Page 1

GT408/412/424e

Printer

OPERATOR MANUAL

PN 9001138C

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support Hotline: (704) 644.1660

Technical Support Fax: (707) 644.1661

E-Mail: satosales@satoamerica.com

technical support@satoamerica.com

www.satoamerica.com

WARNING

THE EQUIPMENT REFERENCED IN THIS DOCUMENT COMPLIES WITH THE REQUIREMENTS IN

PART 15 OF FCC RULES FOR A CLASS B COMPUTING DEVICE. OPERATION OF THIS EQUIPMENT

IN A RESIDENTIAL AREA MAY CAUSE UNACCEPTABLE INTERFERENCE TO RADIO AND TV

RECEPTION.

Page 3

TABLE OF CONTENTS

INTRODUCTION

About This Manual 1-2

General Description 1-3

Control Features 1-4

TECHNICAL DATA

Physical Characteristics 2-2

Power 2-2

Enviromental 2-2

Processing 2-2

Command 2-2

Interface Modules 2-2

Print 2-3

Media 2-3

Ribbon 2-3

Sensing 2-3

Character Font Capabilities 2-4

Barcode Capabilities 2-5

Regulatory 2-5

INSTALLATION

Unpacking & Parts Identification 3-2

Printer Installation 3-2

Site Location 3-3

Cable Connection 3-3

Media Selection 3-4

Media & Ribbon Loading 3-4

Interface Selection 3-6

RS232C Serial Interface 3-6

IEEE1284 Parallel Interface 3-8

Universal Serial BUS (USB) Adapter 3-9

Local Area Network (LAN) Ethernet 3-9

802.11B Wireless 3-9

Receive Buffer 3-10

ACK/NAK Protocol 3-10

Accessories Installation 3-11

External Signal Connector 3-11

Memory Expansion 3-12

Interface Upgrade 3-13

Label Cutter 3-14

Label Peeler 3-14

PN 9001138C

Page 4

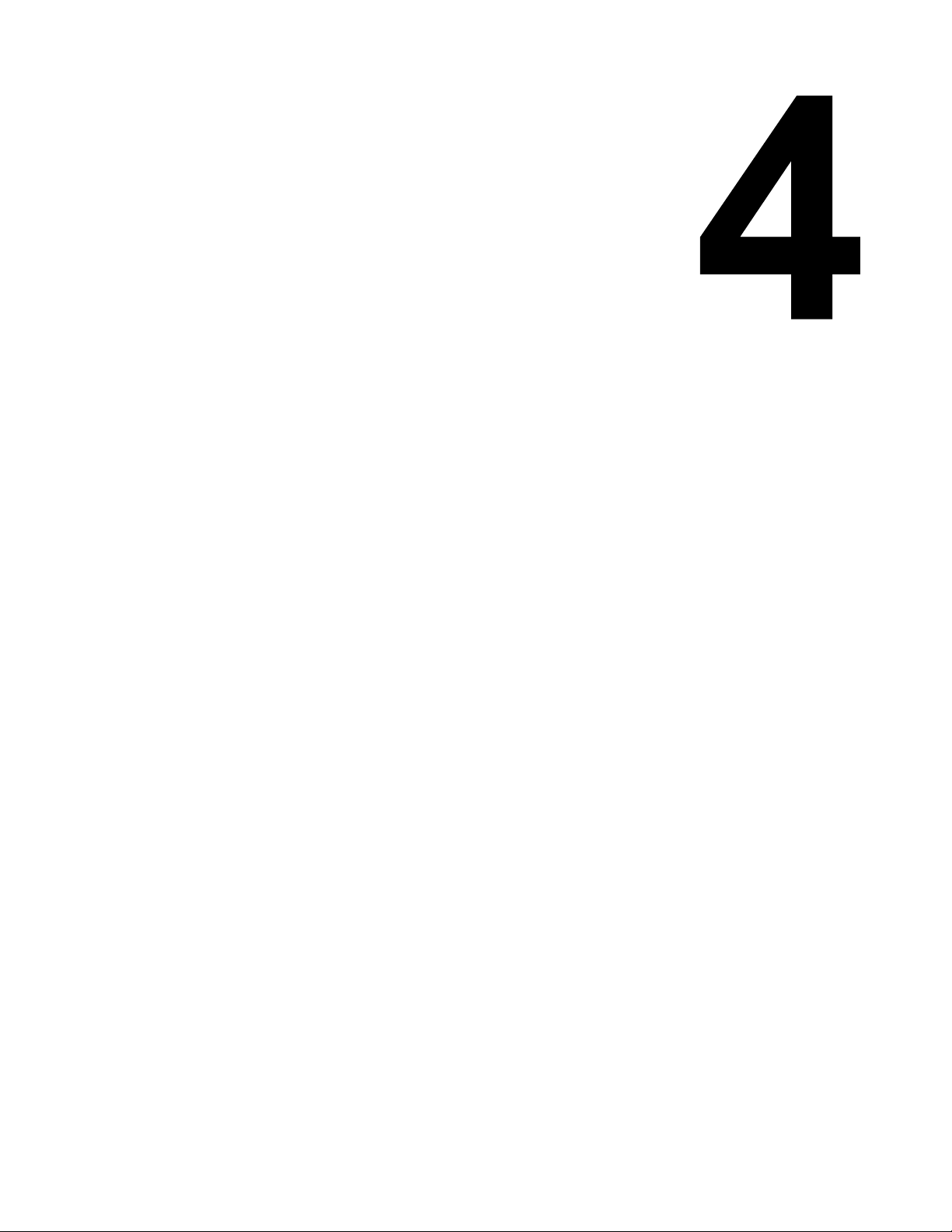

PRINTER CONFIGURATION

Configuration Modes 4-2

Normal Mode 4-2

User Mode 4-3

Advanced Mode 4-4

IEEE1284 Interface Setup Mode 4-5

RS232C Interface Setup Mode 4-6

Centronics Interface Setup Mode 4-7

LAN Interface Setup Mode 4-8

USB Interface Setup Mode 4-9

Cartidge Mode 4-10

SEMBL Mode 4-11

Test Print Mode 4-12

Download Mode 4-13

Hex Dump Mode 4-14

Boot Download Mode 4-15

Data Save Mode 4-16

Default Settings Mode 4-17

Print Cancel Mode 4-18

Print Darkness Default Mode 4-19

Service Mode 4-20

Factory Mode 4-21

Screen Identification 4-22

TROUBLESHOOTING

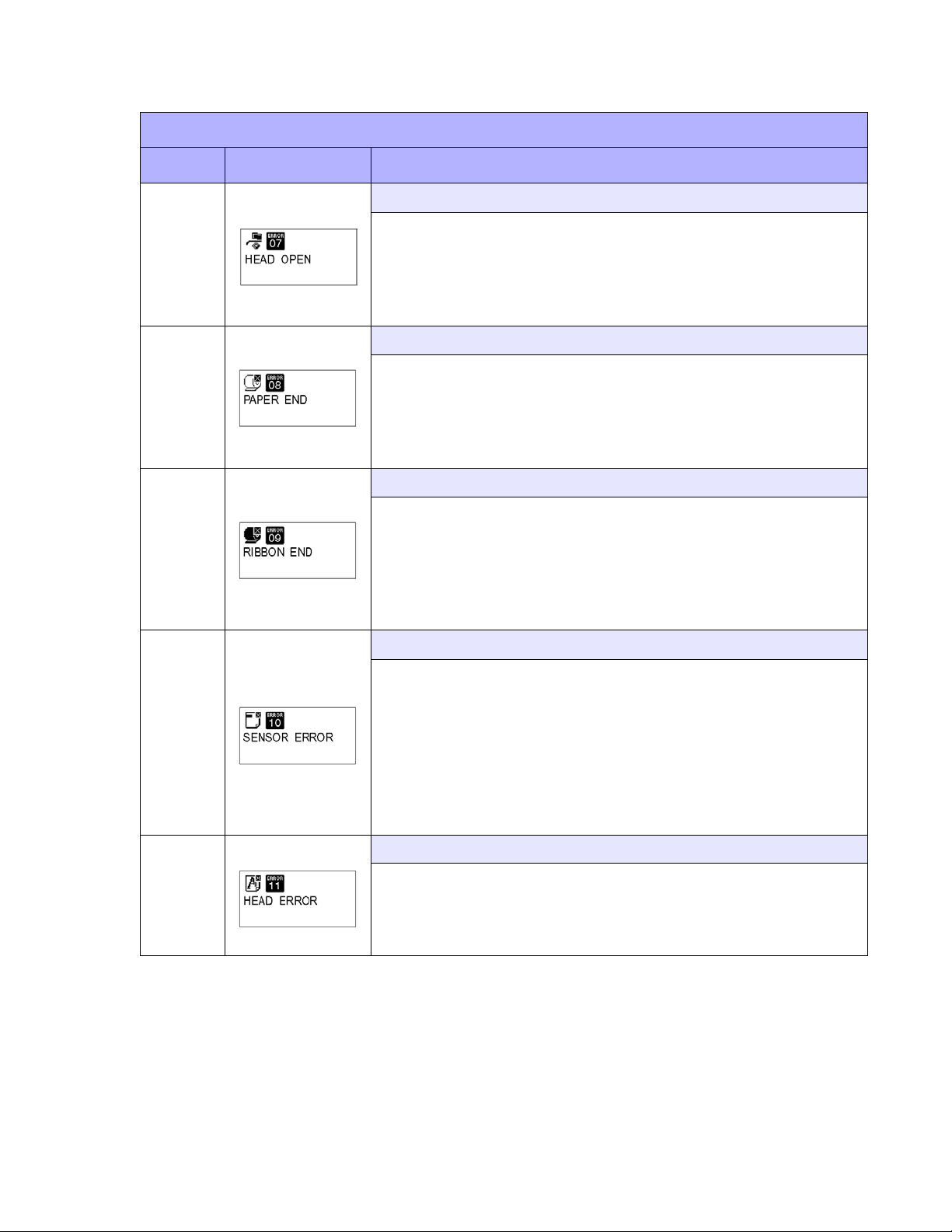

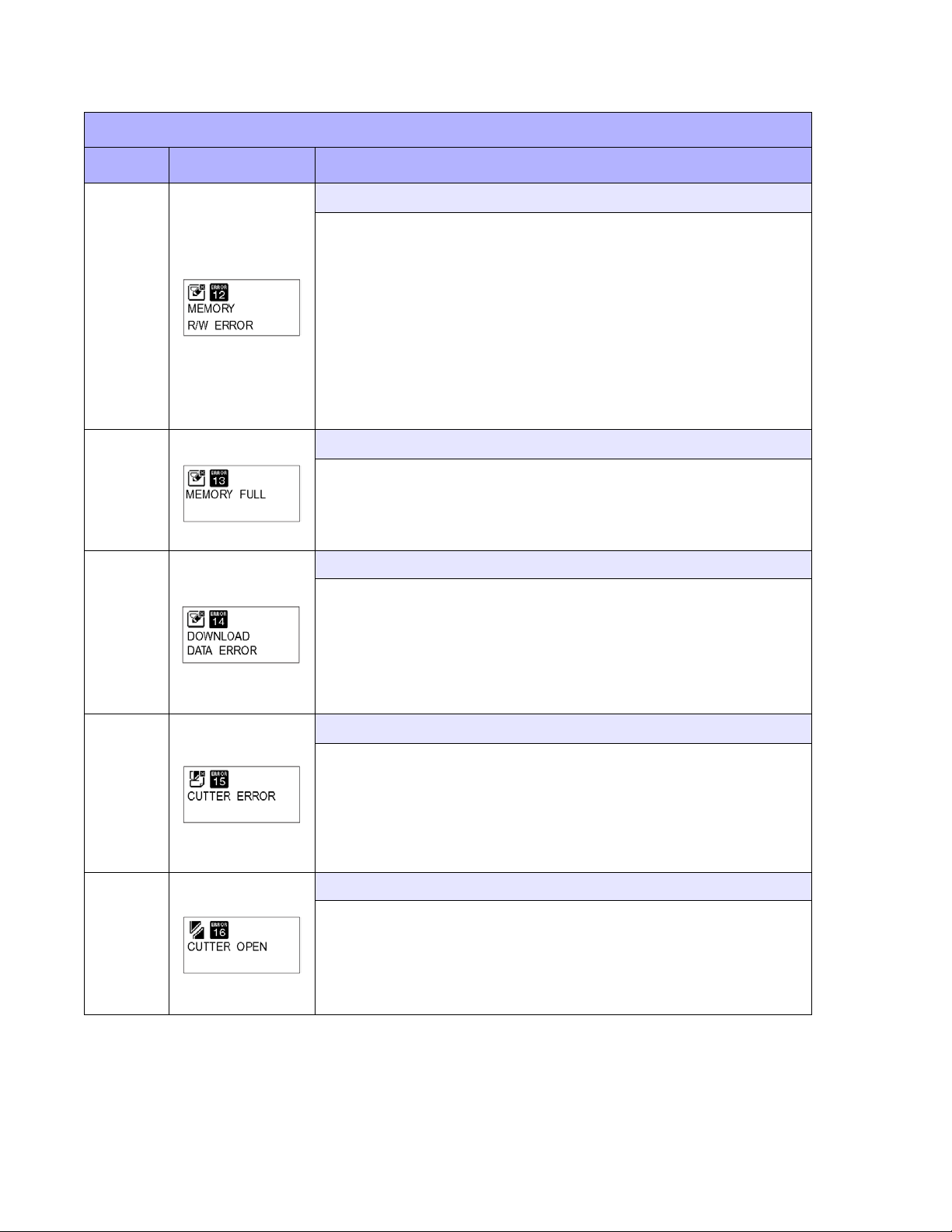

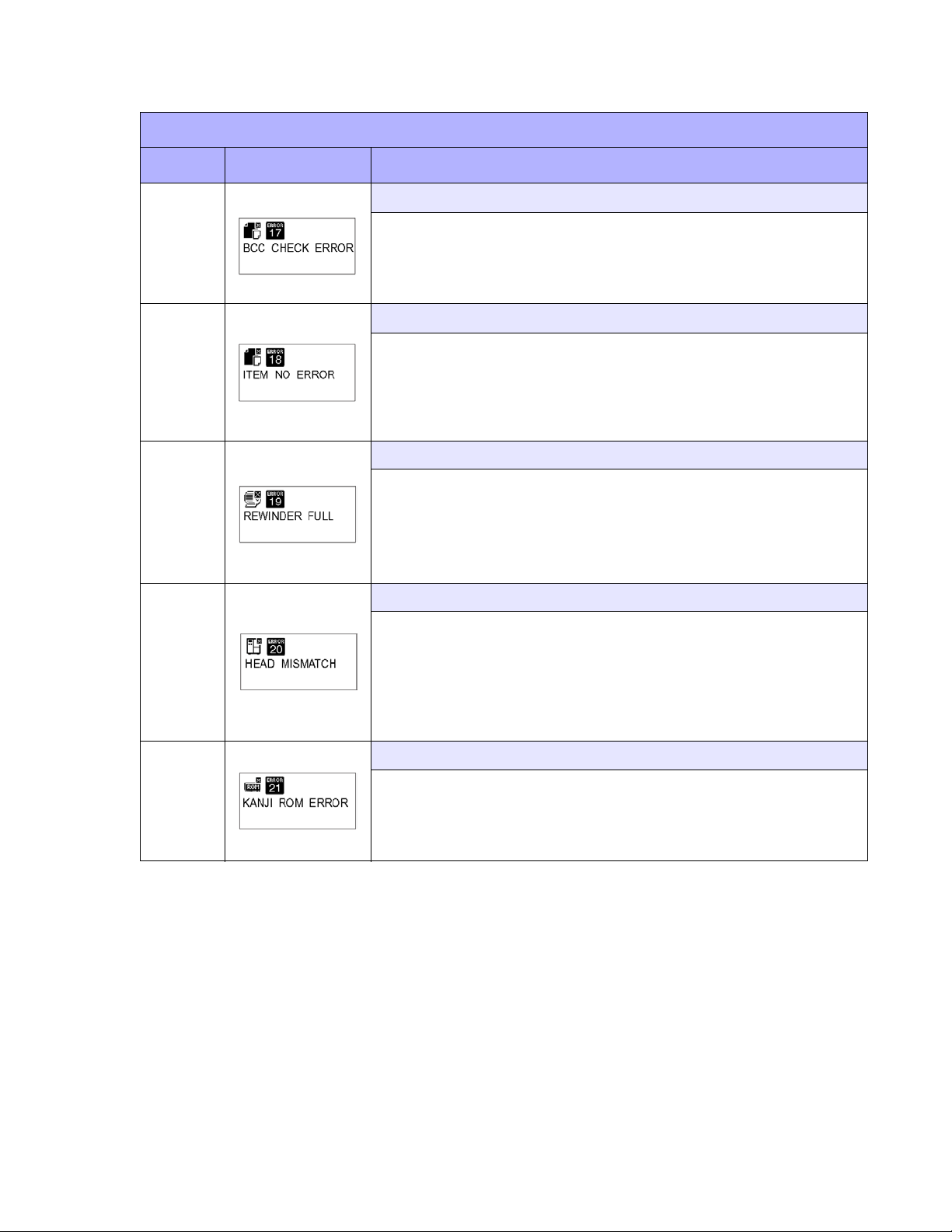

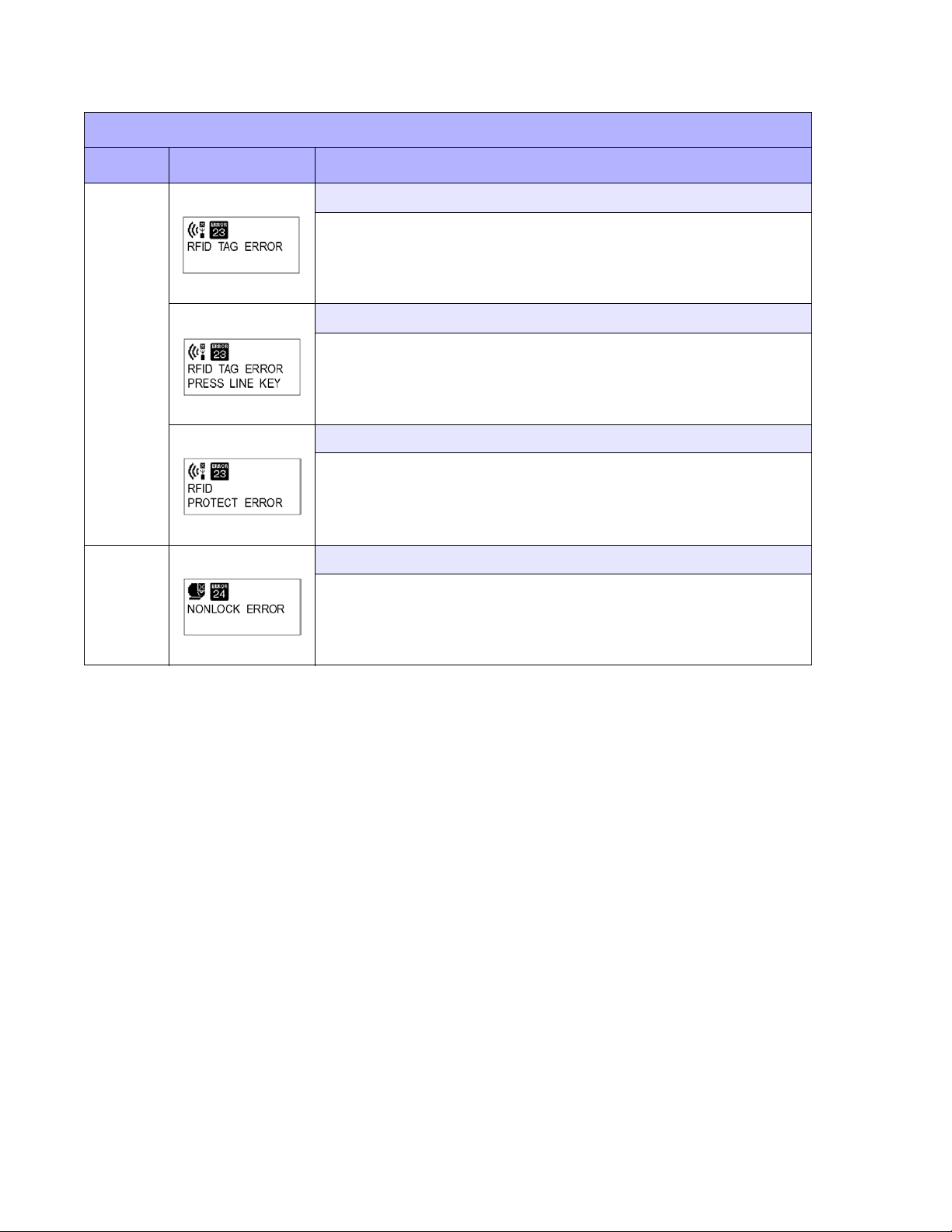

Error Signals 5-2

Troubleshooting Table 5-7

Interface Troubleshooting 5-9

Parallel Interface 5-9

RS232 Serial Interface 5-9

LAN Ethernet Interface 5-10

Universal Serial Bus (USB) Interface 5-10

Test Print Troubleshooting 5-11

Hex Dump Mode 5-11

Test Label Printing 5-12

Sensor Locations 5-14

MAINTENANCE

Cleaning Procedures 6-2

Replacement Procedures 6-3

Print Head 6-3

Platen Roller 6-4

Adjustment Procedures 6-6

Print Head Alignment 6-6

Print Head Pressure 6-7

Print Head Balance 6-8

Ribbon Guide 6-9

Label Sensor Positioning 6-10

Potentiometer Adjustments 6-11

PN 9001138C

Page 5

INTRODUCTION

• About This Manual

• General Description

• Control Features

SATO GT4xxe Series Operator Manual PN 9001138C Page 1-1

Page 6

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information

required for printer maintenance and repair by SATO approved personnel. For the repair

technician, this manual is intended to compliment, and to be used as an extension of, owner/

operator literature.

This manual also incorporates the use of special information boxes. Examples of these boxes

and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN PRESONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN EQUIPMENT DAMAGE.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

LCD DISPLAY: Provides the specific display that should be visible on

the LCD at that point.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different Units, Chapters, and Sections. Each

references the page number of their commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying

his or her exact position within the manual. The header provides the section number followed by

its name. The footer identifies the product on the left, the manual’s part number in the center, and

the page number to the right side of the page.

Page enumeration is two-part with each separated by a hyphen. The first character set

references the Unit and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new unit and ascends sequentially.

SATO GT4xxe Series Operator Manual PN 9001138C Page 1-2

Page 7

Unit 1: Introduction

GENERAL DESCRIPTION

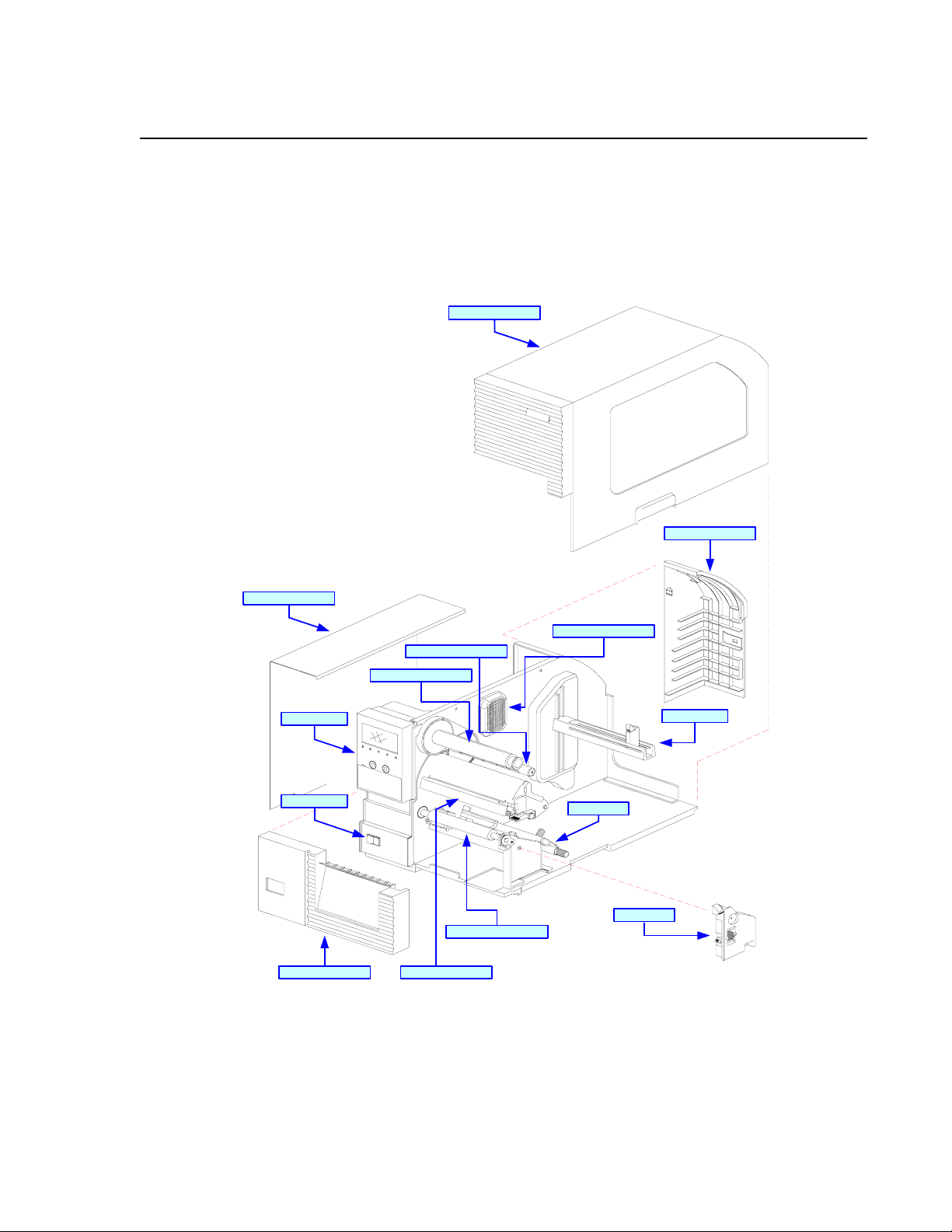

The GT4xxe series printer is a high-performance printer capable of printing all popular bar codes

and twelve human-readable fonts; providing an inventory of thouasnds of styles and sizes. Its

heavy metal construction is designed to deliver optimum performance in demanding

environments.

