Page 1

Installation Instructions For

Keypad 10 Line Lock KP10G77

A7113E

8/08

Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

Page 2

Table of Contents

1

General Description ............................................................................1

2

Specifications .....................................................................................1

3

Parts Breakdown.............................................................................2-3

4

Features ..............................................................................................4

5

Installation Instructions................................................................5-12

6

Programming Instructions

English ...................................................................................12-15

Chain Programming ....................................................................16

7

Transaction Log ................................................................................17

8

Guide De Progammation (French) ...................................................18

Page

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, Sargent Manufacturing Company,an ASSA ABLOY Group company. All rightsreser ved.

Page 3

Keypad 10 Line Lock

1

General Description

The SARGENT Keypad 10 Line Lock is designed for areas which require authorized entry. It is a

self-contained microprocessor-controlled keypad with non volatile solid-state memory. The keypad will

hold a total of 100 different User Codes. User Codes “01” and “03” are utilized for Master Code and

Supervisory Code, respectively. All programming is done at the keypad, with over 1,100,000 possible

user combinations.

This lock is operated by four (4) “C” batteries with a life span of approximately 50,000 cycles.

A portable infrared printer (52-2069) may be used to download user information.

2

Specifications

• Latch bolt - 1/2" standard

3/4" available (41-prefix)

• Deadlocking latch

• Outside lever controlled by keypad or key retracts latch bolt

• Inside lever retracts latch

• Locks furnished for 1-3/4" doors only

• U.L. Listed

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

1

Reproduction in wholeor in part without the express written permissionof Sargent Manufacturing Company is prohibited.

8/14/08 Copyright © 2005,2007,2008, Sargent Manufacturing Company,an ASSA ABLOY Group company. All rightsreser ved.

