Schneider Electric ACECFR20101SE, ACECFR40200SE, ACECFR20200SE, ACECFR20201SE, ACECFR40101SE User Manual

...Page 1

Installation Manual

Cooling Solutions

EcoBreeze™ System

ACECFR20101SE, ACECFR20200SE,

ACECFR20201SE, ACECFR40101SE,

ACECFR40200SE, ACECFR40201SE

990-3976D-001

Publication Date: June 2014

COIL

ACCESS

Y

SUPPL

R

BLOWE

CESS

AC

COIL

ACCESS

Y

SUPPL

R

BLOWE

ACCESS

COIL

ACCESS

SUPPLY

R

BLOWE

SS

ACCE

COIL

ACCESS

SUPPLY

BLOWER

ACCESS

Page 2

Schneider Electric IT Corporation Legal Disclaimer

The information presented in this manual is not warranted by the Schneider Electric IT Corporation to be authoritative,

error free, or complete. This publication is not meant to be a substitute for a detailed operational and site specific

development plan. Therefore, Schneider Electric IT Corporation assumes no liability for damages, violations of codes,

improper installation, system failures, or any other problems that could arise based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of evaluating

data center design and construction. This Publication has been compiled in good faith by Schneider Electric IT

Corporation. However, no representation is made or warranty given, either express or implied, as to the completeness or

accuracy of the information this Publication contains.

IN NO EVENT SHALL SCHNEIDER ELECTRIC IT CORPORATION, OR ANY PARENT, AFFILIATE OR

SUBSIDIARY COMPANY OF SCHNEIDER ELECTRIC IT CORPORATION OR THEIR RESPECTIVE

OFFICERS, DIRECTORS, OR EMPLOYEES BE LIABLE FOR ANY DIRECT, INDIRECT,

CONSEQUENTIAL, PUNITIVE, SPECIAL, OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT

LIMITATION, DAMAGES FOR LOSS OF BUSINESS, CONTRACT, REVENUE, DATA, INFORMATION, OR

BUSINESS INTERRUPTION) RESULTING FROM, ARISING OUT, OR IN CONNECTION WITH THE USE

OF, OR INABILITY TO USE THIS PUBLICATION OR THE CONTENT, EVEN IF SCHNEIDER ELECTRIC

IT CORPORATION HAS BEEN EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SCHNEIDER ELECTRIC IT CORPORATION RESERVES THE RIGHT TO MAKE CHANGES OR UPDATES

WITH RESPECT TO OR IN THE CONTENT OF THE PUBLICATION OR THE FORMAT THEREOF AT

ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software, audio, video,

text, and photographs) rests with Schneider Electric It Corporation or its licensors. All rights in the content not expressly

granted herein are reserved. No rights of any kind are licensed or assigned or shall otherwise pass to persons accessing this

information.

This Publication shall not be for resale in whole or in part.

Page 3

Contents

General Information................................................................... 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Inspecting the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Storing the equipment before installation . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Model identification label location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Other components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Access Door and Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Component Identification......................................................... 5

EcoBreeze Frame and Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Module — front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remote display interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Site Preparation .......................................................................... 8

Incoming power supply requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Piping/plumbing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Weights and Dimensions .......................................................12

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation ..................................................................................13

Lifting and Rigging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EcoBreeze System Installation i

Page 4

Mechanical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Position the EcoBreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unwrap the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Remove the tension rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Lower Module drop-down box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Power supply to EcoBreeze Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Remote display interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Building Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EcoBreeze System Installationii

Page 5

General Information

Safety

Read and adhere to the following important safety considerations when working with this

cooling unit.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Turn off all power supplying this equipment before working on the equipment. All electrical

work must be performed by licensed electricians. Practice Lockout/Tagout procedures. Do

not wear jewelry when working with electrical equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the equipment for

foreign objects before closing the doors and starting the equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

The equipment is heavy and can easily be tipped. For safety purposes, adequate

personnel must be present when moving this equipment.

Failure to follow these instructions can result in death, injury, or equipment

damage.

CAUTION

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric authorized personnel.

Failure to follow these instructions can result in injury or equipment damage.

1EcoBreeze System Installation

Page 6

Inspecting the Equipment

Inspect for missing components. All shipped loose components are identified by part number

and description on the bill of lading. Ensure each item is present before accepting delivery of

the unit.

