Page 1

INSTALLATION INSTRUCTIONS

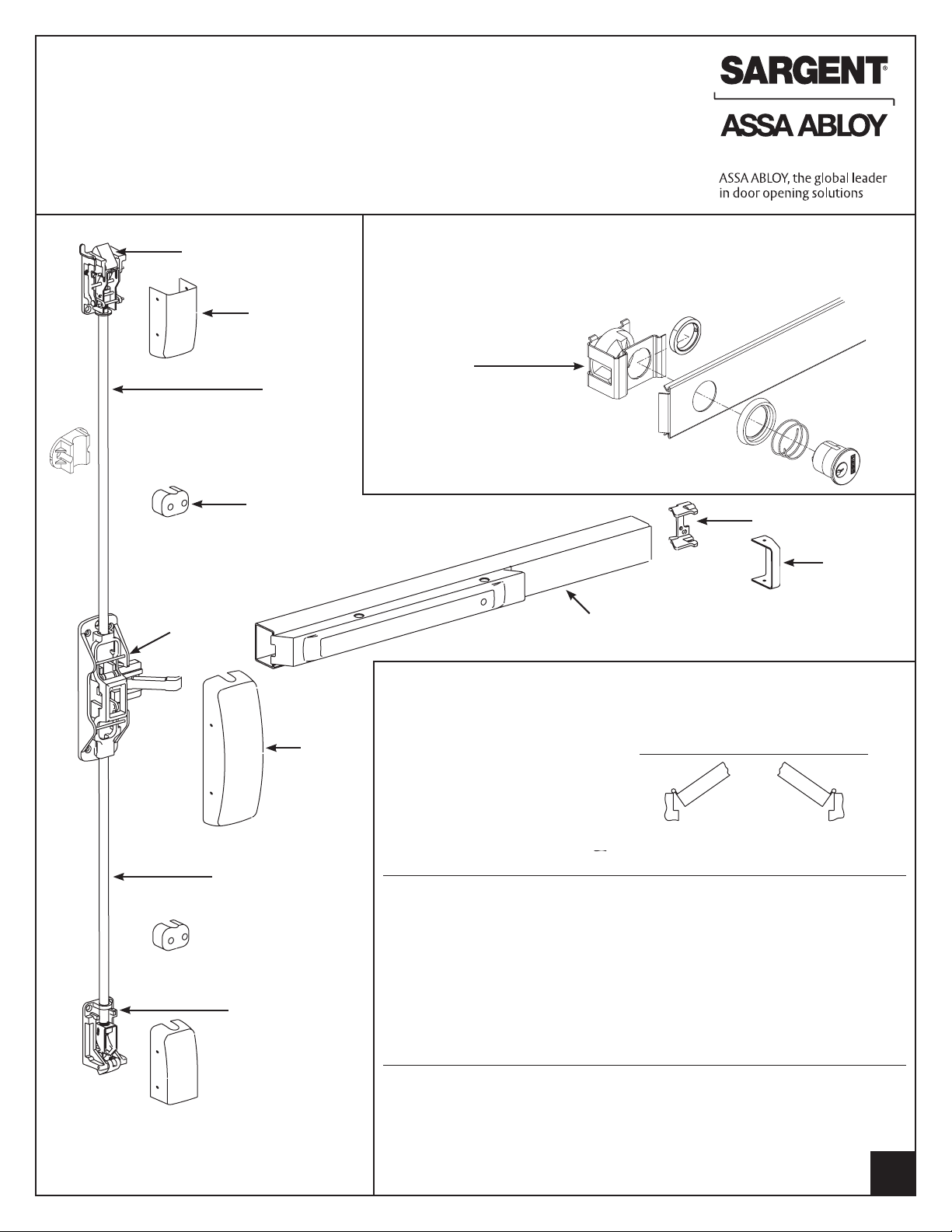

8700, 12-8700, HC8700 & HC4-8700

SURFACE VERTICAL ROD EXIT DEVICE

U.S. Patent No. 268,003 Canadian Patent No. RD 1981

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

Top case

Chassis

Top cover

Top rod

Rod guide

CYLINDER DOGGING (16- PREFIX)

For complete assembly

information see

Instruction Sheet A6848

Must be installed

with opening in

plastic cam

TO OPERATE:

• Depress push rail

• Insert key and turn counterclockwise to lockdown

(dog) push rail

Slide mounting rail insert with cylinder

dogging (16- prefix) into mounting rail

End cap bracket

End cap

Push rail assembly

CAUTION: CHECK BEFORE STARTING DOOR PREP

Door should be tted and hung.