Page 4

Keypad 10 Line Lock

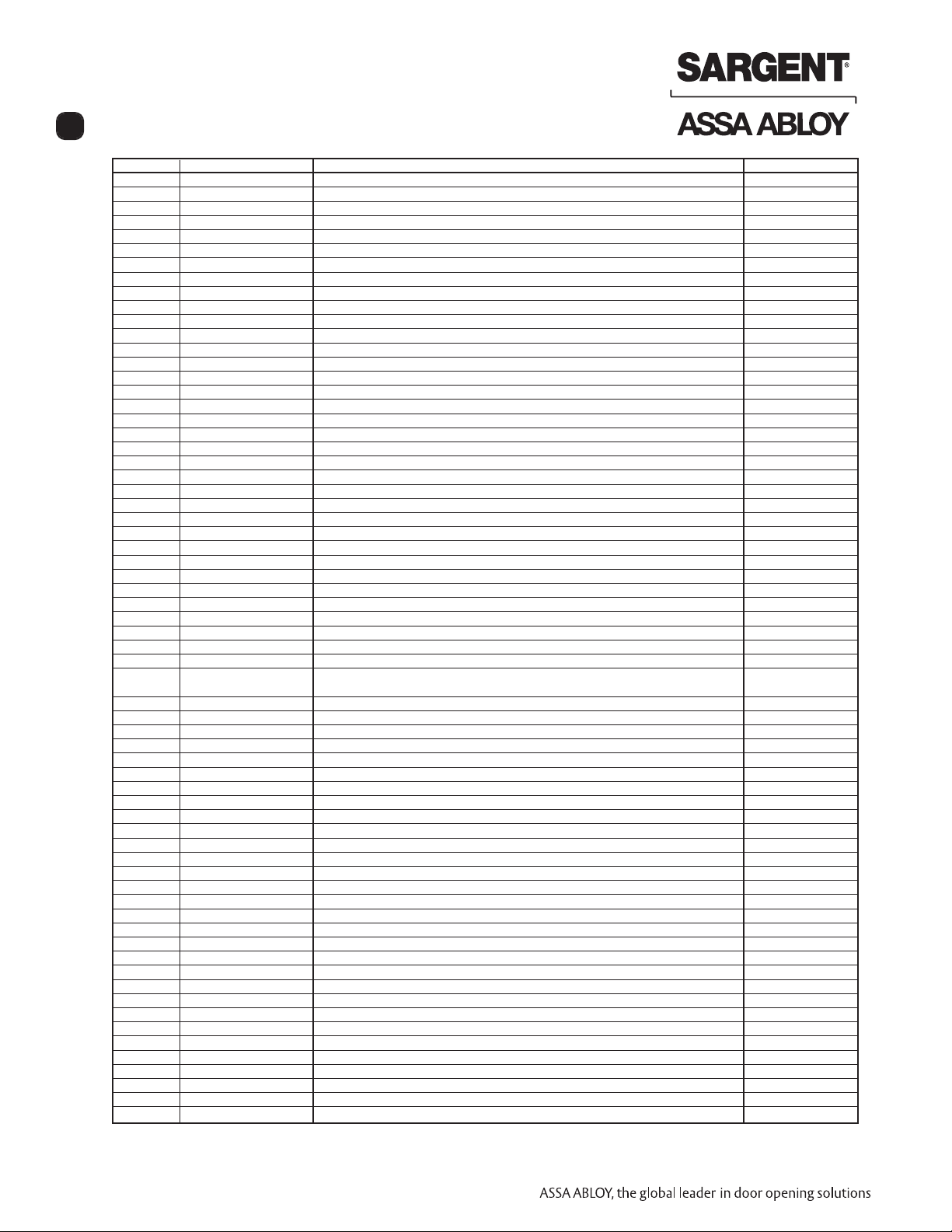

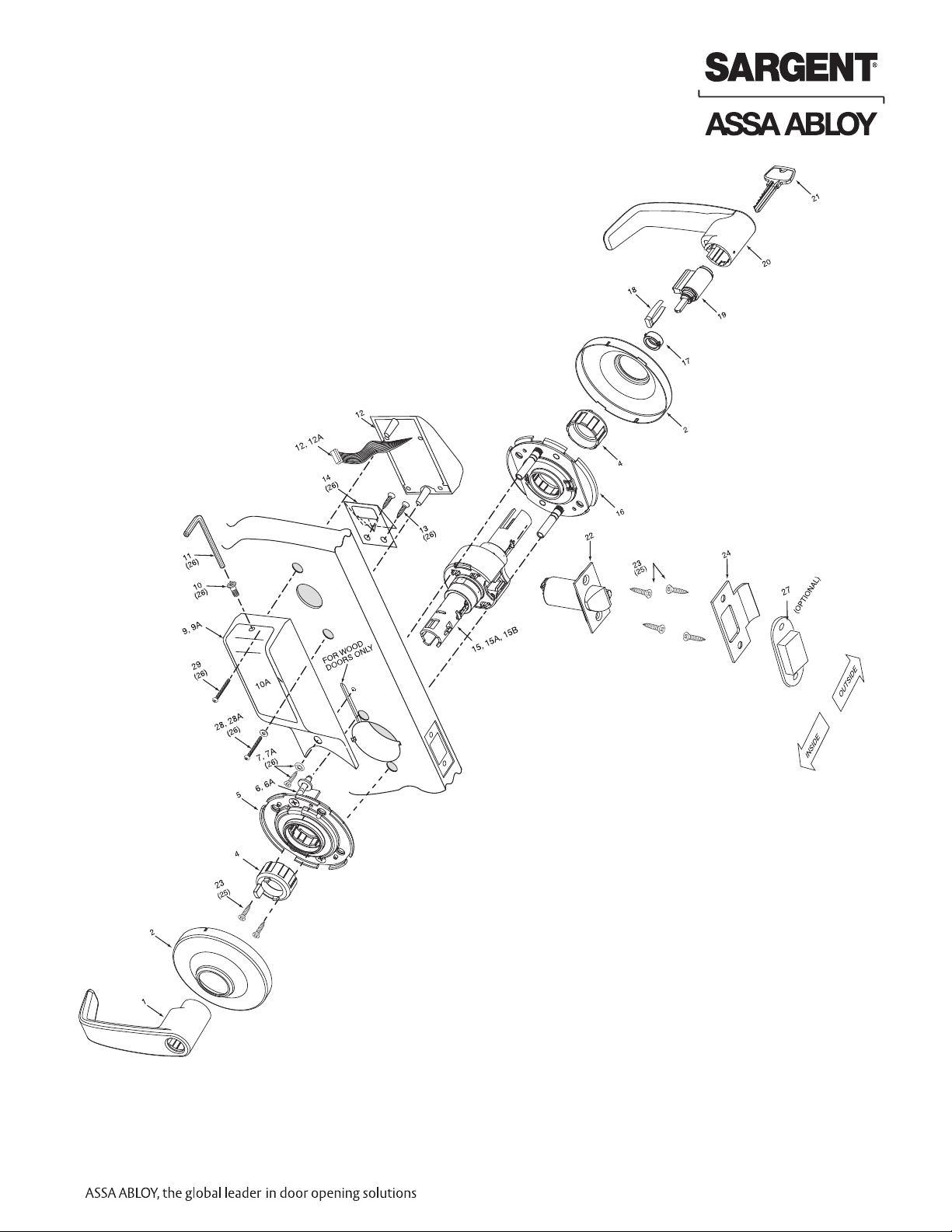

3

Parts Breakdown

ITEM PART NUMBER DESCRIPTION NO. REQ’D

1

2 *10-0790 Rose scalp "G" 2

2A *10-0798 Rose scalp "L" 2

4

5

6 01-9170 Through-bolt screws 2

6A 10-0802 Plastic screw holder 2

7 01-4388 8 X 1 SELF TAP SCREW 1

A 82-0443 Turn lever cover plate, plastic -black. not shown 1

7

9

9A 52-2400 Controller/circuit board assembly only 1

10 45-1340 Flat head screw (security) 1

0A 52-0069 Battery cover only 1

1

1 01-0297 SOCKET ALLEN SAFETY KEY 1

1

2 *52-2340 Outside escutcheon & keypad 1

1

12A 52-2299 Keypad assembly only 1

13 01-1500 SELF TAP SCREW TYPE "AB" 2

14 52-0033 Fire stop plate and screws 1

15 10-2642 77 Lockbody (std, 10, 21, 23, 30, SC, SE, VA & VS prefixes only) 1

15A 10-2643 77 Lockbody (60, 63, 64 prefixes only) 1

15B 10-2644 77 Lockbody (70, 72, 65-73, 65-73P lockbody) 1

16 10-3049 Outside rose spring assembly (not finished) 1

17 10-0019 Cylinder spacer 1

17A 13-3613 Schlage (SC) cylinder (provide keying details) 1

17B 13-3614 Schlage (SE) cylinder (provide keying details) 1

17C 13-3713 Cylinder (10-Signature) 1

18 10-0312 Cylinder retainer 1

18A 10-0313 Cylinder retainer for removable core, 1

19 13-3266 Cylinder (standard) provide keying details 1

20 *10-2251 “B” Lever outside standard cylinder 1

21 Key (provided with cylinder) A/R

22 *10-2000 2-3/4" Backset latch (standard) 1

22A 10-2053 3-3/4" Backset latch (23 prefix) 1

22B *10-2058 5" Backset latch (25 prefix) 1

22C *10-2634 3/4" Throw (41 prefix) 1

23 01-4414 Screw for standard front and strike 4

24 *08-0312 #800 Strike 1

24A *08-0066 #808 Strike (28-prefix) 1

25 *10-2052 Screw pack- standard (screws (latch, strike, #3) & push pin tool) 1

26 52-2300 Screw pack (includes #’s 7, 11, 13, 14, 28, 28A, 29) 1

27 08-0055 Strike Box- standard 1

28 01-1157 8-32unc-2ax 1 1/4 1

28A 01-9063 WASHER 1

29 01-1119 PH FL HD 8-32 X 1 1/2 1

30 10-0043 Lever Retainer Push Pin, Not Shown 1

*10-0523 “B” Inside lever/regular and 30- 1

10-2204 “J” Inside lever/regular and 30- 1

*

10-0503 “L” Inside lever/regular and 30- 1

*

*10-0547 “P” Inside lever/regular and 30- 1

*10-0536 “B” Inside lever/75 handicap warning 1

10-2247 “J” Inside lever/75 handicap warning 1

*

10-0514 “L” Inside lever /75 handicap warning 1

*

10-0558 “P” Inside lever/75 handicap warning 1

*

10-0792 Spacer bushing 2

10-3048 Inside rose spring assembly (not finished) 1

*10-2875 Inside escutcheon assembly 1

*10-2205 “J” Lever outside standard cylinder 1

*10-0502 “L” Lever outside standard cylinder 1

*10-0546 “P” Lever outside standard cylinder 1

*10-0525 “B” Outside lever/30-competitive cylinder 1

