Page 1

Phaseo power outage solution

User guide

03/2008

W9 1489436 10 11 A01

Page 2

2

Page 3

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview of the solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Presentation of Battery Modules ABL 8BPK24A•• . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation of Battery control modules ABL 8BBU24•00. . . . . . . . . . . . . . . . . 12

Chapter 2 Choice of solution components . . . . . . . . . . . . . . . . . . . . . . . . 15

Choice of components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3 Implementation stages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Implementation stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 4 Assembly and temperature conditions . . . . . . . . . . . . . . . . . .21

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting of the Battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting of Battery control module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 5 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

24 VDC circuit wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Diagnostics contact and inhibition input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wiring of an auto power off circuit of the Battery Module . . . . . . . . . . . . . . . . . . 35

Chapter 6 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

First powering on / Minimum setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

The SETTINGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Settings transfer by memory card type SR2 MEM02 . . . . . . . . . . . . . . . . . . . . . 47

3

Page 4

Chapter 7 Diagnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Faults - causes - remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 8 Operation timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Timed function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

All functions (timed or max) : voltage feedback before module cut-off . . . . . . . . 59

Max function with long power outage (complete discharge of Battery module). . 60

Output behaviour in the case of overload or short-circuit . . . . . . . . . . . . . . . . . . 61

Chapter 9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SERVICE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Battery modules replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix A Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Electrical Characteristics of the Battery control modules. . . . . . . . . . . . . . . . . . . 70

Operating and environmental characteristics of Battery control modules . . . . . . 71

Electrical characteristics of the Battery modules . . . . . . . . . . . . . . . . . . . . . . . . . 72

Operating and environmental characteristics of Battery modules . . . . . . . . . . . . 73

Appendix B Battery general information . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Battery Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendix C FAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

FAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

4

Page 5

Safety Information

§

Important Information

NOTICE Read these instructions carefully, and look at the equipment to become familiar with

the device before trying to install, operate, or maintain it. The following special

messages may appear throughout this documentation or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result

in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result

in injury or equipment damage.

W9 1489436 10 11 A01 03/2008 5

Page 6

Safety Information

PLEASE NOTE Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 2008 Schneider Electric. All Rights Reserved.

6

W9 1489436 10 11 A01 03/2008

Page 7

About the Book

At a Glance

Document Scope This user manual contains the necessary information for the implementation of the

Phaseo power outage solution.

Related

Documents

Title of Documentation Reference Number

Phaseo Universal power supply instruction sheet 1489414_01

Battery Control module instruction sheet 1489436_01

Battery module instruction sheet 1489436_06

User Comments We welcome your comments about this document. You can reach us by e-mail at

techpub@schneider-electric.com

W9 1489436 10 11 A01 03/2008 7

Page 8

About the Book

8

W9 1489436 10 11 A01 03/2008

Page 9

Overview

1

Overview

Introduction This chapter presents the constitutive elements of the Phaseo power outage

solution.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Overview of the solution 10

Presentation of Battery modules ABL 8BPK24A•• 11

Presentation of Battery control modules ABL 8BBU24•00 12

W9 1489436 10 11 A01 03/2008 9

Page 10

Overview

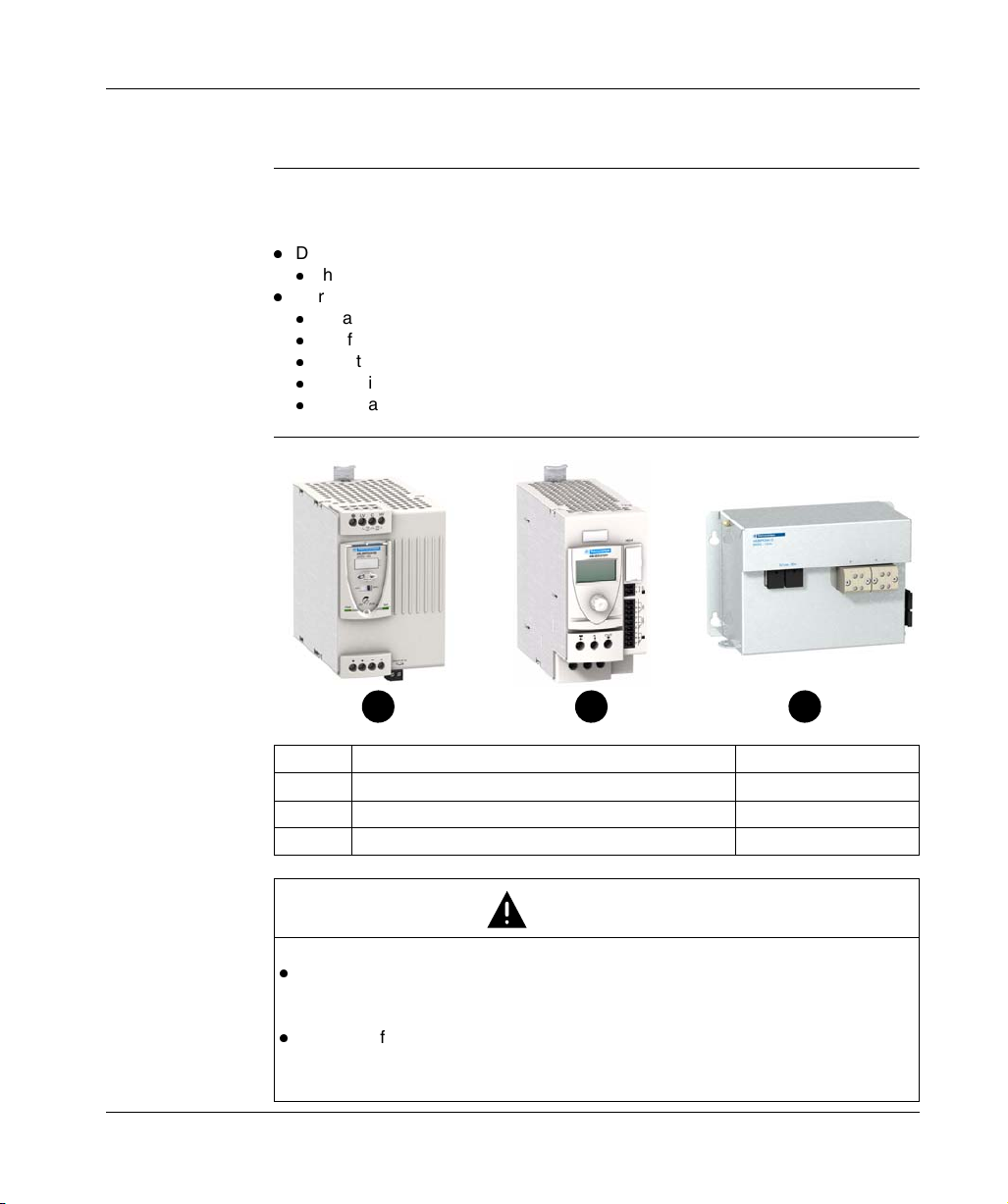

Overview of the solution

Introduction The Phaseo power outage solution allows the 24 VDC supply of the installation (or

with one part) in case there is a network voltage cut-off:

During the entire duration of the cut-off, in order to allow :

the continuity of the installation service.

During a limited time, in order to allow :

data backup,

the fallback of the actuators,

the startup of generators,

operating system shut-down,

data transmission by remote monitoring...

Constitution of

the solution

++

1

Marker Description Reference

1 Phaseo Universal power supply ABL 8•P•24••0

2 Battery control module ABL 8BBU24•00

3 Battery module ABL 8BPK24A••

RISKS OF EQUIPMENT DAMAGE

When the supply is provided by the Battery module, the voltage is not regulated

and can vary between 19 VDC and 28 VDC. It is suitable to check carefully that

the supplied circuits can support a voltage tension between these 2 values.

The use of batteries other than those included in the Battery modules

ABL 8BPK24A•• is not possible (risk of battery deterioration).

Failure to follow these instructions can result in injury or equipment damage.

2 3

CAUTION

10

W9 1489436 10 11 A01 03/2008

Page 11

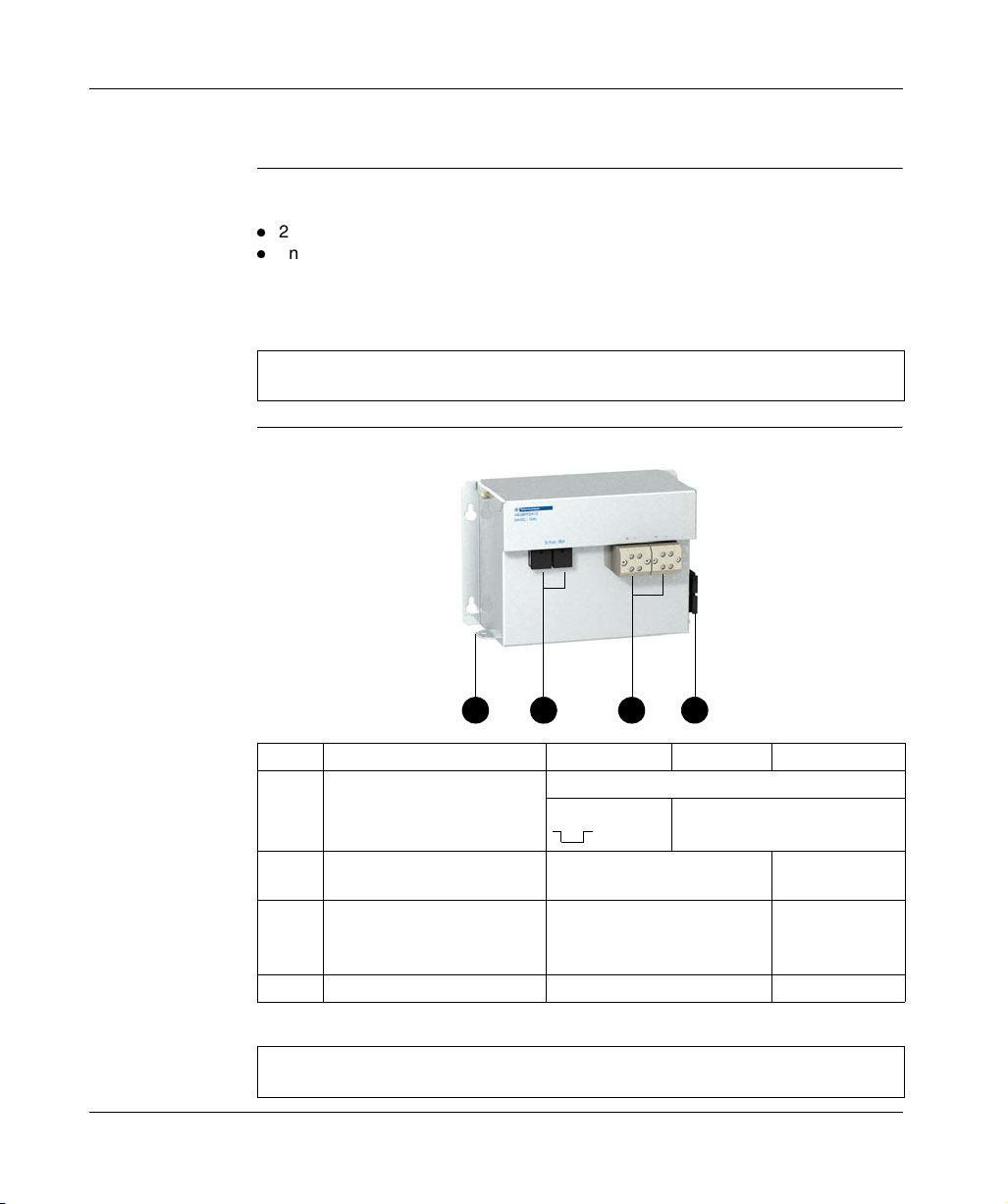

Presentation of Battery Modules ABL 8BPK24A••

Introduction Each Phaseo Battery module consists of:

2 lead sealed batteries mounted serially,

one fuse protection (automobile type).

The Phaseo Battery module range proposes 3 different battery capacities according

to the backup time and the current required for the application desired. See Choice

of components, p. 15.

