Page 1

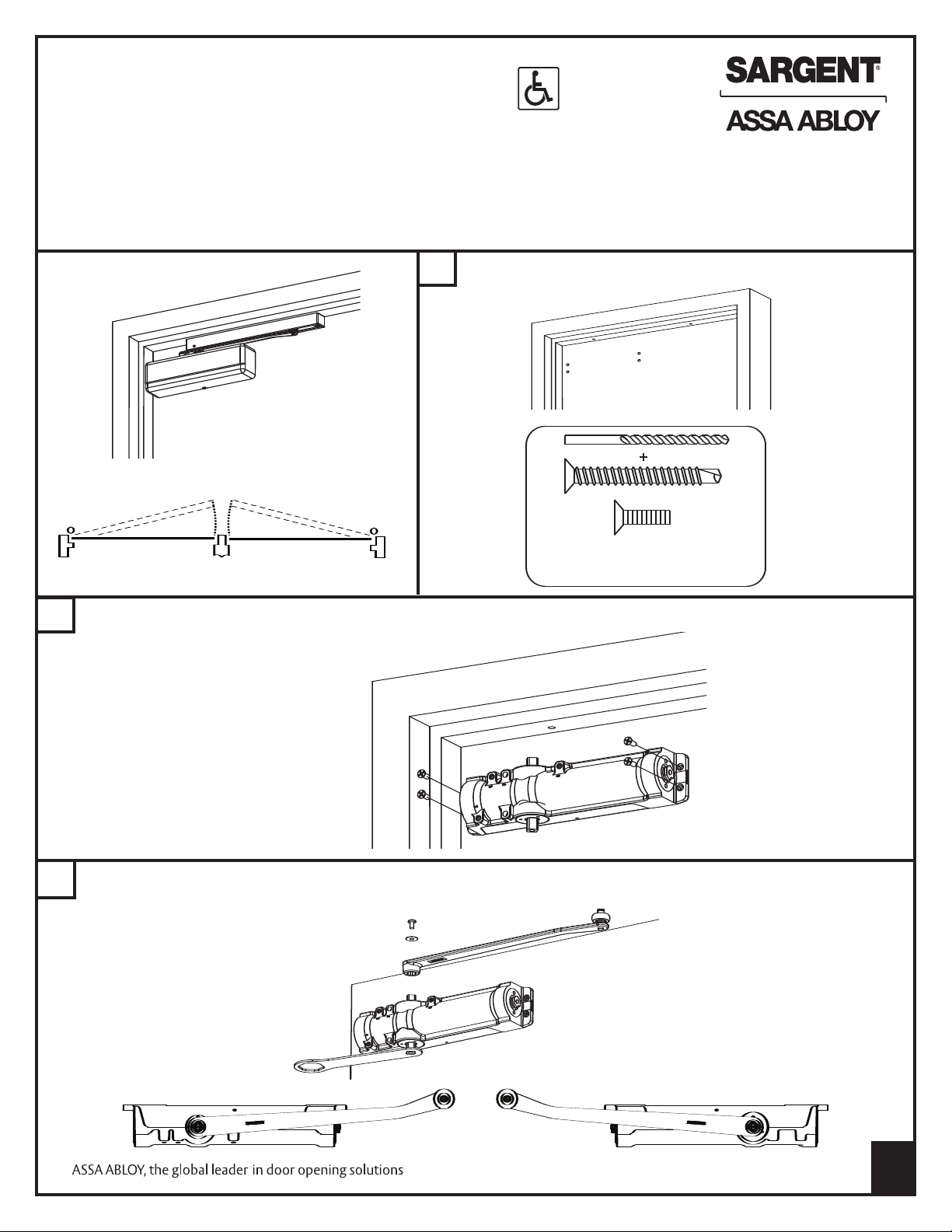

421 CAM ACTION DOOR CLOSER

H

INGE SIDEHINGE SIDE

S

TOP SIDE STOP SIDE

R

IGHT

HAND DOOR

L

EFT

HAND DOOR

(PCTB & PCHTB) PUSH SIDE TRACK

APPLICATION INSTALLATION INSTRUCTIONS

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE

For assistance, contact SARGENT at 800-727-5477 or www.sargentlock.com

NOTE: AN AUXILIARY DOOR STOP IS REQUIRED

MEASURE & MARK HOLES. PREP HOLES USING DIMENSIONS

A

ON PAGE 4

EFT HAND

L

SHOWN

OR

for self tapping screws or #16 drill and tap

WITH PROVIDED FASTENERS, SECURE CLOSER BODY TO DOOR WITH POWER ADJUSTMENT FACING

B

AWAY FROM HINGE SIDE OF DOOR.

