is supplied to the

humidifier. Water temperature must be

between 1°C and 40°C (34°F and 104°F).

Do not use softened, de-mineralized, or

de-ionized water.

CONNECTION

THROUGH TOP

na2193a

na2345a

CONNECTION

THROUGH

BOTTOM

See the manual included with the humidifier for more information about water quality, mineral

content, hardness, and minimum/maximum levels for conductivity.

NOTE: Before making any connections, clear any debris that may have accumulated during assembly from the

humidifier water supply line.

NOTE: It is recommended that a solenoid water valve be installed in the humidifier supply line, connected to a

leak detector.

NOTE: Perform all piping in accordance with applicable industry guidelines as well as local and national codes

and regulations.

Connect the fittings to the humidifier water supply line as shown, then connect the water

supply line quick-connector to the top or bottom humidifier input.

Item Description

Flexible tubing (field supplied and installed)

Compression fitting (field supplied and installed)

Straight reduction (supplied)

Quick connector (supplied)

na2536a

31InRow RD Installation Manual

Page 38

Condensate pump

NOTICE

HAZARD TO EQUIPMENT

• Failure to properly route the condensate pump drain line before operation could result in

water damage.

• Do not route drain or supply lines above computer equipment, Uninterruptible Power

Supply (UPS) units, Power Distribution Units (PDUs), or light fixtures.

Failure to follow these instructions can result in equipment damage.

The pump is factory-wired and piped

internally to the condensate drain pan.

The pump can move liquid a maximum

of 18 m (60 ft), which may include a

maximum lift of 3.5 m (11.5 ft) at a flow

rate of 32 l/hr (8.45 gph). For example,

if your lift is 3 m (10 ft), you will have

15 m (50 ft) of usable run remaining.

The pump uses an on-board

condensate high level float switch

wired into the equipment for alarm

capabilities.

The condensate drain line can be

connected through either the top or the bottom of the equipment using factory-installed male

quick connectors and tubing approved by local building codes that will allow the drain line

connector to be moved approximately 25 mm (1 in.) away from the equipment. This facilitates

removing the equipment from a row. Female quick connectors and reduction fittings are

supplied with the equipment. Connect the fittings as shown, then connect the drain line quick

connector to the top or bottom condensate pump output line.

CONNECTION

THROUGH TOP

na2345b

CONNECTION

THROUGH BOTTOM

Item Description

Tubing (field supplied and installed)

1/2-in. male NPT or 1/2-in. male BSPT fitting

(field supplied and installed)

Straight reduction (supplied)

Quick connector (supplied)

na2534a

NOTE: Perform all piping in accordance with applicable industry guidelines as well as local and national codes

and regulations.

InRow RD Installation Manual32

Page 39

Condensate overflow

NOTICE

WATER DAMAGE

Failing to perform the following procedure may result in condensate pan overflow and

possible damage to the data center.

Failure to follow these instructions can result in equipment damage.

Connect the equipment condensate overflow line to an external drain using the fittings, as shown.

Item Description

InRow RD

Hose adapter clamp (supplied)

Hose adapter (supplied)

7/8-in. copper tubing (field supplied and installed)

na2538a

33InRow RD Installation Manual

Page 40

Leak sensor (optional)

Install up to four leak sensors (AP9326) in series, as needed.

na1584a

1. Connect the leak sensor to the equipment using

the plug located on the service bracket, as shown.

2. Position the leak sensor inside or outside the

equipment.

NOTE: Install leak sensors on a clean surface, and

do not allow them to touch metal that is in an air

stream.

3. Route the leak sensor to the outside of the

equipment through the hole provided in the base.

4. Secure the leak sensor wire to surfaces using

cable ties and cable tie holders (provided with the

leak detector).

LEAK SENSOR PORT

LOCATION

LEAK

DETECTOR

CABLE

SERVICE

DISCHARGE

SUCTION

LEAK

DETECTOR

CABLE

SUCTION

DISCHARGE

SERVICE

na2266e

na2073a

InRow RD Installation Manual34

Page 41

Adding a holding charge

NOTICE

DAMAGE TO THE BALL VALVE

Install a ball valve before the micron gauge to prevent damage to the micron gauge during

charging.

Failure to follow these instructions can result in equipment damage.

R-410A is a mixed refrigerant. When charging this equipment with mixed refrigerant, only liquid refrigerant must

be charged.