Filing a claim. If damage has occurred, or if shipped loose parts are missing, report it

immediately to the delivering carrier and note the problem on the receiving copy of the bill of

lading. Failure to do so will result in replacement parts and repairs being billed to the customer.

In case of shipping damage, do not operate the equipment. Keep all packaging for inspection

by the shipping company and contact Schneider Electric.

Storing the equipment before installation

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• Do not remove tension rods until the EcoBreeze™ Frame is placed and secured on

its supports.

• Move the EcoBreeze Frame directly from the truck to its permanent foundation or

supports. If it must be stored temporarily, it must be placed on a flat and level

surface to avoid damage.

• Leave the protective plastic wrap in place until you are prepared to install the

equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Heavy: Ensure the lifting equipment has sufficient capacity for the load.

The recommended tools for moving the equipment include the following:

Crane

(Frame,

ductwork)

EcoBreeze System Installation2

Page 7

Model Identification

Model identification label location

Frames

SKU Description

ACECFR20101SEn* 6 m (20 ft) ISO Frame 400/3/50

ACECFR20200SEn* 6 m (20 ft) ISO Frame 480/3/60

ACECFR20201SEn* 6 m (20 ft) ISO Frame 600/3/60

ACECFR40101SEn* 12 m (40 ft) ISO Frame 400/3/50

ACECFR40200SEn* 12 m (40 ft) ISO Frame 480/3/60

ACECFR40201SEn* 12 m (40 ft) ISO Frame 600/3/60

*Where n is the number of Modules populating the Frame upon order.

