Sargent Fireguard 2900 Series, Fireguard 12-2960, Fireguard 9-2960, Fireguard 2960 Installation Instructions Manual

Page 1

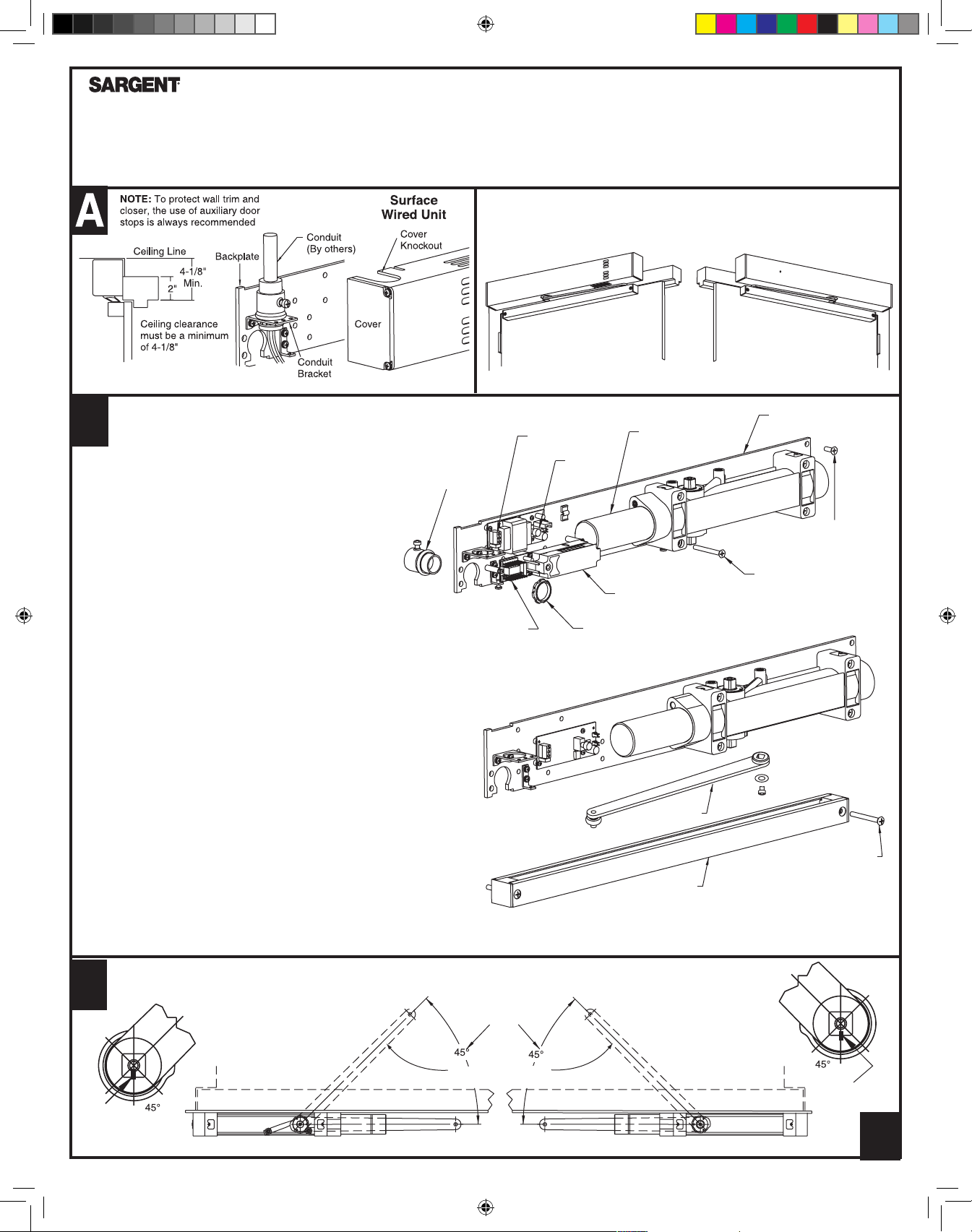

2900 FIREGUARD® Electromechanical Closer-Holder Device Models

B

NOTE:

