Page 1

Schaerer Coffee Art Plus Best Foam™

Operating instructions

V02 / 06.2016

Schaerer Ltd. P.O. Box 336 Original operating instructions

Page 2

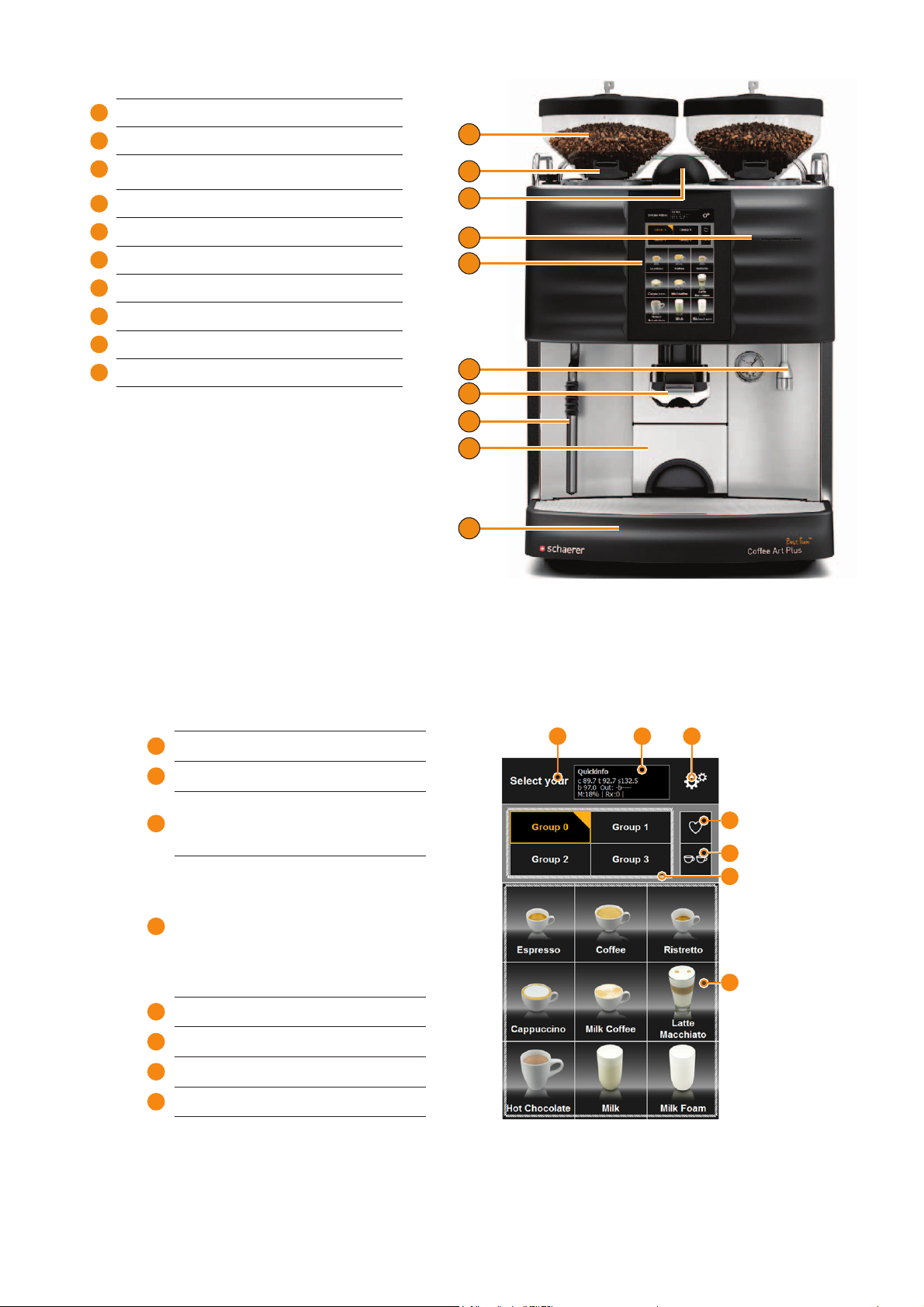

1

Bean hopper with lid

2

Bean hopper lock

3

Inlet for ground coffee/cleaning tablets

(cleaning programme)

4

Card reader

5

Display (see below)

6

Hot water outlet

7

Beverage outlet

8

Steam wand Powersteam (option)

9

Grounds container

10

Drip tray with drip grid

Schaerer Coffee Art Plus Best Foam™

1

2

3

5

4

7

8

9

10

6

1

Statusbar

2

Quick info

3

Selection list: Standby mode

Ɣ [Quick Menu] ¿HOG

Ɣ [Cancel] ¿HOG

3

Selection list: „Operator“ mode

Ɣ [Cleaning] ¿HOG

Ɣ [Rinsing] ¿HOG

Ɣ [Flavour Point] ¿HOG

Ɣ [Cleaning touchscreen] ¿HOG

Ɣ [Quick info] ¿HOG

Ɣ [Standby] ¿HOG

4

3UHVHOHFWLRQ¿HOG>'ecaf]

5

3UHVHOHFWLRQ¿HOG>2x@>%DULVWD@¿HOG

6

Beverage group (programmable)

7

%HYHUDJH¿HOGSURJUDPPDEOH

1 2 3

4

5

6

7

Schaerer Ltd.

P.O. Box 336

Allmendweg 8

CH-4528 Zuchwil

info@schaerer.com

www.schaerer.com

Original operating instructions

BASCAP_BF_en

N° 021316

Page 3

www.schaerer.com

Schaerer Coffee Art Plus Best Foam™

Operating instructions

V02 / 06.2016

Published by

Schaerer Ltd., P.O. Box 336, Allmendweg 8, CH-4528

Zuchwil

Edition

Version 02 | 06.2016

Software

V1.23

Concept and editorial department

Schaerer Ltd., P.O. Box 336, Allmendweg 8, CH-4528

Zuchwil

Copyright by ©

Schaerer Ltd., P.O. Box 336, Allmendweg 8, CH-4528

Zuchwil

This document is copyrighted. All rights are reserved. The reproduction, distribution, transmission via electronic systems or translation of this document in another language is not permitted without the written consent of Schaerer Ltd. This applies to the entire

document, as well as to individual excerpts thereof. The contents of the document are based on the most current data available at

the time of printing. Schaerer Ldt. reserves the right to make changes at any time without further notice. All pictures, illustrations

and display messages in this manual serve only as examples. Due to the wide variety of possible options, a particular machine

may differ from the devices depicted here. Schaerer AG is only liable for the contents of the original German document.

BASCAP_BF_EN

V02 | 06.2016

3

Page 4

www.schaerer.com

Table of contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Signs and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General safety notes . . . . . . . . . . . . . . . . . . . . . . . . . 7

Danger to the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Risk of damage to the machine . . . . . . . . . . . . . . . . . . . . . . 10

Product description . . . . . . . . . . . . . . . . . . . . . . . . 11

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Beverage types and output . . . . . . . . . . . . . . . . . . . . . . . . . 11

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Scope of delivery and accessories. . . . . . . . . . . . . . . . . . . . 12

Options and optional accessories . . . . . . . . . . . . . . . . . . . . 12

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Serial plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manufacturer's address . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Applied standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation and commissioning. . . . . . . . . . . . . . . 18

Setting up the coffee machine . . . . . . . . . . . . . . . . . . . . . . . 18

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Water connection/drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Deinstallation and disposal . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Check before switching on . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Switching the machine on . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Starting the PC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Standby Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Switch on coffee machine (touch screen). . . . . . . . . . . . . 22

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Quick info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Main touch screen window. . . . . . . . . . . . . . . . . . . . . . . . . . 24

Barista Silver (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Beverage selection with groups . . . . . . . . . . . . . . . . . . . . . . 27

Beverage groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

None (all beverages on one page) . . . . . . . . . . . . . . . . . . 28

Before/after product selection. . . . . . . . . . . . . . . . . . . . . . 28

Self-service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Filling and connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coffee beans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Milk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Automatic machine powder. . . . . . . . . . . . . . . . . . . . . . . . 32

Flavour Point (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adjusting the outlet height. . . . . . . . . . . . . . . . . . . . . . . . . 32

Coffee beverages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Beverages with ground coffee. . . . . . . . . . . . . . . . . . . . . . 33

Hot water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Milk beverages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Flavoured beverages . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dispensing options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Stop dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Pre-selecting beverages . . . . . . . . . . . . . . . . . . . . . . . . . .35

Double beverage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Emptying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Grounds container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Under-counter grounds disposal . . . . . . . . . . . . . . . . . . . . 36

Waste water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Transport requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Display notes/instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Switching the machine off. . . . . . . . . . . . . . . . . . . . . . . . . . .38

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Extended downtimes (1 week or more). . . . . . . . . . . . . . .38

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Cleaning instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Cleaning options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Hot rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Automatic rinsing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Daily cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Automatic cleaning programme . . . . . . . . . . . . . . . . . . . . 42

Touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Milk container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Drinking water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Grounds container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

External waste water tank . . . . . . . . . . . . . . . . . . . . . . . . . 43

Side cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Manual weekly cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Bean hoppers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Defrosting the cooling unit (Option). . . . . . . . . . . . . . . . . . 44

Flavour Point (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Schaerer Coffee Art Plus with powder system (Option) . . 45

As needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Flavour Point (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Drip tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Cup Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

HACCP cleaning concept . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Service and maintenance . . . . . . . . . . . . . . . . . . . . 49

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

External water filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4

BASCAP_BF_EN

V02 | 06.2016

Page 5

Enable/Disable parameters . . . . . . . . . . . . . . . . . . . . . . . .51

Selection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Adjusting the setting range . . . . . . . . . . . . . . . . . . . . . . . .51

Parameters with lettering. . . . . . . . . . . . . . . . . . . . . . . . . .51

Parameters with numbers . . . . . . . . . . . . . . . . . . . . . . . . .52

Standby Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Entering the programming level . . . . . . . . . . . . . . . . . . . . . .53

TouchIT configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Counters and statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Product settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Dispensing a test product . . . . . . . . . . . . . . . . . . . . . . . . .59

Coffee setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Milk setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Choco setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Hot water settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Steam setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Flavour settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

System settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Automatic timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Cleaning instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Screen design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Logo/Screensaver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Change standby logo . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Change screensaver picture . . . . . . . . . . . . . . . . . . . . . . .64

Image and file formats. . . . . . . . . . . . . . . . . . . . . . . . . . . .64

www.schaerer.com

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Faults in the Best Foam™ milk system . . . . . . . . . . . . . . . .66

Faults with display message. . . . . . . . . . . . . . . . . . . . . . . . .66

Faults without display message . . . . . . . . . . . . . . . . . . . . . .68

Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Danger posed by cleaning products . . . . . . . . . . . . . . . . . . .69

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Emergency information . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Hygiene rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Coffee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Milk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Automatic machine powder / Instant powder . . . . . . . . . .71

Syrup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Operator responsibilities. . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

BASCAP_BF_EN

V02 | 06.2016

5

Page 6

www.schaerer.com Introduction

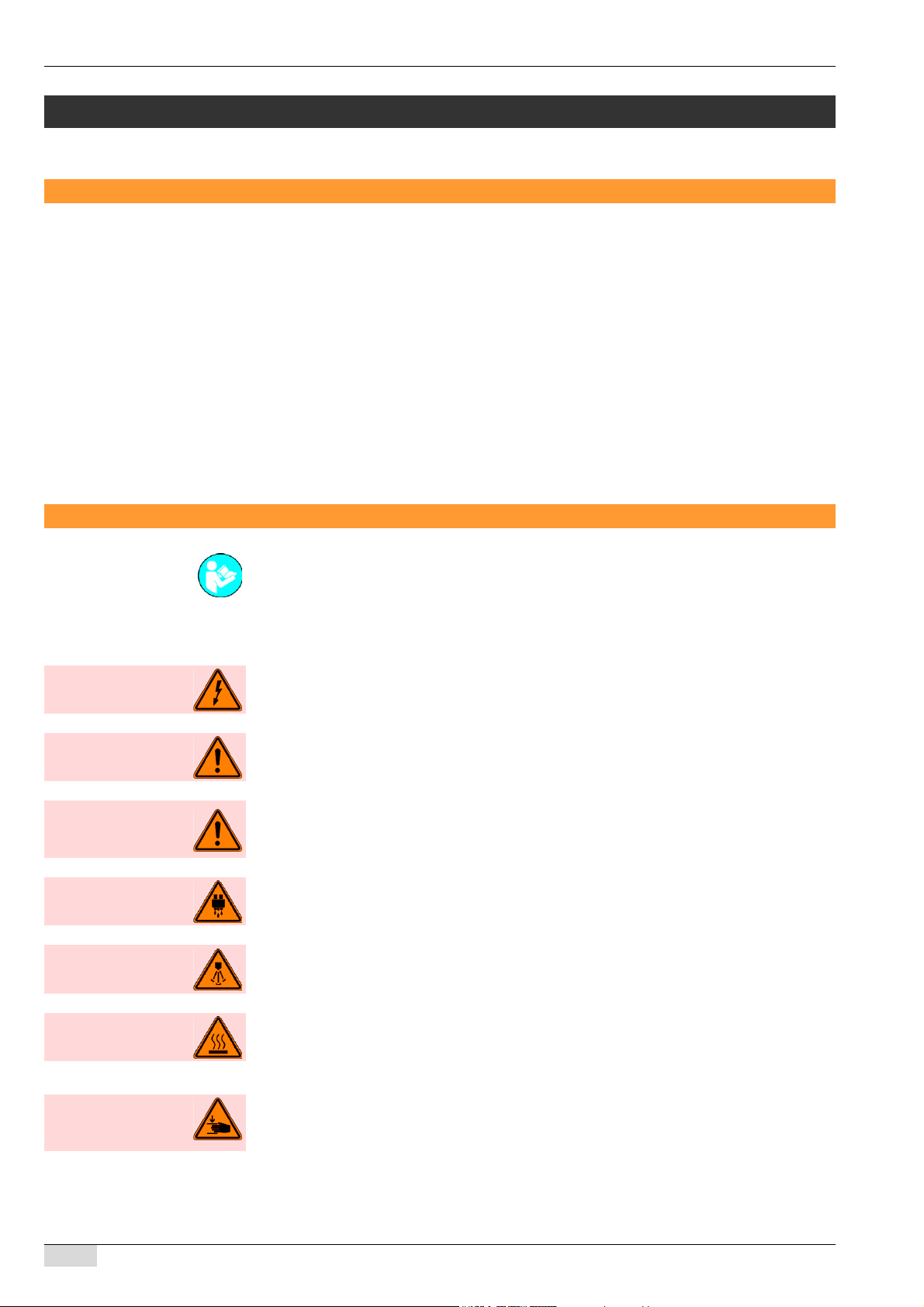

DANGER!

Risk of electrocution!

CAUTION!

User at risk!

CAUTION!

Risk of machine

damage!

CAUTION!

Hot fluid!

CAUTION!

Hot steam!

CAUTION!

Hot surface!

CAUTION!

Risk of trapping

fingers!

Introduction

Welcome

This coffee machine is part of the next generation of fully automatic coffee machines. In designing this equipment, we utilised both our company's core competencies and our decades

of experience.

These operating instructions provide information about the product, its operation and how to

clean the coffee machine. If the coffee machine is not used in accordance with the instructions,

we cannot be held liable for any damages. However, these operating instructions cannot take

every possible application into account. For further information, please contact our customer

service.

The performance of the coffee machine depends on its proper operation and maintenance.

Carefully read the operating instructions before using the machine for the first time, and keep

the instructions in an easily accessible place.

We hope you enjoy using your new coffee machine!

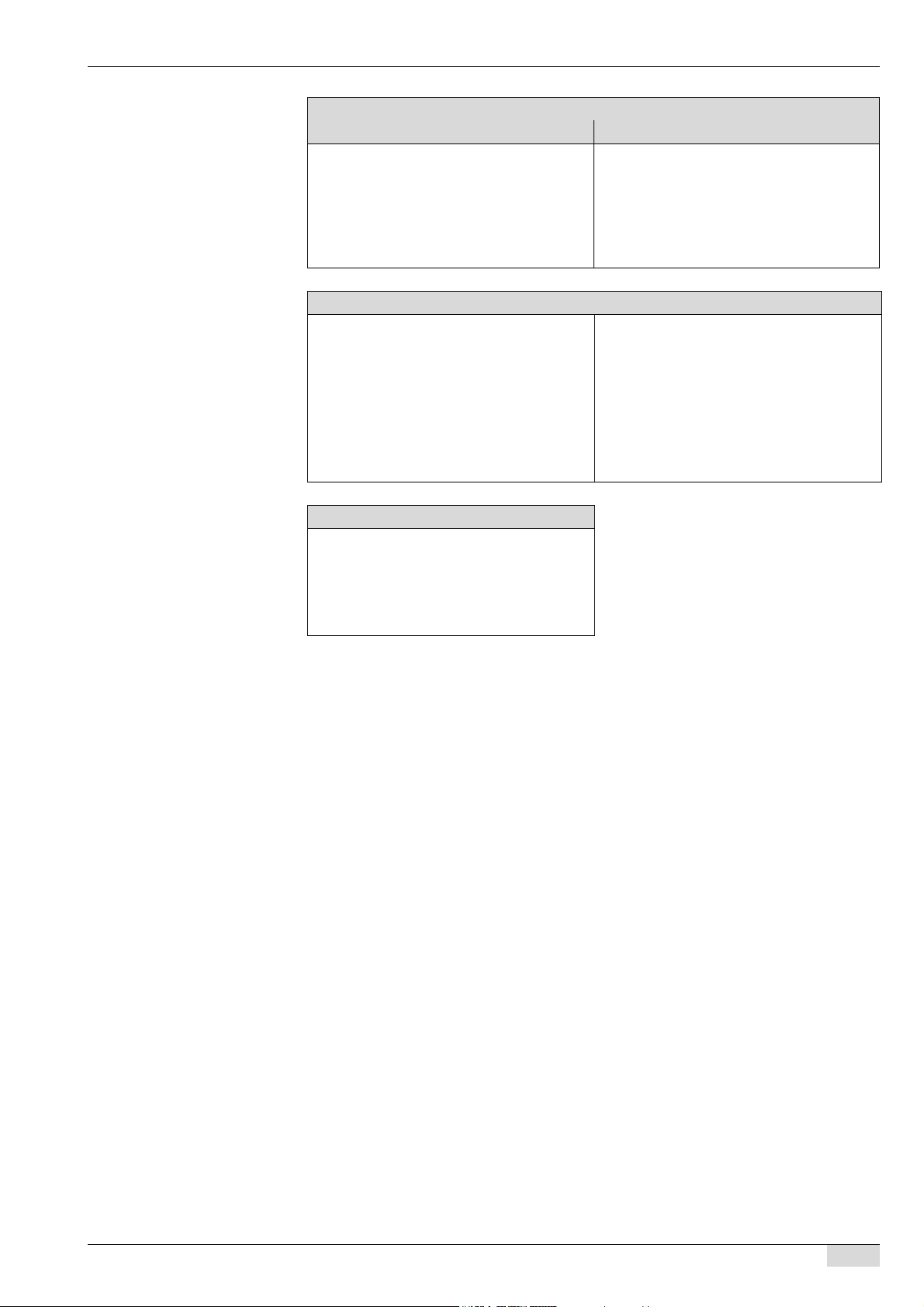

Signs and symbols

See also "General safety notes"

The following signs and symbols are used in these operating instructions to point out sources

of danger and special features:

An imminently dangerous situation that may result in death or serious injury from electric shock.

The measures described to prevent this danger must be adhered to.

A generally dangerous situation that may result in injury.

The measures described to prevent this danger must be adhered to.

A situation that may result in damage to the machine.

The measures described to prevent this danger must be adhered to.

A dangerous situation that may result in scalding injuries. This danger arises at the dispensing areas. It is only indicated by the symbol in the following instructions.

The measures described to prevent this danger must be adhered to.

A dangerous situation that may result in scalding injuries. This danger arises at the dispensing areas. It is only indicated by the symbol in the following instructions.

The measures described to prevent this danger must be adhered to.

