Page 1

Page 2

M.Schaerer Ltd. Phone: +41 31 858 51 11 User manual

Gewerbestrasse 15 Fax: +41 31 858 51 40 BASE 2 - 02

3302 Moosseedorf E-Mail: info@schaerer.com

Switzerland Internet: www.schaerer.com Order number: 020'221

Page 3

Header

User manual for the

coffee machine

Euroca-2

Published by : M. SCHAERER AG

CH-3302 Moosseedorf

Edition : 2. Edition / March 1998

Replaces : 1. Edition / June 1998

Software : NT 2000 V 1.00

Designed and edited by: M. SCHAERER AG, CH-3302 Moosseedorf

© Copyright by M. SCHAERER AG, CH-3302 Moosseedorf

All rights reserved, including translations into foreign languages. It is prohibited to copy,

reproduce, distribute or communicate by electronic means all or any parts of this

document in any form without the express permission of the publisher.

All information, technical data and illustrations contained in this guide reflect the latest

factual position at the time of going to print. M. SCHAERER AG reserves the right to

introduce modifications at any time without specific notification.

BASE-2-02.00 Page 0-1

Page 4

Header

Page 0-2 BASE-2-02.00

Page 5

Header

Safety Instructions & Warnings!

Before using the machine for the first time,

please read the information in the Operating

Instructions very carefully. They contain

important directions concerning safety, and

the use and maintenance of the machine.

Before using the machine for the first time,

please read the information in the Operating

Instructions very carefully. They contain

important directions concerning safety, and

the use and maintenance of the machine.

Proper Use

The coffee machine is only intended for commercial

use. It is strictly forbidden to make technical

alterations to it or use the machine improperly on

account of the risk that may ensue!

The manufacturer is not liable for any damages that

may be caused by improper use or incorrect operation of the machine.

Use of the Operating Instructions

These Operating Instructions cannot cover every

imaginable use. If you would like additional

information or if you have problems that are not

covered in these Operating Instructions, or not

covered in sufficient detail, please contact an

authorised specialist.

Please keep the Operating Instructions carefully and

pass them on to any subsequent operator.

BASE-2-02.00 Page 0-3

Page 6

Header

Safety Instructions & Warnings!

Unauthorised Operators

Persons unfamiliar with the Operating Instructions, children or those

under the influence of alcohol, drugs or medicines may not operate

the coffee machine or only do so under supervision. Dangerous parts

of self-service coffee machines, such as steam and hot water outlet

points must be clearly marked for customers to see.

Electricity supply

Never touch live parts! They can give an electric shock, which can

lead to serious injury or even death. The coffee machine must only

be connected to alternating current. The voltage must correspond to

that shown on the machine nameplate. It is strictly forbidden to force

objects into the machine or to opening the housing!

Mains cable

Never use the machine with a damaged mains cable. Have faulty

cables and plugs replaced immediately by authorised specialists. Do

not pull or clip the mains cable around corners or sharp edges. Do

not place the mains cable on hot objects or allow it to hang down

over them; protect it from oil. Never lift or pull the machine by the

cable. Never pull the plug by the mains cable or pull it out of the

socket with wet hands. Do not allow the mains cable to hang down

from a table or shelf. Only use an extension cable if you have

confirmed that it is in perfect condition. The extension cable must

have a minimum cross-section of 1.5 mm2 and be fitted with a 5-pole

plug. Get a specialist to install or check the fitting.

Voltage

Make sure that the voltage in your premises at the socket being used

is the same as the voltage on the nameplate of the coffee machine.

The socket must have a 16A fuse at least.

Page 0-4 BASE-2-02.00

Page 7

Header

Safety Instructions & Warnings!

Location

Install the coffee machine in a secure place, so that no one can

knock the machine over or hurt themselves against it. Make sure that

there is no possibility of children playing with the machine. Hot water

or steam could escape: Danger of burns! Do not use the coffee

machine out of doors. Do not place the machine on a hot surface or

in the vicinity of an oven.

The machine may not be used in a large-scale kitchen without the

specific written approval of an M. Schaerer AG authorised Customer

Service Agent.

7 Temperature

The ambient temperature must not fall below 10 °C or exceed 40 °C.

, Protection for your hands

Never reach into the bean container(s) with the machine switched on.

Never put your fingers into the central unit, while coffee is being

prepared:Æ Danger of injury! The central unit moves while coffee is

being prepared, so your fingers could get caught.

Risk of burns

Never tamper with the coffee, hot water or steam outlet points, while

any product is being dispensed:Æ Risk of burns.

Sound emissions

The level of sound emissions can reach 70db(A), particularly when

drinks are being heated.

Coffee bean container

Never put anything other than coffee beans in the coffee bean

container:Æ Danger of damage to the machine.

BASE-2-02.00 Page 0-5

Page 8

Header

Safety Instructions & Warnings!

, Cleaning

Never spray the machine with a hose or high-pressure cleaner when

cleaning it. The use of steam cleaning machines must also be

avoided.

6 Cup rack

No liquids should be emptied out on to the cup rack. Never immerse

the machine in water.

Repairs

If there is a malfunction or fault in the machine, or suspected defect

if the machine has been dropped, pull out the plug immediately.

Never operate a faulty machine. Æ

Repairs must only be carried out by authorised specialists. If

inexpert repairs are carried out, no liability will be accepted for any

damages.

Servicing

The machine must be serviced by an M. Schaerer AG authorised

Customer Service Agent every 12 to 15 months.

Storage

If the machine is to be out of service for a lengthy period, clean and

empty it, switch it off and remove plug from socket. Store the coffee

machine in a dry place, which is not accessible to children.

In order to empty the coffee machine, get advice and assistance from

an M. Schaerer AG authorised Customer Service Agent.

Disposal

If the machine is unusable, it must be disposed of correctly, in

accordance with local and statutory regulations.

Page 0-6 BASE-2-02.00

Page 9

Header

CONTENTS

KAP. TEXT

1 INTRODUCTION.............................................................................................................................................. 1-1

1.1 Welcome to the SCHAERER-Euroca-2 ................................................................................................... 1-1

1.2 Purpose .................................................................................................................................................... 1-1

1.3 How this manual is organised .................................................................................................................. 1-1

2 PRODUCT DESCRIPTION .............................................................................................................................. 2-1

2.1 Introduction of Euroca-2........................................................................................................................... 2-2

2.2 Product data of Euroca-2.......................................................................................................................... 2-5

2.3 How is the machine equipped of Euroca-2 .............................................................................................. 2-6

3 INDICATION- AND OPERATING ELEMENTS ............................................................................................... 3-1

3.1 Indicating- and operating elements of Euroca-2 ...................................................................................... 3-2

3.2 Chip card functions...................................................................................................................................3-3

3.3 Error and display messages..................................................................................................................... 3-5

3.4 Messages when the machine is operating............................................................................................... 3-9

3.5 Operating modes...................................................................................................................................... 3-9

4 INSTALLATION AND OPERATION OF THE MACHINE................................................................................ 4-1

4.1 First installation an operation ................................................................................................................... 4-1

4.2 Installation (basic conditions)................................................................................................................... 4-1

5 OPERATION .................................................................................................................................................... 5-1

5.1 Introduction of Euroca-2........................................................................................................................... 5-3

5.2 Daily use...................................................................................................................................................5-3

5.3 Daily cleaning......................................................................................................................................... 5-10

5.4 Shutdown / switch off the machine......................................................................................................... 5-19

5.5 Guidance on operating specially adapted machines.............................................................................. 5-19

5.6 Programming of the machine ................................................................................................................. 5-20

5.7 Programming with options-chip cards.......................................................................................

6 ACCOUNTING SYSTEMS............................................................................................................................... 6-1

6.1 The MASTER card ................................................................................................................................... 6-2

6.2 MONEY chip card system ........................................................................................................................ 6-3

6.3 Programm chip card................................................................................................................................. 6-9

6.4 Token tester............................................................................................................................................ 6-14

6.5 Coin tester.............................................................................................................................................. 6-15

6.6 Via bar tills.............................................................................................................................................. 6-15

7 FRIGO............................................................................................................................................................... 7-1

7.1 Product description Frigo.......................................................................................................................... 7-2

7.2 Product data of the Frigo.......................................................................................................................... 7-4

7.3 Malfunctions and remedies ...................................................................................................................... 7-5

7.4 Operating elements of the Frigo............................................................................................................... 7-6

7.5 Setting up the Frigo.................................................................................................................................. 7-7

7.6 Cleaning of the Frigo................................................................................................................................ 7-8

8 STANDARD-PROGRAMMING........................................................................................................................ 8-1

9 LIST OF INDEX................................................................................................................................................ 9-1

A APPENDIX.......................................................................................................................................................A-1

A.1 Declaration of conformity.........................................................................................................................A-1

A.2 Performance of container elements.........................................................................................................A-2

A.3 Environmental information on the Euroca................................................................................................A-3

SEITE

............. 5-27

BASE-2-02.00 Page 0-7

Page 10

Header

Page 0-8 BASE-2-02.00

Page 11

1 INTRODUCTION

1.1 Welcome to the SCHAERER-Euroca-2

Congratulations on your purchase of the Schaerer coffee machine

"Euroca-2 "!

