Page 1

Schaerer Coffee Club

Operating instructions

V02 / 11.2018

Page 2

Schaerer AG

P.O.Box 336

Allmendweg 8

CH-4528 Zuchwil

info@schaerer.com

www.schaerer.com

Translation of the original operating inructions

English

021081

Page 3

Schaerer Coffee Club

Operating instructions

Publisher

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

Edition

Version 02 | 11/2018

Software

V1.5.4

Concept and editing:

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

Copyright ©

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

This document is protected by copyright. All rights are reserved. The reproduction, distribution or transmission of this document, as well as the transmission via electronic systems or

translation into another language, are not permitted without the written consent of Schaerer

AG. This applies to both the entire document and individual excerpts thereof. The contents

of the document are based on the most current data available at the time of printing. Schaerer AG reserves the right to make changes at any time without further notice. All images,

gures and display messages in this manual are only shown by way of example. Due to the

wide variety of possible options, each individual machine may dier from the devices de-

picted herein. Schaerer AG is only liable for the contents of the original German document.

Page 4

|

Introduction and general information

Congratulations on the purchase of your

Schaerer coee machine.

The Schaerer Coee Club coee machine is a

single-cup fully-automatic machine for espresso,

coee, cappuccinos, lattes, latte macchiatos, milk

foam and hot water.

With the powder container available as an option,

the Schaerer Coee Club can also dispense hot

chocolate with milk or milk foam.

Follow the operating instructions

> Read the operating instructions before use.

> Always follow the operating instructions

exactly, especially the safety notes and the

Safety chapter.

> Keep the operating instructions accessible

to the sta and all users.

Risk of death due to electrocution!

• There risk of death due to the mains voltage

inside the coee machine.

> Never open the housing.

> Never loosen the screws and do not

remove housing parts.

Conditions for use and installation

• If the maintenance specications are not

observed, no liability is assumed for any

damages.

> Follow the operating instructions.

> Maintenance work and repairs may only

be performed by Schaerer Service using

original spare parts.

CAUTION

Note the signs and symbols in

the operating instructions

page 19

Observe the Safety chapter

w from page 9

WARNING

Observe the Safety chapter

w from page 9

IMPORTANT

Technical data

w from page 107

Maintenance

w from page 94

4

SCClub operating instructions

Page 5

Table of Contents

Table of Contents 5

1 Safety 9

1.1 General safety notes 9

1.2 Intended use 15

1.3 Conditions for use and installation 16

2 Introduction 17

2.1 Labelling of coee machine parts 17

3 Commissioning 21

3.1 Installation location 22

3.2 Unpacking 22

3.3 Commissioning programme 23

4 Operation 25

4.1 Operation safety notes 25

4.2 Switching on the coee machine 25

4.3 Beverage dispensing 26

4.4 Selection elds (optional) 26

4.5 Special elds (optional) 26

4.6 Connecting the milk 27

Milk nozzle ..................................................................27

With Schaerer milk cooler ......................................................27

Milk lance (optional) ...........................................................28

4.7 Milk or milk foam dispensing 28

4.8 Hot water dispensing 29

4.9 Basic Steam (optional) 29

4.10 Cup grid 32

4.11 Bean hopper/Powder container 32

4.12 Manual inlet 33

4.13 Grounds container 34

4.14 Counter grounds disposal (optional) 34

4.15 Drip tray 35

4.16 Mains water supply (optional) 36

4.17 Switching o the coee machine 36

5 Software 37

5.1 Overview 37

5.2 Readiness for use 39

5.3 Care 41

Readiness for use ............................................................37

Ready for operation display elds ................................................37

Main menu functions ..........................................................38

Menu control elds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.2.1 Ready for operation display elds ................................................39

Beverage buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Warm rinse eld ..............................................................39

Barista eld – coee strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2.2 SteamJet cup warmer .........................................................40

System cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Mixer rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Milk system rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

SCClub operating instructions

5

Page 6

Table of Contents

CleanLock ...................................................................42

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Filter change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Descaling ...................................................................42

Brewer care .................................................................43

5.4 Beverages 43

5.5 Operating options 50

5.6 Info 55

5.7 Accounting 56

5.8 PIN rights 57

5.9 Timer 59

5.10 System 60

General information ...........................................................43

Filling quantity, animation cup tray, multiple brewing and dosing type ....................44

Changing recipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Text and image ...............................................................49

Operating elements ...........................................................50

Button layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

PostSelection ................................................................53

Decaeinated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Beverage pre-selection ........................................................54

Cancel beverage .............................................................54

Last brewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Timer .......................................................................55

Service .....................................................................55

Care .......................................................................55

Water lter and descaling .......................................................55

Journal .....................................................................55

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

coeeMYsation (App). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning PIN ................................................................58

Setting PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Accounting PIN ...............................................................58

Time/Date ...................................................................59

Status of button layout .........................................................59

Button layout overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Milk and foam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Progress display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Display and lighting ...........................................................61

Water lter ..................................................................63

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Switch-o rinsing .............................................................64

Automatic milk system rinsing ...................................................64

Calibration of “beans empty” message ............................................64

Frost protection/ transport preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Drip tray sensor ..............................................................65

Portioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Bluetooth (optional) ...........................................................65

S-M-L function ...............................................................66

6

SCClub operating instructions

Page 7

Table of Contents

5.11 USB 67

Loading recipes ..............................................................67

Loading beverage symbols .....................................................67

Saving recipes ...............................................................67

Saving recipes as PDF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Exporting counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

HACCP export ...............................................................68

Data backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Loading data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Loading language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Firmware update .............................................................68

System recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

5.12 Language 68

6 Other settings 69

6.1 Setting the grind level 69

7 Care 70

7.1 Care safety notes 70

7.2 Overview of cleaning intervals 72

7.3 Dishwasher-safe parts 73

7.4 Cleaning programmes 73

7.4.1 System cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.4.2 System cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

7.4.3 Mixer rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.4.4 Milk system rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.5 Descaling 76

7.6 Manual cleaning 78

7.6.1 Cleaning the control panel (CleanLock). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.6.2 Cleaning the grounds chute (ground slide, optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

7.6.3 Cleaning the collecting tray .....................................................79

7.6.4 Cleaning the water tank ........................................................79

7.6.5 Cleaning the drip tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

7.6.6 Cleaning the housing ..........................................................81

7.6.7 Cleaning the outlet by hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.6.8 Cleaning the brewing unit .......................................................82

7.6.9 Cleaning the milk system by hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Cleaning the milk hose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7.6.10 Cleaning the mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

7.6.11 Cleaning the bean hoppers .....................................................89

7.6.12 Cleaning the powder container ..................................................90

8 HACCP cleaning concept 92

9 Maintenance and descaling 94

9.1 Maintenance 94

9.2 Schaerer Service 95

SCClub operating instructions

7

Page 8

Table of Contents

10 Notications and notes 96

10.1 Operation notications 96

10.2 Error messages and faults 97

10.3 Error without error message 100

11 Safety and warranty 102

11.1 Hazards for the coee machine 102

11.2 Directives 104

11.3 Operator responsibilities 105

11.4 Warranty claims 106

Appendix: Technical data 107

Technical data of the coee machine 107

Appendix: Accessories and spare parts 110

8

SCClub operating instructions

Page 9

1 Safety

Safety

Incorrect use

• Non-compliance with the safety

notes can result in serious

injuries.

> Observe all safety notes.

1.1 General safety notes

Dangers for the operator

Maximum safety is one of the most

important features of Schaerer products.

The eectiveness of the safety devices is

only ensured as long as the following is

observed:

> Read the operating instructions

carefully before using the

device.

> Do not touch any hot machine

parts.

> Do not use the coee machine

if it is not working properly or is

damaged.

> Only use the coee machine if it

is completely installed.

> Under no circumstances may

the installed safety devices be

modied.

WARNING

CAUTION

SCClub operating instructions

9

Page 10

Safety

> Under continuous supervision

this device can be used by

children aged 8 and up and by

persons with limited physical,

sensory or mental capabilities

or a lack of experience and/

or knowledge, provided they

have been instructed about

the safe use of the device

and understand the potential

hazards resulting from said use.

> Children must not play with the

device.

> Children must also not be

allowed to perform cleaning

procedures or user service.