Note: The Phaseo battery modules do not require maintenance. In the case of

failure, please replace the module set.

Description The scheme below presents the structure of the Phaseo Battery module:

Overview

1 2 3 4

Marker Description 3.2 Ah 7 Ah 12 Ah

1 Metal protective housing Bolt mounting by vertical or horizontal panel

Rail mounting

(1)

2 Protection fuse carrier and

shutdown of module

3 Terminal block of the 24 VDC

output voltage

4 Fuse storage attachment 1 attachment 2 attachments

(1)

Kit usage ABL 1A02

1 fuse carrier 2 fuse carriers

1 block

2

10 mm

screw terminal block

-

2 blocks

10 mm2 screw

terminal block

Note: The fuses are delivered with the module, but not mounted, please mount

them by following the implementation. See Implementation stages, p. 19.

W9 1489436 10 11 A01 03/2008 11

Page 12

Overview

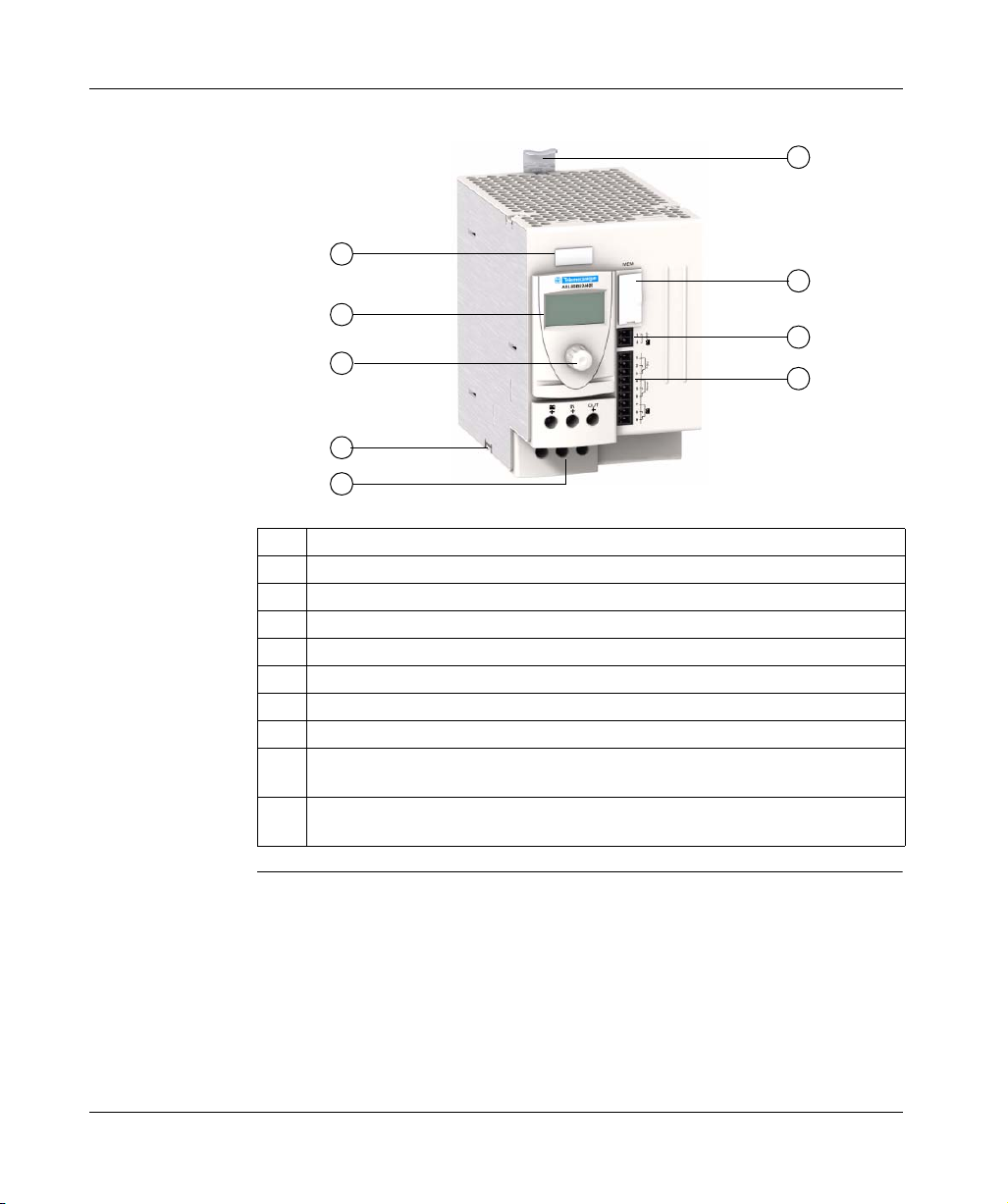

Presentation of Battery control modules ABL 8BBU24•00

Introduction The battery Control modules ABL 8BBU24•00 allowing the following functions :

Optimize the use and life of the batteries:

charge if necessary and as a function of the ambient temperature,

shutdown of the Battery module before the deep discharge

maintenance charge to compensate for self-discharge,

measurement of Battery module ageing

Automatic switch without interruption between power supply and battery:

adjustable operating time on the battery (holding time),

diagnostic of the system state.

The range of the Phaseo battery Control module consists of 2 modules according to

the maximum usage current (20 A or 40 A). See Choice of components, p. 15.

(1)

Important: When the Battery control module ABL 8BBU24•00 is not supplied by

the power supply ABL 8RP••/ABL 8WP••, the Battery module ABL 8BPK24A••

continues to provide a residual current necessary for the power supply of the module

electronics.

In the case of prolonged absence of the power supply voltage in the IN+ and INterminals, it is advisable to unplug the Battery module by removing its fuse(s) in

order to avoid deep discharge.

When this power-off is expected (machine transport or requested power-off), it is

also recommended to turn on the entire control module and Battery module until the

batteries are charged completely (battery icon OK on the display).

It is also possible to insert a contactor between the Battery module and the Battery

control module in order to execute an automatic cut-off (see Wiring of an auto power

off circuit of the Battery Module, p. 35).

(1)

,

12

W9 1489436 10 11 A01 03/2008

Page 13

Description The scheme below presents the structure of the Battery control module:

6

1

7

2

8

3

4

5

9

N° Description

1 Click-on marker label

2 LCD display

3 Browse selection button

4 Grounded lug

5 24 VDC I/Os and the Battery module terminals

6 Mounting flange on DIN rail

7 Memory card (SR2 MEM02) slot to backup and copy configuration settings

8 2-point removable screw terminal block for the input terminal of the 'inhibition of the

Battery module voltage'

9 9-point removable screw terminal block for the input terminal of diagnostic contacts

(power supply presence, alarm and battery presence)

Overview

W9 1489436 10 11 A01 03/2008 13

Page 14

Overview

14

W9 1489436 10 11 A01 03/2008

Page 15

Choice of solution components

Choice of components

Introduction The application settings to be considered in the component choice are :

the current to be provided during t2 backup (holding current),

the t2 backup time (see timing diagram below).

AC input voltage

t

DC output voltage

2

t2

Guidance in

choosing

W9 1489436 10 11 A01 03/2008 15

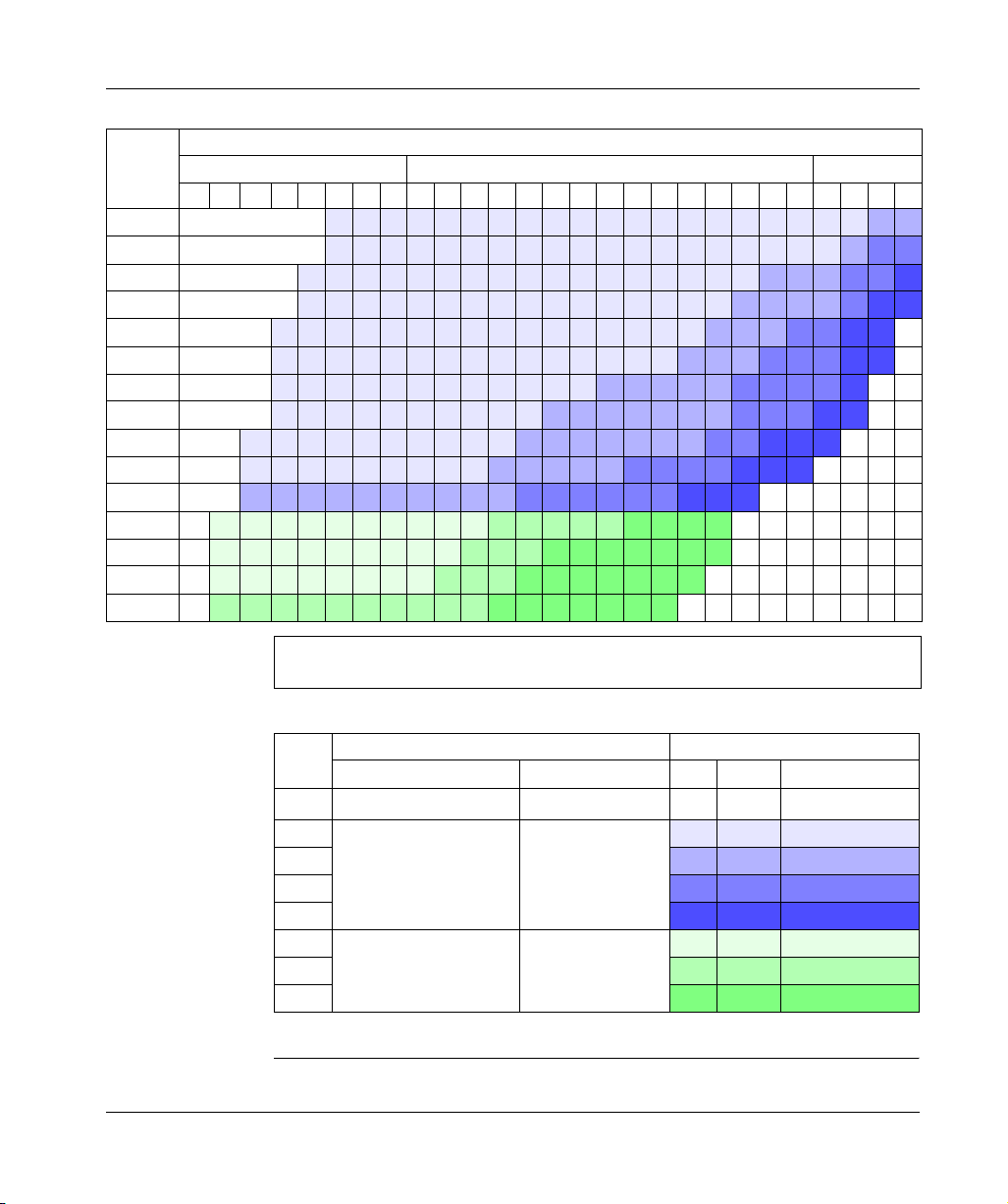

According to the necessary holding current and desired backup time, the table below

indicates the associations of appropriate modules.

Note: This table is based on the characteristics of new Battery module. At the end

of life, once the autonomy of a battery is capable of being divided by 2, it is suitable

to take this into account when choosing the module(s) by multiplying the holding

time by 2 if desired to guarantee the holding time during the life of the modules. For

backup times greater than 5 hours, refer to the table on the following page.

t

Page 16

Choice of components

Holding

current

t2 holding time (see timing diagram)

Seconds Minutes Hours

0.1 0.2 0.5

12510301234567891015203040501235

1A 1 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 3

2 A 1

3 A 1

4 A 1

5 A 1

6 A 1

7 A 1

8 A 1

10 A 1

15 A 1

20 A 1

25 A 1

30 A 1

35 A 1

40 A 1

2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 3 4 4 5 5 5

2 2 2 2 2 2 2 2 2 3 3 3 3 3 4 4 4 4 5 5 5

3 3 3 3 3 3 3 3 3 3 4 4 4 4 4 4 5 5 5

6 6 6 6 6 6 6 6 6 6 7 7 7 7 7 8 8 8 8

6 6 6 6 6 6 6 6 6 7 7 7 8 8 8 8 8 8 8

6 6 6 6 6 6 6 6 7 7 7 8 8 8 8 8 8 8

7 7 7 7 7 7 7 7 7 7 8 8 8 8 8 8 8

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 4 4

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 4 4 5

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 3 4 5 5

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 4 4 5 5

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 4 4 4 5 5

2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 4 4 4 4 5

2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 3 4 4 4 5 5

Note: Data for an ambient temperature of 20°C (68°F), the capacity of a battery

increases with temperature.

