Page 1

For printer model:

Operator Manual

HR2 Series

Read this Operator Manual before using this product.

Keep this document available for future reference.

Page 2

NOTE:

The printer complies with the requirements in Part 15 of FCC Rules for a Class B Computing Device.

Operating the printer in a residential area may cause unacceptable interference to radio and TV reception. If

the interference is unacceptable, you can reposition the equipment, which may improve reception.

Be sure to ask your SATO representatives about our maintenance

contracts to ensure peace of mind during your usage of SATO

products.

Please visit our SATO home page at www.satoworldwide.com for

extensive contact information of our worldwide SATO Group

Member Company closest to your location.

Copyrights

Any unauthorized reproduction of the contents of this document, in part or whole, is strictly prohibited.

Limitation of Liability

SATO Corporation and its subsidiaries in Japan, the U.S and other countries make no representations or

warranties of any kind regarding this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. SATO Corporation shall not be held responsible for errors

contained herein or any omissions from this material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or use of this material.

Specifications and contents in this document are subject to change without notice.

Trademarks

SATO is a registered trademark of SATO Corporation and its subsidiaries in Japan, the U.S. and other

countries. All other trademarks are the property of their respective owners.

Version: GBS-HR2-01rA-23-03-12OM

©2012 SATO Corporation.

All rights reserved.

Page 3

Safety Precautions

HR2 Series Operator Manual Page i

Safety Precautions

Please read the following information carefully before installing and using the printer.

Pictographic Symbols

This instruction manual and the printer labels use a variety of pictographic symbols to facilitate safe and

correct use of the printer and to prevent injury to others and property damage. The symbols and meanings for

them are given below. Be sure to understand these symbols well before reading the main text.

Warning

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

in death or serious injury.

Caution

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

in injury or property damage.

Warning

Do not set on an unstable area

• Do not set on an unstable

area, such as a wobbly table

or slanted area or an area

subject to strong vibration. If

the printer falls off or topples

over, it could injure someone.

Do not place containers full of water

or other liquid on the printer

• Do not place flower vases,

cups, or other containers

holding liquids, such as water

or chemicals, or small metal

objects near the printer. If they

are spilled and get inside the

printer, immediately turn off

the power switch, unplug the

power cord from the outlet,

and contact your SATO

reseller or technical support

center. Using the printer in this

condition could cause a fire or

electric shock.

Do not put objects inside the printer

• Do not insert or drop in metal

or burnable objects inside the

printer’s openings (cable

outlets, etc.). If foreign objects

do get inside the printer,

immediately turn off the power

switch, unplug the power cord

from the outlet, and contact

your SATO reseller or

technical support center.

Using the printer in this

condition could cause a fire or

electric shock.

Do not use other than the specified

voltage

• Do not use other than the

specified voltage. Doing so could

result in fire or electric shock.

Always ground the connections

• Always connect the printer’s

ground wire to a ground. Not

grounding the ground wire

could result in electric shock.

Handling of the power cord

• Do not damage, break, or

modify the power cord. Also,

do not place heavy objects on

the power cord, heat it, or pull

it because doing so could

damage the power cord and

cause a fire or electric shock.

• If the power cord becomes

damaged (core is exposed,

wires broken, etc.), contact

your SATO reseller or

technical support center.

Using the power cord in this

condition could cause a fire or

electric shock.

• Do not modify, excessively

bend, twist, or pull the power

cord. Using the power cord in

such a condition could cause a

fire or electric shock.

When the printer has been dropped or

broken

• If the printer is dropped or

broken, immediately turn off

the power switch, unplug the

power cord from the outlet,

and contact your SATO

reseller or technical support

center. Using the printer in this

condition could cause a fire or

electric shock.

Do not use the printer when something is abnormal about it

• Continuing to use the printer in

the event something is

abnormal about it, such as

smoke or unusual smells

coming from it, could result in

fire or electric shock.

Immediately turn off the power

switch, unplug the power cord

from the outlet, and contact

your SATO reseller or

technical support center for

repairs. It is dangerous for the

customer to try to repair it, so

absolutely do not attempt

repairs on your own.

Do not disassemble the printer

• Do not disassemble or modify

the printer. Doing so could

result in fire or electric shock.

Contact your SATO reseller or

technical support center to

conduct internal inspections,

adjustments, and repairs.

Example Pictographs

The pictograph means “Caution is required.” A specific

warning symbol is contained inside this pictograph (The symbol at left is for electric shock).

The pictograph means “Should not be done.” What is specifically prohibited is contained in or near the pictograph (The

symbol at left means “Disassembly prohibited”).

The pictograph means “Must be done.” What is specifically

to be done is contained in the pictograph (The symbol at left

means “Unplug the power cord from the outlet”).

Page 4

Safety Precautions

Page ii HR2 Series Operator Manual

Warning

Using the head cleaning fluid

• Use of flame or heat around

the head cleaning fluid is

prohibited. Absolutely do not

heat it or subject it to flames.

• Keep the fluid out of reach of

children to prevent them from

accidentally drinking it. If the

fluid is drunk, immediately

consult with a physician.

Caution

Do not place in areas with high

humidity

• Do not place the printer in

areas with high humidity or

where condensation forms. If

condensation forms,

immediately turn off the power

switch and do not use the

printer until it dries. Using the

printer while condensation is

on it could result in electric

shock.

Carrying the Printer

• When moving the printer,

always unplug the power cord

from the outlet and check to

make sure all external wires

are disconnected before

moving it. Moving the printer

with the wires still connected

could damage the cords or

connecting wires and result in

a fire or electrical shock.

• Do not carry the printer with

paper loaded in it. The paper

could fall out and cause an

injury.

• When setting the printer on the

floor or a stand, make sure not

to get your fingers or hands

pinched under the printer feet.

Power supply

• Do not operate the power

switch or plug in/unplug the

power cord with wet hands.

Doing so could result in

electric shock.

Power cord

• Keep the power cord away

from hot devices. Getting the

power cord close to hot

devices could cause the cord’s

covering to melt and cause a

fire or electrical shock.

• When unplugging the power

cord from the outlet, be sure to

hold it by the plug. Pulling it by

the cord could expose or

break the core wires and

cause a fire or electric shock.

• The power cord set that

comes with the printer is

especially made for this

printer. Do not use it with any

other electrical devices.

Top cover

• Be careful not to get your

fingers pinched when opening

or closing the top cover. Also

be careful the top cover does

not slip off and drop.

Print head

• The print head is hot after

printing. Be careful not to get

burned when replacing paper

or cleaning immediately after

printing.

• Touching the edge of the print

head immediately after printing

could result in injury. Use

caution when replacing the

label or cleaning the print

head.

• You should not replace the

print head without having

received the proper training.

Loading paper

• When loading roll paper, be

careful not to get your fingers

pinched between the paper roll

and the supply unit.

When not using the printer for a long

time

• When not using the printer for

a long time, unplug the power

cord from the outlet to

maintain safety.

During maintenance and cleaning

• When maintaining and

cleaning the printer, unplug the

power cord from the outlet to

maintain safety

Page 5

Safety Precautions

HR2 Series Operator Manual Page iii

Precautions for Installation and Handling

Printer operation can be affected by the printer environment.

Refer to the following instructions for installation and handling of HR2 Series printer.

Select a Safe Location

Power Supply

Place the printer on a surface that is flat and level.

If the surface is not flat and level, this may result in poor

print quality. This may also cause malfunction and

shorten the life span of the printer.

Do not place the printer on a location that

produces vibration.

Giving serious vibration or shock to the printer may

cause malfunction and shorten the life span of the

printer.

Keep the printer out of high temperature and humidity.

Avoid locations subject to extreme or rapid changes

in temperature or humidity.

Do not place the printer in a location subject to

water or oil.

Do not place the printer in a location where it will be

splashed with water or oil. Water or oil entering

inside the printer may cause a fire, electric shock, or

malfunction.

Avoid dust.

Dust build up may result in poor print quality.

Keep out of direct sunlight.

This printer has a built-in optical sensor. Exposure to

direct sunlight will make the sensor less responsive

and may cause the label to be sensed incorrectly.

Close the top cover when printing.

This printer requires an AC power supply.

Be sure to connect the printer to an AC power supply.

Connect the power cord to a grounded power

outlet.

Make sure that the printer is plugged into a grounded

power outlet.

Provide a stable source of electricity to the

printer.

When using the printer, do not share its power outlet

with other electrical devices that could result in

power fluctuations and performance issues with your

printer.

Page 6

Table of Contents

Page iv HR2 Series Operator Manual

TABLE OF CONTENTS

Introduction 1 - 1

1.1 Features of the Printer................................................................................................. 1 - 2

1.2 Unpacking ................................................................................................................... 1 - 2

1.2.1 Included Accessories......................................................................................... 1 - 2

1.3 Parts Identification....................................................................................................... 1 - 3

Installation 2 - 1

2.1 Site Location................................................................................................................ 2 - 2

2.2 Media Selection........................................................................................................... 2 - 2

2.3 Loading Media............................................................................................................. 2 - 3

2.3.1 To load the label when using the dispenser ...................................................... 2 - 3

2.3.2 When operating in continuous mode for the first time........................................ 2 - 7

2.3.3 To load the media when operating in continuous mode .................................... 2 - 7

2.3.4 Overview of the media/ ribbon loading path ...................................................... 2 - 8

2.4 Loading the Carbon Ribbon ........................................................................................ 2 - 9

2.5 Removing the Carbon Ribbon ................................................................................... 2 - 15

2.6 Basic Connections..................................................................................................... 2 - 17

2.6.1 Connecting the Interface board ....................................................................... 2 - 17

2.6.2 To Configure the Connected Interface............................................................. 2 - 18

2.6.3 Interface Combination...................................................................................... 2 - 18

2.6.4 Connecting the Power Cable ........................................................................... 2 - 19

2.6.5 Turning On the Power...................................................................................... 2 - 20

2.6.6 Turning Off the Power ..................................................................................... 2 - 20

2.7 Connections of optional accessories......................................................................... 2 - 21

2.8 LCD Power Saving Mode .......................................................................................... 2 - 24

2.8.1 Turning off the LCD Backlight.......................................................................... 2 - 24

2.8.2 Turning on the LCD Backlight.......................................................................... 2 - 24

Operation and Configuration 3 - 1

3.1 Operator Panel ............................................................................................................ 3 - 2

3.2 Operating Modes......................................................................................................... 3 - 5

3.3 ONLINE And OFFLINE Modes.................................................................................... 3 - 8

3.3.1 Online Mode ...................................................................................................... 3 - 8

3.3.2 Offline Mode ..................................................................................................... 3 - 8

3.3.3 To Adjust the Screen Contrast........................................................................... 3 - 8

3.4 Adjustment Screen...................................................................................................... 3 - 9

3.5 Cancel Print Job Mode ............................................................................................. 3 - 11

3.6 User Mode................................................................................................................. 3 - 12

3.7 Interface Mode .......................................................................................................... 3 - 15

3.7.1 Overview of Interface Mode Configurations .................................................... 3 - 15

3.7.2 Enabling Interface Card Configuration............................................................. 3 - 18

3.8 CARTRIDGE Mode ................................................................................................... 3 - 25

3.9 SEMBL Mode ............................................................................................................ 3 - 27

3.10 Advanced Mode ...................................................................................................... 3 - 28

3.11 HEX Dump Mode .................................................................................................... 3 - 34

3.12 Received Data Saving Mode................................................................................... 3 - 35

3.13 Test Print Mode ....................................................................................................... 3 - 36

3.13.1 Types of Test Print......................................................................................... 3 - 39

3.13.2 Explanation of the contents of each piece of Factory Test Print 1................. 3 - 39

Page 7

Table of Contents

HR2 Series Operator Manual Page v

3.13.3 Explanation of the contents of each piece of Factory Test Print 2................. 3 - 43

3.13.4 Explanation of the contents of Configuration Test Print................................. 3 - 48

3.13.5 Print of Supported Barcodes.......................................................................... 3 - 50

3.13.6 Print of Head Check....................................................................................... 3 - 50

3.13.7 Print Head and Sensor Check ....................................................................... 3 - 50

3.13.8 Memory State ................................................................................................ 3 - 50