Check box label for size of exit device, function, hand and design.

Chassis

cover

Bottom rod

Bottom

case

Standard 8700 Exit Shown

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

Surface of the door must

be flush. Clear away any

raised projections to allow

exit device to rest on flat

surface of the door.

AVAILABLE STOCK LENGTHS

Length “E”: 32" door, no cut off required.

Can be cut to fit doors down to 24" wide.

Length “F”: 36" door, no cut off required.

Can be cut to fit doors down to 33" wide.

Length “J”: 42" door, no cut off required.

Can be cut to fit doors down to 37" wide.

Length “G”: 48" door, no cut off required.

Can be cut to fit doors down to 43" wide.

TOOLS REQUIRED

1. Measuring tape

2. Power drill

3. Drill bits: #7, #16, #25, 3/32", 1/4",

11/32", 3/8", 25/64", and 3/4"

4. Taps: #10-24, #12-24, 1/4"-20 and

7/16"-20

THIS EXIT DEVICE IS HANDED

OUT

5

Right hand

reverse bevel

5. Hacksaw or any power cutter (to cut

rail if necessary)

6. Screwdrivers: Phillips #2 and #3

7. Hex Wrenches: 3/16" and 3/8"

8. Level

Left hand

reverse bevel

A6701L

11-30-11

1

Page 2

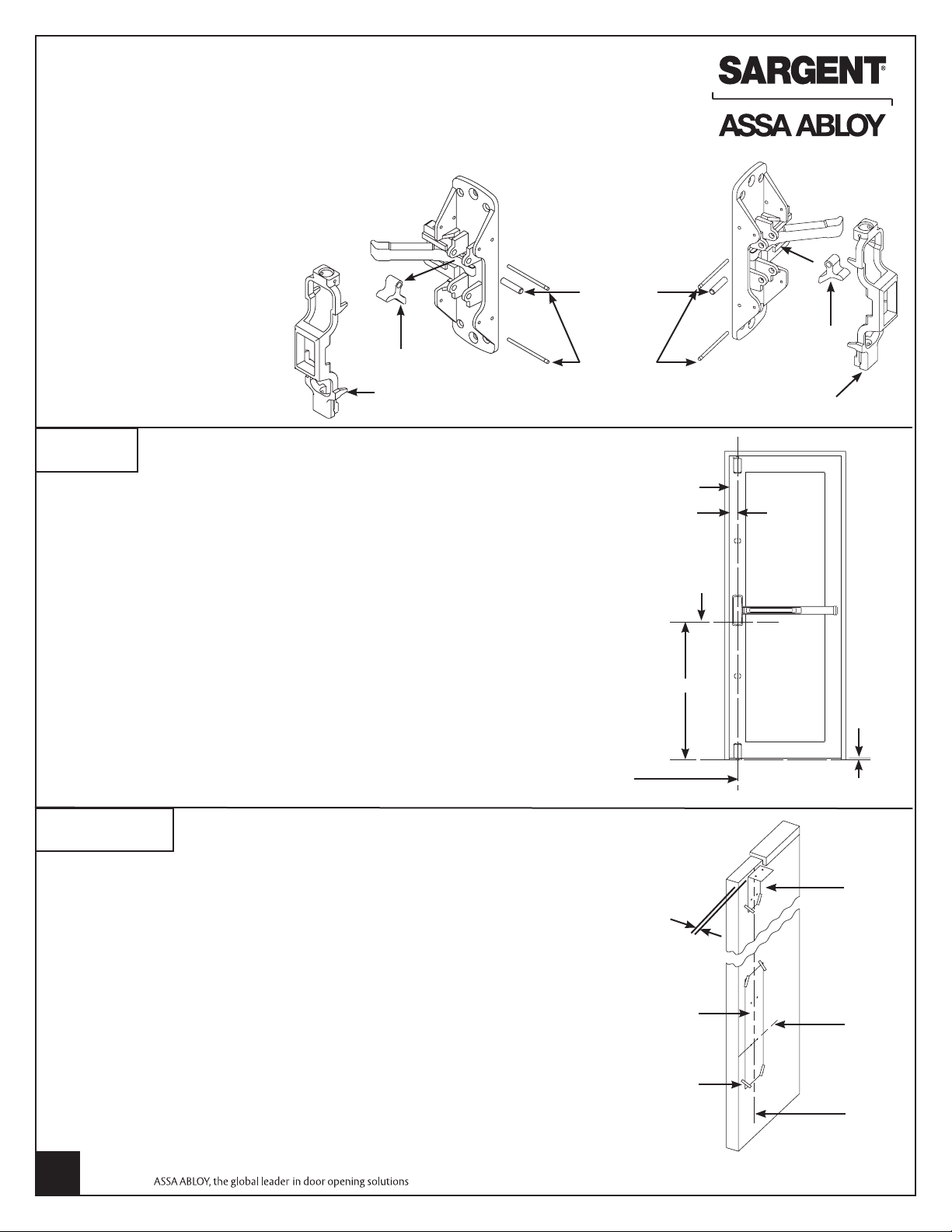

All 8700 series exit devices are handed except the 8710, which is eld reversible.

The 8710 is shipped as LHR unless ordered as RHR.

TO CHANGE HAND OF 8710 EXIT DEVICE:

1. Remove both chassis pins and main slide.

2. Remove lift lever pin and lift lever.

3. Rotate chassis 180° and reposition lift lever

and lift lever pin as shown.

4. Position main slide with large end of