*10-2206 “J” Outside lever/30-competitive cylinder 1

*10-0503 “L” Outside lever/30-competitive cylinder 1

*10-0547 “P” Outside lever/30-competitive cylinder 1

*10-0535 “B” Outside lever/standard cylinder 76 handicap warning 1

*10-2246 “J” Outside lever/standard cylinder 76 handicap warning 1

*10-0513 “L” Outside lever/standard cylinder 76 handicap warning 1

*10-0557 “P” Outside lever/standard cylinder 76 handicap warning 1

10-2070 Screw pack- 28- prefix (screws (front, strike, #3) &push pin tool)

*

ee SARGENT web page for Costal Series Levers.

S

Interchangeable core & Keso

See SARGENT web page for Costal Series Levers.

1

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

*Specify Finish

2

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 5

Keypad 10 Line Lock

Parts Breakdown (Continued)

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

3

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 6

Keypad 10 Line Lock

4

Features

KP10G77

• Non volatile memory

• Motor driven, battery operated cylindrical lock

• Battery operated with 4 each “C” Alkaline Batteries

• Low battery alert–4 chirps after code entry

• Option Code available to sound horn every time keypad is pressed

• External remote “request to exit” connector

• External battery input connector included to power unit in event of battery failure

• 100 users total: one Master Code, one Supervisory Code, with the rest being standard codes,

passage codes, or one time only codes

• All programming done at keypad

• Operates utilizing any two to six digits per code. Digits may be repeated and codes may start

with zero

• Minimum 40,000 cycles per set of batteries

• Cylinder override provided

• Entry of three wrong User Codes disables all codes for ten seconds. Green LED flashes

• Piezo horn can be heard with each keystroke or turned off by Master or Supervisory Code

• Last 15 transactions can be output to portable printer via infrared link

Keypad

• Made of ultraviolet stable material

• LED’s indicate valid or invalid entries

• Green LED indicates unlocked. Yellow LED indicates unit is in programming mode

• Flashing green and yellow LED’s indicate lock in passage mode

• Infrared LED for transaction output. Indicates last 15 valid codes

Items included in your KP10G77 Keypad Cylindrical Lock:

• Outside Escutcheon with Keypad

• Motorized Cylindrical Lock with cylinder

• Inside escutcheon with circuit board and battery pack

• Batteries (4 “C”)

• Tools

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

4

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 7

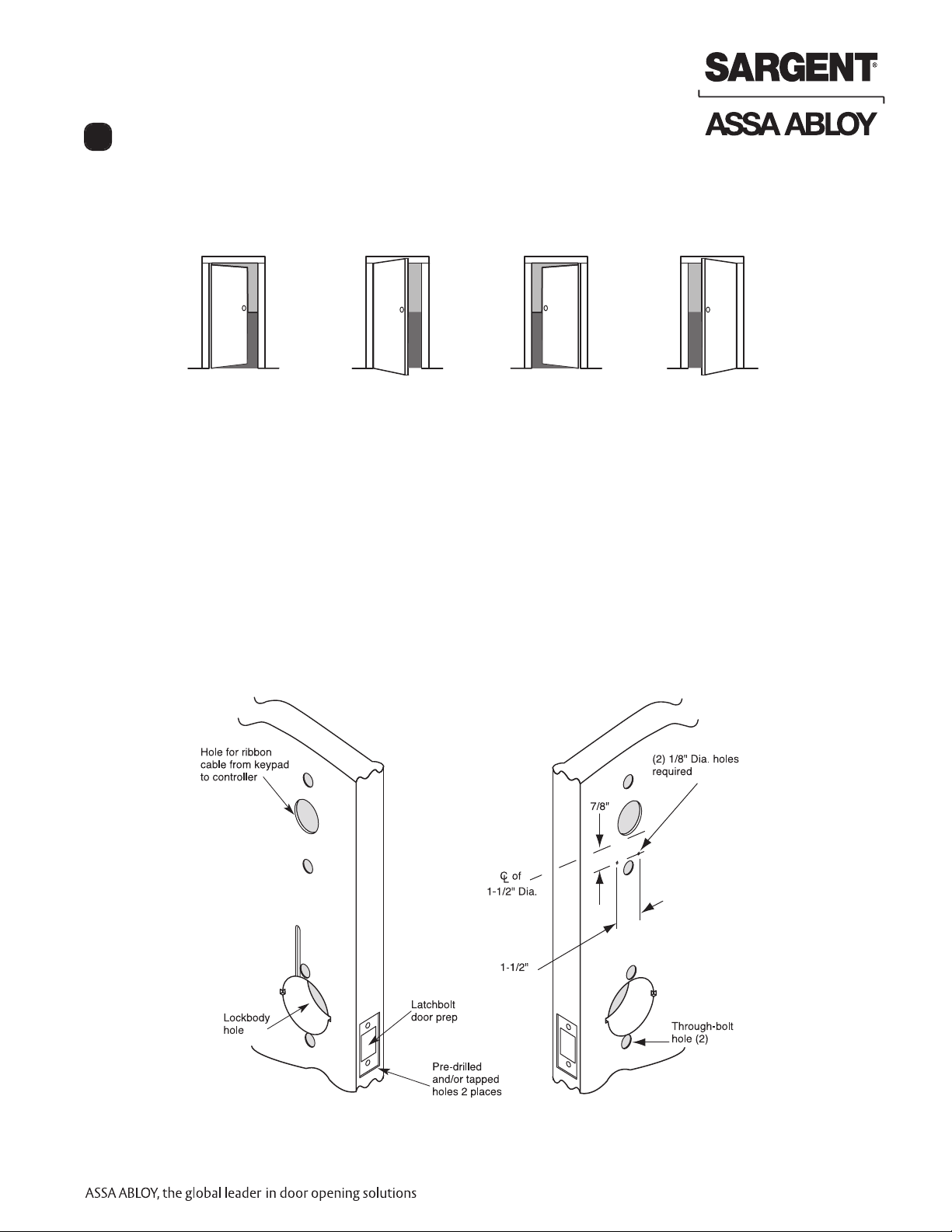

Keypad 10 Line Lock

Left Hand

Hinges Left.