na3462a

Modules

SKU Description

ACEC101SE EcoBreeze Module 400/3/50

ACEC200SE EcoBreeze Module 480/3/60

ACEC201SE EcoBreeze Module 600/3/60

Other components

SKU Description

ACECINS100SE Frame install kit

ACECCP100SE EcoBreeze remote interface panel

ACECSJ100SE EcoBreeze screw-jack assembly

3EcoBreeze System Installation

Page 8

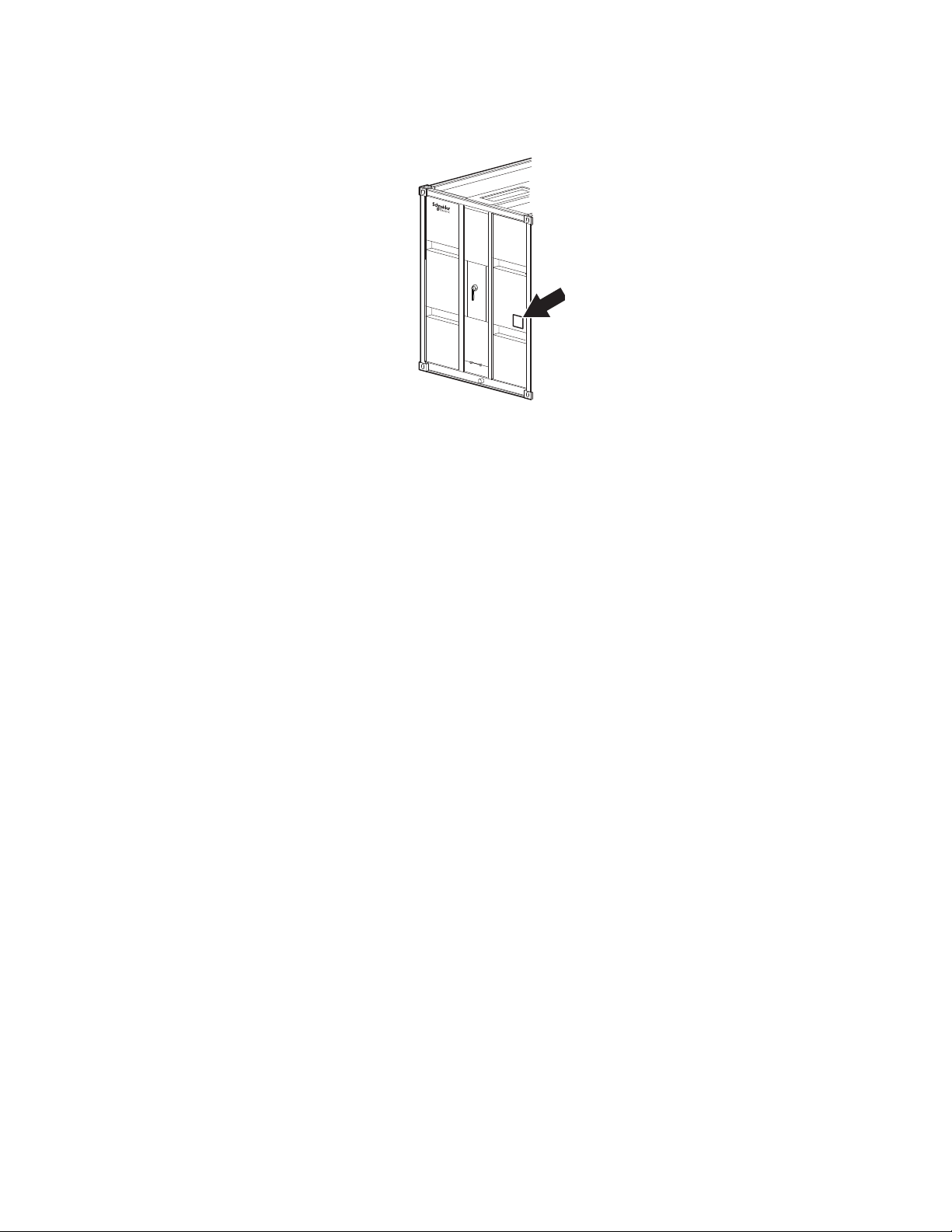

Access Door and Panel Operation

Module access doors and panels have latches with a locking mechanism. Secondary door

latches are provided on doors on compartments that have positive air pressure to prevent the

doors from opening quickly if a door is opened while the unit is in operation.

WARNING

HAZARD OF ELECTRIC SHOCK

To avoid possible personal injury or death, re-engage the access door locking mechanism

after access to a compartment for inspection or service requirements.

Failure to follow these instructions can result in death or serious injury.

na3463a

Frame access panels and the main power enclosure have locking latches that open with a key.

na3584a

EcoBreeze System Installation4

Page 9

Component Identification

SUPPLY

OWER

BL

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

COIL

UPPLY

S

BLOWER

CCESS

A

COIL

ACCESS

ACCESS

na3449a

Item Description

EcoBreeze Frame and Module assembly* 1 1

Remote display interface 1 1

Frame electrical panel latch tool 4 4

Module access door latch tool 4 8

Water treatment module signal generator key 1 1

Technical manuals 5 5

Pipe adapter kit (50 Hz only)

3/4 NPT x 3/4 - 14 BSPT (4)

2-in. NPT x 2 - 11 BSPT (1)

* Version shown is the 12 m (40 ft) model.

Esc

Quantity

20 ft

Quantity

40 ft

11

5EcoBreeze System Installation

Page 10

EcoBreeze Frame and Modules

SUPPLY

BLOWER

ACCESS

Item Description

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

ACCESS

ACCESS

ISO corner fittings

Return air inlets

Module anchor brackets

Module

Tension rods and mounts

Screw-jack mounting points

Water drain outlet

Water supply inlets

Frame main power enclosure

Frame power distribution panel

Direct digital controller (DDC)

panel

COIL

SUPPLY

BLOWER

ACCESS

COIL

ACCESS

ACCESS

ns3560a

EcoBreeze System Installation6

Page 11

Module — front

COIL

ACCESS

na3665a

Remote display interface

Item Description

Condenser coil

Sprayer head and mist

eliminator access door

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

Water coupling and water

strainer access door

Air filter and DX evaporator

coil access door

Module supply air duct access

door

Outdoor air intake

Compressor and wiring

connections access door

Indoor air fans access door

na3466a

Item Description

NEMA case

Display

LCD touch screen

Escape key

Esc

Esc

Left arrow key

Up arrow key

Down arrow key

Right arrow key

Enter key

7EcoBreeze System Installation

Page 12

Site Preparation

Incoming power supply requirements

NOTE: This equipment requires three-phase electrical service. Electrical service must conform

to national and local electrical codes. The equipment must be grounded.

N

OTE: To facilitate routing of main power supply wiring, run parallel wires for the main power

connections.

Ductwork

Provide supply and return ducting at the site to connect to the supply and return ductwork on

the EcoBreeze System.

See the ductwork drawings in submittal package for recommendations for ducting

sizes and supply and return duct configurations.