The "Euroca-2 " - with its ergonomic design - provides you with a spacious

working area. The modern design and the individual choice of colours make

it possible to adapt the machine to the local circumstances. The machine

combines highest quality and revolutionary technique and has a unique

operating comfort.

1.2 Purpose

These operating instructions will help you to get acquainted with the

fantastic features of the Schaerer office coffee machine Euroca-2 very soon.

Information regarding the correct maintenance, operating features and

technical data can be found therein.

It is imperative that you follow these instructions if you expect the machine to

work properly. Please read them carefully and keep them close to the

machine so that they can be used if the occasion should arise

(programming, cleaning, malfunction...).

1.3 How this manual is organised

Working cycle

Options That pictogram means that it is the question of a model version or an option.

Note This pictogram means "information". The corresponding text will give a

Italic characters When you see that pictogram, please pay special attention to that

Please turn

overPage following page.

This symbol can be seen at the bottom right corner of a page.

Display-Message

) That pictogram means "working cycles to be executed by the enduser".

Your machine may not be equipped with those accessories.

better understanding and is meant as a completion to the functionning

courses.

information.

ª Please turn over the page, you will find further text on this matter on the

Introduction

Every display text changing, by using the push button, will be shown with the

Select product

12:00 22.01.1999

Chip cards The card name (for example PROGRAM, SAVE DATA, etc.) is indicated

The chip card has to be introduced into the machine the proper way (see

BASE-2-02.01 Page 1-1

display message.

with Capital letters. A picture of the chip card can always be found on the left

side of the corresponding information.

arrow)

Page 12

Introduction.

Page 1-2 BASE-2-02.01

Page 13

Product description

2. PRODUCT DESCRIPTION OF EUROCA-2

Sect. TEXT.............................................................................................................................Page

2.1. Introducing the Euroca-2 ..............................................................................................2-2

2.1.1 Overall instructions .......................................................................................................... 2-2

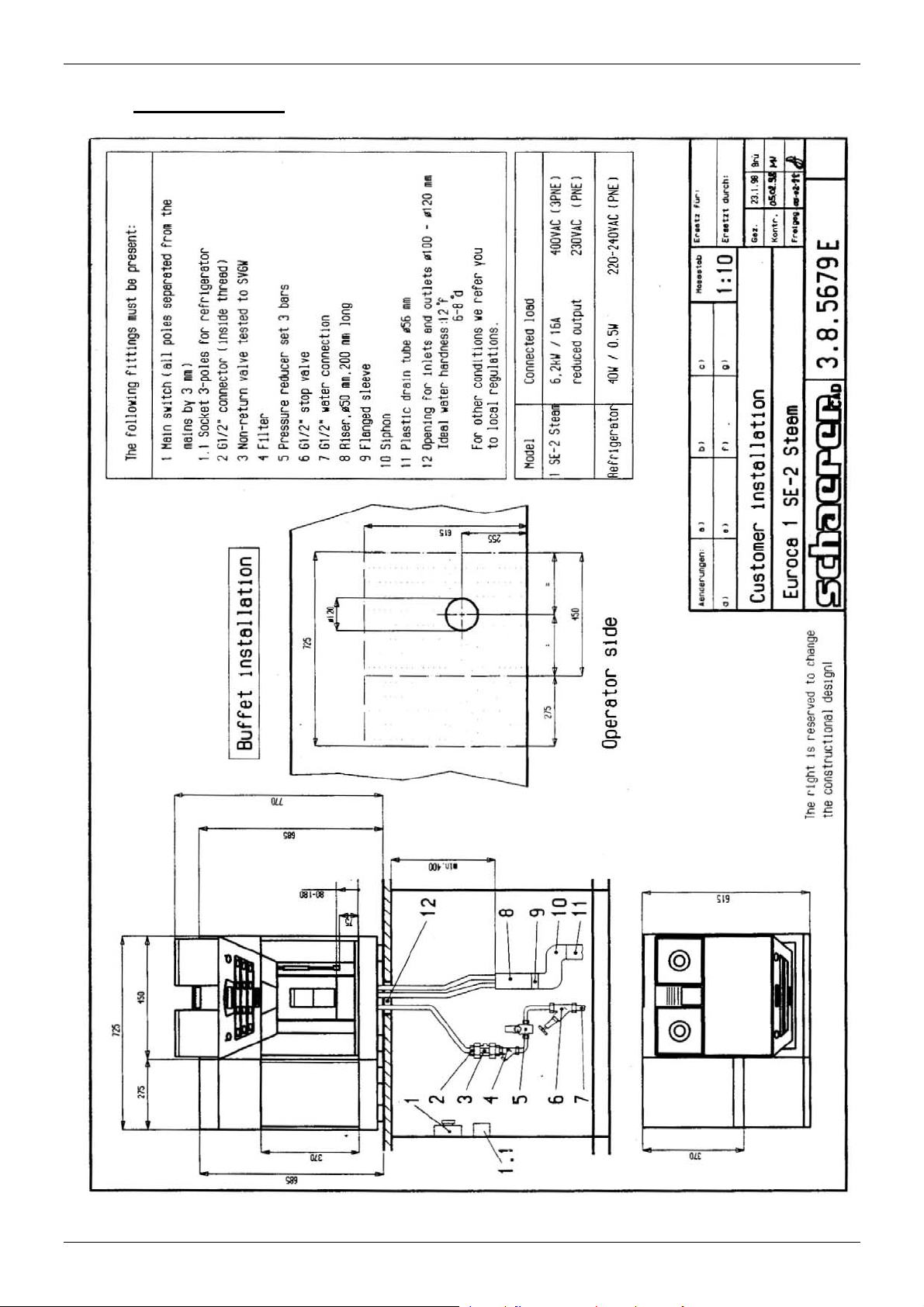

2.1.2. Installation plan................................................................................................................ 2-3

2.1.3. Purpose of use.................................................................................................................2-4

2.1.4 Safety precautions...........................................................................................................2-4

2.1.5. Labelling of the Euroca-2.................................................................................................2-5

2.2 Product data of the Euroca-2........................................................................................2-5

2.2.1. Performance features of the Euroca-2............................................................................. 2-5

2.2.2. Dimensions of the Euroca-2 ............................................................................................ 2-5

2.2.3. Energy supply .................................................................................................................. 2-5

2.2.4. Water connection / discharge.......................................................................................... 2-6

2.3. Equipment.......................................................................................................................2-6

2.3.1. Design variants................................................................................................................2-6