NOTE: The equipment must be charged only with R-410A. The installing contractor is responsible for providing

sufficient refrigerant for a complete system charge during start-up.

1. Pressurize the system to 17.2 bar (250 psi) with nitrogen (use the service and discharge ports). Leave

the system pressurized for 24 hours, and check the gauges for a drop in pressure.

2. Use a deep vacuum pump and pull the first vacuum down to 750 microns (use the two vacuum ports on

the connection piping). The initial pull down can take up to 24 hours.

VACUUM PORT

LOCATIONS

3. Once the vacuum level has reached 750 microns, close the manifold gauge valves and turn off the

vacuum pump. Wait for one hour (the vacuum should not rise above 1500 microns) and then break the

vacuum with nitrogen gas (use the service and discharge ports) until the system pressure equals

atmospheric pressure.

4. Pull a final vacuum down to 300 microns for a

minimum of two hours.

5. Charge with liquid R-410A through service port and

needle valve on condenser until the pressure

equalizes with the refrigerant canister.

6. Open the ball valves and then start the system and

charge the refrigerant slowly through the suction

port.

Adding compressor oil

Unit shall be field charged with 0.44 l (15 oz.) POE oil

during startup to make sure oil separator functions

normally.

na5838a

LEAK

DETECTOR

CABLE

SERVICE

DISCHARGE

SUCTION

LEAK

DETECTOR

CABLE

SUCTION

DISCHARGE

SERVICE

na2266e

SUCTION PORT

LOCATION

35InRow RD Installation Manual

Page 42

Electrical Connections

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Potentially dangerous and lethal voltages exist within this equipment. More than one

disconnect switch may be required to energize or de-energize this equipment. Observe all

cautions and warnings. Failure to do so could result in serious injury or death. Only

qualified service and maintenance personnel may work on this equipment.

• Three-phase electrical service is required. Electrical service must conform to local and

national electrical codes and regulations. The equipment must be grounded. Check the

equipment nameplate for correct ratings.

• Use a voltmeter to ensure that power is turned off before making any electrical

connections.

Failure to follow these instructions will result in death or serious injury.

The following electrical connections are required in the field:

• Controls (customer interface, Network Management Card)

• Communication (A-Link, Building Management System)

• Power to the InRow RD cooling unit (3-phase plus ground)

• Power to flooded receiver heater

All electrical connections must be in accordance with applicable industry guidelines as well as local and

national codes and regulations.

See the equipment nameplate for voltage and current requirements.

Make all low-voltage connections, including data and control connections, with properly insulated wires.

Insulation of low-voltage wiring must be rated for at least the voltage of any adjacent wiring.

InRow RD Installation Manual36

Page 43

Customer interface connections

NOTE: Wire all input and output connections as Class 2 circuits.

Depending on the configuration, additional customer interface connections may be required for the A-Link

remote communications through the Network Management Card support or traditional equipment-monitoring

software.

Item Description

Rack inlet temperature sensors 1, 2, 3

A-Link IN

A-Link OUT

Network port

Customer output, NC (normally closed)

Customer output, COM (common)

Customer output, NO (normally open)

Supply GND (Ground)

Supply 12 Vdc (current limit: 20 mA)

Supply 24 Vdc (current limit: 20 mA)

Customer input + (12–30 Vac/Vdc, 24 Vdc @ 11 mA)

Supply COM

Modbus D1

Modbus D0

Modbus GND

Supply air temperature sensor (front)

Supply air humidity sensor (front)

na2009b

NOTE: For a top installation, route control wiring through the wire channel

located at the top left hand corner just above the customer interface

connectors.

For a bottom installation, route the control wiring to the customer access

hole in the bottom of the equipment through wire clamps from the customer

interface connectors. Then, route the wiring down along the electrical panel

and secure with wire clamps.

37InRow RD Installation Manual

Page 44

Item Description

Rack temperature sensors 1, 2, 3 Three temperature sensors which must be installed

A-Link IN In and out connections for A-Link. The terminators

A-Link OUT

Network port 10/100 Base-T Network port. Connects the

Customer output, Normally Closed (NC) Customer-configurable output relay which can be

Customer output, Common (COM)

Customer output, Normally Open (NO)

Supply GND Can be used for customer input and output interface.

Supply 12 Vdc Can be used for customer input and output interface.