CAUTION

10

SCClub operating instructions

Page 11

In spite of the safety devices, every coee

machine carries some potential risk if

used improperly. Please comply with the

following instructions when handling the

coee maker in order to prevent injuries or

health hazards:

Safety

Risk of death due to electrocution!

• There risk of death due to the

mains voltage inside the coee

machine.

> Never open the housing.

> Never loosen the screws and do

not remove housing parts.

> Never use a damaged power

cord.

> Avoid damages to the power

cord. Do not kink or crush.

> Never put the power plug into

water or other liquids or pour

water or other liquids over the

power plug. Always keep the

power plug dry.

WARNING

SCClub operating instructions

11

Page 12

Safety

Risk of burns/

Danger of scalding

• Hot liquid comes out of the

outlets during beverage and

steam dispensing. The adjacent

surfaces and outlets get hot as

well.

> Do not touch the area under

the outlets during beverage and

steam dispensing.

> Do not touch the outlets

immediately after dispensing.

> Always put a suitable container

under the outlet before use.

Risk of injury

• Very long hair could get stuck in

the grinder head and get pulled

into the coee machine.

> Always protect hair with a

hairnet before you open the

bean hoppers.

CAUTION

CAUTION

12

SCClub operating instructions

Page 13

Safety

Risk of trapping/Risk of injury

• The coee machine contains

moving parts which could injure

ngers or hands.

> Always switch o the coee

machine and pull out the power

plug before reaching into

the coee grinder or into the

opening of the brewing unit.

Health risk

> Only make products which are

suitable for consumption and

the use of the coee machine.

> The powder container, the

bean hoppers and the manual

inlet may only be lled with the

materials intended for use.

CAUTION

CAUTION

Health risk

• The milk system cleaners

and the cleaning tablets are

irritating.

> Follow the protective measures

on the packaging of the cleaning

products.

> Do not add the cleaning tablets

into the machine until the

notication appears on the

display.

SCClub operating instructions

CAUTION

13

Page 14

Safety

Health risk/

Risk of irritation and burns

• During cleaning, hot cleaning

liquid and hot water ow out of

the outlets.

• The hot liquids could irritate the

skin and the heat creates a risk

of burns.

• Hot liquids could be in the drip

tray.

> Never reach under the outlets

during cleaning.

> Ensure that no one ever drinks

cleaning liquid.

> Carefully move the drip tray.

Risk of slipping

• Liquids can escape from the

machine if it is used incorrectly

or if errors are made. These

liquids can cause a slipping

hazard.

> Regularly check whether the

coee machine is leak-free and

that no water can escape.

CAUTION

CAUTION

14

SCClub operating instructions

Page 15

1.2 Intended use

Safety

Incorrect use

WARNING

• If the machine is not used

correctly, it could cause an

injury hazard.

> The coee machine must only

be used in the correct manner.

The Schaerer Coee Club is designed to dispense beverages

made of coee and/or milk and/or powder (e.g. choco or

toppings) into suitable containers. This device is intended

for commercial use in hotels, restaurants and similar

establishments. The device is permitted to be installed at

self-service locations when a sta member is present for

supervision purposes. The device can be used in businesses,

oces and other similar work environments, hotels, motels

and bed and breakfast establishments and can be operated by

non-experts and customers. Use of this equipment is subject

these operating instructions. In legal terms, any other use is

not an intended use. The manufacturer accepts no liability for

damage resulting from unintended use.

Schaerer Coee Club must not be used for heating

and dispensing any liquids other than coee, hot water

(beverages, cleaning) or milk (cooled, pasteurised,

homogenised, UHT).

SCClub operating instructions

15

Page 16

Safety

1.3 Conditions for use and installation

Risk of burning/Risk of injury

> The conditions for installation

and use must be observed.

> The conditions for installation

and use specied in the

Technical data chapter must be

observed.

Preparatory structural work for the electrical

connection, the water connection and

the waste water connection must be

commissioned by the operator of the

machine. It must be carried out by licensed

installers observing all general, national

as well as locally applicable regulations.

Schaerer Service may only connect the

coee machine to the prepared connections.

They are neither authorised to carry

out structural installation, nor are they

responsible for its implementation.

WARNING

Technical data

w page 108

16

SCClub operating instructions

Page 17

2 Introduction

2.1 Labelling of co ee machine parts

Introduction

13

12

11

10

Display

1 2

14

15

16

31 2

4

5

6

7

8

9

3

4

19 18 17

SCClub operating instructions

20

17

Page 18

Introduction

1

Bean hopper

Second bean hopper or powder container (for example choco, topping or

2

double powder container) (optional)

3

Manual inlet/Tablet insert

4

On/o switch

5

Beverage outlet (coee, milk and choco)

6

Water tank

7

Cup grid

8

SteamJet cup warmer

9

Removable drip tray with drip grid

10

Grounds container

11

Steam outlet

12

Hot water outlet

13

Touch display for beverage buttons and settings

Ready for operation display

14

Menu eld (opens the main menu)

15

Warm rinse eld

16

Notication box

17

Barista eld

18

Filling quantity

19

SteamJet eld

20

Steam button in the beverage eld

18

SCClub operating instructions

Page 19

Signs and symbols in the operating instructions

Introduction

Personal injury safety notes

If the safety notes are not observed, mild

to serious injury could occur in the event of

incorrect operation.

Personal injury safety notes

If the safety notes are not observed, mild injury

could occur in the event of incorrect operation.

Risk of

electrocution

Risk of trapping

ngers

Hot steam

Hot surfaces

Risk of slipping

Property damage notes

• For the coee machines

• For the installation location

> Always follow the operating instructions

exactly.

WARNING

Safety notes

Observe the Safety chapter

w from page 9

CAUTION

Operation safety notes

w page 25

Care safety notes

w page 70

Observe the Safety chapter

w from page 9

IMPORTANT

Observe the Warranty chapter

w from page 106

Technical data

w from page 107

Notes/Tip

• Notes for safe handling and tips for easier

operation.

SCClub operating instructions

NOTE

TIP

19

Page 20

Introduction

Glossary

Term Explanation

• • Counting, selection options

* * Individual work steps

Cursive text Description of condition of the coee machine and/or

explanations of automatic steps.

Barista Personal coee maker

Choco Hot chocolate

DECAF Decaeinated coee

Beverage

dispensing

Main water valve Stopcock, angle valve

Carbonate

hardness

Coee outlet Double outlet is the standard.

Milk system Single outlet, milk foamer, milk foam adapter, steam

Mixer system Entire assembly, mixer with portioner for powder-based

Preinfusion The coee is briey pre-brewed before the brewing

Pressing Automatic pressing of the ground coee before brewing

Powder based

beverages

Service life For example: Litre capacity of the water lter

Grounds container

Self-service mode Customer self-service

Rinsing Intermediate cleaning

Extras Components of a recipe for a beverage, for example

Dispensing of coee, hot water or powder beverages

Given in °dKH Water hardness is a measure of the

limescale dissolved in drinking water.

nozzle and milk hose

beverages

process to bring out a more intense aroma. Pre-brewing.

For example, choco or topping

Grounds chute

coee, milk, milk foam, choco

w Counter grounds disposal, side 34

• The software contains QR codes for videos

which illustrate the dierent steps in a

simple manner. Simply scan the QR code

to do so.

20

TIP

SCClub operating instructions

Page 21

3 Commissioning

(For the rst commissioning after delivery from the

factory)

Commissioning

Follow the operating instructions

> Always follow the operating instructions

exactly, especially the safety notes and the

Safety chapter.

> Keep the operating instructions accessible

to the sta and all users.

> Read the operating instructions before use.

Risk of death due to electrocution if

not observed

There risk of death due to the mains voltage

inside the coee machine.

• Never open the housing.

• Never loosen the screws and do not

remove housing parts.

Conditions for use and installation

Follow the operating instructions.

CAUTION

Important!

Note the signs and symbols in

the operating instructions

w page 19

Observe the Safety chapter

wfrom page102

WARNING

Observe the Safety chapter

wfrom page 102

IMPORTANT

Technical data

wfrom page 107

SCClub operating instructions

21

Page 22

Commissioning

3.1 Installation location

• The installation location must be dry and

protected from spray water.

• Water, condensation or steam can always

escape from a coee machine.

> Do not use the coee machine in the open.

> Set up the coee machine so that it is

protected from spray water.

> Make sure to set the coee machine on

a water-resistant surface which is not

sensitive to heat to protect the installation

surface from damage.