2.3.2. Normal accessories of the Euroca-2 are included in the specification............................2-6

2.3.3. Special accessories of the Euroca-2 are not included in the specification...................... 2-7

BASE-2-02.02 Page 2-1

Page 14

Product description

2.1 Introduction

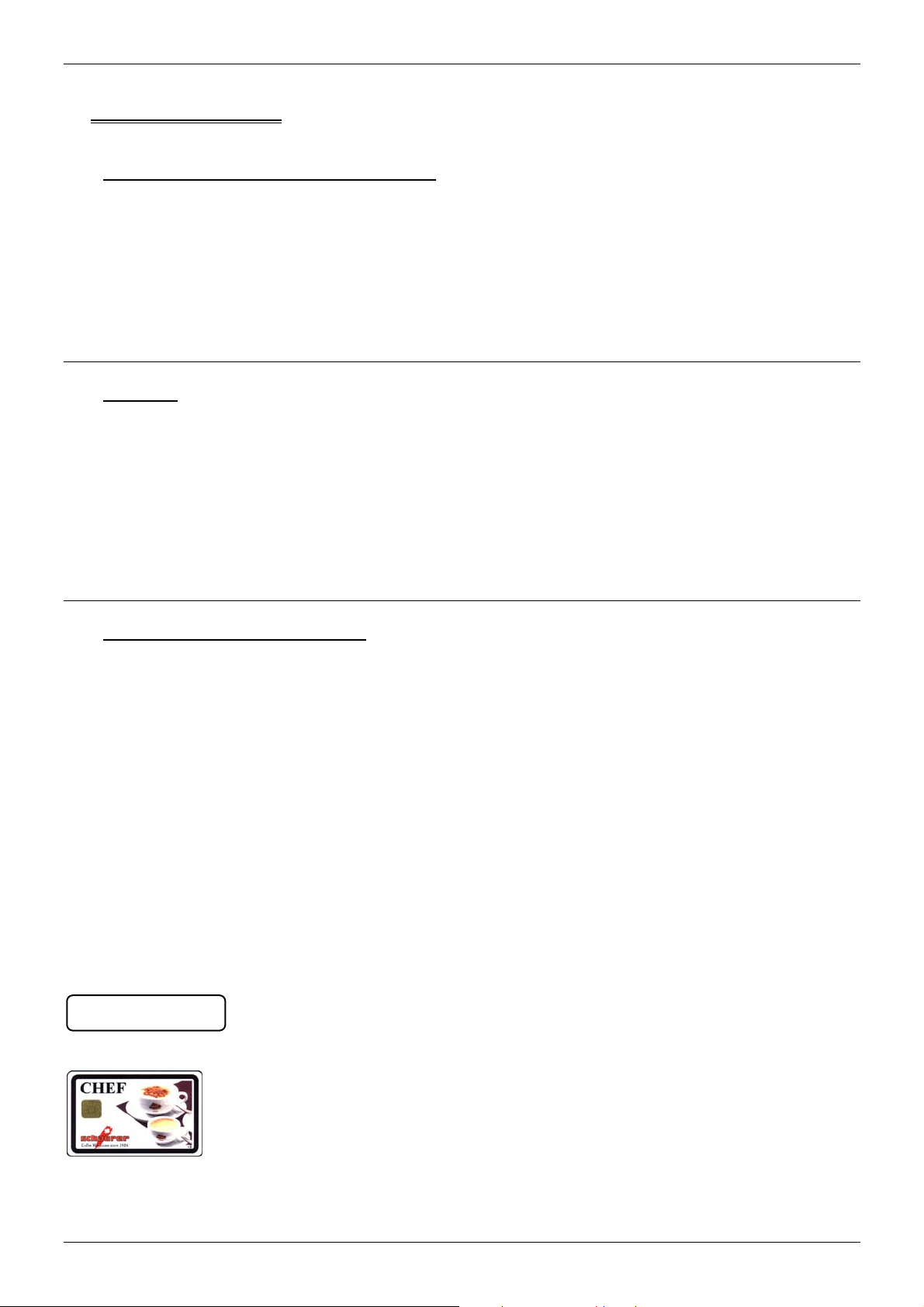

2.1.1 Introduction

3

6

17

16

12

7

8

1

4

2

5

14

13

15

11

10

9

1. Bean container grinder 1 (standard grinder)

2. Bean container grinder 2 (option)

3. Slide for closing the beans container

4. Inlet opening for additional coffee powder and cleaning tabs

5. Cup platform ( heated )

6. Cup frame

7. Drip grille

8. Drip grille basin with/without outlet

9. Grounds drawer ( push outflow completely up )

10. Coffee delivery spout adjustable for height min. Ø 80 mm, max. × 180 mm (deliver carriage)

11. Steam outlet

12. Hot water outlet

13. Illuminated display with 2 lines

14. Operator panel

15. Chip cards slide-in unit

16. Refrigerator for milk ( option )

17. Bean container grinder right (option)

Page 2-2 BASE-2-02.02

Page 15

Product description

2.1.2 Installation planning

BASE-2-02.02 Page 2-3

Page 16

Product description

2.1.3 User facility

2.1.4 Safety precautions

- Cappuccino (option)

- Milky coffee

- Latté

- Hot milk

- Milk foam

The maintenance of the machine must be executed by qualified

& This machine may not be used in commercial kitchens without the

7 The ambient temperature must not fall below 10ºC or rise above 40ºC.

, The machine must never be sprayed from a hose or with a high-

6 Never spill any liquids into the cup stand..

Never put your hand into the bean containers when the machine is

The following beverages can be made with the Schaerer office:

- Coffee creme

- Ristretto

- Espresso coffee

- Decaffeinated coffee („light coffee“)

- Steam to heat up milk

- Hot water for aromatic tea

personnel, every 12 - 15 months. The authorization is given by M.

SCHAERER Ltd. only.

prior permission of the authorized M. SCHAERER Ltd. representative.

pressure jet cleaner. Neither should the use of steam cleaning

appliances be considered.

switched on.

Never put your hand under the coffee, hot water or steam outlets

during product delivery or when drawing hot water, to avoid risk of

scalding.

The machine should only be operated by trained staff.

: The manufacturer will entertain no liability for damage or

consequential losses of any kind.

The noise value can increase up to 70 db(A), especially by heating up

of drinks.

Page 2-4 BASE-2-02.02

Page 17

Product description

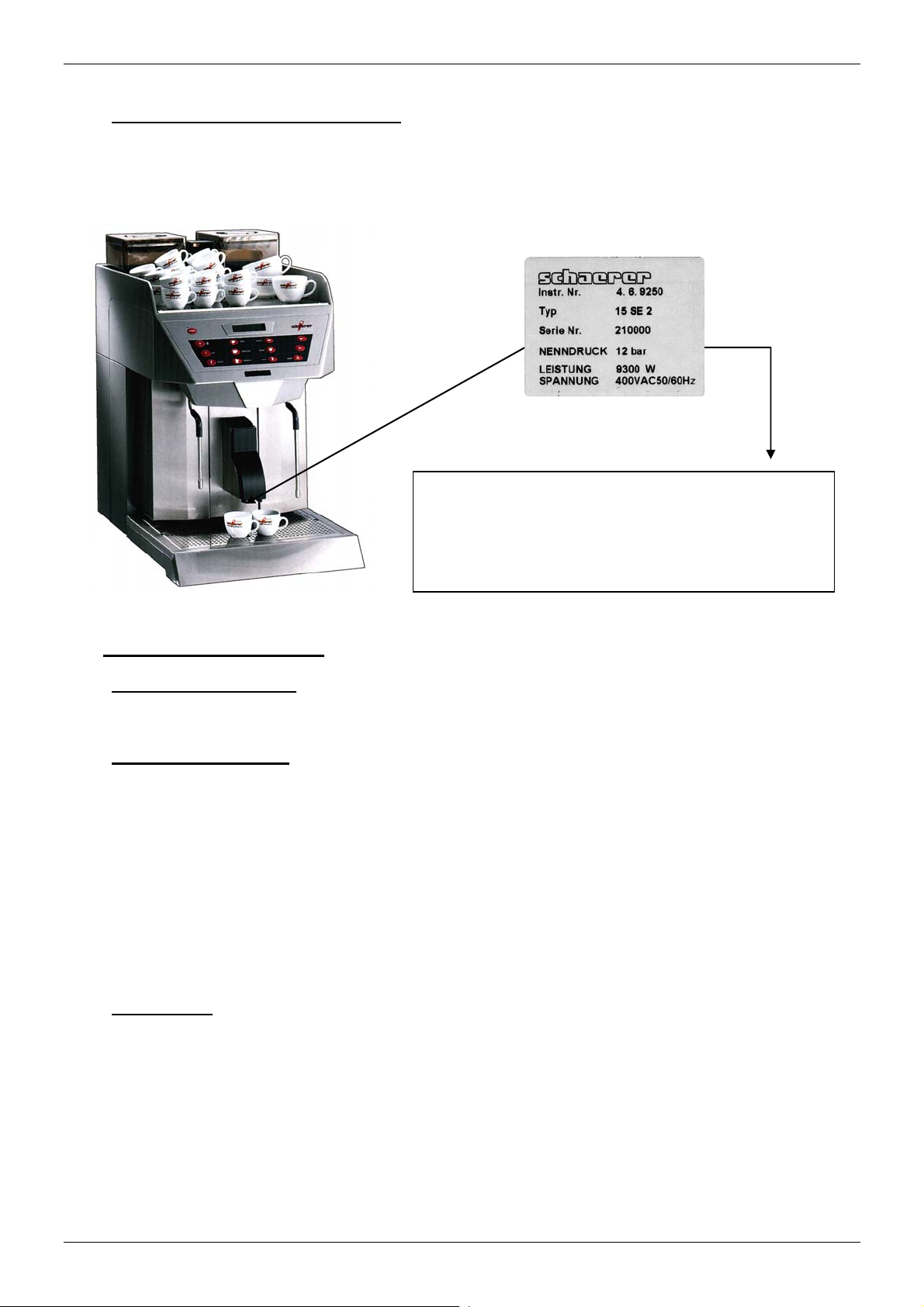

2.1.5 How is the product marked of Euroca-2

Just in case of a warranty or malfunction please write the type plate data

from your machine in the following field! The type plate is to be found in the

machine above the grounds drawer.

2.2 Product data of Euroca-2

2.2.1 Performance of Euroca-2

The output is 100 to 120 cups of coffee or tea per hour.

2.2.2 Dimensions of Euroca-2

Width 480 mm

Height 780 mm

Depth 620 mm

Outlet height 90 / 180 mm

Net weight 64 kg (15 SE-2 )

Subject to change!

2.2.3 Power supply

Model Connecting values

1 SE-2 Steam 6.3 kW / 16 A 400 V AC (3 PNE) 50/60 Hz

1 SE-2 Tea 9.3 kW / 16 A 400 V AC (3 PNE) 50/60 Hz

15 SE-2 9.3 kW / 16 A 400 V AC (3 PNE) 50/60 Hz

The electrical connection must be effected according to the existing

prescriptions (VDE 0100) and the local laws and prescriptions.