When using mortise nuts,

see accessories on page 3

WITH A WRENCH, ROTATE THE BOTTOM SPINDLE TOWARD HINGE APPROXIMATELY 15°. SECURE ARM TO SPINDLE

C

WITH SCREW AND WASHER PROVIDED

Warning: If not properly indexed, door

closer will not operate properly

Left Hand Shown

(Right Hand Opposite)

Pre-drill - 3/32” holes

#12-24 UNC for machine screws

Left Hand

© Sargent Manufacturing Company 2007

Right Hand

A7959A

1

Page 2

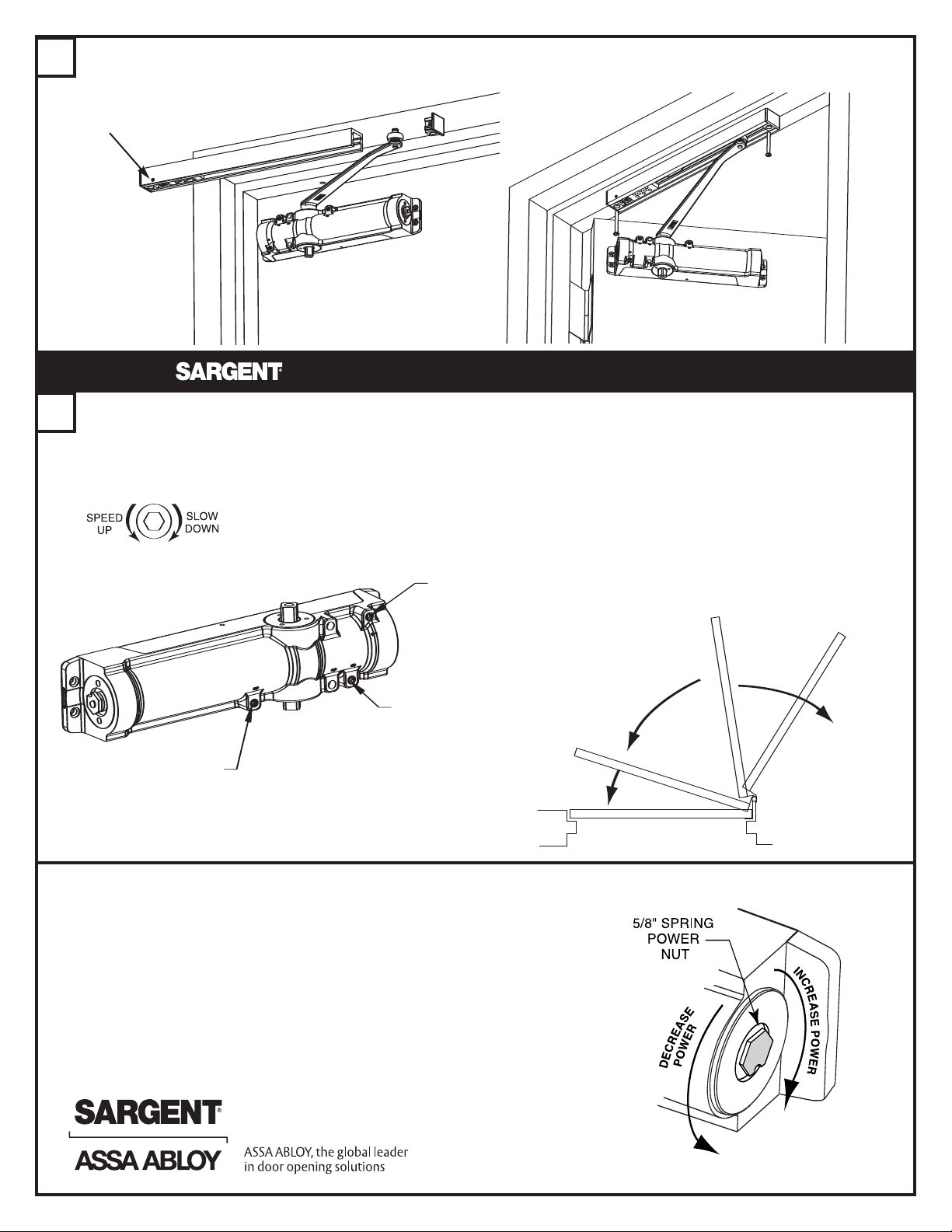

SLIDE TRACK OVER ROLLER AND INSTALL END CAPS. SECURE TRACK TO FRAME WITH SCREWS PROVIDED.

