Page 1

Piazza D‘Oro 500 TWIN

Operating instructions

V05 / 07.2010

Page 2

For more information please contact: Original operating instructions

Douwe Egberts technical service BAPdO500TW_EN

www.douweegberts.com N° 021201

Page 3

Introduction

Piazza D’Oro 500 TWIN

Operating instructions

Published by: Schaerer Ltd., CH-4528 Zuchwil

Version: Version 05 / 07.2010

Software: PSE V3.04

User manual

Designed and edited by: Schaerer Ltd., CH-4528 Zuchwil

© Copyright by Schaerer Ltd., CH-4528 Zuchwil

All rights reserved, including translation into other languages. This manual may not be

copied, photocopied or distributed, in whole or in part, by any means, nor transmitted

electronically, without the publisher’s written consent.

All information, illustrations, and specifications in this manual are based on the latest

product information available at the time of publication approval. Schaerer Ltd. reserves the right to change the content at any time without any prior notice.

BAPdO500 - EN - V05 Page 1-1

Page 4

Introduction

1. INTRODUCTION

1.1 Welcome

Dear customer

With this new coffee machine, you have purchased a Swiss quality product especially designed for the catering

trade.

Two separate brewing units allow for the simultaneous filling of up to four cups.

This manual will inform you in detail on programming, commissioning, use and cleaning of your new machine. It

also contains important safety instructions to ensure safe use.

Important!

Prior to commissioning the machine, carefully read the chapter "Safety instructions". The manufacturer rejects any liability for damages that are caused by improper use of the machine.

Performance of the coffee machine depends to a great extent on proper use and careful maintenance of the

machine. We therefore recommend that you read all instructions carefully before commissioning the machine

and that you keep them handy for future reference.

We hope you enjoy using your new coffee machine!

Page 1-2 BAPdO500 - EN - V05

Page 5

Introduction

1.2 Symbols and pictograms

Note:

This section provides you with important notes and information.

Important!

This note indicates possible damage to property as well as possible financial and

statutory penalties (e.g. loss of rights to claim under guarantee, liability suits, etc.).

Danger!

This note indicates a risk of severe and/or fatal injury if specific procedural

rules are violated.

Whenever you see this symbol in the operating manual, take all necessary

safety precautions.

Electric shock!

Risk of severe and/or fatal injury due to electric shock!

Environmental protection!

This symbol indicates that you have to comply with environmental regulations and/or

legislation.

select product

12:00 01.07.2010

Display messages

The displays shown in the manual always follow immediately after their respective description and relate to the display on the coffee machine.

Chip cards

The card name (e.g. CHEF, SAVE DATA, etc.) is written in capital letters. You will

also find an illustration of the chip cards to the left of the respective texts

BAPdO500 - EN - V05 Page 1-3

Page 6

Introduction

TABLE OF CONTENTS

Chapter Page

1 Introduction......................................................................................................................................... 1-2

1.1 Welcome............................................................................................................................................... 1-2

1.2 Symbols and pictograms...................................................................................................................... 1-3

2 SAFETY INSTRUCTIONS ................................................................................................................... 2-2

2.1 General................................................................................................................................................. 2-2

2.2 Safety symbols ..................................................................................................................................... 2-2

2.3 Prevention of accidents........................................................................................................................ 2-3

2.4 Hygiene ................................................................................................................................................ 2-5

2.5 Designated use .................................................................................................................................... 2-6

2.6 Liability.................................................................................................................................................. 2-6

3 Product description ........................................................................................................................... 3-2

3.1 Coffee machine data ............................................................................................................................ 3-2

3.2 Operating information for the coffee machine...................................................................................... 3-8

3.3 Equipment and accessories ............................................................................................................... 3-10

3.4 Special settings .................................................................................................................................. 3-11

3.5 Chip card functions............................................................................................................................. 3-12

3.6 Commissioning................................................................................................................................... 3-15

4 Operation............................................................................................................................................. 4-3

4.1 Introduction........................................................................................................................................... 4-3

4.2 Operating Modes.................................................................................................................................. 4-4

4.3 Messages displayed when coffee machine is ready for operation ...................................................... 4-4

4.4 Routine operation ................................................................................................................................. 4-5

4.5 Longer idle time.................................................................................................................................. 4-17

4.6 Programming using standard chip cards ........................................................................................... 4-18

4.7 Programming using optional chip cards............................................................................................. 4-28

5 Cleaning .............................................................................................................................................. 5-2

5.1 Important

5.2 Daily cleaning ....................................................................................................................................... 5-3

5.3 Weekly cleaning ................................................................................................................................... 5-6

5.4 Defrosting the refrigerator .................................................................................................................... 5-9

5.5 Care of the refrigerator......................................................................................................................... 5-9

6 Error messages and malfunctions ................................................................................................... 6-2

6.1 Error messages with display ................................................................................................................ 6-2

6.2 Malfunctions without display messages............................................................................................... 6-7

7 Optional features................................................................................................................................ 7-2

7.1 Payment systems ................................................................................................................................. 7-2

7.2 Chip cards ............................................................................................................................................ 7-2

7.3 Chip card loader ................................................................................................................................... 7-2

7.4 Water softener (Filados/Brita) .............................................................................................................. 7-2

7.5 Cup warmer.......................................................................................................................................... 7-3

7.6 User instructions for special machines (water tank) ............................................................................ 7-3

8 Payment systems ............................................................................................................................... 8-2

8.1 Cards compatible with all payment systems ........................................................................................ 8-2

8.2 Payment with internal systems............................................................................................................. 8-3

8.3 Payment with self-service systems .................................................................................................... 8-13

general cleaning instructi

ons ............................................................................................... 5-2

Page 1-4 BAPdO500 - EN - V05

Page 7

Introduction

TABLE OF CONTENTS

Chapter Page

9 Appendix ..............................................................................................................................................9-2

9.1 CE Declaration of conformity ................................................................................................................9-2

9.2 Cleaning agent ......................................................................................................................................9-3

9.3 Serial plate of steam generator and instant heater...............................................................................9-6

9.4 Environmental aspects..........................................................................................................................9-7

9.5 Hazardous Substance...........................................................................................................................9-7

10 Index ...................................................................................................................................................10-1

BAPdO500 - EN - V05 Page 1-5

Page 8

Introduction

Page 1-6 BAPdO500 - EN - V05

Page 9

Safety instructions

2 Chapter

Table of contents

Chapter Text Page

2

2.1

2.2

2.3

2.4

2.5

2.6

General ..............................................................................................................................................2-2

Safety symbols .................................................................................................................................2-2

Prevention of accidents ...................................................................................................................2-3

Hygiene..............................................................................................................................................2-5

Designated use .................................................................................................................................2-6

Liability ..............................................................................................................................................2-6

SAFETY INSTRUCTIONS .................................................................. 2-2

BAPdO500 - EN - V05 Page 2-1

Page 10

Safety instructions

2 SAFETY INSTRUCTIONS

2.1 General

The coffee machine is handed over by a service technician authorised by the manufacturer. Prior to commissioning the machine, read the operating instructions carefully

and ensure that you fully understand them.

Always keep this manual in the immediate vicinity of the coffee machine.

2.2 Safety symbols

The following symbols appear next to all safety instructions in this manual. Follow the

instructions to the letter and proceed with particular care in the cases described.

Danger!

This note indicates a risk of severe and/or fatal injury if specific procedural

rules are violated.

Whenever you see this symbol in the operating manual, take all necessary

safety precautions.

Electric shock!

Risk of severe and/or fatal injury due to electric shock!

Important!

This note indicates possible damage to property as well as possible financial and

statutory penalties (e.g. loss of rights to claim under guarantee, liability suits, etc.).

Note:

This section provides you with important notes and information.

Page 2-2 BAPdO500 - EN - V05

Page 11

Safety instructions

2.3 Prevention of accidents

In the event of incorrect operation or misuse, one or more of the following might occur:

Risk to life and limb of the operator, other persons or animals that are in close

proximity to the coffee machine,

Risk of damage to the coffee machine and other property of the operator or third

parties,

Inefficient performance of the coffee machine.

Danger!

People who are not familiar with these operating instructions, as well as children or people under the influence of alcohol, drugs or medication may not operate the machine. At self-service units, danger zones such as the steam pipe

and the hot water outlet must be clearly labelled in such a manner that the warning is visible to the customer.

Important!

The installation, programming, maintenance and repair of the coffee machine must be

carried out only by authorised service technicians.

Important!

For connection of the dispenser to the power supply system and the drinking water

lines, comply with the instructions of the local service providers.

Danger!

The machine must be connected to a fuse-protected circuit.

We recommend connection through a residual current operated circuit-breaker.

The dispenser must be connected to a properly fitted and earthed safety socket.

The voltage must comply with the information given on the machine's serial

plate.

Important!

To prevent water damage caused by tube breakage, it is recommended to feed the

water through a water stop valve.

Danger!

Never insert the power plug into the socket when wet and do not touch the plug

with wet hands.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Danger!

Parts of the foamer head, the hot water pipe and the steam pipe become very

hot during the cleaning of the coffee machine and when coffee, milk, hot water

or steam are delivered. Do not touch these parts during and shortly after use.

BATW 500 - EN - V05 Page 2-3

Page 12

Safety instructions

Important!

When the coffee machine is not used for a prolonged period of time (e.g. overnight, on

weekends) close the water tap.

Press the [Stand-by] button to switch off the coffee machine. Do not disconnect the

power supply, as otherwise the cooling system is switched off.

Important!

Do not operate the coffee machine if the water supply is shut off, as otherwise the

boiler will not refill.

Important!