Water supply

Supply water requirements. The water supply must be clean, potable water. The inlet water

pressure provided to the unit must be between 207 and 448 kPa (30 and 65 psig). If the water

pressure available is less than 207 kPa (30 psig), a booster pump (not supplied) may be

needed to operate the equipment properly. If the water pressure available is higher than 448

kPa (65 psig), use an external pressure regulator (not supplied).

NOTE: Installation of back flow prevention and a water hammer arrestor is recommended.

N

OTE: For 50 Hz models, use the pipe adapters to make the connections. See “Water supply

connection” on page 18.

NOTICE

DAMAGE TO EQUIPMENT

External water piping must have adequate freeze protection and must be correctly applied

based on local climatic conditions and best practices. Any exposed piping must be

electrically heat-traced and insulated (supplied by others).

Failure to follow these instructions can result in equipment damage.

Foundation

Provide a foundation for the EcoBreeze System as recommended in the submittal package.

Corner supports must have clamp connectors installed to secure the EcoBreeze Frame. See

“Position the EcoBreeze” on page 14. Intermediate supports must have vibration damper pads

installed on the top surface before the frame is placed on the permanent supports.

See EcoBreeze Frame Install Kit installation instructions for additional information.

EcoBreeze System Installation8

Page 13

Environment

NOTE: Locating the EcoBreeze system near areas of increased airborne debris may result in

more frequent service intervals.

Piping/plumbing diagram

na3453a

WATER RETURN GUTTER

X

FIELD

CONNECTIONS

OPTIONAL SAND FILTER CONNECTIONS

Item Description Item Description

Clear T-strainer

Two-way motorized valve*

Quick connect coupling

Water treatment module

Automatic vent

Pressure relief valve

Conductivity sensors

Water level sensors

Pump suction vent valve

Water sample service valve

Pump suction isolation valve

Redundant water pumps

Drain line cap

*Controlled from module

** Use electric schematic #APC-CFR-02 to confirm valve wiring connections

*** Make sure the pressure switches are set to 7 psi

Check valves

Pump line drain solenoid valve

Basin overflow

Supply water piping drain solenoid valve**

Basin drain valve

Water supply A & B pressure switches***

Supply water A & B solenoid valves**

Blow down valve

Basin water supply pipe

Piping to other modules

Spray nozzles

Module water pressure switch

X

9EcoBreeze System Installation

Page 14

PRIMARY WATER SUPPLY

SECONDARY WATER SUPPLY

na3615a

Item Description

Shut-off

Water pressure reducing valve (if necessary)

Backflow preventer

Water hammer arrestor

Alternate water supply (if available)

Inline strainer

Water pressure booster pump (if necessary)

EcoBreeze Frame

Note: All plumbing components shown are field installed.

Refrigeration

Each EcoBreeze Module contains its own closed refrigeration circuit. No field connections are

required.

EcoBreeze System Installation10

Page 15

Service access

Install a service platform (not supplied) to facilitate maintenance activities. Regular

maintenance activities require a of minimum 1219 mm (48 in.) clearance on all sides to

remove, maneuver, and install Modules and components.

1219 (48)

1219 (48) 1219 (48)

1219 (48)

N

OTE: Consider local soil conditions, codes, and loading when determining appropriate

support footings.

na3526a

To prevent short cycling of outdoor air, each EcoBreeze Frame must have a minimum of 1219

mm (48 in.) clearance on each side, totaling 2438 mm (96 in.) between Frames, and 1219 mm

(48 in.) at the end of the Frame.

1219 (48) 1219 (48)

2438 (96)

1219 (48)

WALL OR OTHER OBSTRUCTION

* Dimensions are shown in millimeters with inches in parentheses.

na3677a

11EcoBreeze System Installation

Page 16

Weights and Dimensions

Frame

ACECFR20101SEn

6058 (238.5)

SUPPLY

BLOWER

ACCESS

COIL

ACCESS

2438 (96)

SUPPLY

BLOWER

ACCESS

COIL

ACCESS

ACECFR20200SEn

ACECFR20201SEn

2896 (114)

12192 (480)

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

ACECFR40101SEn

ACECFR40200SEn

ACECFR40201SEn

na3447a

* Dimensions are shown in millimeters, with inches in parentheses.

† Where n is the number of Modules populating the Frame upon order.

