Page 1

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip

Units

Unidades de disparo electrónico Micrologic™ 2.0A, 3.0A,

5.0A y 6.0A

MC

Déclencheurs électroniques Micrologic

2.0A, 3.0A, 5.0A et

6.0A

Instruction Bulletin

Boletín de instrucciones

Directives d'utilisation

48049-136-05

Rev. 01, 04/2012

Retain for Future Use. /

Conservar para uso futuro. /

À conserver pour usage ultérieur.

Page 2

Page 3

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A

Electronic Trip Units

Instruction Bulletin

48049-136-05

Rev. 01, 07/2012

Retain for future use.

ENGLISH

Page 4

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

DANGER

WARNING

E

IEC

ANSI

Rev. 01, 07/2012

Hazard Categories and Special

ENGLISH

Symbols

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain

it. The following special messages may appear throughout this bulletin or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal injury if

the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, can

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, can

result in minor or moderate injury.

NOTIC

NOTICE is used to address practices not related to physical injury. The

safety alert symbol is not used with this signal word.

NOTE: Provides additional information to clarify or simplify a procedure.

Please Note Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel. No responsibility is assumed by

Schneider Electric for any consequences arising out of the use of this

material.

FCC Notice This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense. This

Class A digital apparatus complies with Canadian ICES-003.

© 1999–2012 Schneider Electric All Rights Reserved2-EN

Page 5

48049-136-05 Micrologic® 2.0A, 3.0A, 5.0A and 6.0A Electronic Trip Units

Rev. 01, 07/2012 Table of Contents

Table of Contents

SECTION 1: GENERAL INFORMATION ...................................................................................................................... 5

Introduction ................................................................................................. 5

Communications ......................................................................................... 5

Trip Unit Settings ........................................................................................ 5

Micrologic 2.0A Trip Unit ....................................................................... 6

Micrologic 3.0A Trip Unit ....................................................................... 6

Micrologic 5.0A Trip Unit ....................................................................... 7

Micrologic 6.0A Trip Unit ....................................................................... 8

Zone-Selective Interlocking ......................................................................... 9

Trip Unit Switches ..................................................................................... 10

Long-Time Protection .......................................................................... 10

Short-Time Protection ......................................................................... 11

Instantaneous Protection ..................................................................... 12

Ground-Fault Protection ...................................................................... 13

Indicator Lights .......................................................................................... 13

Overload Indicator Light ...................................................................... 13

Trip Indicator Lights ............................................................................. 14

Ammeter ................................................................................................... 14

Trip Unit Testing ........................................................................................ 14

Micrologic Trip Unit Configuration ............................................................. 14

Control Power ...................................................................................... 14

External Power Supply ........................................................................ 15

ENGLISH

SECTION 2: AMMETER .................................................................................................................... 16

Display ...................................................................................................... 16

Ammeter Measurements ........................................................................... 16

Accessing Information ............................................................................... 16

Current Menu ...................................................................................... 17

Peak Menu .......................................................................................... 18

Switch Settings Menu .......................................................................... 19

SECTION 3: OPERATION .................................................................................................................... 20

Switch Setting Adjustment ........................................................................ 20

Examples .................................................................................................. 20

Micrologic 2.0A Trip Unit ..................................................................... 20

Micrologic 3.0A Trip Unit ..................................................................... 21

Micrologic 5.0A Trip Unit ..................................................................... 21

Micrologic 6.0A Trip Unit ..................................................................... 22

Zone-Selective Interlocking (ZSI) .............................................................. 23

Communication Module values ................................................................. 24

Trip Unit Settings Check ........................................................................... 26

Trip Unit Operation Verification ................................................................. 26

Equipment Ground-Fault Trip Functions Testing ...................................... 27

Trip Unit Resetting .................................................................................... 27

Trip Unit Status Check .............................................................................. 27

SECTION 4: TRIP UNIT REPLACEMENT .................................................................................................................... 28

Required Tools .......................................................................................... 28

Preparation ............................................................................................... 28

Record Switch Settings ....................................................................... 28

Circuit Breaker Disconnection ............................................................. 28

Circuit Breaker Accessory Cover Removal ......................................... 28

Rating Plug Removal ........................................................................... 29

Trip Unit Removal ................................................................................ 29

© 1999–2012 Schneider Electric All Rights Reserved 3-EN

Page 6

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

Table of Contents Rev. 01, 07/2012

ENGLISH

SECTION 5: ADJUSTABLE RATING PLUG REPLACEMENT .............................................................................................. 33

SECTION 6: BATTERY REPLACEMENT ....................................................................................................................34

Trip Unit Replacement ..............................................................................29

Battery Installation ...............................................................................29

Trip Unit Installation .............................................................................30

Circuit Breaker Accessory Cover Replacement ........................................ 31

Trip Unit Installation Check .......................................................................32

Secondary Injection Testing ................................................................32

Primary Injection Testing ..................................................................... 32

Check Accessory Operation ................................................................ 32

Trip Unit Setup ..........................................................................................32

Circuit Breaker Reconnection ...................................................................32

Rating Plug Removal ................................................................................ 33

New Rating Plug Installation ..................................................................... 33

Circuit Breaker Disconnection ...................................................................34

Circuit Breaker Accessory Cover Removal ...............................................34

Withstand Module Shifting ........................................................................34

Battery Replacement .................................................................................34

Withstand Module Replacement ............................................................... 35

Circuit Breaker Accessory Cover Replacement ........................................ 35

Circuit Breaker Reconnection ...................................................................35

APPENDIX A: REGISTER LIST ....................................................................................................................36

List of Registers ........................................................................................36

© 1999–2012 Schneider Electric All Rights Reserved4-EN

Page 7

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

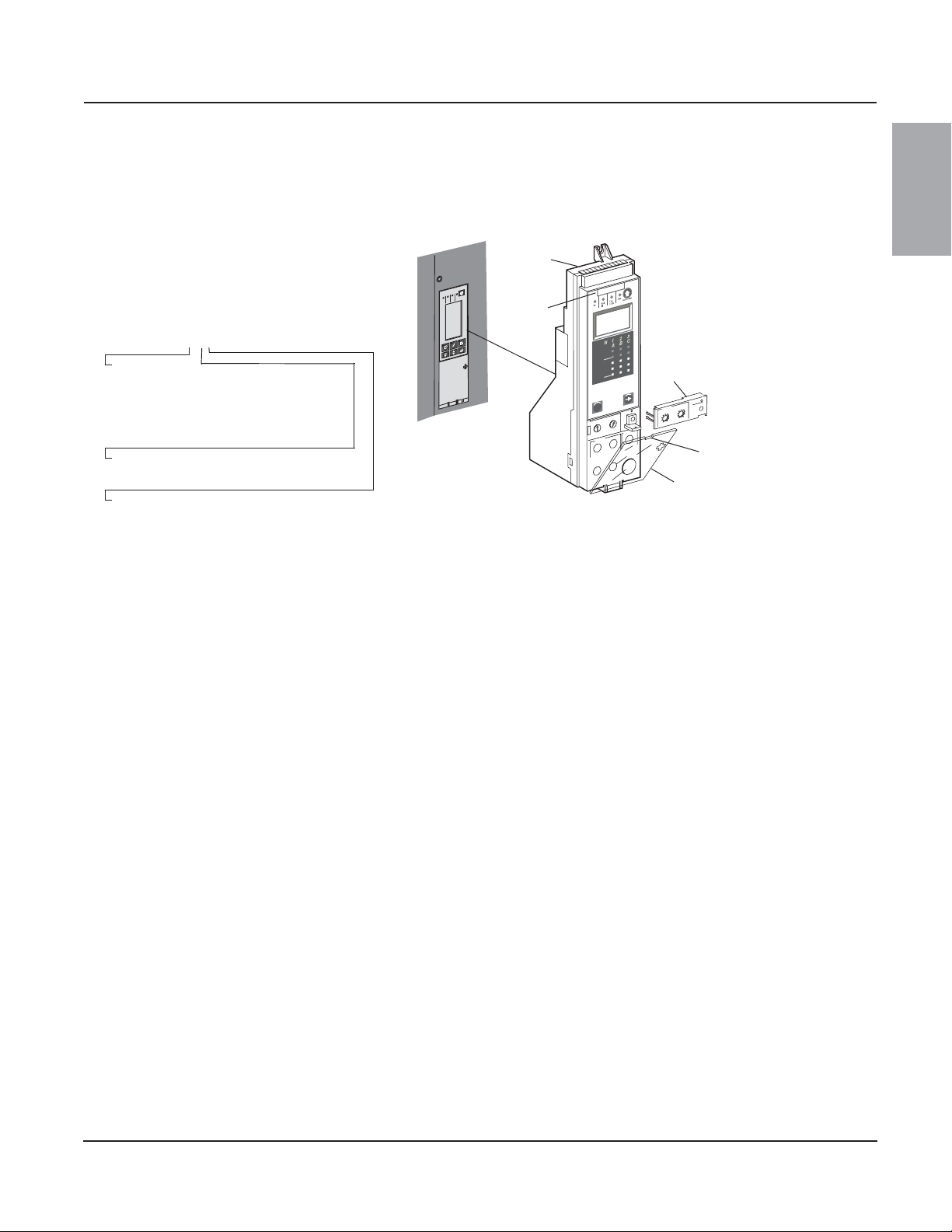

06134858

A

B

D

E

C

A—Micrologic Trip Unit

B—Product Name

C—Switch Cover

D—Switch Cover Opening Slot

E—Adjustable Rating Plug

Rev. 01, 07/2012 Section 1—General Information

Section 1—General Information

Introduction

Micrologic™ trip units (A) provide adjustable

tripping functions on electronic trip circuit

breakers. The product name (B) specifies the

level of protection provided by the trip unit.

