Page 1

Modicon

Lexium 17S Series SERCOS Servo Drive

User Guide

890 USE 121 00 Eng

Page 2

Page 3

Preface

Preface The data and illustratio ns f ound in this boo k are not bindin g. We reserve the right to

modify our products in line with our policy of continuous product development. The

information in this document is subject to change without notice and should not be

construed as a commitment by Schneider Electric.

Schneider Electric assumes no responsibility for any errors that may appear in this

document. If you have any suggestions for improvements or amendments or have

found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means,

electronic or mechanical, including photocopying, without express written

permission of the Publisher, Schneider Electric.

CAUTION!

All pertinent state, regional, and local safety regulations must be observed when

installing and using this product. For reasons of safety and to assure compliance

with documented sy st em d ata , re pa irs to c om po nen ts s hou ld be performed o nly b y

the manufacturer.

Failure to observe this precaution can result in injury or equipment damage.

MODSOFT® is a registered trademark of Schneider Electric.

®

(SERCOS

interface is a tradema rk o f SERC O S Inte rfac e, I nc ., pro mot io n so ci ety. )

The following are trademarks of Schneid er Electric:

Modbus Modbus Plus Modicon Quantum 984 Concept

IBM® and IBM AT® are registered trademar ks of International Business Machines

Corporation.

Microsoft® , MS-DOS®, Windows®, Windows 95®, Windows 98® and

Windows NT® are registered trademarks of Microsoft Corporation.

©Copyright 2001, Schneider Electric

890 USE 121 00 v

Page 4

Preface

vi

890 USE 121 00

Page 5

Contents

Chapter 1 Introduction

At a Glance...................................................................................................... 1

Document Scope.............................. ...... ..... ...... ........................................ 1

What’s in this Chapter ............................................................................... 1

About this User Guide .................................................................................... 2

Who Should Use this User Guide ............................................................. 2

How this User Guide Is Organized ............................................................ 2

Related System Components ......................................................................... 4

SERCOS Multi-Axis Motion Control System ............................................ . 4

UniLink Commissioning Software for 17S ................................................. 4

Related Documentation .................................................................................. 5

Documents................................................................................................. 5

Hazards, Warnings and Guidelines................................................................. 6

Hazards and Warnings ............................................................................. 6

Additional Safety Guidelines...................................................................... 9

Qualified Personnel ................................................................................... 9

Standards and Compliances .......................................................................... 1 0

European Directives and Standards ......................................................... 10

EC Directive Compliance .......................................................................... 10

SERCOS Standard .................... ............................................................... 11

UL and cUL Compliance ........................................................................... 11

Conventions .................................................................................................... 12

Acronyms and Abbreviations .................................................................... 12

890 USE 121 00 vii

Page 6

Contents

Chapter 2 Product Overview

At a Glance...................................................................................................... 15

Introduction ............................................................................................... 15

What’s in this Chapter ............................................................................... 15

The 17S Series SERCOS Drive Family ......................................................... 16

Introducing the 17S SERCOS Drive Family ............................................. 16

Drives Available ..................................... ..... .............................................. 16

Implementing the Drives ........................................................................... 16

Applicable Servo Motor Types .................................................................. 16

Electrical Considerations .......................................................................... 17

17S Drive Family Portrait .......................................................................... 18

17S Drives Front View ................................................. ...... ..... ...... ............ 19

Equipment Supplied .................................................................................. 20

Equipment Available ................................................................................. 20

17S System Configuration Diagram ......................................................... 21

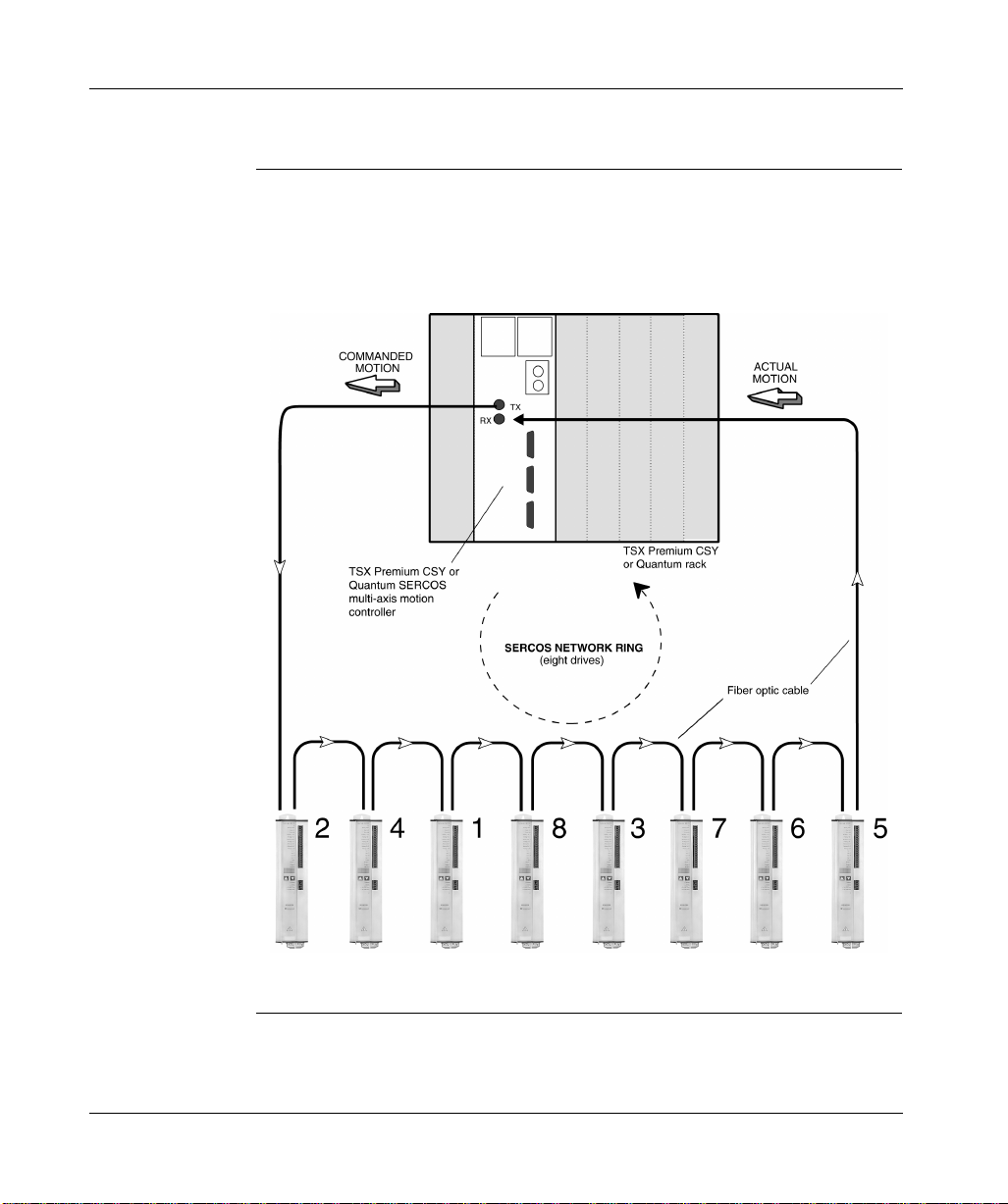

Modicon Multi-Axis Motion SERCOS Network Configuration ......................... 22

Overview ................................................................................................... 22

Which Motion Controllers run a SERCOS Network .................................. 22

SERCOS Fiber- Optic Transmit and Receive Connectors........................ 22

Example of a Typical SERCOS Network Ring Configuration ................... 23

Benefits of Fiber-Optic Communication .................................................... 24

Two Types of Fiber-Optic Communication ............................................... 24

Digital Control ........................................................................................... 25

Usability Enhancements ........................................................................... 26

viii

Overview of 17S Internal Electronics ............................................................. 27

17S Internal Electronics Block Diagram ................................................... 27

General Characteristics ............................................................................ 28

Primary Power .......................................................................................... 28

Bias Power ................................................................................................ 28

EMI Suppression ........................................ ...... ...... .................................. 28

Internal Power Section .............................................................................. 29

DC Link Capacitor Reconditioning ............................................................ 29

Integrated Safe Electrical Separation ................................................. ..... . 29

Keypad ...................................................................................................... 29

LED Display and Discrete Indicators ........................................................ 30

Overview of System Software ........................................................................ 31

Setup ........................................................................................................ 31

Setting Parameters ..................................... ...... ...... ..... ............................. 31

Default Settings .......................................... ...... ........................................ 31

UniLink Commissioning Software ............................................................. 32

890 USE 121 00

Page 7

Contents

Chapter 3 Mounting and Physical Dimensions

At a Glance...................................................................................................... 33

What’s in this Chapter ............................................................................... 33

Installation Safety Precautions ....................................................................... 34

Power Supply Overcurrent Protection .... ..... ...... ...... ..... ............................. 36

Earth Connections .................................................................................... 36

Cable Separation ...................................................................................... 36

Air Flow ..................................................................................................... 36

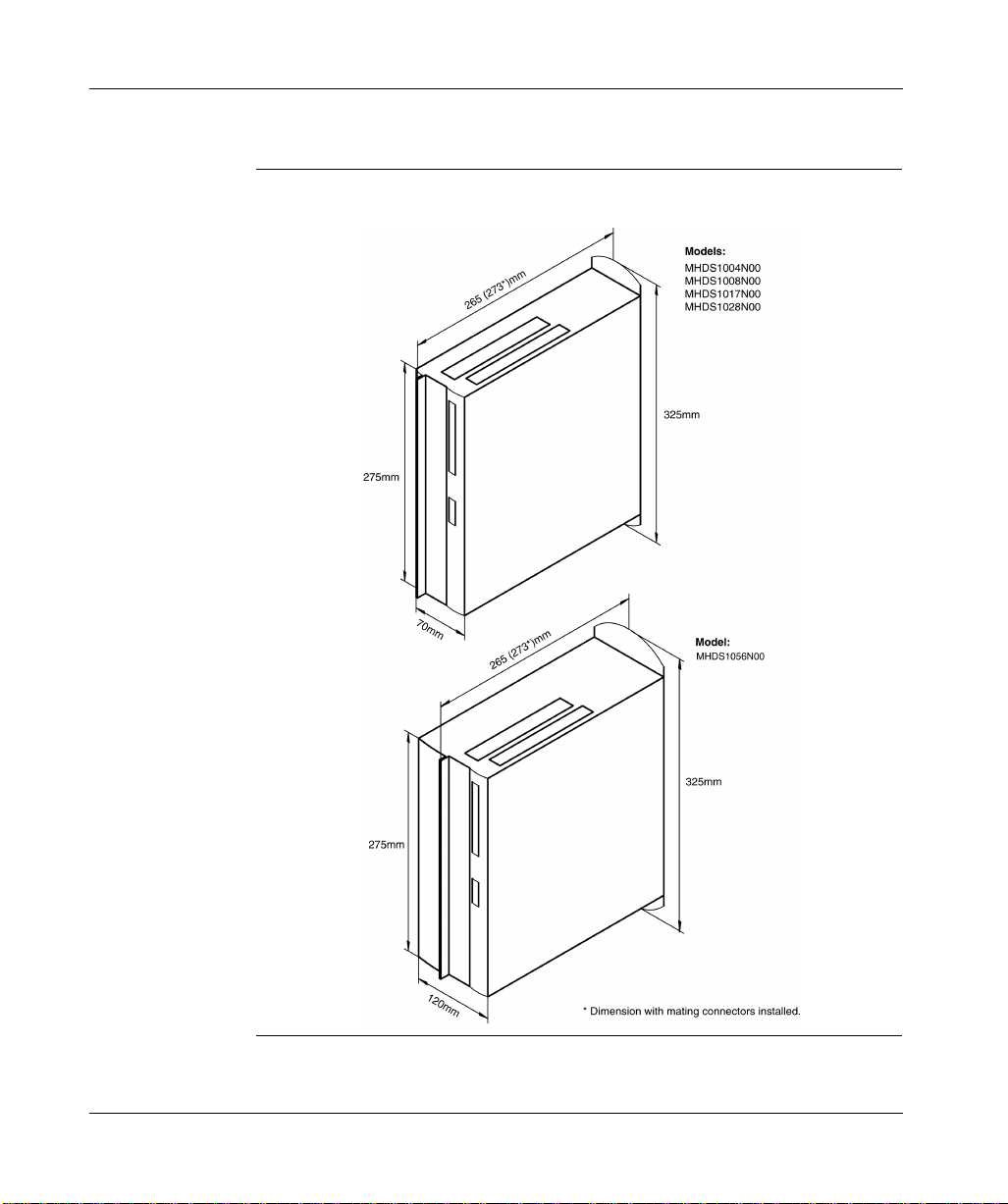

Drive Mounting and Physical Dimensions ...................................................... 37

17S Height, Width and Depth Dimensions .............. ..... ...... ..... .................. 37

17S Drive and Mounting Area Dimensions ............................................... 38

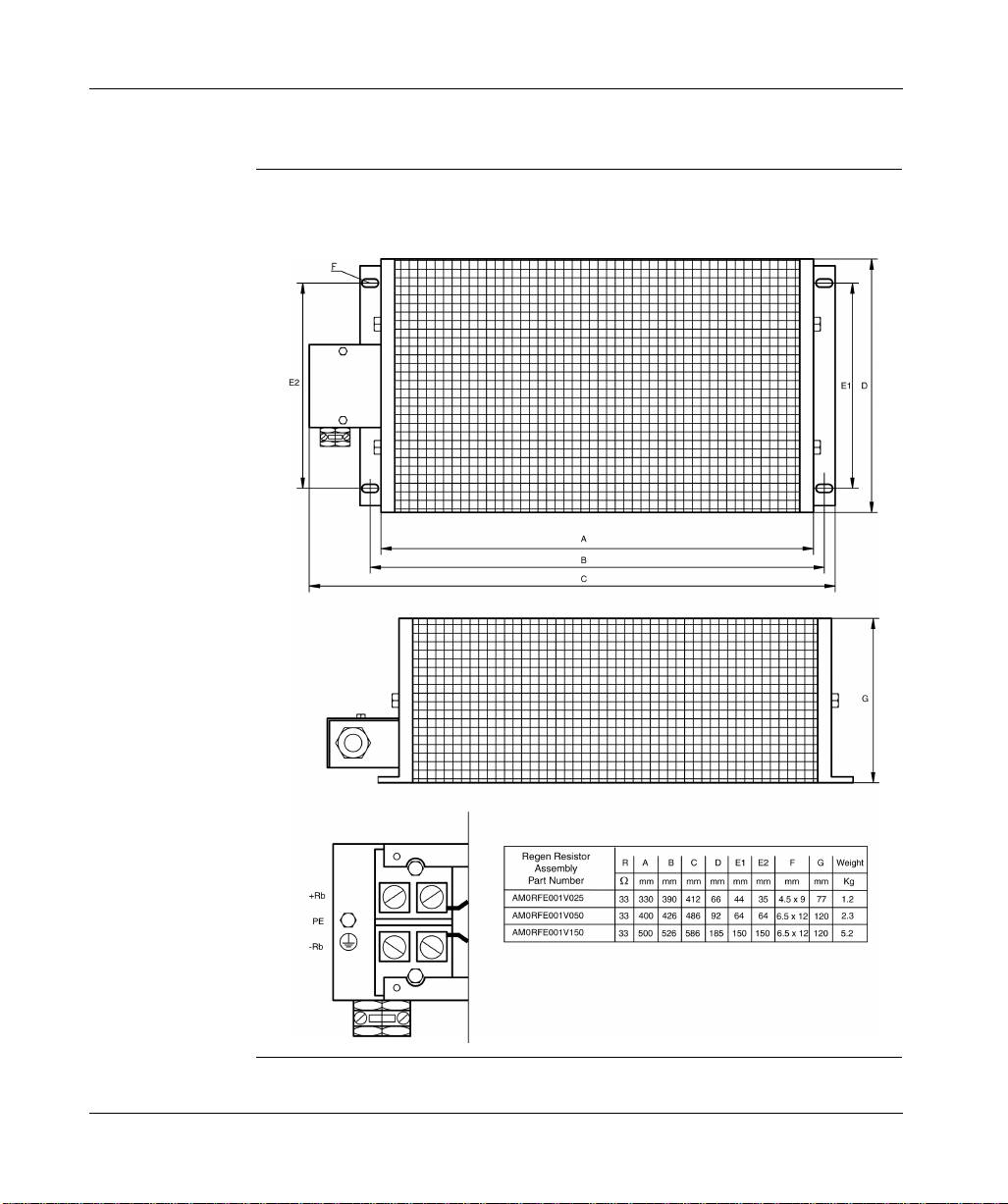

Optional External Regen Resistor Assembly Dimensions......................... 39

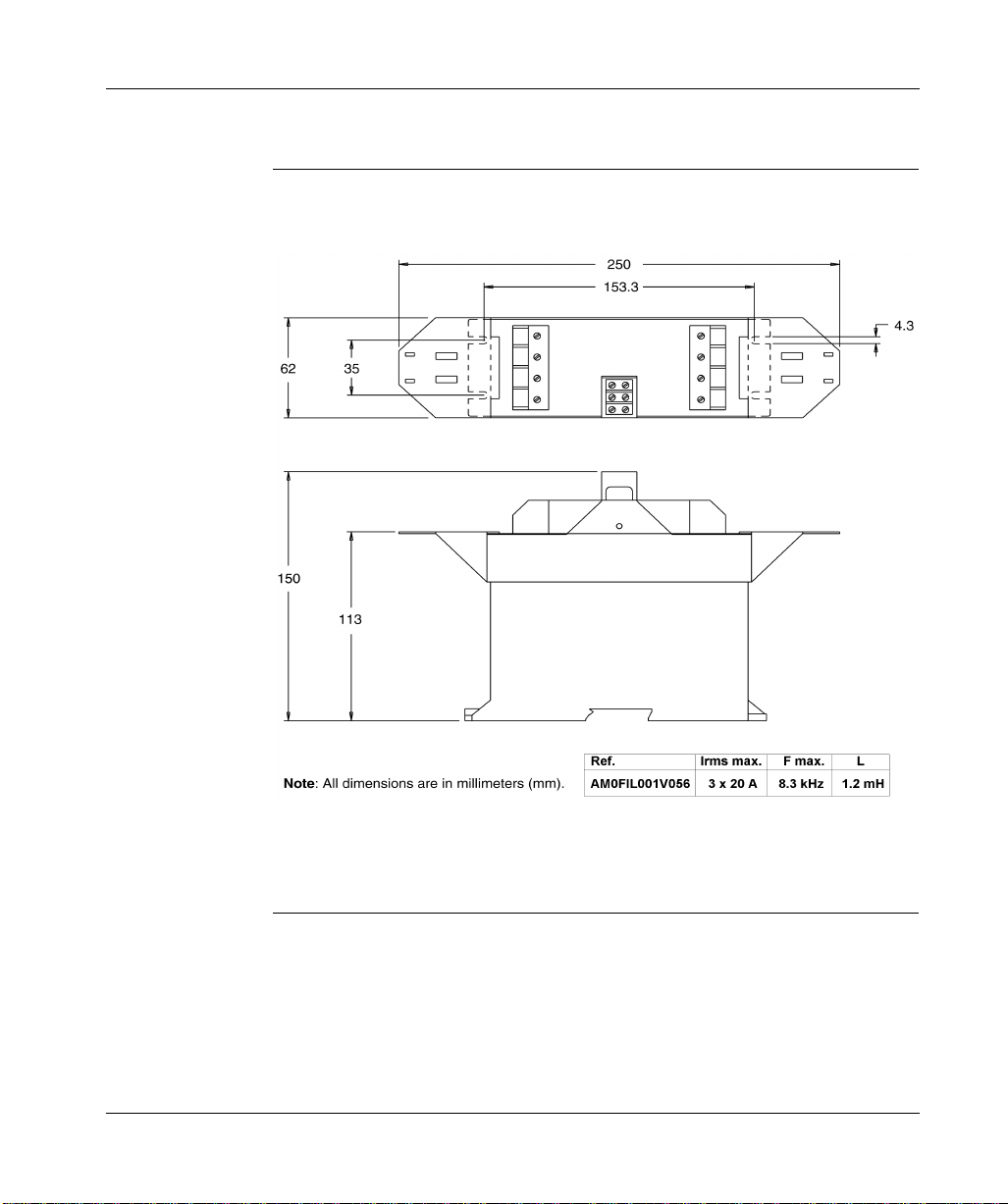

Optional Motor Choke Assembly Dimensions ........................................... 40

Chapter 4 Wiring and I/O

At a Glance...................................................................................................... 41

Introduction ............................................................................................... 41

What’s in this Chapter ............................................................................... 42

Wiring and I/O Initial Considerations .............................................................. 43

Initial Considerations ................................................................................. 43

Grounding ................................................................................................. 43

Wiring Overview ............................................................................................. 44

Overview of 17S Wiring Connections........................................................ 44

Cable Shield Connections .............................................................................. 47

Connecting Cable Shields to the Front Panel ........................................... 47

Cable Shield Connection Diagram ............................................................ 48

Power Wiring .................................................................................................. 49

AC Mains Power Supply Connection ........................................................ 49

Bias Supply Connection ............................................................................ 49

Serial Power Connections ......................................................................... 50

Optional External Regen Resistor Connection ......................................... 51

Regen Circuit Functional Description......................................................... 51

Lexium BPH Servo Motor Connection (excluded BPH055) ...................... 52

Lexium BPH 055 Servo Motor Connection................................................ 53

Servo Motor (with Optional Dynamic Brake...............................................

