SATO GT408, GT 410 User Manual

GT408/410/424e

Printer

OPERATOR MANUAL

PN 9001138A

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support Hotline: (704) 644.1660

Technical Support Fax: (707) 644.1661

E-Mail: satosales@satoamerica.com

technical support@satoamerica.com

www.satoamerica.com

WARNING

THE EQUIPMENT REFERENCED IN THIS DOCUMENT COMPLIES WITH THE REQUIREMENTS IN

PART 15 OF FCC RULES FOR A CLASS B COMPUTING DEVICE. OPERATION OF THIS EQUIPMENT

IN A RESIDENTIAL AREA MAY CAUSE UNACCEPTABLE INTERFERENCE TO RADIO AND TV

RECEPTION.

TABLE OF CONTENTS

INTRODUCTION

About This Manual 1-2

General Description 1-3

Control Features 1-4

TECHNICAL DATA

Physical Characteristics 2-2

Power 2-2

Enviromental 2-2

Processing 2-2

Print 2-2

Media 2-2

Ribbon 2-3

Sensing 2-3

Processing 2-3

Character Font Capabilities 2-4

Barcode Capabilities 2-5

Regulatory Approvals 2-5

INSTALLATION

Unpacking & Parts Identification 3-2

Printer Installation 3-2

Site Location 3-3

Cable Connection 3-3

Media Selection 3-4

Media & Ribbon Loading 3-4

Interface Selection 3-6

RS232C Serial Interface 3-6

IEEE1284 Parallel Interface 3-8

Universal Serial BUS (USB) Adapter 3-9

Local Area Network (LAN) Ethernet 3-9

802.11B Wireless 3-9

Receive Buffer 3-10

ACK/NAK Protocol 3-10

Accessories Installation 3-11

External Signal Connector 3-11

Memory Expansion 3-12

Interface Upgrade 3-13

Label Cutter 3-14

Label Peeler 3-14

PN 9001138A

PRINTER CONFIGURATION

Configuration Modes 4-2

Normal Mode 4-2

User Mode 4-3

Advanced Mode 4-4

IEEE1284 Interface Setup Mode 4-5

RS232C Interface Setup Mode 4-6

Centronics Interface Setup Mode 4-7

LAN Interface Setup Mode 4-8

USB Interface Setup Mode 4-9

Cartidge Mode 4-10

SEMBL Mode 4-11

Test Print Mode 4-12

Download Mode 4-13

Hex Dump Mode 4-14

Boot Download Mode 4-15

Data Save Mode 4-16

Default Settings Mode 4-17

Print Cancel Mode 4-18

Print Darkness Default Mode 4-19

Service Mode 4-20

Factory Mode 4-21

Screen Identification 4-22

TROUBLESHOOTING

Error Signals 5-2

Troubleshooting Table 5-7

Interface Troubleshooting 5-9

Parallel Interface 5-9

RS232 Serial Interface 5-9

LAN Ethernet Interface 5-10

Universal Serial Bus (USB) Interface 5-10

Test Print Troubleshooting 5-11

Hex Dump Mode 5-11

Test Label Printing 5-12

Sensor Locations 5-14

MAINTENANCE

Cleaning Procedures 6-2

Replacement Procedures 6-3

Print Head 6-3

Platen Roller 6-4

Adjustment Procedures 6-6

Print Head Alignment 6-6

Print Head Pressure 6-7

Print Head Balance 6-8

Ribbon Guide 6-9

Label Sensor Positioning 6-10

Potentiometer Adjustments 6-11

PN 9001138A

INTRODUCTION

• About This Manual

• General Description

• Control Features

SATO GT4xxe Series Operator Manual PN 9001138A Page 1-1

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information

required for printer maintenance and repair by SATO approved personnel. For the repair

technician, this manual is intended to compliment, and to be used as an extension of, owner/

operator literature.

This manual also incorporates the use of special information boxes. Examples of these boxes

and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN PRESONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN EQUIPMENT DAMAGE.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

LCD DISPLAY: Provides the specific display that should be visible on

the LCD at that point.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different Units, Chapters, and Sections. Each

references the page number of their commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying

his or her exact position within the manual. The header provides the section number followed by

its name. The footer identifies the product on the left, the manual’s part number in the center, and

the page number to the right side of the page.

Page enumeration is two-part with each separated by a hyphen. The first character set

references the Unit and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new unit and ascends sequentially.

SATO GT4xxe Series Operator Manual PN 9001138A Page 1-2

Unit 1: Introduction

GENERAL DESCRIPTION

The GT4xxe series printer is a high-performance printer capable of printing all popular bar codes

and twelve human-readable fonts; providing an inventory of thouasnds of styles and sizes. Its

heavy metal construction is designed to deliver optimum performance in demanding

environments.