Open inward.

“LH”

Left Hand

Reverse Bevel

Hinges Left.

Open Outward

“LHRB”

Right Hand

Hinges Right

Open Inward.

“RH”

Right Hand

Reverse Bevel

Hinges Right.

Open Outward.

“RHRB”

5

Installation Instructions

Step #1 Verify Hand and Bevel of Door

Stand on outside/locked side of the door when determining the door hand

Left hand

hinges left

open inward

LH

Left hand

reverse bevel

hinges left

open outward

LHRB

Right hand

hinges right

open inward

RH

Right hand

reverse bevel

hinges right

open outward

RHRB

Step #2 Door Preparation

Prepare door according to appropriate template (see website www.sargentlock.com):

• For metal door template, see 4486 and 4494

• For wood door template, see A7332 (scale paper template ships with product) and 4375-1

• Prior to installation, all holes must be free of burrs, debris and sharp edges

• If doors are not properly reinforced per ANSI115.2, commercially available reinforcements

should be installed

Inside of

door

Wood Door Preparation

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

Outside of

door

5

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 8

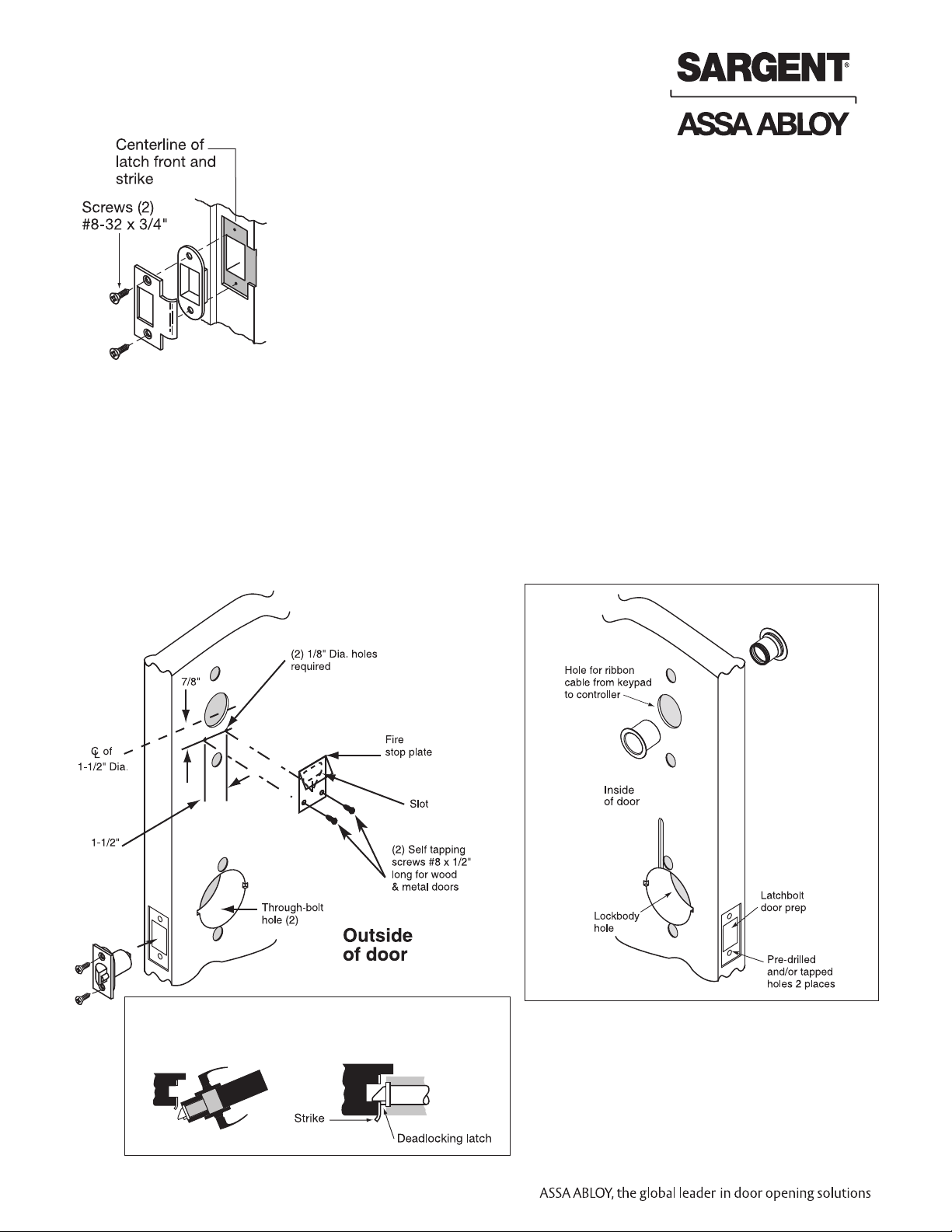

Keypad 10 Line Lock

Step #3 Frame Preparation for Strike

Step #4 Latch and Fire Stop Plate Installation

1. Install latch with beveled bolt facing the strike

2. Attach with two screws, but DO NOT tighten completely at this time

3. Attach Fire Stop Plate with two screws

Note: Required for all Fire Rated doors

Fire Rated Doors– Install Fire Stop Plate

(P/N 52-0033) as shown below

Non Fire Rated Exterior Doors–

Install Weather Conduit (P/N 52-2847)

as shown below

Important: Latch bevel must match door

bevel and deadlocking latch must stop on

strike when door is closed

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

6

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 9

Keypad 10 Line Lock

Screws partially

tightened

For wood

door only

Inside

of door

1

2

3

1-3/4" thick door

2" thick door

T

hrough-bolt

holes

Rotate to match

through-bolt holes in door

Spacer bushing

Step #5 Lock Installation

Lock Preset to:

• Through-bolt location– 12 & 6 o'clock

• Door thickness– 1-3/4" thick- see below for other door conditions

Adjustment for different through-bolt and door thickness:

• Remove outside lever (usually keyed), scalp and spacer bushing

• Rotate mounting plate to either align with through-bolt holes in door,

or adjust for proper door thicknesses (see markings on through-bolt)

• Reinstall spacer bushing (to align with back of lever) scalp and lever

1. Feed wires into the lock body hole from outside of door

2. Install lock body into cross-bore hole from outside of the door (locked side)

3. Lock body must engage both the latch unit prongs and tail piece (as shown)

IMPORTANT:

Door must remain open

during installation.

