Page 1

MB200i

Printer

SERVICE MANUAL

PN 9001145B

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support Hotline: (704) 644.1660

Technical Support Fax: (707) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

WARNING

THE EQUIPMENT REFERENCED IN THIS DOCUMENT COMPLIES WITH THE REQUIREMENTS IN

PART 15 OF FCC RULES FOR A CLASS B COMPUTING DEVICE. OPERATION OF THIS EQUIPMENT

IN A RESIDENTIAL AREA MAY CAUSE UNACCEPTABLE INTERFERENCE TO RADIO AND TV

RECEPTION.

Page 3

TABLE OF CONTENTS

INTRODUCTION

About This Manual 1-2

General Description 1-3

Theory Of Operation 1-3

Switches & Indicators 1-4

TECHNICAL DATA

Physical Characteristics 2-2

Enviromental 2-2

Power 2-2

Processing 2-2

Sensing 2-2

Regulatory Approvals 2-2

Print 2-3

Interface Modules 2-3

Media 2-3

Character Font Capabilities 2-3

Barcode Capabilities 2-4

INTERFACE SPECIFICATIONS

Interface Specifications 3-2

802.11B Wireless 3-3

RS232 Serial Interface 3-4

Infrared Rays (IrDA) 3-5

Bluetooth 3-7

All Interface Types 3-8

Receive Buffer 3-8

ACK/NAK Protocol 3-8

AD-HOC Connectivity 3-9

MB200i Wireless LAN Configuration Tool 3-9

MB200i Driver 3-9

Printer Setup 3-9

Computer Setup 3-12

LCD DISPLAY

Display Fields 4-2

Battery Level 4-2

Wireless Field Strength 4-3

Operational Status 4-3

LCD Screens 4-4

Startup 4-4

Normal Mode 4-4

Test Print Mode 4-4

Default Setting Mode 4-5

Factory Clear Mode 4-5

Hex Dump Mode 4-5

Printer Errors 4-6

Maintenance Mode 4-7

LCD Setup 4-7

Wireless LAN 4-8

PN 9001145B

Page 4

PRINTER CONFIGURATION

Printer Configuration 5-2

Factory Defaults 5-2

RS232C Quick Reference Table 5-2

IRDA Quick Reference Table 5-2

Bluetooth Quick Reference Table 5-3

Wireless LAN Quick Reference Table 5-3

Configuration Modes 5-4

Normal Mode 5-4

Label Sensor Selection 5-5

Dispense Mode 5-6

Download Mode 5-7

Font Download Mode 5-9

Online Command Mode 5-11

CRC (Cyclic Redundancy Check) Mode 5-12

Sleep & Auto-Off Mode 5-13

TROUBLESHOOTING

Error Signals 6-2

Troubleshooting Table 6-3

Interface Troubleshooting 6-4

RS232 Serial Interface 6-4

LAN Ethernet Interface 6-4

Test Print Troubleshooting 6-6

Hex Dump Mode 6-6

Test Label Printing 6-7

REPLACEMENT PROCEDURES

Print Head 7-2

Dispense Bar 7-3

Platen Roller 7-5

Dispenser Roller 7-6

Main Circuit Board (A) 7-7

Main Circuit Board (B) 7-8

Panel & LCD Board 7-9

Eye-Mark Sensor 7-10

Gap Sensor 7-12

Cover Open Sensor 7-13

Drive Gear 7-15

Drive Motor 7-16

ADJUSTMENT PROCEDURES

Pitch Adjustment 8-2

Print Darkness 8-3

Default Setting 8-4

Factory Clear 8-5

CHARTS & DIAGRAMS

Cover Removal Diagram (A) 9-2

Cover Removal Diagram (B) 9-3

PN 9001145B

Page 5

INTRODUCTION

• About This Manual

• General Description

• Theory Of Operation

• Switches & Indicators

SATO MB2i Service Manual PN 9001145B Page 1-1

Page 6

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information

required for general printer configuration, troubleshooting, and maintenance. For specialized

programming, refer to the Programming Manual located on the utility CD-ROM.

Step-by-step maintenance instructions are provided with typical problems and solutions. It is

recommended that you become familiar with each section before installing and maintaining the

printer.

This manual also incorporates the use of special information boxes. Examples of these boxes

and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN PERSONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN EQUIPMENT DAMAGE.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different unit sections and their respective subsections. Each references the page number of their commencement.

The pages of this manual has embedded headers and footers to assist the user in identifying his

or her exact position within the manual. The header provides the section number followed by its

name. The footer identifies the product on the left, the manual’s part number in the center, and

the page number to the right side of the page.

Page inumeration is two-part with each separated by a hyphen. The first character set references

the section number and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new section and ascends sequentially.

SATO MB2i Service Manual PN 9001145B Page 1-2

Page 7

Unit 1: Introduction

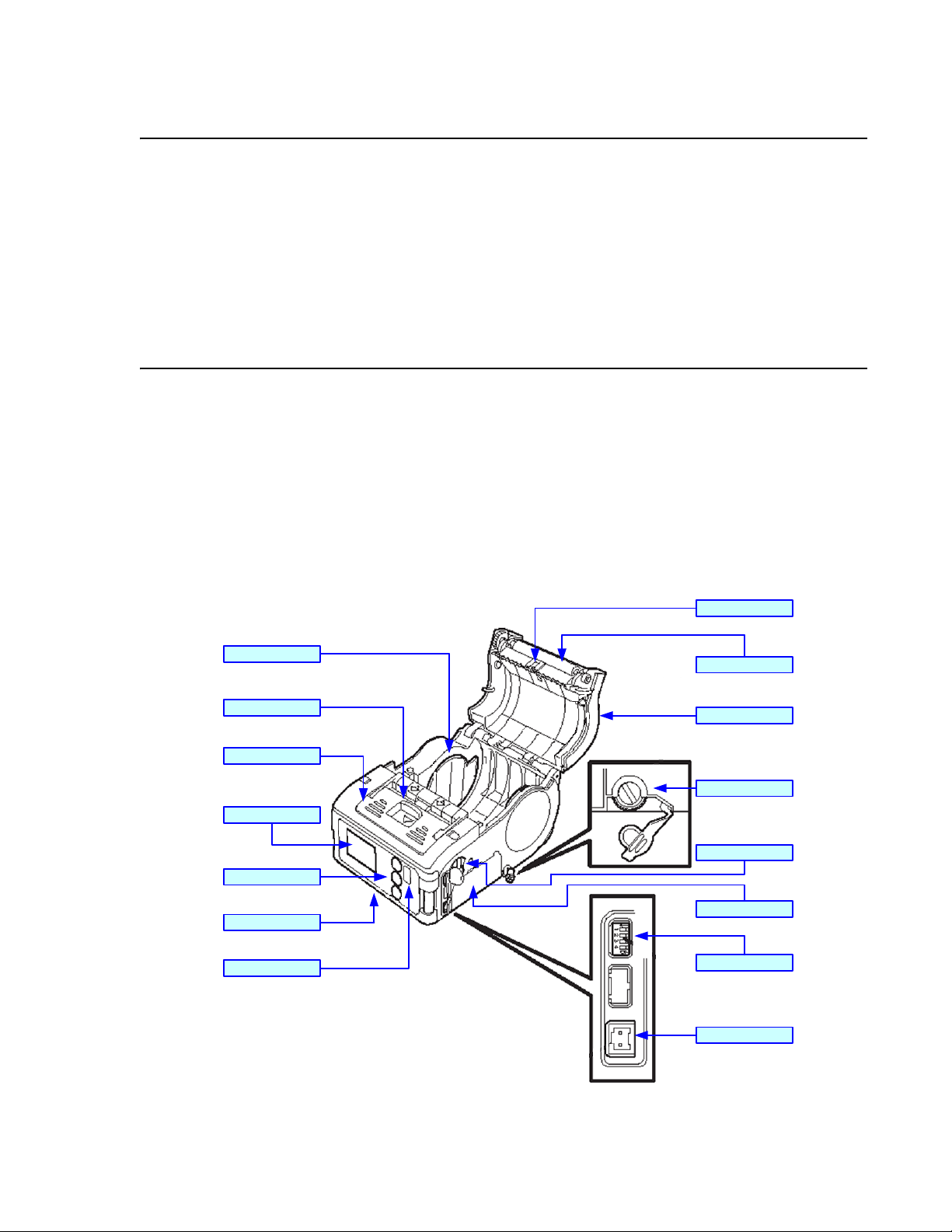

GENERAL DESCRIPTION

The MB200/201i are compact, transportable printers designed for frequent, but intermittant use.

Their direct thermal print head not only allows high performance two-color printing (with special

media), but also clear barcode printing.

Their ABS housing provides a durable, impact-resistant product. An intergrated dispenser

enables application of labels upon print. Rechargeable battery packs and a DC power

transformer ensures operation anywhere, under any conditions. An automatic power off function

turns the printers off after the last print.

THEORY OF OPERATION

When activated, the media is fed past the print head by an integrated drive train. The drive train

is electric motor driven, coupled to a gear configuration located on the left side of the printer

chassis. Kinetic energy is transferred to a platen roller which is the driving force of media

movement. Paper guides within the chassis assembly ensure that the media remains properly

positioned during the printing process and is fed unimpeded through an opening in the front.

A series of strategically located sensors sends signals to the processing unit. The processing unit

in turn sends response signals to the various features based on programmed and received data.

Correct signals initiates print head activity.

Eye-Mark Sensor

Label Guide

Open/ Clo se Lever

Dispenser Unit

LCD Display

Function Keys

Front Housing Cover

IrDA Filter

Platen Roller

Top Housing Cover

Label Guide Dial

RS232C Port

Battery Compartment

Dip Switches

DC Power Port

Figure 1-1, Primary Features & Components

SATO MB2i Service Manual PN 9001145B Page 1-3

Page 8

Unit 1: Introduction

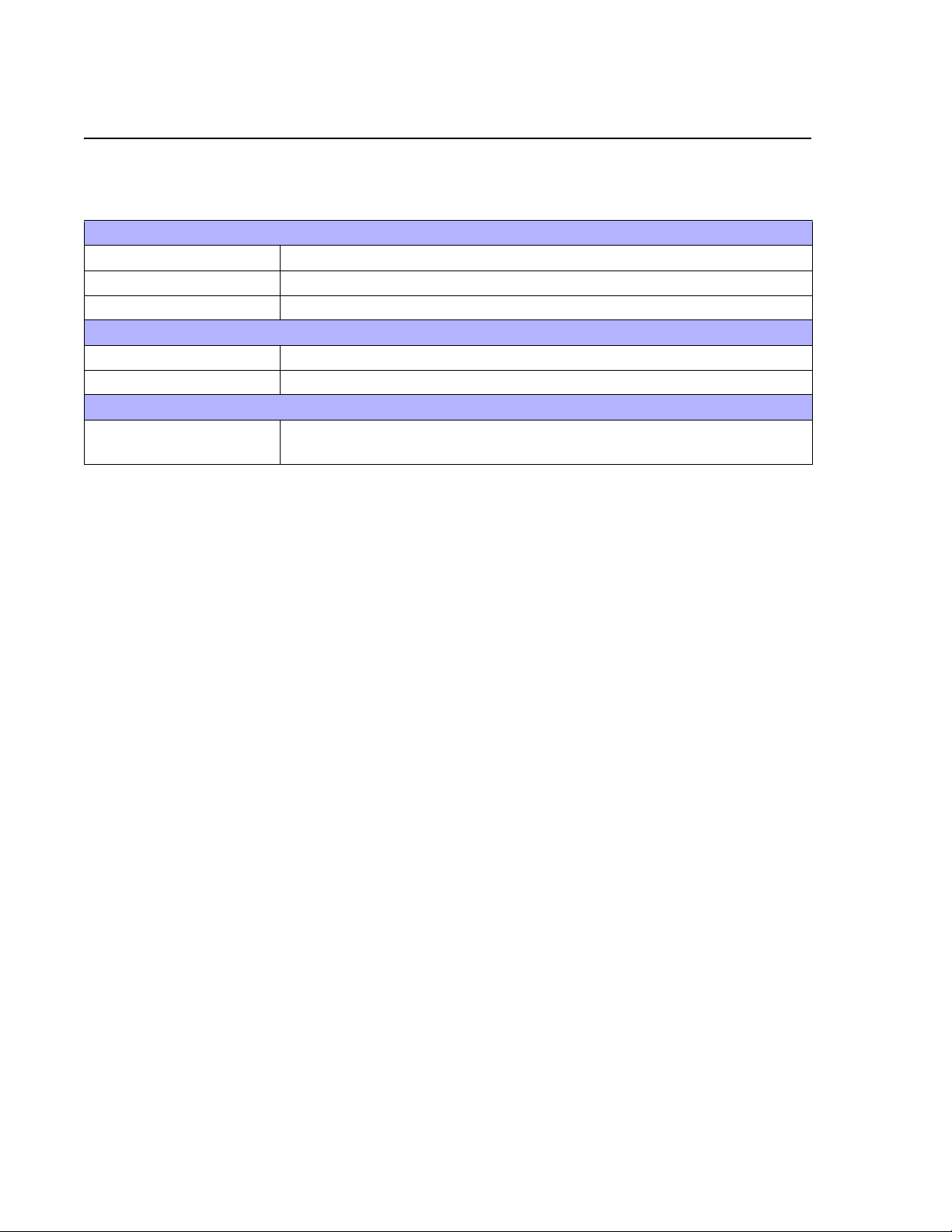

SWITCHES AND INDICATORS

The table below identifies and defines printer switches and indicators for operator interface. The

accompanying graphics display their locations and appearance

SWITCHES

Power Button Two position on/off switch that controls power flow to the system.

Print Button Two position on/off button that activates and deactivates print action.

Feed Button Two position on/off button that activates and deactivates feed action.

INDICATORS

Charge LED Indicates the resource level of the power pack.

Status LED Indicates the systems’ operational status.

DIP SWITCHES

1 through 4 Various positions of the four accumilatively decides some printer

configuration activities.

