Page 1

2230-018

Pneumatic Room Humidistat

Installation Instructions

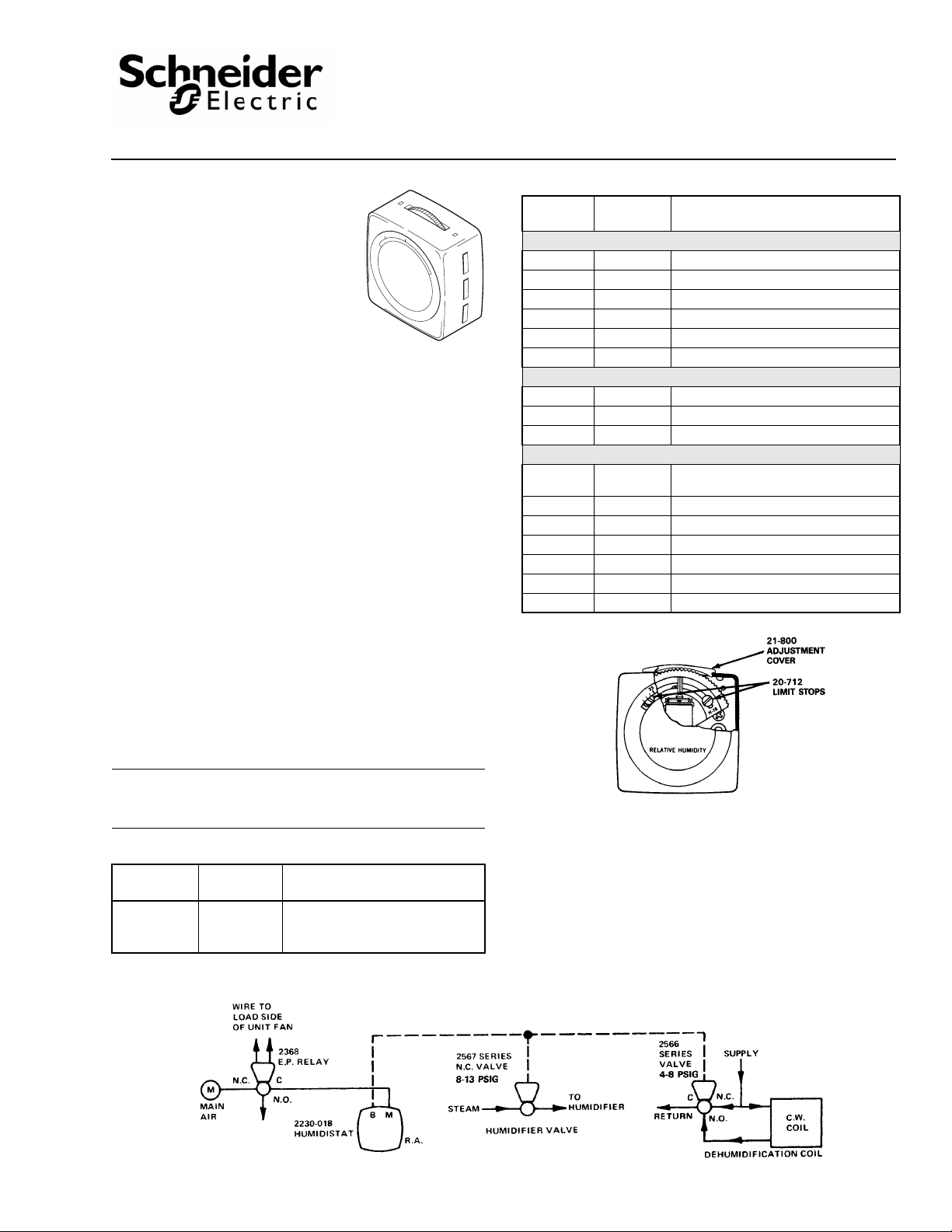

APPLICATION

The 2230-018 Pneumatic Room Humidistat

is a proportioning-type device designed to

control pneumatic valves or damper

actuators associated with heating or cooling

coils, humidifiers, air washers, or other

humidifying or dehumidifying equipment to

maintain constant relative humidity. This

device uses a highly sensitive hygroscopic

nylon ribbon and a pilot bleed relay with

pneumatic feedback. Throttling range, action

(direct or reverse), and set point are easily adjusted by graduated

dials. Internal limit stops are available to restrict adjustment range

when required.

The component parts are die cast alumin

glass-filled nylon. Diaphragms are fabric-reinforced neoprene. Air

lines are connected to the humidistat with spring-reinforced plastic

tubes, and both main and branch connections are provided with

internal filters.

20

50

90

um, stainless steel, and

SPECIFICATIONS

Action: Proportional, direct or reverse (factory set for reverse

action)

Range: 20% to 90% R.H.

