Page 1

KP

KP Series

Keypad Mortise Lock

Installation & Programming

Instructions

A7373C

03/14

Copyright 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Page 2

Page 3

1

2

3

4

5

6

7

8

1

Table of Contents

Warning ...................................................................................3

General Description .................................................................4

Specifications ..........................................................................4

Features ...................................................................................5

Parts Breakdown .....................................................................6

Installation Instructions ..........................................................8

Operational Check .................................................................18

Programming Instructions ....................................................18

Warning

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced TV technician for help

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme avec la norme NMB-003 du Canada.

Any retrofit or other field modification to a fire rated opening can potentially impact the fire rating of the opening,

and SARGENT makes no representations or warranties concerning what such impact may be in any specific

situation. When retrofitting any portion of an existing fire rated opening, or specifying and installing a new

fire-rated opening, please consult with a code specialist or local code official (Authority Having Jurisdiction) to

ensure compliance with all applicable codes and ratings

To comply with “Fire Listed” doors, the batteries must be replaced with alkaline batteries only.

!

Do not install batteries if controller is powered by external power supply.

Warning SARGENT Mfg. Co. locksets utilizing a door position switch (DPS)

!

are not rated for, or intended for use in life safety applications.

03/31/14

1-800-810-WIRE • www.sargentlock.com • A7373C

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Page 4

2

General Description

The SARGENT KP Series Mortise Lock is designed for areas which require stand alone

authorized entry. It is a self-contained microprocessor-controlled keypad with non-volatile memory.

The keypad holds a total of 100 different user codes. User codes 01, 02 and 03 are utilized for

Master Code, Emergency Code and Supervisory Code, respectively.

This motorized 8200 mortise lock is operated by four (4) “C” alkaline batteries.

SARGENT mortise locks are designed with quality components to provide high security,

performance and durability.

3

Specifications

KP Series

Keypad Mortise Lock

• Latchbolt - Stainless Steel

• Deadbolt - Stainless Steel

• Guardbolt - Stainless Steel, non handed

• Handed - Easily field reversible without

disassembling the lock body

• Case - 12 gauge heavy duty wrought steel

• Outside lever controlled by keypad

• Inside lever retracts latchbolt and deadbolt

4

Features

• Non-volatile memory

• Motor driven, battery operated mortise lock

• Battery operated with 4 (each) “C” Alkaline

• Low battery alert – 4 chirps after code entry

• Option Code available to sound horn every

time keypad is pressed

• External remote “request to enter” connector

requires wire harness (52-2071)

• External battery input connector included to

power unit in event of battery failure

• All programming done at keypad

• Deadbolt switch inside mortise lock allows

Emergency Code and Master Code users to

gain entry when deadbolt is thrown*

• Locks furnished for 1 3/4” doors. Can

be furnished for other door sizes upon

request. (Consult factory)

• UL Listed (3 hr.)

• Accepts size 41(standard) and 42

(removable core) SARGENT mortise

cylinders (KP8276 and KP8278)

• Key retracts latchbolt (KP8276 and

KP8278)

• Operates utilizing any two to six digits

per code. Digits may be repeated and

codes may start with zero

• Adjustable unlock time

• Entry of three wrong User Codes

disables all codes for ten seconds.

Green LED flashes.

• Piezo horn can be heard with each

keystroke or turned off by Master or

Supervisory Code

• Last 15 transactions can be output to

printer via Data Transfer Device (DTD)

• 100 users total: one Master Code, one

Emergency Code, one Supervisory

Code, with the rest being standard

codes, passage codes, or one time

only codes

* PHR-prefix locks will not allow Emergency or Master Code users entry when deadbolt is thrown.

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

4 1-800-810-WIRE • www.sargentlock.com • A7373C

Entry is through key cylinder override only.