3.13.9 Print of Supported Fonts................................................................................ 3 - 50

3.13.10 Print Test Pattern for Small Pitch Label....................................................... 3 - 50

3.14 Default Setting Mode............................................................................................... 3 - 51

3.14.1 Table of Default Settings ............................................................................... 3 - 52

3.15 Maintenance Mode.................................................................................................. 3 - 55

3.16 Service Mode .......................................................................................................... 3 - 56

3.16.1 Overview of Sensor Level adjustment in Service Mode................................. 3 - 56

3.16.2 Pitch adjustment in Service Mode ................................................................. 3 - 58

3.16.3 Dispense or Tear off offset adjustment in Service Mode ............................... 3 - 60

3.16.4 Backfeed Offset adjustment in Service Mode ............................................... 3 - 62

3.16.5 Overview of Setting menu in Service Mode................................................... 3 - 64

3.17 Download Mode ...................................................................................................... 3 - 66

3.18 Upload Mode........................................................................................................... 3 - 70

Cleaning and Maintenance 4 - 1

4.1 Cleaning The Print Head, Platen and Rollers.............................................................. 4 - 2

4.2 How To Clean The Printer (Cleaning Kit).................................................................... 4 - 2

4.3 How To Clean The Printer (Cleaning Sheet)............................................................... 4 - 3

4.4 Adjusting Print Quality ................................................................................................. 4 - 4

4.4.1 Adjusting Print Darkness ................................................................................... 4 - 4

4.4.2 Adjusting Print Speed ....................................................................................... 4 - 4

Troubleshooting 5 - 1

5.1 Error signal Troubleshooting ....................................................................................... 5 - 2

5.1.1 Error Message .................................................................................................. 5 - 2

5.1.2 More information about Command Error ........................................................... 5 - 6

5.1.3 Warning Message.............................................................................................. 5 - 7

5.2 Troubleshooting Table................................................................................................. 5 - 8

5.3 Interface Troubleshooting.......................................................................................... 5 - 10

5.4 Test Print Troubleshooting ........................................................................................ 5 - 11

5.4.1 Hex Dump........................................................................................................ 5 - 11

5.4.2 Test label printing ............................................................................................ 5 - 11

Basic Specifications 6 - 1

6.1 Printer Basic Specifications......................................................................................... 6 - 1

Interface Specifications 7 - 1

7.1 Interface Types............................................................................................................ 7 - 1

7.2 RS232C High Speed Serial Interface.......................................................................... 7 - 2

7.2.1 Basic Specifications .......................................................................................... 7 - 2

7.2.2 Ready/Busy ....................................................................................................... 7 - 3

7.2.3 X-ON/X-OFF ...................................................................................................... 7 - 4

7.3 Universal Serial Bus (USB) Interface .......................................................................... 7 - 5

7.3.1 Basic Specifications .......................................................................................... 7 - 5

7.3.2 Pin Assignments ................................................................................................ 7 - 5

7.4 Local Area Network (LAN) Ethernet ............................................................................ 7 - 6

7.4.1 Basic Specifications .......................................................................................... 7 - 6

Page 8

Table of Contents

Page vi HR2 Series Operator Manual

7.4.2 Software Specifications ..................................................................................... 7 - 8

7.4.3 TCP/IP Specifications ........................................................................................ 7 - 8

7.4.4 LPD Specifications............................................................................................. 7 - 8

7.4.5 FTP Specifications............................................................................................. 7 - 8

7.4.6 TELNET Specifications...................................................................................... 7 - 9

7.4.7 Setting/Displayed Items ................................................................................... 7 - 10

7.4.8 Socket Connection........................................................................................... 7 - 10

7.4.9 Operating Suggestions .................................................................................... 7 - 11

7.5 External Signal Interface (EXT)................................................................................. 7 - 11

7.5.1 Basic Specifications......................................................................................... 7 - 12

7.5.2 Pin Assignments .............................................................................................. 7 - 13

Appendix 8 - 1

8.1 Positions of Sensors and Options ............................................................................... 8 - 2

8.2 Operation Mode Selection........................................................................................... 8 - 3

8.3 Base Reference Point ................................................................................................. 8 - 4

8.4 Base Reference Point Adjustment .............................................................................. 8 - 5

8.4.1 Adjustment of Print Position............................................................................... 8 - 5

8.4.2 Adjustment of Stop Position When Using Dispenser/ Tear-off .......................... 8 - 6

8.4.3 Adjustment of Stop Position in Tear-off Mode (only for the first label)............... 8 - 7

8.5 Paper End ................................................................................................................... 8 - 8

8.5.1 Paper End Detection during Paper Feed........................................................... 8 - 8

8.5.2 Paper end detection in print motion ................................................................... 8 - 8

8.6 Ribbon End................................................................................................................ 8 - 10

8.7 Rewinder Full ............................................................................................................ 8 - 11

Page 9

Section 1: Introduction

HR2 Series Operator Manual Page 1-1

INTRODUCTION

Thank you for your investment in this SATO printer product.

This Operator Manual contains the basic information about the installation, setup, configuration, operation

and maintenance of the printer.

A total of eight topics are covered herein, and they are organized as follows:

Section 1: Introduction

Section 2: Installation

Section 3: Operation and Configuration

Section 4: Cleaning and Maintenance

Section 5: Troubleshooting

Section 6: Basic Specifications

Section 7: Interface Specifications

Section 8: Appendix

It is recommended that you read carefully and become familiar with each section before installing and

maintaining the printer. Refer to the TABLE OF CONTENTS at the front of this manual to search for the

relevant information needed. All page numbers in this manual consist of a section number followed by the

page number within the stated section.

This section assists you in unpacking the printer from the shipping container. You will also be guided through

a familiarization tour of the main parts and controls.

The following information is provided herein:

• Features of the printer

• Unpacking

• Parts Identification

Page 10

Section 1: Introduction

Page 1-2 HR2 Series Operator Manual

1.1 FEATURES OF THE PRINTER

The SATO HR2 Series printers (Thermal Transfer) are complete, high-performance labeling systems

designed specifically for printing labels.

The key features of the HR2 Series are:

• Full metallic durable casing

• High accuracy printer

• Large internal Memory Size (32MB Flash-ROM)

• Built-in multiple interfaces (USB, LAN or high speed RS-232C interface available)

• Easy Media loading

• Easy Maintenance

1.2 UNPACKING

When unpacking the printer, take note of the following:

2. The box should stay right-side up. Lift the printer out of the box carefully.

3. Remove all the packaging from the printer.

4. Remove the accessory items from their protective containers.

5. Set the printer on a solid, flat surface. Inspect the shipping container and printer for any sign of damage

that may have occurred during shipping. Please note that SATO shall hold no liability of any damage of any

kind sustained during shipping of the product.

Notes:

• If the printer has been stored in the cold, allow it to reach room temperature before turning it on.

• Please do not discard the original packaging box and cushioning material after installing the printer. They

may be needed in future, if the printer needs to be shipped for repairs.

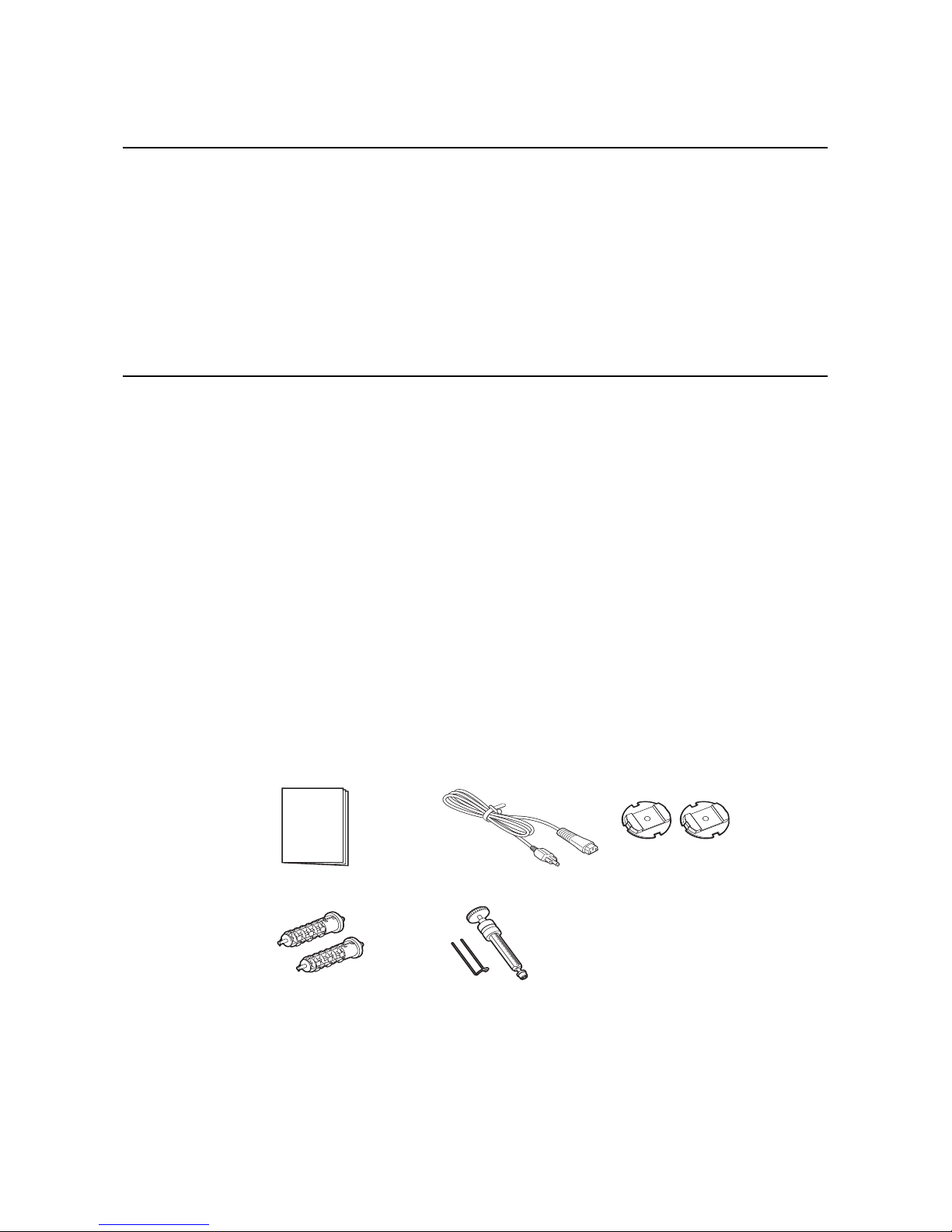

1.2.1 Included Accessories

After unpacking the printer, verify that you have the following materials:

User Documents

(Quick Guide, Warranty, etc)

* The shape of the power plug may vary, depending on the location where it was purchased.

