Page 1

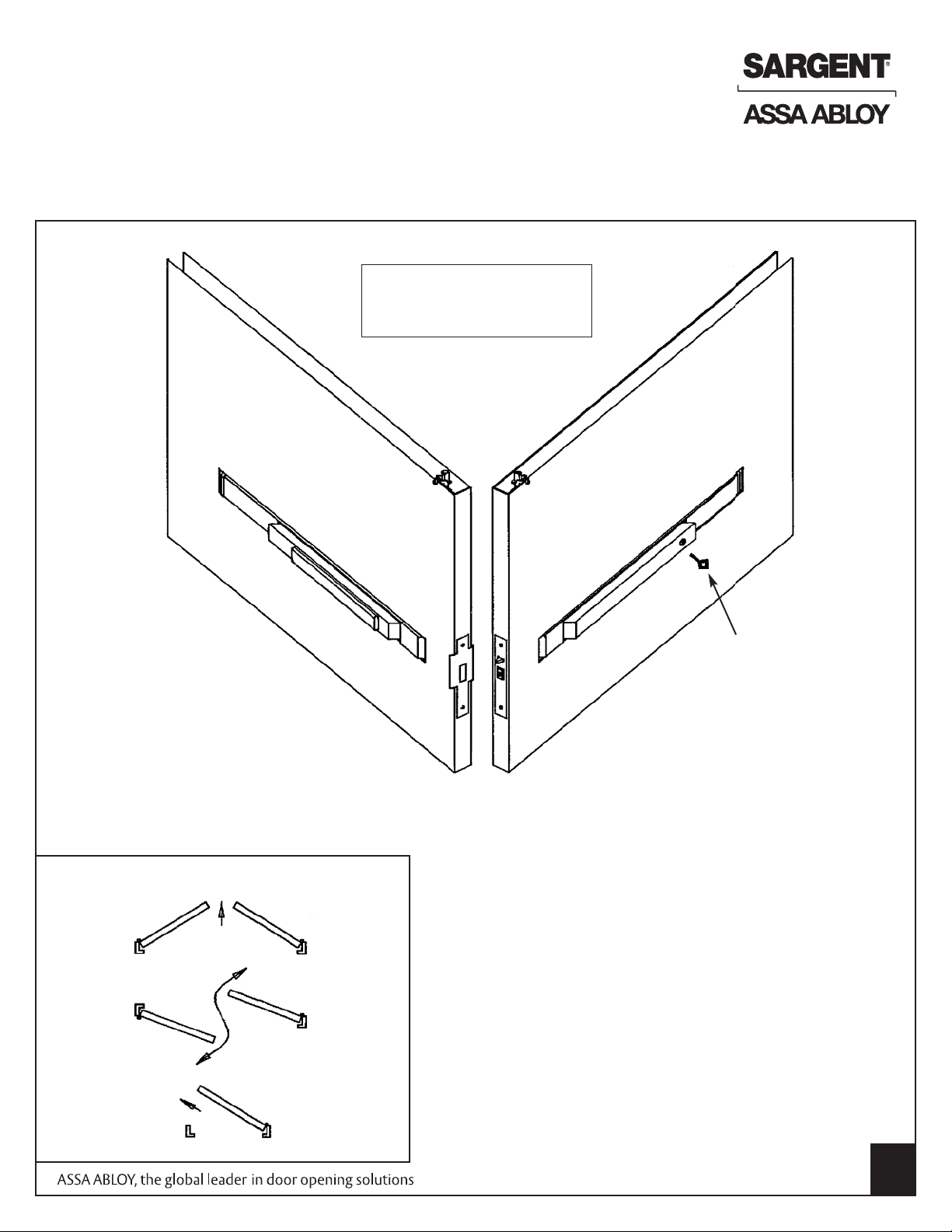

SARGENT Installation Instructions for LP8600 x LR8600

& 12-LP8600 x 12-LR8600 Series Low Profile Panic and

Fire Exit Devices on Double Egress & Double Doors or

LS8600 & 12-LS8600 Low Profile Exit Device on Single Door

For installation assistance, contact SARGENT at 800-727-5477 • www.sargentlock.com

U.S. PATENT No. 268003; 5,531,492 / CANADIAN PATENTNo. RD1981

DOORS SHOWN HERE SWING

IN FOR ILLUSTRATION

PURPOSES ONLY.

12-LR8600 19-LP8600

NOTES:

1) The doors should be properly reinforced and should be

fully prepared by the door manufacturer.

2) Rails can not be cut down in the field.