6

A dangerous situation that may result in burn injuries. This danger arises at the dispensing areas and cup warmer locations (option). It is only indicated by the symbol in

the following instructions.

The measures described to prevent this danger must be adhered to.

A dangerous situation that may result in crushing injuries. It is only indicated by the

symbol in the following instructions.

The measures described to prevent this danger must be adhered to.

BASCAP_BF_EN

V02 | 06.2016

Page 7

www.schaerer.comGeneral safety notes

CAUTION!

User at risk!

General safety notes

Maximum safety is one of the most important features of Schaerer AG products. The effectiveness of the safety equipment can only be ensured if the chapter containing precautions to

avoid injury and danger to health are adhered to.

The safety notes can be requested from Schaerer AG or downloaded directly from the MediaCentre on the website (http://www.schaerer.com/member).

Danger to the user

Improper handling of the coffee machine can lead to minor injuries.

Please observe the following points:

• Read the operating instructions carefully before using the device.

• Do not use the coffee machine if it is not working properly or is damaged.

• Under no circumstances must the installed safety devices be modified.

• Do not touch hot machine parts.

• Under continuous supervision this device can be used by children

aged 8 and up and by persons with limited physical, sensory or

mental capabilities or a lack of experience and/or knowledge, provided they have been instructed about the safe use of the device

and understand the potential hazards resulting from said use.

• Supervise children to ensure that they do not play with the device.

• Cleaning and user maintenance must not be performed by children.

• The coffee machine must be installed so that care and maintenance

are possible without any interference.

• Whether the machine is used for self-service or full-service operation, trained personnel must supervise the machine to ensure that

care measures are performed and that personnel is available to answer questions regarding its use.

• Only fill the bean hopper with coffee beans, the powder container

with automatic machine powder and the manual inlet with ground

coffee (or cleaning tablets during cleaning).

BASCAP_BF_EN

V02 | 06.2016

7

Page 8

www.schaerer.com General safety notes

DANGER!

Risk of electrocution!

CAUTION!

User at risk!

CAUTION!

User at risk!

Improper handling of electrical devices can result in electric

shock.

Please observe the following points:

• Work on electrical systems must only be performed by qualified

electricians.

• The device must be connected to a fused electrical network (we recommend routing the connection through a residual-current device).

• All applicable low voltage guidelines and/or country-specific or local

safety regulations and laws must be observed.

• The connection must be properly earthed and protected against

electric shock.

• The voltage must match the specified values on the device's serial

plate.

• Never touch live parts.

• Before performing service work, always switch off the main switch

and/or disconnect the device from the power supply.

• The power cable must only be replaced by qualified service technicians.

Beverages containing additives or traces of additives may trigger

allergies.

Please observe the following points:

• For self-service mode, a sign should be displayed in the vicinity of

the machine to provide information about any additives used which

could trigger an allergic reaction.

• For full-service mode, trained personnel should be on hand to pro-

vide information about any additives used which could trigger an allergic reaction.

Danger of poisoning from swallowing cleaning products.

Always observe the following points:

• Store cleaning products away from children and unauthorised per-

sons.

• Do not swallow the cleaning products.

• Never mix cleaning products with other chemicals or acids.

• Never pour cleaning products into the milk container.

• Never pour cleaning products into the drinking water tank (internal/

external).

• Only use the cleaning and descaling products for their intended purpose (see label).

• Do not eat or drink while handling cleaning products.

• Ensure that the area is well ventilated when handling cleaning products.

• Wear safety gloves when handling cleaning products.

• Wash your hands thoroughly after handling cleaning products.

8

Before using cleaning products, read the information on the package carefully. If it is not already on hand, the health and safety data sheet can be obtained from the sales partner (see

cleaning product packaging).

BASCAP_BF_EN

V02 | 06.2016

Page 9

www.schaerer.comGeneral safety notes

CAUTION!

Hot fluid!

CAUTION!

Hot surface!

CAUTION!

Risk of trapping

fingers!

There is a risk of scalding in the area where beverages, hot water

and steam are dispensed.

Never reach under the dispensing units while the machine is dispensing or during cleaning.

The dispensing units and brewing unit can become hot.

Do not touch any part of the dispensing equipment except for the

grips provided. Only clean the brewing unit after the coffee machine has cooled down.

When working with moving components, there is a risk of fingers

or hands becoming trapped.

While the coffee machine is switched on, never reach into the

bean hoppers or powder containers or into the opening of the

brewing unit.

BASCAP_BF_EN

V02 | 06.2016

9

Page 10

www.schaerer.com General safety notes

CAUTION!

Risk of machine

damage!

Risk of damage to the machine

Improper handling of the coffee machine can lead to damage or

contamination.

Please observe the following points:

• For water with a carbonate hardness above 5 °dH, install a calcium

filter, as the coffee machine can otherwise be damaged by limescale deposits.

• For insurance reasons, always ensure that at the end of the business day, the stop valve on the water supply (coffee machine with

mains water supply) is closed and the main power switch is

switched off or the power cable is unplugged.

• Applicable low voltage guidelines and/or country-specific or local

safety regulations and laws must be observed.

• Do not operate the device if the water supply is blocked. Otherwise,

the boilers will not be refilled and the pump will run dry.

• To prevent water damage in case of hose breakage, Schaerer AG

recommends routing the water supply connection through a water

shut-off valve (at the installation site).

• After extended downtime (e.g. holiday), the coffee machine must be

cleaned before it is put back into operation.

• Protect the coffee machine from weather elements (frost, moisture,

etc.).

• Faults must only be remedied by a qualified service technician.

• Only use Schaerer AG original spare parts.

• Report any noticeable damage or leaks immediately to an authorised service partner, and have any faulty parts replaced and/or repaired.

• Never spray off the device with water or clean it using a steam

cleaner.

• Do not set up the device on surfaces on which a water jet might be

used.

• When using caramelised coffee (flavoured coffee), clean the brewing unit twice daily.

• Only fill the bean hopper with coffee beans, the powder container

with automatic machine powder and the manual inlet with ground

coffee (or cleaning tablets during cleaning).

• Never use freeze-dried coffee as it clogs the brewing unit.

• If the coffee machine and/or auxiliary equipment is transported at

temperatures below 10°C, the coffee machine and/or auxiliary

equipment must be stored at room temperature for three hours before it can be connected to the power supply and switched on. If

these instructions are not followed, condensation may cause short

circuits or damage electrical components.

• Always use the new hose set supplied with the machine (drinking

water/waste water hose). Never use old hose sets.

10

BASCAP_BF_EN

V02 | 06.2016

Page 11

www.schaerer.comProduct description

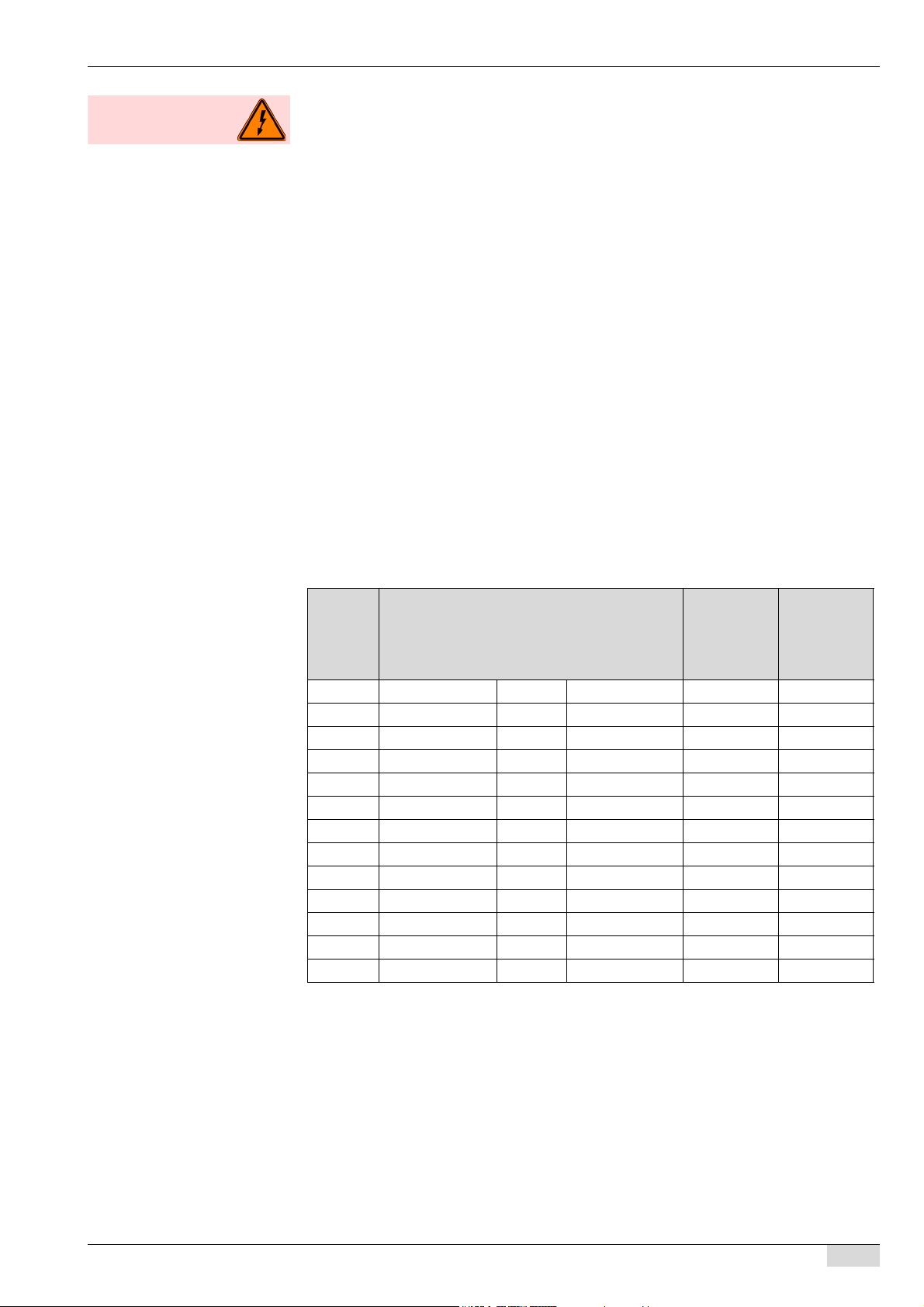

CAUTION!