Power plug*

Roll Holders (x2)

Ribbon Adapters (x2)

Core clip, Rewinder

Page 11

Section 1: Introduction

HR2 Series Operator Manual Page 1-3

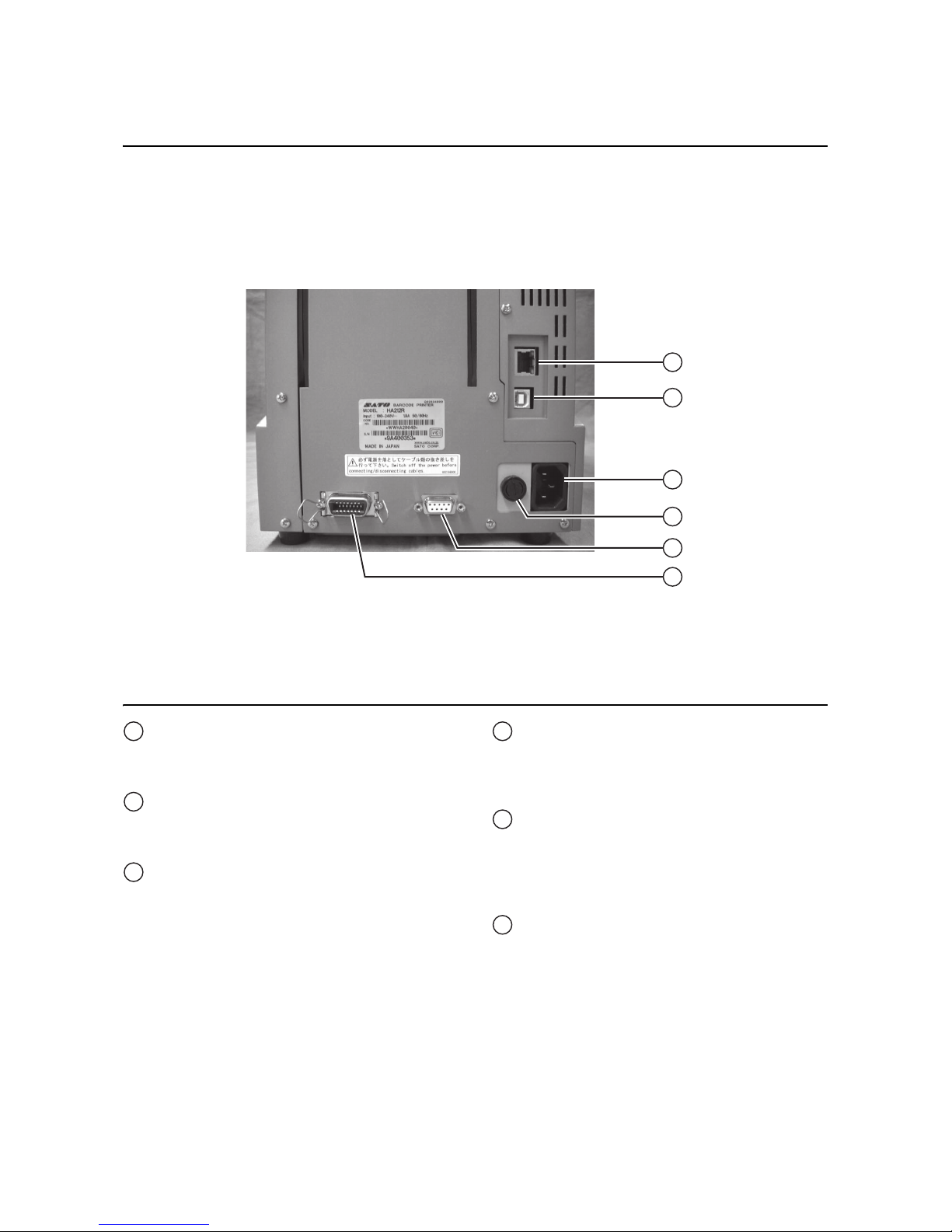

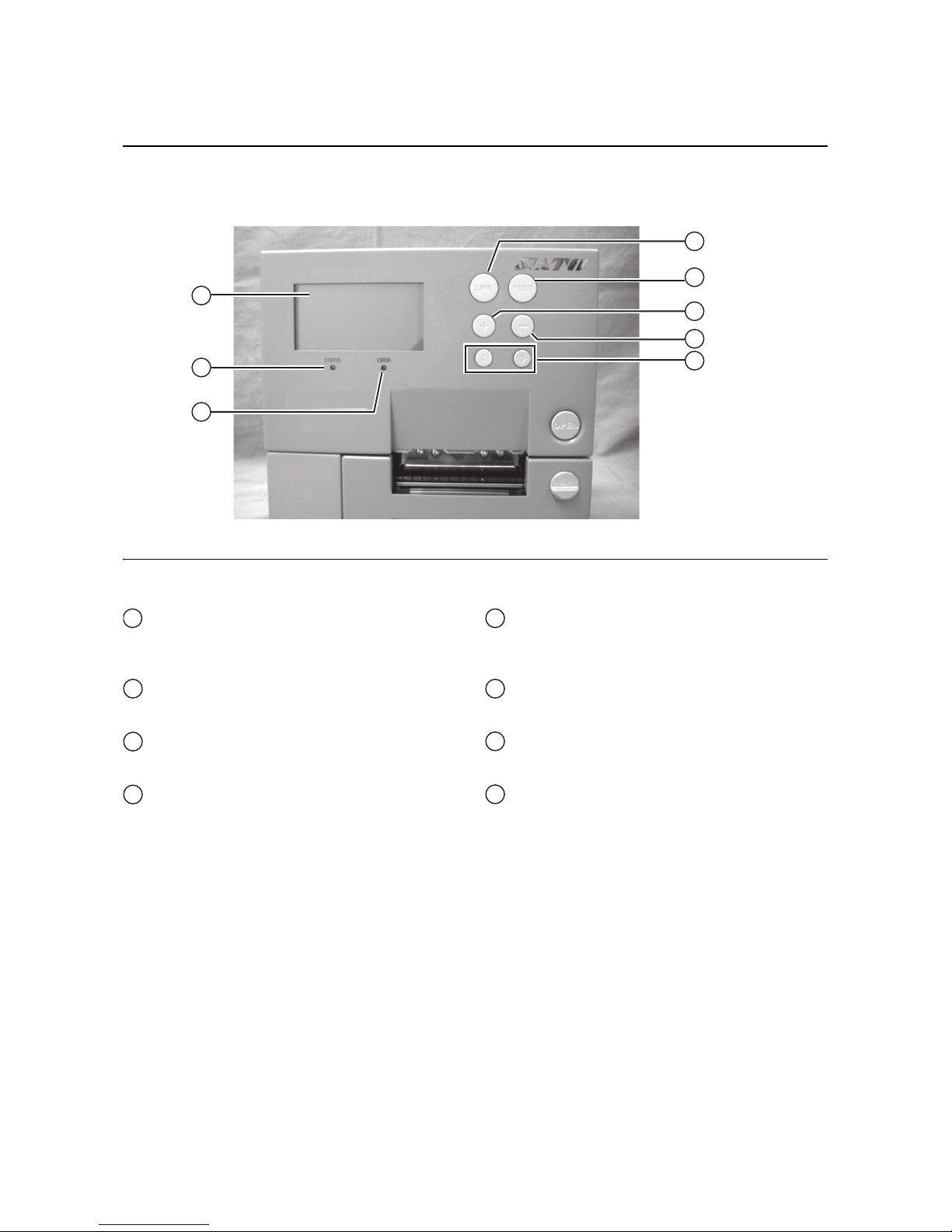

1.3 PARTS IDENTIFICATION

7

6

1

2

3

4

5

Front view

Operator panel

It consists of six contact buttons and two

LED indicators. Please refer to Section 3.1

Operator Panel.

Top cover

Open this cover to load the media and ribbon.

OPEN button

Press this button to open the Top cover.

Dispenser unit open button

Slide this button downwards to open the cover

of the Dispenser unit.

Label issuing slot

Labels are issued from this slot.

Dispenser sensor sliding knob

To adjust the position of the dispenser sensor.

Power (I/O) switch

Press this switch to turn the power on (I) or

off (O).

1

234

5

6

7

Page 12

Section 1: Introduction

Page 1-4 HR2 Series Operator Manual

1.3 PARTS IDENTIFICATION (cont’d)

1

2

3

4

5

6

Back view

LAN Interface connector

To connect printer to the host computer using

the LAN interface.

USB Interface connector

To connect printer to the host computer using

the USB interface.

AC IN power terminal

Supplies power to the printer by inserting the

power cable.

Before connection, ensure that the AC voltage

of your region is within the range of AC 100 to

240V, 50/60 Hz.

FUSE (F-400-01A2) holder

Used to hold a fuse which protect the printer

from unstable power supply surge. Use fuse

with rating, 250V/5A -LF (218 005.MXP) only.

RS-232C (DSUB9 pin-female) Interface

connector

To connect printer to the host computer using

the RS232C serial interface.

Or, to connect to the optional SATO keypad.

External connector terminal (EXT)

Interface connector for external signals.

Connect the optional application to this

terminal.

1

2

3

4

5

6

Page 13

Section 1: Introduction

HR2 Series Operator Manual Page 1-5

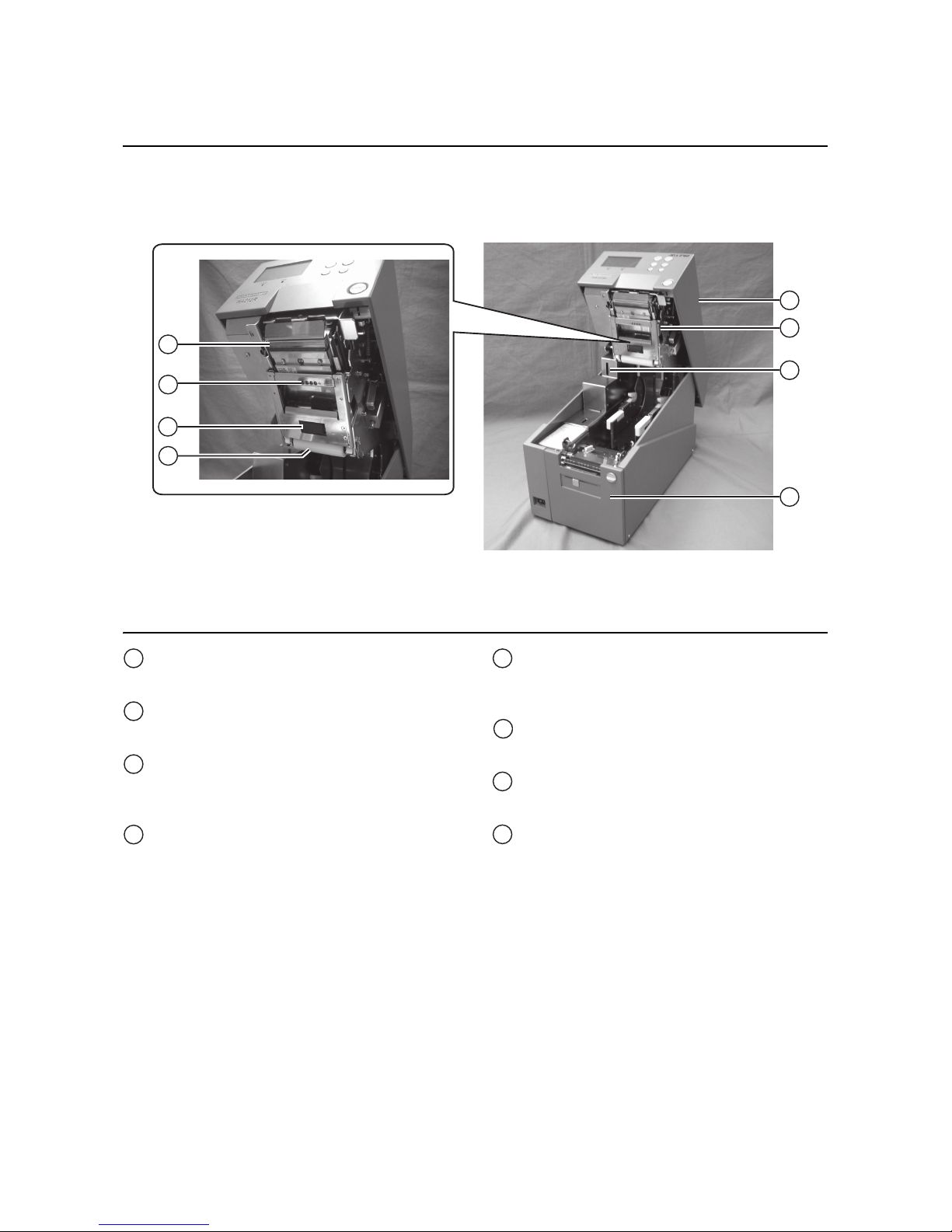

1.3 PARTS IDENTIFICATION (cont’d)

5

6

7

8

1

2

3

4

Internal view when Top cover is opened

Top cover

Ribbon unit

A unit for loading ribbon.