12-2960, 9-2960 and 2960 Multipoint Hold Open with Rigid Arms

Pull (Hinge) Side Installation Instructions

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE

For assistance, contact SARGENT at 800-810-WIRE (9473) or www.sargentlock.com

FOR MODELS 12-2960 / 9-2960 / 2960

1. Use dimensions shown on page 5 provided to locate

attaching screws on frame and door. Prepare holes

For concealed wire applications only

Locate and drill 1-1/8" diameter hole in the frame face for

3/4" conduit. (This is normally done at the time the frame

is being installed.) Connect conduit to backplate before

fastening backplate to frame

2. Attach backplate/closer assembly to frame. Position backplate

end with terminal strips away from hinge edge of frame

3. Make electrical connections:

A) 12-2960: Select and follow the wiring diagram from wiring

instructions sheet A7408 and 'Checkout Procedure' from Page 3.

B) 9-2960: Make solenoid wire connections with power input wires

from 12-2960 using two wire nuts provided in screw pack. Select

proper wiring diagram and 'Checkout Procedure' from Page 3.

4. Make input power connections to the power supply board as directed.

NOTE: If electrical connections are to be made at a later date,

place cover on chassis now to prevent its loss, see Step F.

3/4" Conduit

(By others)

MODEL

12-2960

RH - Right Hand Door

LHR - Left hand Reverse

Terminal

Strips

On/Off

Switch

Terminal

Strips

Devices are handed

and must be the same

hand as door.

Closer/Holder

Smoke

Detector

Conduit Nut

(By others)

12-2960

MODELS

2960/9-2960

LH - Left Hand Door

RHR - Right Hand Reverse

Backplate

Backplate

Screw (6)

Closer

Screw (4)

5. Installation of arm on closer: With appropriate size wrench, rotate

closer top spindle approximately 45ϒ (see step C below) (NOTE:

Closing both valves for door speed and latching speed makes this

procedure much easier). Position closer arm on bottom spindle

approximately parallel to the door and arm length away from hinge.

Secure arm with screw and washer

6. Installation of track on door: Remove end cap from track. Position

track with open side up. Insert roller end of closer arm in sliding

groove of track. With arm engaged in slide groove, slide track, into

position so that prepared holes on door align with track holes

Replace end cap and secure track to door

Companion unit (without electronics) not shown

Position of Arms and Index Settings

C

View Looking Up When

Assembling Arm to Spindle

Index

Mark on

Spindle

Right Hand Door

2960

9-2960

Approximate

Preload

Position of Main Arm

When Assembled to Spindle

Rigid Arm

Track

View Looking Up When

Assembling Arm to Spindle

Left Hand Door

Track Screw

(2 Reqd)