Use door stop.

IMPORTANT:

Lockbody

must be

centered in

the door.

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

7

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 10

Keypad 10 Line Lock

Step #6 Securing the Lock to Door

1A. If wood door, feed wires up through

the routed channel as shown

1B. If metal door, feed wire connector within the

door core and out hole on inside of door

2. Attach inside rose assembly and spacer

bushing and secure with screws shown

Step #7 Installation of Outside Escutcheon

• From the outside of the door,

feed keypad wires through fire

stop plate and to the inside of

the door. Lift plate cover if needed.

• IMPORTANT – Fire stop

plate cover must lay flat

before installing the keypad

to avoid interference

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 11

Keypad 10 Line Lock

Step #8 – Security of Outside Escutcheon

• From the inside of the door, use

the #8-32 x 1 1/4” round head

screw with the flat washer to

attach the escutcheon thru the

lower lug

• Straighten escutcheon and tighten

the #8-32 round head screw

Step #9 – Installation of Inside Escutcheon

• Plug the smaller lockbody

wires into the inside

escutcheon. Access holes

vary based on wood or

metal door application

• Plug keypad ribbon

cable connector into

inside escutcheon

IMPORTANT: Both wire

plug connectors go on

only one way. Do not

offset the connectors.

If not seated, keypad

will not function properly

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

9

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 12

Keypad 10 Line Lock

Step #10 Securing of Inside Escutcheon

• Remove black plastic battery cover with security hex wrench (provided)

• Carefully tuck the wire into the routed groove in wood door. The remainder can fit within

bottom portion of escutcheon. Make certain that wires are not pinched by obstructions in escutcheon

• Place inside escutcheon flat against the door

• Secure inside escutcheon with one flat head screw thru interior of inside escutcheon and into

post of exterior escutcheon

• Secure bottom of escutcheon with flat head screw and ferrule

Step #11 Test Lockset

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

• Rotate inside lever

to test for latch

bolt retraction

• Place key into

cylinder and rotate

key for latch

bolt retraction

• Tighten latch

bolt screws on

edge of door

• Test keypad

operation per

manual's

instructions

10

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 13

Keypad 10 Line Lock

Step #12 – Battery Installation

• Place (4) C batteries into the compartment as indicated inside escutcheon

• Attach battery cover to inside escutcheon and secure with #8-32 x 3/8" security screw

DO NOT OVER TIGHTEN

How to Remove Outside Lever Only

1.Insert key, rotate 45° clockwise and hold

2.Depress lever retainer with push pin tool (provided)

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

11

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 14

Keypad 10 Line Lock

Washers

(only 30- prefix)

C

ylinder

r

etainer

Cylinder

O

utside

lever

K

ey

C

ylinder

s

pacer

How to Change Cylinder (if required)

1. With outside lever in handuse standard pliers; pull out

cylinder retainer

2. Remove key and cylinder from lever

3. Insert new cylinder

4. Secure by pressing cylinder retainer

flush with shelf*

* NOT SHOWN

6

Programming Instructions

The 10 Line Keypad Lock can support 100 users. Each user is assigned a User Number in addition to

the code used for entry.

Example:

USER USER USER CODE*

TYPE NUMBER (2-6 DIGITS)

Master 01 1 2 3 4

Supervisor 03 3 0 3 0 3 0

Standard 04-97 2 6 5

Special Factory 98

10 Sec. Time Preset 99 1 3 6 8

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

12

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 15

Keypad 10 Line Lock

6

Programming Instructions (Continued)

This Keypad 10 Line Lock has 99 User Codes available for programming purposes.

• The Master Code is always User “01”. The Master Code assigns the Emergency and Supervisory Codes.

It is also used for programming. Users are deleted through the Master Programming Code only.

• The Emergency Code is always User “02”. The Emergency Code has an unlock time of 10 seconds.

• The Supervisory Code is always User “03”. The Supervisory Code allows temporary lockout of selected

users, changes duration of unlock time, requests infrared interrogation output, and may add additional

User Codes.

• The first User Code will be User “04” or higher. User numbers do not have to be used or entered

sequentially.

• User codes “98” and “99” have a factory-set unlock time of ten seconds. This allows a handicapped person

extra time which would not be required by other users.

To Begin Programming:

The Keypad 10 Line Lock is preset at the factory with Master Code “1234”. Entering 1234 * will unlock

the lock allowing the lever handle to retract the latchbolt.

Initial Set-Up Procedures:

• The following are typical procedures to follow when setting up your KP10G77 Keypad.

• If a mistake is made during any of procedures, depress the “*” several times until the yellow LED goes out.

• If no keystroke is made in a 30 sec. time frame, the programming up to that point will default and you will

have to start over.

All of the following procedures start with 99#.

If after the last “*” is depressed, the yellow LED does not go out, depress “*” once more.

Change Master Code:

• 1234* (Yellow LED Begins to Blink Slowly) This example uses the Factory Default Master Code

• 50# 1# 01# New Master Code* (Yellow LED Blinks Quickly)

• New Master Code* (Yellow LED Blinks Slowly) *(Yellow LED Goes Out)

To Enter the Emergency Code: (Unlock Duration is Factory Set at 10 Sec)

• Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# 02# Emergency Code* (Yellow LED Blinks Quickly)

• Emergency Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)"

To Enter the Supervisory Code:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# 03# Supervisory Code* (Yellow LED Blinks Quickly)

• Supervisory Code* (Yellow LED Blinks Slowly) *(Yellow LED Goes Out)

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

13

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 16

Keypad 10 Line Lock

All of the following procedures start with 99# (continued).