Top Housing Cover

Left Housing Cover

Operator Panel

Power Switch

Front H ousing Cover

Rear Housing Cover

Memory Card Access

Ribbon Supply Spindle

Ribbon Rewind Spindle

Media Holder

Media Guide

Side Cover

Platen Rolle r A ssembly

Print Head Assembly

Figure 1-1a, Primary Components

SATO GT4xxe Series Operator Manual PN 9001138A Page 1-3

Unit 1: Introduction

CONTROL FEATURES

This chapter identifies the interactive control features of the printer. These functions are

generally defined here. More specific explainations will be found throughout this manual on how

to use them.

LCD Display

Communicates operational conditions via the use

of icons and text.

POWER ON LINE STATUS LABEL RIBBON

LINE

FUNCTION

VOLUME PITCH OFFSET DARKNESS

FEED

ENTER

CANCEL

LED Indicators

POWER

Illuminates when the power on.

ONL INE

Illuminates when communication is available .

Flashes when fails.

STAT US

Flashes when an error occurs. Flashes when

sending/receiving data.

LABEL

Flashes when paper error occurs.

RIBBON

Flashes when ribbon error occurs.

Operator Buttons

FEED

Feeds the equivalent of a sheet of paper when

pressed once. Posit ions p ape r if misalig ned .

LINE

Starts and stops printing and transmission of

data.

Maintenance Panel

FUNCTION

Allows movement through the various menus

and modes.

Permits the movement of the cursor for input.

ENTER

Allows the selection of an option .

CANCEL

Cancels a print job. Allows return to the previous

screen when moving through the menus.

VOLUME

For buzzer volume adjustment.

PITCH

For adjusting print position.

OFF SET

Adjusts cut, peel, and tear-off stop positions.

DARKNESS

Adjust s pr int density .

Power Switch

Breaks the circuit providing power to the printer.

Figure 1-2, Operator Panel

SATO GT4xxe Series Operator Manual PN 9001138A Page 1-4

TECHNICAL DATA

• Physical Characteristics

•Power

• Enviromental

• Processing

•Print

•Media

•Ribbon

• Sensing

• Interface Modules

• Character Font Capabilities

• Barcode Capabilities

• Regulatory Approvals

SATO GT4xxe Series Operator Manual PN 9001138A Page 2-1

Unit 2: Technical Data

PHYSICAL CHARACTERISTICS

Width 10.67 Inches (271 mm)

Height 12.00 Inches (305 mm)

Depth 17.90 Inches (455 mm)

Weight 33.07 Pounds (15.0 Kg) standard

POWER

Input Voltage 100-240 Volts AC +/- 10%, 50/60 Hertz +/-5%

Power Consumption 200 Volts/200 Watts Operating, 62 Volts/89 Watts Idle

ENVIRONMENTAL

Operating Temperature 32° to 104°F (0° to 40°C)

Storage Temperature 23° to 140°F (-5° to 60°C)

Storage Humidity 30 to 90% RH Non-Condensing

Operating Humidity 30 to 80% RH Non-Condensing

PROCESSING

CPU 32 Bit RISC

FLash ROM 2 Megabytes

SDRAM 16 Megabytes

Receive Buffer 2.95 Megabytes

Memory Expansion Flash Memeory Board (8 Megabytes)

PRINT

Method Direct Thermal / Thermal Transfer

Speed (user selectable)

Print Module (dot size) .0049 Inches (.125 mm)

Resolution 203 Dots Per Inch (8 dpmm)

Maximum Print Width 4.10 Inches (104 mm)

Maximum Print Pitch

Thermal Transfer: 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 Inches/Second

Direct Thermal: 2, 3, 4, 5, 6 Inches/Second

GT408 Printer: 98.43 Inches (2500 mm)

GT412 Printer: 59.06 Inches (1500 mm)

GT424 Printer: 15.75 Inches (400 mm)

MEDIA

Roll Paper: 10.43 Inch (265 mm) maximum diameter.

Roll Media:

Fan-Fold Media: Maximum folded height varies depending on installation location.

SATO GT4xxe Series Operator Manual PN 9001138A Page 2-2

Core Size: 1.5, 3, 4 Inch (.06, .12, .16 mm) internal diameter.

Wound: Face In / Face Out. Face In is for linerless only.

Unit 2: Technical Data

MEDIA

Standard Mode

Cutter w/ backfeed

Cutter w/o backfeed

Dispenser

Te ar - Of f

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Pitch: 0.20 to 5.04 Inches (5-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Pitch: 0.35 to 15.75 Inches (9-400 mm)

Media Width: 0.98 to 5.16 Inches (25-131 mm)

Media Pitch: 0.20 to 5.04 Inches (5-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Pitch: 0.79 to 15.75 Inches (20-400 mm)

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Pitch: 0.20 to 5.04 Inches (5-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Pitch: 0.35 to 15.75 Inches (9-400 mm)

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Pitch: 0.67 to 5.04 Inches (17-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Pitch: 0.79 to 15.75 Inches (20-400 mm)

Media Width: 0.87 to 5.04 Inches (22-128 mm)

Media Pitch: 0.20 to 5.04 Inches (5-397 mm)

Backing Paper Width: 0.98 to 5.16 Inches (25-131 mm)

Backing Paper Pitch: 0.79 to 15.75 Inches (20-400 mm)

RIBBON

Minimum: 1.56 Inches (39.5 mm)

Width

Length 492 yards (450 m) roll.