3.2 Unpacking

> The packaging material in the box contains

accessories. Do not throw away.

> The water tank and the grounds container

contain spare parts. Remove the spare

parts before commissioning and thoroughly

rinse the grounds container and the water

tank.

> Check whether the coee machine is

intact. In case of doubt, do not put the

coee machine into operation and contact

Schaerer Service.

> Therefore, be sure to keep the original

packaging in a safe place should a return

delivery be necessary.

IMPORTANT

Observe the Warranty chapter

wfrom page 106

Technical data

wfrom page 107

IMPORTANT

Observe the Warranty chapter

wfrom page 106

Accessories and labelling of

machine parts

w page 17

Technical data

wfrom page 107

Option double powder

The optional double powder container is sent

in separate packaging. If the coee machine

is equipped with this option, the double

powder container must be mounted before

commissioning the coee machine. Operating

without the container mounted is not permitted.

22

IMPORTANT

Chapter Warrenty

w from page 106

Technical data

w from page 107

SCClub operating instructions

Page 23

* Unpack the Schaerer Coee Club and set the

coee machine on a stable, horizontal surface .

* Observe the technical data.

* Plug the connection cable of the coee machine

into the respective socket.

3.3 Commissioning programme

* Switch on the coee machine using the on/o

switch.

The coee machine switches on.

The commissioning programme starts.

* Follow all instructions on the display.

The commissioning programme

proceeds step-by-step through the further

commissioning process via the display.

> Follow the display messages.

• The set values can be changed after

commissioning.

Other instructions

• Connecting milk w Chapter 4.6 page 27

Commissioning

Technical data

wpage 107

IMPORTANT

Changing settings

w Setting

from page 37

Once the commissioning process has been run in its

entirety and all necessary settings have been made,

the coee machine restarts. Calibration is performed

automatically.

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage dispensing. The adjacent

surfaces and outlets get hot as well.

> Do not touch the area under the outlets

during beverage dispensing.

> Do not touch the outlets immediately after

dispensing.

SCClub operating instructions

CAUTION

Observe the Safety chapter

w from page 9

23

Page 24

Commissioning

Inserting the water lter for the water tank

(optional)

This point is a step taken during the commissioning

programme.

For drinking water with a carbonate hardness above

5°dKH, a Schaerer water lter should be installed, as

otherwise the coee machine can be damaged due

to calcication.

Determining the water hardness

* Obtain the water hardness of the drinking water

from the water supplier or use the carbonate

hardness tester (with instructions) in the

accessories.

The carbonate hardness test is included in the

accessories.

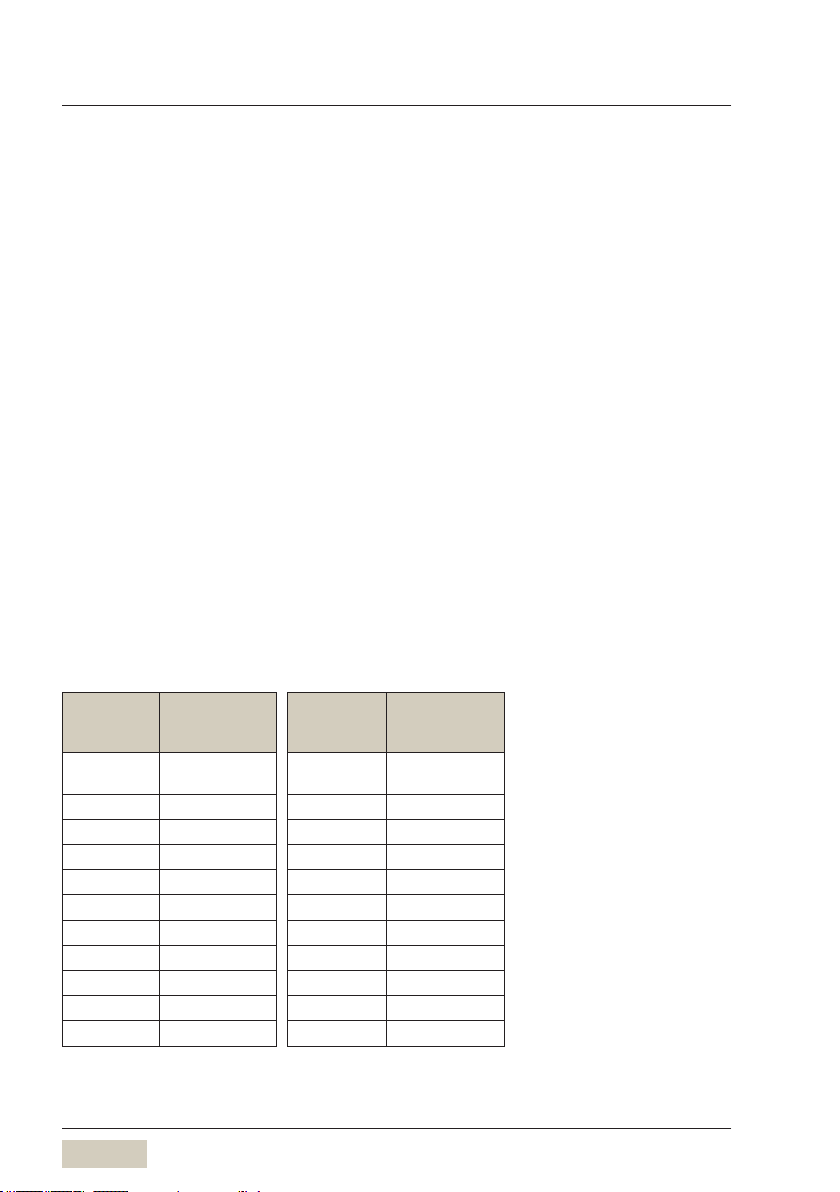

Service life

The supplied water lter for the water tank

(200 l) at 10 °dkH has a service life for

200 litres of water. The actual service life is

dependent on the drinking water hardness and can

be found in the following table.

The "German carbonate

hardness" unit (°dKH) applies.

Water

- hardness

< 5

Service life in

litres

No lter

necessary

Water

- hardness

15 135

5 400 16 125

6 335 17 120

7 285 18 110

8 250 19 105

9 220 20 100

10 200 21 95

11 180 22 90

12 165 23 85

13 155 24 80

14 145 > 25 70

24

Service life in

litres

Note

No water lter is required at a

water hardness of 0 to 5 °dKH.

w Commissioning programme,

page 20

SCClub operating instructions

Page 25

4 Operation

4.1 Operation safety notes

Operation

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage and steam dispensing. The

adjacent surfaces and outlets get hot as

well.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets immediately after

dispensing.

> Always put a suitable container under the

outlet before use.

Health risk

> Only make products which are suitable

for consumption and the use of the coee

machine.

> The powder container, the bean containers

and the manual inlet may only be lled with

the materials intended for use.