Never disconnect the water line while the coffee machine is switched on or in stand-by

mode.

Danger!

Danger to life and limb due to electric shock!

Always switch off the main switch before carrying out any maintenance work.

Do not introduce any objects into the device and do not open the housing!

Important!

Malfunctions may be repaired only by authorised and qualified personnel.

Important!

Only use original spare parts.

Danger!

If the mains cable is damaged, it must be replaced by a service technician

authorised by the manufacturer.

Important!

If any parts of the unit are leaking or if any cables, hoses, screw connections, flanges,

valves, seals, etc. have external signs of damage then this must immediately be reported to the authorised specialist staff and rectified by them!

Environmental protection!

When selecting cleaning agents, make sure that they are environmentally safe, bear

no health risks, and comply with local disposal regulations.

Use cleaning agents recommended by the manufacturer.

Page 2-4 BAPdO500 - EN - V05

Page 13

Safety instructions

2.4 Hygiene

Note:

Run the cleaning program before initial commissioning (see “Cleaning”)

Important!

Always follow hygiene regulations according to HACCP!

Always follow hygiene regulations according to HACCP!

(HACCP= Hazard Analysis and Critical Control Point)

For daily and weekly cleaning, proceed as described in chapter "Cleaning".

Never spray the machine with water or other liquids.

For cleaning, never immerse the machine in water or any other liquid.

Do not use raw milk. Use only pasteurised or UHT milk. Homogenized milk must

always be used.

Milk that has already been heated up or for which the expiry date has lapsed may

not be used.

When using packaged milk, it is recommended for hygienic reasons to use the

milk directly from the original packaging.

The milk in the refrigerator must have a temperature of approx. 3 °C to 5 °C If

this rule is not followed, it is not possible to dispense an optimal product.

Only refill with milk which has not exceeded 5 °C. Never put warm milk in the re-

frigerator. It takes too long for a temperature of 3 °C to 5 °C to be reached. The

refrigerator will also ice up. (Frequent defrosting required).

Always wash and disinfect your hands before cleaning the coffee machine.

Note:

For reasons of hygiene and to ensure proper functioning of the machine, it must be

regularly cleaned.

To clean the brewing units and the interior of the machine, use a moist clean paper

tissue. Only use cleaning products that are approved by the manufacturer for the respective machine type. The supplier of the coffee machine will be glad to assist you in

this matter.

To clean the interior of the refrigerator, only wipe with a clean, dry paper tissue. To

clean the outside of the coffee machine, use a moist cloth and a mild soap solution.

Do not use aggressive and/or scouring cleaning products. Never spray the machine

with water or other liquids.

Danger!

During cleaning and usage of cleaning tools or products, there is a risk of injury.

BATW 500 - EN - V05 Page 2-5

Page 14

Safety instructions

2.5 Designated use

The Schaerer Twin has been designed to dispense coffee beverages and/or milk beverages in different versions – in cups or coffeepots. Additionally, the unit can supply

steam for heating up milk and/or hot water. This unit is designed for industrial and

commercial use. The unit may be placed in self-service areas if attended to by trained

personnel.

Note:

Use of this equipment is subject to the "General Terms and Conditions" of Schaerer

Ltd. and these operating instructions. In legal terms, any other use is not an intended

use. The manufacturer accepts no liability for damage resulting from unintended use.

Gefahr!

The Schaerer Twin may not under any circumstances be used to heat up or dispense any other liquids than coffee, hot water (for beverages or cleaning) or

milk (cooled, pasteurised, homogenised, UHT).

2.6 Liability

Guarantee and liability claims in the event of injury to people and damage to property

cannot be entertained if they are due to one or more of the following causes:

Improper use of the coffee machine.

Improper assembly, commissioning, operation and maintenance of the coffee

Operation of the coffee machine with defective or improperly mounted or oper-

Non-compliance with safety instructions in this manual with special regard to stor-

Inadequate monitoring of component parts that are subject to wear.

Repairs not carried out by a qualified technician.

Catastrophic damage due to the influence of foreign bodies, accidents, vandalism

If cleaning agents other than those recommended by Schaerer Ltd. have been

Important!

The manufacturer’s warranty exclusively covers machines that have been properly

maintained at the specified intervals and where original spare parts are used that were

directly supplied by the manufacturer or one of the manufacturer’s authorised suppliers.

machine.

ated safety devices.

age, installation, commissioning, operation and maintenance of the machine.

and force majeure.

used.

Page 2-6 BAPdO500 - EN - V05

Page 15

Product description

3 Chapter

Table of contents

Chapter Text Page

3

3.1

3.1.1 Overview.............................................................................................................................................3-2

3.1.2 Coffee machine operating panel.........................................................................................................3-3

3.1.3 Open front door...................................................................................................................................3-4

3.1.4 Machine interior view..........................................................................................................................3-5

3.1.5 Installation layout................................................................................................................................3-6

3.1.6 Purpose of coffee machine.................................................................................................................3-7

3.1.7 Serial plate..........................................................................................................................................3-7

3.2

3.2.1 Performance Characteristics ..............................................................................................................3-8

3.2.2 Dimensions and weight ......................................................................................................................3-8

3.2.3 Power supply ......................................................................................................................................3-8

3.2.4 Power consumption ............................................................................................................................3-9

3.2.5 Water supply/drain..............................................................................................................................3-9

3.2.6 Volumes..............................................................................................................................................3-9

3.3

3.3.1 Make of the coffee machine .............................................................................................................3-10

3.3.2 Standard accessories (included) ......................................................................................................3-10

3.3.3 Special accessories (not included in shipment) ...............................................................................3-11

3.3.4 Optional features for the coffee machine .........................................................................................3-11

3.4

3.4.1 Time-specific settings .......................................................................................................................3-11

3.4.2 Cleaning settings ..............................................................................................................................3-12

3.4.3 Miscellaneous...................................................................................................................................3-12

3.5

3.5.1 Standard chip cards..........................................................................................................................3-13

3.5.2 Chip card options for normal operating mode ..................................................................................3-14

3.5.3 Chip cards for payment mode ..........................................................................................................3-14

3.6

3.6.1 Initial commissioning of the coffee machine.....................................................................................3-15

3.6.2 Set-up conditions..............................................................................................................................3-15

Product description ..........................................................................3-2

Coffee machine data ........................................................................................................................3-2

Operating information for the coffee machine ..............................................................................3-8

Equipment and accessories ..........................................................................................................3-10

Special settings ..............................................................................................................................3-11

Chip card functions........................................................................................................................3-12

Commissioning...............................................................................................................................3-15