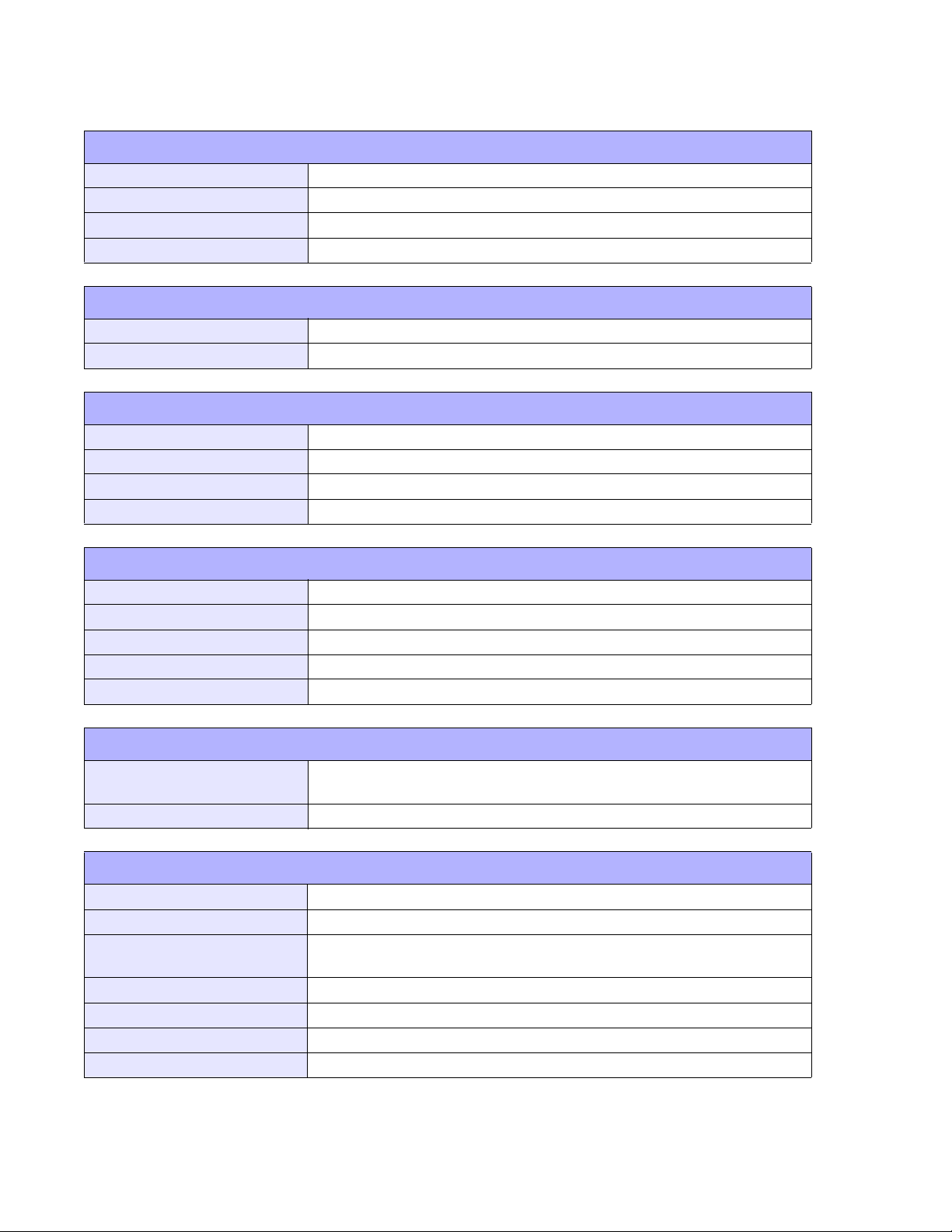

Top Housing Cover

Left Housing Cover

Operator Panel

Power Switch

Front H ousing Cover

Rear Housing Cover

Memory Card Access

Ribbon Supply Spindle

Ribbon Rewind Spindle

Media Holder

Media Guide

Side Cover

Platen Rolle r Assembly

Print Head Assembly

Figure 1-1a, Primary Components

SATO GT4xxe Series Operator Manual PN 9001138C Page 1-3

Page 8

Unit 1: Introduction

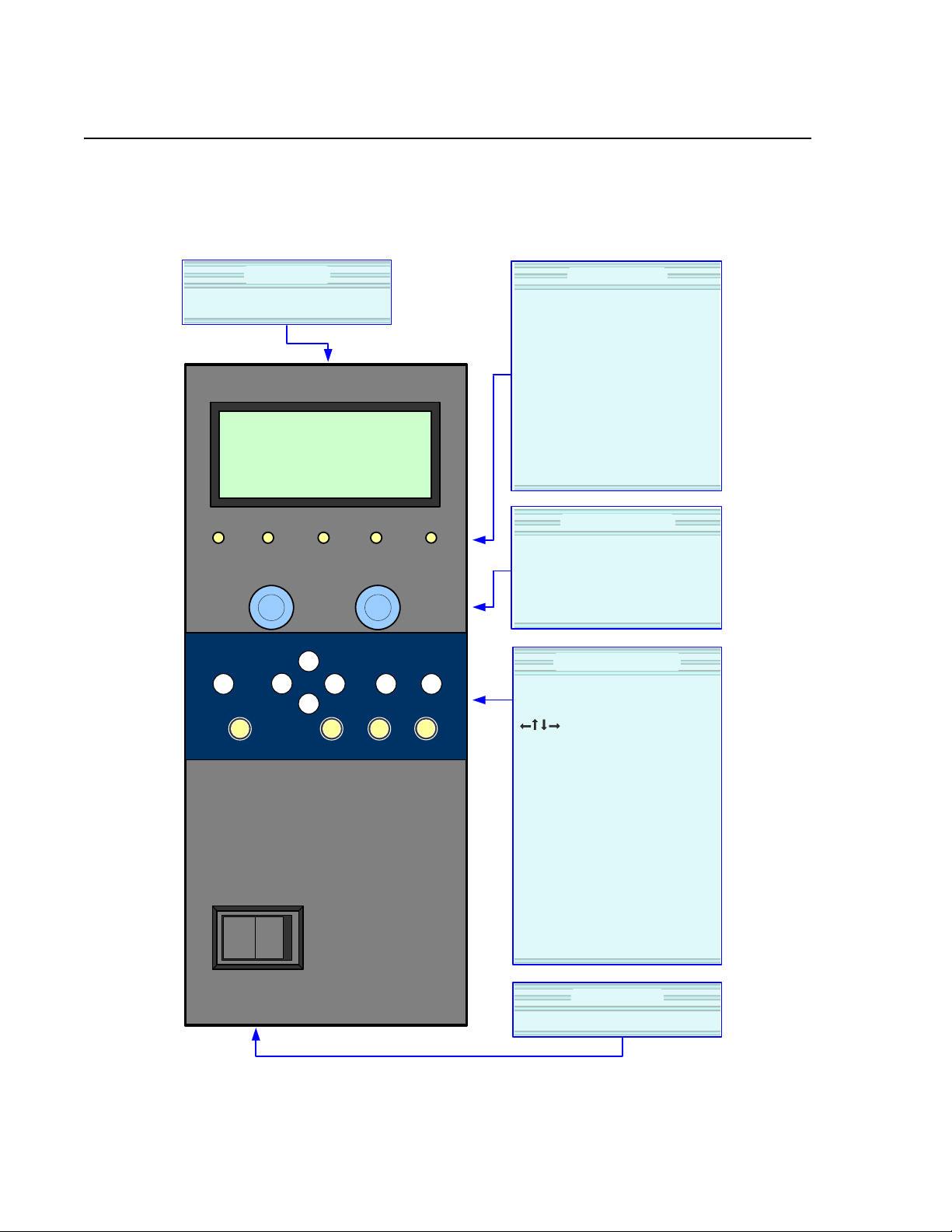

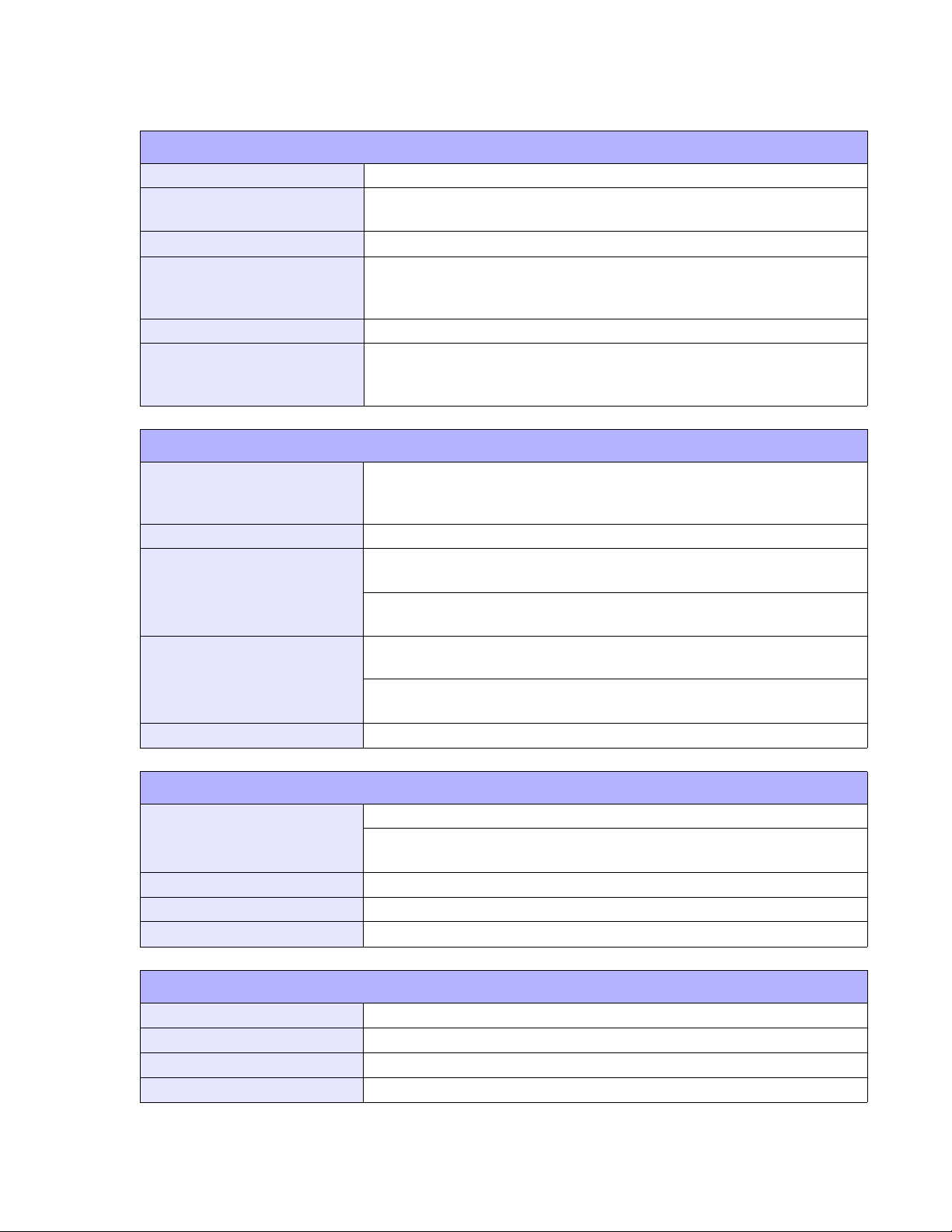

CONTROL FEATURES

This chapter identifies the interactive control features of the printer. These functions are

generally defined here. More specific explainations will be found throughout this manual on how

to use them.

LCD Display

Communicates operational conditions via the use

of icons and text.

POWER ON LINE STATUS LABEL RIBBON

LINE

FUNCTION

VOLUME PITCH OFFSET DARKNESS

FEED

ENTER

CANCEL

LED Indicators

POWER

Illuminates when the power on.

ONL INE

Illuminates when communication is available .

Flashes when fails.

STAT US

Flashes when an error occurs. Flashes when

sending/receiving data.

LABEL

Flashes when paper error occurs.

RIBBON

Flashes when ribbon error occurs.

Operator Buttons

FEED

Feeds the equivalent of a sheet of paper when

pressed once. Posit ions paper if misaligne d .

LINE

Starts and stops printing and transmission of

data.

Maintenance Panel

FUNCTION

Allows movement through the various menus

and modes.

Permits the movement of the cursor for input.

ENTER

Allows the selection of an option .

CANCEL

Cancels a print job. Allows return to the previous

screen when moving through the menus.

VOLUME

For buzzer volume adjustment.

PITCH

For adjusting print position.

OFF SET

Adjusts cut , peel, and tear-off stop positions.

DARKNESS

Adjust s pr int densit y .

Power Switch

Breaks the circuit providing power to the printer.

Figure 1-2, Operator Panel

SATO GT4xxe Series Operator Manual PN 9001138C Page 1-4

Page 9

TECHNICAL DATA

• Physical Characteristics

•Power

• Enviromental

• Processing

•Print

•Media

•Ribbon

• Sensing

• Interface Modules

• Character Font Capabilities

• Barcode Capabilities

• Regulatory Approvals

SATO GT4xxe Series Operator Manual PN 9001138C Page 2-1

Page 10

Unit 2: Technical Data

PHYSICAL CHARACTERISTICS

Width 10.67 Inches (271 mm)

Height 12.00 Inches (305 mm)

Depth 17.90 Inches (455 mm)

Weight 33.07 Pounds (15.0 Kg) standard

POWER

Input Voltage 100-240 Volts AC +/- 10%, 50/60 Hertz +/-5%

Power Consumption 200 Volts/150 Watts Operating, 89 Volts/40 Watts Idle

ENVIRONMENTAL

Operating Temperature 32° to 104°F (0° to 40°C)

Storage Temperature 23° to 140°F (-5° to 60°C)

Storage Humidity 30 to 90% RH Non-Condensing

Operating Humidity 30 to 80% RH Non-Condensing

PROCESSING

CPU 32 Bit RISC

FLash ROM 2 Megabytes

SDRAM 4 Megabytes

Receive Buffer 2.95 Megabytes

Extended Memory Flash Memory Board (8 Megabytes)

COMMAND

Standard

Optional SATO Embedded Basic Language (SEMBL)

SATO Barcode Printer Language (SBPL)

Intelligent Command

INTERFACE MODULES

Enhanced Parallel Port IEEE1284 (ECP Compatible)

Centronics Parallel Port Centronics

Serial Port

Universal Serial Bus USB Adapter (12 Mbps)

LAN 10BASE-T/100BASE-TX Automatic Switching

Ethernet (Wireless LAN) 10/100 Base T, 802.11B Wireless Wi-Fi

Mini LAN 10BASE-T/100BASE-TX Automatic Switching

RS232C (9600 to 57,600 bps) Standard

RS422/485 (9600 to 57600 bps) Optional

SATO GT4xxe Series Operator Manual PN 9001138C Page 2-2

Page 11

Unit 2: Technical Data

PRINT

Method Direct Thermal / Thermal Transfer

Speed (user selectable)

Print Module (dot size) .0049 Inches (.125 mm)

Resolution

Maximum Print Width 4.10 Inches (104 mm)

Maximum Print Length

Thermal Transfer: 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 Inches Per Second

Direct Thermal: 2, 3, 4, 5, 6 Inches Per Second

203 Dots Per Inch (8 dpmm)

305 Dots Per Inch (12 dpmm)

609 Dots Per Inch (24 dpmm)

GT408 Printer: 98.43 Inches (2500 mm)

GT412 Printer: 59.06 Inches (1500 mm)

GT424 Printer: 15.75 Inches (400 mm)

MEDIA

Roll Paper: 10.43 Inch (265 mm) maximum diameter.

Roll Media

Fan-Fold Media Maximum folded height: 7.87 Inches (200 mm)

Standard Mode

Te ar - Of f

Thickness 0.002 to 0.010 Inches (0.06 - 0.268 mm)

Core Size: 1.5, 3, 4 Inch (38.1, 76.2, 101.6 mm) internal diameter.

Wound: Face In / Face Out. Face Out is for linerless only.

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Length: 0.24 to 5.04 Inches (6-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Length: 0.35 to 15.75 Inches (9-400 mm)

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Pitch: 0.67 to 5.04 Inches (17-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Length: 0.79 to 15.75 Inches (20-400 mm)

RIBBON

Minimum: 1.56 Inches (39.5 mm)

Width

Length 492 yards (450 m) roll.

Wound Face In / Face Out.

Roll Diameter 3.34 Inches (85 mm)

Maximum: 1.77, 2.32, 2.99, 3.31, 3.62, 4.02, 4.37, 5.04

(45, 59, 76, 84, 92, 102, 111, 128 mm)

SENSING

Gap Adjustable

Reflective Eye-Mark Adjustable

Label Adjustable

Continuous Form Sensor not used.

SATO GTxxe Series Operator Manual PN 9001138C Page 2-3

Page 12

Unit 2: Technical Data

CHARACTER FONT CAPABILITIES

MATRIX FONTS

U 5 dots W x 9 dots H

S 8 dots W x 15 dots H

M 13 dots W x 20 dots H

XU 5 dots W x 9 dots H (Helvetica)

XS 17 dots W x 17 dots H (Univers Condensed Bold)

XM 24 dots W x 24 dots H (Univers Condensed Bold)

OA Font (OCR-A)

OB Font (OCR-B)

AUTO SMOOTHING FONTS

WB 18 dots W x 30 dots H

WL 28 dots W x 52 dots H

XB 48 dots W x 48 dots H (Univers Condensed Bold)

XL 48 dots W x 48 dots H (Sans Serif)

VECTOR FONT

Proportional or Fixed Spacing

Font Size 50 x 50 dots to 999 x 999 dots

Helvetica, 10 Font Variations

AGFA RASTER FONTS

A Font CG Times, 8 to 72 pt.

B Font CG Triumvirate, 8 to 72 pt.

DOWNLOADABLE FONTS

Bit Mapped True Type Fonts with Utility Program

CHARACTER CONTROL

Expansion up to 12 x in either the X or Y coordinates.

Character Pitch Control

Line Space Control

Journal Print facility

0, 90, 180, and 270 Degree Rotation

SATO GT4xxe Series Operator Manual PN 9001138C Page 2-4

Page 13

Unit 2: Technical Data

BAR CODE CAPABILTIES

UPC-A/E

CODABAR

Code 39

Code 93

Code 128

Interleaved 2 of 5

Linear Bar Codes

Two Dimemsional

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User progammable

Rotation 0, 90, 180, and 270 Degrees

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Expansion Ratio of Character Height: 1-12 times, Width: 1-12 times

Graphics Full dot addressable graphics, SATO Hex/Binary, BMP or PCX formats

Form Overlay Form overlay for high-speed editing of complex formats

Matrix 2 of 5

Bookland

RSS-14

MSI

POSTNET

UCC/EAN 128

Customer Barcode

QR Code

Data Matrix

Macro BDF

Maxi Code

PDF417

Micro PDF417

Truncated PDF

QR Code

NW-7 (Codabar)

Composite Symbology

REGULATORY

Safety EN 55022 (Class B), UL (CUL), TUV

Radiant Noise VCCI (Class B)

AC Line Noise Over 1000V p-p

Static Electricity IEC (Level 3)

SATO GTxxe Series Operator Manual PN 9001138C Page 2-5

Page 14

Unit 2: Technical Data

SATO GT4xxe Series Operator Manual PN 9001138C Page 2-6

Page 15

INSTALLATION

• Unpacking

• Parts Identification

• Printer Installation

• Interface Selection

• Accessories Installation

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-1

Page 16

Unit 3: Installation

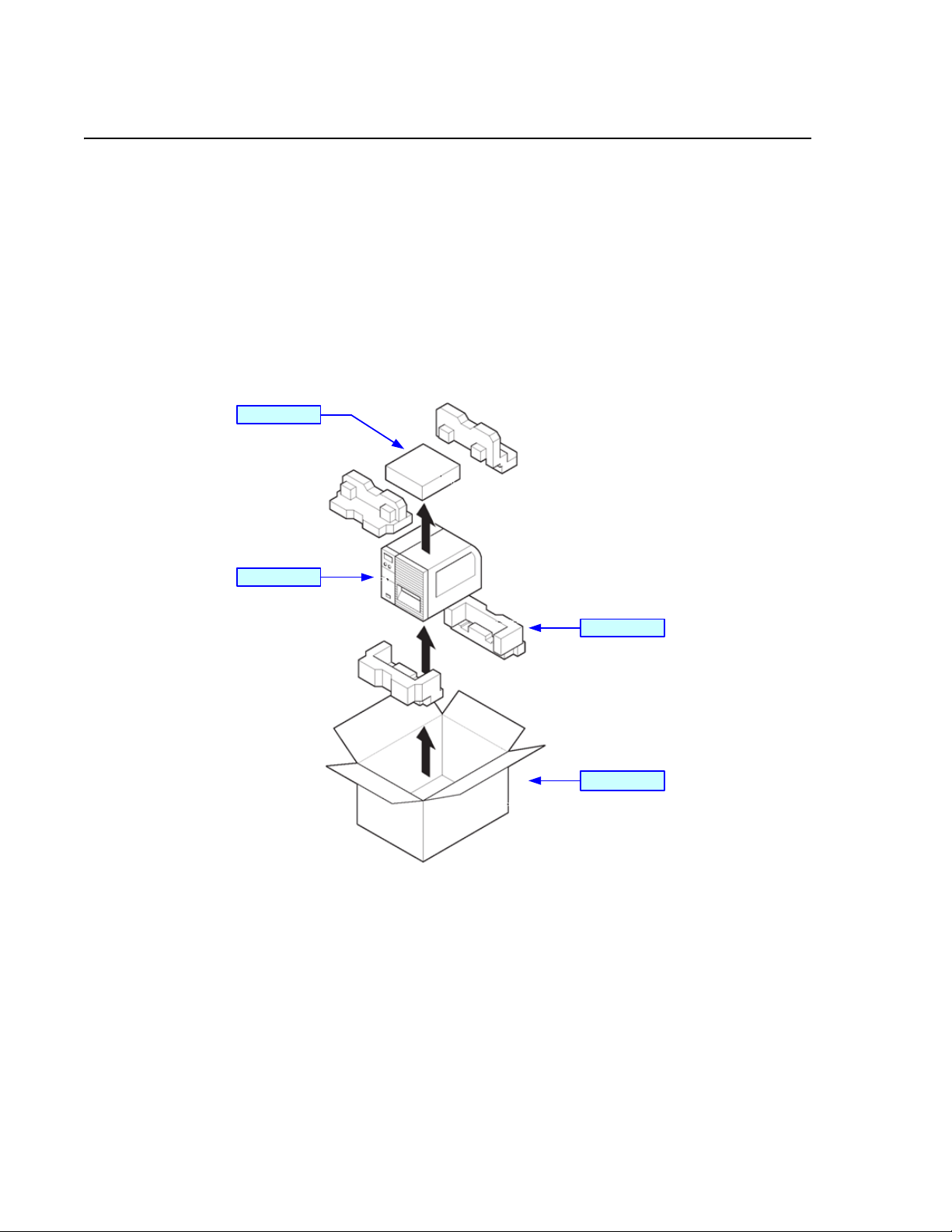

UNPACKING & PARTS IDENTIFICATION

Unpack the printer as directed in the following procedure.

1 Place the shipping container (box) upright on a soid, flat surface.

2 Open the box, remove any loose items and the first layer of packing material.

3 Carefully lift the printer and accessories from the box and place them on a solid flat surface.

4 Remove the plastic covers from the packed items and visually inspect for physical damage.

5 Ensure all components are present as dictated on the Packing List.

6 Report damaged property.

Accessory Bo x

Printer

Cushion

Shipping Container

Figure 3-1, Unpacking

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-2

Page 17

Unit 3: Installation

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked.

Following printer setup, procede to the next chapter for information on interface selection.

SITE LOCATION

• Stationed on a solid flat surface.

• Stationed away from hazardous materials.

• Stationed within operational distance of the host based on interface specifications.

CABLE CONNECTION

The procedure below provides instruction on typical cable connection. The same procedure will

apply to others that are not mentioned, but their connectors are also located behind the rear

housing cover.

1 Press the rear housing ocver catch and remove laterally (Figure 3-2a).

2 Locate and identify the required connectors (Figure 3-2b).

3 Connect the power supply and interface cables to their respective connectors (Figure 3-2c).

4 Replace rear housing cover (Figure 3-2d).

Rear Housing Cover

Interface Connectors

Figure 3-2a

Housing Cover Catch

Power Supply Connector

Figure 3-2b

Rear Housing Cover

Pull Prevent ion Slot

Figure 3-2c

Figure 3-2d

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-3

Page 18

Unit 3: Installation

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration

before printer purchase. Ideally, the media width will be equal to, or just narrower than, the print

head. Using media that does not cover the print head will allow the platen roller to tread on it and

wear it out. The media edge will also wear a groove in the platen roller affecting print quality.

