Page 1

Altivar Library

SoMachine

Function blocks

Software manual

V2.08, 04.2011

0198441113880, V2.08, 04.2011

www.schneider-electric.com

Page 2

Important information Altivar Library

Important information

This manual is part of the product.

Carefully read this manual and observe all instructions.

Keep this manual for future reference.

Hand this manual and all other pertinent product documentation over

to all users of the product.

Carefully read and observe all safety instructions and the chapter

"Before you begin - safety information".

Some products are not available in all countries.

For information on the availability of products, please consult the catalog.

Subject to technical modifications without notice.

All details provided are technical data which do not constitute warranted qualities.

Most of the product designations are registered trademarks of their

respective owners, even if this is not explicitly indicated.

2 Function blocks

0198441113880, V2.08, 04.2011

Page 3

Altivar Library Table of contents

Table of contents

Important information 2

Table of contents 3

About this manual 7

1 Before you begin - safety information 9

1.1 Qualification of personnel 9

1.2 Intended use 9

1.3 Hazard categories 10

1.4 Basic information 11

1.5 Standards and terminology 12

2 Altivar Library Guide 13

2.1 List of the function blocks 14

2.2 Basic inputs and outputs 17

2.2.1 Signal behavior of function blocks with the input Enable 19

2.2.2 Signal behavior of function blocks with the input Execute 21

2.3 Single axis 23

2.3.1 Initialization 23

2.3.1.1 MC_Power_ATV 23

2.3.2 Operating mode Jog 24

2.3.2.1 MC_Jog_ATV 24

2.3.3 Operating mode Speed Control 26

2.3.3.1 VelocityControlAnalogInput_ATV 26

2.3.3.2 VelocityControlSelectAI_ATV 27

2.3.4 Operating mode Profile Velocity 28

2.3.4.1 MC_MoveVelocity_ATV 28

2.3.5 Stopping 29

2.3.5.1 MC_Stop_ATV 29

2.4 Administrative 30

2.4.1 Reading a parameter 30

2.4.1.1 MC_ReadActualVelocity_ATV 30

2.4.1.2 MC_ReadActualTorque_ATV 31

2.4.1.3 MC_ReadStatus_ATV 32

2.4.1.4 MC_ReadParameter_ATV 34

2.4.1.5 GetSupplierVersion 35

2.4.2 Writing a parameter 36

2.4.2.1 MC_WriteParameter_ATV 36

2.4.2.2 SetDriveRamp_ATV 37

2.4.2.3 SetFrequencyRange_ATV 38

2.4.2.4 ResetParameters_ATV 39

0198441113880, V2.08, 04.2011

Function blocks 3

Page 4

Table of contents Altivar Library

2.4.2.5 StoreParameters_ATV 40

2.4.3 Saving and restoring device configuration 41

2.4.3.1 UploadDriveParameter_ATV 41

2.4.3.2 DownloadDriveParameter_ATV 42

2.4.4 Inputs and outputs 43

2.4.4.1 ReadAnalogInput_ATV 43

2.4.4.2 MC_ReadDigitalInput_ATV 44

2.4.4.3 MC_ReadDigitalOutput_ATV 46

2.4.4.4 MC_WriteDigitalOutput_ATV 48

2.4.5 Error handling 49

2.4.5.1 MC_ReadAxisError_ATV 49

2.4.5.2 MC_Reset_ATV 53

2.5 Device Function 54

2.5.1 Startup 54

2.5.1.1 Altivar_Startup 54

2.5.2 Control 63

2.5.2.1 Altivar31_Control 63

2.5.2.2 Altivar71_Control 72

2.5.2.3 Altivar32_Control 81

3 Glossary 93

3.1 Units and conversion tables 93

3.1.1 Length 93

3.1.2 Mass 93

3.1.3 Force 93

3.1.4 Power 93

3.1.5 Rotation 94

3.1.6 Torque 94

3.1.7 Moment of inertia 94

3.1.8 Temperature 94

3.1.9 Conductor cross section 94

3.2 Terms and Abbreviations 95

4 Index 97

4 Function blocks

0198441113880, V2.08, 04.2011

Page 5

Altivar Library

0198441113880, V2.08, 04.2011

Function blocks 5

Page 6

Altivar Library

6 Function blocks

0198441113880, V2.08, 04.2011

Page 7

Altivar Library

About this manual

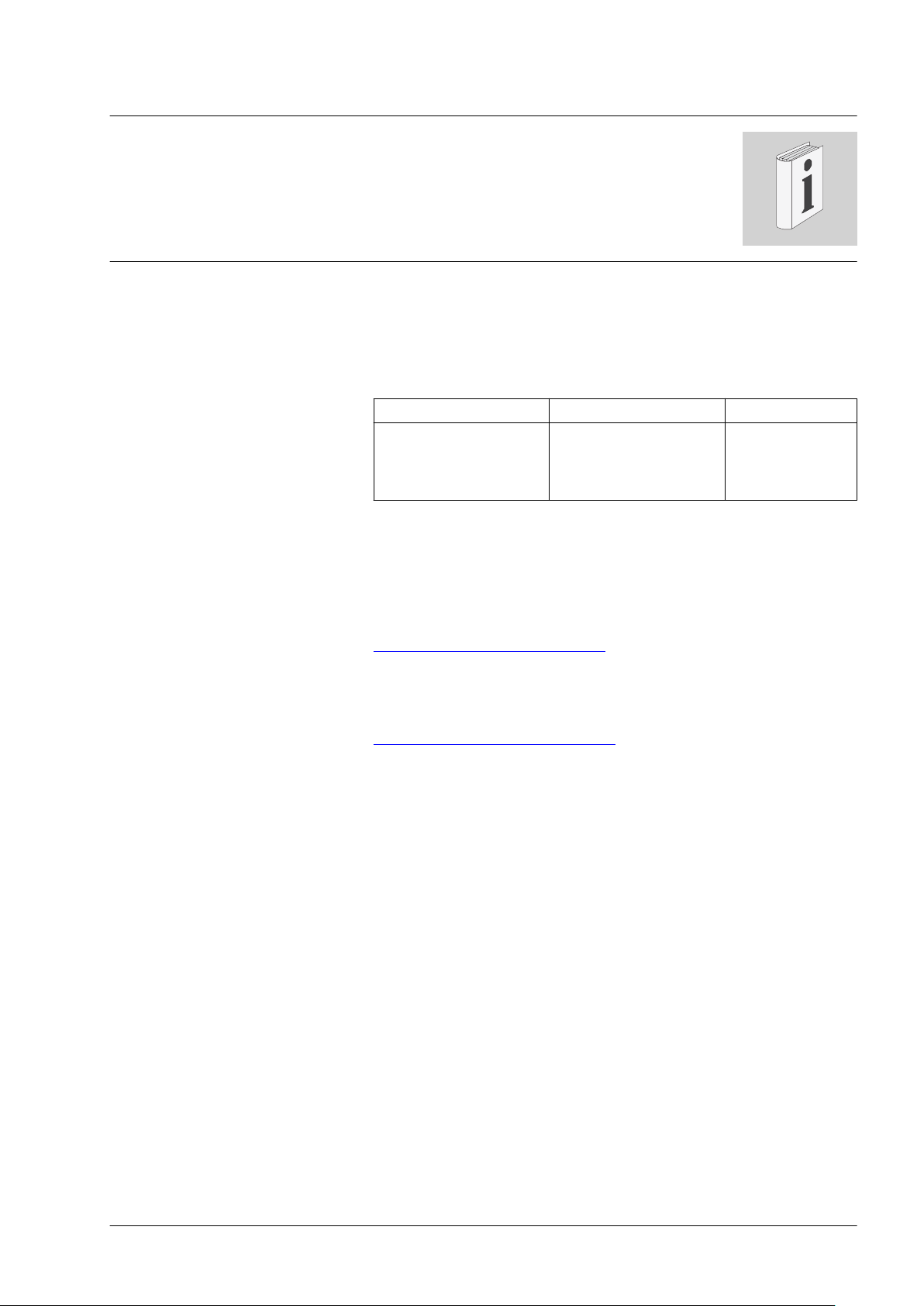

Purpose of this document

Validity note

About this manual

This manual is an extract of the SoMachine Online Help. Fully read

and understand all manuals of the SoMachine Online Help and of the

products used.

This document describes the functions of the Altivar Library.

Software environment Devices Fieldbus

SoMachine

Device Descriptions of version 4.0.0.0 and higher are

supported.

ATV31/ATV312

ATV71/ATV32

CANopen

This document is valid for SoMachine as of Version 2.0.

Source manuals The latest versions of the manuals can be downloaded from the Inter-

net at:

http://www.schneider-electric.com

Corrections and suggestions We always try to further optimize our manuals. We welcome your sug-

gestions and corrections.

Please get in touch with us by e-mail:

techcomm@schneider-electric.com.

Work steps If work steps must be performed consecutively, this sequence of steps

is represented as follows:

■

Special prerequisites for the following work steps

▶

Step 1

◁

Specific response to this work step

▶

Step 2

If a response to a work step is indicated, this allows you to verify that

the work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

SI units SI units are the original values. Converted units are shown in brackets

behind the original value; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm2 (AWG 14)

Glossary Explanations of special technical terms and abbreviations.

Index List of keywords with references to the corresponding page numbers.

0198441113880, V2.08, 04.2011

Function blocks 7

Page 8

About this manual

Altivar Library

Disclaimer The information provided in this documentation contains general

descriptions and/or technical characteristics of the performance of the

products described here. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user applications. It is the duty of

any user or integrator to perform the appropriate and fully comprehensive risk analyses, evaluation and testing of the products with respect

to the relevant specific application or use of the products. Neither

Schneider Electric nor any of its affiliate or subsidiaries shall be

responsible or liable for misuse of the information contained herein. If

you have any suggestions for improvements or amendments or have

found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be

observed when installing and using this product. For reasons of safety

and to help ensure compliance with documented system data, only

the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use Schneider Electric software or approved software with

our hardware products may result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment

damage.

8 Function blocks

0198441113880, V2.08, 04.2011

Page 9

Altivar Library

1 Before you begin - safety information

1 Before you begin - safety information

1.1 Qualification of personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product documentation are authorized to work on and with this product. In addition,

these persons must have received safety training to recognize and

avoid hazards involved. These persons must have sufficient technical

training, knowledge and experience and be able to foresee and detect

potential hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with

all applicable standards, directives, and accident prevention regulations when performing such work.

1

1.2

Intended use

This product is a library for industrial use with the appropriate controllers and drives.

The product may only be used in compliance with all applicable safety

regulations and directives, the specified requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view

of the planned application. Based on the results, the appropriate

safety measures must be implemented.

Since the product is used as a component in an entire system, you

must ensure the safety of persons by means of the design of this

entire system (for example, machine design).

Any use other than the use explicitly permitted is prohibited and can

result in hazards.

Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel.

0198441113880, V2.08, 04.2011

Function blocks 9

Page 10

1 Before you begin - safety information

1.3 Hazard categories

Safety instructions to the user are highlighted by safety alert symbols

in the manual. In addition, labels with symbols and/or instructions are

attached to the product that alert you to potential hazards.

Depending on the seriousness of the hazard, the safety instructions

are divided into 4 hazard categories.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not

avoided, can result in death, serious injury, or equipment damage.

CAUTION indicates a potentially hazardous situation, which, if not

avoided, can result in injury or equipment damage.

Altivar Library

DANGER

WARNING

CAUTION

CAUTION

CAUTION used without the safety alert symbol, is used to address

practices not related to personal injury (e.g. can result in equipment

damage).

10 Function blocks

0198441113880, V2.08, 04.2011

Page 11

Altivar Library

1.4 Basic information

1 Before you begin - safety information

WARNING

LOSS OF CONTROL

•

The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop,

overtravel stop, power outage and restart.

•

Separate or redundant control paths must be provided for critical

functions.

•

System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

•

Observe all accident prevention regulations and local safety

guidelines.

•

Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death or serious injury.

1)

1)

For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control”

and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems”.

WARNING

UNINTENDED BEHAVIOR DUE TO IMPROPER ERROR HANDLING

Improper error handling can change movements or signals or deactivate monitoring functions.

•

Carefully program the error handling routines.

•

Verify the effectiveness of error handling.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

WARNING

UNINTENDED BEHAVIOR DUE TO CHANGES TO THE LIBRARY

•

Do not change or manipulate the library in any way whatsoever.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

0198441113880, V2.08, 04.2011

Function blocks 11

Page 12

1 Before you begin - safety information

1.5 Standards and terminology

Technical terms, terminology and the corresponding descriptions in

this manual are intended to use the terms or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms

such as "safety function", "safe state", "fault", "fault reset", "failure",

"error", "error message", "warning", "warning message", etc.

Among others, these standards include:

•

IEC 61800 series: "Adjustable speed electrical power drive systems"

•

IEC 61158 series: "Industrial communication networks - Fieldbus

specifications"

•

IEC 61784 series: "Industrial communication networks - Profiles"

•

IEC 61508 series: "Functional safety of electrical/electronic/programmable electronic safety-related systems"

Also see the glossary at the end of this manual.

Altivar Library

12 Function blocks

0198441113880, V2.08, 04.2011

Page 13

Altivar Library

2 Altivar Library Guide

Library name Altivar Library (ATV)

Software environment Devices Fieldbus

SoMachine

Device Descriptions of version 4.0.0.0 and higher are

supported.

The function blocks described here are used to control ATV drives in

CANopen fieldbuses under the SoMachine software environment. The

function blocks are compliant with the IEC 61131-3 standard.

ATV31/ATV312

ATV71/ATV32

2 Altivar Library Guide

2

CANopen

Naming conventions

Simple application

Categorization of the function

blocks

Preparing the drive Before you can access the drive via CANopen or CANmotion, you

•

Function blocks with the prefix MC_ ("Motion Control") are compliant with the PLCopen specifications. They conform to a global

standard for programming motion control applications.

•

Function blocks without a prefix are vendor-specific (Schneider

Electric); however, they comply with the general PLC open rules.

•

The function blocks are used in the same way.

•

The function blocks comply with the PLCopen state diagram.

•

The function blocks feature a visualization that can be easily integrated into the application.

•

Single axis: These function blocks are used for movements or

functions of a single, independent axis.

•

Administrative: These function blocks are used for configuration

tasks (such as reading and writing of parameters, restoring a

device configuration, etc.).

•

Device Function: These function blocks support you in commissioning a drive at a controller. Before these function blocks can be

used, you must correctly set the communication parameters baud

rate and node address.

must make a number of settings. Among others, these settings

include:

•

Address and baud rate

•

Profile (CHCF) = Separate

•

Reference 1 (Fr1) = CAN

•

Control channel (Cd1) = CAN

•

Control channel switching (CSS) = Cd1

•

Reference switching (rFC) = C214

Note the pertinent information in the product manual.

If you do not know the existing configuration, it may be useful to

restore the factory settings. See "2.4.2.4 ResetParameters_ATV".