16

Associations proposed:

Code Module Battery module

Type Reference Qty. Type Reference

1

40 A Buffer Module

2 20 A Battery Control ABL 8BBU24200

3

4

5

6 40 A Battery Control ABL 8BBU24400

7

8

(1)

Solution for microbreaks (< 2 s), for more information please consult the catalog.

(1)

ABL 8BUF24400 - - ABL 8BUF24400

1 3.2 Ah ABL 8BPK24A03

1 7Ah ABL 8BPK24A07

1 12 Ah ABL 8BPK24A12

2 12 Ah ABL 8BPK24A12

1 7Ah ABL 8BPK24A07

1 12 Ah ABL 8BPK24A12

2 12 Ah ABL 8BPK24A12

W9 1489436 10 11 A01 03/2008

Page 17

Choice of components

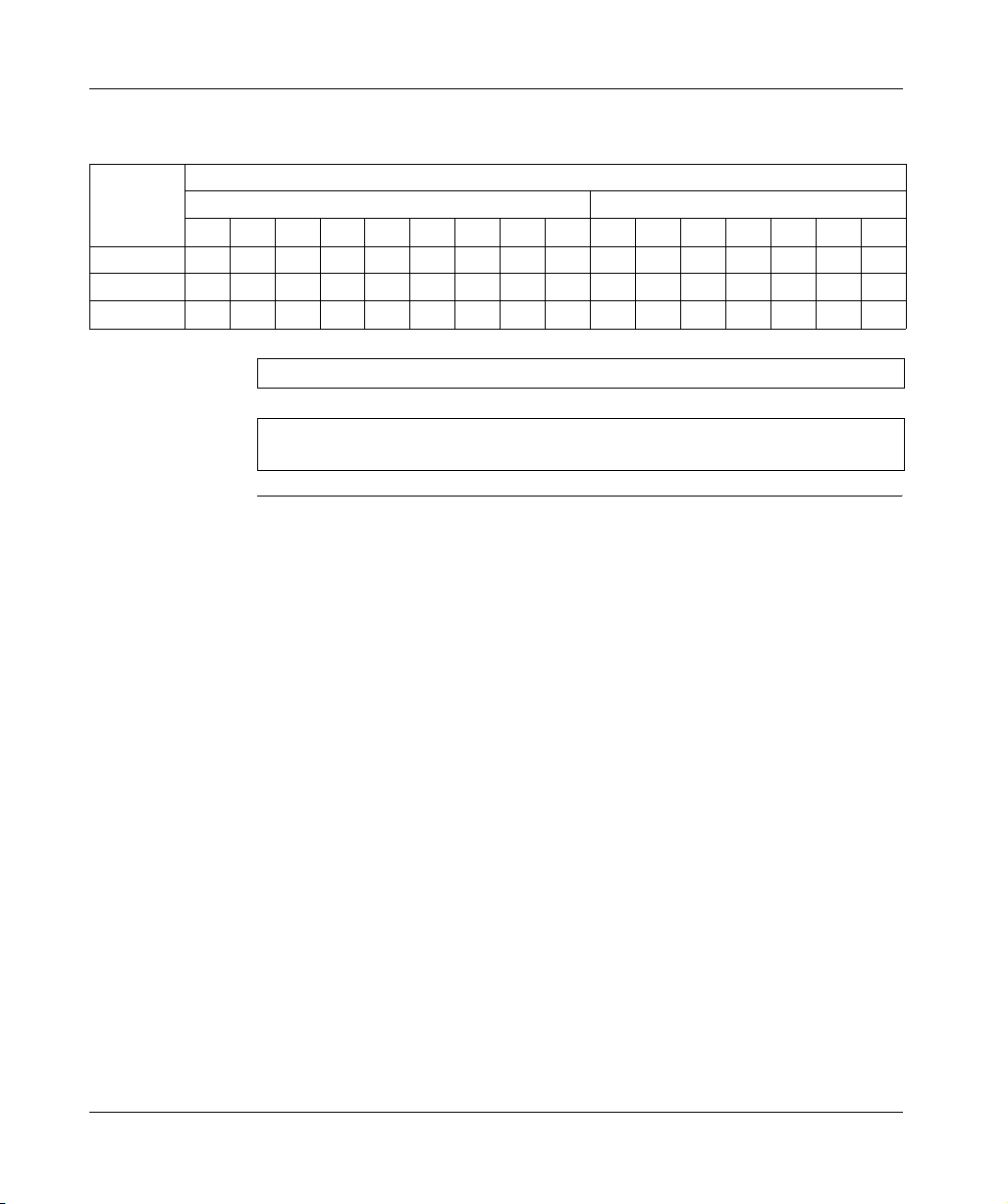

Discharge

current

Battery

module

capacity

3.2 Ah 8.4 6.3 4.9 4.2 3.6 3.1 2.8 2.6 2.3 2.0 1.1 0.86 0.50 0.38 0.30 0.16

7 Ah 18.2 13.6 11.0 9.0 7.7 6.8 6.1 5.6 5.0 4.2 2.5 1.8 1.2 0.80 0.64 0.35

12 Ah 31.3 23.4 18.6 15.5 13.3 11.6 10.5 9.6 8.6 7.1 4.2 3.1 2.0 1.3 1.1 0.60

t2 holding time (see timing diagram)

Minutes Hours

5 10152025303540451 2 3 5 8 1020

The following table indicates the likely discharge current (in A) as a function of the

desired holding time and the capacity of the Battery module:

Note: Data for an ambient temperature of 20°C (68°F).

Note: The holding times are multiplied by the number of parallel Battery modules

(3 MAXI).

W9 1489436 10 11 A01 03/2008 17

Page 18

Choice of components

18

W9 1489436 10 11 A01 03/2008

Page 19

Implementation stages

Implementation stages

3

Operation to be

To implement the Phaseo power outage solution proceed as follows:

followed

Stage Action See

1 Check that the products commissioned correspond to

commanded references.

2 Cut the primary power supply network. -

3 Install the Phaseo power supply. Service instruction delivered with the Phaseo

4 Install the Battery control module. Mounting of Battery control module, p. 26

5 Install the power supply.

connect the power supply to the network protection,

wire, if necessary, the diagnostics relay,

place the power supply switch to the MANU restart

mode.

6 Install the Battery module(s).

Do not plug in the fuse(s) for the moment.

7 Wiring:

connect the Battery control module and the Battery

module(s).

wire, if necessary, the 9-point terminal block of the

Battery control module.

8 Plug in the fuse(s) of the Battery module, then turn on the

power supply.

Note : A light sparkle may appear when plugging in the

fuses. This is not a failure.

9 Adjust and check the power supply:

adjust, if necessary, the output voltage,

check that the 2 lights are green.

Choice of solution components, p. 15

power supply, (Related Documents, p. 7).

Service instruction delivered with the Phaseo

power supply, (Related Documents, p. 7).

Mounting of the Battery module, p. 22

24 VDC circuit wiring, p. 28

Diagnostics contact and inhibition input

wiring, p. 33

-

Instruction sheet delivered with the Phaseo

power supply, (Related Documents, p. 7).

W9 1489436 10 11 A01 03/2008 19

Page 20

Implementation stages

Stage Action See

10 Set up the Battery control module. First powering on / Minimum setup, p. 40

11 Wait for full charge of the Battery module before carrying

out a network outage test (up to 72h for a first

commissioning).

12 Check that the screen of the Battery control module is

green. It is possible to check also the information provided

by the output relays of the 9-point terminal block.

-

Diagnostic, p. 51

CAUTION

RISK OF EQUIPMENT DAMAGE

The power supply ABL 8•P must be configured in the manual reset mode (selector

on MANU). If the power supply is configured in the automatic reset mode (AUTO),

the Battery control module can be destroyed in the case of overcurrent in its output.

Failure to follow these instructions can result in injury or equipment damage.

20

W9 1489436 10 11 A01 03/2008

Page 21

Assembly and temperature conditions

4

Presentation

Introduction This chapter presents the assembly and assembly conditions to be considered in the

installation of Battery modules and the Battery control module.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Mounting of the Battery module 22

Mounting of Battery control module 26

W9 1489436 10 11 A01 03/2008 21

Page 22

Assembly and temperature conditions

Mounting of the Battery module

Important Install the Battery module(s) in the freshest possible location. This prolongs their life

(see Lead Battery Generalities, p. 76).

Choice of

mounting

Depending on the temperature inside the enclosure, the following mountings are

recommended:

Temperature inside the enclosure = T Mounting

T ≤ 40 °C (104°F) Battery module inside the enclosure

T > 40 °C (104°F)

(No regulation of the temperature inside the

enclosure)

Battery module outside the enclosure

Note: The mounting with the Battery module inside the enclosure is favored in

order to allow the charge to be corrected as a function of temperature.

22

W9 1489436 10 11 A01 03/2008

Page 23

Assembly and temperature conditions

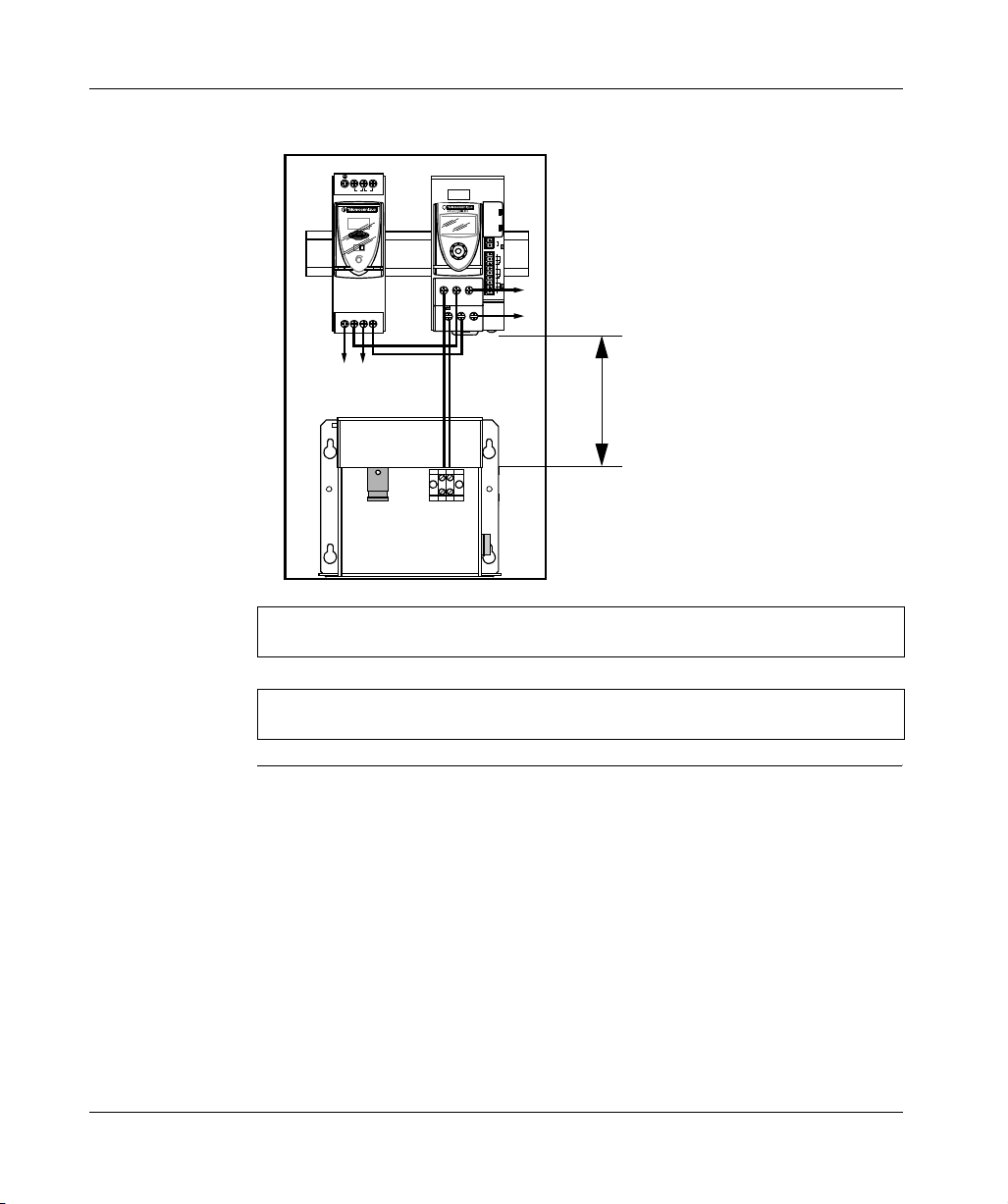

Mounting 1:

T ≤ 40°C (104°F)

Battery module below the enclosure :

MEM

FFO

1

+–

IN OUT

++

–

+

IN

–––

2

1

2

3

4

mralAUSP

5

6

7

+–

8

9

OUT

AUTO MANU

24V 28.8 V

++

IoutUout

–

–

<5m (196.85 in)

+–

Note: The charge voltage is adjusted automatically as a function of the

temperature measured by the control module.

