Page 1

GT Series

OPERATOR’S MANUAL

Page 2

SATO ASIA PACIFIC PTE. LTD.

438A ALEXANDRA ROAD

#05-01/02 ALEXANDRA TECHNOPARK

SINGAPORE 119967

Tel: (65) 6271 5300

Fax: (65) 6273 6011

Sales Hotline: (65) 6276 2722

Service Hotline: (65) 6273 6455

Email: sales@satoasiapacific.com

Website: www.satoworldwide.com

Copyright 2003

SATO Asia Pacific Pte. Ltd.

Warning : This equipment complies with the requirements in Part 15 of FCC rules for a

Class A computing device. Operation of this equipment in a residential area may cause

unacceptable interference to radio and television reception requiring the operator to take

whatever steps necessary to correct the interference. All rights reserved. No part of this

document may be reproduced or issued to third parties in any form whatsoever without

the express permission of SATO Asia PacificPte. Ltd. The materials in this document are

provided for general information andare subjected to change without prior notice. SATO

Asia Pacific Pte. Ltd. assumes no responsibilities for any errors that may appear.

Page 3

TABLE OF CONTENTS

1OVERVIEW

1.1 General Specifications.................................................................................1-2

2 INSTALLATION

Safety Precautions..................................................................................................... 2 -2

2.1 Unpacking......................................................................................................2-4

2.1.1 Included Accessories......................................................................................2-5

2.1.2 Parts Identification ..........................................................................................2-6

2.2 Loading the Carbon Ribbon.........................................................................2-10

2.2.1 Removing the Carbon Ribbon ........................................................................2-11

2.2.2 OPTION: Using A Paper Tube to Wind Used Ribbon ....................................2 -12

2.3 Loading Labels And Tags............................................................................2-13

2.3.1 Loading Roll Paper ......................................................................................2-14

2.3.2 Loading Fanfold Paper ...................................................................................2-17

2.3.3 Loading Fanfold Paper under the printer .......................................................2-19

2.3.4 Adjusting the paper sensor ............................................................................ 2 -21

2.4 Replacing the Print Head..............................................................................2-22

2.5 Turning the printer ON/OFF .........................................................................2-23

3 CONFIGURATION AND OPERATION

3.1 Operating Modes...........................................................................................3-1

3.2 The Operation Panel.....................................................................................3-2

3.3 Screen Icons And Their Meaning ................. ............................................ ...3-3

3.4 ONLINE And OFFLINE Modes......................................................................3-5

3.4.1 Online Mode ...................................................................................................3-5

3.4.2 Offline Mode ...................................................................................................3-5