Page 5

KP Series

Keypad Mortise Lock

4

Features (continued)

KP8276

• Deadbolt function

• Cylinder override provided

KP8277

• Cylinder override provided

• No deadbolt function

KP8278

• Deadbolt function

• No cylinder override

KP8279

• No cylinder override

• No deadbolt function

Keypad

• Tactile keypad made of Ultraviolet stable material

• LED’s indicate valid or invalid entries

• Green LED indicates unlocked.Yellow LED indicates unit is in programming mode

• Flashing green and yellow LED’s indicate deadbolt thrown or lock set in passage mode

• Infrared LED for transaction output. Provides last 15 valid codes.

Items included in your KP8276/KP8278

Keypad Mortise Lock:

Items included in your KP8277/KP8279

Keypad Mortise Lock:

• Outside Escutcheon with Keypad

• Outside Lever Handle Assembly

• Inside Lever Handle

• Mortise cylinder

• Inside Escutcheon with Circuit Board

and Battery Pack

• Batteries (4 “C”)

• Tool (security socket screw key 1/8”)

• Outside Escutcheon with Keypad

• Outside Lever Handle Assembly

• Inside Lever Handle

• Inside Escutcheon with Circuit Board

and Battery Pack

• Batteries (4 “C”)

• Tool (security socket screw key 1/8”)

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1-800-810-WIRE • www.sargentlock.com • A7373C 5