BAPdO500 - EN - V05 Page 3-1

Page 16

Product description

3 PRODUCT DESCRIPTION

3.1 Coffee machine data

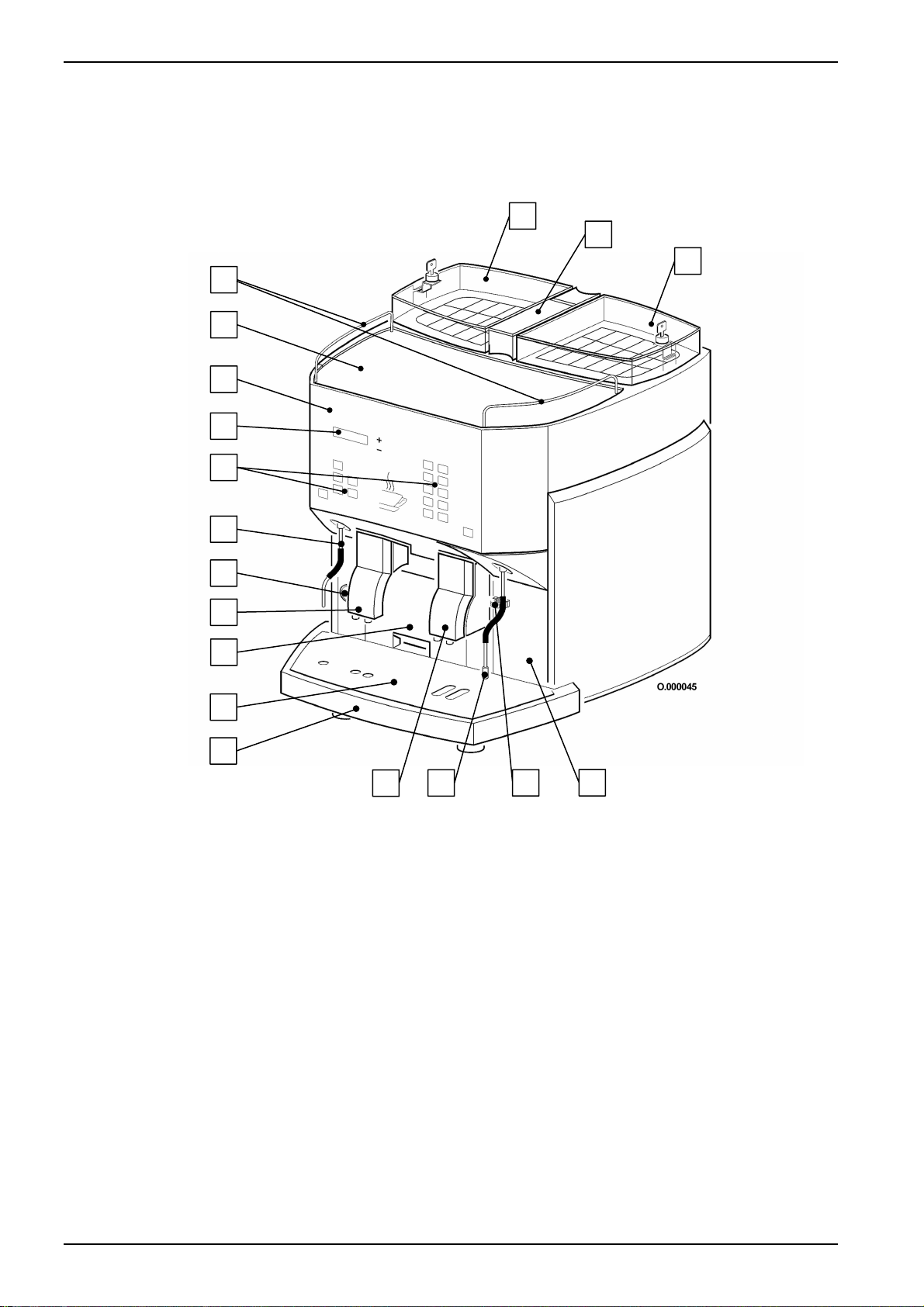

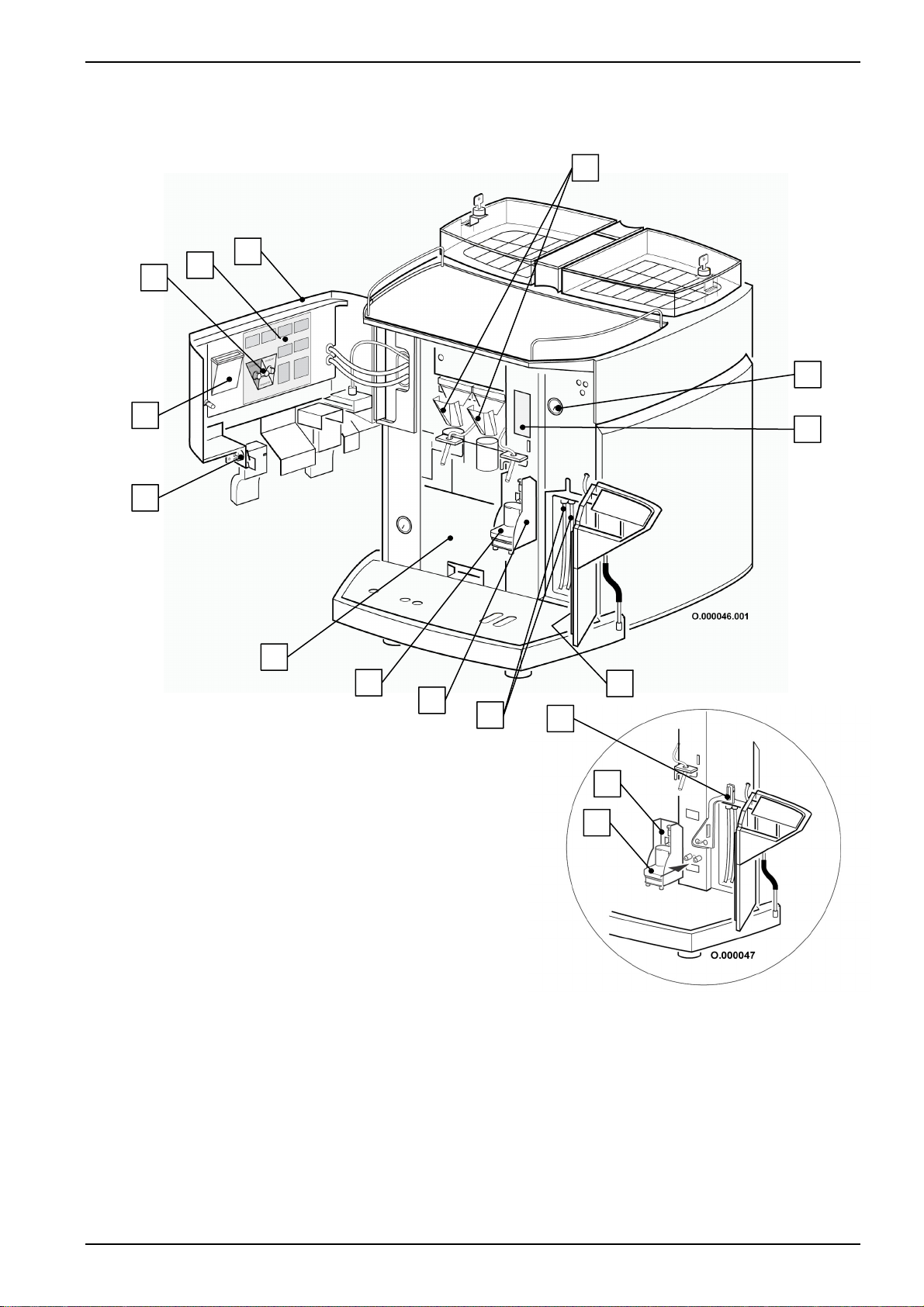

3.1.1 Overview

Legend:

1 Coffee beans container

2 Funnel for ground coffee ("decaf")

3 Cup plate frame

4 Heated cup plate

5 Front door (cf. "3.1.3 Open front door." on page 4)

6

7 Operating panel (left and right)

8 Hot water outlet

9 Manometer for pump pressure

10 Left beverage outlet (coffee)

11 Coffee grounds container

12 Drip grid

13 Drip tray with drain

14 Right beverage outlet (coffee/milk)

15 Steam pipe

16 Refrigerator door handle

17 Refrigerator door

3

4

5

6

7

8

9

10

11

12

13

T

wo-line illuminated LC display

14

15

1

16

2

1

17

Page 3-2 BAPdO500 - EN - V05

Page 17

Product description

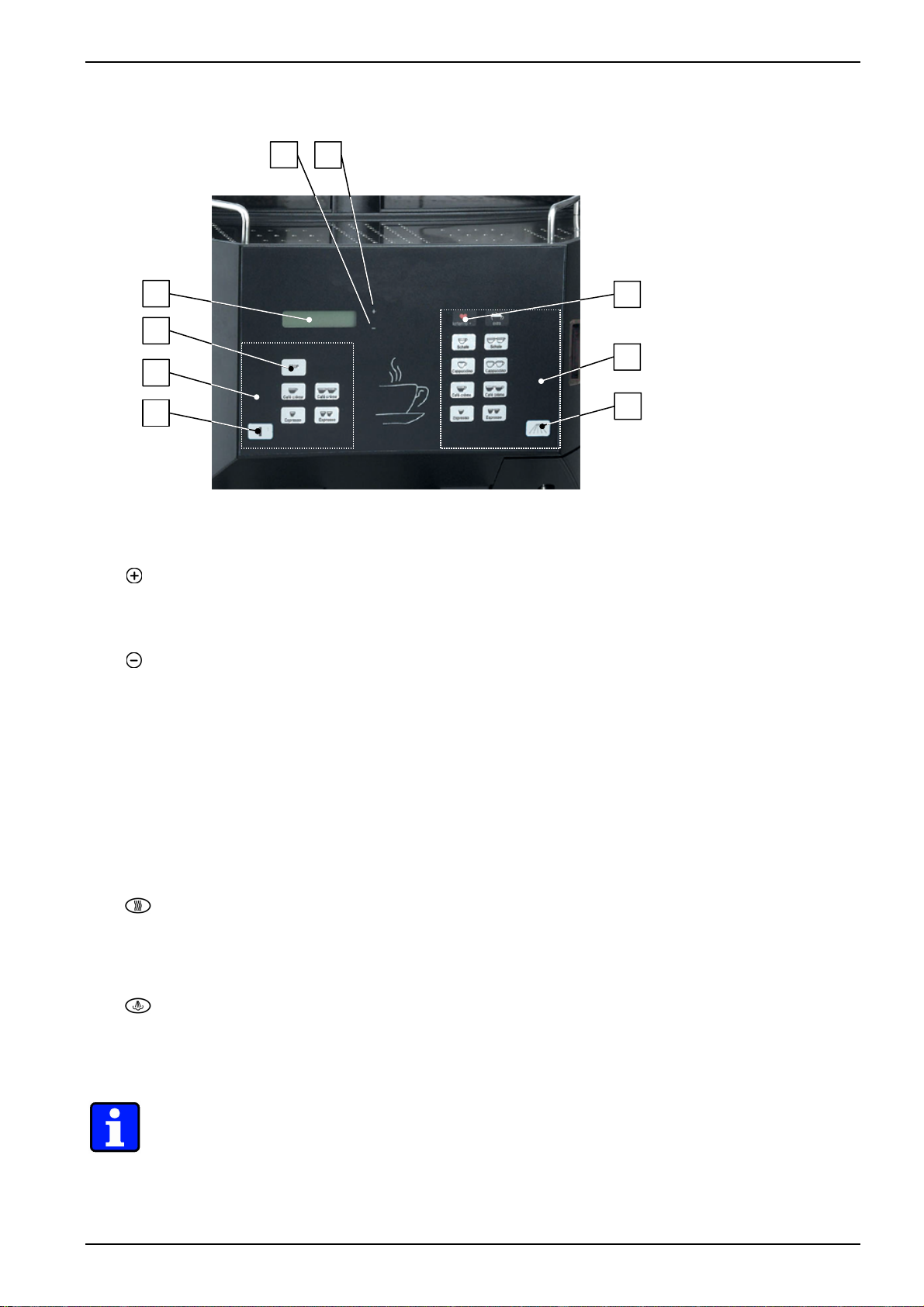

A

3.1.2 Coffee machine operating panel

1

2

3

+

4

5

_

9

7

6

8

Fig. 2.1

Legend:

[ ] button

1

- Input confirmation during cleaning program

- Select functions

- Change settings

[ ] button

2

- Select functions

- Change settings

3 Two-line illuminated LC display

4 [STOP] button:

- Terminate current beverage delivery

- Cancellation of pre-selected products

5 Control panel left:

- Programmable product buttons for serving of coffee

- Each product button features a green LED operating indicator and a customised product symbol

- Product buttons can be assigned a second product level

[

6

7 Control panel right:

8

9 Button (decaf) for decaffeinated or other ground coffee mixture

] button

- Programmable product buttons for the output of coffee, hot milk, and milk coffee beverages

- Each product button features a green LED operating indicator and a customised product symbol.