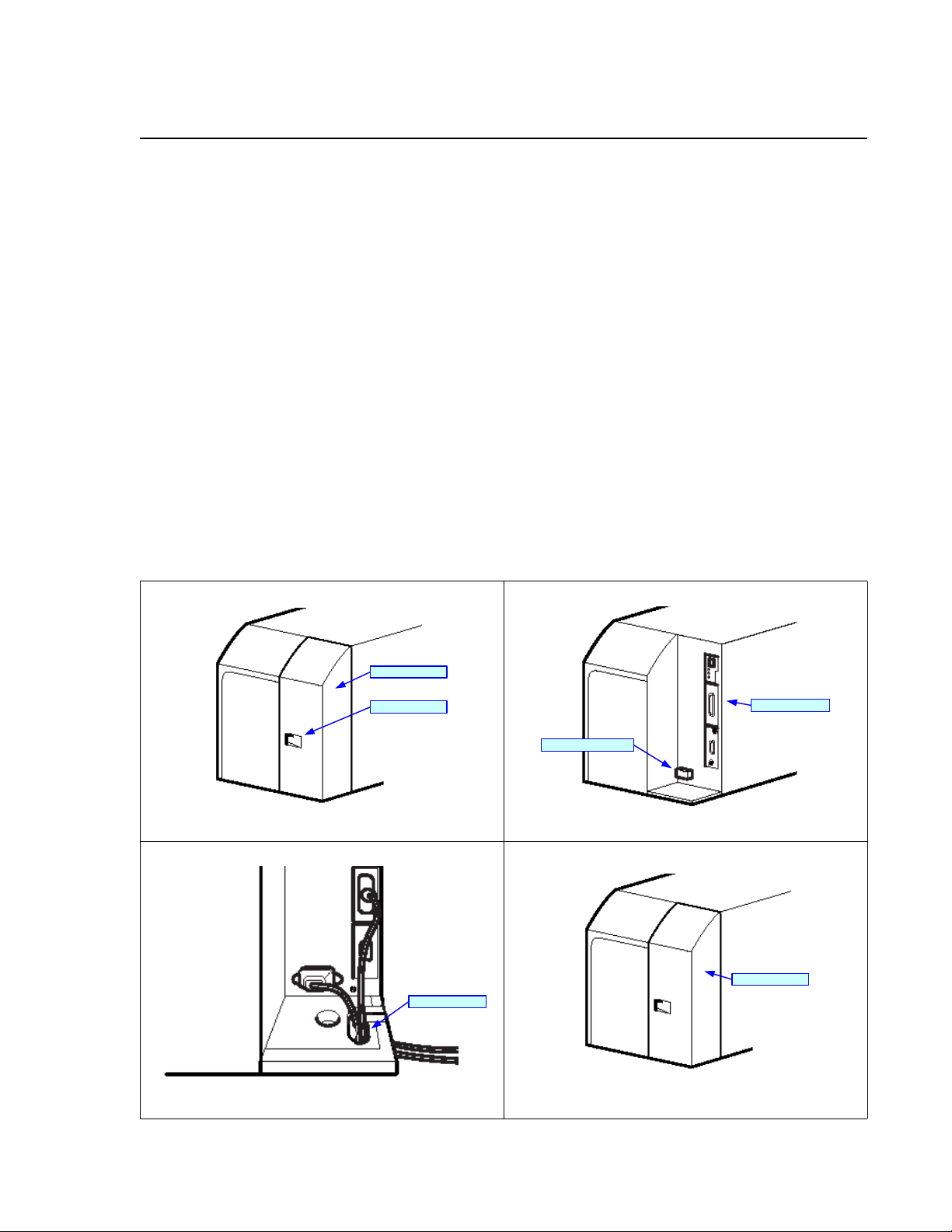

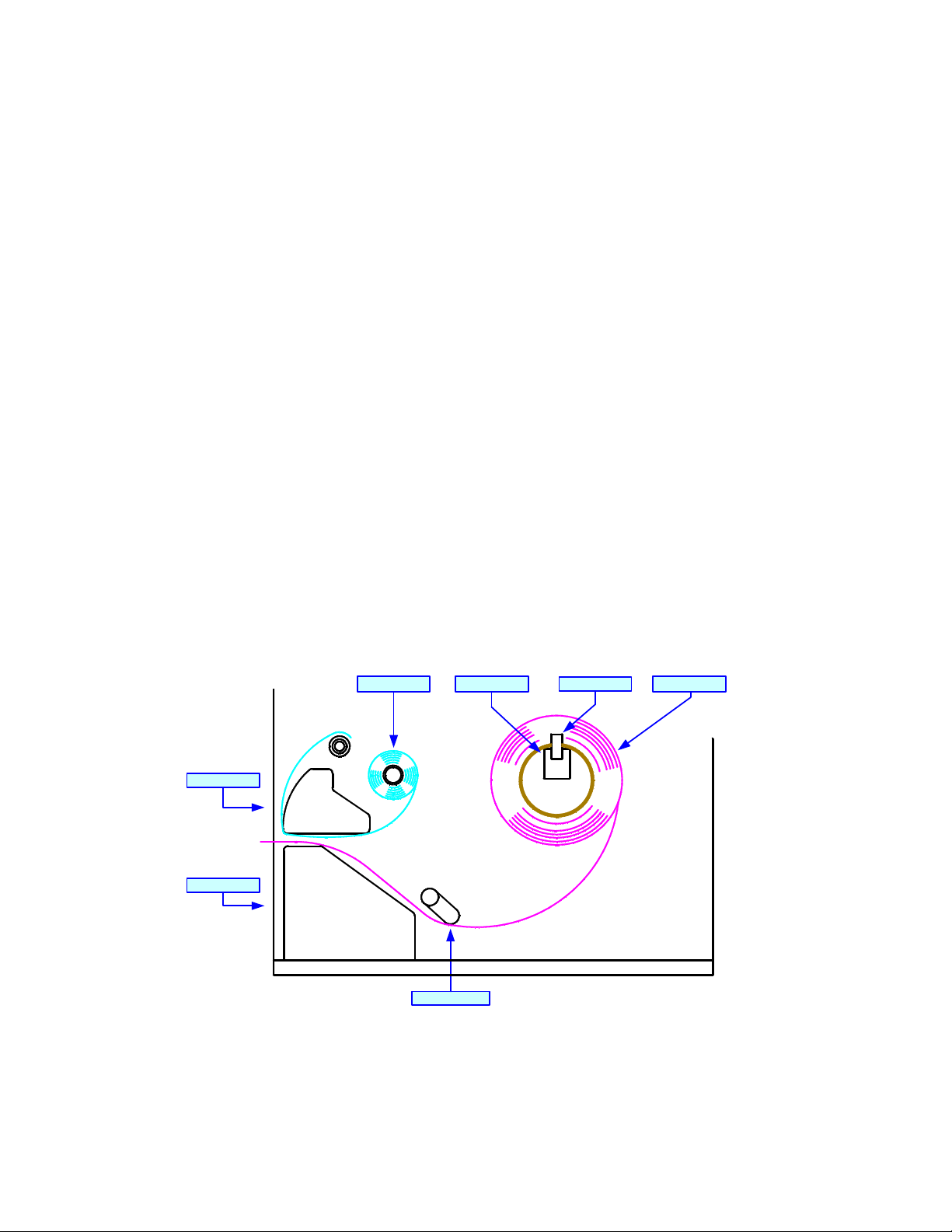

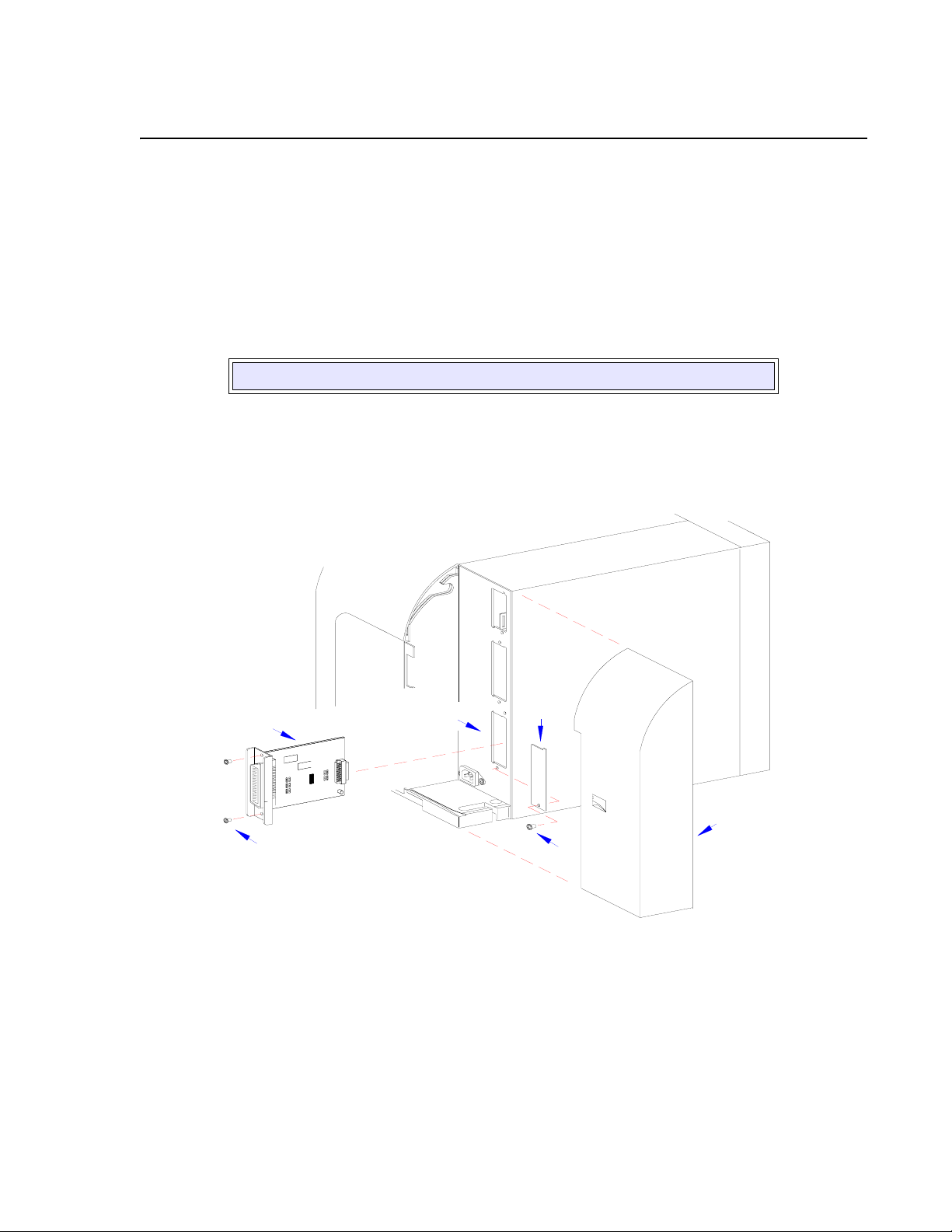

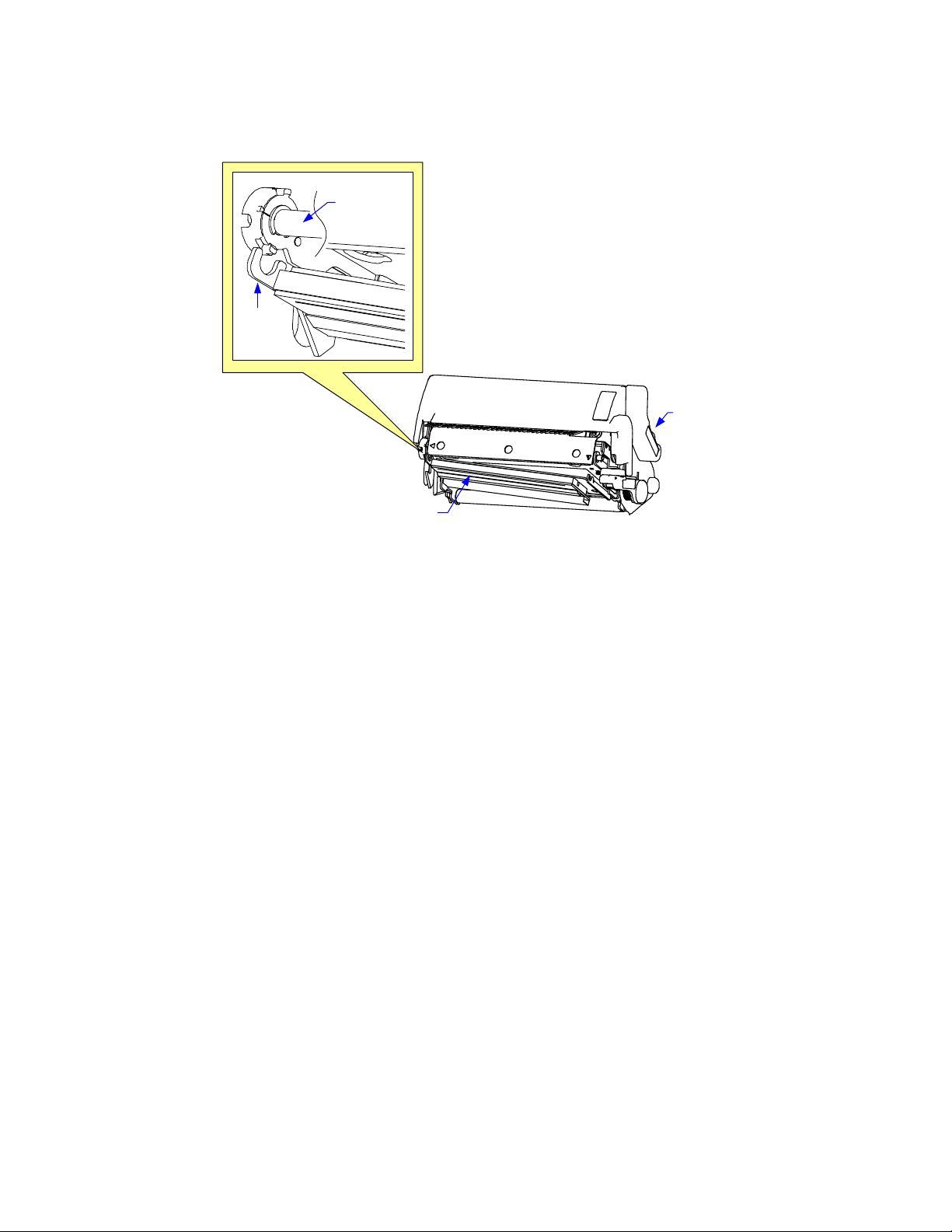

MEDIA & RIBBON LOADING

There are two general media types that may be loaded and used; rolled and fan-folded. Each of

those types may again be defined by whether their print application is direct thermal or thermal

transfer. Those factors determine how the media is loaded and if ribbon stock is loaded at all.

Thermal transfer media requires the use of ribbon stock for print application. In such a scenario,

it is the ribbon stock (carbon paper) that contains the ink that will be transfered to the media.

Direct thermal media has the ink embedded within and is brought to the surface through heat

penetration by print head contact.

Rolled media of standard diameter is loaded within the printer and suspended by the media

holder. Larger, non-standard rolled media would be suspended outside the printer at its rear and

fed inward. Fan-folded media would also be fed inward from the rear but is stacked as opposed

to suspended.

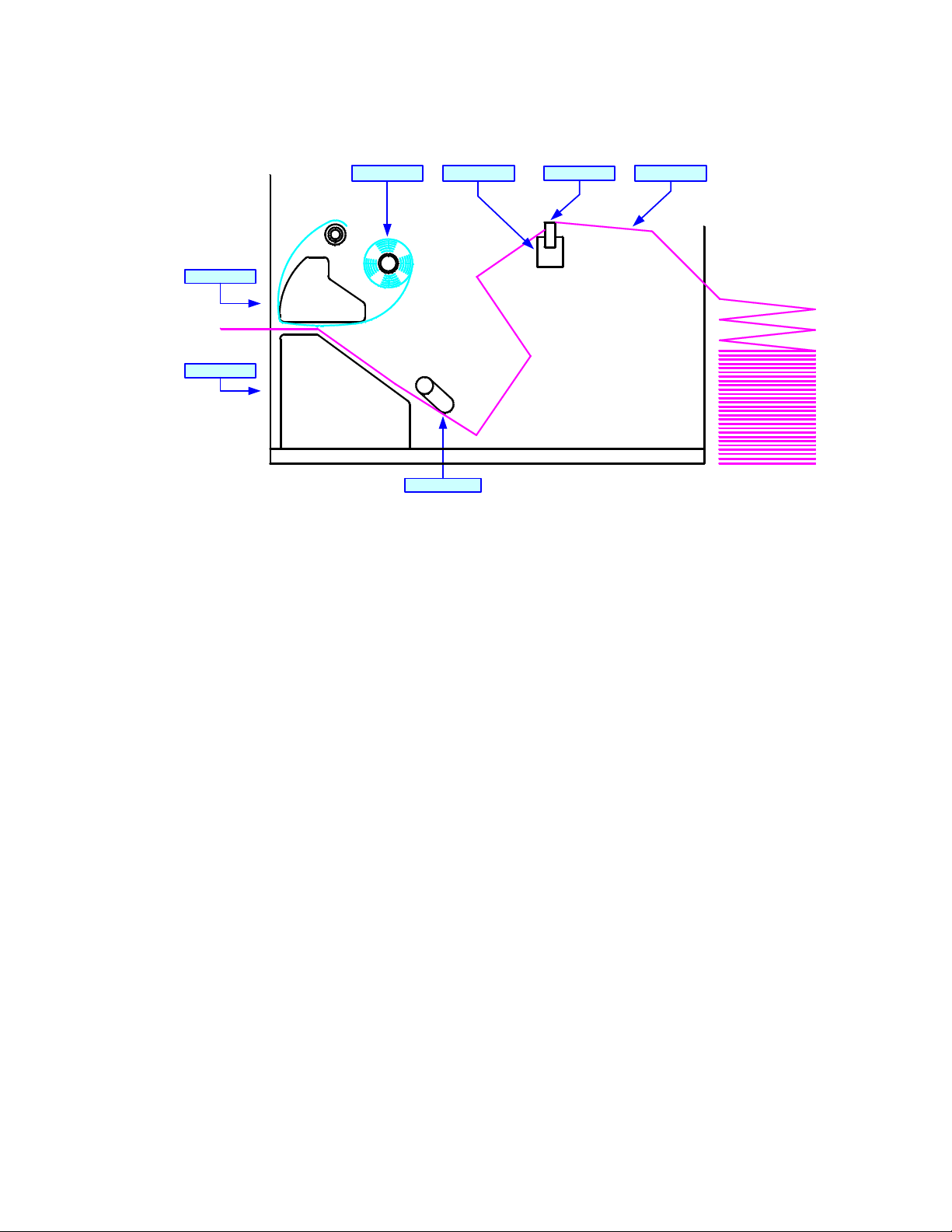

Refer to Figures 3-3a and 3-3b for proper media routing relative to the type to be used. If that to

be used is direct thermal, ignore the ribbon stock in the figures and do not load that.

MediaRibbon Roll

Prin t Assem bly

Media Ramp

Media Holder

Label Damper

Media Guide

Figure 3-3a, Rolled Media & Ribbon Loading

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-4

Page 19

Unit 3: Installation

Print Assemb ly

Media Ramp

Media Holder

Label Damper

Media Guide

MediaRibbon Roll

Figure 3-3b, Fan-fold Media & Ribbon Loading

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-5

Page 20

Unit 3: Installation

INTERFACE SELECTION

This chapter presents the printer interface types and their specifications. These specifications

include detailed information to assist in the selection of the most appropriate method for the

printer to interface with the host. The four acceptable interface methods are:

• RS232C Asynchronous Serial

• IEEE1284 Parallel

• Universal Serial Bus (USB) Adapter

• Local Area network (LAN) Ethernet

• 802.11B Wireless

Following the selection of the desired interface, proceed to the following unit for instructions on

how to Configure the printer for that interface type.

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

HOST OR THE PRINTER. THIS MAY CAUSE DAMAGE TO THE

INTERFACE CIRCUITRY IN THE PRINTER/HOST AND IS NOT COVERED

BY WARRANTY.

NOTE: Some hosts monitor the Request-To-Send (RTS) signal (pin 4 of 25)

to determine if the printer is ready to receive data. Since the printer does not

generate this signal, the RTS line must be held true (high) in order to allow

communication. This can be performed by connecting the RTS pin to the

Clear-To-Send (CTS) signal (pin 5 of 25).

RS232C SERIAL INTERFACE

This High Speed Serial Interface is a Plug-In Interface Module that can be installed in the printer

by the user. The only difference between this interface and the TTL is their signal levels and

cable pinouts.

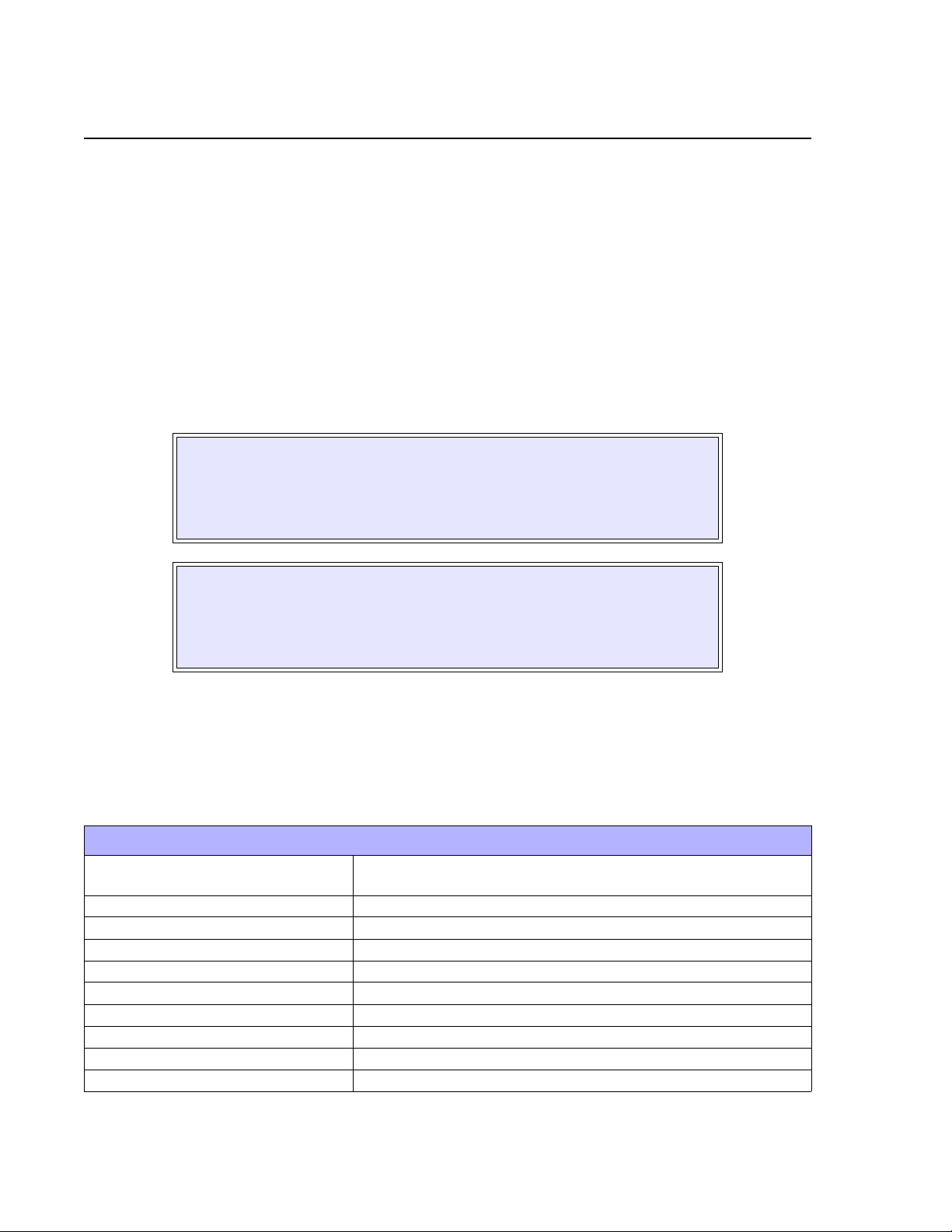

RS232C SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Bi-Directional Communication

Data Transmission Rate 9600, 19200, 38400, 57600 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC II Character Codes, JIS Kanji Codes

Control Codes STX (02H), ETX (03H), ACK (06H), NAK (15H)

Connector Special

Cable Special

Signal Levels High = +5V to +12V, Low = -5V to -12V

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-6

Page 21

Unit 3: Installation

RS232C SERIAL INTERFACE SIGNALS

PIN DIRECTION SIGNAL DEFINITION

1 Reference FG (Frame Ground)

2 To Host TD (Transmit Data) - Data from the printer to the host computer. Sends X-On/

X-Off characters or status data (bi-directional protocols).

3 To Printer RD (Receive Data) - Data to the printer from the host computer.

4 To Host RTS (Request to Send) - Used with Ready/Busy flow control to indicate an

error condition. RTS is high and remains high unless the print head is open (in

this case, RTS would return to the high state after the print head is closed and

the printer is placed back on-line) or an error condition occurs during printing

(e.g., ribbon out, label out).

5 To Printer CTS (Clear to Send) - When this line is high, the printer assumes that data is

ready to be transmitted. The printer will not receive data when this line is low. If

this line is not being used, it should be tied high (to pin 4).

6 To Printer DSR (Data Set Ready) - When this line is high, the printer will be ready to

receive data. This line must be high before data is transmitted. If this line is not

being used, it should be tied high (to pin 20).

7 Reference SG (Signal Ground)

20 To Host DTR (Data Terminally Ready) - This signal applies to Ready/Busy flow control.

The printer is ready to receive data when this pin is high. It goes low when the

printer is off-line, either manually or due to an error condition, and while

printing in the single job buffer mode. It will also go low when the data in the

buffer reaches the buffer near full level.

113

1425

Figure 3-4, Serial Interface Pin Assignments

CABLE REQUIREMENTS

DB9 DB25 HOST CONNECTION DB9 PRINTER

1 1 FG (Frame Ground) Bi-Directional 1 FG (Frame Ground)

2 3 RD (Receive Data) To Host 2 TD (Transmit Data)

3 2 TD Transmit Data) To Printer 3 RD (Receive Data)

8 5 CTS (Clear To Send) To Printer DB9-6 4 RTS (Request to Send)

4 20 DTR (Data Temrinal Ready) To Printer DB9-4 6 DSR (Data Set Ready)

6 6 DSR* (Data Set Ready) To Host 9 DTR (Data Terminal Ready)

5 7 SG (Signal Ground) Bi-Directional 7 SG (Signal Ground)

* This connection at the host side of the interface would depend upon the pin that is being used as the

Ready/Busy signal by the driving software. Typically, on a PC, it would be either CTS (pin5) or DSR (pin

6) on a DB-25 connector.

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-7

Page 22

Unit 3: Installation

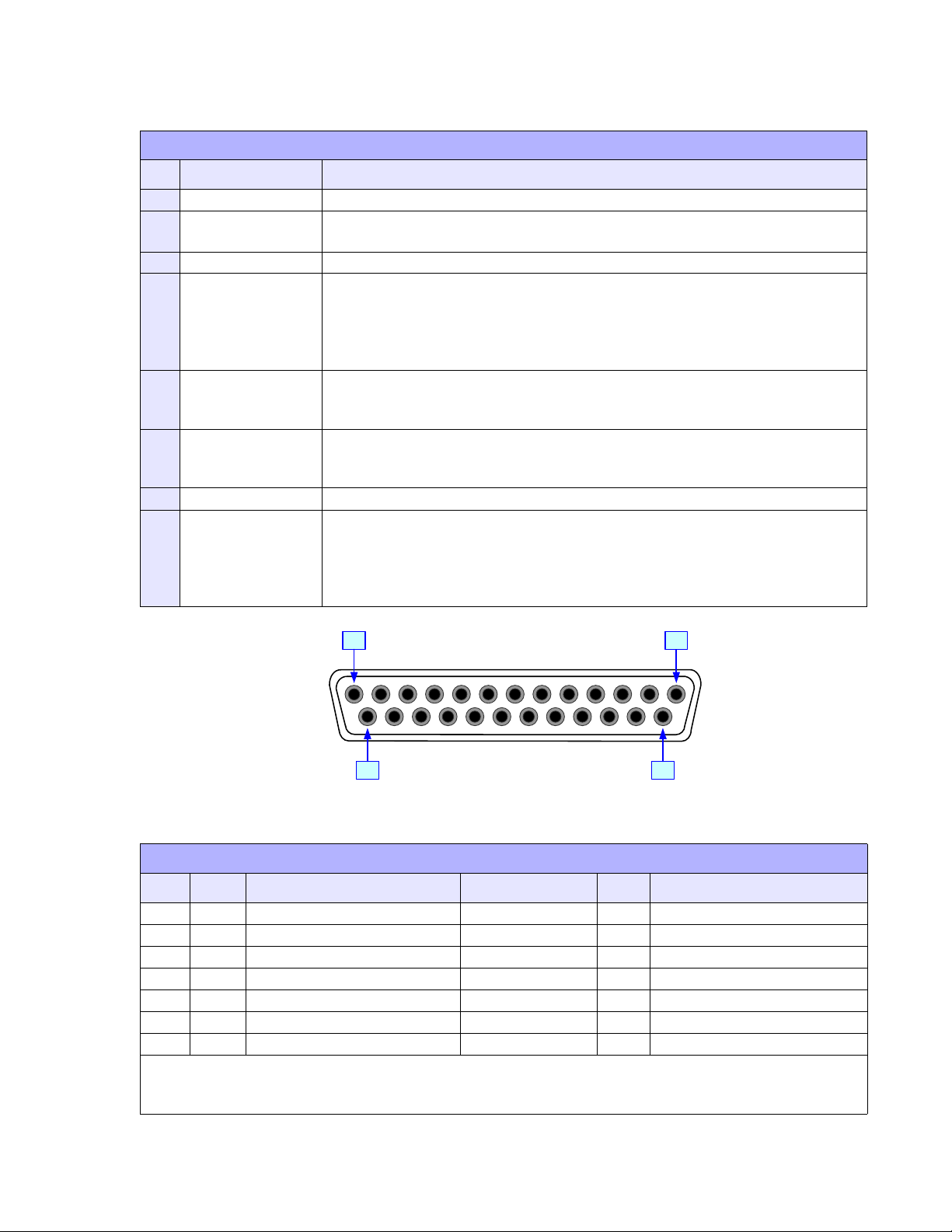

IEEE1284 PARALLEL INTERFACE

The parallel interface is a plug-in module that can be installed by the user and conforms to

IEEE1284 specifications. It automatically detects the IEEE1284 signals and operates in the high

speed mode. If the IEEE1284 signals are not detected, it will operate in the slower standard

Centronics mode. For this reason, an interface cable and host interface conforming to the

IEEE1284 specification must be present to fully utilize the speed capabilities. This interface also

operates bi-directionally and can report the status of the printer back to the host.

SPECIFICATIONS

Printer Connector AMP 57-40360 DDK (or equivalent)

Cable Connector AMP 57-30360 DDK (or equivalent)

Cable IEEE1284 Parallel, 10 ft. (3 m) or less

Signal Level High = +2.4V to +5.0V, Low = 0V to -0.4V

Data Stream <ESC>A . . Job#1 . . <ESC>Z<ESC>A . . Job#n . . <ESC>Z

18

36

1

19

Figure 3-5, Parallel Interface Pin Assignments

IEEE 1284 PARALLEL INTERFACE PIN ASSIGNMENTS

PIN SIGNAL DIRECTION PIN SIGNAL DIRECTION

1 Strobe To Printer 19 Strobe Return Reference

2 Data 1 To Printer 20 Data 1 Return Reference

3 Data 2 To Printer 21 Data 2 Return Reference

4 Data 3 To Printer 22 Data 3 Return Reference

5 Data 4 To Printer 23 Data 4 Return Reference

6 Data 5 To Printer 24 Data 5 Return Reference

7 Data 6 To Printer 25 Data 6 Return Reference

8 Data 7 To Printer 26 Data 7 Return Reference

9 Data 8 To Printer 27 Data 8 Return Reference

10 ACK To Host 28 ACK Return Reference

11 Busy To Host 29 Busy Return Reference

12 Ptr Error To Host 30 PE Return Reference

13 Select To Host 31 INIT From Host

14 AutoFD1 To H os t 32 Fault To Host

15 Not Used 33 Not Used

16 Logic Gnd 34 Not Used

17 FG Frame Gnd 35 Not Used

18 +5V (z=24k ohm) To Host 36 SelectIn1 From Host

1 Signals required for ieee 1284 mode.

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-8

Page 23

Unit 3: Installation

UNIVERSAL SERIAL BUS (USB) ADAPTER

The Universal Serial Bus (USB) interface is a Plug-In Interface Module that can be installed by

the user. It requires a driver (shipped with each printer that has the interface installed) that must

be loaded on your PC and the PC must be configured to support USB peripherals using Windows

98 or above. Details for loading the USB driver are contained in the USB Interface Manual that is

shipped with each printer with a USB Optional interface installed. Up to 127 devices may be

connected to a USB port using powered hubs.

SPECIFICATIONS

Printer Connector USB Type B Plug

Cable 10 feet (3 m) maximum

Host Windows 98 or above with USB Port

Power Supply BUS Power through cable

Power Consumption +5 V at 80 ma

LOCAL AREA NETWORK (LAN) ETHERNET

A Local Area Network (LAN) interface is an optional Plug-In Interface Module that can be

installed by the user. It requires a driver shipped with each printer that has the interface installed.

The driver that must be loaded on your PC and the PC must be configured to run one of the

supported network protocols using a 10/100BaseT LAN connection. Details for loading the LAN

driver are contained in the LAN Interface Manual that is shipped with each printer with a LAN

Optional interface installed.

SPECIFICATIONS

Connector RJ-45 Receptacle

Cable 10/100BaseT Category 5

Power Supply Powered from printer

802.11B WIRELESS

The wireless print server provides easy printer interface with 802.11b Wi-Fi compliant networks

free of wired connections. Each printer is shipped with an integrated driver and interface

installed. The driver must be loaded on your PC and the PC must be configured to run one of the

supported protocols.

802.11B WIRELESS SPECIFICATIONS

Variable Data Rates 11, 5.5, 2 and 1 Mbps

Frequency Band 2.4 GHz ISM Band

Wired Equivalent Privacy 128 bit, 64 bit (compatible with 40bit), none

Sensitivity (typ, AAWGN, 8E-2 PER): -91dBm at 1Mbps, -88dBm at 2 Mdps,

-87dBm at 5.5Mbps, -84dBm at 11Mbps.

Range 100m indoors, 300m outdoors

Protocols TCP/IP, IPX/SPX, Direct Mode IPX/IP, DLC/LLC, NetBEUI,

NetBIOS/IP

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-9

Page 24

Unit 3: Installation

RECEIVE BUFFER

The data stream is received from the host to the printer one job at a time. This allows the

software program to maintain control of the job print queue so that it can move a high priority job

in front of ones of lesser importance.

A multiple job buffer allows the printer to continuously receive print jobs while compiling and

printing other jobs at the same time. It acts much like a Print buffer to maximize the performance

of the host and the printer.

The printer receives and prints one job at a time. If a print job exceeds the buffer size,

transmission will be rejected by the printer. Flow control protocols to throttle transmission are not

used. Error conditions that occur during the Print Data transmission will cause the printer to

return a NAK.

ACK/NAK PROTOCOL

Bi-Directional ACK/NAK protocol is used for error control. In a normal transmission sequence

when the transmission is received, the printer will return an ACK (06H) signifying that it was

received without a transmission error. After the transmission command structure has been

analyzed, a status byte is returned to the host. This status byte informs the host of the validity of

the command structure.

If the command structure is error free, the printer proceeds with the print operation. When the

print operation is completed, a Printer Status message is returned to the host. If an error was

detected during the initial transmission sequence, a NAK (15H) will be returned signalling to the

host that the received transmission contained errors and must be resent. If the returned Status

byte indicates a command structure error, the error must then be corrected before the print data

is resent to the printer.

A valid transmission to the printer must be bounded by an STX/ETX pair, with the STX (02H)

signifying the start of the Print Data and ending with an ETX (03H) signifying the end.