03/31/14

Page 6

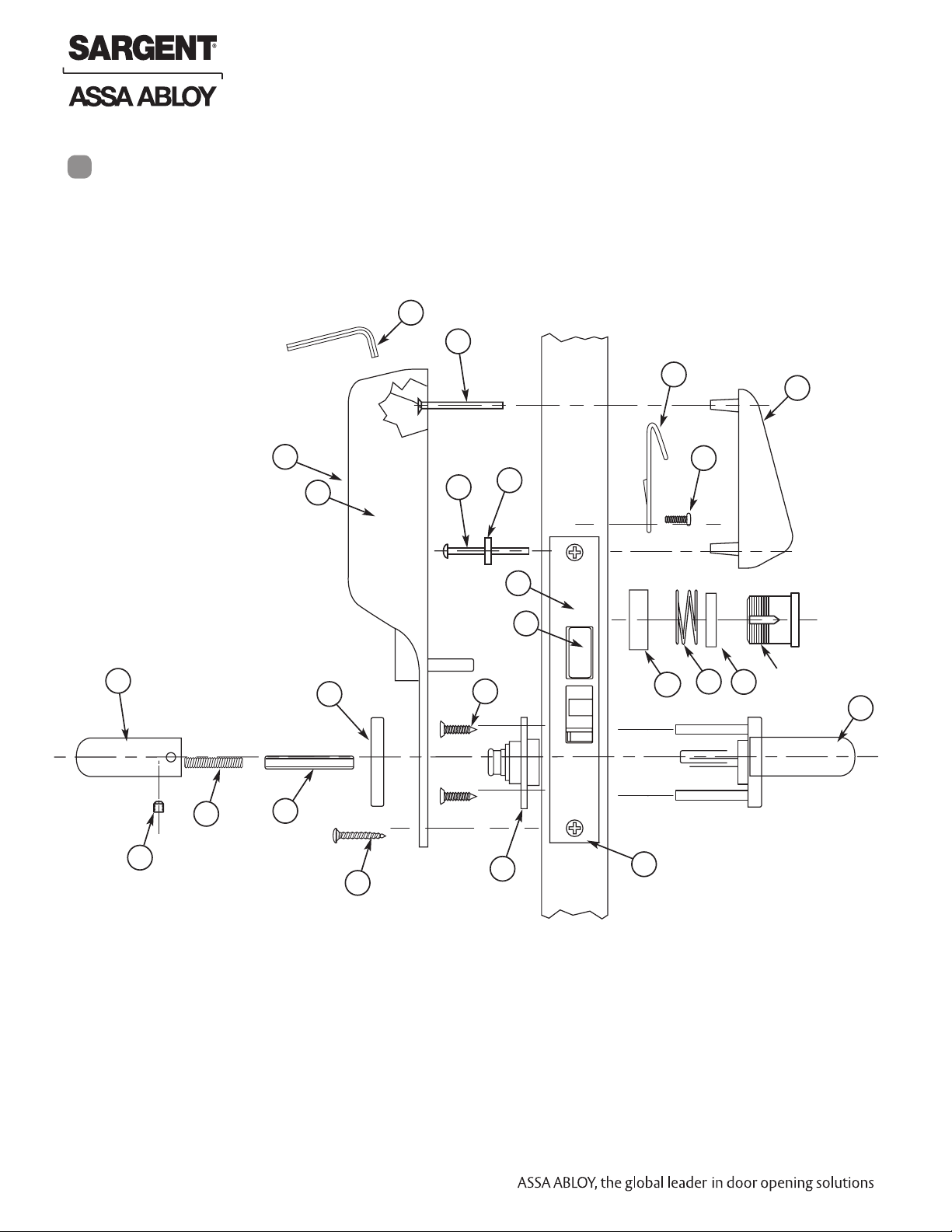

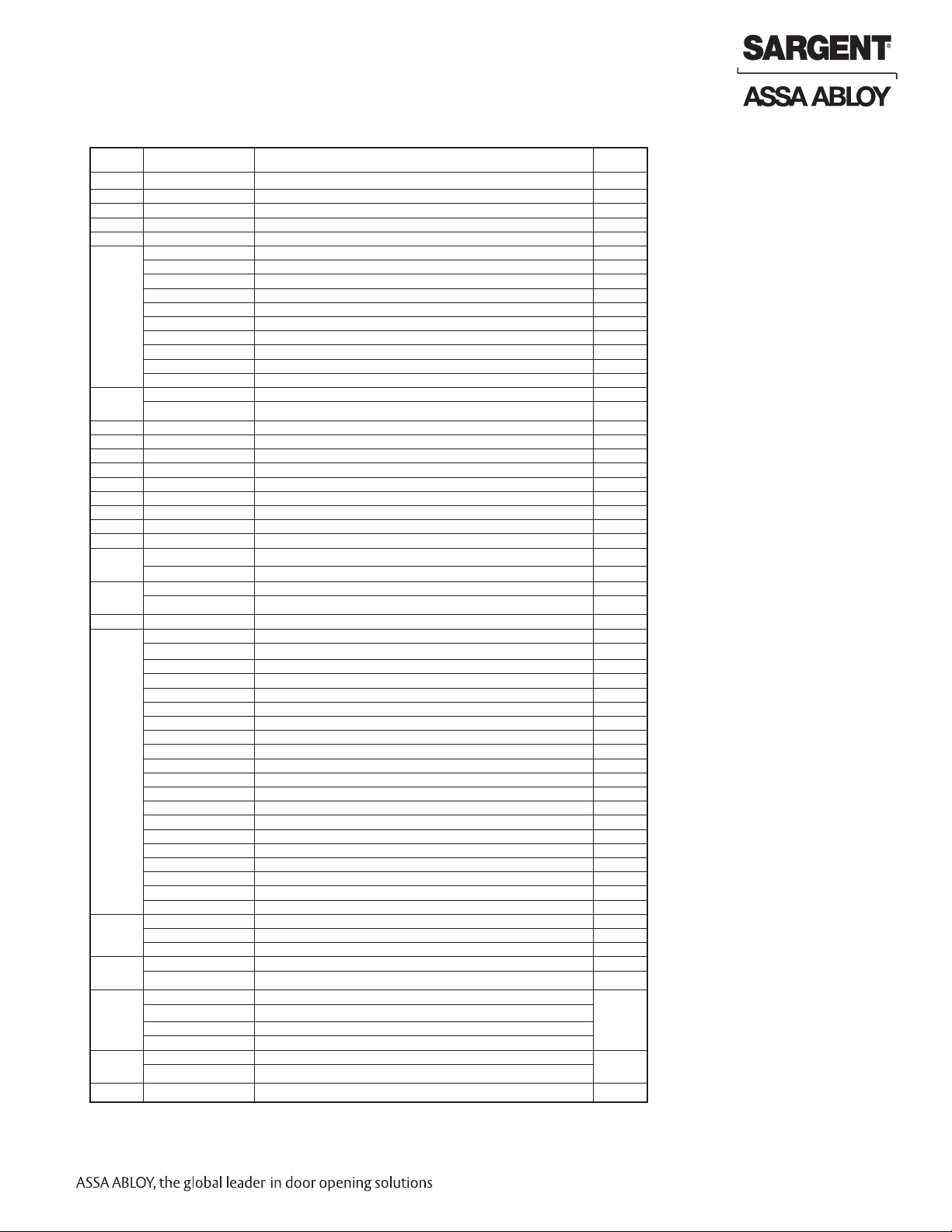

5

Parts Breakdown

KP Series

Keypad Mortise Lock

KP Series Parts List

3

2

14

25

1

6

8

10

9

4

5

22

23

12

15

19

17

18

16

KP8276

KP8278

ONLY

20

7

11

Inside of Door Outside of Door

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

6 1-800-810-WIRE • www.sargentlock.com • A7373C

13

21

Page 7

KP Series

Keypad Mortise Lock

Parts Breakdown (Continued)