SATO MB2i Service Manual PN 9001145B Page 1-4

Page 9

TECHNICAL DATA

• Physical Characteristics

• Enviromental

•Power

• Processing

• Sensing

• Regulatory Approvals

•Print

• Interface Modules

•Media

• Character Font Capabilities

• Barcode Capabilities

SATO MB2i Service Manual PN 9001145B Page 2-1

Page 10

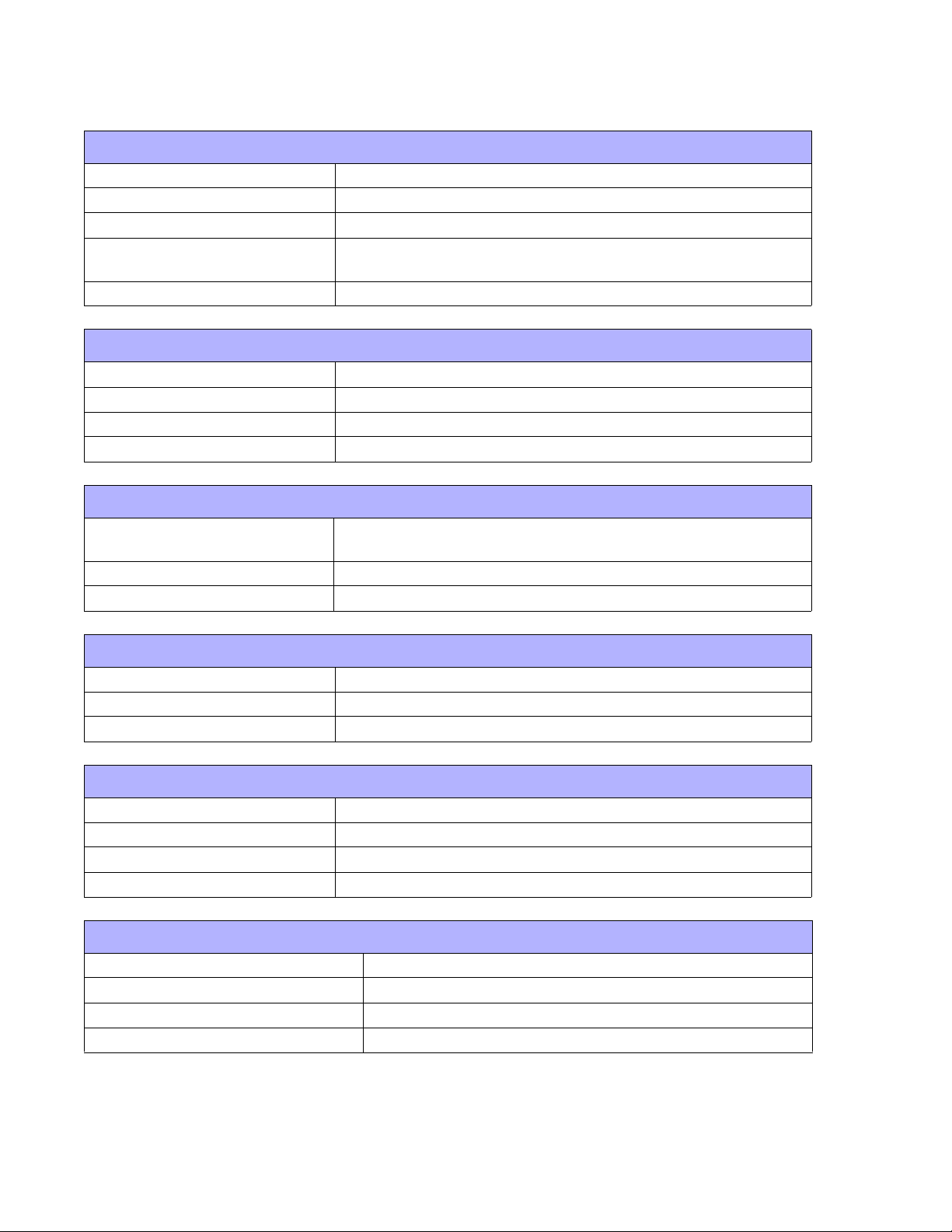

Unit 2: Technical Data

PHYSICAL CHARACTERISTICS

Height (maximum) 2.87 Inches (73 mm)

Width (maximum) 3.47 Inches (88 mm)

Depth (maximum) 5.04 Inches (128 mm)

Weight (maximum)

Drop Specification 9.84 Feet (3.0 m) all six sides

MB200i: 405 Grams (includes 105 grams for battery bag)

MB201i: 390 Grams (includes battery)

ENVIRONMENTAL

Operating Temperature 5° to 122°Fahrenheit (-15° to 50°C)

Storage Temperature -13° to 140°Fahrenheit (-25° to 60°C)

Storage Humidity 30 to 90% RH Non-Condensing

Operating Humidity 30 to 80% RH Non-Condensing

POWER

Print Capacity

Battery Lithiun ion 7.4 volts, 2400mAh standard pack

AC Adapter DC 9 Volt

Four rolls with full charge (equivalent of 48 meters). Continuous

printing is permitted (provided print duty is 16% or less).

PROCESSING

CPU 32 Bit RISC

Flash ROM 2 Megabytes

Receive Buffer 12 Kilobytes

SENSING

Gap/Dispense Fixed

Reflective Eye-Mark Fixed

Label Fixed

Head-Open Yes

REGULATORY APPROVALS

Safety UL 60950

EMC FOC, Class B

Wireless LAN R & TTE (FOC15B, FOC15C)

Bluetooth R & TTE (FOC15B, FOC15C)

SATO MB2i Service Manual PN 9001145B Page 2-2

Page 11

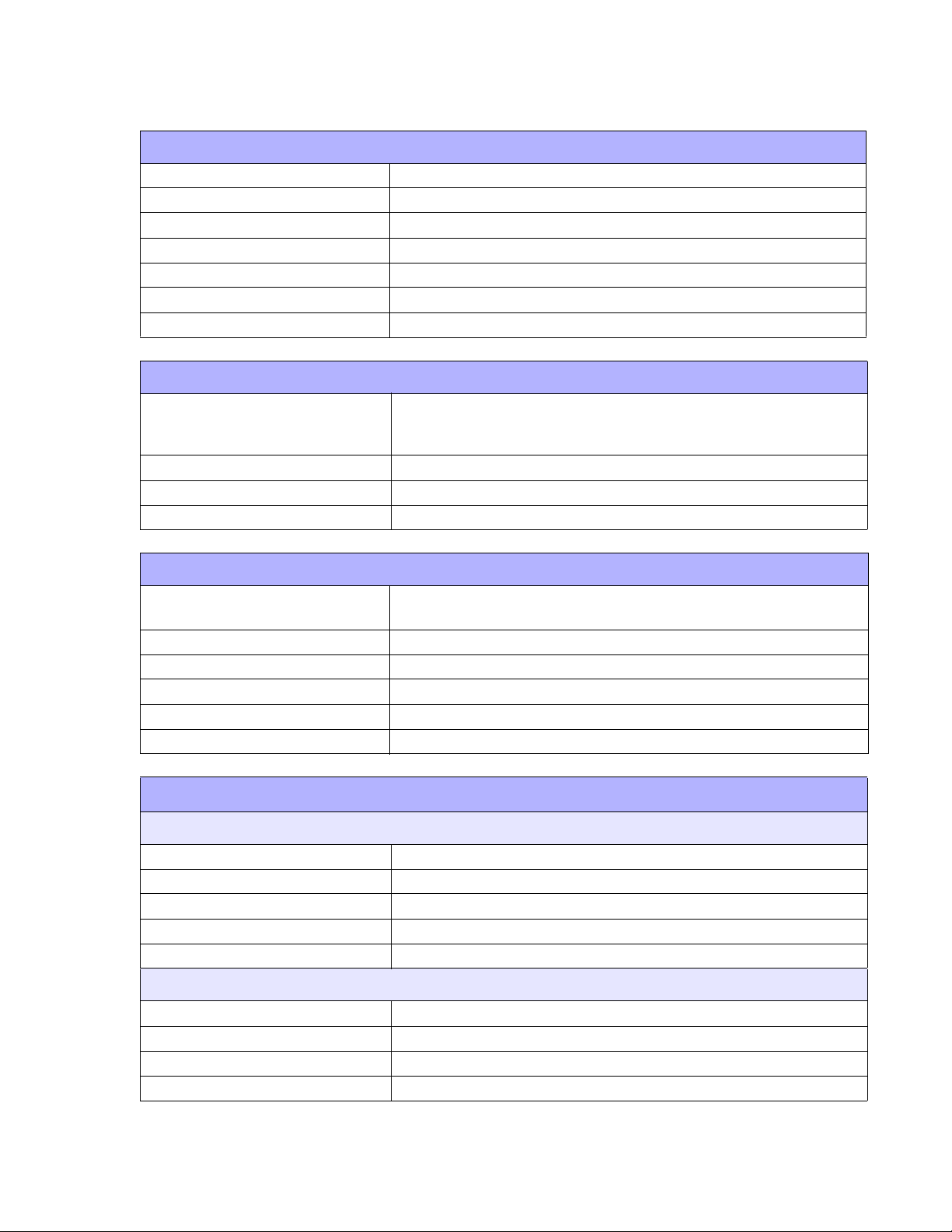

Unit 2: Technical Data

PRINT

Method Direct Thermal

Speed (maximum) 4.05 Inches Per Second (103 mm/s) (varies with print duty)

Print Module (dot size) .0049 Inches (.125 mm)

Resolution 203 Dots Per Inch (8 dpmm)

Maximum Print Width 1.89 Inches (48 mm)

Maximum Print Pitch 6.30 Inches (160 mm)

Angle 0°, 90°, 180°, 270°

INTERFACE MODULES

RS232C (9600 to 57,6000 dps) Standard

Serial Port

IrDA Ir. Std., BHT, Ir Comm (3-wire cooked), Ir Obex (optional)

Ethernet 802.11B Wireless Wi-Fi (with built-in display)

Bluetooth Version 1.1 Compliant

Ready/Busy or X-On/X-Off Flow Control

Bi-Directional Status

MEDIA

Media Types

Linerless Media Standard (strong/weak adhesive)

Media Thickness 0.0025 to 0.0075 Inches (0.064 - 0.190 mm)

Roll Media Outside Diameter 2.64 Inches (67 mm +/- 0.5) MB200i only

Wound Face In / Face Out. Face In is for linerless only.

Core Size 0.75 to 1.0 Inches ( 19.05-25.40 mm) internal diameter

Super High Sensitive, Techno-Thermal A, Sythetic Paper Thermal

C, Non-Sticky Thermal 64, Two-Color Thermal

CHARACTER FONT CAPABILITIES

MATRIX FONTS

XU Font 5 dots W x 9 dots H (Helvetica)

XS Font 17 dots W x 17 dots H (Univers Condensed Bold)

XM Font 24 dots W x 24 dots H (Univers Condensed Bold)

OA Font (OCR-A)

OB Font (OCR-B)

AUTO SMOOTHING FONTS

WB 18 dots W x 30 dots H

WL 28 dots W x 52 dots H

XB 48 dots W x 48 dots H (Univers Condensed Bold)

XL 48 dots W x 48 dots H (Sans Serif)

SATO MB2i Service Manual PN 9001145B Page 2-3

Page 12

Unit 2: Technical Data

CHARACTER CONTROL

Expansion up to 12 x in either the X or Y coordinates.

Charcter Pitch Control

Line Space Control

Journal Print facility

0, 90, 180, and 270 Degree Rotation

BAR CODE CAPABILTIES

UPC-A/E

EAN-13/8

NW-7 (Codabar)

Code 39

Linear Bar Codes

Two Dimemsional

Composite Symbology

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User progammable

Rotation 0, 90, 180, and 270 Degrees

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Expansion Ratio of Character Height: 1-12 times, Width: 1-12 times

Graphics

Form Overlay Form overlay for high-speed editing of complex formats

Full dot addressable graphics, SATO Hex/Binary, .BMP or

Code 93

Code 128

RSS-14

JAN/EAN

ITF

QR Code

Data Matrix

Maxicode

PDF417

.PCX formats

SATO MB2i Service Manual PN 9001145B Page 2-4

Page 13

INTERFACE

SPECIFICATIONS

• Interface Specifications

• AD-HOC Connectivity

SATO MB2i Service Manual PN 9001145B Page 3-1

Page 14

Unit 3: Interface Secifications

INTERFACE SPECIFICATIONS

This chapter presents the printer interface types and their specifications. These specifications

include detailed information to assist in the selection of the most appropriate method for the

printer to interface with the host. The acceptable interface methods are:

• 802.11B Wireless

• RS232C Serial

• Infrared Rays (IrDA)

• Bluetooth

Following the selection of the desired interface, proceed to the following unit for instructions on

how to Configure the printer for that interface type.

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

HOST OR THE PRINTER. THIS MAY CAUSE DAMAGE TO THE

INTERFACE CIRCUITRY IN THE PRINTER/HOST AND IS NOT COVERED

BY WARRANTY.

SATO MB2i Service Manual PN 9001145B Page 3-2

Page 15

Unit 3: Interface Specifications

802.11B WIRELESS INTERFACE

802.11 refers to a family of specifications developed by the IEEE for wireless LAN technology to

communicate between a wireless client and a base station or between two wireless clients. This

interface only uses DSSS which allows wireless functionality comparable to Ethernet.

The wireless print server provides easy printer interface with 802.11b Wi-Fi compliant networks

free of wired connections. Each printer is shipped with a Windows driver and interface installed.

To print from a PC, the driver must be loaded and the PC must be configured to run one of the

supported protocols.

Default Parameters: DSW1, 3, 4 OFF / DSW2 ON.

802.11B WIRELESS SPECIFICATIONS

Variable Data Rates 11, 5.5, 2 and 1 Mbps

Frequency Band 2.4 GHz ISM Band

Wired Equivalent Privacy & WPA WEP 128 bit, 64 bit (compatible with 40bit), WPA, 802.11x

Sensitivity (typ, AAWGN, 8E-2 PER): -91dBm at 1Mbps, -88dBm at 2 Mdps,

-87dBm at 5.5Mbps, -84dBm at 11Mbps.