3.5 User Mode......................................................................................................3-6

3.5.1 Entering User Mode .......................................................................................3-6

3.5.2 Setting Buzzer Volume, Print Pitch, Print Offset, Print Darkness ...................3-7

3.5.2 Setting Print Speed ........................................................................................3-7

3.5.3 Setting Print Darkness ....................................................................................3-8

3.5.4 Setting Print Offset .........................................................................................3-8

3.5.5 Setting Zero Slash Changeover .....................................................................3-9

3.5.6 Setting JIS Kanji Code Changeover* .............................................................3-9

3.5.7 Setting Kanji Font Style* ................................................................................3-9

3.5.7 Setting Proportional Pitch ..............................................................................3-10

3.6 Interface Mode...............................................................................................3-11

3.6.1 Entering Interface Mode .................................................................................3-11

3.6.2 Enabling Interface Card Configuration ...........................................................3-11

3.6.3 Assigning An Interface Card For Printing .......................................................3 -12

3.6.4 Selecting The Data Input Port ........................................................................3-12

3.6.5 Enabling or Disabling The Status Return Port ...............................................3 -12

i

Page 4

3.7 Cartridge Mode..............................................................................................3-13

3.7.1 Entering Cartridge Mode ................................................. ...............................3-13

3.7.2 Cartridge Formatting Option ...........................................................................3-13

3.7.3 Start Cartridge Formatting ..............................................................................3-13

3.7.4 Cartridge Formatting Progress .......................................................................3-14

3.8 SEMBL Mode .................................................................................................3-15

3.8.1 Entering SEMBL Mode .......................................................................... .........3-15

3.8.2 Selecting The Start Program ..........................................................................3-15

3.8.3 The SEMBL Status Screen ............................................................................3-16

3.9 Advanced Mode.............................................................................................3-17

3.9.1 Entering Advanced Mode ...............................................................................3-17

3.9.2 Selecting The Print Density ............................................................................3-17

3.9.3 Setting the Automatic Detection of Optional Units ........................................3-17

3.9.4 Choosing Continuous or Tear Off Operation ..................................................3-18

3.9.5 Backfeed Operation Settings ..........................................................................3-18

3.9.6 Configuring the Internal Winding Unit .............................................................3-18

3.9.7 Setting the Print Mode ....................................................................................3-19

3.9.8 Configuring the Paper Sensor ........................................................................3-19

3.9.9 Configuring the Paper Sensor Type ...............................................................3-19

3.9.10 Turning Head Check Function ON/OFF .........................................................3-20

3.9.11 Choosing the Type of Head Check ............................................................3-20

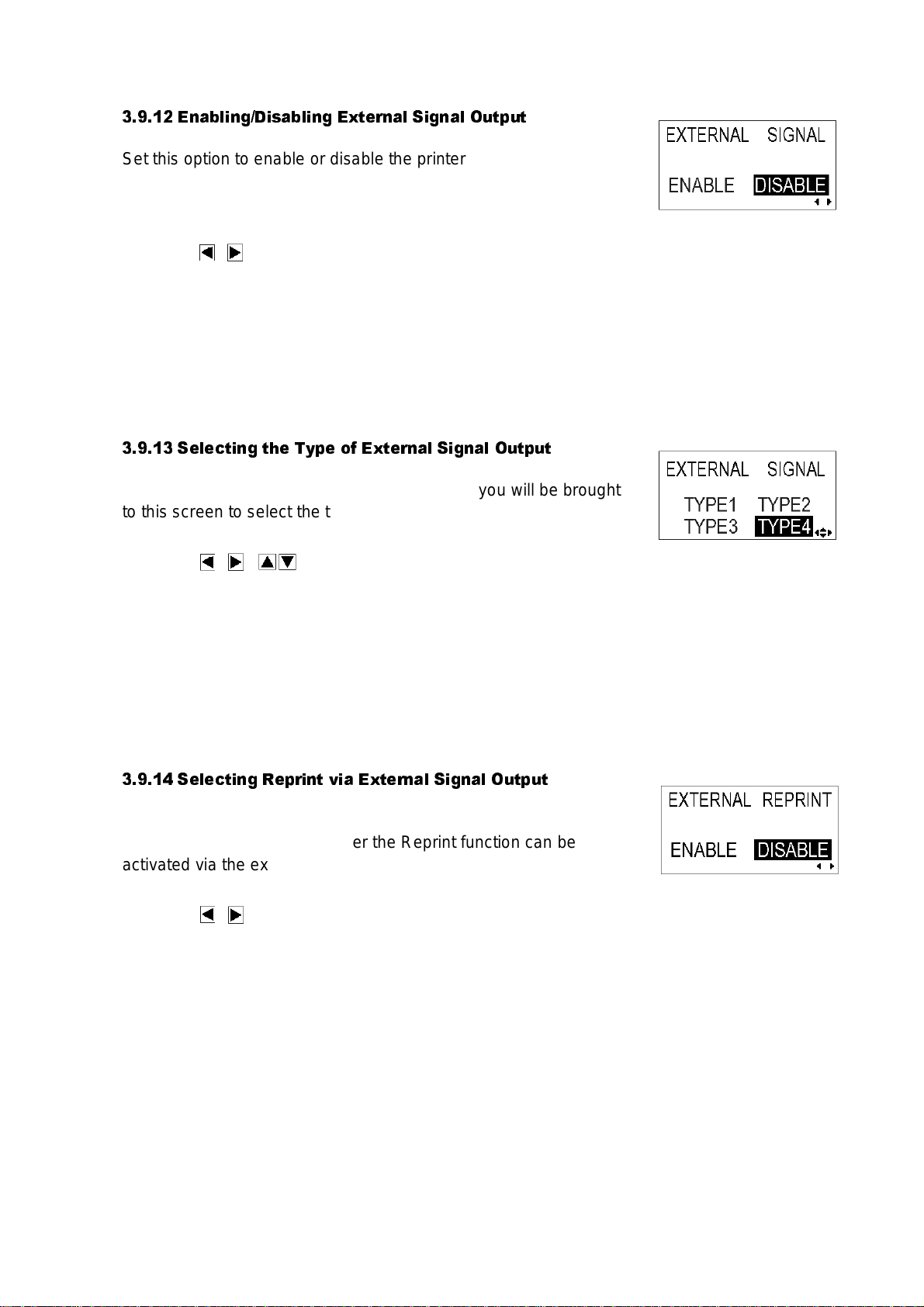

3.9.12 Enabling/Disabling External Signal Output .....................................................3-21

3.9.13 Selecting the Type of External Signal Output .................................................3-21

3.9.14 Selecting Reprint via External Signal Output .................. ...............................3-21

3.9.15 Using the Auto Online Feature .......................................................................3-22

3.9.16 Enabling Auto Feed ........................................................................................3-22

3.9.17 Enabling Auto Feed On Error .........................................................................3-22

3.9.18 Specifying the Protocol Code Format .............................................................3-23

3.9.19 Specifying The SEMBL Start Mode ................................................................3-23

3.9.20 Specifying The SEMBL Auto Start Program ................................................... 3-23

3.10 HEX Dump Mode ...........................................................................................3-24

3.10.1 Entering HEX Dump Mode ............................................................................. 3-24

3.10.2 Selecting Data To Dump ................................................................................3-24

3.10.3 Controlling the H ex Dump Mo de ....................................................................3-24

3.11 Test Print Mode .............................................................................................3-25

3.11.1 Entering Test Print Mode ................................................................................3-25

3.11.1 Choosing What The Test Print Contains ........................................................3-25

3.11.2 Setting Test Print Width for Configuration, Barcode and Head Check ..........3-26

3.11.3 Setting the Size of the Factory Test Print .......................................................3-26

3.11.4 Starting the Test Print .....................................................................................3-26

3.12 Overview of All Modes............................................... ...................................3-27

3.13 Restoring Factory DeFault Settings............................................................3-37

3.13.1 Entering Default Mode ....................................................................................3-37

3.13.2 If You Chose to Reset Printer Settings ...........................................................3-38

3.13.2 If You Chose Alt Protocol Code ......... .............................................................3-38

3.13.3 Completion of Default Setting ............................................. ............................3-38

3.14 Understanding Continuous Print and Tear Off Operations.......................3-39

ii

Page 5

4 CLEANING AND MAINTENANCE

4.1 Introduction...................................................................................................4-1

4.2 Cleaning The Print Head, Platen and Rollers.............................................4-1

4.3 How To Clean The Printer (Cleaning SET)..................................................4-2

4.4 How To Clean The Printer (Cleaning SHEET).............................................4-3

4.5 Adjusting Print Quality.................................................................................4-4

4.5.1 Adjusting Pr int Darkness 4-4

4.5.2 Adjusting Pr int Speed 4-5

5 INTERFACE SPECIFICATIONS

5.1 Interface types...............................................................................................5-1

5.2 Interface Card DIP SWITCH Settings (RS-232C) ........................................5-2

5.3 Interface Card DIP SWITCH Settings (LAN)................................................5-3

5.4 Interface Card DIP SWITCH Settings (Wireless LAN).............. ..................5-3

5.5 Interface Card DIP SWITCH Settings (Mini LAN)........................................5-4

5.6 Serial Interface SPECIFICATIONS (RS-232C).............................................5-5

5.7 READY/BUSY ................................................................................................5-6

5.8 Single Job Buffer ..........................................................................................5-7

5.9 Multi Job Buffer.............................................................................................5-8

5.10 X-ON/X-OFF ...................................................................................................5-8

5.11 Single Job Buffer ..........................................................................................5-10

5.12 Multi Job Buffer.............................................................................................5-11

5.13 Driver Protocol..............................................................................................5-11

5.14 Status 3..........................................................................................................5-24

5.15 Multi Job Buffer.............................................................................................5-25

5.16 Reference Flowchart.....................................................................................5-32

5.17 Parallel Interface SPECIFICATIONS (Centronics)......................................5 -33

5.18 Single Job Buffer ..........................................................................................5-35

5.19 Multi Job Buffer.............................................................................................5-37

5.20 IEEE 1284 Interface.......................................................................................5-39

5.21 Interface Signals...........................................................................................5-42

5.22 Single Job Buffer ..........................................................................................5-43

5.23 Multi Job Buffer.............................................................................................5-45

5.24 Driver Protocol..............................................................................................5-47

iii

Page 6

TROUBLESHOOTING

6.1 Initial Checklist..............................................................................................6-1

6.2 Using the Centronics (Parallel) Interface............................ ........................6-1

6.3 Using the RS232C (SERIAL) Interface.........................................................6-3

6.4 Understanding the STATUS INDICATORS..................................................6-4

6.5 Understanding the LCD Error Messages ....................................................6-5

6.6 LCD Warning Messages ...............................................................................6-10

6.7 Troubleshooting Guide.................................................................................6-11

OPTIONAL ACCESSORIES

7.1 Introduction ...................................................................................................7-1

7.2 Available Interface Boards ...........................................................................7-1

7.3 Label Management Accessories..................................................................7-2

7.3 PCMCIA Memory Cartridge ..........................................................................7-3

7.3.1 Installing the memory card..............................................................................7-3

iv

Page 7

Section 1: Introduction

OVERVIEW

Thank you for your investment in this SATO printer product.

This Operator’s Manual contains basic information about the installation, setup,

configuration, operation and maintenance of the printer.

A total of seven topics are covered herein, and they are organized as follows:

Section 1: Overview

Section 2: Installation

Section 3: Configuration and Operation

Section 4: Cleaning and Maintenance

Section 5: Interface Specifications

Section 6: Troubleshooting

Section 7: Optional Accessories

1

It is recommended that you become familiar with each section before installing and maintaining the printer. Refer to the Table Of Contents at the front of this manual to search

for the relevant i nfor mation need ed. Al l p age num bers in this manual co nsist of a secti on

number followed by the page number within the stated section.

For specialized pro gram ming, refer to the sep arate Programming Man ual located on the

utility CD-ROM.

GT Series Operator’s Manual Page 1-1

Page 8

Section 1: Introduction

1.1 GENERAL SPECIFICATIONS

The SATO GT 4xx “e” series of dual use (Thermal Transfer and Direct Thermal) printers

are complete, high-performance labeling systems designed for printing tags and labels.

The key features of the GT series are:

• Faster print speed and better print quality than ever

• Large 3-line LCD screen and icon-rich user interface

• Fully configurable without the need for setting DIP switches

• Easy operation via multiple control buttons and status indicators

• Easy upgrading to higher resolution print heads and additional memory by users

• Richer SBPL command set for better control via software/network

• Supports standalone operation via execution of BASIC programs stored in memory

• Supports two I/O connections

• User friendly label and ribbon path

• Ribbon saving feature

All printer p aram eter s are programmable using the fr ont p ane l control s an d via soft wa re.

All popular bar codes, including 2-D codes, eight human-readable fonts with two Care

Symbol fonts and a fast and efficient vector font, are resident in memory, providing literally thousands of combinations of type styles and sizes.

Page 1-2 GT Series Operator’s Manual

Page 9

Section 1: Introduction

Features of SATO GT4xxe Series Printers

Feature GT408e GT412e GT424e

Print resolution 203dp i for economical

labeling solution

(user upgradable to higher

resolution print assembly)

Print method Thermal Transfer an d

Direct Thermal

Label sizes supported

(using default internal

memory)

Label sizes supported

(using additional

optional PCMCIA

memory card)

Integral Cutter unit Optional Optional Optional

Stacker option Up to 500 3.9 inch (W) by

Interfaces available Optional RS-232C, LAN,

4 inches (W) by 9.4 inches 4 inches (W) by 9.4 inches 4 inches (W) by 9.4 inches

4 inches (W) by 49.2 inches

at 203 d pi

5.9 inch labels

USB, RFID, IEEE 1284 or

high spe ed RS-232C

305dpi for laser quality

printing and graphic

images

Thermal Transfer and

Direct Thermal

4 inches (W) by 32.8

inches at 305 dpi

Up to 500 3.9 inch (W) by

5.9 inch labels

Optional RS-232C, LAN,

USB, RFID, IEEE 1284 or

high speed RS-232C

608dp i for laser qual ity

printing and gr aphic

images

Thermal Transfer and

Direct Thermal

4 inches (W) by 32.8

inches at 305 dpi

Up to 500 3.9 inch (W) by

5.9 inch labe ls

Optional RS-232C, LAN,

USB, RFID, IEEE 1284 or

high sp eed RS-232C

GT Series Operator’s Manual Page 1-3

Page 10

Section 1: Introduction

1.1 GENERAL SPECIFICATIONS (CONT’D)

Specification/

Model Name

Print method Thermal transfer or thermal

Head density 8 dots/ mm (203 dpi)

Print valid range (w idth) 104 mm x pitch 2500 mm

Print speed (Max) 12 inch es/sec

(Approx 300 mm/sec)

Note:

Maximum speed may be further dependent on the type of print layout, paper,

or carbon ribbon in use.

Paper Thickness 0.060 mm to 0.268 mm suppor ted.

Label size

(mounting

and

cardboard

size)

Standard Width: 22 t o 12 8 mm (25 t o 13 1 mm )

Tear off Wi dth : 22 t o 12 8 mm (25 to 131 mm)

Peel Width: 22 t o 12 8 mm (25 t o 13 1 mm )

Cutter Width: 22 to 12 8 mm (25 to 131 mm)

Note:

Be sure to use only print er supplies manufactured or c ertifi ed by SATO.

Pitch: 5 to 397 mm (9 to 400 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

GT408 GT412 GT424

12 dots/ mm (305 dpi) 24 dots/ mm (609 dpi)

104 mm x pitch 1500 mm 104 mm x pitch 400 mm

Not printable for 3 mm from the backside.

12 inches/sec

(Approx 300 mm/sec)

6 inches/sec

(Approx 150 mm/sec)

Note:

Supported sizes may be

regulated due to the quantity of print jobs or size of

paper.

Other us ag e co nditions

may restrict the range of

label sizes supported.

Non-separate

Number of

loadable

sheets

Carbon ribbon

Width

Length

Thickness of base material

Color

Winding direction

Label dispen sing mod es Continuous, tear off, peeler, dispenser and non-separate

Dimensions W 271 mm x D 455 mm x H 305 mm x (Standard)

Weight 14 kg (for a st andard configuration)

Power suppl y Input voltage: AC 100 V to 240 V ±10%

Operating Environment Opera tio na l am bient temperature : 0 to 40 ×C

Roll paper Maximum external diameter:

Fanfold

paper

Width: 22 t o 12 8 mm (25 t o 13 1 mm )

Pitch: 17 to 397 mm (20 to 400 mm)

200 mm (Approximately 150 m/roll) 3-inch paper tube used

Back winding (only front winding for no n-separate mode)

Maximum folded height: 20 0 m m

See the section in this manual on Setting Fanfold Paper

Be sure t o use the s pecified carbon ribbon manufactured by SATO.