Wound Face In / Face Out. Compatible with coreless paper.

Maximum: 1.77, 2.32, 2.99, 3.31, 3.62, 4.02, 4.37, 5.04

(45, 59, 76, 84, 92, 102, 111, 128 mm)

SENSING

Gap Fixed

Reflective Eye-Mark Fixed

Label Fixed

Continuous Form Sensor not used.

INTERFACE MODULES

Parallel Port IEEE 1284 (Communication Mode: ECP/Compatible)

RS232C (9600 to 57,6000 dps) Standard

Serial Port

Universal Serial Bus USB Adapter

LAN 10BASE-T/100BASE-TX Automatic Switching

RS422/485 (9600 to 57600 bps) Optional

Ready/Busy or X-On/X-Off Flow Control

Bi-Directional Status

SATO GTxxe Series Operator Manual PN 9001138A Page 2-3

Unit 2: Technical Data

INTERFACE MODULES

Ethernet 10/100 Base T, 802.11B Wireless Wi-Fi

Mini LAN 10BASE-T/100BASE-TX Automatic Switching

Centronics

CHARACTER FONT CAPABILITIES

MATRIX FONTS

U Font 5 dots W x 9 dots H

S Font 8 dots W x 15 dots H

M Font 13 dots W x 20 dots H

XU Font 5 dots W x 9 dots H (Helvetica)

XS Font 17 dots W x 17 dots H (Univers Condensed Bold)

XM Font 24 dots W x 24 dots H (Univers Condensed Bold)

X20

X21

X22

X23

X24

OA Font (OCR-A)

OB Font (OCR-B)

AUTO SMOOTHING FONTS

WB 18 dots W x 30 dots H

WL 28 dots W x 52 dots H

XB 48 dots W x 48 dots H (Univers Condensed Bold)

XL 48 dots W x 48 dots H (Sans Serif)

VECTOR FONT

Proportional or Fixed Spacing

Font Size 50 x 50 dots to 999 x 999 dots

Helvetica, 10 Font Variations

AGFA RASTER FONTS

A Font CG Times, 8 to 72 pt.

B Font CG Triumvirate, 8 to 72 pt.

DOWNLOADABLE FONTS

Bit Mapped True Type Fonts with Utility Program

SATO GT4xxe Series Operator Manual PN 9001138A Page 2-4

Unit 2: Technical Data

CHARACTER CONTROL

Expansion up to 12 x in either the X or Y coordinates.

Charcter Pitch Control

Line Space Control

Journal Print facility

0, 90, 180, and 270 Degree Rotation

BAR CODE CAPABILTIES

UPC-A/E

EAN-13/8

CODABAR

Code 39

Code 93

Code 128

Linear Bar Codes

Two Dimemsional

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User progammable

Rotation 0, 90, 180, and 270 Degrees

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Expansion Ratio of Character Height: 1-12 times, Width: 1-12 times

Graphics

Form Overlay Form overlay for high-speed editing of complex formats

Full dot addressable graphics, SATO Hex/Binary, .BMP or

Interleaved 2 of 5

Matrix 2 of 5

Bookland

RSS-14

JAN/EAN

MSI

POSTNET

UCC/EAN-128

QR Code

Vari Co d e

Data Matrix

Maxicode

PDF417

Micro PDF

Truncated PDF

QR Code

NW-7 (Codabar)

Composite Symbology

.PCX formats

REGULATORY APPROVALS

Safety VCCI (Class B), EN 55022 (Class B), UL (CUL), TUV

SATO GTxxe Series Operator Manual PN 9001138A Page 2-5

Unit 2: Technical Data

SATO GT4xxe Series Operator Manual PN 9001138A Page 2-6

INSTALLATION

• Unpacking

• Parts Identification

• Printer Installation

• Interface Selection

• Accessories Installation

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-1

Unit 3: Installation

UNPACKING & PARTS IDENTIFICATION

Unpack the printer as directed in the following procedure.

1 Place the shipping container (box) upright on a soid, flat surface.

2 Open the box, remove any loose items and the first layer of packing material.

3 Carefully lift the printer and accessories from the box and place them on a solid flat surface.

4 Remove the plastic covers from the packed items and visually inspect for physical damage.

5 Ensure all components are present as dictated on the Packing List.

6 Report damaged property.

Accessory Bo x

Printer

Cushion

Shipping Container

Figure 3-1, Unpacking

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-2

Unit 3: Installation

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked.

Following printer setup, procede to the next chapter for information on interface selection.

SITE LOCATION

• Stationed on a solid flat surface.

• Stationed away from hazardous materials.

• Stationed within operational distance of the host based on interface specifications.

CABLE CONNECTION

The procedure below provides instruction on typical cable connection. The same procedure will

apply to others that are not mentioned, but their connectors are also located behind the rear

housing cover.