Range 100m indoors, 300m outdoors

Protocols TCP/IP, IPX/SPX, Direct Mode IPX/IP, DLC/LLC, NetBEUI,

NetBIOS/IP

SATO MB2i Service Manual PN 9001145B Page 3-3

Page 16

Unit 3: Interface Secifications

RS232C SERIAL INTERFACE

This interface is an industry standard for serially transmitting data using a wired cable. Separate

transmit and receive lines enable data to flow in both directions simultaneously. Data transmitted

using this protocol is defined in its parameters; baud/bps (speed), data bits, stop bit, parity, and

hand-shaking method. To change the parameter settings, refer to the Programming Reference

document for this product. The Programming Reference and a ready-made cable with DIN and

DB9 connectors may be acquired from SATO.

Default Parameters: DSW1-4 OFF, 19200bps, 8 data bits, 1 stop bit, no parity.

Figure 3-1, RS232 Male Connector Pin Assignments

Figure 3-2, RS232 Female Connector Pin Assignments

READY/BUSY CABLE REQUIREMENTS

DB9 DB25 HOST DIRECTION 8-PIN PRINTER

2 3 RD (Receive Data) To Host 1 TD (Transmit Data)

3 2 TD (Transmit Data) To Printer 6 RD (Receive Data)

8 5 CTS (Clear To Send) To Printer DB9-6 2 RTS (Request To Send)

5 7 SG (Signal Ground) Bi-Directional 7 SG (Signal Ground)

7 4 RTS (Request To Send) To Host 5 CTS (Clear To Send)

RS232C SPECIFICATIONS

Asynchronous ASCII Half-duplex communication, Bi-Directional Communication

Data Transmission Rate 9600, 19200, 38400, 57600, 115200 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC II Character Codes

Control Codes STX (02h), ETX (03h), ACK (06h), NAK (15h)

Connector 8-pin mini - DIN

Cable (8-pin DIN to 9-pin host) Call 704.644.1650

Signal Levels High: +12V, -12V

SATO MB2i Service Manual PN 9001145B Page 3-4

Page 17

Unit 3: Interface Specifications

INFRARED RAYS (IRDA)

Infrared communications is based on technology which is similar to entertainment remote control

devices used in homes today. This technology offers a convient, interoperable, low power, and

reliable way to connect computer and printer without the use of cables. The half-duplex, serial

data interconnection capabilities supports walk up point-to-point use.

The infrared tranmission of print data is transferred from the terminal to the printer in four phases:

(1) Connection, (2) Printer Status Check, (3) Data Transfer, (4) Disconnection.

The limitations of this interface type is that it requires a direct line of sight with a reading span of

30 degrees at a maximum distance of 7-8 inches (20cm). When the peripherals are aligned, they

negociate and transmit/receive data between the two devices.

Default Parameters: DSW1 ON / DSW2-4 OFF.

IRDA SPECIFICATIONS (STANDARD PROTOCOL)

Baud Rate 9600, 19200, 38400, 57600, 115200

Data Bit Length 8

Stop Bit 1

Parity Bit None, Odd, Even

Codes Used ASC-II: 7 bit, Graphics: 8 bit.

Control Codes STX (02h), SYN (16h), ETX (03h), DLE (10h)

Communication Time Time-Out: 5.99 seconds, Retry: over 500 milliseconds.

Receiving Type Single item.

Operations Mode IrSIR v1.2

BHT protocol is the communication procedure used to transmit files between DENSO data

collection devices by adopting the response method using the ACK/NAK codes defined for the

use with these types of devices. Note the IrDA parameters must be set according to PDA/DCS

methods and appropriately configured to direct data transmission to the printer. Refer to the IrDA

command settings in the Programming Reference document for this printer, as well as,

documentation provided by the manufacturer of the data collection device for the proper steps.

The appropriate firmware must be installed to function.

IRDA SPECIFICATIONS (BHT PROTOCOL)

Baud Rate 9600, 19200, 38400, 57600, 115200

Data Bit Length 8

Stop Bit 1

Parity Bit None, Odd, Even

Codes Used ASC-II: 7 bit, Graphics: 8 bit.

Control Codes SOH (01h), STX (02h), ETX (03h), EOT (04h), ENQ (05h), ACK

(06h), DLE (10h), NAK (15h).

Communication Time Time-Out: 5.99 seconds, Retry: over 500 milliseconds.

Receiving Type Single item.

SATO MB2i Service Manual PN 9001145B Page 3-5

Page 18

Unit 3: Interface Secifications

The IrCOMM protocol runs on top of IrDA and supports the emulation of a peer device similar to

what’s connecting it by a serial or parallel cable for applications that access those ports through

the operating system. Since various communication and printing applications utilize cables

differently, cable emulation must account for those differences.

IRDA SPECIFICATIONS (IRCOMM PROTOCOL)

Baud Rate 9600, 19200, 38400, 57600, 115200

Data Bit Length 8

Stop Bit 1

Parity Bit None, Odd, Even

Codes Used ASC-II: 7 bit, Graphics: 8 bit.

Control Codes STX (02h), ETX (03h), ACK (06h), NAK (15h).

Communication Time Time-Out: 5.99 seconds, Retry: over 500 milliseconds.

Receiving Type Single item.

Operations Mode 3-wire cooked

IrOBEX is a communictions protocol that facilitates the exchange of binary objects between

devices and functions similar to HTTP in that a client uses a reliable transport to connect to a

server to request or provide objects. The appropriate firmware must be installed for this to

function.

This is a one-way communications protocol so therefore flow control and printer response are

absent.

IRDA SPECIFICATIONS (IrOBEX PROTOCOL)

Baud Rate 9600, 19200, 38400, 57600, 115200

Data Bit Length 8

Stop Bit 1

Parity Bit None, Odd, Even

Codes Used ASC-II: 7 bit, Graphics: 8 bit.

Control Codes STX (02h), ETX (03h), ACK (06h), NAK (15h).

Communication Time Time-Out: 5.99 seconds, Retry: over 500 milliseconds.

Receiving Type Single item.

SATO MB2i Service Manual PN 9001145B Page 3-6

Page 19

Unit 3: Interface Specifications

BLUETOOTH

Bluetooth is a short-range, wireless technology operating in the unlicensed 2.4GHz band and

offers greater flexibility than IrDA. Its signal is broadcast omni-directional and transmits/receives

up to a distance 30 feet (10 meters).

Typically, the data is directed through a Bluetooth assigned COM port on a PDA which handles

all COM port protocols. Refer to the manufacturer’s documentation PocketPC device setup.

Default Parameters: DSW1,3,4 OFF / DSW2 ON.

SATO MB2i Service Manual PN 9001145B Page 3-7

Page 20

Unit 3: Interface Secifications

ALL INTERFACE TYPES

RECEIVE BUFFER

The data stream is received from the host to the printer one job at a time. This allows the

software program to maintain control of the job print queue so that it can move a high priority job

in front of ones of lesser importance.

The printer receives and prints one job at a time. If a print job exceeds the buffer size,

transmission will be rejected by the printer. Error conditions that occur during the Print Data

transmission will cause the printer to return a NAK.

ACK/NAK PROTOCOL

Bi-Directional ACK/NAK protocol is used for error control. In a normal transmission sequence

when the transmission is received, the printer will return an ACK (06H) signifying that it was

received without a transmission error. After the transmission command structure has been

analyzed, a status byte is returned to the host. This status byte informs the host of the validity of

the command structure.

If the command structure is error free, the printer proceeds with the print operation. When the

print operation is completed, a Printer Status message is returned to the host. If an error was

detected during the initial transmission sequence, a NAK (15H) will be returned signalling to the

host that the received transmission contained errors and must be resent. If the returned Status

byte indicates a command structure error, the error must then be corrected before the print data

is resent to the printer.

A valid transmission to the printer must be bounded by an STX/ETX pair, with the STX (02H)

signifying the start of the Print Data and ending with an ETX (03H) signifying the end.

SATO MB2i Service Manual PN 9001145B Page 3-8

Page 21

Unit 3: Interface Specifications

AD-HOC CONNECTIVITY

To configure the printer for ad-hoc connectivity, an RS232 port and cable is initially required to

use the Wireless Utility. The following two sections provides direction to the necessary tools, then

procede to the next consecutive sections to begin setup.

NOTE: An 8-pin DIN to 9-pin RS232 cable may purchased from SATO.

MB200i WIRELESS LAN CONFIGURATION TOOL (v1.0.0)

The software may be downloaded from:

http://techsubweb.satoamerica.com/public/SAI_site/networking/MB/MB20xi_Cfgtool-setup.zip

Once downloaded, unzip the package and run “setup.exe” to begin installation. Upon completion,

procede as follows: Start/Programs/Sato Tools/LAN Config Tool.

MB200i DRIVER

The driver may be downloaded from: http://techsuweb.satoamerica.com/public/SAI_site/drivers/

v4/SI_PORT.zip. Once downloaded, unzip the package and procede as follows: Control Panel/

Printer and Faxes/Add a Printer. Make the necessary entries on this menu screen to install the

MB200i driver.

.

PRINTER SETUP

Perform the following procedure to configure the printer for ad-hoc interface connectivity.

1. Ensure all of the necessary tools are present.

2. Set all dipswitches to the OFF position to place the printer in the serial mode.

3. Connect the serial cable to the printer and the applicable host computer.

4. Power on the printer.

5. At the host computer, access Control Panel, followed by MB200i folder, and then click on

MB200i Printer Driver.

6. Procede to the SATO MB200i Properties screen (Figure 3-3a/b), then select the Ports tab.

SATO MB2i Service Manual PN 9001145B Page 3-9

Page 22

Unit 3: Interface Secifications

Figure 3-3a/b, SATO MB200i Properties

7. Check the COM1: Serial Port option to assign “SATO MB200i” to that port, then click on

Apply.

8. On the same screen, click on the Configure Port button.

9. When the COM1 Properties screen appears, click on each drop-down menu to change the

settings as follows: 19200 Bits Per Second, 8 Data Bits, no Parity, 1 Stop Bit, no Flow

Control. (Figure 3-4)

Figure 3-4, COM1 Properties

10. Click on the OK button to record the settings.

11. When the Properties screen appears, click on the OK button to record all settings.

12. When the main MB200i driver screen appears, click on its OK button.

SATO MB2i Service Manual PN 9001145B Page 3-10

Page 23

Unit 3: Interface Specifications

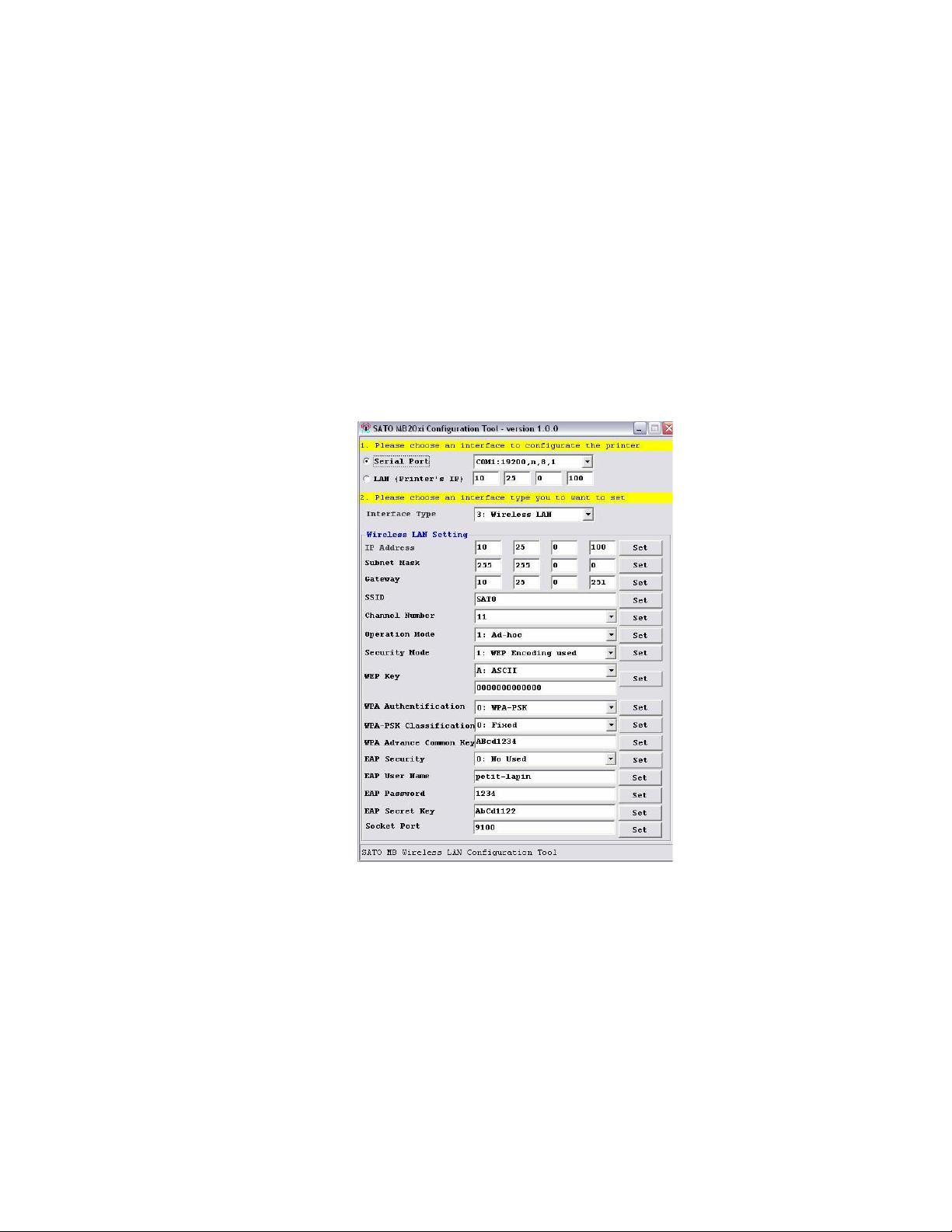

13. Open the SATO MB200i Configuration Tool screen (Figure 3-5) and enter as follows:

• Select the Serial Port option for the interface type. Ensure COM1:19200,n,8,1

displays in the field to the right.

• IP Address: to 150.100.100.1, then press the SET button.

• Subnet Mask: to 255.255.255.0, then press the SET button.

• Gateway: to 0.0.0.0, then press the SET button.