0198441113880, V2.08, 04.2011

Function blocks 13

Page 14

2 Altivar Library Guide

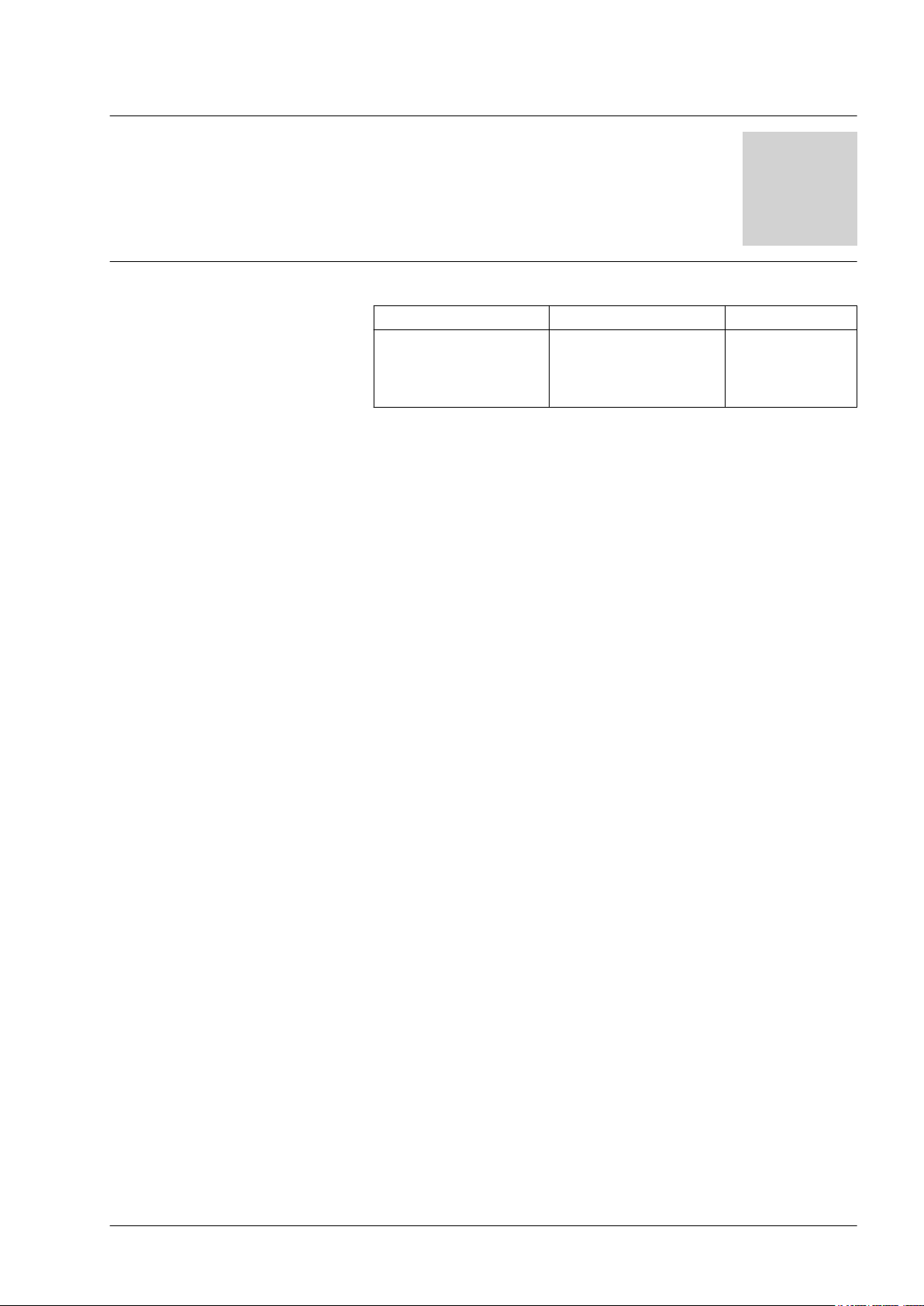

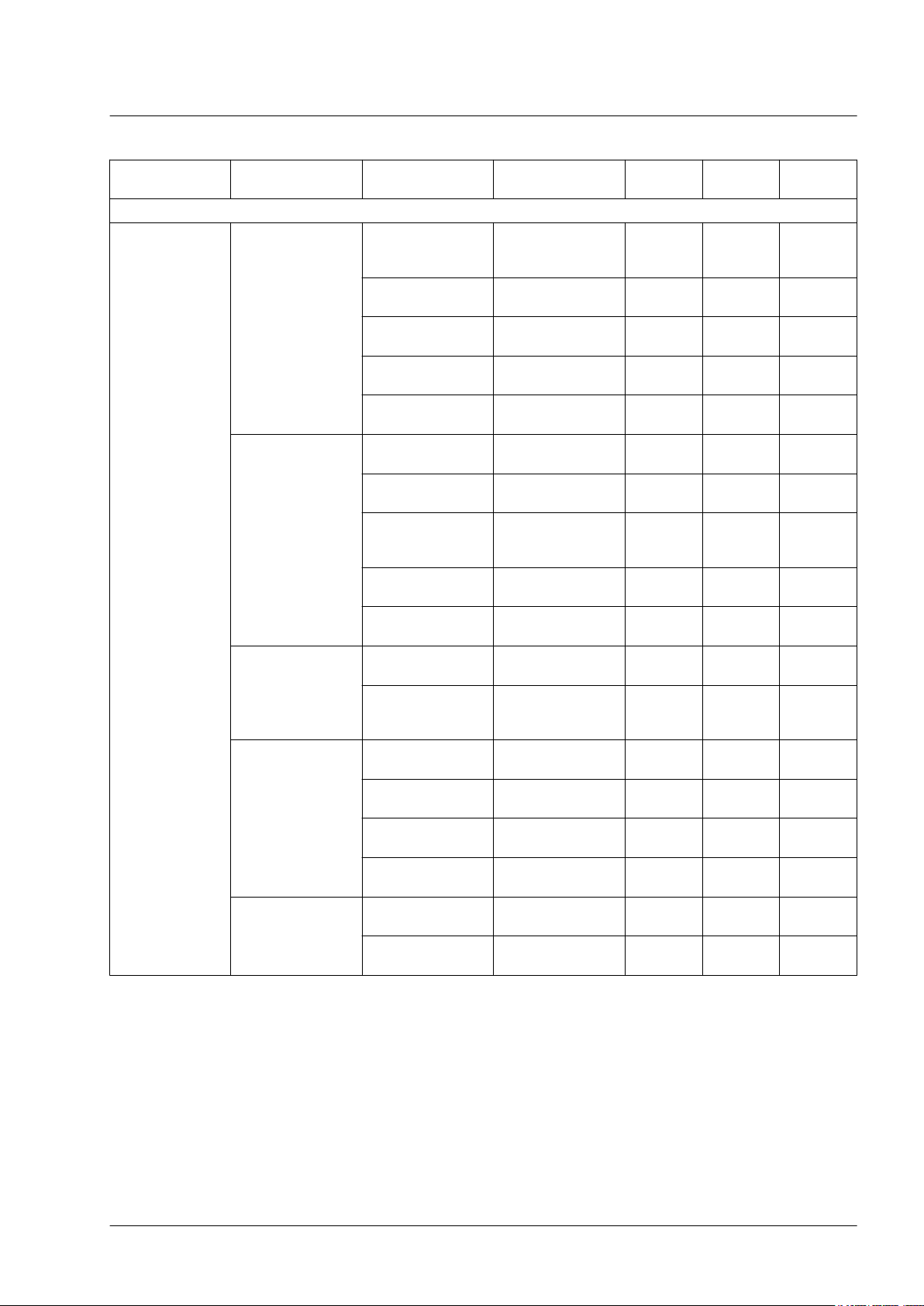

2.1 List of the function blocks

Category Single axis

Altivar Library

Category Subcategory Function block Type ATV31/

ATV312

Single axis

Initialization "2.3.1.1

MC_Power_ATV"

Operating mode

Jog

Operating mode

Speed Control

Operating mode

Profile Velocity

Stopping "2.3.5.1

"2.3.2.1

MC_Jog_ATV"

"2.3.3.1 VelocityControlAnalogInput_ATV"

"2.3.3.2 VelocityControlSelectAI_ATV"

"2.3.4.1 MC_MoveVelocity_ATV"

MC_Stop_ATV"

PLCopen X X X

PLCopen X X X

Vendor-specific X X X

Vendor-specific X X X

PLCopen X X X

PLCopen X X X

ATV71 ATV32

14 Function blocks

0198441113880, V2.08, 04.2011

Page 15

Altivar Library

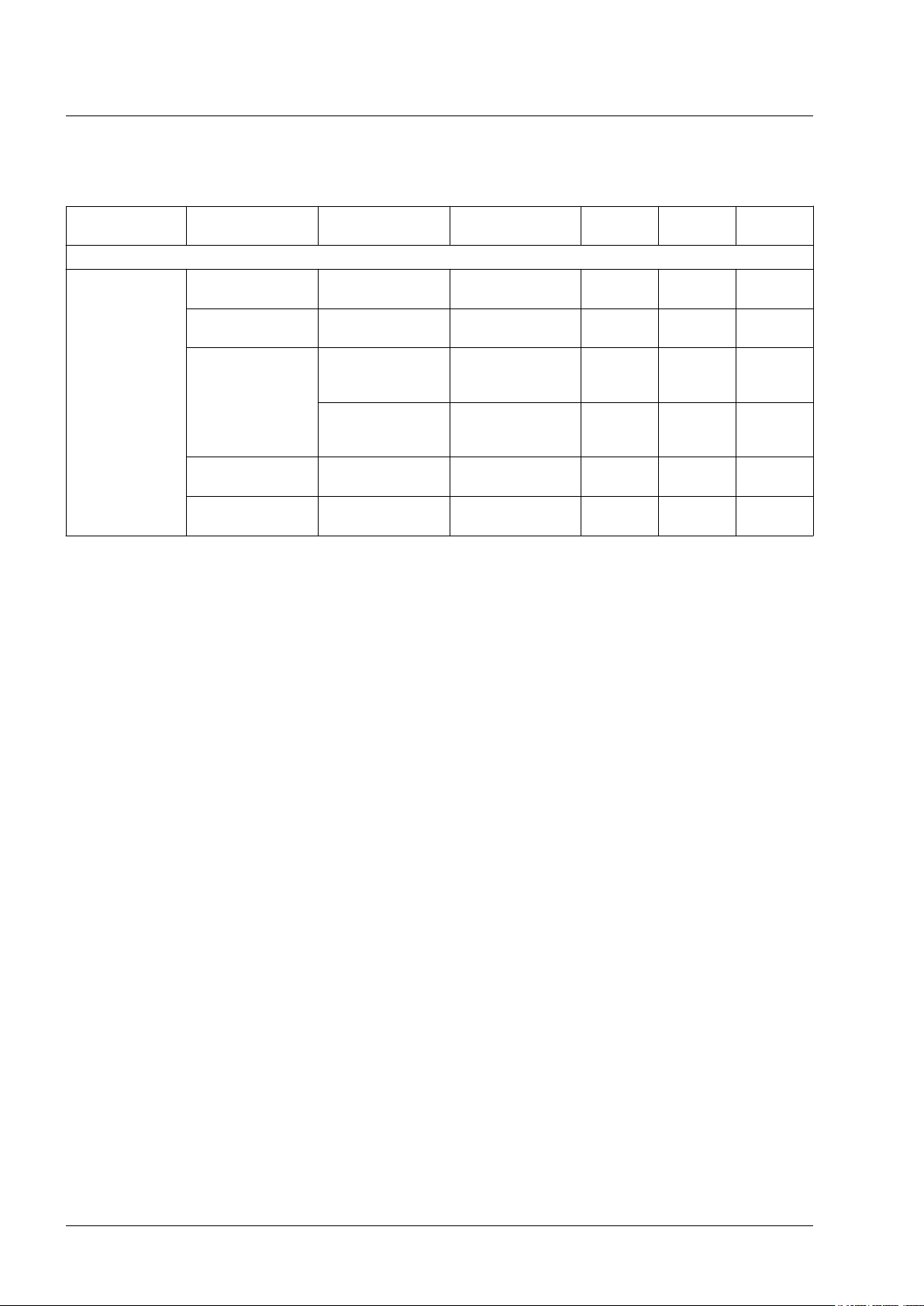

Category Administrative

2 Altivar Library Guide

Category Subcategory Function block Type ATV31/

ATV312

Administrative

Reading a parameter

Writing a parameter "2.4.2.1 MC_Write-

Saving and restoring device configuration

Inputs and outputs "2.4.4.1 ReadAna-

Error handling "2.4.5.1 MC_Read-

"2.4.1.1 MC_ReadActualVelocity_ATV"

"2.4.1.2 MC_ReadActualTorque_ATV"

"2.4.1.3 MC_ReadStatus_ATV"

"2.4.1.4 MC_ReadParameter_ATV"

"2.4.1.5 GetSupplierVersion"

Parameter_ATV"

"2.4.2.2 SetDriveRamp_ATV"

"2.4.2.3 SetFrequencyRange_ATV"

"2.4.2.4 ResetParameters_ATV"

"2.4.2.5 StoreParameters_ATV"

"2.4.3.1 UploadDriveParameter_ATV"

"2.4.3.2 DownloadDriveParameter_ATV"

logInput_ATV"

"2.4.4.2 MC_ReadDigitalInput_ATV"

"2.4.4.3 MC_ReadDigitalOutput_ATV"

"2.4.4.4 MC_WriteDigitalOutput_ATV"

AxisError_ATV"

"2.4.5.2

MC_Reset_ATV"

PLCopen X X X

PLCopen X X X

PLCopen X X X

PLCopen X X X

Vendor-specific X X X

PLCopen X X X

Vendor-specific X X X

Vendor-specific X X X

Vendor-specific X X X

Vendor-specific X X X

Vendor-specific X X X

Vendor-specific X X X

Vendor-specific X X X

PLCopen X X X

PLCopen X X X

PLCopen X X X

PLCopen X X X

PLCopen X X X

ATV71 ATV32

0198441113880, V2.08, 04.2011

Function blocks 15

Page 16

2 Altivar Library Guide

Category Device Function

Altivar Library

Category Subcategory Function block Type ATV31/

ATV312

Device Function

Startup "2.5.1.1 Alti-

var_Startup"

Control "2.5.2.1 Alti-

var31_Control"

"2.5.2.2 Altivar71_Control"

"2.5.2.3 Altivar32_Control"

Vendor-specific X X X

Vendor-specific X - -

Vendor-specific - X -

Vendor-specific - - X

ATV71 ATV32

16 Function blocks

0198441113880, V2.08, 04.2011

Page 17

Altivar Library

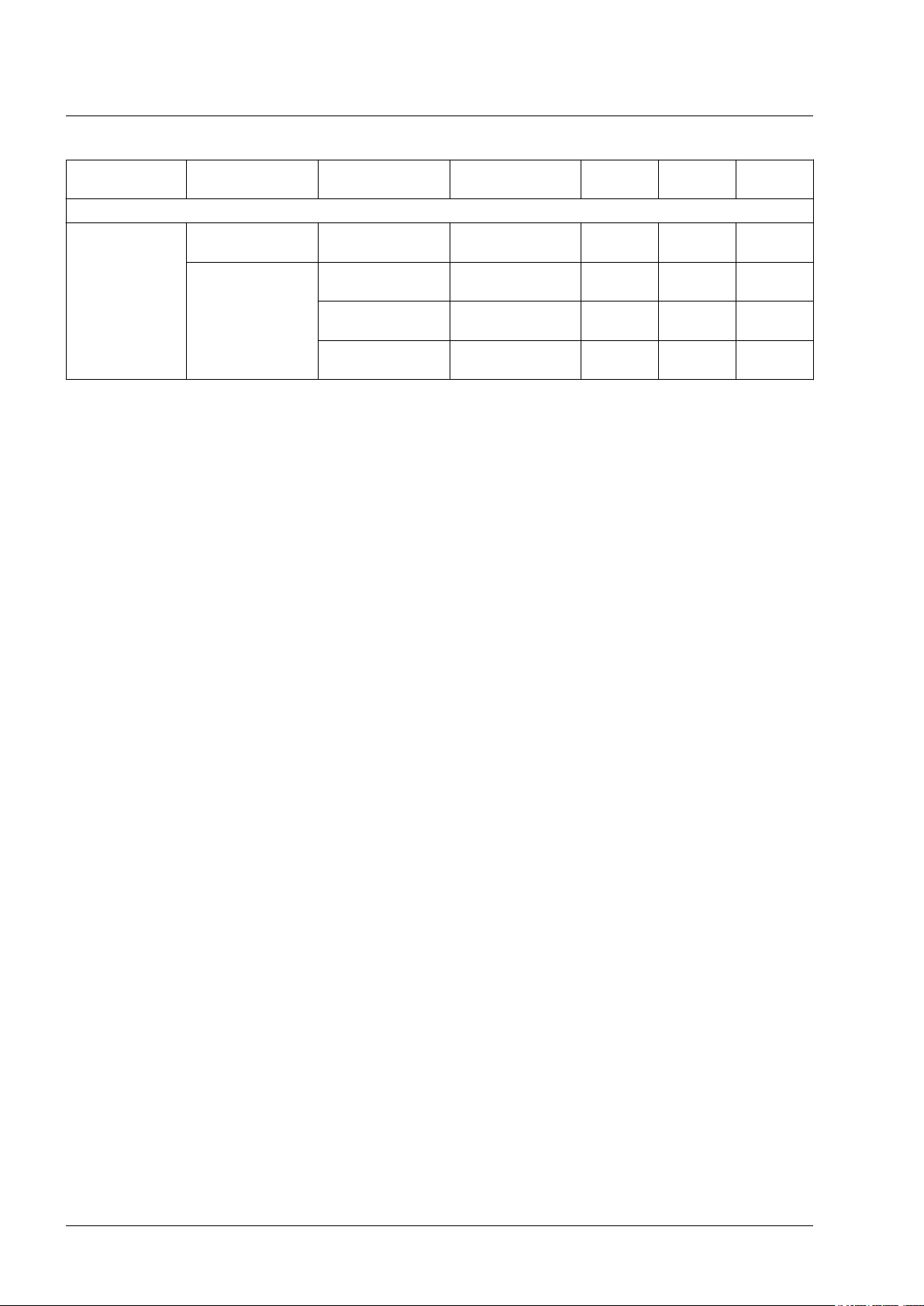

2.2 Basic inputs and outputs

Input/output Data type Description

Axis Axis_Ref_ATV

Input Input_Ref_ATV

Output

Input Data type Description

Enable BOOL

Execute

Output_Ref_ATV

BOOL

Name of the axis (instance) for which the function block is to

be executed. The name must be declared in the PLC configuration. The name of the axis can be found to the left in the tree

structure of your software.