Chassis

main slide at the bottom and retain

with chassis pins.

Lift lever pin

Lift lever

Main slide

Large end

Right Hand

Reverse

Chassis pin

Left Hand

Reverse

Lift lever

Main Slide

Large end

FIRST

MARK VERTICAL AND HORIZONTAL

REFERENCE LINES ON DOOR

WITH DOOR CLOSED:

1. Determine dimension “A” to locate vertical reference line.

If door stile is 4-1/2" wide or wider, “A” is 2-3/4".

If door stile is less than 4-1/2", “A” is 1/2 the exposed

width of the door stile when the door is closed against the stop.

2. Standard rail centerline height is 41" above the finished floor.

Horizontal reference line is 37-5/8" standard.

(Location of lower chassis mounting holes)

Vertical reference line

(CL chassis, top and bottom case)

SECOND

WITH DOOR CLOSED:

1. Tape template for Chassis/Trim on inside of door, along vertical and

horizontal reference lines.

2. Fold top case template and tape on inside of door along vertical

reference lines.

3. Spot and drill all holes from inside of door.

4. Mortise pockets for outside trim, if required. See trim installation

instructions supplied with trim for details.

NOTE: Any holes drilled from the outside need pilot holes drilled

from the inside to ensure good alignment.

NOTE: For electrical trim applications, ensure access to a race-

way from the trim to the electric hinge or armored door loop.

A6701L

2

11-30-11

PREPARE DOOR

Door

Stop

“A”

Inside

Horizontal

reference

line

37-5/8"

Stop

thickness

Chassis/Trim

Template

Tape (supplied)