• SSID: to MBPRINT, then press the SET button.

• Channel Number: to 11, then press the SET button.

• Operation Mode: to Ad-Hoc, then press the SET button.

• Security Mode: to Disable WEP, then press the SET button.

• Socket Port: to 9100, then press the SET button.

Figure 3-5, SATO MB200i Configuration Tool

14. Perform the following steps print a test label and verify the settings:

1. Power off the printer and change DSW2 to the ON position.

2 Press and hold the FEED button while powering on the printer. Release when indi-

cators are on.

3 Press the FEED button again to print a test label. Press FEED again to stop.

4 Ensure the contents of the label match those settings of step 13.

15. Ensure the contents of the label match those settings listed in step 13.

16. Repeat steps 2 through 15 if there is a discrepancy between the two.

SATO MB2i Service Manual PN 9001145B Page 3-11

Page 24

Unit 3: Interface Secifications

COMPUTER SETUP

Perform the following procedure to configure the host computer for AD-HOC interface

connectivity.

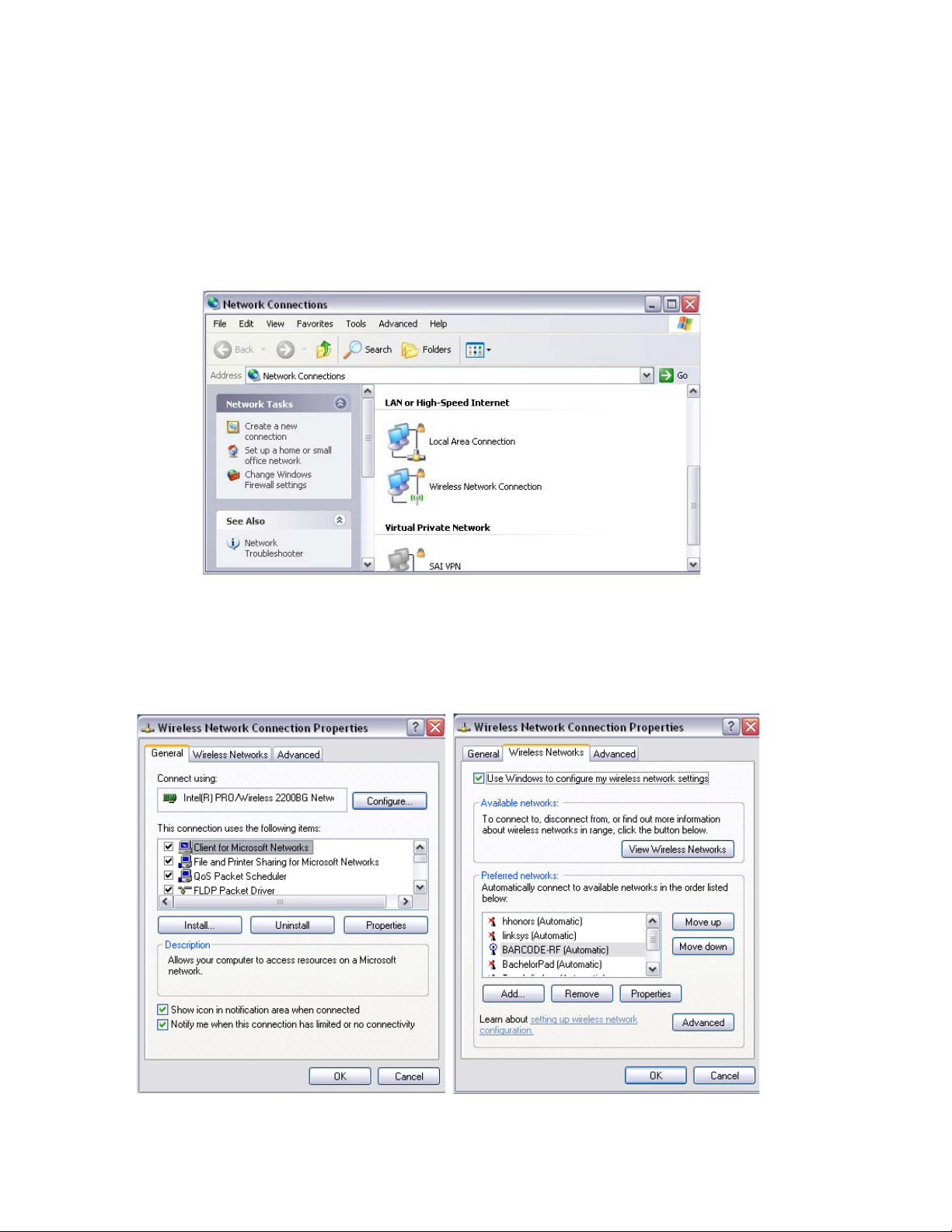

1. At the host computer, access Control Panel and then Network Connections.

2. When the Network Connections screen (Figure 3-6) appears, ensure the icon to the left of

“Wireless Network Connection” does not have a red X over it. Proceed to step 3 if so, exit if

not.

Figure 3-6, Network Connections

3. Click on the icon mentioned in step 2 to proceed to the Wireless Network Connection

Properties screen (Figure 3-7a/b).

4. Click on the Wireless Networks tab to view that menu, then on the Advanced button.

Figure 3-7a/b, Wireless Network Connection Properties

SATO MB2i Service Manual PN 9001145B Page 3-12

Page 25

Unit 3: Interface Specifications

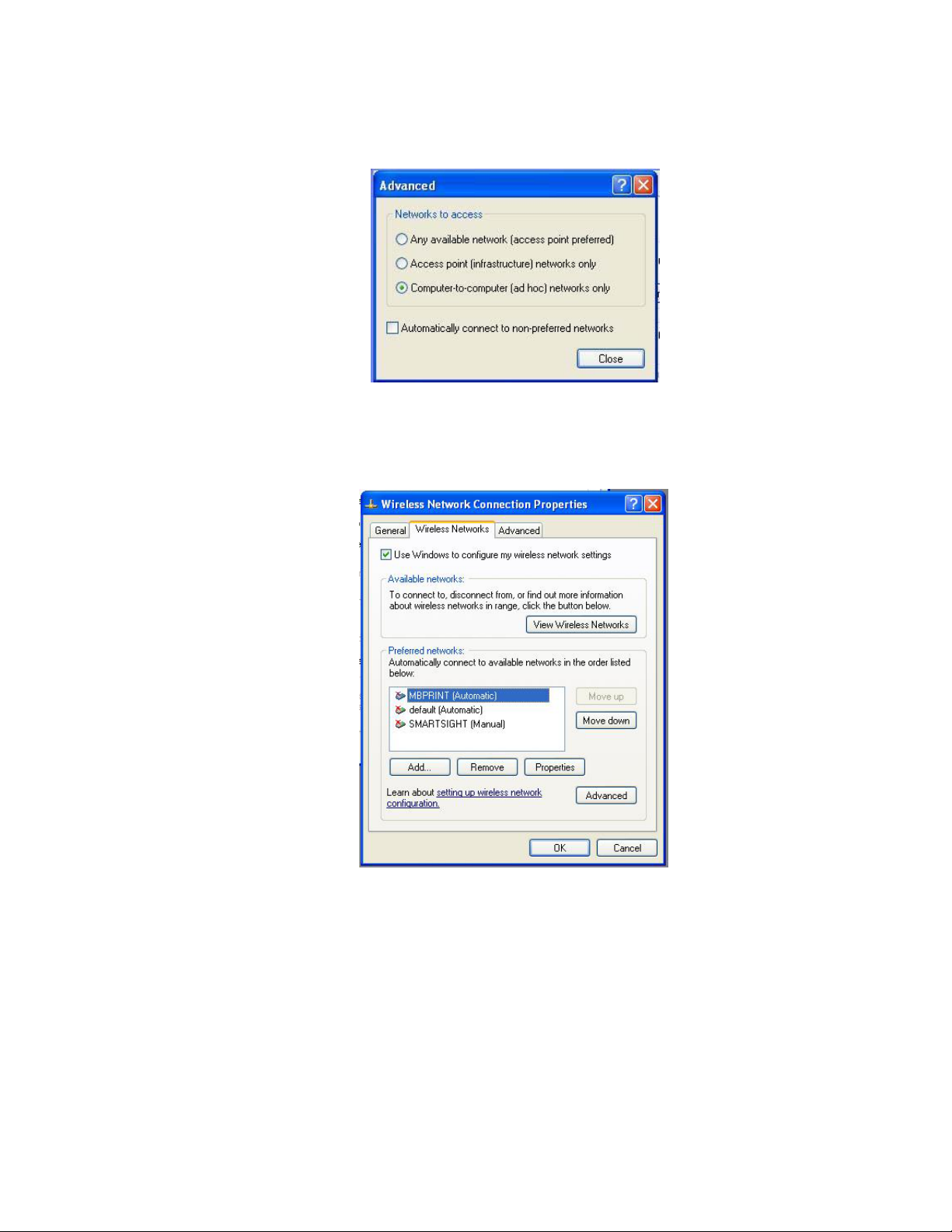

5. When the Advanced screen (Figure 3-8) appears, select the Computer-To-Computer

option, followed by the Close button.

Figure 3-8, Advanced

6. When the Wireless Network Connection Properties Figure 3-9) screen reappears, click on

the Add button to add a network matching that of the printer.

Figure 3-9, Wireless Network Connection Properties

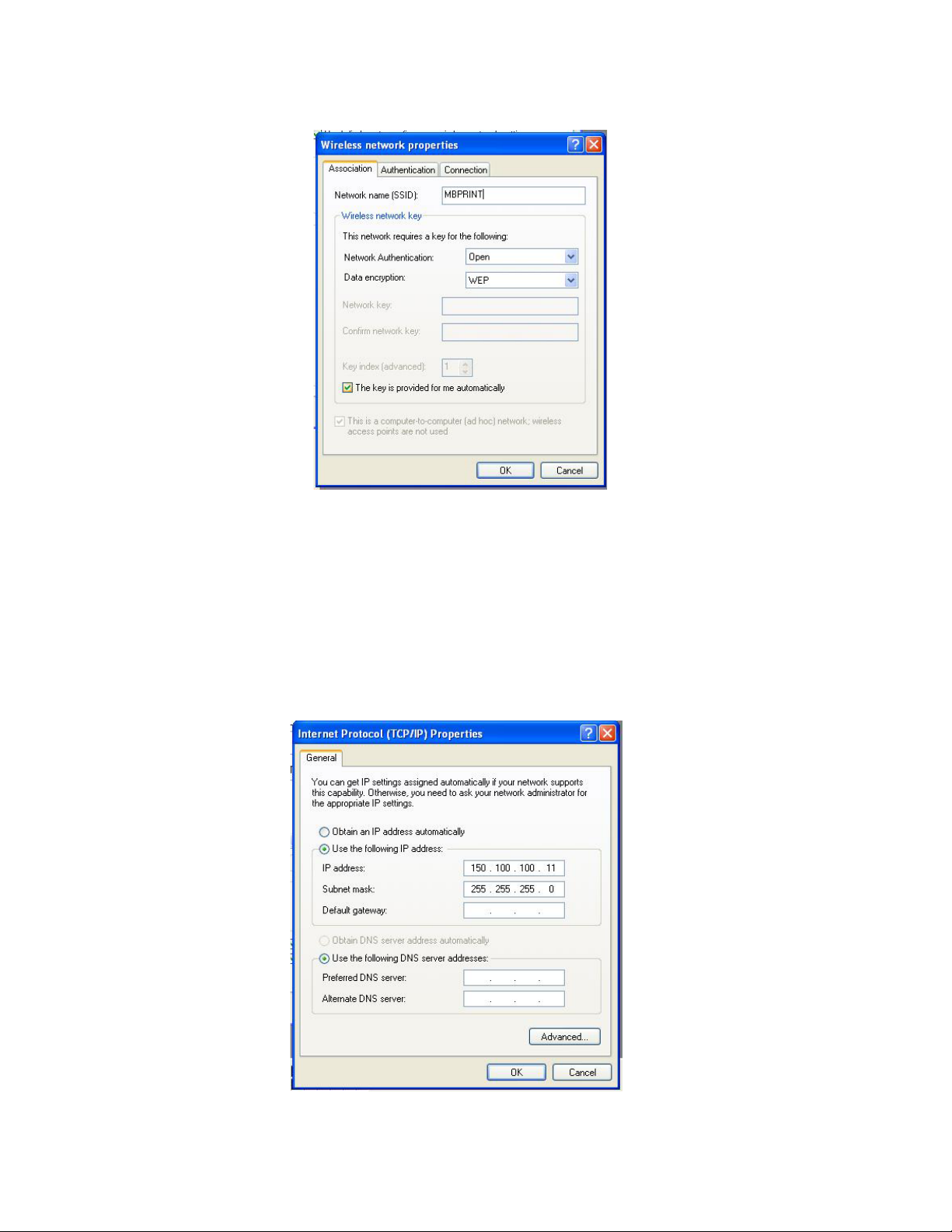

7. When the Wireless Network Properties (Figure 3-10) screen appears, input MBPRINT in

the Network Name (SSID) field.

8. Alter the following fields as necessary:

• Network Authentication: Open.

• Data Encryption: Disabled.

9. Press the OK button to enter the selections.

SATO MB2i Service Manual PN 9001145B Page 3-13

Page 26

Unit 3: Interface Secifications

Figure 3-10, Wireless Network Properties

10. When the Wireless Network Connection Properties screen (Figure 3-9) appears, ensure

that MBPRINT is displayed as the preferred network. If not, repeat steps 4 through 10.

11. Click on the General tab to view that menu.

12. Scroll the “This connection uses” field to view the Internet Protocol (TCP/IP) option and

select it.

13. When the Internet Protocol (TCP/IP) Properties screen (Figure 3-11) appears, select the

“Use the following IP address” option to activate those items.

Figure 3-11, Internet Protocol (TCP/IP) Properties

SATO MB2i Service Manual PN 9001145B Page 3-14

Page 27

Unit 3: Interface Specifications

14. Alter the following fields as necessary:

• IP Address: Change to 150.100.100.11 .

• Subnet Mask: 255.255.255.0 (should always be the same)

15. Click on the OK button to exit the Internet Protocol (TCP/IP) screen.

16. When the Wireless Network Connection Properties screen (Figure 3-9) reappears, click on

the OK button to exit.