Input is a special data type for digital and analog inputs. The

data type corresponds to the name of the axis (instance) to

which the inputs belong (similar to Axis).

In the case of function blocks specifically provided for reading

analog and digital inputs, Input replaces the input Axis.

Output is a special data type for digital and outputs. The data

type corresponds to the name of the axis (instance) to which

the outputs belong (similar to Axis).

In the case of function blocks specifically provided for writing

and reading analog and digital inputs, Output replaces the

input Axis.

Value range: TRUE, FALSE

Initial value: FALSE

The input Enable starts or terminates the execution of a function block. (exception "2.3.1.1 MC_Power_ATV")

FALSE: Execution of the function block is terminated. The outputs Valid, Busy, CommandAborted and Error are set to

FALSE.

TRUE: The function block is executed repeatedly.

Value range: TRUE, FALSE

Initial value: FALSE

The input Execute starts the execution of a function block in

the case of a rising edge (FALSE->TRUE).

If a second rising edge is detected during the execution of the

function block, the current execution is aborted and the function block is executed again.

Execution is terminated as soon as the output Busy is FALSE.

FALSE and, at the same time, Busy = FALSE:

Either Done, Error or CommandAborted are set to TRUE for

one call.

TRUE and, at the same time, Busy = FALSE:

Either Done, Error or CommandAborted are set to TRUE

and remain TRUE until Execute is set to FALSE.

2 Altivar Library Guide

0198441113880, V2.08, 04.2011

Function blocks 17

Page 18

2 Altivar Library Guide

Output Data type Description

Done BOOL

Valid

Busy

CommandAborted

Error

BOOL

BOOL

BOOL

BOOL

Value range: TRUE, FALSE

Initial value: FALSE

FALSE: Execution has not (yet) been terminated without an

error.

TRUE: Execution has been completed without an error.

Value range: TRUE, FALSE

Initial value: FALSE

FALSE: Execution has not (yet) been terminated without an

error. The values at the outputs are not (yet) valid.

TRUE: Execution has been completed without an error. The

values at the outputs are valid and can be further processed.

Value range: TRUE, FALSE

Initial value: FALSE

FALSE: Execution of the function block has been terminated.

TRUE: Function block is being executed.

NOTE: In the operating mode Profile Velocity, the output

remains TRUE even when the target velocity has been

reached or Execute becomes FALSE. The output Busy is set

to FALSE as soon as another function block such as MC_Stop

is executed.

Value range: TRUE, FALSE

Initial value: FALSE

FALSE: Execution has not (yet) been canceled without an

error.

TRUE: Execution has been aborted by another function block.

Value range: TRUE, FALSE

Initial value: FALSE

FALSE: Execution of the function block is running, nor error

has occurred up until now.

TRUE: An error has occurred in the execution of the function

block.

Altivar Library

18 Function blocks

0198441113880, V2.08, 04.2011

Page 19

Altivar Library

2 Altivar Library Guide

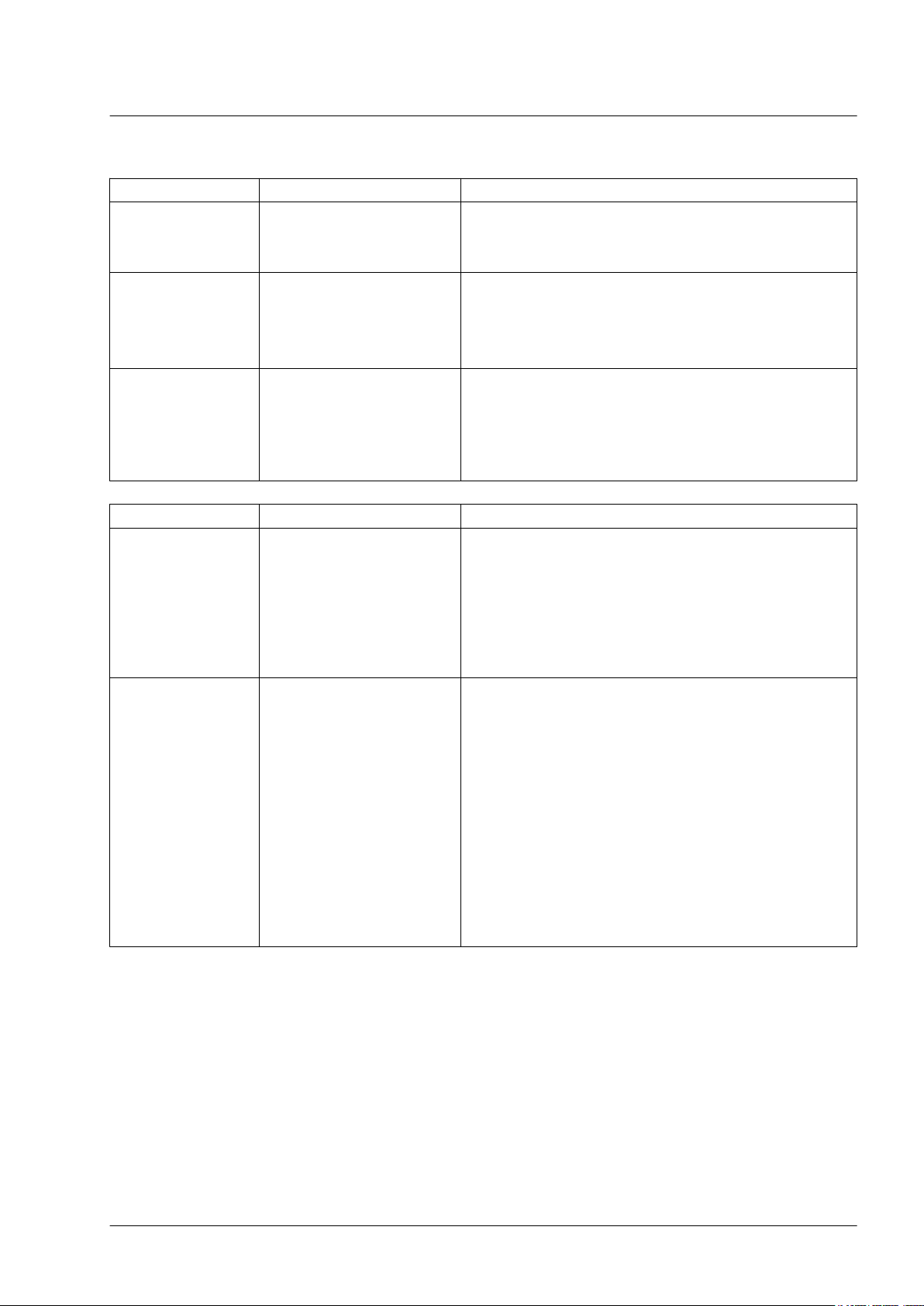

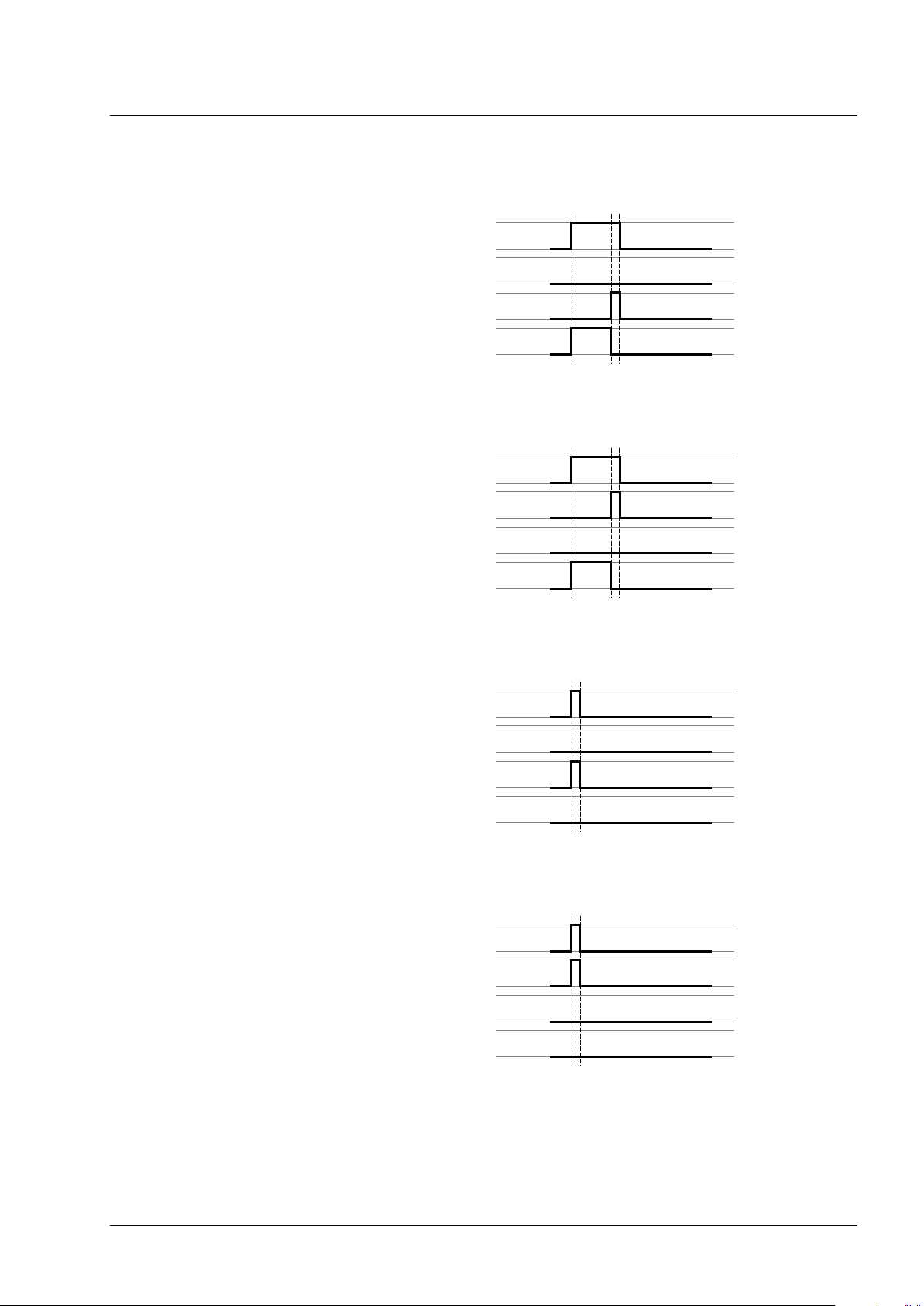

2.2.1 Signal behavior of function blocks with the input Enable

Example 1 Single execution without error (execution requires more than one call).

Enable

Error

Valid

Busy

Example 2 Single execution with error (execution requires more than one call).

Enable

Error

Valid

Busy

Example 3 Single execution without error (execution requires only one call).

Enable

Error

Valid

Busy

Example 4 Single execution with error (execution requires only one call).

Enable

Error

Valid

Busy

0198441113880, V2.08, 04.2011

Function blocks 19

Page 20

2 Altivar Library Guide

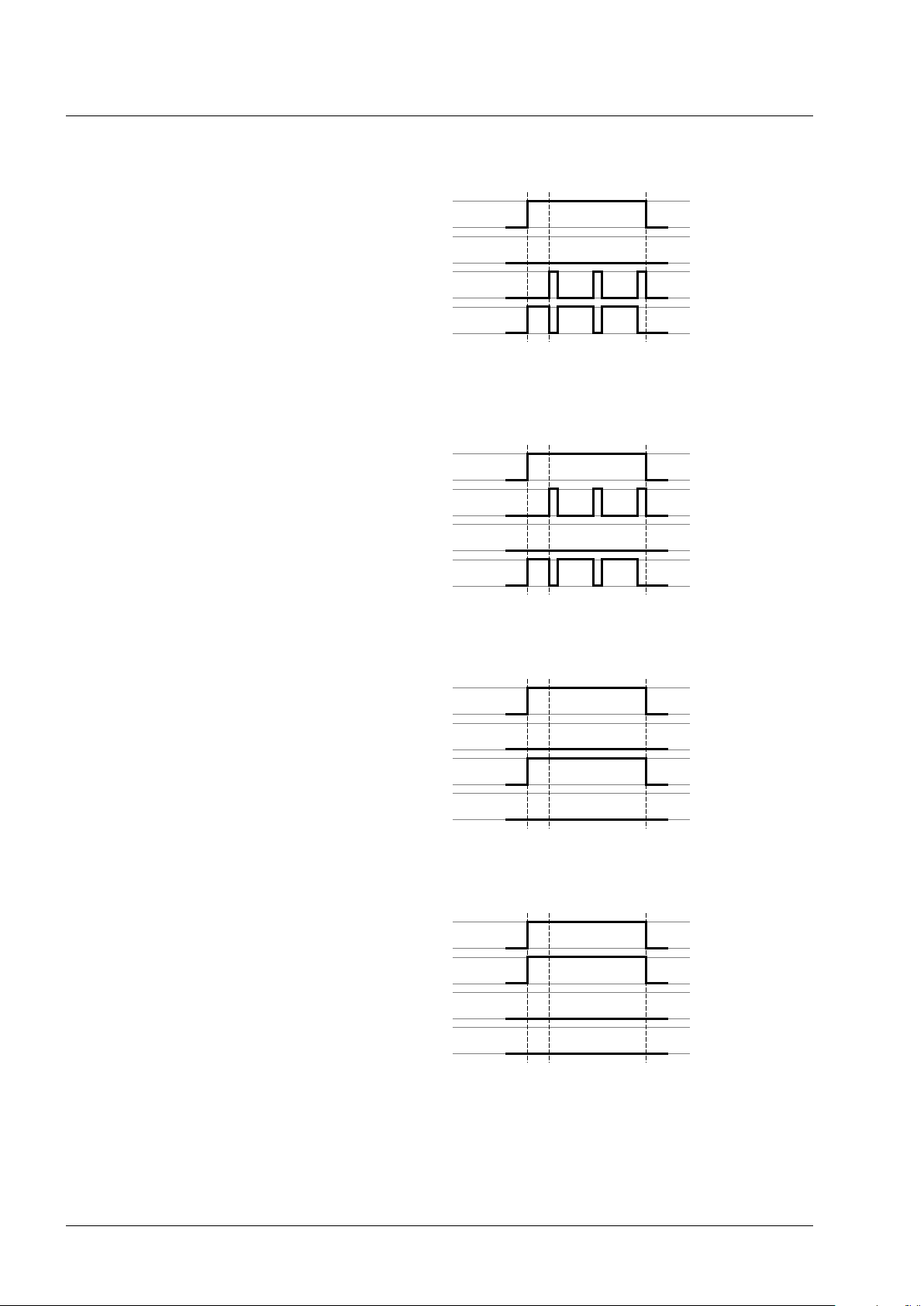

Example 5 Repeated execution without error (execution requires more than one

Example 6 Repeated execution with error (execution requires more than one

Altivar Library

call).