ª

Type plate

Draw out the grounds drawer,

to the side on the inner side

Inst.-Nr. ................................

Type: ................................

Serial-No: ................................

Pressure: ................................bar

Voltage: ................................Watt

Power: .............VAC............Hz

BASE-2-02.02 Page 2-5

Page 18

Product description

The power supply line must be at least H 07 RN-F. The voltage indicated on

the machine type plate must be identical with the one where the machine will

be used.

The phase must be secured with 16A.

For special voltages please contact M. Schaerer Ltd or an authorized

representative.

2.2.4 Water connection / outlet

If the machine is connected to a newly installed water supply line then

please make sure that the supply line and the connecting tube are rinsed

carefully so that no dirt can get into the machine.

The coffee machine must be connected to an installed drinking water supply

line (with water tap). The installation is done via the fitted pressure hose and

the screwing G 1/2" to the pressure reducer which is fitted directly on the

water tap (adjust on 3 bar).

For the water outlet you have to connect a temperature resistant outlet hose

to the waste water metal blade and the syphon. Fix the same firmly on the

outlet and make sure that the water can flow out easily.

The ideal limestone of the water should not be higher than 6-8°dWH

(German water hardness measure) or 8-12°fWH (French water hardness

measure). The chlorine content should not be higher than 100 mg per liter.

Ideal ph-value is 7. Otherwise see the local rules.

2.3 How is the machine equipped ?

2.3.1 Different types of models

There are three different versions:

1 SE-2 Steam = Coffee and steam only

1 SE-2 Tea = Coffee and hot water

15 SE-2 = Coffee, hot water and steam

Standard colours white and anthrazite. Upon request the machine can be

ordered in any RAL colour (extra charge).

2.3.2 Standard accessories of the Euroca-2 are included in the specification

-1 Chip carte ” CHEF “ 063930

-1 Chip carte ” SAVE DATA A “ 063933

-1 Chip carte“ SAVE DATA B “ 063920

-1 Spoon 067111

-1

-1

-2

-1 Nipple (G1/2“) 068179

-1

-1

-1

-1

-1 Buckle to Outlet hose without ø 25 mm 067767

-2 Milchbehälter 063243

-1 Dosierbecher clean-up 061020

-1 Reinigungsmittel (Milch) clean-up 2 Liter 061019

-1 O – Ring Set zum Schäumerkopf 050415

-2.5 m Siliconschlauch 067722

-1 Ablaufschlauch 067862

-1 Bride zum Ablaufschlauch Ø 29 mm 066794

-1 Blende 1.2 mm 063446

Designation

Order No.

Packing of cleaning tablets 065221

User manual -

Seals 064249

Brush 067409-A

Reinforced hose 067766

Wallet to hold 2 chipcards 065278

Outlet hose (without Frigo) 067784

Page 2-6 BASE-2-02.02

Page 19

Product description

2.3.3 Standard accessories of the Euroca-2 are not included in the specification

Designation Order No.

- Additional chip card

„ PROGRAMM “ 063941

„ KEY BLOCK “ 063931

„ COFFEE TEST “ 063932

„ MANAGER “ 063940

„ LOAD “ 063937

„ MASTER “ 063934

„ WAITER “ 063936

„ COPY WAITER “ 063942

„ PRINT “ 063943

„ MONEY A “ 063921

„ MONEY B – J “

„ Cup “ 063939

„ Credit – Look “ 063946

„ Clean “ ( for claning the card reader ) 063945

- Chip card loading system.

- Accounting systems (waiter account or chip cards MONEY)..

- Accounting systems (CCI - credit coffee system, CSI - coffee standard

interface).

- Water softener (Filados / Brita).

- 2nd grinder (DUO).

- Water tank (for operation without fresh water connection).

- Cappuccinatore (for a comfortable heating up of milk).

- Frigo for keeping milk cool

BASE-2-02.02 Page 2-7

Page 20

Product description

Page 2-8 BASE-2-02.02

Page 21

Indicating- and operating elements

3. INDICATING- AND OPERATING ELEMENTS

Kap. TEXT.............................................................................................................................Page

3.1. Indicating and operating elements .............................................................................. 3-2

3.2 Chip card functions ....................................................................................................... 3-3

3.2.1. Standard chip cards.........................................................................................................3-3

3.2.2. Optional chip cards for normal operation......................................................................... 3-4

3.2.3. Chip cards for accounting operation................................................................................ 3-4

3.3. Malfunction indications and messages....................................................................... 3-5

3.3.1. Machine blocked, no more drawing possible................................................................... 3-5

3.3.2. Output of coffee products blocked................................................................................... 3-6

3.3.3. Output of steam products blocked................................................................................... 3-7

3.3.4. Output of tea water products blocked.............................................................................. 3-7

3.3.5. Products are being output again......................................................................................3-7

3.3.6. Chip card error messages ...............................................................................................3-8

3.4. Messages in operational readiness............................................................................. 3-9

3.5. Modes of operation........................................................................................................ 3-9

BASE-2-02.03 Page 3-1

Page 22

Indicating- and operating elements

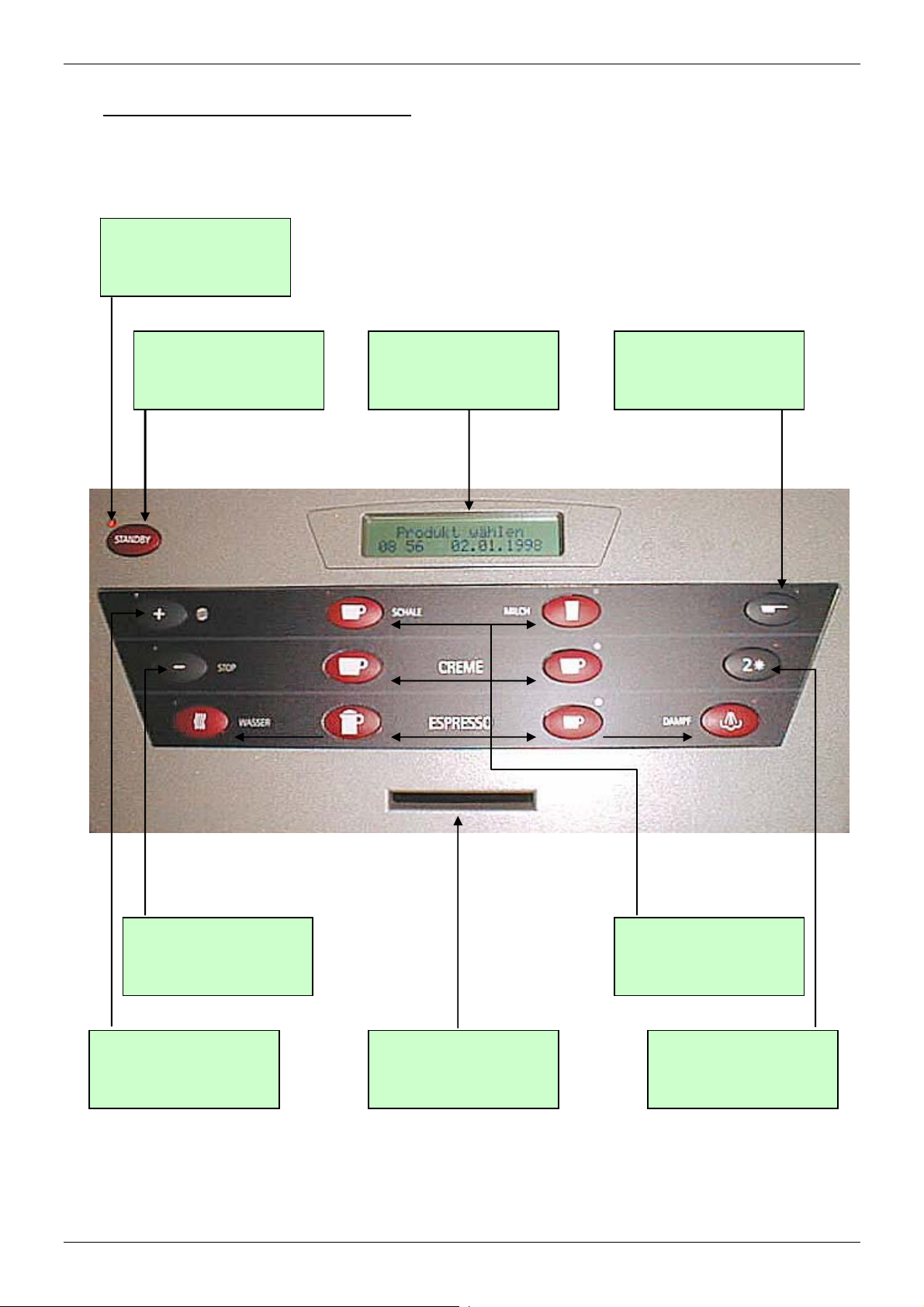

3.1 Indicating- and operating elements

on / off LED

Stand-By Key

Stop- and minus-key

incl. LED

Cleaning and

plus-key incl. LED

Two-lined illuminated LCDDisplay

Chip card insertion which

recognises the single chip

card function

Decaf-key incl. LED

Free selection product key

incl. LED and product

symbols

Shift-key and LED

Page 3-2 BASSE-2-02.03

Page 23

Indicating- and operating elements

3.2 Chip card function

The office coffee machine has been equipped with a modern control unit. In order to

ensure a simple programming of the machine, a few programming groups have been

created, which can be activated by the corresponding chip card. By using those chip

cards these programming groups can be protected from misuse. As an addition important

cards like CHEF, PROGRAMM etc. can be provided with a programmable security code

from the service engineer, which increases the protection from misuse further.