If after the last “*” is depressed, the yellow LED does not go out, depress “*” once more.

To Enter a User Code:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 1# User Number (04-97)# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly)* (Yellow LED Goes Out)

To Enter a Passage (Maintained Mode) Code: When Passage Mode is used, the same User Code

must be used to Re-lock the Lock.

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 2# User Number (04-97)# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly)* (Yellow LED Goes Out)

To Enter a One Time User Code:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 50# 3# User Number# User Code* (Yellow LED Blinks Quickly)

• User Code* (Yellow LED Blinks Slowly) * (Yellow LED Goes Out)

To Deactivate “Beep” With the Depression of Each Key:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 30# 0# 0# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (No Beep on Depression and Yellow LED Blinks Slowly)

• * (No Beep on Depression and Yellow LED Goes Out)

To Reactivate “Beep” With the Depression of Each Key:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 30# 0# 1# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (Beep on Depression and Yellow LED Blinks Slowly)

• * (Beep on Depression and Yellow LED Goes Out)

To Clear the Entire Memory:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 46# 00000# 00000# (Yellow LED Continues to Blink Slowly)

• * (Yellow LED Blinks Quickly)

• * (No Beep on Depression and Yellow LED Goes Out)

• PAUSE, Yellow LED Begins to Blink Again

• * (Yellow LED Goes Out)

Note: This Deletes ALL Codes, including Master, Emergency and Supervisory. The Master Code is set back to

1234, Door Number to 0001 and Unlock time 5 Sec. If the Master Code is not known, Factory Assistance will be

required to clear the memory. 1-800-810-WIRE.

To Program Door Numbers into Keypad:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 43# 0# Door Number# (must be four digits) (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blink Slowly)

• * (Yellow LED Goes Out)

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

14

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 17

Keypad 10 Line Lock

Sargent also offers a Data Transfer Device (DTD) To Interrogate the lock.

Go to WWW.SARGENTLOCK.COM for information.

All of the following procedures start with 99# (continued).

If after the last “*” is depressed, the yellow LED does not go out,

depress “*” once more.

To Interrogate Transaction Log:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 70# 0# 0# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Goes Out)

For additional information, see “Transaction Log”.

Door #5666

Note: Seq. # 1 is the

programming request

to output the entries.

Sequence numbers

2-6 are the actual

entries.

Door

Number

Transaction

Number

Seq User Trans

1 001 003

2 003 001

3 003 001

4 020 001

5 003 001

User

Number

Transaction

type

To Reset / Clear Transaction Log:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 76# 00000# 00000# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Goes Out)

Hold an infrared printer up to the

red infrared LED (as shown). An

HP82240B Infrared Printer can

be used to download information

from the keypad to a printout.

To Delete a User Number:

• Master Code* (Yellow LED Begins to Blink Slowly)

• User Number# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

To Disable / Enable a User Number:

• Supervisory or Master Code* (Yellow LED Begins to Blink Slowly)

• 56# 0# = Enable, 1# = Disable, User Number# (04-99) (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

To Set Unlock Time:

• Master Code* (Yellow LED Begins to Blink Slowly)

• 85# Time Duration# (01-99 Sec) 0# (Yellow LED Blinks Slowly)

• * (Yellow LED Begins to Blink Quickly)

• * (Yellow LED Blinks Slowly)

• * (Yellow LED Goes Out)

Note: The Unlock Time is Adjustable for Momentary Operation. A 5 second unlock time is recommended to

extend battery life. Once the unlock time is entered, it is the same for ALL users except 02, 98 and 99 which are

factory set for 10 seconds.

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

15

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 18

Keypad 10 Line Lock

Chain Programming

When programming multiple User Numbers and Codes into the

10 Line Keypad Lock, it is not necessary to leave and re-enter the

programming mode (50) for each entry. Multiple entries may be chained

together and the three different types of user codes (Standard, Passage

and One Time) may be mixed.

The format to be used is as follows where:

“T” is the Type of user code with “1” Standard, “2” Passage and “3” One Time.

“UN_” is User Number (04-99)

“UC_” is User Code (2 to 6 digits) which correlates with the User Number 99# Master or Supervisor

Code* 50# Type# User Number a# User Code a*

User Code a* T# UNb# UCb* UCb* T# UNc# UCc* UCc* ...... T# UN_# UC_* UC_**

An example with four user codes is shown below:

Type User Number User Code

1 05 875

3 12 2226

2 08 5444

1 50 3367

Using Master Code 4732 and above information, the lock would be programmed as follows:

99# 4732* 50# 1# 05# 875* 875* 3# 12# 2226* 2226* 2# 08# 5444* 5444* 1# 50# 3367*

3367**

If all user codes are the same type, it is not necessary to enter the type number with each

entry. The type number has to be entered with the first user code only.

The format now simplifies to:

99# Master or Supervisor Code* 50# Type# User Number a# User code a* User Code a*

UNb# UCb* UCb* UNc# UCc* UCc*....... UN_# UC_* UC_**

An example with three user codes is shown below:

Type User Number User Code

1 07 77

1 15 67832

1 91 7568

Using Master Code 45988 and above information, the lock would be programmed as follows:

99# 45988* 50# 1# 07# 77* 77* 15# 67832* 67832* 91# 7568* 7568**

To chain the User Number delete procedure:

99# Master Code* User Number a#** UNb#** UNc#**....... UN_#****

Using the information from the above example:

99# 45988* 07#** 15#** 91#****

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

16

12/15/07 © SARGENT Manufacturing Company 2005, 2007. All rights reserved.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 19

Keypad 10 Line Lock

To output the last 15 entries, enter 99 # Supervisory or Master Code * 70 # 0 # 0 # **.