1 Press the rear housing ocver catch and remove laterally (Figure 3-2a).

2 Locate and identify the required connectors (Figure 3-2b).

3 Connect the power supply and interface cables to their respective connectors (Figure 3-2c).

4 Replace rear housing cover (Figure 3-2d).

Rear Housing Cover

Interface Connectors

Figure 3-2a

Housing Cover Catch

Power Supply Connector

Figure 3-2b

Rear Housing Cover

Pull Prevent ion Slot

Figure 3-2c

Figure 3-2d

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-3

Unit 3: Installation

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration

before printer purchase. Ideally, the media width will be equal to, or just narrower than, the print

head. Using media that does not cover the print head will allow the platen roller to tread on it and

wear it out. The media edge will also wear a groove in the platen roller affecting print quality.

MEDIA & RIBBON LOADING

There are two general media types that may be loaded and used; rolled and fan-folded. Each of

those types may again be defined by whether their print application is direct thermal or thermal

transfer. Those factors determine how the media is loaded and if ribbon stock is loaded at all.

Thermal transfer media requires the use of ribbon stock for print application. In such a scenario,

it is the ribbon stock (carbon paper) that contains the ink that will be transfered to the media.

Direct thermal media has the ink embedded within and is brought to the surface through heat

penetration by print head contact.

Rolled media of standard diameter is loaded within the printer and suspended by the media

holder. Larger, non-standard rolled media would be suspended outside the printer at its rear and

fed inward. Fan-folded media would also be fed inward from the rear but is stacked as opposed

to suspended.

Refer to Figures 3-3a and 3-3b for proper media routing relative to the type to be used. If that to

be used is direct thermal, ignore the ribbon stock in the figures and do not load that.

MediaRibbon Roll

Prin t Assem bly

Media Ramp

Media Holder

Label Damper

Media Guide

Figure 3-3a, Rolled Media & Ribbon Loading

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-4

Unit 3: Installation

Print Assemb ly

Media Ramp

Media Holder

Label Damper

Media Guide

MediaRibbon Roll

Figure 3-3b, Fan-fold Media & Ribbon Loading

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-5

Unit 3: Installation

INTERFACE SELECTION

This chapter presents the printer interface types and their specifications. These specifications

include detailed information to assist in the selection of the most appropriate method for the

printer to interface with the host. The four acceptable interface methods are:

• RS232C Asynchronous Serial

• IEEE1284 Parallel

• Universal Serial Bus (USB) Adapter

• Local Area network (LAN) Ethernet

• 802.11B Wireless

Following the selection of the desired interface, proceed to the following unit for instructions on

how to Configure the printer for that interface type.

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

HOST OR THE PRINTER. THIS MAY CAUSE DAMAGE TO THE

INTERFACE CIRCUITRY IN THE PRINTER/HOST AND IS NOT COVERED

BY WARRANTY.

NOTE: Some hosts monitor the Request-To-Send (RTS) signal (pin 4 of 25)

to determine if the printer is ready to receive data. Since the printer does not

generate this signal, the RTS line must be held true (high) in order to allow

communication. This can be performed by connecting the RTS pin to the

Clear-To-Send (CTS) signal (pin 5 of 25).

RS232C SERIAL INTERFACE

This High Speed Serial Interface is a Plug-In Interface Module that can be installed in the printer

by the user. The only difference between this interface and the TTL is their signal levels and

cable pinouts.

RS232C SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Bi-Directional Communication

Data Transmission Rate 9600, 19200, 38400, 57600 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC II Character Codes, JIS Kanji Codes

Control Codes STX (02H), ETX (03H), ACK (06H), NAK (15H)