The four possibilities of programmable security code:

Security code - 0 Customer-No.

Main board checks automatically, if the right customer number is

available on the chip card.

Security code - 1 Customer-No. / Pin-code

Checking the customer number and an additional pin code is to be

given at the machine.

Security code - 2 Customer-No. / Card-No.

Checking the customer number

In addition, the internal *card number will be recognised. Another

card from the same programming group will not be accepted.

Security code - 3 Customer-No. / Card-No. / Pin-code

Highest security consisting of level 1 and 2.

*The manufacturer will provide every single chip card with an own

card number.

If a NEW card is inserted into the card reader by programmed security level 1 or 3, every

number can be used as PIN-code, even 0000. This value will be transfered to the card

and from then on it is valid as actual code.

3.2.1 Standard chip cards

The CHEF card allows you to customise the operation of your Euroca-2 machine to your

own requirements. It is also used for control purposes:

- to read the day counter for coffee and per key

- to clear counter

- new product dosage (changing the quantity of water supplied)

- to change grinding quantity

- Changing On / Off times

- to change time

- to change date

- to change PIN-Code (Personal-Identification-number)

- key switch function - if programmed accordingly by the service technician, the machine

can only be switched on and off with the CHEF- or SERVICE-card (with SERVICE-card

only switch on).

The SAVE DATA card is a back-up card on which a machine configuration can be stored

or transmitted to the machine.

Two SAVE cards are required for the Euroca-2:

The " SAVE DATA A " card saves the data of level 1

The " SAVE DATA B " card saves the data of level 2

The respective card recognises automatically which level must be saved.

BASE-2-02.03 Page 3-3

Page 24

Indicating- and operating elements

3.2.2 Optional chip cards

In normal operation the PROGRAM card serves for statistical purposes. With an installed

accounting system the necessary settings can be made with it.

- Switch accounting operation ON / OFF

- Price switching level 1 + 2 (automatic machine on, off and switching times)

- Change product price and article number

- Display MONEY sales

- Delete MONEY sales

- Display MASTER sales

- Delete MASTER sales

- Log in MASTER card

- Delete MASTER cards table

- PROGRAM card - change PIN code

The KEY BLOCK card is being needed to block a single or all product keys.

With the COFFEE TEST card you have a direct access to the coffee test program

(Dosage of grinding quantity).

3.2.3 Chip card for accounting system

With the MONEY cards (available from A - J) price level adaptions are possible when

using the MONEY SYSTEM. The grinding quantity and dosage can be individually

programmed on every money card.

The CUP card works in combination with cup financing by interrogating and keeping

running totals of the meter counts for each product. However, there is no Delete function.

Change with the CREDIT-LOOK – card between standard running operation and

account system.

Page 3-4 BASSE-2-02.03

Page 25

Indicating- and operating elements

pty

p

y

p

g

g

3.3 Error and display message

3.3.1 Machine blocked, no more drawing possible

If the following information appears on the display, any product delivery will be

blocked:

selection locked

heatin

After switching on the machine all drinks drawing is blocked whilst the system

warms up ( approx. 5 min.).

selection locked

container n.i.

lace

Insert ground container. If this message is still shown, it might be a fault by the

microswitch:

) Call your customer service!

<<Button?>>

selection locked

The product key is stuck or dirty. Can be released by cleaning or pushing the key

again. If the fault can not be erased:

) Call your customer service!

selection locked

clean machine

At this display message no product purchase is possible.

Run cleaning program. See chapter 3.5 in the instruction manual.

selection locked

watertank em

Refill fresh water tank with drink water and then push

without fixed water connection)

-key (only for machines

selection locked

waste watertank full

Empty waste water tank and then press -key (only for machines without fixed

water connection)

selection locked

12:00 22.01.1999

All product keys have been blocked with the KEY BLOCK card.

selection locked

heatin

timeout

The heating is defective.

) Call your customer service !

selection locked

comms.interru

ted

The communication to an external unit has been interrupted. Check whether the

external units are connected to the power supply and are correctly connected to

the Euroca-2. But if that is the case, the display message will always be:

) Call your customer service !

selection locked

** LAN-Timeout **

The communication to an external unit has been interrupted. Check whether the

external units are connected to the power supply and are correctly connected to

the Euroca-2. But if that is the case, the display message will always be:

) Call your customer service !

selection locked

error account s

stem

The communication to an external unit has been interrupted. Check whether the

external units are connected to the power supply and are correctly connected to

the Euroca-2. But if that is the case, the display message will always be:

) Call your customer service !

ª

BASE-2-02.03 Page 3-5

Page 26

Indicating- and operating elements

g

p

g

pty

g

g

g

p

selection locked

door o

en

The Frigo door is open ( option ). Check the refrigeratordoor for correct locking. If

the problem exist further:Î

) Call your customer service !

battery flat

The battery of the machine's own control system must be replaced.

) Call your customer service !

** EEPROM error

Serial EEPROM is defective.

) Call your customer service !

motor current

Switch off the Euroca-2, wait 10 - 30 seconds and switch on again. If the problem

persists, switch off the Euroca-2.

) Call your customer service !

motor driver error

Switch off the Euroca-2.

) Call your customer service !

3.3.2 Delivery of coffee product locked

If these messages are shown on the lower display line, the machine will be blocked

for delivery of products.

selection locked

clean machine

At this display message no product purchase is possible.

Run cleaning program. See chapter 3.5 in the instruction manual.

select product

rinder right empty

Pleace fill up the right side grinder with coffeebeans.

select product

rinder left blocked

Pleace fill up the left side grinder with coffeebeans.

selection locked

container

em

Empty the coffee ground container and insert it again.

select product

rinder right blocked

Press

remove the beans container. Remove the remaining coffee beans (e.g. with a

-key. If the problem persists push in the slide of the beans container and

vacuum cleaner) and check the grinder for a jammed object such as a pebble. If no

select product

rinder left blocked

alien element is nipped and the problem exist further:

) Call your customer service !

The temperature sensor in the flow heater for coffee water is defective. Steam

output is disabled::

.sensor coffee

tem

) Call your customer service !

Wait approximately five minutes (it is possible too much coffee water has been

drawn off). If the message does not disapear after this time:

heatin

coffee

) Call your customer service !

rinsing

selection locked

The machine is automatically rinsed.

If this is so Î No fault.

ª

Page 3-6 BASSE-2-02.03

Page 27

Indicating- and operating elements

p

p

g

p

p

g

g

istonmotor timeout

The lifting motor is defective.

) Call your customer service !

select product

outlet missin

The Cappuccinatore is missing or incorrectly assembled.

If the problem persists.

) Call your customer service !

3.3.3 Output of steam products disabled

If one of the following messages appears on the bottom line of the display, delivery

of steam products is barred.

selection locked

clean machine

At this display message no product purchase is possible.

Run cleaning program. See chapter 3.5 in the instruction manual.

The temperature sensor in the steam generator is defective. Steam output is

disabled:

.sensor steam

tem

) Call your customer service !

The level sensor in the steam generator is defective. Steam output is disabled. Tea

and coffee output is also automatically disabled for two minutes after this message

level

robe steam

appears or after the machine is first switched on.

Check the tap for opening. If the problem persists:

Switch off the machine, wait 10-30 seconds and switch on again. If the problem

persists:

) Call your customer service !

timeout heat steam

If system has not reached the reference temperature, following message will

appear at the display: Timeout heating steam.

heatin

steam

Wait ~ 5 minutes ( hotwater consume to great )wen the display

message does not disapeard : The display shows “ timeout heating steam “

) Call your customer service !

3.3.4 Output of tea products disabled

selection locked

clean machine

At this display message no product purchase is possible.

Run cleaning program. See chapter 3.5 in the instruction manual.

timeaut heater tea

If system has not reached the reference temperature, following message will

appear at the display: Timeout heating tea.

The feeler gauge in the boiler is faulty :

Hotwaterporchase is blocked.

) Call your customer service !

tem

.sensor tea

Wait ~ 2 minutes ( hotwater consume to great )wen the display

message does not disapeard : The display shows “ timeout heating the “

heatin

tea

) Call your customer service !