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

face of

door

Finished floor

Top case

template

Horizontal

reference

line

Vertical

reference

line

Page 3

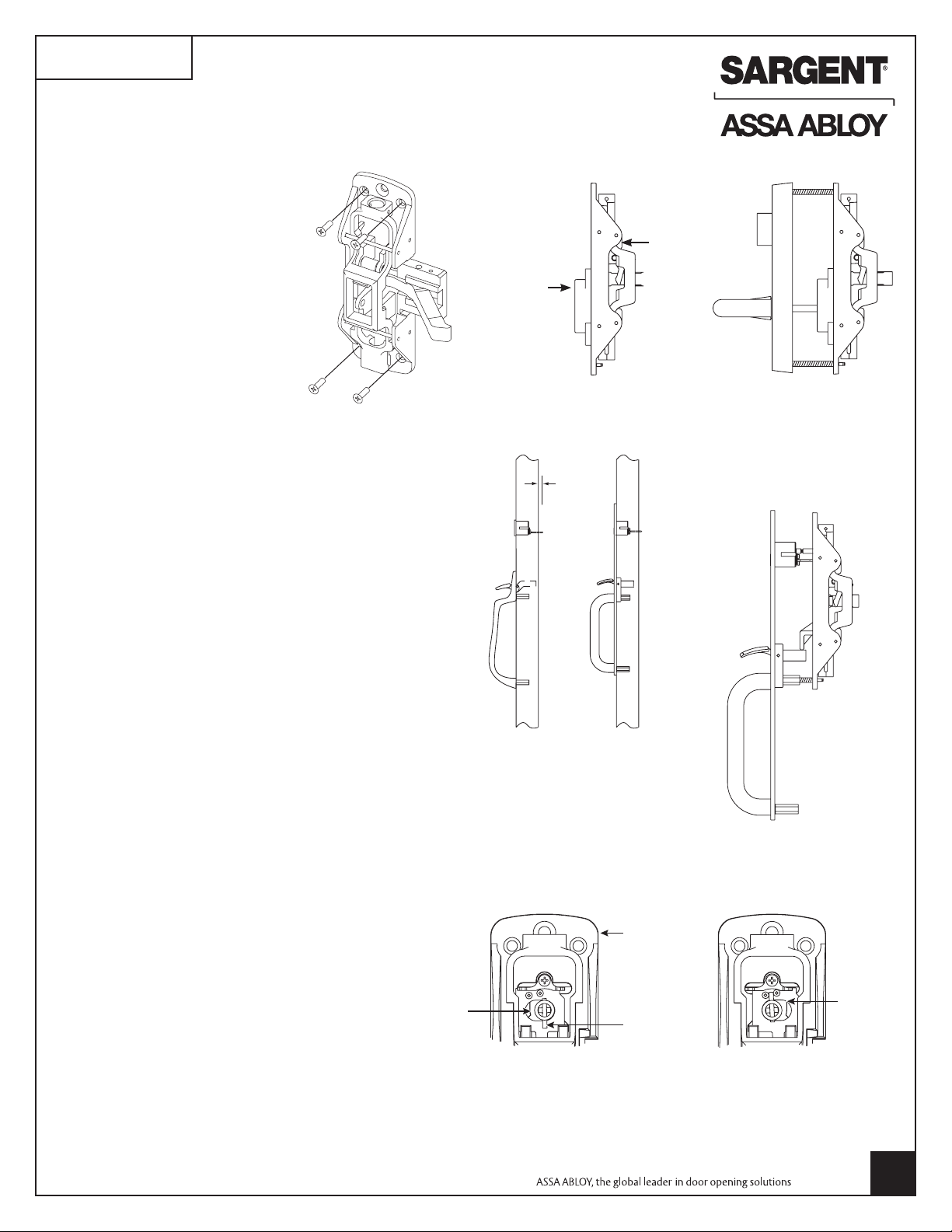

THIRD

APPLY CENTER CHASSIS AND TRIM

700 SERIES ET TRIM:

1. Secure chassis to door with (4)

#10 flat head screws using corner

mounting holes.

NOTE: Electrical functions –

see instruction sheet A6374 for

wire connections.

2. Position ET trim on door, align

spindle with bell housing.

3. Through-bolt chassis to ET trim

with (2) 1/4-20 flat head screws.