[

] button

:

:

: hot water

: steam

Note:

The product buttons shown in Fig. 2.1 A are examples only.

BAPdO500 - EN - V05 Page 3-3

Page 18

Product description

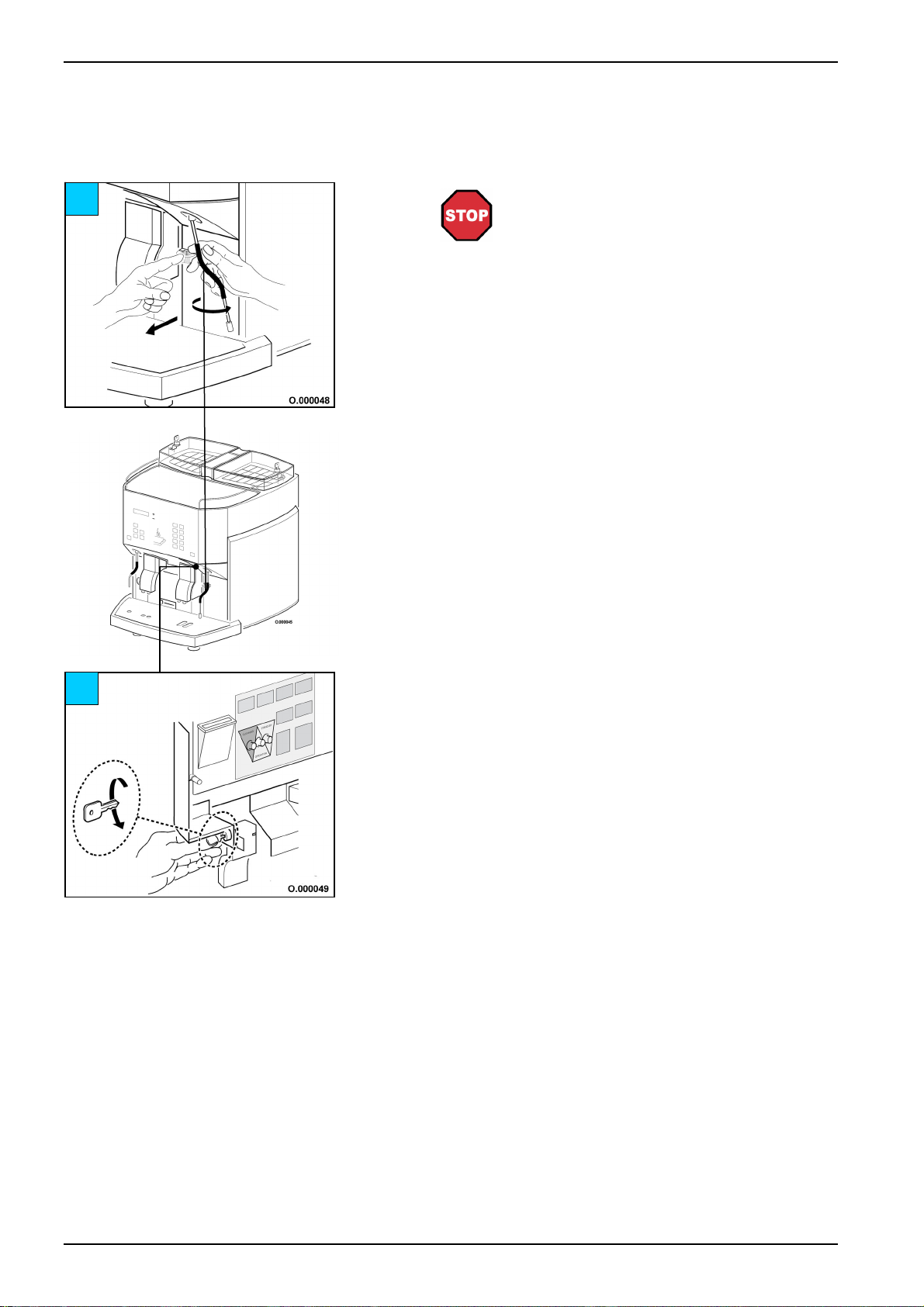

3.1.3 Open front door.

The front door lock is located behind the refrigerator door and can only be opened

with the key (supplied).

1

2

! Danger!

To open the front door, you must place your

hand near the steam pipe.

Caution: the steam pipe may be hot!

1. Open the refrigerator door.

2. Unlock the front door by turning the key

counter-clockwise until it reaches the stop.

Page 3-4 BAPdO500 - EN - V05

Page 19

3.1.4 Machine interior view

2

3

1

4

5

6

7

Legend:

Front door (see "3.1.3 Open front door.” 2-4)

1 Front door sticker

2 [Cleaning], [Operator], [Stand-by] buttons

3 Chip card insertion

4 Lock with key

5 Coffee grounds container

6 Foamer head

7 Foamer head cover

8 Milk pipes

9 Tube

10 Sticker refrigerator door

11 Sticker front shelf

12 Manometer of steam boiler

13 Brewers left and right

holder

Product description

14

13

12

11

8

9

10

8

7

BAPdO500 - EN - V05 Page 3-5

Page 20

Product description

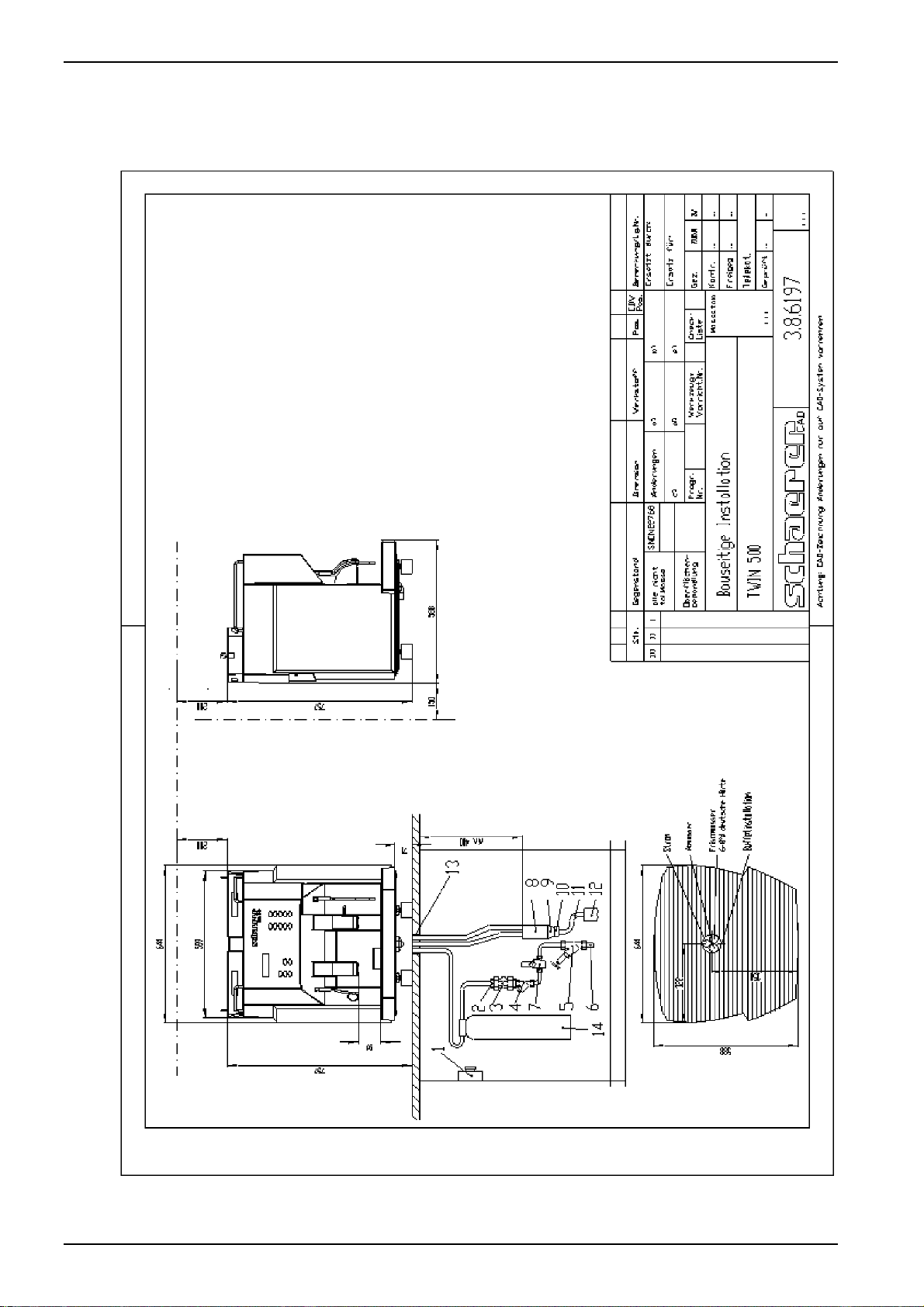

3.1.5 Installation layout

(fully isolated from the power supply by min. 3 mm

gap)

1 Main switch type 26, 3 x 400 VAC (3PNE), 16 A

The following installations must be present:

Non-return valve SVGW tested

2 G 1/2" connection

3

4 Filter

5 G 1/2" stop valve

6 G 1/2" water supply pipe

7 Pressure reduction set to 3 bar

Ideal water hardness:

12 °fH (French water hardness)

6 ... 8 °dH (German water hardness)

8 Upright pipe, ø 110 mm, length 200 mm

9 Reduction, ø 110/50 mm

10 Nipple-type fitting, ø 48 mm

11 Siphon

12 Outlet (plastic), ø 56 mm

13 Opening for supply and drain ø 80 mm

14 Britta water filter jumbo type

15 Opening for grounds ejection container Ø 140 mm

16 Buffet bushing (063834)

17 Coffee grounds container

All local statutory regulations apply

Subject to changes without notice!