Risk of machine

damage!

Product description

Intended use

The Schaerer Coffee Art Plus has been designed to dispense coffee beverages, hot water,

powder-based beverages (toppings & chocolate) and milk beverages, optionally with syrup, in

different versions and combinations in cups, mugs, glasses or pots. The steam wand is intended solely for warming up milk.

This device is intended for commercial use in hotels, restaurants and similar establishments.

The device is permitted to be installed at self-service locations when a staff member is present

for supervision purposes. The device can be used in businesses, offices and other similar work

environments, hotels, motels and bed and breakfast establishments and can be operated by

non-experts and customers.

Under continuous supervision this device can be used by children aged 8 and up and by persons with limited physical, sensory or mental capabilities or a lack of experience and/or knowledge, provided they have been instructed about the safe use of the device and understand the

potential hazards resulting from said use. Children must not play with the device. Children

must also not be allowed to perform cleaning procedures or user service.

Use of this equipment is subject to the "General Terms and Conditions" of Schaerer AG and

these operating instructions. In legal terms, any other use is not an intended use. The manufacturer accepts no liability for damage resulting from unintended use.

Improper handling of the coffee machine can result in damage.

Under no circumstances may the Schaerer Coffee Art Plus be used to heat or dispense

any liquid other than the named or cooled milk (pasteurised, homogenised, UHT).

Beverage types and output

Depending on the machine variant and options, the following beverages can be prepared:

Beverage output per hour

Espresso 50-60 ml ± 250 cups

Coffee 120 ml ± 250 cups

Available beverages:

Ristretto Espresso

Coffee Americano

White Americano Milk coffee

Cappuccino (Light, Classic, Fujiyama(light)) Latte Macchiato

Espresso Macchiato Chociatto

Flat white Hot chocolate

Coffee with liquor Coolmacc

Hot milk Cold milk

Hot milk foam Cold milk foam

Caffeine-free beverages Mug

Flavoured coffee and milk beverages Powder based beverages

Steam Hot water

BASCAP_BF_EN

V02 | 06.2016

11

Page 12

www.schaerer.com Product description

Models

The Schaerer Coffee Art Plus Best Foam™ is available in the following models:

• Schaerer Coffee Art Plus Best Foam™ with under-counter milk system

• Schaerer Coffee Art Plus Best Foam™ with Centre Milk

• Schaerer Coffee Art Plus Best Foam™ with powder system

• Schaerer Coffee Art Plus Best Foam™ with Flavour Point

Scope of delivery and accessories

Quantity Designation Article number

Documentation

1 Operating instructions

*

*

Cleaning instructions

Supplementary instructions for cup warmer + Cup &

Cool

Smart card

1 CHEF card 063930

1 SAVE DATA card 063933

Cleaning/cleaning accessories

1 Cleaning brush 067409

1 Set for daily cleaning -

*

Cleaning container (8 litres) (milk system) 061308

General accessories

*

Milk container (8 litres) (milk system) 070742

1 Measuring spoon 067111

1 Flat seal 064249

1 Drain hose 067862

*

*

Connection cable, CH standard 063260

Connection cable, CH standard 063261

1 Grinding adjustment tool 070907

1 set Milk suction nozzles (8 pcs) 071246

1 60 cm hose (transparent) 061108

**

**

**

* * Depending on machine version.

** Language-specific article number.

Options and optional accessories

Example Option Description

Bean hopper Optional bean hopper with coffee shop de-

sign Not lockable

Machine height: 794 mm

Capacity: 1000 g

12

BASCAP_BF_EN

V02 | 06.2016

Page 13

Example Option Description

Under-counter grounds disposal The grounds container and the bottom of the

coffee machine have a cutout that is continued through the counter. The coffee grounds

are collected in a large container underneath

the counter.

Cup warmer For preheating multiple cups of varying ty-

pes. The cup heating can be regulated.

Cup capacity: ca. 70 – 100

Centre Milk Milk system for two coffee machines

Coolant: R134 a

Coolant quantity: 40 g

Centre Milk milk capacity 8 l or 2 x 4 l

www.schaerer.comProduct description

Under-counter cooling unit for cold milk system

Under-counter cold milk system with integrated milk pump for the preparation of warm

and hot milk and milk foam beverages. The

milk temperature can be regulated. This option is well suited for use with large milk

consumption and little counter space. The

system can optionally supply two coffee machines at the same time or it can supply one

machine with two milk types.

Powder system For the preparation of beverages with choco-

late powder.

Available in the following versions: Choco

and Twin Choco.

Flavour Point Integrated flavour system for the preparation

of flavoured coffee and milk beverages.

The side unit offers space for up to four different varieties.

BASCAP_BF_EN

V02 | 06.2016

13

Page 14

www.schaerer.com Product description

Example Option Description

Cup dispenser Cup dispenser for approx. 40 cups in two dif-

ferent sizes.

Ø 60-90 mm

Coin changers Coin changer with MDB interface. Up to 2

coffee machines can be connected. Up to 99

different sale prices can be set.

The coin changer can be switched off, and

the unit can be switched to push-button operation.

Accepts coins from 5 cents to 2 euros, CHF

0.10 – CHF 5.00 and two different tokens.

The coin changer contains coin tubes for

change.

Coin testers The coin tester allows the dispensing of cof-

fee in the Self mode after the necessary

coins or tokens have been inserted.

The coin tester can be switched off, and the

unit can be switched to push-button operation.

Accepts coins from 5 cents to 2 euros, CHF

0.10 – CHF 5.00 and two different tokens.

The coin tester does not return any change.

Powersteam Manual heating and foaming of milk.

Ideal for the professional barista.

14

Autosteam Automatic heating of milk to a programmed

temperature.

Milk is foamed manually.

Steam cup warmer For pre-warming individual cups immediately

before beverage dispensing.

Only available in Switzerland.

BASCAP_BF_EN

V02 | 06.2016

Page 15

Example Option Description

Swan neck For dispensing coffee into pots.

High feet If needed, the coffee machine can be placed

on high feet.

Trolley Together with a drinking water and a waste

water tank, the trolley allows the coffee machine to become a mobile unit.

www.schaerer.comProduct description

External drinking and waste water An external monitored drinking and waste

water tank replaces a mains water supply

and waste water outlet.

Please contact your local sales partner for more detailed information.

Technical data

Nominal power* Steam boiler Hot water boiler

2000 W/3000 W 2000 W/3000 W

Operating temperature

Minimum operating temperature (T min.) 10 °C 10 °C

Maximum operating temperature (T

max.)

Operating temperature 127 °C 95 °C

Overpressure

Working overpressure 2.5 bar 2.5 bar

Permissible operating overpressure (p

max.)

Test overpressure 24 bar 24 bar

Drinking water tank capacity Mains water supply

192 °C 192 °C

5 bar 12 bar

BASCAP_BF_EN

V02 | 06.2016

15

Page 16

www.schaerer.com Product description

Nominal power* Steam boiler Hot water boiler

Bean hopper capacity 1000 g each ±

Grounds container capacity 35 coffee grounds cakes

External dimensions

Width 420 mm

Height 538 mm

Depth 668 mm

Empty weight ± 40 kg

Permanent noise level** <70 dB (A)

We reserve the right to make technical changes.

* For special equipment, see serial plate. The values specified here apply to the basic con-

figuration.

** The A-weighted noise level (slow) and Lpa (impulse) at the workplace of the operating per-

sonnel is below 70 dB (A) for every operating mode.

Serial plate

Machine-specific data are listed on the serial plate. The serial plate is affixed to the inside of

the machine and is visible when the coffee grounds container and the lid above it are removed.

► In the event of a fault or warranty claim, specify the information on the serial plate.

Declaration of conformity

Manufacturer's address

Manufacturer Documentation specialist

Schaerer AG

P.O. Box 336

Allmendweg 8

CH-4528 Zuchwil, Switzerland

T +41 (0)32 681 62 00

F +41 (0)32 681 64 04

info@schaerer.com

www.schaerer.com

Schaerer AG

Hans-Ulrich Hostettler

P.O. Box

Allmendweg 8

CH-4528 Zuchwil, Switzerland

16

Applied standards

The aforementioned manufacturer declares herewith that this machine complies with all relevant stipulations of the specified directives. In case of any modifications of the units that have

not been approved by Schaerer, this declaration is rendered invalid. The following harmonised

standards have been applied. For proper implementation of the requirements a quality management system certified in 2008 by Bureau Veritas in accordance with SN EN ISO 9001 is

applied.

BASCAP_BF_EN

V02 | 06.2016

Page 17

For CE conformity

Machinery Directive 2006/42/EC EMC Directive 2004/108/EC

• EN 60335-1:2002 +A1 +A11 +A12 +A13

+A14 +A2

• EN 60335-2-75:2004 +A1 +A11 +A2

• EN 62233: 2008-04

• EN 55014-1: 2006 +A1

• EN 55014-2: 1997 +A1 +A2

• EN 61000-3-2: 2006 +A1 +A2

• EN 61000-3-3: 2008

• EN 61000-6-2: 2005

• EN 61000-6-4: 2007 +A1

International (CB)

Safety

• IEC 60335-1 Ed4.2: 2006

• IEC 60335-2-14 Ed5.1: 2008

• IEC 60335-2-15 Ed5.2: 2008

• IEC 60335-2-24 Ed7: 2010

• IEC 60335-2-75 Ed2.2: 2009

• IEC 62233 Ed1: 2005

EMC

• CISPR 14-1 Ed 5.1: 2009

• CISPR 14-2 Ed 1.2: 2008

• IEC 61000-3-2 Ed 3.2: 2009

• IEC 61000-3-2 Ed2.1: 2001

• IEC 61000-3-3: 2008

• IEC 61000-6-2: 2005

• IEC 61000-6-4: 2006 +A1

www.schaerer.comProduct description

China (CCC)

Safety

• GB4706.1-2005

• GB4706.13-2008

• GB4706.19-2008

• GB4706.30-2008

BASCAP_BF_EN

V02 | 06.2016

17

Page 18

www.schaerer.com Installation and commissioning

CAUTION!