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-10

Page 25

Unit 3: Installation

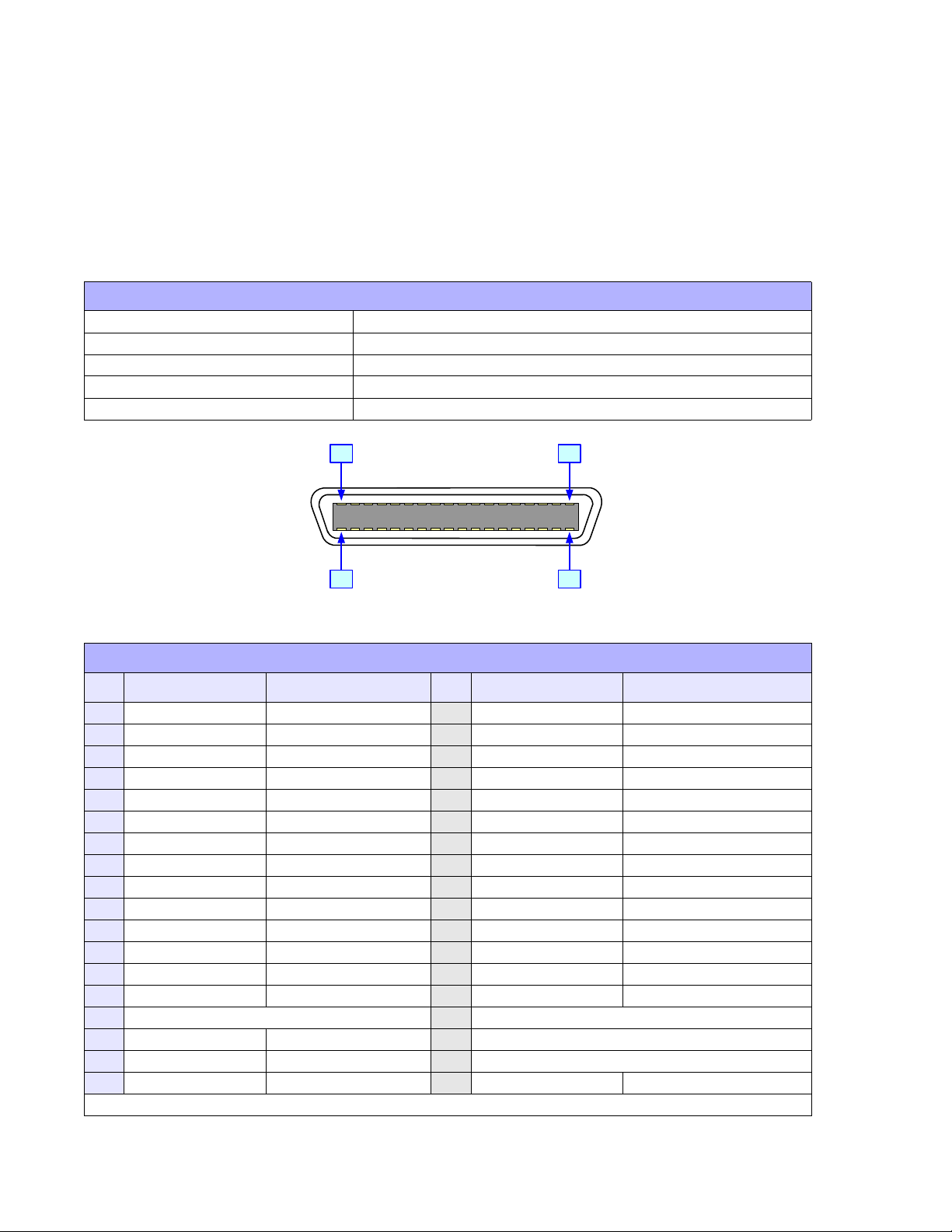

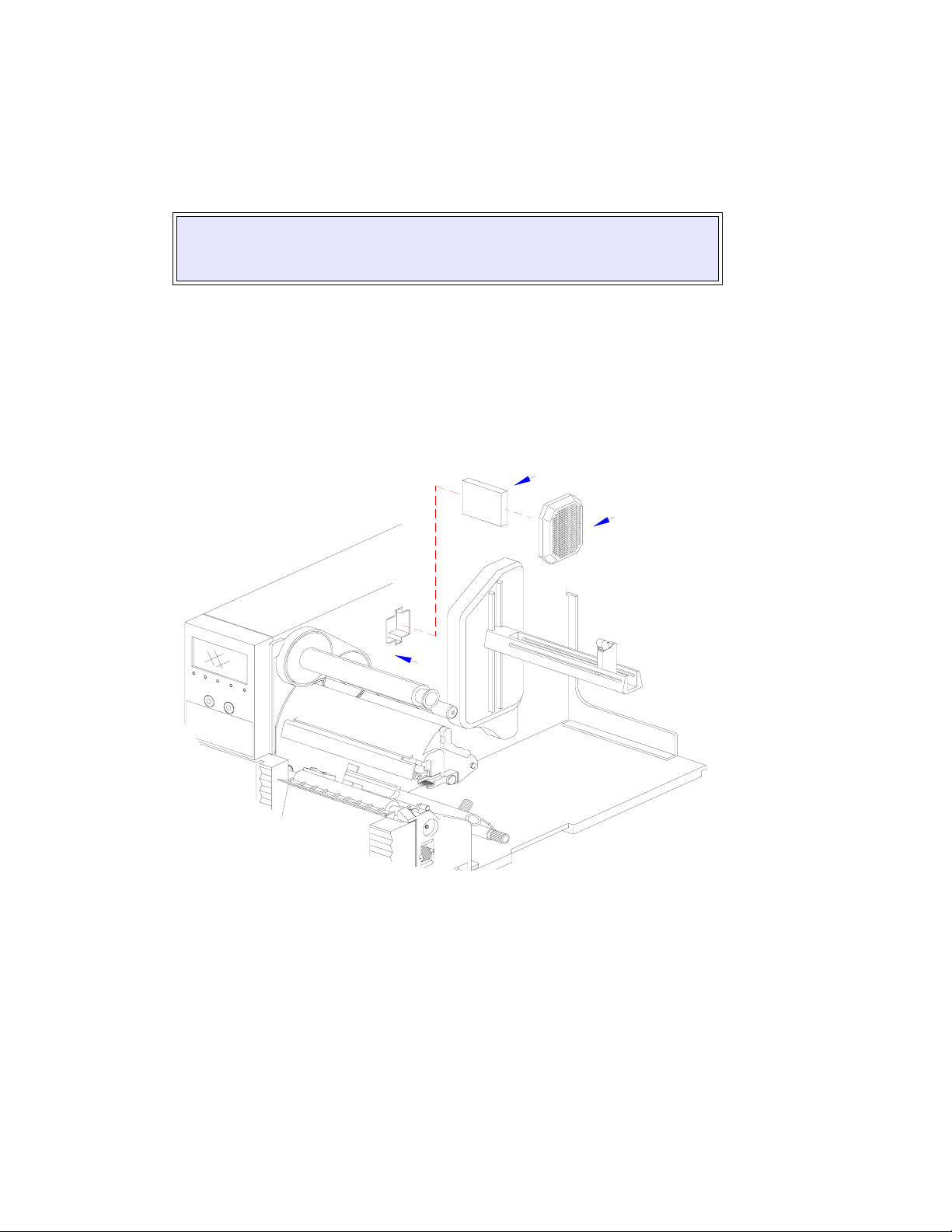

ACCESSORIES INSTALLATION

EXTERNAL SIGNAL CONNECTOR

This connector permits the interface of an external source with the printer for the purpose of

regulating print actiivity to coincide with those external requirements (i.e.: production flow, etc.).

1 Disconnect power supply cord and remove the rear housing cover (1, Figure 3-6).

2 Remove screw (2) and plate (3) as required to expose the EXT port.

3 Remove two screws (4) and withdraw existing board (5) from frame (6) as required.

NOTE: The above step only applies if replacing an exisiting board.

4 Insert external signal board (5) into slot in frame (6) and secure using two screws (4).

5 Connect the interface cord, power cord, and reinstall rear housing covers.

5

D

D

R

R

A

A

O

O

B

B

S

S

R

R

+

+

4

4

8

8

2

2

1

1

E

E

E

E

E

E

I

I

6

3

1

4

2

Figure 3-6, External Signal Connector

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-11

Page 26

Unit 3: Installation

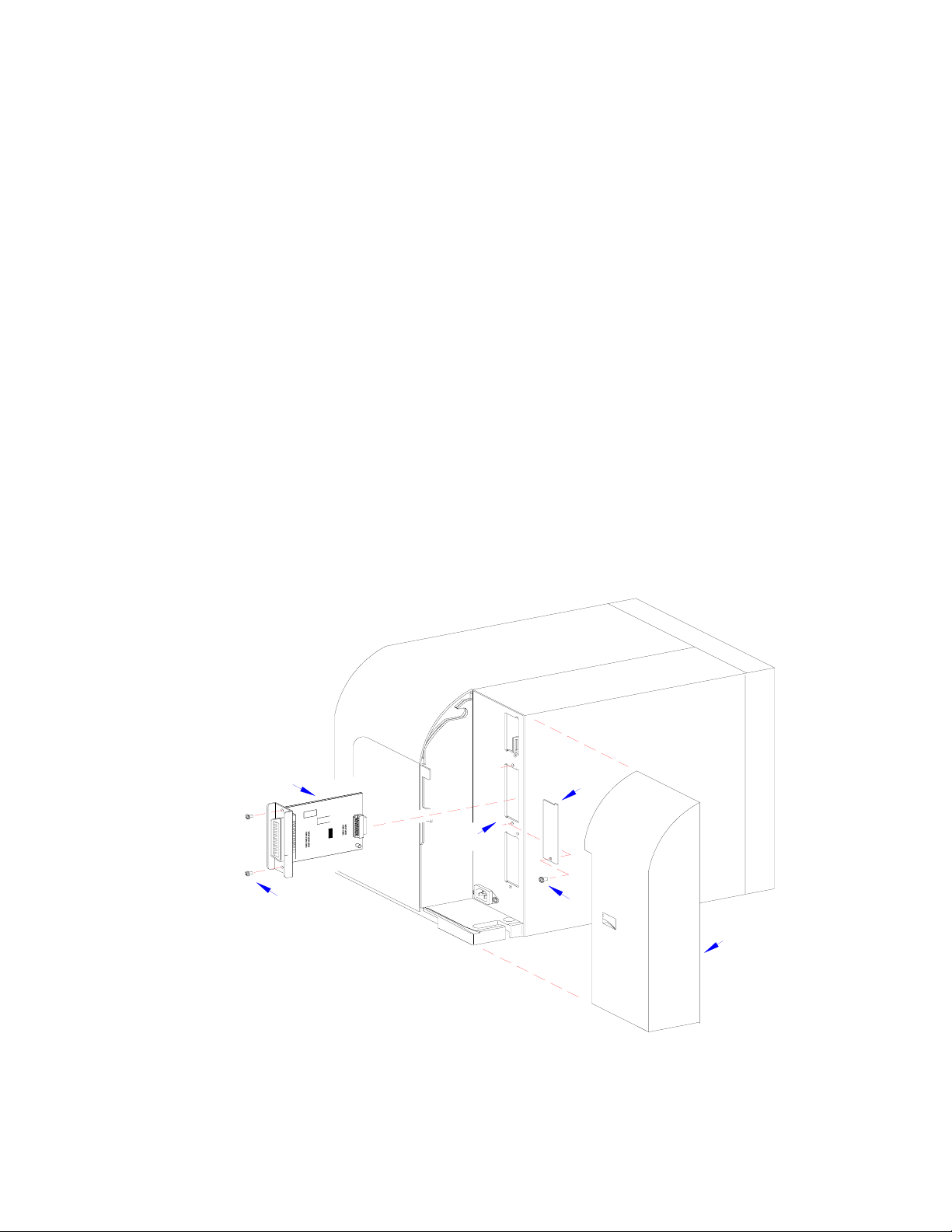

MEMORY EXPANSION

The memory cartridge provides additional storage of user data and graphics. Access to the

memory cartridge port, and its installation, is very simple. The instructions below provide

guidance.

CAUTION: INSTALL THE MEMORY CARTRIDGE PRIOR TO SENDING

RELATIVE COMMANDS OR AN ERROR WILL OCCUR. REMOVE POWER

TO THE PRINTER PRIOR TO INSTALLING THE CARTRIDGE.

1 Disconnect power supply cord.

2 Detach memory cartridge cover (1, Figure 3-7) from center frame (2).

3 Fully insert memory cartridge (3) into its respective port and replace cover (1).

4 Restore power to the printer and send commands.

3

1

2

Figure 3-7, PCMCIA Memory Expansion

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-12

Page 27

Unit 3: Installation

INTERFACE UPGRADE

The printer is typically ordered with a high-speed parallel interface board installed. However,

interface requirements sometimes change and an upgrade is desired. All of the interface boards

are installed within the same slot (middle) located in the rear of the printer with little or no

difference in installation methodology with the exception of the mini-LAN interface (top slot).

Parallel Interface (IEEE1284) (Optional or Bundled)

Serial Interface (RS232C) (Optional)

USB Interface (Optional)

10BaseT/100Base-TX Lan Interface (Optional)

Wireless LAn 802.11b Interface (Optioanl)

10BaseT/100Base-TX mini LAN (Optional(

EXT Connector (External Signal Interface) (Optional)

1 Remove the rear housing cover (1, Figure 3-8). Disconnect the power and interface cords.

2 Remove screw (2) and plate (3) as required to expose the interface port.

3 Remove two screws (4) and withdraw existing board (5) from frame (6) as required.

4 Insert replacement board (5) into slot in frame (6) and secure using two screws (4).

5 Connect the interface cord, power cord, and reinstall rear housing covers.

5

D

D

R

R

A

A

O

O

B

B

S

S

R

R

+

+

4

4

8

8

2

2

1

1

E

E

E

E

E

E

I

I

3

6

4

2

1

Figure 3-8, Interface Upgrade

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-13

Page 28

Unit 3: Installation

LABEL CUTTER INSTALLATION

The label cutter, when installed, replaces the printer’s lower front housing cover. Its internal

sensor monitors media feed and activates the cut sequence based on user established values.

The cutter assembly is powered through relayed current from the printer’s power supply and

derives its primary intelligence from the main circuit board. The activated cut sequence severs

the printed media from the unprinted media allowing the operator to retrieve and apply at will.

Installation instructions are provided with the purchased product.

LABEL PEELER INSTALLATION

The label peeler, when installed, replaces the printer’s lower front housing cover. As the label is

printed and fed forward, the peel bar separates the printed label from its paper backing and

presents it for application. When the printed label is retrieved by the operator, the printer feeds

the unprinted media back into position for another print sequence. The cycle is again repeated.

Installation instructions are provided with the purchased product.

SATO GT4xxe Series Operator Manual PN 9001138C Page 3-14

Page 29

PRINTER

• Configuration Modes

• Operational Adjustments

OPERATION

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-1

Page 30

Unit 4: Operation

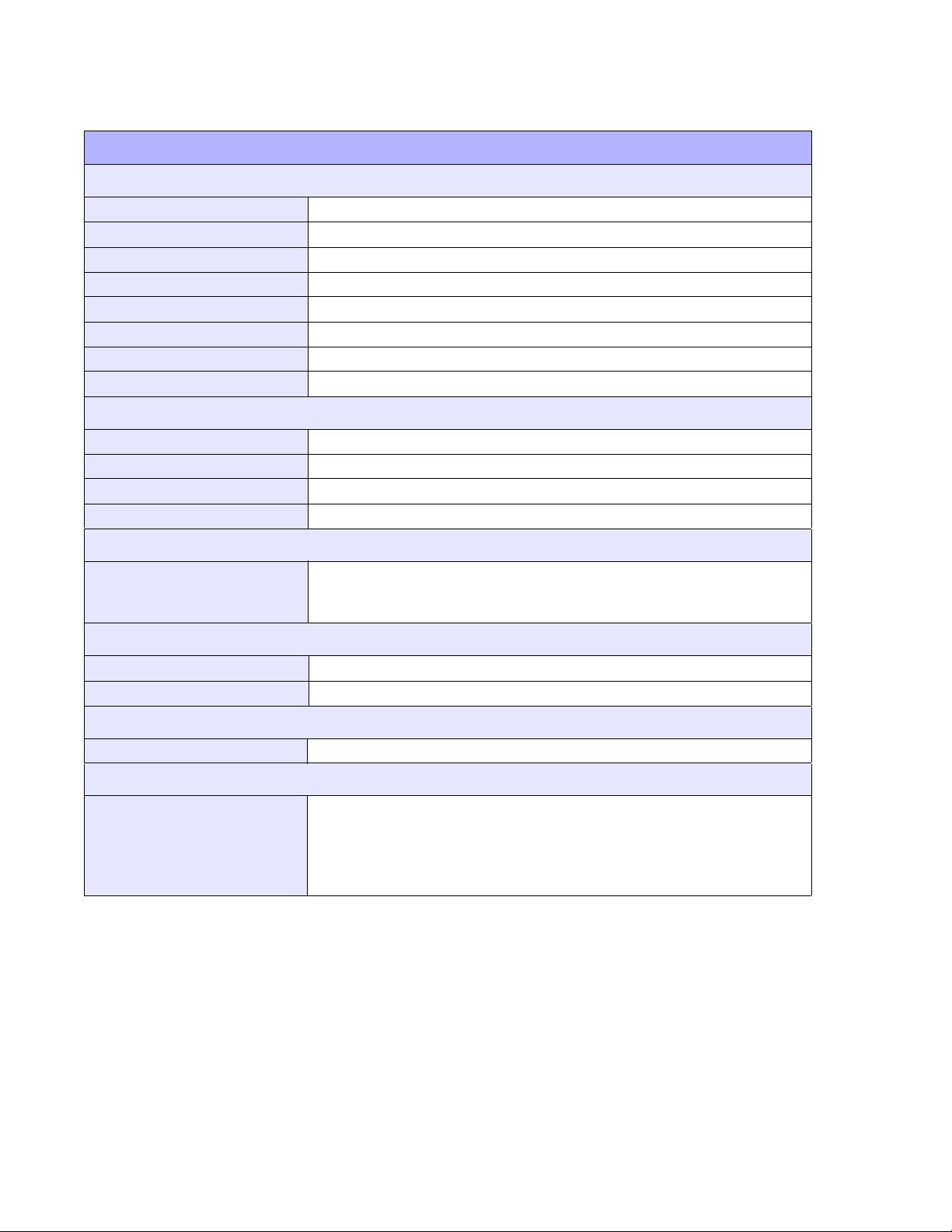

CONFIGURATION MODES

This chapter provides an overview of the various configuration modes of the operation menu. All

of the following configuration activities are performed via the use of the operator panel located on

the printer front. However, many settings may also be controlled via software commands. In the

case of conflict between the software and control panel settings, the printer will always use the last

entered valid setting.

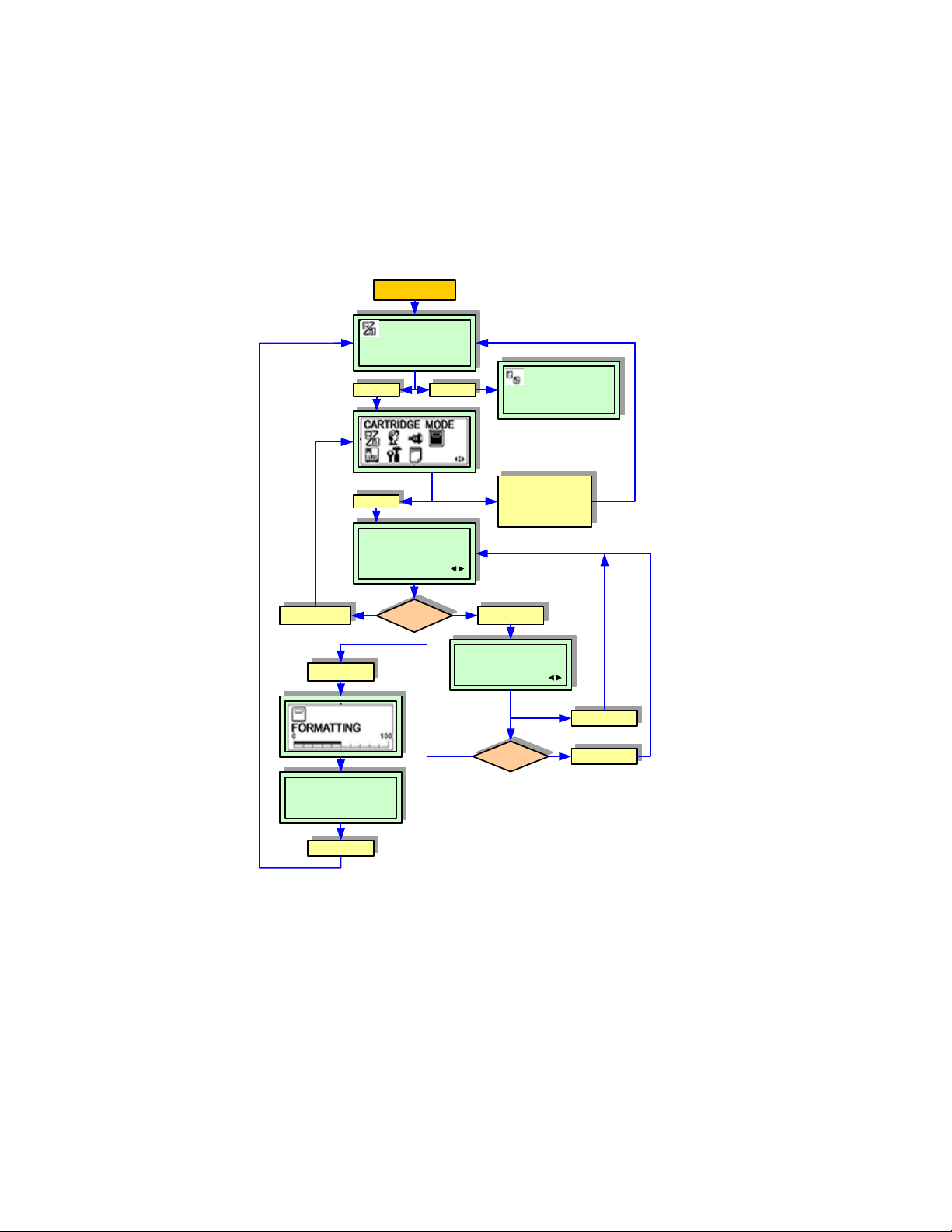

NORMAL MODE

When a print job is received, the LCD will display the number of labels to be printed and will

numerically descend as each label is printed.

POWER

ONLI NE

QTY: 000000

LINE

OFF LINE

000000

CANCEL

CANCEL PRINT JOB

YES NO

Yes / No

CANCEL PRINT JOB

COMPLETED

Printing

star ts

LINE

ENTER +

ENTER + for 5 seconds

DATA SAVE STAR T

YES NO

Yes / No

COPYING

0 100

software issued

print stop request

PAUSE

QTY: 000000

CANCEL or

Refer

to User

Mode flow

char t.

Refer

No

to Interface

Mode flow

char t.

Refer

to Cartridge

Mode flow

char t.

DATA SAVE

COMPLETED

ENTER

Refer

to SEMBL

Mode flow

char t.

Refer

to Advanced

Mode flow

char t.

Refer

to Hex Dump

flow chart.

Figure 4-1, Normal Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-2

Page 31

Unit 4: Operation

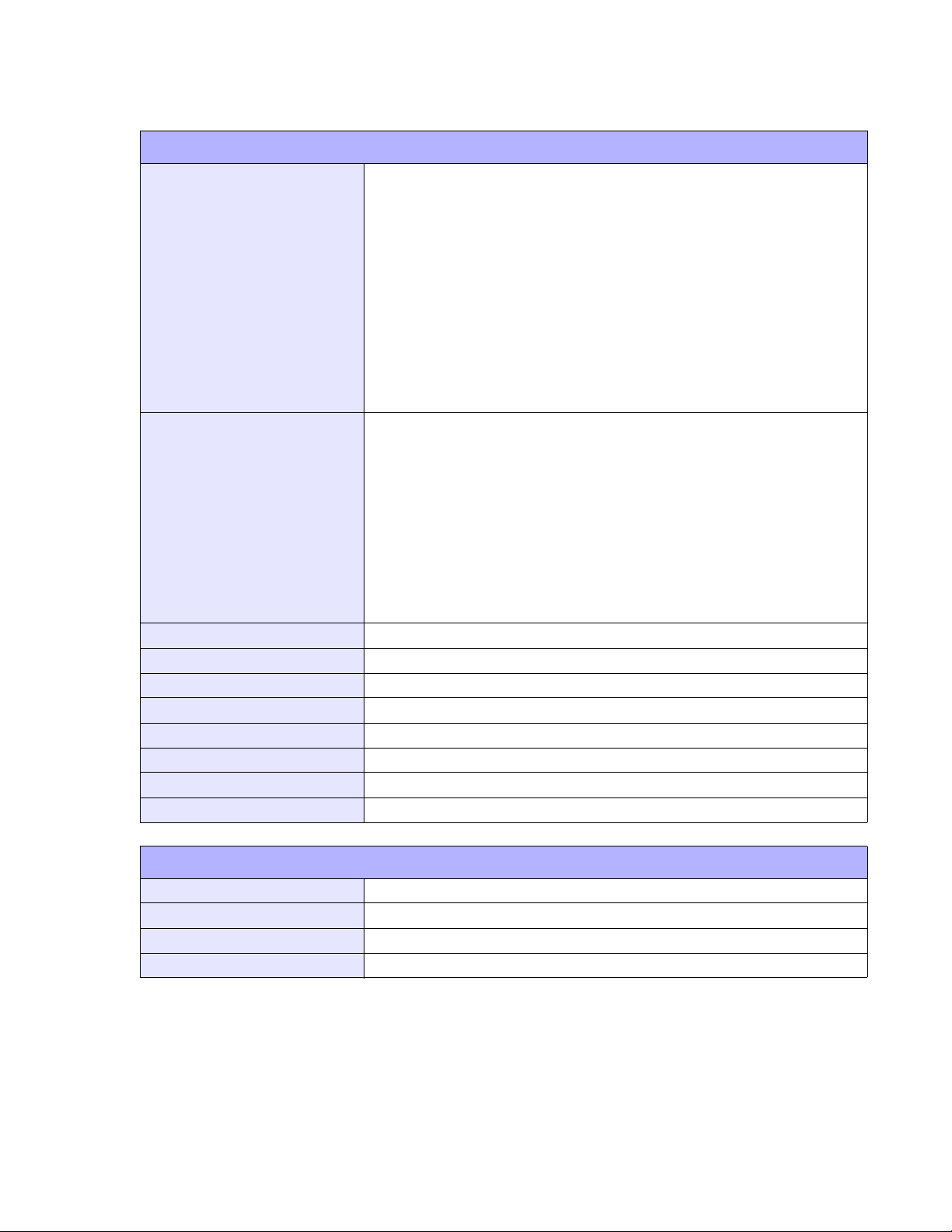

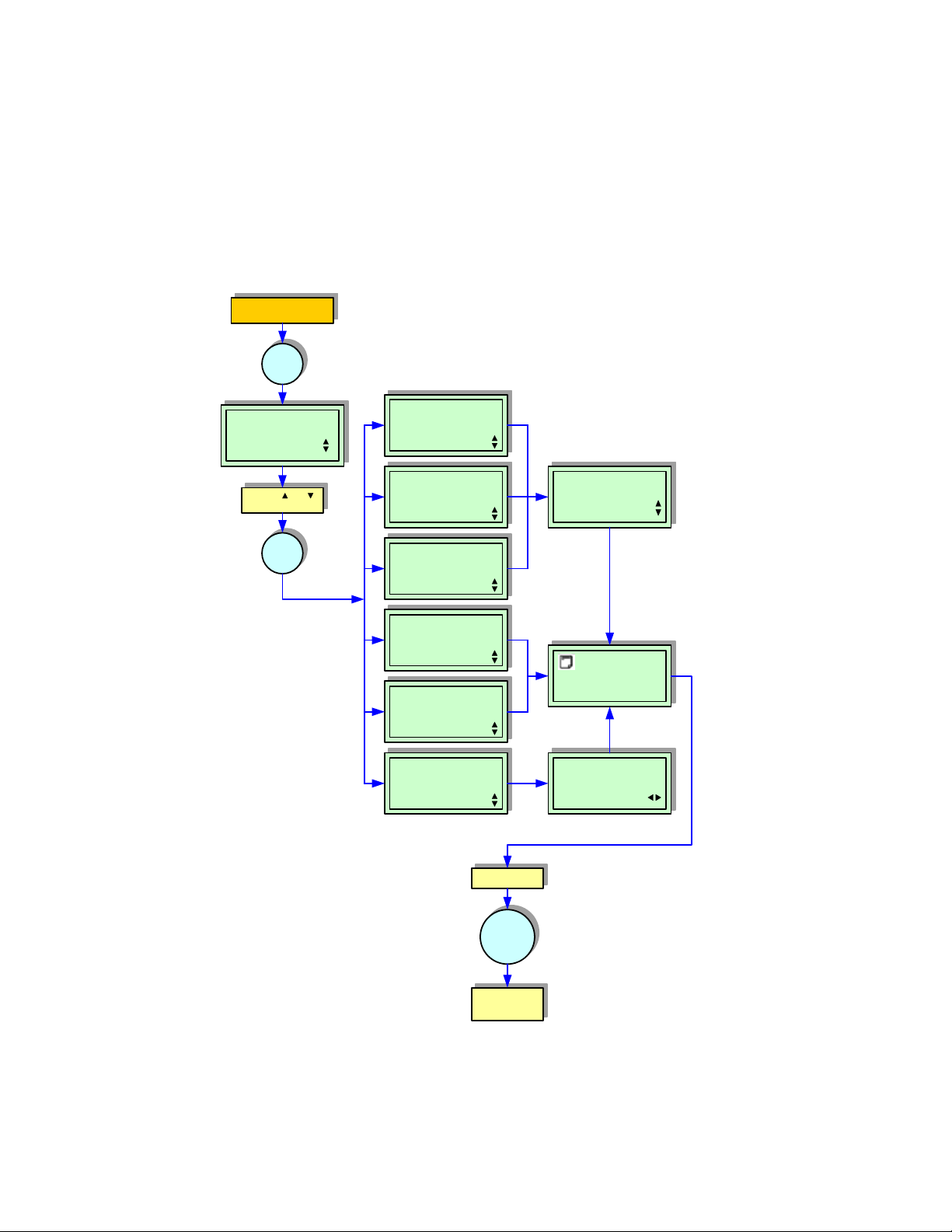

USER MODE

This mode allows cofiguration of printing features that are prone to change from job to job. These

are some of the most basic and common adjustments of all of the configuration modes.

POWER

ENTER

ONLIN E

QTY: 000000

Pre ss FUNCTION

anytime to return to

User Mode.

ENTER LINE

ENTER

OFFSET VOLUME

PITCH +0.00

OFFSET +0.00

DARKNESS 00

CANCEL ENTER

Kanji Font Card

Insta lled ?

Yes / No

JIS CODE

JIS SJIS

KANJI F ONT

MINCHO GOTHIC

CHARACTER PITCH

PROPOR TIONAL

FIXED

Displays

when valid.