Page 3-6 BAPdO500 - EN - V05

Page 21

3.1.6 Purpose of coffee machine

The coffee machine can be configured to serve the following beverages:

- Coffee

- Espresso

- Ristretto (short espresso)

- Coffee Pot

- Decaffeinated Coffee (Decaf)

- Milk coffee

- Latté

- Hot milk

- Milk foam

- Cappuccino

- Macchiato

- Hot water for tea, punch etc.

- Steam for heating of milk for hot chocolate, etc.

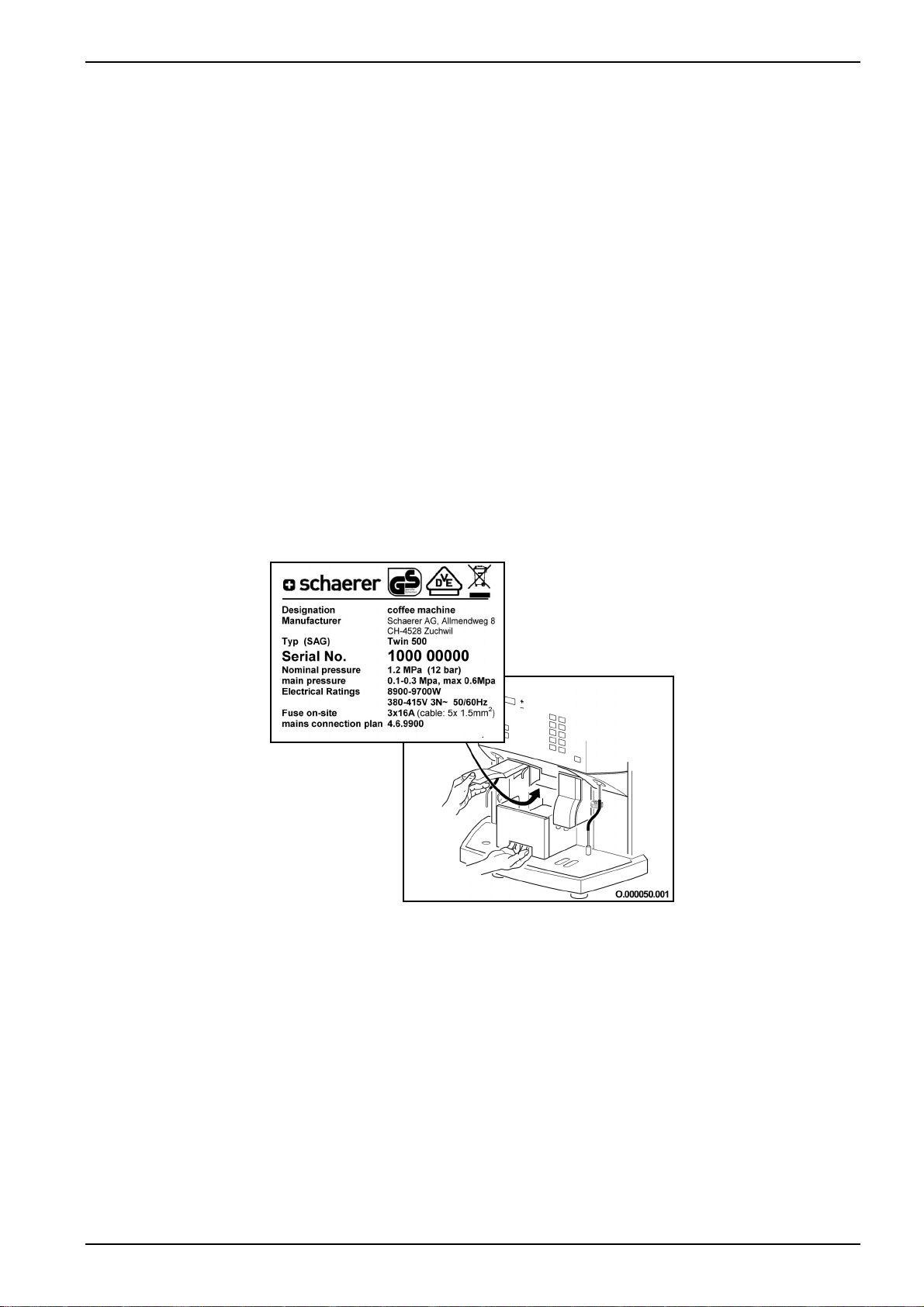

3.1.7 Serial plate

The serial plate contains the machine-specific data. This serial plate is on the inside of

the machine and is visible when the coffee ground container is removed (cf. Fig. 2.1

B).

Product description

Fig. 2.1 B

BAPdO500 - EN - V05 Page 3-7

Page 22

Product description

3.2 Operating information for the coffee machine

3.2.1 Performance Characteristics

Max. beverage production per hour:

280 cups of coffee of 120 ml

-

-

500 espressos of 40 ml

- 225 cappuccino of 140 ml

- 330 cups of tea, punch of 120 ml, corresponding to approx. 40 litres of hot water

3.2.2 Dimensions and weight

Height:

Width: 660

Depth: 610 mm (+ 150 mm clearance at the back for air circulation

Outlet height: Right beverage output 91 mm

Left beverage output: 190 mm

Weight 87 kg (empty)

93 kg (ready for operation)

3.2.3 Power supply

Model Power rating

Europe 380-415V 3NAC 50/60 Hz 8900-9700W 3 x 16 5 x 1.5mm2

Japan, Saudi Arabia,

Norway (grid B)

200-220V 3AC 50/60Hz 7300-8300W 3 x 25 4 x 2.5mm2

The device must be electrically connected according to all valid regulations (VDE

0100) as well as national stipulations. Design of network implementation line, at least

H05 VV-F, harmonized. The voltage specified on the serial plate must match the supply voltage at the installation location.

Danger!

The installation must be installed and/or inspected by authorised personnel

only!

The phase must be protected with 16 A fuse.

Never operate the coffee machine if the mains cable is defective. A defective or

damaged mains cable or plug must immediately be replaced by an authorised service technician.

Use extension cords only when you are sure that they are in perfect condition. Ex-

tension cords must be equipped with a 5-way plug (3 PNE) and it must be able to

carry at least 16 A per phase.

Power cable and/or extension cords must be placed so that they pose no safety or

health hazard. Do not pinch the cords or pull them around sharp corners and over

sharp edges; do not let them hang exposed in the room. Do not place the cords on

hot surfaces and protect them from oil and harsh cleaning agents.

Never lift or pull the machine by the mains cable. Never pull the plug out of the

socket by gripping the mains cable or extension cord. Do not touch cable or plug

with wet hands. Never insert a wet plug into the socket.

750 mm (1010 mm with opened cover of the coffee beans container)

mm

Fuse

(installation site)

Connection cable

conductor crosssection

Page 3-8 BAPdO500 - EN - V05

Page 23

3.2.4 Power consumption

Ready for operation: max. 9,8 kW *)

-

- in Stand-by:

Cooling (Peltier element):approx. 55 W

Cup plate: approx. 28 W

Total: approx. 83 W

*) See 10.3 "Serial plates of steam generator and instant heater" on

page 10-6.

3.2.5 Water supply/drain

The coffee machine must be connected as shown in the installation on page 3-6 diagram to a G 3/8" drinking water line with a pressure hose.

If the coffee machine is to be connected to a newly installed water line, the line and

the pressure hose must be properly rinsed to ensure that no dirt particles are fed into

the machine.

If the machine is to be connected to a water drain, the supplied drainage hose should

be connected to the drip tray and the siphon and fastened securely. The hose should

point downwards so that water can easily flow out of the drip tray.

Note:

Ideally, water hardness should be 7-5°dH (standard German hardness) or 8-12°fH

(standard French hardness). Chlorine content should not exceed 100 mg per litre.

The ideal pH value is 7. For all other values, local regulations apply.

Water inlet pressure

Note:

We recommend setting the decompression valve to 3 bar.

Feed water temperature

3.2.6 Volumes

a

3 hot w

ter boiler

1.2 l hot water

0.8 l coffee water left:

0.8 l coffee water right:

1 steam boiler

0.8 l, of which 0.4 l are steam

2 coffee grinders

1.3 kg coffee beans per coffee grinder

Refrigerator

1 l or 2 l milk pack or

2 l milk container

Product description

Recommended: 0.1 MPa – 0.3 MPa (1 – 3 bar)

Maximum: 0.6 MPa (6 bar)

Minimal: 10°C

Maximum: 30°C

BAPdO500 - EN - V05 Page 3-9

Page 24

Product description

3.3 Equipment and accessories

3.3.1 Make of the coffee machine

The TWIN model is equipped with a double outlet, refrigerator and with a chip card

3.3.2 Standard accessories (included)

reader. The following models are available:

Model Ordering no.