Risk of machine

damage!

CAUTION!

Risk of machine

damage!

Installation and commissioning

Setting up the coffee machine

Location

The l oca tio n wh ere the coffee machine is installed must satisfy the conditions specified

below. If they are not satisfied, the coffee machine may become damaged.

Be sure that the following conditions are met:

• The installation surface must be stable and level so that it does not become deformed under the weight of the coffee machine.

• Do not set up the coffee machine on hot surfaces or close to heat sources.

• Set up the coffee machine in such a way that it can be monitored by trained personnel at

all times.

• Route the necessary supply connections to within 1 m of the machine location according

to the on-site installation plans.

• Maintain the following clearances for maintenance work and operation:

• Allow enough space above the machine for refilling the beans.

• Leave min. 5 cm of clearance between the back of the machine and the wall (for air cir-

culation).

• Comply with all applicable local regulations for kitchen equipment.

Ambient conditions

The location where the coffee machine is set up must provide the ambient conditions

specified below. If these conditions are not ensured, the coffee machine may become

damaged.

Please adhere to the following conditions:

• Ambient temperature of +10 °C to +40 °C (50 °F to 104 °F)

• Relative humidity of max. 80% RH

• The coffee machine is designed for indoor use only. Do not use in the open and never expose to the weather (rain, snow, subzero temperatures).

If the coffee machine was exposed to subzero temperatures:

► Contact customer service before commissioning.

Power supply

Conditions

The equipment must be connected in accordance with the regulations of the country in which

it is installed. The voltage specified on the serial plate must match the mains voltage at the

installation location.

18

BASCAP_BF_EN

V02 | 06.2016

Page 19

www.schaerer.comInstallation and commissioning

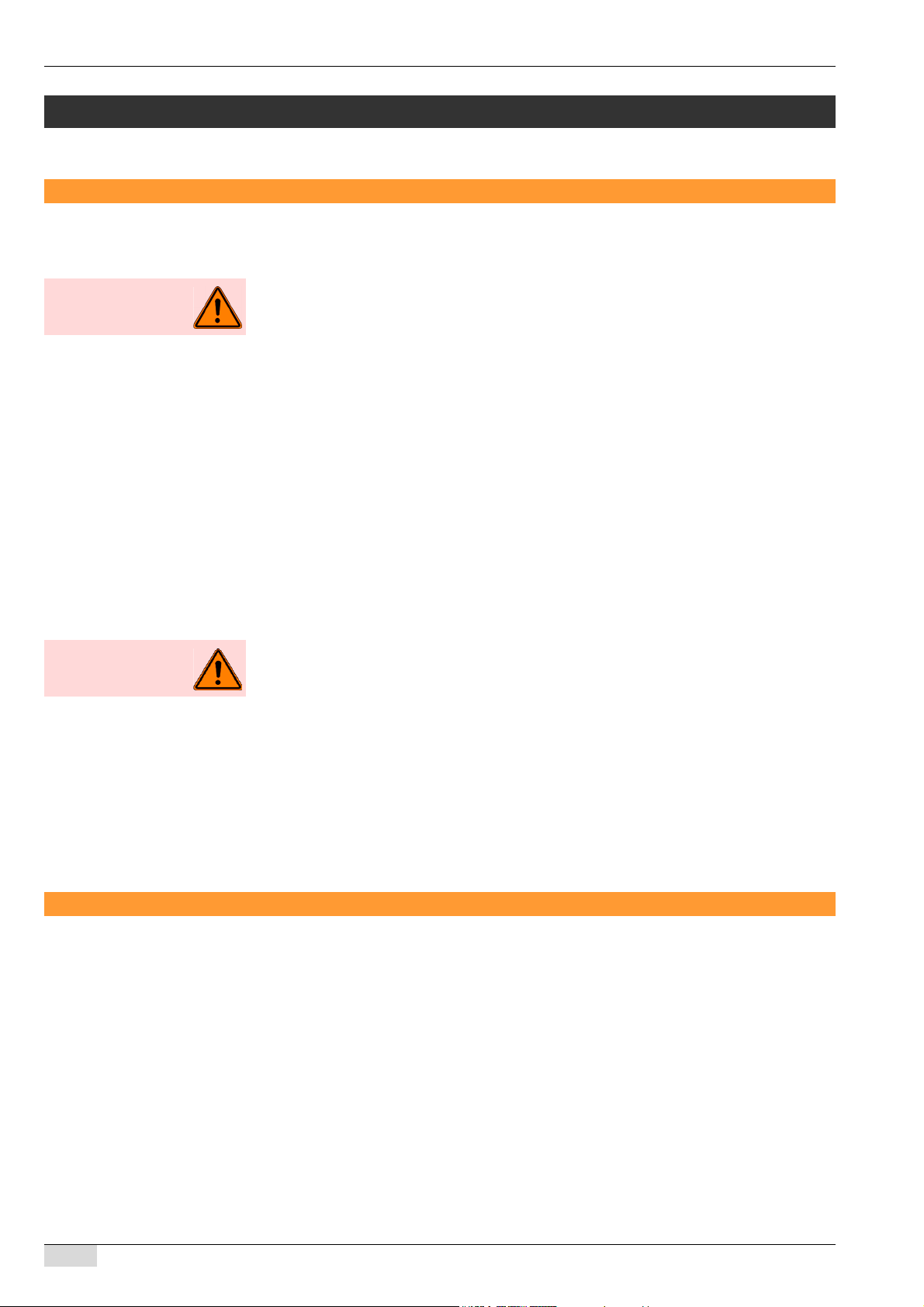

DANGER!

Risk of electrocution!

Risk of electrocution!

Always observe the following points:

• The phase must be fused at the ampere value specified on the serial plate.

• It must be possible to disconnect the device from the mains power supply at all poles.

• The local power supply must be constructed according to the currently valid IEC 364 (DIN

VDE 0100). An isolated ground outlet or a country-specific single-phase outlet for singlephase connection, or a 5-pole CEE / CEKON socket per EN 60309 or a country-specific

multi-pole socket for a three-phase connection, must be available near the machine. The

sockets are part of the customer‘s on-site installation. The mains cable must not come into

contact with hot surfaces. If the mains cable for this device is damaged then it must be replaced by our service personnel or a similarly qualified person, in order to prevent hazards.

• Never operate a device with a damaged power cable. Have a defective power cable or plug

replaced immediately by a qualified service technician.

• Schaerer AG does not recommend using an extension cable. If an extension cable is nevertheless used (minimum cross-section: 1.5 mm²), please comply with the manufacturer’s

specifications for the cable (operating instructions) and with applicable local regulations.

• Route the power cable in such a way that it does not pose a tripping hazard. Do not pull

the cable over corners or sharp edges, pinch it between objects or allow it to hang loosely

in open spaces. Do not position the cable over hot objects, and be sure to protect the cable

from exposure to oil and aggressive cleaning products.

• Never lift or pull the device by the power cable. Never pull the plug out of the socket by its

cable. Never touch the power cable or plug with wet hands. Never insert a wet plug into a

power socket.

Power requirements

Mains Fuse protec-

tion (site

face)