Connector Special

Cable Special

Signal Levels High = +5V to +12V, Low = -5V to -12V

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-6

Unit 3: Installation

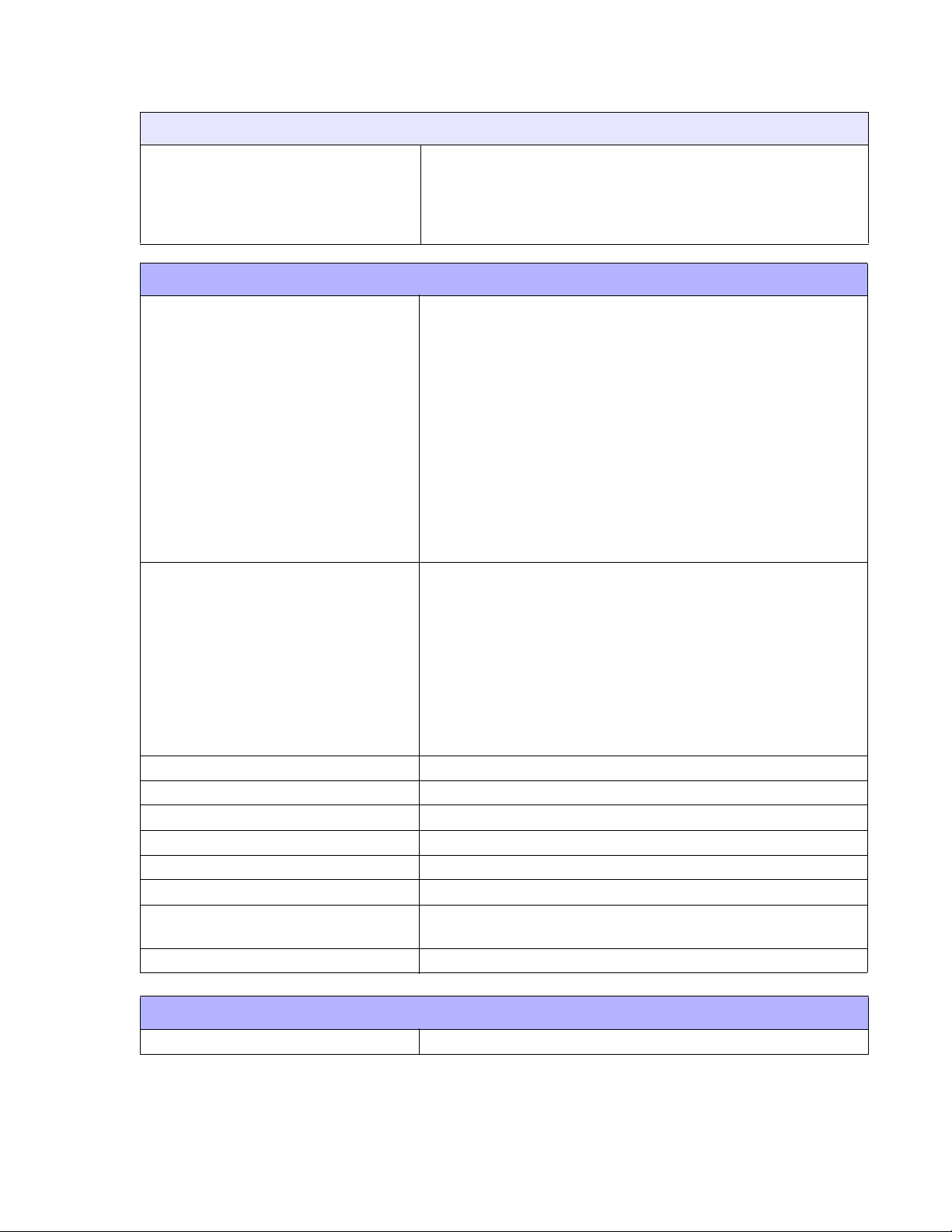

RS232C SERIAL INTERFACE SIGNALS

PIN DIRECTION SIGNAL DEFINITION

1 Reference FG (Frame Ground)

2 To Host TD (Transmit Data) - Data from the printer to the host computer. Sends X-On/

X-Off characters or status data (bi-directional protocols).

3 To Printer RD (Receive Data) - Data to the printer from the host computer.

4 To Host RTS (Request to Send) - Used with Ready/Busy flow control to indicate an

error condition. RTS is high and remains high unless the print head is open (in

this case, RTS would return to the high state after the print head is closed and

the printer is placed back on-line) or an error condition occurs during printing

(e.g., ribbon out, label out).

5 To Printer CTS (Clear to Send) - When this line is high, the printer assumes that data is

ready to be transmitted. The printer will not receive data when this line is low. If

this line is not being used, it should be tied high (to pin 4).

6 To Printer DSR (Data Set Ready) - When this line is high, the printer will be ready to

receive data. This line must be high before data is transmitted. If this line is not

being used, it should be tied high (to pin 20).

7 Reference SG (Signal Ground)

20 To Host DTR (Data Terminally Ready) - This signal applies to Ready/Busy flow control.

The printer is ready to receive data when this pin is high. It goes low when the

printer is off-line, either manually or due to an error condition, and while

printing in the single job buffer mode. It will also go low when the data in the

buffer reaches the buffer near full level.

113

1425

Figure 3-4, Serial Interface Pin Assignments

CABLE REQUIREMENTS

DB9 DB25 HOST CONNECTION DB9 PRINTER

1 1 FG (Frame Ground) Bi-Directional 1 FG (Frame Ground)

2 3 RD (Receive Data) To Host 2 TD (Transmit Data)

3 2 TD Transmit Data) To Printer 3 RD (Receive Data)

8 5 CTS (Clear To Send) To Printer DB9-6 4 RTS (Request to Send)

4 20 DTR (Data Temrinal Ready) To Printer DB9-4 6 DSR (Data Set Ready)

6 6 DSR* (Data Set Ready) To Host 9 DTR (Data Terminal Ready)

5 7 SG (Signal Ground) Bi-Directional 7 SG (Signal Ground)

* This connection at the host side of the interface would depend upon the pin that is being used as the

Ready/Busy signal by the driving software. Typically, on a PC, it would be either CTS (pin5) or DSR (pin

6) on a DB-25 connector.