†

2438 (96)

COIL

UPPLY

S

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

2896 (114)

Frame (fully populated with Modules) Weight (dry)

ACECFR20101SE4, ACECFR20200SE4, ACECFR20201SE4 7 863 kg (17,300 lb)

ACECFR40101SE8, ACECFR40200SE8, ACECFR40201SE8 14 290 kg (31,440 lb)

Frame (with Modules and water) Weight (wet)

ACECFR20101SE4, ACECFR20200SE4, ACECFR20201SE4 8 203 kg (18,047 lb)

ACECFR40101SE8, ACECFR40200SE8, ACECFR40201SE8 14 630 kg (32,187 lb)

Frame (no Modules) Weight

ACECFR20101SE0, ACECFR20200SE0, ACECFR20201SE0 2 863 kg (6,300 lb)

ACECFR40101SE0, ACECFR40200SE0, ACECFR40201SE0 4 290 kg (9,440 lb)

Module Weight

ACEC101SE, ACEC200SE, ACEC201SE 1 250 kg (2,750 lb)

EcoBreeze System Installation12

Page 17

Installation

Lifting and Rigging

DAMAGE TO EQUIPMENT OR PERSONNEL

• Do not remove tension rods until the EcoBreeze Frame is placed and secured on

its supports.

• Before lifting the EcoBreeze Frame, ensure the lifting equipment is adequately

sized for the load.

• Lift and rig the EcoBreeze Frame from the top four ISO corners only.

• Move the EcoBreeze Frame directly from the truck to its permanent foundation. If

the Frame must be placed elsewhere temporarily, it must be placed on a flat and

level surface in order to avoid damage.

• Check for overhead obstructions such as power cables.

• Maintain a minimum safe distance while equipment is hoisted.

• Control access of personnel at lift site.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

EcoBreeze Frame. The EcoBreeze Frame is not equipped with forklift pockets. Lift and rig only

from the four upper ISO corner blocks on each EcoBreeze Frame using a crane.

Recommended horizontal sling angles are greater than 45 degrees. Lifting equipment must be

rated for at least 18 144 kg (40,000 lb) for lifting a 12.2 m (40 ft) Frame, and at least 12 247 kg

(27,000 lb) for a 6 m (20 ft) Frame.

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

13EcoBreeze System Installation

Page 18

Mechanical Connections

Install the EcoBreeze Frame per the EcoBreeze Frame Install Kit instructions.

Position the EcoBreeze

NOTE: The power and plumbing connections for the EcoBreeze Frame are located on the end

where the unpacking sheet is placed on the protective wrap. Typically this is the end that will

face the building.

1. Ensure that clamp connectors and vibration damper pads are installed per the

EcoBreeze Frame Install Kit instructions.

2. Use a crane with sufficient lifting capacity to place the EcoBreeze onto the permanent

supports. Typically the end of the frame with plumbing and power connections is placed

nearest to the building.

3. Using a 15/16-in. open-end wrench to turn the drive stud, lock down the clamp

connectors located at each of the four corners. Maximum torque on the drive stud is 68

N-m (50 ft/lb).

na3561a

EcoBreeze System Installation14

Page 19

Unwrap the equipment

na3679a

DAMAGE TO EQUIPMENT

• Do not remove the plastic wrap until the EcoBreeze Frame is placed on its

permanent supports and you are prepared to install the return air ductwork. If the

plastic is removed, ensure that the return air plenums on top of the Frame are

protected.

• When removing protective plastic wrap, be careful to cut only the plastic and not

damage the exterior of the equipment.

• The plastic wrap protects the return air plenum openings on top of the Frame until

the return air ductwork is installed.

NOTICE

Failure to follow these instructions can result in equipment damage.

15EcoBreeze System Installation

Page 20

Remove the tension rods

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

ACCESS

ACCESS

na3450a

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• Loosen the nuts on the ends of the tension rods to relieve tension before removing

tension rod brackets.

• Do not remove the tension rods until EcoBreeze Frame is placed and secured on

its supports.

• Move the EcoBreeze Frame directly from the truck to its permanent foundation or

supports. If it must be stored temporarily, it must be placed on a flat and level

surface to avoid damage.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Tension rods are installed diagonally across each Module bay to provide support during

shipping.

1. Release tension on the rods by loosening the nuts on the ends of the tension rods.

2. Using an M12 wrench, remove the eight bolts securing the tension rod brackets.

3. Remove the tension rods and brackets.

EcoBreeze System Installation16

Page 21

Lower Module drop-down box

1. Open the lower-right door on each Module.

2. For shipping, the drop-down box is secured upside down inside the Module. Remove the

screws securing the drop-down box (a).