Micrologic 3.0A

Type of protection

2—Basic IEC protection (LS0)

3—Basic UL protection (LI)

5—Selective protection (LSI)

6—Selective protection plus ground fault

protection for equipment (LSIG)

Trip unit series

0—Indicates the first version

Type of measurement

None—Provides protection only

A—Provides protection plus ammeter measurements

Micrologic trip units are field replaceable to allow

for upgrading of the trip unit in the field. For

complete information on available circuit breaker

models, frame sizes, interrupting ratings, sensor

plugs, rating plugs and trip units, see the product

catalog.

Figure 1: Micrologic Trip Unit

rolo

ic

M

06133249

%

0

0

1

%

0

4

u

n

e

m

ENGLISH

A

7.0

ic

g

m

ar

l

a

e

m

i

8

t

r

12

t

ng

o

l

)

4

6

s

(

1

8

.

r

9

I

.

2

20

7

.

5

9

.

1

24

6

8

.

9

.

5

.

r

I

6

@

5

.

1

n

.4

I

x

Communications Micrologic trip units can communicate with other devices if the optional

Circuit Breaker Communication Module (BCM) is installed. For information

on the communication module, see the product catalog and Modbus™

Communications System, Data Bulletin 0613IB1201.

Trip Unit Settings On the face of the trip unit are adjustable switches to allow changing of trip

characteristics. Trip units are shipped with the long-time pickup switch set at

1.0 and all other trip unit adjustments set at their lowest settings.

© 1999–2012 Schneider Electric All Rights Reserved

5-EN

Page 8

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

0 Ir Isd I

t

06134245

06134246

Micrologic 2.0 A

menu

long time

alarm

instantaneous

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

setting

Isd

2.5

5

6

1.5

2

3

4

8

10

x Ir

G

F

A

H

J

I

F

G

H

K

B

C

E

D

N

M

L

06133243

Micrologic 3.0 A

menu

long time

alarm

instantaneous

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

3

6

8

setting

Ii

1.5

2

4

5

10

12

x In

0 Ir Ii I

t

06133201

G

F

A

H

J

I

F

G

H

K

B

C

E

D

N

M

L

Section 1—General Information Rev. 01, 07/2012

ENGLISH

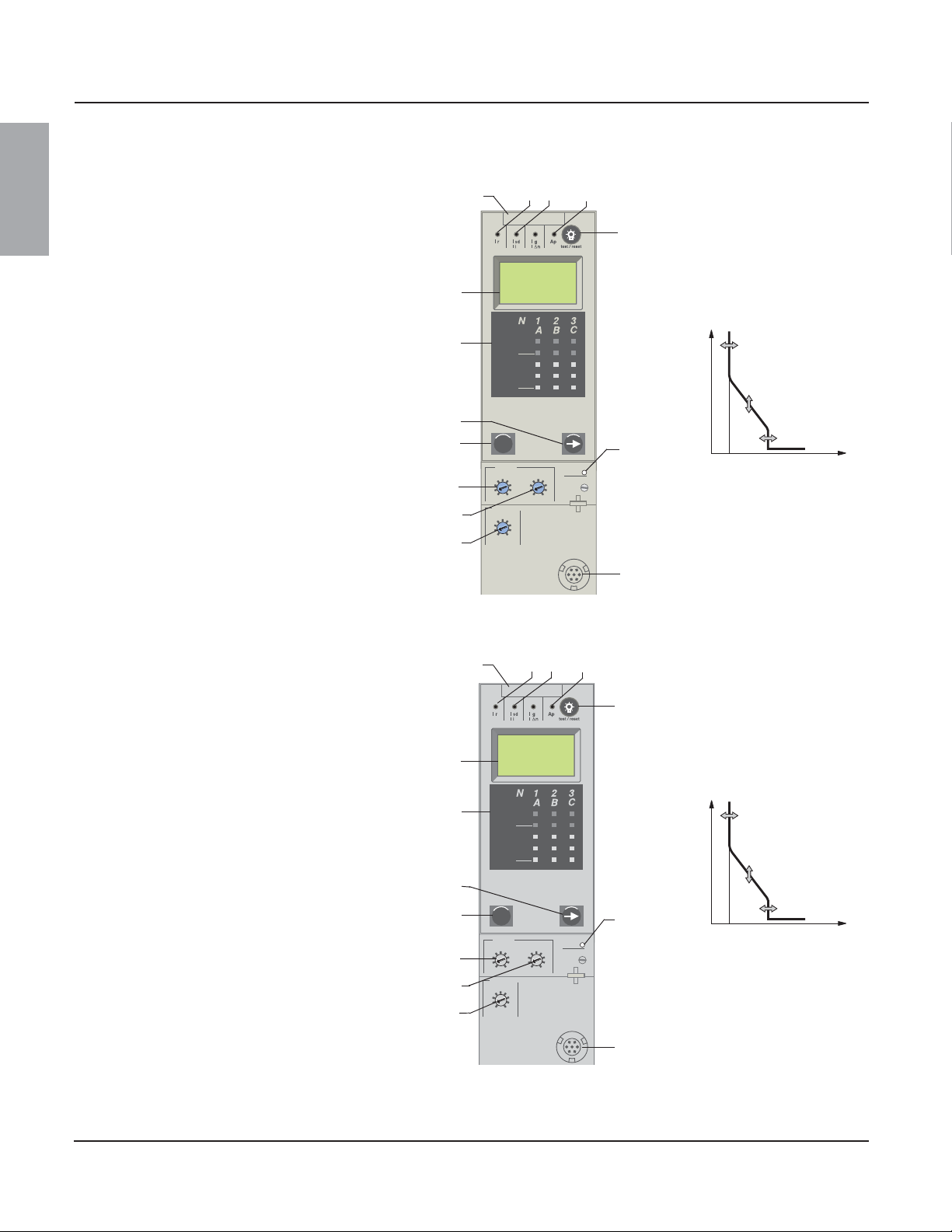

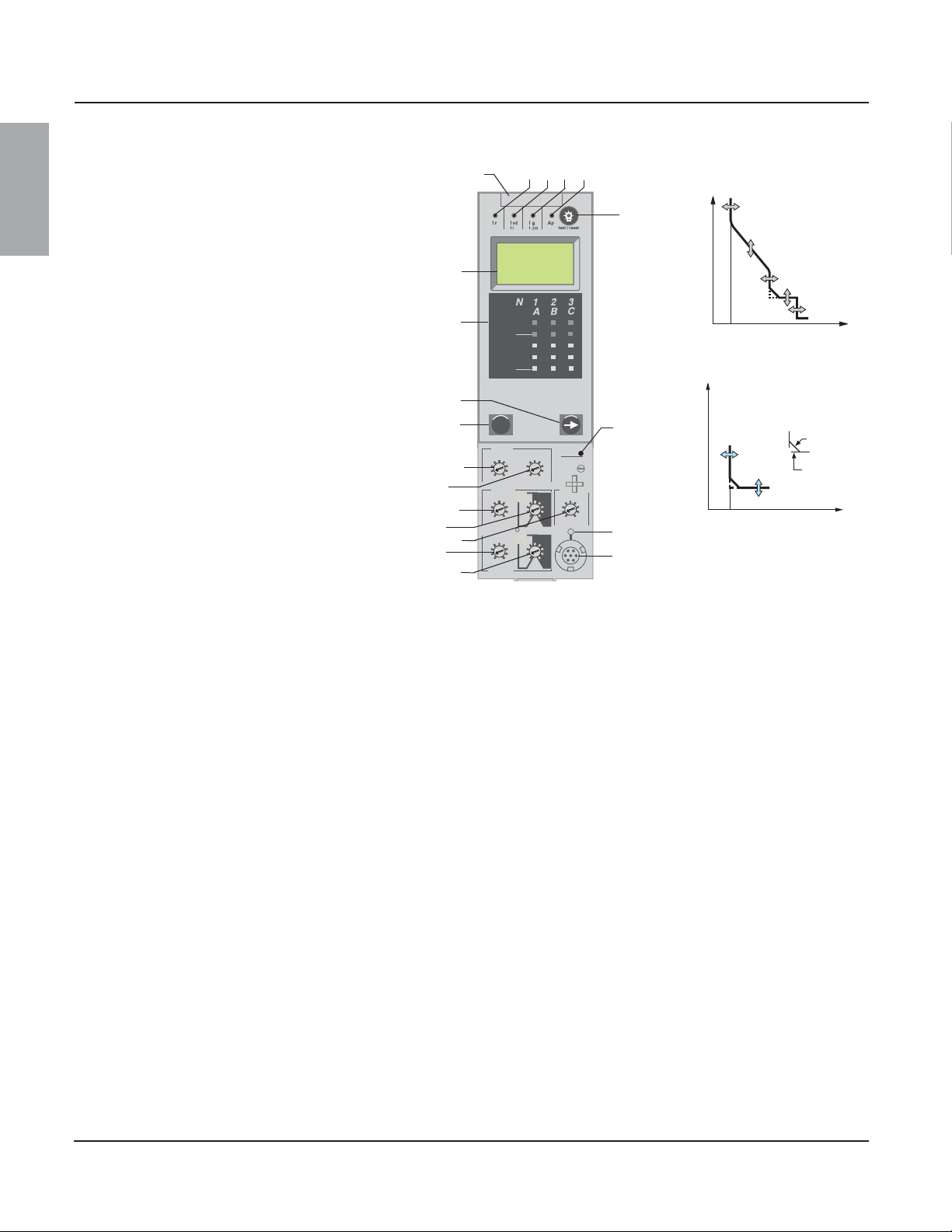

Micrologic 2.0A Trip Unit

The Micrologic 2.0A trip unit provides basic IEC

(LS0) protection and a built-in ammeter.