Supply 24 Vdc Can be used for customer input and output interface.

Customer input + Used for remote shutdown of an InRow RD unit.

Supply COM– Ground connection point for remote shutdown supply

Modbus D1 (RXTX+) Connections for Building Management System. Wire

Modbus D0 (RXTX–)

Modbus GND

Supply air temperature sensor (front) Temperature sensor installed on the front of the

Supply air humidity sensor (front) Humidity sensor installed on the front of the

on the cold aisle side of the server racks. See “Rack

temperature sensors” on page 39.

supplied with the equipment must be plugged into the

first A-link port and the final A-Link port for the group.

equipment to the network; Status and Link LEDs

indicate network traffic.

• Status LED—blinks orange and green at startup;

indicates the status of the network connection (solid

green—IP address established; blinking green—

attempting to obtain an IP address).

• Link LED—blinks to indicate network traffic (green—

operating at 10 mbps; orange—operating at 100

mbps).

activated for all types of alarms or critical alarms. The

relay can be connected to external equipment using

30 Vac/dc, 2 A.

Current limit is 20 mA.

Current limit is 20 mA.

Voltage is applied from the internal power supply or

by using an external power supply.

source.

a 150-Ohm terminator resistor (supplied) into the final

InRow RD, between Modbus D0 and Modbus D1.

equipment.

equipment.

InRow RD Installation Manual38

Page 45

Form C alarm contacts and shutdown input

+

_

na225 0a

See items 5 through 12 in “Customer interface connections” on page 37. A relay internal to the customer

interface is controlled by a user-defined alarm (for example, malfunctioning fans). Before an alarm condition,

the signal on the COM (common) terminal is routed to the NC (normally closed) terminal. When the alarm is

activated, the relay is energized, causing the signal on the COM terminal to be routed to the NO (normally

open) terminal. The NO and NC terminals could be connected to remote indicator lights, a warning buzzer, or

another device to alert an operator to the presence of an alarm condition.

The equipment may be remotely disconnected by supplying a voltage to the shutdown inputs as shown above.

Option shows a remote switch that uses internal +12 Vdc or +24 Vdc supply to manually stop operation.

Option shows how any external source of 12 Vac/dc or 24 Vac/dc may be connected to the shutdown input.

Rack temperature sensors

The rack temperature sensors control the equipment airflow and ensure adequate supply of cooling air to the

server racks in the data center.

The equipment is supplied with three external rack temperature sensors.

See “Install kit inventory” on page 5. These sensors, along with cable ties

and wire clips, are included in the installation kit shipped with the

equipment.

39InRow RD Installation Manual

Page 46

How to install the rack temperature sensors

gen0767a

1. Insert the rack temperature sensor connector in the temperature sensor port at the customer interface

connections. See “Customer interface connections” on page 37.

a. For a top installation, push the rack temperature sensor

through the wire channel located at the top of the

equipment in the left hand side just above the customer

interface connectors.

b. For a bottom installation, route the sensor through the

wire clamps along the electrical panel and then push

the sensor through the customer access hole in the

TEMPERATURE

SENSOR

bottom of the equipment.

2. Route the sensor through either the top or the bottom of the

WIRE CLIP

adjacent server rack.

3. Secure the temperature sensor cable to the front door of the

adjacent server rack at multiple locations using the provided

wire clips as shown. See “Install kit inventory” on page 5.

NOTE: Remote rack temperature sensors must be installed

for proper operation.

The sensors should be located on racks that are adjacent to the cooling unit. The optimum position of

the rack temperature sensors will vary from installation to installation, but should be located in close

proximity to fan-cooled IT equipment to ensure accurate readings.

Servers most likely to have insufficient or inadequately cooled cooling air due to the recirculation of hot

air from the hot aisle include:

a. Servers positioned at the top of a rack

b. Servers positioned at any height in the last rack at an open end of a row

c. Servers positioned behind flow-impairing obstacles such as building elements

d. Servers positioned in a bank of high-density racks

e. Servers positioned next to racks with Air Removal Units (ARU)

f. Servers positioned very far from the equipment

g. Servers positioned very close to the equipment

InRow RD Installation Manual40

Page 47

Communication connections

A-Link connections: The A-Link bus connection allows multiple InRow RD units (up to twelve) to

communicate with one another. Only one InRow RD unit needs to be defined through the display interface;

other InRow RD units are numbered automatically.