Resistors and Contactor) Connection ....................................................... 54

Servo Motor Holding-Brake Control Functional Description ...................... 55

890 USE 121 00 ix

Page 8

Contents

Signal Wiring .................................................................................................. 57

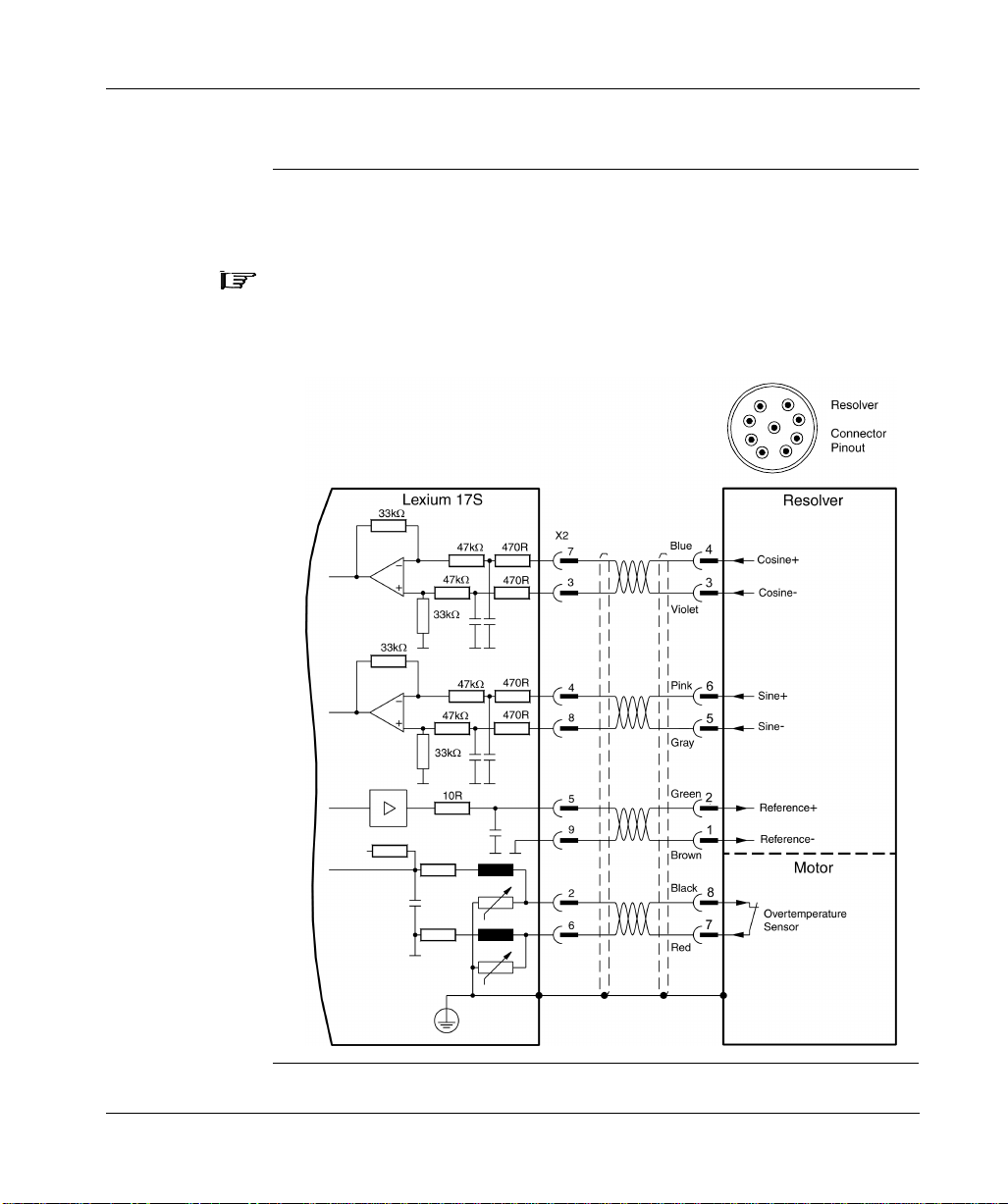

Lexium BPH Resolver Connection (excluded BPH055) ........................... 57

Lexium BPH055 Resolver Connection ..................................................... 58

Encoder Input Connection ........................................................................ 59

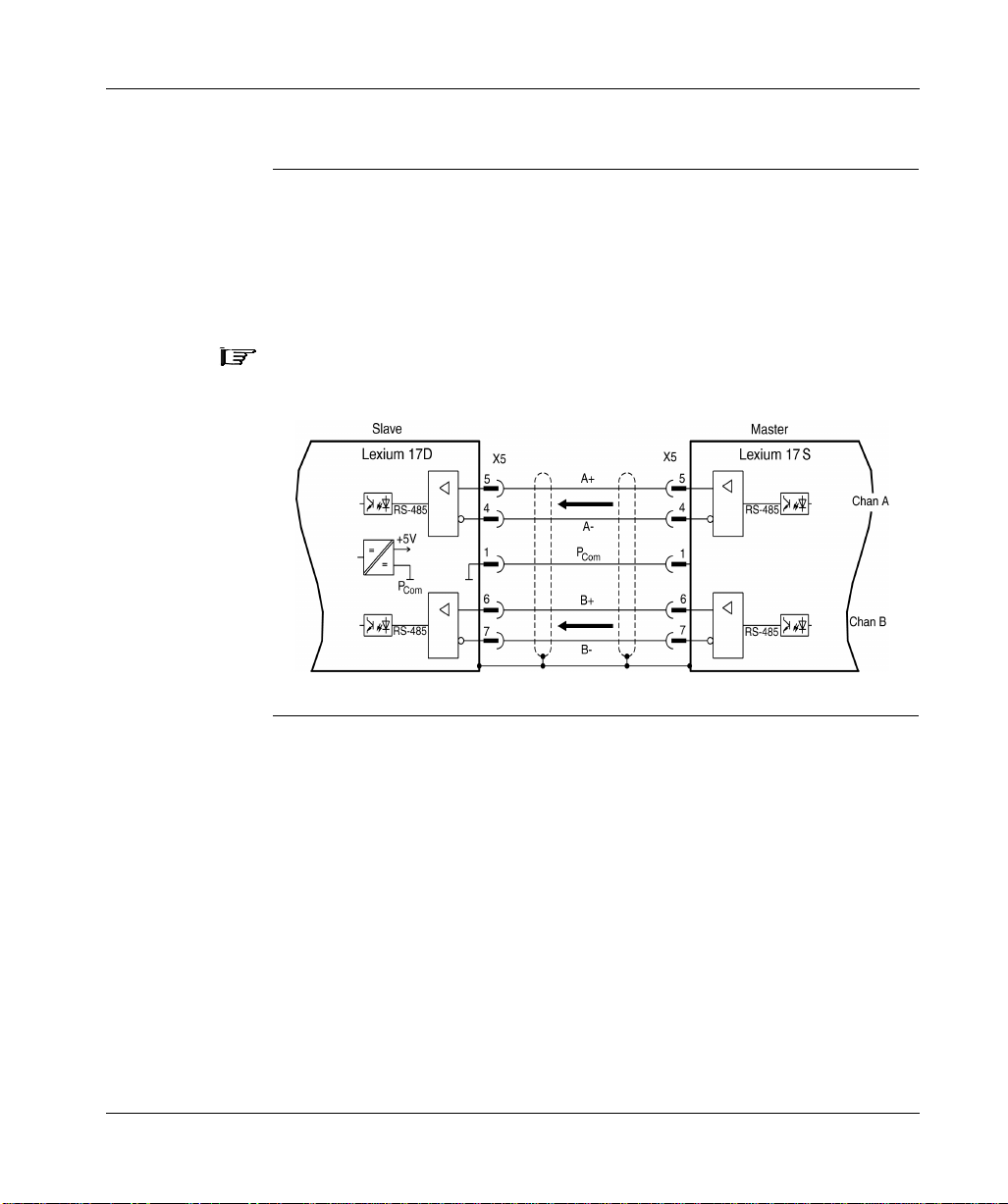

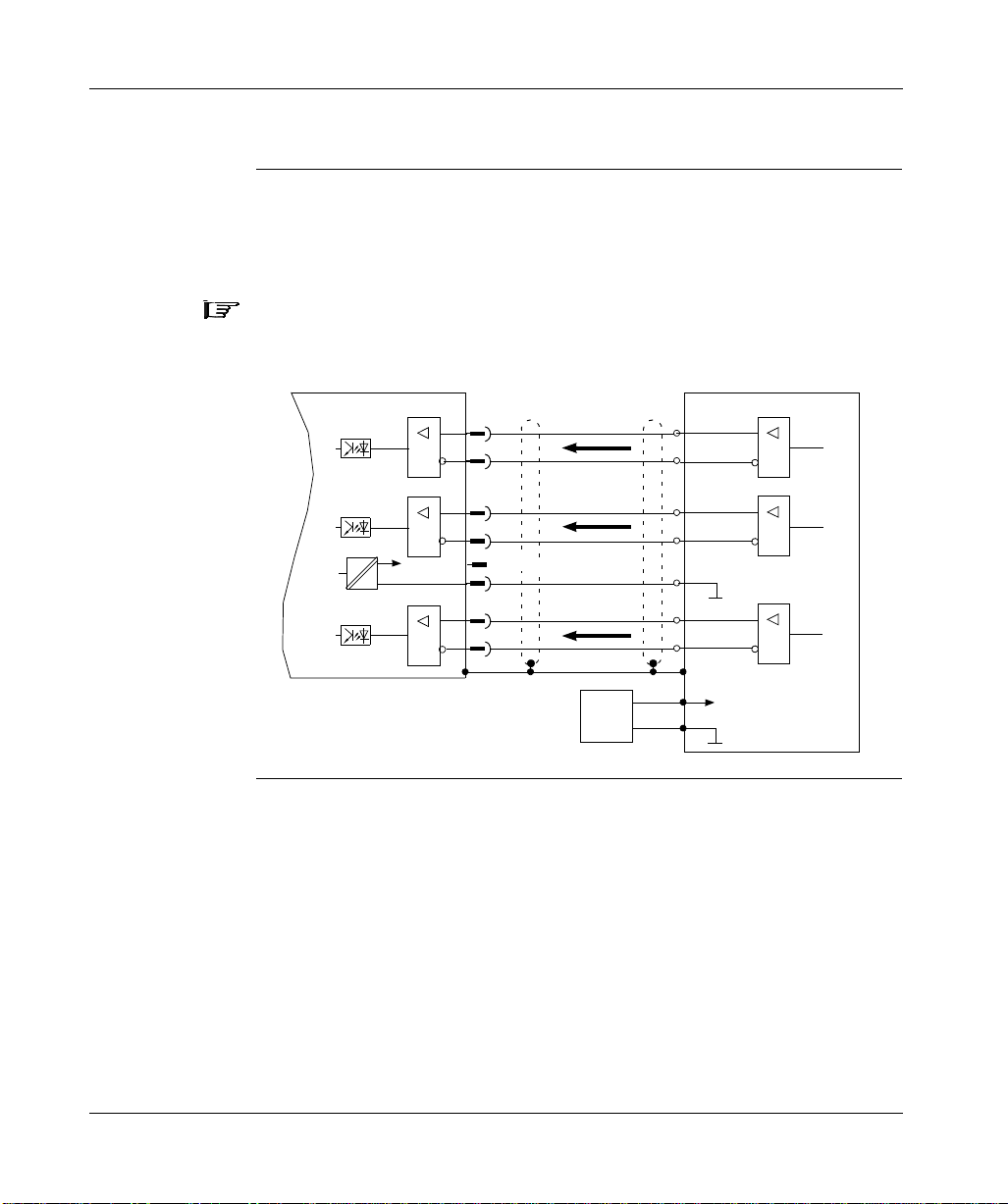

Auxiliary Encoder Interface ....................................................................... 60

Analog Input Connection ................................................................................ 63

Analog Inputs .................................................... ...... ..... ...... ....................... 63

Fault Relay and Digital I/O Connection .......................................................... 64

Digital Inputs and Outputs ........................................................................ 64

Using Functions Pre-programmed into the Drive ...................................... 65

Serial Communications Connection ............................................................... 66

RS-232 Null Modem Type Communication Connection Diagram ............. 66

Chapter 5 System Operation

At a Glance...................................................................................................... 67

What’s in this Chapter ............................................................................... 67

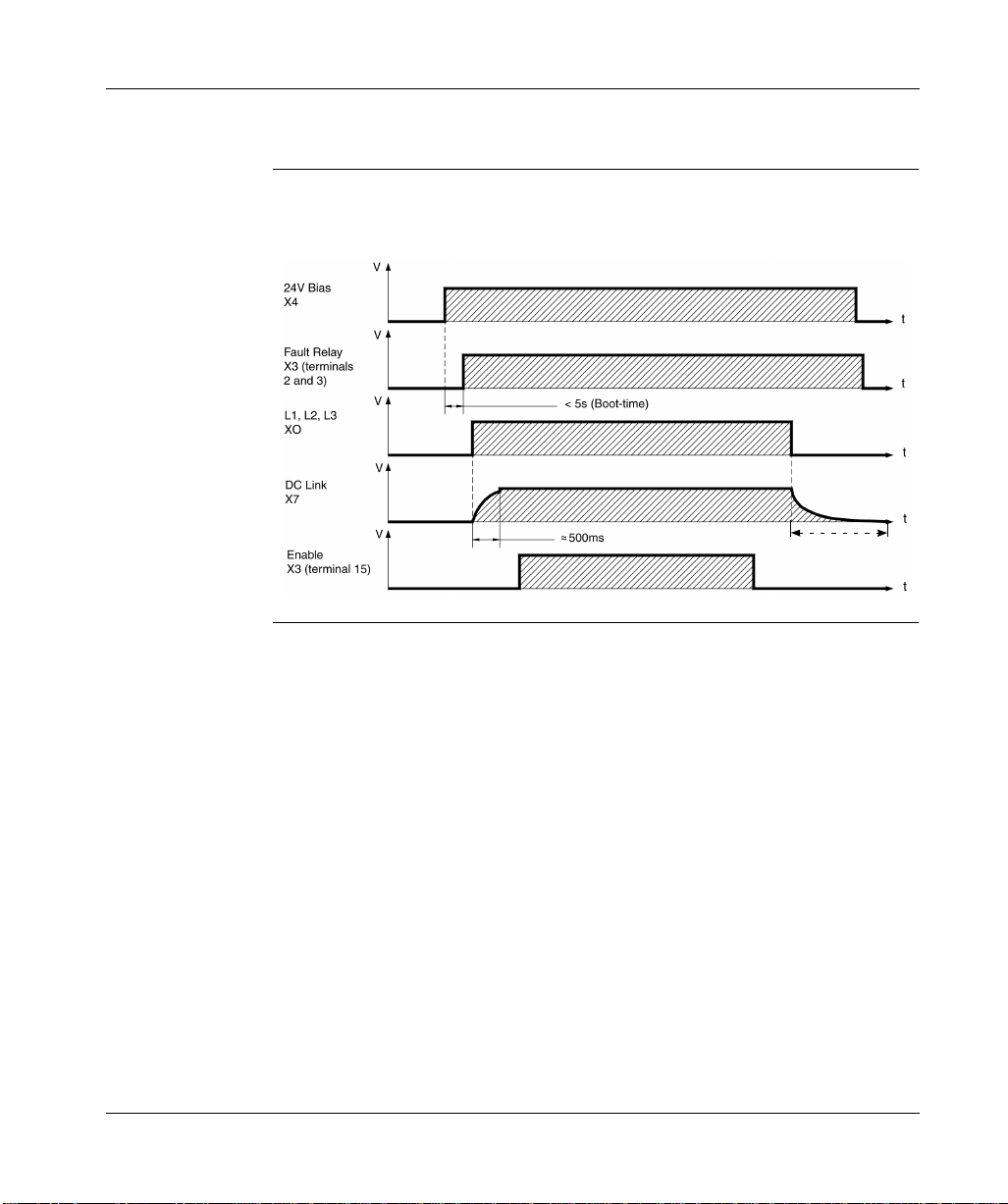

Powering Up and Powering Down the System ............................................... 68

Power-on and Power-off Characteristics .................................................. 68

Stop Function ............................................................................................ 69

Emergency Stop strategies ....................................................................... 69

Wiring example ........................................... ...... ...... ..... ...... ....................... 70

Procedure for Verifying System Operation ..................................................... 71

Overview ................................................................................................... 71

Quick Tuning Procedure ........................................................................... 71

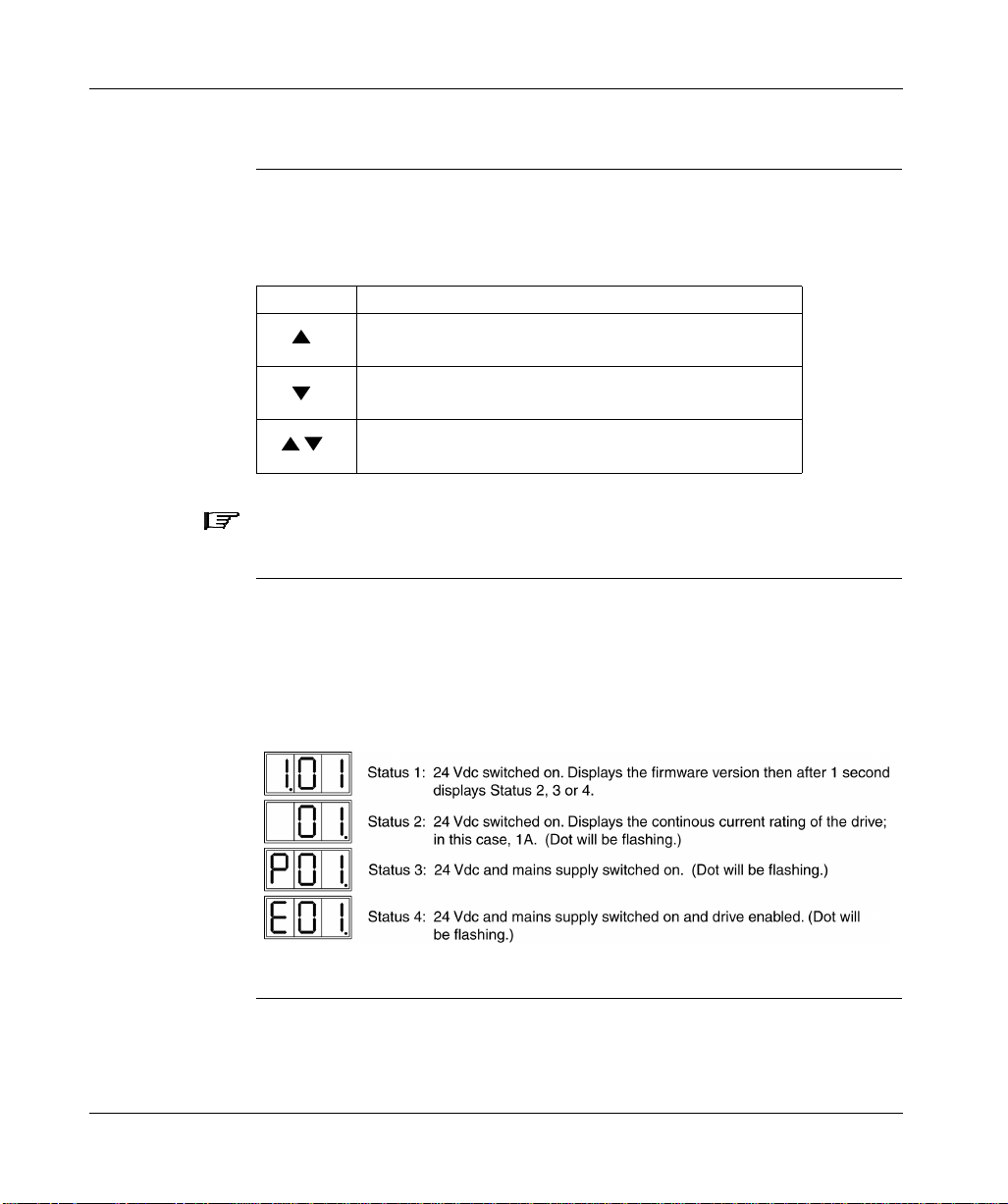

Front Panel Controls and Indicators ............................................................... 73

Keypad Operation ..................................................................................... 73

LED Display .............................................................................................. 73