39.5, 45, 59, 76, 84, 92, 102, 111, and 128 mm

Use a carbon rib bon that is wider than the paper used.

300 m/roll

4.5 µm

Black (standard), also red, blue, purple, and green

Front winding and back winding

Power consumption: Maximum 200 VA 150 W, print rate 30% (89 VA 40 W on standby)

Opera tio na l am bient humi dity: 30 to 80% (without condensation)

Storing ambient temperature: -5 to 60 ×C

Storing amb ient humidity: 30 to 90% (no condensation)

Paper, and ca rbo n r ib bo n ex cl ud ed .

Page 1-4 GT Series Operator’s Manual

Page 11

1.1 GENERAL SPECIFICATIONS (CONT’D)

Section 1: Introduction

Specification/

Model Na m e

External interface

Operation

Panel

Buttons

Switch POWER ON/OFF

LCD Green LCD (with backlight), Vertical 32 dots x horizontal 128 dots, displaying up to five

LEDs POWER, ONLIN E, STATUS, LABEL, RIBBON status indicators

Adjustment

Potentiometer

GT408 GT412 GT424

Interface board

¤ Parallel (IEEE1284)

¤ RS-232 C

• READY/BUSY

• XON/XOFF

• Status 2/3

• Driver specif ic protocol

• Sta tus 5

¤ USB (Ver. 2.0)

¤ LAN (10BASE-T/ 100BASE-TX automatic changeover)

¤ Wireless LAN (IEE E802.11b)

¤ Mini LAN (10BASE-T/ 100BASE-TX automatic changeover)

External (EXT) signal interface (14-pin)

LINE, FEED

FUNCTION, 4 navigation but tons (up/down/left/right), E N TER, CANCEL

icons at the top of the screen

VOLUME: buzzer loudness adjustme nt

PITCH: print-head pitch adjustment

OFFSET: tear off, peel, and cutter stop position adjustment

DARKNESS: print density adjustment

Sensor Paper sensor : reflection type, penetration type

Memory cartridge

Print Form at Transmitted from host (computer) or recall ed from print for mats stored by user

Stored

Font Types

Standard X20 5 x 9 dots (a lp hanumer i c, sy m bol, and ka na )

Truetype Fonts

Kanji Fonts

(where applicable)

16 MB FLASH ROM, 4 MB non-volatile user me mory

on memory card (optional)

X21 17 x 17 dots (alphanumeric, symbol, and kana)

X22 24 x 24 dots (alphanumeric, symbol, and kana)

X23 48 x 48 dots (alphanumeric, symbol, and kana)

X24 48 x 48 dots (alphanumeric, symbol, and kana)

Outline font (alphanumeric, symbol, and kana)

OCR-A GT408 15 x 22 dots (alphanumeri c and symbo l)

GT412 22 x 33 dots (alphanumeric and symbol)

GT424 44 x 66 dots (alphanumeric and symbol)

OCR-B GT408 20 x 24 dots (alphanumeri c and symbo l)

GT412 30 x 36 dots (alphanumeric and symbol)

GT424 60 x 72 dots (alphanumeric and symbol)

CG Times (alphanum er i c an d sy mbol)

CG Triumvirate (alphanumeric and symbol)

16 x 16 dots (JIS level-1 and -2 kanj i sets. Selectable either Mincho or Gothic)

24 x 24 dots (JIS level-1 and -2 kanj i sets. Selectable either Mincho or Gothic)

22 x 22 dots (JIS level-1 and -2 kanj i sets. Selectable either Mincho or Gothic)

32 x 32 dots (JIS level-1 and -2 kanj i sets. Selectable either Mincho or Gothic)

40 x 40 dots (JIS level-1 and -2 kanj i sets. Selectable either Mincho or Gothic)

Kanji ou tli ne font

GT Series Operator’s Manual Page 1-5

Page 12

Section 1: Introduction

1.1 GENERAL SPECIFICATIONS (CONT’D)

Specification/

Model Name

Barcode

Onedimensional

code

• UPC-A/E, EAN8/13, JAN8/13

• NW-7

• INTERLEAVED 2 of 5 (ITF)

GT408 GT412 GT424

• INDUSTRIAL 2 of 5

• MATRIX 2 of 5

• CODE39, CODE93, CODE128

• UCC/EAN128

• Customer barcode

• RSS-14

Twodimensional

code

• QR code model 2, Micro QR (Ver 8.1)

• PDF417 (Ver. 2.4, including micro PDF)

• Veri code (Ver. 1.0)

• MAXI code (Ver. 3.0)

• Data matrix ECC200 (Ver. 2.0)

• Synthetic symbol (UPC-A/E, EAN8/13, JAN8/13, CODE39, CODE128 CC-A/B/C

supporte d with RSS -14 )

Magnification Vertical 1 to 12 times

Horizontal 1 to 12 times (characters)

1 to 12 L (barcodes)

Rotation Characters : 0°, 90 °, 18 0°, and 270°

Barcode Ratio 1:2, 1:3, 2:5, arbitrary

Barcode: parallel 1, serial 1, parallel 2, serial 2

User mode 1. Volume set value indication 2. Print speed 3. Print density

4. Print position cor rection 5. Zero s lash changeover 6. Kanji code changeover

7. Kanji font setting 8. Proportional pitch setting

Automat ic dia gno sti cs Head check/ Head open/ Paper end/ Ribbon end/ Winding full/ Kanji ROM

Noise emission

Optional accessories

Radiant nois e VCCI Class B

Static with-

stand pressure

AC line noise 1000 Vp-p or more ( 50 nS to 1 µS pulse)

check/ T est print

IEC Level 3

• Peel unit (with mounting winder)

• Cutt er un it

• Non-separat e unit

• Simplified peel unit

• Internal wind ing unit

• External winding unit

• RFID unit

• Dete c tio n sc an ner unit

• EXT connector (external signal)

• Interface boards (serial R S- 23 2 C or Par all el IEEE128 4)

• USB Interface board

• LAN (10BASE-T/1 00BASE-TX),

• Wirele s s LA N ( IEE E 802.11b),

• Mini LAN (10BASE-T/100BASE-TX)

Memory cartridge 24 MB

Note:

All the GT printers use th e same command codes. The only difference s are the al lowable values representing print posi tions o n the label. These val ues are spec ifie d in “dots” and will vary depending upon the

resolution of the printer and the amount of memory available for imaging the label.

Page 1-6 GT Series Operator’s Manual

Page 13

Section 2: Installation

2

INSTALLATION

This section assists yo u in unpacking and instal ling the printer from the shi pping container.

You will als o be guided through a familiarization to ur of t he main parts and controls.

The following information is provided:

• Safety Precautions

• Unpackin g and Parts Identification

• Loading the Carbon Ribbon

• Loading Labels and Ta gs

• Adjusting the Sensors

• Replacing the Print Head

• Tur n i ng the Printer O N/OFF

GT Series Operator’s Manual Page 2-1

Page 14

SECTION 2: INSTALLATION

SAFETY PRECAUTIONS

Please read the following information carefully before

SAFETY PRECAUTIONS

THE CAUTION SYMBOL

Whenever the triangular Caution logo appears in this manual, pay special attention to the warning(s) cited

below it. Failure to abide by the warnings may result in injury or damage to property.

PRINTER PLACEMENT TIPS

• Place the printer on a solid, stable,

horizontal surface that is not subject to strong vibrations from adjacent mechanical devices.

• Avoid shaky or slanting tables, or

platforms that are liable to collapse under a heavy

weight. If the printer is dropped or damaged, immediately turn off the power, pull out the power plug and

contact a service center. In this case, continued use

of the printer may cause a fire or electric shocks.

• Avoid installing the printer in direct sunlight, or in

dusty, very hot or slippery areas. Also avoid placement in damp, unventilated or humid areas. If condensation forms, immediately turn off the power, and

do not use the printer until the condensation disappears. Otherwise the moisture may cause electric

shocks.

• Avoid placing the printer near large high-current

equipment, as such equipment can cause sp ikes or

undervoltages in the power supply.

installing and using the printer

• Do not leave containers of

water or chemicals around the

printer. If any liquid is spilled

onto the printer, immediately

turn off the power, pull out the

power cable from the AC outlet, and contact a

sales outlet, dealer, or service center. In this

case, continued use of the printer may cause

fires or electric shocks.

• Do not move the printer with any paper loaded.

The stack of paper may fall off, causing trips

and accidents.

• When laying the printer down, be careful not to

catch your foot or fingers under it.

• When moving the printer, be sure to pull out the

power cable from the AC outlet, and check that

any other external interface cables have been

disconnected. Otherwise, the connected cables

may be damaged, or may cause trips and falls,

in addition to or a fire or electric shocks.

ELECTRICAL PRECAUTIONS

• Do not damag e, break, or process the power cable.

Hanging heavy objects on it, heating or pulling it may

damage the power cable and cause fires or electric

shocks.

• When the power cable is damaged (cable conductors

are exposed or cut, etc.), contact a sales outlet,

dealer, or service center. In this case, continued use

of the printer may cause fires or electric shocks.