Index

Mark on

Spindle

A7395C

1

A7395C.indd 1 10/29/18 12:44 PM

Page 2

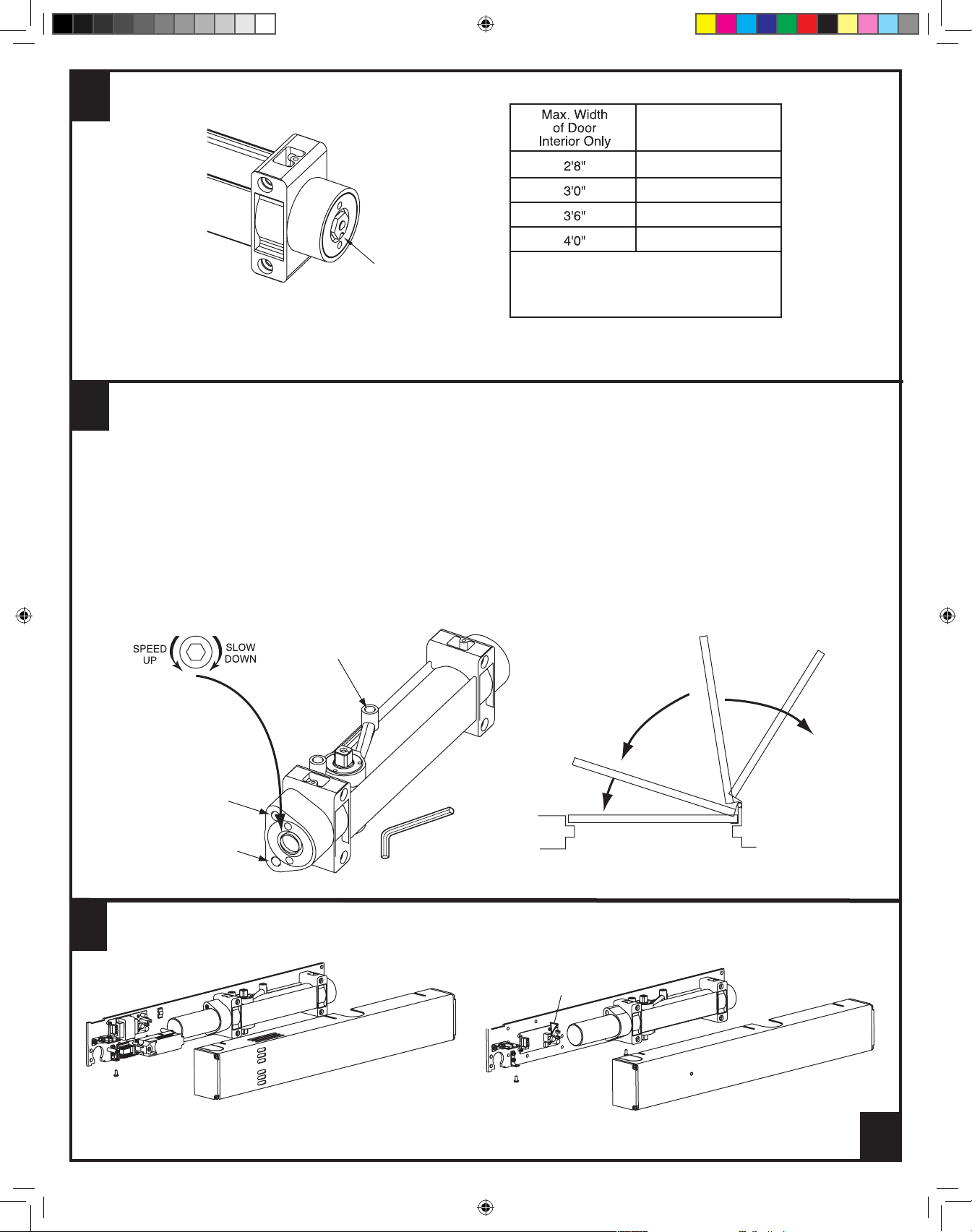

Adjust Spring Power According to Chart

D

Clockwise Turns

of Adjusting Nut

8

8

12

16

5/8 " Adjustment Nut

Tu rn the spring adjusting nut clockwise the required number of turns to match door width as indicated in chart. Where strong drafts exist, increase spring power

as needed. 351 Series door closers leave the factory with the spring adjustment set at eight (8) turns

Maximum adjustment is

approximately 20 turns.

Do not forcibly extend

adjustment beyond limits.

Adjustment Instructions

E

Minimum recommended door closing time is 6 seconds for doors opened to 90 degrees.

Use 1/8" hex (Allen) wrench to adjust valves as needed.

Closing and latching speeds:

Turn valves clockwise to slow down or counterclockwise to speed up door movement.

F

Backcheck:

To regulate the intensity of backcheck action, turn valve clockwise to increase or counterclockwise to decrease checking.

Caution: Set valve for slight cushioning effect. Closer can be damaged if the checking action is too abrupt. Never use the backcheck

as a door stop. Always use a door stop to stop the door.

Backcheck

valve

CLOSING SPEED

RANGE

Closing

speed

valve

Latching

speed

valve

To Install Cover

Adjust closers as directed

in steps D and E

LATCHING SPEED

1/8” HEX SOCKET

WRENCH

1. Assemble (3) short cover screws

(#8-32 x 5/16") into bottom of

closer body and cover mounting

bracket, approx. one turn

RANGE

2. Slide cover onto backplate and

closer assembly. Secure with

three cover screws

BACKCHECK

RANGE

12-2960

CAUTION: Avoid

interference with

electronics and wires

during installation of cover

A7395C.indd 2 10/29/18 12:44 PM

9-2960 Without Electronics not shown

On/Off

Switch

2960

A7395C

2

Page 3

CAUTION

1. DISCONNECT ALL POWER BEFORE BEGINNING INSTALLATION

TO PREVENT ELECTRICAL SHOCK AND EQUIPMENT DAMAGE

2. INSTALLER MUST BE A TRAINED, EXPERIENCED SERVICE

PERSON

Typical Wiring

Stand-Alone Units 2960

• Wire stand-alone unit to appropriate

power supply and fire alarm

• Refer to data sticker for proper

input voltage and current specifications

• Energize power supply

• Open door to hold-open point

Door should hold open

• Depress On/Off Switch. Door should

close and latch

• Adjustment of spring power may be

necessary to ensure proper latching

• Depress on/off switch again. Open door to

hold open position; door will hold open.