A. Trip unit name

B. Alphanumeric display

C. Three-phase bar graph

D. Scroll button

E. Menu button

F. Long-time pickup (Ir) switch

G. Long-time delay (tr) switch

H. Short-time pickup (Isd) switch*

I. Test plug receptacle

J. Overload indicator light

K. Reset button for battery status check and trip

L. Self-protection indicator light

M. Short-time or instantaneous trip indicator

N. Long-time trip indicator light

NOTE: For use with IEC circuit breakers only.

Figure 2: 2.0A Trip Unit

indicator LED

light

Micrologic 3.0A Trip Unit

The Micrologic 3.0A trip unit provides basic UL

(LI) protection and a built-in ammeter.

A. Trip unit name

B. Alphanumeric display

C. Three-phase bar graph

D. Scroll button

E. Menu button

F. Long-time pickup (Ir) switch

G. Long-time delay (tr) switch

H. Instantaneous pickup (Ii) switch

I. Test plug receptacle

J. Overload indicator light

K. Reset button for battery status check and trip

L. Self-protection indicator light

M. Short-time or instantaneous trip indicator

N. Long-time trip indicator light

*Short-time delay is factory set at 0 (no delay), thus short-time

pickup provides instantaneous protection.

indicator LED

light

Figure 3: 3.0A Trip Unit

© 1999–2012 Schneider Electric All Rights Reserved6-EN

Page 9

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

Micrologic 5.0 A

menu

d

elay

sh

o

r

t

ti

me

lon

g

ti

me

a

l

a

rm

tr

(s)

se

tting

.4

.5

.

6

.7

.8

.9

.9

5

.

9

8

1

Ir

x

In

.5

1

2

4

8

1

2

1

6

2

0

@

6 I

r

2

4

06133244

e

4

I i

x In

3

6

8

10

12

15

off

2

tsd

(s)

on I2t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.5

i

n

stantan

eo

u

s

G

F

A

H

L

K

F

G

J

M

B

C

E

D

P

O

N

I

J

I

H

Rev. 01, 07/2012 Section 1—General Information

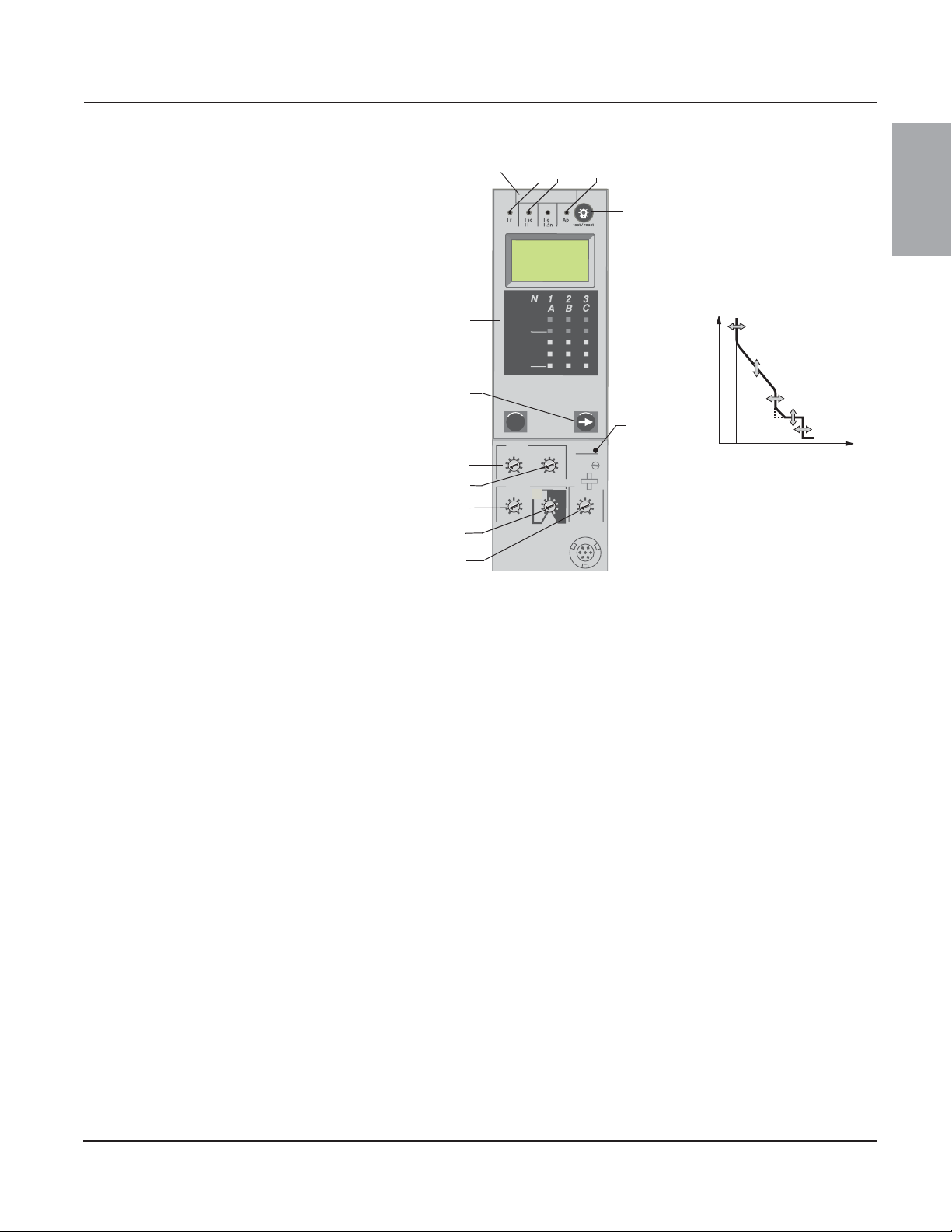

Micrologic 5.0A Trip Unit

The Micrologic 5.0A trip unit provides selective

(LSI) protection and a built-in ammeter.

A. Trip unit name

B. Alphanumeric display

C. Three-phase bar graph

D. Scroll button

E. Menu button

F. Long-time pickup (Ir) switch

G. Long-time delay (tr) switch

H. Short-time pickup (Isd) switch

I. Short-time delay (tsd) switch

J. Instantaneous pickup (Ii) switch

K. Test plug receptacle

L. Overload indicator light

M. Reset button for battery status check and trip

indicator LED

N. Self-protection indicator light

O. Short-time or instantaneous trip indicator

light

P. Long-time trip indicator light

Figure 4: 5.0A Trip Unit

t

06133202

0 Ir Isd I

Ii

ENGLISH

© 1999–2012 Schneider Electric All Rights Reserved

7-EN

Page 10

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

Micrologic 6.0 A

menu

delay

short tim

e

long time

alarm

ground fault

setting

test

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

tsd

tg

06133245

4

I i

x In

3

5

6

10

12

15

off

2

tsd

(s)

on I2t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.5

on

I

2

t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

B

C

D

E

F

G

H

J

Ig

A

(s)

instantaneous

40

100

%

%

0 Ir Isd I

t

Ii

06133202

0 I

t

I2t off

I2t on

Ig

06133247

G

F

A

H

O

M

F

G

J

P

B

C

E

D

T

S

Q

I

J

I

H

K

L

N

R

K

L

Section 1—General Information Rev. 01, 07/2012

ENGLISH

Micrologic 6.0A Trip Unit

The Micrologic 6.0A trip unit provides selective

and ground-fault protection for equipment

(d1200 A) (LSIG) and a built-in ammeter.