• Do not process, forcibly bend, twist, or pull the power

cable. Continued use of such a cable may cause

fires or electric shocks.

• If the printer emits any smoke or peculiar odors at

any time, turn it OFF and prevent further usage until

you have contacted a qualified service personnel.

• Do not use any other voltage except the specified

power voltage for the printer that matches your

domestic power supply. Otherwise, it may cause

fires or electric shocks.

• Do not operate the power switch or handle the

power cable with a wet hand.

• Do not inse rt or drop anything metallic or flammable into the openings of the printer (the cable

outlet or mounting hole of the memory cartridge). Otherwise, immediately turn off the

power, pull out the power cable, and contact a

sales outlet, dealer, or service center. In this

case, continued use of the printer may cause

fires or electric shocks.

• To reduce electrical risks, be

sure to connect the printer to

ground before use. Also, try

not to share the printer’s AC

outlet with other electrical

equipment, especially those that draw high

amounts of current or cause electrical interference.

Page 2-2 GT Series Operator’s Manual

Page 15

GENERAL PRECAUTIONS

• The supplied head cleaning liquid is flammable.

Never heat it or throw it into a fire. Keep it out of children’s reach to avoid accidental consumption.

Should this occur, consult a doctor immediately.

• When opening/closing the cover, beware of getting

your fingers caught. Also, hold the opening/closing

cover well so that it will s lip and f all.

• After printing, the print head remains hot. When

replacing paper or cleaning the printer immediately

after printing, be careful not to burn yourself.

• Touching even the edge of the printer head may

cause injuries. When replacing paper or cleaning the

printer, be careful not to hurt yourself.

Section 2: Installation

• Do not disassemble or perform modifications to

the printer, as this renders the product unsafe.

For maintenance, troubleshooting and repairs,

consult a sales outlet, dealer, or service center

for help, instead of attempting to perform this

yourself. Renewable annual service contracts

are available.

• When maintaining or cleaning the printer,

always disconnect the power cable for safety.

• Do not insert your hand or other objects into the

cutter.

• When loading roll paper, be careful not to catch

your fingers between the paper and the feed.

• If the printer will not be used for extended periods of

time, disconnect the power cable for safety.

• When releasing and locking down the printer head,

be careful not to catch any other foreign in it except

label paper.

This equipment is a piece of Class B information technology equipment based on the standards of the

Voluntary Control Council for Interference by Information Technology Equipment (VCCI). Although this

equipment is for use in home environment, if it is used close to a radio or television set, it may cause poor

reception. Handle it properly in accordance with the content from the instruction manual.

• B e careful not to hurt yourself when detaching

the back cover of the fanfold through the hole

and attaching it.

• The simplified cutter is structured as a blade.

Be careful not to cut yourself .

GT Series Operator’s Manual Page 2-3

Page 16

SECTION 2: INSTALLATION

1

2

2.1 UNPACKING

When unpacking the printer, ta k e note of the foll ow ing:

The box sh ould stay right-s ide up.

Lift the print er out of the box ca ref ully.

If the printer was been stored in the

4

cold, allow it to reach room

temperature before turning it on.

Remove the plastic covering from the

printer.

Set the printer on a solid , flat su rface.

5

Inspect the shipping container and

printer fo r any s ign of damage that

Remove the accessory items from their

3

may have occurred during shipping.

protective contai ners.

Note

The following illustratio ns are representative only. Your printer may not be packed exactly as shown, but

the unpacking steps are similar.

Page 2-4 GT Series Operator’s Manual

Page 17

Section 2: Installation

2.1.1 INCLUDED ACCESSORIES

After unp ac k ing the printer , verify that th e fo llowing materials are in the accessor ies or packaging:

Global Warranty

document

Information

leaflet*

Items m arked w ith a n asterisk m ay be different from what you see here, or m ay be ex c luded.

Cleaning

Set

Sample paper*

Head cleaning sheet

(wrapping sheet)

Power cable*

Two-pole adaptor*Accesso r y C D -R OMOperator’s Manual

Important!

Please f ill out the Globa l W arranty car d and submit it

to us in order that we can provide fast and efficient

after-sales service . For malfunc ti ons under normal

use, this product will be repaired free of charge

according to the warranty terms applicable for the

country of us e.

Please do not discard t he original packaging b ox and

cushion ing material after installing the printer. T hey

may be needed in future, if the printer needs to be

shipped for repairs.

GT Series Operator’s Manual Page 2-5

Page 18

SECTION 2: INSTALLATION

2.1.2 PARTS IDENTIFICATION

IDENTIFYING THE MAIN PRINTER PARTS

Operation Panel

Consists of an liqui d crystal display screen, five status indicators and the LINE and FEED

buttons.

Power switch

Pushing the I side turns t he

printer ON. Pushing the O side

turns the printer OFF.

Front View

Lift this cove r

upwards to access

ribbon and label

Pull down this panel

to access controls

Fixed front plate

Front Cover

(lifted up)

Ribbon take-up shaft

Head pressure

adjustment knob

Angled Front View

Ribbon feeder

Label supply arm

Roll Guide lever

Roll Guide

Head lock lever

Head open lever

Front cover plate

Page 2-6 GT Series Operator’s Manual

Page 19

2.1.2 PARTS IDENTIFICATION (CONT’D)

IDENTIFY ING THE MAIN PRINTER PARTS

Rear View

Section 2: Installation

Release screw

Rear access cover

When us ing fanfold media,

remove the release screw

of the rear cover and lift up

the front cover. The hinged

rear cover will drop do wnwards to a vertical position.

How to

remove the

cable co ver

Positi on your bod y

to face the rear of

the printer. Press

down on the

release catch with

your thum b, and

slide the cable

cover to your right.

Cable cover

Cable cover

release catch

Positio n your

body to face the

rear of the printer.

Press down on

the release catch

with your thumb,

and slid e the

cable cover to

your right.

Mini LAN interface

board (optional)

Interface board

Available interfaces include

RS-232C, high speed RS232C, USB, IEEE 1284,

LAN and wireless LAN.

EXT connector

(optional)

Allows co nnection to external

devices

Power cable hook

Provide s a neat an d sa fe w ay

to hang the power cable.

AC power connector

GT Series Operator’s Manual Page 2-7

Page 20

SECTION 2: INSTALLATION

C

o

r

IDENTIFY ING THE MAIN PRINTER PARTS

Side View

(Media assembly)

onnector for

ptional memory card

Ribbon take-up shaft

Ribbon feeder

Head lock lever

Print head*

Head pressure knob

Head release lever

Platen roller*

(under the print head)

Maintenance screw

Stopper screw

Label Guide

Stopper for

AA

label damper

(push downwards to

release the

label damper)

Paper sensor

B

AA

B

Label Guide

C

handle

C

D

Fanfold cover

* Clean and maintain this part regularly

Label Guide

D

damper

Angled Front View

Print head

This component generates

heat to the ribbon or media f or

printing. Clean and maintain

this part regularly.

Platen roller

The rubber roller feeds or

retracts the media as ne eded.

Clean and maintain this

part regularly.

Page 2-8 GT Series Operator’s Manual

Head lock leve

Head release

lever

Label Gu id e

handle

Page 21

2.1.2 PARTS IDENTIFICATION (CONT’D)

P

s

O

n

m

S

i

C

d

a

o

F

i

U

t

IDENTIFY ING THE MAIN PRINTER PARTS

View of Front Panel

Section 2: Installation

LCD screen

Icons , prompts and system messag es

are displayed here.

FEED button

Feeds the label forward. When it is pressed once,

the equivalent of a sheet of paper or label is ejected.

*There are times when the paper is not aligned properly whe n po w er is tur ne d on or when the paper wa s

set. In this case, always press the FEED button to

align the paper properly.

Operation buttons

FUNCTION button: Selects the various setting modes.

CURSOR buttons: Each button moves the cursor up,

down, left or right on the LCD screen.

ENTER button: Confirms the choice of a selection or value.

Light Emitting Diodes

OWER LED: Ligh ts up whe n power is

upplie d to the pr in te r.

NLINE LED: Lights up when commu-

ication is available. Flashes with com-

unication fails.

TATUS LED: Lig hts up and flashes to

ndicate exchange of data.

ANCEL button: Cancels pr inting

ata. In each setting mode, the button

lso retur n s yo u to t he previous me nu

r menu item.

or details of each indicator’ s behav -

or, see Page 6-4 of Section 6,

nderstanding the STATUS Indica-

ors.

Var iable Resistors

VOLUME: Adjusts the loudness of the built-

in speaker (buzzer).

PITCH: Adjusts the vertical print position

with reference to the top edge of a label.

OFFSET: Adjusts the stop position offset

values for the cutter, peeler and tear off

modes (cutter, peeler must be inst alled).

DARKNESS: Adjusts the print darkness

(print de ns it y) .

CANCEL button: Cancels printing data. In each setting

mode, the button also returns you to the previous menu or

menu item.

Adjustment screwdrive r

Fits into the VOLUME, PITCH, OFFSET and DARKNESS

variable resistors to allow adjustments.

GT Series Operator’s Manual Page 2-9

Page 22

SECTION 2: INSTALLATION

Ribbon feeder

2.2 LOADING THE CARBON RIBBON

1. Lift up the main cover. Make sure that the cover

rests firmly o n the top of the pr inter so that it will not

fall forward and injure your hands.

2. Release the purple head release lever by pushing

it downwards. The print head assem bly will be

lifted up to allow label loading.

3. Insert th e c arbon ribbon in t he ribbon fee der.

Push it inwards all the way, with the ribbon winding

in a clockwise direction around the print head, as

shown. Note: Use only genuine SATO carbon

ribbons for maximum print quality and printer

durability.