Throttling range: Adjustable 5% to 15% (factory set @ 10%)

Main air pressure*: 20 psig (137.8 kPa) operating, 30 psig (206.8

a) maximum

kP

Air consumption: 17 scim (4.6 mL/s) (DA), 30 scim

(8.2 mL/s) (RA)

Ambient temperature limits:

Shipping & storage, -40 to 150°F (-40 to 65°C)

Operating, 40 to 140°F (4 to 60°C)

Calibration point: Factory calibrated @ 9 psig (62 kPa).

*When set for the reverse acting mode

drop below 16 psig (110.3 kPa). Pressure lower than 16 psig (1

a) will cause the humidistat to switch from reverse to direct acting.

kP

, main air pressure MUST NOT

10.3

Accessories

Part

Number

20-660 6-441 Cover screw

20-707 10-53 Metal thermostat guard

20-715 10-62 Clear thermostat guard

21-876 10-76 Opaque thermostat guard

21-928 Gray plastic cover, blank dial

21-933 Gray plastic cover,

20-881 N2-4 Calibration wrench

22-138 MCS-GA Branch tap gauge adaptor

900-002

10-82-SS

20-850 10-82 Outlet box mounting plate, black

20-642 Mounting ring

21-473 Snap-in drywall mounting

22-021 Universal drywall mounting kit

22-022 N5-95 Competitor replacement mounting kit

22-024 Standard mounting kit

Replaces

Model

Description

Accessories

°F/°C dial

Calibration

Thermostat calibration kit

Installation

Outlet box mounting plate, stainless

l

stee

Caution: This device should be installed by a qualified person with

due regard for safety, as improper installation could result in a

hazardous condition.

Model Chart

Part Number

2230-018 H18-301

Replaces

Model

Description

Includes 1/4" by 3/16" barbed

couplings

mounting plate and screws.

, 20-693 tubing, standard

1. Humidistat should be located to sense average room

ity. Free circulation of air must exist and locations

humid

that are affected by drafts, radiant heat, water pipes, air

ducts, etc., should be avoided.

2. Mount Humidistat only after wall surface has been

ed. Allow the device time to reach ambient

finish

conditions before calibration.

Typical Applications

Printed in U.S.A. 6-10 Copyright 2010 Schneider Electric All Rights Reserved. F-274503-2

Page 2

Installation

Connect to

Main and Branch

Connect to Thermostat

Main and Branch

4 Eyelet

Tube Clamps

Eyelet

Tube Coupler

Tubing

Eyelet

Tube Coupler

Tools (not provided):

•

– Appropriate screwdriver for mounting the thermostat

– 20-881 Thermostat calibration and cover screw wrench (or

and 1/4" he

x wrenches)

1/16"