17. To test the ad-hoc wireless connection, perform the following procedure:

1. Access Control Panel/MB200i Print Driver/Printer and Faxes, then click on

MB200i Printer Driver.

2. When SATO MB200i Properties screen (Figure 3-12a) appears, select Ports tab.

3. When the Ports menu (Figure 3-12b) appears, click on the Add Port button.

Figure 3-12a/b, Ports

4. When the Printer Ports screen (Figure 3-13) appears, select the Standard TCP/IP

Port option followed by the New Port button.

Figure 3-13, Printer Ports

SATO MB2i Service Manual PN 9001145B Page 3-15

Page 28

Unit 3: Interface Secifications

5. When the TCP/IP Wizard welcome screen (Figure 3-14) appears, press the Next

button.

Figure 3-14, TCP/IP Wizard Welcome Screen

6. Input the same IP Address as the printer in the field adjacent to the Printer Name/

IP Address prompt. Press the Next button. (Figure 3-15)

Figure 3-15, TCP/IP Wizard Entry Screen

SATO MB2i Service Manual PN 9001145B Page 3-16

Page 29

Unit 3: Interface Specifications

7. Press the Finish button when the TCP/IP Wizard exit screen (FIgure 3-16)

appears.

Figure 3-16, TCP/IP Wizard Exit Screen

18. At the SATO MB200i Properties screen, ensure the following is displayed:

• Port: IP Address of the printer.

• Description: Standard TCP/IP

• Printer: MB200i

19. At the SATO MB200i Properties screen (Figure 3-17), press the Print Test Page button to

print a test label.

20. Press the Apply button, followed by the OK button, to exit the SATO MB200i Properties

screen.

SATO MB2i Service Manual PN 9001145B Page 3-17

Page 30

Unit 3: Interface Secifications

Figure 3-17, SATO MB200i Properties

SATO MB2i Service Manual PN 9001145B Page 3-18

Page 31

LCD DISPLAY

• Display Fields

•LCD Screens

• Maintenance Mode

SATO MB2i Service Manual PN 9001145B Page 4-1

Page 32

Unit 4: LCD Display

DISPLAY FIELDS

The LCD Display is an intergrated purchase option only and applicable only for the Wireless LAN

and interface. Due to its limited application, this is the only unit within this manual that covers the

LCD display. All of its features, functions, and menus are identified and defined here.

1

2

3

Figure 4-1, LCD Display

The LCD has three field areas of display; two graphical and one for text. They are as follows:

1. Graphical Battery charge status.

2. Graphical Electrical field strength for the Wireless LAN.

3. Text Two text lines showing the printer’s status.

BATTERY LEVEL (1)

The battery charge of the printer’s power pack is displayed in four graduations as identified in the

table below. The battery charge will always be displayed in field 1 as shown in Figure 4-1 above.

ICON DESCRIPTION

Displays a full charge of 8.0 volts or more.

Displays the detected voltage is between 7.8 and 7.9.

Displays the detected voltage is between 7.6 and 7.7. The printer

will go into the Sleep Mode and the LED will blink every 4 seconds.

Displays the detected voltage level is less than 7.5. The printer will

automatically power off 30 seconds after displaying this icon.

SATO MB2i Service Manual PN 9001145B Page 4-2

Page 33

Unit 4: LCD Display

WIRELESS FIELD STRENGTH (2)

When the Wireless LAN has been set, the received electric field strength will be displayed using

one of the following four icons. The field strength will always be displayed in field 2 as shown in

Figure 4-1 above.

ICON DESCRIPTION

Maximum Strength.

Medium Strength.

Minimum Strength.

No Strength.

OPERATIONAL STATUS (3)

The printer’s operational status is displayed in text form and will always be located in field 3 as

shown in Figure 4-1 above. The following tables identify and define each of the LCD screens

within the operational and maintenance menus.

SATO MB2i Service Manual PN 9001145B Page 4-3

Page 34

Unit 4: LCD Display

LCD SCREENS

STARTUP

STATUS LCD DETAIL

Formatting Displays the SATO logo and the phase “Farm

Version” (Farm Ware Version) for a second upon

SATO

DCS & Labeling Wordwide

[Firm Version]

NORMAL MODE

STATUS LCD DETAIL

Online Displays the operational condition in the first line

startup.

and the remaining print quantity in the second.

ONLINE

QTY: 0000

Offline Displays the operational condition in the first line

and the remaining print quantity in the second.

OFFLINE

QTY: 0000

Sleep Mode Not Available. Nothing is displayed while in the sleep mode.

TEST PRINT MODE

STATUS LCD DETAIL

Pausing Test Printing Displays the current mode to be performed.

Electric field strength icon for Wireless LAN is not

TEST PRINT

PRESS FEED KEY

Test Printing Displays the current mode and that the function

TEST PRINT

PRINTING

displayed.

has been completed.

Electric field strength icon for Wireless LAN is not

displayed.

SATO MB2i Service Manual PN 9001145B Page 4-4

Page 35

Unit 4: LCD Display

DEFAULT SETTING MODE

STATUS LCD DETAIL

Default Setting Displays the current mode to be performed.

Electric field strength icon for Wireless LAN is not

DEFAULT

SETTING

displayed.

Default Setting

Completed

COMPLETE

Displays the current mode and that the function

has been completed.

Electric field strength icon for Wireless LAN is not

displayed.

FACTORY CLEAR MODE

STATUS LCD DETAIL

Factory Clear Displays the current mode to be performed.

Electric field strength icon for Wireless LAN is not

FACTORY CLEAR

Factory Clear

Completed

FACTORY CLEAR

PRESS FEED KEY

displayed.

Displays the current mode and that the function

has been completed.

Electric field strength icon for Wireless LAN is not

displayed.

HEX DUMP MODE

STATUS LCD DETAIL

Hex Dump Displays the current mode to be performed.

Electric field strength icon is only displayed if

HEX DUMP MODE

SATO MB2i Service Manual PN 9001145B Page 4-5

Wireless LAN is set as the interface type.

Page 36

Unit 4: LCD Display

PRINTER ERRORS

STATUS LCD DETAIL

Low Battery Displays location of error. The battery icon will

display a low charge condition and blink.

BATTERY

ERROR

Module Error Displays location of error. This will indicate an

MODULE

ERROR

Head Error Displays location of error. This will indicate an

HEAD

ERROR

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

error was detected in the Wireless LAN or

Bluetooth interface as applicable.

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

error was detected with the print head.

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

Cover Open Displays location of error. This will indicate the top

housing cover is not latched.

COVER

OPEN

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

Paper End Displays location of error. This will indicate that

the paper supply is exhausted. Reload.

PAPER

END

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

Sensor Error Displays location of error. This will indicate an

error was detected with a sensor. Troubleshoot.

SENSOR

ERROR

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

Buffer Near Full Displays location of error. This will indicate the

receive buffer is at capacity.

NEAR

FULL

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

Head Protect Displays location of error. This will indicate the

status of the head protect feature.

HEAD

PROTECT

The electric field strength icon will only be

displayed if Wireless LAN is set as the interface

type.

SATO MB2i Service Manual PN 9001145B Page 4-6

Page 37

Unit 4: LCD Display

MAINTENANCE MODE

The Maintenance Mode allows for the Wireless LAN to be configured and/or the LCD Display.

While in this mode, the PRINT key is used for option selection and the FEED key serves to enter

the selection.

MAINTENANCE MODE

STATUS LCD DETAIL

Initial Screen Allows the selection of whether to setup the

Wireless LAN interface or to modiy the LCD

=> SET UP

DISPLAY

LCD SETUP

STATUS LCD DETAIL

display.

Setup menu Allows the selection of whether to modify the LCD

display or to exit. If EXIT is chosen, the display will

return to the initial screen of the Maintenance

=> ADJUST LCD

EXIT

Mode.

Electric field strength icon for Wireless LAN is not

displayed.

Contrast Adjustment Allows the adjustment of the LCD contrast.

Electric field strength icon for Wireless LAN is not

CONTRAST

xx

displayed.

Backlight Setting Allows the adjustment of the LCD backlighting.

Electric field strength icon for Wireless LAN is not

BACK LIGHT

ON

displayed.

SATO MB2i Service Manual PN 9001145B Page 4-7

Page 38

Unit 4: LCD Display

WIRELESS LAN

STATUS LCD DETAIL

Setup Menu Allows the selection of whether to setup the

wireless LAN or to exit. If EXIT is chosen, the

=> WLAN INFO

EXIT

Wireless LAN Mode Socket Port Number is displayed.

WLAN MODE

[information]

Channel Channel information is displayed.

WLAN CHANNEL

[information]

display will return to the initial screen of the

Maintenance Mode.

IP Address Current IP Address is displayed.

IP ADDRESS

XXX.XXX.XXX.XXX

Subnet Mask Current subnet mask is displayed.

SUBNET MASK

XXX.XXX.XXX.XXX

Gateway Address Gateway address is displayed.

DEFAULT GATEWAY

XXX.XXX.XXX.XXX

Socket Port Number Socket Port Number is displayed.

SOCKET PORT

XXXX

SATO MB2i Service Manual PN 9001145B Page 4-8

Page 39

PRINTER

CONFIGURATION

• Printer Configuration

• Configuration Modes

SATO MB2i Service Manual PN 9001145B Page 5-1

Page 40

Unit 5: Printer Configuration

PRINTER CONFIGURATION

The keys of the operator panel and dip switches are used either singularly or in conjuction to

perform configuration activities. The dip switch complex is accessible from the right housing

cover.

Refer to the Control Features chapter of the Introduction Unit for identification of specific

interface features.