Front Cover

Print h ead

Head

release lever

(purple)

4. Check t hat t he purple knob of the ribbon take-up

shaft is pushed inwards, toward the back. If not,

push it in.

Caution

• Failure to ensure that the knob is pushed fully inwards before

winding the new ribbon onto the shaft, will result in difficulties

later when you wish to removing the used ribbon.

5. Pass t he car bon ribbon under the print head to the

ribbon tak e-up shaft. Aff ix th e c arbon ribbon

directly to the grip sheet o n the take-up shaft. Wind

the ribbon s ev eral times in th e direction of th e

arrow in the picture. Check from sideways that the

carbon ribbon is installed according to Step 3

above.

6. Now remount the print head by pushing down on

the head lock lever. The print head should lock into

place firmly . You can now pr oceed to ins ta ll th e

label media as described in the follow ing sections .

Knob

Carbon

ribbon

Grip s hee t

on take-up

shaft

Carbon

ribbon

Print head

Page 2-10 GT Series Operator’s Manual

Page 23

2.2 LOADING THE CARBON RIBBON (CONT’D)

2.2.1 Removing the Carbon Ribbon

Pull the purple knob on th e ribbon take-up shaft

outward s . Hold the carbo n ribbon reel an d pull it

outward s . S om e carbon pow der may adhere to your

hand during this process—if so, wash your hands to

remove the powder.

Note:

Do not insta ll a new c arbon ribbon an d th en wind it over

any used ribbon in the ribbon take-up shaft. That is,

always remove all used ribbon from the ribb on t ak eup shaft (us ing the purple k nob to relea s e t he used

ribbon) before changing to a new ribbon.

Section 2: Installation

Knob

Carbon

ribbon

Caution

• When replacing the carbon ribbon, bear in mind that the print

head and its surrounding area remain hot. Keep your fingers

away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

GT Series Operator’s Manual Page 2-11

Page 24

SECTION 2: INSTALLATION

Replacement

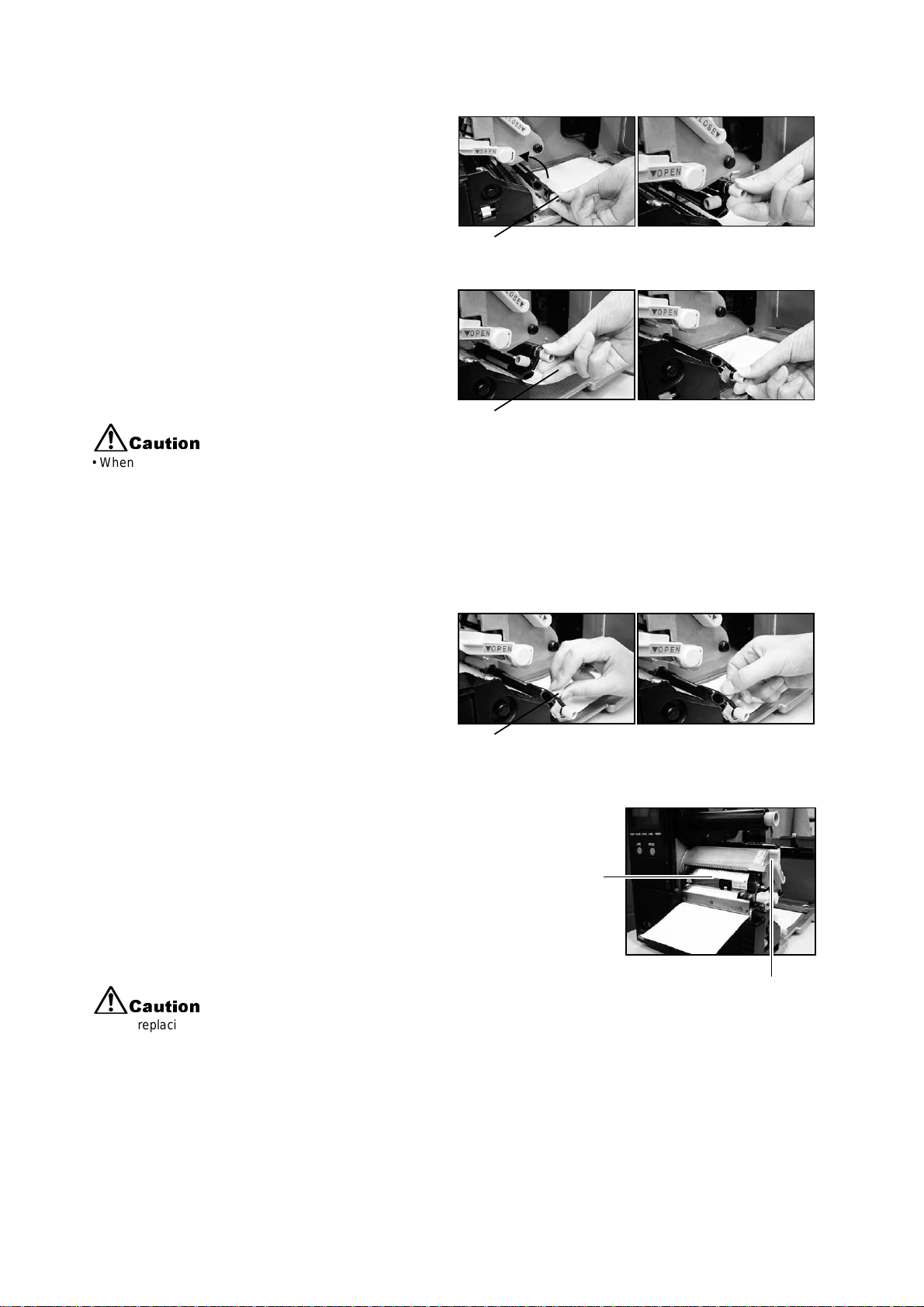

2.2.2 OPTION: Using A Paper Tube to Wind Used Ribbon

Under certain circumstances, instead of using the GT printer’s ribbon take-up shaft to collect

used ri bb on, us ers ma y pr efer to us e p aper tu be s to fo rm a cor e for wi ndi ng th e us ed r i bbon . T his

is a possible option that requires replacing the ribbon winding shaft with a different shaft (optional

access ory). Once th e optional shaft is installed, y ou can follow th e s t eps below to us e paper

tubes for winding used ribbon.

1. Lift up t he m ain cover an d push the purple head

release lever downwards. The print head assembly

will be lifted up.

2. Insert th e c arbon ribbon in t he ribbon fee der and

push it inwards all the way . In se rt th e paper tube

into the new ribbon take -up shaft by pushing it

inwards a ll th e w ay .

3. Pass t he c arbon ribbo n f rom t he ribbon fe eder

under the print head to the paper tub e on the

ribbon tak e-up shaft. Aff ix th e ribbon to the p aper

tube with ta pe. Wind the ribbon several times

around the tube.

take-up shaft

Paper tube

Ribbon feeder

Paper tube

Print head

4. Check from sideways that the carbon ribbon is set

5. Now remount the print head by pushing down on

• When replacing ribbons, bear in mind that the print head and its

surrounding area remain hot. Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Page 2-12 GT Series Operator’s Manual

as shown in t he following pic t ure.

the head lock lever. The print head should lock into

place firmly. You can now proceed to load labels or

other me dia as described in the follow ing sections .

Caution

Paper tube

Print head

Label loaded

Page 25

Section 2: Installation

2.3 LOADING LABELS AND TAGS

This printer can print on roll paper and fanfold paper.

The method of setting paper is different with roll pa per and fanfo ld paper.

This printer can be set to detect the I-mark on the paper to feed each label correctly.

Note:

For optimal print performance and durability, please use SATO-certified label and ribbon

supplies on this printer. Using suppl ies not tested an d approved for us e by SATO can re s ult in

unneces s ary w ear and damage to vital part s of th e printer, and ma y vo id t he warranty .

Roll Paper Characteristics

Label

Fanfold Paper Characteristics

Label

GT Series Operator’s Manual Page 2-13

Page 26

SECTION 2: INSTALLATION

R

R

L

R

L

t

i

2.3 LOADING LABELS AND TAGS (CONT’D)

2.3.1 Loading Roll Paper

1. Lift up the main cover. Make sure that the cover

rest s firm ly on the top of the pr inte r so tha t it wi ll not

fall forward and injure your hands.

2. Release the purple head release lever by pushing

it downwards. The print head assem bly will be

lifted up to allow label loading.

3. Push th e s pring-loade d purple Roll Guide lever

sideways (t o t he right) to relea s e t he Roll Guid e.

Pull the Roll Guide outwards to the edge. Once the

Roll Guide is m ov ed to the edg e, it will tilt

backwards to allow a label roll to be inserted easily.

Front Cover

Print h ead

Head

release lever

(purple)

oll Guide

ever

oll Guide

4. Insert th e label roll and p us h t he Roll Guide back

into place. Make sure that the Roll Guide pushes

snugly against the label roll to prevent label drift

during prin t ing.

Lift up the

Roll Guide.

Push the

purple lever to

the right and

move th e R o l l

Guide toward

the label roll.

elease th e

ever to loc k

he Roll Guide

n place.

Page 2-14 GT Series Operator’s Manual

Page 27

2.3 LOADING LABELS AND TAGS (CONT’D)

5. Pull out the purple label damper to release the label guide

assembly. The label guide will drop downwards.

6. Insert the paper into th e label guide from a sidew ay s

angle, so that the paper passes under the label guide and

paper sensor.