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-7

Unit 3: Installation

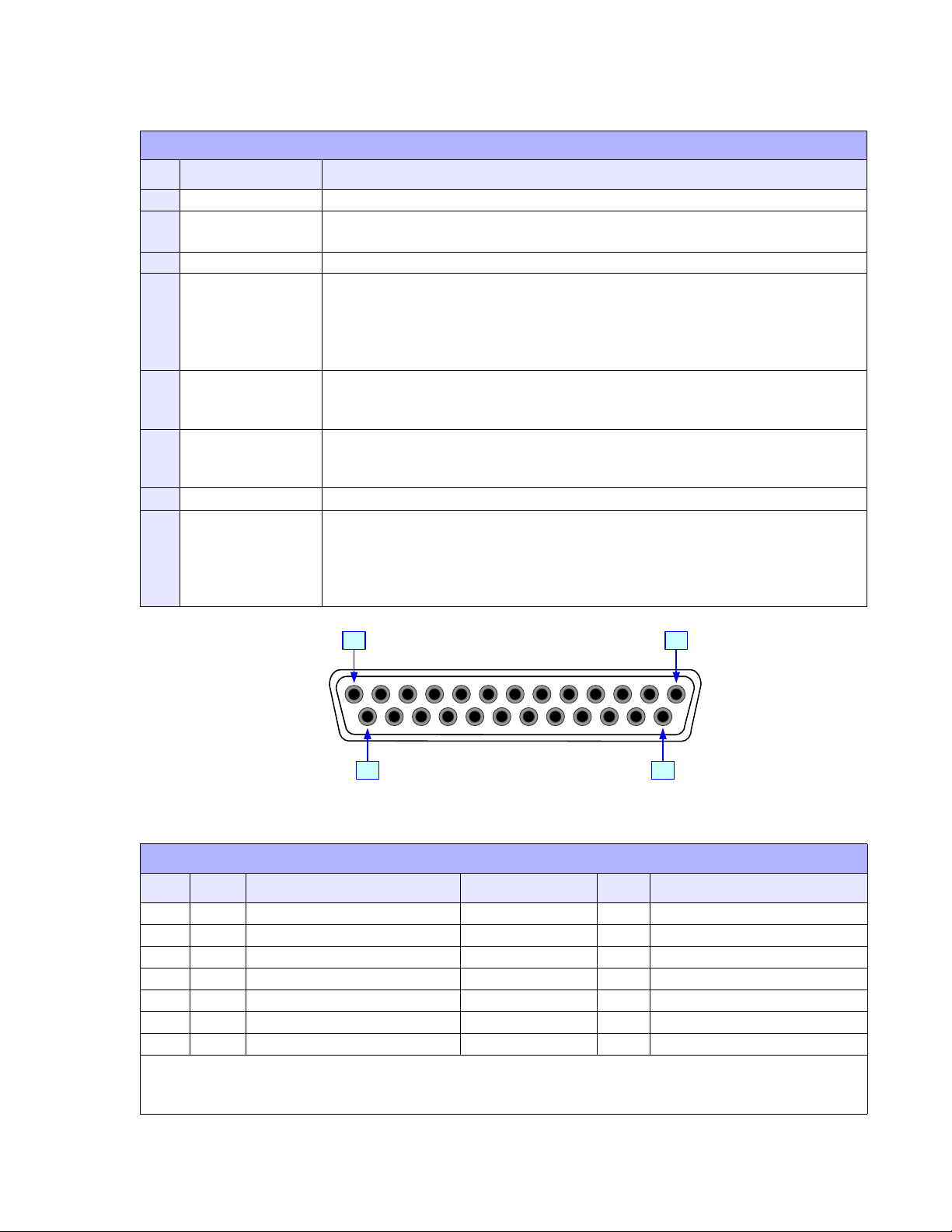

IEEE1284 PARALLEL INTERFACE

The parallel interface is a plug-in module that can be installed by the user and conforms to

IEEE1284 specifications. It automatically detects the IEEE1284 signals and operates in the high

speed mode. If the IEEE1284 signals are not detected, it will operate in the slower standard

Centronics mode. For this reason, an interface cable and host interface conforming to the

IEEE1284 specification must be present to fully utilize the speed capabilities. This interface also

operates bi-directionally and can report the status of the printer back to the host.

SPECIFICATIONS

Printer Connector AMP 57-40360 DDK (or equivalent)

Cable Connector AMP 57-30360 DDK (or equivalent)