FACTORY DEFAULTS

DSW1 DSW2 DSW3 DSW4

OFF OFF OFF OFF

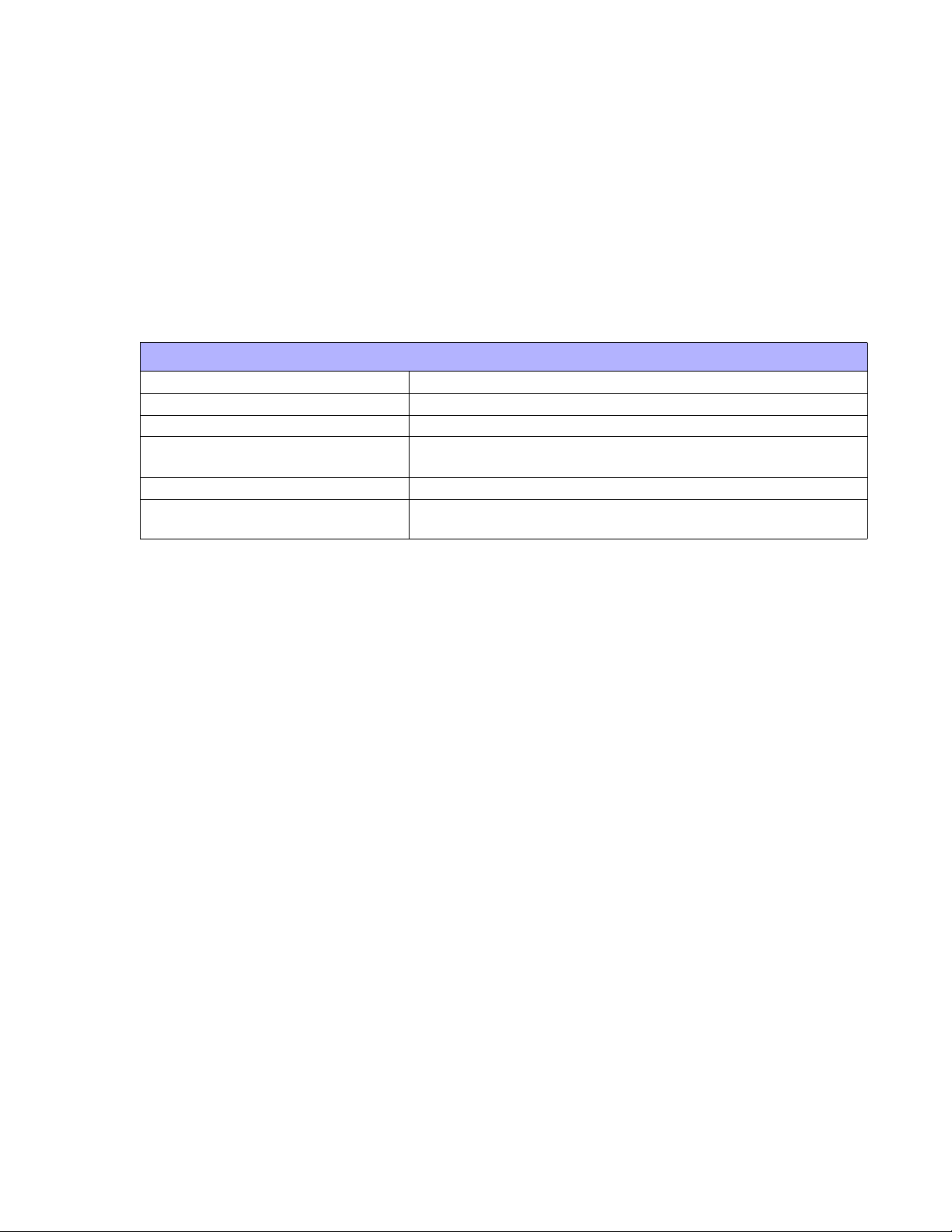

RS232C QUICK REFERENCE TABLE

DESCRIPTION DIP SWITCHES HEAD PRINT KEY FEED KEY

Standard Start-Up OFF OFF OFF OFF Closed OFF OFF

User Test Print Closed OFF ON

Default Reset Opened ON OFF

Hex Dump OFF OFF ON ON Closed OFF OFF

Font Download OFF OFF OFF ON Closed OFF OFF

Dispense Auto Print Opened ON OFF

Dispense Manual Print Opened OFF OFF

Program Download OFF OFF ON OFF Closed OFF OFF

Factory Clear (w/o counter) Opened ON ON

Head Check OFF ON OFF ON Opened ON OFF

Cancel Head Check Opened OFF ON

Factory Clear (w’counter) OFF ON ON OFF Opened ON ON

IRDA QUICK REFERENCE TABLE

DESCRIPTION DIP SWITCHES HEAD PRINT KEY FEED KEY

Standard Start-Up ON OFF OFF OFF Closed OFF OFF

User Test Print Closed OFF ON

Hex Dump ON OFF ON ON Closed OFF

Head Check ON OFF OFF ON Opened ON OFF

Cancel Head Check Opened OFF ON

Factory Clear (w/counter) ON OFF ON OFF Opened ON ON

Online Command (MB200) ON ON ON ON Opened ON OFF

Online Command (SBPL) Opened OFF ON

SATO MB2i Service Manual PN 9001145B Page 5-2

Page 41

Unit 5: Printer Configuration

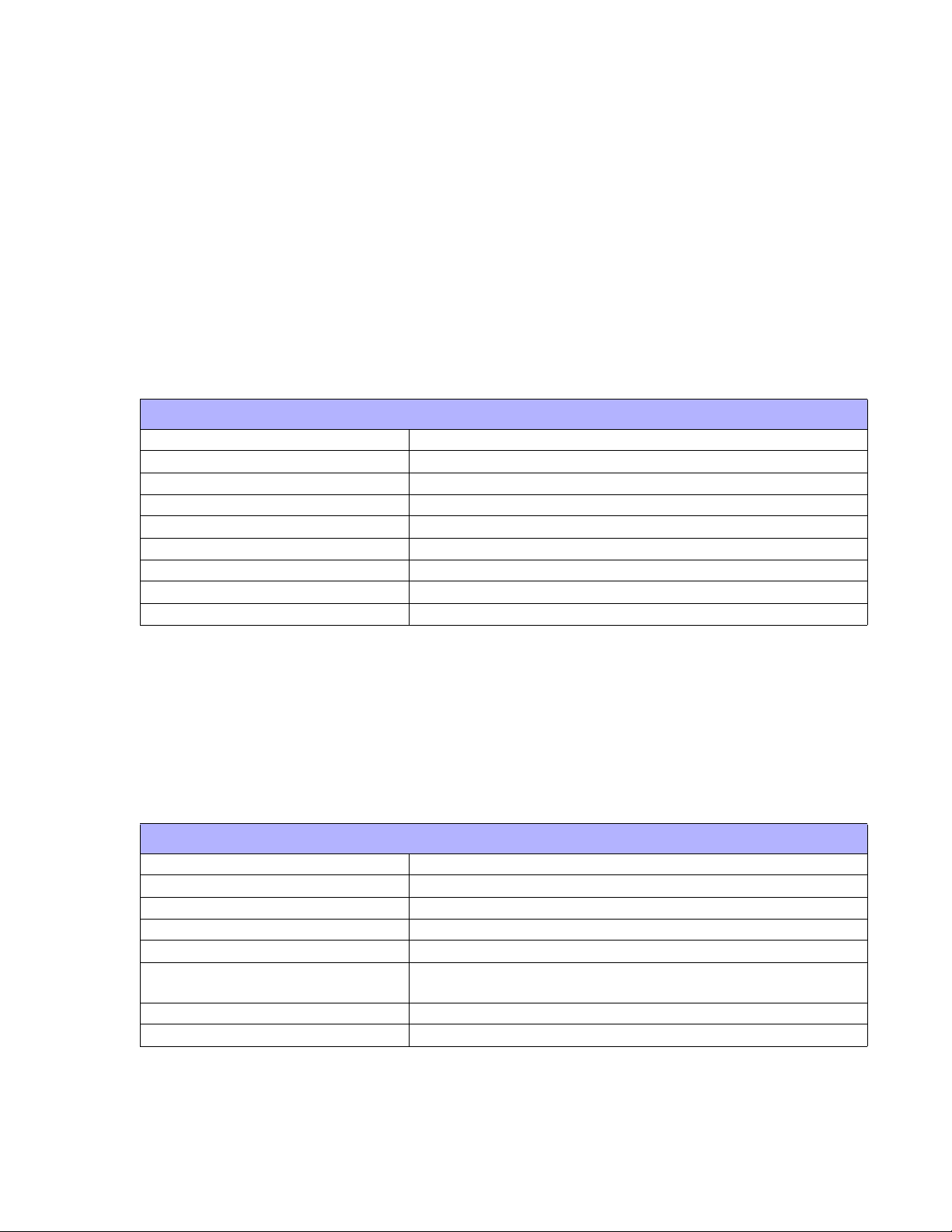

BLUETOOTH QUICK REFERENCE TABLE

DESCRIPTION DIP SWITCHES HEAD PRINT KEY FEED KEY

Normal Mode OFF ON OFF OFF Closed OFF OFF

User Test Print Mode Opened OFF ON

Maintenance Mode Opened ON OFF

Hex Dump OFF ON ON ON Closed OFF OFF

Enable CRC (Digit Check) OFF OFF OFF ON Closed OFF OFF

Disable CRC (Digit Check) Opened ON OFF

Set Head Check OFF ON OFF ON Opened ON OFF

Cancel Head Check Opened OFF ON

Factory Clear (w/head clear) OFF ON ON OFF Opened ON ON

WIRELESS LAN QUICK REFERENCE TABLE

DESCRIPTION DIP SWITCHES HEAD PRINT KEY FEED KEY

Normal Mode OFF ON OFF OFF Closed OFF OFF

User Test Print Mode Opened OFF ON

Maintenance Mode Opened ON OFF

Hex Dump OFF ON ON ON Closed OFF OFF

Enable CRC (Digit Check) OFF OFF OFF ON Closed OFF OFF

Disable CRC (Digit Check) Opened ON OFF

Set Head Check OFF ON OFF ON Opened ON OFF

Cancel Head Check Opened OFF ON

Factory Clear (w/head clear) OFF ON ON OFF Opened ON ON

SATO MB2i Service Manual PN 9001145B Page 5-3

Page 42

Unit 5: Printer Configuration

CONFIGURATION MODES

This chapter provides an overview of the various configuration modes of the operation menu. All

of the following configuration activities are performed via the use of the operator panel located on

the printer front. However, many settings may also be controlled via software commands. In the

case of conflict between the software and control panel settings, the printer will always use the last

entered valid setting.

NORMAL MODE

When in the Normal Mode the printer is online and ready for print activity. If print activity,

downloading, or other interaction does not occur, the printer will go into the Sleep Mode and from

there, into the Offline Mode.

Refer to Figure 1-1 in the Introduction unit of this manual for dipswitch location.

RS232C: (DSW = 1: OFF, 2: OFF, 3: OFF, 4: OFF) + POWER

Wireless LAN: (DSW = 1: OFF, 2: ON, 3: OFF, 4: OFF) + POWER

Bluetooth: (DSW = 1: OFF, 2: ON, 3: OFF, 4: OFF) + POWER

Infrared: (DSW = 1: ON, 2: OFF, 3: OFF, 4: OFF) + POWER

Flashes orange,

goes onli ne,

flashes green

PRINT

terminates and pr int er goes

LED

offline

FEEDFEED

Label is fed

Figure 5-1, Normal Mode

SATO MB2i Service Manual PN 9001145B Page 5-4

Page 43

Unit 5: Printer Configuration

LABEL SENSOR SELECTION

This function allows for the determination of the sensor to be used to control label positioning

relative to the media type that will be used. The two options are; eye-mark and gap. This

selection can only be made through host interface using a RS232C cable.

POWER = OFF

Connect the printer to the

host with RS232C cable.

Send printer operation

registration command

from the host and select

the desired label type.

Print a label.

Power off and

disconnect cable.

Printer shuts down.

Adjustment

successful?

Yes / No

Figure 5-2, Label Sensor Selection

SATO MB2i Service Manual PN 9001145B Page 5-5

Page 44

Unit 5: Printer Configuration

DISPENSE MODE

This feature allows for the determination of the method of dispense.

AUTO Prints a single label after receiving data, waits for

the label to be retrieved, then automatically prints

the next label.

MANUAL Prints a single label after receiving data and then

goes offline. Prints a single label each time the

PRINT key is pressed until the specified number of

labels has been printed. A new job will have to be

dowloaded to print more.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

Auto Dispense: (DSW = 1: OFF, 2: OFF, 3: OFF, 4: ON) + PRINT + POWER

Manual Dispense: (DSW = 1: OFF, 2: OFF, 3: OFF, 4: ON) + FEED + POWER

Choose Applicabl e Option

Blinks green whil e setting.

Flashes gr een when complete.

Press POWER and

return dip switches to

their previous positions.

Printer shuts down and exits

Dispense Mode.

Figure 5-3, Dispense Mode

SATO MB2i Service Manual PN 9001145B Page 5-6

Page 45

Unit 5: Printer Configuration

DOWNLOAD MODE

This download feature allows the operator to download print jobs to the printer. The data is

received through an RS232C interface in binary form using XMODEM protocol for file transfer.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

DSW = 1: OFF, 2: OFF, 3: ON, 4: OFF + POWER

Flashes

orange and enters the

Program Download Mode.

Format storage area if

never done.

Blinks green while waiti ng

for data.

Confirm the printer is

standing by for data

before sending.

Send data.

Ensure the printer is

waiting for data to be

sent before powering off.

Press POWER.

Printer

shuts down. Must be restarted

to use the downloaded

data.

Flashes green whil e receiving

changes from red to orange to

green when writi ng data to

data.

LED

Flash ROM.

Flashes green when

complete.

Figure 5-4, Program Download Mode

In XMODEM protocol, data is transferred block by block. Each starts with SOH(01h) and consists

of 132 bytessuch as block number (BLK) of 1 byte, complement of block number (_BLK), 128

bytes main data, and check sum (SUM) of 1 byte.

SATO MB2i Service Manual PN 9001145B Page 5-7

Page 46

Unit 5: Printer Configuration

The block number starts from 1, and when counting to 255, the number goes back to 0 again. If

the block number is [01h], complement of block number becomes [FEh]. In the main data, the

section of data by 128 bytes is stored. SUM is the check sum computed from 128 bytes of main

data.

NOTE: The above method is XMODEM (check sum) option. Select

check sum option in the XMODEM settings on the host side.

When downloading data, the format is such that the first 16 bytes are used as header information

and the rest is considerred as data. The header information is divided thusly: code (4 bytes), start

address (4 bytes), file size (4 bytes), and reserved area (4 bytes). The remaining optional data is

to be stored in Flash ROM.

The basic sequence of XMODEM is to transfer data blocks by individually checking response

blocks. NAK (15h) transmission by the receiving end initiates the sequence, and the sending end

sends the first data block after receiving NAK. The receiving end receives and checks this data

block, and then returns ACK (06h) in case of no error or NAK (15h) in case of an error. The

sending end sends the next block when receiving ACK, and resends the same block when

receiving NAK. This process repeats to the first block. EOT (04h) is sent from the sending end to

receiving end at the end of all data transmission. After receiving EOT (04h), the receiving end

returns ACK to terminate the sequence.

SATO MB2i Service Manual PN 9001145B Page 5-8

Page 47

Unit 5: Printer Configuration

FONT DOWNLOAD MODE

A flash ROM is used to internally store and delete font data and custom designed data. The

storage capacity for custom designed characters is a maximum of 95 for each of type of 16 x 16,

22 x 22, 24 x 24 dots.

There are four transmission protocols for font download: (1) Download Font Storage, (2)

Download Font Selection, (3) Download Font Information Aquisition, (4) Storage CustomDesigned Character. The return status from the printer is set between STX (02h) and ETX (03h),

and transferred in 3 bytes.

Wiring on the computer side may require a CTS (pin 5) and RTS (pin 4) cable connection.

Confirm the host settings before downloading.

Figure 5-5 provides the specific sequence of events required by the operator, the printer, and the

printers software for font download mode to be activated.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

A detailed description of how to download data is in the Programming Reference.

DSW = 1: OFF, 2: OFF, 3: OFF, 4: ON + POWER

Flashes

orange and enters the

Font Download Mode.

Format storage area if

never done.

Blinks green whil e waiting

for data.

Confirm the printer is

standing by for data

before sending.

Send data.

Flashes green while receiving

data.

LED

changes from red to orange to

green when writing data to

Flash ROM.

Ensure the printer is

waiting for data to be

sent before powering off.

Press POWER.

Printer shuts down.