OFF LINE

000000

PASSWORD

0000

Scroll to enter.

Pre ss ENTER.

PRINT SPEED

06 IPS

ENTER CANCEL

PRINT DARKNESS

1 2 3 4 5

CANCEL ENTER

PITC H OFF SET

+00mm

ENTER CANCEL

PRINT OFF SET

V:+0000 H:+0000

CANCEL ENTER

ZERO SLASH

YES NO

ENTER CANCEL

Figure 4-2, User Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-3

Page 32

Unit 4: Operation

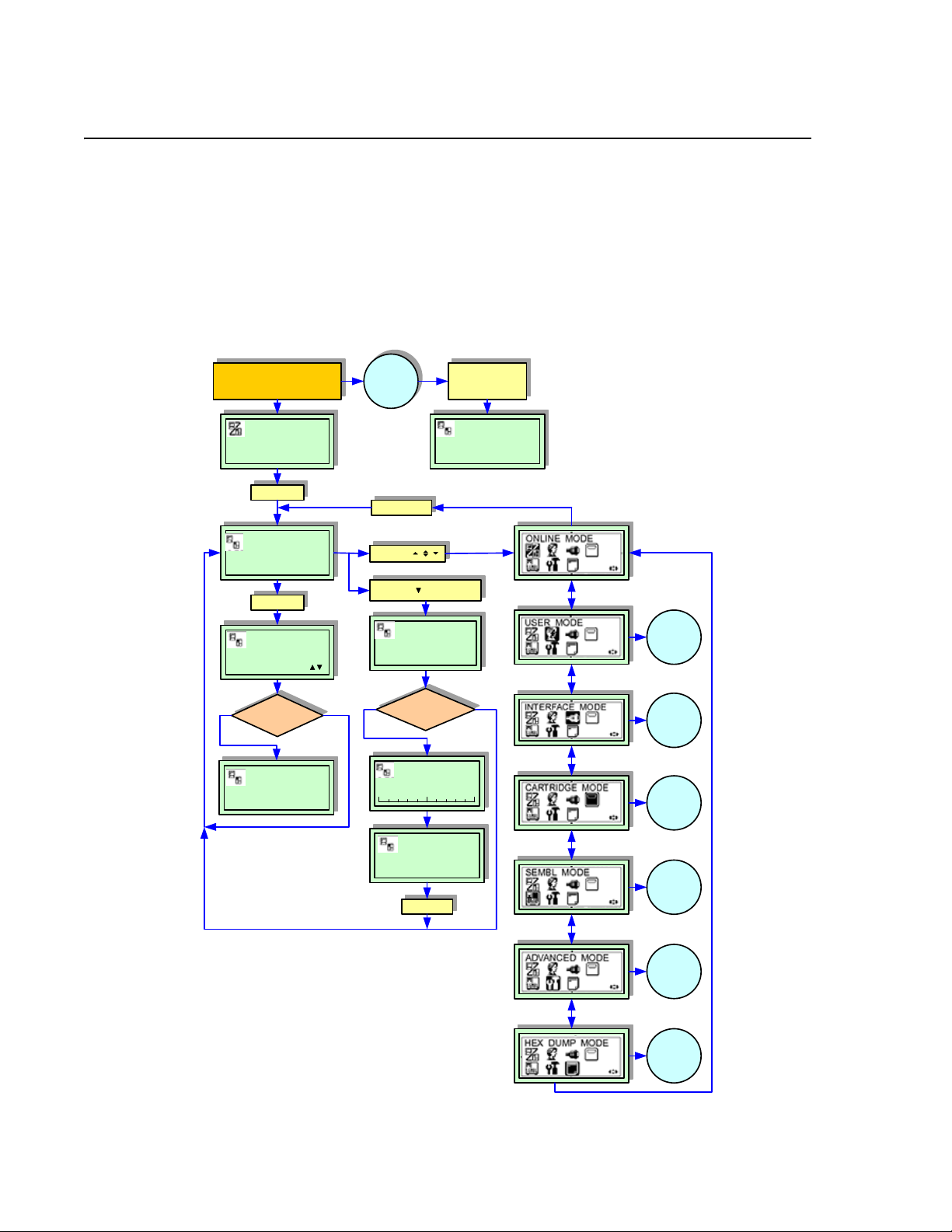

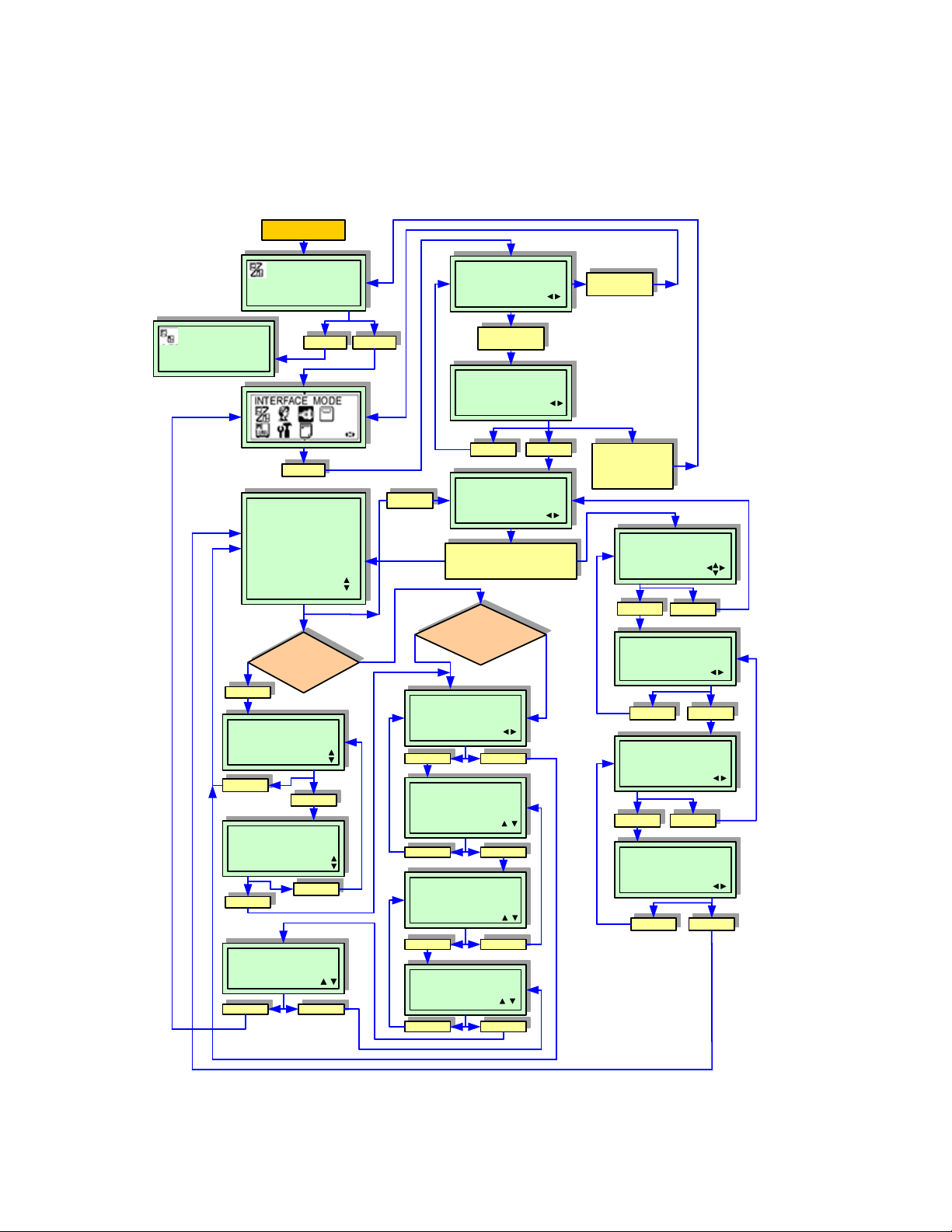

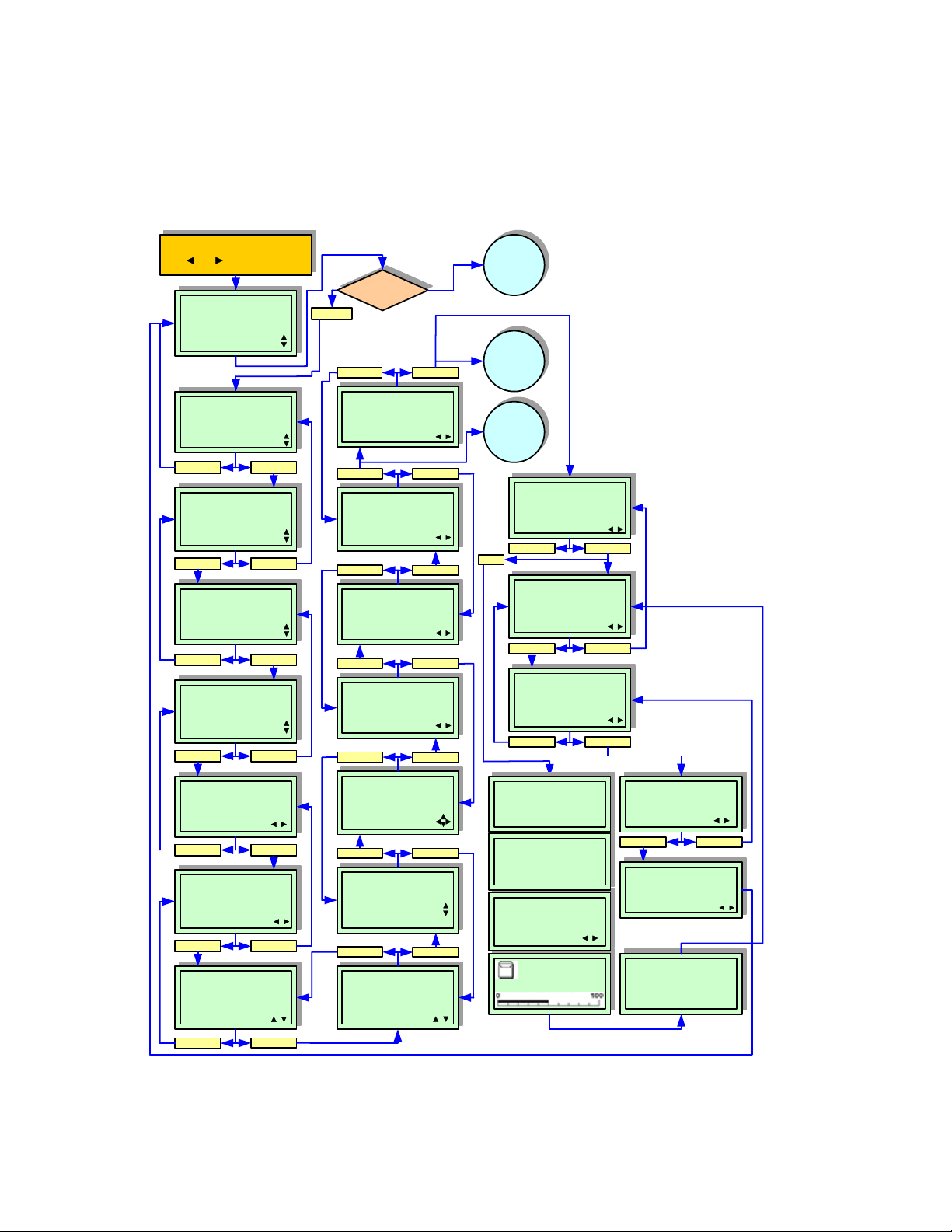

ADVANCED MODE

The Advanced Mode is provided to make basic printer operational adjustments. Typically, once

these adjustments or settings have been made, they will not require additional address unless a

new job is downloaded. The following table identifies the menus of the Advanced Mode and their

purpose.

CANCEL + POWER

Printer

beeps

Pre ss FUNCTION

anytime to return to

Advanced Mode.

Only

visible w hen har dware

is instal led an d

detected by the

printer.

Only

visible if the Cut ter ,

Dispenser and or

Linerless features are

selecte d . Only BEFOR or

NONE can be selected

for Linerless

feature.

ENTER

DARKNESS RANGE

A B C D E F

CANCEL ENT ER

PRINTER TYPE

AUTO SETTING

YES NO

ENTER CANCEL

PRINTER TYPE

CONTINUOUS

TEAR OFF

DISPEN SER

CUTTER

LINERLESS

CANCEL ENT ER

BACKFEED MOTI ON

AFT ER

BEFOR

NONE

ENTER CANCEL

HEAD CHECK

ENABLE DISABLE

Disable +

ENTER

EXTERNAL SI GNAL

ENABLE DISABLE

CANCEL

Disable +

ENTER

EXTERNAL R EPRINT

ENABLE DISABLE

ENTER CANCEL

AUTO ONLINE

YES NO

CANCEL ENT ER

AUTO ONLINE FEED

YES NO

ENTER CANCEL

Enable +

ENTER

Enable +

ENTER

HEAD C HECK

NORMAL BARCODE

EXTERNAL SIGNAL

TYPE1 T YPE2

TYPE3 T YPE4

FEED ON ERROR

YES NO

CANCEL ENT ER

PROT OCOL C ODE

STANDAR D

NON-STANDARD

ENTER CANCEL

SEMBL MODE

AUTO START

YES NO

No / Yes

ENTER

ENTER

START PROGRAM

OWN_PROG.BA S

SAMPLE_1.BAS

Only

visible if the

Dispenser feature has

been selected and the

Continuous print

operation mode

is active.

ENTER

SENSOR TYPE

I-MARK1

GAP

I-MARK2

REWINDER

ON OFF

CANCEL ENT ER

PRINT METHOD

TRANSFER DIRECT

ENTER CANCEL

PITC H SENSOR

ENABLE DISABLE

Enable /Disable

ENTER

Figure 4-3, Advanced Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-4

Page 33

Unit 4: Operation

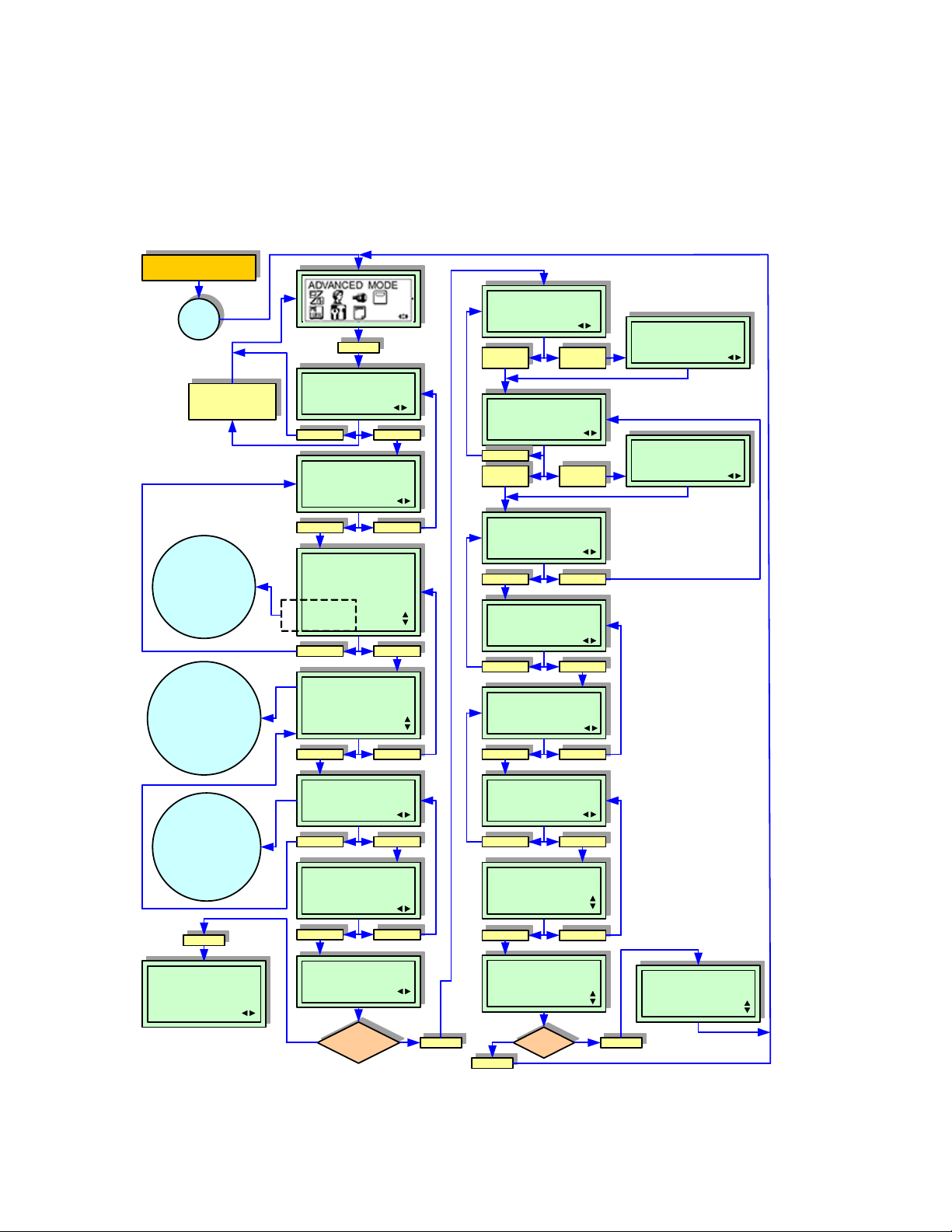

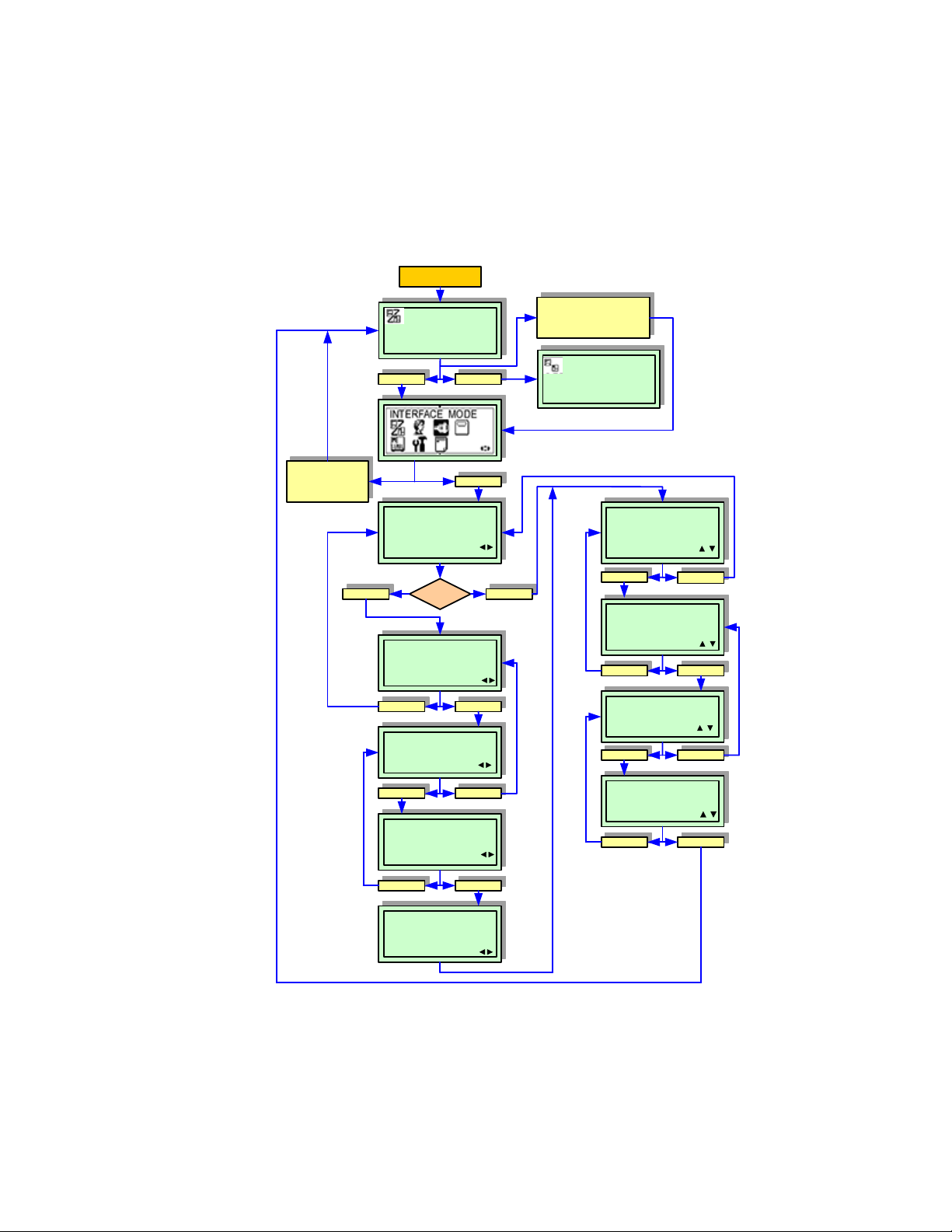

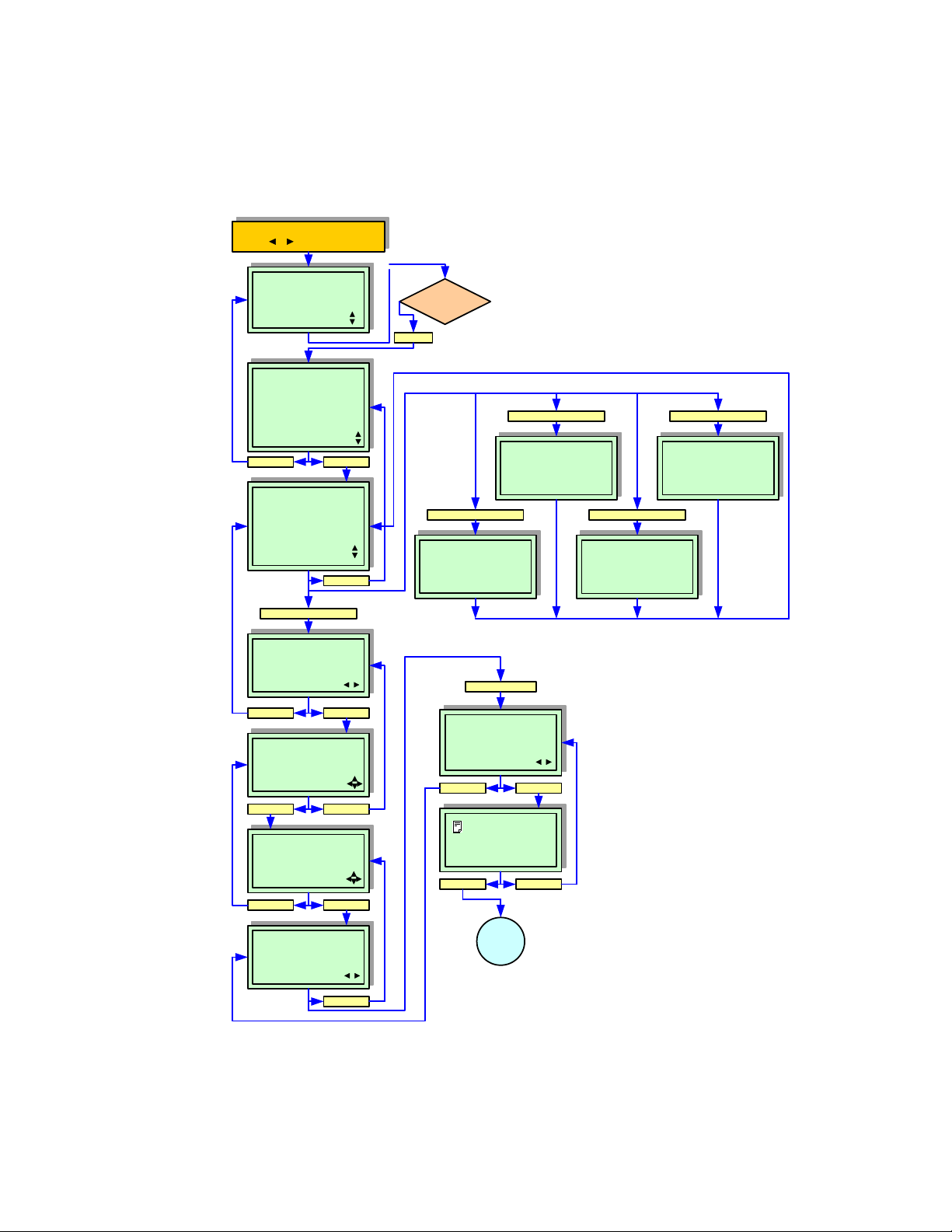

IEEE1284 INTERFACE SETUP MODE

This chapter provides the programming sequences required for IEEE1284 interface setup. Use

the keys of the printer’s operator panel to select and enter the required options.

POWER

Type password if

prompted, then press

ONLI NE

QTY: 000000

ENTER.

ENTER

Press FUNCTION anytime

during configuration.

CANCEL ENTER

RECEIVE BUFF ER

MULTI 1ITEM

CANCEL

Multip le / Sin gle

item?

IEEE1284

ACK SIGNAL

00.5 µs

CANCEL

IGNORE CR/LF

YES NO

CANCEL ENTER

IGNORE CAN/DLE

YES NO

ENTER CANC EL

+ ENTER

LINE

ENTER

ENTERENTER

OFF LINE

000000

INTERFACE CARD

SETTING

YES NO

ENTER ENT ER

Yes / No

INTERFACE CARD

SETTING

CARD1 CARD2

ENTER CAN CEL

PROT OCOL

STAT US4

STAT US5

Status 4 / Status 5

DATA PORT

CARD1 CARD2

CANCEL ENT ER

STAT US PORT

ENABLE DISABLE

ENTER CAN CEL

Returns

to previous

Interface

Mode

ENTER CANCEL

ITEM NO CHECK

ENABLE DI SABLE

CANCEL ENT ER

BCC CHECK

ENABLE DI SABLE

ENTER CANCEL

Figure 4-4, IEEE1284 Interface Setup Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-5

Page 34

Unit 4: Operation

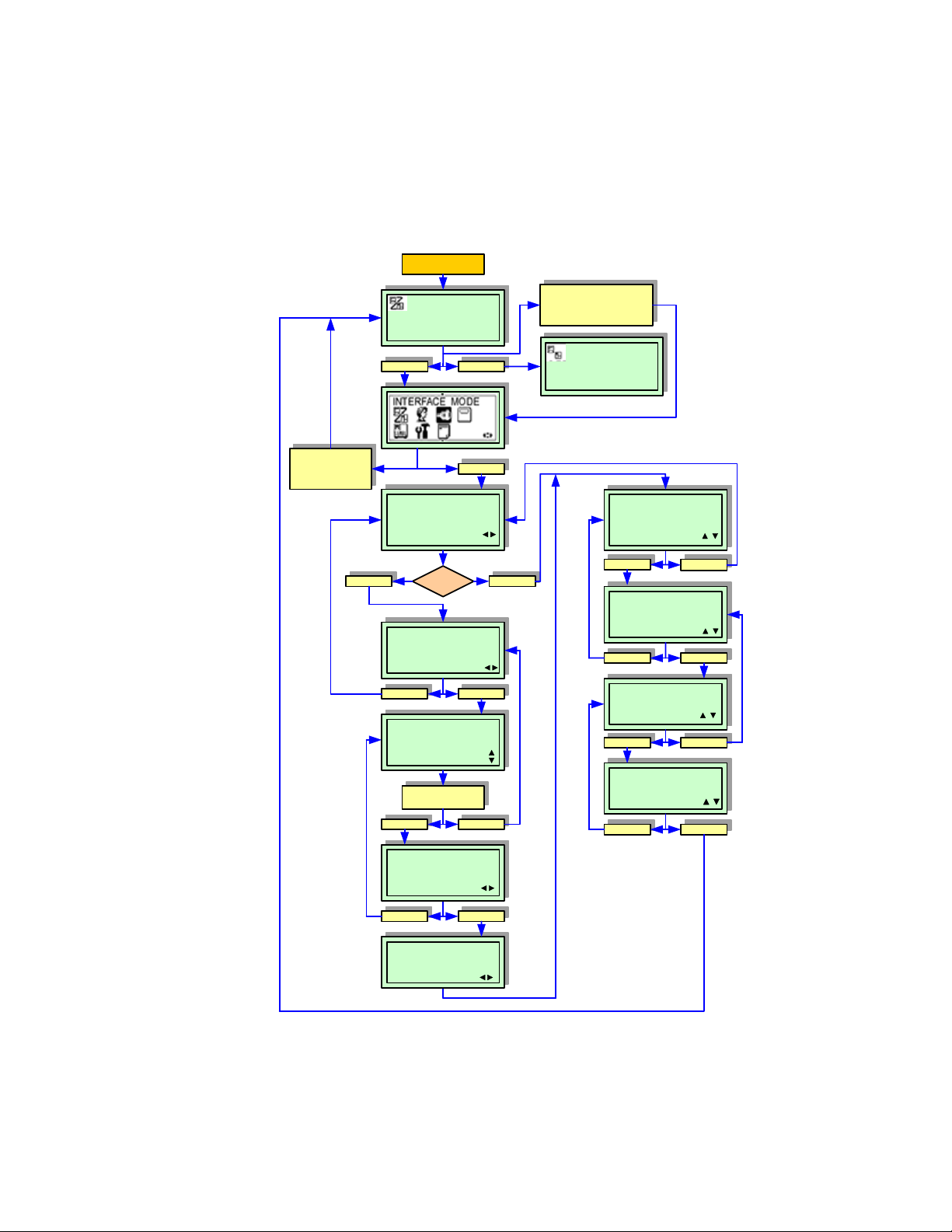

RS232C INTERFACE SETUP MODE

This chapter provides the programming sequences required for RS232C interface setup. Use the

keys of the printer’s operator panel to select and enter the required options.