Note: This mounting corresponds to the Battery module temperature setup in

Differential mode (see Battery module temperature, p. 46).

W9 1489436 10 11 A01 03/2008 23

Page 24

Assembly and temperature conditions

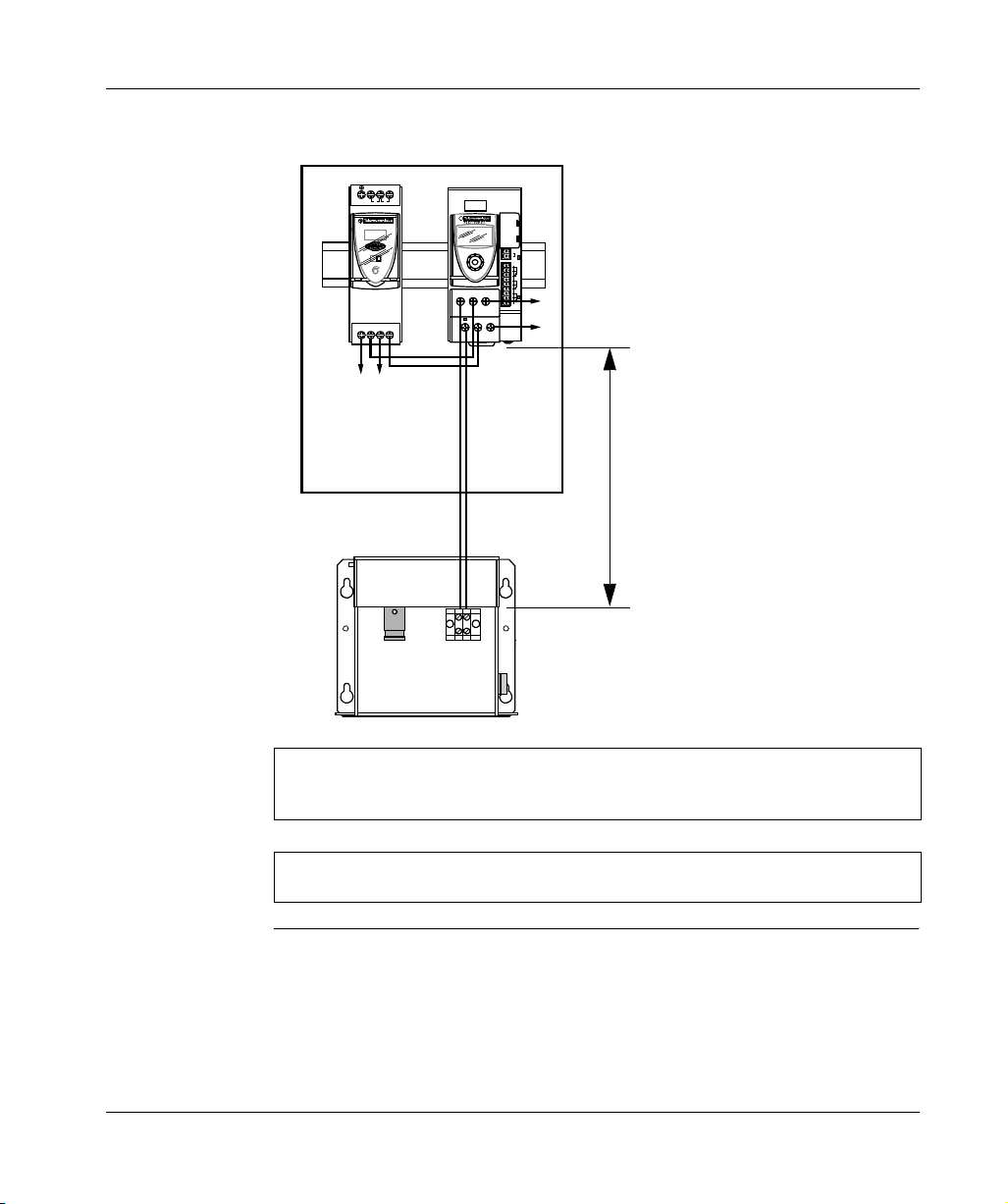

Mounting 2:

T > 40°C (104°F)

Battery module outside the enclosure, in a location where the temperature

approximates 20°C (68°F):

MEM

FFO

1

+–

IN OUT

++

–

+

–––

2

1

2

3

4

mralAUSP

5

6

7

+–

8

9

OUT

IN

AUTO MANU

24V 28.8 V

++

IoutUout

–

–

<5m (196.85 in)

+–

24

Note: This solution is only recommended if it is impossible to lower the temperature

inside the enclosure (ventilation, climatization). There is no automatic charge

voltage correction as a function of the temperature.

Note: This mounting corresponds to the Battery module temperature setup in

Absolute mode (see Battery module temperature, p. 46).

W9 1489436 10 11 A01 03/2008

Page 25

Assembly and temperature conditions

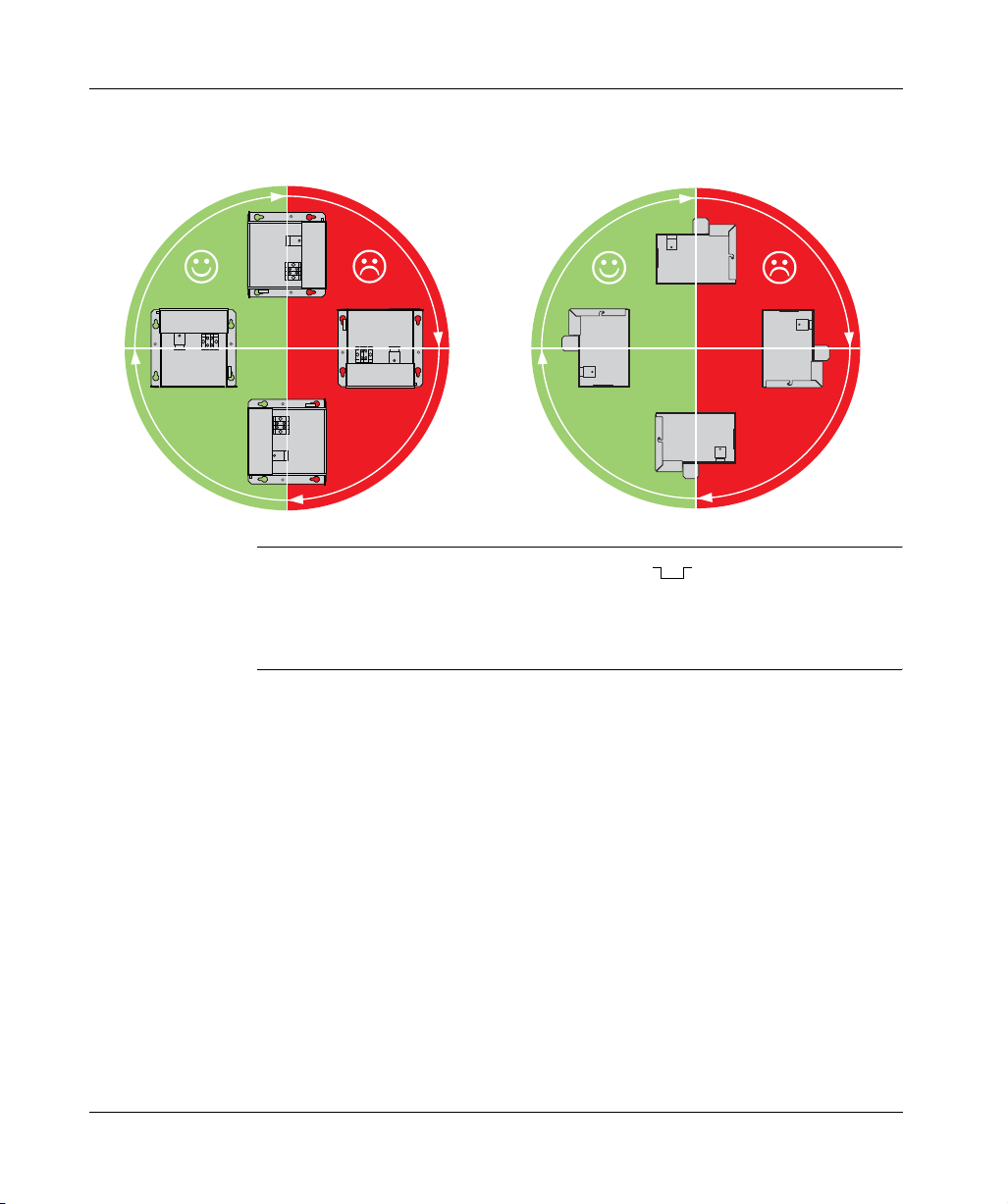

Mounting

position

The scheme below illustrates the positions to be considered during the mounting of

the Battery modules:

90°

+

–

+

0° 180°

–

+

–

+

–

270°

Dimensions and

mounting

The Battery modules are mounted by screw or rail for the module

ABL 8BPK24A03.

The module dimensions and drilling templates of mounting holes are located in the

instruction sheet of the Battery modules. See Related Documents, p. 7.

90°

0° 180°

270°

W9 1489436 10 11 A01 03/2008 25

Page 26

Assembly and temperature conditions

Mounting of Battery control module

Rail The Battery control modules must be installed on a rail . The scheme below

provides the characteristics and the references of the compatible rails for the

mounting of the modules:

AM1 DE200

IEC/EN 60715

83.1

53

AM1 ED200 AM1 DP200

DZ5 MB200

Dimensions

160/6.3

Mounting/

Dismantling

15

0.59

6

0.24

15

0.59

7,5

0.30

/11 34.0

/521 29.4

2.0

5

60/2.36 86/3.39

MEM

FFO

1

+

2

141 / 55.5

–

+

IN OUT

+ + +

–

+

IN OUT

–––

–

1

USP

2

3

4

m

ralA

5

6

7

+

–

8

9

55.5

/

141

–

+

IN OUT

+ + +

–

+

IN OUT

–––

MEM

F

FO

1

+

2

–

1

USP

2

3

4

mralA

5

6

7

+

–

8

9

mm

inch

The scheme below illustrates the mounting (left) and the dismantling (right) of the

Battery control module on a rail :

1

1

26

2

2

1

1

W9 1489436 10 11 A01 03/2008

Page 27

Wiring

5

Overview

Introduction This chapter presents the elements necessary for the wiring of Battery modules and

the Battery control module.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

24 VDC circuit wiring 28

Diagnostics contact and inhibition input wiring 33

Wiring of an auto power off circuit of the Battery module 35

W9 1489436 10 11 A01 03/2008 27

Page 28

Wiring

24 VDC circuit wiring

Preliminaries

RISKS OF EQUIPMENT DAMAGE

The input terminals of the Battery control module must, by obligation, be connected

to the output terminals of the ABL8 supply or other Phaseo ABL8 modules.

Failure to follow these instructions can result in injury or equipment damage.