Cable IEEE1284 Parallel, 10 ft. (3 m) or less

Signal Level High = +2.4V to +5.0V, Low = 0V to -0.4V

Data Stream <ESC>A . . Job#1 . . <ESC>Z<ESC>A . . Job#n . . <ESC>Z

18

36

1

19

Figure 3-5, Parallel Interface Pin Assignments

IEEE 1284 PARALLEL INTERFACE PIN ASSIGNMENTS

PIN SIGNAL DIRECTION PIN SIGNAL DIRECTION

1 Strobe To Printer 19 Strobe Return Reference

2 Data 1 To Printer 20 Data 1 Return Reference

3 Data 2 To Printer 21 Data 2 Return Reference

4 Data 3 To Printer 22 Data 3 Return Reference

5 Data 4 To Printer 23 Data 4 Return Reference

6 Data 5 To Printer 24 Data 5 Return Reference

7 Data 6 To Printer 25 Data 6 Return Reference

8 Data 7 To Printer 26 Data 7 Return Reference

9 Data 8 To Printer 27 Data 8 Return Reference

10 ACK To Host 28 ACK Return Reference

11 Busy To Host 29 Busy Return Reference

12 Ptr Error To Host 30 PE Return Reference

13 Select To Host 31 INIT From Host

14 AutoFD1 To H os t 32 Fault To Host

15 Not Used 33 Not Used

16 Logic Gnd 34 Not Used

17 FG Frame Gnd 35 Not Used

18 +5V (z=24k ohm) To Host 36 SelectIn1 From Host

1 Signals required for ieee 1284 mode.

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-8

Unit 3: Installation

UNIVERSAL SERIAL BUS (USB) ADAPTER

The Universal Serial Bus (USB) interface is a Plug-In Interface Module that can be installed by

the user. It requires a driver (shipped with each printer that has the interface installed) that must

be loaded on your PC and the PC must be configured to support USB peripherals using Windows

98 or above. Details for loading the USB driver are contained in the USB Interface Manual that is

shipped with each printer with a USB Optional interface installed. Up to 127 devices may be

connected to a USB port using powered hubs.

SPECIFICATIONS

Printer Connector USB Type B Plug

Cable 10 feet (3 m) maximum

Host Windows 98 or above with USB Port

Power Supply BUS Power through cable

Power Consumption +5 V at 80 ma

LOCAL AREA NETWORK (LAN) ETHERNET

A Local Area Network (LAN) interface is an optional Plug-In Interface Module that can be

installed by the user. It requires a driver shipped with each printer that has the interface installed.

The driver that must be loaded on your PC and the PC must be configured to run one of the

supported network protocols using a 10/100BaseT LAN connection. Details for loading the LAN

driver are contained in the LAN Interface Manual that is shipped with each printer with a LAN

Optional interface installed.

SPECIFICATIONS

Connector RJ-45 Receptacle

Cable 10/100BaseT Category 5

Power Supply Powered from printer

802.11B WIRELESS

The wireless print server provides easy printer interface with 802.11b Wi-Fi compliant networks

free of wired connections. Each printer is shipped with an integrated driver and interface

installed. The driver must be loaded on your PC and the PC must be configured to run one of the

supported protocols.

802.11B WIRELESS SPECIFICATIONS

Variable Data Rates 11, 5.5, 2 and 1 Mbps

Frequency Band 2.4 GHz ISM Band

Wired Equivalent Privacy 128 bit, 64 bit (compatible with 40bit), none

Sensitivity (typ, AAWGN, 8E-2 PER): -91dBm at 1Mbps, -88dBm at 2 Mdps,

-87dBm at 5.5Mbps, -84dBm at 11Mbps.

Range 100m indoors, 300m outdoors

Protocols TCP/IP, IPX/SPX, Direct Mode IPX/IP, DLC/LLC, NetBEUI,

NetBIOS/IP

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-9

Unit 3: Installation

RECEIVE BUFFER

The data stream is received from the host to the printer one job at a time. This allows the

software program to maintain control of the job print queue so that it can move a high priority job

in front of ones of lesser importance.

A multiple job buffer allows the printer to continuously receive print jobs while compiling and

printing other jobs at the same time. It acts much like a Print buffer to maximize the performance

of the host and the printer.

The printer receives and prints one job at a time. If a print job exceeds the buffer size,

transmission will be rejected by the printer. Flow control protocols to throttle transmission are not

used. Error conditions that occur during the Print Data transmission will cause the printer to

return a NAK.

ACK/NAK PROTOCOL

Bi-Directional ACK/NAK protocol is used for error control. In a normal transmission sequence

when the transmission is received, the printer will return an ACK (06H) signifying that it was

received without a transmission error. After the transmission command structure has been

analyzed, a status byte is returned to the host. This status byte informs the host of the validity of

the command structure.

If the command structure is error free, the printer proceeds with the print operation. When the

print operation is completed, a Printer Status message is returned to the host. If an error was

detected during the initial transmission sequence, a NAK (15H) will be returned signalling to the

host that the received transmission contained errors and must be resent. If the returned Status

byte indicates a command structure error, the error must then be corrected before the print data

is resent to the printer.

A valid transmission to the printer must be bounded by an STX/ETX pair, with the STX (02H)

signifying the start of the Print Data and ending with an ETX (03H) signifying the end.

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-10

Unit 3: Installation

ACCESSORIES INSTALLATION

EXTERNAL SIGNAL CONNECTOR

This connector permits the interface of an external source with the printer for the purpose of

regulating print actiivity to coincide with those external requirements (i.e.: production flow, etc.).

1 Disconnect power supply cord and remove the rear housing cover (1, Figure 3-6).

2 Remove screw (2) and plate (3) as required to expose the EXT port.

3 Remove two screws (4) and withdraw existing board (5) from frame (6) as required.

NOTE: The above step only applies if replacing an exisiting board.