1L, N, PE 220 – 240 V~ 50/60 Hz 2000 - 2400 W 10 A 3 x 1 mm²

3000 -3600 W 16 A 3 x 1.5 mm²

5700 - 6900 W 30 A 3 x 4 mm²

3L, N, PE 380 – 415 V 3N~ 50/60 Hz 5700 - 6900 W 3 x 16 A 5 x 1.5 mm²

8300 - 10100 W 3 x 16 A 5 x 1.5 mm²

2L, PE 200 – 220 V 2~ 50/60 Hz 2000 - 2200 W 2 x 15 A 3 x 1.5 mm²

2600 - 3200 W 2 x 15 A 3 x 1.5 mm²

4700 - 5800 W 30 A 3 x 10 AWG

4700 - 5900 W 2 x 30 A 3 x 10 AWG

4700 - 5900 W 2 x 25 A 3 x 2.5 mm²

3L, PE 200 V 3~ 50/60 Hz 7000 W 3 x 20 A 4 x 2.5 mm²

3L, PE 200 V 3~ 50/60 Hz 6900 - 8500 W 3 x 25 A 4 x 2.5 mm²

7700 W 25 A 4 x 2.5 mm²

Connecting

cable, conductor

cross-section

BASCAP_BF_EN

V02 | 06.2016

19

Page 20

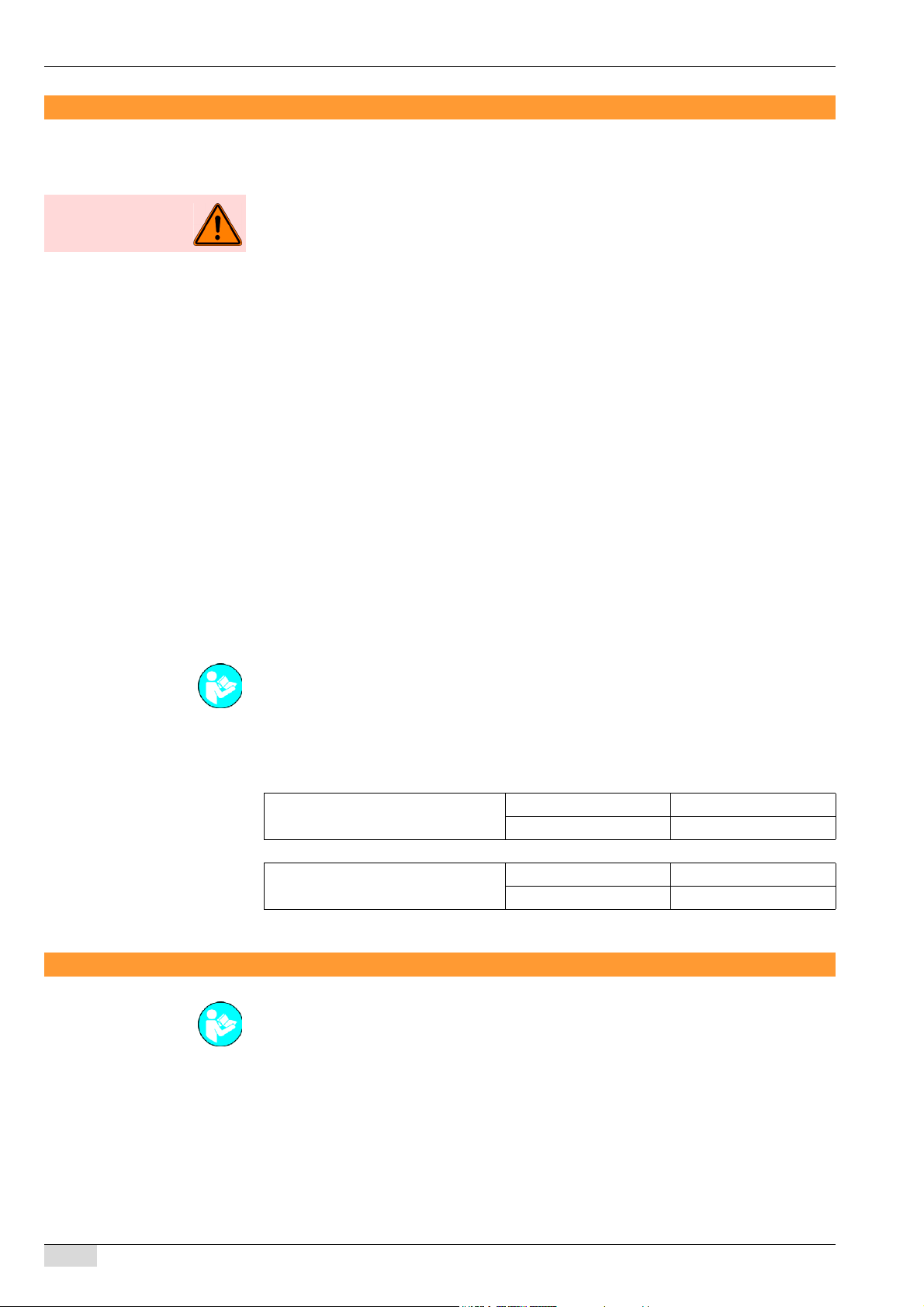

www.schaerer.com Installation and commissioning

CAUTION!

Risk of machine

damage!

Water connection/drain

Conditions

The machine can become damaged as a result of poor material and incorrect water values.

Always observe the following points:

• The water must be free of contaminants and the chlorine content must not exceed 100 mg

mg per litre.

• Do not connect the machine to pure reverse osmosis water or other aggressive types of

water.

• The carbonate hardness must not exceed 5 – 6°dKH (German carbonate hardness) or 8.9

– 10.7°fKH (French carbonate hardness), and the total hardness value must always be

greater than the carbonate hardness.

• The minimum carbonate hardness is 5 °dKH or 8.9 °fKH. The pH value must be between

6.5 and 7.

• Always use the new hose set (fresh water/waste water hose) supplied with the machine.

The machine must be connected to the water supply in accordance with applicable requirements and the regulations of the respective country. If the machine is connected to a newly

installed water pipe, the pipe and intake hose must be rinsed thoroughly to ensure that no dirt

gets into the machine.

The coffee machine must be connected to an installed drinking water line with a shut-off valve.

The machine is connected to the pressure reducing valve on the main water valve (set to

0.3 MPa (3 bar)) using the mounted pressure hose and the G 3/8" screw connection.

If the machine is connected to a drain, the supplied thermally stable drain hose must be connected to the drip tray and the siphon. This hose must be firmly attached to the drain and slanted at a downward angle (so that the water is able to drain).

The "Water quality" supplementary instructions include information about recording water values and using filter equipment. The supplementary instructions can be requested from

Schaerer AG or downloaded directly from the MediaCentre on the website (http://www.schaerer.com/member).

Power requirements

Water pressure

Water inlet temperature

Recommended: 0.1 – 0.3 MPa (1 – 3 bar)

Maximum: 0.6 MPa (6 bar)

Minimum: 10 °C

Maximum: 30 °C

Installation

Read the "Setting up the coffee machine" and "Power supply" chapters carefully before installing.

► Unpack the machine.

► Check the remaining package contents for accessories.

► Remove the accessories supplied in the grounds container and water tank.

► Keep the original packaging in case the equipment needs to be sent back.

20

BASCAP_BF_EN

V02 | 06.2016

Page 21

www.schaerer.comInstallation and commissioning

Deinstallation and disposal

The coffee machine must be disposed of correctly in conformity with local and legal regulations.

► Contact your service partner.

BASCAP_BF_EN

V02 | 06.2016

21

Page 22

www.schaerer.com Operation

CAUTION!

Risk of machine

damage!

Operation

Incorrect use may damage the touch screen.

Never use force, strong pressure or sharp objects when pressing on the display.

Check before switching on

► Before switching on the coffee machine, check whether the following conditions are ful-

filled.

Conditions for switching on the coffee machine:

• The main water valve (in machines with a mains water supply) is open/the drinking water

tank is filled with fresh water.

• The waste water outlet has been correctly laid/the waste water tank is connected.

• The bean hopper(s) is/are filled and the lock is open.

• The grounds container is empty and inserted correctly.

• The coffee machine is connected to the mains power supply.

Switching the machine on

Starting the PC board

Starting up the PC board takes approx. 1 minute. Nothing is displayed on the Touch Screen

during this phase. Once the PC board has been started, the machine is in standby mode and

can be switched on.

Standby Quick Menu

In standby mode, the standby Quick Menu can be called up by pressing the [ ] field. The

following submenus can be called up in the Quick Menu:

•Set clock

• Set date

• Error and cleaning statistics

• Information

• Machine number (factory setting)

• Customer number (factory setting)

• Display SCA software version (factory setting)

• Display SCA TouchIT software version (factory setting)

• External keys

See chapter "Programming" - "Timer" See chapter "Programming" - "Counters and statistics"

- "Error and cleaning statistics".

22

Switch on coffee machine (touch screen)

► Switch on the machine using the [ ] field.

The machine starts and warms up (see information in Quick Info at top right).

BASCAP_BF_EN

V02 | 06.2016

Page 23

www.schaerer.comOperation

Service menu

The machine must be switched on. The following submenus and function s are cont ained in th e

"Service" menu:

• [Cleaning] starts a cleaning programme. A PIN entry prompt can be set for the "self-service" mode. This is configured in the "Self mode settings" parameter.

• [Rinsing] starts a machine rinse.

• [Flavour Point]

• [Exchange flavour bottle] starts the routine for exchanging a flavour bottle.

• [Clean flavour system] starts the Flavour Point cleaning process.

• [Touch screen cleaning] deactivates the touch screen for 30 sec.

• [Quick Info On] displays the "Quick Info" window in the top right corner of the touch screen.

• [Standby] switches the machine into standby. Only in "self-service mode"

• [Cancel] closes the "Service" menu again.

Option: [Service] field visible.

"Service button visible" activated in [TouchIT configuration].

► Press the [Service] field at the top right.

The "Service" menu opens.

Option: [Service] field hidden.

"Service button visible" deactivated in [TouchIT configuration].

► Press and hold the top right corner of the touch screen for ±2 sec.

The "Service" menu opens.

Quick info

► Press the [Service] field at the top right.

The "Service" menu opens.

► Select the [Quickinfo on] field.

The Quickinfo appears at the top of the touch screen.

► Pressing and holding the Quickinfo window, move it into the required location.

Quickinfo provides information on the following temperatures:

• (c) shows the coffee boiler temperature.

• (t) shows the tea boiler temperature (option).

• (s) shows the steam boiler temperature (option).

• (b) shows the booster temperature.

Optional accessories

Option 1: Cup warmer

► Switch on the cup warmer unit via the main switch (1).

The switch lights up.

BASCAP_BF_EN

V02 | 06.2016

23

Page 24

www.schaerer.com Operation

Option 2: Cooling unit on the cold milk system

► Remove the cooling unit cover.

► Set the cooling unit temperature switch (see the arrow).

► Reassemble the cooling unit cover.

The cooling unit is switched on.

Option 3: Under-machine cooling unit

► Open the door of the under-machine cooling unit.

► Switch on the switch, see arrow.

The cooling unit is switched on.

The cooling temperature is preset at the factory.

► Close the door.

Main touch screen window

Three user interfaces can be selected in the "Configuration" - "View setup" - "View Mode"

menu:

• [Silver design mode] (standard)

• [Self mode]

• [Operator mode]

The machine must be operated with the "Barista Silver" interface so that the Best Foam™ machine functions optimally and all operating options are available. The other screen designs are

described below in this operating manual. Should one of the old screen designs be used, however, the Standard SCAP operating manual must be consulted.

See also "Configuration" – "TouchIT configuration" – "Screen layout".

Barista Silver (standard)

With pre-selection (2x, Barista, DECAF), max. 4 groups with 9 beverages each can be configured. If this pre-selection is deactivated, 12 beverages can be displayed on one page.

► Select [Silver design mode] in the "Configuration" - "View setup" - "View Mode" menu.

Option 1: Design variants

► Select [Beverage groups] in the "Configuration" - "View Mode" - "Group selection" menu.

► Select the corresponding selection in the "TouchIT configuration" - "Icon set for product

keys" menu.

24

Different icon sets for beverage buttons:

• (A) With [Text only] selected.

• (B) With [Set1 ] selected.

• (C) With [Set 2] selected.

• (D) With [Set 3] selected.

BASCAP_BF_EN

V02 | 06.2016

Page 25

www.schaerer.comOperation

Option 2: Selection varieties

► Define the selection procedure by the selection concerned in the "Configuration" - "View

Mode" - "Group selection" menu.

Selection list with groups:

• (A) [None (all beverages on one page)]

• (B) [Before production selection] selection.

• (C) [On product page with tabs] selection.

• (D) Flavour selection, if configured.

BASCAP_BF_EN

V02 | 06.2016

25

Page 26

www.schaerer.com Operation

Operating fields

The following elements in the main window depend on the machine state:

Symbol Description

Groups In "Barista Silver", there are max. 4 groups that can be selected. Each

group can hold max. 9 beverages.

Selecting a beverage group shows the corresponding beverage page with

the beverages stored there.

The beverage groups can be configured in the "Configuration" menu in the

"Product configuration" submenu.