A. Trip unit name

B. Alphanumeric display

C. Three-phase bar graph

D. Scroll button

E. Menu button

F. Long-time pickup (Ir) switch

G. Long-time delay (tr) switch

H. Short-time pickup (Isd) switch

I. Short-time delay (tsd) switch

J. Instantaneous pickup (Ii) switch

K. Ground-fault pickup (Ig) switch

L. Ground-fault delay (tg) switch

M. Test plug receptacle

N. Ground fault push-to-trip button

O. Overload indicator light

P. Reset button for battery status check and trip

Q. Self-protection indicator light

R. Ground-fault trip indicator light

S. Short-time or instantaneous trip indicator

T. Long-time trip indicator light

Figure 5: 6.0A Trip Unit

indicator LED

light

© 1999–2012 Schneider Electric All Rights Reserved8-EN

Page 11

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

Rev. 01, 07/2012 Section 1—General Information

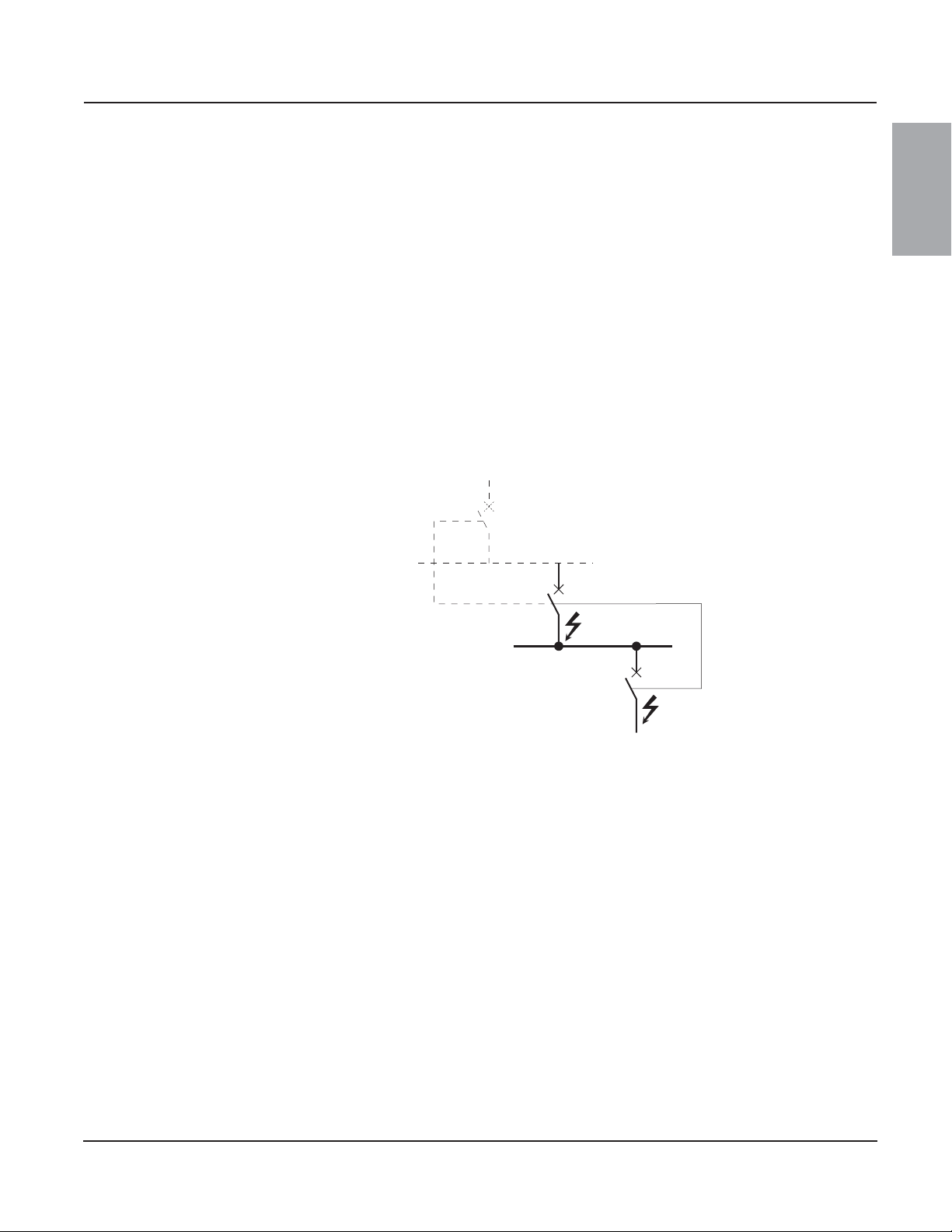

Zone-Selective Interlocking

Short-time and ground-fault protection can be

interlocked to provide zone-selective

interlocking.

Control wiring links several trip units in the

distribution network and in the event of a fault, a

trip unit will obey the set delay time only if

receiving a signal from a downstream trip unit.

If the trip unit does not receive a signal, tripping

will be instantaneous (with no intentional delay).

• The fault is cleared instantaneously by the

nearest upstream circuit breaker.

• Thermal stresses (I

2

t) in the network are

minimized without any effect on the correct

time delay coordination of the installation.

Figure 6 shows circuit breakers 1 and 2 zoneselective interlocked.

• A fault at A is seen by circuit breakers 1 and

2. Circuit breaker 2 trips instantaneously and

also informs circuit breaker 1 to obey set

delay times. Thus, circuit breaker 2 trips and

clears the fault. Circuit breaker 1 does not

trip.

• A fault at B is seen by circuit breaker 1.

Circuit breaker 1 trips instantaneously since

it did not receive a signal from the

downstream circuit breaker 2. Circuit breaker

1 trips and clears the fault. Circuit breaker 2

does not trip.

2

NOTE: Use I

t off with ZSI for proper coordination. Using I2t on with ZSI is

not recommended as the delay in the upstream device receiving a restraint

signal could result in the trip unit tripping in a time shorter than the published

trip curve.

NOTE: Setting short-time delay (tsd) or ground-fault delay (tg) to the 0

setting will eliminate selectivity for that circuit breaker.

Figure 6: Zone-Selective Interlocking

06133376

1

B

2

A

ENGLISH

© 1999–2012 Schneider Electric All Rights Reserved

9-EN

Page 12

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

x Ir

2

2.5

3

4

5

6

8

10

1.

5

setting

Isd

instantaneous

long time

alarm

tr

(s)

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

.5

1

2

4

8

12

16

20

@ 6 Ir

24

06134243

x In

2

3

4

5

6

8

10

12

1.

5

setting

Ii

instantaneous

long time

alarm

tr

(s)

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

.5

1

2

4

8

12

16

20

@ 6 Ir

24

06133203

.4

.5

.6

.7.8.9

.95

.98

1

delay

short tim

e

I itsd

(s)

on I2t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

instantaneous

long time

alarm

Ir

x In

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

setting

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.

5

x In

3

4

6

8

10

12

15

off

2

06133204

.4

.5

.6

.7.8.9

.95

.98

1

delay

short tim

e

I itsd

(s)

on I2t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

off

instantaneous

long time

alarm

Ir

x In

ground fault

B

C

D

E

F

G

H

J

Ig tg

(s)

on I2t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

off

A

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

setting

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.

5

x In

3

4

5

8

10

12

15

off

2

test

06133351

Section 1—General Information Rev. 01, 07/2012

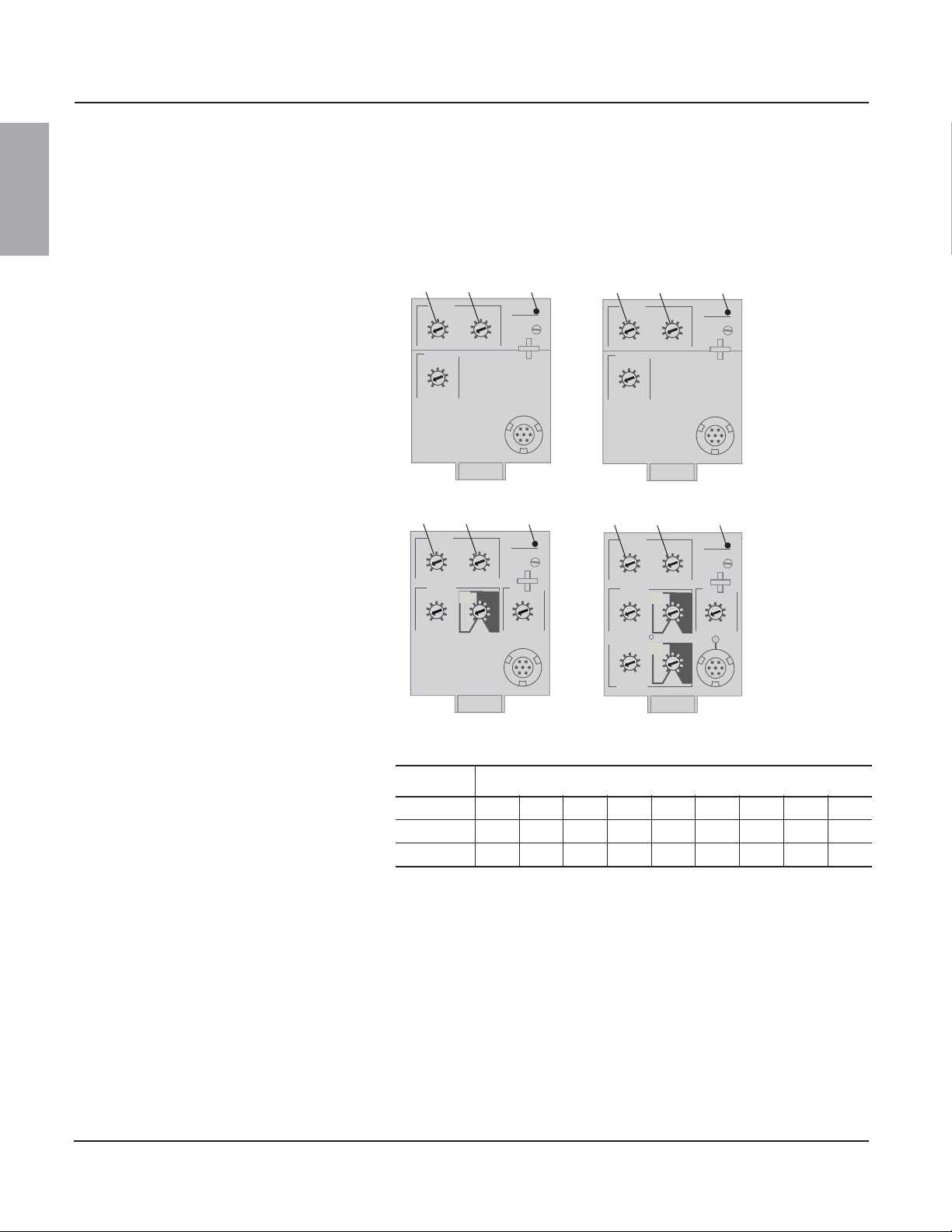

Trip Unit Switches

ENGLISH

Long-Time Protection

Long-time protection protects equipment against

overloads.

• Long-time protection is standard on all trip

units.

• The long-time pickup (Ir) (A) sets the

maximum current level (based on sensor

plug rating In) which the circuit breaker can

continuously carry. If current exceeds this

value, circuit breaker will trip after the preset

time delay. The long-time pickup (Ir) is

adjustable from 0.4–1.0 times the sensor

plug rating (In).

• The long-time delay (tr) (B) sets the length of

the time that the circuit breaker will carry an

overcurrent (below the short-time or

instantaneous pickup current level) before

tripping. See Table 1 for delay settings.

• Both long-time pickup and long-time delay

are on the field-replaceable adjustable rating

plug. To change settings to more precisely

match the application, various rating plugs

are available. For instructions on replacing

the rating plug, see Section

5 —Adjustable

Rating Plug Replacement.

• For Masterpact™ NT and NW circuit

breakers, the In value can be changed by

replacing the sensor plug below the trip unit.

For further information, see the instructions

packed with the sensor plug replacement kit.