RISKS OF EQUIPMENT DAMAGE

Consider the tightening torque indicated in this document to avoid hazardous

terminal block warm-up.

Do not allow liquids or foreign bodies to penetrate inside the product.

Failure to follow these instructions can result in injury or equipment damage.

Read carefully the regulations and recommendation of the following wiring :

Check that the operating and environmental conditions are well situated in the

specified zones, see Characteristics, p. 69.

As a function of the charge, a downstream protection circuit may be required. The

selectivity module ABL 8PRP24100 fulfils this role.

Use wire end ferrules for the wires.

Use the wires in the appropriate section in order to consider the demands in

current and voltage :

Connect the junction of the functional earth by means of a 10 mm² (AWG 6)

section conductor.

CAUTION

CAUTION

input and output of the Battery control module and the Battery module:

0.5...10 mm2 (AWG 20...8) with wire end ferrules.

28

W9 1489436 10 11 A01 03/2008

Page 29

Wiring

Tightening

torque

Internal schemes

The scheme below indicates the screws to be used and the tightening torque to be

considered:

MEM

ABL8BBU24200

1

OFF

+

2

–

1

2

PSU

3

4

5

Alarm

+

IN OUT

IN

–

+

+

OUT

–

OFF

6

7

+

–

8

9

+–

+ + +

–

–

1

2

11

1

14

2

12

21

22

31

32

PSU

3

4

24

5

ALARM

6

7

34

8

9

Ø 2.5 mm (0.10 in)

0.4 Nm (3.6 lb-in)

+ +

+

+ -

Ø 4.5 mm (0.18 in)

1.7 Nm (15 lb-in)

IN

IN

+

--

OUT

+

OUT

-

Note: The IN- et OUT - terminals are internally relinked.

W9 1489436 10 11 A01 03/2008 29

Page 30

Wiring

Basic wiring

LV C HV

200

100

120

AUTO MANU

24V 28. 8V

++

500

IoutUout

+ + +

+–

–

+

– –

ABL8BBU24200

IN OUT

MEM

+

-

1

OFF

+

2

–

1

2

PSU

3

4

5

Alarm

6

7

+

–

8

9

OUT

IN

–

1 2

N° Description

1 Non-protected output

2 Protected output, for circuit requiring continuous supply in the case of primary

network shut-off.

30

Important: The rated current delivered on the control module output may reach

20 A (ABL 8BBU24200) or 40 A (ABL 8BBU24400) in a prolonged manner,

regardless of the current delivered by the supply.

CAUTION

RISKS OF EQUIPMENT DAMAGE

The polarities of the Battery module must be considered. A polarity inversion can

lead to destruction or malfunction of the Battery module.

Failure to follow these instructions can result in injury or equipment damage.

W9 1489436 10 11 A01 03/2008

Page 31

Wiring

Maximal

capacitive load

on the supply

output

The non-protected circuits connected directly to the supply (marker 1) must have a

capacitive load less than the values in the table below:

Power Supply Maximal capacity of the non-protected load (μF)

ABL 8RPS24030 30,000

ABL 8RPS24050 50,000

ABL 8RPS24100 100,000

ABL 8RPM24200 100,000

ABL 8WPS24400 100,000

CAUTION

RISK OF EQUIPMENT DAMAGE

When the maximal values of the capacitive load connected to the power supply

output are not considered (non-protected output), the Battery control module can

be destroyed if an overload is produced on the protected output.

Failure to follow these instructions can result in injury or equipment damage.

W9 1489436 10 11 A01 03/2008 31

Page 32

Wiring

Wiring of several

Battery modules

(max 3)

LV C HV

100

200

120

500

AUTO MANU

24V 28.8V

IoutUout

++

1 2

In the case of parallel wiring of several Battery modules, the wiring is constructed

as follows:

MEM

ABL8BBU24200

+–

IN OUT

+ + +

–

+

IN

– –

+ - + -

1

OFF

+

2

–

1

2

PSU

3

4

5

Alarm

6

7

+

–

8

9

OUT

–

+ - + -

N° Description

1 Non-protected output

2 Protected output for circuit requiring continuous supply in the case of primary

network shut-off.

32

W9 1489436 10 11 A01 03/2008

Page 33

Wiring

F

F

Diagnostics contact and inhibition input wiring

Introduction Three diagnostics relays inform if the supply is operating, if the Battery module is

operating and if there is an alarm.

The two removable screw terminal blocks accept wires of section 0.14...1 mm

(AWG 26...16) with wiring end ferrule.

2

Description

1

OF

+

2

–

1

2

PSU

3

4

5

Alarm

6

7

+

8

–

–

+

IN OUT

+ + +

–

+

IN OUT

–––

MEM

1

OFF

+

2

–

1

2

PSU

3

4

5

Alarm

6

7

+

–

8

9

9

N° Connector Relay Contact description

1 Inhibition input

(2-point terminal

Inhibition: Open circuit terminals: Operating Battery module

–

+

OF

Connected terminals: Off-loaded Battery module

block)

2 Diagnostics relay

(9-point terminal

block)

Power Supply mode:

PSU

Alarm:

Alarm

Note : The alarm can be

suppressed in some cases

by deactivating some tests

(see SERVICE menu, p. 64).

Contact 11/14 closed: The power supply provides the

current to the application

Contact 21/22 closed: output overload / absence of Battery

module / defective Battery module / inhibited Battery module

/ capacity or battery charge insufficient for the set backup

time or non-measurable charge rate (in backup mode)

Note : the 21/22 contact is also closed when it is neither in

the backup mode nor in the Power Supply mode (new

product state or shut-off state after a backup cycle).

Backup mode: Contact 31/14 closed: the Battery modules provide the

–

+

current to the application

11

14

12

21

24

22

31

34

32

(1)

(1)

Important: the Battery module continues to provide a residual current essential

for supplying the module electronics. In the case of prolonged absence of the power

supply voltage in the IN+ and IN- terminals, it is advisable to unplug the Battery

module by removing its fuses in order to avoid deep discharge.

W9 1489436 10 11 A01 03/2008 33

Page 34

Wiring

CAUTION

RISK OF EQUIPMENT DAMAGE

The pins 1 and 2 of the inhibition input terminal block must not be connected to any

other part of a circuit, they must be free of all potential.

Failure to follow these instructions can result in injury or equipment damage.

Admissible current in the relay contact:

Voltage Current

24 VDC 5 mA mini

230 VAC 500 mA maxi

34

W9 1489436 10 11 A01 03/2008

Page 35

Wiring

Wiring of an auto power off circuit of the Battery Module

Overview The wiring present is an additionnal protection against the risk of deep discharge of

the Battery module.

This solution consists of inserting a contactor between the Battery module(s) and the

Battery control module. The contactor switches automatically in order to insulate the

Battery module of the circuit.

Contactor wiring

LV C HV

200

100

120

500

ABL8BBU24200

MEM

0.5A fuse

AUTO M ANU

24V 28.8V

++

1

OFF

+

2

–

1

2

PSU

IoutUout

+–

+ + +

–

+

– –

IN OUT

3

4

5

Alarm

6

7

+

–

8

9

OUT

IN

–

1L/12/1T

2L/34/2T

3L/5

ON/31

1A2A

41

6/3T

22CN/12

+ -

LC1 D32BL

W9 1489436 10 11 A01 03/2008 35

Page 36

Wiring

36

W9 1489436 10 11 A01 03/2008

Page 37

Setup

6

Overview

Introduction This chapter presents the information necessary for the setup of the Battery control

module as a function of the application desired.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

User interface 38

First powering on / Minimum setup 40

The SETTINGS Menu 42

Settings transfer by memory card type SR2 MEM02 47

W9 1489436 10 11 A01 03/2008 37

Page 38

Setup

User interface

Description

1

2

N° Description

1 LCD display (3 background colours)

2 Browse selection button

Function The user interface allows:

During the operation visualize (see chapter Diagnostic, p. 51):

The system status (Power Supply mode / backup mode).

The status of the Battery module(s)

The diagnostic information in case of failure.

During the commissioning (see The SETUP Menu, p. 42):

Setup the application.

During the maintenance and breakdown check, (see SERVICE menu, p. 64):

To inhibit certain test functions in order to allow the downgraded operation.

Test the system elements.

(1)

The measurement of the charge of the Battery module(s) is inactive during the

first charge or during the replacement of the Battery module or if this function has

been deactivated in the SERVICE menu.

38

(1)

.

W9 1489436 10 11 A01 03/2008

Page 39

Browse rule Use of the browse button :

Press the button Description

Rotation Browse the menus / Select a setting

Short pressing (< 1 s) Validation / Modification

Long pressing (2 s) Go to a menu

Initial screen

Setup

IN 23.9V

OK

< 1 s

SETUP

2 s

LANG.

English?

EXIT

SERVICE

2 s

off ?

EXIT

< 1 s

W9 1489436 10 11 A01 03/2008 39

Page 40

Setup

First powering on / Minimum setup

Operation to Be

Followed

The minimum setup for the system to function consists of informing the capacity of

the Battery module.

Important: This setup allows the system to function; however, to optimize the life of

the Battery module, it is strongly advisable to enter other parameters (see The

SETTINGS Menu, p. 42).

40

W9 1489436 10 11 A01 03/2008

Page 41

The following scheme presents the operation to be followed during the first powering

on of the Battery control module.

ENGLISH

< 1 s

1

2

Press to select the interface language

1

2

3

4

–

5

+

I

N

O

6

U

T

+

+

(scrolling on different languages)

+

Setup

SETTINGS

LANG.

English?

7.0 Ah x 1?

3.2 Ah x 1?

•••••••••

EXIT

2 s

1

2

1

Press to enter the menu

2

3

4

–

5

+

I

N

O

6

U

T

+

+

+

Turn to switch to the

1

2

1

following menu

2

3

4

–

5

+

I

N

O

U

T

6

+

+

+

Press to modify

< 1 s

< 1 s

1

2

1

2

3

4

–

5

+

I

N

O

6

U

+

T

+

+

1

2

1

Press to validate

2

3

4

–

5

+

I

N

O

6

U

+

T

+

+

Press to leave and return

to the main screen

< 1 s

1

2

1

2

3

4

–

5

+

I

N

O

6

U

+

T

+

+

1

2

1

2

3

4

–

5

+

I

N

O

U

T

6

+

+

+

IN 23.9V

Turn to select the Battery

module capacity

At the end of this first setup, the control module starts the charge of the Battery

module(s). Since the charge rate is not measurable, the screen is orange until the

end of the charge. After 72 H maximum of powering on of the power supply set and

control module, the screen switches to green and the charge percentage of the

Battery modules is displayed (see Diagnostic, p. 51).

W9 1489436 10 11 A01 03/2008 41

Page 42

Setup

The SETTINGS Menu

Introduction The SETTINGS menu defines the settings related to the choice of components and

to the application.

(*)

Note:

indicates the value by default of the setting.

Menu tree

Screens Description See

Charging of a

configuration, p. 49

Backup of a configuration,

p. 47

MEM

?

?

MEM

Charge a configuration

from the memory card

(visible only if a memory

card is present)

Back up a configuration in

the memory card (visible

only if a memory card is

present)

Language choice Interface language, p. 43

LANG.

english ?

Battery module(s) choice Battery module type, p. 43

7.0 Ah x 1?

Backup time setup Backup time, p. 44

OO:1O:OOs ?

IN

Setup of the Battery

module activation voltage

Switching threshold, p. 44

42

21.0 V

L

2.Om ?

Setup of the link length

between the Battery

control module and the

Battery module(s).

Wiring length, p. 45

W9 1489436 10 11 A01 03/2008

Page 43

Screens Description See

O

Setup of the Battery

module(s) temperature

C

Battery module

temperature, p. 46

Tbat.=25

Setup

Interface

language

Battery module

type

The setting LANG. defines the interface language:

English

Français

Deutsch

Italiano

Espanol

The setting defines the capacity and the number of Battery module connected

to the Battery control module.