3.3.5 Product can still be selected

The following display messages are not accompanied by automatic suspension of

product delivery. Nevertheless it is important to remedy the situation as quickly as

possible.

selection locked

container full !

Empty grounds container and insert again.

After this message appears, 5 more coffee products can be delivered, if the

grounds container is not emptied in this time, then the Euroca-2 is blocked as a

consequence Î Empty grounds container.

ª

BASE-2-02.03 Page 3-7

Page 28

Indicating- and operating elements

g

y

p

p

pty

Select product

ulseswitch defective

There is a malfunction in the automatic coffee powder portioner (obtainable as option).

) Call your customer service !

select product

clean machine

With appropriate programming (forced cleaning) 50 more coffees can be drawn or

1 more hour of coffee before delivery is blocked and the machine must be cleaned.

select product

button locked

Product key is locked. (Keyblock or not programmed)

credit system

button locked

Product key is locked.

select product

.sensor outside

tem

Option of automatic steam cut-off. Steam can continue to be drawn via the timeout.

) Call your customer service !

select product

flowmeter defect

Execute machine cleaning. Product delivery possible again.

With the appropriate programming (forced cleaning ) 50 more coffees can be

drawn until delivery is blocked and the machine must be cleaned.

) Call your customer service !

system data error!

An error has occured in the programming of product keys or in the general system

data. If in addition a product key is illuminated, it might be possible that you cannot

-button in order to continue working.

product-data error

use the same anymore. Press the

) Call your customer service !

select product

e of filter

chan

The installed water filter needs to be cleaned, refilled or replaced.

) Call your customer service !

select product

milk em

The message occurs when the optional milk monitoring is fitted and is released.

Dispensing of product possible when released

Dispensing of product not possible when blocked.

3.3.6 Chip card error messages

The following indications on the display inform you about operating errors with chip

cards:

*read error

remove card

The card has not been inserted correctly (see arrows) or is defective.

*wrong card

remove card

The Euroca-2 requires a different card type in the current menu.

A MONEY card has been inserted for the first time or the credit is 0.00.

The MONEY card is not logged in. A credit must be loaded onto the MONEY card

with the LOAD card, and/or must be logged in.

No accounting system is installed.

*write error

remove card

The data were not correctly stored on transmission from machine Î SAVE card.

The card was taken out of the card reader too soon. The data could not be

completely transmitted or they are defective.

Repeat the data save.

Product - T5 Error!

Press an

key...

The data were not correctly stored on transmission from SAVE card Î machine.

The card was taken out of the card reader too soon. The data could not be

completely transmitted or they are defective.

Repeat the data save Î

Press

-key, wait five seconds and repeat the data save.

ª

Page 3-8 BASSE-2-02.03

Page 29

Indicating- and operating elements

g up

pty

**data error

remove card

Either the structural integrity of the data on the card has been damaged by

removing the card from the card reader too soon or the card is new and needs to

be logged-on, released or charged up.

* wrong PIN-code

remove card

A wrong PIN-Code (Personal-Identification-Number) has been entered.

Process repetition.

no accounting

There is no accounting system installed.

3.4 Messages when the machine is operating

These messages will only be shown when the machine stands still - no beverages

are delivered. They do not block the delivery of the products.

.....

container full

Empty the ground container. It can only deliver 5 more coffees, afterwards the

machine will block.

.....

heatin

The temperature of a hot water boiler is more than 10° C below the regulated

temperature. Wait for choosing of he next product until the Euroca-2 is heated up.

.....

clean machine

Please start the cleaning process (see chapter 5.3).

credit x.xx

to less amount

Credit insufficient (too little credit).

select product

milk em

The milk container is empty ( option )

3.5 Operating modes

The SCHAERER Euroca-2 has three operating modes:

select product

12:00 22.01.1999

credit operation

12:00 22.01.1999

<< standby >>

If this information appears on the display, then your machine is ready for use, i.e.

by pressing the button the machine will make the corresponding product.

This information appears on the display if the machine is equipped with an internal

or external accounting system ?

The machine has been switched off, but is still connected to the main power

supply. If the Economy mode (energy saving program) has been released by the

technician during programming, then the heating will also be switched off!

ATTENTION: When re-operating the machine needs a short time to reach the

programmed operating temperature.

BASE-2-02.03 Page 3-9

Page 30

Indicating- and operating elements

Page 3-10 BASSE-2-02.03

Page 31

Installation and operation of the machine

4 INSTALLATION AND OPERATION OF THE MACHINE

4.1 First installation and operation

Your office coffee machine will be installed by one of our authorized Schaerer

representatives.

) It is important that after the basic adjustment of the machine and after every adjustment

done by you to save the news data on the SAVE DATA cards which is delivered with

every machine. Please keep the card ready for the technician at all times.

4.2 Installation (basic conditions)

The required feed connections are to be advanced to up to one meter (acc. to the

installation plans) to the place where the machine will be installed.

When installing / connecting the machine please pay attention to the technical data.

Please put the machine on a plane, massive basement, protected from heat, humidity

and steam (do not put the machine in commercial kitchens).

Please pay attention and respect to the local regulations regarding kitchens.

A minimum distance of 1 cm from the wall to the machine must be respected

(air circulation).

Plan and respect free spaces on the top and on the side for maintenance works.

Please pay attention and respect to the ambient temperatures.

At the option “grinding waste dropping” additional hole.

Buffet-, counter version

Option-frigo

BASE-2-02.04 Page 4-1

Page 32

Installation and operation of the machine

Page 4-2 BASE-2-02.04

Page 33

Local control

5. OPERATION

Sect. TEXT.............................................................................................................................Page

5.1. Introduction.................................................................................................................... 5-3

5.2. Daily operation............................................................................................................... 5-3

5.2.1. Set up operational readiness........................................................................................... 5-3

5.2.2. Prepare coffee products ..................................................................................................5-3

5.2.2.1. Prepare coffee products by the second level .................................................................. 5-4

5.2.3. Caffeine-free coffee ....................................................................................................... 5-4

5.2.3.1. Prepare caffeine-free coffee manually............................................................................. 5-4

5.2.3.2. Caffeine-free coffee via grinder and DECAF key ............................................................ 5-5

5.2.3.3. Caffeine-free coffee via grinder without DECAF key....................................................... 5-5

5.2.4. Prepare tea ...................................................................................................................... 5-5

5.2.5. Heat up drinks..................................................................................................................5-6

5.2.6. Prepare hot milk ( with Frigo option )...............................................................................5-7

5.2.7. Prepare milk foam ( with Frigo option )............................................................................5-7

5.2.8. Automatically prepare Cappuccino Magic, milky coffee or latté ( with Frigo option )...... 5-8

5.2.9. Manually prepare Cappuccino Magic and hot milk with a CPT ( option )........................ 5-8

5.2.10. Prepare Cappuccino with Cappuccinatore CPT ( option ) ..............................................5-9

5.3. Daily cleaning...............................................................................................................5-10

5.3.1. Clean coffee machine.................................................................................................... 5-10

5.3.2. Cleaning instructions for Cappuccinatore CPT ( option ).............................................. 5-18

5.4. Ending use / Switch off unit........................................................................................ 5-19

5.5. Operating advice..........................................................................................................5-19

5.5.1. Fill up fresh water tank...................................................................................................5-19

5.5.2. Empty waste water tank.................................................................................................5-19

5.5.3. Operating advice for units with fresh and waste water tank (on mobile trolley)............5-20

5.6. Programming with standard chip cards....................................................................5-20

5.6.1. CHEF card ..................................................................................................................... 5-21

5.6.1.2. Menu overview...............................................................................................................5-21

5.6.1.2. Read off product counters for coffee and tea by key.....................................................5-21

5.6.1.3. Reset product counter to zero ....................................................................................... 5-21

5.6.1.4. Change grinding quantity (coffee powder )....................................................................5-22

5.6.1.5. Change filling quantity water and / or milk to coffee products..................................... 5-22

5.6.1.6. Change metering time steam, hot milk and / or milk foam ..........................................5-23

5.6.1.7. Change switching on and off times................................................................................5-23

5.6.1.8. Change time...................................................................................................................5-24

5.6.1.9. Change date .................................................................................................................. 5-24

5.6.1.10 Change PIN code........................................................................................................... 5-25

5.6.2. SAVE DATA card...........................................................................................................5-25

5.6.2.1. Menu overview...............................................................................................................5-25

5.6.2.2. Store machine data on card........................................................................................... 5.26

5.6.2.3. Load machine data from card to machine ..................................................................... 5-26

BASE-2-02.05 Page 5-1

Page 34

Local control

5.7. Programming with option chip cards........................................................................ 5-27

5.7.1. PROGRAM card ............................................................................................................5-27

5.7.1.1. Menu overview...............................................................................................................5-27

5.7.1.2. Programmable security level ......................................................................................... 5-27

5.7.1.3. Release and block accounting operation....................................................................... 5-28

5.7.1.4. Price switching............................................................................................................... 5-28