To enable the InRow RD units to work as a group, link them using standard (Category 5 or higher) Ethernet

cables with RJ-45 connectors. A supplied terminator (150 Ohm, 1/4 W) is factory installed in the A-Link port,

and must remain inserted into the A-Link ports of the first and final InRow RD units only.

The maximum wire length for the entire group may not exceed 1000 m (3,280 ft).

INROW RD 1 INROW RD 2 INROW RD 3

na0733a

Item Description Item Description

A-Link in (with provided RJ-45

A-Link in

terminator)

A-Link cable (CAT-5 ethernet

cable)

A-Link out

A-Link out (with provided RJ-45

terminator)

Building Management System (BMS): The Modbus interface allows each InRow RD cooling unit to

communicate with the BMS. Use a three-wire cable to connect each InRow RD cooling unit in turn. Wire a

terminator resistor (150 Ohm, 1/4 W) into the Modbus master and the final InRow RD cooling unit between

Modbus D0 and Modbus D1. This terminator is included in the installation kit (see “Install kit inventory” on

page 5).

Each cooling unit has a three-wire Modbus terminal on the customer interface connections. A connector with

screw terminals is used to attach wiring.

See “Customer interface connections” on page 37 for specific layout of the customer interface

connections. For information on setup of Modbus parameters, see the InRow RD Operation and

Maintenance Manual.

41InRow RD Installation Manual

Page 48

INROW RD 1

MODBUS MASTER

Item Description

Termination resistor (provided)

Modbus cable (RS-485)

INROW RD 2 FINAL INROW RD

na1766a

InRow RD Installation Manual42

Page 49

Network port

The network port allows communication from the cooling unit to the network.

INROW RD 1 INROW RD 2 INROW RD 3

SWITCH/HUB

na2554a

Item Description

Network port

LAN cable (10/100 Base-T)

43InRow RD Installation Manual

Page 50

Power Connections

Wiring configurations

Route incoming power from the PDU or electrical service panel to the electrical panel located in the left side of

the equipment. Route power either through the top or the bottom of the equipment.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. See NFPA 70E or CSA Z462.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTE: To ease installation and later removal of the equipment for repairs, use flexible conduit for the power

wiring.

Top routing

1. Remove the electrical panel cover. See “Removing the electrical panel cover”

on page 25.

2. Locate the power connection plate at the top of the equipment. See “Top piping

and power access locations (top view)” on page 19.

3. Loosen the screw securing the connection plate, and remove the plate.

4. Attach the conduit connector using the pilot hole in the connection plate.

5. Route the cabling to the main breaker as shown.

6. Connect the power wiring to the top of the main circuit breaker using the torque

specified on the breaker. Connect the phases as marked next to the terminals.

7. Connect the ground wire to the ground terminal block located above the main circuit breaker.

8. Reinstall the connection plate and the electrical panel cover.

na2308a

InRow RD Installation Manual44

Page 51

Bottom routing

1. Remove the electrical panel cover. See “Removing the electrical panel cover” on page 25.

2. Locate the power connection plate in the bottom of the equipment. See “Bottom piping and power

access locations—bottom view, looking up (ACRD600/P series)” on page 20.

3. Loosen the screw securing the connection plate, and remove the plate.

4. Attach the conduit connector using the pilot hole in the connection plate.

5. For ACRD602 and ACRD602P, perform the steps in “Strain relief (ACRD602/602P only)” on page 45.

6. Route the cabling to the main circuit breaker as shown.

7. Connect the power wiring to the top of the main circuit breaker using the torque specified on the

breaker. Connect the phases as marked next to the terminals.

8. Connect the ground wire to the ground terminal block located just above the main circuit breaker.

9. Fasten the cabling inside the equipment with the provided tie wraps. See “Install kit inventory” on

page 5.

10.Reinstall the connection plate and the electrical panel cover.

Strain relief (ACRD602/602P only)

Adjustable metal strain relief brackets are provided. See “Install

kit inventory” on page 5.

1. Hook one strain relief into a pair of slots in each of the

two locations shown.

2. Route the electrical cable up from the bottom of the

equipment, passing through the strain reliefs.

3. Tighten the screws on the strain reliefs to capture the

electrical cable, taking the weight off of the inner

conductors.