NOTE: The screws will be re-used to install the drop-down box.

3. Turn the drop-down box over (b) so it faces right-side up (c).

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

COIL

SUPPLY

BLOWER

ACCESS

ACCESS

ACCESS

4. Drop the drop-down box through the opening in the bottom of the Module and attach it to

the Module with the supplied screws (a).

5. Line up the drop-down box with the supply air transition and attach it to the supply air

transition (b).

N

OTE: The drop-down box is flexible enough to adjust for slight misalignments.

N

OTE: Hardware to attach the drop-down box to the supply air transition is field

supplied.

MODULE DROPDOWN BOX

FOR CLARITY,

MODULE STRUCTURE

IS NOT SHOWN

MODULE

SUPPLY AIR

TRANSITION

na4450a

na4453a

17EcoBreeze System Installation

Page 22

6. Locate the insulation strips packed in the ship-loose kit.

7. Remove the backing from the insulation and apply the insulation around the air transition

ducts.

8. Open the damper on the supply air transition.

Water supply connection

NOTE: There are two water supply inlets on the EcoBreeze Frame. Use separate sources if

possible to provide a redundant water supply.

NOTICE

DAMAGE TO EQUIPMENT

Install adequate freeze protection (not supplied) on all external water piping.

Freeze protection (which may consist of any combination of insulation and electric

heat-tracing) must be correctly applied based on local climatic conditions and best

practices.

Failure to follow these instructions can result in equipment damage.

Sand filtration connections are provided if further filtration of the water supply is required. Sand

filtration systems can be acquired from a third-party vendor.

EcoBreeze System Installation18

Page 23

Connect the water supply to the two 3/4-inch water supply fittings on the EcoBreeze Frame. If

necessary, make the connections using the appropriate fittings from the pipe adapter kit. See

“Component Identification” on page 5.

Drain

(60 Hz) 2-in. NPT FEMALE FITTING

(50 Hz) 2 - 11 BPST PIPE ADAPTER

WATER INLET

(60 HZ) 3/4-in. NPT FEMALE

FITTING

(50 Hz) 3/4 - 14 BSPT PIPE

ADAPTER

334.44 (13.16)

69.85 (2.75)

* Dimensions are shown in millimeters with inches in parentheses.

WATER DRAIN

1120.78 (44.13)

1303.27 (51.31)

1317.63 (51.88)

WATER INLET

(60 HZ) 3/4-in. NPT FEMALE

FITTING

(50 Hz) 3/4 - 14 BSPT PIPE

ADAPTER

OPTIONAL SAND FILTER

CONNECTIONS

na3521a

Connect the external 2-in. drain line on the EcoBreeze Frame to an open drain used for

collection of wastewater. If necessary, make the connection using the appropriate fitting from

the pipe adapter kit. See “Component Identification” on page 5.

19EcoBreeze System Installation

Page 24

NOTE: Separate the drain line from the EcoBreeze Frame and the external drain line by a

50 mm (2 in.) air gap in order to prevent back up of contaminated water into the cooling system.

AIR GAP

na3564a

N

OTE: Pitch the external drain piping at a minimum of 25 mm (1 in.) per 3048 mm (10 ft)

towards the wastewater drain.

EcoBreeze System Installation20

Page 25

Electrical Connections

The electrical connections required are the following:

• Power to Frame

• Control (remote display interface)

• Communication - Building Management System (BMS) - optional

Make all electrical connections in accordance with applicable industry guidelines as well as

national and local codes.

Make all low-voltage connections, including data and control connections, with properly

insulated wires. The low-voltage wires and connections must have at least 300V insulation.

DANGER

HAZARD OF ELECTRIC SHOCK

Use a voltmeter to ensure that power is turned off before making any electrical

connections.

Failure to follow these instructions will result in death or serious injury.

OTE: Three-phase electrical service is required. Electrical service must conform to national

N

and local electrical codes.

21EcoBreeze System Installation

Page 26

Power supply to EcoBreeze Frame

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Turn off all power supplying this equipment before working on the equipment. All electrical

work must be performed by licensed electricians. Practice Lockout/Tagout procedures. Do

not wear jewelry when working with electrical equipment.

Failure to follow these instructions will result in death or serious injury.