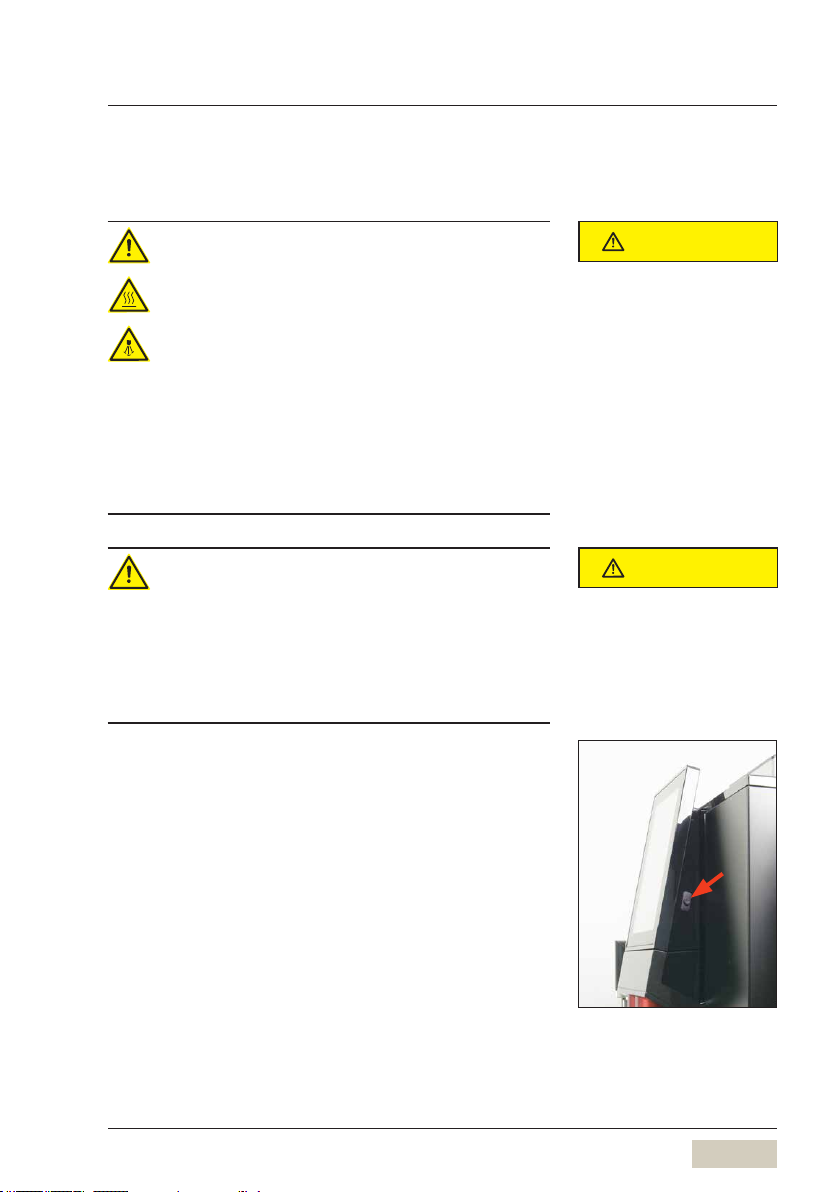

4.2 Switching on the coee machine

The on/o switch is on the right side of the control

panel.

* Press on the on/o switch

A single tone goes o.

The coee machine switches on and heats up.

Automatic warm rinsing starts.

When the coee machine is ready to dispense

beverages, the display will show "Ready for use".

CAUTION

Observe the Safety chapter

w from page 9

CAUTION

Observe the Safety chapter

w from page 9

SCClub operating instructions

PIN access control

w PIN rights

page 57

25

Page 26

Operation

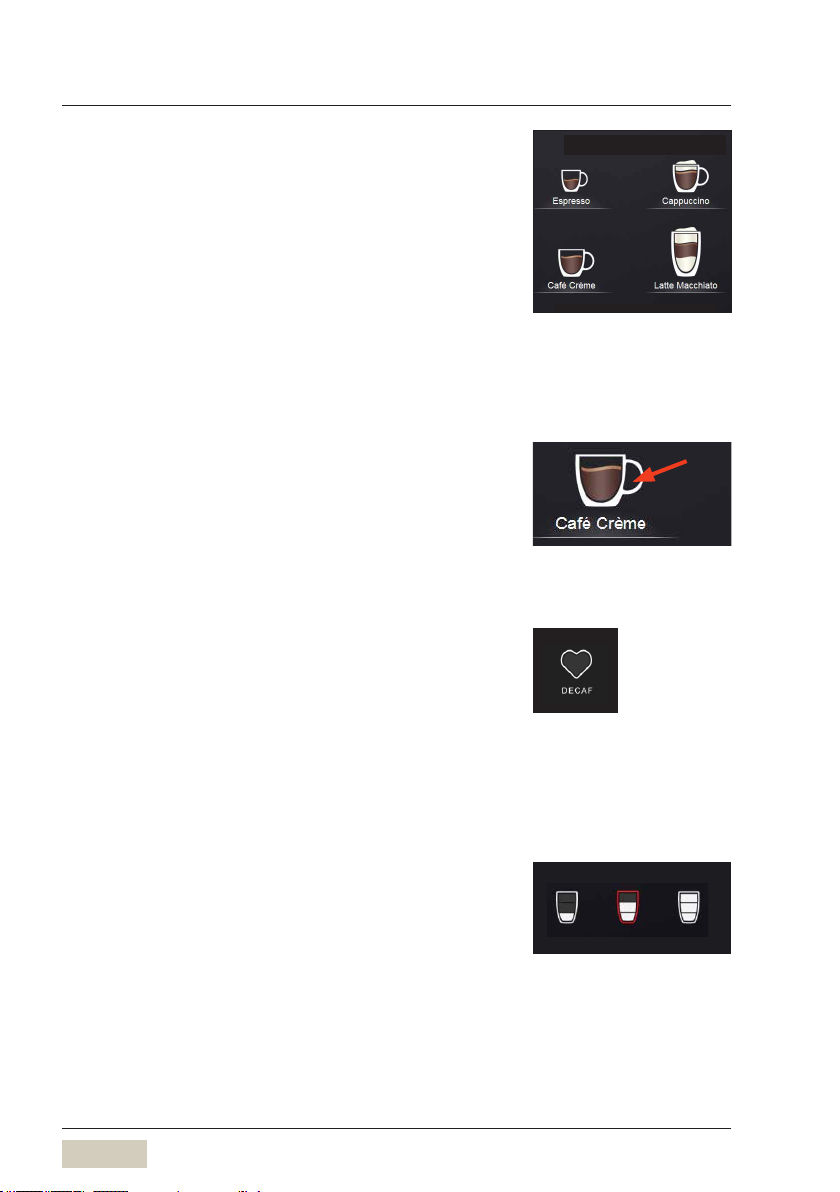

4.3 Beverage dispensing

Pressing on the beverage buttons starts dispensing

of the set beverages.

• Illuminated button = Ready for dispensing

• Unilluminated button/

red triangle in the

header

= Not ready for dispensing/

button locked

* Set a beverage container of a suitable size below

the outlet.

* Press on the desired beverage button.

Beverage interruption

* Tap on the beverage button again

4.4 Selection elds (optional)

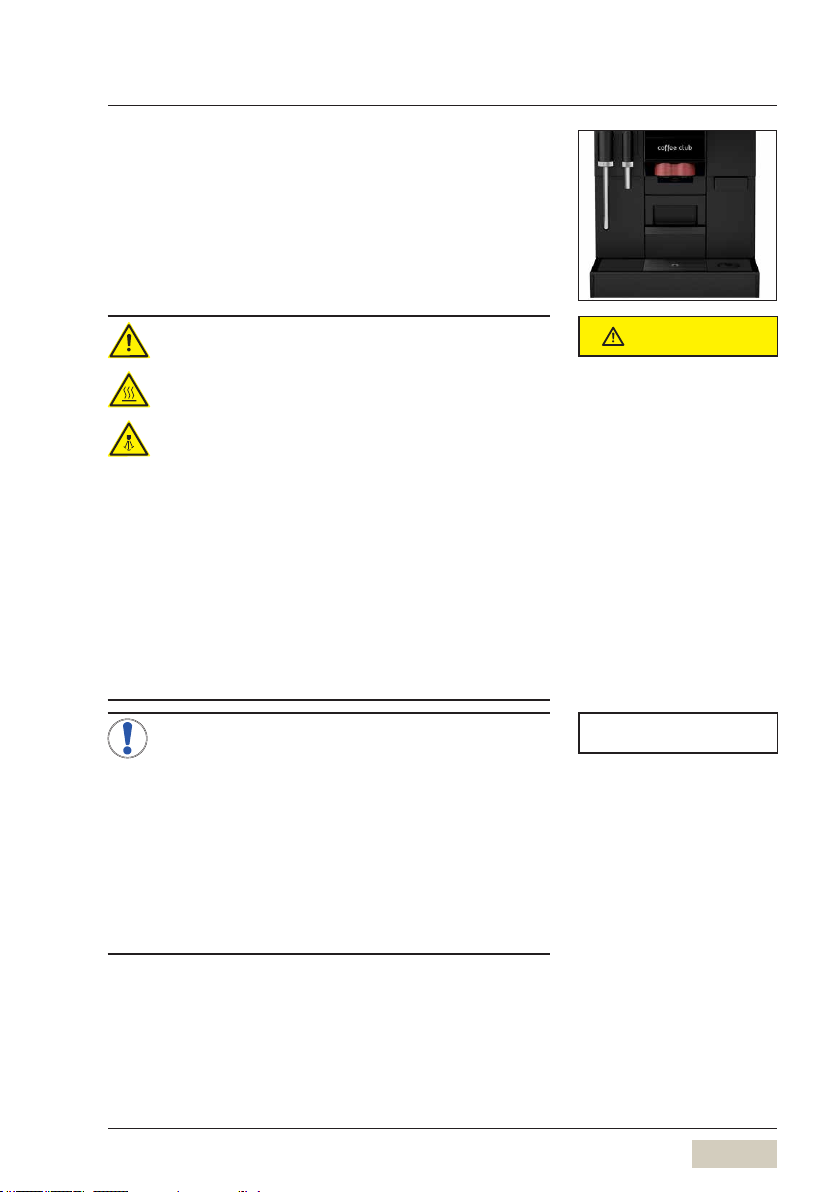

Selection elds, like the DECAF eld in the example,

are available as an option. These selection elds

appear on the display after beverage selection.