4. Continue connecting electrical wiring to the circuit

breaker.

na2542a

45InRow RD Installation Manual

Page 52

Connect flooded receiver heater

WARNING

ELECTRICAL HAZARD

Electrical service must conform to local and national electrical codes and regulations.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

The flooded receiver is equipped with a heater to keep the refrigerant warm during extremely cold weather

conditions. If your location is subject to subfreezing temperatures for extended periods of time, you must

connect the self-regulating heater to a convenient source of electrical power. If you are not sure your location or

application requires the heater, contact Schneider Electric Customer Support.

See the documentation included with the flooded receiver for more information on voltage

requirements.

Voltage selections—ACRD60x units

Your equipment can operate at various supply voltages, provided the proper voltage jumpers are connected to

the input transformers. Read the part number on the jumpers connected at the factory and compare that

number to the table below. If the correct jumpers for your input voltage are not connected, remove them and

connect the proper jumper. See “Install kit inventory” on page 5.

na2540b

Jumper Connections

Transformer A connected to J50

Model Input Voltage Use Jumper Part Number

ACRD600 208 (50/60 Hz) 0W2540 (default)

230 (50/60 Hz) 0W2541

ACRD601 460 (60 Hz) 0W2545

480 (60 Hz) 0W2546 (default)

ACRD602 380 (50/60 Hz) 0W2542

400 (50/60 Hz) 0W2543 (default)

415 (50/60 Hz) 0W2544

InRow RD Installation Manual46

Page 53

Voltage selections – ACRD60xP units

na2540a

Jumper Connections

Transformer B connected to J51

Transformer A connected to J50

Model Input Voltage Use Jumper Part Number

ACRD600P 208 (50/60 Hz) 0W2540 (default)

230 (50/60 Hz) 0W2541

ACRD601P 460 (60 Hz) 0W2545

480 (60 Hz) 0W2546 (default)

ACRD602P 380 (50/60 Hz) 0W2542

400 (50/60 Hz) 0W2543 (default)

415 (50/60 Hz) 0W2544

47InRow RD Installation Manual

Page 54

Charging with Refrigerant

Calculating R410A charge

Use the following table and formula when calculating the total R410A charge.

Condenser Model

LCS5213-099-2C ACCD75228 35.0–40.6 (95–105) 6.1 (13.3) 9.7 (21.4) 9.7 (21.4) 10.3 (22.8) 10.4 (22.9) 10.8 (23.7)

LCS5213-113-2C ACCD75229 46 (115) 8.1 (17.9) 13.0 (28.6) 12.9 (28.5) 13.8 (30.4) 13.9 (30.6) 14.3 (31.6)

LCS5213-099-4C ACCD75230 35.0–40.6 (95–105) 6.1 (13.3) 9.7 (21.4) 9.7 (21.4) 10.3 (22.8) 10.4 (22.9) 10.8 (23.7)

LCS5213-113-4C ACCD75231 46 (115) 8.1 (17.9) 13.0 (28.6) 12.9 (28.5) 13.8 (30.4) 13.9 (30.6) 14.3 (31.6)

CAP2001P ACCD75232 35.0–46.0 (95–115) 7.7 (17.0) 12.4 (27.2) 12.4 (27.2) 13.1 (28.9) 13.2 (29.1) 13.7 (30.1)

CAP2001P ACCD75232-C 35.0–46.0 (95–115) 7.7 (17.0) 12.4 (27.2) 12.4 (27.2) 13.1 (28.9) 13.2 (29.1) 13.7 (30.1)

CAP2001P.0005 ACCD75233-C 35.0–46.0 (95–115) 7.7 (17.0) 12.4 (27.2) 12.4 (27.2) 13.1 (28.9) 13.2 (29.1) 13.7 (30.1)

LCV8211-009-2C ACCD75234* 35.0–40.6 (95–105) 6.1 (13.3) 9.0 (19.9) 9.3 (20.6) 9.9 (21.7) 10.0 (21.9) 10.4 (23.0)

LCV8211-009-4C ACCD75235* 35.0–40.6 (95–105) 6.1 (13.3) 9.0 (19.9) 9.3 (20.6) 9.9 (21.7) 10.0 (21.9) 10.4 (23.0)

* Make-to-order.