Item

1 01-0803 Battery Alkaline (“C” cell) 4

2 01-1119 #8-32 x 1-1/2 Flat Head Screw 1

3 01-0297 Security Socket Screw Key (1/8) 1

4 01-1157 #8-32 x 1-1/4 Phillips Pan Head Screw 1

5 01-0440 Flat Washer 1

6 81-0467 Inside Lever (L.H.) A” Design 1

7 01-1472 Lever Handle Screw A, E, F & H (Lever) 1

8 82-0347 Handle Spring 1

9 82-0368 Spindle 1

10 81-0093 LN” Rose 1

11 01-4388 #8 x 1 Phillips Flat Head Screw 1

12 01-1495 #8-32 x 5/8 Machine Screw 2

13 82-3088 Inside Lever Adapter & Plate Assembly 1

14 52-0033 Fire Stop Plate 1

15 01-1500 #8 x 1/2 Pan Head Self Tapping Screw 2

16 52-2340 Outside Escutcheon & Keypad Assembly 1

17 77-0566 Cylinder Rosette (Size 41 Cylinder) 1

18 13-0489 Cylinder Ring (Size 41 Cylinder) 1

19 13-0140 Compression Spring 1

20 OS-8276 x LNA Outside Lever (R.H.) A” Design 1

21 01-1028 Outside Front #8-32x1/4 FL HD Screw 2

22 82-0084 Outside Front (KP8276 & KP8277) 1

23 KP-8276-hand-finish

242582-3730 Inside Escutcheon Assembly (Turn Lever-KP8276/KP8777) 1

26 52-4758 Inside Escutcheon Assembly (Turn Lever-KP8276 only*) 1

Part #

81-0468 Inside Lever (R.H.) A” Design 1

81-0490 Inside Lever B” Design 1

81-0470 Inside Lever E” Design 1

81-0471 Inside Lever F” Design 1

81-4648 Inside Lever H” Design 1

81-0447 Inside Lever J” Design 1

81-0489 Inside Lever L” Design 1

81-0513 Inside Lever P” Design 1

81-0445 Inside Lever W” Design 1

01-1174 Lever Handle Screw B, J, L, P & W (Lever) 1

13-0596 Cylinder Rosette (Size 42 Cylinder) 1

13-0490 Cylinder Ring (Size 42 Cylinder) 1

(L.H.) A” Design “ 1

OS-8276 x LNB Outside Lever B” Design “ 1

OS-8276 x LNE Outside Lever E” Design “ 1

OS-8276 x LNF Outside Lever F” Design “ 1

OS-8276 x LNH Outside Lever H” Design 1

OS-8276 x LNJ Outside Lever J” Design 1

OS-8276 x LNL Outside Lever L” Design 1

OS-8276 x LNP Outside Lever P” Design 1

OS-8276 x LNW Outside Lever W” Design “ 1

OS-8276 x LA Outside Lever (R.H.) A” Design “ 1

(L.H.) A” Design “

OS-8276 x LB Outside Lever B” Design “ 1

OS-8276 x LE Outside Lever E” Design “ 1

OS-8276 x LF Outside Lever F” Design “ 1

OS-8276 x LH Outside Lever H” Design “ 1

OS-8276 x LJ Outside Lever J” Design “ 1

OS-8276 x LL Outside Lever L” Design 1

OS-8276 x LP Outside Lever P” Design “ 1

OS-8276 x LW Outside Lever W” Design 1

01-2299 Lockbody Screws for Wood #12x1-1/4 FL HD (not shown) 2

01-1019 Lockbody Screws for Metal #12-24x1/2 FL HD (not shown) 2

82-0081 Outside Front (KP8278 & KP8279) 1

Lockbody Assembly with deadbolt & cylinder

KP-8277-hand-finish Lockbody Assembly with deadbolt only (no cylinder)

KP-8278-hand-finish Lockbody Assembly with cylinder only (no deadbolt)

KP-8279-hand-finish Lockbody Assembly without deadbolt & without cylinder

82-3729 Inside Escutcheon Assembly (Hole Plug-KP8278/KP8779)

Description

Req.

1

1

* PHR-prefix locks will not allow Emergency or Master Code users entry when deadbolt is thrown.

Entry is through key cylinder override only.

1-800-810-WIRE • www.sargentlock.com • A7373C 7

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 8

6

Installation Instructions

Step #1 – Verify Hand and Bevel of Door

A. Verify Hand and Bevel of Door

Stand on outside/locked side of door when determining the door hand

KP Series

Keypad Mortise Lock

LH

Left Hand

Hinges Left

Open Inward

LHRB

Left Hand

Reverse Bevel

Hinges Left

Open Outward

RH

Right Hand

Hinges Right

Open Inward

Fig. 1A

B. Prepare Door

Prep door according to Instruction Sheet A7454 and appropriate template:

Manufacturer Door Template: 4632

Documents are available at www.sargentlock.com

Outside of DoorInside of Door

Ribbon Cable Hole

(Controller to Keypad)

Inside Cylinder Hole

Thumb Turn Lever Hole

RHRB

Right Hand

Reverse Bevel

Hinges Right

Open Outward

Through-bolt Hole

Outside Cylinder Hole

(76 and 78 Functions)

Mortised

Lever Handle Hole

Fig. 1B Wood Door Preparation

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Pocket

Pre-drilled

and/or

Tapped Holes

(2 places)

8 1-800-810-WIRE • www.sargentlock.com • A7373C

Lever Handle Hole

Through-bolt Hole

Page 9

KP Series

Keypad Mortise Lock

Step #2 – Verify Hand and Bevel of Door

A. Reverse Lock Hand

Red surface of locking piece must face the outside/locked side of door. To rotate locking piece (Fig. 2A):

1. Position lock body with red surface of locking piece visible.

2. Insert blade type screwdriver into locking piece slot to rotate locking piece toward back of lock body.

3. Rotate the locking piece 180° until RED surface is on opposite side.

Note: Red indicates locked side (outside).

Right Hand

Lock Shown

Locking Slide

Red on Locked Side

Push In

Fig. 2A

B. Reverse Latch Hand

Beveled surface of latchbolt must face strike (Fig. 2B).

The deadlatch is self adjusting.

To change the hand of the latchbolt:

1. Insert the blade of a slotted screwdriver (>1/4”)

into the spade shape slot behind latch.

2. Rotate the screwdriver 90° to push latchbolt out

until back of bolt clears lock case front.

3. Rotate latchbolt 180° until the latchbolt

drops back into the lock body.

Note: Latch cannot be unscrewed.