APPLICATION ILLUSTRATION

Right hand

reverse bevel

Left hand

reverse bevel

OUT

Double Doors

Double Egress

reverse bevel

Left hand

reverse bevel

Left hand

reverse bevel

Left hand

Lock down key

To operate:

– Depress pushrail

– Insert hex key and turn

CAUTION, BEFORE STARTING:

• Check hand of door – LP8600 & LR8600 exit devices are non handed,

ET trim is field reversible. LS86000 curved lip strike is handed.

• 2-3/4" backset only

• 1-3/4" thick doors only

• Verify box label for size, function and hand of exit device

• Available lengths:

Length “L” for 36" wide doors

Length “M” for 42" & 44" wide doors

Length “N” for 46 & 48" wide doors

• Door should be fitted and hung unless low ceiling condition exists

(For low ceiling conditions, install mortise lock and top rod before

hanging door. Low ceiling exists if ceiling height is less than:

(2 x door height) – mounting height i.e. 7' door with device mounted

at 41" aff would need (2 x 7') – 41" or 10'7" ceiling.)

• Doors that are hung should be square and plumb. Clearance between

the doors should be per the door manufacturers specification; i.e. gap

between doors should be 1/4" at center line of bevels. (If gap is over

1/4" doors must be shimmed to decrease the gap.)

SINGLE DOOR

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission of

Sargent Manufacturing Company is prohibited.

A7393D 3-10-10

1

Page 2

EQUIRED TOOLS:

R

Hammer

Needle nose pliers

#2 Phillips screw driver

#3 Phillips screw driver

Tape measure

Drill with 11/32" drill bit

Locking pliers

Flash light

B

INSTALL TRIM (IF APPLICABLE)

1) Using the appropriate portion of template

A6381, supplied with trim, drill all required

holes in the door.

2) Align the spindle with the outside hub and

install ET trim.

3) Secure with 1/4-20 screws and cup washers.

A

C

INSTALL MORTISE LOCKS

) Mount primary and secondary mortise locks in doors with

1

(2) #12 flat head machine screws provided.

2) Install outside fronts to mortise locks with (2) #8 flat head

achine screws provided.

m

Secondary

mortise lock

Primary

mortise lock

ASSEMBLE TOP ROD AND EXTENSION

1) If rod assembly is in two pieces, continue

with step 2.

If rod assembly is in one piece go, to part “D”.

2) Slide rod together and align holes.

3) Secure with spiral pin.

D

Outside

hub

Cup

washer

INSTALL TOP ROD ASSEMBLY

1) Insert rod assembly into door,

as shown.

2) Align connecting tube with top

mount.

3) Rotate rod assembly clockwise until

bolt projects 1/4" above the door.

Connecting tube

Extension rod

and bolt

Connector

Spiral pin

Top rod

Connecting tube

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission

of Sargent Manufacturing Company is prohibited.

2

A7393D 3-10-10

Top mount

Latchbolt tail

NOTE:

After rods are installed, doors can be

blocked open until chassis is installed.

If doors are closed and latched before

chassis is installed, the bolts can be

retracted from the inside by pulling

the latchbolt tail toward the hinge.

Page 3

E

Top case

button

Top

case

INSTALL TOP CASE AND STRIKE

1) Slide top case over top bolt until

threaded holes line up with 2 C-Sunk

holes at the top of the door.

2) Using (2) #10-24 x 3/8" oval head screws

fasten top case in place.

3) Mount top strike to frame using (2)

#10-24 flat head screws provided.

F

INSTALL CHASSIS IN RAIL

) Depress lift arm and slide chassis into

1

rail as shown.

Top

bolt

G

INSTALL RAIL

1) Rotate link connector up and place rail assembly in door cavity as shown.

2) Align C-Sunk holes in chassis with tapped holes in door and secure with (2) #10-24 flat head screws.

3) Position mounting bracket to support end of rail and secure with (2) #10-24 pan head screws.

NOTE: Ensure notch at the

top of the door is large

enough, so that there is no

interference or bind with

the top case button.

Frame header

section

650

strike

2) Align tapped holes in chassis to C-Sunk

holes in rail. Using (2) #6-32 flat head

screws, secure chassis to rail.

Link

connector

#10-24 flat

head screws

#10-24 pan

head screws

Mounting

bracket

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission of

Sargent Manufacturing Company is prohibited.

A7393D 3-10-10

3

Page 4

H

CONNECT LINKAGE

I

ADJUST SECONDARY MORTISE LOCK (LR8600)

1) Rotate link connector down and pull toward mortise lock.

2) Align one pair of holes on link connector with mortise tail and

ecure using (2) #8 truss head screws.

s

REPEAT FROM PART “B” ON OPPOSITE DOOR.

Link

connector

Mortise

tail

J

ADJUST PRIMARY MORTISE LOCK (LP8600)

1) With both doors closed, check for proper top and center

latchbolt throw and engagement with strikes.

