Page 1

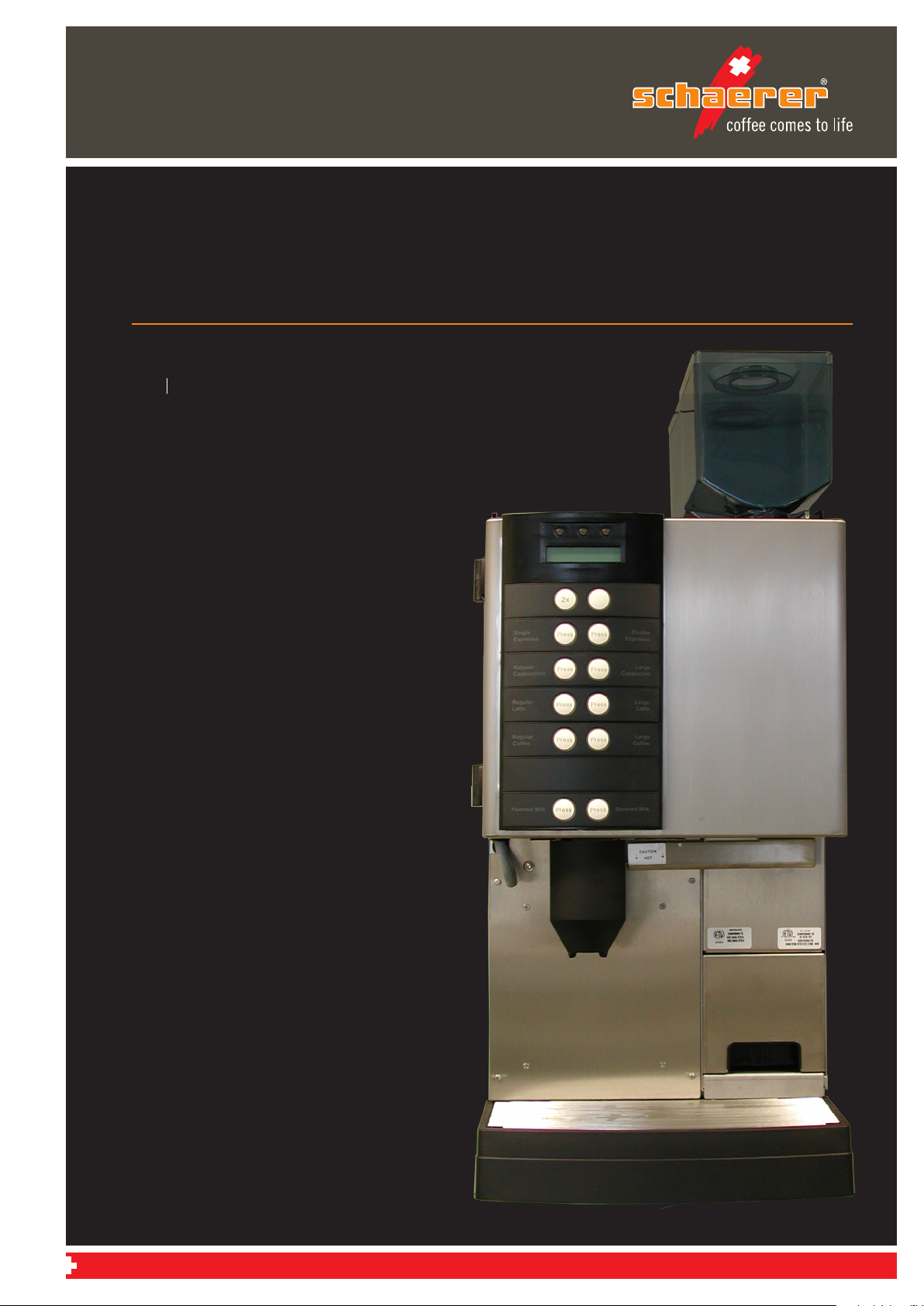

E6 Milk Unit

User Manual

V03 01.2008

SWISS MADE www.schaerer.com

Page 2

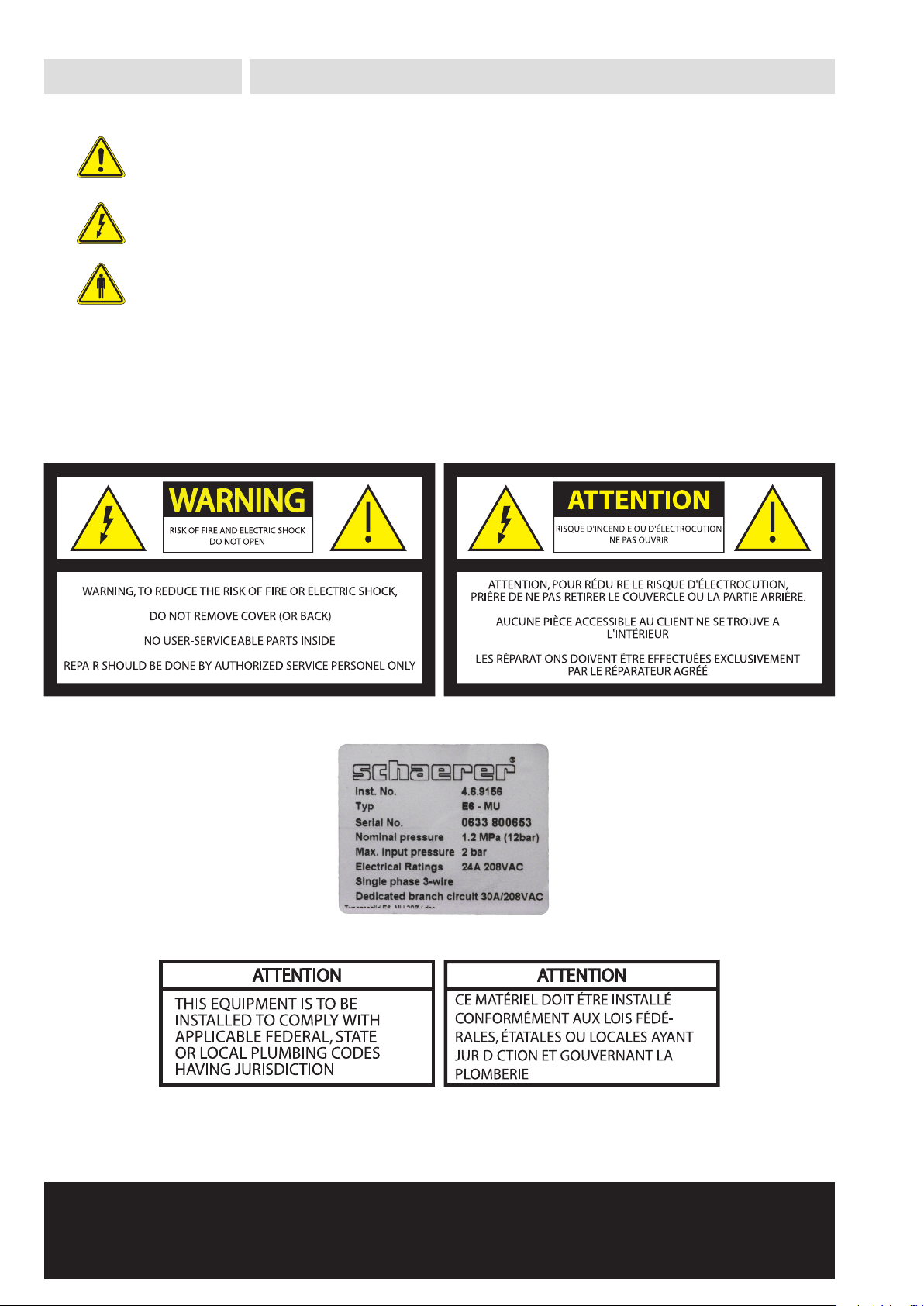

ADDITIONAL SAFETY INFORMATION

This Symbol requires special attention. It will inform you in detail on the safety instructions, commissioning, usage, operation, handling and programming of the E6Mu. It contains important safety instructions to ensure safe use and

operation.

This symbol indicates a risk of re and/or to life and health due to electric shock. Work on electric system must be carried out by authorized service personnel only. The supply voltage must comply with the information given on the machine’s serial plate. Never open the machine or expose its internal parts.

Read the safety notes on page 8 to 10 inside this User Manual.

Contact address USA: Contact address all other countries:

Schaerer USA Corporation M. Schaerer Ltd. BAMU - EN

2900 Orange Avenue, Suite 102 Gewerbestrasse 15

Signal Hill, CA 90755 3302 Moosseedorf

USA Switzerland

www.schaererusa.com www.schaerer.com Order number: 021700

Page 3

Introduction www.schaerer.com

www.schaerer.com

E6 Milk Unit

User Manual

V03 01.2008

Herausgeber:

M. Schaerer Ltd., CH-3302 Moosseedorf

Version:

Version 03

Software:

V 2.22

Designed an edited by:

M. Schaerer Ltd., CH-3302 Moosseedorf

© Copyright by:

M. Schaerer Ltd., CH-3302 Moosseedorf

01.2008

MIPA

The safety chapter (page 8) must be read before operating the coffee maker for the rst time!

All rights reserved, including translations into foreign languages. It is prohibited to copy, reproduce and distribute this document

or any excerpts thereof in any manner – including electronic means – without rst obtaining the publisher’s written consent. All of

the information, technical data, pictures and illustrations in this manual are based on the most current data available at the time of

printing. M. Schaerer Ltd. reserves the right to make changes at any time without issuing a separate notication. All pictures, illus-

trations and display messages in this manual serve only as examples. Due to a variety of possible options, your machine may differ

from the devices shown in this manual.

BAE6Mu - EN

Version 03 01.2008

3

3

Page 4

www.schaerer.com

4

BAE6Mu - EN

Version 03 01.2008

Introduction

CAUTION & WARNINGS

USE CAUTION WHILE OPERATING AND CLEANING THE E6Mu MACHINE!

WARNING:

TO PREVENT ELECTRICAL SHOCK, DO NOT REMOVE SIDE OR BACK PANELS FROM THIS MACHINE.

NO USER SERVICABLE PARTS INSIDE. REFER SERVICING TO AUTHORIZED SERVICE PERSONNEL ONLY.

WARNING:

IF WATER OR SMOKE IS COMING FROM INSIDE THE MACHINE, TURN OFF MACHINE IMMEDIATELY.

UNPLUG THE MACHINE, TURN OFF WATER SUPPLY, AND CONTACT AN AUTHORIZED SERVICE

AGENT.