SD Card Slot

To insert SD card for additional memory up to

2 GB.

Dispenser unit

A unit to peel off label automatically after

printing.

Print head assembly

This component is used to print on the media.

Perform maintenance at regular intervals.

Label sensor

Used to sense label during printing.

Pinch roller

Used to pinch the roll media.

Guide roller

Roller to guide the roll media.

1

2

3

4

5

6

7

8

Page 14

Section 1: Introduction

Page 1-6 HR2 Series Operator Manual

1.3 PARTS IDENTIFICATION (cont’d)

1

2

3

4

6

5

Internal view when Ribbon unit is opened

Top cover

Ribbon pinch lever

Used to pinch the ribbon.

Ribbon unit

A unit for loading ribbon.

Ribbon unit lever

Press this lever to release ribbon unit from the

top cover.

Ribbon supply shaft bearing

To hold the Ribbon supply shaft.

Ribbon rewind shaft bearing

To hold the Ribbon rewind shaft.

2

3

4

5

6

1

Page 15

Section 1: Introduction

HR2 Series Operator Manual Page 1-7

1.3 PARTS IDENTIFICATION (cont’d)

Media and Rollers Section

6

7

8

1

2

3

4

5

Feed roller

Enable smooth feeding of the label.

Label guide lock lever

Used to lock the label guide.

Label guide

Used to guide the label.

Platen roller

Enable smooth movement of the label during

printing.

Dispenser roller

Enable smooth movement of the label during

dispensing.

Roll shaft bearing

Used to latch roll holder.

Roll media guide lock lever

Used to lock the roll media guide.

Roll media guide

Set to meet the size of the media used.

1

2

3

4

5

6

7

8

Page 16

Section 1: Introduction

Page 1-8 HR2 Series Operator Manual

1.3 PARTS IDENTIFICATION (cont’d)

Operating Panel

1

6

7

8

2

3

4

5

LCD screen

Displays various information such as printer

modes and settings.

STATUS LED

Indicates current status of the printer.

ERROR LED

Indicates the printer is in error state.

LINE button

Press this button to toggle between printer

modes or go back to previous setting in various

modes

FEED button

Press this button to start/stop printing or feed

the label.

+ button

Increment value in various modes.

- button

Decrement value in various modes.

Arrow buttons

Press to move the cursor left or right in various

modes.

1

2

3

4

5

6

7

8

Page 17

Section 2: Installation

HR2 Series Operator Manual Page 2-1

INSTALLATION

This section assists you in general printer set up and installing consumable media in the printer, as well as

interface connection with host computer and other optional attachment units.

The following information is provided:

• 2.1 Site Location

• 2.2 Media Selection

• 2.3 Loading Media

• 2.4 Loading the Carbon Ribbon

• 2.5 Removing the Carbon Ribbon

• 2.6 Basic Connections

• 2.7 Connections of optional accessories

• 2.8 LCD Power Saving Mode

Page 18

Section 2: Installation

Page 2-2 HR2 Series Operator Manual

2.1 SITE LOCATION

Consider the following when setting up the printer:

• Place the printer on a solid flat surface with adequate space. Make sure there is enough space above

the printer to provide clearance for the top cover to swing open.

• Place it away from hazardous materials or dusty environments.

• Place it within operational distance of the host computer, within interface cable specifications.

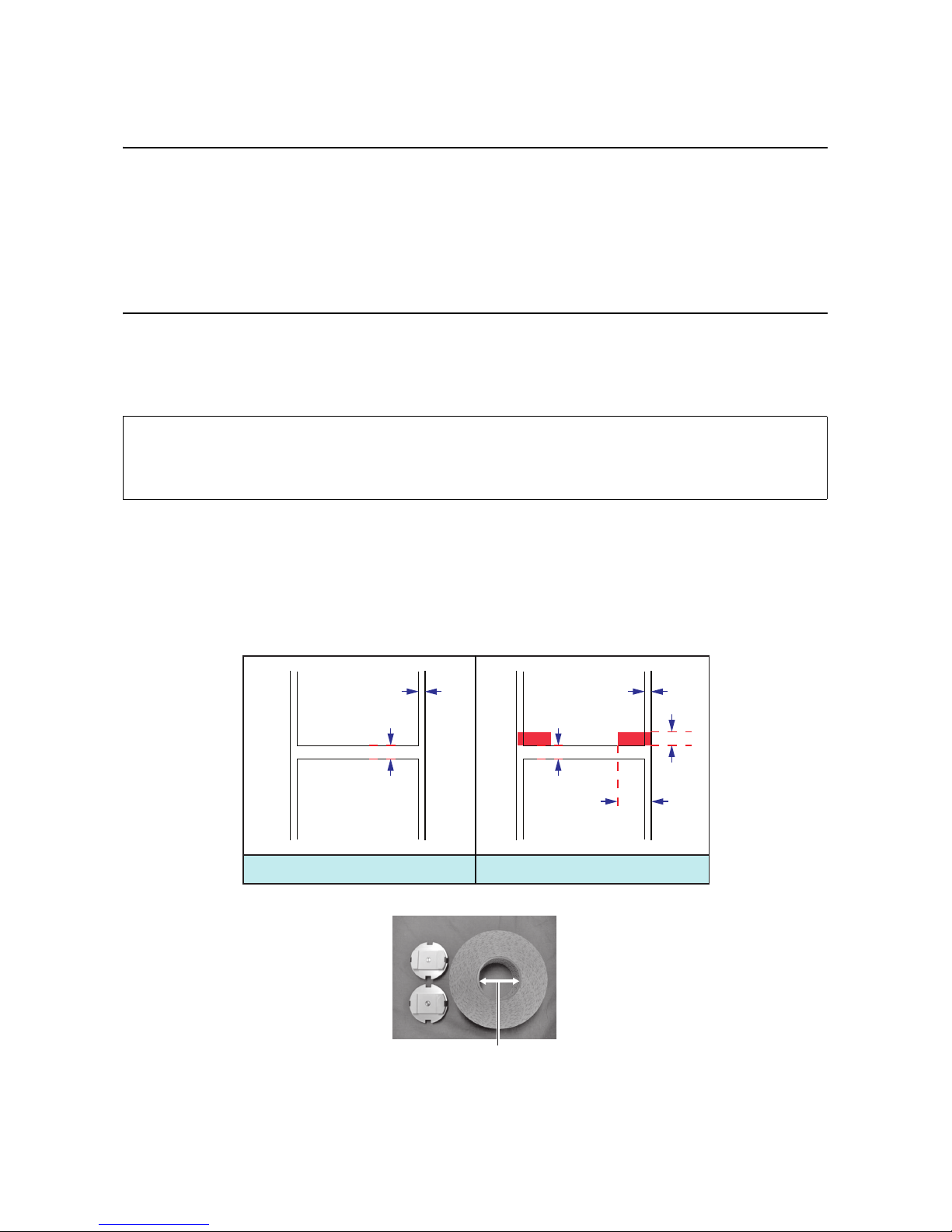

2.2 MEDIA SELECTION

The size and type of the labels to be printed should have been taken into consideration before printer

purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that

does not cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also

wear a groove in the platen roller, which can affect print quality.

This printer can use 2 different types of media, the figures below identifies the media types and their

specifications. The printer uses different sensors to detect the I-Marks or Gap on the media in order to

precisely position the print content.

Note:

For optimal print performance and durability, please use SATO-certified media and ribbon supplies

on this printer. Using supplies not tested and approved for use by SATO can result in unnecessary

wear and damage to vital parts of the printer, and may void the warranty.

10mm

(0.39”)

1.5mm (0.06”)

Gap Label I-Mark Label

3mm

(0.12”)

3mm

(0.12”)

1.5mm (0.06”)

3mm

(0.12”)

76.4mm (3”)