1 TWIN-500 040700

1 PDO-500 TWIN 040702

1 DE SCHAERER-500 TWIN 040703

Item Ordering

1

User manual *

1 Quick Reference Card *

2 Insert foils *

1 CPM sticker *

1 Refrigerator sticker *

1 Front door sticker *

1 CHEF chip card 063930

1 SAVE DATA PLUS chip card 063929

1 Wallet for 2 chip cards 065278

1 Coffee measuring spoon 067111

2.0 l Cleaning agent for daily cleaning 061299

6 x 2 litre bottles

2.0 l Cleaning agent for weekly cleaning 061019

1 Package cleaning tablets 065221

1 Dosing apparatus 061020

1 Air valve cleaner 061454

1 Brush 067409

1 Small brush 061174

1 Large brush 061175

1 3/8" screw fitting 068178

1 G1/2“ screw fitting 068179

2 Flat packing D = 15 x 9 x 0.8 mm 064249

1 90° bow 067784

1 Milk container 061975

1 Cleaning container 061862

1.5 m Silicone discharge hose 061845

* customised articles!

Subject to changes without notice!

no.

Page 3-10 BAPdO500 - EN - V05

Page 25

3.3.3 Special accessories (not included in shipment)

Item Ordering no.

Supplementary chip cards:

PROGRAM 063941

KEY BLOCK 063931

COFFEE TEST 063932

MANAGER 063940

LOAD 063937

MASTER 063934

WAITER 063936

COPY WAITER 063942

PRINT 063943

MONEY A-F 063921 - 063926

CUP 063939

CREDIT-LOCK 063946

“Clean” (for cleaning card reader) 063945

3.3.4 Optional features for the coffee machine

Note:

You can read the details on the additional optional features listed in "Options" or obtain information from a manufacturer-authorised dealer.

- Payment systems such as Waiter Account and MONEY

- Payment systems such as coffee-bar systems (CSI = Coffee Standard Interface),

cash payment systems (CCI = Coffee Credit Interface, e.g. coin and token slots)

- Chip card loader

- Alarm functions

- Water softener (Filados/Brita)

- Cup warmer

- Water tank for trolley version (mobile operation)

- Coffee grounds ejection into ext. container (coffee ground container omitted)

3.4 Special settings

Note:

All settings described in this section can only be programmed by an authorised service technician.

3.4.1 Time-specific settings

3.4.1.1 Service reminder

After a certain period or a certain number of beverages, a reminder is displayed that it

is time to have the machine serviced by a service technician.

3.4.1.2 Timer

This enables the coffee machine to be programmed to come on the days it is used. In

this case, it switches itself on automatically.

Product description

BAPdO500 - EN - V05 Page 3-11

Page 26

Product description

3.4.2 Cleaning settings

3.4.2.1 Cleaning reminder

The cleaning reminder and the time for it can be enabled or programmed by the service technician.

After the message appears on the display, you can dispense products for 4 hours. If

cleaning is not done during this time, another product output is not possible. You can

delay the cleaning by another 4 hours by pressing the [Operator] button.

Should the machine be cleaned before the cleaning reminder appears, displaying the

reminder will be suppressed.

3.4.2.2 Sample coffee

A sample coffee is automatically served immediately after the coffee machine is

switched on.

3.4.3 Miscellaneous

3.4.3.1 Product mix

Pre-selection of different beverage types

technician.

3.4.3.2 [ DECAF ] button (manual dosing)

The service technician can enable or disable the [DECAF] button.

3.5 Chip card functions

Important!

Chip cards should be handled with the same care as bank cards (do not bend, do not

use as “door openers”, etc.)

This coffee machine features the latest control technology. To facilitate programming,

various program groups have been created which can be programmed directly with

the aid of the respective chip cards. Using these chip cards protects the program

groups from misuse. Security against misuse is not increased because important chip

cards such as the CHEF, PROGRAM, LOAD and MANAGER chip card must be programmed with a security level by the service technician.

4 security levels can be programmed.

Security level - 0 Customer ref.

The control system automatically checks whether the card

Security level - 1 Customer ref. / PIN code

Verifies the customer reference number and inputs of a PIN

quantities can be enabled by the service

and

bears the correct customer reference number.

code before the card is ready.

Page 3-12 BAPdO500 - EN - V05

Page 27

Security level - 2 Customer ref. / Card ref.

Verification of the customer reference number.

The card reference number

Security level - 3 Customer ref. / Card ref. / PIN code

The highest security level, combining levels 1 and 2.

If a new chip card is inserted into the card reader with security level 1 or 3, any number, including 0000, may be entered as the PIN code. This value is then transferred to

the card and considered as the current code.

3.5.1 Standard chip cards

The CHEF card enables the principal settings or modifications to be undertaken for

routine operation.

- Display product counter total for coffees and teas by key

- Reset counter

- Read monthly counter for coffee and tea

- Change grinding quantity.

- Set filling quantity of coffee water and milk

- Set dosage time for water and steam

- Change time display

- Change date display

- Change on/off time (timer)

- Remove the “service wanted” message

- Change PIN code (Personal Identification Number)

- Changing the display language

The SAVE DATA chip card is a security card which enables the machine settings to

be saved or data from the card to be transferred to the machine.

The SAVE DATA PLUS chip card is required for the coffee machine:

Product description

1)

is also entered in the internal chip

card table. This makes it impossible to use any other card, as

the system authorizes one card only per program group.

1)

Every chip card bears a manufacturer-supplied incremental

card reference number.

BAPdO500 - EN - V05 Page 3-13

Page 28

Product description

3.5.2 Chip card options for normal operating mode

In normal operating mode, the PROGRAM card is used for statistical purposes. If a

payment system is installed, the requisite settings are made using the PROGRAM

card:

- Enable/disable payment mode

- Switch prices (price level 1 and 2 time-dependant)

- MONEY price level 1 and 2

- Change token price with or without MONEY card price levels 1 and 2

- Change product prices and article numbers (Only for external payment mode)

- Display sales on MONEY chip card

- Delete sales on MONEY chip card

- Display sales on MASTER chip card

- Delete sales on MASTER chip card

- Log on MASTER chip card

- Delete MASTER chip card table

- Changing the PIN code

The KEY BLOCK card is used to disable either individual or all product keys simultaneously for all uses, or to enable them.

The COFFEE TEST card is used to check the ground coffee (quantity dispensed and

fineness) and to change the quantity ground.

3.5.3 Chip cards for payment mode

MONEY cards, from A-F, enable a scale of prices to be used in conjunction with the

MONEY chip card system. The amount of coffee ground and dispensed can be individually programmed on each MONEY card for all coffee products.

The CUP card queries and adds up the counter levels for each individual product without resetting them.

The CREDIT LOCK card switches between normal operating mode and payment

mode.

Page 3-14 BAPdO500 - EN - V05

Page 29

3.6 Commissioning

3.6.1 Initial commissioning of the coffee machine

The coffee machine must be installed and commissioned by a service technician

authorised by the manufacturer.

Note:

Once the coffee machine is installed and after subsequent changes, it is important to

save the new data on the SAVE DATA card provided. The SAVE DATA cards should

be on hand at all times, including for the service technician.

3.6.2 Set-up conditions

3.6.2.1 Location

Danger!

- Prior to installing, ensure that the coffee machine will not be positioned on a

hot surface or near an oven.

- Never expose the coffee machine to rain, snow, frost, etc.

- The support surface for the unit must be stable and level and may not be deformed by the weight of the coffee machine.

Note:

- The location must comply with the following climatic conditions:

- Ambient temperature from 10 °C to 35 °C

- Relative humidity max. 80 %

- The machine is designed exclusively for interior use.

Important!

Protect the machine from frost. If the coffee machine has been exposed to temperatures below freezing point, contact an authorised customer service representative before you start the unit.

3.6.2.2 Installation of the coffee machine

Installation of the coffee machine should be done under the following conditions:

- Install the supply lines as shown in the mains-side installation diagrams to within one

- Conform with technical data (see "Product description", page 2-1).

- Leave a space (above and at the sides) for servicing.

- Install the machine at least 15 cm away from the wall (for ventilation).

- Comply with the respective local statutory regulations regarding catering premises.

meter of the place of installation.

(Ideally leave about 35 cm free on each side.)

Product description

BAPdO500 - EN - V05 Page 3-15

Page 30

Product description

Page 3-16 BAPdO 500 TW - 02.03 - V02

Page 31

Operation

4 Chapter

Table of contents

Chapter Text Page

4

4.1

4.2

4.3

4.4

4.4.1 Refilling of coffee beans .....................................................................................................................4-5

4.4.2 Adding ground coffee .........................................................................................................................4-5

4.4.3 Replace milk pack or refill milk ...........................................................................................................4-6

4.4.4 Making the coffee machine ready for operation .................................................................................4-7

4.4.4.1 Pre-checks..........................................................................................................................................4-7

4.4.4.2 Switching on the coffee machine........................................................................................................4-7

4.4.5 Pre-selecting type of beverage:..........................................................................................................4-8

4.4.6 Special-size beverage containers ......................................................................................................4-8

4.4.7 Preparing products using the second product level ...........................................................................4-9

4.4.8 Double distribution button (2x)..........................................................................................................4-10

4.4.9 Dispensing coffee and hot milk beverages.......................................................................................4-10

4.4.10 Dispensing coffee with previously ground coffee powder ................................................................4-12

4.4.11 Dispensing milk or milk foam............................................................................................................4-13

4.4.12 Dispensing hot water........................................................................................................................4-14

4.4.13 Generating steam.............................................................................................................................4-15

4.4.14 End of operation/switching off the machine......................................................................................4-16

4.5

4.5.1 Several weeks (e.g. business vacation): ..........................................................................................4-17