Enable

Error

Valid

Busy

call).

Enable

Error

Valid

Busy

Example 7 Repeated execution without error (execution requires only one call).

Enable

Error

Valid

Busy

Example 8 Repeated execution with error (execution requires only one call).

Enable

Error

Valid

Busy

20 Function blocks

0198441113880, V2.08, 04.2011

Page 21

Altivar Library

2 Altivar Library Guide

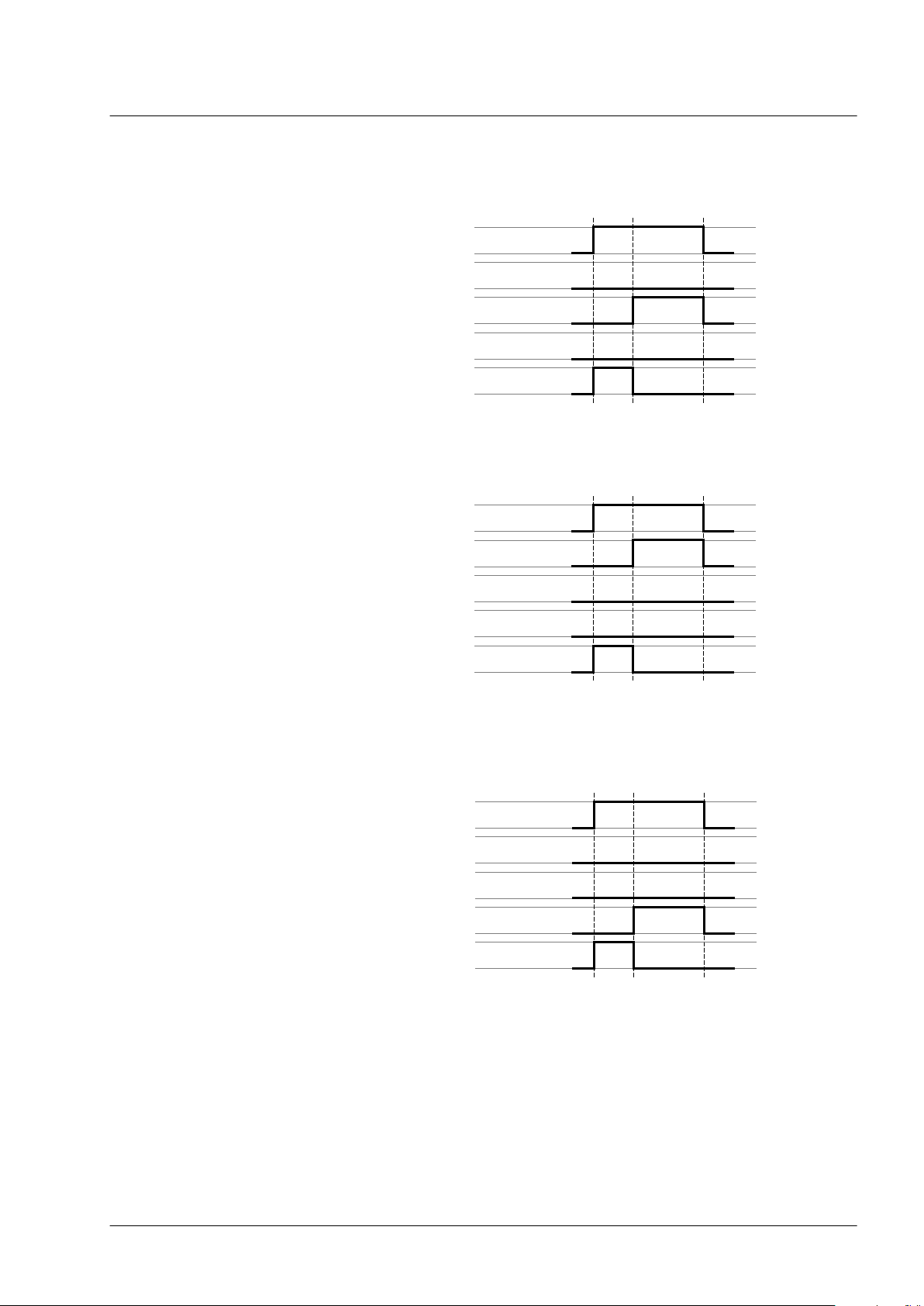

2.2.2 Signal behavior of function blocks with the input Execute

Example 1 Execution terminated without error.

Execute

Error

Done

CommandAborted

Busy

Example 2 Execution terminated with error.

Execute

Error

Done

CommandAborted

Busy

Example 3 Abortion of the execution because another function block takes over

control.

Execute

Error

Done

CommandAborted

Busy

0198441113880, V2.08, 04.2011

Function blocks 21

Page 22

2 Altivar Library Guide

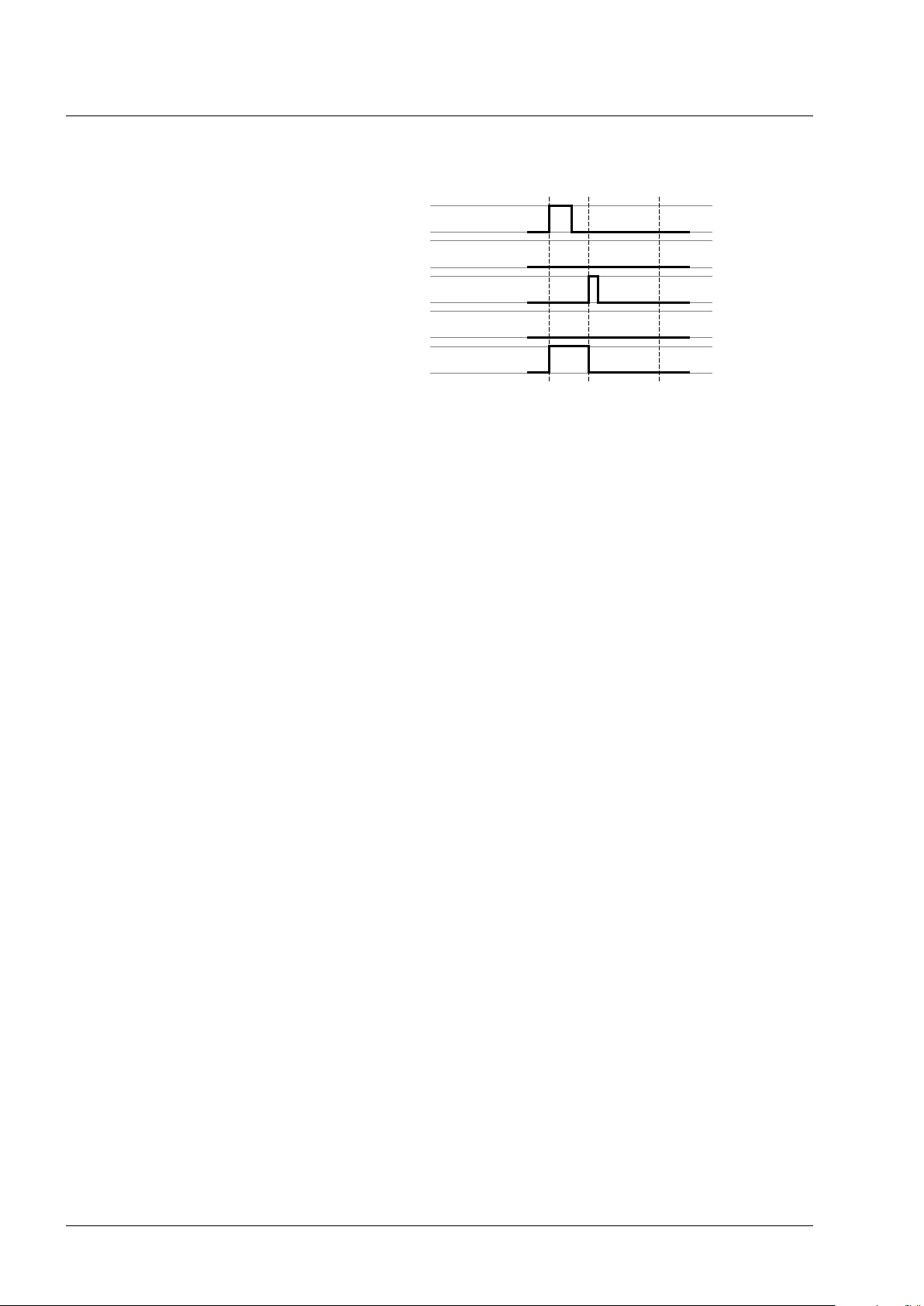

Example 4 Execution completed without error after Execute has been set to

Altivar Library

FALSE during execution.

Execute

Error

Done

CommandAborted

Busy

22 Function blocks

0198441113880, V2.08, 04.2011

Page 23

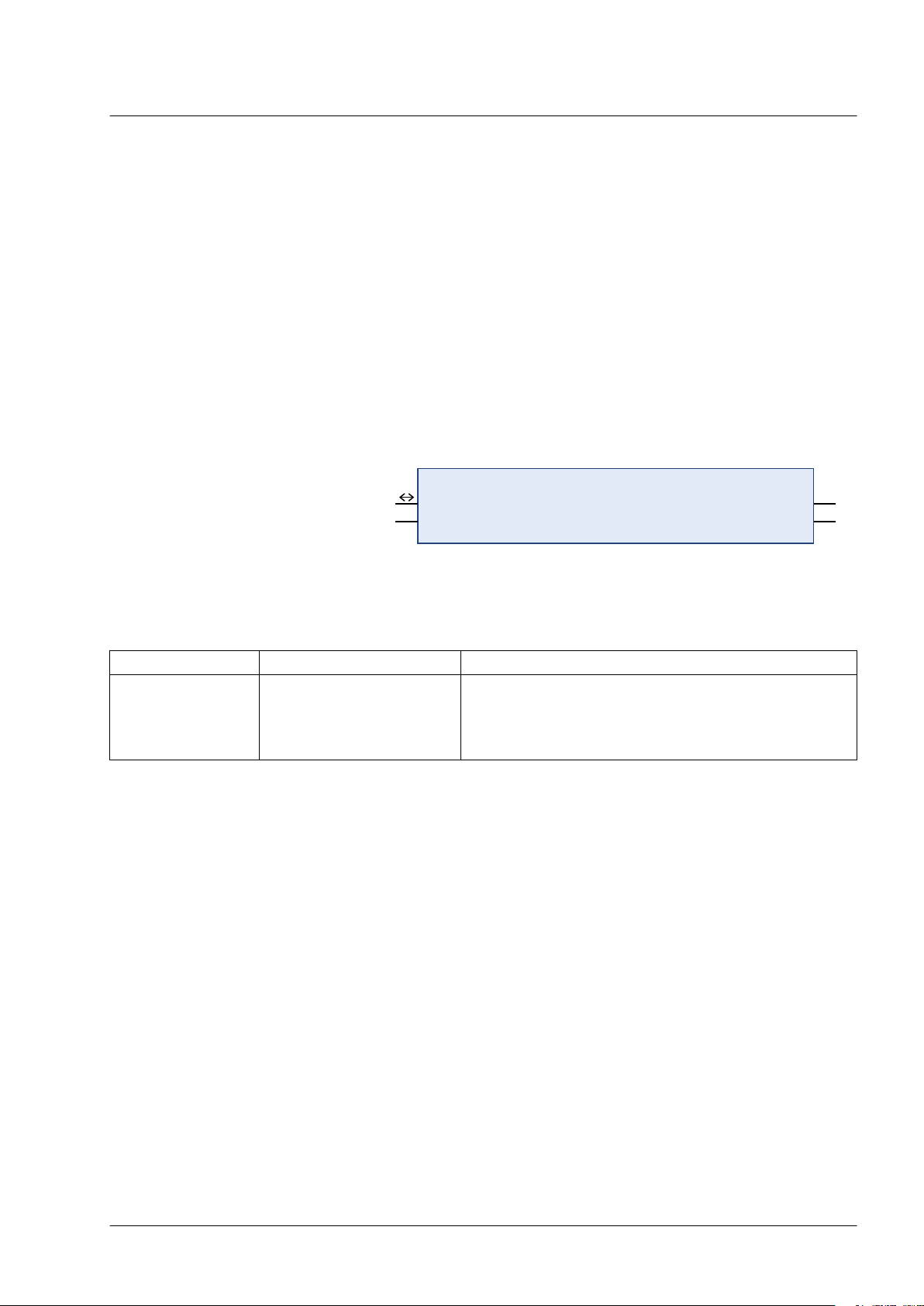

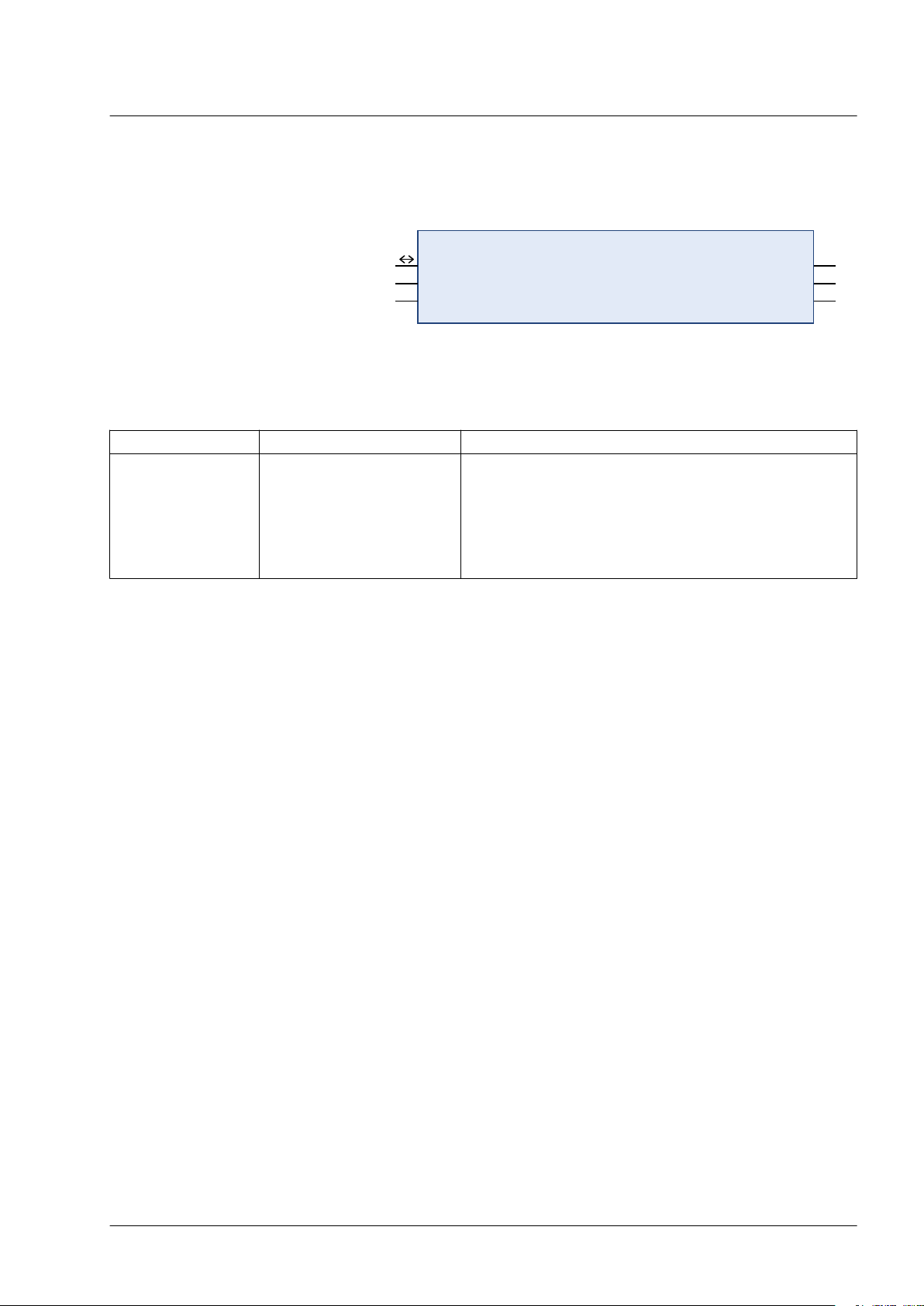

MC_Power_ATV

Axis Axis_Ref_ATV

Enable BOOL

BOOL Status

BOOL Error

Altivar Library

2.3 Single axis

2.3.1 Initialization

2.3.1.1 MC_Power_ATV

Function description The function block enables or disables the power stage. TRUE at the

Graphical representation

2 Altivar Library Guide

The initialization function block enables or disables the power stage.