WARNING:

DO NOT MOVE MACHINE WHILE IT IS STILL CONNECTED TO UTILITIES.

CAUTION:

ALL DISPENSED PRODUCTS ARE EXTREMELY HOT! USE CAUTION WHILE OPERATING ALL

FUNCTIONS. KEEP HANDS AWAY FROM FOAMER/COFFEE SPOUT/SPLITTER WHILE DISPENSING OR

CLEANING (EXTREMELY HOT).

CAUTION:

DO NOT PLACE HANDS INSIDE MACHINE WHILE OPERATING, EXCEPT WHEN FOLLOWING

CLEANING PROCEDURES.

CAUTION:

DO NOT TILT MACHINE TO EITHER SIDE (VERY HEAVY).

CAUTION:

DO NOT PLACE LIQUID CONTAINERS (SYRUPS, MILK, ETC.) ON TOP OF THIS EQUIPMENT.

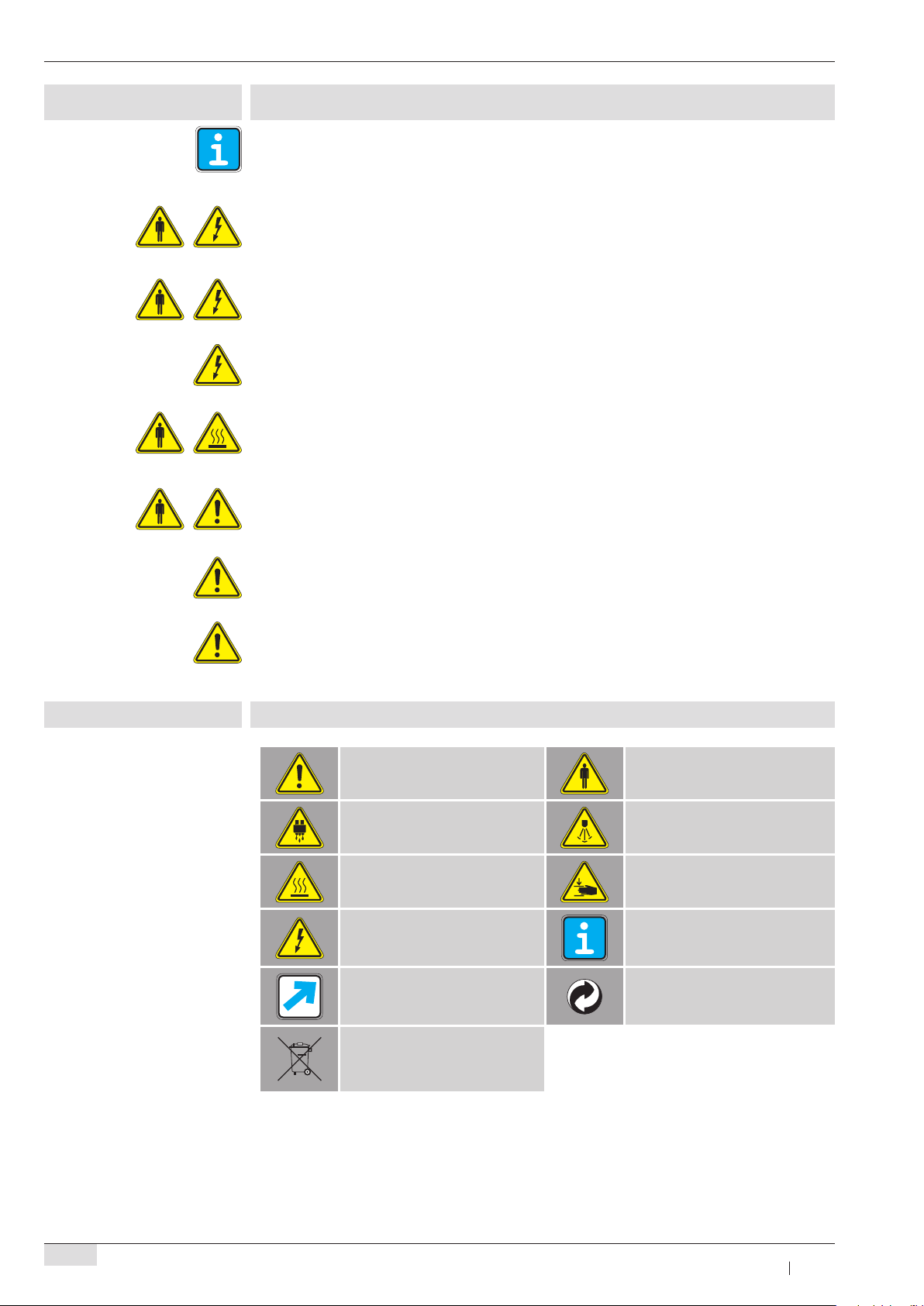

GENERAL SAFETY SYMBOLS AND PICTOGRAMS

CAUTION!

RISK OF DAMAGE TO MACHINE!

CAUTION!

HOT FLUID!

CAUTION!

HOT SURFACE!

CAUTION!

ELECTROCUTION!

CROSS-REFERENCE ENVIRONMENTAL ASPECTS

CAUTION!

USER AT RISK!

CAUTION!

HOT STEAM!

CAUTION!

RISK OF SQUEEZING!

REMARK

INFORMATION, TIPS

DISPOSAL!

THE MACHINE MUST BE

DISPOSED OF ACCORDING TO

REGULATIONS!

Page 5

www.schaerer.com

5

BAE6Mu - EN

Version 03 01.2008

Introduction

INTRODUCTION

WELCOME

With this new coffee machine, you have purchased a Swiss quality product especially designed

for the catering trade.

This manual will inform you in detail on the programming, commissioning, usage and cleaning of

your new machine. It also contains important safety instructions to ensure safe use.

Prior to commissioning the machine, carefully read the chapter "Safety notes". The manufacturer re-

jects any liability for damages that are caused by improper usage of the machine. Performance of the

coffee machine depends to a great extent on proper usage and careful maintenance of the machine.

We therefore recommend that you read all instructions carefully before commissioning the machine.

Keep the user manual at hand for future reference.

We trust you will enjoy using your new coffee machine!

Page 6

www.schaerer.com

6

BAE6Mu - EN

Version 03 01.2008

Introduction

TABLE OF CONTENTS

ADDITIONAL SAFETY INFORMATION ...................................................... 2

CAUTION & WARNINGS

GENERAL SAFETY SYMBOLS AND PICTOGRAMS ..............................................................4

............................................................................. 4

INTRODUCTION ............................................................................................. 5

WELCOME .............................................................................................................. 5

SAFETY NOTES ................................................................................................ 8

USER AT RISK ............................................................................................................8

RISK OF DAMAGE TO THE MACHINE ............................................................................. 9

HYGIENE ................................................................................................................. 9

INTENDED USE

LIABILITY

........................................................................................................ 10

................................................................................................................ 10

COMMISSIONING ......................................................................................11

INITIAL COMMISSIONING OF THE COFFEE MACHINE ...................................................... 11

SET-UP CONDITIONS ................................................................................................ 11

LOCATION ............................................................................................................ 11

INSTALLATION OF THE COFFEE MACHINE ..................................................................... 11

POWER SUPPLY ...................................................................................................... 12

WATER SUPPLY/DRAIN ............................................................................................. 12

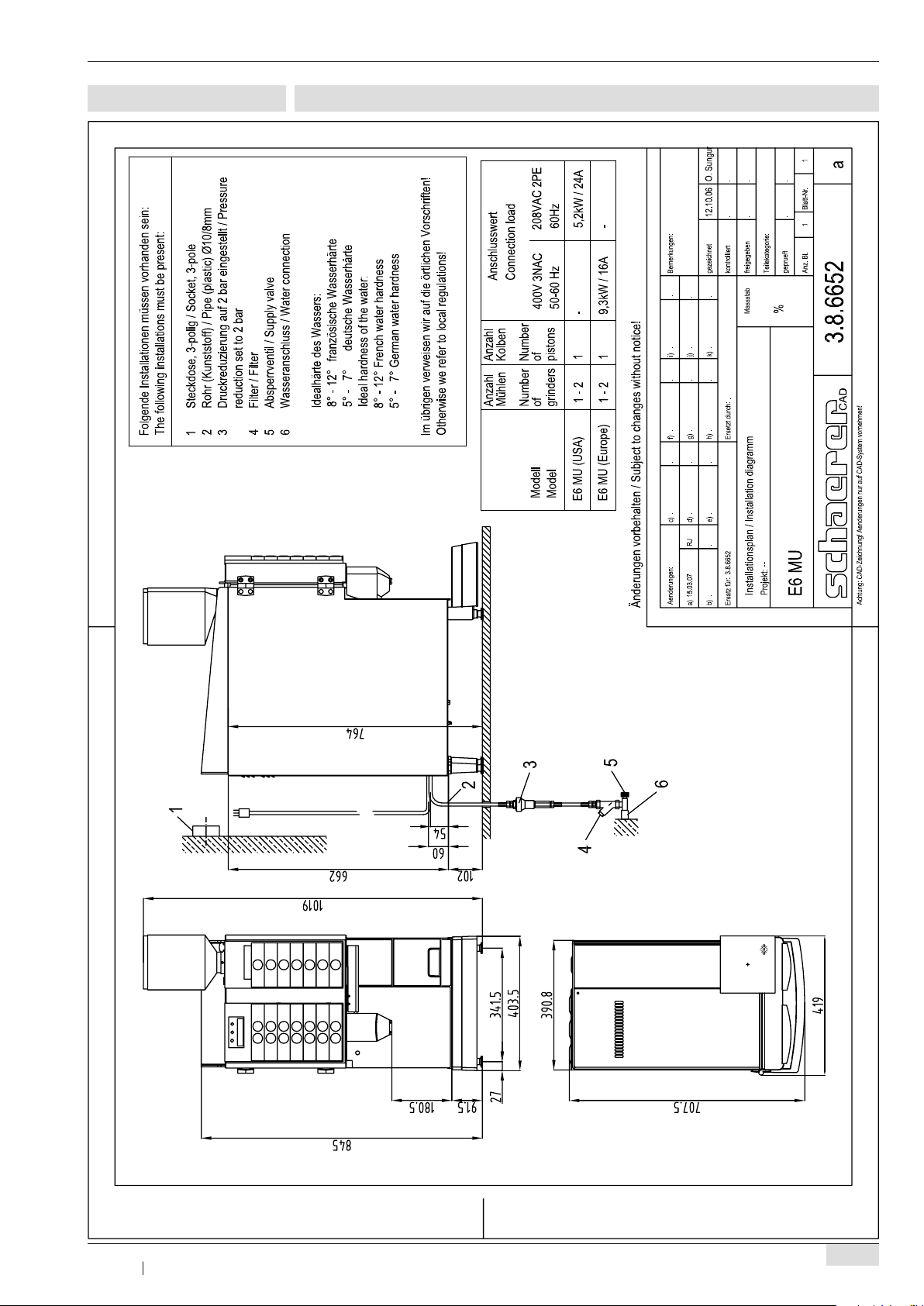

INSTALLATIONSPLAN E6MU ....................................................................................... 13

PRODUCT DESCRIPTION ........................................................................... 14

GENERAL INFORMATION FOR THE MACHINE ................................................................ 14

MACHNINE OVERVIEW ............................................................................................ 15

E6MU INSIDE VIEW

ACCESSORIES ........................................................................................................ 17

.................................................................................................. 16