4.5 Special elds (optional)

Special elds are optional and, if desired,

are activated in the settings. For example, the

pre-selection of the S-M-L lling quantities are special

elds. These S-M-L lling quantities must be set for

the beverages to make them available. Then, the

lling quantity "S" or "L" can be selected and only the

beverage buttons provided for this size light up.

M = set beverage size, no pre-selection

S = approx. 25% less than M

L = approx. 25% more than M

Button layout

w Operating options

page 50

Cancel button

Example:

Decaeinated eld (with 2

grinders)

Size

S M L

Example:

S-M-L eld

26

SCClub operating instructions

Page 27

4.6 Connecting the milk

Milk nozzle

Use the appropriate steam nozzle on the milk foamer.

Colour Milk temperature

• Green (standard) Uncooled milk

(16 to max. 22 °C)

• Orange

(accessories)

With Schaerer milk cooler

* Use the appropriate steam nozzle for cooled milk

(orange)

* Remove the milk container from the cooler

* Push the lid of the milk container back

* Fill milk into the milk container

* Place the lid back on the container

* Plug the adapter on the milk hose into the

connection on the milk container lid

* Carefully push back the milk container

Cooled milk

(up to 10 °C)

Operation

The milk storage temperature

must be adapted to the milk

temperature and the matching

steam nozzle. Milk storage

temperature

w Milk and foam page 60

Milk container

SCClub operating instructions

The milk storage temperature

must be adapted to the milk

temperature and the matching

steam nozzle. Milk storage

temperature

w Milk and foam page 60

27

Page 28

Operation

Milk lance (optional)

Note

• Clean the milk lance daily.

• The milk hose must not be kinked.

* Use the appropriate steam nozzle on the milk

foamer

* Put the milk package to the left next to the coee

machine

* Open the milk lance lid

* Connect the Plug&Clean adapter to the milk lance

* Insert the milk lance into the milk packaging

The milk lance must reach to the base of the milk

packaging.

NOTE

The milk storage temperature

must be adapted to the milk

temperature and the matching

steam nozzle. Milk storage

temperature

w Milk and foam page 60

4.7 Milk or milk foam dispensing

* Set a beverage container of a suitable size below

the outlet

* Tap on the beverage button for milk or milk foam

Dispensing is done in line with the setting in the

recipe (dosing type, foam quality, etc.).

28

Dosing types

w Software

w Beverages

page 44

SCClub operating instructions

Page 29

4.8 Hot water dispensing

* Set a beverage container of a suitable size below

the hot water outlet

* Tap on the hot water button

Dispensing is done in line with the set dosing type.

4.9 Basic Steam (optional)

Operation

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage and steam dispensing. The

adjacent surfaces and outlets get hot as

well.

• The lower part of the steam outlet gets very

hot.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets immediately after

dispensing.

> Do not touch the lower part of the steam

outlet.

> Always put a suitable container under the

outlet before use.

Note

The dosing type for steam can be set under

the

"Beverage" menu item.

Dosing types Start-stop, Portion control,

Freeow and Start-stop-freeow

are available.

The dosing types are described in the

Beverage chapter

.

CAUTION

Observe the Safety chapter

w from page 9

NOTE

Dosing types

w Software

w Beverages

page 44

* Press on the steam button.

Steam is output as long as the steam button is

pressed.

• Steam warms up beverages

• Steam manually foams milk

SCClub operating instructions

29

Page 30

Operation

Heating up beverages

* Hold a cloth in front of the steam pipe for your own

protection

* Briey press the steam button

This blows out the condensation.

* Use a tall and narrow container with a handle

* Fill the container no more than halfway

* Put the steam nozzle deep down in the container

without touching the bottom on the container with

the steam nozzle

* Tap on the steam button

* Tap on the steam button again when the desired

temperature is reached

This stops steam dispensing.

* Swivel the steam outlet to the drip tray

* Tap on the steam button and then tap on it again

* a second later

The remainders in the steam tube are rinsed out.

* Wipe o the steam outlet with a moist cloth

The steam dispensing starts

after the rst tap on the steam

button. Tapping a second time

stops steam dispensing.

30

SCClub operating instructions

Page 31

Foaming milk

Operation

> Do not overheat the milk, or the amount of

milk foam will decrease

* Hold a cloth in front of the steam pipe for your own

protection

* Briey press the steam button

This blows out the condensation.

* Use a tall and narrow container with a handle

* Fill the container no more than halfway

* Put the steam nozzle into the container just under

the surface

* Press on the steam button.

This creates silky, compact milk foam.

* Release the steam button

* Swivel the steam outlet to the drip tray

* Briey press on the steam button

The remainders in the steam tube are rinsed out.

* Swivel the steam outlet to the drip tray

* Tap on the steam button and then tap on it again

after a short time

The brief burst of steam rinses residues out of the

steam pipe.

* Wipe o the steam outlet with a moist cloth

TIP

SCClub operating instructions

31

Page 32

Operation

4.10 Cup grid

* Grab the handle at the top of the grounds

container

* Pull out the cup grid as far as it will go

Base height with cup grid Max. 100 mm

Base height without cup grid Max. 177 mm

4.11 Bean hopper/Powder container

Top o the containers as soon as possible to the time

of use.

Fill the containers with no more than is needed for a

day to ensure the products remain fresh. Always ll

the container from front to back.

• Foreign particles may damage the grinder.

These damages are excluded from the

warranty.

> Ensure that no foreign particles enter the

bean hopper.

> Do not over ll the powder container.

> Do not press on the powder and compress

it.

Option double powder

The optional double powder container will be

shipped in a separate packaging. If the co ee

machine is equipped with this option, the

double powder container must be mounted

before commissioning. Operation without

mounted container is prohibited.

Some powder types may leave residues in

the powder container that may accumulate on

the front of the container

IMPORTANT

Observe the Warranty chapter

w from page 106

IMPORTANT

Chapter Warrenty

w from page 106

Technical data

w from page 107

NOTE

32

SCClub operating instructions

Page 33

4.12 Manual inlet

The manual inlet is located at the centre on the coee

machine lid.

The manual inlet is used:

• As an inlet for cleaning tablets

• For other types of coee, for example

decaeinated coee

• For coee sampling

Operation

Tablet inlet

• Do not add the ground coee or cleaning

tablets into the machine until the

notication appears on the display.

• Only use ground coee for the manual

inlet.

• Do not use instant coee powder. Do not

use coee powder that is ground too ne.

Preparation with ground coee via the manual

inlet

* Push on the top on the manual inlet ap to open it

* Fill in the ground coee (maximum 15 g)

* Close the manual inlet ap

* Press on the desired beverage button.

IMPORTANT

Observe the Warranty chapter

w from page 106

Manual inlet

SCClub operating instructions

33

Page 34

Operation

4.13 Grounds container

The grounds container collects the used ground

coee. It holds coee grounds from approx. 30

brewings. A notication appears on the display

when the grounds container needs to be emptied.

Dispensing of beverages is blocked if the grounds

container is not in place.

* Insert the cup grid into the grounds container.

* Remove the grounds container.

* Empty the grounds container.

The cup grid rests on the grounds container. Always

hold the grounds container tightly when emptying it.

* Reinsert the grounds container.

* Conrm the process on the display.

w Cleaning the grounds

container

page 78

• Inserting without emptying causes

the grounds container to overll. The

coee machine is dirty. This can cause

consequential damages.

> Always empty the grounds container

before inserting it.

> If the grounds container cannot be

reinserted, check the shaft for remaining

coee and remove it.

4.14 Counter grounds disposal

(optional)

The coee machine can be equipped with a counter

grounds disposal. In this case, the grounds container

and the bottom of the coee machine have a cut-out

that is continued through the on-site counter. The

coee grounds are collected in a separate container

underneath the counter.