Other function blocks can only be used when the power stage is enabled.

input Enable enables the power stage. Once the power stage is enabled, the output Status is set. FALSE at the input Enable disables

the power stage. Once the power stage is disabled, the output Sta-

tus is reset. If errors occur during execution, the output Error is set.

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the outputs.

Output Data type Description

Status BOOL

"2.2 Basic inputs and outputs"

Notes In the case of a Node Guarding error, the error memory must be reset

by means of the function block "2.4.5.2 MC_Reset_ATV" before the

power stage can be enabled again.

•

An asynchronous motor has no torque when it is at a standstill.

Enabling the power stage does not automatically generate torque.

•

If the input Enable = TRUE, one of the following errors is signaled if

the power supply is lost.

-

3120h (undervoltage)

-

ATV71/ATV32: FF34h (PowerOnTimeout_ATV)

-

If the 24V power supply is lost: 8100hh (NodeguardError_ATV)

-

The output Status is set to FALSE and the output Error to

TRUE. Once the power supply is available again, the output

Status is set back to TRUE.

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Power stage is disabled.

TRUE: Power stage is enabled.

0198441113880, V2.08, 04.2011

Function blocks 23

Page 24

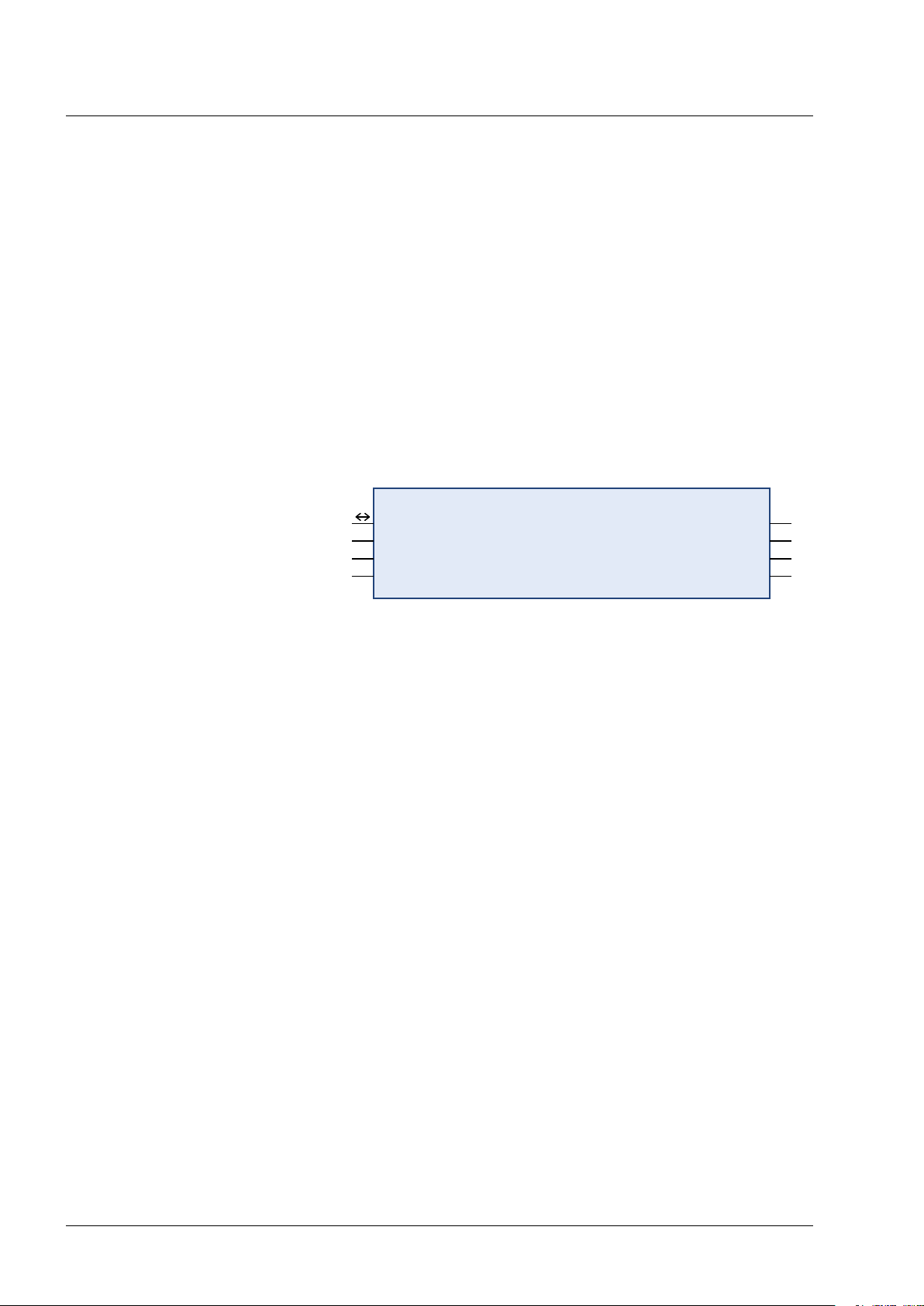

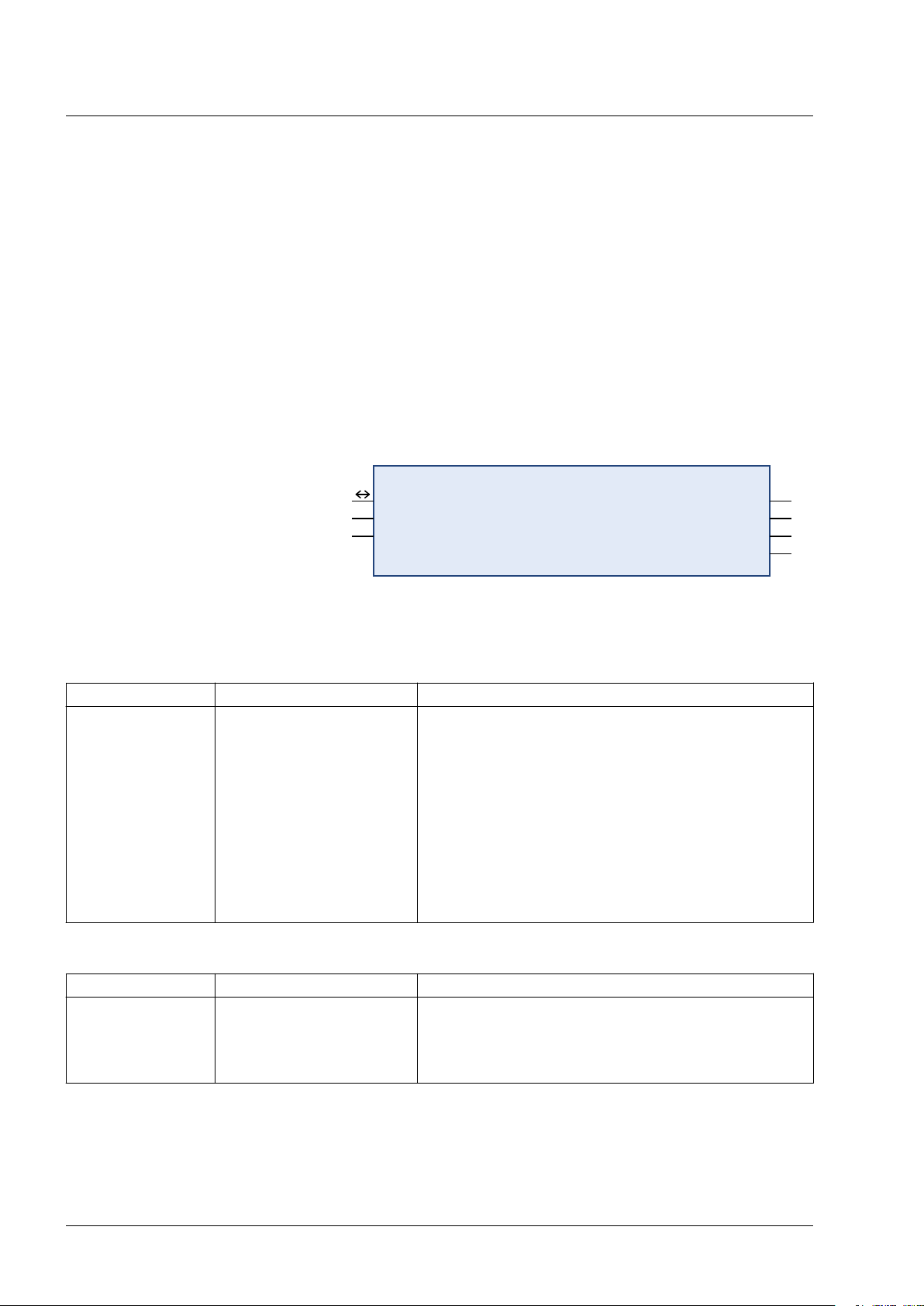

MC_Jog_ATV

Axis Axis_Ref_ATV

Forward BOOL

Backward BOOL

Velocity INT

BOOL Done

BOOL Busy

BOOL CommandAborted

BOOL Error

2 Altivar Library Guide

2.3.2 Operating mode Jog

2.3.2.1 MC_Jog_ATV

Function description The function block starts the operating mode Jog. TRUE at the input

Graphical representation

Altivar Library

In the operating mode Jog, a movement is made from the actual motor

position in the desired direction. The velocity can be set. As long as

the signal for the direction is available, a continuous movement is

made in the desired direction.

If movements in positive and negative directions are requested at the

same time, there is no motor movement.

Forward or the input Backward starts the jog movement. If both the

inputs Forward and Backward are FALSE, the operating mode is

terminated and the output Done is set. If both the inputs Forward and

Backward are TRUE, the operating mode remains active, the jog

movement is stopped and the output Busy remains set.

Compatible devices ATV31/ATV312 and ATV71/ATV32

24 Function blocks

0198441113880, V2.08, 04.2011

Page 25

Altivar Library

Inputs/outputs The table below shows the inputs.

Input Data type Description

Forward BOOL

Backward

Velocity

BOOL

INT

Value range: FALSE, TRUE

Initial value: FALSE

Forward = FALSE and Backward = FALSE:

Movement is terminated.

Forward = TRUE and Backward = FALSE:

Movement in positive direction is started if Velocity >0.

Movement in negative direction is started if Velocity <0.

Forward = FALSE and Backward = TRUE:

Movement in negative direction is started if Velocity >0.

The movement is stopped if Velocity <0.

Forward = TRUE and Backward = TRUE:

The movement in the current direction continues. If the inputs

Forward or Backward are set to FALSE, the movement is

continued in the direction and at the velocity valid at that point

in time.

Value range: FALSE, TRUE

Initial value: FALSE

Forward = FALSE and Backward = FALSE:

Movement is terminated.

Forward = TRUE and Backward = FALSE:

Movement in positive direction is started if Velocity >0.

Movement in negative direction is started if Velocity <0.

Forward = FALSE and Backward = TRUE:

Movement in negative direction is started if Velocity >0.

The movement is stopped if Velocity <0.

Forward = TRUE and Backward = TRUE:

The movement in the current direction continues. If the inputs

Forward or Backward are set to FALSE, the movement is

continued in the direction and at the velocity valid at that point

in time.

Value range: -5000 ... +5000

Initial value: 0

Target velocity for the operating mode. Adjustable in increments of 0.1 Hz.

NOTE:

The values for LowFrequency and HighFrequency are set

in the function block SetFrequencyRange_ATV.

If the value for the target velocity velocity is less than the

value for LowFrequency, the movement is made with the

velocity value for LowFrequency. No error is signaled.

If the value for the target velocity velocity is greater than the

value for HighFrequency, the movement is made with the

velocity value for HighFrequency. No error is signaled.

2 Altivar Library Guide

"2.2 Basic inputs and outputs"

0198441113880, V2.08, 04.2011

Function blocks 25

Page 26

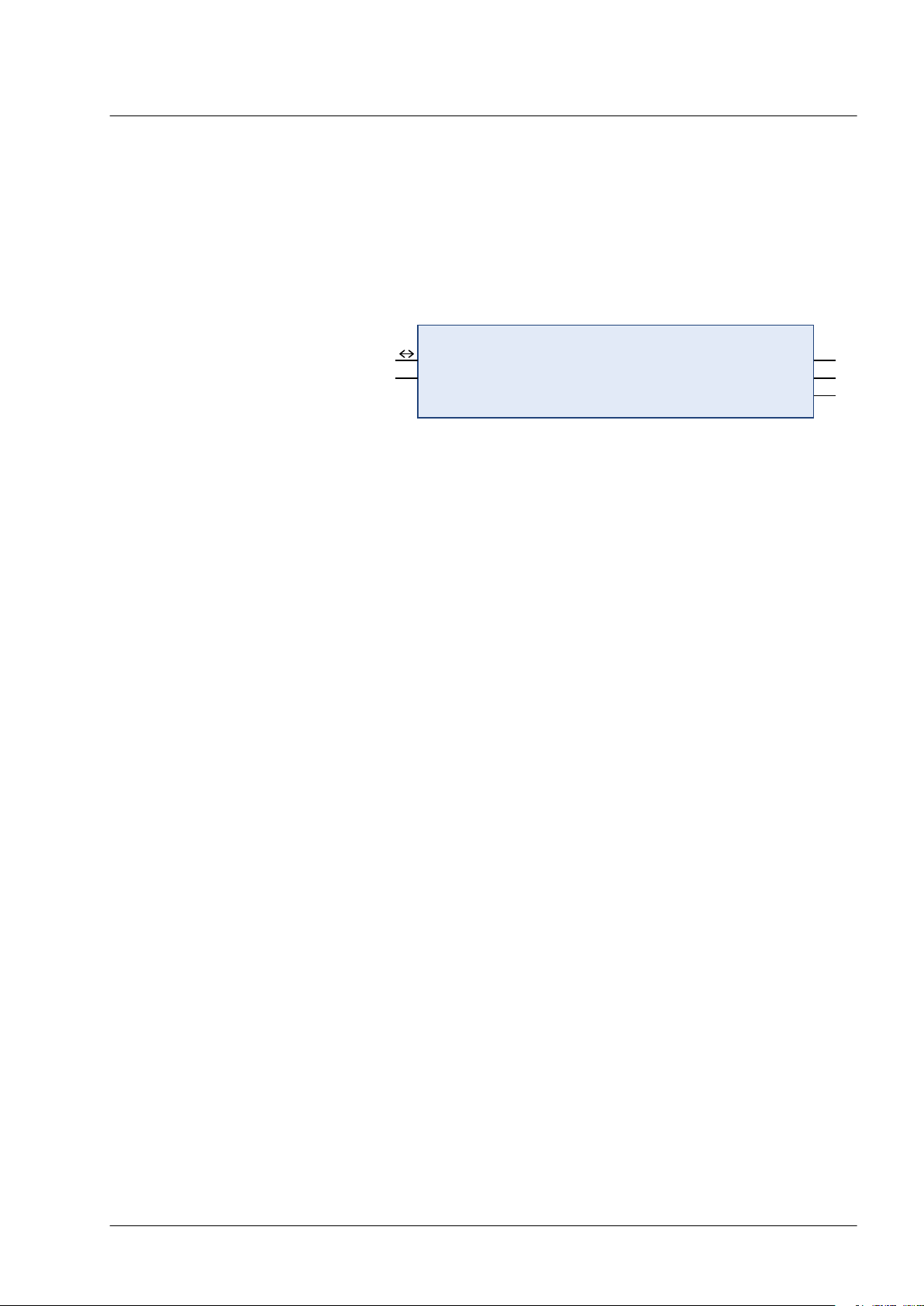

VelocityControlAnalogInput_ATV

Axis Axis_Ref_ATV

Execute BOOL

NegativeDir BOOL

BOOL InVelocity

BOOL Busy

BOOL CommandAborted

BOOL Error

2 Altivar Library Guide

2.3.3 Operating mode Speed Control

In the operating mode Speed Control, you can set a reference velocity

via an analog input.