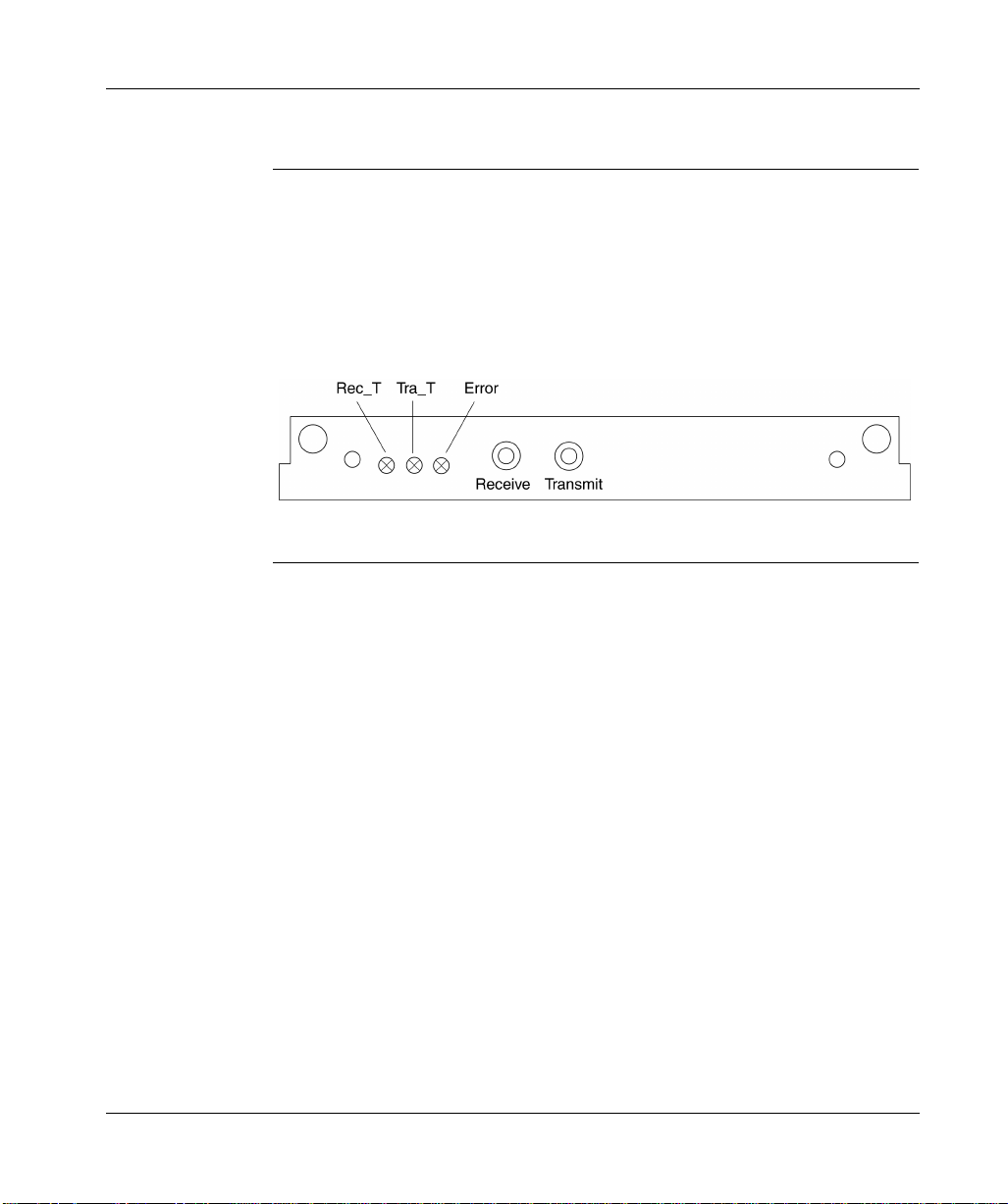

SERCOS Communication LED Indicators ................................................ 74

x

890 USE 121 00

Page 9

Contents

Chapter 6 Troubleshooting

At a Glance...................................................................................................... 75

What’s in this Chapter ............................................................................... 75

Warning Messages ......................................................................................... 76

Warning Identification and Description...................................................... 76

Error Messages ............................................................................................. . 77

Error Identification and Description ........................................................... 77

Troubleshooting............................................................................................... 81

Problems, Possible Causes and Corrective Actions.................................. 81

Appendix A Specifications

At a Glance...................................................................................................... 83

What’s in this Appendix ............................................................................. 83

Performance Specifications............................................................................. 84

Performance Specifications Table ............................................................ 84

Environmental and Mechanical Specifications................................................ 85

Environmental Specifications Table........................................................... 85

Mechanical Specifications Table ............................................................... 86

Electrical Specifications................................................................................... 87

What’s in this Section ................................................................................ 87

Electrical Specifications - Power .................................................................... 88

Line Input Specifications Table ................................................................. 88

Bias Input Specifications Table ................................................................. 89

External Fuse Specifications Table ........................................................... 89

Motor Output Specifications Table ............................................................ 90

Internal Power Dissipation Specifications Table........................................ 91

Electrical Specifications - Regen Resistor ...................................................... 92

Regen Circuit Specifications ..................................................................... 92

Electrical Specifications - Signal ..................................................................... 93

Motor Overtemperature Input Specifications Table .................................. 93

Resolver Input Specifications Table .......................................................... 93

Encoder Input Specifications Table........................................................... 94

Emulated Encoder Output (Incremental Format) Specifications Table...... 94

Encoder Output (Incremental Format) Timing Diagram ............................ 95

890 USE 121 00 xi

Page 10

Contents

Auxiliary Incremental Encoder Input Specifications Table ........................ 95

Discrete Input Specifications Table .......................................................... 96

Discrete Output Specifications Table ........................................................ 96

Fault Relay Output Specifications Table ................................................... 97

Brake Output Specifications Table ........................................................... 97

Analog Input Specifications Table ............................................................ 98

Serial Communications Specifications Table ............................................ 98

Wire Specifications ................................................................................... 99

Appendix B Parts List

At a Glance...................................................................................................... 101

What’s in this Appendix ............................................................................ 101

Lexium 17S Drives ......................................................................................... 102

Drives Available ..................................... ..... .............................................. 102

External 24Vdc supply .................................................................................... 103

External 24Vdc supply .............................................................................. 103

Drive Cables ................................................................................................... 104

Drive to Motor Cables .............................................................................. 104

RS-232 Serial Communications Cable Part Table .................................... 104

Encoder Output Cable Parts Table ........................................................... 104

Fiber Optic Cables Parts Table ......................... ...... .................................. 105

Optional External Regen Resistor Assemblies ............................................... 106

Optional Regen Resistor Assembly Part Table......................................... 106

Optional Motor Choke..................................................................................... 107

Optional Motor Choke Part Table.............................................................. 107

Spare Parts ..................................................................................................... 108

Spare Parts Table...................................................................................... 108

Appendix C Cable Connection Wiring Diagrams

At a Glance...................................................................................................... 109

What’s in this Appendix ............................................................................ 109

Wiring a Sub-D Connector with Shielding ...................................................... 110

Wiring the Sub-D Connector............................................... ....................... 110

Sub-D Connector Diagram ....................................................................... 111

Wiring the Motor Power Connector (Drive end) ............................................. 112

xii

890 USE 121 00

Page 11

Contents

Wiring the Motor Power Connector ........................................................... 112

Motor Power Connector (Drive end) Diagram (excluded BPH055) ........... 113

BPH055 Motor Power Connector (Drive end) Diagram ............................ 114

Serial Communication Interface Conne cti on (X6) .............................. ............ 115

Serial Communication Interface Cable Connectors .................................. 115

Appendix C Servo Loop Diagrams

At a Glance...................................................................................................... 117

What’s in this Appendix ............................................................................. 117

17S Current Controller Overview .................................................................... 118

17S Current Controller Diagram ............................................................... 118

17S Velocity Controller Loop .......................................................................... 119

17S Velocity Controller Loop Diagram .................................... .................. 119

17S Position Controller Loop .......................................................................... 120

17S Position Controller Loop Diagram....................................................... 120

Appendix D Optional External Regen Resistor Sizing

At a Glance...................................................................................................... 121

What’s in this Appendix.............................................................................. 121

Overview ................................................................................................... 122

Determining When Energy Is Absorbed .................................................... 122

Determining Optional External Regen Resistor Size ...................................... 123

Power Dissipation Calculation Proce dure .......................... ..... ...... ...... ..... . 123

Drive Energy Absorption Capability .......................................................... 124

Example Regen Resistor Power Dissipation Ca lc ula tio n ............................... 125

Example Motor and Drive Specifications................................................... 125

Example Step 1........................... ...... ...... ..... .............................................. 126

Example Step 2 ................................ ...... ..... ...... ........................................ 127

Example Step 3 ................................ ...... ..... ...... ........................................ 127

Example Step 4 ................................ ...... ..... ...... ........................................ 128

Example Step 5 ................................ ...... ..... ...... ........................................ 128

Example Step 6........................... ...... ...... ..... .............................................. 128

Example Step 7 ................................ ...... ..... ...... ........................................ 128

Example Step 8 ................................ ...... ..... ...... ........................................ 129

890 USE 121 00 xiii

Page 12

Contents

xiv

890 USE 121 00

Page 13

Introduction

1

At a Glance

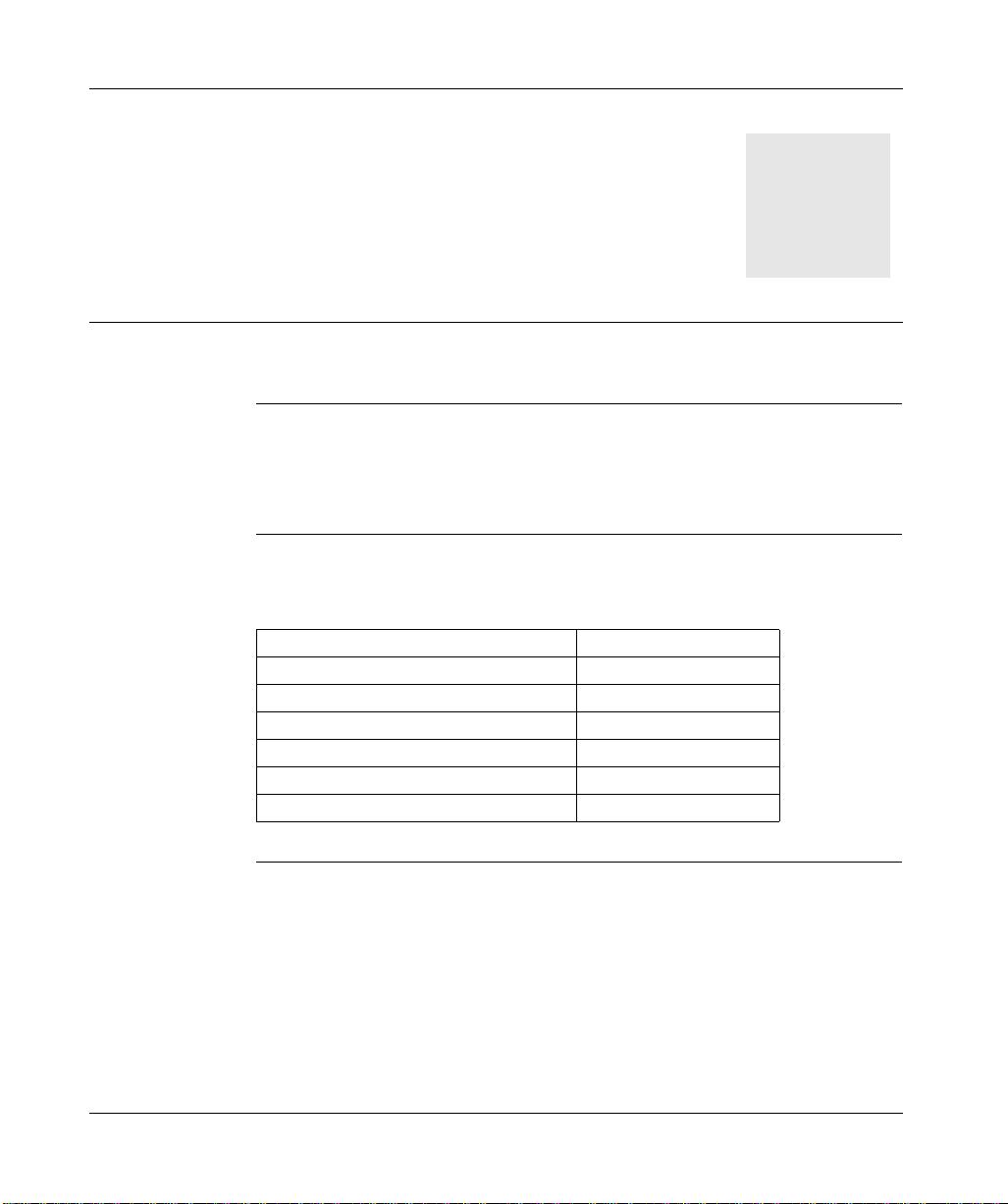

Document Scope This user guide contains complete installation, wiring interconnection, power

application, test and maintenance information on the Lexium 17S series SERCOS

drive.

What’s in this Chapter

This chapter provides general information about this user guide and contains the

following topics:

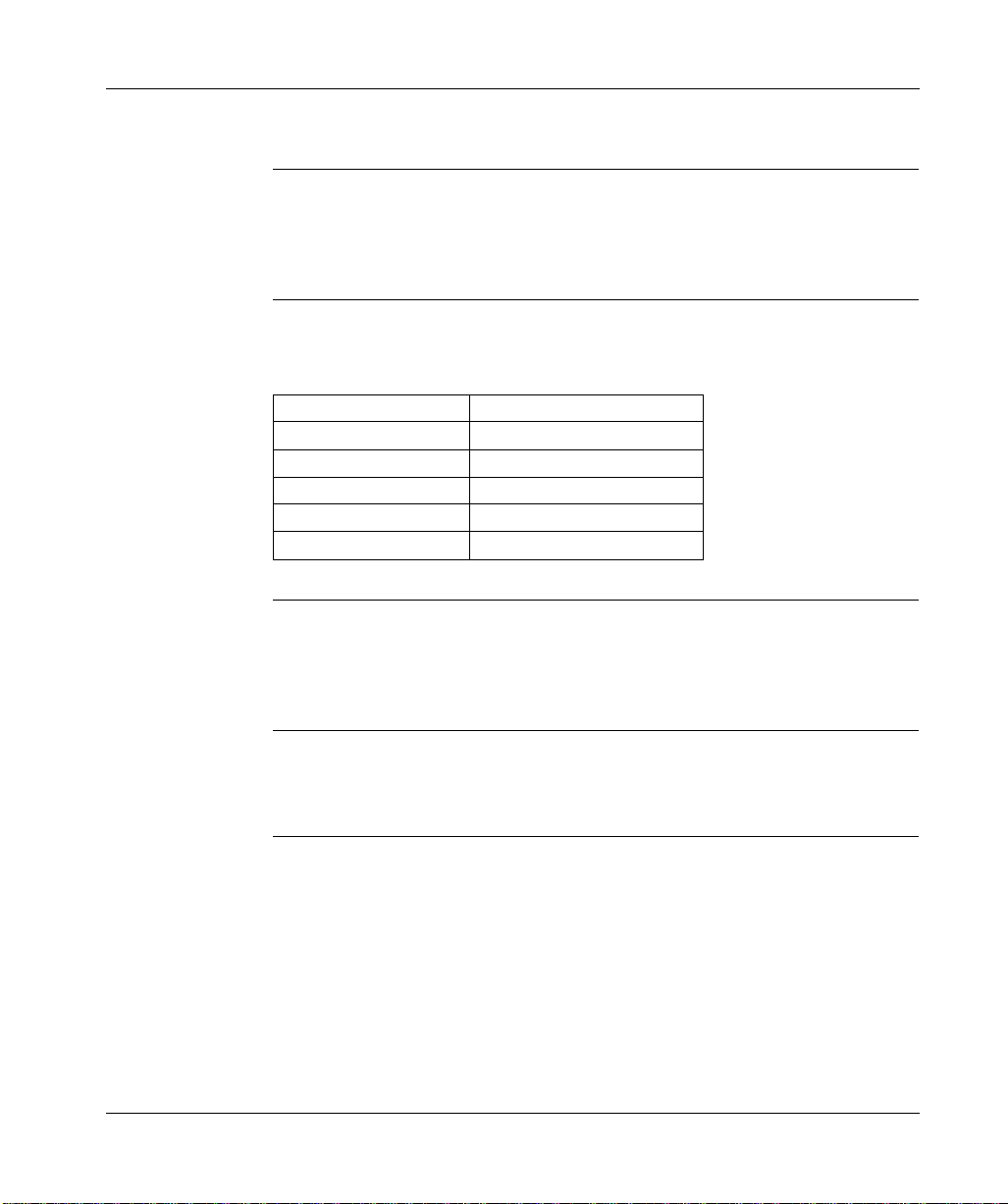

Topic Page

About this user guide 2 Related system components and standards 4 Related documentation 5 Hazards, warnings, and guidelines 6 Standards and compliances 10 Conventions 12

1

Page 14

About this User Guide

Who Should Use this User Guide

How this User Guide Is Organized

This user guide is written for any qualified person at your site who is responsible for

installing (mounting and interconnecting), operating, testing and maintaining your

Lexium 17S SERCOS drive and the servo system equipment with which it

interfaces. In addition, the following precautions are advised:

l Transportation of the drive to, or from, an installation site should only be

performed by personnel knowledgeable in handling electrostatically sensiti ve

components.

l Commissioning of the equipment should only be performed by personnel

having extensive knowledge of, and experience with, electrical and drive

technologies.

You are expected to have some overall understanding of what your 17S SERCOS

drive does and how it will function in a high-performance, multi-axis motion control

system. Accordingly, be sure you read and understand the general information,

detailed descriptions and associated procedures presented in this manual, as well

as those provided in other relevant manuals, before installing your 17S. (See

Related System Components

later in this chapter.)

If you have questions, please consult your Schneider Electric customer

representative.

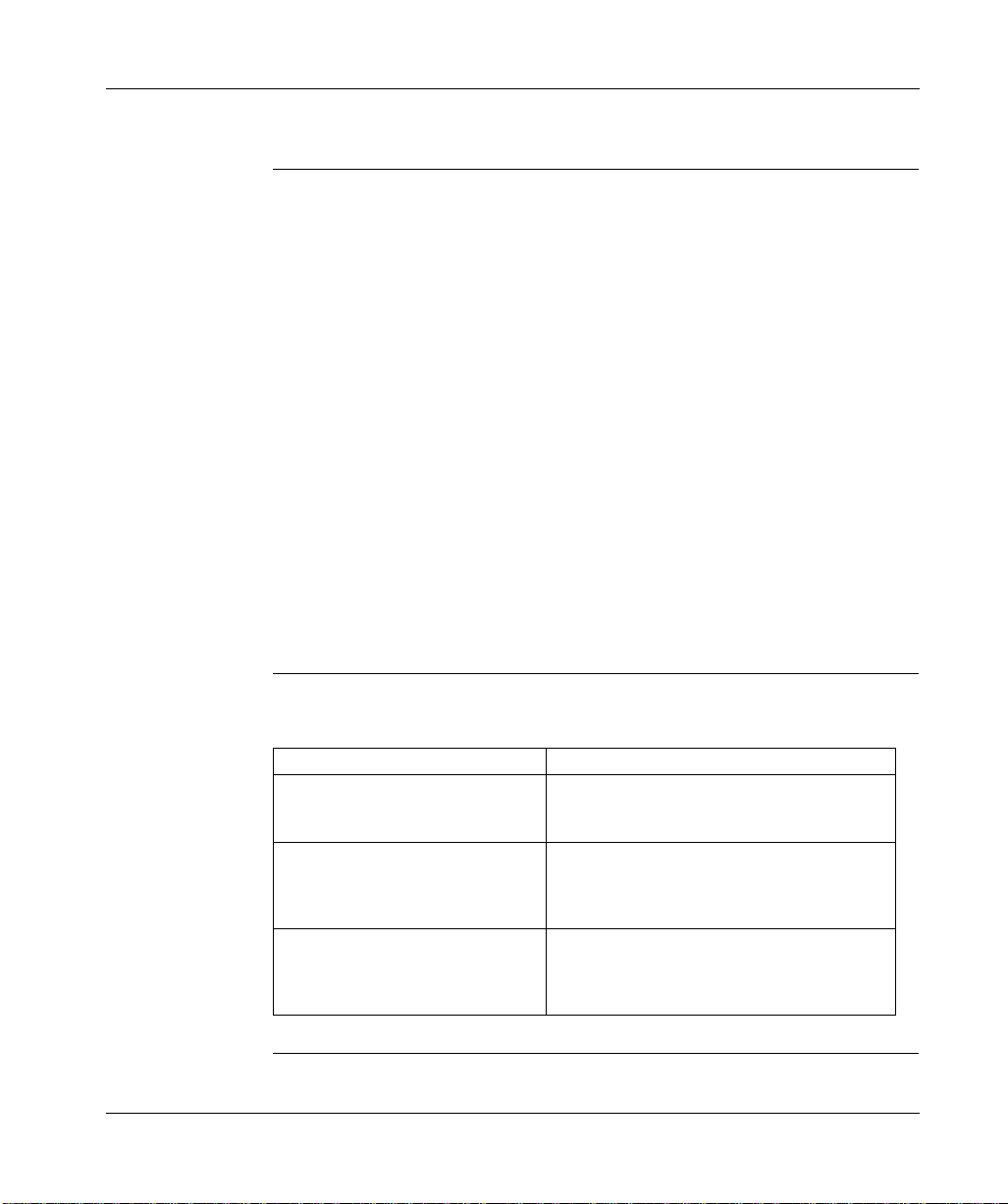

This manual is organized as follows.