IMPORTANT

Observe the Warranty chapter

w from page 106

Important

Clean the grounds chute daily

w Manual cleaning

page 78

34

SCClub operating instructions

Page 35

4.15 Drip tray

Operation

Danger of scalding

• Hot liquids could be in the drip tray.

> Carefully move the drip tray.

> Reinstall it carefully so that no unintended

water leakage occurs.

In co ee machines without an outlet connection, the

lling level sensor reports when the drip tray is full.

* Carefully remove the drip pan, empty it and

reinstall it.

The drip pan can also be removed, for

cleaning for instance, in co ee machines with

a drain connection.

Drip tray sensor

A sensor monitors whether the drip tray is inserted

and what the ll level is. A noti cation appears on the

display if the ll level is at the maximum amount.

* After receiving a noti cation, carefully remove the

drip pan, empty it and reinstall it.

CAUTION

Observe the Safety chapter

w from page 9

Clean the drip tray daily

Care w from page 70

NOTE

The underside of the drip tray and the area

of the drip tray sensor must be dry before

insertion. The sensor is located on the right

under the drip tray. If moisture remains in this

area, the “Empty drip tray” message appears

again.

SCClub operating instructions

IMPORTANT

This sticker marks the area

which should be kept dry.

35

Page 36

Operation

4.16 Mains water supply (optional)

The mains water supply to water and waste water is

only possible using a retrot kit.

With a mains water supply, the water tank

must only be removed if the coee machine is

switched o.

4.17 Switching o the coee machine

Follow hygiene standards

• Hazardous bacteria can grown in the

coee machine.

> Before switching o the coee machine,

perform the daily switch-o rinsing.

Follow the instructions

• No liability is assumed for damage

resulting from the failure to do so

The on/o switch is on the right side of the control

panel

* Briey press on the On/O switch

(approx. 1 second)

The coee machine switches o.

* Pull the power plug

IMPORTANT

Mains water retrot kit

CAUTION

Observe the Safety chapter

w from page 9

Clean the coee machine as

specied in the instructions.

Care w from page 70

IMPORTANT

Observe the Warranty chapter

w from page 106

Coee machines with mains water supply:

* Close the main water valve of the water supply line

36

PIN access control

w PIN rights

page 57

SCClub operating instructions

Page 37

5 Software

Software

• When setting beverages, the same safety

notes apply as for the operation of the

coee machine.

> Observe all operating safety notes.

5.1 Overview

Readiness for use

CAUTION

Operation safety notes

w page 25

Page 39

Button layout

w Operating options

page 50

The elds and buttons on the

display are available depending

on the setting and machine

version.

Ready for operation display elds

SteamJet cup warmer

Page 40

Barista (coee strength)

Page 39

Decaeinated eld

Page 26

SCClub operating instructions

Page 39

Warm rinsing

Page 39

Notications

Page 96

S-M-L eld

Page 66

37

Page 38

Software

Main menu functions

Care

Page 41

Beverages

Page 43

Accounting

system

Page 56

Info

Page 55

Operating option

Page 50

PIN rights

Page 57

Menu control elds

To the main menu Con rm the value/setting

Return to the previous menu Delete the value/setting

PIN entry Test preparation

Timer

Page 59

USB

Page 67

from page 41

System

Page 60

Language

Page 64

Next, previous, start Back

Loading settings Calling up temperature

Saving settings

Messages on the display

Error message

38

Milk temperature display

(optional)

SCClub operating instructions

Page 39

5.2 Readiness for use

Ready for operation display

The display shown when the machine is ready for use

depends on the options of the coee machine and

individual settings.

5.2.1 Ready for operation display elds

Beverage buttons

All output-ready beverage buttons are illuminated.

Swiping the display vertically shows the other

beverages available for display. The beverage

dispensing starts after tapping on the desired

beverage button.

Warm rinse eld

* Tap the "warm rinsing" eld.

A process of rinsing the coee lines with warm water

starts. The water warms up the brewing system and

ensures that the brewed coee is at an optimum

temperature.

This is recommended after a long brewing pause,

especially before dispensing a cup of espresso.

Software

Button layout

w Operating options

page 50

Example: Cappuccino button

Warm rinse eld active/inactive

w Operating options

page 51

Barista eld – coee strength

Display Coee strength

Standard 2 beans Normal, as set

Tap 1 x 3 beans 15% stronger than set*

Tap 2 x 1 bean 15% weaker than set*

* Maximum coee ground quantity 15 g per brew

The coee strength is changed one time for the next

brew.

SCClub operating instructions

Barista eld active/inactive

w Operating options

page 50

39

Page 40

Software

5.2.2 SteamJet cup warmer

Risk of burns/

Danger of scalding

• Hot steam is output through the SteamJet

cup warmer. At the same time, the cups and

the adjacent surfaces are hot.

> Use heat-resistant drink containers.

> Always put a cup with the opening at the

bottom over the cup warmer before steam

is dispensed.

> Do not touch the adjacent surfaces shortly

after dispensing.

> Do not touch the outlets immediately after

dispensing.

> Never use the SteamJet function without

using a drip grid or the cup warmer insert.

Health risk/Hygiene

• The SteamJet function is intended for

warming up drink containers and is not

suitable for cleaning.

> Instead, use a freshly-rinsed drink

container to warm the cups.

CAUTION

Observe the Safety chapter

w from page 9

Clean the drip tray daily

Care w from page 70

CAUTION

Observe the Safety chapter

w from page 9

The SteamJet cup warmer heats cuts with hot steam.

* Place a cup into the cup warmer with the opening

facing down.

* Tap the eld.

Hot steam slowly ows into the cup from below.

The steam ow is output as long as is specied in the

settings.

* Tap on the SteamJet eld again.

The steam ow immediately stops.

40

SteamJet eld active/inactive

w Operating options

page 51

SCClub operating instructions

Page 41

5.3 Care

System cleaning

Mixer rinsing

Milk system rinsing

System cleaning

After system cleaning with or without switching o the

co ee machine.

A system cleaning notice appears automatically

after 6 days or 200 brewings. After 7 days or 250

brewings, beverage dispensing is locked.

The machine cannot be used until after cleaning.

Software

Menu control elds

w Overview

page 38

Care chapter

w from page 70

HACCP cleaning concept

w from page 92

System cleaning

Care

w from page 73

Mixer rinsing

Mixer rinsing is an intermediate rinsing of the mixer.

Milk system rinsing

The milk system rinse rinses the milk hose with the

milk nozzles and the milk foamer.

SCClub operating instructions

Mixer

Care

w page 75

Milk system rinse

Care

w page 75

41

Page 42

Software

CleanLock

Instructions

Filter change

CleanLock

* Tap on CleanLock

A 15-second countdown starts.

The touch display can now be cleaned.

The touch display is reactivated 15 seconds after the

last time it is touched.

Instructions

Animated instructions on the available cleaning

programmes and for the installation and disassembly

of the coee outlet, milk foeamer, milk hose, mixer

system, water lter change and SteamJet.

Filter change

From 25% remaining lter service life, the remaining

service life is displayed each time the machine is

switched on. If the remaining lter service life is 0%,

a message is displayed every 3 hours that the water

lter must be changed. The lter must be changed to

avoid machine damage.

* Change the lter

* Conrm that the lter has been changed

After the lter has been changed, a programme

sequence for rinsing and bleeding the water lter and

the water system is performed. While doing so, hot

water ows out of the hot water outlet.

Follow the water lter

instructions!

The displays lead through the

programme step-by-step.

Follow the instructions!

Descaling

The water hardness, the water ow and whether a

water lter is used determine the

remaining litres until descaling is necessary.

This litre specication is calculated and displayed by

the Schaerer Coee Club.

42

Brewer change

Descaling

Descaling chapter

w from page 76

SCClub operating instructions

Page 43

Brewer care

Software

After 15,000 brewing cycles, the O-ring on the

brewing unit must be changed. When the end of the

service life is reached, a daily noti cation appears as

a reminder that a change is overdue.

* Change the O-ring

* Con rm the change

5.4 Beverages

General information

Test output

For many beverage settings, it is possible to start a

test output with the new settings before the recipe is

saved.

* Change the settings as desired

* Tap on the "Test output" icon eld

The beverage is dispensed with newly-set values.

* If the beverage is as desired, tap on the Save icon

The recipe is saved.