OPERATION ..................................................................................................18

REFILLING COFFEE BEANS ......................................................................................... 18

MAKING THE COFFEE MACHINE READY FOR OPERATION ............................................... 18

OPERATION MODES ................................................................................................ 18

SWITCHING ON THE COFFEE MACHINE ....................................................................... 18

CHANGING MILK BAG............................................................................................. 19

CHANGING MILK GALLON ...................................................................................... 20

FILLING MILK CONTAINER ......................................................................................... 21

BUTTON OVERVIEW ................................................................................................. 22

DRINK PREPARATION (SHOWN WITH OPTIONAL BUTTON PANEL) ....................................... 22

PREPARING ESPRESSO ............................................................................................. 22

PREPARING LATTE ................................................................................................... 23

PREPARING CAPPUCCINO ....................................................................................... 23

PREPARING "DECAF" PRODUCTS ................................................................................ 24

PREPARING TWO PRODUCTS AT ONE TIME .................................................................. 24

PREPARING FOAMED MILK ....................................................................................... 25

PREPARING STEAMED MILK ....................................................................................... 25

TIPS DURING OPERATION ......................................................................................... 26

Page 7

www.schaerer.com

7

BAE6Mu - EN

Version 03 01.2008

Introduction

PROGRAMMING: CHEF CARD ...............................................................27

NAVIGATION IN PROGRAMMING-LEVEL ...................................................................... 27

OVERVIEW PROGRAMMING: CHEF CARD

READ OUT COUNTERS: DAILY COUNTERS

READ OUT COUNTERS: MACHINE COUNTER ................................................................. 29

READ OUT COUNTERS: SERVICE COUNTER ................................................................... 30

READ OUT COUNTERS: CLEANING STATISTICS ............................................................... 31

READ OUT COUNTERS: ERROR STATISTICS

PRODUCT BUTTONS: ALL PRODUCTS

PRODUCT BUTTONS: CAPPUCCINO ............................................................................ 33

PRODUCT BUTTONS: MACCHIATO .............................................................................. 35

PRODUCT BUTTONS: LATTE ........................................................................................ 37

PRODUCT BUTTONS: HOT MILK

PRODUCT BUTTONS: MILK FOAM

PRODUCT BUTTONS: STEAM ...................................................................................... 41

SYSTEM SETTINGS .................................................................................................... 42

.................................................................................. 39

................................................................................ 40

................................................................... 27

..................................................................... 28

.................................................................... 31

........................................................................... 32

CLEANING ...................................................................................................43

DAILY CLEANING E6MU WITH MILK BAG ...................................................................... 43

DAILY CLEANING E6MU WITH MILK GALLON ................................................................ 45

DAILY CLEANING E6MU WITH MILK CONTAINER ............................................................ 47

WEEKLY CLEANING ................................................................................................. 49

TROUBLESHOOTING ...................................................................................51

E6MU DISPLAY & ERROR MESSAGES ........................................................................... 51

HELP DESK PROCEDURE (USA ONLY) .......................................................................... 53

HOW TO CONTACT US (USA ONLY)

INFORMATION AND SUPPORT (ALL OTHER COUNTRIES) .................................................. 54

............................................................................ 53

APPENDIX .....................................................................................................55

DECLARATION OF CONFORMITY ............................................................................... 55

SERIAL PLATE ......................................................................................................... 55

CLEANING PRODUCTS ............................................................................................. 56

CLEANING TABLET SCHAERER (ART.-NO.: 065221).......................................................... 56

TECHNICAL DATA FOR COFFEE MACHINE ................................................................... 57

CONDITIONS FOR USE AND INSTALLATION ................................................................... 57

ENVIRONMENTAL ASPECTS ....................................................................................... 58

WATER QUALITY ..........................................................................................59

GENERAL .............................................................................................................. 59

PURITY OF WATER ................................................................................................... 59

WATER CHARACTERISTICS FOR SCHAERER COFFEE MACHINES ........................................ 59

CONVERSION TABLE ............................................................................................... 59

FILTER TECHNICS ..................................................................................................... 59

Page 8

www.schaerer.com

8

BAE6Mu - EN

Version 03 01.2008

Safety notes

SAFETY NOTES

USER AT RISK

Maximum safety is one of M. Schaerer AG’s most important product features. The effectiveness

of the safety devices is only ensured as long as the following is observed to prevent injuries or

health hazards:

► Read the User Manual carefully before using the device!

► Do not touch any hot machine parts!

► Do not use the coffee maker if it is not functioning optimally or is damaged!

► Keep children away from the coffee maker!

► Under no circumstances may the installed safety devices be modied!

Health hazard!

Children as well as persons under the influence of drugs, alcohol or medication or with limited

physical, sensorial or mental abilities may not use the device unless they are supervised.

Health hazard!

Only place the appliance where it can be supervised by trained personnel.

Risk of scalding!

There is a risk of scalding in the area where coffee, hot water and steam are dispensed. Never

reach under the outlet while a beverage is being dispensed!

Risk of burns!

The brew unit may only be cleaned when the coffee maker is cold. The brew unit can become

hot.

Risk of squeezing!

There is risk of squeezing ngers or hands when handling moving components!

While the coffee maker is switched on, never reach into the bean containers or into the opening

of the brew unit.

Health hazard!

The bean containers and the manual slot may only be lled with the materials (coffee beans)

intended for use!

Health hazard!

When handling cleaning tablets and cleaning agents, follow the safety instructions on the packaging. Cleaning tablets and cleaning agents are irritants. Do not insert the cleaning tablet or

solution with cleaning agents until a request appears on the display asking you to do so.

Risk of irritation and burns!

Never reach under the outlets during a cleaning cycle or during beverage output! Cleaning fluid

and hot beverages come out of the combination outlet (Splitter) during cleaning cycles and

beverage outputs.

Caution, electrocution!

► Only skilled electricians may carry out work on electrical systems!

► The device must be connected to a secured circuit! (We recommend using an earth leakage

circuit breaker in the connection).

► All relevant guidelines on low voltage and/or country-specic or local safety regulations and

laws must be observed.

► The connection must be grounded according to regulations and safeguarded against elec-

trocution.

► The voltage must correspond to the data on the device’s serial plate.

► Never insert the power plug into the socket while it is wet or touch it with wet hands!

► Never touch energized parts!

► Before carrying out service work, always switch off the main switch and/or disconnect the

device from the power supply system.

► The power cord may only be replaced by a qualied service technician.

When choosing cleaning products, please pay attention to its environmental friendliness, health

risks, disposal requirements and any local options for proper disposal.

Page 9

www.schaerer.com

9

BAE6Mu - EN

Version 03 01.2008

Safety notes

RISK OF DAMAGE TO THE MACHINE

Please comply with the following instructions in order to prevent technical problems or damage

to the coffee maker:

► For water with a carbonate hardness of more than 5°dKH, a lime-scale lter should be con-

nected; otherwise the coffee maker could be damaged through limescale deposits.

► For insurance reasons, always make sure that the main tap for the water supply (coffee maker

with xed water connection) is closed after operating hours have ended and that the main

electrical switch has been switched off or the power cord has been pulled out.

► The device may not be operated if the water supply is blocked, since the boilers otherwise

cannot be relled and the pump runs "dry".

► To prevent water damage in the event of a ruptured hose, it is recommended to (structurally)

direct the water supply through a water stop valve.

► After extended down times (e.g. holidays), the coffee maker must be cleaned before it is

placed in operation again.

► Protect the coffee maker from weather conditions (frost, moisture, etc.).

► Malfunctions may only be rectied by a qualied service technician!

► Only use M. Schaerer Ltd. original spare parts!

► In devices with a refrigerator, the power supply must never be completely interrupted, or the

cooling function will not work.

► In the event of noticeable damage or leaks, notify a qualied service representative ap-

proved by the manufacturer and have faulty parts replaced and/or repaired!

► Never spray the device with water or any other fluid (e.g. steam cleaner)!

► Never immerse the device in water or in any other fluid!

► When using caramelized coffee (aromatized coffee), the brew unit must be cleaned at least

twice a day!

► If the coffee machine and/or auxiliary devices are transported at temperatures below 10°C,

the coffee machine and/or auxiliary devices must remain for 3 hours at room temperature

before it can be connected to a power supply and switched on. If this is not observed, there is

a risk of short circuits or damage to the electrical components as a result of condensation.

► Always use the new hoses supplied with the machine (fresh-/drain water hose)! Do not use old

fresh- and drain water hoses!

HYGIENE

Before using the coffee maker for the rst time, carry out the cleaning program

(refer to User Manual, chapter Cleaning).

Observe the general applicable hygiene regulations according to HACCP!

(HACCP= Hazard Analysis and Critical Control Point)

Coffee, milk and other contents:

► Do not use any raw milk! Only use pasteurized milk or UHT milk!

In all cases, the milk must be homogenized!

► Only use pre-refrigerated milk with a maximum temperature of 5 °C. If the milk is warmer than

5 °C, an optimal product cannot be dispensed.

► For hygienic reasons, it is recommended to use milk directly out of its original package.

► When using a milk container: Never top up milk; always clean the container thoroughly be-

fore relling it.

► Do not ll with more coffee or milk than is needed in a day.

► It is recommended to pour out remaining milk at the end of the day (if the milk was in contact

with the milk tube).

► Before opening milk packages, check them for damage.

► Store coffee and products in a dry, cool and dark place.

► Use the oldest products rst ("rst-in-rst-out" rule of thumb).