Schneider Electric

SKU

Selected Ambient

Temperature –

°C (°F)

Condenser

Summer

Charge –

kg (lb)

Condenser Flooded Charge for Different Minimum Outdoor

Ambient Temperatures

– kg (lb)

4°C (40°F) –7°C (20°F) –18 °C (0°F) –29 °C (–20°F) –40°C (–40°F)

Total charge = Equipment charge + condenser summer charge + condenser flooded charge (for minimum

possible ambient temperature) + liquid R410A in liquid pipe

Equipment charge: 5.5 kg (12.1 lb)

Liquid line charge for 7/8 in. ACR copper tube: 0.28 kg/m (0.186 lb/ft)

Density of liquid R410A at 40.6 °C (105 °F) and 27.5 bar (400 psig): 0.975 g/cm3 (60.9 lbm/ft3)

Example: Calculate the total R410A charge for an ACCD75232 condenser with 7.6 m (24.9 ft) of 7/8-in. liquid

piping. Outdoor temperature is –18°C (0 °F).

Total R410A charge:

• Metric: 5.5 + 7.7 + 13.1 + (7.6 * 0.28) = 28.4 kg

• Imperial: 12.1 + 17.0 + 28.9 + (24.9 * 0.186) = 62.6 lb

Charging the equipment

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric authorized personnel.

Failure to follow these instructions can result in injury or equipment damage.

HAZARD OF HIGH PRESSURE REFRIGERANT OR EQUIPMENT DAMAGE

• Use R410A refrigerant only.

• Use hose and manifold set suitable for R410A.

• The unit display interface should be used to obtain pressure readings.

WARNING

CAUTION

Failure to follow these instructions can result in injury or equipment damage.

InRow RD Installation Manual48

Page 55

NOTICE

HAZARD TO EQUIPMENT

Introducing a fast charge of liquid refrigerant through the suction port may damage the

compressor.

Failure to follow these instructions can result in equipment damage.

Perform the “Add initial refrigerant amount—“fast charge” method:” on page 49 first, and then select one of the

following to complete charging the system: “Top off the system refrigerant charge—“fast charge” method:” on

page 50 or “Top off the system refrigerant charge—“slow charge” method:” on page 51.

Add initial refrigerant amount—“fast charge” method: Perform the following with the system not in

operation.

CONDENSER

na5840a

RECEIVER

COOLING

UNIT

Item Description Item Description

Discharge isolation valve

Liquid line isolation valve

Receiver outlet

Receiver inlet

1. Open the discharge isolation valve, the liquid line isolation valve. The receiver outlet valve and receiver

inlet valve should be back seated.

2. Attach a refrigerant cylinder and charging hose to the receiver outlet valve and purge the hose if

necessary.

3. Open the receiver outlet valve and add the liquid refrigerant until the calculate initial amount is charged

into the system.

4. Close the receiver outlet valve, and remove the refrigerant cylinder and charging hose.

49InRow RD Installation Manual

Page 56

Top off the system refrigerant charge—“fast charge” method: Perform the following with the system in

operation.

CONDENSER

na5840a

RECEIVER

COOLING

UNIT

Item Description Item Description

Discharge isolation valve

Liquid line isolation valve

1. Attach a refrigerant cylinder and charging hose to

the service port on the cooling unit and purge the

hose if necessary.

2. Close the liquid line isolation valve and wait for

bubbles to appear in the liquid line sight glass.

3. Open the refrigerant cylinder valve and add

refrigerant.

4. When charging is complete, close the refrigerant

cylinder valve and remove the charging hose from

the service port.

5. Slowly open the liquid line isolation valve.

Receiver outlet

Receiver inlet

LEAK

DETECTOR

CABLE

SERVICE

DISCHARGE

SUCTION

LEAK

DETECTOR

CABLE

SUCTION

DISCHARGE

SERVICE

na2266e

InRow RD Installation Manual50

Page 57

Top off the system refrigerant charge—“slow charge” method: Perform the following with the system in

operation.

CONDENSER

na5840a

RECEIVER

COOLING

UNIT

Item Description Item Description

Discharge isolation valve

Liquid line isolation valve

1. Attach a refrigerant gauge manifold to the

discharge and suction ports on the cooling unit.

2. Attach a manifold charging hose to the refrigerant

cylinder and purge the hose if necessary.

