Page 1

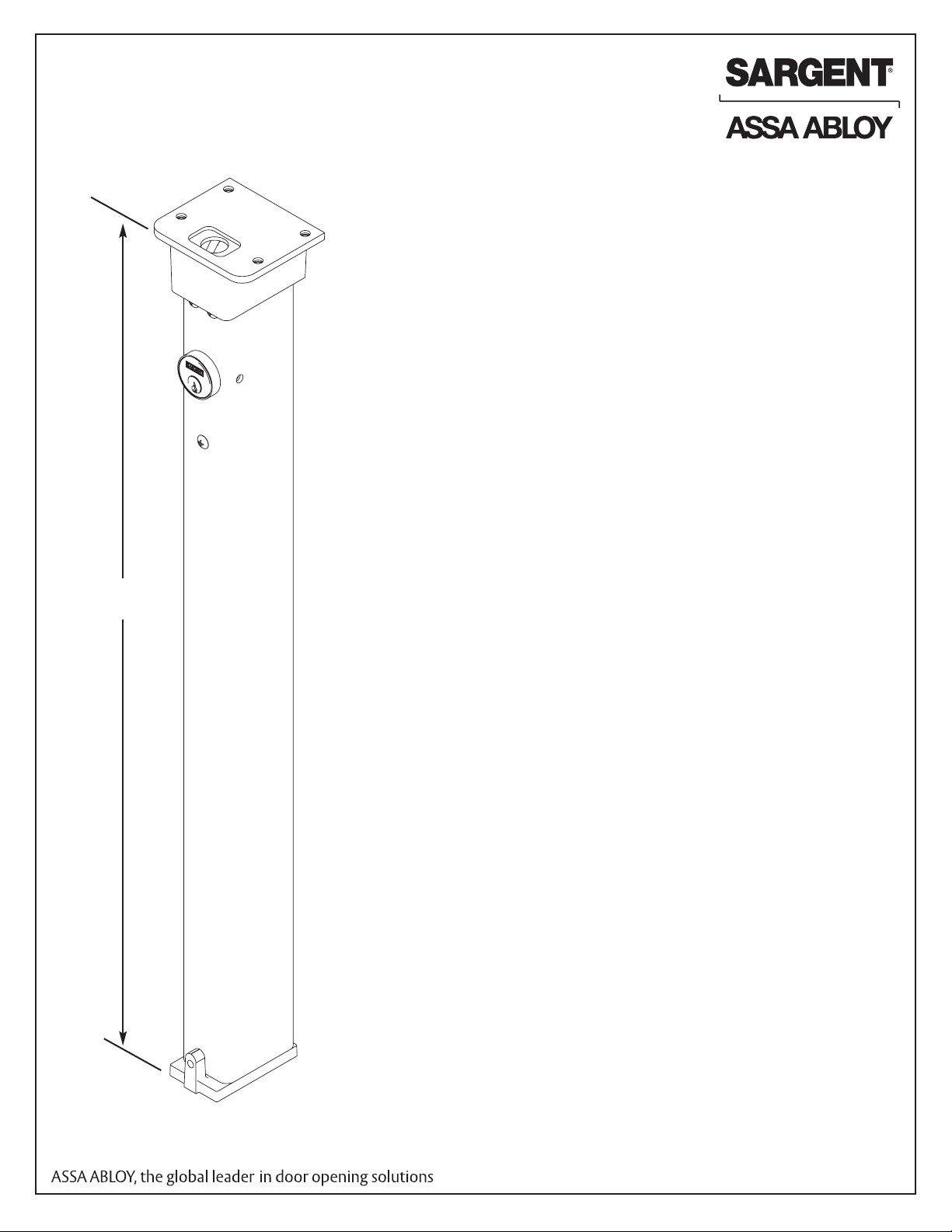

INSTALLATION INSTRUCTIONS FOR

L980S & 12-L980 STEEL MULLIONS

FOR ASSISTANCE CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

Tools Required:

· Measuring Tape

· Pencil

· Drill & Tap Sizes: #7 drill and 1/4"-20 tap

· Concrete Drill: 3/8" diameter

· Center Punch

· Hammer

· #3 Phillips Screw Drivers

· 5/64" Allen Wrench

· 1/8" Allen Wrench

To install mullion in frame

1. Close and block the doors against the frame stops. Check gap

between door leaves and door to frame and correct if necessary.

2. Locate the center of the opening on the floor. Using the bottom

retainer mark the positions for the two drop-in fasteners.

a. The bottom of the door should come to rest against the

surface of the mullion.

b. Modify threshold as required.

3. Drill holes with 3/8" diameter cement bit to a minimum depth

of 2-1/2".

4. Fasten bottom bracket to floor.

5. Locate the center of the opening on the top of the frame.

Using the top retainer mark the positions for the four fasteners.

a. The door should evenly rest against both the frame stop

and the mullion.

b. If a top retainer mounting kit is used, modify

weather-stripping as required.