► Use the products before their expiry date.

► Always seal opened packages tightly so that their contents will remain fresh and are protect-

ed from dirt.

► Store coffee and products separately from cleaning products.

► Close the bean hopper lids immediately after adding beans!

Page 10

www.schaerer.com

Safety notes

Cleaning:

► Thoroughly wash and disinfect hands before cleaning the machine!

► Clean the machine daily once beverage output has been completed.

► For daily cleaning, follow the steps in the User Manual (chapter "Cleaning") and on the clean-

ing card.

► Never mix cleaning products!

► Never use abrasive substances or cleaning tools made of metal!

► Do not touch parts that come into contact with beverages (during output) after they have

been cleaned.

► Follow the dosage and safety instructions on the cleaning product! Information about clean-

ing products can be found in the User Manual, chapter "Appendix".

INTENDED USE

The intended use of the device and corresponding options is subject to the purpose agreed upon

in the contract and, if applicable, to any existing supplementary agreements, the "General terms

and conditions" of M. Schaerer Ltd. and this User Manual. In legal terms, any other use is not an in-

tended use. The manufacturer accepts no liability for damage resulting from unintended use.

LIABILITY

No responsibility will be taken for warranty or liability claims in the event of personal injury or

material damage as a result of one or more of the following causes:

► Improper use of the device;

► Improper installation, commissioning, operation and servicing of the device and its corre-

sponding options;

► Non-observance of maintenance intervals;

► Operation of the device with defective safety devices, non-functioning safety devices or im-

properly attached protective devices;

► Non-observance of safety notes in the User Manual with respect to storing, installing, commis-

sioning, operating and servicing the machine;

► Operation of the device in less than optimal condition;

► Improperly conducted repairs;

► Catastrophes due to the effects of a foreign body, accident or vandalism as well as acts of

God;

► Insertion of objects into the device as well as opening of the housing.

The manufacturer only accepts liability or honors warranty claims provided that all specied

maintenance and service intervals have been kept and that only original spare parts supplied

by the manufacturer or an approved authorized supplier have been used.

M. Schaerer AG must be notied in writing immediately of any material flaws.

The device must be serviced every 12 months or after 30'000 products have been dispensed.

Safety-relevant parts such as safety valves, safety thermostats, boilers, etc. must never be repaired under any circumstances. They must be replaced!

► Safety valves every 12 months

► Boiler (steam boiler, flow heater) every 60 months

10

BAE6Mu - EN

Version 03 01.2008

Page 11

Commissioning

www.schaerer.com

COMMISSIONING

INITIAL COMMISSIONING OF THE COFFEE MACHINE

The coffee machine must be installed and commissioned by a qualied technician.

If the coffee machine and/or auxiliary devices are transported at temperatures below 10°C, the

coffee machine and/or auxiliary devices must remain for 3 hours at room temperature before

it can be connected to a power supply and switched on. If this is not observed, there is a risk of

short circuits or damage to the electrical components as a result of condensation.

Always use the new hoses supplied with the machine (fresh-/drain water hose)!

SET-UP CONDITIONS

LOCATION

► Do not install the machine near an oven or any other heat source.

► Not suitable for outdoor use. Never expose the coffee machine to external conditions such

as rain, snow, frost, etc.

► Do not place the coffee machine on a surface cleaned with a hose.

► Only place the appliance where it can be supervised by trained personnel.

► The support surface for the unit must be stable and level and may not be deformed by the

weight of the coffee machine.

The location must comply with the following climatic conditions:

► Ambient temperature from 10°C to 35°C (50°F to 104°F)

► Relative humidity max. 80 % rF

The machine is designed exclusively for interior use!

Protect the coffee machine from frost. If the coffee machine has been exposed to

temperatures below freezing point, contact an authorised customer service representative

before starting the machine.

INSTALLATION OF THE COFFEE MACHINE

Installation of the coffee machine should be done under the following conditions:

► Install the supply lines as shown in the mains-side installation diagram to within one meter of

the place of installation.

► Conform to the technical data (see page 50).

► Provide and maintain sufcient clearance for maintenance work and operation:

- Above for lling coffee beans

- Keep approx. 35 cm clear on the right side

- A minimum of 15 cm between machine back panel to wall (air circulation)

► Comply with the respective local statutory regulations regarding catering / restaurant

premises.

The dimensions of the installed coffee machine are given in the corresponding installation plan

(see page 13).

BAE6Mu - EN

Version 03 01.2008

11

Page 12

www.schaerer.com

12

BAE6Mu - EN

Version 03 01.200

Commissioning

POWER SUPPLY

Model Power rating

E6Mu USA 5.5 kW / 2 x 30 A 60 Hz 208 V / 2N AC

E6Mu Europe 6.1 kW / 3 x 16 A 50/60 Hz 400 V / 3N AC

The device must be electrically connected according to all valid regulations (VDE 0100) as well as

national stipulations. The type of power cable must be at least H 07 RN-F. The voltage specied on

the serial plate must match the supply voltage at the installation location.

Electric shock!

An authorised specialist must install or inspect the installation!

► The phase must be protected with USA = 30 A / Europe = 16 A fuse.

► The machine must be fully disconnected from the power supply.

► Never operate the coffee machine if the mains cable is defective. A defective mains

cable or plug must immediately be replaced by a qualied service technician.

► Use extension cords only when you are sure that they are in perfect condition. The

extension cord must have a minimum cross section of 1.5 mm² for each core and a

permitted 5 pole plug (PNE) for 30 A / 16 A.

► Power cable and/or extension cords must be placed so that they pose no safety or health

hazard. Do not pinch the cords or pull them around sharp corners and over sharp edges;

do not let them hang exposed in the room. Do not place the cords on hot surfaces and

protect them from oil and harsh cleaning agents.

► Never lift or pull the appliance by the mains cable. Never pull the plug out of the socket

by gripping the mains cable or extension cord. Never touch cord and plug with wet hands.

Never insert a wet plug into the socket.

WATER SUPPLY/DRAIN

The water supply must be connected according to all valid regulations as well as national stipulations.

The machine must be connected as shown in the installation layout to a G 1/2“ drinking water

line (see page 13). If the machine is to be connected to a newly installed water line, the line

and the pressure hose must be properly rinsed to ensure that no dirt particles are fed into the

machine. If the machine is to be connected to a water drain, the supplied drainage hose

should be connected to the Drip Tray and the siphon and fastened securely. The hose should

point downwards so that water can easily flow out of the Drip Tray.

Always use the new hoses supplied with the machine (fresh-/drain water hose)!

The water must be free of contaminants and the chlorine content may not exceed 100 mg/l.

Do not use RO water (Reverse Osmosis) or any other type of aggressive water. The carbonate

hardness may not exceed 5 – 7°dH (German hardness) or 8 – 12°fH (French hardness) and the

total hardness must be always higher than the carbonate hardness. The minimal carbonate

hardness is 4°dH or 7°fH. The pH value must be between 6.5 and 7.

Water pressure:

Minimum: 1 bar

We recommend setting the decompression valve to 3 bar.

Feed water temperature:

Minimum: 10 °C

Maximum: 3 bar

Maximum: 30 °C

Page 13

www.schaerer.com

13

BAE6Mu - EN

Version 03 01.2008

Commissioning

INSTALLATIONSPLAN E6MU

Page 14

www.schaerer.com

14

BAE6Mu - EN

Version 03 01.2008

Product description

PRODUCT DESCRIPTION

GENERAL INFORMATION FOR THE MACHINE

Drip Tray Grill

Is removable for easy cleaning and access to the inside of the Drip Tray.

Drip Tray:

Is not connected to a xed drain line (optional). Check and empty regularly to prevent overflow.

Also, do not pour large amounts of liquid into the Drip Tray.

The Discharge Tube discharges a small amount of water into the Drip Tray after dispensing each

espresso shot.

Coffee Grounds Bin:

Holds the used grounds which are disposed after each espresso shot is brewed. The Bin slides

straight out from the machine and must be emptied periodically or when prompted by the Display

Screen.