2.3.3.1 VelocityControlAnalogInput_ATV

Function description The function block uses the reference values supplied by the analog

input selected with the function block

"2.3.3.2 VelocityControlSelectAI_ATV".

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Altivar Library

Input Data type Description

NegativeDir BOOL

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Clockwise rotation.

TRUE: Counter-clockwise rotation.

The table below shows the outputs.

Output Data type Description

InVelocity BOOL

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: The velocity does not correspond to the reference

value.

FALSE: The velocity corresponds to the reference value.

"2.2 Basic inputs and outputs"

Notes See also "2.4.2.3 SetFrequencyRange_ATV" and

"2.3.3.2 VelocityControlSelectAI_ATV".

If voltage levels -10V ... 10V are used, the direction of movement

(rotation) is inversed when the sign changes. If the voltage is 0 V, this

may result in jumps in the direction of movement, in the minimum frequency and in jumps at standstill.

NOTE for ATV31: If you have selected the analog current input

(0 mA ... 20 mA), the following frequency levels are used:

•

The minimum frequency is used below 4 mA.

•

The medium frequency is used at 12 mA.

•

The maximum frequency is used at 20 mA.

26 Function blocks

0198441113880, V2.08, 04.2011

Page 27

VelocityControlSelectAI_ATV

Axis Axis_Ref_ATV

Execute BOOL

InputNumber INT

BOOL Done

BOOL Busy

BOOL Error

Altivar Library

2.3.3.2 VelocityControlSelectAI_ATV

Function description This function block is used to select the analog input for supplying the

reference value. See also "2.3.3.1 VelocityControlAnalogInput_ATV".

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

InputNumber INT

Value range: 1 ... 16

Initial value: 1

1: AI1

2: AI2

3: AI3 (ATV71 only with expansion card)

4: AI4 (ATV71 only and only with expansion card)

16: AIP (internal potentiometer, ATV31/312 only)

2 Altivar Library Guide

"2.2 Basic inputs and outputs"

Notes The function block can only be executed if the drive is in the operating

state 3 Switch On Disabled (operating state of drive). To transition to

this state, disable the power stage with the function block

"2.3.1.1 MC_Power_ATV".

0198441113880, V2.08, 04.2011

Function blocks 27

Page 28

MC_MoveVelocity_ATV

Axis Axis_Ref_ATV

Execute BOOL

Velocity INT

BOOL InVelocity

BOOL Busy

BOOL CommandAborted

BOOL Error

2 Altivar Library Guide

2.3.4 Operating mode Profile Velocity

You can set a target velocity in the operating mode Profile Velocity.

The movement is performed with this target velocity in the operating

mode Profile Velocity. The movement continues until a new target

velocity is set or until the operating mode is aborted.

Transitions between two target velocities are performed on the basis

of a motion profile. The motion profile is determined by the profile generator in the drive on the basis of the actual velocity, the target velocity and the acceleration and deceleration ramps.

2.3.4.1 MC_MoveVelocity_ATV

Function description The function block starts the operating mode Profile Velocity with the

velocity Velocity. When the target velocity is reached, InVelocity

is set.

Graphical representation

Altivar Library

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

Velocity INT

Value range: -5000 ... +5000

Initial value: 0

Target velocity in [0.1Hz]

NOTE:

The values for LowFrequency and HighFrequency are set

in the function block SetFrequencyRange_ATV.

If the value for the target velocity velocity is less than the

value for LowFrequency, the movement is made with the

velocity value for LowFrequency. No error is signaled.

If the value for the target velocity velocity is greater than the

value for HighFrequency, the movement is made with the

velocity value for HighFrequency. No error is signaled.

The table below shows the outputs.

Output Data type Description

InVelocity BOOL

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Target velocity not yet reached.

TRUE: Target velocity reached.

"2.2 Basic inputs and outputs"

Notes In the operating mode Profile Velocity, a position overtravel does not

trigger an error. A position overtravel results in a loss of the zero point.

28 Function blocks

0198441113880, V2.08, 04.2011

Page 29

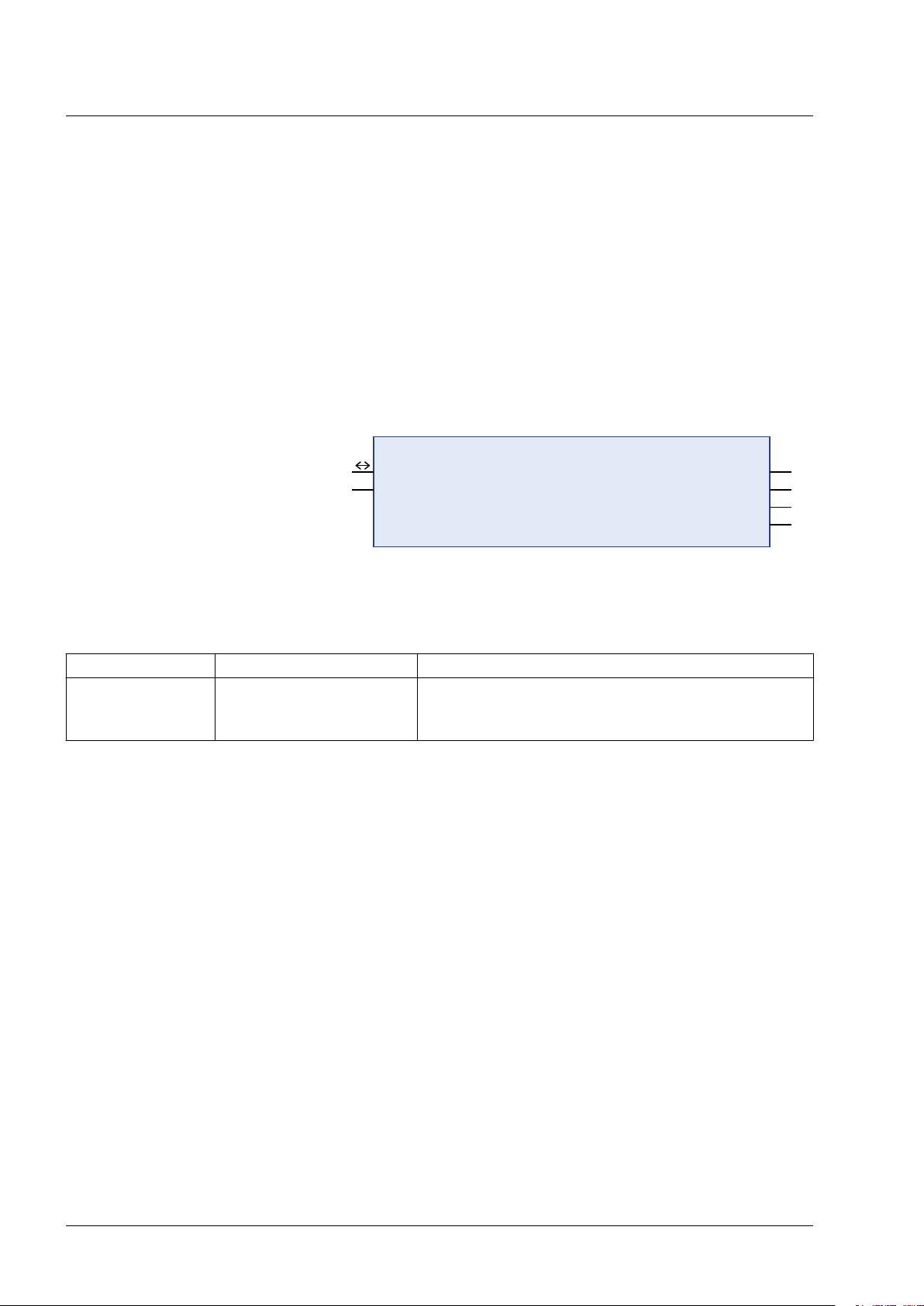

MC_Stop_ATV

Axis Axis_Ref_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

Altivar Library

2.3.5 Stopping

2.3.5.1 MC_Stop_ATV

Function description The function block is used to stop the current movement. The operat-

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs "2.2 Basic inputs and outputs"

2 Altivar Library Guide

Each operating mode can be canceled by stopping. Stopping the

operating mode does not generate an error.

ing mode is stopped by the function block.

Notes

The type of deceleration (deceleration ramp, coasting down without

braking) is set via the parameter Stt. Note the pertinent information in

the product manual.

•

The deceleration ramp is set with the function block

"2.4.2.2 SetDriveRamp_ATV".

•

The function block can only be interrupted by disabling the power

stage via the function block "2.3.1.1 MC_Power_ATV".

•

As long as the input Execute is TRUE, no other function block

with the exception of "2.3.1.1 MC_Power_ATV" can be started.

0198441113880, V2.08, 04.2011

Function blocks 29

Page 30

MC_ReadActualVelocity_ATV

Axis Axis_Ref_ATV

Enable BOOL

BOOL Valid

BOOL Busy

BOOL Error

INT Velocity

2 Altivar Library Guide

2.4 Administrative

2.4.1 Reading a parameter

The following functions blocks allow you to read drive parameters

such as the actual position or the actual velocity.

An additional function block provides read access to individual parameters of the device. See the product manual for a description of the

parameters.

2.4.1.1 MC_ReadActualVelocity_ATV

Function description The function block is used to read the actual velocity of the motor.

Graphical representation

Altivar Library

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the outputs.

Output Data type Description

Velocity INT

Value range: -5000 ... +5000

Initial value:

Actual velocity in min

"2.2 Basic inputs and outputs"

Notes The function block uses Service Data Objects (SDO) to read the

parameter from the device. Therefore, it is strongly recommended not

to permanently set the input Enable to TRUE. This may cause overload on the fieldbus. It is recommended to deactivate the function

block when the output Busy is set to FALSE.

The value is specified in min-1. Example: At a frequency of 3 Hz and 2

pairs of poles, this results in a velocity of 90 min-1. (3 Hz * 60 s / 2

pairs of poles = 90 min-1). Note that the reference value for the velocity

("2.3.4.1 MC_MoveVelocity_ATV") is specified in increments of 0.1 Hz

(3 Hz -> Velocity = 30).

-1

30 Function blocks

0198441113880, V2.08, 04.2011

Page 31

MC_ReadActualTorque_ATV

Axis Axis_Ref_ATV

Enable BOOL

BOOL Valid

BOOL Busy

BOOL Error

INT Torque

Altivar Library

2.4.1.2 MC_ReadActualTorque_ATV

Function description The function block is used to read the actual torque of the motor.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the outputs.

Output Data type Description

Torque INT

"2.2 Basic inputs and outputs"

Value range: -3276.7 ... 3276.7

Initial value:

Actual torque of the motor on increments of 0.1 %.

2 Altivar Library Guide

Notes The function block uses Service Data Objects (SDO) to read the

parameter. Therefore, it is strongly recommended not to permanently

set the input Enable to TRUE. This may cause overload on the fieldbus. It is recommended to deactivate the function block when the output Busy is set to FALSE.

0198441113880, V2.08, 04.2011

Function blocks 31

Page 32

MC_ReadStatus_ATV

Axis Axis_Ref_ATV

Enable BOOL

BOOL Valid

BOOL Busy

BOOL Error

BOOL Errorstop

BOOL Disabled

BOOL Stopping

BOOL StandStill

BOOL DiscreteMotion

BOOL ContinuousMotion

BOOL ConstantVelocity

BOOL Accelerating

BOOL Decelerating

2 Altivar Library Guide

2.4.1.3 MC_ReadStatus_ATV

Function description The function block is used to read the current status of the device.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Altivar Library

32 Function blocks

0198441113880, V2.08, 04.2011

Page 33

Altivar Library

Inputs/outputs The table below shows the outputs.

Output Data type Description

ErrorStop BOOL

Disabled BOOL

Stopping

StandStill

DiscreteMotion BOOL

ContinuousMotion BOOL

ConstantVelocity BOOL

Accelerating BOOL

Decelerating BOOL

BOOL

BOOL

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The movement has been interrupted by an error.

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Power stage is enabled.

TRUE: Power stage is disabled

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The function block "2.3.5.1 MC_Stop_ATV" is being

executed or the movement is being stopped.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The movement hast been stopped.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The operating mode Profile Position has been started.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The operating mode Profile Velocity has been started.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: A movement at a constant velocity is performed.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The motor accelerates.

Value range: FALSE, TRUE

Initial value: FALSE

TRUE: The motor decelerates.

2 Altivar Library Guide

"2.2 Basic inputs and outputs"

Notes At any given point in time, the drive is in one of the states: StandStill,

DiscreteMotion, ContinuousMotion, Stopping, Disabled or ErrorStop.

The corresponding output is then TRUE.

0198441113880, V2.08, 04.2011

Function blocks 33

Page 34

MC_ReadParameter_ATV

Axis Axis_Ref_ATV

Enable BOOL

ParameterNumber INT

Index UINT

Subindex UINT

BOOL Valid

BOOL Busy

BOOL Error

DINT Value

UINT Length

2 Altivar Library Guide

2.4.1.4 MC_ReadParameter_ATV

Function description The function block reads an object from the device parameter list.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

ParameterNumber INT

Index

Subindex

UINT

UINT

Value range: 0 ... 65535

Initial value: 1000

Number of the parameter:

10: Actual velocity.

11: Target velocity.

1000: Selection via index and subindex.

Value range: 0 ... 65535

Initial value:

Index of parameter to be read. Only valid if ParameterNum-

ber = 1000.

See the product manual for an overview of the parameters.

Value range: 0 ... 255

Initial value:

Subindex of parameter to be read. Only valid if Parameter-

Number = 1000.

See the product manual for an overview of the parameters.

Altivar Library

The table below shows the outputs.

Output Data type Description

Value DINT

Length UINT

Value range: -2147483648 ... 2147483647

Initial value: 0

Value of the parameter.

Value range: 1 ... 4

Initial value: 4

Length of the parameter in bytes.

"2.2 Basic inputs and outputs"

Notes The function block uses Service Data Objects (SDO) to read the

parameter. Therefore, it is strongly recommended not to permanently

set the input Enable to TRUE. This may cause overload on the fieldbus. It is recommended to deactivate the function block when the

input Busy is set to FALSE.

34 Function blocks

0198441113880, V2.08, 04.2011

Page 35

GetSupplierVersion

WORD GetSupplierVersion

Altivar Library

2.4.1.5 GetSupplierVersion

Function description The function block returns the version of the library of the device.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the outputs.

Output Data type Description

GetSupplierVersion

WORD

The output provides the version number of the library. Convert

the decimal value to hex.

Example: GetSupplierVersion = 12368 = 3050h = Version

3.0.5.0

2 Altivar Library Guide

0198441113880, V2.08, 04.2011

Function blocks 35

Page 36

MC_WriteParameter_ATV

Axis Axis_Ref_ATV

Execute BOOL

ParameterNumber INT

Value DINT

Index UINT

Subindex UINT

Length UINT

BOOL Done

BOOL Busy

BOOL Error

2 Altivar Library Guide

2.4.2 Writing a parameter

2.4.2.1 MC_WriteParameter_ATV

Function description The function block is used to write a value to a specific parameter.

Graphical representation

Altivar Library

The following function bocks allow you to write drive parameters, for

example the values for the acceleration and deceleration ramps.

An additional function block provides write access to individual parameters of the device. See the product manual for a description of the

parameters.

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

ParameterNumber INT

Value DINT

Index UINT

Subindex

Length

UINT

UINT

Value range: 1000

Initial value: 1000

Reserved.

Value range: -2147483648 ... 2147483647

Initial value: 0

New value to be written to the parameter.

Value range: 0 ... 65535

Initial value: 0

Index of the parameter to be written.

See the product manual for a list of the parameters with the

corresponding CANopen address.

Value range: 0 ... 255

Initial value: 0

Subindex of the parameter to be written.

See the product manual for a list of the parameters with the

corresponding CANopen address.

Value range: 0 ... 4

Initial value: 0

Length of the parameter to be written in bytes.