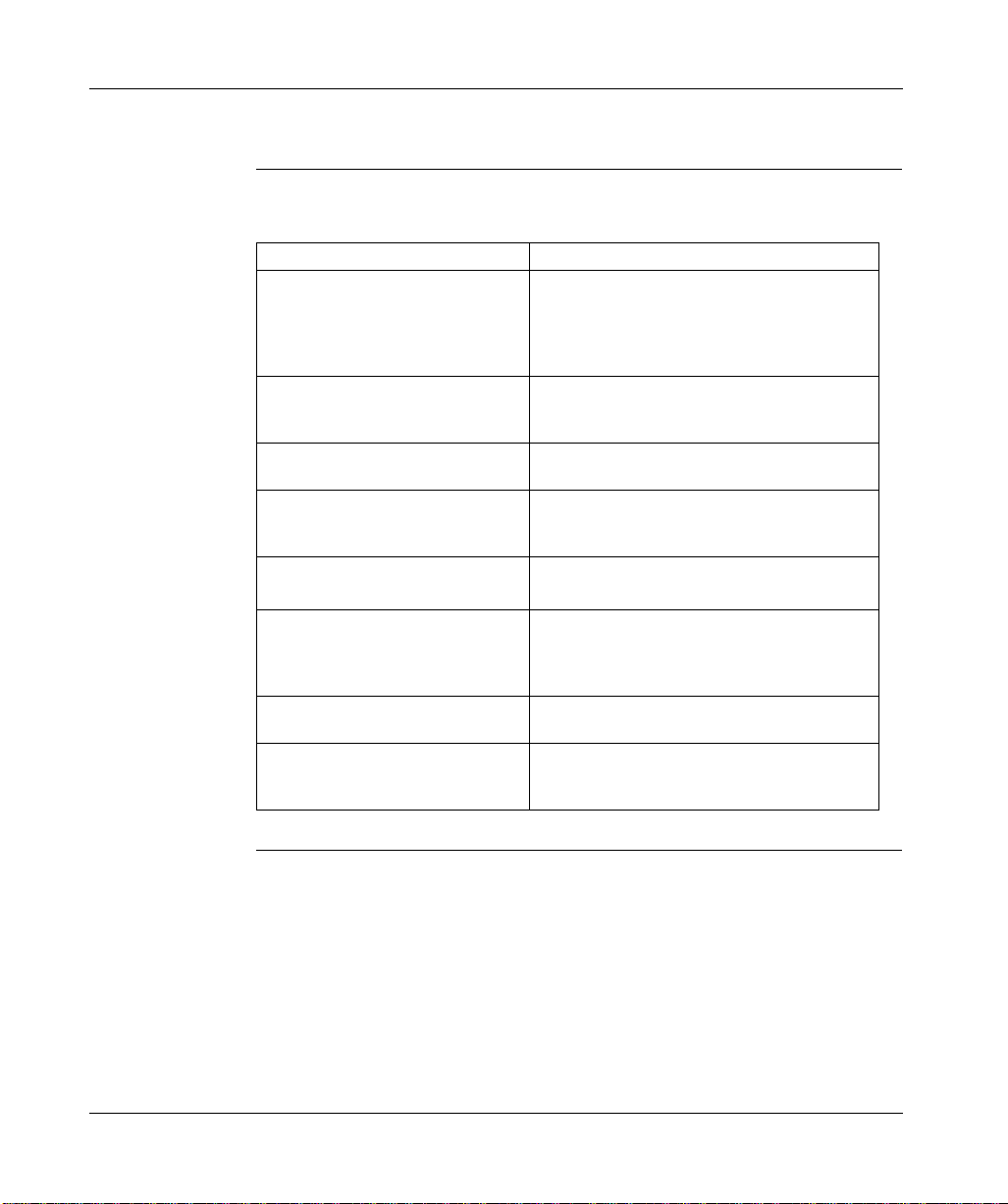

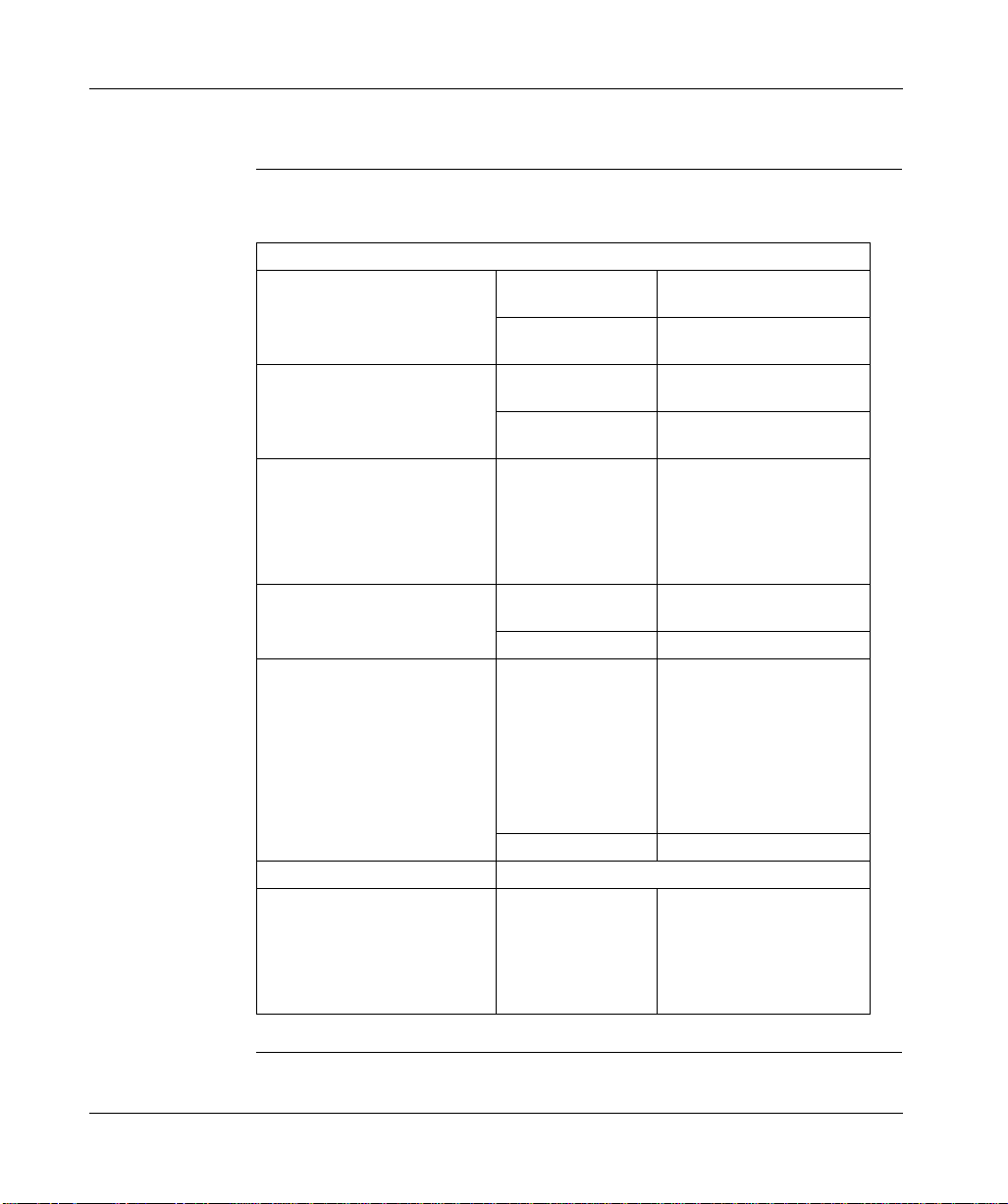

Chapter/Appendix Description

Chapter 1

About this User Guide

Chapter 2

Lexium 17S Product Overview

Chapter 3

Mounting and Physical Dimensions

An introduction to this manual — who should use

this manual, how this manual is organized,

related publications, hazards and warnings.

General descriptions of the 17S SERCOS

drives, descriptions of components that are

supplied by Schneider in a typical 17S system,

and a block diagram for internal electronics.

Physical dimensions and information for

mounting the 17S SERCOS drive, optional

Regen resistor and (if required) optional servo

motor choke.

Continued on next page

2

Page 15

About this User Guide, continued

How this User

Guide Is

Organized,

continued

Chapter/Appendix Description

Chapter 4

Wiring and I/O

Chapter 5

System Initialization, Commissioning and Operation

Chapter 6

Troubleshooting

Appendix A

Specifications

Appendix B

Parts List

Appendix C

Cable Connection Wiring Diagrams

Appendix D

Servo Loop Diagrams

Appendix E

Optional External Regen Resistor Sizing

Wiring diagrams for the power connections and

wiring diagrams and descriptions for all signal

wiring connections — encoder, resolver, analog

input, discrete I/O, fiber-optic and serial

communications cable.

Detailed procedures and associated descriptions

on how to initialize, commission and operate a

typical 17S system.

Description of faults, probable causes and recommended corrective actions.

Specifications for the 17S SERCOS drives,

including general, electrical, signal, and power

specifications.

Part numbers related to the 17S SERCOS drive

system.

Procedures and associated diagrams that show

how to wire Sub-D and power cable connectors

as well as the serial communication cable used

with the drive.

Illustrations of several servo loops within the 17S SERCOS drive system.

Description and procedure for determining the

power dissipation requirement for the optional

external Regen resistor.

3

Page 16

Related System Components

SERCOS MultiAxis Motion

Control System

UniLink Commissioning Software for 17S

The 17S SERCOS drive is typically only one component in a larger, multi-axis

motion control system. A multi-axis system is comprised of one motion controller

and (depending on the controller) up to 32 drives. Each drive controls one servo

motor.

To configure your multi-axis system, you will be using the UniLink axis

commissioning software, which Schneider supplies.

UniLink allows you to configure and tune your 17S axis quickly and easily. With its

graphical user interfa ce and osci lloscop e tuning feat ures, UniL ink provides an easy

point-and-click me thod for confi guring moti on setup p arameters. U niLink mi nimizes

or eliminates cumbersom e programming tasks.

For complete information on UniLink, please see the UniLink online help.

4

Page 17

Related Documentation

Documents Related documentation that covers all these system components is illustrated

below.

You will need these:

UniLink

Online Help

(included

in software)

Depending on which SERCOS motion controller you have, you will also need there:

QUANTUM:

Quantum

SERCOS

Multi-axis Motion

Controller

Guide

MMF

Programmer’s

Kit

User Guide

840 USE 116 X

PREMIUM:

PREMIUM PLCs

Motion Control

SERCOS Module

TSX CSY 84

User Manual

TSXDM5740

If you have a BPH motor, you will also need this:

Lexium BPH

Series

Servo Motors

Motors Reference

Guide

* AMOMAN001U

* included in AM0 CSW 001V•00 (CDROM)

890 USE 119 00

PL7 JUNIOR/PRO

PREMIUM PLCs

Application

Motion Control

SERCOS Module

TSX CSY 84

TLXDS57PL740

5

Page 18

Hazards, Warnings and Guidelines

Hazards and Warnings

Read the followi ng precautions very carefully to ensure the safety of personnel at

your site. Failure to comply will result in death, serious injury or equipment damage.

DANGER!

ELECTRIC SHOCK HAZARDS

l During operation, keep al l covers and cabine t doors closed.

l Do not open the drives; depending on degree of enclosure protection, the

drives may have exposed components.

l Control and power connections on the drive may be energized even if the

motor is not rotating.

l Never attempt to disconnect the electrical connections to the drive with power

applied. Failure to comply may result in arcing at the contacts.

l Wait at least five minutes after disconnecting the drive from the mains supply

voltage before touching energized sections of the equipment (for example,

contacts) or disconnecting electrical connections. Capacitors can still have

dangerous voltages present up to five minutes after switching off the supply

voltages. To ensure safety, measure the voltage in the DC Link circuit and wait

until it has fallen below 40V before proceeding.

l Check to ensure all energized connecting elements are protected from

accidental contact. Lethal voltages up to 900V can be present. Never

disconnect any electrical connections to the drive with power applied;

capacitors can retain residual and dangerous voltage levels for up to five

minutes after switching off the supply power.

Failure to follow any one of these instructions will result in death, serious

injury or equipment damage.

Continued on next page

6

Page 19

Hazards, Warnings and Guidelines, continued

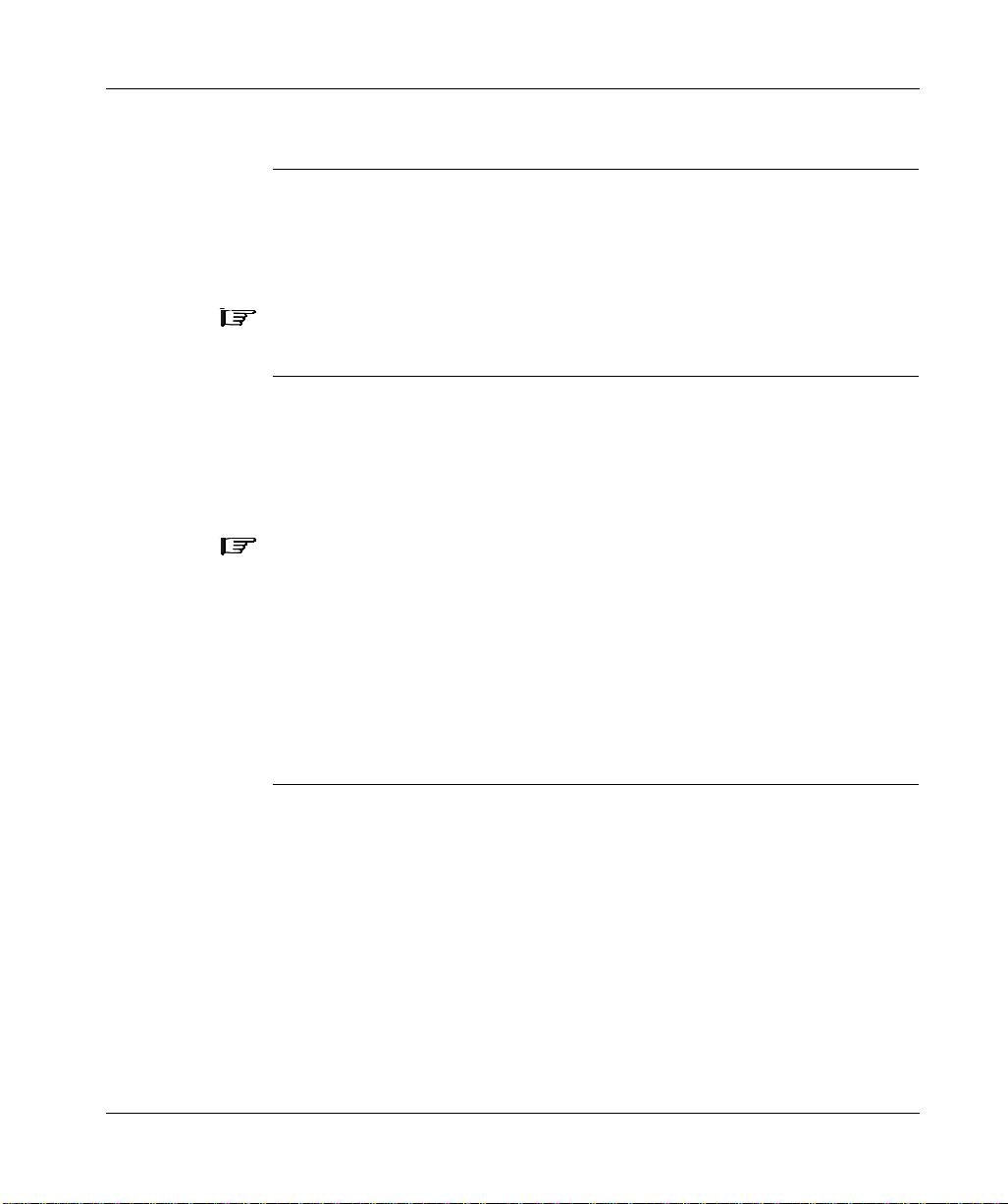

WARNING!

THERMAL HAZARD

During operation, the front panel of the drive, which is used as a heat sink, can

become hot and may reach temperatures above 80°C. Check (measure) the heat

sink temperature and wait until it has cooled below 40°C before touching it.

Failure to observe this precaution can result in severe injury.

WARNING!

OVERCURRENT, OVERLOAD AND OVERHEATING PROTECTION

Separate motor overcurrent, overload and overheating protection is required to be

provided in accordance wit h the Ca nad ian Elec tric al Code, Part 1 an d the National

Electrical Code.

Failure to observe this precaution can result in severe injury.

Continued on next page

7

Page 20

Hazards, Warnings and Guidelines, continued

CAUTION!

SAFETY INTERLOCKS

Schneider recommends the installation of a safety interlock with separate contacts

for each motor. Such a system should be hard w ire d wi th over–travel limit s w itc he s

and a suitable emergency stop switch. Any interruption of this circuit or fault

indication should:

l Open the motor contacts

l Shunt dynamic braking resistors across each motor, if they are present.

Failure to observe this precaution can result in equipment damage.

CAUTION!

ELECTROSTATIC COMPONENTS

The drives contain electrostatically sensitive components that may be damaged by

improper handling. Appropriately discharge yourself before touching the drive and

avoid contact with highly insulating materials (artificial fabrics, plastic film, and so

on). Place the drive on a conductive surface.

Failure to observe this precaution can result in equipment damage.

Continued on next page

8

Page 21

Hazards, Warnings and Guidelines, continued

Additional Safety Guidelines

Qualified Personnel

Read this documentation and adhere to the safety guidelines contained herein

before engaging in any activities involving the drives.

l Ens ure that al l wiri ng is in a ccorda nc e with the Nati ona l Ele ctr ical Cod e (NEC)

or its national equivalent (CSA, CENELEC, and so on), as well as in

accordance with all prevailing local codes.

l Exercise extreme caution when using instruments such as oscilloscopes, chart

recorders, or volt–ohm meters with equipment connected to line power.

l Handle the drives as prescribed herein. Incorrect handling can result in

personal injury or equipment damage.

l Adhere to the technical information on connection requirements identified on

the nameplate and specified in the documentation.

l The drives may only be operated in a closed switchgear cabinet with

appropriate compensation for ambient conditions (as defined in Appendix A).

Only properly qualified personnel having extensive knowledge in electrical and

drive technologies should install, commission and/or maintain the Lexium 17S

SERCOS drives.

9

Page 22

Standards and Compliances

European Directives and Standards

EC Directive Compliance

The Lexium 17S SERCOS drives are incorporated into an electrical plant and into

machinery for industrial use.

When the drives are b ui lt int o mac hines or a plant, do no t oper ate the d riv e until the

machine or plant fulfills the requirements of these European Standards:

l EC Directive on Machines 89/392/EEC

l EC Directive on EMC (89/336/EEC)

l EN 60204

l EN 292

In connection with the Low Voltage Directive 73/23/EEC, the associated standards

of the EN 50178 series in conjunction with EN 60439-1, EN 60146 and EN 60204

are applied to the drives.

The manufacturer of the mach ine or plant is responsible for meeting the

requirements of the EMC regulations.

Compliance with the EC Directive on EMC 89/336/EEC and the Low Voltage

Directive 73/23/EEC is mandatory for all drives used within the European

Community.

The Lexium 17S SERCOS drives were tested by an authorized testing laboratory

and determined to be in compliance with the directives identified above.

10

Continued on next page

Page 23

Standards and Compliances, continued

SERCOS Standard

UL and cUL Compliance

If you want to reference the internatio nal SERCO S communic ations st andard , get a

copy of:

International Standard IEC 1491,

Electrical Equipment of Industrial Machines –

Serial Data Link for Real-Time Communication between Controllers and Drives.

SERCOS is an industry standard term that refers to a special type of fiber–optic

communication protocol, as defined by the SERCOS Interface, Inc., promotion

society. (SERCOS® interface is a trade mark o f SERCO S Interf ace, I nc., pro motion

society.)

UL Listed (cUL Certified) drives (Underwriters Laboratories Inc.) comply with the

relevant American and Canadian standards (in this case, UL 840 and UL 508C).

This standard describes the minimum requirements for electrically operated power

conversion equipme nt (such as frequen cy con v erters and drive s) and is intended to

eliminate the risk of inj ury to personnel fro m electric sh ock or d amage to eq uipment

from fire. Conformance with the United States and Canadian standard is

determined by an indepe nde nt UL (cU L ) fire in spe ct or th roug h th e ty pe tes tin g and

regular checkups.

UL 508C

UL 508C describes the minimum requirements for electrically operated power

conversion equipme nt (such as frequen cy con v erters and drive s) and is intended to

eliminate the risk of fire caused by that equipment.

UL 840

UL 840 describes ai r and in sulat ion creep age spa cings f or electrical equipment and

printed circuit boards.