Page 15

www.schaerer.com

15

BAE6Mu - EN

Version 03 01.2008

Product description

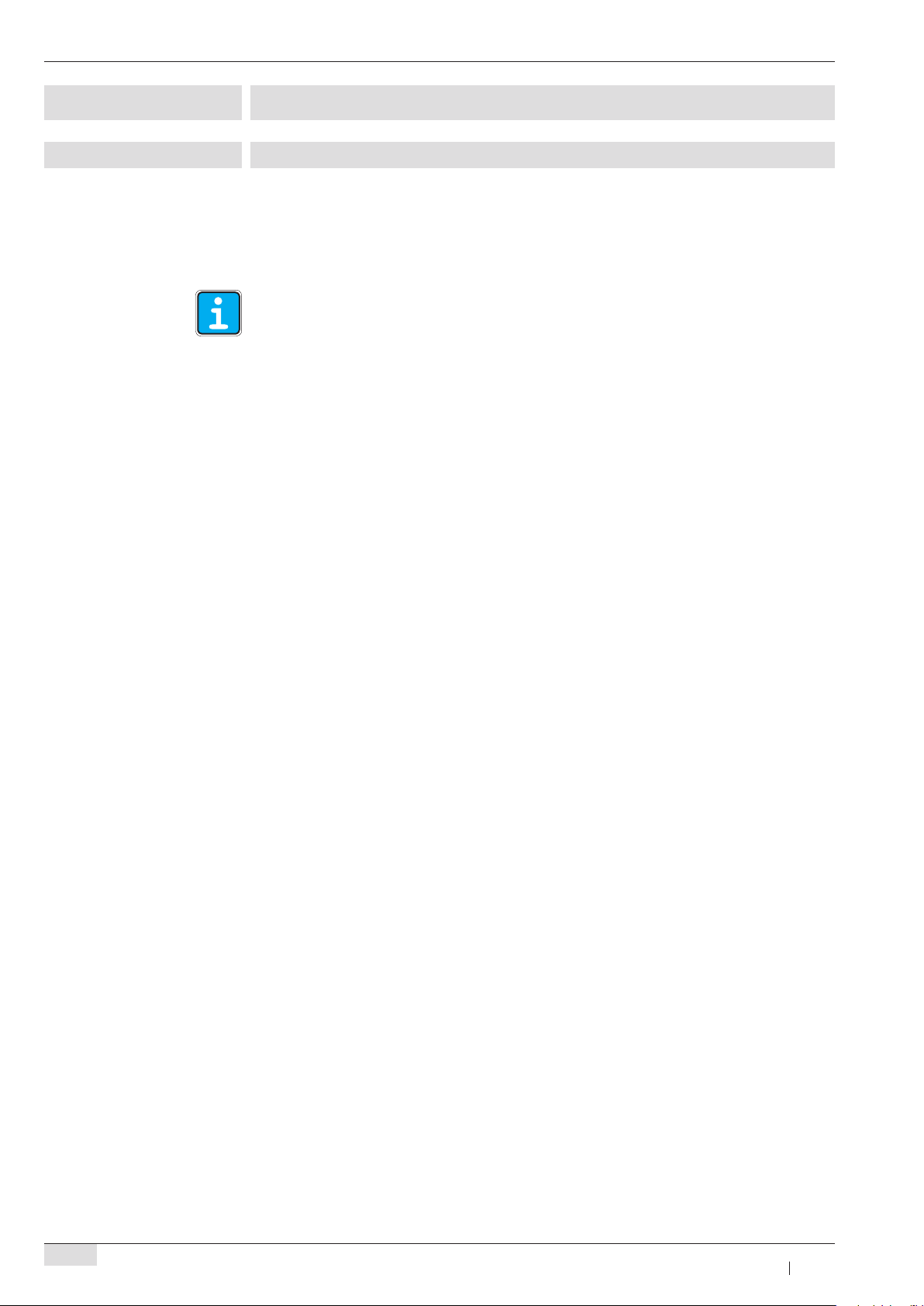

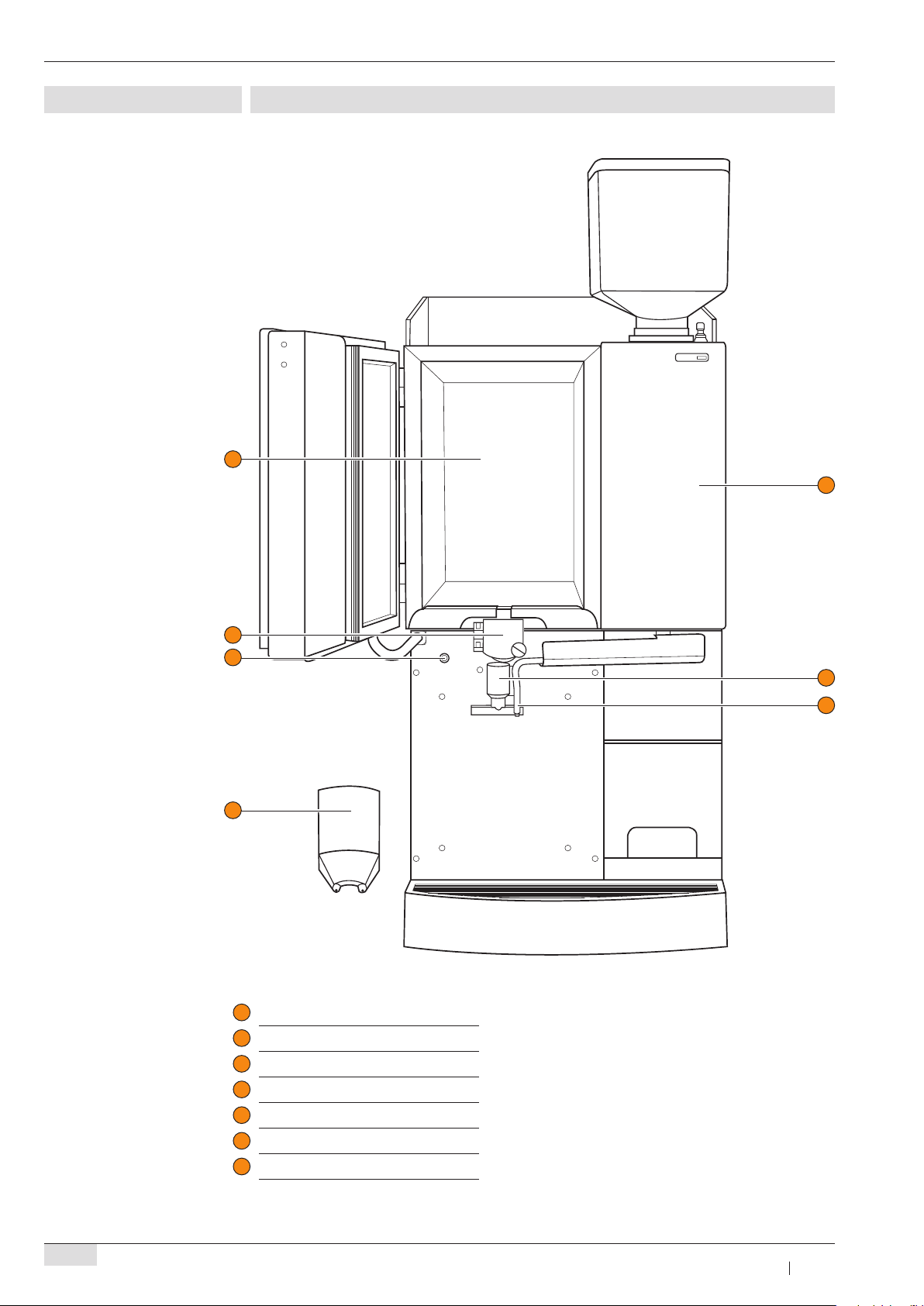

Front Bean Hopper /

1

Rear Bean Hopper for DECAF (unseen)

2

Slot for Cleaning Tablet (unseen)

3

Front Door

4

Button Panel (detail see below)

Coffee Spout (see page 16)

5

Foamer (see page 16)

6

Splitter

7

Trip Tray Grill

8

Trip Tray

9

10

Espresso Arm with Putlet

Coffee Grounds Bin

11

MACHNINE OVERVIEW

1

2

3

4

5

6

7

10

1

Cleaning Button / Minus Button

2

ON / OFF Button

3

STOP Button / Plus-Button

4

Display Screen

Programmable Product (with

5

label)

6

Optional second Button Panel

11

8

9

1 2 3

4

5

6

Page 16

www.schaerer.com

16

BAE6Mu - EN

Version 03 01.2008

Product description

E6MU INSIDE VIEW

1

7

2

3

6

Refrigerator Compartment

1

Pinch door for milk hose

2

Air adjustment knob

3

Coffee Spout

4

Foamer

5

Splitter

6

Espresso unit door

7

5

4

Page 17

www.schaerer.com

17

BAE6Mu - EN

Version 03 01.2008

Product description

ACCESSORIES

The Foamer and Hose should be replaced every day.

The Cleaning Brush is used to remove coffee grounds residue from the Brewing mechanism

behind the Front Door.

Schaerer Cleaning Tablets are used during the Daily Espresso Unit cleaning cycle

(see page 37 - 44). One Tablet is used per cycle.

The Splitter Cleaning Brush is used to remove residue from the dispensing points of the Splitter.

Page 18

www.schaerer.com

18

BAE6Mu - EN

Version 03 01.2008

Operation

OPERATION

Please refer to the Safety notes on page 8!

REFILLING COFFEE BEANS

The bean container may be lled with a maximum of 1000 grams of fresh coffee beans. Only

pour roasted coffee beans into the bean container(s)! Never reach with your hands into the

bean container(s) when the machine is switched on!

► Open the bean container lid.

► Fill with coffee beans (max. 1000 grams per bean container).

► Reclose lid to bean container.

A well closed cover prevents the loss of aroma.

MAKING THE COFFEE MACHINE READY FOR OPERATION

Prior to switching on the machine, check the following:

► The Fresh Water Supply is open.

► The Coffee Bean Hoppers are lled (see above).

► The Grounds Bin is empty.

► The coffee machine is connected to the power supply.

► Check whether the Coffee Bean Slides are open.

<< Stand by >>

select product

select product

OPERATION MODES

The E6Mu has two (2) operating modes:

The machine is switched off, but is still plugged in and has AC power.

The Display will be slightly darkened. The Refrigerator will stay ON during "Stand by" mode.

The machine is ready for normal operation.

The Display will be illuminated.

SWITCHING ON THE COFFEE MACHINE

Switch on the coffee machine by pressing the [ON/OFF] button.

A product selection can be made when the message "select product" appears on the Display.

Page 19

www.schaerer.com

19

BAE6Mu - EN

Version 03 01.2008

Operation

CHANGING MILK BAG

1

► Open the Refrigerator door. ► Crimp (tight) the Milk Hose.

4

► Turn the Pinch door knob

counter clockwise to open the

pinch door.

2

5

► Pull out the Foamer. ► Remove the Milk Hose from

3

1

2

► Remove Splitter by carefully tilt-

ing up 1 and pulling down 2 .

► Clean Splitter under warm, run-

ning water.

6

Foamer.

7

► Pull out the metal drawer from

the Refrigerator.

► Remove and discard the emp-

ty Milk Bag.

► Keep the crimper for the new

Milk Bag.

10

► Place the new Milk Bag on a

flat surface (see picture).

► Place the crimper on the Milk

Hose (as close to base as possible).

11

98

► Place the new Milk Bag (hose

facing downward) into the

milk drawer.

► Feed Milk Hose through the

drawer opening.

12

► Re-insert the Milk Drawer into

the Refrigerator.

► Align scissors with the top noz-

zle and cut the Milk Hose while

holding it taut.

► Re-attach Milk Hose on the

Foamer.

► Place the Foamer back onto

the nozzles.

Page 20

www.schaerer.com

20

BAE6Mu - EN

Version 03 01.2008

Operation

BAD

GOOD

13

14

1

2

► Release the crimper.► Close pinch door. ► Replace Splitter by pushing

15

up (onto the screws) 1 and

droping down 2 to rest on the

mounting ledge.

► Close the Refrigerator door.

CHANGING MILK GALLON

1

32

► Open the refrigerator door. ► Remove the cap with milk

4

► Close the refrigerator door

hose from the milk gallon.

► Discard the empty milk gallon.

5

► Press and hold the Latte or

Cappuccino button for 2 seconds to prime the line.

► Place a new milk gallon inside

the refrigerator.

► Place the milk hose into the

new milk gallon.

Page 21

www.schaerer.com

21

BAE6Mu - EN

Version 03 01.2008

Operation

FILLING MILK CONTAINER

1

► Open the Rrefrigerator door ► Crimp the Milk Hose.

4

► Turn the Pinch door knob

counter clockwise to open the

pinch door.

2

1

2

► Remove Splitter by carefully

tilting up

.