4.5.2 Standstill for several months (e.g. end of season): ..........................................................................4-17

4.5.3 Disassembly of the coffee machine..................................................................................................4-17

4.6

4.6.1 Inserting the chip card into the chip card reader ..............................................................................4-18

4.6.2 CHEF chip card ................................................................................................................................4-18

4.6.2.1 Menu view of the CHEF chip card....................................................................................................4-18

4.6.2.2 Read product counter for coffees and teas by key...........................................................................4-19

4.6.2.3 Resetting counter..............................................................................................................................4-19

4.6.2.4 Reading monthly counter..................................................................................................................4-20

4.6.2.5 Changing grinding quantity (coffee powder).....................................................................................4-20

4.6.2.6 Changing the water and/or milk quantity for coffee products...........................................................4-21

4.6.2.7 Dosage time for hot water, steam, hot milk and milk foam. .............................................................4-22

4.6.2.8 Changing time display ......................................................................................................................4-23

4.6.2.9 Changing date display......................................................................................................................4-23

4.6.2.10 Changing on/off time.........................................................................................................................4-24

4.6.2.11 Changing the PIN code ....................................................................................................................4-25

4.6.2.12 Service reminder...............................................................................................................................4-26

4.6.2.13 Changing the display language........................................................................................................4-26

4.6.3 DATA SAVE PLUS chip card ...........................................................................................................4-27

4.6.3.1 Menu view of the DATA SAVE PLUS chip card...............................................................................4-27

4.6.3.2 Saving coffee machine data to chip card .........................................................................................4-27

4.6.3.3 Saving data from the chip card to the coffee machine .....................................................................4-28

OPERATION ....................................................................................... 4-3

Introduction.......................................................................................................................................4-3

Operating Modes ..............................................................................................................................4-4

Messages displayed when coffee machine is ready for operation .............................................4-4

Routine operation.............................................................................................................................4-5

Longer idle time ..............................................................................................................................4-17

Programming using standard chip cards ....................................................................................4-18

BAPdO500 - EN - V05 Page 4-1

Page 32

Operation

Table of contents

Chapter Text Page

4.7

4.7.1 PROGRAM chip card....................................................................................................................... 4-28

4.7.1.1 Menu view of the PROGRAM chip card .......................................................................................... 4-29

4.7.1.2 Programmable security levels ......................................................................................................... 4-29

4.7.1.3 Enabling / disabling payment mode................................................................................................. 4-30

4.7.1.4 Switching prices............................................................................................................................... 4-31

4.7.1.5 Changing MONEY price level 1 and 2............................................................................................. 4-32

4.7.1.6 Changing token price, with or without MONEY price level 1 and 2................................................. 4-33

4.7.1.7 Changing product price and item number (for external CCI / CSI payment systems) .................... 4-34

4.7.1.8 Displaying sales on MONEY chip card............................................................................................ 4-35

4.7.1.9 Deleting sales on MONEY chip card ............................................................................................... 4-35

4.7.1.10 Displaying sales on MASTER chip card.......................................................................................... 4-36

4.7.1.11 Deleting sales on MASTER chip card ............................................................................................. 4-36

4.7.1.12 Logging on MASTER chip card ....................................................................................................... 4-37

4.7.1.13 Deleting MASTER chip card table................................................................................................... 4-38

4.7.1.14 Changing the PIN code.................................................................................................................... 4-38

4.7.2 KEY BLOCK chip card..................................................................................................................... 4-39

4.7.2.1 Menu view........................................................................................................................................ 4-39

4.7.2.2 Disabling product buttons ................................................................................................................ 4-39

4.7.2.3 Enabling product buttons................................................................................................................. 4-40

4.7.3 COFFEE TEST card ........................................................................................................................ 4-41

4.7.3.1 Menu view........................................................................................................................................ 4-41

4.7.3.2 Ground coffee test program............................................................................................................. 4-41

4.7.4 “Operator mode” .............................................................................................................................. 4-42

4.7.4.1 Postponing the coffee machine cleaning time................................................................................. 4-42

4.7.4.2 Displaying refrigerator and boiler temperature................................................................................ 4-42

Programming using optional chip cards..................................................................................... 4-28

Page 4-2 BAPdO500 - EN - V05

Page 33

4 OPERATION

4.1 Introduction

This chapter describes the basic functions of the coffee machine. Read them carefully

to ensure easy and problem-free routine operation.

Note:

Proper installation and programming of the coffee machine by an authorised service

technician are crucial for a smooth operation and good product quality.

Danger!

- During product release, never move cups or other objects positioned below

the beverage outlet, the hot water outlet or the steam pipe! The beverages delivered by the machine are hot! After having pressed the selection button,

keep hands and other body parts away from the outlets to prevent scalding!

- Never aim steam or hot water jets against persons!

- Do not touch the hot cup plate or the beverage outlets. Touch the hot water

outlet and the steam pipe only at the insulated handles.

- The coffee machine does not stop when a cup is removed during delivery from

underneath an outlet. Delivery (including pre-selected delivery) can only be

terminated by pressing the [STOP] button.

Note:

The noise emission level of the machine is less than 70dB (A).

Operation

BAPdO500 - EN - V05 Page 4-3

Page 34

Operation

4.2 Operating Modes

There are 3 operating modes, shown on the display as follows:

Select product

12:00 01.07.2010

Your coffee machine is ready for operation. When a product button is pressed,

the selected beverage is delivered.

Credit operation

12:00 01.07.2010

The internal or external payment system is active. Products can be dispensed

according to the installed system.

. << Standby >> .

12:00 01.07.2010

The control board is switched off. The coffee machine is, however, still connected to the power supply. The refrigerator and the cup plate heating (cf.

Pos. 4, page 2-2) is in normal operating mode.

Note:

When switched on again, the machine will need a short time to reach the programmed operating temperature.

4.3 Messages displayed when coffee machine is ready for operation

Note:

These messages only appear when the coffee machine is idle, i.e. when no

beverages are being served. Displaying these messages does not mean that

the dispensing process will be interrupted.

.....

Container full

.....

Heat up...

.....

clean machine

credit ####.##

too little credit

Empty the grouts container. Up to five more coffees can be made; after that, the

coffee machine blocks.

The temperature of an instantaneous water heater has fallen to more than 10°C

below the programmed value. Please wait until the machine has warmed up

again before dispensing the next product.

Start the cleaning program (cf. 5 "Cleaning", page 5-1).

Insufficient credit

Page 4-4 BAPdO500 - EN - V05

Page 35

4.4 Routine operation

4.4.1 Refilling of coffee beans

Both coffee bean containers (1) should only be filled with max. 1.3 kg of coffee beans

each.

Note:

Never fill the coffee bean containers with a different product than roasted coffee

beans!

The coffee grinders are set for a specific coffee mixture. When changing the mixture,

the grinder and the dosing apparatus must be readjusted by a manufacturerauthorised service technician.

Danger!

Never reach with your hands into the coffee bean container(s) when the machine is switched on. When refilling the bean container(s), do not reach into the

grinder and do not press a product button!

1

1

Fig. 4.4 A

4.4.2 Adding ground coffee

2

Fig. 4.4 B

Operation

1. Open the cover of the empty coffee bean container (1) with the spoon supplied.

2. Refill with coffee beans (max. 1.3 kg). Close

and lock the cover again.

In order to brew pre-ground coffee (e.g. decaffeinated

coffee) fill container (2) with one serving (see fig. 4.4

B). Use the supplied measuring spoon.

The product is subsequently delivered at the right

beverage outlet.

BAPdO500 - EN - V05 Page 4-5

Page 36

Operation

4.4.3 Replace milk pack or refill milk

You can use both milk packs and the supplied milk container.

Note:

Generally, any type of homogenized milk can be used, skim, reduced fat or whole

milk. The fatter the milk, the thicker the foam. As the foamer head is set for a particular type of milk, it is recommended to always use the same milk product.

Important!

- Do not use raw milk! Use only pasteurised or ultrahigh temperature treated (UHT)

milk.

- Milk that has already been heated up or for which the expiry date has lapsed may

not be used.

- For proper function of the foamer head, the milk must have a temperature of between approx. 3 °C and 5 °C. Do not leave the refrigerator open with milk inside.

- Milk pack:

- Use a new milk pack every day.

- For reasons of hygiene, it is recommended to use the milk directly from the original

pack.

- Milk container:

Pour out any milk remaining in the milk container.

- Always thoroughly clean the milk container before refilling it with fresh milk.

- Only pour in milk cooled to between 3 °C to 5 °C.

Fig. 4.4 C

Fig. 4.4 D

1. Before handling any products inside the refrigerator, wash your hands thoroughly!

2. Open the refrigerator door and remove the

empty milk pack or milk container.

3.1 Milk pack: Insert the hoses into the opening in

the new milk pack. Then place the milk pack in

the refrigerator with the opening to the front

(see Fig. 4.4 C). Ensure than none of the hoses

is bent.

3.2 Milk container: Pour out the remaining milk.

Clean the container thoroughly before you pour

in fresh milk. Then place the container in the refrigerator. Insert the tubes into the container.

Ensure than none of the tubes is bent (cf. Fig.

4.4 D).

4. Close the refrigerator door.

The coffee machine is now ready for the deliv-

ery of heated milk or milk foam.

Page 4-6 BAPdO500 - EN - V05

Page 37

4.4.4 Making the coffee machine ready for operation

4.4.4.1 Pre-checks

Prior to switching on the machine, check the following:

1.

- The fresh water supply is open

- The coffee bean containers are filled (see 4.4.1 "Refilling of coffee beans”,

page 4-5).