See also "Programming" - "Beverage selection with groups".

Beverage field The desired beverage can be assigned to each beverage field and pro-

grammed accordingly.

The display of the beverage fields can be selected under [Icon set for product keys] in the [Configuration] menu.

The respective beverage is dispensed by pressing a beverage field.

The beverages can be configured in the "Configuration" menu in the "Product configuration" submenu.

When using the "Barista Silver", the beverage file contains the information

that the beverage contains a flavour or that a flavour can be selected for it.

DECAF To be able to dispense decaffeinated beverages (DECAF), two grinders are

needed, one of which is filled with decaffeinated beans. Another possibility

is to manually add decaffeinated ground coffee.

The [DECAF] field is used to define the beverage configuration with decaffeinated coffee.

The [DECAF] field can be activated in the [View setup] submenu of the

"Configuration" menu.

Double The [2x] field is used to dispense a double beverage. The beverage

selected after pressing this field is dispensed with double the usual quantity.

The [2x] field can be activated in the "View setup" submenu of the "Configuration" menu and is available with the "Operator mode" and "Barista Silver"

design.

In "Barista Silver", the [2x] field is available alternately with the "Barista"

field.

Barista field The Barista field can be used to adjust the strength of the dispensed beve-

rage for one brewing. After beverage dispensing the Barista field returns to

the standard setting of "medium". See figure to the left.

Selecting the barista field toggles between the 3 coffee strengths [black,

medium and strong].

In "Barista Silver", the [Barista] field is available alternately with the "2x"

field.

26

Service This field opens the "Quick Menu" in standby mode or the "Service" menu

when the machine is switched on.

See "Basic operation"- "Switching on" - "Quick Menu in standby mode" for

further information.

The [Service] field is located in the top right corner in the display.

Stop The [Stop] field is only displayed while a beverage is being dispensed. The

beverage currently being dispensed and any other previously selected beverages can being cancelled using this field.

BASCAP_BF_EN

V02 | 06.2016

Page 27

www.schaerer.comOperation

Symbol Description

Back The [Back] field returns the user to the previous page and is located in the

top right corner in the display.

Info The [Quick Info] field at the top right is activated in the [Service] field of the

Quick Menu. The Quick Info provides information on the current boiler temperatures.

See "Basic operation"- "Switching on" - "Quick Info" for further information.

ON/OFF The [ON] field at the bottom right is used to switch the machine from stand-

by into the operating mode.

Dispensing information

The flashing symbol at the bottom of the touch screen appears while a beverage is being dispensed.

Beverage selection with groups

Settings can only be changed by a service technician.

The additional [DECAF], [Barista] and [Double products (2x)] functions can be set in the "Configuration" menu in the "View setup" submenu.

If not pre-selection option has been selected, 12 beverages can be displayed for each group.

(Not possible when [On product page with tabs] is selected)

The following beverage selection variants are listed in the [Group selection] selection list:

• [none (only one group)]

• [Before product selection]

• [After product selection]

• [On product page with tabs]

BASCAP_BF_EN

V02 | 06.2016

Beverage groups

The [Beverage page and groups] selection is only available in [Barista Silver mode].

The additional [DECAF] and [Double products (2x)] functions can be set in the "Configuration"

menu in the "View setup" submenu in accordance with the selected operating mode.

27

Page 28

www.schaerer.com Operation

• 1) Selection of group and from the beverages stored in the group.

• 2) Optional if with flavour [Selection] (aromatisation)

• 3) Beverage dispensing

► Configure all beverages in the "beverage settings".

► Select from the [Beverages with groups] selection list in the "View setup" menu.

Beverages are selected via a displayed beverage page with max. 9 beverages.

None (all beverages on one page)

• 1) Selection from beverage page

• 2) Selection from product page without pre-selection options

• 3) Beverage dispensing

► Configure all beverages in the "beverage settings".

► From the selection list, select [none (only one group)] in the "View setup" menu.

Select the beverage on the beverage page displayed with up to 12 beverages.

28

Before/after product selection

Before beverages are configured for group selection, we recommend defining the following requirements:

• The function of the groups (e.g. SMALL – MEDIUM – LARGE).

• The number of beverage fields which are to be displayed per group.

• The total number of beverages should be taken into consideration.

► Select the [View setup] submenu in the "Configuration" menu.

BASCAP_BF_EN

V02 | 06.2016

Page 29

www.schaerer.comOperation

► Select [Silver design mode] in the "View Mode" parameter.

► Select [Before product selection] or [After product selection] in the "Group selection" pa-

rameter.

► Set the required number of beverages to be displayed in the "Number of products per

group" parameter.

• 1 - 9 beverages

• 1 - 12 beverages with pre-selection options

► Enter the name in the "Group name" parameter.

► Store an image from the selection list in the "Group button picture" parameter as needed.

► Perform a "restart" by removing the SERVICE card.

► After the restart, reselect the "Configuration" menu with the SERVICE card.

► Open the "Product configuration" submenu.

► Define the beverages in the respective beverage groups.

See also "Configuration" - "Beverage configuration".

The configuration of the 1st group (A) should contain all available basic beverages, if possible.

Configuration example, 4 groups with 6 beverages per group:

Group A

[Small]

Group B

[Medium]

Group C

[Large]

Group D

[+Flavour]

Espresso Espresso-1 – –

Coffee Coffee-1 – Coffee 1.1.1

Cappuccino Cappuccino-1 Cappuccino-1.1 Cappuccino 1.1.1

Latte macchiato – Latte macchiato-1.1 Latte macchiato- 1.1.1

Chocciato Chocciato-1 Chocciato-1.1 –

CoolMacc – CoolMacc-1.1 CoolMacc- 1.1.1

This configuration example enables beverage selection which works in two directions

(Group > Beverage or Beverage > Group).

BASCAP_BF_EN

V02 | 06.2016

Option 1: Before product selection

The beverage is now selected from the 4 defined groups:

• Selection (1) from beverage groups, e.g. small - medium - large + flavour.

• Selection (2) from beverage page.

• Selection (3) from flavour types.

29

Page 30

www.schaerer.com Operation

Option 2: Options after beverage selection

Beverages are selected via the beverage page - in the next step, the group is selected (e.g.

small - medium - large + flavour)

• 1) Selection from beverage page

• 2) Group selection

• 3) Optional with flavour [Selection] (aromatisation)

30

► Configure all beverages in the "beverage settings".

► Select from the [After product selection] selection list in the "View setup" menu.

The beverage is selected from a beverage page displayed.

Self-service

In order to operate the machine with the "Barista Silver" design, only the beverage selection

must be deactivated.

The pre-selection must be deactivated under "Configuration - General parameters - General

pre-selection". Access only possible with the SERVICE card.

BASCAP_BF_EN

V02 | 06.2016

Page 31

www.schaerer.comOperation

CAUTION!

User at risk!

CAUTION!

Risk of machine

damage!

CAUTION!

Risk of machine

damage!

Filling and connecting

Coffee beans

Rotating grinding discs in the grinder are an injury hazard.

Never reach into the bean hopper while the coffee machine is switched on.

Filling the bean hopper with foreign objects can cause jamming or destruction of the

grinder.

Never fill the bean hopper with anything other than beans.

► Unlock bean hopper lid and unlatch using knob.

► Fill with coffee beans (max. 1,000 g).

► Replace lid. Twist knob to latch and use key to lock.

Water

Option 1: Mains water supply

The machine can suffer damage if the pump runs dry.

Before switching on the machine, make sure that the main water valve is open.

► Open the stop valve on the main water valve.

For reasons relating to insurance law, it is advisable that the main water valve be closed at the

end of the day.

Option 2: External drinking water tank

► Remove the cover on the drinking water tank.

► Remove the drinking water tank daily and rinse out thoroughly with fresh water.

► Fill the drinking water tank with fresh drinking water before using it.

► Reinsert the drinking water tank.

► Reattach the cover.

Milk

Option 1: Side cooling unit

► Open the door.

► Remove and rinse the milk container.

► Pour in fresh, pre-cooled milk (3 – 5°C).

► Place the milk container in the cooling unit.

► Place the hose or hoses in the container.

The hose end must be in contact with the container floor.

► Close the door.

BASCAP_BF_EN

V02 | 06.2016

Option 2: Under-counter milk

► Open the door.

► Remove and rinse the milk container.

► Fill in fresh, pre-cooled milk (3 – 5°C).

► Place the milk container into the cooling unit.

► Hang the hose into the container.

The hose end must be in contact with the container floor.

31

Page 32

www.schaerer.com Operation

CAUTION!

Risk of machine

damage!

CAUTION!

User at risk!

CAUTION!

Risk of machine

damage!

CAUTION!

Hot fluid!

CAUTION!

Hot surface!

► Close the door.

Automatic machine powder

Improper use can damage the machine.

Never fill substances other than coffee machine powder into the powder container. The

powder containers must be filled with no more than 500 g (Twin container) or 1,000 g

(Standard container) of coffee machine powder.

Moving parts in the powder container are an injury hazard.

Never reach into the powder container(s) while the unit is switched on.

Option 1: Choco

► Add the desired choco powder.

Option 2: Twin Choco

The powder container for Twin Choco is divided in the middle and has two compartments for

two different types of chocolate powder.

► Pour the desired chocolate powder into compartments 1 and 2.

Flavour Point (option)

Improper use can damage the machine.

Never use the Flavour Point to dispense anything other than syrup or spirits.

To prevent a full bottle from overflowing, the hose must first be inserted into the bottle and then

connected to the Flavour Point.

► Press the [ ] field.

The "Service" menu opens.

► Select the [Flavour Point] field.

The Flavour Point submenu is displayed.

► Select the [Flavour Point bottle exchange] field.

The exchange routine starts.

► Follow the instructions on the display.

Dispensing

All beverages dispensed from the machine are hot.

Never reach beneath the beverage outlet or into the machine when beverages are being

dispensed.

32

Adjusting the outlet height

Hot surfaces can cause burns.

Do not touch the beverage outlet during operation.

The outlet height can only be set by a service technician.

BASCAP_BF_EN

V02 | 06.2016

Page 33

www.schaerer.comOperation

CAUTION!

Hot fluid!

CAUTION!