POWER

INT ERFACE CAR D

ONLI NE

QTY: 000000

SETTIN G

YES NO

No + ENTER

OFFLINE

000000

ENTER

ITEM NO CHECK

ENABLE D ISABLE

CANCEL

BCC CHECK

ENABLE D ISABLE

ENTER

IGNORE CAN/DLE

YES NO

ENTER CANCEL

ENTER

PROT OCOL

READY/BUSY

XON/OFF

STAT US2

STAT US3

STAT US4

STAT US5

MULTIDR OP

STAT US5 Selected ?

Yes / No

ENTER

CANCEL

LINE

ENTER

INT ERFACE CAR D

SETTIN G

CARD1 CARD2

RS-232C/422/485

CANCEL

CANCEL ENT ER

CANCEL ENT ER

CONFIGURATION

DIPSW LCD

Select DIPSW to bypa ss

baudrate and bit configuration.

Select LCD to configure those.

Ready / Busy,

X-On / Of f se lect ed ?

Yes / No

RECEIVE BUFF ER

MULTI 1ITEM

ENTER CANCEL

DATA PORT

CARD1 CARD2

STAT US PORT

ENABLE DISABLE

ENTER CANCEL

IGNORE CR/LF

YES NO

Select Yes .

Press EN TER

CANCEL

ENTER

Press FUNCT ION

anytime during

sequence returns

to Normal Mode.

BAUDR ATE

2400 4800

9600 19200

PARIT Y BIT

NONE ODD EVEN

CANCEL

STOP BIT

1BIT 2BIT

CHARACTER BIT

7BIT 8BIT

CANCELENTER

ENTER

CANCELENTER

ENTERCANCEL

Figure 4-5, RS232C Interface Setup Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-6

Page 35

Unit 4: Operation

CENTRONICS INTERFACE SETUP MODE

This chapter provides the programming sequences required for Centronics interface setup. Use

the keys of the printer’s operator panel to select and enter the required options.

POWER

Type password if

prompted, then press

ONLI NE

QTY: 000000

ENTER.

Press FUNCTION

anytime during

configuration.

ENTER

INT ERFAC E CARD

SETTING

YES NO

INT ERFAC E CARD

SETTING

CARD1 CARD2

CANCEL ENT ER

RECEIVE BU FF ER

MULTI 1 ITEM

ENTER CANCEL

CENTRONICS

ACK SIGNAL

ON OFF

CANCEL ENT ER

LINE

ENTER

Yes / NoENTER ENTER

OFFLINE

000000

DATA PORT

CARD1 CARD2

ENTER CANCEL

STATUS PORT

ENABLE D ISABLE

CANCEL ENT ER

IGNORE CR/LF

YES NO

ENTER CANCEL

IGNORE CAN/DLE

YES NO

CANCEL ENT ER

CENTRONICS

FAULT SIGNAL

ON OFF

Figure 4-6, Centronics Interface Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-7

Page 36

Unit 4: Operation

LAN INTERFACE SETUP MODE

This chapter provides the programming sequences required for LAN and mini-LAN interface

setup. Use the keys of the printer’s operator panel to select and enter the required options.

POWER

INTERFACE CARD

SETT ING

YES NO

No + ENT ER

Select Yes.

Pre ss ENTER

OFFLINE

000000

INTERFACE CARD

SETTING

CARD1 CARD2

ONLI NE

QTY: 000000

ENTERLINE

STAT US5 Selected ?

ENTER

ITEM N O CHECK

ENABLE DISABLE

CANCEL ENT ER

BCC CHECK

ENABLE DISABLE

STATUS

REPLY T IMIN G

ENG CYCLE

DATA PORT

CARD1 CARD2

CANCEL ENT ER

STAT US PORT

ENABLE DISABLE

ENTER CANCEL

IGNORE CR/LF

YES NO

CANCEL ENT ER

Yes / No

CANCELENTER

STAT US4 Selected ?

Yes / No

CANCELENTER

CANCEL

LAN

CONFIGURATION

CARD LCD

Card Selected?

LAN card detected?

Yes / No

WIRELESS MODE

802.11 Ad Hoc

Ad Hoc

Infrastructure

SSID

1234567890ABCDEF

CHANNEL

01

PROT OCOL

STAT US3

STAT US4

STAT US5

IGNORE CAN/DLE

YES NO

CANCEL

Yes / No

ENTERCANCEL

CANCELENTER

ENTERCANCEL

ENTER

ENTER

CANCELENTER

Press FUNCTION anytime

during sequence returns to

Normal Mode.

IP ADDRESS

0. 0. 0. 0

CANCELENTER

SUBNET MASK

0. 0. 0. 0

CANCEL

GATEWAY ADDRESS

0. 0. 0. 0

PORT NUMBER 1

01024

PORT NUMBER 2

01024

PORT NUMBER 3

01024

CANCEL ENT ER

ENTER

CANCELENTER

ENTERCANCEL

CANCELENTER

Figure 4-7, LAN Interface Setup Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-8

Page 37

Unit 4: Operation

USB INTERFACE SETUP MODE

This chapter provides the programming sequences required for USB interface setup. Use the

keys of the printer’s operator panel to select and enter the required options.

POWER

Type password if

prompted, then press

ONLI NE

QTY: 000000

ENTER.

Press FUNCTION

anytime during

configuration.

ENTER

INT ERFAC E CARD

SETTING

YES NO

INT ERFAC E CARD

SETTING

CARD1 CARD2

CANCEL ENT ER

PROT OCOL

STATUS4

STATUS5

Select STAT US4

for USB Interface.

ENTER CANCEL

LINE

ENTER

Yes / NoENTER ENTER

OFFLINE

000000

DATA PORT

CARD1 CARD2

ENTER CANCEL

STATUS PORT

ENABLE D ISABLE

CANCEL ENT ER

IGNORE CR/LF

YES NO

ENTER CANCEL

IGNORE CAN/DLE

YES NO

CANCEL ENT ER

ITEM NO CHECK

ENABLE D ISABLE

CANCEL ENT ER

BCC CHECK

ENABLE D ISABLE

Figure 4-8, USB Interface Setup Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-9

Page 38

Unit 4: Operation

CARTRIDGE MODE

This mode permits the configuration of an optional memory cartridge. This cartridge, when

loaded, provides increased storage capacity for text and graphics. Use the keys of the printer’s

operator panel to select and enter the required options.

POWER

ONLI NE

QTY: 000000

ENTER

ENTER

CARTRIDGE FORMAT

YES NO

YES + ENTER

CARTRIDGE FORMAT

COMPLETED

PRESS ENT ER KEY

LINE

No / Yes YES + ENT ERNO + ENTER

FORMAT ST ART

YES NO

OFF LINE

000000

Press FUNCTION

anytime during

configuration to retur n

to Normal Mode.

CANCEL

Yes / No NO + ENTER

ENTER

Figure 4-9, Cartridge Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-10

Page 39

Unit 4: Operation

SEMBL MODE

SEMBL (SATO Embedded Basic Language) allows software programs written in standard Basic

language to be loaded into the printer and executed without additional computer connections.

Use the keys of the printer’s operator panel to select and enter the required options.

Press FUNCTION anytime

during sequence returns to

SEMBL MODE.

POWER

ONLI NE

QTY:000000

LINE

OFFLINE

QTY:000000

ENTER

ENTER

START PROGRAM

FIRST.BAS

SECOND.BAS

Scroll options to select

the desired program.

ENTER CANCEL

SEMBL MODE

AUTO START

YES NO

ONLI NE

QTY:000000

SEMBL

Program

is executed .

SEMBL

Program

terminates.

LINE

OFF LINE

QTY:000000

SEMBL

Program

is halte d .

LINE

Figure 4-10, SEMBL Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-11

Page 40

Unit 4: Operation

TEST PRINT MODE

Figure 4-11 provides the specific sequence of events required by the operator, the printer, and

the printer’s software for a test label to be printed. Test labels are designed to identify failures in

configuration, adjustment problems, and mechanical defects.

Use the keys of the printer’s operator panel to select and enter the required options.

FEED + POWER

Printer

beeps

TEST PR INT MODE

CONFIGURATION

BARCODE

Press or

+ ENTER

Scrolls

options

TEST PRINT MODE

CONFIGURATION

TEST PRINT MODE

BARCODE

TEST PRINT MODE

HEAD CHECK

TEST PRINT MODE

MEMORY

TEST PRINT MODE

FONT

TEST PRINT MODE

FACTORY

TEST PRINT SIZ E

10 mm

TEST PRINT

PRESS ENT ER KEY

TEST PRINT SIZ E

LARGE SMALL

ENTER

Test Prints

Power off t o

cease printing.

Figure 4-11, Test Print Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-12

Page 41

Unit 4: Operation

DOWNLOAD MODE

This download feature allows the operator to download print jobs to the printer. When

downloading is complete, the LCD screen will return to the original display. If an error occurs, a

DOWNLOAD ERROR will display.

Use the keys of the printer’s operator panel to select and enter the required options.

+ POWER

Printer

beeps

DOWNLOAD

WAITING

User prepar es and

sends data.

DOWNLOADING

DOWNLOAD COMPLETE

PRESS ENT ER KEY

ENTER

Figure 4-12, Download Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-13

Page 42

Unit 4: Operation

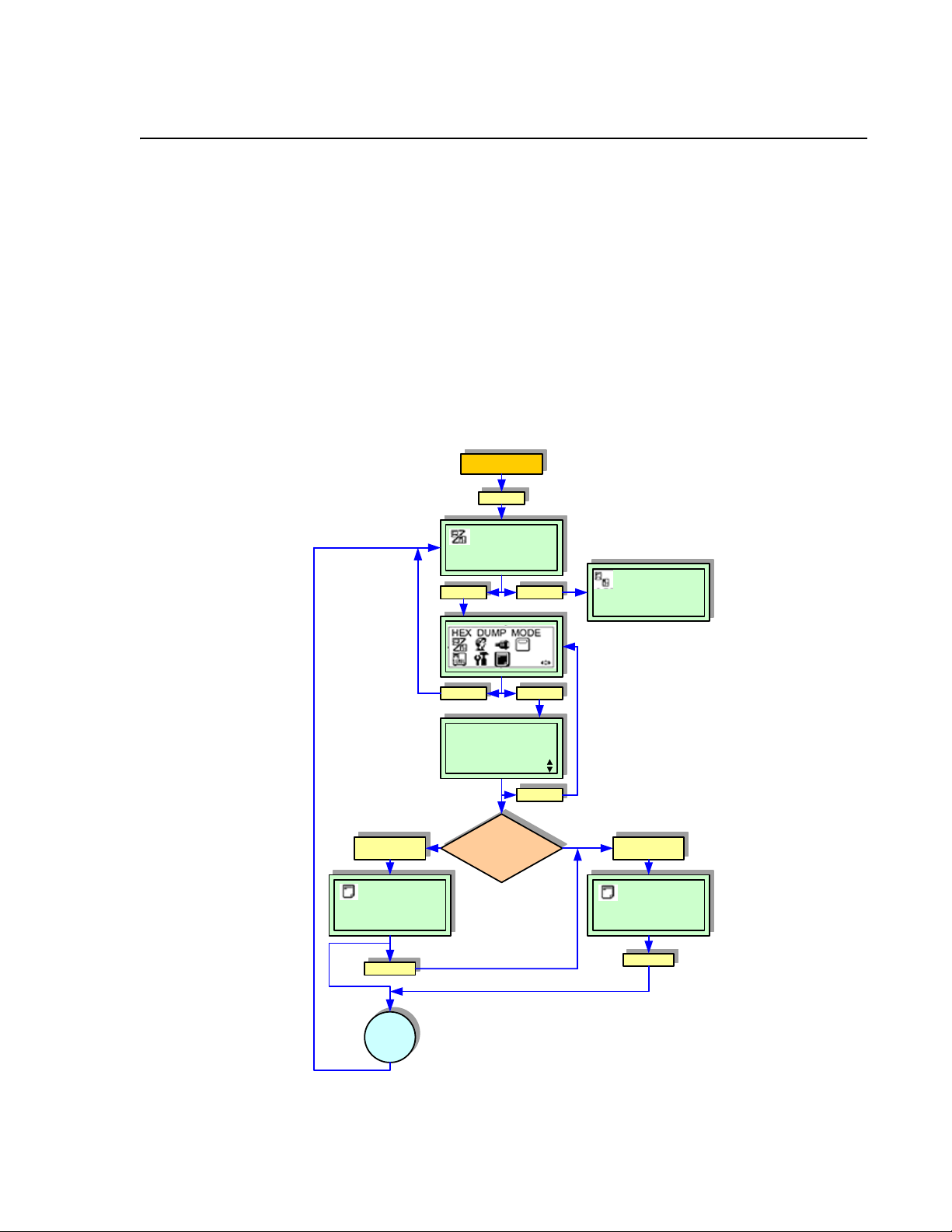

HEX DUMP MODE

The contents of the print buffer and the data received before it is placed into the print buffer may

be examined through the use of the Hex Dump Mode. Each line of the printed data is inumerated

in the first column, the second column contains the data in hexadeicimal format, and the right

column contains the same data in ASCII format.

Only one type of data may be printed on a single label. Repeat the dump process to print the

other data type.

Use the keys of the printer’s operator panel to select and enter the required options.

POWER

ENTER

ONLINE

QTY: 000000

Receive Data

ENTER

ONLI NE

000000

LINE

Hex

Dump is

printed

ENTER LINE

CANCEL ENT ER

SELECT DUMP DATA

RECEIVE DATA

RECEIVE BU FF ER

CANCEL

RECEIVE DATA/

RECEIVE BU FF ER

OFFLINE

000000

Receive Buffer

ENTER

OFFLINE

000000

LINE

Figure 4-13, Hex Dump Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-14

Page 43

Unit 4: Operation

BOOT DOWNLOAD MODE

Figure 4-14 provides the specific sequence of events required by the operator, the printer, and

the printer’s software Use the keys of the printer’s operator panel to select and enter the

required options.

FUNCTION + + ENTER + POWER

BOOT

DOWNLOADER

INTERFACE

Press FUNCT ION

anytime returns to

Download Mode

ENTER

CARTRIDGE

Interface / Cartr idge

ENTER

SELECT

INTERFACE

CARD1

CARD2

CANCEL

PROGRAM

DOWNLOAD

READY

PROGRAM

DOWNLOADING

0 100

PROGRAM

DOWNLOAD

COMPLETED

PRESS ENT ER

Data

received

Download

comp lete

ENTER

PROGRAM

DOWNLOAD

YES NO

ENTER CANCEL

ENTER

Figure 4-14, Boot Download Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-15

Page 44

Unit 4: Operation

DATA SAVE MODE

Figure 4-15 provides the specific sequence of events required by the operator, the printer, and

the printer’s software to store the printer’s history.

Use the keys of the printer’s operator panel to select and enter the required options.

LINE

OFFLINE

Press FUNCTION

anytime returns to

Download Mode

000000

Press and hold

more than 5 seconds.

SAVING PRIN T

LOG

History

data save

completed.

DATA SAVE

START

YES NO

Yes / No

ENTER ENTER

COPYING

0100

Received

data save

completed.

DATA SAVE

COMPLETED

ENTER

Figure 4-15, Data Save Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-16

Page 45

Unit 4: Operation

DEFAULT SETTINGS MODE

Figure 4-16 provides the specific sequence of events required by the operator, the printer, and

the printer’s software to return the printer to the configuration state as recieved from the factory.

Use the keys of the printer’s operator panel to select and enter the required options.

CANCEL + POWER

Printer

beeps

DEFAULT MODE

PRINTER SETTING

ALT. PROTOCOL

DEFAULT MODE

PRINTER SETTING

YES NO

Printer

beeps

3 times

DEFAULT SETTING

COMPLETED

PLEASE POWER OFF

PRINTER SETTING/

ALT PROT OCOL

Press or

+ ENTER

DEFAULT

ALT. PROTOCOL

YES NO

Yes / NoENTER ENTER

Figure 4-16, Default Settings Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-17

Page 46

Unit 4: Operation

PRINT CANCEL MODE

Figure 4-17 provides the specific sequence of events required by the operator, the printer, and

the printer’s software to cancel a print job once initiated. Use the keys of the printer’s operator

panel to select and enter the required options.

LINE

OFFLINE

Pre ss FUNCTION

anytime returns to

Download Mode

000000

CANCEL

CANC EL PRIN T

JOB

YES NO

Yes / No

ENTER

CANCEL PRINT

JOB

COMPLETED

Allow 3

seconds

Figure 4-17, Print Cancel Mode

ENTER

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-18

Page 47

Unit 4: Operation

PRINT DARKNESS DEFAULT MODE

Figure 4-18 provides the specific sequence of events required by the operator, the printer, and

the printer’s software to return to the print darkness (density) setting as received from the factory.

Use the keys of the printer’s operator panel to select and enter the required options.

Change Print Head

POWER

Printer

beeps

HEAD CHANGE

08->12 [dot / mm]

YES NO

Select Yes then

press ENTER

PASSWORD

0000

Type 0003 then

press ENTER

DEFAULT

SETT ING

COMPLETED

PLEASE POWER OF F

POWER OFF

Figure 4-18, Print Density Default Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-19

Page 48

Unit 4: Operation

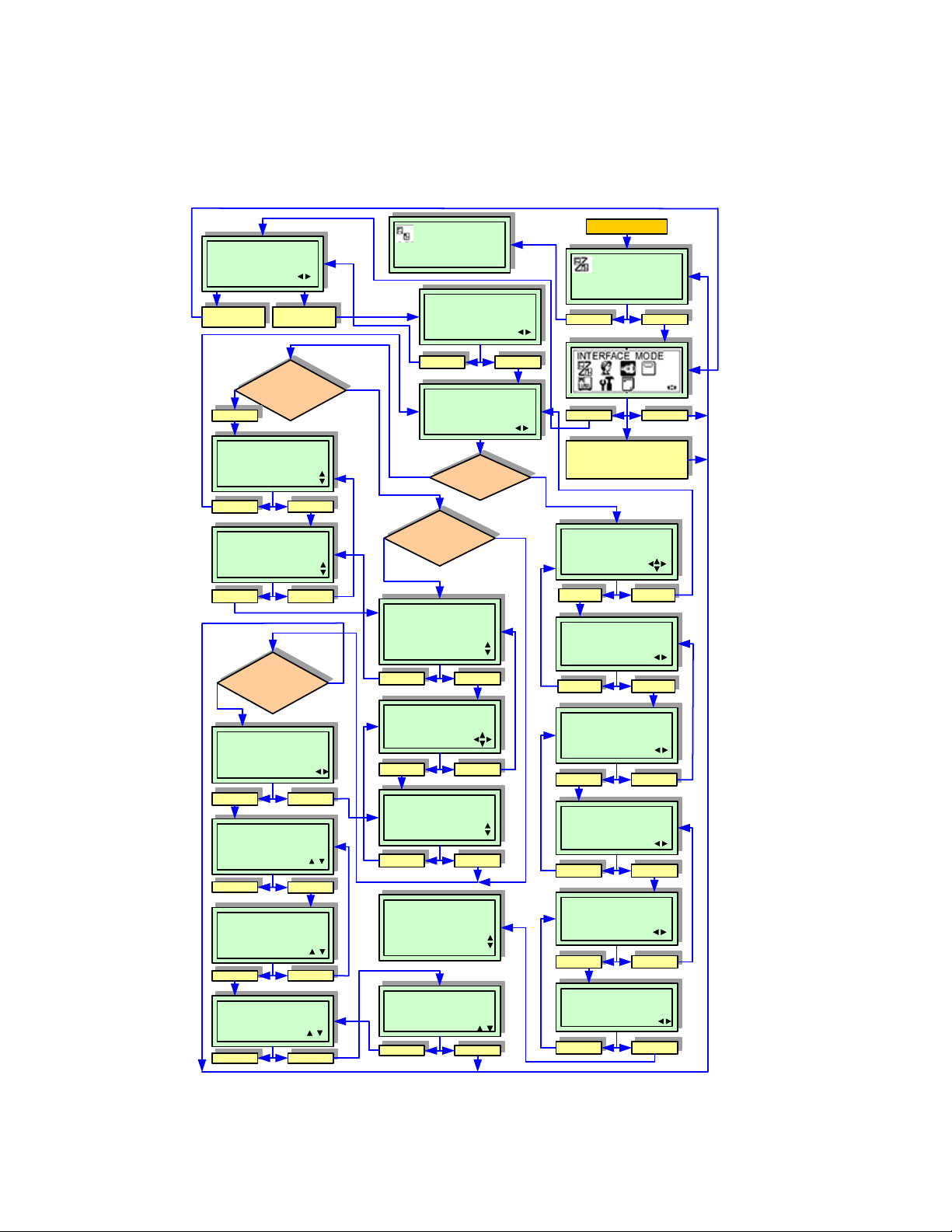

SERVICE MODE

Allows the programming of various dimensional settings, sensor thresholds, and language

options. Use the keys of the printer’s operator panel to select and enter the required options.

HEAD OPEN + ENTER +

+ + POWER

MAINTENANCE MODE

SERVICE MODE

FACTORY MODE

SENSOR LEVEL

I-MARK X.XV

LEVEL OFFSET 50

ENTERCANCEL

SENSOR LEVEL

I-MARK X.XV

SLICE L EVEL 1.0V

CANCELENTER

SENSOR LEVEL

GAP X.XV

LEVEL OFFSET 50

ENTERCANCEL

SENSOR LEVEL

GAP X.XV

SLICE LEVEL 50

LABEL NEAR END

ENABLE DISABLE

RIBBON TENSION

ADJUST MENT

ENABLE DISABLE

RIBBON TENSION

ADJUST MENT

ENABLE DISABLE

No

CANCELENTER

ENTERCANCEL

CANCELENTER

Service / Factory

ENTER

COMPATIBLE MODE

ON OFF

SET PASSWORD

ON OFF

PRIORITY SETTING

COMMAND INTERNAL

EXT 9PIN SELECT

MODE1 MODE2

FORWAR D/BACKFEED

DIST ANCE

DEFAULT 000mm

FUNCTION KEY

NONE

REPRINT

SBI MODE

RIBBON N EAR END

ENABLE D ISABLE

Advances

to Factory

Mode.

Asks for

media length

ENTERCANCEL

CANCELENTER

ENTERCANCEL

CANCELENTER

ENTERCANCEL

CANCELENTER

ENTERCANCEL

if On

select ed.

Asks for

password if

On

select ed.

PROGRAM COPY

YES NO

Yes

TRACE MODE

ON OFF

SAVE PRINT LOG

ENABLE D ISABLE

PROGRAM COPY

CARTRIDGE>ROM

ROM>CARTRIDGE

CARTRIDGE->ROM

COPY STAR T

YES NO

ROM->CARTRIDGE

COPY STAR T

YES NO

COPYING

ENTERCANCEL

CANCELENTER

ENTERCANCEL

CLEAR PRINT LOG

YES NO

OUTPUT PRINT LOG

ENABLE D ISABLE

PROGRAM COPY

COMPLETED

PRESS ENT ER KEY

CANCELENTER

ENTERCANCEL

Figure 4-19, Service Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-20

Page 49

Unit 4: Operation

FACTORY MODE

The Factory Mode permits counter reset of various printer components. Use the keys of the

printer’s operator panel to select and reset those features.

HEAD OPEN + ENTER +

+ + POWER

MAINTENANCE MODE

SERVICE MODE

FACTORY MODE

COUNTER CLEAR

NONE

ALL

HEAD

CUT

DISPENSE

CANCEL ENT ER

COUNTER

INDICATION

NONE

LIFE

HEAD

CUT

DISPENSE

CANCEL

Fact or y / Se rvice

ENTER

LIFE + ENTER

LIFE COUNTER

0. 0 M

HEAD + ENTER

HEAD COUNTER

[1] 0. 0 M

[2] 0. 0 M

[3] 0. 0 M

CUT COUNTER

0

DISPENSE + ENTER

DISPENSE COUNTER

0. 0 M

HEAD + ENTER

NONE + ENT ER

SERIAL N O

S/N 00000000

CANCEL ENT ER

MAIN PCB

REVISION

REV 0. 0

ENTER CAN CEL

INTERFACE CARD

REVISION

REV 0. 0

CANCEL ENT ER

TEST PRINT

YES NO

CANCEL

YES + ENTER

PRINT SIZE

SMALL LARGE

CANCEL ENT ER

TEST PRINT

PRESS ENT ER KEY

ENTER CANCEL

Test

printing

begins.