11

Page 24

Conventions

Acronyms and Abbreviations

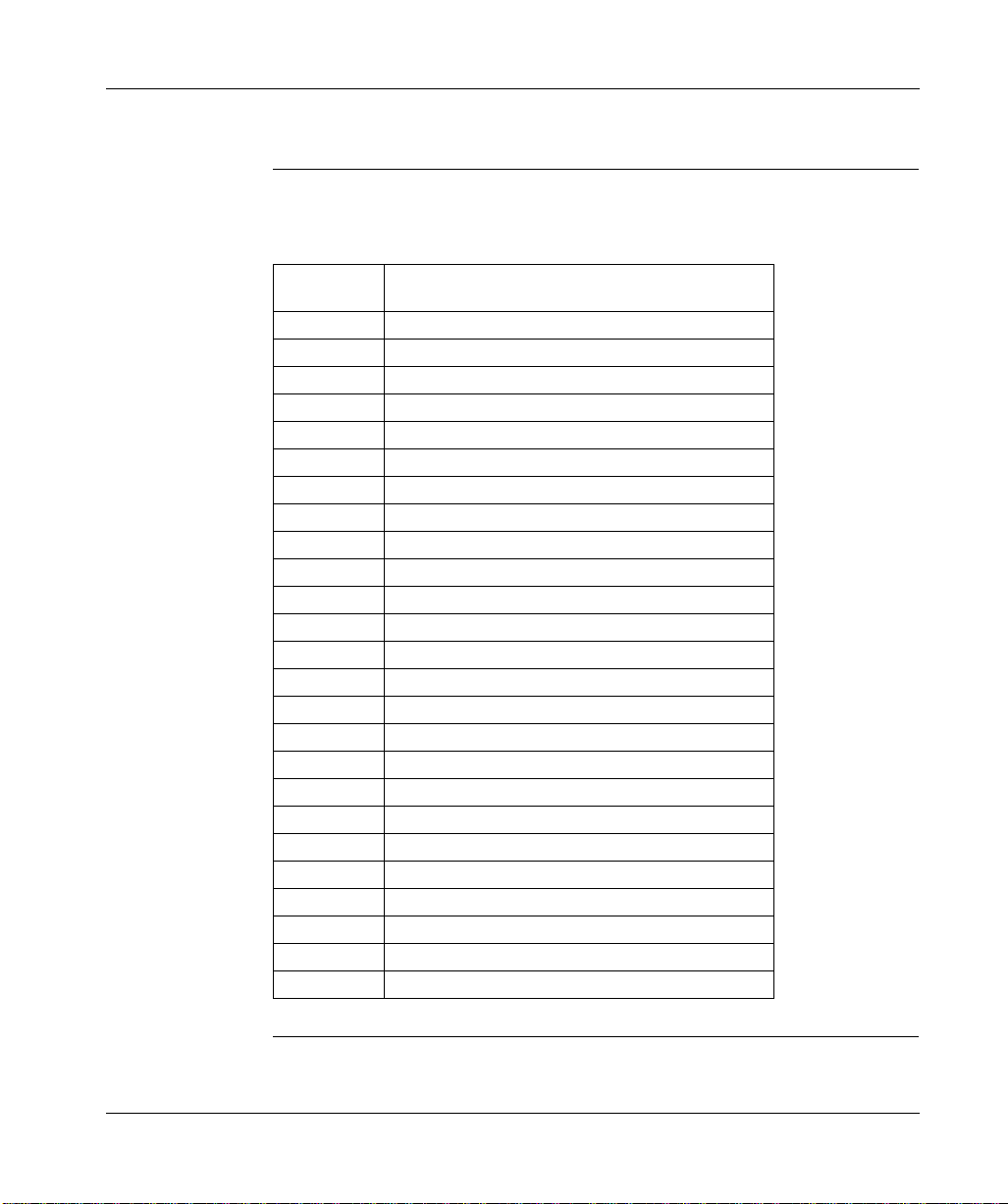

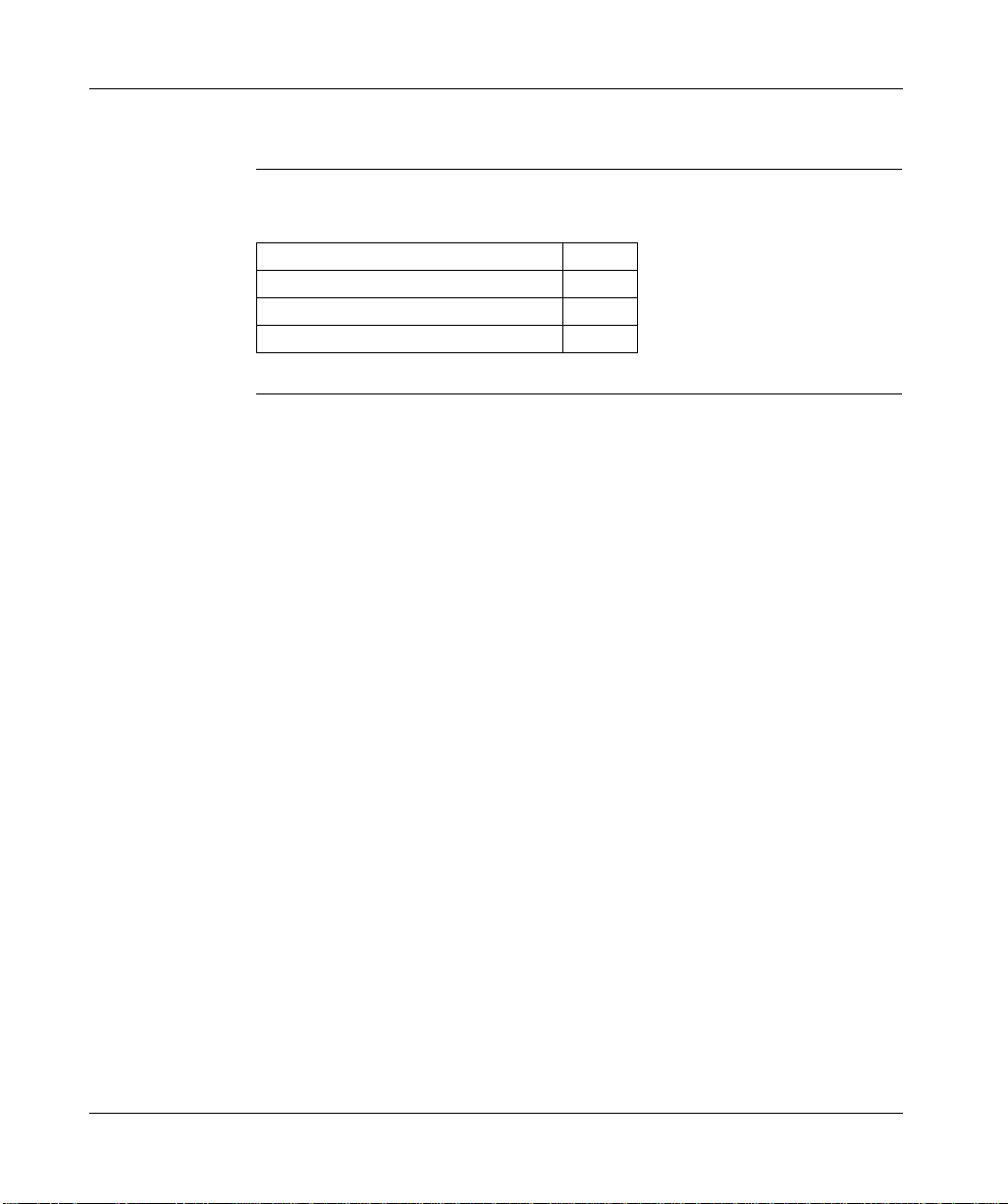

The acronyms and abbreviations used in this manual are identified and defined in

the table below.

Acronym or

Abbreviation Description

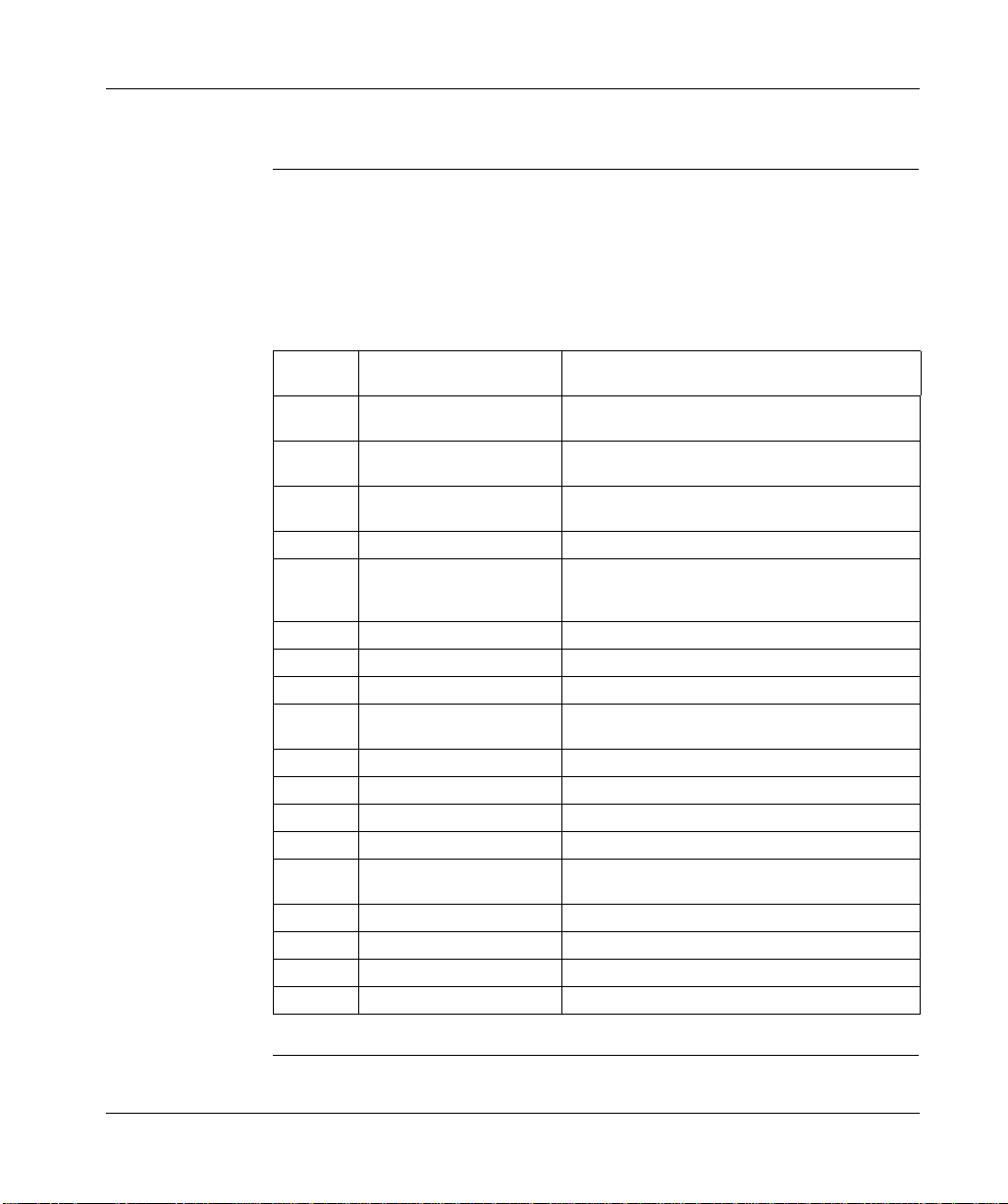

CE European Community (EC) CLK Clock signal COM Serial communication interface for a PC-AT cUL Underwriters Laboratory (Canada) DIN German Institute for Norming Disk Magnetic storage (diskette, hard disk) EEPROM Electrically erasable programmable read only memory EMC Electromagnetic compatibility EMI Electromagnetic Interference EN European norm ESD Electrostatic discharge IEC International Electrotechnical Commission IGBT Insulated Gate Bipolar Transistor ISO International Standardization Organization LED Light Emitting Diode MB Megabyte MS-DOS Microsoft Disk Operating System for PC-AT PC-AT Personal computer in AT configuration PELV Protected extra low voltage PWM Pulse-width modulation RAM Random Access Memory (volatile) Regen Regen resistor RBext External Regen resistor RBint Internal Regen resistor RFI Radio Frequency Interference

12

Continued on next page

Page 25

Conventions, cont inued

Acronyms and

Abbreviations,

continued

Acronym or

Abbreviation Description

PLC Programmable Logic Controller SERCOS Serial Realtime Communication System SRAM Static RAM SSI Synchronous Serial Interface UL Underwriters Laboratory Vac Voltage, Alternating Current Vdc Voltage, Direct Current

13

Page 26

14

Page 27

Product Overview

2

At a Glance

Introduction This chapter contains a product o v erview of th e Le xium 17S series SERCOS driv es

and includes:

l Available drive models and related system components

l Feedback and performance information

l Power and signal electronics

l Software and axis configuration

What’s in this Chapter

This chapter contains the following topics:

Topic Page

The 17S series SERCOS drive family 16 Modicon Multi-Axis Motion SERCOS

Network Configuration

Overview of usability features 25

Overview of 17S internal electronics 27

Overview of system software 31

22

15

Page 28

The 17S Series SERCOS Drive Family

Introducing the 17S SERCOS Drive Family

Each member of the Lexium 17S series SERCOS drive family is comprised of a

three-phase brushless servo amplifier, power supply, high-performance digital

controller and SERCOS fiber optic interface all housed in a single enclosure.

Drives Available The 17S drives are available in five models which are correlated to different output

current levels as identified in the following table.

Output Current (Peak) 17S Drive

4.2 A MHDS1004N00

8.4 A MHDS1008N00

16.8 A MHDS1017N00 28 A MHDS1028N00 56 A MHDS1056N00

Implementing the Drives

The Lexium 17S SERCOS drives are intended for incorporation into electrical

equipment or ma ch ine ry and can on ly be commissioned as integr al com ponents of

those types of devices.

Applicable Servo Motor Ty pes

The Lexium 17 S SERCO S drives are i ntended to driv e BPH series brush less se rvo

motors.

16

Continued on next page

Page 29

The 17S Series SERCOS Drive Family, continued

Electrical Considerations

The Lexium 17S family of servo amplifiers is to be used on earthed three-phase

industrial mains supp ly networks (TN- system, TT-syste m with earthed neutral point,

not more than 5000 rms symmetrical amperes).

The Lexium drives are incompatible with the IT system because interference

suppression filter s are i nternal and c onnec ted to e arth. If the us er wa nts to c onnec t

Lexium drives to an IT system, he may:

l us e an insul ation sta r transformer in order to re-create a local TT or T N system .

This way allows the rest of the wiring to stay an IT system (only warning in case

of the first fault.)

l us e a special R esidual Curren t Circuit Break er (RCC B) that is ab le to work w ith

dc and high peak currents. This device detects unbalance of phases with

regard to earth.

Warning: When the first fault occurs, the RCCB has to switch off quickly power

of the drives. Set of the residu al curre nt v alu e mu st be c arefull y done and m ust

be started with the lowest available value (for exampl e: 30mA.)

Following equipm ent of Merlin Gerin can be used:

l Vigirex, model RH328AF (Reference: 50055)

l One of these magnetic cores:

- model TA, 30mm in internal diameter (Reference: 50437)

- model PA, 50mm in internal diameter (Reference: 50438)

- model IA, 80mm in internal diameter (Reference: 50439)

If the servo amplifiers are used in residential areas, or in business or commercial

premises, then additional filter measures must be implemented by the user.

The Lexium 17S family of servo amplifiers is only intended to drive specific

brushless synchronous servomotors from th e Lexium BPH series, with closed-loo p

control of torque, speed and/or position. The dielectric withstand voltage of the

motors must be at least as hight as the DC-link voltage of the servo amplifier.

Use only copper wire. Wire siz e may be determinated from EN 60204 (or table 310-

16 of the NEC 60°C or 75°C column for AWG size).

We only guarantee the conformance of the servo amplifiers with the standards for

industrial areas, if the co mp onents (motors, cables, amplifi ers etc ) are d elivered by

Schneider Automa tio n.

Continued on next page

17

Page 30

The 17S Series SERCOS Drive Family, continued

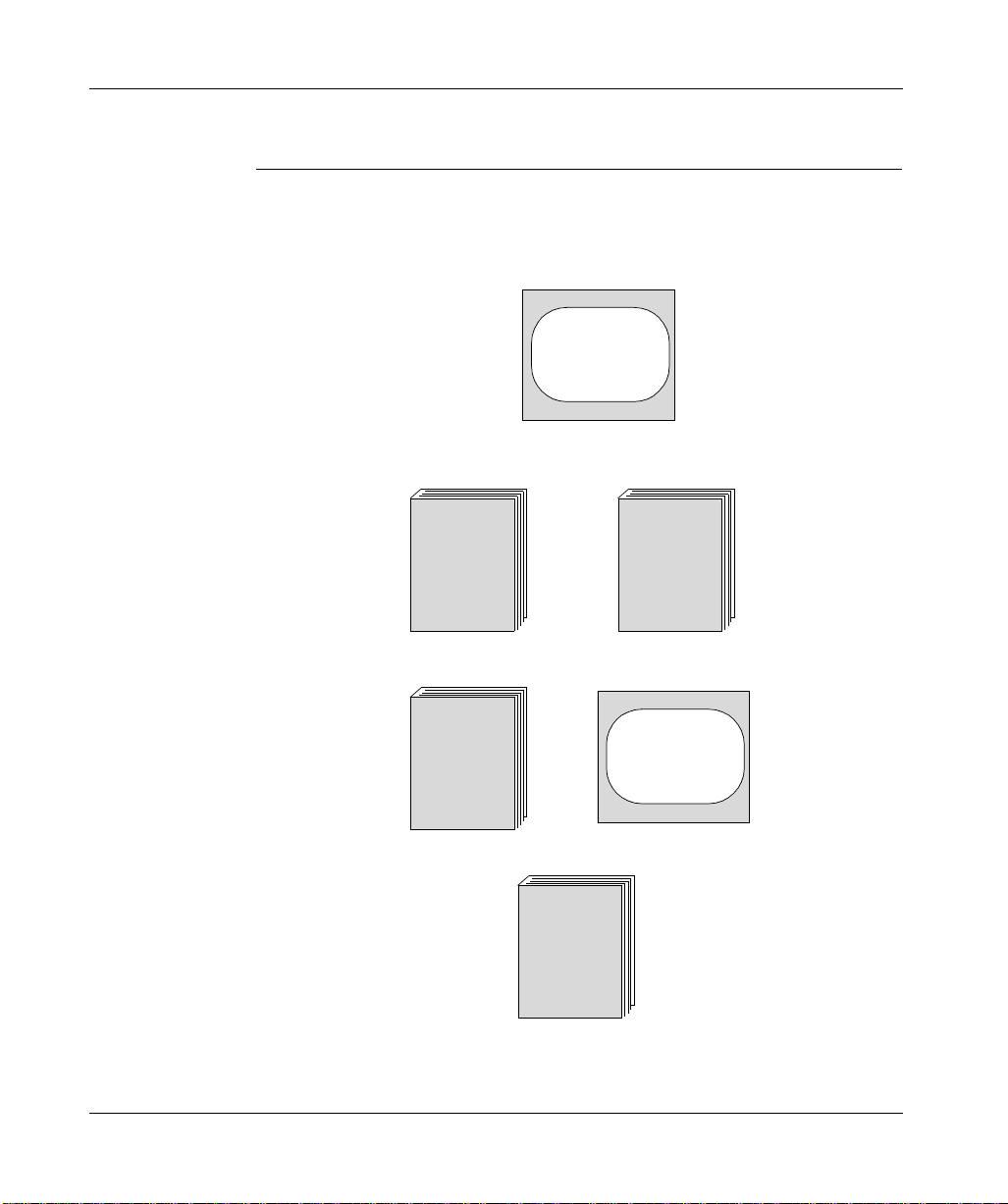

17S Drive Family Portrait

The following photograph shows a representative member of the 17S drive family.

The complete family consists of five models partitioned into two physical sizes.

Models MHDS1004N00, MHDS1008N00, MHDS1017N00 and MHDS1028N00

have dimensionally identical physical housings while Model MHDS1056N00 has a

wider housing. (See Chapter 3 for detailed dimensional information.)

18

Continued on next page

Page 31

The 17S Series SERCOS Drive Family, continued

17S Drives Front View

The following photograph shows a typical 17S front view with legends and labels.

Continued on next page

19

Page 32

The 17S Series SERCOS Drive Family, continued

Equipment Supplied

Equipment Available

Each 17S SERCOS drive includes the following hardware.

l Mating connectors X3, X4, X0

, X0B, X7 and X8

A

l Read me first

Note: The mating Sub-D connectors and servo motor connector X9 are supplied

with the appropriate cabl e.