Risk of machine

damage!

After the beverage button is pressed, the automatic beverage outlet moves to a predefined position.

► Place a cup under the automatic beverage outlet.

► Press beverage button.

Automatic beverage outlet moves into position.

Beverage is dispensed.

Automatic beverage outlet returns to initial position.

► Once this is complete, remove the cup.

Coffee beverages

► Place a cup under the beverage outlet.

► Press the desired beverage button.

The beverage button flashes while the machine is dispensing the beverage.

The beverage name and the dispensing progress are shown on the display.

► Remove the cup after the beverage has been dispensed.

Beverages with ground coffee

The manual inlet/ground coffee is located between the bean hoppers.

Incorrect use may damage the machine.

Never fill instant coffee into the manual inlet. Only fill with ground coffee or cleaning

tablets.

Option 1: With manual inlet monitoring

► Place a cup under the beverage outlet.

► Open the inlet for ground coffee.

"DECAF inlet open" is displayed in the status bar.

The remaining available beverages are shown on the display.

► Press the desired beverage button.

"Add decaffeinated coffee powder" appears in the display.

► Add the ground coffee within 15 seconds.

► Close the inlet for ground coffee.

The beverage is dispensed.

► Remove the cup after the beverage has been dispensed.

Option 2: Without manual inlet monitoring

► Place a cup under the beverage outlet.

► Press the DECAF field.

The remaining available beverages are shown on the display.

► Press the desired beverage button.

"Add decaffeinated ground coffee" appears in the display.

► Open manual inlet for ground coffee.

► Add ground coffee within 15 seconds.

► Close manual inlet for ground coffee.

The beverage is dispensed.

► Remove the cup after the beverage has been dispensed.

BASCAP_BF_EN

V02 | 06.2016

33

Page 34

www.schaerer.com Operation

CAUTION!

Hot fluid!

CAUTION!

Hot fluid!

CAUTION!

Risk of machine

damage!

CAUTION!

Hot fluid!

CAUTION!

Hot steam!

Hot water

Dispensing of hot water can be preset as follows using the SERVICE card:

• [Hot water] button with the "Start-stop" function.

• [Hot water] button with the "Press and hold" function.

• [Hot water] button with the "Double beverage" function.

► Place a cup under the hot water outlet.

► Press the [Hot water] button or press it and keep it held down.

► Remove the cup after the beverage has been dispensed.

Milk beverages

If the machine has a milk system, milk beverages can be dispensed with the beverage buttons.

► Place a cup under the beverage outlet.

► Press the desired beverage button.

► Remove the cup after the beverage has been dispensed.

Flavoured beverages

Improper use can damage the machine.

Never use the Flavour Point to dispense anything other than syrup or spirits.

Option 1: Select flavour

► Place a cup against the cup stop under the beverage outlet.

► Press the desired beverage button.

The selection screen is displayed.

► Select a flavour.

► Select Regular or Decaf coffee.

► Press the [Make my drink!] field.

The selected combination is dispensed.

The beverage overview is once again displayed.

► Remove the cup after the beverage has been dispensed.

34

Option 2: Predefined beverages

► Place a cup against the cup stop under the beverage outlet.

► Press the desired beverage button.

► Remove the cup after the beverage has been dispensed.

Steam

► Place the cup/container beneath the steam wand.

The tip of the steam wand must be completely under the surface of the milk.

► Press the [Steam] button.

► After steam dispensing is finished, remove the cup/container.

BASCAP_BF_EN

V02 | 06.2016

Page 35

www.schaerer.comOperation

► Clean the outside of the steam wand with a moist paper towel.

► Point steam wand at drip grid and briefly press the [Steam] button.

Milk and beverage residues are flushed out of the steam wand.

Option 1: Powersteam

► Aerate the milk by injecting steam beneath the surface.

The milk is heated from 5 °C to 37 °C.

► Dense milk foam is created by injecting steam on the bottom third of the milk height, rolling

and turning clockwise.

The milk is heated from 37 °C to 65 °C.

Option 2: Autosteam

► Aerate the milk by injecting steam beneath the surface.

The milk is heated from to the set temperature.

When the set temperature is reached, Autosteam switches off.

► Dense milk foam is created by injecting steam on the bottom third of the milk height, rolling

and turning clockwise.

The milk is heated from 37 °C to 65 °C.

Dispensing options

Stop dispensing

If the wrong beverage has been selected, it is possible to stop the dispensing process.

Option 1: Stopping continuous dispensing

► Press the [ ] button.

Continuous dispensing is stopped.

Option 2: Deleting beverages in the pre-selection.

► Press the [ ] button.

The pre-selected beverages are deleted.

The current beverage is fully dispensed.

Pre-selecting beverages

If configured, multiple different beverages can be selected and dispensed consecutively. The

coffee machine dispenses the beverages in the order in which they were selected.

While the current beverages are being dispensed, it is possible to select additional beverages

that are to be dispensed consecutively. These are displayed in the top right corner.

► Place a cup under the beverage outlet.

► Press the desired beverage button(s).

► After the first beverage has been dispensed, remove the cup and place the next cup under

the beverage outlet.

BASCAP_BF_EN

V02 | 06.2016

Deleting beverages in the pre-selection.

► Press the [ ] button.

The pre-selected beverages are deleted.

The current beverage is fully dispensed.

► Pressing [ ] again will also end the current dispensing process prematurely.

35

Page 36

www.schaerer.com Operation

CAUTION!

Risk of machine

damage!

CAUTION!

User at risk!

Double beverage

If the option is configured, you can press the [2 x] button to dispense two beverages at once.

► Place cups under the beverage outlet.

► Press the [2 x] button.

► Press the desired beverage button.

► Remove the cups after the beverages have been dispensed.

Emptying

Grounds container

Coffee grounds land in the grounds container. The beverage output is blocked as long as the

grounds container has not been inserted.

Operating the automatic beverage outlet manually will damage it.

When removing the grounds container, make sure this does not affect the automatic

beverage outlet.

► Push the manual beverage outlet into the highest position.

► Remove the grounds container.

► Empty the grounds container and reinsert it.

The machine is ready for use again.

Under-counter grounds disposal

The coffee grounds cakes ejected out of the brewing unit pass through the under-counter

grounds disposal cutout and into the grounds container below the counter.

► Open the counter door and remove the under-counter grounds container.

► Empty the under-counter grounds container.

► Return the under-counter grounds container to its proper position and close the counter

door.

When the container is full, no instruction to empty it will appear on the machine’s display. The

under-counter grounds container should therefore be checked at regular intervals.

Waste water tank

In coffee machines with an external waste water tank, the tank needs to be emptied regularly,

at the latest when the empty instruction appears on the display.

► Remove and empty the waste water tank.

► Clean the waste water tank thoroughly with household cleaner and rinse with fresh water.

► Replace the waste water tank.

36

Transport requirements

Improper transport of the coffee machine can result in injuries.

Observe general regulations for health and safety.

► Before moving the coffee machine, be certain to disconnect the drinking water supply,

power supply and waste water outlet.

► Before moving the coffee machine, check the floor for obstacles and uneven areas.

BASCAP_BF_EN

V02 | 06.2016

Page 37

www.schaerer.comOperation

CAUTION!

Risk of machine

damage!

Improper transport of the machine can result in damage to the machine.

Adhere to the following instructions when moving machines on a cart:

• For safety reasons, the cart must be pulled and not pushed when moving the coffee machine.

• Only pull the cart; never pull the machine directly.

• The cart is not intended to be used for transporting freight.

The manufacturer cannot be held liable for any damage resulting from unintended use of the

cart or the failure to comply with the operating instructions.

Display notes/instructions

Display message Cause What to do

Grounds container missing • The grounds container was pulled out

(cleaning programme, emptying, etc.).

• The limit switch is faulty.

Empty grounds container The grounds container is full. ► Empty the grounds container.

Cleaning programme Appears when a programmed number of bever-

ages has been dispensed without the machine

being cleaned.

Left/right G, beans empty Appears when the bean hopper is empty or

when a coffee bean has become stuck.

► Insert the grounds container.

► If the message persists: Contact your ser-

vice partner.

► Carry out the daily cleaning routine (refer to

the "Cleaning" chapter).

► Fill bean hopper with coffee beans (max.

1,000 g per hopper) and confirm.

Left/right G blocked An object (e.g. stone) is stuck in the grinder. ► Check the grinder for clogging and remove

the remaining beans with a vacuum cleaner

if necessary.

Heating coffee/hot water/

steam

Filter exchange The programmed water volume (litres/month)

Service instruction The programmed number of beverages (cups/

Drinking water tank empty • Drinking water tank is empty.

Waste water tank full • Waste water tank is full.

Add ground coffee • [DECAF] field has been pressed in order to

The temperature is 10 °C below the programmed temperature.

has passed through the filter.

month) has been reached. Service is required.

• The float switch is defective.

• The float switch is defective.

dispense a decaffeinated beverage.

• The inlet for ground coffee and cleaning tablets has been opened.

► Wait until the target temperature has been

reached.

► If the message persists: Contact your ser-

vice partner.

► Contact your service partner.

► Contact your service partner.

► Fill the drinking water tank and place it be-

neath the counter.

► If the message persists: Contact your ser-

vice partner.

► Empty the waste water tank and place it be-

neath the counter.

► If the message persists: Contact your ser-

vice partner.

► Add ground coffee to dispense a decaffein-

ated beverage.

► Close the inlet for ground coffee and clean-

ing tablets.

► If the message persists: Contact your ser-

vice partner.

Flavour 1 empty

Flavour 2 empty

Flavour 3 empty

Flavour 4 empty

BASCAP_BF_EN

V02 | 06.2016

• The corresponding bottle is empty.

• The sensor is defective.

► Place full bottle in the Flavour Point and

connect.

► If the message persists: Contact your ser-

vice partner.

37

Page 38

www.schaerer.com Operation

CAUTION!

Risk of machine

damage!

Switching the machine off

End of operation

Option 1: Operator service mode

► Perform the daily cleaning routine.

The machine switches to standby once the cleaning programme is finished.

Option 2: External drinking and waste water tank

► Empty the drinking water tank and rinse it with fresh water.

► Empty the waste water tank and clean it thoroughly with fresh water.