Section 2: Installation

Pull the

purple

label

damper.

Label

sensor

7. Adjust th e label guide knob so that it lig ht ly to uc hes the

edge of th e label. Faste n t he k nob tightly .

8. Now rem ount the print head by push ing down on the

Head loc k lev er. The print head should loc k int o place

firmly.

9. If desire d, cl os e t he main cover and do a test print to

check th at th e label roll has been loaded properly. B e

careful not to get your fingers caught at the bottom ledge

when yo u are closing the main cove r.

Caution

• When replacing paper, bear in mind that the print head and its surrounding

area remain hot. Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Adjust

the label

guide

knob

Print

Head

Head lock

lever

GT Series Operator’s Manual Page 2-15

Page 28

SECTION 2: INSTALLATION

2.3 LOADING LABELS AND TAGS (CONT’D)

Adjusting for the paper width

This pri nt er is adjusted so th at quality print ing can be obta ined without any adjustm ents.

However, in certain s it uations, be tter results can be obtained if you adjust the “head pres s ure

balance” to compensate for di fferent widths of label paper used.

The head pressure balance knob adjusts the amount of pressure being applied along different

sections along the length of the print head. For suggested settings of the pressure knob (1 to 5),

see the table below:

SETTING PAPER WIDTH

125~42 mm

242~59 mm

359~78 mm

478~95 mm

5 95~131mm

Note:

Adjustments are only necessary if print quality is not satisfactory. Otherwise, you do not need to

vary the head pressu re balance.

Head pressure

balance

adjustment

knob

Page 2-16 GT Series Operator’s Manual

Page 29

2.3 LOADING LABELS AND TAGS (CONT’D)

Section 2: Installation

2.3.2 Lo ad in g Fa nfo ld Pap er

1. Lift up the main cover. Make sure that th e cover r est s

firmly on th e t op of the printer s o that it will not fa ll

forwa rd and injure yo ur hands.

2. Remove the release screw that holds the rear cover in

place. K eep the screw in a safe place f or easy

retrieva l lat er.

3. Tilt the re ar c ov er until it rests on the table s urf ace.

On the surfac e of the cover yo u w ill see a factory imprinted line that guide s y ou in aligning th e f anf old

paper so th at it feeds at the correct angle int o t he

printer.

Front Cover

Rear cover

rele ase screw

Rear cover

Rear cover

4. Load fanfold paper on top of the cover, up to 20 cm in

height. A lign the stack of fa nf old paper to th e fa c t ory imprinte d line.

5. Pass the paper from th e t ray ov er the Roll Pa per

Feeder. Adjust the Ro ll Guide so that it is in contact

with the side of the paper. This will ensure that the

paper m ov es forw ard at a consistent angle. (To m ove

the Roll Guide forward or backward, first push the

purple le v er at the top of the guide sidew ay s . )

Roll Guide

Roll Paper

Feeder

GT Series Operator’s Manual Page 2-17

Page 30

SECTION 2: INSTALLATION

2.3 LOADING LABELS AND TAGS (CONT’D)

6. Pull out the purple label da mper to release th e label

guide ass em bly. The label guide will drop downwa rds .

7. Insert the paper so that i t passes under t he la bel guide

and pape r s ensor.

8. Adjust the label guide knob so that it lightly touches the

edge of th e label. Fasten th e k nob tightly.

Pull the

purple

label

damper

Label

sensor

Adjust

the label

guide

knob

9. Now rem ount the pri nt head by pushing down on t he

Head lock lever. The print head should lock into place

firmly.

10. If desired, close the main cover and do a test print to

check t hat the label roll has been l oaded properly. Be

careful not to get your fingers caught at the bottom

ledge when you are cl os ing the main c ov er.

Note:

The proc edure described above is recommended for

loadin g a s t ac k of fa nf old paper tha t is 2 0 c m in height or

higher.

For loading smaller reams of fanfold paper, use the rear

cover as described in the previous section. Avoid loading

stacks of paper from the rear if the height is greater than

20 cm.

Print

Head

Head lo ck

lever

Caution

• When replacing paper, bear in mind that the print head and its surrounding area remain hot. Keep your fingers away from

these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Page 2-18 GT Series Operator’s Manual

Page 31

2.3 LOADING LABELS AND TAGS (CONT’D)

F

c

s

t

o

d

2.3.3 Loading Fanfold Paper under the printer

Section 2: Installation

1. Lift up the main cover. Make sure that th e cover r est s

firmly on th e t op of the printer s o that it will not fa ll

forwa rd and injure yo ur hands.

Note:

It is assumed that the printer is supported on stands to

allow fanfold paper to be loaded fro m beneath the

printer.

2. Release the purple head release lever by pus hing it

downw ards. The print head assembly w ill be lifted up

to allow la bel loading later.

3. Unscrew the fanfold cover and remove

it. Keep the cover and the screw in a

safe place for future use.

anfold

over

crew

Front Cover

Print h ead

Head

release lever

(purple)

4. Loa d the s tack of f anfol d pa per st raig ht

through t he fanfold loa ding slot.

5. Pass the paper through t he fanfold

loading slot and pull it into the c hassis

near the print head assem bly.

Fanfold cover Fanfold loading slo

Fanfold paper

before loading

Pull the paper

into the chassis

Fanfold paper

loaded into slot

Paper is now ready t

load under print hea

GT Series Operator’s Manual Page 2-19

Page 32

SECTION 2: INSTALLATION

P

H

6. Pull up the Label Damper by the

purple knob in a count erc lockwise

directio n until it locks int o place

vertically. If it is already in a vertical

position proceed to th e next step.

7. Pass the paper under the label

guide an d paper senso r. Pull the

label damper knob, a nd the label

damper will drop down to press

against the paper.

Caution

• When replacing paper, bear in mind that the

print head and its surrounding area remain hot.

Keep your fingers away from these areas to

prevent injury.

• Avoid touching even the edge of the print head

with your bare hands.

8. Loosen the label guide knob, and

adjust the s lide guide so th at it

lightly touc hes the edge of th e

paper. Now fasten the label guide

knob tightly.

Label Guide Knob

Label Guide

Label Damper

Label Damper

Label Guide Knob

9. Remount the print head by pushing down on the head lock

lever. The print head sh ould lock into place firmly.

10. If desired, close the main cover and do a test print to

check th at th e label roll has been loaded properly. B e

rint

ead

careful not to get your fingers caught at the bottom ledge

when yo u are closing the main cov er.

Head lo ck

Caution

• When replacing paper, bear in mind that the print head and its surrounding

area remain hot. Keep your fingers away from these areas to prevent injury.

lever

Page 2-20 GT Series Operator’s Manual

Page 33

Section 2: Installation

P

2.3 LOADING LABELS AND TAGS (CONT’D)

2.3.4 Adj ustin g the pa pe r Senso r

Adjustment of the paper sensor is us ually not neces s ary, but the procedure is des c ribed here.

1. Lift up the main cover. Make sure that th e cover r est s

firmly on the top of the printer so that it will not fall

Front Cover

forwar d and injure your hands.

2. The purp le sensor unit is loc ated just abov e the label

damper as s em bly. Slide it out w ards to adjus t it s

position.

aper se n so r

3. You can continue to load media by following the steps

in previous sections, or close the front cover.

Caution

• When closing the front cover, be careful not to injure your fingers due to a sudden release of the heavy cover.

GT Series Operator’s Manual Page 2-21

Page 34

SECTION 2: INSTALLATION

2.4 REPLACING THE PRINT HEAD

Before at t em pting to repla c e t he print head, it is adv isable to con t ac t yo ur local dealer or s ervice

center so that they can assist you in case of problems.

1. Make sure the printer has been turned off for at least 30 minutes so that the print head is not

hot. Lift up the main cover.

2. Push the purple slide lever outwards, in the direction shown

here. Th e print head wil l be released .

Caution

• Do not touch the print head’s heating elements. If you do so inadvertently, use the

cleaning pen (supplied) to clean the area thoroughly. For more details, see Section

4, Cleaning and Maintenance.

4. Pull the print head outwards and disconnect the two connectors

attached to it.

5. Attac h t he connectors t o t he new print head.

6. Ther e ar e tw o hoo ks on th e l ef t an d ri gh t si de s of t he p ri nt hea d.

Insert the left-side hook into the printer first. Mount the hook

under the c y linder marked w it h t he arrow sym bol.

7. Now mount the right-side hook of the print head under the

cylinder ma rk ed with the arrow symbo l. Th e print head

should sn ap into place firm ly. If not, release the prin t h ead and

try ag ain from St ep 6 above .

Page 2-22 GT Series Operator’s Manual

Page 35

2.5 TURNING THE PRINTER ON/OFF

1. After rem ov ing the cable co v er at t he rear of the prin t er

(See Pag e 2-7), you can proceed to install the inte rf ac e and

power cables as shown.

2. To limit mov ement of the ca bles, you can optionally ch annel

the cables t hrough the cable hook area at the base of the

printer.

Section 2: Installation

3. Insert the power cable fir s t to t he printer, th en connect th e

other end to the power outlet. If necessary, use an adapter to

match the prongs on the power cable to the sockets in the

AC outl et.

Caution

• Always use a grounded power cable to protect against electrical leakage and

electrical shocks.

4. To turn the printer ON, press the power switch to the “I” side.

When the printer is succes s f ully turned on, the LCD sc reen

will display something similar to that shown here.

Caution

• To prevent electric shocks, make sure your hands are dry when you operate the

power switch, or when you pull out or insert power cables and switches.

5. If the printer does not respond, refer to the Troubleshooting

section of this manu al.