Spade

Shaped

Slot

Latchbolt

Deadlatch

Fig. 2B

1-800-810-WIRE • www.sargentlock.com • A7373C 9

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 10

KP Series

Keypad Mortise Lock

Step #3 – Install Lock Body

1. Insert lock body into mortised cutout (Fig. 3A).

Inside of Door

Fig. 3A

2. Hold lock body loosely in place with (2) lock

body screws.

Note: Do not completely tighten screws at this time.

(2) #12-24 x 1/2”

Flat Head Screws

(Metal Doors)

(2) #12 x 1-1/4”

Flat Head Screws

(Metal Doors)

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

10 1-800-810-WIRE • www.sargentlock.com • A7373C

Outside of Door

Harness exits

Non-Cylinder side

Fig. 3B

Page 11

KP Series

Keypad Mortise Lock

Step #4 – Exterior Door Options

A. Fire Stop Plate (P/N 53-0033)

Fire-rated doors require a fire stop plate on

the outside of the door (Fig. 4A).

1. Drill (2) 1/8” x 1-1/4” deep holes

in the door if not already present.

Refer to template for fire-stop

prep locations.

2. Attach with flap up and

out using (2) #8 x 1/2”

self-tapping screws for

wood and metal doors.

B. Weather Conduit

(P/N 52-2847)

Install weather conduit on

NON FIRE-RATED exterior

doors only.

1. Carefully insert the weather

conduit into the ribbon cable

hole on the inside of the door

(Fig. 4B).

2. Place the O-ring around the

weather conduit on the outside and up against the door

(Fig. 4C).

of 1-1/2”

Diameter

1-1/2”

7/8”

Fig. 4A

(2) 1/8” Diameter

Holes Required

Slot

Fire Stop Plate

(2) Self Tapping

Screws #8 x 1/2”

for Wood and

Metal Doors

Outside of Door

Ribbon Cable Hole

Fig.4B

O-Ring

Fig.4C

Step #5 – Install Weatherseal Gasket (Exterior Doors)

1. Carefully remove adhesive backing from the gasket (Fig. 5A).

2. Apply gasket to escutcheon:

• Starting in one place, press the adhesive side

of the gasket firmly against the escutcheon.

• Work around the escutcheon, pressing the sticky side

of the gasket firmly against the escutcheon edge.

• The gasket should be aligned so that all edges

of the escutcheon are covered.

3. Attach escutcheon to the door.

Note: The 43 cylinder may be used with or without a gasket.

1-800-810-WIRE • www.sargentlock.com • A7373C 11

Fig. 5A

Fig. 5B

Peel back

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 12

Step #6 – Install Outside

Escutcheon and Lever

Assembly

KP Series

Keypad Mortise Lock

Install Outside

Lever Assembly

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

12 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 13

KP Series

Keypad Mortise Lock

Step #7 – Install Inside Escutcheon

Inside Escutcheon

Assembly

1-800-810-WIRE • www.sargentlock.com • A7373C 13

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 14

Step #8 – Inside Lever Installation

KP Series

Keypad Mortise Lock

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

14 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 15

KP Series

Keypad Mortise Lock

Step #8 – Continued

1-800-810-WIRE • www.sargentlock.com • A7373C 15

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 16

Step #9 – KP8276 and KP8278 Only - Install Cylinder

KP Series

Keypad Mortise Lock

Position cylinder so that the

SARGENT logo is right-side up.

Correct Incorrect

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

16 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 17

KP Series

Keypad Mortise Lock

Step #10 – Application of Front Plate

Step #11 – Battery Installation

1-800-810-WIRE • www.sargentlock.com • A7373C 17

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 18

KP Series

Keypad Mortise Lock

7

Operational Check

• Place key into cylinder and rotate key.

• The key will retract the latchbolt.

• If the deadbolt is thrown, the key will retract both the deadbolt and the latchbolt.

• Inside handle lever retracts latchbolt and (if provided).

• Enter 1234* to unlock outside lever handle and retract latchbolt and deadbolt (if provided).

N O P

Q RS

T U V

M

G

@

Deadbolt

(KP8276/KP8278)

Inside of Door

• Key should rotate freely. There should be no friction against lock case, wire harness or any

other obstructions.