• The overload indicator light (C) indicates that

the Ir long-time pickup threshold has been

exceeded.

• Long-time protection uses true RMS

measurement.

Thermal imaging provides continuous

temperature rise status of the wiring, both before

and after the device trips. This allows the circuit

breaker to respond to a series of overload

conditions which could cause conductor

overheating, but would go undetected if the

long-time circuit was cleared every time the load

dropped below the pickup setting or after every

tripping event.

NOTE: Micrologic trip units are powered from the circuit to always provide

fault protection. All other functions (display, metering, communications, etc.)

require external power. See 15 for more information.

Figure 7: Long-Time Protection Switches

Micrologic 2.0A Trip Unit

B

A

Micrologic 5.0A Trip Unit

B

A

C

C

Micrologic 3.0A Trip Unit

B

A

Micrologic 6.0A Trip Unit

B

A

C

C

Table 1: Micrologic Trip Unit Long-Time Delay Values

1

Setting

Long-Time Delay in Seconds

tr at 1.5 x Ir 12.5 25 50 100 200 300 400 500 600

tr at 6 x Ir 0.51 2 4 8 12162024

3

tr at 7.2 x Ir 0.34

1

Ir = In x long-time pickup. In = sensor rating. Trip threshold between 1.05 and 1.20 Ir.

2

Time-delay accuracy +0/-20%

3

For Micrologic 5.0A and 6.0A trip units, when tsd is set to 0.4 on or 4.0 off, then tr = 0.5 instead of 0.34.

0.69 1.38 2.7 5.5 8.3 11 13.8 16.6

2

NOTE: If checking trip times, wait a minimum of 15 minutes after circuit

breaker trips before resetting to allow the thermal imaging to reset

completely to zero or use a full-function test kit to defeat the thermal

imaging.

© 1999–2012 Schneider Electric All Rights Reserved10-EN

Page 13

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

A

B

.4

.5

.6

.7.8.9

.95

.98

1

delay

short tim

e

I itsd

(s)

on I2t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

off

instantaneous

long time

alarm

Ir

x In

ground fault

B

C

D

E

F

G

H

J

Ig tg

(s)

on I2t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

off

A

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

setting

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.

5

x In

3

4

5

8

10

12

15

off

2

test

06133351

Rev. 01, 07/2012 Section 1—General Information

Short-Time Protection

Short-time protection protects equipment

against short circuits.

• Short-time protection is standard on 2.0A,

5.0A and 6.0A trip units. It is not available on

3.0A trip units.

• Short-time protection is based on the long-

time pickup (Ir).

• The short-time pickup (Isd) (A) sets current

level (below instantaneous trip level) at

which circuit breaker will trip after the preset

time delay.

• The short-time delay (tsd) (B) sets the length

of time that the circuit breaker will carry an

overcurrent above the short-time pickup

current level before tripping. It is adjustable

on the 5.0A and 6.0A trip unit and factory set

to zero on the 2.0A trip unit.

• The I

2

t on/I2t off option provides improved

selectivity with downstream protective

devices:

—With I

2

t off selected, fixed time delay is

provided.

2

—With I

t on selected, inverse time I2t

protection is provided up to 10 x Ir.

Above 10 x Ir, fixed time delay is

provided.

• Intermittent currents in the short-time tripping

range which do not last sufficiently long to

trigger a trip are accumulated and shorten

the trip delay appropriately.

• Short-time protection can be zone-selective

interlocked (ZSI) with upstream or

downstream circuit breakers.

• Setting tsd to the 0 setting turns off zone-

selective interlocking.

• Short-time protection uses true RMS

measurement.

• Short-time pickup and delay can be adjusted

to provide selectivity with upstream or

downstream circuit breakers.

Figure 8: Short-Time Protection Switches

Micrologic 5.0A Trip Unit

Ir

06133204

.6

.5

Isd

2.5

2

1.

long time

.7.8.9

.4

x In

short tim

3

5

x Ir

setting

tr

(s)

.95

2

1

.98

1

e

4

(s)

5

6

.3

.2

8

10

on I2t

alarm

8

4

12

16

20

24

.5

@

6 Ir

instantaneous

I itsd

.4

.3

.4

6

4

.2

3

.1

0

.1

2

off

delay

8

10

12

15

off

x In

Micrologic 6.0A Trip Unit

A

B

Table 2: Micrologic Trip Unit Short-Time Delay Values

Setting Short-Time Delay

I2t off (Isd at 10 Ir) (seconds) 0 0.1 0.2 0.3 0.4

2

t on (Isd at 10 Ir) (seconds) 0.1 0.2 0.3 0.4

I

tsd (min. trip) (milliseconds) 20 80 140 230 350

tsd (max. trip) (milliseconds) 80 140 200 320 500

NOTE: Use I2t off with ZSI for proper coordination. Using I2t on with ZSI is

not recommended as the delay in the upstream device receiving a restraint

signal could result in the trip unit tripping in a time shorter than the

published trip curve.

ENGLISH

© 1999–2012 Schneider Electric All Rights Reserved

11-EN

Page 14

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

Section 1—General Information Rev. 01, 07/2012

ENGLISH

Instantaneous Protection

Instantaneous protection protects equipment

against short circuits with no intentional time

delay.

• Instantaneous protection (Ii) (A) is standard

• Instantaneous protection on 2.0A trip units is

• Instantaneous protection on the 3.0A, 5.0A

• Instantaneous protection on the 2.0A trip unit

• Circuit breaker open command is issued as

• Instantaneous protection uses peak current

• When instantaneous protection switch is set

on the 3.0A, 5.0A and 6.0A trip units.

achieved by using short-time protection (Isd)

with the short-time delay factory set to 0

(zero).

and 6.0A trip units is based on the circuit

breaker sensor rating (In).

is based on the long-time pickup setting (Ir).

soon as threshold current is exceeded.

measurement.

to off, the instantaneous protection is

disabled.

Figure 9: Instantaneous Protection Switches

Micrologic 2.0A Trip Unit

long time

tr

Ir

(s)

.7.8.9

06134243

.6

.95

2

1

.5

.98

.4

1

x In

instantaneous

Isd

4

3

5

2.5

6

2

8

5

1.

10

setting

x Ir

A

Micrologic 5.0A Trip Unit

long time

Ir

tr

(s)

.7.8.9

06133204

.6

.95

2

1

.5

.98

.4

1

.5

x In

e

short tim

Isd

4

(s)

5

3

6

2.5

.3

.2

2

8

.1

1.

5

10

on I2t

x Ir

setting

alarm

8

4

12

16

20

24

.5

@ 6 Ir

alarm

8

4

12

16

20

24

@

6 Ir

instantaneous

I itsd

8

.4

.3

.4

delay

10

6

4

12

.2

3

15

.1

off

0

2

off

x In

Micrologic 3.0A Trip Unit

long time

Ir

.7.8.9

06133203

.6

.5

.4

x In

instantaneous

Ii

5

4

3

2

1.

5

A

setting

x In

Micrologic 6.0A Trip Unit

long time

Ir

.7.8.9

06133351

.6

.5

.4

x In

short time

Isd

4

3

2.5

2

1.

A

5

x Ir

setting

Ig tg

E

D

C

B

A

ground fault

tr

(s)

4

.95

2

1

.98

1

.5

6

8

10

12

tr

(s)

4

.95

2

1

.98

1

.5

(s)

.

4

5

.

3

6

.

2

8

.

1

10

on I2t

(s)

.

4

F

.

3

G

.

2

H

.

1

J

on I2t

alarm

8

12

16

20

24

@ 6 Ir

alarm

8

12

16

20

24

6 Ir

@

instantaneous

I itsd

.

4

8

.

3

10

5

.

2

4

12

.

1

3

15

0

2

delay

.

4

test

.

3

.

2

.

1

0

off

off

off

x In

A

Table 3: Micrologic Instantaneous Values

Setting Interruption Current

2.0A Isd (= Ir x..) 1.522.53456810

Ii (= In x..) 1.52345681012

3.0A

Ii (= In x..) 23468101215off

5.0A

Ii (= In x..) 23468101215off

6.0A

Ii = UL and ANSI instantaneous

Isd = IEC instantaneous (short-time with zero delay)

In = sensor rating

Ir = long-time pickup

© 1999–2012 Schneider Electric All Rights Reserved12-EN

Page 15

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

A

B

Micrologic 6.0A Trip Unit

delay

short tim

e

I itsd

instantaneous

long time

alarm

test

800

earth leakage

1

2

3

5

7

10

20

30

ΔI

(ms)

60

.5

140

230

350

IΔn

(A)

setting

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.

5

on

I2t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

x In

2

2.5

3

4

5

6

8

10

1.

5

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

.4

.5

.6

.7.8.9

.95

.98

1

Ir

x In

40

%

%

100

06133352

Rev. 01, 07/2012 Section 1—General Information

Ground-Fault Protection

Equipment ground-fault protection protects

conductors against overheating and faults from

ground-fault currents (d1200 A).

• Equipment ground-fault protection is

standard on 6.0A trip units.

• Ground-fault pickup (Ig) (A) sets ground

current level where circuit breaker will trip

after the preset time delay.

• Ground-fault delay (tg) (B) sets the length of

time that the circuit breaker will carry a

ground-fault current above the ground-fault

pickup current level before tripping.

• Equipment ground-fault protection can be

zone-selective interlocked (ZSI) with

upstream or downstream circuit breakers.

• Setting the ground-fault delay (tg) to the 0

setting turns off zone-selective interlocking.

• Neutral protection and equipment ground-

fault protection are independent and can

operate concurrently.

Figure 10: Ground-Fault Protection Switches

long time

Ir

.7.8.9

06133351

.6

.5

.4

x In

short time

Isd

3

2.5

2

1.