The following items are optionally available to you from Schneider for use with the

17S SERCOS drives:

l Lexium BPH series brushless servo motors

l Servo motor power and feedback cables

Note: Power and feedback cables are available in lengths from 5...75 m and are

supplied by Schneider with the connector for the servo motor attached to the cable

and with the connector for the drive unassembled and unattached to the cable. The

10 m length cable is su pplied (from stoc k) b y Schneider with connectors att ached to

each end of the cable.

l Optional servo motor choke (for motor power cable lengths exceeding 25m)

l Optional external Regen resistor

l Serial communications cable (between drive and PC)

l SERCOS fiber optic cables in lengths of 0.3...38 m

20

Continued on next page

Page 33

The 17S Series SERCOS Drive Family, continued

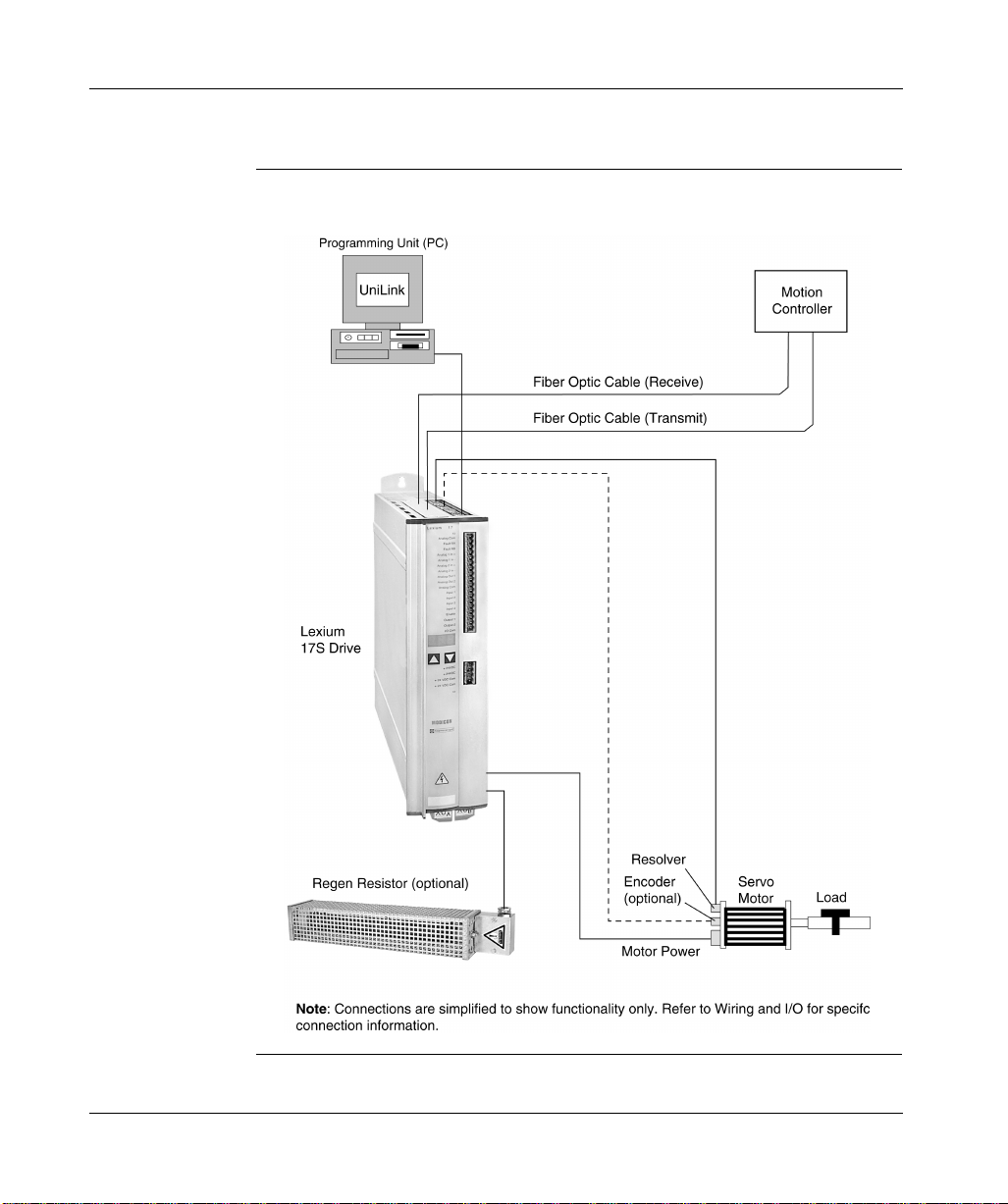

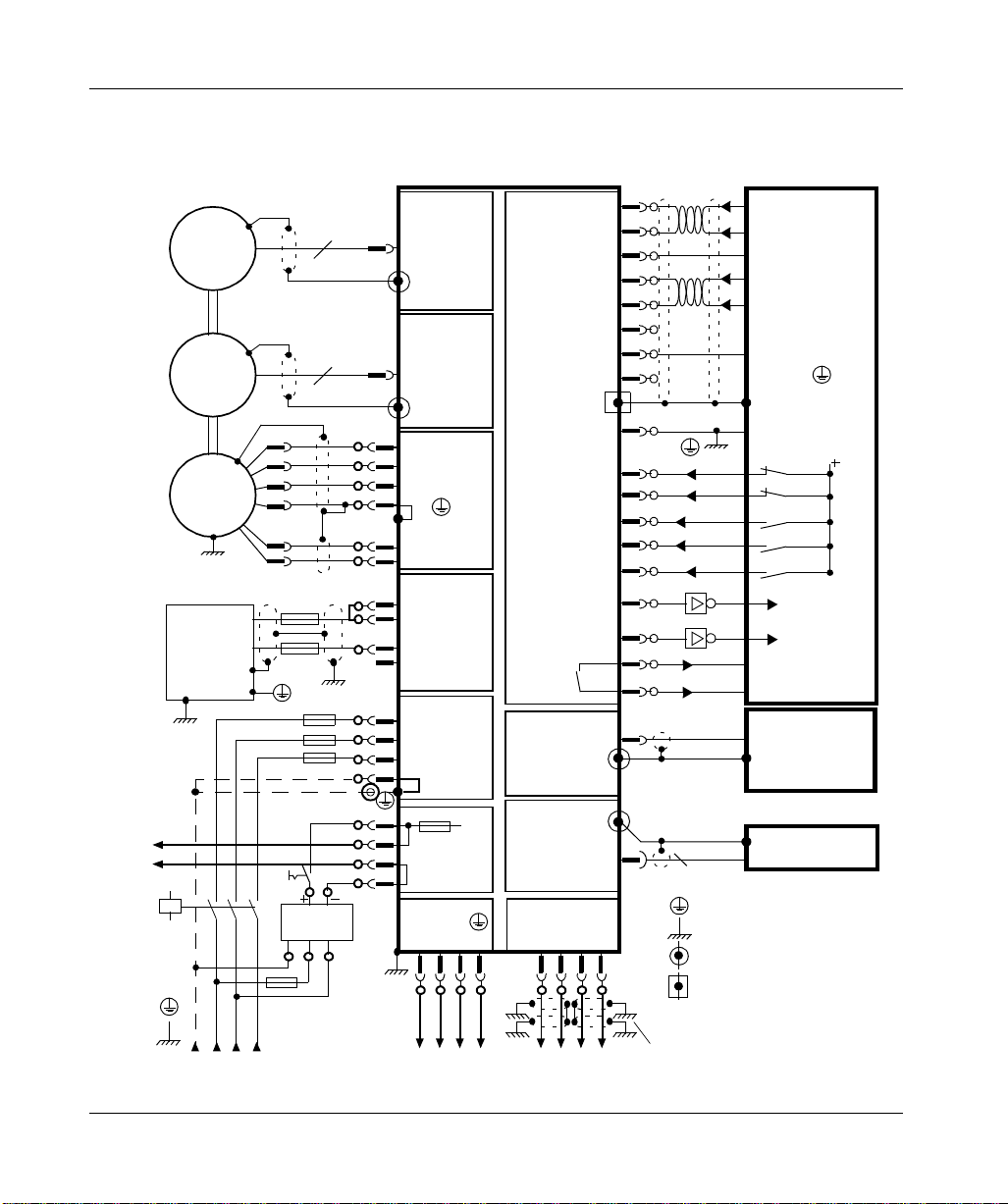

17S System Configuration Diagram

The following illustration shows a typical 17S system configuration.

21

Page 34

Modicon Multi-Axis Motion SERCOS Network Configuration

Overview The 17S drive is typica lly c onfigu red in a SERC OS net work con tai ning m any a xes.

A Schneider multi–axis motion controller configured with a SERCOS processor

board transmits motion instructions to all the 17S drives that are properly

configured in the fiber–optic loop.

Which Motion Controllers run a SERCOS Network

SERCOS FiberOptic Transmit

and Receive

Connectors

The controller that runs a network of many SERCOS axes is a Modicon Quantum

Automation Series SERCOS multi–axis motion controller (part number

141MMS42501) or TSX Premium CSY motion controller. Each controller supports

one independent SERCOS network ring. Each ring can contain up to 8 axes (8

drives and their motors). The 17S may also be configured with a compatible non–

Modicon SERCOS controller. Schneider also offers a 32-axis motion controller

(part number 141MMS53502).

Each 17S drive has two SERCOS–compliant SMA type fiber–optic connectors:

l TX (transmit)

l RX (receive)

Through a SERCOS–compliant, fiber–optic cable, the RX connector receives the

controller’s command instructions (as well as actual motion information from the

previous axes) from the previous drive in the ring. Likewise, the TX connector

transmits the controller’s command instructions (along with actual motion

information from the axes) to the next drive in the ring. The SERCOS multi–axis

motion controller also has a fiber–opti c transmitt er (TX) connector and a fiber–optic

receiver (RX) connector. The transmitter sends command instructions

commanded motio n

(

real feedback (

Transmission flows in one direction, with typical cycle times of 2ms to 4ms,

depending on the number or drives, volume of data, and data rate.

) to all the 17S axes in the ne tw ork ring. The receiver accepts

actual motion information

) from all the axes in the ring.

22

Continued on next page

Page 35

Modicon Multi-Axis Motion SERCOS Network Configuration, continued

Example of a Typical SERCOS Network Ring Configuration

The following figure shows a typical configuration of 17S SERCOS axes with

arbitrary node addresses receiving and transmitting instructions from a multi–axis

motion controller.

Continued on next page

23

Page 36

Modicon Multi-Axis Motion SERCOS Network Configuration, continued

Example of a

Typical SERCOS

Network Ring

Configuration,

continued

Benefits of Fiber-Optic Communication

Two Types of Fiber-Optic Communication

As shown in the figure, the ring ha s eight ax es. Thes e axes ne ed not be c onfigured

sequentially. Any axis in the ring can be identified as axis 1, axis 2, axis 3, and so

on. However, each address within a ring must be unique.

The SERCOS multi–axis motion controller coordinates the motion activities of the

various SERCOS axes on the network ring. Fiber optic communication allows

efficient synchronization of multiple axes through flexible SERCOS networking

rather than through a constraining backplane bus configuration. SERCOS

networking allows you to place each drive close to its motor. This reduces and

eliminates cumbersome wiring from the motor to the controller. The fiber–optic

SERCOS protocol provides com plete electrical is olation between drive axes as w ell

as between each drive axis and the motion controller. This eliminates wiring

difficulties, such as ground loops, which are present in hard–wired systems.

The SERCOS protocol allows two types of communication simultaneously

throughout the network ring:

l Constant real–time data updates

l Slower intermittent messaging

This flexibility allows the communication to serve many different types of motion

applications.

24

Note: For more information on fiber optic connections and signal wiring, see

Chapter 4 and Appendix C.

Page 37

Overview of Usability Features

Digital Control The 17S drive provides complete digital control of a brushless servo system. This

includes:

l A digital field-oriented current controller operating at an update rate of 62.5 µs

l A fully programmable digital PI-type speed controller operating at an update

rate of 250 µs

l Ful l digita l e v aluation of motor position f eedbac k (primary feed back ) from e ither

a standard two-poles resolver or a high precision Sin-Cos type encoder

(hiperface).

Continued on next page

25

Page 38

Overview of Usability Features, continued

Usability Enhancements

The following features are incorporated into the 17S drive to facilitate the set-up

and operation of the servo system:

l Two analog +/-10 V inputs can be programmed for a multitude of functions

depending upon the application. Both inputs incorporate automatic offset

compensation, dead-band limitation and slew-rate limitation.

l Four fully programmable 24 V discrete inputs; two of which are typically defined

as hardware limit switches.

l Two fully programmable 24 V outputs and a separate 24 V brake output

capable of driving a maximum of 2 Amps.

l An integrated and fully isolated RS-232 connection for communication with a

PC; used to set configuration parameters and tune the system with the Unilink

configuration software.

l A separate 24V bias supply input which may be connected through a UPS to

preserve system data in the event of an interruption in the AC mains supply.

26

Page 39

Overview of 17S Internal Electronics

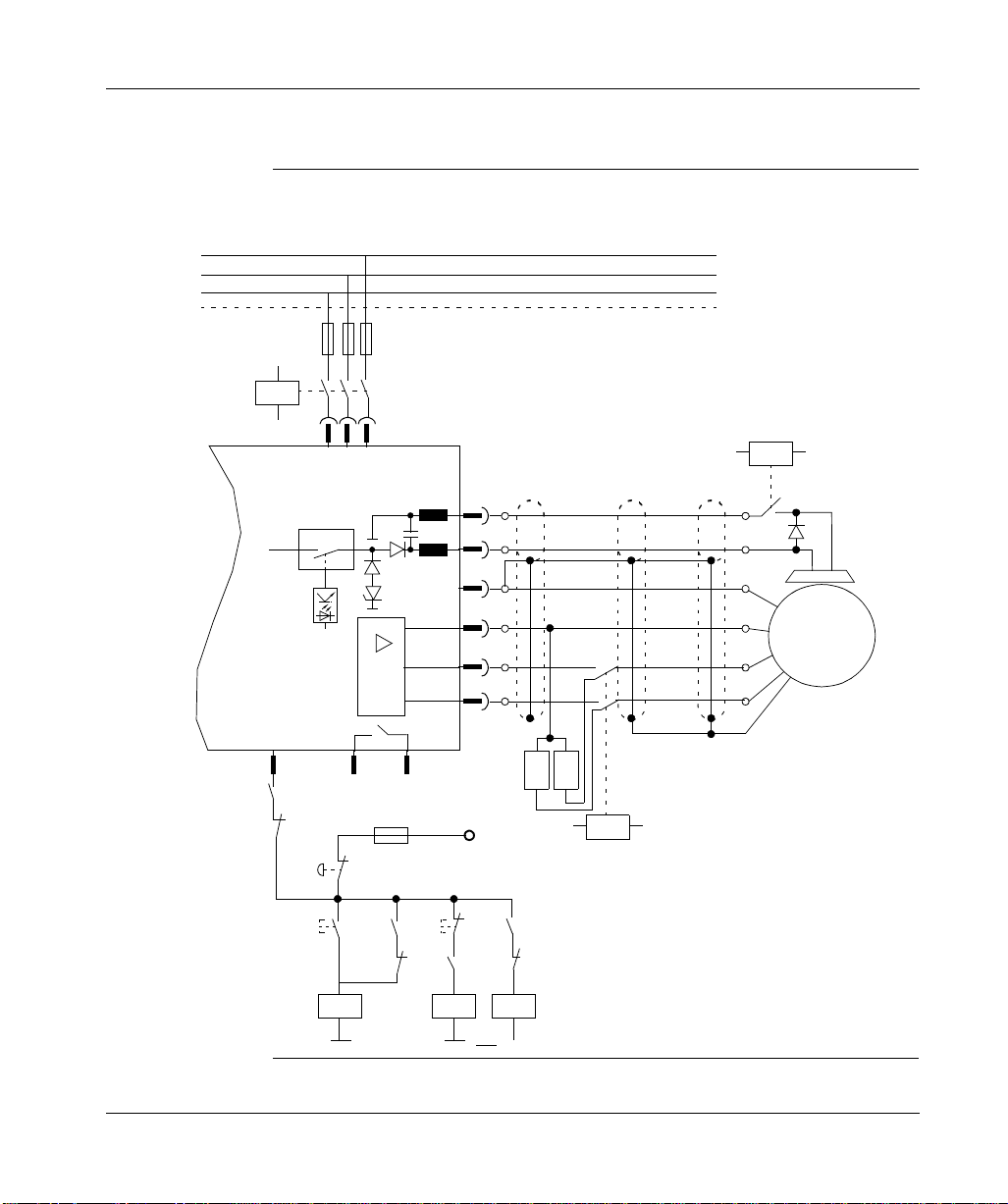

17S Internal Electronics Block Diagram

The following block diagram illustrates the 17S internal electronics and depicts

internal interfaces for power, signal I/O, and communication.

ROD SSI

2

Analog1 in+

Analog1 in-

Analog2 in+

Analog2 in-

ROD

SSI

+Rb ext

+Rb int

-Rb

X9

X2

X1

X9

Continued on next page

27

Page 40

Overview of 17S Internal Electronics, continued

General Characteristics

The Lexium 17S SERCOS drives are available in five peak output current ratings

(4.2, 8.4, 16.8, 28 and 5 6 A) th at are partitioned into two grou ps ba sed o n the width

of the package; the 70 mm drives are rated to handle currents up to 28 A and the

120 mm wide drive i s ra ted to handl e currents up to 56 A. All Le x ium d rive s opera te

with an input voltage whic h may range from 208 V -10% 60 Hz, 230 V -10%

50 Hz through 480 V +10% 50-60 Hz.

Each drive pr ovides:

l Direct shield connection points

l Two analog setpoint inputs

l Integrated and electrically isolated RS-232 communications

Primary Power A single phase input supply may be used for commissioning and set-up and for

continuous operation with various smaller drive/motor combinations. See the

Lexium 17/ BPH motor torque speed curves for details.

Fusing (e.g. fuse cut-out) is provided by the user.

Bias Power The 17S drive requires 24 Vdc bias power from an external, electrically isolated

supply.

EMI Suppression EMI suppression for the 17S drives is integrally provided by filters on both the

primary power (EN550011, Class A, Group 1) input as well as on the 24 Vdc bias

supply (Class A) input.

Continued on next page

28

Page 41

Overview of 17S Internal Electronics, continued

Internal Power Section

DC Link Capacitor Reconditioning

Integrated Safe Electrical Separation

The Internal power section of the 17S drive includes the following:

l Power input: A rectifier bridge directly connected to the three-phase earthed

supply system, integral power input filter and inrush current limiting circuit.

l Motor po w er out put: PWM curren t-controlle d vo ltage so urce IGBT-inv e rter with

isolated current measurement

l Regen circuit: Dynamic distribution of Regen power between several drives on

the same DC Link circuit. An internal Regen resistor is standard; optional

external Regen resistors are available as required by your application.

l DC Link voltage: 300...700 Vdc, nominal (900 Vdc, intermittent) and can be

operated in parallel.

If the servo drive has been stored for longer than one year, then the DC Link

capacitors will have to be reconditionned as follows:

Step Action

1 Ensure that all electrical connections to the drive are disconnected.

2 Provide 230 Vac, single-phase power to connector XO

servo drive for about 30 minutes to recondition the capacitors.

(terminals L1/L2) on the

A

The 17S drive ensures safe electrical separation (in accordance with EN 50178)

between the power input/motor connections and the signal el ectronics through the

use of appropriate insul ati on-c r ee pag e di stances and electrical isolation. The driv e

also provides soft-s tart characteristic s, o v ervoltage an d ov ertemperat ure detecti on,

short-circuit protection and input phase-failure monitoring. When using BPH series

servo motors in conjunction with Schneider’s pre-assembled cables, the drive also

monitors the servo motor for overtemperature.

Keypad The operation of the keypad on the front panel of the 17S drive is described in

System Operation. The se two keys can be used (as an al ternative to using the PC)

to enter the SERCOS address fo r the drive

29

Page 42

LED Display and Discrete Indicators

A three-character LED display on the front of the 17S drive indicates drive status

after the 24 Vdc bias supply is turned on. If applicable during operation, error and/

or warning codes are displayed. In addition, three individual LED indicators (one

red and two green) on the SERCOS communication card (at the top of the drive)

are used to indicate the status of that communications.

Continued on next page

30

Page 43

Overview of System Software

Setup Configuration software is used for setting up and storing the operating parameters

for the Le x ium 17S s eries d rives. The drive is commissioned wi th th e as si stance of

the UniLink software and, during this process, the drive can be controlled directly

through this software.

Setting Parameters

You must adapt the SERCOS driv es to the requi remen ts of y our inst all ation. T his is

usually accomplish ed by co nnecting a PC (progra mming unit) t o the drive’s RS-232

serial interface th en running the Schnei der-sup plied U niLi nk con figur ation so ftw are .

The UniLink software and the associated documentation are provided on a CDROM. Use the UniLink software to alter parameters; you can instantly observe the

effect on t he drive because there is a contin uous (onl ine) c onnec tion to the driv e . In

addition, actual val ues are si multan eously rec eived from the drive an d displa y ed on

the PC monitor.

Default Settings Motor-specific default settings for all the reasonable combinations of drive and

servo motor are incorporated i nto the driv e’ s firmware. In most appl ications , y ou will

be able to use these default values to get your drive running without any problems.

(Refer to the UniLink online help for additional information on default values.)