• Refer to Step 7 if harness friction exists.

• Rotate cylinder further into lock case to eliminate lockbody obstruction.

8

Programming Instructions

The KP Keypad Lock can support 100 users. Each user is assigned a User Number in addition to

the code used for entry.

Example:

USER TYPE USER NUMBER USER CODE

Master

Emergency

Supervisor

Standard 04-97 2 6 5

Special Factory

10 Sec. Time Preset

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

01

02

03

98 99 1 3 6 8

Latchbolt

Outside of Door

(2-6 DIGITS)

1 2 3 4

2 2 2 2 2

3 0 3 0 3 0

03/31/14

18 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 19

KP Series

Keypad Mortise Lock

This Keypad Mortise Lock has 99 User Codes available for programming purposes.

• The Master Code is always User “01”. The Master Code assigns the Emergency and Supervisory Codes. It is

also used for programming and will override the deadbolt*. Users are deleted through the Master Programming

Code only.

• The Emergency Code is always User “02”. The Emergency Code will override the deadbolt* in the mortise lock

and has an unlock time of 10 seconds.

• The Supervisory Code is always User “03”. The Supervisory Code allows temporary lockout of selected users,

changes duration of unlock time, requests infrared interrogation output, and may add additional User Codes.

• The first User Code will be User “04” or higher. User numbers do not have to be used or entered sequentially.

• User codes “98” and “99” have a factory-set unlock time of ten seconds. This allows a handicapped person

extra time which would not be required by other users.

*NOTE: PHR-prefix locks will not allow Emergency or Master Code users entry when deadbolt is thrown.

Entry (with deadbolt thrown) is through key cylinder override only.

To Begin Programming:

The Keypad Mortise Lock is preset at the factory with Master Code “1234”. Entering “1234*” will unlock the

lock allowing the lever handle to retract the latchbolt.

Initial Set-Up Procedures:

• The following are typical procedures to follow when setting up your KP Series Keypad.

• If a mistake is made during any of procedures, depress the “*” several times until the yellow LED goes out.

• If no keystroke is made in a 30-sec time frame the programming up to that point will default and you will

have to start over.

All of the following procedures start with 99#.

If after the last “ *” is depressed, the yellow LED does not go out, depress “ *” once more.

Change Master Code:

• 1234* (Yellow LED Begins to Blink Slowly) This example uses the Factory Default Master Code

• 50# 1# 01# New Master Code* (Yellow LED Blinks Quickly)

• New Master Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

To Enter the Emergency Code:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# 02# Emergency Code* (Yellow LED Blinks Quickly)

• Emergency Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

To Enter the Supervisory Code:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# 03# Supervisory Code* (Yellow LED Blinks Quickly)

• Supervisory Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

(Unlock Duration is Factory Set at 10 Sec)

To Enter a User Code:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# User Number (04-97)# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

1-800-810-WIRE • www.sargentlock.com • A7373C 19

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 20

KP Series

Keypad Mortise Lock

All of the following procedures start with 99# (continued).

If after the last “*” is depressed, the yellow LED does not go out, depress “*” once more.

To Enter a Passage (Maintained Mode) Code:

When Passage Mode is used, the same User Code must be used to re-lock the lock.

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 2# User Number (04-97)# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

To Enter a One Time User Code:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 3# User Number# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

To Deactivate “Beep” With the Depression of Each Key:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 30# 0# 0# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (No Beep on Depression and Yellow LED Blinks Slowly)

• * (No Beep on Depression and Yellow LED Goes Out)

To Reactivate “Beep” With the Depression of Each Key:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 30# 0# 1# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (Beep on Depression and Yellow LED Blinks Slowly)

• * (Beep on Depression and Yellow LED Goes Out)

To Clear the Entire Memory:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 46# 00000# 00000# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (No Beep on Depression and Yellow LED Goes Out)

• PAUSE, Yellow LED Begins to Blink Again

• * (Yellow LED Goes Out)

NOTE This Deletes ALL Codes, including Master, Emergency and Supervisory. The Master Code is set back

to 1234, Door Number to 0001 and Unlock time to 5 Sec. If the Master Code is not known, Factory

Assistance will be required to clear the memory. 1-800-810-WIRE.