3. Add liquid refrigerant very slowly through the

suction port at a pressure of about 1 bar (15 psig)

above the suction pressure. Do not charge for

longer than two-minute intervals; stop charging

and wait 3–5 minutes for the system to stabilize.

4. Repeat step 3 as necessary.

5. When charging is complete, close the refrigerant

cylinder valve and remove the charging hose from

the suction port.

6. Slowly open the liquid line isolation valve.

Receiver outlet

Receiver inlet

LEAK

DETECTOR

CABLE

SERVICE

DISCHARGE

SUCTION

LEAK

DETECTOR

CABLE

SUCTION

DISCHARGE

SERVICE

na2266e

51InRow RD Installation Manual

Page 58

Compressor Oil Charge

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Oil charging procedure

HAZARD TO EQUIPMENT

Do not overcharge the compressor, or compressor damage could result. The only way to

drain oil from the compressor is to remove the compressor from the equipment, which

cannot be done when the equipment is in the row.

WARNING

NOTICE

Failure to follow these instructions can result in equipment damage.

NOTICE

DAMAGE TO EQUIPMENT

Be careful not to charge more oil than is necessary. Excessive oil in the system may

cause system damage, including the following:

• Failure of valves and pistons due to oil slugging.

• Excessive oil carryover.

• Loss of evaporator performance due to oil level build-up in the low-pressure side of the

system.

Failure to follow these instructions can result in equipment damage.

1. Prepare to add oil:

a. Use a new sealed oil can and a manual oil pump. The pump hose must be sized for 1/4 in. flare

fittings and must include a valve depressor at its end, which will open the valve on the suction port

of the compressor.

b. Use high quality polyolester (POE) type 160SZ oil or equivalent.

2. Purge the pump and hose:

a. Ensure that the oil pump is clean. Insert the pump in the oil container and make sure that the

container is open to the atmosphere for as short a period of time as possible. When available, use

a plug adapter kit to further reduce the exposure of the oil to the atmosphere.

b. Bleed all air from the pump and hose with a few strokes of the pump. Purging the pump removes

the moisture-saturated oil left inside the hose from previous usage.

c. Connect the hose to the suction port of the compressor immediately after purging to avoid

moisture contamination.

InRow RD Installation Manual52

Page 59

3. While the equipment is running, charge 0.44 l (15 oz.) POE oil through the suction port. Pump the oil

very slowly. (This is to ensure the oil separator is functioning properly.)

4. Other than the amount required for the oil separator,

no additional oil should be required.

Let the compressor run at full capacity for at least

one hour and check the oil level in the oil sight glass.

The level should be between 1/4 and 3/4 full, or

within the limit shown on the oil level sticker. If the oil

is not within the acceptable limit, check the oil return

line for restrictions. When oil is flowing properly, the

oil return line should feel warm to the touch.

NOTE: Dispose of the oil waste appropriately.

SIGHT GLASS

na5849a

53InRow RD Installation Manual

Page 60

Accessories

Low Temperature Kit

The low temperature kit provided by Schneider Electric includes a pressure relief valve on the liquid receiver

vessel. If the low temperature kit is not installed, then Schneider Electric recommends the installation of a

pressure relief valve on the discharge pipe near the condenser. The pressure relief valve selection and

installation is the responsibility of the installer and shall comply with local authorities.

Unpacking

GCN-GB and EMEA-PED versions (ACAC75013 and ACAC75015)

1. Remove plywood top and sides from the pallet.

na5817a

2. Remove the valve box (contains safety valve, ball valve, head pressure valve, and check valve).

3. Remove brackets.

VALVE BOX

BRACKET

na5818a

InRow RD Installation Manual54

Page 61

4. Remove receiver kit.

NAM-ASME versions (ACAC75014)

1. Remove plywood top and sides from the pallet.

RECEIVER KIT

na5819a

na5825a

2. Remove the valve box (contains safety valve, ball valve, head pressure valve, and check valve).

3. Remove brackets.

VALVE BOX

na5826a

BRACKET

4. Remove receiver kit.

RECEIVER KIT

na5827a

55InRow RD Installation Manual

Page 62

Install kit inventory

GCN-GB versions (ACAC75013)

cate

i

Cert

ity

al

Qu

Quality Certicate

na5834a

Item Description Quantity Item Description Quantity

Ball valve, 7/8 in. (inlet) 1

Ball valve, 5/8 in. (outlet) 1

Head pressure valve and check valve 1