Continued on next page

31

Page 44

Overview of System Software, continued

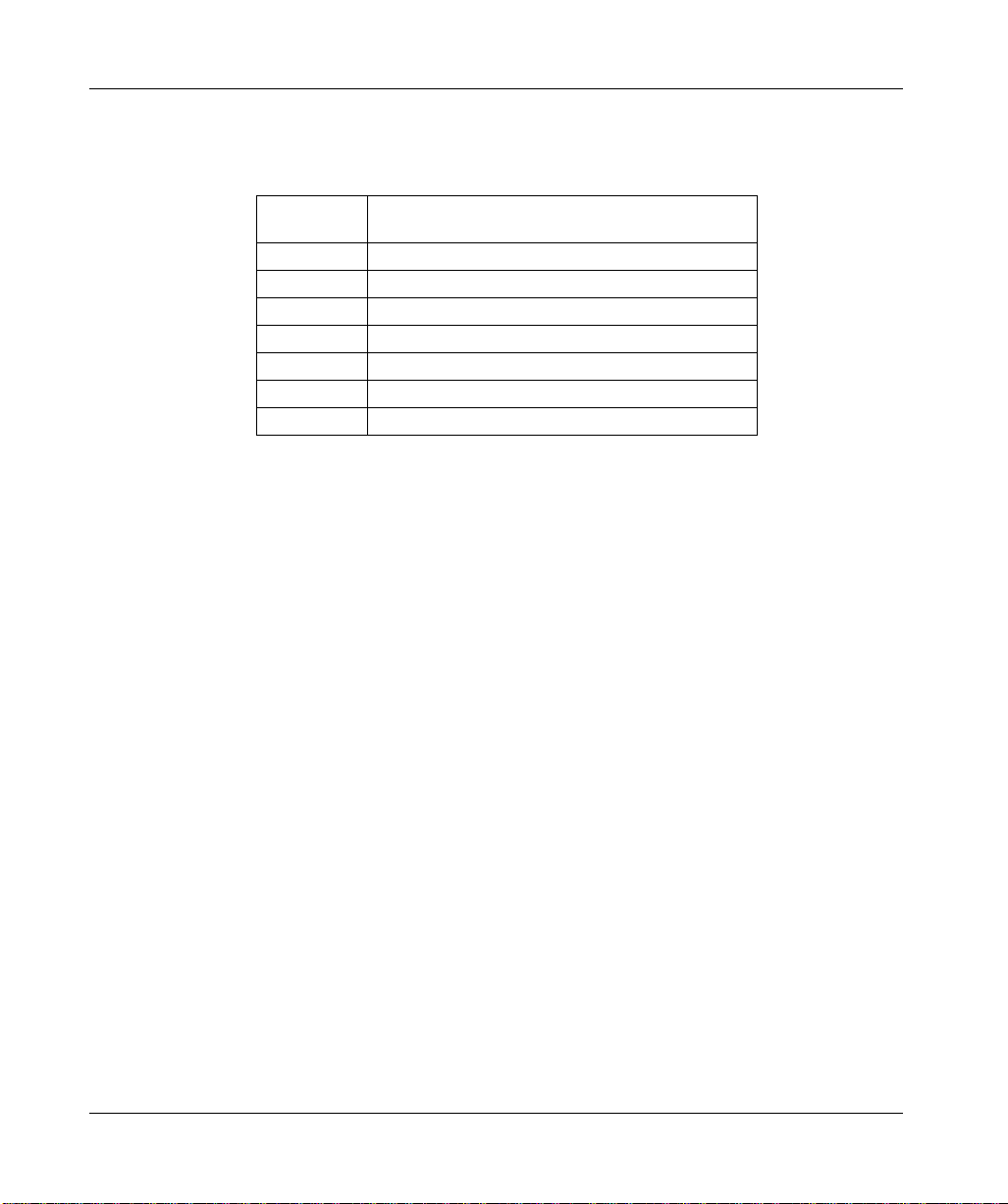

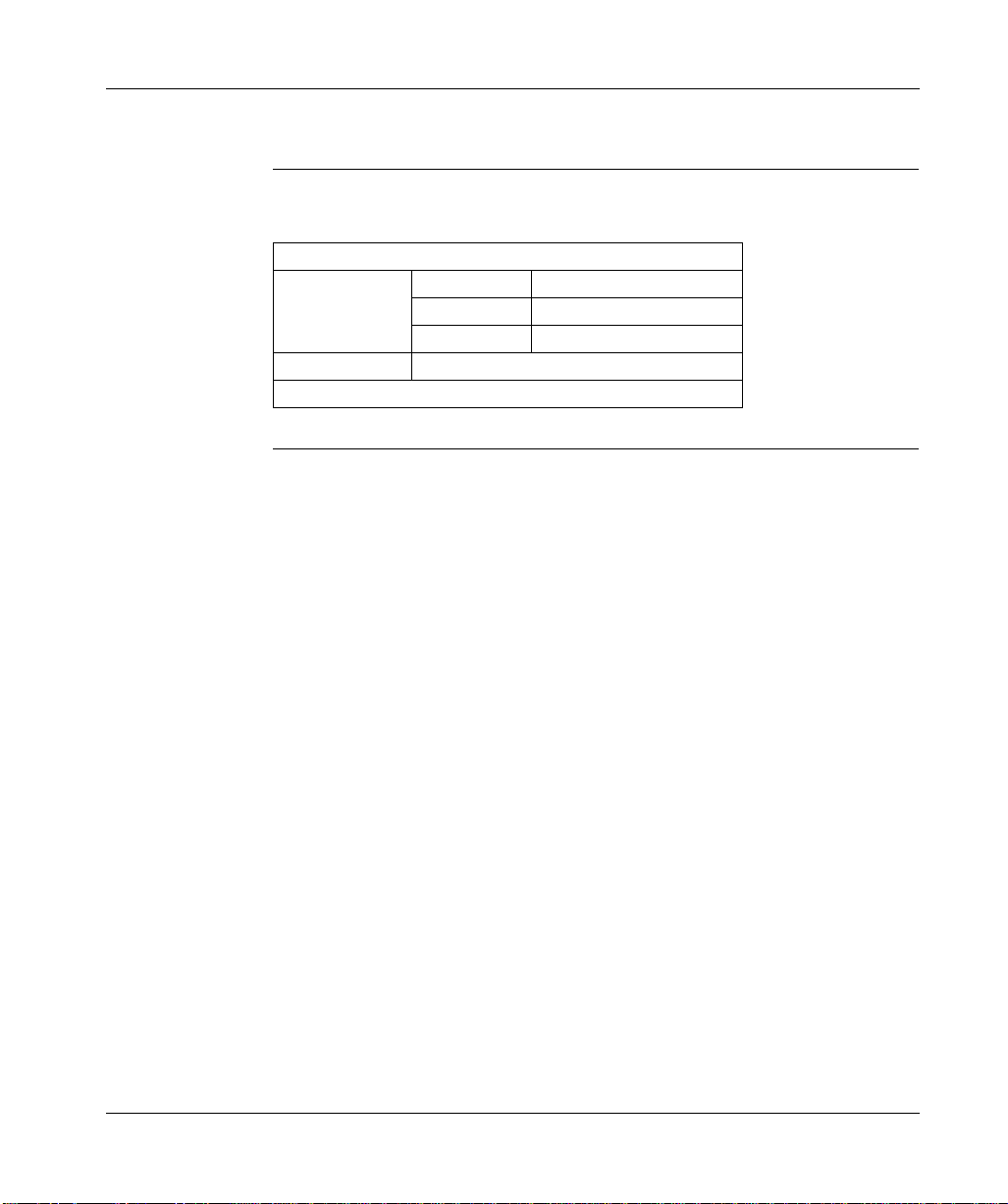

UniLink Commissioning Software

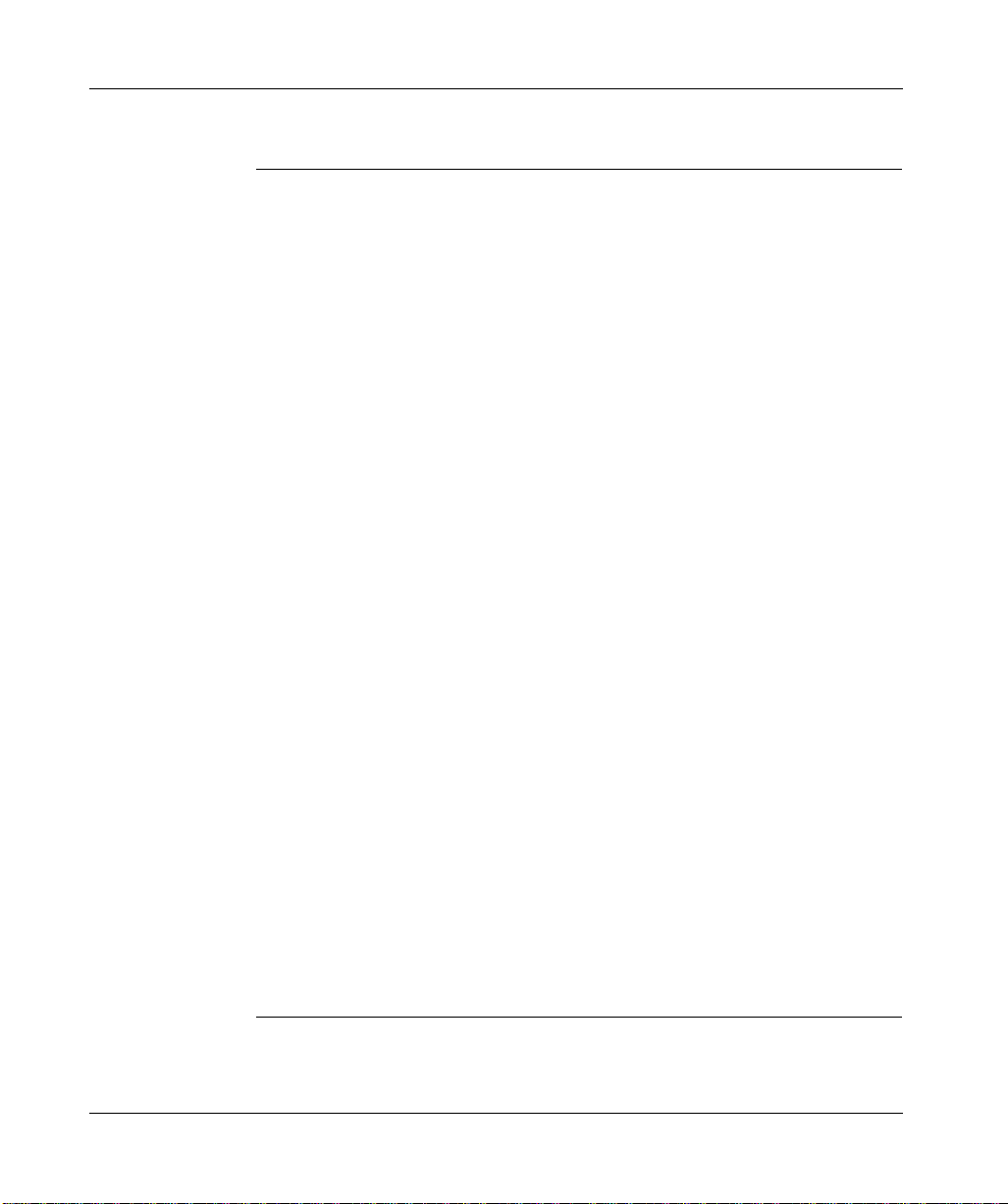

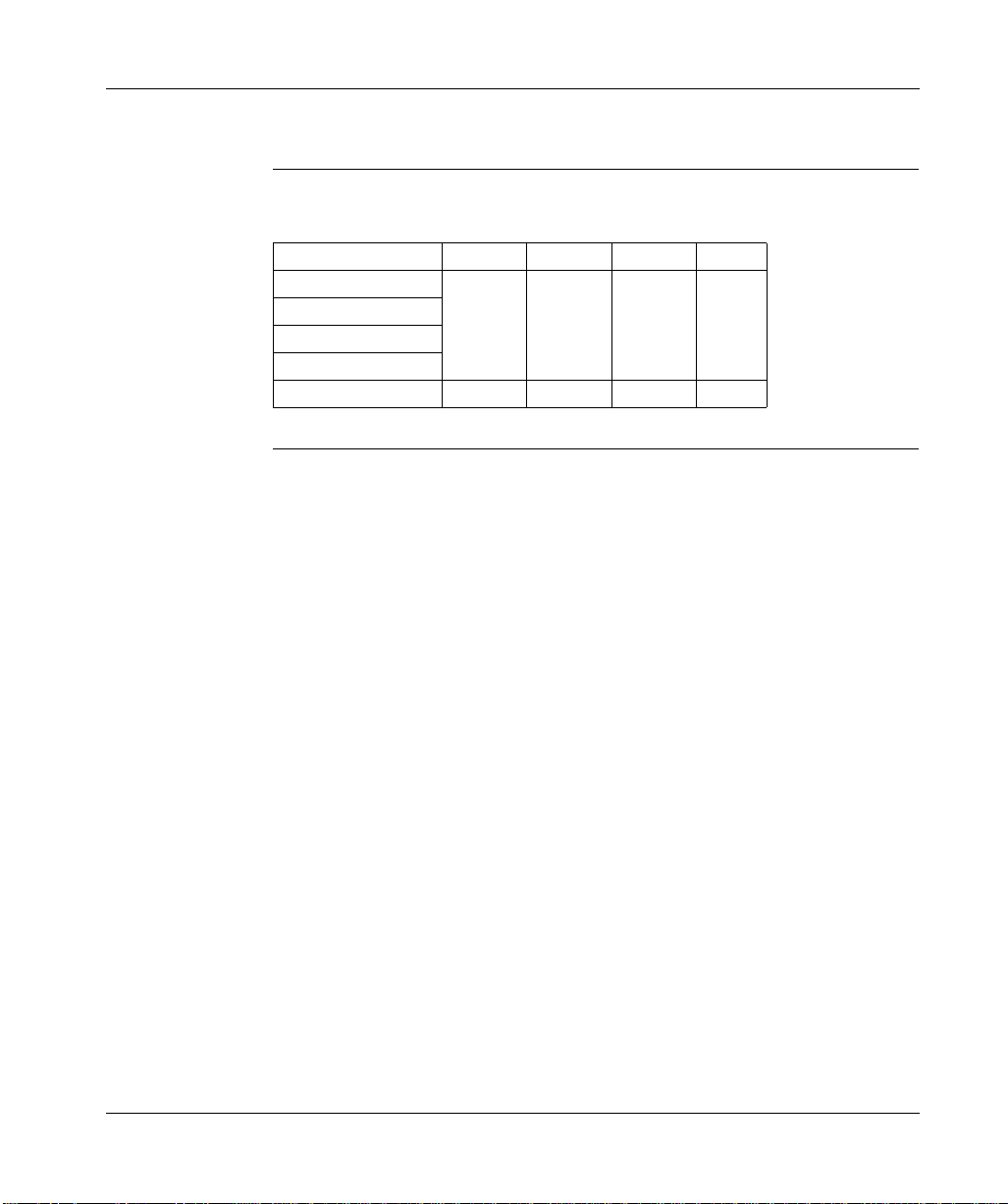

The minimum PC system requirements needed for the UniLink commissioning

software ar e specified in the following table:

Item Minimum Requirement

Operating System Windows 95

Hardware:

Processor

Graphics adapter

RAM

Hard drive space

Communications

Windows 98

486 or higher VGA 8 Mbytes 5 Mbytes available One RS-232 serial port

32

Page 45

At a Glance

Mounting and Physical Dimensions

3

What’s in this Chapter

This chapter provides information on the mounting requirements for, and physical

dimensions of, the Lexium 17S series SERCOS drives and includes the following

topics:

Topic Page

Installation safety precautions 34 Installation considerations 36 Drive mounting and physical dimensions 37 Optional external Regen resistor mounting and

dimensions

Optional choke mounting and dimensions 40

39

33

Page 46

Installation Safety Precautions

CAUTION!

MECHANICAL STRESS

Protect the drive from physical impact during transport and handling. In particular,

do not deform an y exterior surfaces; doing so may damage internal components or

alter critical insulation distances.

Failure to observe this precaution can result in injury or equipment damage.

CAUTION!

ELECTRICAL STRESS

At the installation site, ensure the maximum permissible rated voltage at the Mains

and bias input connectors on the drive are not exceeded. (See EN 60204-1,

Section 4.3.1.) Excessive voltages on these terminals can result in destruction of

the Regen circuit and/or the drive’s electronics.

Failure to observe this precaution can result in injury or equipment damage.

34

CAUTION!

ELECTRICAL CONNECTIONS

Never disconnect the electrical connections to the SERCOS drive while power is

applied.

Failure to observe this precaution can result in injury or equipment damage.

Continued on next page

Page 47

Installation Safety Precautions, continued

CAUTION!

CONTAMINATION AND THERMAL HAZARD

Ensure the 17S drive is mounted within an appropriately vented and closed

switchgear cabinet that is free of conductive and corrosive contaminants. Ensure

the ventilat ion clearanc es above and below the drive conform to requirements.

(Refer to Chapter 3 for additional information.)

Failure to observe this precaution can result in injury or equipment damage.

DANGER!

ELECTRIC SHOCK HAZARD

Residual voltages on the DC link capacitors can remain at dangerous levels for up

to five minutes after switching off the mains supply voltage. Therefore, measure the

voltage on the DC Link (+DC/-DC) and wait until the voltage has fallen below 40 V.

Control and power connections can still be energized, even when the motor is not

rotating.

Failure to observe these instructions will result in death or serious injury.

35

Page 48

Installation Considerations

Power Supply Overcurrent Protection

Earth Connections

Cable Separation Route power and control (signal) cables separately. Schneider recommends a

Air Flow Ensure that there is an adequate flow of coo l, filtered air into the bottom of the

You are responsible for providing overcurre nt p rote ction (via circuit breakers and/or

fuses) for the Vac mains supply and the 24 Vdc bias supply that are connected to

the drive.

Ensure the drive and associated servo motor are properly connected to earth.

separatio n of at least 20 cm. This degree of separation improves the performance

of the system. If a servo motor power cable includes wires for brake control, those

wires have a se parate shield which must be connected to earth at both en ds of the

cable.

switchgear cabinet containing the drive.

36

Page 49

Drive Mounting and Physical Dimensions

17S Height, Width and Depth Dimensions

The following diagram sh ow s hei ght , w id t h an d depth dimensions for the 17S drive.

Continued on next page

37

Page 50

Drive Mounting and Physical Dimensions, continued

17S Drive and Mounting Area Dimensions

The following diagram shows depth dimensions and mounting area requirements

for the 17S drive.

38

Page 51

Optional External Regen Resistor Mounting and Physical Dimensions

Optional External Regen Resistor Assembly Dimensions

The following diagram shows the dimensions for all three optional external Regen

resistor assemblies.

39

Page 52

Optional Motor Choke Mounting and Dimensions

Optional Motor Choke Assembl y Dimensions

The following diagram shows the dimensions for the motor choke assembly

40

Page 53

Wiring and I/O

4

At a Glance

Introduction This chapter describes an d illu str ates all po w er wiring c onnec tions , a ll sig nal wiring

connections, and I/O wiring connections on the 17S drive. Power and signal wiring

connections are:

l AC mains power through a four-position, plug-in, terminal block connector

l Bias power through four-position, plug-in, terminal block connector

l Serial power connections among multiple drives

l Servo motor power through a six-position, plug-in, terminal block connector

l Optional Regen power resistor through a four-position, plug-i n, terminal

block connector

l Reso lve r feedb ack input through a nine-pin, plug-in, Sub-D connector

l Encoder feedback input through a 15-pin, plug-in, Sub-D connector

l Auxiliary encoder interface through a nine-pin, plug-in, Sub-D connector

l Fiber optic Interface through two SMA connectors

l Analog in and digital I/O through an 18-position, plug-in terminal block

connector

l Serial communications interface through a nine-pin, plug-in, Sub-D

connector

Continued on next page

41

Page 54

At a Glance, continued

What’s in this Chapter

This chapter contains the following topics.

Topic Page

Wiring and I/O initial considerations 43 Wiring overview 44 Cable shield connections 47 Power wiring 49 Signal wiring 57 Analog input connections 63 Fault Relay and Digital I/O connections 64 Serial communications connections 66

42

Page 55

Wiring and I/O Initial Considerations

Initial Considerations

Some descriptions and illustrations contained in this chapter are provided as

examples. Actual implementation depends on the application of the equipment;

thus, appropriate variations are allowed provided they neither violate any safety

precautions nor jeopardize the integrity of the equipment.

DANGER!

ELECTRIC SHOCK HAZARD

Before you wire and connect cables, ensure the mains power supply, the 24 Vdc

bias power supply and the power supplies to any other connected equipment, are

OFF. Ensure any cabinet to be accessed is first electrically disconnected, secured

with a lock-out and tagged with warning signs.

Failure to observe these safety instructions will result in death or serious

injury.

Grounding Ensure the drive mounting plate, SERCOS motor housing and Analog Com for the

controls are connected to common panel earth ground point.