Saving recipes

Brewer care

Example: Cappuccino button

The changed recipe is saved here

Loading recipes

A saved recipe is loaded here on a beverage button

* Tap on a beverage button

* Tap on the "Load recipes" icon eld

A sub-menu opens.

* Mark the desired recipe

* Tap on the "Save recipes" eld

The beverage button is assigned with the

newly-selected recipe.

SCClub operating instructions

43

Page 44

Software

S M L

Filling quantity, animation cup tray, multiple brewing and dosing type

Filling quantity

Set the desired lling quantity. The recipe is adjusted

appropriately.

100% corresponds to the previously saved value.

Animation cup tray

The “animation cup tray” is displayed after the

beverage selection, if it was previously activated

under “lling quantity” per beverage. Check the check

mark in the “animation cup tray” eld.

Procedure for beverage dispensing:

* Press the desired beverage button

The animation is shown on the display.

* Conrm with the green check mark

* The beverage is dispensed

S-M-L lling quantity

Display only if the S-M-L function is activated in the

system. The recipes are generated for the sizes S

and L. M is as set (medium).

The standard values are:

S = 25% less than M

L = 25% more than M

S-M-L function

The S-M-L function can be activated in the System

menu. A deviation from the standard lling quantity

can also be changed in general for all beverages

under System.

The S-M-L quantities must be changed under Filling

quantity (beverage settings) for deviating individual

beverages.

Every size can be individually set to active or inactive.

Inactive means the size cannot be selected for this

beverage in this case (remove check mark for each

size to do this). Then save.

44

97

98

99

100

101

102

103

122

123

124

125

126

127

128

72

73

74

%

75

76

77

78

S-active Active L-active

Changing S-M-L for individual

beverages

w Filling quantity

Activating S-M-L and changing

generally for all beverages

w System

w S-M-L

page 66

Operation

w Special buttons

w page 26

SCClub operating instructions

Page 45

Multiple brewing

The beverage is brewed several times as set. Up to

12 times the set quantity can be dispensed at the

push of a button.

Available for coee and mixed milk beverages as well

as for hot water with the “Portion control” dosing type.

Dosing type

The dosing type can be determined for hot water,

milk foam, milk and steam. All other beverages are

already dispensed with dosing.

• Start-stop

The dispensing is carried out until the set quantity

has been reached. Dispensing can be stopped

earlier by pressing the button again.

• Dosed

The set quantity is dispensed. The dosing type is

available for milk, foam and hot water.

• Freeow

The beverage or steam is dispensed as long as

the button remains pressed.

• Start-stop freeow

Briey pressing the button starts the start-stop

dispensing process.

Pressing the button for longer than 1 second starts

the freeow dispensing process.

Software

SCClub operating instructions

45

Page 46

Software

Changing recipes

Current recipe composition

The additions contained in the recipe are shown here.

The preparation order is from left to right. Additions

listed under one another are prepared at the same

time.

The software reports if the desired options are

technically impossible.

Menu control elds

w Overview

page 38

Stock default additions

The additions which can be used for the recipes are

shown here.

* Tap on the desired addition and push it into the

current recipe composition.

46

SCClub operating instructions

Page 47

Deleting addition

Delete a marked addition from the current recipe

composition.

Changing addition

* Mark the addition and tap on the "Change

addition" symbol.

The Change addition menu opens.

The setting options for the desired addition are

displayed.

The saved and the current data is displayed.

The current values

The values saved by Service

The factory values

Ground coee quantity

Given in grams (g)

Water/Milk volume

Software

Given in millilitres (ml)

SCClub operating instructions

47

Page 48

Software

Coee quality

The quality levels inuence the brewing of the coee.

The higher the quality level, the more intensive is the

release of the coee’s avouring agents.

Quality levels

1 After being pressed, the ground coee is given

room to swell.

2 After being pressed, the beverage is brewed

directly.

3 After being pressed, a pre-brewing takes place

4 After being pressed and pre-brewing, the

ground coee is pressed while wet.

5 Like quality 4, but more forceful wet pressing.

6 Like quality 5, but longer and more forceful wet

pressing.

7 Like quality 6, but longer and more forceful wet

pressing.

Select coee grinder (optional)

For each coee recipe, you can choose which coee

grinder to use.

The value 1 is assigned to the desired coee grinder

Note

If very ne ground coee is

used with a very small amount

of brewing water, a high quality

level can lead to brewing water

errors.

Grinder 1 Grinder 2 Ground coee

1 0

0 1

The ground coee from grinder

1 is used.

The ground coee from grinder

2 is used.

The ground coee is taken

1 1

half each from grinder 1 and

grinder 2.

“Select coee grinder” is possible for coee

machines with two grinders.

48

NOTE

SCClub operating instructions

Page 49

Text and image

Cappuccino

Change text + picture

Recipe number 10 Factory: 10

Text + picture

Cappuccino

Note

The beverage name and the picture of a beverage

button are adjusted here.

For text adjustments: Activate the keyboard with the

keyboard icon.

For picture adjustment: Tap on the current picture.

Software

Menu control elds

w Overview

page 38

Remarks

A note on the beverage can be stored here.

SCClub operating instructions

49

Page 50

Software

Operating elements

5.5 Operating options

Operating elements

Self-service mode

Some functions could be switched to be inactive for

self-service mode.

These functions and their elds are not shown when

they are inactive.

Options: • Active

• Inactive

Standard value:

Self-service mode means the following settings are

switched at the same time.

• Barista eld: inactive

• Warm rinse eld: inactive

• Menu eld: delayed

• SteamJet: inactive

• Error indication: Symbol

• Adjustment cup size: inactive

• Language pre-selection: inactive

• Animation cup tray: active

Inactive

Standard settings

Barista eld

Options: • Active

Standard value:

Active The eld appears at the bottom when the

machine is ready for use. Three-stage co ee

strength setting.

Active

• Inactive

50

SCClub operating instructions

Page 51

Warm rinse eld

Software

Options: • Active

Standard value:

Active

• Inactive

Active The eld appears at the very bottom when

the machine is ready for use. Recommended

for longer breaks or espresso.

Menu eld

Options: • Immediately

• Delayed

Standard value:Immediately

Immediately The menu eld immediately reacts after

tapping on the eld.

SteamJet

Options: • Active

Standard value:

Inactive

• Inactive

Active Cup warmer option. The eld appears at the

bottom when the machine is ready for use.

Error indication

The fault is reported with dierent colours in the

display header.

Options: • Text

• Symbol

Standard value:Text

SCClub operating instructions

51

Page 52

Software

Cup size adjustment

The free lling quantity selection can be activated in

the operating options.

The lling quantity can thus be adapted to the cup

size used before beverage selection.

Options: • Active

• Inactive

Standard value:

Inactive

If the cup is pushed to the right on the controller, the

lling quantity increases, while pushing to the left

lowers the lling quantity.

The lling quantity is given in percent.

Controller in the middle 100% as set

Controller all the way to the left 50% less

Controller all the way to the right 50% more

Language pre-selection

Whether the pre-selection of languages and ags

is possible when the machine is ready for use is set

here. “Language pre-selection” can be activated here

individually for up to 5 language buttons.

The second option under “Operating options” is the

selection of the “Self-service + ags” button layout.

Options: • Active

Standard value:

Inactive

• Inactive

Animation cup tray

Here you can set whether the “Animation cup tray”

is enabled in the beverage settings. The animation

can be activated or deactivated here for all recipes

dened in the beverage settings.

Options: • Active

• Inactive

Button layout “self-service +

ags”

wButton layout page 53

Standard value:

52

Active

SCClub operating instructions

Page 53

Button layout

Button layout

Dierent standard layouts are saved here and can be

selected.

PostSelection

Software

Options: • Active

Standard value:

Inactive

• Inactive

Active The selection of the coee type and the

beverage size are queried after the beverage

has been selected.

The names of the coee types and the sizes

can be changed. (Coee type and S-M-L).

• Size 1

• Size 2

• Size 3

• Portioner 1

• Portioner 2

Some functions could be switched to be inactive for

self-service mode.

The functions and their elds are not shown when

they are inactive.

Display mode

Options: • Single-page

• Multi-page

Standard value:• Single-page

PostSelection

Display mode

Decaeinated

Options: • Active

Standard value:

Inactive

Active Percentage of the coee grind quantity of the

standard recipe.