HAZARD TO EQUIPMENT AND PERSONNEL

Only Schneider Electric authorized personnel may energize the equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

1. Use a punch tool to create an access hole as needed for power supply wires entering

the main power enclosure.

DANGER

WARNING

2. Attach the conduit connector to the access hole on the main power enclosure.

OTE: A service loop is factory-installed in the main power enclosure.

N

3. If permitted by local and national codes, route the cable to the disconnect switch as

shown. If local and national codes do not permit service loops, make all connections per

code.

4. Connect the power wiring to the disconnect switch. Connect the phases as marked next

to the disconnect switch.

5. Connect the ground wire to the grounding lug beside the disconnect switch.

L1

L2

L3

GND

SUPPLY

BLOWER

ACCESS

na3490a

EcoBreeze System Installation22

Page 27

Remote display interface

NOTICE

DAMAGE TO EQUIPMENT

Damage to LCD display will result from exposure to temperatures below 0°C (32°F).

Outdoor installations will require a third-party heat source as needed to ensure the LCD

display is not subjected to temperatures below 0°C (32°F).

Failure to follow these instructions can result in equipment damage.

See EcoBreeze remote display installation instructions for additional information.

The remote display interface enclosure contains the LCD display that is used to control the

EcoBreeze from a remote location. The EcoBreeze connects to the remote display interface

over an expansion bus.

N

OTE: Separate incoming power cables from low voltage wiring by 150 mm (6 in.).

N

OTE: Communication wiring from the EcoBreeze to the remote display interface enclosure

must be a minimum of 24-gauge, 3-core wire with shield with a maximum length of 300 m (984

ft).

1. Install the remote display interface enclosure in the desired location.

I

MPORTANT: For outdoor applications, use weather-proof conduit connectors.

O

PERATING CONDITIONS: Ambient temperature 0 - 55°C (32 - 131°F). Relative

humidity 5% - 95% non-condensing.

N

OTE: Connect shield wire to GND.

2. Connect the bus wiring to the contacts labeled 124, 125, and 126 on the expansion bus

terminal block, located behind the direct digital controller (DDC) access door on the

Frame.

DDC PANEL

ENCLOSURE

na3716a

124

125

126

GND

23EcoBreeze System Installation

Page 28

3. Wire the expansion bus to the 124, 125, and 126 contacts on the terminal block in the

remote display interface enclosure.

AC POWER

(85-265

VAC,

50/60 Hz)

ANALOG INPUT

(4-20mA OR 0-10

VDC)

DIGITAL

INPUTS

(DRY

CONTACT)

DIGITAL

OUTPUTS

(DRY

CONTACT,

5A, 250VAC)

L1

L2N

PE - GND

SUPPLY AIR DP SIGNAL

POWER RETURN / SIGNAL

ACTIVE SENSOR POWER (+24 VDC)

RUN / DAMPER END COMMON

RUN SIGNAL

DAMPER END SWITCH SIGNAL

DAMPER COMMON

DAMPER OPERATION

ALARM COMMON

ALARM (NORMALLY OPEN)

CAN - H

G4K4 N4

124 125 126 188 189 190 192 193 194 195 196 197 198

FRAME

BUS

(CAN)

CAN - L

CAN - GND

na3576a

EcoBreeze System Installation24

Page 29

Building Management System

The Modbus interface allows the EcoBreeze System to communicate with a building

management system (BMS).

The Modbus connection is available in two locations on the Modbus hub:

• RJ-45 In port

• 3-wire on terminal block

For an RJ-45 connection, wire as follows:

Pin 4 D(A)

Pin 5 D(B)

Pin 8 Ground

For a direct 3-wire connection, connect to the corresponding contacts on the green terminal

block on the side of the Modbus hub. No connection is necessary to the 0V contact.

na3660a

WIRING CONTACTS

FOR DIRECT 3-WIRE

CONNECTION

D(B)

D(A)

1MOD

0 V

1MOD

RJ-45 IN PORT

DDC PANEL

ENCLOSURE

25EcoBreeze System Installation

Page 30

Page 31

Page 32

Worldwide Customer Support

Customer support is available at no charge via e-mail or telephone. Contact information is available at

www.apc.com/support/contact.

© Schneider Electric is owned by Schneider Electric Industries S.A.S., or its affiliated companies. All other

trademarks are property of their respective owners.

990-3976D-001

6/2014

Loading...

Loading...