Continued on next page

43

Page 56

Wiring Overview

Overview of 17S Wiring Connections

The following diagram shows the wiring connections for the 17S drive.

CAUTION:

Do not connect a Modbus serial port to the X6 connector!

Pin1 carries +8 Vdc which would be shorted out by a Modbus cable.

Instead, use a standard 3-core null-modem cable (not a null-modem link cable) with only

pins 2, 3 and 5 wired.

Failure to observe this precaution can result in equipment damage.

44

Note: The connectors described above appear in many wirin g diagrams throughou t

the remainder of this document and are identified in those diagrams by their

alphanumeric designations only (for example, X4); the term

connector

is excluded.

Page 57

Connection diagram for Lexium 17S

Reference Safety Instructions

and Use As Directed!

Sine-Cosine

Encoder

Resolver

U2

V2

M

Remove jumper if external

regen resistor is connected

Regeneration

resistor

Master

contactor

PEL1 L2 L3

W

PE

B+

B-

thermal control

included

thermal control

included

F

B1

FB2

FN

FN

FN

supply unit

24V DC

FH

+ +/-10V speed

setpoint1

referenced to GND

GND

+ +/-10V speed

setpoint2

referenced to GND

GND

GND

I/O-GND

+24V referenced

to 0V/GND

Digital1

Digital2

Safety

circuit

encoderevaluation,

slave/master

amplifier

COM1/COM2

3

PE-connection (protective earth)

earth connection (panel)

shield connection via plug

shield connection at the front panel

Input 3

Input 4

Input 1

Input 2

Enable

ROD

SSI

Ma./SI.

PC

4

5

1

6

7

8

10

9

18

13

14

11

12

15

16

17

2

3

shielding if cable

is longer than 20cm

X1

15

8

high

resolution

single /

multiturn

X2

Resolver

6

U

5

V

4

W

3

P

2

Brake+

1

Brake-

2

+RBint

1

-RB

3

+R

4

n.c.

1

L1

2

L2

3

L3

4

1

2

+24 Vdc

3

24 Vdc Com

4

L1 L2 L3 PE

1234 1234

X9

X8

Bext

X0A

PE

X4

X0B

to other amplifiers

Analog 1 in +

Analog 1 in -

Analog Com

Analog 2 in +

Analog 2 in -

Reserved

Analog Com

Reserved

X3

I/O Com

Output 1

Output 2

Fault RA

Fault RB

X5

X6

X7

DC+ DC+DC- DC-

45

Page 58

Pin assignments for LEXIUM 17 S

X2 RESOLVERX5 ROD/SSIX6 PC X1 ENCODER

1 Reserved

Analog Com 1

Fault Ra 2

Fault Rb 3

Analog 1 In+ 4

Analog 1 In- 5

Analog 2 In+ 6

Analog 2 In- 7

Reserved 8

Reserved 9

Analog Com 10

Input 1 11

Input 2 12

Input 3 13

Input 4 14

Enable 15

Output 1 16

Output 2 17

I/O Com 18

+24Vdc 1

+24Vdc 2

+24Vdc Com 3

+24Vdc Com 4

2 RxD

3 TxD

4 N.C.

5 PGND

7

8

Reserved 6

X3

X4

Reserved 9

1 Pcom

2 M+

B+ (DATA) 6

3 M-

B- (/DATA) 7

4 A- (CLK)

5 A+ (/CLK)

N.C. 9

Reserved 8

B

0

X

5 R1

4 S2

3 S321 Shield

S4 8

R2 9

V

S1 7

V 6

V

8 Clock7 6 N.C.

14

V

Clock 15

5 DATA(+485)

4 Up (8V)

3 B+ (COS)

0V SENSE 10

Up SENSE 12

DATA (-485) 13

B- (REFCOS) 11

2 0V(GND)

1 A+ (SIN)

A- (REFSIN) 9

View: looking at the

face of the built-in

connectors

e

ak

br

/

or

ot

m

9

X

e+

e-

ak

N

E

G

E

R

8

T

X

X

.

E

c

B

nt

i

n.

R

B

+

4

R

+

3

RB

-

2

E

P

1

L3

4

2

L

3

L1

2

1

A

0

X

1

C

D

7

X

4

3

E

2

L3

2

L

L1

r

ak

B

r

B

1

t

ui

c

r

i

c

-

4

3

C

2

C

1

D

C

+

D

C

-

D

+

P

2

U

2

2

V

6

W

5

E

P

4

3

2

Coding

D

-

46

Continued on next page

Page 59

Cable Shield Connections

Connecting Cable Shields to the Front Pa nel

The following procedure and associated diagram describe how to connect cable

shields to the front panel of the 17S drive:

Step Action

Remove a length of the cable’ s outer covering and braided shield sufficient to

1

expose the required length of wires.

Secure the exposed wires with a cable tie.

2

Remove approximately 30 mm of the cable’s outer covering while ensuring the

3

braided shield is not damaged during the process.

At the front panel of the drive, insert a cable tie into a slot in the shielding rail.

4

Use the previously inserted cable tie to secure the exposed braided shield of

5

the cable firmly against the shielding rail.

Continued on next page

47

Page 60

Cable Shield Connections, continued

Cable Shield Connection Diagram

The following diagram shows the cable shield connections at the front of the 17S

drive.

48

Page 61

Power Wiring

AC Mains Power Supply Connection

Bias Supply Connection

The following diagram shows the connections for the AC mains power supply input

to the 17S drive.

*

*3 x 230 V +10% max. with a BPH055 Servo motor

The following diagram shows the connections for the bias power supply input to the

17S drive.

Continued on next page

49

Page 62

Power Wiring, continued

Serial Power Connections

The following diagram shows the serial connections for the AC mains and bias

power among multiple 17S drives.

AC supply

Lexium 17S

X4

+24

~

=

L1

L2

L3

+24

COM

COM

X0AX7X0B

L1

L2

L3

PE

+DC

-DC

+DC

-DC

PE

L1

L2

L3

Lexium 17S

X4

+24

+24

COM

COM

X0AX7X0B

L1

L2

L3

PE

+DC

-DC

+DC

-DC

PE

L1

L2

L3

Lexium 17S

X4

+24

+24

COM

COM

X0AX7X0B

L1

L2

L3

PE

+DC

-DC

+DC

-DC

L1

L2

L3

PE

To

Next

Drive

DC supply

NCNC

Lexium 17S

X4

+24

+24

COM

COM

X0AX7X0B

L1

L2

L3

PE

+DC

-DC

+DC

-DC

PE

L1

L2

L3

NC

To

Next

Drive

POWER

SUPPLY

+DC

-DC

24 Vdc

Power Supply

1

2

Fuse

Max fuse: 20 A

1

schielded if length > 20 cm

2

Lexium 17S

X4

+24

+24

COM

COM

X0AX7X0B

L1

L2

L3

PE

+DC

-DC

+DC

-DC

PE

L1

L2

L3

50

Notes: -Inrush current must be limited to 20 A between power supply and drives.

- Drives have to be configured (see Unilink commands) to suppress faults.

Continued on next page

Page 63

Power Wiring, continued

Optional External Regen Resistor Connection

Regen Circuit Functional Description

The follo win g dia gra m sh ows the conne ctions betw ee n the optio nal external Regen

resistor and the 17S drive. The drive is shipped with a jumper installed on

connector X8, terminals RB and R

. If you are going to use an optional external

Bint

Regen resistor, then remove the jumper to disconnect (and thus disable) the

internal Regen resistor.

Fusing of the two lines to external Regen Resistor is mandatory.

Use high voltage AC/DC and fast fuses.

During braking, energy from the servo motor is returned to the driv e an d co nverted

into heat in the Regen resistor. Operation of the Regen resistor is controlled by the

Regen circuit using thresholds that are adjusted to the main supply voltage that is

configured in the UniLink software. The following is an abbreviated functional

description of the Regen circuit operation.

l Ind ividual drive (not coupled through the DC Link circu it) - The circuit sta rts to

respond at a DC L ink voltage of 400V, 720V or 840V (depending on the supply

voltage). If the energy fed back from the servo motor is higher than the preset

Regen power, then the drive issues a "Regen power exceeded" signal and the

Regen circuit will be switched off. Upon the next i nternal check of the DC Link

voltage, an overvoltage will be detected, the fault relay contact will be opened

and the drive will be switched off with the error message "Overvoltage".

l Mu ltipl e driv es (coupled through the DC Link circu it) - In thi s c as e , the R ege n

energy is distributed equally among all the drives.

Continued on next page

51

Page 64

Power Wiring, continued

Lexium BPH Servo Motor Connection (excluded BPH055)

The following diagrams show the connections between a servo motor (excluded

BPH055) and the 17S drive. When the interface cable length exceeds 25 m, a

motor choke must be i nstal led as sho wn a nd at a d istance of one m eter or les s from

the drive.

52

Continued on next page

Page 65

Power Wiring, continued

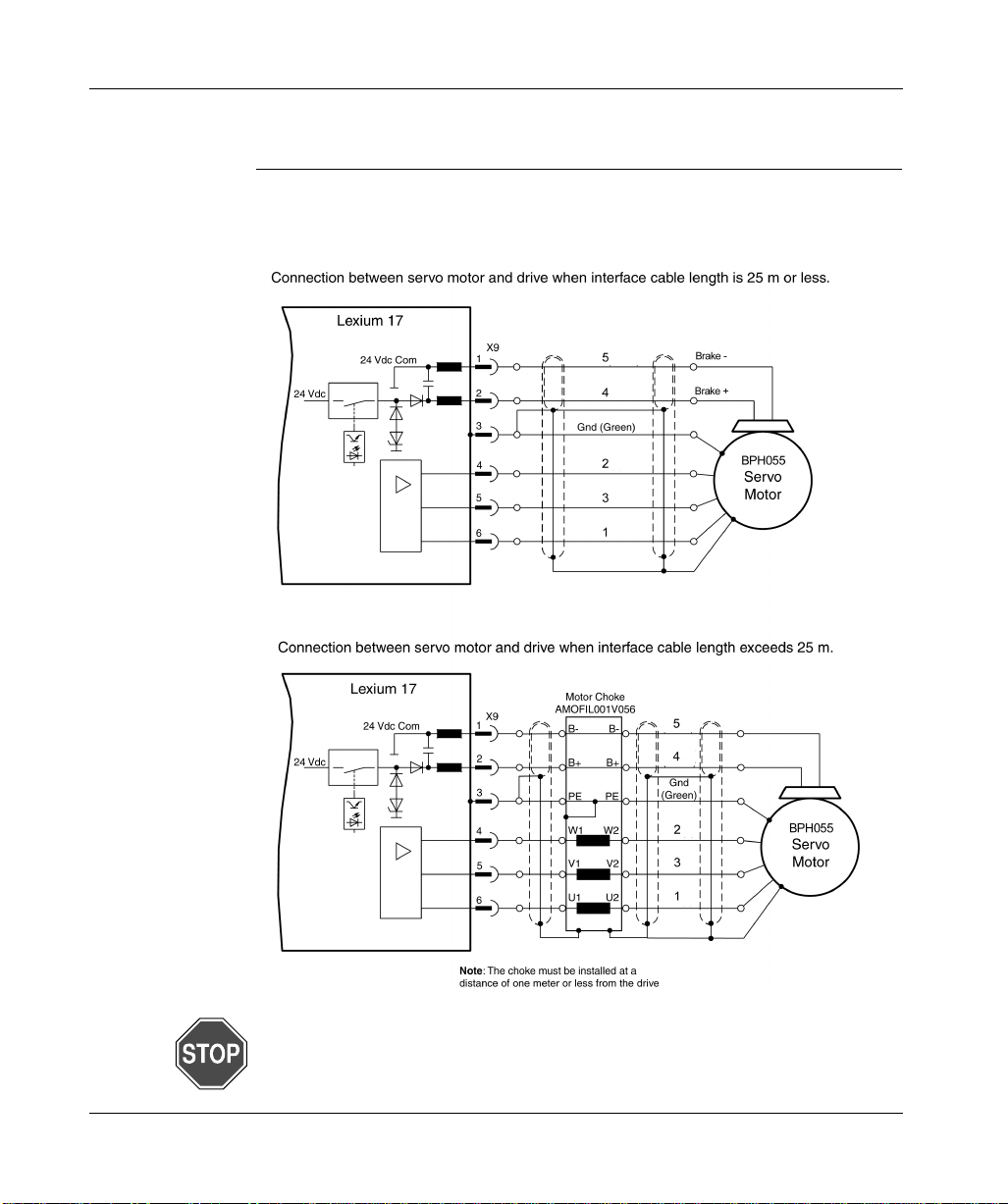

Lexium BPH 055 Servo Motor Connection

The follo w ing d iag rams show the connections between a BPH055 servo motor and

the 17S drive. When the interface cable length exceeds 25 m, a motor choke must

be installed as shown and at a distance of one meter or less from the drive.

WARNING!

With a BPH055 Servo motor, power supply of the 17S drive must be limited to

3 x 230 Vac +10%

53

Page 66

Power Wiring, continued

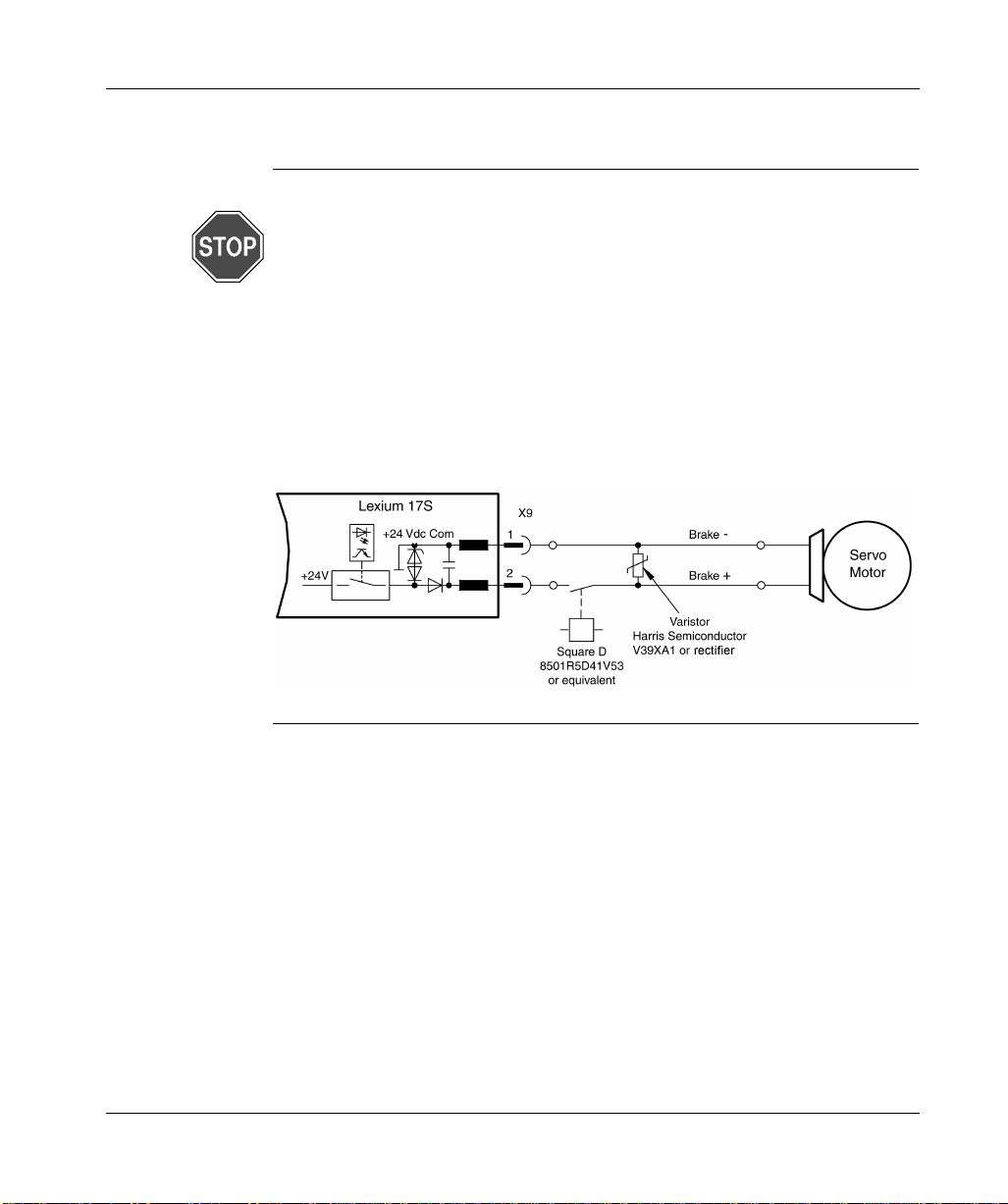

Servo Motor (with Optional Dynamic Brake Resistors and Contactor) Connection

The following diagram shows the connections between a servo motor and the 17S

drive when the optional dynamic brake rersistors and associated contactor are

incorporated.

54

10

Continued on next page

Page 67

Power Wiring, continued

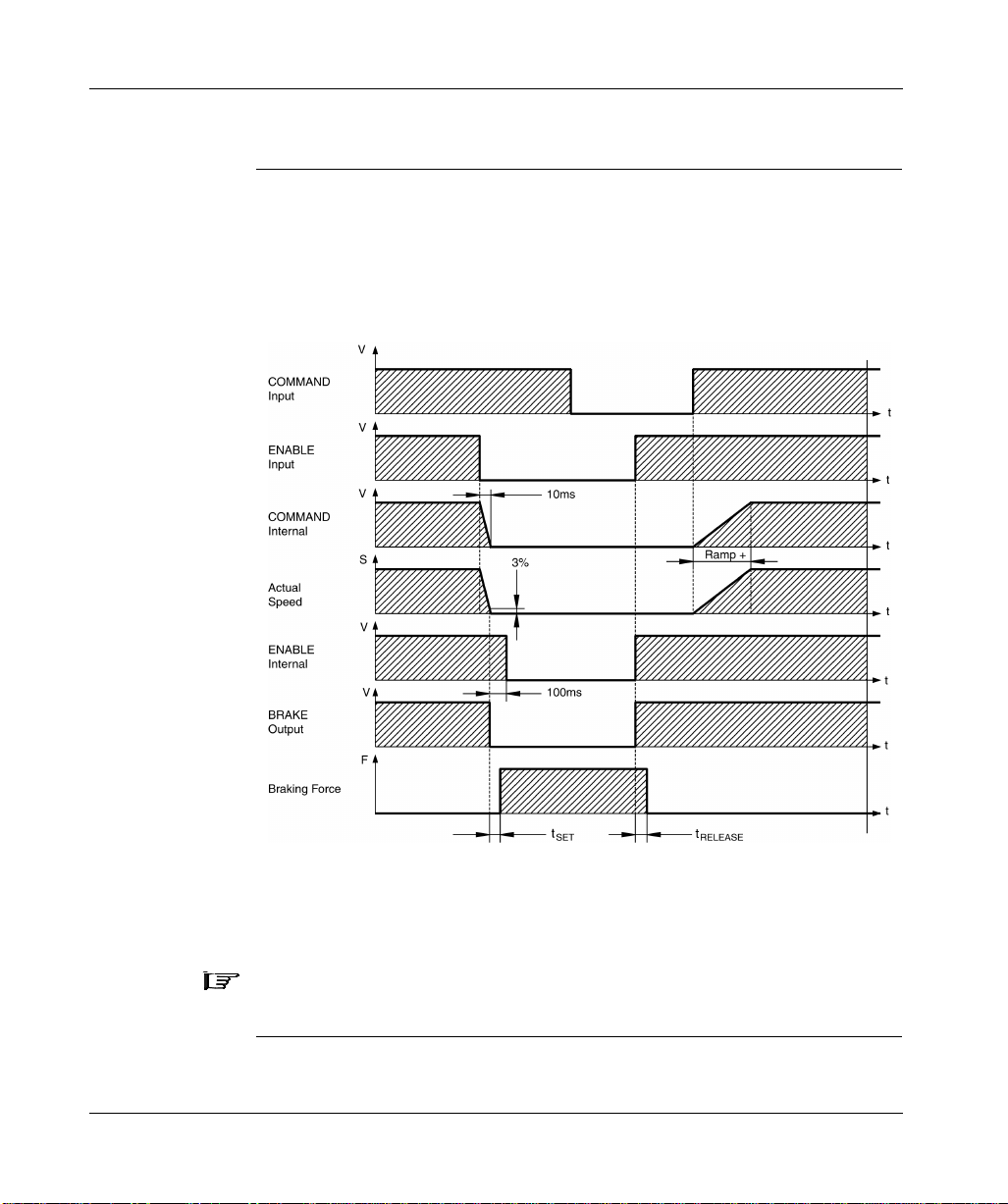

Servo Motor Holding-Brake Control Functional Description

A 24V holding brake in the servo motor is controlled directly by the 17S drive

through software-selectable BRAKE parameter settings. The time and functional

relationships betw een the EN ABLE signa l, speed setpoint, speed an d braki ng f orce

are shown in the following diagram.

During the fixed ENABLE delay time of 100 ms, the speed setpoint of the drive is

internally driven down a 10 ms ramp to 0V. The 3 % region of actual speed is