Figure 4-20, Factory Mode

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-21

Page 50

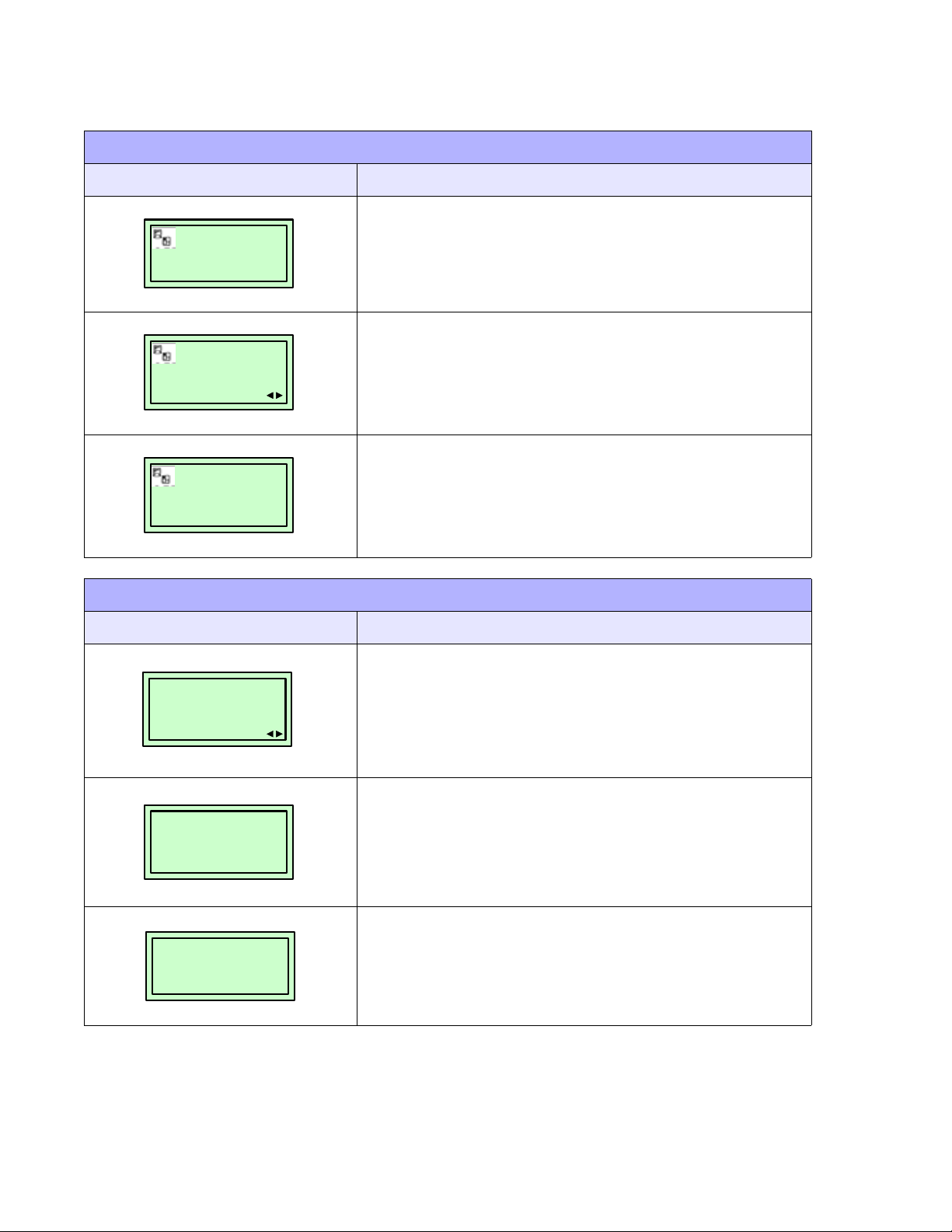

Unit 4: Operation

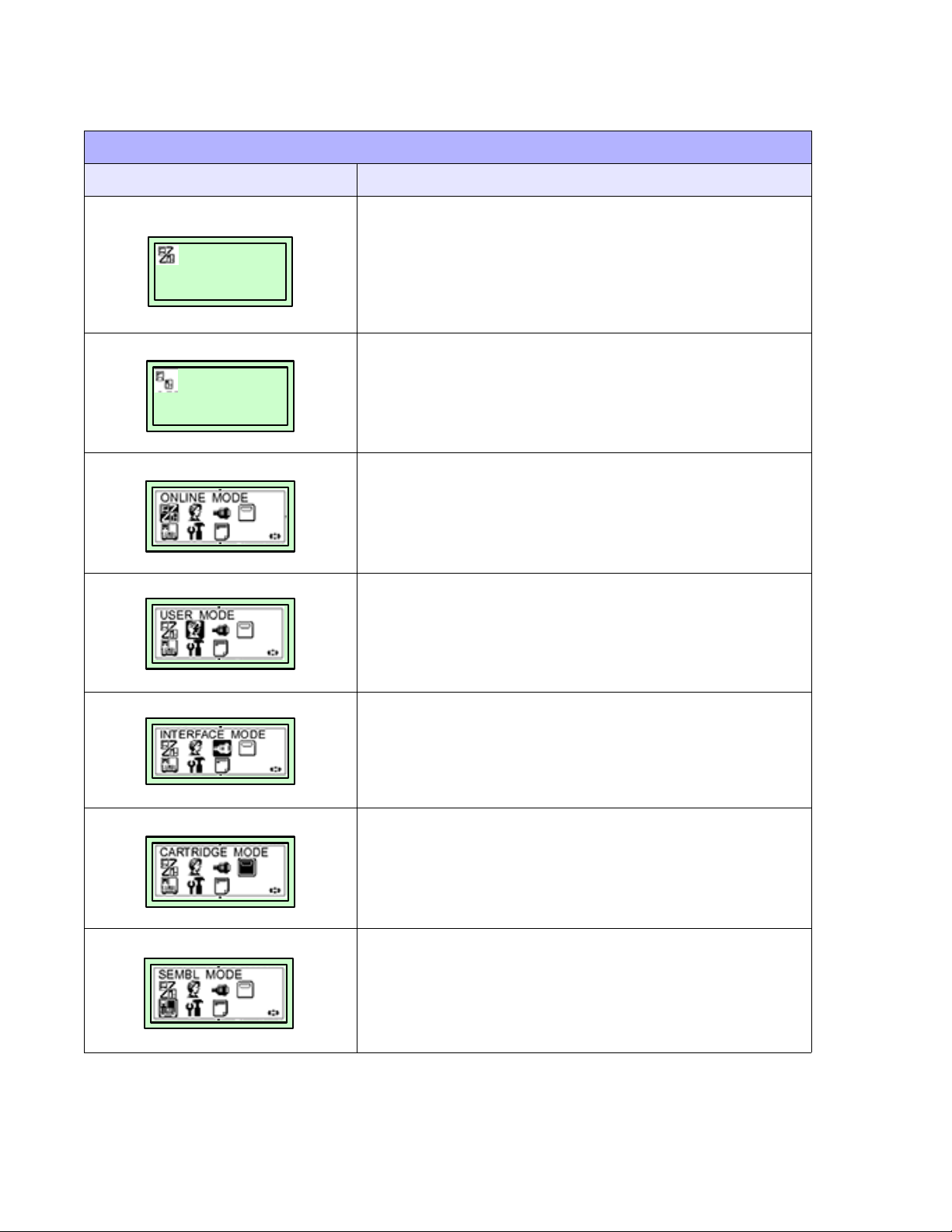

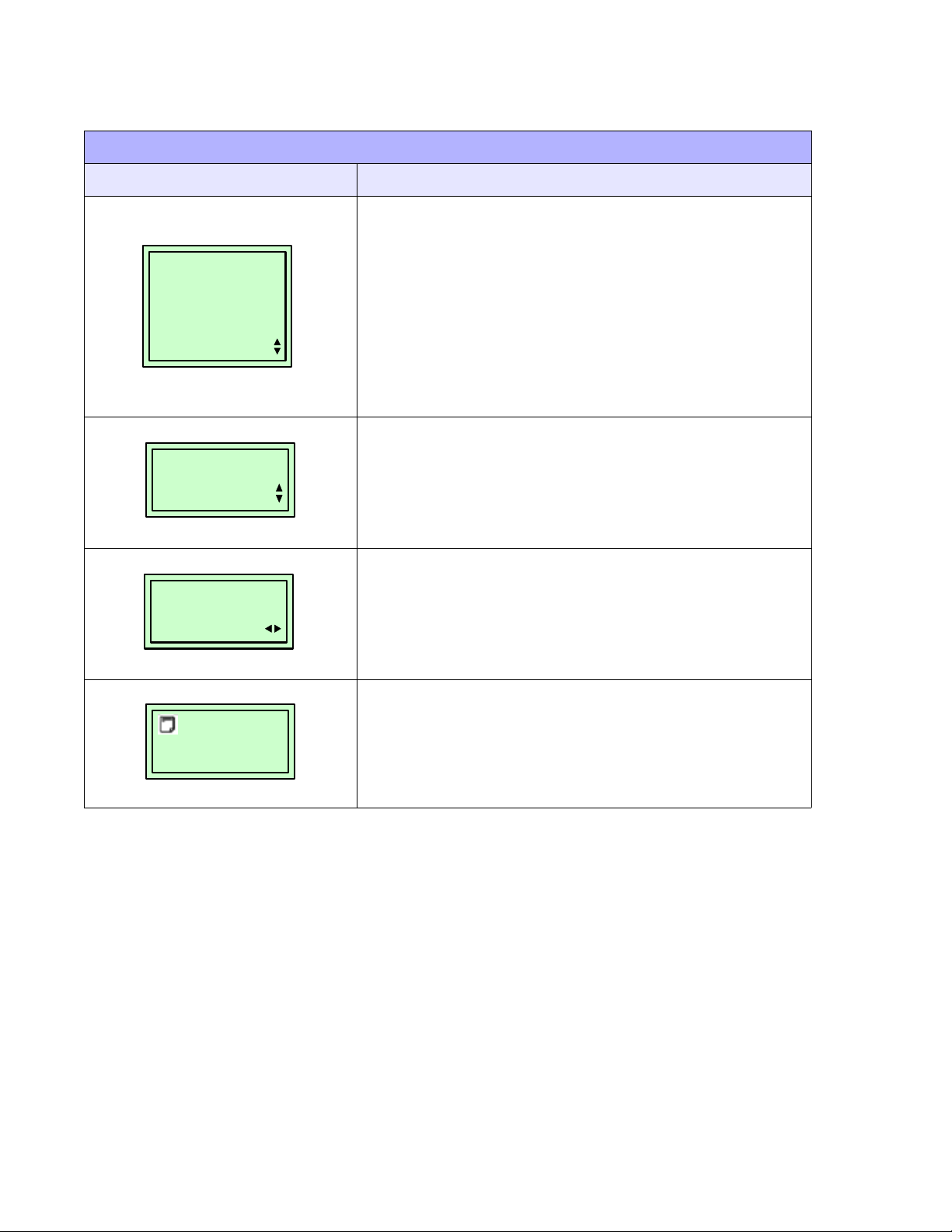

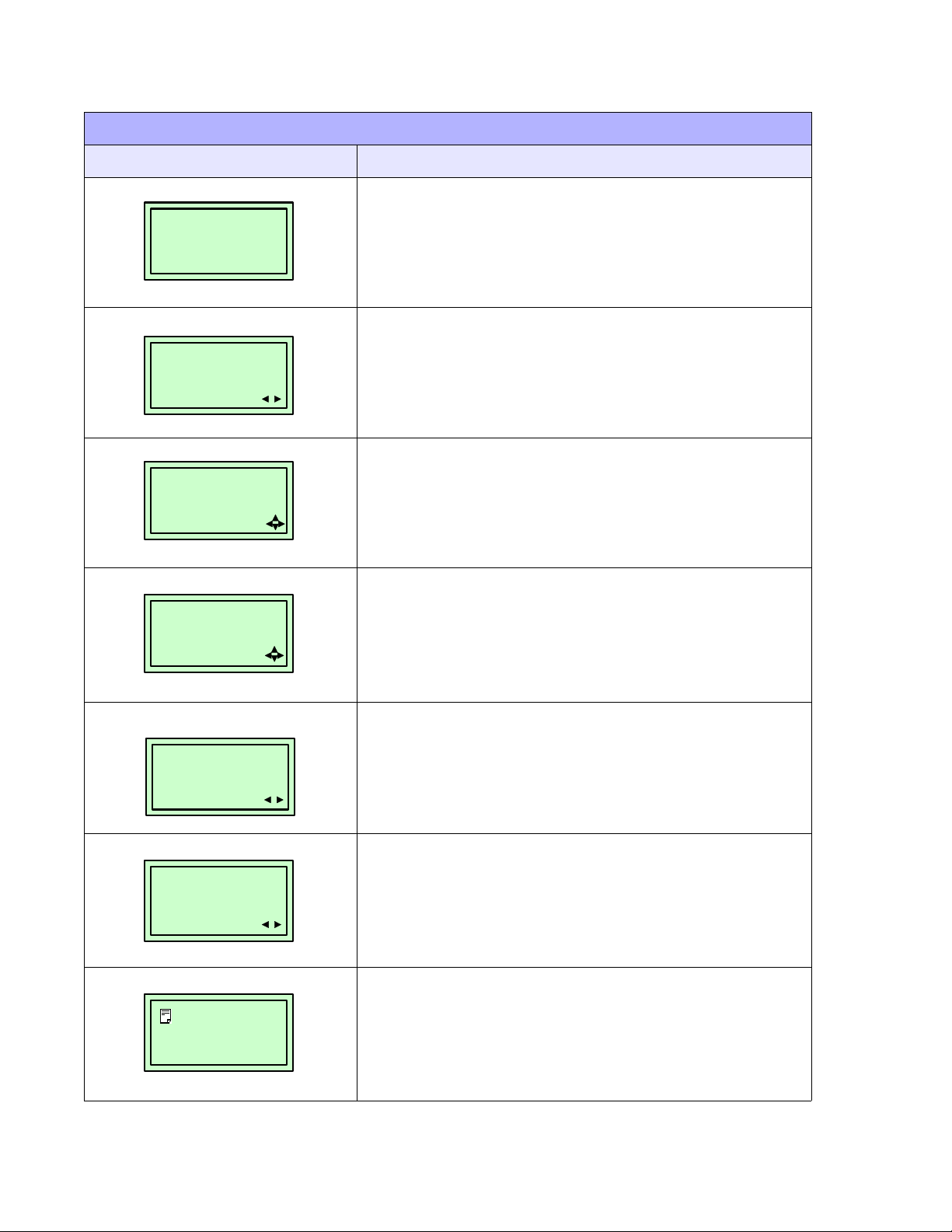

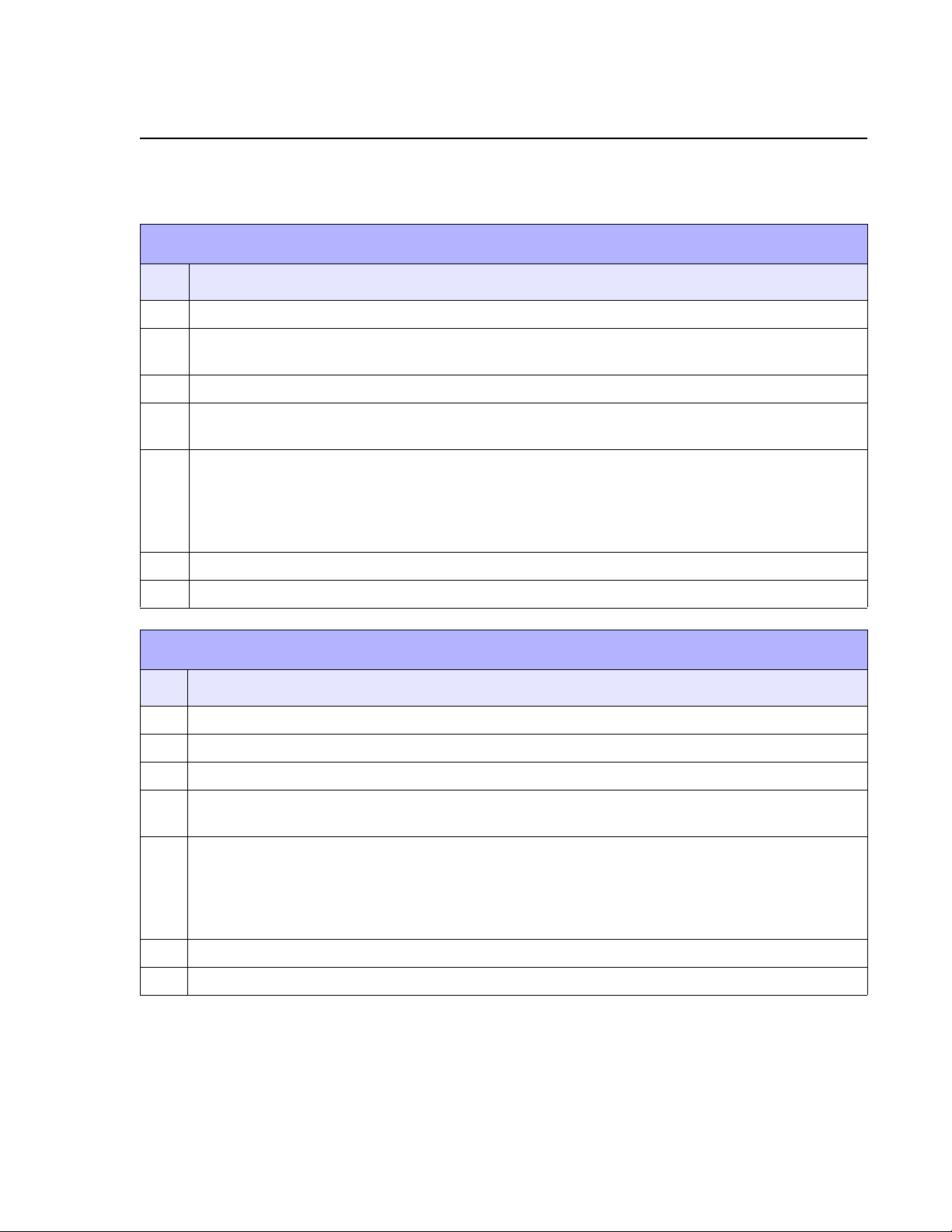

MENU DESCRIPTION

ONLINE

QTY: 000000

OFF LINE

000000

NORMAL MODE (4-1)

Displays the operational status of the printer. The ONLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to OFFLINE

whenever the printer is switched offline by pressing the LINE

key. When a print job is received, the quantity line will indicate

the number of labels to be printed. As the label job prints, the

display indicates the number of labels remaining to be printed.

Displays the operational status of the printer. The OFFLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to ONLINE

whenever the printer is switched online by pressing the LINE

key.

Is the first screen of the Normal Mode. Allows indepth analysis

of the printer’s status.

Is the premiere screen of the User Mode. The User Mode

allows various print parameters to be set.

Is the premiere screen of the Interface Mode. Interface Mode

allows the parameters to be set for the printer to communicate

with a host and vise-versa.

Is the premiere screen of the Cartridge Mode. Permits setup

and use of the memory cartridge.

Is the premiere screen of the SEMBL Mode. SEMBL (SATO

Embedded Basic Language) allows software programs written

in standard Basic language to be loaded into the printer and

executed without additional computer connections.

Use the keys of the printer’s operator panel to select and enter

the required options.

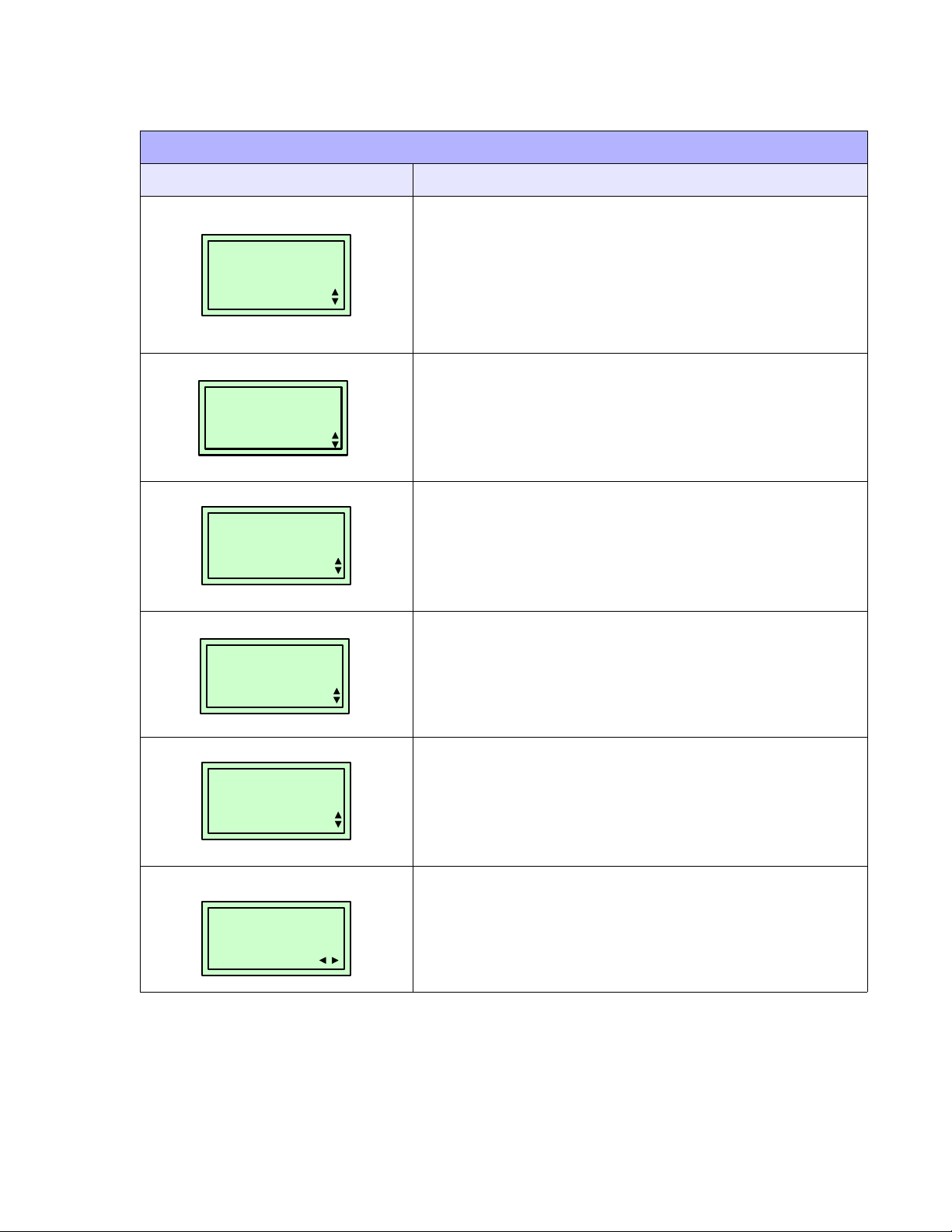

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-22

Page 51

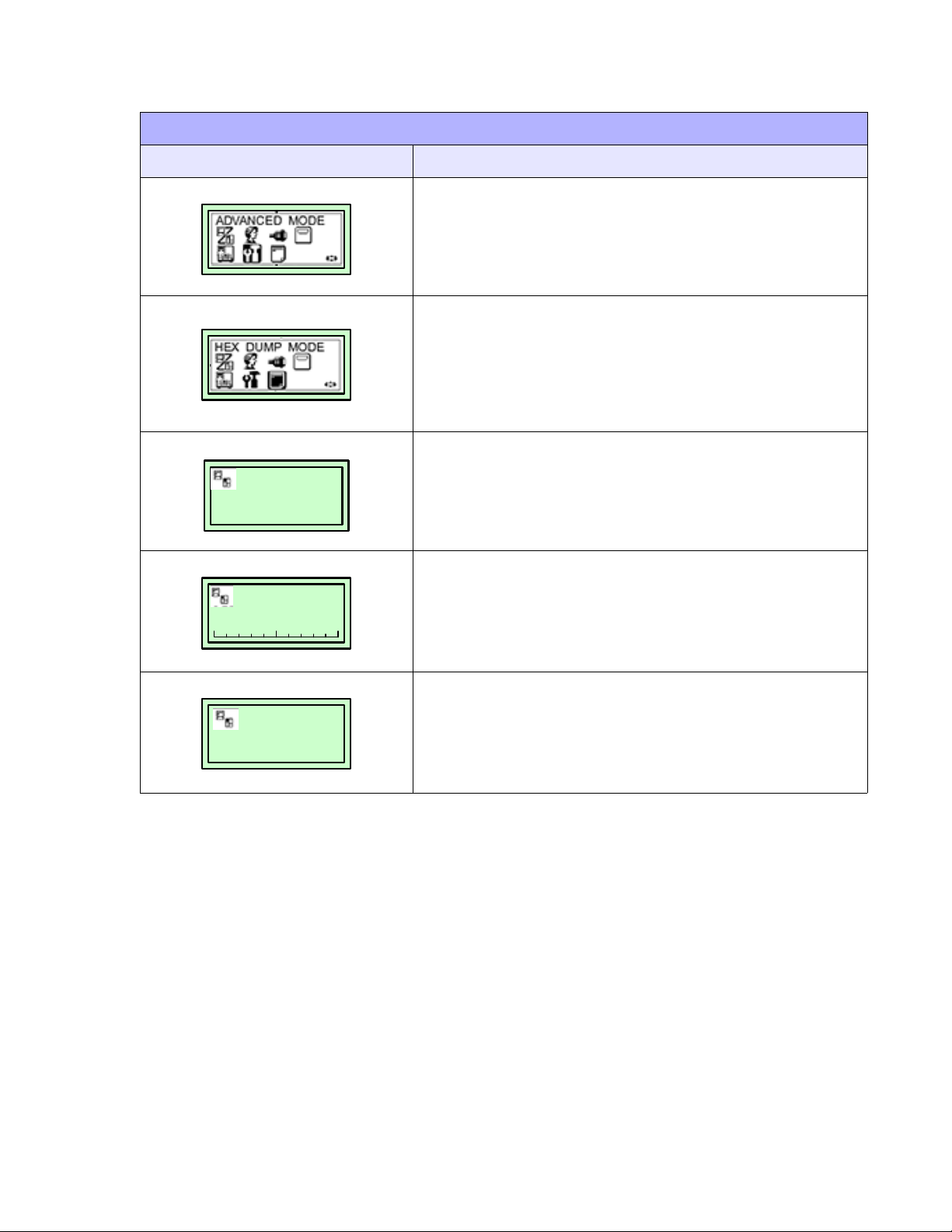

Unit 4: Operation

DATA SAVE START

YES NO

NORMAL MODE (4-1)

MENU DESCRIPTION

Is the premiere screen of the Advanced Mode. The Advanced

Mode is provided to make basic printer operational

adjustments. Typically, once these adjustments or settings have

been made, they will not require additional address unless a

new job is downloaded. The following table identifies the menus

of the Advanced Mode and their purpose.

Is the premiere screen to the Hex Dump Mode. The contents of

the print buffer and the data received before it is placed into the

print buffer may be examined through the use of the Hex Dump

Mode. Each line of the printed data is inumerated in the first

column, the second column contains the data in hexadeicimal

format, and the right column contains the same data in ASCII

format.

Allows the status of the receive buffer to be saved to the

memory cartridge. If the YES option is chosen, a cofiguration

screen will then be displayed. If the NO option is selected, the

printer goes offline without saving.

This screen shows the status of saving the receive buffer to the

memory cartridge. Data entry is not required.

COPYING

0100

This screen confirms the receive data was saved. Press

ENTER key to go offline.

DATA SAVE

COMPLETED

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-23

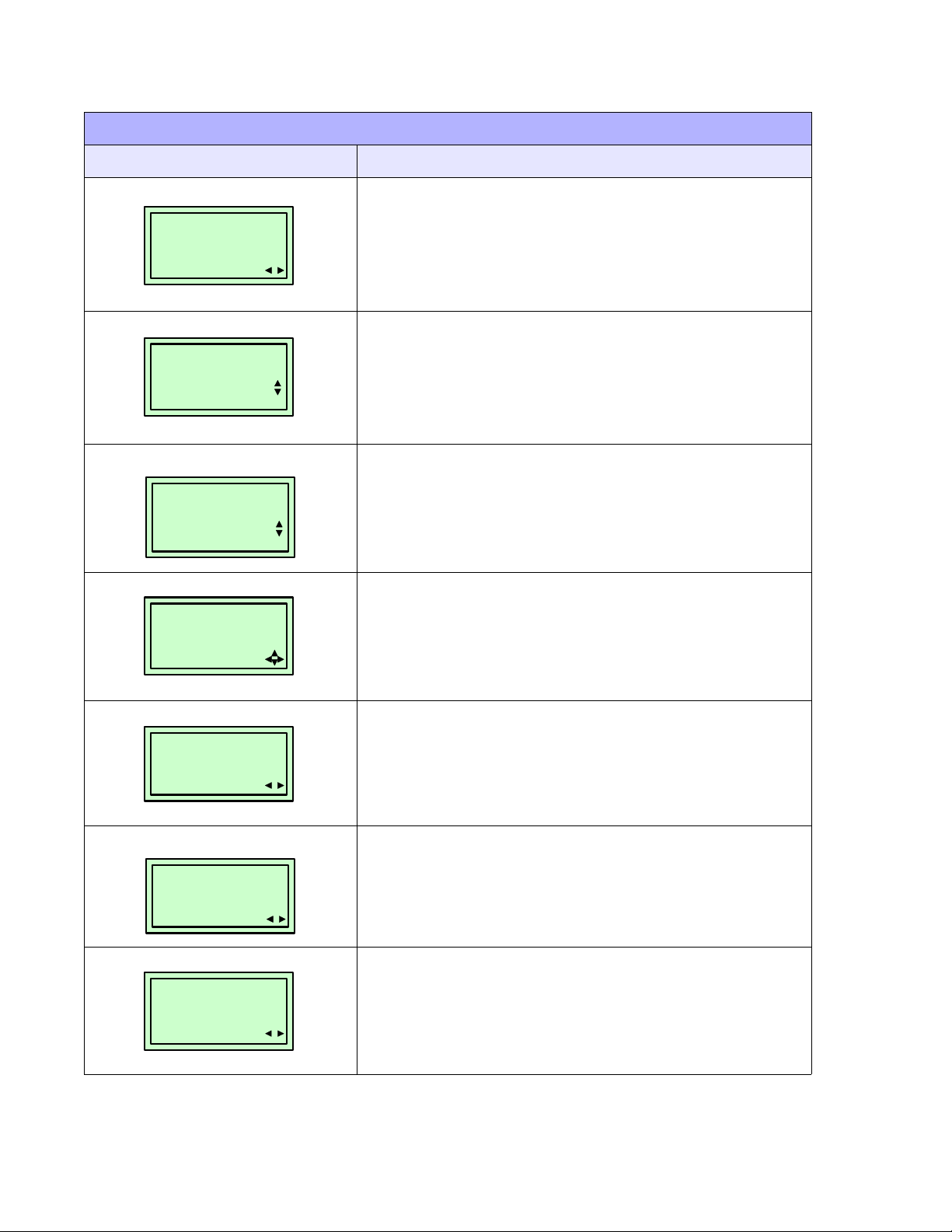

Page 52

Unit 4: Operation

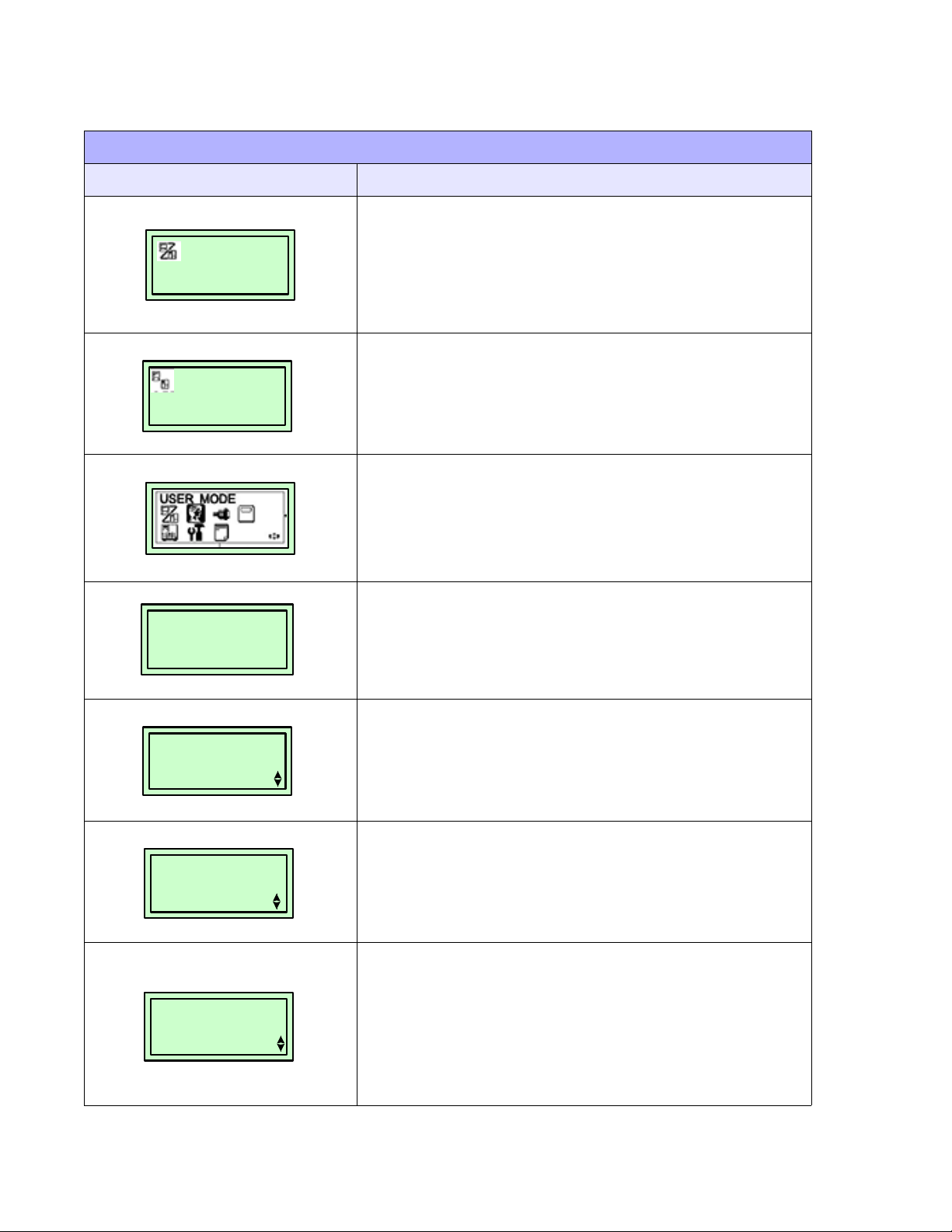

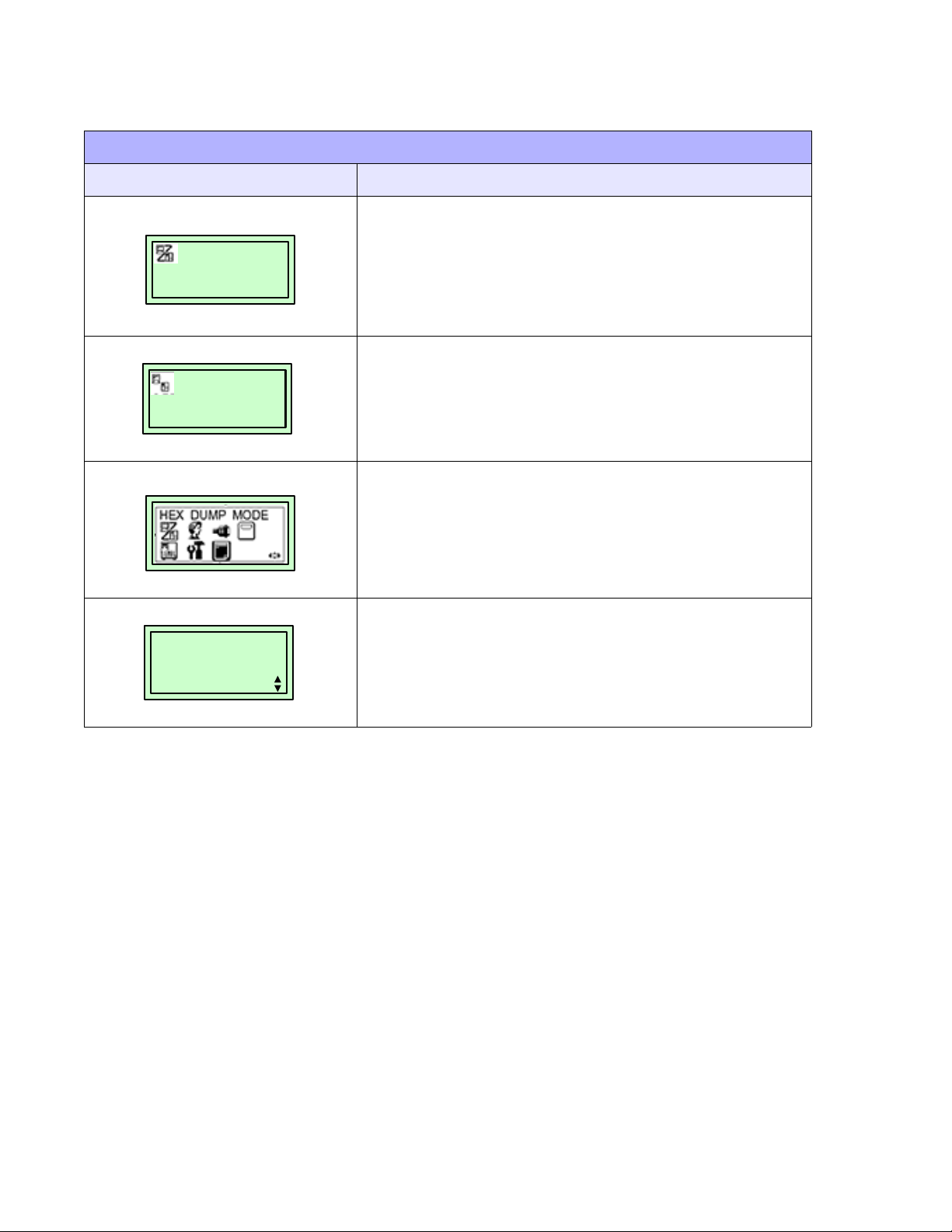

MENU DESCRIPTION

ONLIN E

QTY: 000000

OFF LINE

000000

USER MODE (4-2)

Displays the operational status of the printer. The ONLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to OFFLINE

whenever the printer is switched offline by pressing the LINE

key. When a print job is received, the quantity line will indicate

the number of labels to be printed. As the label job prints, the

display indicates the number of labels remaining to be printed.