CLOSING SPEED

LATCHING SPEED

BACKCHECK

D

NOTE: ORIENT TRACK SO STOP PIN IS

ON HINGE SIDE OF DOOR

FINAL ADJUSTMENT AND REGULATING PROCEDURE

– Adjust door speed and latching speed valves to achieve the desired closing time. 6 seconds minimum from 90° to the

E

closed position is recommended.

– If backcheck is required, adjust valve to achieve a slight cushioning effect. Auxiliary stop required.

Use 5/32" hex wrench to

adjust valves

CLOSING SPEED

RANGE

LATCHING SPEED

RANGE

ADJUST POWER TO MINIMUM REQUIRED TO RELIABLY CLOSE AND LATCH DOOR

– If door is hard to open, decrease power slightly

– If door does not latch, increase power as required

– Doors adjusted with high closing power to overcome strong

draft conditions may exceed ADA standards.

BACKCHECK

RANGE

421 CLOSERS

FIELD ADJUSTABLE

FOR SIZES 1-6

ARE

© Sargent Manufacturing Company 2007 A7959A

Page 3

HOLD OPEN

MECHANISM

BUMPER

STOP PIN

TENSIONER

F

GAP

Move insert

as needed

Small screw

Long screw

FRAME

UNREINFORCED

DOOR

DOOR STOP

MORTISE NUT

DRILL 3/8" DIA.

HOLE FOR MORTISE

NUT BODY

DRILL 1/4" DIA. HOLE

FOR MOUNTING SCREWS

INSTALL COVER AS FOLLOWS:

1. SCREW SHORT COVER SCREW (#8-35 x 5/16)

INTO TOP OF CASE APPROXIMATELY 2 TURNS

2. ASSEMBLE PLASTIC SUPPORT AND LONG

COVER SCREW (# 8-32 x 1-1/4 ) INTO BOTTOM

OF CASE APPROXIMATELY 2 TURNS.

3. HOLD SUPPORT AGAINST CASE AND SLIDE

OVER INTO GAP BETWEEN FLANGE AND

C

SCREW HEAD

4. POSITION COVER ON CLOSER AND

TIGHTEN SCREWS

FOR MODELS HAVING “PCHT” HOLDER

ARMS

The holder device is set for 85° door holding position at the factory.

Tension is set at the highest setting.

- To decrease holding tension: Remove tensioner mounting screw and move tension adjuster away

from hold open mechanism by using either of the two hole locations.

- To change hold open position: Remove hold open mechanism and tensioner mounting screws;

slide both to desired position and reinstall screws.

- To decrease the degree of door opening: Move stop pin to desired position

ACCESSORIES INFORMATION

MORTISE NUT INSTRUCTIONS

© Sargent Manufacturing Company 2007 A7959A

Page 4

3/4"

RELEASE DATE

TEMPLATE NO

.

100 Sargent Drive New Haven, CT 06511

Manufacturing Company

8 May , 2007

C

L

OF

HINGE

DATA SHEET

421 SERIES CLOSER WITH PCTB OR PCHTB

ARMS - PUSH SIDE APPLICATION

NOTE:

LEFT HAND DOOR SHOWN, RIGHT HAND OPPOSITE1.REINFORCE METAL DOORS AND FRAMES PER ANSI A250.8 AND

2.

SDI-100 , 12 GAUGE RECOMMENDED

USE 1431-J PLATE WHEN CLOSER BODY IS VISIBLE THROUGH GLASS

3.

THE MINIMUM TOP RAIL MAY BE REDUCED BY 3/4" BY USING THE

4.

1431-D MOUNTING PLATE. SEE TEMPLATE A7168

MAXIMUM OPENING POSITION 125°

5.

ADJUSTABLE HOLD OPEN RANGE: 75° -120° (HOLDER MODEL ONLY)6.AUXILIARY STOP REQUIRED

7.

FRAME

REINFORCEMENT

DOOR

REINFORCEMENT

2

2

#12-24 X 5/8 FLAT HEAD MACHINE

SCREW OR #12 X 1 1/2 SCREW

PROVIDED

#12-24 X 1 3/4 FLAT HEAD MACHINE

SCREW OR #12 x 1 3/4" SCREW PROVIDED

TOP OF

DOOR

3

TRACK

421 CLOSER

OUTLINE OF

COVER

FACE OF

STOP

4

C

L

OF TRACK

A 7961 A

1 3/8"

6"

21 5/8"

1"

11 1/8"

1/2"1/2"

3 1/4"

TOP RAIL

2 3/8"

15 1/8"

4 5/8" MIN

5 1/2"

1/2"

© Sargent Manufacturing Company 2007 A7959A

Loading...

Loading...