Value Reference Description

3.2 Ah x 1 ABL 8BPK24A03 x 1

(*)

7 Ah x 1

12 Ah x 1 ABL 8BPK24A12 x 1

3.2 Ah x 2 ABL 8BPK24A03 x 2 2 x 3.2 Ah Battery module mounted in parallel

7 Ah x 2 ABL 8BPK24A07 x 2 2 x 7 Ah Battery module mounted in parallel

12 Ah x 2 ABL 8BPK24A12 x 2

3.2 Ah x 3 ABL 8BPK24A03 x 3 3 x 3.2 Ah Battery module mounted in parallel

7 Ah x 3 ABL 8BPK24A07 x 3 3 x 7 Ah Battery module mounted in parallel

12 Ah x 3 ABL 8BPK24A12 x 3 3 x 12 Ah Battery module mounted in parallel

(1)

Combinations proposed in the selected table, see Guidance in choosing, p. 15.

ABL 8BPK24A07 x 1

1 3.2 Ah Battery module

1x 7 Ah Battery module

1 x 12 Ah Battery module

2 x 12 Ah Battery module mounted in parallel

(1)

(1)

(1)

(1)

Note: If this parameter is badly adjusted, the charge rate and ageing test for the

Battery module indications will be erroneous.

W9 1489436 10 11 A01 03/2008 43

Page 44

Setup

Backup time

Switching

threshold

The setting defines the desired backup time. Two functions are proposed:

Timed function: back up from 10 s to 72h adjustable by 10 s steps

Max function: backup until power supply feedback or until the discharge of the

Battery module(s) (shut-off when the voltage in the Battery module terminals

reach 21 V, before the deep discharge threshold).

Timing diagram of the two functions:

Input voltage

t

Output voltage

Timed function

ts = backup time

MAX function

ts

t

t

If the power supply voltage decreases below this threshold, the control module

switches to the backup mode and the voltage delivered in the OUT+ and OUToriginates from the Battery module. In the current versions, this threshold is fixed at

21 V and is non-adjustable.

Important: To allow transition from a backup mode to the Power Supply mode, the

output voltage of the power supply must be at least greater than 1 V at the switching

threshold.

The following timing diagram illustrates the transition from the sbackup mode to the

Power Supply mode:

U power supply

44

Switching threshold

Power supply mode

Backup mode

1V mini

Power supply mode

t

W9 1489436 10 11 A01 03/2008

Page 45

Setup

Wiring length

The setting defines the length of the wires between the Battery module and

the Battery control module (in m or ft). This setting is used by the Battery control

module to calculate the voltage at the Battery module terminals.

The table below indicates the choice of possible lengths:

Unit selected Adjustment range Adjustment step Default value

m 0.1...5 m 0.1 m 2 m

ft 0.3...16.4 ft 0.1 ft -

Example: the Battery module is linked to the Battery control module by two 3 m

(9.84 ft) wires (+ and -) each. The value to enter is 3 m or 9.8 ft.

W9 1489436 10 11 A01 03/2008 45

Page 46

Setup

Battery module

temperature

The setting defines the temperature of the Battery module(s). This setting

°C

is used by the Battery control module in order to:

Calculate the charge rate of the Battery module(s),

Adapt the end of charge voltage in order to optimize the life of the Battery

module(s).

The possible temperature setup modes are related to the Battery module assembly

in comparison to the enclosure containing the Battery control module (see Mounting

of the Battery module, p. 22):

Mode Mounting

Differential Battery module inside the enclosure (the temperatures within the

proximity of the Battery modules and Battery control module develop

in same proportions)

Absolute Battery module outside the enclosure

Description of the two available usage modes:

Differential:

The control module has a built-in sensor measuring the temperature in its

environment.

The user obtains the temperature difference estimated between the control

module and the Battery module such as:

ΔT = T Battery control module - T Battery module.

Note : The temperatures may be measured near the modules (1 cm of housing)

after the temperature has been stabilized inside the enclosure, where the

modules are mounted and then reported in the menu.

The charge voltage is adjusted automatically as a function of the temperature

measured by the control module.

Absolute:

The user enters directly the Battery module temperature.

There is no automatic charge voltage correction.

The table below indicates the possible temperature setup:

Mode Adjutment range Adjustment step Default value

Differential

0...40°C

(1)

1°C -

Δ XX=

Absolute

Tbat = XX

(*)

0...50°C 1°C

25°C

(*)

46

(1)

There is no Δ negative, the temperature of the battery Control module is always

greater than that of the Battery module.

Note: It is recommended to use the differential mode when possible.

W9 1489436 10 11 A01 03/2008

Page 47

Settings transfer by memory card type SR2 MEM02

Introduction The Battery control module is equipped with a memory card slot allowing the :

Execution of a backup copy of the settings,

Transfer the settings from one control module to another (repetitive equipment,

maintenance,...).

Note: All SETTINGS menu parameters as well as the test activation in the

SERVICE menu are transferred.

Setup

Backup of a

configuration

Stage Description

1 Remove the cover.

2 Insert the memory card in the slot (module on or off).

3 Go to the SETTINGS menu.

4 Turn the button to connect to the screen below and press the button (< 1 s):

MEM

?

5 Press the button (< 1 s):

MEM

yes

6 Press the button to confirm (< 1 s):

MEM

confirm

Note : After confirmation, the data already in the memory card will be erased.

This menu does not appear if the card is blank.

7 Loading in progress:

MEM

W9 1489436 10 11 A01 03/2008 47

Page 48

Setup

Stage Description

8 End of loading:

MEM

terminal

9 Remove the memory card.

10 Place back the cover.

CAUTION

RISKS OF EQUIPMENT DAMAGE

Do not put anything in the slot of the memory card next to the card and always

close the access using the cover.

Failure to follow these instructions can result in injury or equipment damage.

48

W9 1489436 10 11 A01 03/2008

Page 49

Setup

Loading of a

configuration

The table below indicates the stages to be followed:

Stage Description

1 Remove the cover.

2 Insert the memory card in the slot (module on or off).

3 Go to the SETTINGS menu.

4 Press the button (< 1 s):

MEM

?

5 Press the button (< 1 s):

MEM

yes

6 Loading in progress:

MEM

7 End of loading:

MEM

terminal

8 Remove the memory card.

9 Place back the cover.

CAUTION

RISKS OF EQUIPMENT DAMAGE

Do not put anything in the slot of the memory card next to the card and always

close the access using the cover.

Failure to follow these instructions can result in injury or equipment damage.

W9 1489436 10 11 A01 03/2008 49

Page 50

Setup

50

W9 1489436 10 11 A01 03/2008

Page 51

Diagnostic

7

Overview

Introduction This chapter presents the elements necessary for the analysis of diagnostic

information and fault as well as solutions to bring it about.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Diagnostic 52

Faults - causes - remedies 55

W9 1489436 10 11 A01 03/2008 51

Page 52

Diagnostic

Diagnostic

Overview The diagnostic information facilitates an easy commissioning and a rapid error

diagnostic.

The diagnostic information of the Battery control module is provided to the users in

3 forms:

LCD background screen colour:

Green OK

Orange: Warning

Red: Alarm

Diagnostic pictorial sign displayed on the screen

Diagnostics relay

Description of

the displayed

zones

The scheme below presents the different displayed zones:

1

IN 24.9V

2

OK

3

4

N° Description

Power Supply mode Backup mode

1 Input voltage = value of the supply output voltage

2 The state and charge level of the Battery module

3 Charge rate if measurable or alarms

(battery inhibited or disconnected)

4 Alarm on the output : overload

Timed function: remaining backup

time.

Max function: backup time elapsed

since the last transition in backup

mode.

Format : hour:minute or s

52

W9 1489436 10 11 A01 03/2008

Page 53

Diagnostic

Visualisation and

relay state

Screen

color

Green

Display State of diagnostics

IN 24.9V

Green

IN 24.9V

Orange

IN 24.9V

Orange

IN 24.9V

Orange

IN 24.9V

Red

IN 24.9V

Red

IN 24.OV

The scheme below regroups the diagnostics information according to the state of the

Battery control module :

Signification

relay

PSU Alarm Bat

1

1

1

1

2

4

2

1

2

4

2

2

The Power Supply mode and battery

1

3

charged at 100%.

3

4

3

2

OK

1

1

1

1

2

4

2

1

2

4

2

2

Power Supply mode, charging battery,

1

3

battery charge sufficient for the chosen

4

3

backup time.

3

2

82 %

1

1

1

1

1

1

1

2

1

4

2

1

4

2

4

2

2

2

2

1

2

4

2

2

Power Supply mode, first battery charging

3

1

and non-measurable charge rate.

4

3

3

2

Power Supply mode, battery charged at

1

3

100% and battery life < 50%.

3

4

3

2

OK

1

1

4

1

2

1

1

2

4

2

2

2

Power Supply mode, charging battery,

1

3

battery charge insufficient for the chosen

3

4

backup time.

2

3

12 %

1

1

1

1

2

4

2

1

4

2

2

2

Power Supply mode and disconnected

3

1

battery.

4

3

2

3

NO

1

1

1

1

2

4

2

1

4

2

2

2

The Power Supply mode and inhibited

3

1

battery.

4

3

3

2

Red

W9 1489436 10 11 A01 03/2008 53

IN 24.OV

1

1

4

1

2

1

1

2

2

4

2

2

The Power Supply mode and battery to be

1

3

replaced.

3

4

3

2

Page 54

Diagnostic

Screen

color

Red

Orange

Red

Display State of diagnostics

relay

PSU Alarm Bat

-

IN 19.OV

>>

I

IN O.9V

1

1

4

1

2

1

- Overload on the output.

1

2

4

2

2

2

1

2

4

2

2

2

16:21

IN O.9V

1

1

4

1

2

1

1

2

4

2

2

2

43s

Signification

Backup mode, 16h21min remain in

1

3

comparison to the backup time set or

4

3

16h21min have passed since the transition

2

3

to the backup mode, sufficient battery

charge.

Backup mode, 43 s remain in comparison

1

3

to the backup time set or 43 s have passed

4

3

since the transition to the backup mode,

2

3

sufficient battery charge for backup time

set.

54

W9 1489436 10 11 A01 03/2008

Page 55

Diagnostic

Faults - causes - remedies

Introduction A fault is signaled on the Battery control module by the red background colour of the

LCD screen and by a pictorial sign linked to each fault type.