5.7.1.5. MONEY card price level 1+2 ......................................................................................... 2-29

5.7.1.6. Change jeton price, with or without MONEY card price level 1+2.................................5-29

5.7.1.7. Change product price and article no. ( for external accounting system CCI / CSI )......5-30

5.7.1.8. Display MONEY sales.................................................................................................... 5-31

5.7.1.9. Delete MONEY sales..................................................................................................... 5-31

5.7.1.10. Display MASTER card...................................................................................................5-31

5.7.1.11. Delete MASTER card..................................................................................................... 5-31

5.7.1.12. Log in MASTER card..................................................................................................... 5-32

5.7.1.13. Delete MASTER table....................................................................................................5-32

5.7.1.14. Change PIN code........................................................................................................... 5-33

5.7.2. KEY BLOCK card........................................................................................................... 5-33

5.7.2.1. Menu overview...............................................................................................................5-33

5.7.2.2. Block key........................................................................................................................5-33

5.7.2.3. Release key ................................................................................................................... 5-34

5.7.3. COFFEE TEST card...................................................................................................... 5-34

5.7.3.1. Menu overview...............................................................................................................5-34

5.7.3.2. Grinding quantity test programme ................................................................................. 5-34

Page 5-2 BASE-2-02.05

Page 35

Local control

g up

5.1 Introduction

The indications in this chapter will help you to get acquainted with the basic functions of

your machine. They are the basic conditions for a simple daily use without any

difficulties.

A correct installation by the authorized Schaerer representative is the basic condition for

a proper functionning of the Euroca-2.

CAUTION : Improper use can result in scalding!

5.2 Daily use

Preparation / to put the machine in operation

5.2.1

1. Before switching on the machine make sure that :

- the machine is connected to the main power supply

- the water connection is open

- the beans container is filled up

- the bean container is empty

- on the display (not illuminated yet) appears :

<<stand by>>

12.00 22.01.1999

Preparation of beverages

5.2.2

2. Push button

The following indication appears on the display:

selection locked

heatin

For machines with fresh water tank, see chapter 5.5.

Depending on the programming of your machine, especially when operated with an

active accounting system, a different information appears on the display when the

machine is in the basic operation mode.

When the cleaning program has been used before turning off the machine, a rinsing

program will follow right after putting the machine in operation again. Afterwards, only if

programmed, a „blind coffee“ will be delivered.

By active key-switch function, the CHEF-card must be inserted into the card reader for

switching on.

If your machine has been installed and logged-on to an accounting system, please read

the instructions in chapter 6.0.

Coffee and hot water are simultaneously ready for drawing.

By pressing the key, preselected products are deleted ( only if no accounting is active ).

If the

interrupted (Coffeeproducts can producted only draving brewphase).

1. Put the cup underneath the outlet. ( The delivery height can be adapted to the cup)

2. Press the desired product key.

3. The key you have selected lights up green. The following message appears on the

display:

key is pressed for more than two seconds, then all active products are

-> All keys are illuminated for a short period.

as soon as the machine

has the right temperature:

select product

12:00 22.01.1999

ª

BASE-2-02.05 Page 5-3

Page 36

Local control

pply

p

pply

4. The whole production process is now being done completely automatically.

Depending on your machine’s program :

- The product keys can be repressed as often as you wish - the same goes for pre-

- Other texts are possible in the display messages ( malfunction message ).

Push button

select product

choise 1 su

selection or mixed operation.

cancel preselected products when the machine is operated with an accounting system.

1

-and the preselection or mixed operation may be blocked. You cannot

CAUTION : Improper use can result in scalding!

5.2.2.1 Prepare coffee products by the second level

If the second level is installed on the Euroca-2 and is released, the product keys can be

selected for two different products

Level 1: Normal application. See Section 5.2.2.

Level 2: As follows

1. Place cup under coffee delivery spout ( The spout height can be adapted to the cup).

2.

3. Press required product key.

4. The LED of the selected key lights up red and in the display appears:

5. The coffee is freshly prepared automatically and is delivered.

Depending on the programming:

- the keys can be optionally repeated and can be selected for mixing.

- other texts are possible in the display messages ( malfunction message ).

Coffee and hot water are simultaneously ready for drawing.

By pressing the

If the

= Press shift key.

select product

choise 1 su

key is pressed for more than two seconds, then all active products are

interrupted (Coffeeproducts can producted only draving brewphase).

1

key preselected products are deleted (only if no accounting is active).

CAUTION : with improper operation there is a danger of scalding.

5.2.3. Caffeine-free coffee

5.2.3.1. Prepare caffeine-free coffee manually

The Euroca-2 has to be manually prepared for caffeine-free, released ex works or by the

service technician.

1. Place cup under the coffee delivery spout. ( The spout height can be adapted to the cup.

2. Press

3. Press the relevant programmed coffee product key:

On the display appears:

ª

Page 5-4 BASE-2-02.05

key.

select product

coffee

owder

Page 37

Local control

g

p

pply

4. Fill coffee powder into the charging hopper.

5. Press the red blinking key.

6. The coffee is prepared and delivered.

Always only use ground coffee.

CAUTION: with improper operation there is a danger of scalding.

5.2.3.2. Coffeine-free coffee via grinder and DECAF key

The Euroca-2 has to be prepared for caffeine-free by means of the grinder, released ex

works or by the service technician.

1. Place cup under the coffee delivery spout ( The spout height can be adapted to the cup).

2. Press

3. Press the relevant programmed coffee product key:

On the display appears:

key.

select product

coffee

owder

By using the key the caffeine-free coffee is drawn and ground by the right- or left-

Note :

hand coffee grinder. In this way caffeine-free and caffeine-containing coffee can be

drawn via the same keys, but via two different grinders.

CAUTION : with improper operation there is a danger of scalding.

5.2.3.3. Caffeine-free coffee via grinder without DECAF key

1. Place cup under the coffee delivery spout. ( The spout height can be adapted to the cup. )

2. Press the relevant programmed caffeine-free coffee product key:

On the display appears:

Note :

The caffeine-free beans coffee is automatically drawn and ground by the right-hand

select product

choise 1 su

coffee grinder.

It should be noted that in this type of programming the caffeine-free products require the

allocation of a separate product key.

1

CAUTION : with improper operation there is a danger of scalding.

5.2.4.

ª

Preparation of tea

1. Put the tea cup underneath the hot water outlet.

2. Push the

3. The hot water is now delivered. If the programmed temperature is not yet reached,

Coffee and tea can be drawn simultaneously.

-button. The following message appears on the display:

select product

12.00 22.01.1999

appears on the display:

select product

heatin

tea

BASE-2-02.05 Page 5-5

Page 38

Local control

By pushing the

Start / Stop-operation is released.

Hot water can not be preselected.

When the Euroca-2 is switched on and is heating up, a selection of hot water is locked.

CAUTION : Improper use can result in scalding!

5.2.5. Heating up of beverages

1. Push the

2. Plunge the steam tube into the filled cup (down to the bottom).

3. Push the

At the same time the steam flows out.

4. The beverage is heated by lifting and lowering the cup (the deeper the sound, the higher

5. Repeat step 3 and 4 until the required temperature is reached.

6. Put the cup aside.

7. Clean the steam tube with a wet towel.

8. Push

By pushing the

The steam tube has to be plunged in the liquid during the outcome.

When the liquid has reached the boiling point, it may start to splash.

If you purchase steam and the machine is working with an accounting system, right after

The steam can not be preselected.

When the Euroca-2 is switched on and is heating up, a selection of steamproducts is

select product

the temperature). The delivery of steam will automatically stop, after the programmed

time has been reached.

Start / Stop-operation has been released.

the purchase you can push the cleaning key then a short steam output is released to

clean the steam tube.

locked.

-key again, the outcome of the water will be finished, as long as the

-key twice shortly, in order to remove the condensed water out of the lines

-key again

-key twice again (= steam tube is now cleaned).

-key again, the steam delivery can be stopped in advance, if the

CAUTION : Improper use can result in scalding!

Page 5-6 BASE-2-02.05

Page 39

Local control

5.2.6. Prepare hot milk ( with Frigo option )

Option :

1. Place an empty cup under the delivery spout.

2. Select the key for milk

select product

12:00 22.01.1999

3. The product is delivered.

By repeated pressing of the key the drawing of milk can be prematurely ended, providing

Start / Stop operation has been released.

Hot milk can not

The milk in the Frigo (refrigerator) has to be kept at a temperature of 3°-5° . If the

milk is not kept at those temperature, a first class appearance of milk foam will

not be guaranteed.

5.2.7. Prepare milk foam ( with Frigo option)

Option :

1. Place a cup or other vessel under the delivery spout.

2. Select the key for milk foam.

select product

12:00 22.01.1999

3. The product is delivered.

By repeated pressing of the key the drawing of milk foam can be prematurely ended,

providing Start / Stop operation has been released.