2) Depress push rail to retract latches and open door. If center

bolt does not retract to clear the LR8600 outside front,

adjustment is required.

3) Remove (2) #8 screws from linkage.

4) Rotate lever trim to align next set of holes.

5) Reinstall the #8 screws.

6) Repeat step 1 to verify adjustment.

Activation

bolt

1) Depress rail and observe center bolt. If bolt is projected, flush

or just beyond outside front, adjustment is correct.

2) If adjustment is required, remove (2) #8 screws from linkage.

3) Rotate lever trim to align next set of holes.

4) Reinstall the #8 screws and repeat step 1.

Center

bolt

5) If binding condition occurs where

top bolt remains retracted and

center bolt remains extended

when door closes, remove the (2)

#8 screws installed in part

6) Install link spacer between the link

connector and mortise tail, reinstall

LR8600

outside front

#8 screws. Then repeat step 1.

Link

connector

“H”.

Link

spacer

Mortise

tail

Latchbolt

7) If binding condition occurs where top bolt remains retracted

and center bolt remains retracted when door closes, remove

the (2) #8 screws installed in part “H”.

8) Install link spacer between the link connector and mortise

tail. Reinstall #8 screws. Then repeat step 1.

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission

of Sargent Manufacturing Company is prohibited.

4

A7393D 3-10-10

Link

spacer

Page 5

K

CENTER BOLT ADJUSTMENT

L

TOP BOLT ADJUSTMENT

1) If there is not enough center latchbolt projection and

ngagement into the other door, the center bolt can be

e

adjusted.

2) Open door and depress the activation bolt to project the

latchbolt.

3) Using locking pliers, grip the latchbolt near the lock front.

) Insert a 5/32" allen wrench into the latchbolt. Pull the

4

latchbolt out until you can freely turn the adjusting screw.

5) To increase projection, turn the adjusting screw counterclockwise. To decrease projection, turn the adjusting screw

clockwise. When desired projection is achieved, rotate the

adjusting, screw so the flats are aligned with the 2 press fit pins.

6) Release the pliers and allow the latchbolt to snap back.

Activation

bolt

Press

fit pin

Adjustment

screw

Center

latchbolt

1) If there is not enough top latchbolt engagement into top

strike to latch the door securely, complete the following

teps:

s

) Remove top case from door and rotate the top bolt counter-

2

clockwise to increase projection.

3) Reinstall top case, and recheck the adjustment.

Top

case

Top

bolt

M

N

OPERATION VERIFICATION

1) Open and close doors several times in different sequences to ensure proper operation and latch engagement into strikes.

Center latchbolt should project into opposing door regardless of closing order.

2) If bolts are not retracting or projecting properly, review/repeat parts I thru L.

INSTALL COVERS

1) Verify that all adjustments have been made and all mounting

screws are tight.

2) Install front cover and end cap, secure with

(2) #8 cover screws on each.

End

cap

Front

cover

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission of

Sargent Manufacturing Company is prohibited.

A7393D 3-10-10

5

Page 6

REQUIRED SCREWS

(2) #8-32

Under-cut flat head

(Lock fronts)

(2) #6-32

Under-cut flat head

(Chassis to rail)

(2) Cup washer

(Trim mounting)

(2) #10-24

Pan head

(Mounting bracket to door)

(2) #12-24

Under-cut flat head

(Mortise lock to door)

(2) #10-24

Under-cut oval

(Top case to door)

(4) #8-32

#8 Under-cut oval

(Covers)

(4) #10-24

Under-cut flat head

(2 Chassis to door)

(2 Strike to frame)

(2) #8-32

Truss head

(Link connector to

mortise tail)

(2) 1/4-20

Flat head

(Trim mounting)

SCREW PACKS AND MISCELLANEOUS PARTS

68-1317 Front cover (Finished)

68-1316 End cap (Finished)

01-0696 Spiral pin

68-1186 Primary outside front

68-1183 Secondary outside front

77-0883 Curved lip strike (Left hand)

77-0884 Curved lip strike (Right hand)

650 Top strike pack

77-4236 Screw pack (Mortise lock)

68-4373 Screw pack (Chassis)

68-3677 Screw pack (Top case)

68-4383 Screw pack (Mounting plate)

651 Kit Lexan touch pad

816 Cylinder dogging kit

FOR ADDITIONAL INFORMATION CONTACT SARGENT AT 1.800.727.5477

Copyright©2009, 2010, Sargent Manufacturing Company,anASSAABLOY Group company.

All rights reserved. Reproductioninwholeorinpart without the express written permission

of Sargent Manufacturing Company is prohibited.

6

A7393D 3-10-10

Loading...

Loading...