Page 19

Section 2: Installation

HR2 Series Operator Manual Page 2-3

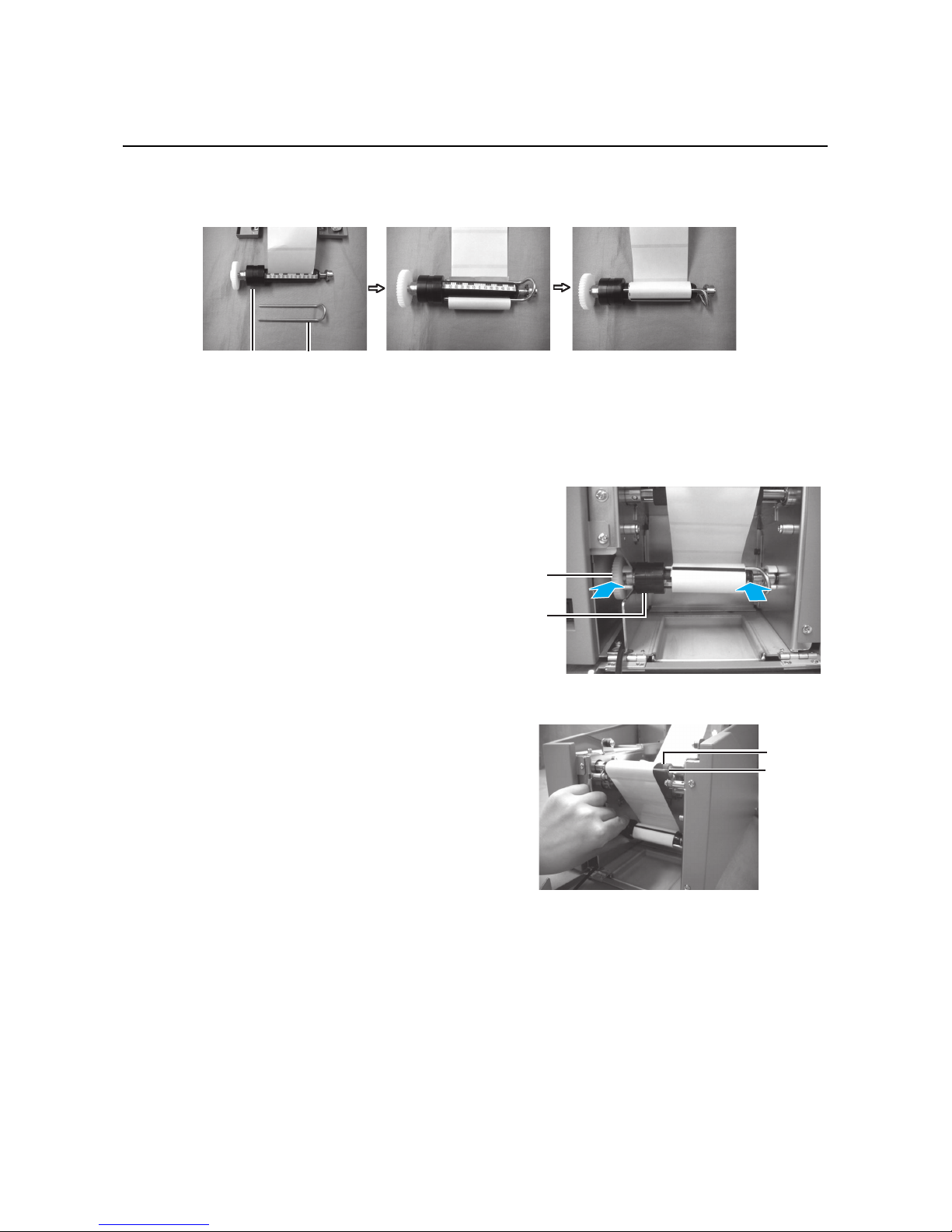

2.3 LOADING MEDIA

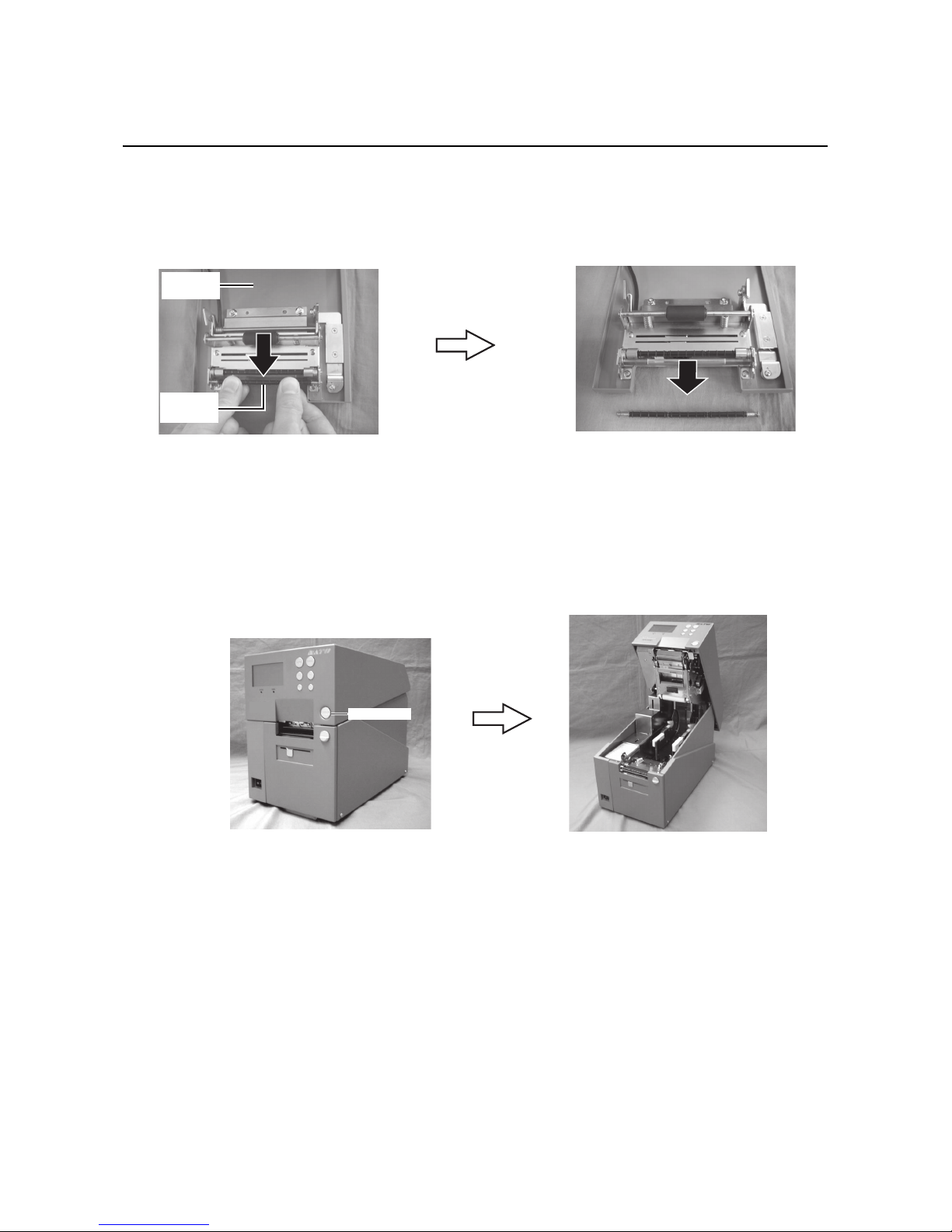

2.3.1 To load the label when using the dispenser

1.

Lift up the Top cover while holding down the OPEN button.

Slide down the Dispenser unit open button to open the dispenser unit.

Note:

Make sure that the cover rests firmly so that it will not fall forward and injure your hands.

2. Attach the supplied roll holders to the left and right sides of the roll media respectively.

OPEN button

Dispenser unit

open button

Roll holders

Outer side

Inner side

Page 20

Section 2: Installation

Page 2-4 HR2 Series Operator Manual

2.3 LOADING MEDIA (cont’d)

3.

Release the lock levers of roll media guide and label

guide.

4. Slide the roll media guide to the width of the roll media

and then load the media by latching the Roll media

assembly to the roll shaft bearing.

5. Slide the label guide so that it fits the label width.

After alignment, lock the levers of roll media guide

and label guide.

Notes:

Make sure the media leader is pulled out from the top

and the printed side is facing upwards. Push the roll

firmly towards the end of the roll shaft bearing.

Roll

media guide

lock lever

Roll

media

guide

Label

guide

lock lever

Label

guide

Roll

shaft

bearing

Roll

media

guide

Label

guide

Page 21

Section 2: Installation

HR2 Series Operator Manual Page 2-5

2.3 LOADING MEDIA (cont’d)

6.

Align the liner (backing paper) by referring to the scale of the rewinder and wrap it to the rewinder in

clockwise direction. Then secure it with the clip.

After clipping, rewind the liner (backing paper) more than 3 turns (150 mm).

7. Push the rewinder onto the rewinder shaft bearing

until you hear a “tick” sound.

8. Turn the rewinder until the label to be printed

reaches the platen roller.

Rewinder

core

Clip

Rewinder

gear

Rewinder

core

Platen

roller

Dispenser

plate

Page 22

Section 2: Installation

Page 2-6 HR2 Series Operator Manual

2.3 LOADING MEDIA (cont’d)

9.

Close the dispenser unit.

10.If the label is not taut, roll the media in the arrow direction, close the top cover.

You may need to set the Dispenser sensor adjustment. Refer to Section 8.4.2 Adjustment of Stop Position When Using Dispenser/ Tear-off for more details.

Note:

Be careful not to get your fingers caught at the bottom edge when you are closing the top cover.

Caution

• When replacing media, bear in mind that the print head and its surrounding area remain hot.

Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Page 23

Section 2: Installation

HR2 Series Operator Manual Page 2-7

2.3 LOADING MEDIA (cont’d)

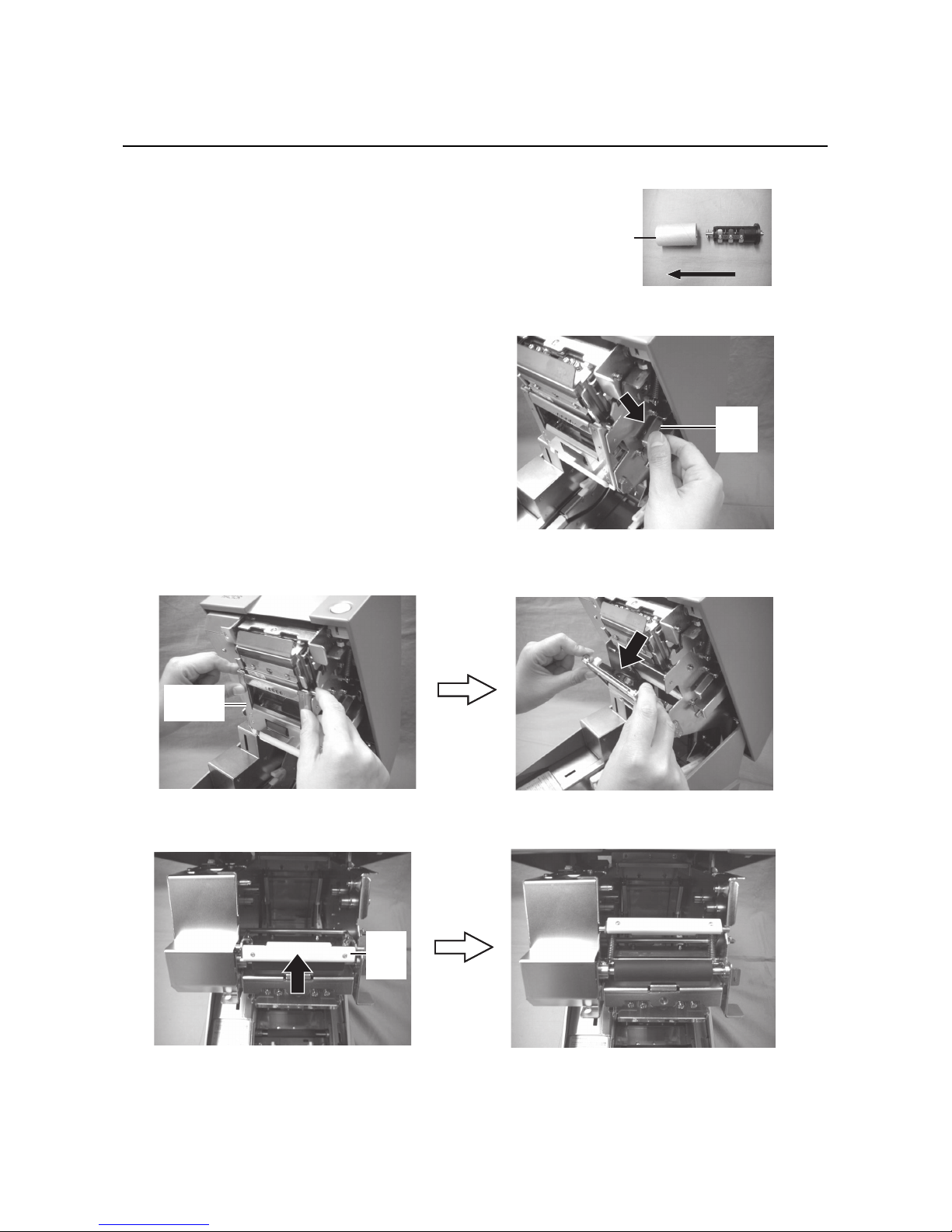

2.3.2 When operating in continuous mode for the first time

1.

Slide down the Dispenser unit open button to open the dispenser unit.

2. Remove the dispenser roller mounted in the dispenser unit.

While pushing the dispenser roller downwards, pull towards your side to remove it.

Notes:

• Keep the dispenser roller in a safe place.

• Mount with the reversed procedures when you need to issue labels in dispense mode.

3. Close the dispenser unit.

2.3.3 To load the media when operating in continuous mode

1.

Lift up the Top cover while holding down the OPEN button.