CAUTION: Input power supply must match circuit

board voltage rating, either 24VAC/DC or 120VAC.

Optional remote

release connection

3. ALL WIRING MUST COMPLY WITH APPLICABLE LOCAL

ELECTRICAL CODES, ORDINANCES AND REGULATIONS

4. MAXIMUM WIRE SIZE IS 18AWG

Opening for

Concealed Wiring

Appropriate

Power Supply

Data

Sticker

On/Off

Switch

Earth Ground

3

Negative (-)

2

Positive (+)

1

Terminal Strip

for Power Input Connections

A7395C

A7395C.indd 3 10/29/18 12:44 PM

3

Page 4

Checkout Procedure for both 12- and 9- units

1. Turn the power to the unit “On”. Red LED pilot light should illuminate at 8 sec. intervals

2. Open door to the hold open point. The door should hold open. Manually pull door out of hold open and release. Door should close

3. Open door to the hold open position. Depress (maintained type) On/Off “test switch” button on the power supply board. Door should close

4. Depress On/Off test switch again. Open door to the hold open position. Introducing smoke into the smoke detector chamber assembly will bring the unit

into alarm. The red LED will be continuously illuminated and the door will close. After clearing the smoke chamber, reset unit per instructions below

Resetting Instructions

1. Remote Reset: Cycle main power by turning the facility main power supply OFF then ON.

NOTE: If there are other units connected to the same power supply, those doors will close.

They will have to be reopened returning them to the hold open position

2. Local Reset: Insert a small flat head screwdriver through the cover and into the slotted

light tube on the smoke detector as shown. Turn screwdriver slightly (about 1/8 turn)

clockwise until hitting stop and hold for 2 seconds until the Red LED turns OFF

WARNING: Do not force past the stop. Doing so may damage the smoke detector

Once the detector is reset and the smoke has cleared, the detector’s Red LED should flash

once every 8 seconds. The door(s) should hold open now

Smoke Detector Maintenance

SARGENT recommends cleaning smoke detectors at least every six months. The frequency of cleaning will depend upon local ambient conditions

The smoke detector in this door closer-holder has been enhanced with a feature that detects when a smoke-sensing chamber requires cleaning

due to dirt and dust. The need for cleaning is indicated by the flashing of the Red LED light once per second

• Normal Supervisory Operation — Red LED flashes once every 8 seconds

• Dirty Chamber needs cleaning — Red LED flashes once every second

• Smoke Detection — Red LED is continuously illuminated

To clean the smoke detector assembly, follow the instructions below:

NOTE: Before servicing the system, notify the proper authorities

that the smoke detector system is undergoing maintenance

and will be temporarily out of service. Disable the zone undergoing

maintenance to prevent unwanted alarms

• Remove detector cover and screen assembly using a standard screwdriver. Turn the screwdriver in the cover slot to loosen the cover and carefully

rock the cover back and forth until it snaps out of place. See slot location above

• Inspect chamber for particles and dust. Vacuum the screen, cover, and photo chamber. Then, use clean compressed air to loosen and blow out

any remaining debris

• Before reassembling the detector, be sure all parts are free of dust and debris

Chamber

Cover and

screen

Slot for screwdriver

To remove cover

Slotted light tube (Red LED)

RP1 test point

RP2 test point

• Replace cover and screen, aligning cover snaps, press cover onto chamber until it snaps into place

• Measure and record the test voltage at test points RP1 and RP2 (see above). If the smoke detector is operating normally and was cleaned

effectively, the test voltage will be greater than .90VDC and less than 1.58VDC. The test voltage will increase with dust accumulation in the

smoke sensing chamber. A difference in test voltages over time will provide an indication of dust accumulation

• Enable system and inform proper authorities that system is operational

A7395C

A7395C.indd 4 10/29/18 12:44 PM

4

Page 5

A7395C

A7395C.indd 5 10/29/18 12:44 PM

5

Page 6

FIREGUARD

A7395C

A7395C.indd 6 10/29/18 12:44 PM

6

Loading...

Loading...