4 Insert external signal board (5) into slot in frame (6) and secure using two screws (4).

5 Connect the interface cord, power cord, and reinstall rear housing covers.

5

D

D

R

R

A

A

O

O

B

B

S

S

R

R

+

+

4

4

8

8

2

2

1

1

E

E

E

E

E

E

I

I

6

3

1

4

2

Figure 3-6, External Signal Connector

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-11

Unit 3: Installation

MEMORY EXPANSION

The memory cartridge provides additional storage of user data and graphics. Access to the

memory cartridge port, and its installation, is very simple. The instructions below provide

guidance.

CAUTION: INSTALL THE MEMORY CARTRIDGE PRIOR TO SENDING

RELATIVE COMMANDS OR AN ERROR WILL OCCUR. REMOVE POWER

TO THE PRINTER PRIOR TO INSTALLING THE CARTRIDGE.

1 Disconnect power supply cord.

2 Detach memory cartridge cover (1, Figure 3-7) from center frame (2).

3 Fully insert memory cartridge (3) into its respective port and replace cover (1).

4 Restore power to the printer and send commands.

3

1

2

Figure 3-7, PCMCIA Memory Expansion

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-12

Unit 3: Installation

INTERFACE UPGRADE

The printer is typically ordered with a high-speed parallel interface board installed. However,

interface requirements sometimes change and an upgrade is desired. All of the interface boards

are installed within the same slot (middle) located in the rear of the printer with little or no

difference in installation methodology with the exception of the mini-LAN interface (top slot).

Parallel Interface (IEEE1284) (Optional or Bundled)

Serial Interface (RS232C) (Optional)

USB Interface (Optional)

10BaseT/100Base-TX Lan Interface (Optional)

Wireless LAn 802.11b Interface (Optioanl)

10BaseT/100Base-TX mini LAN (Optional(

EXT Connector (External Signal Interface) (Optional)

1 Remove the rear housing cover (1, Figure 3-8). Disconnect the power and interface cords.

2 Remove screw (2) and plate (3) as required to expose the interface port.

3 Remove two screws (4) and withdraw existing board (5) from frame (6) as required.

4 Insert replacement board (5) into slot in frame (6) and secure using two screws (4).

5 Connect the interface cord, power cord, and reinstall rear housing covers.

5

D

D

R

R

A

A

O

O

B

B

S

S

R

R

+

+

4

4

8

8

2

2

1

1

E

E

E

E

E

E

I

I

3

6

4

2

1

Figure 3-8, Interface Upgrade

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-13

Unit 3: Installation

LABEL CUTTER INSTALLATION

The label cutter, when installed, replaces the printer’s lower front housing cover. Its internal

sensor monitors media feed and activates the cut sequence based on user established values.

The cutter assembly is powered through relayed current from the printer’s power supply and

derives its primary intelligence from the main circuit board. The activated cut sequence severs

the printed media from the unprinted media allowing the operator to retrieve and apply at will.

Installation instructions are provided with the purchased product.

LABEL PEELER INSTALLATION

The label peeler, when installed, replaces the printer’s lower front housing cover. As the label is

printed and fed forward, the peel bar separates the printed label from its paper backing and

presents it for application. When the printed label is retrieved by the operator, the printer feeds

the unprinted media back into position for another print sequence. The cycle is again repeated.

Installation instructions are provided with the purchased product.

SATO GT4xxe Series Operator Manual PN 9001138A Page 3-14

PRINTER

• Configuration Modes

• Operational Adjustments

OPERATION

SATO GT4xxe Series Operator Manual PN 9001138A Page 4-1

Unit 4: Operation

CONFIGURATION MODES

This chapter provides an overview of the various configuration modes of the operation menu. All

of the following configuration activities are performed via the use of the operator panel located on

the printer front. However, many settings may also be controlled via software commands. In the

case of conflict between the software and control panel settings, the printer will always use the last

entered valid setting.

NORMAL MODE

When a print job is received, the LCD will display the number of labels to be printed and will

numerically descend as each label is printed.

POWER

ONLI NE

QTY: 000000

LINE

OFF LINE

000000

CANCEL

CANCEL PRINT JOB

YES NO

Yes / No

CANCEL PRINT JOB

COMPLETED

Printing

star ts

LINE

ENTER +

ENTER + for 5 seconds

DATA SAVE STAR T

YES NO

Yes / No

COPYING

0 100

software issued

print stop request

PAUSE

QTY: 000000

CANCEL or

Refer

to User

Mode flow

char t.

Refer

No

to Interface

Mode flow

char t.

Refer

to Cartridge

Mode flow

char t.

DATA SAVE

COMPLETED

ENTER

Refer

to SEMBL

Mode flow

char t.

Refer

to Advanced

Mode flow

char t.

Refer

to Hex Dump

flow chart.

Figure 4-1, Normal Mode

SATO GT4xxe Series Operator Manual PN 9001138A Page 4-2

Loading...

Loading...