6. Drill and tap each location for 1/4"-20 fasteners.

7. Mount top retainer on frame with provided fasteners.

8. Measure “Dim X” as shown. Remove material from the

bottom of the mullion per the formula:

length of mullion = “Dim X” minus 3/4".

Note–This leaves approximately 1/8" clearance between the

mullion and the top bracket when mounted.

9. Place mullion onto bottom bracket and pivot into opening to latch.

10. Tighten bottom bracket set screw to prevent mullion rattle.

11. Install exit devices according to manufacturer’s instructions.

© SARGENT Manufacturing Company All rights reserved A7111C

Dim “X”

Page 2

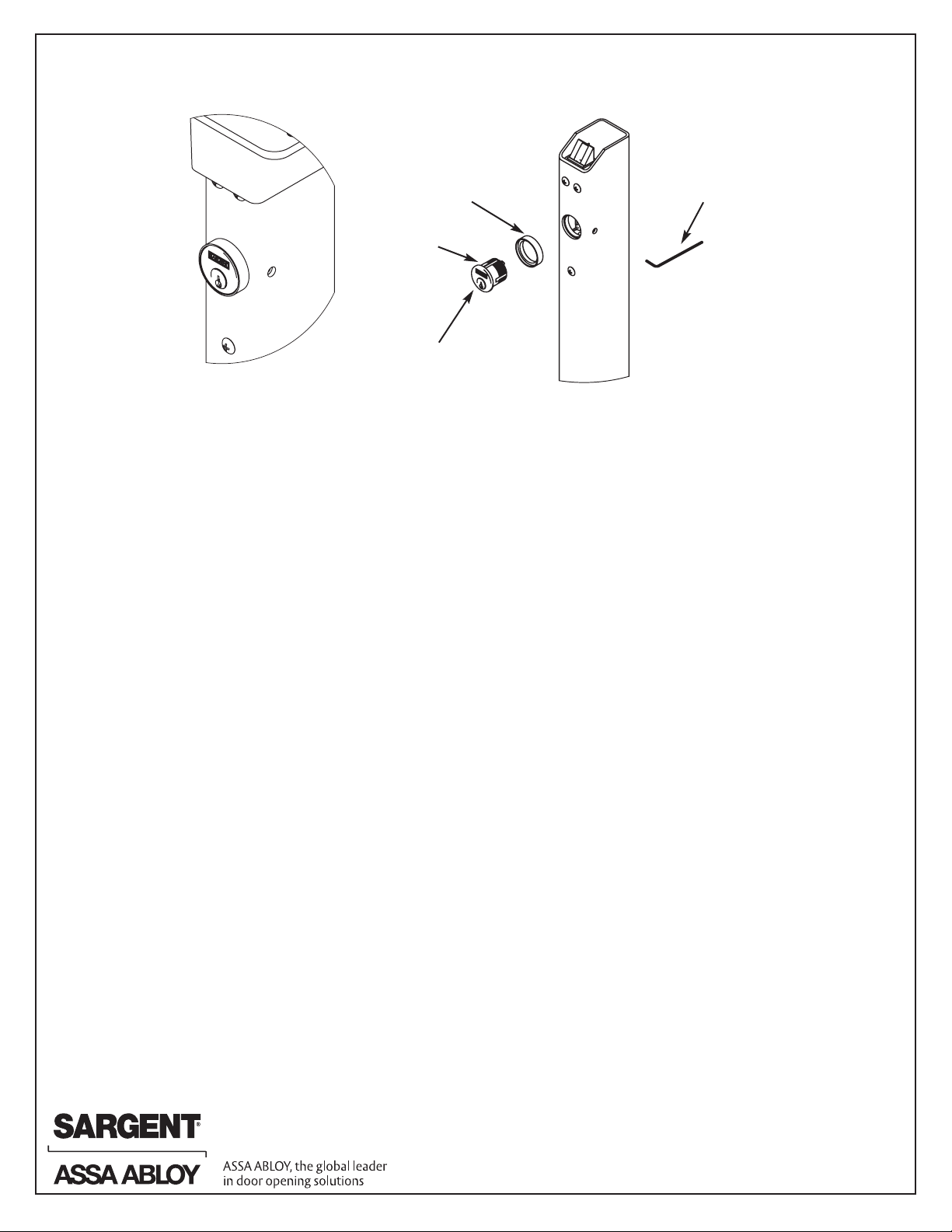

ASSEMBLY INSTRUCTIONS FOR L980S & 12-L980 STEEL MULLIONS

© SARGENT Manufacturing Company All rights reserved A7111C

Keyway

Cylinder

Blocking Ring

5/64" Allen Wrench

Installation of Cylinder

Installation of cylinder:

1. Depress latchbolt and hold fully retracted.

2. Carefully thread cylinder with blocking ring into lock assembly until it bottoms out.

3. Unscrew the cylinder orienting keyway at bottom.

4. Release latch bolt. Note: If latch bolt is not fully projected loosen cylinder an additional 1-2 full turns.

5. Tighten set screw with 5/64” Allen Wrench through access hole in side of mullion.

6. Check operation of cylinder and lock assembly. Note: Key only turns counter-clockwise.

Loading...

Loading...