2

► Clean Splitter under warm,

running water.

and pulling down

1

5

► Pull out the Foamer.

3

4

► Pull out the Milk Container.

► Rinse and clean the Milk Con-

tainer under warm, running

water.

4

► Place the Milk Container back

in.

► Turn the Pinch door knob

clockwise to close the pinch

door.

► Uncrimp the Milk Hose.

► Fill the Milk Container with fresh

Milk.

6

1

2

► Replace Splitter by pushing

up (onto the screws) 1 and

droping down 2 to rest on the

mounting ledge.

► Close the Milk Unit door.

Page 22

www.schaerer.com

22

BAE6Mu - EN

Version 03 01.2008

Operation

BUTTON OVERVIEW

SINGLE CUP SYMBOL:

Buttons with this symbol are used to make drinks one at a time.

DOUBLE CUP SYMBOL:

Buttons with this symbol are used to make drinks two at a time.

DECAF SYMBOL:

Selecting the DECAF Button before selecting espresso size will make DECAF drinks.

Depending on machine programming the buttons can be assigned in a different order then

shown on the following pages (shown with Optional Button Panel).

DRINK PREPARATION (SHOWN WITH OPTIONAL BUTTON PANEL)

PREPARING ESPRESSO

Prepare single Espresso

Press "Single Espresso" Button

1

Attention!

Beverages are hot!

Keep hands away

from the outlets!

Example:

(at one time)

1

Page 23

www.schaerer.com

23

BAE6Mu - EN

Version 03 01.2008

Operation

PREPARING LATTE

Prepare Small Latte

Press "Small Latte" Button

1

Attention!

Beverages are hot!

Keep hands away

from the outlets!

Example:

(at one time)

1

Prepare Small Cappuccino

Press "Small Cappuccino"

1

Attention!

Beverages are hot!

Keep hands away

from the outlets!

Example:

(at one time)

Button

PREPARING CAPPUCCINO

1

Page 24

www.schaerer.com

24

BAE6Mu - EN

Version 03 01.2008

Operation

PREPARING "DECAF" PRODUCTS

(decoffeinated) coffee products

Press the "DECAF" Button

1

Make your Product selection

2

To prepare DECAF

proceed as follows.

Attention!

Beverages are hot!

Keep hands away

from the outlets!

1

2

To prepare two products at one

1

2

time proceed as follows:

Press "2x" Button

Make your Product selection

Attention!

Beverages are hot!

Keep hands away

from the outlets!

PREPARING TWO PRODUCTS AT ONE TIME

1

2

Page 25

www.schaerer.com

25

BAE6Mu - EN

Version 03 01.2008

Operation

PREPARING FOAMED MILK

Prepare Foamed Milk

Press and hold

1

"Foamed Milk" Button

Attention!

Beverages are hot!

Keep hands away

from the outlets!

Example:

1

Prepare Steamed Milk

Press and hold

1

"Steamed Milk" Button

Attention!

Beverages are hot!

Keep hands away

from the outlets!

Example:

PREPARING STEAMED MILK

1

Page 26

www.schaerer.com

Operation

TIPS DURING OPERATION

Periodically press the button once shortly to initiate a brief flush cycle to clean and sanitize

the Foamer. This is especially effective immediatly after peak dispensing hours.

Always start a rince cycle after replacing the Foamer!

Periodically rince the Splitter under warm, running water.

This should be done at least once a day.

Machines without drain:

The Drip Tray and Grill should removed and cleaned under warm, running water once a day.

Remember, the Drip Tray is not connected to a xed drain water connection so it can overflow

if not emptied! Make sure the Drip Grill is clean and free from milk residue.

Machines with drain:

The Drip Grill should removed and cleaned under warm, running water once a day.

The Drip Tray should rinsed with water once a day.

Make sure the Drip Grill is clean and free from milk residue.

Empty the Grounds Bin regularly and clean it under warm, running water when prompted by

the Display.

Periodically clean the machine exterior (don’t use abrasives!) with a clean and sanitized cloth

to remove residue from steamed Milk and Espresso shots.

26

When making two drinks at a time place two cups next to each other with the rims at the

center of the Splitter.

BAE6Mu - EN

Version 03 01.2008

Page 27

Programming

und

= =

PROGRAMMING: CHEF CARD

NAVIGATION IN PROGRAMMING-LEVEL

► Forward and backward in the menu, set parameters

► Access, conrm or continue through a menu

PT

► Product button

OVERVIEW PROGRAMMING: CHEF CARD

Menu selection:

www.schaerer.com

select product

12:00 01.01.2008

counter read out

product buttons

system parameters

► Insert CHEF card

Sub menus:

► Enter with the button

► see page 27 – 31

► Enter with the button

► see page 31 – 41

► Enter with the button

► see page 42

BAE6Mu - EN

Version 03 01.2008

27

Page 28

www.schaerer.com

28

BAE6Mu - EN

Version 03 01.2008

Programming

read out counters

daily counters

READ OUT COUNTERS: DAILY COUNTERS

► To access a menu, see „Programming overview: CHEF card”, page 27.

Range: Daily counters / Machine counter / Service counter / Cleaning statistics / Error satistics.

► Select counter using the

/ buttons / Show selected counter using the button

dispenced product (all)

XXX

+

coffee products

XXX

+

cappuccino / latte

XXX

+

hot milk / milk foam

XXX

+

decaf

XXX

+

double products (2x)

XXX

+

► All product purchases are displayed.

► Use the

► Coffee product purchases are displayed.

► Use the

► Cappuccino and coffee with milk product purchases are displayed.

► Use the

► Hot milk and foam product purchases are displayed.

► Use the

► Decaffeinated product purchases are displayed.

► Use the

► Double product purchases are displayed.

► Use the

button and after the / to erase the counter

button and after the / to erase the counter

button and after the / to erase the counter

button and after the / to erase the counter

button and after the / to erase the counter

button and after the / to erase the counter

steam products

XXX

clear daily counters

execute with 'ON'

daily counters

► Steam purchases are displayed.

+

► Use the

► Use the / to continue without erasing the daily counter

► Use the

button and after the / to erase the counter

button to erase the daily counter

Page 29

www.schaerer.com

29

BAE6Mu - EN

Version 03 01.2008

Programming

counter read out

machine counter

READ OUT COUNTERS: MACHINE COUNTER

► To access a menu, see „Programming overview: CHEF card”, page 27

Range: Daily counters / Machine counter / Service counter / Cleaning statistics / Error satistics.

► Select counter using the

/ buttons / Show selected counter using the button.

dispenced prod. (all)

XXX

coffee products

XXX

cappuccino / latte

XXX

hot milk / milk foam

XXX

decaf

XXX

double products (2x)

XXX

► All product purchases are displayed.

► Coffee product purchases are displayed.

► Cappuccino and coffee with milk product purchases are displayed

► Decaffeinated product purchases are displayed.

► Decaffeinated product purchases are displayed.

► Double product purchases are displayed.

steam products

XXX

cleaning cycle count.

XXX

rins cycle count

XXX

piston cycles

XXX

► Steam purchases are displayed.

► The number of cleaning cycles is displayed

► The number of rins cycles is displayed

► Pressing the desired product button shows all purchases.

Page 30

www.schaerer.com

30

BAE6Mu - EN

Version 03 01.2008

Programming

grind time (total)

XXX.X g.

► The grind quantity (of both grinders) is displayed.

runtime w-pump [h]

XX.X

water quantity

XX Liter

machine counter

read out counters

service counter

► The operating time of the water pump is displayed (in hours).

► The water volume is displayed.

READ OUT COUNTERS: SERVICE COUNTER

► To access a menu, see „Programming overview: CHEF card”, page 27.

Range: Daily counters / Machine counter / Service counter / Cleaning statistics / Error satistics.

► Select counter using the

/ buttons / Show selected counter using the button.

piston cycles

XXX

front grinder qty

XXX.X g.

rear grinder qty

XXX.X g.

runtime w-pump [h]

XXX

change lter after

XXX Liter

last lter change

01.11.2007

► Brew piston strokes are displayed.

► The grind quantity of the front grinder is displayed.

► The grind quantity of the rear grinder is displayed.

► Operating time of the water pump is displayed (in hours).

► Amount of litres until the next lter exchange are displayed.

► The last lter change is displayed.

Page 31

www.schaerer.com

31

BAE6Mu - EN

Version 03 01.2008

Programming

service after

service counter

counter read out

XXX Kaffee

► The next service has to be done after that amount of coffees.

last service

01.10.2007

► The last service is displayed.

READ OUT COUNTERS: CLEANING STATISTICS

► To access a menu, see „Programming overview: CHEF card”, page 27

cleaning statistics

cleaning 3/3

> 01.01.2008 15:07 <

cleaning 2/32

> 01.01.2008 17:55 <

cleaning 1/3

> 01.01.2008 12:00 <

cleaning statistics

Range: Daily counters / Machine counter / Service counter / Cleaning statistics / Error satistics.

► Select counter using the

All carried out cleaning cycles from the machine are displayed (including date and time / MUST

and IS status of the cleaning cycles).

► Use the

► Use the button to return to the menu

/ buttons to show all cleaning cycles

/ buttons / Show selected counter using the button.

READ OUT COUNTERS: ERROR STATISTICS

counter read out

error statistics

► To access a menu, see „Programming overview: CHEF card”, page 27

Range: Daily counters / Machine counter / Service counter / Cleaning statistics / Error satistics.

► Use the

/ buttons to show all errors / ► Use the button to return to the menu

Page 32

www.schaerer.com

32

BAE6Mu - EN

Version 03 01.2008

Programming

> 01.01.2008 08:00 <

Error 1

Error 2

> 01.01.2008 13:00 <

Error 3

> 01.01.2008 17:55 <

Error 10

> 01.01.2008 23:00 <

error statistics

product buttons

All errors registered on the machine are displayed (including date and time).

► Use the

► Use the

/ buttons to show all errors

button to return to the menu

PRODUCT BUTTONS: ALL PRODUCTS

► To access a menu, see „Programming overview: CHEF card”, page 27.

select product

> press button <

PT

select product type

coffee

double product

no

counted products

1

prod. preselection

no

select grinder

rear grinder

► Select the product for which the parameters are to be set.

► The product type can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

Range: Grinder rear / front + rear / Grinder front.

► Parameter can only be changed by a qualied service technician!

coffee grams

9.8 g.

Range: 4.0 – 16.0 g.