NOTE: Thumb Trim is not available for HC8700

Series Exit Devices

Chassis

Bell housing

8706 OR 8713 BY

ETJ CONTROL SHOWN

5/16"

800 SERIES THUMB PIECE TRIM:

Determining rim cylinder tail length

FOR FLL, FLW, MAL, STS OR PTB TRIM:

1. Position trim on door (except STS).

2. Insert rim cylinder through trim plate (or cylinder

collar for STS trim).

3. Mark cylinder tail at 5/16” beyond inside door

surface.

4. Remove cylinder and trim from door and cut tail

piece as marked.

APPLY CHASSIS AND TRIM:

1. Hold trim plate to door.

2. Insert cylinder and secure using supplied back plate.

3. Position cylinder hub with in the chassis to correct

position for desired function (see drawings).

4. Position chassis on door, align cylinder tail with hub

and secure chassis to door with (4) #10 flat head

screws using the corner mounting holes.

5. Through-bolt chassis to trim with 1/4-20 flat head

screws and to door with cup washer and 1/4-20

flat head screw.

Cylinder

hub

NOTE:

STS, FLL, FLW and MAL thru-bolt to chassis

with (1) 1/4-20 at head screw.

PTB trim through-bolts to chassis with (2) 1/4-20

at head screws.

STS TRIM

SHOWN

For 8762 long end of pin

faces down. Cylinder turns

180° in both directions.

FLL TRIM

SHOWN

8762 OR 8763

BY FLW SHOWN

Chassis

Hub pin

down for

62 function

For 8763 long end of pin

faces up. Cylinder turns

360° to the left or right.

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

A6701L

11-30-11

3

Page 4

FOURTH

Check box label.

The following prexes are provided “factory cut” to size: AL-, 56-, 57-, 58- and 59-.

If cutting is required, continue with step “A”.

If cutting is not required, proceed to step “B”.

APPLY RAIL ASSEMBLY

A

Determine rail length dimension “X” by subtracting 1-3/4" from dimension “Y”.

TOP VIEW OF EXIT DEVICE

For doors with stile, the rail

must overlap stile by 1/2" or

more

Vertical reference line

(CL of chassis)

1-3/4" min.

“X”

Cut off mark

1. Dog push rail and cut off

at mark.

2. Cut must be straight.

3. For (43-) flush end cap use

cutting guide provided.

4. Remove sharp edges with file.

1. Slide rail assembly over lift arm and onto chassis.

B

2. Attach rail assembly to chassis with two (2)

#8-32 truss head machine screws.

NOTE: DO NOT tighten screws.

Lift arm

Rail mounting screw

(2 places) #8-32 x 3/8 ph.

truss head machine screw

3. Level rail and position mounting plate tight

against rail and attach to door with two (2) #10

round head screws.

4. Tighten all screws securely.

Level

Rail assembly

Mounting

plate

Mounting plate

screws (#10-24 x

3/4" ph. rd. head

machine screw)

FIFTH

1. Verify rail is not dogged.

2. Screw rod into top case until finger tight.

3. Slide top rod into main slide – do not pin in place.

4. Attach top case as located in second step.

Through-bolts required and supplied for re rated top cases on wood doors.

5. Unscrew top rod until the center hole is aligned with the hole in the main slide.

6. Insert rod adjustment pin.

A6701L

4

11-30-11

MOUNT TOP CASE

Rod adjustment pin

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

Page 5

SIXTH

2-ISOMETRIC

MOUNT BOTTOM CASE

1. Verify rail is not dogged.

2. Screw rod into bottom case until finger tight.

3. Slide bottom rod into main slide.

4. Insert adjustment pin into middle hole.

5. Position bottom case on door, centered on vertical reference line.

Raise or lower to achieve gap indicated for strike application

(see drawings below).

6. Drill and tap mounting holes.

7. Mount bottom case. Tighten fasteners securely.

Rod

adjustment

pin

1/4" Min.

MORTISE APPLIED STRIKES

SEVENTH

ATTACH STRIKES

TOP STRIKES

Mount top strike in position.

Tighten screws securely.