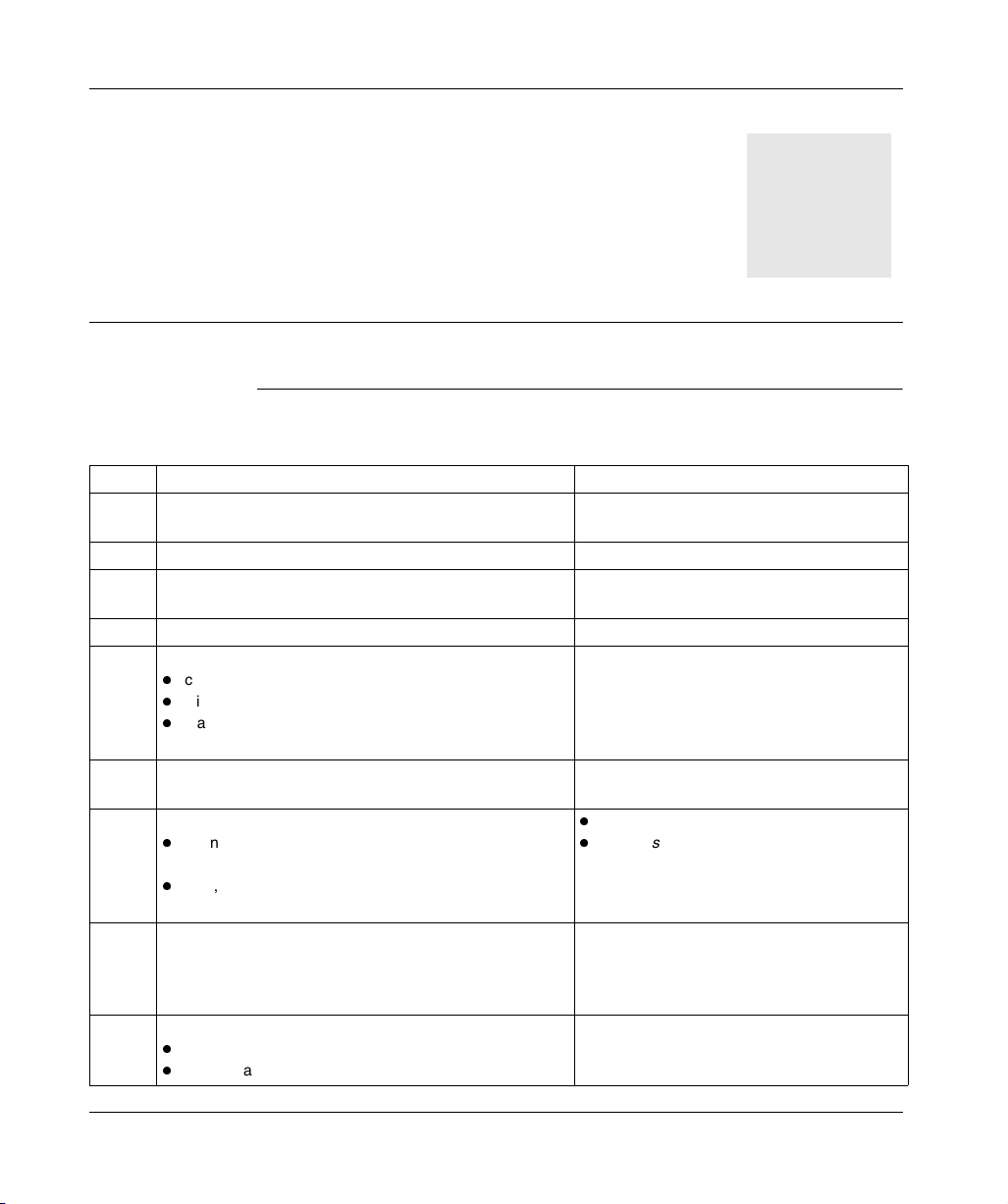

Fault resolution

Fault screen Signification Causes Remedies

Unavailable

Battery module

IN 24.9V

NO

Deactivated

Battery module

IN 24.OV

Replace Battery

module

IN 24.OV

Blown fuse or fuse not

plugged into the attachment

Unplugged wire Check connection

Cut wire Check wires continuity

Internal cut-off in the Battery

module

No connected Battery

module

Activated inhibition input Check the connection of the

Activation function of the

battery turned on OFF

(SERVICE menu)

Battery capacity is less than

80% of its rated capacity,

which corresponds to 50% of

the autonomy.

Plug in the fuse or replace it if

blown (after elimination of the

failure source)

Replace Battery module

Connect Battery module

inhibition input

Check the setting value

Replace the Battery module

Overload Too many elements

IN 19.OV

I

>>

W9 1489436 10 11 A01 03/2008 55

(charges) connected on the

Battery control module

Short-circuit on the output Eliminate the source of the

Check that the sum of the

rated currents of the

elements do not surpass the

rated current of the Battery

control module.

short-circuit

Page 56

Diagnostic

Fault screen Signification Causes Remedies

Charge rate or

IN O.9V

43s

capacity of the

Battery module

insufficient to

allow the setup of

the backup time

for the required

consumption

Capacity of the Battery

module is too weak in

comparison to the

requirement

Too frequent network cutoffs, the Battery module has

no time to recharge

Loss of Battery module

capacity

Check the choice of the

Battery module, possibly

choose a greater capacity

module or use parallel

modules.

Use the Battery modules of

greater capacity with

parallelization if necessary

Replace the Battery module

56

W9 1489436 10 11 A01 03/2008

Page 57

Operation timing diagrams

8

Overview

Introduction You will find in this chapter the timing diagrams illustrating the operation of the

Phaseo power outage solution according to the setup of the operating mode and

different encountered figure cases.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Timed function 58

All functions (time-delayed or max): voltage feedback before module shut-off 59

Max function with long power outage (complete discharge of the Battery module) 60

Output behaviour in the case of overload or short-circuit 61

W9 1489436 10 11 A01 03/2008 57

Page 58

Operation timing diagrams

Timed function

Timing Diagram The following aspects are taken into account in the following example :

the network cut-off time > backup time,

during powering on, when the Battery module is not completely charged (for

example in reference to a previous backup cycle).

1

2

VAC

3

Uout

58

PSU

–

Alarm

Ibat

+

–

11/14

11/12

31/34

31/32

21/24

21/22

+

4

5

4

N° Description

1 During powering on, the control module recharges the Battery module

2 Backup time parameterized

3 Backup mode: voltage provided by the Battery module

There is no additional voltage regulation: Uout = 21...26 VDC

4 Charging phase of Battery module

5 Discharging phase of Battery module

W9 1489436 10 11 A01 03/2008

Page 59

Operation timing diagrams

All functions (timed or max): voltage feedback before module shut-off

Timing Diagram The following aspects are taken into account in the following example:

During powering on, when the Battery module is not completely charged (for

example in reference to a previous backup cycle).

1

VAC

2

Uout

4

3

PSU

–

Alarm

Ibat

+

–

11/14

11/12

31/34

31/32

21/24

21/22

+

3

N° Description

1 During the powering on, the control module recharges the Battery module

2 Voltage provided by the Battery module

There is no additional voltage regulation: Uout = 21...26 VDC

3 Charging phase of Battery module (such as the charge rate is < 80% the alarm relay

is not swtiched).

4 Discharging phase of the Battery module

W9 1489436 10 11 A01 03/2008 59

Page 60

Operation timing diagrams

Max function with long power outage (complete discharge of the Battery module)

Timing Diagram The following aspects are taken into account in the following example :

the network cut-off time > possible backup time,

during powering on, when the Battery module is not completely charged (for

example in reference to a previous backup cycle).

Note: This figure case is to be avoided, if a new close power outage appears, it will

not be possible to provide the current such as the Battery module will not be

charged again.

1

VAC

2

3

Uout

–

+

Ibat

4

11/14

PSU

11/12

31/34

–

+

31/32

21/24

Alarm

21/22

N° Description

1 During powering on, the control module recharges the Battery module

2 Voltage provided by the Battery module

There is no additional voltage regulation: Uout = 21...26 VDC

3 The voltage at the Battery module terminals has reached 21 V, the current is turned off in order to avoid the

deep discharge of the batteries. The 'Alarm' relay falls indicating the low charging level.

4 Battery module charging phase (such as the charge rate is < 80% the alarm relay is not switched).

5 Discharging phase of the Battery module

60

5

4

W9 1489436 10 11 A01 03/2008

Page 61

Operation timing diagrams

Output behaviour in the case of overload or short-circuit

Overview It is possible to execute backup solutions with power supplies, of which the rated

current is less than that of the Battery control modules.

The output behaviour of the Battery control module, thus, depends on the power

supply association/module, it may be different according to the operating modes

(power supply or backup).

The protection against the overcurrents and short-circuits is according to the

ensured case either by the power supply or by the control module.

As a consequence, the junction section in the control module output must take into

account the rated current of this module (20 A or 40 A) and not only the rated power

supply current.

W9 1489436 10 11 A01 03/2008 61

Page 62

Operation timing diagrams

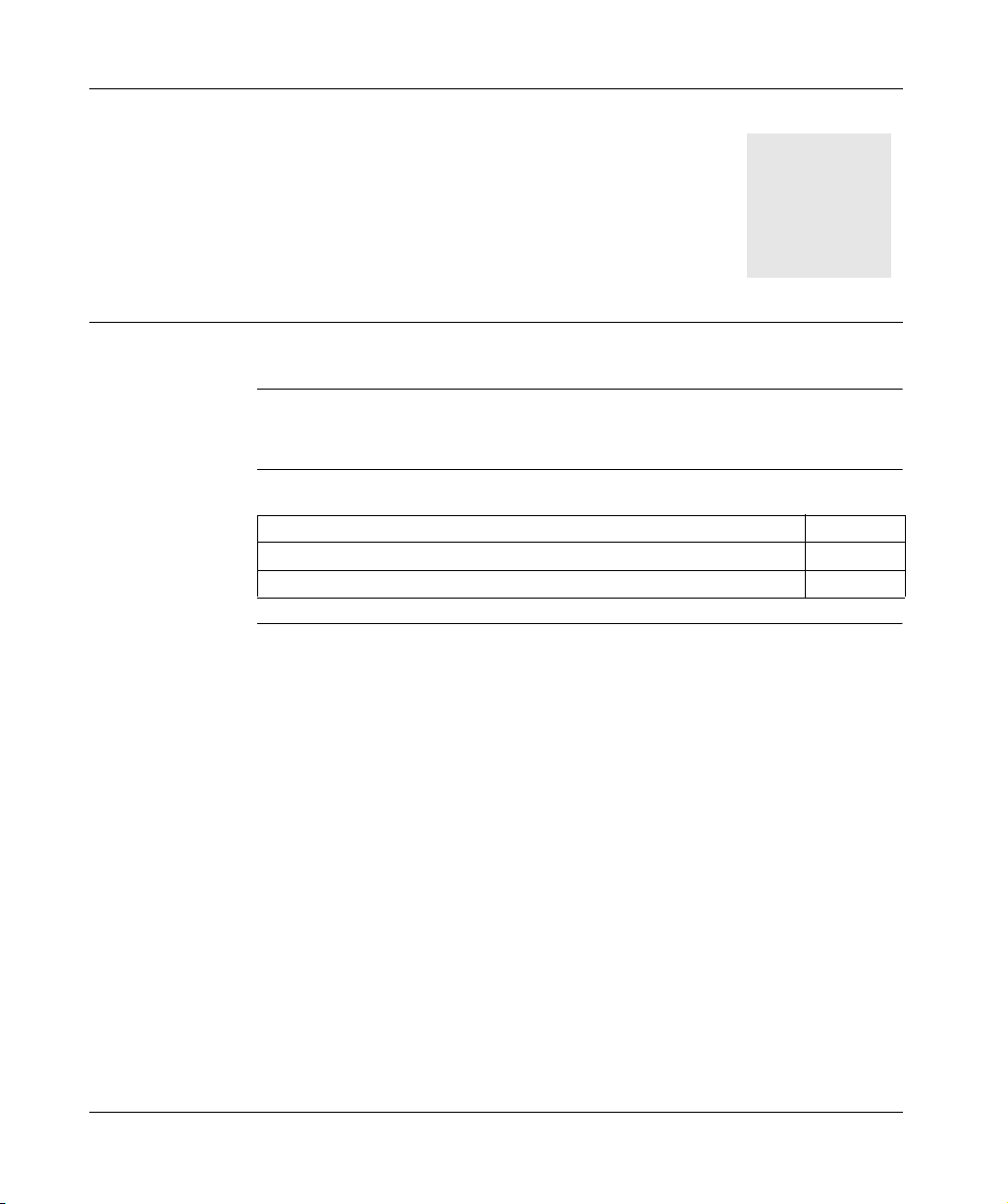

Output behavior The output behavior is detailed in the following table :

Product

associations

Rated current on

the control

module output

Admissible

current on the

control module

output

Behavior in the

case of overload

or short-circuit

Reset after

protection trips

ABL 8

power

supply

Control

module

Power

Supply

mode

Backup

mode

Power

Supply

mode

Backup

mode

Power

Supply

mode

Backup

mode

Power

Supply

mode

Backup

mode

RPS24030 RPS24050 RPS24100 RPS24200 WPS24200 WPS24400

ABL 8BBU24200 ABL 8BBU

3 A 5 A 10 A 20 A 20 A 40 A

20 A 20 A 20 A 20 A 20 A 40 A

4.5 A/4 s

26 A/10 s

(1)

(2)

4.5 A/4 s

26 A/10 s

Power supply protection trips

(1)

(2)

4.5 A/4 s

26 A/10 s

(3)

(1)

30 A/10 s 30 A/10 s 60 A/10 s

(2)

26 A/10 s

Temporary overload: protection trips of

the control module

Permanent overload or short-circuit:

power supply protection trips

the control module

(4)

protection trips of the control module

, then off-loading of the module.

Temporary voltage interruption at the power supply primary for about 5 s.

Power supply powering on (impossible to rearm without the supply output voltage).