Note: Seq. # 1 is the

programming request to output

7

Transaction Log

Door Number

• 4 Digits

• Up to 9999 different doors, assigned by user

Transaction Number

• Single digit - 1-6

• Latest transaction - 1

• Oldest transaction - 6

User Number

• Three digits - 001 through 099

• User numbers assigned at time of programming

Transaction Types

• 001 =Access granted

• 003 = Log printed

Optional Equipment

Door

Number

Transaction

Number

the entries. Sequence numbers

2-6 are the actual entries.

Door #5666

Seq User Trans

1 001 003

2 003 001

3 003 001

4 020 001

5 003 001

Hold an infrared printer up to the

red infrared LED (as shown). An

HP82240B Infrared Printer can

be used to download information

from the keypad to a printout.

User

Number

Transaction

type

• Printer Paper (6 Rolls) - 52-0034 used for infrared printers

• Auxiliary Power Unit (APU) 52-2065 - used to unlock unit if

batteries are too weak and cylinder is not used.

• Infrared Printer - 52-2069 - used to download the user and

transaction type.

• Remote Unlocking - 52-2071 - used for remote unlocking

of keypad 10 Line Lock. When remote unlocking feature is

used, the latchbolt can be retracted by turning the lever

handle. Use a QC2A Hinge.

ElectroLynx

As part of their promise to provide innovative, fast and effective high

security solutions to their customers, ASSA ABLOY Group companies

offer ElectroLynx

electrification of the door opening.

ElectroLynx

®

®

, a universal quick-connect system that simplifies the

®

is a registered trademark of ASSA ABLOY Inc.

Remote

unlocking

connector

placement

TB-2

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

17

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 20

Keypad 10 Line Lock

Serrure à clavier KP10G77

Guide de programmation

La serrure à clavier KP10G77 peut accomoder 100 utilisateurs. On doit assigner à chacun un numéro

d’utilisateur, en plus de son code d’entrée.

Example:

Type d’usager Numéro d’usager Code d’usager

(2 à 6 chiffres)

Maître 01 1 2 3 4

Urgence 02 2 2 2 2 2

Superviseur 03 3 0 3 0 3 0

Ordinaire 04 à 97 2 6 5

Spécial usine 98

10 secondes 99 1 3 6 8

99 codes d’utilisateurs disponibles à la programmation

• Le code maître est toujours l’utilisateur programmation. Les utilisateurs sont

• Le code d’urgence est toujours l’utilisateur temps de déverrouillage de 10 secondes.

• Le code superviseur est toujours modification du temps de déverrouillage,

• Le premier code d’utilisateur sera

• Les codes ‘’98’’ et ‘’99’’ établis en les personnes handicapées.

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

18

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 21

Keypad 10 Line Lock

Pour commencer :

Le code maître établi en usine est “1234’’. Appuyer sur 1234* déverrouille la serrure, permettant au

levier de retirer le pêne.

Codification initiale :

Dans une séquence typique de programmation, le voyant jaune clignotera doucement après l’entrée

du code maître ou superviseur suivi de “ * ”. Il continuera jusqu’à l’entrée du nouveau code suivi de

“ * ”. Il clignotera ensuite rapidement jusqu’à l’entrée de “ * ”. Si le voyant reste allumé, sans clignoter,

durant la programmation, il y a eu une erreur de programmation et la séquence doit être

recommancée.

Pour changer le code maître

Entrer : 99 # 1234 * 50 # 1 # 01 # Nouveau code maître suivi de * Nouveau code maître suivi de * *

Pour entrer le code d’urgence :

Entrer : 99 # Code maître suivi de * 50 # 1 # 02 # Code d’urgence * Code d’urgence * *

Remarque : La durée de déverrouillage est réglée en usine à 10 secondes.

Pour entrer le code superviseur :

Entrer : 99 # Code maître suivi de * 50 # 1 # 02 # Code d’urgence * Code d’urgence * *

Entrer : 99 # Code maître suivi de * 50 # 1 # 03 # Code superviseur suivi de * Code superviseur suivi de * *

Pour entrer un code d’utilisateur :

Entrer : 99 # Code maître ou superviseur suivi de * 50 # 1 # Code d’utilisateur (entre 04 et 97) suivi du

# et du code d’utilisateur suivi de * Code d’utilisateur suivi de *

Pour entrer un code passage (fonction maintenue) :

Entrer : 99 # Code maître ou superviseur suivi de * 50 # 2 # Numéro d’utilisateur (entre 04 et 97) suivi

du # et code d’utilisateur suivi de * Code d’utilisateur suivi de * *

Le même code devra être utilisé pour reverrouiller la serrure.

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

19

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 22

Keypad 10 Line Lock

Pour entrer un code servant une fois seulement :

Entrer : 99 # Code maître ou superviseur suivi de * 50 # 3 # Numéro

d’utilisateur suivi du # et code d’utilisateur suivi de * Code d’utilisateur suivi

de * *

Pour annuler la tonalité entendue en appuyant sur les touches :

Entrer : 99 # Code maître ou superviseur suivi de * 30 # 0 # 0 # * * *

Pour remettre la tonalité entendue en appuyant sur les touches :

Entrer : 99 # Code maître ou superviseur suivi de * 30 # 0 # 1 # * * *

Pour effacer entièrement la mémoire :

Entrer : 99 # Code maître suivi de * 46 # 00000 # 00000 # * * <PAUSE> *

Remarque : Ceci annule tous les codes, incluant les codes maître et superviseur.

Le code maître redevient 1234, le numéro de porte 0001 et le temps de déverrouillage 5 secondes.

Pour programmer les numéros de porte :

Entrer : 99 # Code maître suivi de * 43 # 0 # Numéro de porte (doit être quatre chiffres) suivi de # * * *

Pour lire le rapport des activités :

Entrer : 99 # Code maître ou superviseur suivi de * 70 # 0 # 0 # * *

Pour effacer le rapport des activités :

Entrer : 99 # Code maître suivi de * 76 # 00000 # 00000 # * *

Remarque : Après chaque programmation, le voyant jaune devrait arrêter de clignoter.

S’il clignote toujours après la dernière * , appuyer de nouveau sur *.