5

x Ir

setting

Ig tg

D

C

B

A

ground fault

tr

(s)

.95

.98

1

4

(s)

5

.

6

.

8

10

on I2t

E

(s)

F

.

G

.

H

J

on I2t

alarm

8

4

12

16

2

1

20

24

.5

@

6 Ir

instantaneous

I itsd

.

4

8

.

3

.

4

3

2

.

1

delay

.

4

.

4

3

2

.

1

10

5

.

2

4

12

.

1

3

15

0

2

off

off

x In

test

.

3

.

2

.

1

0

off

Table 4: Micrologic Trip Unit Ground-Fault Pickup Values

Ig (= In x....) ABCDEFG H J

In d 400 A 0.3 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

400 A < In d 1200 A 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

In > 1200 A 500 A 640 A 720 A 800 A 880 A 960 A 1040 A 1120 A 1200 A

In = sensor rating.

Ig = ground-fault pickup.

Table 5: Micrologic Trip Unit Ground-Fault Delay Values

ENGLISH

Indicator Lights

Overload Indicator Light

The overload indicator light (A) lights when the Ir

long-time pickup level has been exceeded (over

100% on the bar graph).

Setting Ground-Fault Delay

I2t off (ms at In) (seconds) 0 0.1 0.2 0.3 0.4

2

t on (ms at In) (seconds) – 0.1 0.2 0.3 0.4

I

tsd (min. trip) (milliseconds) 20 80 140 230 350

tsd (max. trip) (milliseconds) 80 140 200 320 500

NOTE: Use I2t off with ZSI for proper coordination. Using I2t on with ZSI is

not recommended as the delay in the upstream device receiving a restraint

signal could result in the trip unit tripping in a time shorter than the

published trip curve.

Figure 11: Overload Indicator Light

A

© 1999–2012 Schneider Electric All Rights Reserved

13-EN

Page 16

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

Micrologic 6.0 A

06133245

menu

40

100

%

%

Section 1—General Information Rev. 01, 07/2012

ENGLISH

Trip Indicator Lights

The Ir trip indicator light (A) lights when a trip

occurs because the Ir long-time pickup level was

exceeded.

The Isd/Ii trip indicator light (B) lights when a trip

occurs because the Isd short-time pickup or the

Ii instantaneous pickup was exceeded.

The Ig trip indicator light (C) lights when a trip

occurs because the Ig ground fault pickup was

exceeded.

The Ap self-protection indicator light (D) lights

when the trip unit overheats, the instantaneous

override level is exceeded, or a trip unit power

supply failure occurs.

Ammeter

The ammeter monitors and displays the circuit

breaker currents. An alphanumeric screen (A)

continuously displays the phase at the highest

load. Navigation buttons (B) can be pressed to

display the various monitored currents.

The process of checking the ammeter values

can be stopped at any time. After several

seconds, Micrologic trip units automatically

return to displaying the phase at the highest

load.

See the following section for addition information

concerning the ammeter.

Figure 12: Trip Indicator Lights

C

B

A

D

Figure 13: Ammeter

A

B

Trip Unit Testing Trip unit functions can be tested using primary injection testing or secondary

injection testing.

Micrologic Trip Unit Configuration

Control Power The A trip unit was designed to be used with or without an external 24 Vdc

Table 6: Pickup Values

Sensor Plug Value

(In)

100–250 A 30% of Sensor Rating

400–1200 A 20% of Sensor Rating

1600–6300 A 500 A

Minimum Ground-Fault

Pickup

power supply.

The following will be powered and functional even if the trip unit is not

externally powered:

• Fault protection for LSIG functions. The A trip unit is fully circuit powered

for fault protection.

• LED trip indication (powered by an onboard battery). The battery’s only

function is to provide LED indication if all other power is off

• All display functions and trip unit features power-up with current flow on

one phase greater than or equal to the values in Table 6.

• Ground-fault push-to-trip button works for testing ground fault with

current flow on one phase greater than or equal to the values in Table 6.

The ground-fault push-to-trip is also functional if a Hand-Held Test Kit or

Full-Function Test Kit is powering the trip unit.

© 1999–2012 Schneider Electric All Rights Reserved14-EN

Page 17

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

CAUTION

Connections UC3

F1 (-)

F2 (+)

24 Vdc

Rev. 01, 07/2012 Section 1—General Information

The following will be powered and functional with external power:

• All of the above functions which are functional without external power.

• Ammeter and bar graph displays are functional with or without current

flowing through the circuit breaker. With current flow between 0 and 20%

of sensor value, the ammeter may not be accurate.

• Trip settings and max. current readings can be accessed on the display

be pressing the navigation buttons with or without current flowing

through the circuit breaker.

• Ground-fault push-to-trip button works for testing ground fault with or

without current flowing through the circuit breaker.

• Optional Modbus communications are functional, using a separate 24

Vdc power supply for the circuit breaker communications module. This

separate 24 Vdc power supply is required to maintain the isolation

between the trip unit and communications.

The ground-fault push-to-trip is also functional if a Hand-Held Test Kit or

Full-Function Test Kit is powering the trip unit.

External Power Supply

The trip unit display can be powered by a 24 Vdc external power supply.

Table 7: Power Supply Specifications

ENGLISH

HAZARD OF SHOCK, ARC FLASH OR

EQUIPMENT DAMAGE

Trip unit and communication module must use

separate power supplies.

Failure to follow this instruction can result

in personal injury or equipment damage.

Function Specification

Power for Trip Unit Alone 24 Vdc, 50 mA

Minimum Input-to-Output Isolation 2400 V

Output (Including Max. 1% Ripple) ±5%

Dielectric Withstand (Input/Output) 3 kV rms

Connections

Power supply is used for graphic scree display when the circuit breaker is

open or not carrying current.

© 1999–2012 Schneider Electric All Rights Reserved

15-EN

Page 18

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

B

menu

40

100

%

%

0

%

A

Ir=

06133353

40

100

%

%

A

06133354

Section 2—Ammeter Rev. 01, 07/2012

Section 2—Ammeter

ENGLISH

Display NOTE: The ammeter display will function only if the trip unit is powered. The

trip unit is powered by the circuit breaker carrying more than 0.20 x In of

load current, by being connected to a 24 Vdc external power supply, or by

having the Full-Function Test Kit or Hand-Held Test Kit connected and on.

Even with external power supplied, current through the circuit breaker must

exceed 0.20 x In for the ammeter reading to be accurate to within 1.5%.

A. Alphanumeric screen: Displays ammeter

information

B. Bar graph: Displays currents using an LED

bar graph

C. Menu button: Used to navigate between the

various menus

D. Scroll button: Used to scroll to the next

screen in the menus

The default display is the current value of the

phase at the highest load.

If no information is displayed, contact the local

field office.

Ammeter Measurements

Micrologic A trip units measure the true RMS

value of currents. They provide continuous

current measurement from 0.2 to 20 x In with an

accuracy of 1.5% (including sensors). No

auxiliary source is needed where I > 0.2 x In.

The optional external power supply (24 Vdc)

makes it possible to display currents where

I < 0.2 x In and to store values of the interrupted

current.

A digital LCD screen continuously displays the

most heavily loaded phases (Imax) or displays

the Ia, Ib, Ic, Ig, and (on 4-pole circuit breakers

only) In stored current and setting values by

successively pressing the navigation button.

Figure 14: Ammeter

06133245

A

C

D

Accessing Information

Three different menus can be accessed:

A. Current measurements

Figure 15: Menus

A–Currents

B–Peak Currents

06133355

C–Switch Settings

Max

A

B. Stored peak current measurements

C. Switch settings

In addition, the ammeter can be used to address

the circuit breaker communication module

(BCM) in circuit breakers which have the

optional circuit breaker communication module

installed.

1.125 x Ir

1 x Ir

0.8 x Ir

0.6 x Ir

0.4 x Ir

%

100

%

40

© 1999–2012 Schneider Electric All Rights Reserved16-EN

100

4

%

Page 19

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

menu

u

33356

40

100

%

%

A

06133343

06134248

Rev. 01, 07/2012 Section 2—Ammeter

To access the next menu, press the menu

button (A). To access the next screen in a menu,

press the scroll button (B).

Current Menu

The current (default) menu displays:

A. Phase current (IA) in A phase

B. Phase current (IB) in B phase

C. Phase current (IC) in C phase

D. Ground-fault current (Ig) (Micrologic 6.0A trip

units only)

E. Neutral current (In)

To display next current, press scroll button.

NOTE: Neutral current is only displayed with a

4-pole circuit breaker with the neutral protection

set to half or full. Refer to bulletin 48041-082-03

for NC CT wiring guidelines.

Figure 16: Navigation Buttons

A

1

B

Figure 17: Current Menus

A–A-Phase Current (IA)

06133354

%

100

%

40

C–C-Phase Current (IC)

06134248

A

B–B-Phase Current (IB)

06133342

A

%

100

%

40

D–Ground-Fault Current (Ig)

ENGLISH

06134248

E–Neutral Current (In)

06133345

%

100

%

40

06134248

06134248

A

06133344

%

100

%

40

Return to A-Phase Current

06133354

%

100

%

40

A

A

06134248

© 1999–2012 Schneider Electric All Rights Reserved

17-EN

Page 20

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

40

100

%

%

A

Max

06133355

40

100

%

%

A

06133354

menu

06134247

06134248

40

100

%

%

A

Max

06133349

40

100

%

%

A

Max

06133346

C–Peak C-Phase Current (IpC)

06134248

E–Peak Neutral Current (Ipn)

Return to Peak A-Phase Current

Section 2—Ammeter Rev. 01, 07/2012

ENGLISH

Peak Menu

To access the peak menu:

1. Current menu is displayed.

2. Press menu button.

3. Peak menu appears.

To access menu screens, press scroll button.