2. Load the media. (Refer to steps 2~5 of Section 2.3.1 To load the label when using the dispenser)

3. Close the top cover.

Dispenser

roller

Dispenser

unit

OPEN button

Page 24

Section 2: Installation

Page 2-8 HR2 Series Operator Manual

2.3 LOADING MEDIA (cont’d)

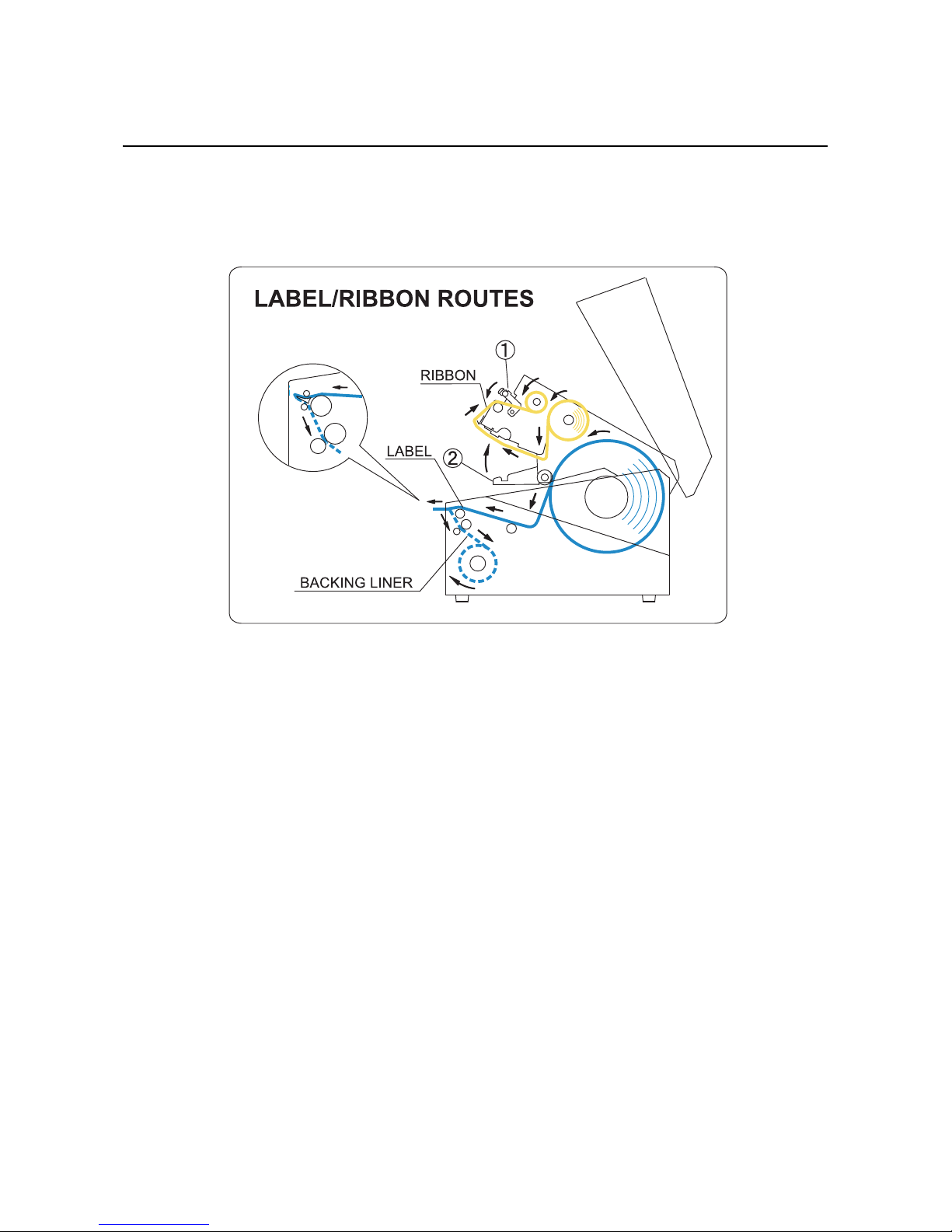

2.3.4 Overview of the media/ ribbon loading path

Note:

You may also refer to the sticker pasted on the inner side of the top cover for the media/ ribbon loading path.

Page 25

Section 2: Installation

HR2 Series Operator Manual Page 2-9

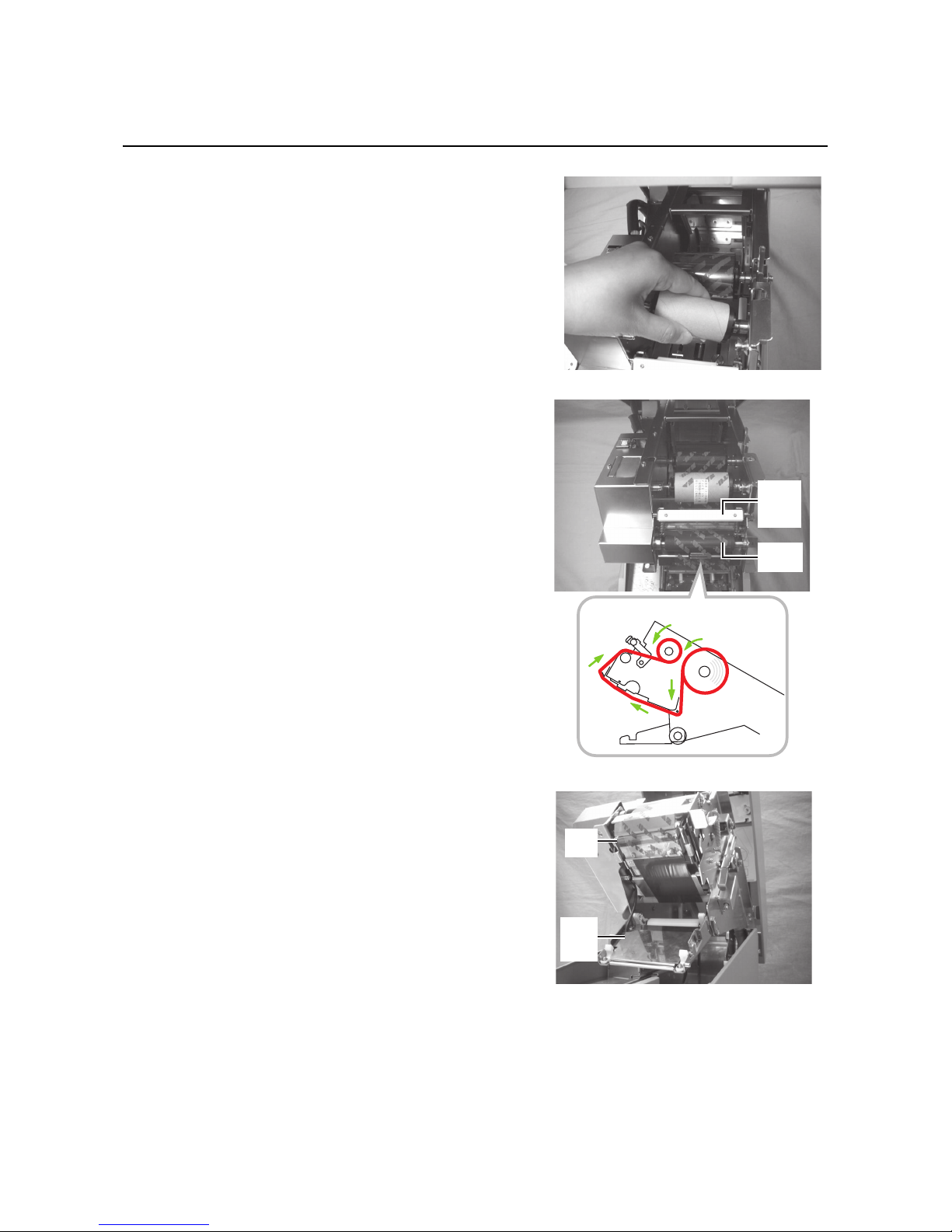

2.4 LOADING THE CARBON RIBBON

The HR2 series printer enables Thermal transfer printing. Thermal transfer paper media requires the use of

carbon ribbon for print application. In such a scenario, it is the carbon ribbon that contains the ink that will be

transferred to the media.

1. Prepare the carbon ribbon and ribbon rewind core.

Use the provided ribbon adapter to load

the carbon ribbon and the ribbon rewind

core.

The position of the ribbon stopper varies

depending on the width of the carbon ribbon.

Example:

When the ribbon width is 65mm

Set the ribbon stopper position to .

2. Insert the ribbon adapter all the way into

the carbon ribbon, while taking note of

the ribbon winding direction.

Caution

• When replacing carbon ribbon, bear in mind that the print head and its surrounding area remain

hot. Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Ribbon stopper

Width: 45mm

Width: 65mm

Width: 59mm

Width: 39.5mm

Ribbon adapter

3

1

2

4

Align and turn this mark to position

1

1

Carbon ribbon

winding direction

Insert this way

Page 26

Section 2: Installation

Page 2-10 HR2 Series Operator Manual

2.4 LOADING THE CARBON RIBBON (cont’d)

3.

Insert the ribbon adapter all the way into the ribbon

rewind core.

When loading the carbon ribbon for the first time, use

the empty ribbon rewind core supplied with the

printer. However, the subsequent ribbon core can be

obtained from the last used up ribbon roll.

4. Press the ribbon unit lever to release the ribbon

unit.

Note:

When loading the carbon ribbon, make sure that the

top cover is fully opened.

5. Hold two corners of the pinch roller unit and pull it

in the arrow direction to unlatch.

6. Lift down the ribbon unit and push the ribbon pinch lever upwards.

Ribbon

rewind core

Insert this way

Ribbon

unit

lever

Pinch roller

unit

Ribbon

pinch

lever

Page 27

Section 2: Installation

HR2 Series Operator Manual Page 2-11

2.4 LOADING THE CARBON RIBBON (cont’d)

7.

Load the carbon ribbon from the right side and make sure it latches into the ribbon supply shaft bearing

firmly.

Push in the ribbon shaft assembly to the right side of the ribbon supply shaft bearing. Then fix the other

side of the ribbon shaft assembly to the left of the ribbon supply shaft bearing. Turn the ribbon shaft until

the cross shape shaft snaps on the groove of the left ribbon supply shaft bearing.

Note:

Use only genuine SATO carbon ribbons for maximum print quality and printer durability.

Ribbon supply

shaft bearing

Align to the cross-shape shaft bearing when

latching the ribbon.

Align to the round shape shaft bearing

when latching the ribbon.

Page 28

Section 2: Installation

Page 2-12 HR2 Series Operator Manual

2.4 LOADING THE CARBON RIBBON (cont’d)

8.

Load the ribbon rewind core to the rewinding side.

The procedures are same as when loading to the supplying

side.

9. From the ribbon supply shaft bearing, pass the carbon

ribbon underneath the print head assembly to the ribbon

rewind shaft bearing.

Route the ribbon between the ribbon pinch lever and

ribbon roller towards the ribbon rewind core. Then route

the ribbon behind and over the top of the ribbon rewind

core. Paste the leader portion of the carbon ribbon onto the

ribbon rewind core.

Ribbon

pinch

lever

Ribbon

roller

Right side view

Print

head

Pinch

roller

unit

Page 29

Section 2: Installation

HR2 Series Operator Manual Page 2-13

10.Turn the rewind shaft bearing several times in the direction

of arrow to wind the ribbon until the ink portion of the ribbon

comes around the ribbon roller.

11. Lift down the ribbon pinch lever back to the ribbon roller

position.

12.Lift up the ribbon unit and remount the pinch roller unit.

Latch the pinch roller unit until you hear a “tick” sound.

Ribbon

pinch

lever

Ribbon

unit

Pinch

roller

unit

Page 30

Section 2: Installation

Page 2-14 HR2 Series Operator Manual

2.4 LOADING THE CARBON RIBBON (cont’d)

13.

Remount the ribbon unit by pushing it towards the top cover

until you hear a “tick” sound.

14.Close the top cover.

After loading the media and the carbon ribbon, close the

main cover, turn on the printer and do a test print to check

that the media roll has been loaded properly. See Section

3.12 Received Data Saving Mode for instructions on how

to run test print

Page 31

Section 2: Installation

HR2 Series Operator Manual Page 2-15

2.5 REMOVING THE CARBON RIBBON

After the carbon ribbon has used up to the end of the roll, remove the wound-up carbon ribbon from the

printer.

1. With the power supply is off, lift up the top cover and

release the ribbon unit by pressing the ribbon lever.

2. Hold two corners of the pinch roller unit to unlatch it.

3. Lift up the ribbon pinch lever.

Caution

• When replacing carbon ribbon, bear in mind that the print head and its surrounding area

remain hot. Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Ribbon

unit

lever

Page 32

Section 2: Installation

Page 2-16 HR2 Series Operator Manual

2.5 REMOVING THE CARBON RIBBON (cont’d)

4.

Push the wound-up carbon ribbon to the right side of the

rewind shaft bearing to remove the ribbon rewind shaft

assembly.

Caution:

Be careful when removing the carbon ribbon, your hands

may get dirty while handling it.

5. Remove the empty core from the ribbon supply shaft in

the same manner.

Note:

Don’t dispose of the empty ribbon core after removing it from the ribbon supply shaft. Instead, transfer it to

the ribbon rewind shaft so that used ribbon can be wound around it after a new ribbon roll has been

loaded.