Figure 5-5, Font Download Mode

SATO MB2i Service Manual PN 9001145B Page 5-9

Page 48

Unit 5: Printer Configuration

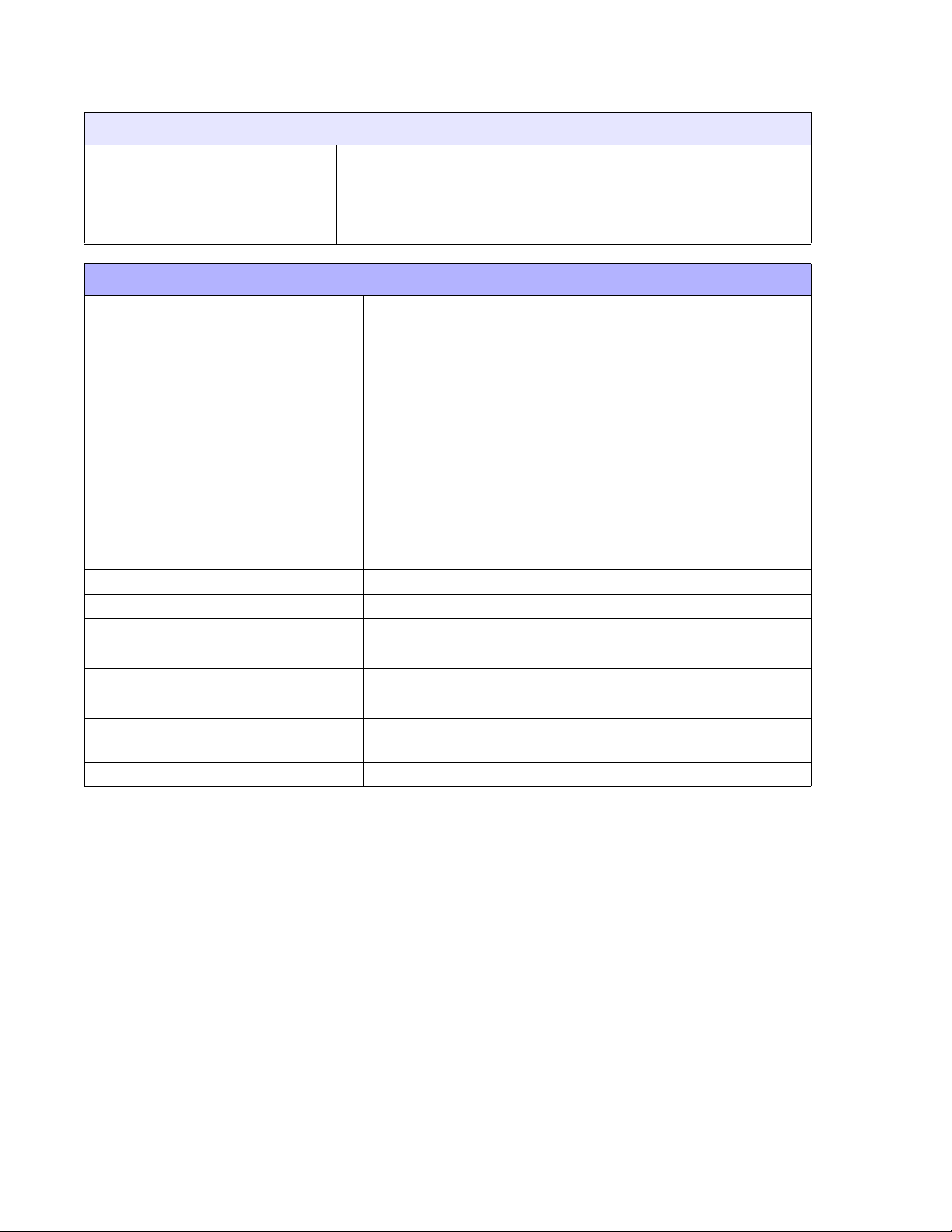

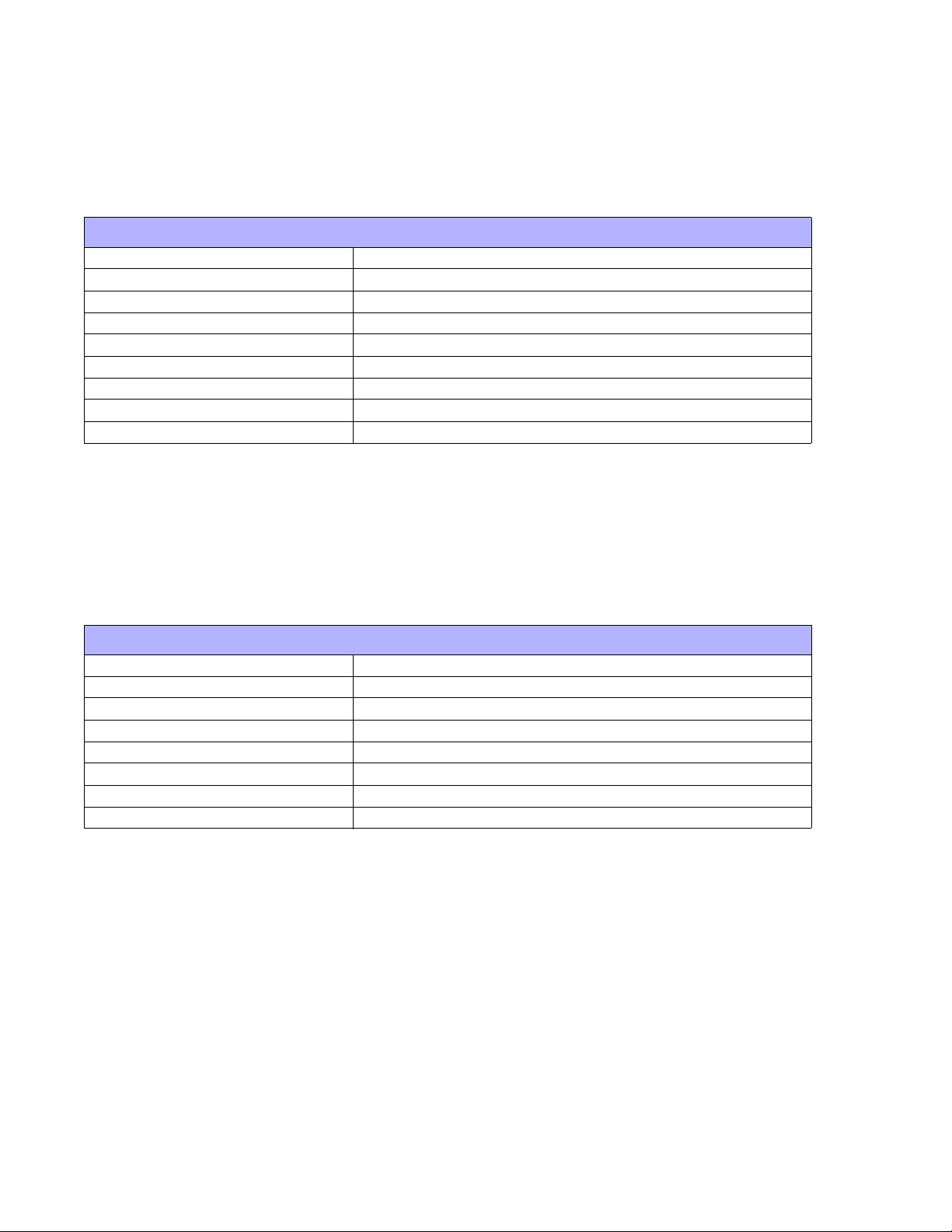

DOWNLOAD FONT REGISTRATION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Storage Area NG N 4E Printer to Host

Store Font 0 30 Host to Printer

Do Not Store Font 1 31 Host to Printer

Ready For Storage Status O 4F Printer to Host

Font Storage Completed Normally E 45 Printer to Host

Font Storage Cancelled S 53 Printer to Host

Font Storage Completed Abnormally Z 5A Printer to Host

DOWNLOAD FONT DELETION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Delete Font 0 30 Host to Printer

Do Not Delete Font 1 31 Host to Printer

Font Deletion Completed Normally E 45 Printer to Host

Font Deletion Cancelled S 53 Printer to Host

Font Storage Completed Abnormally Z 5A Printer to Host

DOWNLOAD FONT INFORMATION AQUISTION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Font Information Transferred OK 0 30 Host to Printer

Number of Transferred Data 000000-

999999

Font Information Font Info Data + Font

6 bytes w/

Data Info

Printer to Host

30-39

Printer to Host

STORAGE OF CUSTOM DESIGNED CHARACTER

STATUS DESCRIPTION ACSII HEX TRANSFER

Storage Ready Status O 4F Printer to Host

Storage Completed Normally E 45 Printer to Host

Storage Completed Abnormally Z 5A Host to Printer

SATO MB2i Service Manual PN 9001145B Page 5-10

Page 49

Unit 5: Printer Configuration

ONLINE COMMAND MODE

This function allows the selection of receiving command by using either standard SATO Barcode

Printer Language (SBPL) or first generation MB200 compatible commands. The MB200

compatible command option should only be chosen if first generation MB200’s will be used along

with the newer generation. This will provide a common command language that will

communicate to both.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

MB200 Compatibility Mode: (DSW = 1: ON, 2: ON, 3: ON, 4: ON) + Cover Open + PRINT + POWER

SBPL Mode: (DSW = 1: ON, 2: ON, 3: ON, 4: ON) + Cover Open + FEED + POWER

Choose Applicable Option

Blinks green when setti ng

Online Command.

Flashes green when setting

completed.

Confirm setting is

complete.

Press POWER.

Printer shuts down.

Figure 5-6, Online Command Mode

SATO MB2i Service Manual PN 9001145B Page 5-11

Page 50

Unit 5: Printer Configuration

CRC (CYCLIC REDUNDANCY CHECK) MODE

Allows the operator to enable or disable the Cyclic Redundancy Check (CRC) for each received

print data when using wireless LAN or Bluetooth interface.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

Enable CRC Check: (DSW = 1: OFF, 2: ON, 3: ON, 4: ON) + Cover Open + PRINT + POWER

Disable CRC Check: (DSW = 1: OFF, 2: ON, 3: ON, 4: ON) + Cover Open + FEED + POWER

Choose Applicable Option

Flashes green when savi ng

the Head Check setti ng.

Flashes green when set ting

completed.

Confirm setting is

complete.

Press POWER.

Printer shuts down.

Figure 5-7, CRC Check Mode

SATO MB2i Service Manual PN 9001145B Page 5-12

Page 51

Unit 5: Printer Configuration

SLEEP & AUTO-OFF MODE

This mode is a non-interactive mode that is provided to explain the timed sequence of events that

relate to the printer going into sleep mode and then futher into offline mode.

Printer in Normal Mode

No operator interaction or printer

operation for 5 seconds.

Sleep Mode. LED blinks green

Send data or press key.

signal occurs and goes into

Error

every 4 seconds.

No operator interaction or printer

operation for 5 minutes.

Error

signal occurs and printer

automatically switches itself off.

LED terminates.

Figure 5-8, Sleep & Auto-Off Mode

SATO MB2i Service Manual PN 9001145B Page 5-13

Page 52

Unit 5: Printer Configuration

SATO MB2i Service Manual PN 9001145B Page 5-14

Page 53

TROUBLESHOOTING

• Error Signals

• Troubleshooting Table

• Interface Troubleshooting

• Test Print Troubleshooting

SATO MB2i Service Manual PN 9001145B Page 6-1

Page 54

Unit 6: Troubleshooting

ERROR SIGNALS

LED MODE DESCRIPTION

Red

illuminated

Red

flashing

2.0 seconds

Red

illuminated

Alternating

Green/Red

2.0 seconds

Red flashing

0.5 seconds

Green

flashing

0.5 seconds

All modes

Online

After power On

Online

Online

Online

(during printing &

data receiving)

Cause: Low battery charge.

Remedy: Recharge/ replace battery.

Cause(s): Bluetooth or Wireless LAN malfunction.

Remedy: Replace the interface module.

Cause(s): 1. Progrom error.

2. Flash ROM error.

Remedy: 1. Download program again.

2. Replace Flash ROM.

Cause(s): Defective print head.

Remedy: Replace print head.

Cause(s): 1. Cover is not latched or sensor is defective.

2. Paper End sensor incorrectly set.

3. Incorrect media sensor selection or adjustment.

Remedy: 1. Latch cover or replace print head.

2. Properly set Paper End sensor.

3. Select correct sensor & adjust. Replace bord as required.

Cause(s): Size of received data exceeds size of receiving buffer.

Remedy: Temporarily stop sending data until space is free.

Green

flashing

4.0 seconds

Alternating

Green/Red

1.0 seconds

All Modes

All Modes

Cause(s): Is in Sleep Mode. Not an error.

Remedy: Will cease when data is received, a key pressed, or cover opened.

Cause(s): Print head is hotter than 70 degrees celsius.

Remedy: Cease printing until the print head has cooled to 50 degrees celsuis

or less.

SATO MB2i Service Manual PN 9001145B Page 6-2

Page 55

Unit 6: Troubleshooting

TROUBLESHOOTING TABLE

IMAGE VOIDS

Damaged print head or electronics. Replace as required.

Damaged or worn platen roller. Replace platen roller.

Vertical line in printed image. Dirty or defective print head.

LIGHT PRINT IMAGES

Low print head energy/darkness. Adjust darkness control.

Foreign material on print head. Clean print head and platen roller.

Excessive print speed. Reduce print speed setting.

UNEVEN PRINT DARKNESS

Worn platen roller. Replace platen roller as required.

Dirty print head. Clean as necessary.

SMEARED PRINT IMAGES

Poor label quality. Use higher quality label stock.

Debris on print head & platen roller. Clean print head and platen roller.

NO LABEL MOVEMENT

Incorrect label pitch sensor selected. Select the correct label sensor type.

No voltage output. Test power supply or battery and replace as required.

Drive motor not operating. Ensure wiring harness connection.

Defective main board. Contact SATO Service or Technical Support.

NO PRINTED IMAGE

No voltage output. Test power supply or battery and replace as necessary.

Damaged print head. Replace as required.

Interface problems. Check interface connection.

Data input error. Ensure correct data stream.

MEANDERING MEDIA

Incorrectly loaded media. Ensure correct loading.

Improperly adjusted media guides. Adjust as required.

PRINTER CREATES A BLANK LABEL

Data input error. Ensure correct data stream.

Improper top of form selected. Ensure correct top of form is in use (Gap, Blackban).

Defective print head. Replace print head as required.

SATO MB2i Service Manual PN 9001145B Page 6-3

Page 56

Unit 6: Troubleshooting

INTERFACE TROUBLESHOOTING

RS232 SERIAL INTERFACE

CHK TROUBLESHOOTING STEP

Ensure the correct interface module is correctly installed. Run self-test to verify.

Ensure the serial cable (Null Modem) meets specifications and is correctly connected at each end.

Ensure the serial cable is not defective.

Ensure the communication parameters for the baud rate, parity, data bits and stop bits are consistent with those being sent from the host computer.

Ensure the printer is receiving information from the computer using the Receive Buffer Hex Dump

mode. Refer to that procedure within this manual for instructions. The command stream should be

continuous and possess 0Dhex and/or 0Ahex (carriage return and line feed) characters throughout. However, there should not be either locate between the start (<ESC>A and the stop

(<ESC>Z) commands.

Replace the interface board with another to isolate the problem.

Replace the interface baord permanently if determined to be the problem.

WIRELESS ETHERNET INTERFACE

CHK TROUBLESHOOTING STEP

Ensure the printer is the Wireless LAN model that comes equipped with an LCD screen.

Ensure the printer’s dipswitches are set to OFF, ON, OFF, OFF.

Ensure the configuration setting for the device is correct. Ensure the network is correctly configured for the MB200i/MB201i printer. This may be verified by performing a test print to view the current settings. Ensure the IP address, subnet mask, gateway and security settings are sychonized

to match the system network’s settings (your network administrator can verify). Alternately, check

the settings via the printer’s LCD by invoking its Maintenance Mode.