"2.2 Basic inputs and outputs"

Notes If the inputs ParameterNumber, Index or Subindex are changed

36 Function blocks

while Busy is TRUE, the function block uses the previous values. The

next time the function block is executed, the new values will be used.

0198441113880, V2.08, 04.2011

Page 37

SetDriveRamp_ATV

Axis Axis_Ref_ATV

Execute BOOL

Acceleration DINT

Deceleration DINT

BOOL Done

BOOL Busy

BOOL Error

Altivar Library

2.4.2.2 SetDriveRamp_ATV

Function description The function block configures the acceleration ramp and the decelera-

tion ramp of the device.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

Acceleration DINT

Deceleration

DINT

Value range: 1 ... 9999

Initial value: 30

Time for the acceleration ramp in 0.1 s.

Example: With a value of 30, 3 seconds are required to accelerate from 0 to the nominal frequency of the motor. It must be

possible to reach the value with the available nominal torque of

the motor.

Value range: 1 ... 9999

Initial value: 30

Time for the deceleration ramp in 0.1 s.

Example: With a value of 30, 3 seconds are required to decelerate from 0 to the nominal frequency of the motor. It must be

possible to reach the value with the available nominal torque of

the motor.

2 Altivar Library Guide

0198441113880, V2.08, 04.2011

Function blocks 37

"2.2 Basic inputs and outputs"

Notes Note the following for drives with high external moments of inertia or

for highly dynamic applications: The motors regenerate energy during

deceleration. The DC bus can absorb a limited amount of energy in

the capacitors. Connecting additional capacitors to the DC bus increases the amount of energy that can be absorbed. If the capacity of the

capacitors is exceeded, the excess energy must be discharged via

internal or external braking resistors. If the energy is not discharged,

an overvoltage monitor will shut off the power stage. Overvoltages can

be limited by adding a braking resistor with a corresponding braking

resistor controller. This converts the regenerated energy to heat

energy during deceleration.

Page 38

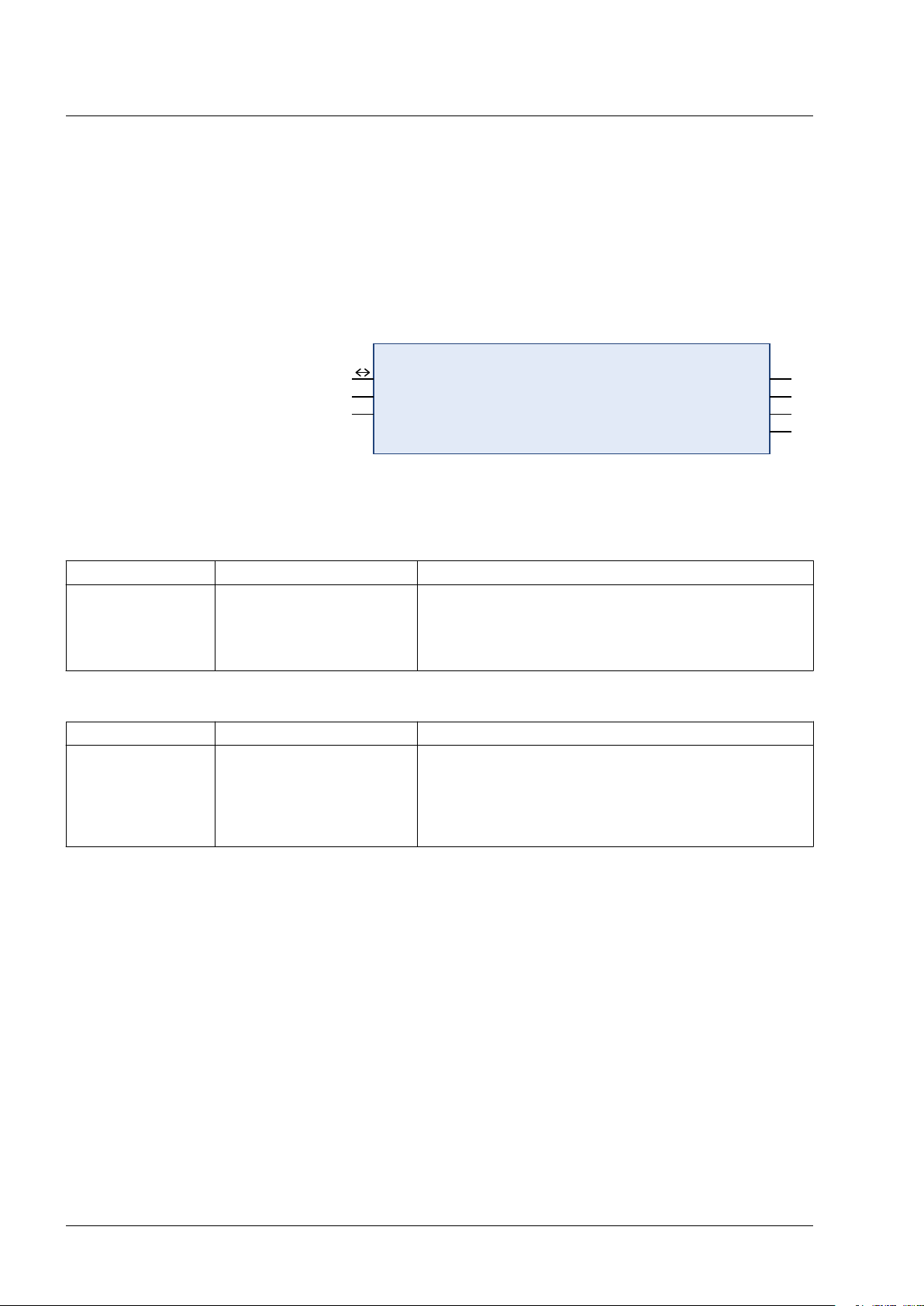

SetFrequencyRange_ATV

Axis Axis_Ref_ATV

Execute BOOL

LowFrequency DINT

HighFrequency DINT

MaxFrequency DINT

BOOL Done

BOOL Busy

BOOL Error

2 Altivar Library Guide

2.4.2.3 SetFrequencyRange_ATV

Function description The function block is used to configure the frequency ranges of the

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Altivar Library

device for the function blocks MC_MoveVelocity and MC_Jog. If the

frequency (speed of rotation) falls below the value in LowFrequency,

the device uses the frequency specified in LowFrequency without

triggering an error message. If the frequency (speed of rotation)

exceeds the value in HighFrequency, the device uses the frequency

specified in HighFrequency without triggering an error message.

Input Data type Description

LowFrequency DINT

HighFrequency DINT

MaxFrequency DINT

Value range: 0 ... HighFrequency

Initial value: 0

Motor frequency at minimum reference value.

Value range: LowFrequency ... MaxFrequency

Initial value: 500

Motor frequency at maximum reference value.

Value range: 100 ... 5000/10000 (see product manual)

Initial value: 600

Maximum permissible motor frequency

Adapt the value to the motor and the mechanical situation. The

maximum frequency depends on certain parameters. Note the

pertinent information in the product manual.

"2.2 Basic inputs and outputs"

38 Function blocks

0198441113880, V2.08, 04.2011

Page 39

ResetParameters_ATV

Axis Axis_Ref_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

Altivar Library

2.4.2.4 ResetParameters_ATV

Function description This function block restores all parameters to the factory settings.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs "2.2 Basic inputs and outputs"

Notes Observe the information provided in chapter "Preparing the drive".

2 Altivar Library Guide

•

The new settings are not saved to the EEPROM. Use

"2.4.2.5 StoreParameters_ATV" to save the new settings to the

EEPROM.

0198441113880, V2.08, 04.2011

Function blocks 39

Page 40

StoreParameters_ATV

Axis Axis_Ref_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

2 Altivar Library Guide

2.4.2.5 StoreParameters_ATV

Function description The function block saves the parameter values to the EEPROM.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs "2.2 Basic inputs and outputs"

Altivar Library

40 Function blocks

0198441113880, V2.08, 04.2011

Page 41

UploadDriveParameter_ATV

Axis Axis_Ref_ATV

ParameterSetVar TypeParameterSetVar_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

UINT Size

Altivar Library

2.4.3 Saving and restoring device configuration

Using a function block, you can upload the device configuration from

the drive to the controller. A further function block lets you download a

device configuration stored on the controller to a drive.

2.4.3.1 UploadDriveParameter_ATV

Function description The function blocks reads the parameter values that can be modified

from the device. See also "2.4.3.2 DownloadDriveParameter_ATV".

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs/outputs.

2 Altivar Library Guide

Input/output Data type Description

ParameterSetVar TypeParameterSetVar_ATV

Value range:

Initial value:

List of the device parameters. Predefined data structure (array

of DINT).

The table below shows the outputs.

Output Data type Description

Size UINT

Value range:

Initial value: 0

Number of parameters read. In the case of an incorrect upload,

the value remains 0.

"2.2 Basic inputs and outputs"

Notes

•

The two function blocks "2.4.3.2 DownloadDriveParameter_ATV"

and "2.4.3.1 UploadDriveParameter_ATV" allow you to save the

parameters stored in a device to an identical device without using

the commissioning software.

0198441113880, V2.08, 04.2011

Function blocks 41

Page 42

DownloadDriveParameter_ATV

Axis Axis_Ref_ATV

ParameterSetVar TypeParameterSetVar_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

UINT Index

UINT Subindex

2 Altivar Library Guide

2.4.3.2 DownloadDriveParameter_ATV

Function description The function blocks writes the parameter values that can be modified

to the device. Before calling the function block, you must execute

"2.4.3.1 UploadDriveParameter_ATV". If not, an error message will be

generated.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs/outputs.

Input/output Data type Description

ParameterSetVar TypeParameterSetVar_ATV

Value range:

Initial value:

List of device parameters

Altivar Library

The table below shows the outputs.

Output Data type Description

Index UINT

Subindex

UINT

Value range: 0 ... 65535

Initial value:

Index of the parameter. See the product manual for an overview of the parameters.

Value range: 0 ... 255

Initial value:

Subindex of the parameter. See the product manual for an

overview of the parameters.

"2.2 Basic inputs and outputs"

Notes

•

The function block can only be executed if the drive is in the operating state 3 Switch On Disabled (operating state of drive). To transition to this state, disable the power stage with the function block

"2.3.1.1 MC_Power_ATV".

•

In order to permanently store the parameters, you must save them

to the EEPROM using the function block

"2.4.2.5 StoreParameters_ATV".

•

The two function blocks "2.4.3.2 DownloadDriveParameter_ATV"

and "2.4.3.1 UploadDriveParameter_ATV" allow you to save the

parameters stored in a device to an identical device without using

the commissioning software.

42 Function blocks

0198441113880, V2.08, 04.2011

Page 43

ReadAnalogInput_ATV

Input Input_Ref_ATV

Enable BOOL

InputNumber INT

BOOL Valid

BOOL Busy

BOOL Error

INT Value

Altivar Library

2.4.4 Inputs and outputs

The following function blocks allow you to access the digital and analog inputs and outputs of all CAN nodes in the system..

2.4.4.1 ReadAnalogInput_ATV

Function description The function block reads the current value of an analog input.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

InputNumber INT

Value range: 1 ... 4

Initial value: 1

1: AI1

2: AI2

3: AI3 (ATV71 only with expansion card)

4: AI4 (ATV71 only and only with expansion card)

2 Altivar Library Guide

The table below shows the outputs.

Output Data type Description

Value INT

Value range: Initial value: 0

Corresponds to the input voltage in mV or the input current in

0.001 mA increments at the selected analog input.

"2.2 Basic inputs and outputs"

Notes

•

The analog inputs of ATV31/ATV312 and ATV71/ATV32 are different. See the product manual for additional information.

0198441113880, V2.08, 04.2011

Function blocks

43

Page 44

MC_ReadDigitalInput_ATV

Input Input_Ref_ATV

Enable BOOL

InputNumber INT

BOOL Valid

BOOL Busy

BOOL Error

BOOL Value

WORD Inputs

2 Altivar Library Guide

2.4.4.2 MC_ReadDigitalInput_ATV

Function description Reads the current state of the digital inputs of the drive.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Altivar Library

44

0198441113880, V2.08, 04.2011

Function blocks

Page 45

Altivar Library

Inputs/outputs The table below shows the inputs.

Input Data type Description

InputNumber INT

Value range: 1 ... 14 (product-dependent)

Initial value: 1

Number of the input to be read.

Assignment of the inputs of the drive.

1: IL1

2: IL2

3: IL3

4: IL4

5: IL5

6: IL6

Inputs of the I/O expansion card (ATV71):

7: IL7

8: IL8

9: IL9

10: IL10

Inputs of the I/O expansion card (ATV71):

11: IL11

12: IL12

13: IL13

14: IL14

15: Reserved. Value = 0.

2 Altivar Library Guide

The table below shows the outputs.

Output Data type Description

Value BOOL

Inputs

WORD

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Level at selected input is 0 V.

TRUE: Level at selected input is 24 V.

Value range: 0000h ... 3FFFh

Initial value: 0000

Image of the inputs as a bit pattern.

Bit 0: IL1

Bit 1: IL2

Bit 2: IL3

Bit 3: IL4

Bit 4: IL5

Bit 5: IL6

Inputs of the I/O expansion card (ATV71):

Bit 6: IL7

Bit 7: IL8

Bit 8: IL9

Bit 9: IL10

Inputs of the I/O expansion:

Bit 10: IL11:

Bit 11: IL12

Bit 12: IL13

Bit 13: IL14

Bit 14 and bit 15: Reserved. Value = 0.

h

0198441113880, V2.08, 04.2011

Function blocks

"2.2 Basic inputs and outputs"

Notes See the product manual for a description of the digital inputs.

45

Page 46

MC_ReadDigitalOutput_ATV

Output Output_Ref_ATV

Enable BOOL

OutputNumber INT

BOOL Valid

BOOL Busy

BOOL Error

BOOL Value

WORD Outputs

2 Altivar Library Guide

2.4.4.3 MC_ReadDigitalOutput_ATV

Function description The function block is used to get the current state of the digital out-

puts.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Altivar Library

46

0198441113880, V2.08, 04.2011

Function blocks

Page 47

Altivar Library

Inputs/outputs The table below shows the inputs.

Input Data type Description

OutputNumber INT

The table below shows the outputs.

Output Data type Description

Value BOOL

Outputs

WORD

Value range: 1 ... 8 (product-dependent)

Initial value: 1

Number of the output to be read.

ATV31/312/32:

1: Relay1

2: Relay2

3: LO

ATV71:

1: Relay1

2: Relay2

3: Relay3

4: Relay4

5: LO1

6: LO2

7: LO3

8: LO4

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: Level at selected output is 0 V.

TRUE: Level at selected output is 24 V.

Value range: 00h ...0Fh

Initial value: 00

Image of the outputs as a bit pattern.

ATV31/312/32:

Bit 0: Relay1

Bit 1: Relay2

Bit 2: LO

ATV71:

Bit 0: Relay1

Bit 1: Relay2

Bit 2: Relay3

Bit 3: Relay4

Bit 4: LO1

Bit 5: LO2

Bit 6: LO3

Bit 7: LO4

The value of the other bits is 0.

2 Altivar Library Guide

h

0198441113880, V2.08, 04.2011

Function blocks

"2.2 Basic inputs and outputs"

Notes See the product manual for a description of the digital outputs.

47

Page 48

MC_WriteDigitalOutput_ATV

Output Output_Ref_ATV

Execute BOOL

OutputNumber INT

Value BOOL

AllOutputs BOOL

Outputs WORD

BOOL Done

BOOL Busy

BOOL Error

2 Altivar Library Guide

2.4.4.4 MC_WriteDigitalOutput_ATV

Function description The function blocks writes values to the digital outputs.

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the inputs.

Input Data type Description

OutputNumber INT

Value

AllOutputs

Outputs

BOOL

BOOL

WORD

Signal output to which to write.

ATV31/312/32:

1: Relay1

2: Relay2

3: LO

ATV71:

1: Relay1

2: Relay2

3: Relay3

4: Relay4

5: LO1

6: LO2

7: LO3

8: LO4.

Value range: FALSE, TRUE

Initial value: FALSE

FALSE: 0V is written to the selected signal output.

TRUE: 24V is written to the selected signal output.