The peak menu displays:

A. Peak current (IpA) in A phase

B. Peak current (IpB) in B phase

C. Peak current (IpC) in C phase

D. Peak ground-fault current (Ipg) (Micrologic

E. Peak neutral current (Ipn)

To display next peak current, press scroll button.

To reset a max value, scroll to the particular max

value screen to be reset and hold the scroll

button for three seconds.

6.0A trip unit only)

Figure 18: Access the Peak Menu

Current Menu

Figure 19: Peak Menus

A–Peak A-Phase Current (IpA)

06133355

100

40

Max

06134248

A

%

%

Peak Menu

B–Peak B-Phase Current (IpB)

06134248

06133347

100

40

D–Peak Ground-Fault Current (Ipg)

Max

06134248

A

%

%

06134248

06133348

100

40

06133355

100

40

Max

A

%

%

Max

A

%

%

© 1999–2012 Schneider Electric All Rights Reserved18-EN

Page 21

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

100

%

A

Ir=

06133353

100

%

A

Max

06133355

menu

06134247

Ii=

06133387

A

A

Ir=

06133382

06134248

s

tr=

06133383

A

Isd=

06133384

A

Ig=

06133388

s

tg=

06133389

06134248

06134248

D–tsd Setting

06134248

06134248

E–Ii Setting

F–Ig Setting

06134248

100

%

A

Ir=

06133353

menu

06134247

Switch Settings Menu

Current Menu

100

%

A

06133354

Rev. 01, 07/2012 Section 2—Ammeter

Switch Settings Menu

The switch settings menu displays the values at

which the switches are set.

To access the switch settings menu:

1. Peak menu is displayed.

2. Press menu button.

3. Switch settings menu will appear.

To access menu screens, press scroll button.

The switch settings menu displays:

A. Long-time pickup (Ir) setting

B. Long-time delay (tr) setting

C. Short-time pickup (Isd) setting

D. Short-time delay (tsd) setting

E. Instantaneous pickup (Ii) setting

F. Ground-fault pickup (Ig) setting (6.0A trip

units only)

G. Ground-fault delay (tg) setting (6.0A trip

units only)

To display next switch setting, press scroll

button.

Figure 20: Access the Switch Settings Menu

Peak Menu

Switch Settings Menu

Figure 21: Trip Unit Switch Settings

A–Ir Setting

C–Isd Setting

B–tr Setting

tsd=

06133385

06134248

s

06134248

ENGLISH

To return to the current menu:

1. Switch settings menu is displayed.

2. Press menu button.

3. Current menu will appear.

Or wait several seconds and ammeter will

automatically return to the current (i.e., default)

menu.

© 1999–2012 Schneider Electric All Rights Reserved

G–tg Setting

A–Ir Setting

06133382

Ir=

A

Figure 22: Return to Current Menu

19-EN

Page 22

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

06133205

33

06

06133207

06133208

0 Ir Isd

t

06134245

alarm

x Ir

2

2.5

3

4

5

6

8

10

1.5

setting

Isd

instantaneous

.4

.5

.6

.7.8.9

.95

.98

1

long time

Ir

x In

06134251

Section 3—Operation Rev. 01, 07/2012

Section 3—Operation

ENGLISH

Switch Setting Adjustment

1. Open switch cover (A).

2. Adjust the appropriate switches (B) to

desired values.

3. Replace switch cover. Use wire seal

MICROTUSEAL (C, not provided), if

necessary, to provide tamper evidence.

Examples

Circuit breaker is rated 2000 A.

Figure 23: Adjust Switch Settings

2

1

A

B

Figure 24: Circuit Breaker Rating

C

Micrologic 2.0A Trip Unit

1. Set pickup levels.

In 2000 A

Figure 25: Set Pickup Levels

In = 2000 A

Ir = 0.7 x In = 1400 A

Isd = 2 x Ir = 2800 A

© 1999–2012 Schneider Electric All Rights Reserved20-EN

Page 23

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

long time

alarm

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

06133211

0 I

t

tr

06133212

6 x Ir

1 s

0 I

t

Ir

Ii

06133210

Ii = 3 x In = 6000 A

alarm

x In

2

3

4

5

6

8

10

12

1.5

setting

Ii

instantaneous

.4

.5

.6

.7.8.9

.95

.98

1

long time

Ir

x In

06133209

In = 2000 A

Ir = 0.7 x In = 1400 A

1400 A

6000 A

long time

alarm

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

06133211

0 I

t

tr

06133212

6 x Ir

1 s

06133213

.4

.5

.6

.7.8.9

.95

.98

1

setting

short tim

e

I i

x Ir

2

2.5

3

4

5

6

8

10

Isd

1.5

off

instantaneous

long time

alarm

Ir

x In

x In

3

4

6

8

10

12

15

off

2

Ii = 6 x In = 12000 A

In = 2000 A

Ir = 0.7 x In = 1400 A

Isd = 2 x Ir = 2800 A

1400 A

2800 A

12000 A

Rev. 01, 07/2012 Section 3—Operation

2. Set time delay. Figure 26: Set Time Delay

tr = 1 s (at 6 x Ir)

ENGLISH

Micrologic 3.0A Trip Unit

Figure 27: Set Pickup Levels

1. Set pickup levels.

2. Set time delay. Figure 28: Set Time Delay

tr = 1 s (at 6 x Ir)

Micrologic 5.0A Trip Unit

1. Set pickup levels.

© 1999–2012 Schneider Electric All Rights Reserved

Figure 29: Set Pickup Levels

t

Ir

06133214

Isd

0

Ii

I

21-EN

Page 24

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

tr

tsd

0

t

06133217

6 x Ir

1 s

10 x Ir

0.2 s

Ir

Isd

Ii

0

I

t

06133214

0

t

g

33359

A

short time

instantaneous

long time

alarm

ground faul

t

.5

1

2

4

8

12

16

20

tr

(s)

@

6 Ir

24

delay

tsd

(s)

on I2t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

tg

(s)

on I2t

.2

.3

.4

.4

.1

.2

.3

.1

0

off

I2t on I2t off

06133358

0

t

g

3336

Section 3—Operation Rev. 01, 07/2012

ENGLISH

2. Set time delay. Figure 30: Set Time Delays

Micrologic 6.0A Trip Unit

1. Set pickup levels.

06133215

long time

short time

tr

(s)

4

2

1

.5

tsd

.

.

3

.

2

.

1

on

alarm

8

12

16

20

24

6 Ir

@

.

4

.

3

4

.

2

.

1

0

2

I

t

delay

Figure 31: Set Pickup Levels

Ir

06133357

.6

.5

Is

2.5

Ig

long time

.7.8.9

.4

short time

3

2

1.5

setting

D

C

B

A

gr

ound fault

x In

x Ir

.95

.98

1

4

5

6

8

1

E

F

G

H

J

alarm

instantaneous

I

8

6

4

3

2

x In

10

12

15

off

tr = 1 s (at 6 x Ir)

tsd = 0.2 s I2t on

I2t on I2t off

In = 2000 A

Ir = 0.7 x In = 1400 A

Ii = 6 x In = 12000 A

Isd = 2 x Ir = 2800 A

BoIg = 640 A

1400 A

1

2800 A

12000 A

I

2. Set time delays. Figure 32: Set Pickup Levels

tr = 1 s (at 6 x Ir)

tsd = 0.2 s I2t on

tg = 0.2 s I2t on

© 1999–2012 Schneider Electric All Rights Reserved22-EN

0.2 s

0.2 s

1 s

t

06133217

0

1

1

640

6 x Ir

tr

10 x Ir

t

tsd

I

Page 25

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

Rev. 01, 07/2012 Section 3—Operation

Zone-Selective Interlocking (ZSI)

The number of devices which can be interlocked

are shown in Table 8.

Table 8: ZSI Combinations

Upstream Device

(receives input from RIM)

Downstream Device

(sends output to RIM)

Micrologic #.0x Trip Units

Square D Micrologic Series B Trip Units

Square D GC-100 Ground-Fault Relay

for Equipment Protection

Square D GC-200 Ground-Fault Relay

for Equipment Protection

Micrologic #.0x Trip Units

Square D Micrologic Series B Trip Units

Square D GC-100 Ground-Fault Relay

for Equipment Protection

Square D GC-200 Ground-Fault Relay for

Equipment Protection

Merlin Gerin STR58 Trip Units

Federal Pioneer USRC and USRCM Trip Units

15R R 1515R

R26RRR15

RR7 RRR

15R R 1515R

ENGLISH

Circuit breaker terminals are shipped with

terminals Z3, Z4 and Z5 jumpered to selfrestrain the short-time and ground-fault

functions. Remove the jumpers when activating

zone-selective interlocking.

Merlin Gerin STR58 Trip Units

Merlin Gerin STR53 Trip Units

Federal Pioneer USRC and USRCM Trip

Units

Square D Add-On Ground Fault Module

for Equipment Protection

R—RIM module is required to restrain any devices.

Numerical References—Maximum number of upstream circuit breakers which can be restrained

without requiring a RIM Module.

15R R 1515R

15R R 1515R

R15RRR15

R5 RRRR

Figure 33: Jumpered Terminals

UC1

Z5

M1

Z3

Z4

Z2

Z1

Auxiliary Connections

© 1999–2012 Schneider Electric All Rights Reserved

23-EN

Page 26

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

100

%

A

06133354

%

06133703

u

33

0

Section 3—Operation Rev. 01, 07/2012

ENGLISH

interlocking.

Communication Module values

If the optional circuit breaker communication

module (BCM) is installed, use the ammeter to

set communication module values.

To access the communication module menu:

1. Current menu is displayed.

2. Simultaneously press both menu button and

3. Communication module addressing menu

Wire circuit breakers for zone-selective

scroll button down for three seconds.

will appear.