Page 33

Section 2: Installation

HR2 Series Operator Manual Page 2-17

2.6 BASIC CONNECTIONS

This section explains the power cable and interface cable connection procedures.

2.6.1 Connecting the Interface board

HR2 Series printers are equipped with three different types of standard interface to perform data

communication with the host. These are described as follows.

• USB interface

• LAN interface

• RS-232C (High-speed) interface

Connect interface cable from the printer to the host computer. Use the cable that is compatible with the

standard of the interface board as stated in Section 7: Interface Specifications. Make sure the cable is

correctly oriented before you insert it.

Caution

• Never connect or disconnect interface cables (or use a switch box) with power applied to either

the host or printer. This may caused damage to the interface circuitry in the printer/ host and is

not covered by warranty.

Host

RS232C

USB

LAN

Page 34

Section 2: Installation

Page 2-18 HR2 Series Operator Manual

2.6 BASIC CONNECTIONS (cont’d)

2.6.2 To Configure the Connected Interface

After connection, you need to set the configuration of the connected interface in the INTERFACE MODE

menu of the printer. Please refer to Section 3.7 Interface Mode for details on setting Interface Mode.

In Interface mode, you will need to determine which interface is set as Data Port and which is set as Sub Port.

An overview of each port is shown as below.

Data Port

When the interface is set to the Data Port, it can receive various SBPL commands and it can execute print

operations.

Data port selection: USB, LAN, RS-232C

* The interface which already set for SUB PORT is not able to select.

Sub Port

This port is for monitoring printer status and connecting to external devices.

Sub Port selection: NONE, USB, LAN, RS-232C

* The interface which already set for DATA PORT is not able to select.

Note:

Data Port and Sub Port cannot use the same interface at the same time.

2.6.3 Interface Combination

The interface combinations that can be used for Data Port and Sub Port are as follows.

[o: configurable, x: not configurable]

The following table shows the combination of interface with keypad and the port type.

[o: configurable, x: not configurable]

Data port

RS-232C USB LAN

Sub Port

RS-232C xoo

USB o

xo

LAN o o

x

Condition

Interface

Keypad connection Keypad disconnection

Data Port Sub Port Data Port Sub Port

RS-232C x x o o

USB x o o o

LAN x o o o

NONE x x x o

Page 35

Section 2: Installation

HR2 Series Operator Manual Page 2-19

2.6 BASIC CONNECTIONS (cont’d)

Notes

• Do not select the same interface for the data and sub ports.

• RS-232C and Keypad can't be used at the same time as they use a common connector.

When Keypad is connected, the data port isn't available. Only the sub port is available, but SBPL commands will be disabled.

When the interface other than [RS-232C] is set to the data port, the interface selection changes to [RS232C]. If [RS-232C] is set to the sub port, the interface selection changes to [NONE].

2.6.4 Connecting the Power Cable

1.

Connect the power cable to the AC IN power terminal on

the rear panel of the printer.

Make sure that the connector is correctly oriented.

Secure the printer with one hand, and insert the connector firmly.

2. Insert the power plug into a AC power outlet.

Make sure that the AC voltage of your region is within

the range of AC 100 to 240V, 50/60 Hz.

A 3-pin plug is attached to the power cord provided with

your printer. One of these pins is the ground wire.

If the power outlet that you plan to use is a 3-pin type,

simply insert the power plug as is.

* The shape of the power plug may vary depending on

the location where the printer was purchased.

Warning

• Be sure to connect the ground wire. Failure to do so may cause an electric shock.

• Do not operate the power switch or insert/remove the power cable while your hands are wet.

Doing so may cause an electric shock.

Caution

The power cable provided with this printer are for use with this printer only.

They cannot be used with other electrical devices.

Page 36

Section 2: Installation

Page 2-20 HR2 Series Operator Manual

2.6 BASIC CONNECTIONS (cont’d)

2.6.5 Turning On the Power

Turn on the power switch located on the front, bottom left

corner of the printer.

Press the side of the switch marked “I”.

• When you turn on the power, the printer start-up and

detect for the loaded media and ribbon. If the media are

correctly loaded, “ONLINE” appears on the display.

• If the media and carbon ribbon are not loaded or properly loaded, the printer will prompt an error message.

Load the media and carbon (refer to Section 2.3 Load-

ing Media and Section 2.4 Loading the Carbon Ribbon) and then press LINE button.

2.6.6 Turning Off the Power

When you have completed the printing job, turn the printer

off.

1. Press the LINE button to put the printer offline.

Be sure to confirm that the printer is in the offline status

before turning it off.

If there is any printed media remaining in the printer,

press FEED button to forward feed the media and cut it

off.

2. Turn off the power switch on the printer’s operation

panel.

Press the side of the switch marked “O”.

Warning

Do not operate the power switch or insert/remove the power cable while your hands are wet.

Doing so may cause an electric shock.

On Off

On

Off

Page 37

Section 2: Installation

HR2 Series Operator Manual Page 2-21

2.7 CONNECTIONS OF OPTIONAL ACCESSORIES

2.7.1 Connecting optional Keypad

The optional keypad can be connected to the HR2 Series printer with the RS-232C terminal, thus providing a

stand-alone function.

1. Make sure that power cable is not connected to the

printer.

2. Connect the cable from the optional Keypad device to

the RS-232C terminal at the rear of the printer.

Note:

Make sure the connector is correctly oriented. Secure

the printer with one hand, and insert the connector firmly.

3. Set the printer for use with the connected device. Refer

to Section 3.7 Interface Mode and perform the

procedures to set the Keypad CONNECT to ENABLE.

4. Then set the DATA PORT as RS-232C and the SUB

PORT as NONE.

Notes:

• Keypad needs to connect to RS-232C connector, and RS-232C interface are not able to use as data port

at the same time.

• You cannot use data port when Keypad is connected and the setting of Keypad connection is valid. (You

can use Sub Port, but SBPL command is not effective.)

2.7.2 Installing optional Memory storage

The optional SD card can be used for uploading and downloading the data (graphics, extended character)

registered in the printer and the printer firmware.

Installing optional SD card

You can connect the optional SD card to the SD card slot

located as shown in the picture.

SD card slot

Page 38

Section 2: Installation

Page 2-22 HR2 Series Operator Manual

2.7 CONNECTIONS OF OPTIONAL ACCESSORIES (cont’d)

1.

Insert the SD card with the orientation as shown in the picture.

2. To seat the SD card in the slot, press it in until it makes a

slight clicking sound and it is completely inside the printer.

3. To remove the SD card from the printer, it is best to switch

off the printer. Then, with your finger, press the card edge a

slight amount to release the card from the slot. The slot will

immediately release the card.

Note:

Do not remove the SD card while the printer is accessing the

data in the SD card. Doing so may result in data corruption.

Page 39

Section 2: Installation

HR2 Series Operator Manual Page 2-23

2.7 CONNECTIONS OF OPTIONAL ACCESSORIES (cont’d)

Folder Configuration

The following is the folder architecture inside the SD card to be used for the printer.

DATA

PROG

FONT

Firmware

Firmware : PRG41_XX.BIN (XX : Reg. No. 01 to 03)

SEMBL Program㸸SEMBL.BIN

Data for memory card command

Form overlay registration 㸸SBPLXXXX.OVL (XXXX : Reg. No.0001 to 0099)

Format registration : SBPLXXXX.FMT (XXXX : Reg. No. 0001 to 0999)

Graphic registration: SBPLXXXX.IMG (XXXX : Reg. No. 0001 to 0999)

BMP file registration : SBPLXXXX.BMP (XXXX : Reg. No. 0001 to 0999)

PCX file registration : SBPLXXXX.PCX (XXXX : Reg. No. 0001 to 0999)

Memory card 16x16 Extended character registration : SBPL16.BMF

Memory card 24x24 Extended character registration : SBPL24.BMF

PR41

SD card route

Download font / log

Download font data : USRFONTX.DAT(X : Reg. No. (1 to 6))

CONF

Printer configuration information

Printer configuration information file : PRN41.INI

RAS

Rasterized font

No corresponding files for HA200R/HR200

LOG

Maintenance

Receive buffer: RCVBUF.DAT

STATUS5 log : HISTSTS5.DAT

FRAM dump:FRAMDMP.DAT

Page 40

Section 2: Installation

Page 2-24 HR2 Series Operator Manual

2.7 CONNECTIONS OF OPTIONAL ACCESSORIES (cont’d)

Notes:

• In the folder architecture, the folders under [PR41] can be created by formatting the SD card in Memory

Card Mode.

- Be sure to format the SD card in Memory Card Mode. If formatting the SD card by Windows or other

methods, you may not be able to save or view the data.

- Attempting to download or upload the data without formatting the SD card properly will cause an

error preliminarily.

• Do not change file name and folder names under the folder [PR41].

• Inside the folders [PROG] and [FONT], if you save files other than released (or uploaded) firmware and

font files, the printer motion after download behavior or download may be unstable. Be sure not to save

any files unless they are released (or uploaded).

• Do not remove the SD card while the printer is accessing the SD card. Doing so may result in data corruption.

• When you save the data to the SD card by using the save-related SBPL commands, its file creation date

will be the firmware release date.

2.8 LCD POWER SAVING MODE

The LCD backlight is turned off for power saving when the printer is not operated for a specified period of

time. The time to turn off the LCD backlight can be set via the LCD POWER SAVING MODE SETTING screen

in the Advanced Mode. Please refer to Section 3.10 Advanced Mode for instructions.

2.8.1 Turning off the LCD Backlight

At the following conditions, the LCD backlight is turned off when the time specified on the LCD POWER

SAVING MODE SETTING screen has elapsed. In this function, only the LCD backlight is turned off and the

on-screen message remains the same.

• The printer has not received the print data (ESC+A~ESC+Z) in various interfaces.

* Omitting status return request and cancel request of each protocol and/or incorrect data.

• No button is pressed.

• The printer is not in error state.

• The printer is neither printing nor feeding paper.

• The printer is in online state, offline state, HEX dump mode or SEMBL mode.

* This function is disabled in the Download Mode.

2.8.2 Turning on the LCD Backlight

Following one of the instructions below will turn on the LCD backlight again.

• The printer received the print data from various interface boards.

* Omitting status return request and cancel request of each protocol and/or incorrect data.

• Some buttons are pressed.

• Printer error such as “Cover open” occurred.

• The printer started printing operation.

Pressing any button while the LCD backlight is off will turn on the LCD backlight only.

(The printer does not go offline by pressing the LINE button when the LCD backlight is off in online state.)

Page 41

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-1

OPERATION AND CONFIGURATION

Before using the printer, it is best to read this manual thoroughly first. Otherwise, you may disturb default

settings around which the instructional procedures in this manual are based upon.

The printer may be manually configured via the LINE, FEED, +, -, < and > buttons with the LCD display on the

operator panel of printer. All of the printer’s buttons are used either singularly, or in conjunction, to perform

configuration activities.

Many of these settings can also be controlled via software commands and in case of conflict between

software and control panel settings, the printer will always use the last valid setting. If you load a label job that

includes software settings and then enter a new setting via the LCD panel, the manually set values will be

used by the printer. If you set the values manually and then download a job with software settings, the

software settings will be used.

Page 42

Section 3: Operation and Configuration

Page 3-2 HR2 Series Operator Manual

3.1 OPERATOR PANEL

The operator panel locate on the front consist of two LED indicators, six momentary contact buttons and one

LCD display.

•LED indicators

When the printer is in normal mode, these two indicators notify the user of various status conditions:

• LINE button

Pressing this button toggles the printer between the online and offline mode. When the printer is online, it

is ready to receive data from host. This button acts as a pause during a print job by taking the printer

offline.

This button also function as returning to the previous item during various printer setting with the LCD display.

When performing long press during various printer setting, the screen will go back to [Mode Menu] directly.

• FEED button

Pressing this button feeds one blank label through the printer.