+

► Quantity of coffee powder (max.: 14.0 gr; depending on the type of grind)

Page 33

www.schaerer.com

33

BAE6Mu - EN

Version 03 01.2008

Programming

cycles per button

1

water quantity

230 ml

+

bypass water

0.0 s

+

base tamp. pressure

Stufe 3

pre-infusion

0 ml

Range: 1 – 9

► Parameter can only be changed by a qualied service technician!

Range: 10 – 600 ml

► Quantity of the coffee water.

Range: 0 – 3.0 s

► Quantity of coffee powder for double products.

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

chamber opening time

0 ms

Produktetasten

product buttons

select product

> press button <

PT

select product

Cappuccino

► Parameter can only be changed by a qualied service technician!

PRODUCT BUTTONS: CAPPUCCINO

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set.

► The product type can only be changed by a qualied service technician!

double produc

counted products

no

► Parameter can only be changed by a qualied service technician!

1

► Parameter can only be changed by a qualied service technician!

Page 34

www.schaerer.com

34

BAE6Mu - EN

Version 03 01.2008

Programming

dispensing sequence

milk and coffee

► Parameter can only be changed by a qualied service technician!

prod. preselection

no

select grinder

front grinder

coffee grams

9.0 g.

+

cycles per button

1

water quantity

40 ml

+

► Parameter can only be changed by a qualied service technician!

Range: Grinder front/ front + rear / Grinder rear.

► Parameter can only be changed by a qualied service technician!

Range: 6.0 – 16.0 g.

► Quantity of coffee powder (max.: 14.0 gr; depending on the type of grind).

Range: 1 – 9

► Parameter can only be changed by a qualied service technician!

Range: 10 – 600 ml

► Quantity of the coffee water.

bypass water

0.1 s

+

base tamp. pressure

level 5

pre-infusion

5 ml

delay pre-infusion

1.0 s

chamber opening time

0 ms

Range: 0 – 3.0 s

► Duration of bypass water

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

wet pressing

no

► Parameter can only be changed by a qualied service technician!

Page 35

www.schaerer.com

35

BAE6Mu - EN

Version 03 01.2008

Programming

milk dispensing time

14.5 s

+

delay time foam

0.0 s

foam ratio

50 %

+

delay time foam

0.0 s

product buttons

Range: 0 - 90.0 s

► Duration of the milk foam output.

► Parameter can only be changed by a qualied service technician!

Range: 0 – 100%

► The lower the pump speed the more hot the milk will be. Recommended value 50 – 55 % (re-

sults in an output temperature of ± 70 – 72 °C, when the milk in the fridge is ± 5 °C).

► Parameter can only be changed by a qualied service technician!

PRODUCT BUTTONS: MACCHIATO

product buttons

select product

> press button <

PT

select product

Latte Macchiato

double product

no

counted products

1

dispensing sequence

milk before coffee

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set.

► The product type can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

prod. preselection

yes

► Parameter can only be changed by a qualied service technician!

Page 36

www.schaerer.com

36

BAE6Mu - EN

Version 03 01.2008

Programming

milk dispensing time

15.0 s

delay time milk

1.0 s

Range: 0.0 – 90.0 Sekunden

+

► Duration of the milk foam output.

► Parameter can only be changed by a qualied service technician!

foam ratio

50 %

+

delay time foam

2.0 s

select grinder

rear grinder

coffee grams

8.0 g

+

cycles per button

1

Range: 0 – 100%

► The lower the pump speed the more hot the milk will be. Recommended value 50 – 55 % (re-

sults in an output temperature of ± 70 – 72 °C, when the milk in the fridge is ± 5 °C).

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

Range: 6.0 – 16.0 g

► Quantity of coffee powder (max.: 14.0 gr; depending on the type of grind)

► Parameter can only be changed by a qualied service technician!

Water quantity

40 ml

+

Bypasswater

0.0 s

+

base tamp. pressure

level 5

pre-infusion

0 ml

chamber opening time

0 ms

Range: 10 – 600 ml

► Quantity of the coffee water.

Range: 0.0 – 30.0 s

► Duration of the bypass water.

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

product buttons

Page 37

www.schaerer.com

37

BAE6Mu - EN

Version 03 01.2008

Programming

product buttons

select product

> press button <

PT

select product

double produc

PRODUCT BUTTONS: LATTE

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set.

Latte

► The product type can only be changed by a qualied service technician!

non

► Parameter can only be changed by a qualied service technician!

counted product1

dispensing sequence

milk and coffee

prod. preselection

no

select grinder

front grinder

coffee grams

9.0 g

+

cycles per button

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

Range: 6.0 – 16.0 g

► Quantity of coffee powder (max.: 14.0 gr; depending on the type of grind)

Water quantity

42 ml

Bypasswasser

0.0 s

► Parameter can only be changed by a qualied service technician!

Range: 10 – 600 ml

+

+

► Quantity of the coffee water.

Range: 0.0 – 30.0 s

► Duration of the bypass water.

Page 38

www.schaerer.com

38

BAE6Mu - EN

Version 03 01.2008

Introduction

base tamp. pressure

level 5

pre-infusion

5 ml

delay pre-infusion

1.0 s

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

chamber opening time

0 ms

wet pressing

non

milk dispensing time

12.5 s

+

delay time milk

0.0 s

foam ratio

20 %

+

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

Range: 0.0 – 90.0 seconds.

► Duration of milk foam output.

► Parameter can only be changed by a qualied service technician!

Range: 0 – 100%

► The lower the pump speed the more hot the milk will be. Recommended value 50 – 55 % (re-

sults in an output temperature of ± 70 – 72 °C, when the milk in the fridge is ± 5 °C).

delay time foam

product buttons

0.0 s

► Parameter can only be changed by a qualied service technician!

Page 39

www.schaerer.com

39

BAE6Mu - EN

Version 03 01.2008

Introduction

product buttons

select product

> press button <

PT

select product

double product

PRODUCT BUTTONS: HOT MILK

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set.

hot milk

► The product type can only be changed by a qualied service technician!

non

► Parameter can only be changed by a qualied service technician!

counted products

1

prod. preselection

no

Start / Stop

no

Press-/Hold

no

milk dispensing time

9.0 s

+

product buttons

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Product output can be stopped by pressing the product button again

► Parameter can only be changed by a qualied service technician!

Ranges: 0.0 – 90.0 seconds

► Duration of milk foam output.

Page 40

www.schaerer.com

40

BAE6Mu - EN

Version 03 01.2008

Introduction

product buttons

select product

> press button <

PT

select product

milk foam

double product

PRODUCT BUTTONS: MILK FOAM

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set.

► The product type can only be changed by a qualied service technician!

no

► Parameter can only be changed by a qualied service technician!

counted products

1

prod. preselection

non

start / stop

no

Press-/ Hold

no

milk dispensing time

9.0 s

+

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Product output can be stopped by pressing the product button again

► Parameter can only be changed by a qualied service technician!

Range: 0.0 – 90.0 seconds.

► Duration of milk foam output.

delay time milk

foam ratio

0.0 s

100%

► Parameter can only be changed by a qualied service technician!

Range: 0 – 100%

► The lower the pump speed the more hot the milk will be. Recommended value 50 – 55 % (re-

+

sults in an output temperature of ± 70 – 72 °C, when the milk in the fridge is ± 5 °C).

Page 41

www.schaerer.com

41

BAE6Mu - EN

Version 03 01.2008

Introduction

delay time foam

product buttons

product buttons

select product

> press button <

PT

0.0 s

► Parameter can only be changed by a qualied service technician!

PRODUCT BUTTONS: STEAM

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Select the product for which the parameters are to be set

select product

steam

counted products

1

start / stop

yes

dosing time

0.15 s

+

product buttons

► The product type can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Parameter can only be changed by a qualied service technician!

► Product output can be stopped by pressing the product button again

Ranges: 0.1 – 99.9 seconds

► Duration of the steam output

Page 42

www.schaerer.com

system settings

machine number

X.XX.XXX’XXX

Programming

SYSTEM SETTINGS

► To access a menu, see „Programming overview: CHEF card”, page 27.

► Parameter can only be changed by a qualied service technician!

machine number

X

language

englisch

+

adjust time

XX.XX

+

adjust date

XX.XX.XXXX

+

summer-/winter time

locked

+

system settings

► Parameter can only be changed by a qualied service technician!

Range: German / French / Englisch

► Use the

Range: HH:MM

►Use the

Range: TT.MM.JJJJ

► Use the

Range: deaktiviert / Europa (EU) / Nord-Amerika

► Use the

button and after the / to change display language

button and after the / to adjust time

button and after the / to adjust date

button and after the / to adjust summertime-/winter time

42

BAE6Mu - EN

Version 03 01.2008

Page 43

Cleaning

Contact address USA: Contact address all other countries:

Schaerer USA Corporation M. Schaerer Ltd. Cleaning instruction 12.2007 V03

2900 Orange Avenue, Suite 102 Gewerbestrasse 15 QRCMU MBd_EN

Signal Hill, CA 90755 3302 Moosseedorf

USA Switzerland

www.schaererusa.com www.schaerer.com Order number: 021705

Daily cleaning

E6Mu with milk bag

7

► Open front door.

► Remove splitter by carefully tilting up

and pulling down

► Clean splitter under warm, running wa-

ter.

► Remove milk hose

► Pull out used foamer

► Dispose used foamer (and milk bag if

empty).

10

For regular operators:

► Switch-ON machine.

► Open front door.

► Connect milk bag with hose to the new

foamer.

► Place new foamer onto the nozzles.

► Close pinch door.

13

BAD GOOD

Refer to the safety instructions and to the chapter cleaning in the user manual!

Never reach into the machine or under the beverage outlets during the automatic cleaning!

The status of the cleaning and some cleaning steps are shown on the display.

Discard the milk bag only when it‘s empty! During stand by mode the refrigerator is still cooling!

► Place large pitcher (volume: ± 1 liter) un-

der the splitter.

► Press the

button for ± 4 seconds.

The display shows:

31

► Remove grounds bin within 6 seconds

and clean it under warm, running water.

► Open front and espresso unit door.

► Clean brew group and brew area with

the brush.

► Replace grounds bin.

► Close espresso unit door and front door.

The display shows:

► Drop one tablet (as shown) into the fun-

nel.

64 5

► Press the button.

cleaning program

clean grounds bin

cleaning program

insert tablet

select product

12:00 01.12.2007

2

Attention! Hot fl uid!

Wait until the display shows:

► After the cleaning cycle is complete, re-

move and empty the pitcher.

If the grounds bin is not removed

within 6 seconds, the machine will

return to "select product" mode.