6. Before turning the print er off, perform the follow ing steps:

Take the pri nt er off lin e by pre ssi n g th e Lin e bu tto n. The LC D

shows the following:

• Press the Feed button to eject any label at the front of the

printer.

• Lightly pu ll th e paper diagonally dow nw ard to tear off the

label.

7. To turn the pr inter of f, press the pow er swit c h to the “O” sid e.

GT Series Operator’s Manual Page 2-23

Page 36

SECTION 2: INSTALLATION

This pag e is intentional ly lef t b lank

Page 2-24 GT Series Operator’s Manual

Page 37

Section 3: Configuration and Operation

Test prints can be performed.

3

CONFIGURATION AND OPERATION

Before using the printer, it is best to read this manual thoroughly first. Otherwise, you may disturb

default set t ings around w hic h t he instructional procedures in this manual are bas ed upon.

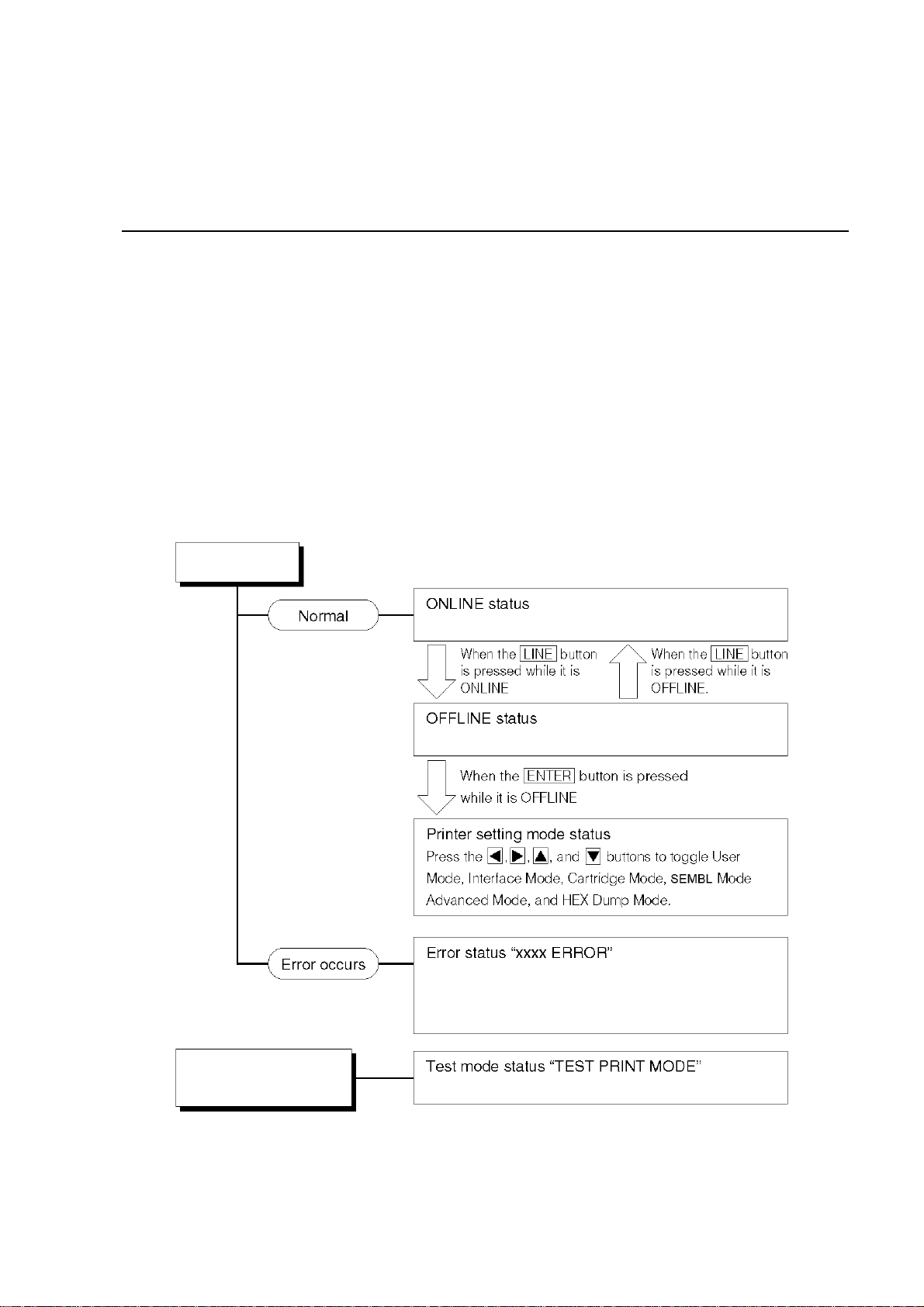

3.1 OPERATING MODES

The operat ing status of th is printer can be s et t o one of five mod es :

1) Online mode

2) Offline mode

3) Printer Set t ing modes:

User Mode, Interface Mode, Cartridge Mode, SEMBL Mode, Advanced Mode, Hex

Dump Mode, Test Print Mode)

4) Error mode

5) Test Print mode

Turn printer on

The printer status is normal; printing can begin

Printing is stopped; ready for configuration

Printer has not been set up correctly. The LCD

shows “H ead Open”, “Paper End”, et c

Hold down Feed key

and turn printer on

GT Series Operator’s Manual Page 3-1

Page 38

Section 3: Configuration and Operation

O

3.2 THE OPERATION PANEL

Overview of the Operation Panel

Status Icon display area

Up to five icons can appe ar here to

indicate the current printer status.

The same area can also display two

lines of alphanumeric text instead.

Two-line M essage di sp l ay area

Other icon s , o r up t o t w o lines of

alphanumeric messages, can be

displayed here.

In total, up to four lines of text can be

displayed on the whole sc r een.

How To Adjust Screen Contrast

In ONLINE or SEMBL mode, press the left/right arrow

buttons repeatedly to adjust the contrast.

Contrast settings are reset whenever you reset the

printer to default settings.

vervie w o f th e Display for Pr i n ter Setting

Description of Setting

The curr ent function b eing set can b e

described in up to two lines of text.

Value to be Set

Available setting va lues or options are

displayed here in up to two lines.

Usable Navigation Buttons

Shows only t hose arrow k ey s t hat are

valid for ch anging the cur rent setting.

The arrow k ey s are a combination of

Page 3-2 GT Series Operator’s Manual

Page 39

3.3 SCREEN ICONS AND THEIR MEANING

Section 3: Configuration and Operation

GT Series Operator’s Manual Page 3-3

Page 40

Section 3: Configuration and Operation

3.3 SCREEN ICONS AND THEIR MEANING (CONT’D)

Page 3-4 GT Series Operator’s Manual

Page 41

Section 3: Configuration and Operation

3.4 ONLINE AND OFFLINE MODES

3.4.1 Online Mode

Pressing the LINE button causes the printer to go ONLINE or

OFFLINE alternately.

When the printer is ONLINE, the following activities will be possible:

• The printer is ready to receive print data from the computer or

other connected devices

• The printer is ready to start printing

3.4.2 Offline Mode

When the printer is ONLINE, pressing the LINE button once will

cause the printer to go OFFLINE.

When the printer is OFFLINE, the activities for ONLINE mode are

no longer p os s ible, but the fol low ing activities will be poss ible:

• The printer can eject labels when you press the FE ED button.

• The printer can be switched to other modes when you press th e

ENTER button.

• Any printing job can be sto pped once the printer is broug ht

OFFLINE

• Any printing job can be ca nc elled once th e CANCE L button is

pressed in OFFLINE mode. The menu for canceling the print job

then appears.

• Received data that is stored in the buf fe r m em ory can be s av ed

into a memory cartridge, if the LINE button is pressed and held

down for at least five seconds in OFFLINE mode. The following

screens will appear.

GT Series Operator’s Manual Page 3-5

Page 42

Section 3: Configuration and Operation

3.5 USER MODE

The follo w ing settings a re av ailable in U s er M ode:

• OFFSET VOLUME (volume of the built-in buzzer/speaker)

• PRINT SPEED (print s peed settin g)

• PRINT DARKNESS (print density setting)

• PRINT OFFSET (print position correction setting)

• ZERO SLASH (zero sl as h c hangeov er s et t ing)

• JIS CODE (JIS code c hangeover se t ti ng)

• KANJI FONT (Kanji fon t ch angeover se tting)

• CHARACTER PITCH (proportional pitch setting)

3.5.1 Entering User Mode

1. Press the LINE button to take the printer OFFLINE.

2. Pull dow n t he cover of the Operation P anel and press ENTER.

The ONL I N E M OD E sc reen ap pears.

3. Press the arrow buttons until you see “USER

MODE”, then press ENTER.

Note:

The bottom right-hand corner of th e s c reen somet im es displays

one to four a rrow symbols (s ee circled s ymbols on the ri ght).

Each arrow s y m bol represe nt s th e c orresponding arrow bu tton

on the operation panel which is valid for the changing the current

screen or its se t ti ngs .

4. When the first User Mo de screen ap pears, you will need the

yellow scre w driver (fastened to the O peration Panel flap), to

adjust the OF F SET VOL U M E, PI T C H , OF F SET and

DARKNESS potentiometers. See Sectio n 3. 5. 2 Setting Pri n t

Speed.

5. Subsequently, pressing the ENTER button brings you to screens

for setting PRINT SPEED, PRINT DARKNESS and OFFSET. At

any time, pr es s ing CANCEL takes you back one screen.