Figure 34: ZSI Wiring Example

UC1

Z5

M1

Z3

Z4

Z2

Secondary

Connector

Position

Z1

Z2

Z3

Z4

Z5

Z1

Auxiliary

Connections 1

Description

ZSI out signal

ZSI out

ZSI in signal

ZSI in short time

ZSI in ground fault

UC1

Z5

M1

Z3

Z4

Z2

Z1

Auxiliary

Connections 2

Figure 35: Access Communication Module Menu

Current Menu

7

7

men

1

Communications Address

UC1

Z5

M1

Z3

Z4

Z2

Z1

Auxiliary

Connections 3

© 1999–2012 Schneider Electric All Rights Reserved24-EN

Page 27

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

06133703

06134248

Communications Address

06133704

06133704

06133705

06134248

06133705

06134888

Parity

Language

06134248

06134888

06134248

Rev. 01, 07/2012 Section 3—Operation

Set communication module values:

1. Press and release scroll button to sequence

addresses (1 through 47). When the correct

address number is reached, enter the value

by pressing and holding scroll button until

the display stops flashing.

Baud rate screen will appear after address

has been entered.

2. Press and release scroll button to sequence

baud rates (4.8k, 9.6k or 19.2k). When the

desired baud rate appears, enter the value

by pressing and holding scroll button until

the display stops flashing.

Parity screen will appear after baud rate has

been entered.

3. Press and release scroll button to sequence

parities (E [even] or n [none]). When the

desired parity appears, enter the value by

pressing and holding scroll button until the

display stops flashing.

Languages screen will appear after parity

has been entered.

4. Press and release scroll button to scroll

through languages (French [Fr], US English

[En US], UK English [En], German [d],

Spanish [SP] or Italian [It]). When the

desired language appears, enter the value

by pressing and holding scroll button until

the display stops flashing.

Ammeter display will return to the default

screen after language is entered.

After the communication module values have

been set, ammeter will automatically return to

the current (i.e., default) menu.

After setting circuit breaker communication

module values, drawout circuit breakers must

have the cradle communication module, if

available, activated. For drawout circuit

breakers, refer to the cradle communication

module instructions to complete setup.

Figure 36: Set Communication Module Values

Baud Rate

06134248

Baud Rate

06134248

06134248

Language

06134248

Parity

ENGLISH

© 1999–2012 Schneider Electric All Rights Reserved

25-EN

Page 28

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

A

Ir=

06133382

menu

06134247

s

tr=

06133383

06134248

A

Isd=

06133384

s

tsd=

06133385

06134248

Ii=

06133387

A

06134248

A

Ig=

06133388

06134248

s

tg=

06133389

06133205

06133218

Section 3—Operation Rev. 01, 07/2012

ENGLISH

Trip Unit Settings Check

Use the ammeter switch setting menu to check

the trip unit settings.

1. Press menu button twice.

2. Switch settings menu will appear.

3. Press scroll button to advance to next

4. After checking trip unit settings, press menu

screen.

button once to return to main menu.

Table 9: Trip Unit Settings

Setting Window 2.0A 3.0A 5.0A 6.0A

menu

Ir

tr

Isd

tsd

Long-Time

Pickup

Long-Time

Delay

Short-Time

Pickup

Short-Time

Delay

06134247

XXXX

06134248

XXXX

XXX

06134248

XX

Trip Unit Operation Verification

Use a test kit connected to the trip unit test plug

receptacle (A) to verify trip unit is functioning as

desired. See instructions shipped with test kit to

perform verification tests.

Instantaneous

Ii

Pickup

Ground-Fault

Ig

Pickup

Ground-Fault

tg

Delay

Figure 37: Verify Trip Unit Operation

XXX

X

X

A

© 1999–2012 Schneider Electric All Rights Reserved26-EN

Page 29

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

06134249

M

icro

log

ic

6.0 A

4

0

1

0

0

%

%

men

u

06133379

A

B

Charged

Half-Charged

Change Battery

Rev. 01, 07/2012 Section 3—Operation

Equipment Ground-Fault Trip

Functions Testing

Paragraph 230-95 (c) of the National Electrical

Code requires that all equipment ground-fault

protection systems be tested when first installed.

With the circuit breaker closed, test the groundfault (Micrologic 6.0A trip unit only) trip

functions. For instructions on how to close circuit

breaker, refer to the circuit breaker installation

instructions shipped with the circuit breaker.

1. Press the ground-fault test button (A). Circuit

breaker should trip.

2. If circuit breaker does not trip, contact the

local field office.

Trip Unit Resetting

When the circuit breaker trips, the fault indicator

will remain lit until the trip unit is reset.

Press the reset/test button (A) to reset the trip

unit after trip.

Do not return circuit breaker to service until cause

of trip is determined. For more information, refer

to the circuit breaker installation instructions

shipped with the circuit breaker.

NOTE: Trip unit must be powered to test ground-fault trip function. The trip

unit is powered if the circuit breaker is carrying more than 0.20 x In of load

current, if the 24 Vdc external power supply is connected or if the FullFunction Test Kit or Hand-Held Test Kit is connected and on.

Figure 38: Test Equipment Ground-Fault Trip Function

A

Figure 39: Reset Trip Unit

Micrologic 6.0

A

ENGLISH

Trip Unit Status Check

To check trip unit battery and trip indicators,

press the test/reset button (A).

• All trip indicators (B) will light up

• Battery status will be displayed

• If no battery status is displayed, there is no

battery installed.

• The battery bar graph reading is valid after

the reset button has been released.

• If the battery bar graph shows the battery

needs to be changed, use Square D battery

catalog number S33593:

— lithium battery

— 1.2AA, 3.6 V, 800 ma/h

For instructions on replacing battery, see

Section 6—Battery Replacement.

© 1999–2012 Schneider Electric All Rights Reserved

NOTE: Trip unit must be powered to test battery. The trip unit is powered if

the circuit breaker is carrying more than 0.20 x In of load current, if the 24

Vdc external power supply is connected or if the Full-Function Test Kit or

Hand-Held Test Kit is connected and on.

Figure 40: Check Trip Unit Status

Micrologic 6.0

06133379

27-EN

Page 30

Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units 48049-136-05

DANGER

Section 4—Trip Unit Replacement Rev. 01, 07/2012

Section 4—Trip Unit Replacement

ENGLISH

Trip unit replacement must be done by qualified

persons, as defined by the National Electric

Code, who are familiar with the installation and

maintenance of power circuit breakers.

Before replacing trip unit, confirm that the circuit

breaker is in good working condition. If the

condition of the circuit breaker is unknown, do

not proceed. For assistance in evaluating the

condition of the circuit breaker, call Technical

Support.

Read this entire section before starting the

replacement procedure.

NOTE: If trip unit being replaced is a Micrologic

2.0, 3.0 or 5.0 trip unit, order connector block

S33101 and circuit breaker or cradle wiring

harness if necessary.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Failure to follow these instructions for installation, trip test and primary

injection testing may result in the failure of some or all protective function.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E or CSA Z462.

• Replacement/upgrading of a trip unit in the field must be done by

qualified persons, as defined by the National Electric Code, who are

familiar with the installation and maintenance of power circuit breakers.

• Before replacing/upgrading trip unit, confirm that the circuit breaker is in

good working condition. If the condition of the circuit breaker is unknown,

do not proceed. For assistance in evaluating the condition of the circuit

breaker, call Technical Support.

• If the circuit breaker fails to function properly in any manner upon

completion of the trip unit installation, immediately remove the circuit

breaker from service and call Field Services.

• Turn off all power supplying this equipment before working on or inside

equipment. Follow instructions shipped with circuit breaker to disconnect

and reconnect circuit breaker.

• Replace all devices, doors and covers before returning equipment to

service.

Failure to follow this instruction will result in death or serious injury.

Required Tools • Torque-controlled screwdriver, set at 7 in-lbs (0.8 N•m) ± 10%

(Lindstrom torque driver MAL500-2 or equivalent)

• Micrologic Full-Function Test Kit (part number S33595)

Preparation

Record Switch Settings Record all trip unit switch settings for later use.

Circuit Breaker Disconnection Disconnect circuit breaker as directed in the circuit breaker instruction

bulletin shipped with the circuit breaker. The circuit breaker must be

completely isolated. (For a drawout circuit breaker, place circuit breaker in

the disconnected position. For a fixed-mounted circuit breaker, all voltage

sources, including auxiliary power, must be disconnected.)

Circuit Breaker Accessory Cover

Removal

Remove circuit breaker accessory cover as directed in the Install

Accessories section of the circuit breaker instruction bulletin shipped with

the circuit breaker.

© 1999–2012 Schneider Electric All Rights Reserved28-EN

Page 31

48049-136-05 Micrologic™ 2.0A, 3.0A, 5.0A, and 6.0A Electronic Trip Units

s

et

t

ing

d

ela

y

sho

rt

t

i

m

e

I

i

x

Ir

2

2

.5

3

4

5

6

8

1

0

Is

d

1

.

5

t

sd

o

n

I

2

t

.

2

.

3

.

4

.

4

.

1

.

2

.

3

.

1

0

i

n

st

a

nt

ane

ous

x

In

2

2

.

5

3

4

5

6

8

1

0

1

.

5

.4

.5

.6

.7

.8

.

9

.95

.98

1

lon

g

ti

m

e

alar

m

Ir

x

In

.5

1

2

4

8

1

2

1

6

2

0

t

r

(s

)

@ 6

Ir

2

4

06133222

06134853

06134854

333

5

Micrologic 6.0 A

06133245

Rev. 01, 07/2012 Section 4—Trip Unit Replacement

Rating Plug Removal

A small Phillips screwdriver is needed to remove

the adjustable rating plug.

1. Open switch cover (A).

2. Unscrew adjustable rating plug mounting