(2)

60 A/10 s

(4)

(4)

24400

(2)

90 A/10 s

(3)

and of

(2)

62

(1) 4.5 A/4 s then transition to the backup mode

(2) maximum time with new Battery module and charged at 100%

(3) LED Uout red and contact 11/14 non-closed

(4) Display 'I>>' in the front face of the module and alarm contact 21/22 closed

W9 1489436 10 11 A01 03/2008

Page 63

Maintenance

9

Overview

Introduction You will find in this chapter the necessary elements for the maintenance of the

backup solution.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

SERVICE menu 64

Battery modules replacement 66

W9 1489436 10 11 A01 03/2008 63

Page 64

Maintenance

SERVICE menu

Introduction The SERVICE menu allows the solving of particular problem such as:

machine transport (off-loading of the Battery module),

machine tests (diagnostics inhibition),

test the Battery module and the LCD screen,

factory configuration reset (setup by default),

on-board software update (only in factory or qualified technical center).

Menu

description

Screens Function Description

Battery module inhibition, Battery

module is turned off (including

recharge)

on->off : Deactivated Battery module (the

alarm is active, 21/22 contact closed)

off->on : Activated Battery module

off ?

Battery module ageing test See description below.

TEST

?

LCD screen test Horizontal and vertical scanning of each

TEST

pixel in the LCD screen

?

%

Activation/deactivation of the

battery charge rate display

Allows the deactivation of the alarm

contact and suppression of the charge rate

display.

Active ?

Activation/deactivation of the

battery ageing display

Allows the deactivation of the alarm

contact and suppression of the fault

screen display.

Deactiv.?

Replace the Battery module(s) Allows the reinitialisation of the ageing

New

Init ?

calculation in the Battery module(s). To

carry out during the replacement of the

Battery module(s). After the setting

reinitialisation of the former Battery

module, a test of the new module is

automatically carried out.

64

W9 1489436 10 11 A01 03/2008

Page 65

Screens Function Description

Reinitialisation Allows the setting to be feedback to their

SETT.

Init ?

Onboard software update Only in factory or qualified technical

P C S W

default value (factory configuration).

The default settings will be taken into

account at the next powering on.

center.

?

Maintenance

Version

?

Battery module

test

Number of On-board software

version and checksum of the

charged parameters.

The Battery module test allows the inspection of the battery module ageing (not to

be confused with the charge level).

Note: This test is also carried out utomatically twice per month.

When this test is issued (the total test duration: approximately 48H from a charged

battery pack and under the condition that the module does not pass to the backup

mode during the test):

if the Battery module has not lost its capacity, no message is shown,

if the capacity of the Battery module has started to decrease (the mode is around

50% of its life), the screen background turns orange in the Power Supply mode,

if the capacity of the module is less than 80%, which corresponds to around 50%

of autonomy, the default screen is displayed and the 21/22 alarm contact

is switched on. The module(s) must be replaced as quickly as possible. While

waiting the Battery module(s) replacement, the alarm can be inhibited using the

Enabling/disabling menu .

Display the On-board software version.

The checksum allows the very rapid

inspection that all configuration

parameters are correct or to carry out

configuration comparisons among several

modules.

W9 1489436 10 11 A01 03/2008 65

Page 66

Maintenance

Battery modules replacement

Replacement A Battery module is considered to reach its end of life when it has lost 50% of its

rated capacity.

The batteries contained in the Battery modules are irreplaceable. When the

batteries have reached their end of life, it is necessary to change the Battery module

in its set.

When several Battery modules are parallel connected, these must be replaced at

the same time.

After the exchange of the Battery modules, it is suitable to reinitialize the ageing test

(see SERVICE menu, p. 64).

Maintenance The Battery modules contain lead sealed batteries. This battery type does not

require maintenance.

WARNING

RISKS OF INJURY

The batteries contained in the Battery modules have no maintenance and must,

under no circumstances, be open.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

66

W9 1489436 10 11 A01 03/2008

Page 67

Appendices

Overview

Introduction This following appendices contain general information on the operation and

characteristics of the 2 Battery control modules and the 3 Battery modules.

What's in this

Appendix?

The appendix contains the following chapters:

Chapter Chapter Name Page

A Characteristics 69

B Battery general information 75

CFAQ 77

W9 1489436 10 11 A01 03/2008 67

Page 68

Appendices

68

W9 1489436 10 11 A01 03/2008

Page 69

Characteristics

A

Overview

Introduction You will find in this chapter the electrical, operating and environmental character-

istics of the Battery control modules and Battery modules.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Electrical Characteristics of the Battery Control modules 70

Operating and environmental characteristics of Battery control modules 71

Electrical characteristics of the Battery modules 72

Operating and environmental characteristics of Battery modules 73

W9 1489436 10 11 A01 03/2008 69

Page 70

Characteristics

Electrical Characteristics of the Battery Control Modules

Certifications

and standards

Electrical

Characteristics

The table below describes the certifications and standards applicable to the Battery

control modules:

Reference ABL 8BBU24200 ABL 8BBU24400

Certifications CB scheme EN60950-1, UL, cCSAus, GL

Conformity with standards Security EN60950-1, EN61204

CEM EN61000-6-2, EN61000-6-3

The table below describes the electrical characteristics of the Battery control module

input:

Reference ABL 8BBU24200 ABL 8BBU24400

Rated voltages 24...28.8 VDC

Admissible voltages 22...30 VDC

Power dissipated at the rated charge < 7 W < 12 W

No load consumption / on load /maxi 0.1/1.7/21.7 A 0.1/1.7/41.7 A

Activation threshold Fixed 21 VDC

The table below describes the electrical characteristics of the Battery control

module output:

Reference ABL 8BBU24200 ABL 8BBU24400

Uout rated voltage rated mode: Uin -0.25 V

battery mode: Ubatt -0.5 V

Maximum rate current 20 A 40 A

Residual ripple - noise < 200 mV

Holding time I = 0.5 A As a function of the battery used, > 20 hours

I = 40 A As a function of the battery used, < 15 minutes

Protection against

short-circuits

Overload protection 1.5 ln

Power Supply

mode

Backup mode Permanent, automatic restart

Protection of the power supply.

70

W9 1489436 10 11 A01 03/2008

Page 71

Characteristics

Operating and environmental characteristics of Battery control modules

Characteristics The table below describes the operating and environmental characteristics of the

Battery control module:

Battery control module reference ABL 8BBU24200 ABL 8BBU24400

Screw terminal block

capacity

Input

Output

Diagnostics

2 x 0.5...10 mm

2 x 0.5...10 mm

0.14...2.5 mm

relay

Degree of protection IP20

Storage temperature - 40...+ 85 °C (- 40...+ 185 °F)

Operating temperature - 25...+ 60 °C (- 13...+ 140 °F)

Max. relative humidity 90 % in operations, 95 % in storage

Vibrations, according to EN 61131-2 3...11.9 Hz amplitude 3.5 mm (0.138 in) and 11.9...150 Hz acceleration 2 g

Installation attachment

Rail , 35 x 7.5 mm (1.38 x 0.29 in) and 35 x 15 mm (1.38 x 0.59 in)

Operating position Vertical

Horizontal

(with downgrading of the maximum power by 20% from 50 °C (122 °F))

Protection class Class II

Charging time As a function of the battery used

Diagnostic LCD screen Green: rated state, Orange : warning, Red: default

By relay 3 OF relays for power supply state, battery state and alarm

Relay characteristic 230 VAC, 0.5 A max

24 VDC, 5 mA max

Dielectric strength of 50 Hz for 1 mn in

500 VAC eff

input/ground

Dielectric strength of 50 Hz for 1 mn in

500 VAC eff

output/ground

Emission

Led/emitted EN 55022 Class B

Immunity

Electrostatic discharges EN 61000-4-2 (6 kV contact/8 kV air)

Emitted electromagnetic fields EN 61000-4-3 level 3 (10 V/m)

Inducted electromagnetic fields EN 61000-4-6 level 3 (10 V/m)

Rapid transitions EN 61000-4-4 level 3 (2 kV)

Shock waves EN 61000-4-5 level 2 (1 kV)

2

(20...8 AWG)

2

(20...8 AWG)

2

(25...14 AWG)

W9 1489436 10 11 A01 03/2008 71

Page 72

Characteristics

Electrical characteristics of the Battery modules

Introduction This part details the electrical characteristics of the Phaseo Universal Battery

module input and output.

Technical

characteristics,

certifications

and standards

Electrical

characteristics

of the Battery

modules

The table below describes the Battery module type and certifications and standards

applicable to the Battery module:

Battery module reference ABL

8BPK24A03

Battery type Lead sealed battery

Certifications UR, CE

Conformity with

standards

Security Conformity in course, consult the

CEM

www.telemecanique.com site

ABL

8BPK24A07

ABL

8BPK24A12

The table below describes the electrical characteristics of the Battery modules:

Battery module reference ABL

8BPK24A03

Rated charge voltage 24...28.8 VDC

Admissible charge voltage 22...29 VDC

Charge current 0.5 A 0.7 A 1.2 A

Un rated voltage 24 VDC

Maximum rate current 32 A 40 A 75 A

Rated capacity 3.2 Ah 7 Ah 12 Ah

Immunity to

cut-offs

Protection against short-circuits and

overloads

Self-discharge rates 1 month : 3 %, 3 months : 9 %, 6 months : 15%

Holding time at 20°C

maximum

Holding time at 20°C

minimum

20 h at 0.16 A 20 h at 0.35 A 20 h at 6 A

5 min at 8.4 A 5 min at 18.2 A 5 min at 31.3 A

1 x 20 A auto

fuse

ABL

8BPK24A07

1 x 30 A auto

fuse

ABL

8BPK24A12

2 x 30 A auto

fuse

72

W9 1489436 10 11 A01 03/2008

Page 73

Characteristics

Operating and environmental characteristics of Battery modules

Introduction This part details the operating and environmental characteristics of the Phaseo

Universal Battery modules.

Characteristics The table below describes the operational and environmental characteristics of the

Battery modules:

Battery module

reference

Input screw terminal

capacity

Output screw terminal

capacity

Degree of protection IP10

Storage temperature - 20...+ 50 °C (-4...+122 °F)

Operating temperature 0...+ 40 °C (32...+104 °F)

Vibrations, according to

EN 61131-2

Installation attachment

Operating position Vertical or horizontal

Serial wiring No

Parallel wiring Yes

Protection class Class III

Life (approximate) 44,000 H at 20°C,

2 x 0.5...10 mm

2 x 0.5...10 mm

3...11.9 Hz amplitude 3.5 mm (0.138 in) and 11.9...150 Hz acceleration 2 g

Rail , 35 x 7.5 mm

(1.38 x 0.29 in)and 35 x

15 mm (1.38 x 0.59 in)

or by 4 screws Ø 5 mm

(0.197 in)

31,000 h at 25°C,

22,000 h at 30°C,

15,000 h at 35°C,

11,000 h at 40°C,

7,300 h at 45°C,

5,000 h at 50°C,

ABL

8BPK24A03

2

(20...6 AWG) 4 x 0.5...10 mm2 (20...6 AWG)

2

(20...6 AWG) 4 x 0.5...10 mm2 (20...6 AWG)

ABL

8BPK24A07

By 4 screws Ø 5 mm (0.197 in)

(1)

ABL

8BPK24A12

1

With ABL 1A02 mounting kit

W9 1489436 10 11 A01 03/2008 73

Page 74

Characteristics

74

W9 1489436 10 11 A01 03/2008

Page 75

Battery general information

Battery Generalities

B

The Capacity and

Battery Charge

Rate

Capacity:

Current provided by a battery for a determined time and completely being

charged.

The capacity provided in the catalog is the new value, expressed in Ah.

Example: In theory, a 12Ah battery will be capable of providing a 0.6A current for

20H.

The capacity diminishes with the battery age.

Charge rate:

Proportion of the capacity available at time t.

Expressed in % of the total capacity.

The charge rate diminishes when the battery provides energy.

Capacity = 1l

Charge = 0%

Capacity = 1l

Charge = 95%

W9 1489436 10 11 A01 03/2008 75

Page 76

Battery general information

Lead Battery

Generalities

Charge:

The performances and battery life depend on the charge efficiency.