Ensure the access point communication link is correct. Perform a communications test to determine if the access point is responding. Start a command prompt window on a Windows PC

through a wired network and ping the wireless access point’s IP adress - the wireless access point

should respond to the ping. If not, there is either a break in the communication link or the access

point is malfunctioning or improperly configured.

Ensure the Wireless communication link is correct. Then execute the Command prompt on a PC

and ping the printer - the device sould respond to the ping. If not, there is either a break in the

communications link or the printer was not properly configured. Check the printer’s settings again.

Attempt to ping the printer again from a wired/wireless client. If the ping still fails, the unit is

probably malfunctioning and should be replaced. Contact SATO technical staff for assistance.

SATO MB2i Service Manual PN 9001145B Page 6-4

Page 57

Unit 6: Troubleshooting

TEST PRINT TROUBLESHOOTING

Chapter provides instruction on special printing to identify and resolve specific print problems.

HEX DUMP Allows the operator to determine if there were

problems in the downloading of data.

TEST LABEL Allows the operator to identify specific problems

regarding mechanical performance and setup.

HEX DUMP MODE

The contents of the print buffer can be examined using the Hex Dump Mode. In the left column,

each line of data received is numbered. The center column provides the data in hexadecimal

format. And in the right column, same data is provided in the ASC ll format. Follow the flow chart

provided below to perform this activity.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

RS232C: (DSW = 1: OFF, 2: OFF, 3: ON, 4: ON) + POWER

Wireless LAN: (DSW = 1: OFF, 2: ON, 3: ON, 4: ON) + POWER

Bluetoot h: (DSW = 1: OFF, 2: ON, 3: ON, 4: ON) + POWER

Infrared: (DSW = 1: ON, 2: OFF, 3: ON, 4: ON) + POWER

Choose Applicable Option

Flashes

orange and enters the

Hex Dump Mode.

Receives data and begins

print ing.

Return dip switches to

their previous positions

and press POWER.

Printer shuts down and exists

Hex Dump Mode.

Figure 6-1, Hex Dump Mode

SATO MB2i Service Manual PN 9001145B Page 6-5

Page 58

Unit 6: Troubleshooting

TEST LABEL PRINTING

The test label is designed to assist in the identification of print problems. Follow the flow chart

provided below to perform this activity.

Refer to Figure 1-1 of the Introduction unit in this manual for dipswitch location.

RS232C: (DSW = 1: OFF, 2: OFF, 3: OFF, 4: OFF) + FEED + POWER

Wireless LAN: (DSW = 1: OFF, 2: ON, 3: OFF, 4: OFF) + FEED + POWER

Bluetooth: (DSW = 1: OFF, 2: ON, 3: OFF, 4: OFF) + FEED + POWER

Infrared: (DSW = 1: ON, 2: OFF, 3: OFF, 4: OFF) + FEED + POWER

Choose Appli cable Opti on

Flashes

orange and enters the

Test Print Mode. Bl inks green

while waiti ng.

FEED

Test printing begi ns.

Flashes green.

FEED

Pause print ing.

Confirm print ing has

stopped and press

POWER.

Printer shut s down.

Figure 6-2, Test Print Mode

SATO MB2i Service Manual PN 9001145B Page 6-6

Page 59

REPLACEMENT

PROCEDURES

• Print Head

• Dispense Bar

• Platen Roller

• Paper Roller

• Main Circuit Board (A)

• Main Circuit Board (B)

• Panel Board

• Eye-Mark Sensor

• Gap Sensor

• Head Open Sensor

•Drive Motor

• Drive Gear

SATO MB2i Service Manual PN 9001145B Page 7-1

Page 60

Unit 7: Replacement Procedures

REPLACEMENT PROCEDURES

This unit contains step-by-step instructions for the removal and replacement of all primary

components and sub-assemblies.

PRINT HEAD REPLACEMENT

If the print head becomes damaged or worn, it can be easily removed and replaced without

having to make critical adjustments.

1 Switch off the printer and remove power supply or battery.

2 Perform a Factory Test Print and check the head counter.

3 Open the top housing cover to access the print head (Figure 7-1a).

4 Insert a flat driver into the slots of the sensor guide and pry upward. Lift away sensor guide.

5 Insert a flat driver between the print head bracket and the sensor bracket and pry free.

6 Lift away defective print head and disconnect its wiring harness.

Sensor Bracket

Print Head

Guide Driver

Shaft

Head

Bracket

Driver

Sensor Guide

Sensor

Bracket

Figure 7-1a, Print Head Replacement

7 Connect the print head wiring harness to the replacement print head.

8 Insert replacement print head into the print assembly and press into position.

9 Insert sensor bracket into the print assembly and press into position.

10 Reset the head counter in accordance with the procedures enclosed.

11 Restore power and test print.

SATO MB2i Service Manual PN 9001145B Page 7-2

Page 61

Unit 7: Replacement Procedures

Print Head

Sensor Guide

Figure 7-1b, Print Head Replacement

DISPENSE BAR REPLACEMENT

1 Switch off the printer and remove power supply or battery.

2 Open the top housing cover to gain better access to the dispense bar.

3 Insert a flat driver between a dispense bracket and the top housing cover (Figure 7-2a).

Sensor Bracket

Print Head

Guide Dri ver

Head

Bracket

Driver

Sensor Guide

Sensor

Bracket

Shaft

Figure 7-2a, Dispense Bar Replacement

SATO MB2i Service Manual PN 9001145B Page 7-3

Page 62

Unit 7: Replacement Procedures

4 Rotate the dispense bracket forward while prying the bracket away from the housing cover.

5 Repeat step 4 for the opposite end of the bracket and lift free the assembly (Figure 7-2b).

Dispense Bar

Left Dispense Bar Bracket

Top Housing Cover

Right Dispense Bar Bracket

Figure 7-2b, Despense Bar Replacement

6 Assemble the replacement dispense bar in the orientation as the original prior to removal

(Figure 7-2c).

Dispense Bar Brackets

Dispense Bar

Figure 7-2c, Dispense Bar Replacement

SATO MB2i Service Manual PN 9001145B Page 7-4

Page 63

Unit 7: Replacement Procedures

PLATEN ROLLER REPLACEMENT

The platen roller is a high wear component due to its treading against the print media. This

treading will eventually wear grooves into the rubber material and negatively effect print output.

1 Switch off the printer and remove power supply or battery.

2 Open the top housing cover to access the platen roller.

3 Remove the dispense bar in accordance with its relative replacement procedure.

4 Move the bearings on each end of the platen roller inward from within the platen roller

bracket (Figure 7-3a).

Platen Roller Bracket

Platen Roller Assembly

Bearings

Figure 7-3a, Platen Roller Replacement

Platen Roller Bracket

Platen Roller Assembly

Top Housing Cover

Figure 7-3b, Platen Roller Replacement

SATO MB2i Service Manual PN 9001145B Page 7-5

Page 64

Unit 7: Replacement Procedures

5 Lift the worn platen roller assembly from the platen roller bracket and discard (Figure 7-3b).

6 Insert the replacement platen roller assembly into the platen roller bracket oriented as the

original prior to removal.

7 Move the bearings on each end of the platen roller assembly outward to nest in the platen

roller bracket.

8 Install the dispense bar in accordance with its relative replacement procedure.

DISPENSER ROLLER

1 Switch off the printer and remove power supply.

2 Remove the top cover from the printer to remove the dispenser assembly (Figure 7-4).

3 Detach the dispenser assembly and open lever from the top cover.

4 Detach the snap ring from the dispense roller shaft and remove the assembly from the

dispenser.

5 Withdraw the worn roller from the shaft and insert the replacement roller in its place.

6 Insert the roller assembly into the dispenser assembly and secure using the snap ring.

7 Reattach the dispenser assembly and open lever to the top cover.

8 Secure top cover to the printer and test print a label.

Dispenser Assembly

Paper Roller

Snap Ring

Shaft

Open Lever

Top Cover

Figure 7-4, Dispense Roller Replacement

SATO MB2i Service Manual PN 9001145B Page 7-6

Page 65

Unit 7: Replacement Procedures

MAIN CIRCUIT BOARD (A) REPLACEMENT

1 Switch off the printer and remove power supply.

2 Remove the front, top, left, and right housing covers.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.

3 Remove the two screws securing main circuit board (A) to the printer chassis (Figure 7-5).

4 Withdraw the defective main circuit board and disconnect all wiring harnesses.

5 Attach all relative wiring harnesses to the replacement circuit board.

6 Insert the replacement circuit board into the printer chassis and secure using the two

screws.

7 Replace all housing covers, restore power, and test print.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

Screws x2

Figure 7-5, Main Circuit Board (A) Replacement

Main Board

SATO MB2i Service Manual PN 9001145B Page 7-7

Page 66

Unit 7: Replacement Procedures

MAIN CIRCUIT BOARD (B) REPLACEMENT

1 Perform steps 1 through 4 of the Main Circuit Board (A) Replacement procedure.

2 Withdraw the two spacers and defective main circuit board (B) from the printer chassis

(Figure 7-6).

3 Connect all relative wiring harnesses to the replacment circuit board (B).

4 Install the replacement circuit board (B) onto the printer chassis followed by the two

spacers.

5 Connect all relative wiring harnesses to main circuit board (A).

6 Apply main circuit board (A) to the assembly and secure using the two screws.

7 Replace all housing covers, restore power, and test print.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

Printer ChassisSpacers Main Board (B)

Figure 7-6, Main Circuit Board (B) Replacement

SATO MB2i Service Manual PN 9001145B Page 7-8

Page 67

Unit 7: Replacement Procedures

PANEL & LCD BOARD REPLACEMENT

1 Switch off the printer and remove power supply or battery.

2 Remove the front housing cover (Figure 7-7).

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.

3 Remove the screw securing the panel board to the back side of the front housing cover.

4 Disconnect all relative wiring harnesses and discard the defective board.

5 Connect all relative wiring harnesses to the replacement panel board and secure using one

screw.

6 Install front housing cover to the printer chassis.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

Panel BoardFront Cover

Figure 7-7, Panel & LCD Board Replacement

Screw x1

SATO MB2i Service Manual PN 9001145B Page 7-9

Page 68

Unit 7: Replacement Procedures

EYE-MARK SENSOR REPLACEMENT

1 Switch off the printer and remove power supply.

2 Remove the front and left housing covers

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.

3 Remove two screws securing the inner cover to the top housing cover (Figure 7-8a).

Screw

Inner Cover

Eye-Mark Sensor Top Housing Cover

Figure 7-8a, Eye-Mark Sensor Replacement

4 Detach the eye-mark sensor from the inner cover.

5 Disconnect the defective eye-mark sensor from the circuit board located on the left side of

the printer (Figure 7-8b).

Standard

Bluetooth &

Wireless LAN

Sensor Connector

Circuit Board

Figure 7-8b, Eye-Mark Sensor Replacement

SATO MB2i Service Manual PN 9001145B Page 7-10

Page 69

Unit 7: Replacement Procedures

6 Insert the replacement eye-mark sensor to the inner cover and route the sensor harness

(Figure 7-8c).

Sensor HarnessEye-Mark Sensor

Figure 7-8c, Eye-Mark Sensor Replacement

7 Secure the inner cover to the top housing cover using the two screws (Figure 7-8a).

8 Connect the sensor to the circuit board and route the wiring harness (Figure 7-8b).

9 Ensure the wiring harness has sufficient slack (Figure 7-8d).

Good

Not Good

Figure 7-8d, Eye-Mark Sensor Replacement

10 Reattach the top, left, and front housing covers.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

SATO MB2i Service Manual PN 9001145B Page 7-11

Page 70

Unit 7: Replacement Procedures

GAP SENSOR REPLACEMENT

1 Switch off the printer and remove power supply.

2 Remove the front housing cover.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.

3 Open the top housing cover to access the gap sensor (Figure 7-9a).

Sensor Bracket

Print Head

Guide Driver

Shaft

Figure 7-9a, Gap Sensor Replacement

Head

Bracket

Driver

Sensor Guide

Sensor

Bracket

4 Insert a flat driver into the slots of the sensor guide and pry upward to remove.

5 Insert a flat driver between the print head bracket and the sensor bracket and pry outward

to detach.

6 Perform step 4 for each end of the print head until it is removed Figure 7-9b).

7 Disconnect the defective sensor from the main circuit board and detach from the sensor

bracket.

8 Connect the replacement sensor to the main circuit board, the sensor bracket, and the

sensor guide.

9 Reapply the print head and the sensor guide to the printer chassis.

10 Install all removed housing covers and test print.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

SATO MB2i Service Manual PN 9001145B Page 7-12

Page 71

Unit 7: Replacement Procedures

Print Head

Sensor Guide

Figure 7-9b, Gap Sensor Replacement

COVER-OPEN SENSOR REPLACEMENT

1 Switch off the printer and remove power supply.

2 Remove the front and left housing covers to gain access to the cover-open sensor.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.

3 Disconnect the eye-mark sensor from cover-open sensor board (Figure 7-10a).

Cover-Open Sensor

Eye-Mark Sensor

Main Board

Screws x1

Screws x2

Figure 7-10, Cover-Open Sensor Replacement

SATO MB2i Service Manual PN 9001145B Page 7-13

Page 72

Unit 7: Replacement Procedures

4 Remove one screw securing the defective sensor to the printer chassis.

5 Remove two screws securing the main circuit board to the printer chassis.

6 Withdraw the main circuit board from the printer chassis and disconnect the defective

cover-open sensor.

7 Connect the replacement cover-open sensor to the circuit board.

8 Secure the main circuit board to the to the printer chassis using two screws.

9 Route the sensor wiring harness (Figure 7-10b).

Eye-Mark Sensor Cover-Open Sensor

Figure 7-10b, Cover-Open Sensor Replacement

10 Attach the sensor to the printer chassis using one screw.

11 Reconnect the eye-mark sensor to the cover-open sensor circuit board.

12 Install all removed housing covers.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover installation.

SATO MB2i Service Manual PN 9001145B Page 7-14

Page 73

Unit 7: Replacement Procedures

DRIVE GEAR REPLACEMENT

1 Switch off the printer and remove power supply.

2 Remove the front and left housing covers.

NOTE: Figure 9-1 of the Charts & Diagrams unit provides guidance on

housing cover removal.