Pressing the FUNCTION button returns you immediately to the

main User Mode screen.

Page 3-6 GT Series Operator’s Manual

Page 43

Section 3: Configuration and Operation

3.5.2 Setting Buzzer Volume, Print Pitch, Print Offset, Print Darkness

The volume level of the built-in speaker buzzer can be adjusted at

the first menu of the User Mode. Use th e y ellow screwd riv er to

adjust the VOLUME po tentiometer below the L C D. The value on

the screen changes as you turn the screwdriver clockwise or

counter-clockwise.

Next, you c an use the scre w driver to rota te th e potentiomet er for

the Print Pitch. This setting adjusts where printing begins

vertically , re lat iv e to the bottom edge (nearest the print head) of

each label. Th e m ax imum val ue allow ed is 3.75 mm.

Adjusting th e OFFSET potentiometer adjusts the tear-off stop

position for use with a cut t er, peeler.

Finally, adjusting the Print Darkness potentiometer adjusts the

pri nt darkne s s .

Print hea d

When all the set tin gs are satisfactor y , pre s s the ENTER button to

proceed to set other parameters in the User Mode.

3.5.2 Setting Print Speed

After setting OFFSET VOLUME, PITCH, OFFSET and

DARKNESS, pressing ENTER takes you to the Print Speed setting.

This setting can be used to achieve a high print speed that does not

compromise print qua lit y .

Press the buttons to change the setting. Press the ENTER

button to co nf irm a setting a nd proceed to the next scree n.

If quality printing cannot be obtained due to the quality of the paper

or the printing contents, lower the speed accordingly. On the GT408

and GT412, the print speed can be set in 11 steps. On the GT424,

the print speed can be se t in fiv e steps in GT4 24. The table below

shows the fa c to ry def ault print speed for diffe rent print resolutions.

ref point 0,0

direction of label motion

Print offse t

Print head resolution:

default print speed setting

203 dpi: default 06 inches/sec 02, 03, 04, 05, 06, 07, 08, 09, 10, 11, 12 inches/sec

305 dpi: default 06 inches/sec 02, 03, 04, 05, 06, 07, 08, 09, 10, 11, 12 inches/sec

609 dpi: default 03 inches/sec 02, 03, 04, 05, 06 inches/sec

GT Series Operator’s Manual Page 3-7

Available print speed settings (lower numbers mean

slower print speeds)

Page 44

Section 3: Configuration and Operation

-

3.5.3 Setting Print Darkness

After se tti ng Pri nt Sp eed, the ne xt s cr een a l low s yo u to set t he Pr i nt

Darkne s s —t he darknes s o f the print on pa per.

This setting can be set from 1 (lightest) to 5 (darkest). The default

setting is 3.

Press the / butto ns to ch ange the sett ing. Press the ENTER

button to c onfirm a setting and proc eed to the next screen.

3.5.4 Setting Print Offset

After setting Print Darkness, the next screen allows you to set the

Print Pos it ion Offset— w hic h refers to the vertical and horizontal

shifting of the entire print area, relative to the start position of

printing (V=0, H=0) , define d by defaul t t o be the bott om righ t hand

corner of th e label.

Use the / buttons to select the V or H setting, and the /

buttons to change a highlighted setting. Press the ENTER

button to c onfirm a setting and proc eed to the next screen.

The V setting is for the Vertical print offset. A positive (+) offset

means the printing is shifted towards the print head; a negative (-)

offset means shifting away from the print head. If the Print Pitch

setting has been used to offset the vertical start position, then all

Vertical offset adjustments are made relative to that start position.

The H set ti ng is f or t he Horizontal print offset . Th e + or - prefix

determines whether the offset is to the left or to the right of the

reference point.

Printer Valid H and V settings (in dots)

GT408 V: +/- 000 to 1424 dots, H: +/- 000 to 832 dots

GT412 V: +/- 000 to 2136 dots, H: +/- 000 to 1248 dots

GT424 V: +/- 000 to 4272 dots, H: +/- 000 to 2496 dots

After setting the Vertical and Horizontal OFFSET, press ENTER

to proceed to the next setting.

directio n of label motion

Print hea d

H+V-H

ref point 0,0

V+

Print offset

Page 3-8 GT Series Operator’s Manual

Page 45

Section 3: Configuration and Operation

3.5.5 Setting Zero Slash Changeover

You can use this setting to determine whether zeroes are printed

with a slash across them or not. The zero slash (excluding Kanji)

can be set to either "0" or "Ø".

Use the / buttons to select YES or NO. ‘YES’ means zeroes

will be print ed w it h a diagonal sla sh across th em . ‘N O’ means

otherwise. The default v alue is ‘NO’.

Press ENTER to select the desired option and proceed to the next

setting.

3.5.6 Setting JIS Kanji Code Changeover*

* option is only valid for printing in Japanese

The printer can be set to use either JIS code or Shift JIS code.

Use the / buttons to select JIS or SJIS. The default value is

JIS code.

Press ENTER to confirm your selection and proceed to the next

setting.

3.5.7 Setting Kanji Font Style*

* option is only valid for printing in Japanese

The Kanji font style can be set to either “GOTHIC” or “MINCHO”.

Use the / buttons to select GOTHIC or MINCHO. The defaul t

value is GO T H I C .

Press ENTER to confirm your selection and proceed to the next

setting.

GT Series Operator’s Manual Page 3-9

Page 46

Section 3: Configuration and Operation

3.5.7 Setting Proportional Pitch

This set tin g determine s whether the s pace surrou nding each te xt

character is of a fixed width, or whether that space is to be varied to

be visually more pleasant.

Use the button s t o se lec t e it her PROPO RT IONA L o r FIX ED.

The defa ult value is FIXED.

Press ENTER to confirm your selection and return to the main User

Mode screen. Pr ess the FUNCTION or CANCEL key to exit the User Mode setting.

Note:

The sub jec t fo nt s are from x21 to x24

Page 3-10 GT Series Operator’s Manual

Page 47

Section 3: Configuration and Operation

3.6 INTERFACE MODE

In this mode, you can set various parameters governing the use of interface cards. Due to the

wide range of interface card s av ailab l e, only th e defaul t inter f ace configurat ion settings are

covered in th is se c ti on. A flowchart overview of adv anced setti ngs for all the op t ional interface

cards is inc luded at the end of th is ch apter, and a detailed discussion of adv anced set tin gs c an

be found in t he GT Series S erv ic e Manual a v ailable upon re quest.

3.6.1 Entering Interface Mode

1. Press the LINE button to take the printer OFFLINE.

2. Pull down the co v er of the Operati on Panel and pre s s ENTER.

The ONL INE MODE s c reen appears.

3. Press the arrow buttons until you see

“INTERFACE MODE”, then press ENTER to perform the first

setting. At any time within this mode, pressing CANCEL takes

you back one screen. Pressing the FUNCTION b utton returns

you immediat ely to th e ma in Interface Mo de screen.

3.6.2 Enabling Interface Card Configuration

The first setting in the Interface Mode lets you select whether you

wish to configure an interface card for bi-directional communication.

If YES is selected, the next screen lets you select an interfa ce card

to configure.

If NO is selected, the next screen lets you choose the correct port

for receiving print data . Se e Section 3.6.4 Selecting The Data

Input Port.

Press the / buttons to select either YES or NO.

Press the ENTER butto n t o c onfir m the sett ing and proceed t o t he

next scree n (s ee either Section 3.6.3 or 3.6.4 on page 3-12).

GT Series Operator’s Manual Pa ge 3-11

Page 48

Section 3: Configuration and Operation

3.6.3 Assigning An Interface Card For Printing

This set tin g lets you select w hic h installed in t erf ac e card is to be

used for bi-directional communication/printing. The other card is

then presumed to be a mini LAN card, which is intended for

transmitting printer status information to a LAN.

The card se lected by def ault for bidirec t ional communication is th e

one that is not a mini LAN card. Card2 is assumed to be a mini LAN card.

Press the / buttons to select either CARD1 or CARD2.

Press the ENTER button to con f irm a s et t ing and proceed to the nex t screen.

3.6.4 Selecting The Data Input Port

Use this setting to define which installed interface card is to be used

as the por t f or rece iv ing print data. The def ault value is CAR D 1

(which is the non mini LAN card).

Press the / buttons to select either CARD1 or CARD2.

Press the ENTER button to con f irm a s et t ing and proceed to the

next screen.

Note:

If you set th e data input po rt to be C ARD2 but print data is received at CAR D 1, printing will not

occur. The reverse also holds true.

3.6.5 Enabling or Disabling The Status Return Port

Use this s etting to enable or disabl e the status ret urn port .

The inte rf ac e c ard which is not being used as th e data input po rt

(see Section 3.6.4 above) is the status ret urn port. The def ault

value is ENABLE.

Press the / buttons to select either ENABLE or DISABLE.

Press the ENTER button to con fi r m a sett ing an d ret urn to t he ma in s cr een of th e Int er fa ce Mod e.

Page 3-12 GT Series Operator’s Manual

Page 49

Section 3: Configuration and Operation

3.7 CARTRIDGE MODE

In this mod e y ou c an manage t he optional me m ory cartridge t hat can be ins t alled to provid e

increased storage capacity for text and graphics.

3.7.1 Entering Cartridge Mode

1. Press the LINE button to take the printer OFFLINE.

2. Pull down the co v er of the Operati on Panel and pre s s ENTER.

The ONL INE MODE s c reen appears.

3. Press the arrow buttons until you see

“CARTRIDGE MODE”, then press ENTER to perform the first

setting. At any time within this mode, pressing CANCEL takes