Milk foam can not

The milk in the Frigo (refrigerator) has to be kept at a temperature of 3°-5° . If the

milk is not kept at those temperature, a first class appearance of milk foam will

not be guaranteed.

be preselected.

be preselected.

BASE-2-02.05 Page 5-7

Page 40

Local control

p

ply

5.2.8. Automatically prepare Cappuccino Magic, milky coffee or latté ( with Frigo option )

Option :

If an accounting system is installed on the Euroca-2 and is released, please read the

instructions in Section 6.0.

Coffee and hot water are simultaneously ready for drawing.

By pressing the

If the

(coffeeproducts can produced only during brewphase).

1. Place cup under the coffee delivery spout ( The spout height can be adapted to the cup ).

2. Press required product key.

3. The LED of the required key lights up red and in the display appears :

4. The product is freshly prepared automatically and is delivered.

Depending on the programming:

- The keys can be optionally repeated and can be preselected for mixing.

-

With the key preselected products can be cancelled.

A cancellation of the preselected products is not possible when in accounting operation.

The milk in the Frigo (refrigerator) has to be kept at a temperature of 3°-5° . If the

milk is not kept at those temperature, a first class appearance of milk foam will

not be guaranteed.

key is pressed for more than two seconds, all active products are interrupted

select product

choice 1 su

Other texts are possible in the display messages ( malfunction message ).

key preselected products are deleted (only if no accounting is active).

1

CAUTION : with improper operation there is a danger of scalding.

5.2.9. Preparation of Cappuccino and hot milk with a CPT ( Option )

Option :

1. Press the

possible when Start / Stop operation is released).

2. Put the milk inlet plastic pipe into the milk box.

3. Put the cup underneath the Cappuccino-Magic.

4. Press

The milk will be delivered.

By pressing the

The froth of the milk can be regulated by the air screw (Pull it out to have more froth,

The difference in height between milk box and cup should not be higher than 40 cm.

The temperature of the milk should not be more than the ambient temperature. Milk that

It doesn’t matter, which one of the products is released first. The only difference is the

If you purchase Cappuccino-Magic and the machine is working with an accounting

When „Magic“ is programmed accordingly, then a purchase of coffee an milk

More detailed information regarding the handling of the Cappuccino-Magic, are shown in

The milk in the Frigo (refrigerator) has to be kept at a temperature of 3°-5° . If the

select product

Start / Stop operation is released.

push it then you have less froth).

has already been heated up and the last consumation date has passed can not be used

for Cappuccino anymore.

the colour of the froth.

system, right after the purchase you can push the cleaning key then a short steam

output is released to clean the steam tube.

simultaneously is possible.

a separate user manual.

milk is not kept at those temperature, a first class appearance of milk foam will

not be guaranteed.

-key twice, in order to release the condensed water out of the tube (only

-key again:

-key again, it is possible to stop the delivery manually, only when

CAUTION : Improper use can result in scalding!

Page 5-8 BASE-2-02.05

Page 41

Local control

5.2.10. Preparing Cappuccino using the Cappuccinatore CPT

Description

Unit components:

1. O-ring seals ( 063111 )

2. Regulating screw

3. Suction hose

4. Cappuccinatore components

5. Steam nozzle (CPT connection)

6. O-ring ( 063112 )

Insert the suction hose (3) into the milk container. Completely close the temperature

regulating screw (2) by turning it clockwise as far as possible, then release one full turn.

Press the button to acurate the valve. If the Cappuccino is too hot, adjust the

temperature by turning the regulating screw slightly conunter-clockwise.

When the required Cappuccino quantity has been output, press the button to close the

valve.

Note:

The height differential between the milk pack and the Cappuccinatore should not be less

than 40 cm.

Milk which has passed ist use-by date or which has been previously heated, will not

foam correctly.

WARNING: Never reach under the delivery spout while a product is being output.

BASE-2-02.05 Page 5-9

Page 42

Local control

5.3. Daily cleaning

To achieve optimal quality of all drinks which are delivered, regular and thorough

cleaning of the Euroca-2 and the installed options is indispensable. Please observe the

safety regulations for the cleaning agent.

Intermediate rinsing:

Intermediate rinsing is available in normal and in accounting operation.

An intermediate rinsing can be executed as required.

1. Hold the

key pressed for 5 seconds ( Cleaning key ).

In the display appears:

2. Press

cleanings

Remove container

key briefly ( water quantity approx. 1 cup ).

rinsing

selection locked

select product

12:00 22.01.1999

Machine is ready for use again.

A servicetechnician may programming an automatical systemflush, a timley

regulary flush will (0-300 min) occur. No product selection is nesessary for this

activation. Six successive peep tones sound immediately before the automatic

rinsing is to be activated to give warning of the imminent automatic rinsing.

5.3.1. Clean coffee machine

The cleaning programme in the Euroca-2 includes manual and

automatic self-cleaning. Together they form a single working process.

Note : For the cleaning of the Euroca-2 without Frigo

points 1 to 12 and point 40 apply.

Options : The Frigo is an option of the Euroca-2.

1.

1. Press the knob of the delivery carriage and push upwards.

2.

2. Hold

key pressed for approx. five seconds, until in the display appears :

cleaning

remove container

Page 5-10 BASE-2-02.05

Page 43

Local control

g

g

g

g

g

3.

3. Draw out the grounds container within five seconds Î otherwise the machine

reverts to normal operational readiness:

The LEDs of the

cleaning

manual cleanin

and keys blink.

4.

4. Simultaneously with both hands ( safety regulation ) press the

and

- keys, until the brewing flask has run into the cleaning position.

!! Caution : Never reach into the machine in this phase Î Danger of accident !!

For safety reasons always use both hands (see illustration)!

5.

5. Clean the brewing cylinder, and especially the part behind the coffee grounds

skimmer, with a brush.

6.

6. Draw out the drip grating from the drip pan and clean.

7.

7. Wipe the coffee powder residues on the machine's shaft into the drip tray and

remove the dirt in the drip tray with a cloth.

With a fixed water drain Î Pour approx. 1 litre of water into the drip tray for

reflushing the line. Dry out the drip tray with a cloth and reinsert the drip grating.

cleaning

manual cleanin

cleaning

manual cleanin

cleaning

manual cleanin

CAUTION : If the Ambiente-2 is equipped with a waste-water tank then the waste-

water tank must be cleaned beforehand.

BASE-2-02.05 Page 5-11

cleaning

manual cleanin

Page 44

Local control

g

8.

9.

10.

11.

12.

8. Clean grounds container and insert again.

LED of the

keys blinks.

cleaning

insert tablet

9. Press the knob of the deliver carriage and push downwards.

cleaning

insert tablet

10. Drop a cleaning agent tablet authorised by the SCHAERER customer service into

the manual charging hopper.

cleaning

insert tablet

Wird eine mehrteilige Reinigungstablette verwendet,ist darauf zu achten das

der ganze Inhalt der Tablettenkapsel in den Trichtr geworfen wird.

11. Press

key briefly.

The automatic cleaning programme is started.

cleaning

selecion locked

Display message without Frigo

Hinweis : Press the

cleanin

cleaning

deterg. CPM

Display message with Frigo

key briefly in order to switch off the Euroca-2

automatically after the cleaning programme. The LED of the

lights up red. A further pressing of the

key deactivates the

key

automatic switching off.

Caution : The machine executes a rinsing cycle. Therefore under no

12.

circumstances place your hands under the coffee delivery spout during the selfcleaning programme as there is danger of scalding.

Without Frigo option move on to paragraph 40.

Page 5-12 BASE-2-02.05

Page 45

Local control

p

13.

13. Open the refrigerator door and draw out the milk container.

14.

14. Place a cleaning container with 4 litres of cold water and the cleaning agent

recommended by Schaerer into the Frigo. Use the water/cleaning agent mixing

ratio in accordance with the description on the packaging of the cleaning agent.

Immerse the two hoses into the cleaning agent.

Caution : You must use a separate cleaning container for the cleaning.

Under no circumstances may the milk container be used for the cleaning.

15.

15. Press

The automatic cleaning programme for the foamer head is started.

16.

key briefly.

Caution : The machine executes a rinsing cycle. Therefore under no

16.

circumstances place your hands under the coffee delivery spout during the selfcleaning programme as there is danger of scalding.

During the rinsing time the milk container can be cleaned with hot water and

rinsed with cold water. Do not use chemical cleaning agents or soap.

17.

17. When the automatic cleaning programme has ended, in the display appears :

Remove the cleaning container from the Frigo, thoroughly wash it out with warm

water and then replace it in the Frigo.

If a milklevelsensor is installed, the following mesage will appear on the display:

”Milk empty “. Besides the

BASE-2-02.05 Page 5-13

cleaning

lease rinse

button flashs.

Page 46

Local control

18.

19.

20.

21.

22.

18. Press

key briefly.

19. The automatic line rinsing from the Frigo to the foamer head is started.

20. Remove the cleaning container from the Frigo. Clean the hoses with a clean cloth.