A fresh milk package or fresh milk is in the milk container (see 4.4.3 "Replace

-

milk pack or refill milk", page 4-6

The coffee grounds container has been emptied.

-

-

The coffee machine is connected to the power supply.

- The following text must be shown on the (dark) display:

<<Standby>>

Display example

12:00 01.07.2010

4.4.4.2 Switching on the coffee machine

1.

2.

Fig. 4.4 E

If the coffee machine was shut off for a longer

Note:

- If the cleaning program was run before the coffee machine was switched off, a rinse

cycle is automatically run when the coffee machine is re-initialised and, if programmed to do so by a service technician, a sample coffee is served. (Place a cup

under the coffee outlet.)

- For coffee machines with fresh water tank see 7.6 "Operating instructions for special

coffee machines" on page 7-3.

- Depending on how the coffee machine is programmed, another message may be

displayed when the coffee machine is ready for operation, especially if payment

mode is activated.

Operation

).

Open the front door and press the [Stand-by]

button to switch the coffee machine on (see

Fig. 4.4 E) and hold the button down until the

display is illuminated.

The following message is displayed:

first and then

. .TWIN – 500. .

by SCHAERER Ltd.

Selection locked

Panel door open

Before you close the front door, check whether

the coffee slides are open.

period of time, the following message appears:

Selection locked

Heat up system

BAPdO500 - EN - V05 Page 4-7

Page 38

Operation

4.4.5 Pre-selecting type of beverage:

If enabled by a service technician, up to 5 different products can be selected in succession per product output side. The coffee machine will dispense the pre-selected

beverages in the order indicated.

Display example:

Select product

1 (4) (2) 2

The display shows:

1 1 beverage on the left product output side is being dispensed.

(4) 4 beverages on the left product output side have been pre-selected.

2 2 beverages on the right product output side are being dispensed.

(2) 2 beverages on the right product output side have been pre-selected.

Deleting pre-selection of beverages and terminating the current beverage delivery:

Press the [STOP] button once to delete the saved pre-selection of the left (4) and right

(2) outlet. The current beverage delivery is however completed.

Press the [STOP] button again to terminate the current beverage delivery.

4.4.6 Special-size beverage containers

You can fill pots or tall glasses of up to 170 mm in height (see fig. 4.4 F) on the left

output side.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Fig. 4.4 F

Perform the following procedure:

1. Lift up the left outlet cover until it engages.

2. Place the beverage container under the beverage outlet.

3. Press one of the product buttons on the left

side of the control panel.

The following message is displayed:

Select product

#

The LED next to the pressed button illuminates.

4. Do not remove the cup before the LED next to

the product button is switched off.

5. Lower the outlet cover again

Page 4-8 BAPdO500 - EN - V05

Page 39

4.4.7 Preparing products using the second product level

If a service technician has installed and enabled the second product level, the product

buttons can be used to pre-select two different products.

Level 1 for normal usage and

Level 2 for e.g. beverages selected less frequently

Note:

No more products can be selected with the button programmed for the [Shift] function.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Perform the following procedure:

1. Position one or two empty cup(s) underneath the left and/or right beverage outlet.

2. Press the product button assigned to the [Shift] key.

Select product

Display example

12:00 01.07.2010

The LED next to the pressed button illuminates.

3. Press the desired product button.

Select product

#

The LED next to the pressed button illuminates.

4. If you do not want to dispense any other products on this level, press the product button assigned to the [Shift] button to return to level 1.

5. Do not remove the cup before the LED next to the product button is switched

off.

Operation

BAPdO500 - EN - V05 Page 4-9

Page 40

Operation

4.4.8 Double distribution button (2x)

If enabled by the service technician, the beverages on the product button can be dispensed twice.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Perform the following procedure:

1. Place one or two empty cup(s) under the left and/or right beverage outlet.

2. Press the product button programmed for double beverage output.

The following message is displayed:

Select product

#

The LED next to the pressed button illuminates.

3. Remove the cup(s) only after the LED next to the product button is switched off.

4.4.9 Dispensing coffee and hot milk beverages

The two beverage outlets work independently of each other. It is thus possible to simultaneously dispense different types and quantities of beverages (max. 5 per output

side).

Note:

- If two cups are to be filled simultaneously, ensure that the cups are positioned ex-

actly underneath the respective outlets. Please note that the milk outlets at the right

dispenser are located behind the coffee outlets. Position the cups accordingly.

- Refilling of coffee beans see 4.4.1 “Refilling of coffee beans”, page 4-5.

Refilling milk: see 4.4.3 "Replace milk pack or refill milk", page 4-6.

-

- Special-size containers: see 4.4.6 "Special-size beverage containers",

page 4-8.

Select type of beverage: see 4.4.5 "Pre-selecting type of beverage:", page 4-8.

-

- If your coffee machine has a payment system installed and enabled, please read the

instructions in chapter 8.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Page 4-10 BAPdO500 - EN - V05

Page 41

Fig. 4.4 G

1. Place one or two empty cup(s) under the left

and/or right beverage outlet (see Fig. 4.4 G).

2. Press the button for the desired product.

Pre-select product quantities and beverage

types: see steps A) to D).

The display indicates the total number of se-

lected cups.

Select product

#

The LED next to the pressed button illuminates.

To terminate current delivery:

see step E).

3. Remove the cup(s) only after the LED next to

the product button is switched off.

Note:

Pre-select or delete product quantities and beverage types:

Follow steps A) to E).

Select quantity: Press the respective product button until the desired number of

A)

cups is displayed.

Delete the product quantity:

B)

- Press the [STOP] button once.

All product pre-selections are deleted.

Start again with step A) to select again.

Select type of beverage: see 4.4.5 "Pre-selecting type of beverage:", page 4-8.

C)

Cancel beverage pre-selection:

D)

Press

All product pre-selections are deleted.

To select again, start again with step D).

E)

the [STOP] button.

To terminate current delivery:

- Press

the [STOP] button once.

- Press the [STOP] button twice, if you have pre-selected product quantities

and/or beverage types.

Operation

BAPdO500 - EN - V05 Page 4-11

Page 42

Operation

4.4.10 Dispensing coffee with previously ground coffee powder

The coffee machine can be enabled for manual coffee preparation by the service

technician. The product is subsequently delivered at the right beverage outlet.

Beverages with ground coffee cannot be pre-selected.

-

- Only use ground coffee.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

1. Place the empty cup(s) under the right bever-

2. Press the [Decaf] button.

Display example

The LED next to the pressed button illuminates.

3. Press the button for the desired product.

Fig. 4.4 H

a

Fig. 4.4 J

The LED next to the pressed button illuminates.

4. Fill ground coffee for one or two cups into fun-

5. Press the [Decaf] button again.

Display example

6.* To terminate current delivery:

7. Remove the cup(s) only after the LED next to

age outlet (see Fig. 4.4 H).

The display does not change:

Select product

12:00 01.07.2010

The following message is displayed:

Select product

coffee powder

The LED next to the

[Decaf ]

button will blink.

nel (a) (see Fig. 4.4 J) by using the (supplied)

measuring spoon.

The following message is displayed:

Select product

1

Press the [STOP] button.

the product button is switched off.

Page 4-12 BAPdO500 - EN - V05

Page 43

4.4.11 Dispensing milk or milk foam

Milk and foam are available in dosed or undosed portions, depending on the current

programming.

The machine can be configured by the service technician to suit the desired product

quantities and beverage types, irrespective of the actually selected delivery mode. If

current, follow the instructions in steps A) to E) as described on page 4-11.

Note:

Coffee beverages without milk and hot water can be dispensed simultaneously. Steam

cannot, however.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Fig. 4.4 K

Operation

If dosed delivery is programmed:

1. Place one or two empty beverage container(s)

under the right beverage outlet (see Fig. 4.4 K).

2. Press the desired product button.

The following message is displayed:

Display example

Select product

1

The LED next to the pressed button illuminates.

3.* To terminate current delivery:

Press the [STOP] button.

4. Do not remove the cup before the LED next to

the product button is switched off.

If a non-dosed delivery is programmed:

1. Place one or two empty beverage container(s)

under the right beverage outlet (see Fig. 4.4 K).

2. Press the desired product button. The product

is delivered continuously.

The following message is displayed:

Display example

Select product

1

The LED next to the pressed button illuminates.

3. Press the same product button to interrupt or to

stop the product output.

BAPdO500 - EN - V05 Page 4-13

Page 44

Operation

g

4.4.12 Dispensing hot water

Press the [

depending on the programming and is via the hot water pipe which is located next to

the beverage outlet (see Fig. 4.4 L).

The machine can be configured by the service technician to suit the desired product

quantities and beverage types, irrespective of the actually selected delivery mode. If

current, follow the instructions in steps A) to E) as described on page 4-11.

Hot water cannot be pre-selected.

-

-

Coffee, coffee/milk mixture and hot water can be dispensed simultaneously.

- Steam output is only possible if no product is dispensed with milk.

Danger!

Risk of injury by scalding! Keep hands and other body parts away from the outlet!

Fi

. 4.4 L

Note:

A “T” is displayed after the output of a large volume of hot water, indicating that the

boiler is being reheated to the set temperature.

] button to dispense hot water. The output is either dosed or undosed

If dosed delivery is programmed:

1. Place an empty container under the hot water

outlet (Fig. 4.4L).

2. Press the [

.

] button

The display does not change during hot water

output:

Display example

Select product

12:00 01.07.2010

3. * To terminate current output early:

Press the [

] button

.

4. Remove the cup.

If a non-dosed delivery is programmed:

1. Place an empty container under the hot water

outlet (Fig. 4.4L).

2. Press the [

.