Displays the operational status of the printer. The OFFLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to ONLINE

whenever the printer is switched online by pressing the LINE

key.

Is the premiere screen of the User Mode. The User Mode

allows various print parameters to be set.

OFFSET VOLUME

PITCH +0.00

OFFSET +0.00

DARKNESS 00

PRINT SPEED

06 IPS

PRINT DARKNESS

1 2 3 4 5

PITCH OFFSET

+00mm

This screenshows the adjusted value for volume on the

Operator Panel.

Permits the printer’s print speed to be established based on

inches per second (IPS). The speed options available are

dependent on the print head’s resolution.

Permits the adjustment of the print density. Higher print density

equates to darker print images.

The label pitch is the distance from the leading edge (the edge

that comes out of the printer first) of a label and the leading

edge of the next label. Once the position has been set, it can be

fine adjusted using the PITCH potentiometer.

Positive (+) digit selection on the display moves the leading

edge forward and away from the print head while a negative (-)

selection moves the label’s leading edge incrementally back

into the mechanism.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-24

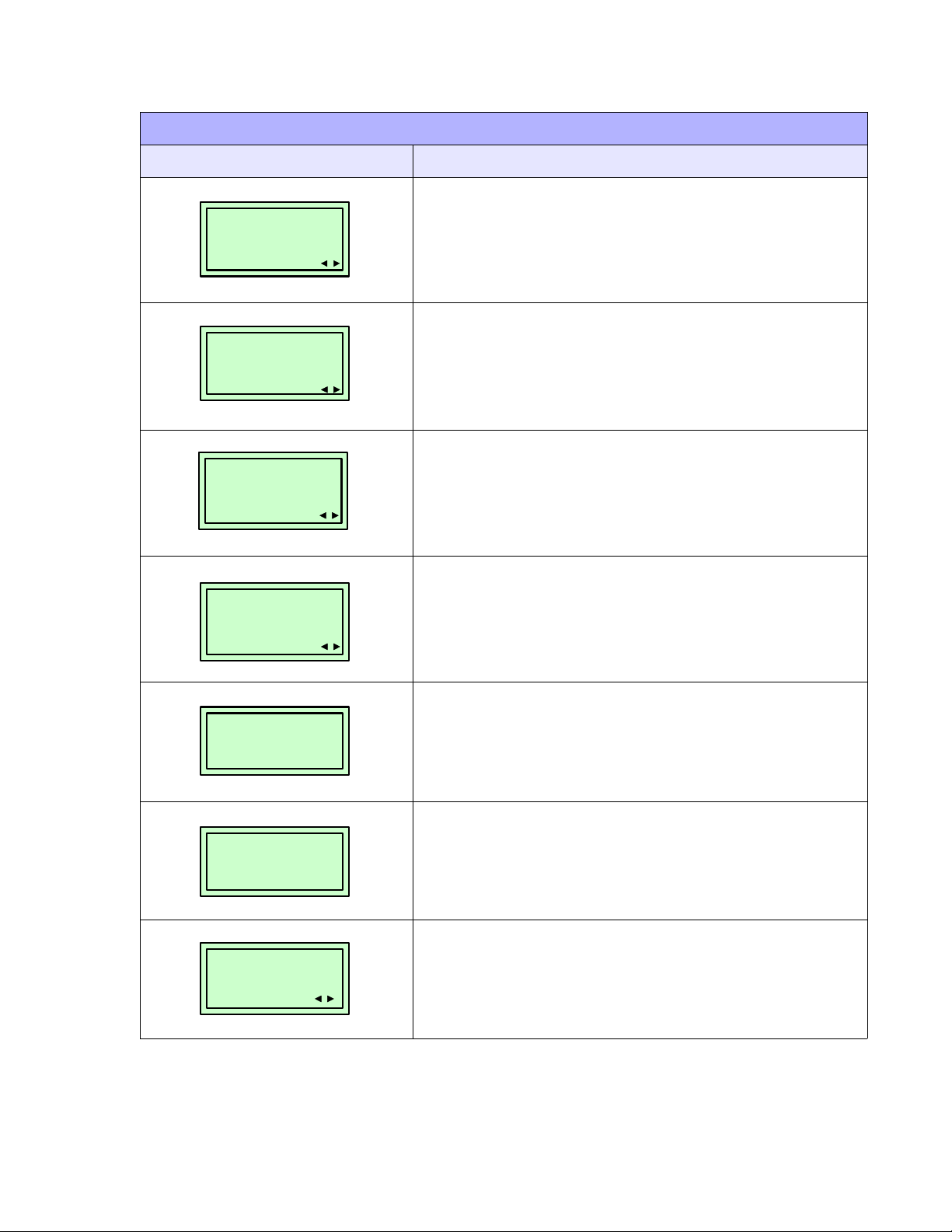

Page 53

Unit 4: Operation

PRINT OF FSET

V:+0000 H:+0000

ZERO SLASH

YES NO

JIS CODE

JIS SJIS

USER MODE (4-2)

MENU DESCRIPTION

Print offset refers to the vertical and horizontal shifting of the

entire print area relative to the label and the print start position.

The movement is incremented by dots in the positive (+) or

negative (-) direction. Positive and negative vertical adjustment

is toward and away from the print head respectively. Positive

and negative horizontal adjustment is to the left or right of the

reference point respectively.

This menu allows for the printer to be configured to print zeros

with or without a diagonal slash through them. This will apply to

all font types with the exception of Kanji font.

This menu allows printer configuration of Kanji files for either

Japanese code (JIS) or Microsoft code (SJIS). If a Microsoft

operating system is being used, SJIS is to be selected.

KANJI F ONT

MINCHO GOTHIC

CHAR ACT ER PITCH

PROPORT IONAL

FIXED

Kanji font may be set to either Mincho or Gothic style. If unsure

of their differences, refer to the Programming Reference for this

printer.

This setting determines whether each character occupies a

designated space (fixed) regardless of the characters width or if

the character’s space is representative of the character’s width

(proportional). Proportional is contemporarily preferred.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-25

Page 54

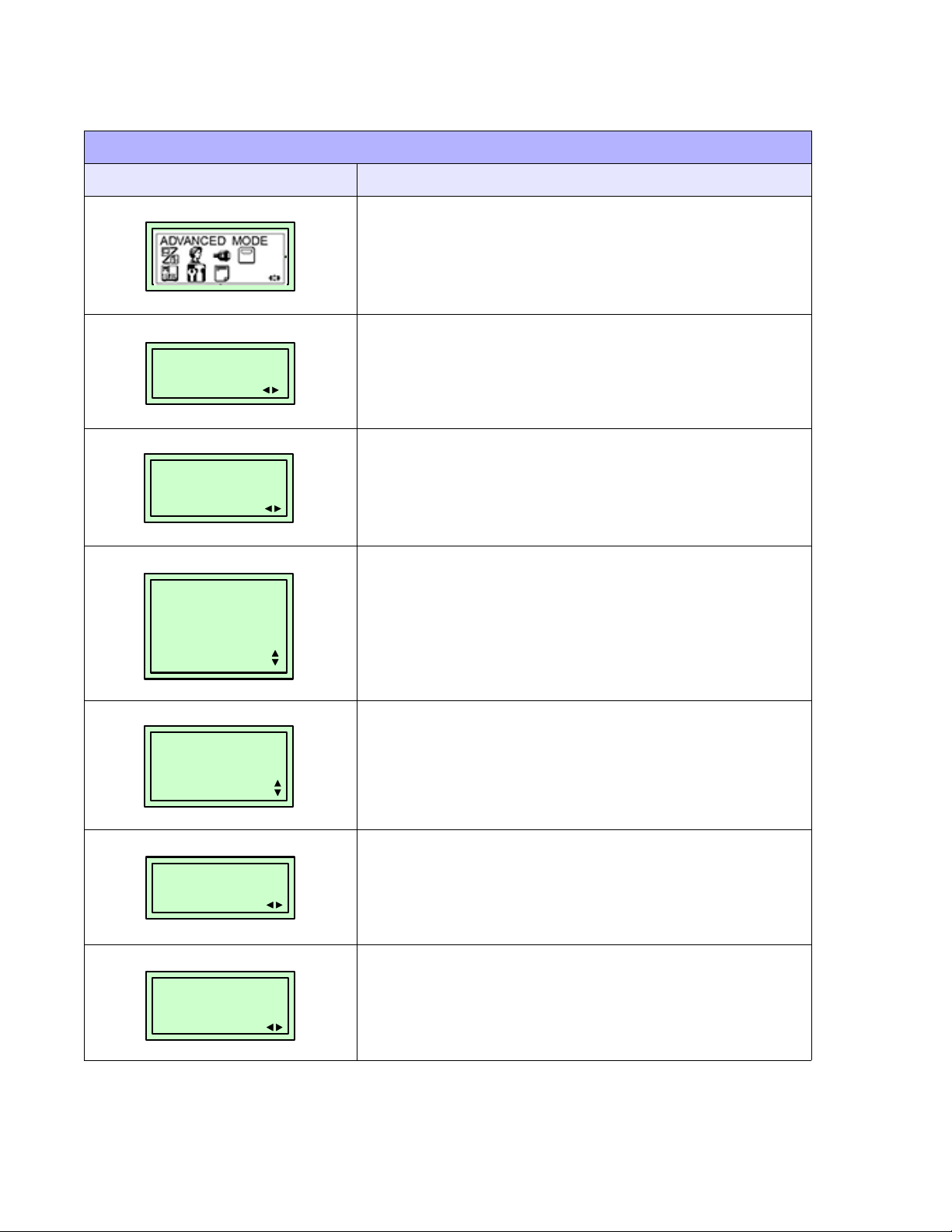

Unit 4: Operation

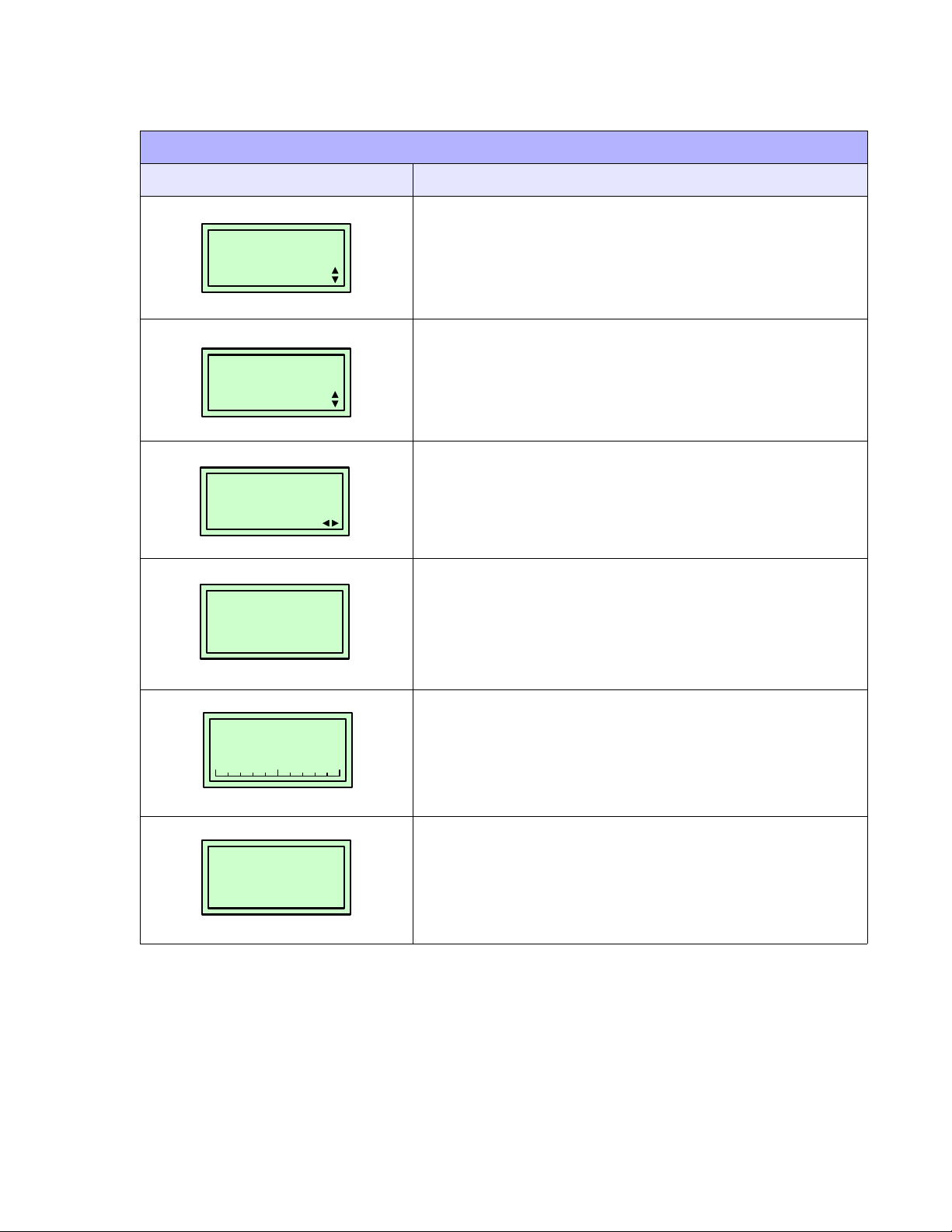

MENU DESCRIPTION

DARKNESS RANGE

A B C D E F

PRINTER TYPE

AUTO SETTING

YES NO

ADVANCED MODE (4-3)

Is the premiere screen of the Advanced Mode. The Advanced

Mode is provided to make basic printer operational

adjustments. Typically, once these adjustments or settings have

been made, they will not require additional address unless a

new job is downloaded. The following table identifies the menus

of the Advanced Mode and their purpose.

Allows the darkness (density) selection of the printed image.

Has six selection options.

Determines whether the printer automatically detects the

installation of optional peripherals such as a peeler or cutter. If

detected, the optional peripherial will be used without further

configuration.

PRINTER TYPE

CONTINUOUS

TEAR OFF

DISPEN SER

CUTTER

LINERLESS

BACKFEED MOT ION

AFT ER

BEFOR

NONE

REWINDER

ON OFF

PRINT METHOD

TRANSFER DIREC T

Allows the choice of continuous feed or tear-off operation. If the

relative accessories have been correctly installed, their

respective options will be displayed.

Allows the determination of wheather a backfeed motion will be

applied. If so, the selection of before or after the printing of each

label.

Allows the internal rewinder option to be turned activated or

deactivated as applicable.

Allows the printer to be switched to operate in the thermal

transfer or direct thermal mode as desired.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-26

Page 55

Unit 4: Operation

PITCH SEN SOR

ENABLE DISABLE

SENSOR T YPE

I-MARK1

GAP

I-MARK2

HEAD CHECK

ENABLE DISABLE

ADVANCED MODE (4-3)

MENU DESCRIPTION

Allows the pitch sensor to be activated or deactivated as

circumstances dictate.

Allows the reference sensor to be selected relative to the media

type to be used.

This feature determines the integrity of the print head elements

when enabled. A few labels will be printed before a print head

error is displayed.

HEAD CHECK

NORMAL BARCODE

EXTERNAL SI GNAL

ENABLE DISABLE

EXTERNAL SI GNAL

TYPE1 TYPE2

TYPE3 TYPE4

EXTERNAL R EPRINT

ENABLE DISABLE

This screen will appear if the head check feature has been

selected. Choose for the head check to be performed

unconditionally or only when barcodes are being printed.

Previously printed barcodes should be scanned following an

error to determine their functionality.

Set this feature to enable or disable the printer’s external signal

communication port. If the port is enabled, data can be sent and

received using an appropriate device plugged into the EXT port.

Appears only if the printer’s external signal feature has been

enabled to allow selection of the output signal. For information

on which type to choose, refer to the Programming Reference

for guidance.

Allows configuration as to whether the reprint function may be

activated via the external signal port.

The printer can be set to automatically go into the online mode

when powered on. Otherwise, the printer starts in the offline

AUTO ONLINE

YES NO

state and must be manually placed online before it is ready to

print.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-27

Page 56

Unit 4: Operation

MENU DESCRIPTION

AUTO ONLINE FEED

YES NO

FEED ON ERROR

YES NO

PROT OC OL COD E

STANDARD

NON-STANDARD

ADVANCED MODE (4-3)

This feature allows one label to be fed upon the printer being

powered on. Enable or disable as desired.

This feature allows one label to be fed following an error being

corrected and the printer going online.

The ESC sequence in SBPL commands may be defined as

standard (using non-printable code 1BH) or non-standard

(some other user code).

SEMBL MODE

AUTO START

YES NO

START PR OGRAM

OWN_ PR OG.BAS

SAMPLE_1.BAS

The printer may be set to go to SEMBL Mode automatically (to

execute a preloaded Basic program) upon being powered on.

If the SEMBL Mode auto-start feature is enabled, this screen

will appear to permit specification of the program to be

executed.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-28

Page 57

Unit 4: Operation

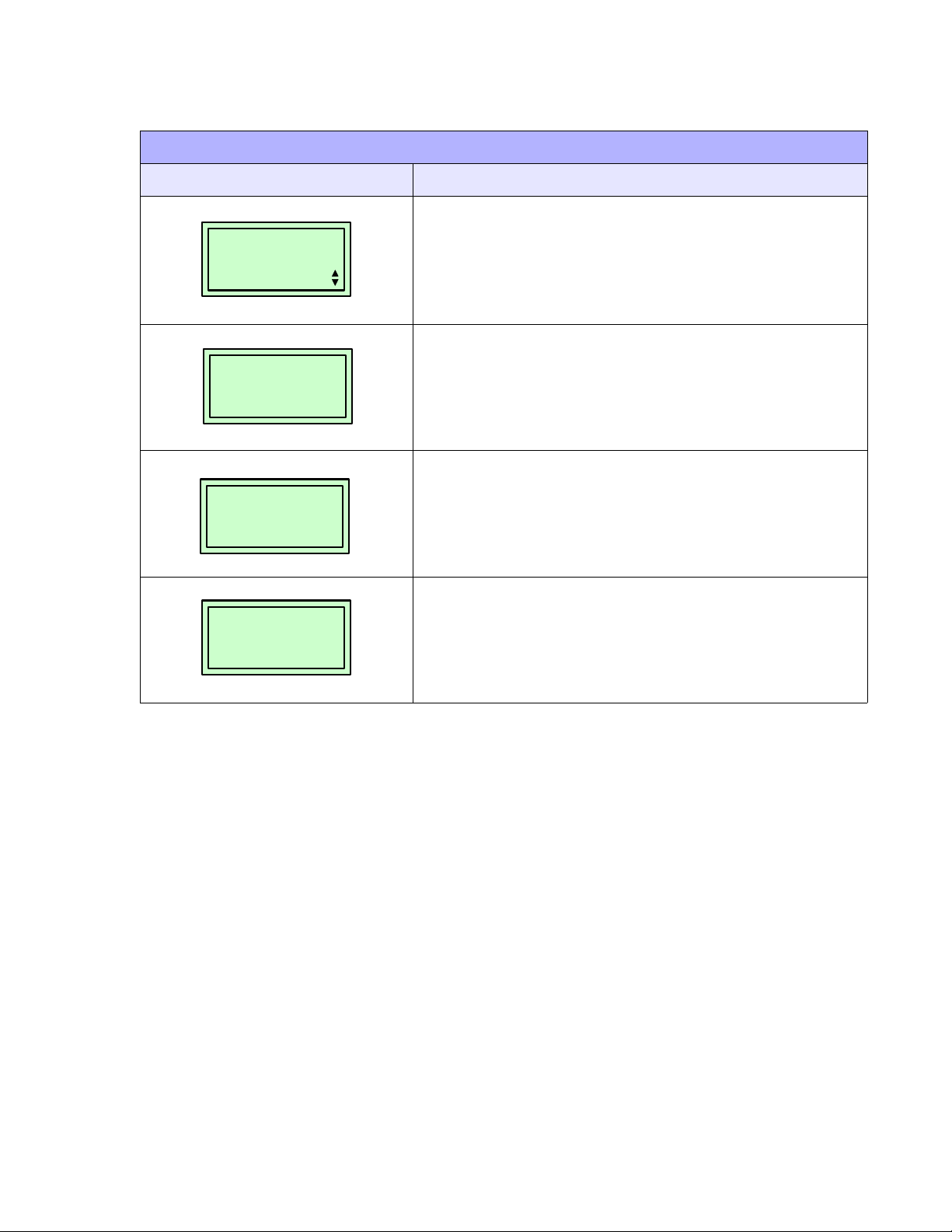

ONLIN E

QTY: 000000

OFF LINE

000000

INTERFACE MODES (4-4 THROUGH 4-8)

MENU DESCRIPTION

Displays the operational status of the printer. The ONLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to OFFLINE

whenever the printer is switched offline by pressing the LINE

key. When a print job is received, the quantity line will indicate

the number of labels to be printed. As the label job prints, the

display indicates the number of labels remaining to be printed.

Displays the operational status of the printer. The OFFLINE

status is displayed on the top line and the label quantity status

on the bottom. The message will be changed to ONLINE

whenever the printer is switched online by pressing the LINE

key.

Is the premiere screen of the Interface Mode. Interface Mode

allows the parameters to be set for the printer to communicate

with a host and vise-versa.

INT ERF ACE C ARD

SETT ING

YES NO

INT ERF ACE C ARD

SETT ING

CARD1 CARD2

PROT OCOL

STAT US4

STAT US5

ITEM NO CHECK

ENABLE DISABLE

Select yes if an interface card for bi-directional communication

will be configured.

This menu allows the identification of which installed interface

card is used for bi-directional communication/printing. The

remaining card, by default, is assigned to the mini-LAN card for

transmitting printer status information to a LAN.

• CARD 1: Normal interface card.

• CARD 2: Mini-LAN

Allows item number check to be enabled or disabled. Will only

appear when Status5 is set for protocol.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-29

Page 58

Unit 4: Operation

MENU DESCRIPTION

BCC CHECK

ENABLE DISABLE

RECEIVE BUFFER

MULTI 1ITEM

IEEE1284

ACK SIGNAL

00.5 µs

INTERFACE MODES (4-4 THROUGH 4-8)

Allows BCC check to be enabled or disabled. Will only appear

when Status5 is set for protocol.

Allows selection of the receive buffer type. Select MULTI for

multiple buffer and 1ITEM for a single item buffer. Will only

appear if RS232C, RS422/485, IEEE1284, or Centronics

interface is installed unless the card is set for RS232C, RS422/

485, or Centronics is set for protocol.

Allows setting for ACK width of IEEE1284 interface. Display will

appear when the IEEE1284 interface is present and one item is

selected as a receive buffer.

IGNORE CR/LF

YES NO

IGNORE CAN/DLE

YES NO

DATA PORT

CARD1 CARD2

STAT US PORT

ENABLE DISABLE

Determines whether the print data code requires deletion.

Hexadecimal graphic data will not be deleted. Select YES to

delete all carriage return (CR) and line feed (LF) commands in

the data stream including graphics and 2D bar codes.

This feature is used primarily to maintain compatibility with

earlier models of SATO printers.

Allows 1 byte command such as CAN and DLE code to be

deleted. Will only appear when the communication protocol is

STATUS4 (for overseas precifications).

Allows select of the port to receive print data. CARD1 will

receive data sent from the exsting interface and CARD2 will

receive print data from the Mini LAN. When print data is

received from a port different from the specified setting, the data

will be dleted.

Use this setting to enable or disable the status return port. The

interface card which is not being used as the data input port is

the status return port. This selection should be relative to the

setting of the prior menu.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-30

Page 59

Unit 4: Operation

RS-232C/422/485

CONFIGURATION

DIPSW LCD

BAUDRATE

2400 4800

9600 19200

PARIT Y BIT

NONE ODD EVEN

INTERFACE MODES (4-4 THROUGH 4-8)

MENU DESCRIPTION

Allows determination of which method of configuration has

priority; the relative dip switch or the LCD menu. This screen is

displayed only when the applicable interface card is installed.

Allows selection of the baud rate. Will only appear when the

RS232C interface is installed and the LCD option is chosen

from the prior menu.

Allows setting of the Parity Bit for the RS232C interface. Will not

display if the dip switch priority option is chosen. The interface

card must be installed.

STOP BIT

1BIT 2BIT

CHAR ACT ER BIT

7BIT 8BIT

PROT OCOL

READY/BUSY

XON/OFF

STAT US2

STAT US3

STAT US4

STAT US5

MULTIDROP

CENTRONICS

ACK SIGNAL

ON OFF

Allows Stop Bit selection for the RS232C interface. Will not

display if the dip switch priority option is chosen.

Allows selection of the data length for the RS232C interface.

Will not display if the dip switch priority option is chosen.

Allows setting of communication protocol. Will only appear if

RS232C or RS422/485 interface is installed (except if the

relative dip switch is set with either as the priority).

Allows setting for output timing of ACK signal for Centronics

interface. Select ON for output outside the busy signal and OFF

for inside the busy signal. Will only display if the Centronics

interface is installed.

SATO GT4xxe Series Operator Manual PN 9001138C Page 4-31

Page 60

Unit 4: Operation

MENU DESCRIPTION

CENTRONICS

FAULT SIGNAL

ON OFF

WIRELESS MOD E

802.11 Ad Hoc

Ad Hoc

Infrastructure

SSID

1234567890ABCDEF

INTERFACE MODES (4-4 THROUGH 4-8)

Allows setting for output timing of fault signal for Centronics

interface. Select ON for synchronous output with Select signal

and OFF with asychronous outputs with Select signal. Will only

display if the Centronics interface is installed.

Allows the selection of the desired communication mode. Will

only appear if mini-LAN interface is present. Will not appear if

Card is selected as the priority. Will become active upon power

reboot.

This display allows setting for SSID of wireless LAN. English

(uppercase/lowercase) and number can be entered up to 32

digits. This display will only appear if wireless LAN is installed.