1/8"

SURFACE APPLIED

STRIKES

ATTACH TOP CASE

1/8"

LATCH TRACK THRESHOLDS (BY

OTHERS)

NOTE: SHIM TOP STRIKE WHEN NECESSARY

TO OBTAIN 1/8" GAP

(2) #12-24

screws

646

Top Strike

(Panic & Fire Rated)

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

(Panic & Fire Rated)

(4) #12-24

screws

654

HC- Top Strike

Panel Strike

648

Transom

(2) #10-24

screws

Note: Use two (2) No. 10 steel screws and mortise

nuts (when provided) in the position illustrated in

the top case. Steel mortise nuts are twin knurled

for identification.

A6701L

11-30-11

5

Page 6

SEVENTH

ATTACH STRIKES (Continued)

BOTTOM STRIKES

For thresholds with integral strikes, skip to next step.

For surface applied strikes 624 or 653:

WITH DOOR CLOSED:

1. Transfer vertical centerline to floor or threshold and mark.

2. Engage bottom strike with latchbolt and center on line marked.

3. Mark mounting holes.

4. Drill holes for required fasteners.

5. Mount strike with fasteners provided.

6. Tighten screws securely.

For mortised strikes: 636 or 655

Follow steps above. Mark mounting holes and outline of strike.

EIGHTH ADJUST TOP & BOTTOM RODS

ATTACH BOTTOM STRIKES & CASE

624 Bottom Strike

(Panic)

(2) #12-24 screws

653 Bottom Strike

Alternate Strike for

HC-, 12-, 14-

(3)

#1/4-20

screws

Steel Screws

and Mortise

Nut

1. Fine adjustment is made by turning rod into top and bottom

case to shorten or out of top and bottom case to lengthen.

2. Rough adjustment is made by changing hole used for

adjustment pin.

3. Top Rod Adjustments: Push on door as you push on the rail

assembly. As soon as the door opens, release rail, the top bolt

should be in the hold back position. If not, extend top bolt.

Note: the top bolt must go into hold back position prior to the

655 Bottom Strike

(HC, 12- & 14-)

(2) 1/4-20

screws

Note: Use two (2) No. 10

steel screws and mortise

nuts (when provided) in

the position illustrated in

the bottom chase. Steel

mortise nuts are twin

knurled for identification.

door opening.

4. Bottom Bolt Adjustments: Extend bottom bolt for maximum engagement with the bottom strike. When the top bolt

is in, hold back, it also holds the bottom bolt in the retracted position. Always verify that when the bottom bolt is in

the retracted position, that the bolt clears the finish floor by at least 1/8" through the swing of the door.

Be sure that both top and bottom latch bolts are adjusted for maximum engagement

NINTH

ELECTRICAL FUNCTION PREFIXES

To access wire channel in door, drill three (3), 1/4" holes in “U”

shaped cutout of mounting bracket.

59- Prex

Connect switch cable to cable coming from the front of the rail.

Refer to instruction book A7690 for additional wire connections and operating instructions.

AL- Prex

There are no external wire connections unless used with 546 wiring harness.

Refer to instruction book A7224 for operating instructions.

55- Prex

Refer to instruction sheet A6808 for wire connections.

1/4” Holes

56- Prex

Refer to instruction sheet A6876 for wire connections.

57- Prex

Refer to instruction sheet A6810 for wire connections and operating instructions.

58- Prex

Refer to instruction sheet A6835 for wire connections.

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

6

A6701L

11-30-11

Mounting

bracket

Page 7

TENTH

INSTALL GUIDES, COVERS AND END CAP

1. Conrm operation of exit device. Adjust rods as needed.

2. Install top, bottom and center chassis covers as shown.

3. Install end cap as shown.

4. Install top and bottom rod guides at center of rod. Rod must oat freely in guide

without rubbing.

5. For doors over 96": Install two (2) top rod guides equally spaced between the

top case and chassis cover. Rod must float freely in guides.

Top case cover

Rod guide

Chassis cover

End cap

Bottom case cover

Copyright © 2009-2011, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

A6701L

11-30-11

7

Loading...

Loading...