This button also function as determining the setting during various printer setting with the LCD display.

• + button

Incrementing setting value in various setting modes, or moving cursor up/down in menus.

Makes the LCD display darker in Online state.

• - button

Decrementing setting value in various setting modes, or moving cursor up/down in menus.

Makes the LCD display lighter in Online state.

• <, > arrow buttons

These cause the cursor to shift left and right for selecting item on the screen in various setting modes.

LED Indicator Color Functions

STATUS Green Illuminates when printer is ready to receive data or is in printing

mode (Online).

Light is off when the printer is in offline or error state.

Blinks when the printer detects buffer near full.

ERROR Red Illuminates or blinks when detecting printer error.

(5525

67$786

+

-

㸺

/,1(

)(('

㸼

Page 43

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-3

3.1 OPERATOR PANEL (Cont’d)

• LCD Display

Up to five icons and two lines of alphanumeric text can appear on the LCD display to indicate the current

printer status.

The same area can also display two lines of alphanumeric text during various setting modes.

List of Icons

[Mode display]

[Mode selection screen]

No Icon Description

1 Displayed when printer is in online state

2 Displayed when printer is in offline state

3 Displayed when printer is in Test Print Mode and HEX Dump Print Mode

4 Displayed when printer is in SEMBL Mode

5 Displayed when printer is in Download Mode

6 Displayed when Keypad is connected to printer

7 Displayed when printer is in Upload Mode

No Icon Description

1 Changing to Normal Mode

2 Changing to User Mode

3 Changing to Interface Mode

4 Changing to Cartridge Mode (Memory Card Mode)

5 Changing to SEMBL Mode

6 Changing to Advanced Mode

7 Changing to HEX Dump Print Mode

Page 44

Section 3: Operation and Configuration

Page 3-4 HR2 Series Operator Manual

3.1 OPERATOR PANEL (Cont’d)

List of Icons (Cont’d)

[Error-related]

[Warning-related]

No Icon Description

1 Displayed when detecting Label End

2 Displayed when detecting Ribbon End

3 Displayed when detecting Sensor Error

4 Displayed when detecting Top cover open and head lift error

5 Displayed when detecting electrical disconnection of print head

6 Displayed when detecting Communication Error

7 Displayed when detecting Receive Buffer Over

8 Displayed when detecting Item No. Error or BCC Error

9 Displayed when having write failure to main ROM or when detecting Kanji

ROM error

10 Displayed when detecting a command error due to the message display func-

tion of command error

11 Displayed when detecting an improper download data

12 Displayed when having a memory access error or when running out of mem-

ory space

13 Displayed when detecting printer error other than the above

14 Error number corresponding to each error

No Icon Description

1 Displayed when detecting Command Error

2 Displayed when detecting Receive Buffer Near Full

3 Displayed when detecting electrical disconnection of print head

Page 45

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-5

3.2 OPERATING MODES

The operating status of this printer can be set within one of the following modes:

1. Normal mode (including ONLINE/OFFLINE modes)

2. Adjustment screen

3. Cancel Print Job mode

4. Printer Setting mode:

• User mode

• Interface mode

• Cartridge mode (Memory Card mode)

• SEMBL mode

• Advanced Mode

•Hex Dump mode

5. Test Print mode

6. Default Setting mode

7. Maintenance mode

8. Service mode

9. Download mode

10.Upload mode

The various modes are accessed by pressing the LINE button, FEED button, + button, - button and <, > arrow

buttons while the printer is Off, On or with certain printer settings in force.

Page 46

Section 3: Operation and Configuration

Page 3-6 HR2 Series Operator Manual

3.2 OPERATING MODES (Cont’d)

The following flow chart provides a clear summary of all the modes and their access methods.

Switch Power

to On “ I ”

Power off

+ & < button

<, >, +, - buttons

<, >, +, - buttons

<, >, +, - buttons

<, >, +, - buttons

<, >, +, - buttons

<, >, +, - buttons

Menu screen

FEED

button

User Mode

FEED

button

Interface Mode

FEED

button

SEMBL Mode

FEED

button

Advance Mode

FEED

button

HEX Dump

Mode

FEED

button

Cartridge Mode

Mode

Adjustment

screen

Cancel print

job

< & > buttons

LINE &

FEED buttons

More operations are shown on the next page.

Online state

+

-

+

-

+

-

+

-

+

-

+

-

+

-

Offline state

LINE

button

63((' &

'$5.1(66 $

3,7&+

2))6(7

+

-

Page 47

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-7

3.2 OPERATING MODES (Cont’d)

FEED &

Power on

Power off

Test print Mode

LINE &

FEED &

Power on

+ & - &

Power on

Default setting

Mode

Maintenance

Mode

Download

Mode

Service Mode

Select SERVICE

MODE &

FEED button

&

Power on

FEED & &

& Power on

Upload

Mode

+ & - & < & Power on

*English LCD message in maintenance mode

Page 48

Section 3: Operation and Configuration

Page 3-8 HR2 Series Operator Manual

3.3 ONLINE AND OFFLINE MODES

The general and basic operation of the HR2 series printer is via the Normal mode, which consists of the

ONLINE and OFFLINE modes.

3.3.1 Online Mode

Pressing the LINE button causes the printer to go ONLINE or OFFLINE

alternately.

When the printer is ONLINE, the following activities will be possible:

• The printer is ready to receive print data from the computer or other connected devices

• The printer is ready to start printing

The number displayed on the bottom line of LCD panel shows the media

quantity status. As soon as a print job is received, the display on the bottom

will indicate the number of labels to be printed. When the label job begins to

print, this display will indicate the remaining number (countdown) of labels to

be printed.

Display method can be changed on the TOTAL QTY DISPLAY screen in the

service mode, refer to Section 3.16.5 Overview of Setting menu in Service

Mode for details.

When the TOTAL QTY DISPLAY screen is set as YES, the number displayed

on the bottom line of LCD panel shows the remaining number (countdown) of

labels to be printed on the left and the total quantity on the right (Total print

quantity from the time the printer is turned on).

3.3.2 Offline Mode

When the printer is ONLINE, pressing the LINE button once will cause the

printer to go OFFLINE. Any printing job will be PAUSE once the printer is

brought OFFLINE.

When the printer is OFFLINE, the activities for ONLINE mode are no longer

possible, but the following activities will be possible:

• The printer can feed a blank label when you press the FEED button.

• The printer can be switched to CANCEL PRINT JOB modes when you

press the LINE and FEED button simultaneously.

• The printer goes to Adjustment screen when you press the and arrow buttons simultaneously.

• In OFFLINE mode, press the + and buttons simultaneously to access the icon-based printer settings

menu. Using the arrow buttons, you can access the ONLINE mode, USER mode, INTERFACE mode,

SEMBL mode, ADVANCED mode, HEX DUMP mode and CARTRIDGE mode from here. These modes

will be discussed in subsequent sections.

3.3.3 To Adjust the Screen Contrast

In Normal mode (ONLINE or OFFLINE), press the +/- buttons repeatedly to adjust the contrast.

remaining number

(countdown) of

labels to be printed

total printed

quantity

remaining number

(countdown) of

labels to be printed

When TOTAL QTY DISPLAY is set

as YES (Default)

When TOTAL QTY DISPLAY is set

as NO

remaining number

(countdown) of

labels to be printed

total printed

quantity

Page 49

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-9

3.4 ADJUSTMENT SCREEN

The printer has a quick access to the Adjustment screen for setting the print position, stop position and the

print darkness. These adjustments are in conjunction with the configuration adjustments done in the Service

mode menu and the User mode menu.

1. When the printer is OFFLINE, pressing both the and arrow buttons at the same time will switch the

printer to Adjustment mode. The setting screen is displayed.

2. Press +/- buttons to set the desired value and press FEED button to save the setting and proceed to the

next Adjustment screen.

3. After adjustment, press LINE button to exit the Adjustment screen and returns to OFFLINE mode.

Pressing the LINE button before pressing the FEED button will not save the adjustment.

You may wish to print a test print after completing the adjustments to ensure they are correct. Refer to

Section 3.13 Test Print Mode for details.

Press FEED button

Press & button

* Press + or - button to set the value.

63((' &

'$5.1(66 $

3,7&+

2))6(7

+

-

63(('

'$5.1(66 $

3,7&+

2))6(7

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

Press FEED button

+

-

Press FEED button

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

Press FEED button

Press FEED button

QTY=0

47<

&

Press FEED button

Press LINE button

Press LINE button

Press LINE button

Press LINE button

Press LINE button

Press LINE button

Page 50

Section 3: Operation and Configuration

Page 3-10 HR2 Series Operator Manual

3.4 ADJUSTMENT SCREEN (Cont’d)

Menu Description

Adjust the print speed.

Setting range is between 1.0 and 4.0IPS, and the initial value is 2.0IPS.

This setting reflects the setting of PRINT SPEED screen in USER MODE.

Command priority setting.

C: Enables Command priority setting.

I: Disables Command priority setting.

The default setting is "C".

This setting reflects the setting PRIORITY SETTING screen in SERVICE

MODE.

Adjust the print darkness of the print-out.

Setting range is 1A, 2A, 3A, 4A, 5A, 1B, 2B, 3B, 4B, 5B. (1A is the lightest

while 5B is the darkest. Default is “3A”)

This setting reflects the setting of PRINT DARKNESS screen in USER

MODE and the DARKNESS RANGE screen in ADVANCED MODE.

Setting value of the selected range is between 00 and 99, and the initial

value is 50. (00 is the lightest while 99 is the darkest.)

After setting the value of print darkness, press FEED button will save the

value and proceed to PITCH position setting if there is no remaining label to

be printed. (QTY=0)

Otherwise, the printer will return to SPEED setting screen. (QTY≠0)

Note:

It is not advisable to set the print darkness to the higher position as a darker

print-out requires the print head to operate in a higher temperature. Operating in high temperature may damage the print head in a long run.

Adjusts the print position or reference point where the printings begins vertically, relative to the leading edge of each media.

Setting value is adjustable by 0.25mm (0.01") regardless of print resolution.

Setting range is ±3.75mm (±0.15") and the initial value is +0.00mm.

Adjust the stop position of each media after printing.

Setting value is adjustable by 0.25mm (0.01") regardless of print resolution.

Setting range is ±3.75mm (±0.15") and the initial value is +0.00mm.

63((' &

'$5.1(66 $

3,7&+

2))6(7

+

-

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

63(('

'$5.1(66 $

3,7&+

2))6(7

+

-

&

Page 51

Section 3: Operation and Configuration

HR2 Series Operator Manual Page 3-11

3.5 CANCEL PRINT JOB MODE

1. When the printer is OFFLINE, pressing both the LINE and FEED buttons at the same time will switch the

printer to CANCEL PRINT JOB mode. The menu for canceling the print job then appears.

2. Press , arrow buttons to switch between the selection, YES or NO. The highlight on display indicates

the selected option. The default setting is NO.

If the printer has a print job in memory, selecting YES will cause the job to be cleared.

Notes:

• Be sure you want to cancel the print job before selecting YES as the job cannot be recovered and will

have to re-transmit to the printer.

•Select NO press FEED button to exit the CANCEL PRINT JOB mode without clearing the print data.

3. Press FEED button to activate the selection.

If YES is selected, the message CANCEL PRINT JOB COMPLETED will display with 3 beeps sound and

then goes to ONLINE mode. All the print jobs were cleared from memory.

Select “YES” +

FEED button

3 beep sound

LINE + FEED

buttons

Select

“NO” +

FEED button

Page 52

Section 3: Operation and Configuration

Page 3-12 HR2 Series Operator Manual

3.6 USER MODE

The following settings are available in the User Mode.

FEED button

FEED button

FEED

button

LINE

button

FEED

button

LINE

button

FEED

button

LINE

button

FEED

button

LINE

button

FEED

button

LINE

button

Displayed only when entry

of PASSWORD is enabled

Return to USER MODE menu