Pour annuler un numéro d’utilisateur :

Entrer : 99 # Code maître suivi de * Numéro d’utilisateur suivi de # * * * *

Pour annuler un numéro d’utilisateur :

Entrer : 99 # Code maître suivi de * Numéro d’utilisateur suivi de # * * * *

Pour invalider et réactiver un numéro d’utilisateur :

Entrer : 99 # Code maître ou superviseur suivi de * 56 # choix # numéro d’utilisateur (04 à 99) suivi de # * *

A noter : choix 0 = réactive, 1 = invalide,

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

20

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 23

Keypad 10 Line Lock

Pour fixer le temps de déverrouillage :

Entrer : 99 # Code maître suivi de * 85 # Durée suivie de # 0 # * * *

Remarque : Le temps de déverrouillage est réglable entre 01 et 99 secondes. On recommande 5

secondes pour prolonger la durée des piles. Le temps sera le même pour TOUS les utilisateurs, sauf

02, 98 et 99 qui sont pré-réglés en usine à 10 secondes.

Programmation en chaîne

Pour programmer des numéros et des codes d’utilisateurs multiples, il n’est pas nécessaire de quitter

le mode de programmation (50) entre chaque entrée. On peut entrer un après l’autre, en désordre, les

trois différents types de codes d’utilisateurs (ordinaire, passage et une fois).

Le format à suivre est le suivant :

‘’T’’ est le type de code d’usager, soit ‘’1’’ pour ordinaire, ‘’2’’ pour passage et ‘’3’’ pour une fois.

‘’UN_’’ est le numéro d’utilisateur (entre 04 et 99)

‘’UC_’’ est le code d’utilisateur (de 2 à 6 chiffres) qui correspond au numéro d’utilisateur.

99# Code maître ou superviseur * 50# Type# Numéro d’utilisateur a# Code d’utilisateur a *

Code d’utilisateur a * T# Unb# Ucb * Ucb * T# Unc# Ucc * Ucc * ..... T# UN_# UC_ * UC_ **

Ceci est un exemple de quatre codes d’utilisateurs :

Type Numéro d’utilisateur Code d’utilisateur

1 05 875

3 12 2226

2 08 5444

1 50 3367

En utilisant le code maître 4732 et les renseignements ci-dessus, la programmation de la serrure serait

la suivante :

99# 4732* 50# 1# 05# 875* 875* 3# 12# 2226* 2226*

2# 08# 5444* 5444* 1# 50# 3367* 3367**

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

21

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 24

Keypad 10 Line Lock

Il n’est pas nécessaire d’entrer le numéro de type à chaque entrée si tout les codes d’utilisateurs sont

du même type. Le numéro de type doit être entré avec le premier code d’utilisateur seulement.

Le format sera donc simplifié:

99# Code maître ou superviseur* 50# Type# Numéro d’utilisateur a#

Code d’utilisateur a* Code d’utilisateur a* Unb# Ucb* Ucb* Unc#

Ucc* Ucc* ..... UN_# UC_* UC_**

Ceci est un exemple de trois codes d’utilisateurs :

Type Numéro d’utilisateur Code d’utilisateur

1 07 77

1 15 67832

1 91 7568

En utilisant le code maître 45988 et les renseignements ci-dessus, la programmation de la serrure sera

la suivante :

99# 45988* 50# 1# 07# 77* 77* 15# 67832* 67832* 91# 7568* 7568**

Pour annuler en chaîne les numéros d’usagers :

99# Code maître * Numéro d’utilisateur a#** Unb#** Unc#** ... UN_#****

En utilisant les renseignements de l’exemple ci-dessus :

99# 45988* 07#** 15#** 91#****

A T T E N T I O N

Bien vérifier le branchement entre le clavier extérieur et la plaque du

côté intérieur de la porte. Toutes les broches doivent être bien en

place pour que le clavier fonctionne. Voir étape 6A du manuel

illustré.

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

22

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

800-810-WIRE (9473) • www.sargentlock.com • A7113E

Page 25

Keypad 10 Line Lock

To output the last 15 entries, enter 99 # Supervisory or Master Code * 70 # 0 # 0 # **.

Note: Seq. # 1 is the

7

Transaction Log

Door Number

• 4 Digits

• Up to 9999 different doors, assigned by user

Transaction Number

• Single digit - 1-6

• Latest transaction - 1

• Oldest transaction - 6

User Number

• Three digits - 001 through 099

• User numbers assigned at time of programming

Transaction Types

• 001 =Access granted

• 003 = Log printed

Optional Equipment

Door

Number

Transaction

Number

programming request to output

the entries. Sequence numbers

2-6 are the actual entries.

Door #5666

Seq User Trans

1 001 003

2 003 001

3 003 001

4 020 001

5 003 001

User

Number

Hold an infrared printer up to the

red infrared LED (as shown). An

HP82240B Infrared Printer can

be used to download information

from the keypad to a printout.

Transaction

type

• Printer Paper (6 Rolls) - 52-0034 used for infrared printers

• Auxiliary Power Unit (APU) 52-2065 - used to unlock unit if

batteries are too weak and cylinder is not used.

• Infrared Printer - 52-2069 - used to download the user and

transaction type.

• Remote Unlocking - 52-2071 - used for remote unlocking

of keypad 10 Line Lock. When remote unlocking feature is

used, the latchbolt can be retracted by turning the lever

handle.

Remote

unlocking

connector

placement

A7113E • 800-810-WIRE (9473) • www.sargentlock.com

23

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

8/14/08 Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Page 26

Founded in the early 1800s, SARGENT®is a market leader in locksets, cylinders, doorclosers, exit devices,

electro-mechanical products and access control systems for newconstruction, renovation, and replacement applications.

The company’s customer base includes commercialconstruction, institutional, and industrial markets.

Copyright © 2005,2007,2008, SARGENT Manufacturing, an ASSA ABLOY Group company. All rightsreser ved.

Reproduction in wholeor in part without the express written permissionof SARGENT Manufacturing is prohibited.

ASSA ABLOYis the global leader in dooropening solutions, dedicated to

satisfying end-user needs forsecurit y, safety and convenience.

A7113E-8/08

Loading...

Loading...