SCClub operating instructions

• Inactive

Decaf

53

Page 54

Software

Decaf factor

Decaf factor

The value for the decaf factor is entered here.

The ground coee quantity for decaf (descaeinated)

is determined in percent of the ground coee quantity

set in the recipe.

This setting applies for all coee beverages with the

“Decaf” pre-selection.

At a 15% decaf factor, coee,

for example, is brewed with

15% more ground coee

compared to the standard recipe

when preparing with the decaf

function.

Options: • Active

Standard value:

Inactive

• Inactive

Beverage pre-selection

Options: • Active

Standard value:

Inactive

Active Previously selected beverages are dispensed

without the button being pushed again.

Beverage cancellation not possible.

• Inactive

Cancel beverage

Options: • Active

Standard value:

Active

Active Beverage dispensing can be cancelled by

pressing the beverage button again.

• Inactive

Beverage pre-selection

Cancel beverage

54

SCClub operating instructions

Page 55

5.6 Info

Timer

Care

Filter/descaling

Journal

The Info menu o ers the selection options described

in the following.

Last brewing

Information on the last brewing.

Timer

The timer weekly overview is called up. All

switching-on and switching-o times are shown in this

overview.

Service

Contact information for Schaerer Service.

Serial number of the co ee machine.

Care

The last cleanings and care measures which run via

co ee machine programmes are shown here.

Software

Last brewing cycle

Service

Water lter and descaling

Information on the remaining service life of the water

lter and the time of the next descaling process.

Journal

Log of events and errors relating to the operation and

cleaning of the co ee machine.

SCClub operating instructions

55

Page 56

Software

DI_abr

5.7 Accounting

Counters

The counters of the dispensed individual beverages

and the sum of the beverages are shown here.

A protocol can be read out using the USB output.

Accounting

Counters

SML 1 2 3 4

Cappuccino M

Cappuccino L

Chociatto M

Chociatto L

Espresso M

Hot water M

Latte

Macchiato

Latte

Macchiato

Milk M

Coffee M

4 66 510 5900

2 40 306 3540

9 48 416 4200

5 24 208 2100

2 33 255 2950

3 44 340 3933

2 33 255 2950

M

2 26 204 2360

L

1 17 128 1475

3 53 408 4720

Counters

Standard setting

Counter 1 = daily counter

Counter 2 = weekly counter

Counter 3 = monthly counter

Counter 4 = annual counter

All counters can be reset.

56

TIP

SCClub operating instructions

Page 57

co eeMYsation (App)

Software

Accounting

The accounting system for users of the

co eeMYsation app can be activated or deactivated

here. With the co eeMYsation app, the user can

dispense individually set beverages via Bluetooth

on the way to the machine. It can be used for all

Schaerer Co ee Club machines. The individual

recipes are therefore not bound to just one machine.

If “Accounting” is activated, the following functions

can be accessed:

• Load user list

• Save user list

• Charge for consumption

In order to use the accounting function of the

app, the Bluetooth function must be activated

under system.

5.8 PIN rights

A PIN can be assigned for all of the areas listed

below.

• Cleaning

• Setting

• Accounting

co eeMYsation

NOTE

The PINs are hierarchically structured.

That means, for example: The setting PIN

simultaneously releases all rights for the cleaning

PIN, but not all the rights for the accounting PIN.

If no PIN is assigned, the area is accessible without

a PIN.

If a PIN is assigned to an area, no access is granted

without that PIN.

SCClub operating instructions

57

Page 58

Software

Cleaning

Settings

Accounting

Cleaning PIN

After the valid PIN is entered, access to:

Care

Setting PIN

After the valid PIN is entered, access to:

Care Timer

Beverages System

Operating option Language

Accounting (without

USB

"deletion")

Accounting PIN

After the valid PIN is entered, access to:

Care PIN

Beverages Timer

Operating option System

Accounting (with

"deletion")

Language

USB

58

SCClub operating instructions

Page 59

5.9 Timer

DI_timer

DI_04_11_00_00

Button layout overview

Time/Date

The current time and data are set here.

Status of button layout

Options: • Active

• Inactive

Software

Time / date

Status of button layout

Standard value:

Inactive

Active Button layouts can be assigned automatically

using the timer.

Button layout overview

Timer

Button layout overview

Button layout

Mo Tu We Th Fr Sa Su

00:00 06:.. 00:00 06:.. 00:00 06:.. 00:00 06:.. 00:00 06:.. 00:00 06:.. 00:00 06:..

00:00

01:00

02:00

03:00

04:00

05:00

06:00

07:00

08:00

09:00

10:00

11:00

12:00

13:00

14:00

15:00

16:00

17:00

18:00

19:00

20:00

21:00 00:.. 21:00 00:.. 21:00 00:..

21:00

22:00

23:00

The weekly overview of all switching times for the

button layout is displayed.

The settings can be changed directly in the overview.

21:00 00:.. 21:00 00:.. 21:00 00:.. 21:00 00:..

For example self-service from 9

pm to 6 am.

The minimum time for displaying

a button layout is 30 minutes.

SCClub operating instructions

59

Page 60

Software

5.10 System

Milk and foam

The central, generally-applicable values for milk and

milk foam are set here. These values apply for all

available recipes.

If special values for milk and milk foam are set in the

recipes, they remain valid and are not changed.

Milk storage temperature

Options:

>16 °C = green milk nozzle (standard)

<10 °C = orange milk nozzle (accessories)

<5 °C = blue milk nozzle

(optional special accessories*)

The green nozzle should be used from 10 °C.

We recommended a milk storage temperature

of 16-22 °C for optimal results when using

uncooled milk. The blue nozzle for a constant

temperature of less than 5 °C must be

ordered and activated by a technician if

needed.

Progress display

Options: Line, circle, o

Milk and foam

*Only in case of constant milk

storage temperature of < 5 °C.

NOTE

Progress indicator

Standard value:Line

60

SCClub operating instructions

Page 61

Display and lighting

Display and illumination

Parameters relating to the display such as brightness

and lighting at the outlet can be found in this system

menu.

Lighting concept

Consisting of two parameters:

1. Lighting (at the outlet)

Software

Options: • Active

Standard value:

Inactive

• Inactive

Active While the machine is ready for use, a small

light is constantly illuminated directly behind

the beverage outlet.

2. Event (message) display

Options: • Active

Standard value:

Inactive

• Inactive

Active The lighting during a message is activated.

Display brightness

The display brightness can be congured in 5 percent

steps.

Decrease display brightness automatically

Options: • Active

Standard value:

Active

• Inactive

SCClub operating instructions

61

Page 62

Software

Active

If „Automatically decreasing brightness“

is activated, the display brightness is

automatically decreased 5 minutes after the

last beverage dispensing process (break in

operation).

If the display brightness has been decreased,

the display goes back to the selected

brightness when the display is tapped for the

rst time. Tapping on the beverage button for

the second time dispenses the corresponding

beverage.

Touch calibration

Recalibrate the touch display.

Display background

The colour design for the touch display can be set

here.

• Background for the main page

• Background for more pages

Beverages: Font + colour

Here you can set whether the font colour and size for

the beverages are allowed to be changed.

Options: • Active

• Inactive

Beverages: font + colour

Standard value:

Active

The precise font colour and size settings can

be made in the next step.

62

Inactive

SCClub operating instructions

Page 63

Water lter

Water lter

Information on water hardness and water lter service

life.

Options: • Active

Standard value:

Inactive

• Inactive

Software

Note

No water lter is required at a

water hardness of 0 to 4 °dKH.

Active

A water lter is present. Measured water

hardness and water lter service life

(according to table) are queried, see below.

Measured carbonate hardness

The measured water hardness in °dKH is entered

here.

* Obtain the water hardness of the drinking water

from the water supplier or use the carbonate

hardness tester (with instructions) in the

accessories.

The carbonate hardness test is included in the

accessories supplied.

Measured total hardness

If the coee machine is operated with

incorrectly set water hardness, this can lead

to a high level of calcication and therefore to

leaky valves.

No liability is assumed for damages resulting

from this.

NOTE

Filter service life (water lter)

The lter service life in litres is entered here if there is

an active water lter.

Example: With a measured carbonate hardness of 10

°dHK, the lter range to be set is 200 litres.

SCClub operating instructions

Water lter service life table

w page 24

63

Page 64

Software

Temperature

Switch-off rinsing

system rinsing

Temperature