Cleaning program is running!

(duration: ± 4,5 minutes)

Machines without drain:

► Remove drip tray and grill.

► Clean parts under warm, running water.

► Replace drip tray and grill.

Machines with drain:

► Remove drip grill.

► Clean drip grill under warm, running

water.

► Replace drip grill.

www.schaerer.com

CLEANING

DAILY CLEANING E6MU WITH MILK BAG

BAE6Mu - EN

Version 03 01.2008

43

Page 44

www.schaerer.com

44

BAE6Mu - EN

Version 03 01.2008

Cleaning

7

► Open front door.

► Remove splitter by carefully tilting up

1

and pulling down

2

.

► Clean splitter under warm, running wa-

ter.

8

► Turn espresso arm to the right side. ► Crimp milk hose.

► Open pinch door.

► Remove milk hose

1

.

► Pull out used foamer

2

.

► Dispose used foamer (and milk bag if

empty).

10

► Uncrimp milk hose.

► Turn espresso arm back.

► Replace splitter by pushing up (onto the

screws)

1

and dropping down 2 .

► Close front door.

15

14

► Press the button once to quickly rinse

the new foamer.

For hygienic reasons we recommend to change the foamer the

following morning!

Attention! Hot fl uid!

2

1

1

2

11 12

► Clean nozzles and the area arround with

a damp towel.

► Clean refrigerator with a damp towel.

► Close front door.

For 24-hour operators:

► Do not switch-OFF machine!

For regular operators:

► Switch-OFF machine.

► Clean external surfaces with a damp

towel.

Do not use any abrasives!

Do not use any abrasives!

9

1

2

For regular operators:

► Switch-ON machine.

► Open front door.

► Connect milk bag with hose to the new

foamer.

► Place new foamer onto the nozzles.

► Close pinch door.

13

BAD GOOD

Page 45

www.schaerer.com

45

BAE6Mu - EN

Version 03 01.2008

Cleaning

Contact address USA: Contact address all other countries:

Schaerer USA Corporation M. Schaerer Ltd. Cleaning instruction 12.2007 V03

2900 Orange Avenue, Suite 102 Gewerbestrasse 15 QRCMU MFd_EN

Signal Hill, CA 90755 3302 Moosseedorf

USA Switzerland

www.schaererusa.com www.schaerer.com Order number: 021710

Daily cleaning

E6Mu with milk gallon

7

► Open front door.

► Remove splitter by carefully tilting up

and pulling down

► Clean splitter under warm, running wa-

ter.

► Pull out used foamer with milk hose

► Dispose used foamer and milk hose (and

milk gallon if empty).

For hygienic reasons we recom-

mend to change the foamer and

milk hose the following morning!

For regular operators:

► Switch-ON machine.

► Open front door.

► Place new foamer with new milk hose

onto the nozzles .

► Place milk hose into the milk gallon.

► Close pinch door.

10

13

BAD GOOD

Machines without drain:

► Remove drip tray and grill.

► Clean parts under warm, running water.

► Replace drip tray and grill.

Machines with drain:

► Remove drip grill.

► Clean drip grill under warm, running

water.

► Replace drip grill.

Refer to the safety instructions and to the chapter cleaning in the user manual!

Never reach into the machine or under the beverage outlets during the automatic cleaning!

The status of the cleaning and some cleaning steps are shown on the display.

Discard the milk gallon only when it‘s empty! During stand by mode the refrigerator is still cooling!

► Place large pitcher (volume: ± 1 liter) un-

der the splitter.

► Press the

button for ± 4 seconds.

The display shows:

31

► Remove grounds bin within 6 seconds

and clean it under warm, running water.

► Open front and espresso unit door.

► Clean brew group and brew area with

the brush.

► Replace grounds bin.

► Close espresso unit door and front door.

The display shows:

► Drop one tablet (as shown) into the fun-

nel.

64 5

► Press the button.

cleaning program

clean grounds bin

cleaning program

insert tablet

select product

12:00 01.12.2007

2

Attention! Hot fl uid!

Wait until the display shows:

► After the cleaning cycle is complete, re-

move and empty the pitcher.

If the grounds bin is not removed

within 6 seconds, the machine will

return to "select product" mode.

Cleaning program is running!

(duration: ± 4,5 minutes)

DAILY CLEANING E6MU WITH MILK GALLON

Page 46

www.schaerer.com

46

BAE6Mu - EN

Version 03 01.2008

Cleaning

7

► Open front door.

► Remove splitter by carefully tilting up

1

and pulling down

2

.

► Clean splitter under warm, running wa-

ter.

8

► Turn espresso arm to the right side. ► Remove milk hose from milk gallon.

► Open pinch door.

► Pull out used foamer with milk hose

1

.

► Dispose used foamer and milk hose (and

milk gallon if empty).

► Turn espresso arm back.

► Replace splitter by pushing up (onto the

screws)

1

and dropping down 2 .

► Close front door.

15

14

► Press the button once to quickly rinse

the new foamer.

For hygienic reasons we recommend to change the foamer and

milk hose the following morning!

Attention! Hot fl uid!

2

1

11 12

► Clean nozzles and the area arround with

a damp towel.

► Clean refrigerator with a damp towel.

► Close front door.

For 24-hour operators:

► Do not switch-OFF machine!

For regular operators:

► Switch-OFF machine.

► Clean external surfaces with a damp

towel.

Do not use any abrasives!

Do not use any abrasives!

1

2

For regular operators:

► Switch-ON machine.

► Open front door.

► Place new foamer with new milk hose

onto the nozzles .

► Place milk hose into the milk gallon.

► Close pinch door.

9

10

1

13

BAD GOOD

Page 47

www.schaerer.com

47

BAE6Mu - EN

Version 03 01.2008

Cleaning

Contact address USA: Contact address all other countries:

Schaerer USA Corporation M. Schaerer Ltd. Cleaning instruction 12.2007 V03

2900 Orange Avenue, Suite 102 Gewerbestrasse 15 QRCMU MCd_EN

Signal Hill, CA 90755 3302 Moosseedorf

USA Switzerland

www.schaererusa.com www.schaerer.com Order number: 021720

Daily cleaning

E6Mu with milk container

Refer to the safety instructions and to the chapter cleaning in the user manual!

Never reach into the machine or under the beverage outlets during the automatic cleaning!

The status of the cleaning and some cleaning steps are shown on the display.Rinse and clean the milk container if empty! During stand

by mode the refrigerator is still cooling!

► Open front door.

► Remove splitter by carefully tilting up

and pulling down

► Clean splitter under warm, running wa-

ter.

► Pull out used foamer with milk hose

► Dispose used foamer and milk hose

(and rinse and clean the milk container

if empty).

For regular operators:

► Switch-ON machine.

► Open front door.

► Place new foamer with new milk hose

onto the nozzles.

► Place milk hose into the milk gallon.

► Close pinch door.

10

13

BAD GOOD

► Place large pitcher (volume: ± 1 liter) un-

der the splitter.

► Press the

button for ± 4 seconds.

The display shows:

31

► Remove grounds bin within 6 seconds

and clean it under warm, running water.

► Open front and espresso unit door.

► Clean brew group and brew area with

the brush.

► Replace grounds bin.

► Close espresso unit door and front door.

The display shows:

► Drop one tablet (as shown) into the fun-

nel.

64 5

► Press the button.

cleaning program

clean grounds bin

cleaning program

insert tablet

select product

12:00 01.12.2007

2

Attention! Hot fl uid!

Wait until the display shows:

► After the cleaning cycle is complete, re-

move and empty the pitcher.

If the grounds bin is not removed

within 6 seconds, the machine

will return to "select product"

Cleaning program is running!

(duration: ± 4,5 minutes)

Machines without drain:

► Remove drip tray and grill.

► Clean parts under warm, running water.

► Replace drip tray and grill.

Machines with drain:

► Remove drip grill.

► Clean drip grill under warm, running

water.

► Replace drip grill.

DAILY CLEANING E6MU WITH MILK CONTAINER

Page 48

www.schaerer.com

48

BAE6Mu - EN

Version 03 01.2008

Cleaning

97

► Open front door.

► Remove splitter by carefully tilting up

1

and pulling down

2

.

► Clean splitter under warm, running wa-

ter.

8

► Turn espresso arm to the right side. ► Crimp milk hose.

If milk container empty:

► Pull off milk hose from container.

If milk container not empty:

► Leave milk hose on container.

► Open pinch door.

► Pull out used foamer with milk hose

1

.

► Dispose used foamer and milk hose

(and rinse and clean the milk container

if empty).

► Turn espresso arm back.

► Replace splitter by pushing up (onto the

screws)

1

and dropping down 2 .

► Close front door.

15

14

► Press the button once to quickly rinse

the new foamer.

For hygienic reasons we recommend to change the foamer and

milk hose the following morning!

Attention! Hot fl uid!

2

1

11 12

► Clean nozzles and the area arround with

a damp towel.

► Clean refrigerator with a damp towel.

► Close front door.

For 24-hour operators:

► Do not switch-OFF machine!

For regular operators:

► Switch-OFF machine.

► Clean external surfaces with a damp

towel.

Do not use any abrasives!

Do not use any abrasives!

1

2

For regular operators:

► Switch-ON machine.

► Open front door.

► Place new foamer with new milk hose

onto the nozzles.

► Place milk hose into the milk gallon.

► Close pinch door.

10

1

13

BAD GOOD

Page 49

www.schaerer.com

49

BAE6Mu - EN

Version 03 01.2008

Cleaning

Weekly cleaning

E6Mu Brewer & bean hopper cleaning

Contact address USA: Contact address all other countries:

Schaerer USA Corporation M. Schaerer Ltd. Cleaning instruction 12.2007 V03

2900 Orange Avenue, Suite 102 Gewerbestrasse 15 QRCMU w_EN

Signal Hill, CA 90755 3302 Moosseedorf

USA Switzerland

www.schaererusa.com www.schaerer.com Order number: 021715

► Place the completely dry brewer back

into the machine.

► Replace splitter by pushing up (onto the

screws)

► Close front door.

13

► Move the brew group back into the

home position.

► Move the lever clockwise

in picture) and slowly place it onto the

cover.

► Move the brew group downwards.

► Pull out and hold the lever

7 8

Carefully read the information given in the user manual as it contains important information regarding safety, hygiene, use and maintenance of the machine.

Never reach into the machine or under the beverage outlets during the automatic cleaning! Turn off power on machine before proceeding with brewer cleaning!