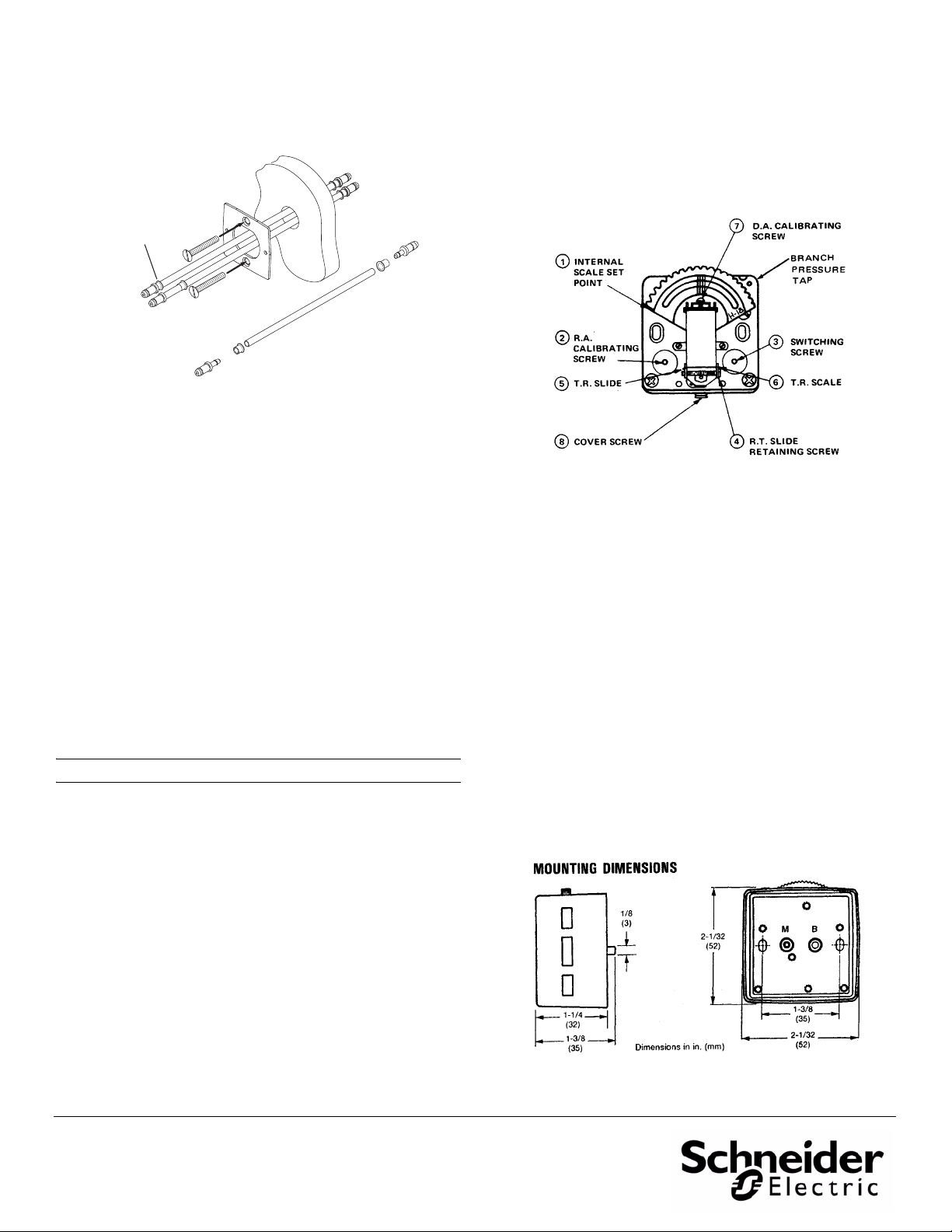

Figure-1

1. Assemble the eyelets and two tube couplers to tubing.

2. Connect the assembly by inserting the tube couplers into existin

tubing in the w

connection is Br

Pull tubing through center hole in mounting plate and screw mounting

3.

plate to w

all (Figure-1). Note which connection is Main and which

anch.

all with flat head screws. Cut tubing and insert two couplers.

The Main and Branch tubing is connected into the correspond

ports on the thermostat (Figure-1).

4. Affix thermostat to mounting ring with round head screws, taking care

not to kink

the tubing.

g

ing

Adjustments

The 2230-018 Humidistat is factory-set for a 10% throttling range, set in

reverse action, and calibrated for 9 psig (62 kPa) when the ambient relative

humidity equals the set point. It should not require calibration upon

installation unless the throttling range is changed.

If adjustments are to be made remove cover by turning the Allen screw (8)

om of co

until bott

follows.

Caution: Do not touch nylon ribbon.

To Set To Direct Action

Rotate the switching screw (3) ten complete turns counterclockwise. This

change should not interfere with the factory calibration or T.R. setting, and

no further adjustment should be necessary.

ver can be moved away from the wall, and proceed as

To Calibrate And Set Control Point

To check humidistat calibration, install a test gauge in the branch and rotate

the cam by adjusting the setpoint until 8-10 psig

(55-69 kPa)branch pressure is obtained (R.H. m

ust be within the range of

the humidistat). Loosen the T.R. slide retaining screw (4) and slide the T.R.

slide (5) to the desired throttling range setting on the T.R. scale (6), making

sure to keep the T.R. slide (5) parallel with the T.R. slide retaining screw (4).

Tighten this screw to secure the slide (do not over-tighten). Adjust the D.A.

calibrating screw (7) to restore 8-10 psig branch pressure.

Reverse Acting

To change calibration in the reverse action mode, adjust setpoint as given

for the calibration check procedure. Adjust the R.A. calibrating screw (2) to

obtain 8-10 psig (55-69 kPa) branch pressure. Clockwise rotation of screw

(2) causes branch pressure to decrease; counterclockwise rotation causes

it to increase. Do not force screw (2).

Direct Acting

To change calibration in the direct action mode, proceed as given for the

calibration check. Then adjust the D.A. calibrating screw (7) to obtain 8-10

psig (55-69 kPa) branch pressure.

To synchronize D.A. and R.A. calibrations, insert test gauge in branch line

and adjust setpoint to

actual humidity, as described above. Rotate switch

screw (3) clockwise until it is snug. Then rotate ten turns counterclockwise

and adjust D.A. calibrating screw (7) for 8-10 psig (55-69 kPa) branch

pressure. Then rotate switching screw clockwise until snug, and adjust the

R.A. Calibrating Screw (2) for 8-10 psig (55-69 kPa) branch pressure. The

instrument is now synchronized from R.A. to D.A. and may be used in either

mode without change in calibration.

Replace cover after making adjustments.

Mounting Dimensions

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-274503-2

To Set To Reverse Action

Control is factory set in reverse acting mode. If control is set in direct acting

mode, to restore to reverse action, rotate the switching screw (3) clockwise

until it becomes snug. Do not force the screw.

To Set Throttling Range

To change the throttling range, install a test gauge in the branch and rotate

the cam by adjusting the set point until 8-10 psig

(55-69 kPa) branch pressure.

October 1st, 2009, TAC became the Buildings business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric, however

On

there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate corporate brand

changes.

Loading...

Loading...