To Program Door Numbers into Keypad:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 43# 0# Door Number# (must be four digits) (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

• * (Yellow LED Blink Slowly)

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

• * (Yellow LED Goes Out)

03/31/14

20 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 21

KP Series

Keypad Mortise Lock

All of the following procedures start with 99# (continued).

If after the last “*” is depressed, the yellow LED does not go out, depress “*” once more.

To Interrogate Transaction Log:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 70# 0# 0# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Goes Out)

Door Number

For additional information, see “Transaction Log”.

Note: Seq. # 1 is the

programming request

to output the entries.

Sequence numbers 2-6

are the actual entries.

Transaction

Number

Door # 5666

Seq User Trans

1 001 003

2 003 001

3 003 001

4 020 001

5 003 001

User Number

Transaction

Type

Hold an infrared printer up to the red

infrared LED (as shown). A Data Transfer

Device (DTD) can be used to download

information from the keypad to a printout.

Illustration

To LED

location

DataTransfer Device

(DTD)

To Reset / Clear Transaction Log

• Master Code* (Yellow LED Begins to Blink Slowly)

• 76# 00000# 00000# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Goes Out)

To Delete a User Number:

• Master Code* (Yellow LED Begins to Blink Slowly)

• User Number# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

To Disable / Enable a User Number:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 56# 0# = Enable, 1# = Disable User Number# (04-99) (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

To Set Unlock Time:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 85# Time Duration# (01-99 Sec) 0# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

The Unlock Time is Adjustable for Momentary Operation. A 5 second unlock time is recommended to extend battery life.

Note:

Once the unlock time is entered, it is the same for ALL users except 02, 98 and 99 which are factory set for 10 seconds.

1-800-810-WIRE • www.sargentlock.com • A7373C 21

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Page 22

Transaction Log

To output the last 15 entries, enter 99 # Supervisory or Master Code * 70 # 0 # 0 # **.

Note: Seq. # 1 is the

Door Number

• 4 Digits

• Up to 9999 different doors, assigned by user

programming request

to output the entries.

Sequence numbers 2-6

are the actual entries.

KP Series

Keypad Mortise Lock

Transaction Number

• Single digit - 1-6

Door Number

• Latest transaction - 1

• Oldest transaction - 6

User Number

• Three digits - 001 through 099

• User numbers assigned at time of programming

Transaction Types

Transaction

Number

• 001 = Access granted

• 002 = Access denied (Deadbolt thrown and code entered did not have

proper access level.)

• 003 = Log printed

Optional Equipment

• Printer Paper (6 Rolls) - 52-0034 used for infrared printers

• Auxiliary Power Unit (APU) 52-2065 - used to unlock unit if batteries are too

weak and cylinder is not used.

• Data Transfer Device (DTD) - used to download the user and transaction type.

• Remote Unlocking - 52-2071 - used for remote unlocking of keypad mortise

lock. When the deadbolt is thrown and the remote unlocking feature is used,

both the latchbolt and deadbolt can be retracted by turning the lever handle.

Door # 5666

Seq User Trans

1 001 003

2 003 001

3 003 001

4 020 001

5 003 001

Transaction

User Number

Hold an infrared printer up to the red

infrared LED (as shown). A Data Transfer

Device (DTD) can be used to download

information from the keypad to a printout.

Illustration

To LED

location

DataTransfer Device

(DTD)

Type

Remote unlocking

connector placement

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

03/31/14

Inside Escutcheon

22 1-800-810-WIRE • www.sargentlock.com • A7373C

Page 23

SARGENT Manufacturing Company

100 Sargent Drive

New Haven, CT 06511 USA

800-810-WIRE (9473) • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A7373C-03/14

Loading...

Loading...