Value range: FALSE, TRUE

Initial value:

FALSE: The signal output to be written to is set via input Out-

putNumber.

TRUE: The signal outputs to be written to are set via input

Output.

Value range: 0000h ... 0003h

Initial value: 0

The input defines the signal outputs to which the value defined

in Value is to be written.

0000 0000 0000 00002 (0000h) = Signal output/relay 1

0000 0000 0000 00102 (0002h) = Signal output/relay 2

0000 0000 0000 00112 (0003h) = Signal output/relay 1 and signal output/relay 2

Altivar Library

48

"2.2 Basic inputs and outputs"

0198441113880, V2.08, 04.2011

Function blocks

Page 49

MC_ReadAxisError_ATV

Axis Axis_Ref_ATV

Enable BOOL

BOOL Valid

BOOL Busy

BOOL Error

WORD ErrorID

Altivar Library

2.4.5 Error handling

2.4.5.1 MC_ReadAxisError_ATV

Function description The function block reads the error information pertaining to the most

Graphical representation

2 Altivar Library Guide

For error handling, each function block has an output Error which is

set if a synchronous or asynchronous error occurs.

The function block MC_ReadAxisError_xxx is called to analyze the

cause of the error. The function block contains the stored error information.

The function block MC_Reset_xxx deletes the error information

entered. Future error information can now be stored.

If an additional error occurs, the error information is only stored if no

stored error information already exists. If there is still information pertaining to a previous error, the new error message is ignored.

recent error.

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs The table below shows the outputs.

Output Data type Description

ErrorID WORD

Value range: 0000h ... FFFFh

Initial value: 0000

0: No error stored.

>0: Stored error number.

See the product manual for an overview of the error numbers.

"2.2 Basic inputs and outputs"

h

0198441113880, V2.08, 04.2011

Function blocks

49

Page 50

2 Altivar Library Guide

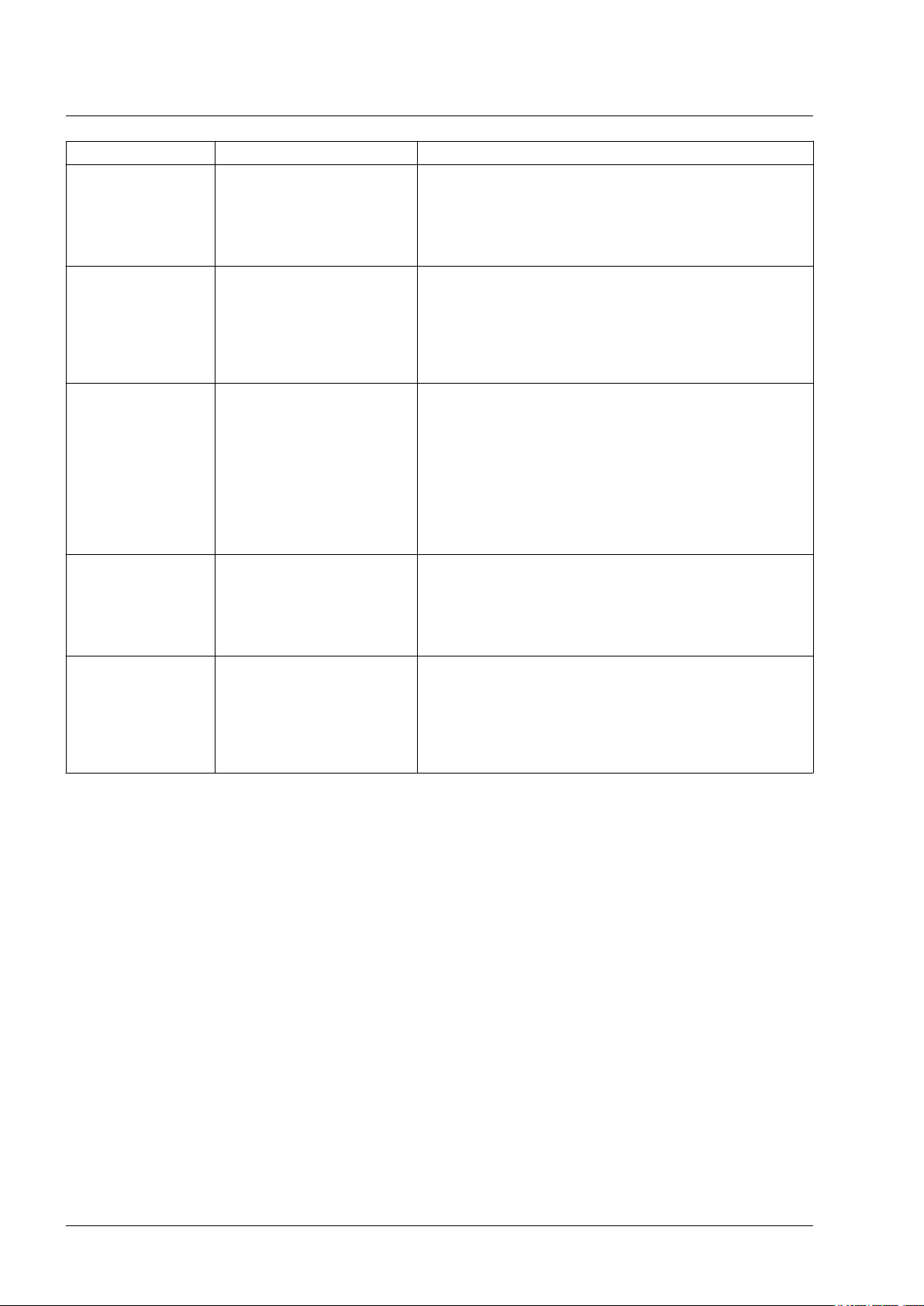

Table of error numbers The table below shows the error numbers of the library. See the prod-

Altivar Library

uct manual for the error numbers of the drive.

ErrorID hexadecimal

1000

h

2310

h

2320

h

2330

h

2340

h

3110

h

3120

h

3130

h

3310

h

4210

h

5520

h

6100

h

6300

h

7300

h

7510

h

8100

h

9000

h

A309

h

FE00

h

FE01

h

FF00

h

FF01

h

FF02

h

FF03

h

FF04

h

FF05

h

FF06

h

FF07

h

FF08

h

FF09

h

FF0A

h

FF0B

h

FF0C

h

FF0D

h

FF0E

h

FF0F

h

FF10

h

ErrorID decimal HMI Description

4096

8976

8992

CrF

OLF

SOF

OCF

SCF

Capacitor error

Motor overload

Speed of rotation too high

Motor overcurrent

Motor short circuit

9008 SCF Short circuit motor phases (ground fault)

9024 SCF Short circuit motor phase (phase to phase)

12560

12576

12592

13072

16912

21792

24832

25344

29440

29968

33024

OSF

USF

PHF

ObF

OPF

OHF

EEF

InF

CCF

LFF

SLF

COF

Overvoltage mains supply

Undervoltage mains supply

Error mains phases

DC bus overvoltage

Error motor phase

Overtemperature

EEPROM error

Internal event

Parameter out of permissible range

Error at AI3

Modbus communication error

CANopen communication error, Heartbeat or Life

Guard error

36864

41737

65024

65025

EPF

tnF

bLF

External error

Drive not in operating state6 Operation Enabled

Error during autotuning

Error brake controller

65280 - Toggle bit unchanged

65281 - SDO timeout

65282 - Server / client command specifier invalid or unknown

65283 - Invalid block size (only in Block Mode)

65284 - Invalid sequence number (only in Block Mode)

65285 - CRC error (only in Block Mode)

65286 - No memory available

65287 - Access to object not possible

65288 - No read access, because write-only object (wo)

65289 - No write access, because read object (ro)

65290 - Object does not exist in object dictionary

65291 - Object does not support PDO mapping

65292 - Number or length of objects exceed the byte length of

the PDO

65293 - Parameters are incompatible

65294 - Device detects internal incompatibility

65295 - Hardware error, access denied

65296 - Data type and parameter length do not match

50

0198441113880, V2.08, 04.2011

Function blocks

Page 51

Altivar Library

2 Altivar Library Guide

ErrorID hexadecimal

FF11

h

FF12

h

FF13

h

FF14

h

FF15

h

FF16

h

FF17

h

FF18

h

FF19

h

FF1A

h

FF1B

h

FF1C

h

FF1D

h

FF1E

h

FF1F

h

FF20

h

FF21

h

FF22

h

FF34

h

FF37

h

FF38

h

FF39

h

FF3A

h

FF3B

h

FF3C

h

FF3D

h

FF3E

h

FF50

h

FF51

h

FF52

h

ErrorID decimal HMI Description

65297 - Data type does not match, parameter too long

65298 - Data type does not match, parameter too short

65299 - Subindex not supported

65300 - Value range of parameter too large (relevant only for

write access)

65301 - Parameter values too great

65302 - Parameter values too small

65303 - Upper value is less than lower value

65304 - General error

65305 - Data can neither be transmitted to the application nor

saved.

65306 - Local access channel is used, data can neither be

transmitted nor saved.

65307 - Device status keeps data from being transmitted and

saved.

65308 - Object dictionary does not exist or cannot be generated

(for example, if data error occurs during generation

from file)

65309 - Reserved

65310 - Reserved

65311 - Reserved

65312 - Unknown status

65313 - Input variable was changed before response was

received ("2.4.1.4 MC_ReadParameter_ATV",

"2.4.2.1 MC_WriteParameter_ATV")

65314 - Attempt to interrupt a non-interruptible function block

("2.3.1.1 MC_Power_ATV", "2.3.5.1 MC_Stop_ATV")

65332 -

Power stage does not switch to operating state 6 Operation Enabled

65335 -

Power stage is not in operating state 6 Operation Enabled

65336 - Parameter list has not yet been read from the device

via "2.4.3.1 UploadDriveParameter_ATV".

65337 - Parameter list and device do not match

65338 - Drive in state PreOperational

65339 -

Drive is not in operating state 3 Switch On Disabled

65340 - STO "Safe Torque Off" (Power Removal) active

65341 - Drive is not compatible

65342 - Error in mapping

65360 - Initialization error of function block

"2.5.1.1 Altivar_Startup"

65361 - The function block "2.5.1.1 Altivar_Startup" cannot be

controlled via the application since i_iControlMode

= 1.

65362 - The function block "2.5.1.1 Altivar_Startup" cannot be

controlled via the visualization since i_iControlMode

= 0.

0198441113880, V2.08, 04.2011

Function blocks

51

Page 52

2 Altivar Library Guide

Altivar Library

ErrorID hexadecimal

FF53

h

FF54

h

ErrorID decimal HMI Description

65363 - The value at the input i_iControlMode is outside of

the valid value range.

65364 - The value at the input iq_iCmd is outside of the valid

value range.

52

0198441113880, V2.08, 04.2011

Function blocks

Page 53

MC_Reset_ATV

Axis Axis_Ref_ATV

Execute BOOL

BOOL Done

BOOL Busy

BOOL Error

Altivar Library

2.4.5.2 MC_Reset_ATV

Function description The function block is used to acknowledge an error. The error memory

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

Inputs/outputs "2.2 Basic inputs and outputs"

2 Altivar Library Guide

is cleared so that it is available for future error messages. If the power

stage has been disabled by the automatic error response, it can be

enabled again, provided that the cause of the error has been rectified

when the error message is acknowledged.

0198441113880, V2.08, 04.2011

Function blocks

53

Page 54

Altivar_Startup

iq_stAxis Axis_Ref_ATV

iq_iCMD INT

i_sUserDeviceName string

i_xActivate BOOL

i_iControlMode INT

i_iVelocity INT

i_udiAcceleration UDINT

i_udiDeceleration UDINT

i_xConfUld BOOL

i_xConfDld BOOL

BOOL q_xReady

BOOL q_xBusy

State q_eStatus

OpState_ATV q_eDrvStatus

DINT q_diActVelUsr

INT q_iActIdq

DriveParams q_stDriveParams

BOOL q_xError

WORD q_wErrorID

2 Altivar Library Guide

2.5 Device Function

2.5.1 Startup

Altivar Library

These function blocks "Startup" support you in commissioning a drive

system at a controller. Before these function blocks can be used, you

must set the communication parameters baud rate and node address

in the drive and in the controller. Function blocks and the visualization

cannot be used simultaneously.

The function blocks "Startup" with visualization elements have the following functions:

•

Switching on the drive system.

•

Displaying the status of the drive system.

•

Fast access to frequently used parameters.

•

The parameters are accessed via their index and subindex.

•

Transmitting a device parameter list from the drive to the controller

and from the controller to the drive (upload and download).

•

Using the operating mode Jog.

•

Using the operating mode Profile Velocity (movement at defined

velocity).

•

Displaying and acknowledging error messages.

2.5.1.1 Altivar_Startup

Function description This function block supports you in commissioning a frequency inver-

Graphical representation

Compatible devices ATV31/ATV312 and ATV71/ATV32

54

ter for the first time. The function block comprises two visualizations to

facilitate usage of the function block. Function blocks and the visualization cannot be used simultaneously.

0198441113880, V2.08, 04.2011

Function blocks

Page 55

Altivar Library

Inputs/outputs The table below shows the inputs/outputs.

Input/output Data type Description

iq_stAxis Axis_Ref_ATV

iq_iCMD

INT

Value range:

Initial value:

Corresponds to the input/output Axis. See

"2.2 Basic inputs and outputs".

Value range:

Initial value:

Commands:

-1: command is active

0: no ongoing command

1: ENABLE (enable power stage)

2: DISABLE (disable power stage)

3: Reset

4: Stop

9: MoveVel

The function to be executed is written by the application as a

command and overwritten by the function block when it is processed.

Condition: The input is only effective if the value of ControlMode is 1.

To start the selected function, the value in the parameter CMD

must be written once. As soon as the command is executed,

the value is overwritten by -1. When the execution of the command is terminated, the value is overwritten by 0.

2 Altivar Library Guide

0198441113880, V2.08, 04.2011

Function blocks

55

Page 56

2 Altivar Library Guide

The table below shows the inputs.

Input Data type Description

i_sUserDeviceName string

i_xActivate

i_iControlMode

i_iVelocity

i_udiAcceleration UDINT

i_udiDeceleration UDINT

i_xConfUld BOOL

i_xConfDld

BOOL

INT

INT

BOOL

Value range:

Initial value:

Name of the axis. The name is defined by the user. If no name

is entered, the node ID is displayed.

Value range: FALSE, TRUE

Initial value:

The selected ControlMode is activated with a rising edge.

If all requirements for the selected ControlMode are met, the

selected ControlMode is started.

If the requirements are not met, the selection is canceled with

an error message.

Value range:

Initial value:

ControlMode = 0: The functions are controlled via the visualization.

ControlMode = 1: The functions are controlled via the application. The visualization is deactivated.

Value range:

Initial value:

Target velocity in usr

Value range:

Initial value: 30

Acceleration ramp in [usr].

Value range:

Initial value: 30

Deceleration ramp in [usr]

Value range: FALSE, TRUE

Initial value:

A rising edge triggers an upload (saving parameters from

device to controller).

Value range: FALSE, TRUE

Initial value:

A rising edge triggers a download (stored parameters from

controller to device).

Altivar Library

56

0198441113880, V2.08, 04.2011

Function blocks

Page 57

Altivar Library

The table below shows the outputs.

Output Data type Description

q_xReady BOOL

q_xBusy BOOL

q_eStatus

q_eDrvStatus

q_diActVelUsr

q_iActIdq INT

q_stDriveParams DriveParams

q_xError

q_wErrorID

State

OpState_ATV

DINT

BOOL

WORD

Value range: FALSE, TRUE

Initial value:

Function block has been activated and is ready for operation.

Value range: FALSE, TRUE

Initial value:

A function is being performed via the function block. If a new

function is started, the currently active function is canceled.

Value range:

Initial value:

State as per PLCopen state diagram:

0: Undefined

1: Errorstop

2: Disabled

3: Stopping

4: StandStill

5: DiscreteMotion

6: ContinuousMotion

7: SynchronizedMotion

8: Homing

Value range:

Initial value:

Operating state of the drive:

1: init

2: nrdy

3: dis

4: rdy

5: son

6: run

7: stop

8: flt

Value range:

Initial value:

Actual velocity in [usr]

Value range: