Page 1

US PATENT NO. 268003

CANADIAN PATENT NO. RD1981

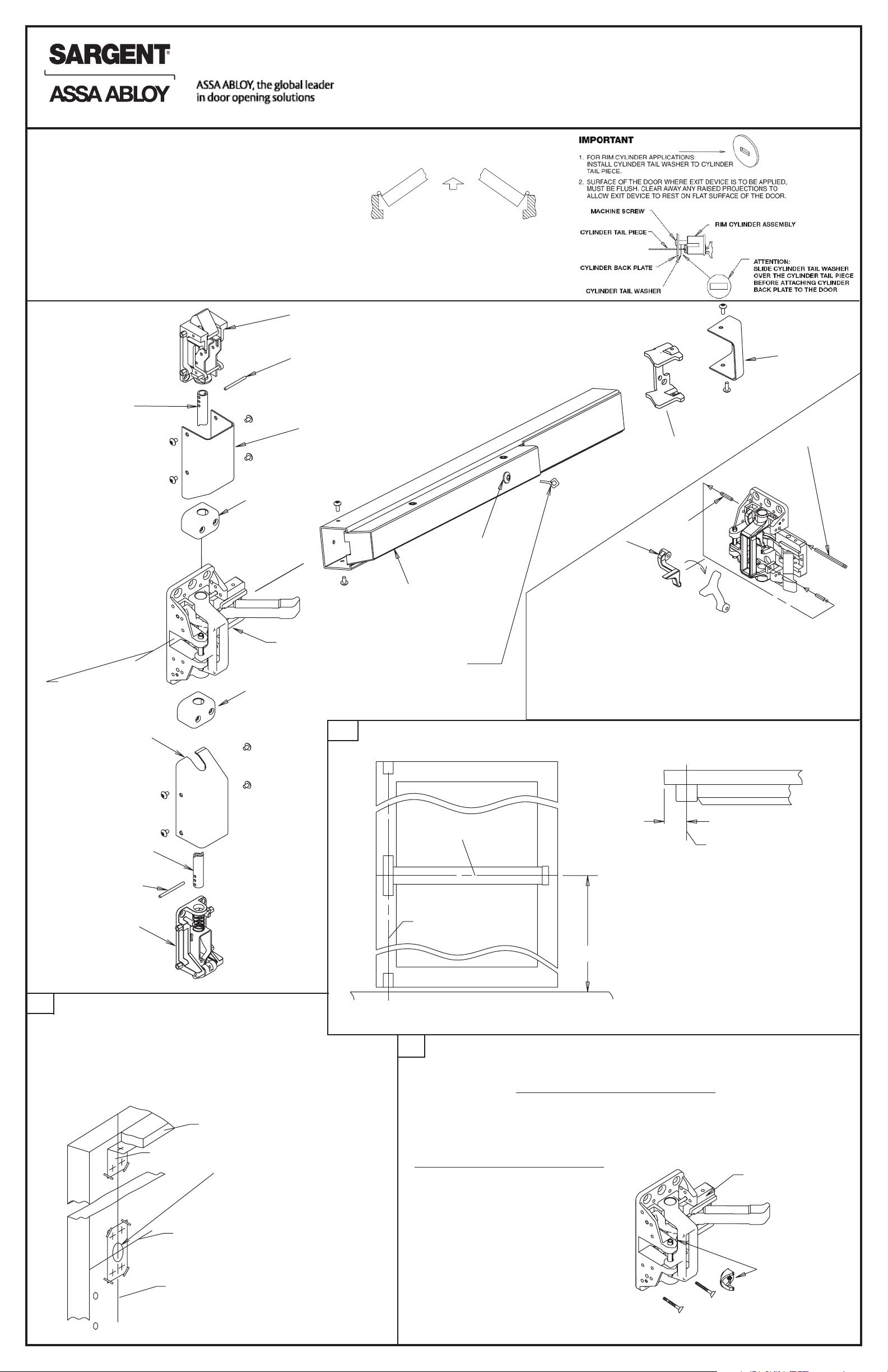

CAUTION: BEFORE STARTING

• DOOR SHOULD BE FITTED AND HUNG

• CHECK BOX LABEL FOR HAND AND SIZE OF EXIT DEVICE

AVAILABLE STOCK LENGTHS

LENGTH E 32" DOOR. CAN BE CUT TO FIT 24" DOOR.

LENGTH F 36" DOOR. CAN BE CUT TO FIT 30" DOOR.

LENGTH G 48" DOOR. CAN BE CUT TO FIT 36" DOOR.

Top case

INSTRUCTIONS FOR INSTALLING

3727 / NB3727 SERIES

VERTICAL ROD EXIT DEVICE

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

THIS EXIT DEVICE IS HANDED

OUT

RIGHT HAND

REVERSE BEVEL

LEFT HAND

REVERSE BEVEL

Top rod

Horizontal reference line

(CL of chassis and rail assembly)

Bottom

cover

Guide

Guide

Adjustment pin

Top cover

Center chassis

assembly

Lockdown

button

Rail assembly

“Lockdown key”

To operate:

Depress pushrail; insert hex key

and turn

1.

MARK VERTICAL AND HORIZONTAL

REFERENCE LINES ON DOOR

End cap

Mounting plate

Lift

lever

pin

Lift

lever

2-1/4" long pin

ALL 3727 SERIES EXIT DEVICES

ARE HANDED AND REVERSIBLE. NORMALLY ASSEMBLED FOR

A LEFT HAND REVERSE BEVEL DOOR AT THE FACTORY.

TO CHANGE HAND OF 3727 EXIT DEVICE:

1. USE 2-1/4" PIN (SUPPLIED IN SCREW PACK) TO PUSH OUT

LIFT LEVER PIN.

2. REMOVE LIFT LEVER. INVERT AND REASSEMBLE WITH LIFT

LEVER PIN AS SHOWN.

Bottom

rod

Adjustment

pin

Bottom

case

PREPARE DOOR

2.

TAPE TEMPLATES ON INSIDE OF DOOR ALONG

REFERENCE LINES WITH SUPPLIED TAPE

IF DOOR ALREADY HAS ANSI DOOR PREP (161 CUT-OUT) OR HAS

2-1/8" DIA. HOLE AT 2-3/4" BACKSET, POSITION TEMPLATE OVER EXISTING

HOLE AND SPOT AND DRILL HOLES

Door stop

Horizontal reference line

(CL of chassis and rail assembly)

Vertical reference line

(CL of chassis)

FINISHED FLOOR

APPLY HARDWARE

3.

SEE SEPARATE INSTRUCTION SHEET PACKED WITH TRIM

Vertical reference line

DETERMINE DIMENSION “A”

- IF LOCK STILE IS APPROX. 4-1/2"

WIDE OR WIDER, DIM. A = 2-3/4"

- IF LOCK STILE IS LESS THAN 4-1/2"

41”

WIDE, DIM. A = 1/2 OF THE VISIBLE

WIDTH OF THE LOCK STILE (WHEN

DOOR IS CLOSED AGAINST STOP)

Refer to template to locate

horizontal reference line

FOR LEVER TRIM APPLICATIONS

Door

Dim “A”

(CL of chassis)

Top case

template

ANSI A156.2 series cross bore hole

when knob rim or lever handle trim

is used

Horizontal reference line

(CL of chassis and rail assembly)

Vertical reference line

(CL of chassis)

NOTE: FOR EXIT APPLICATIONS ONLY

Center

chassis

cam

REMOVE AND DISCARD CAM FROM

CENTER CHASSIS FOR FLUSH

MOUNTING. ATTACH CHASSIS WITH

FOUR (4) #10 WOOD OR MACHINE

SCREWS.

Copyright © 2003, 2008, 2012, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

Cam

A7425F

Page 2

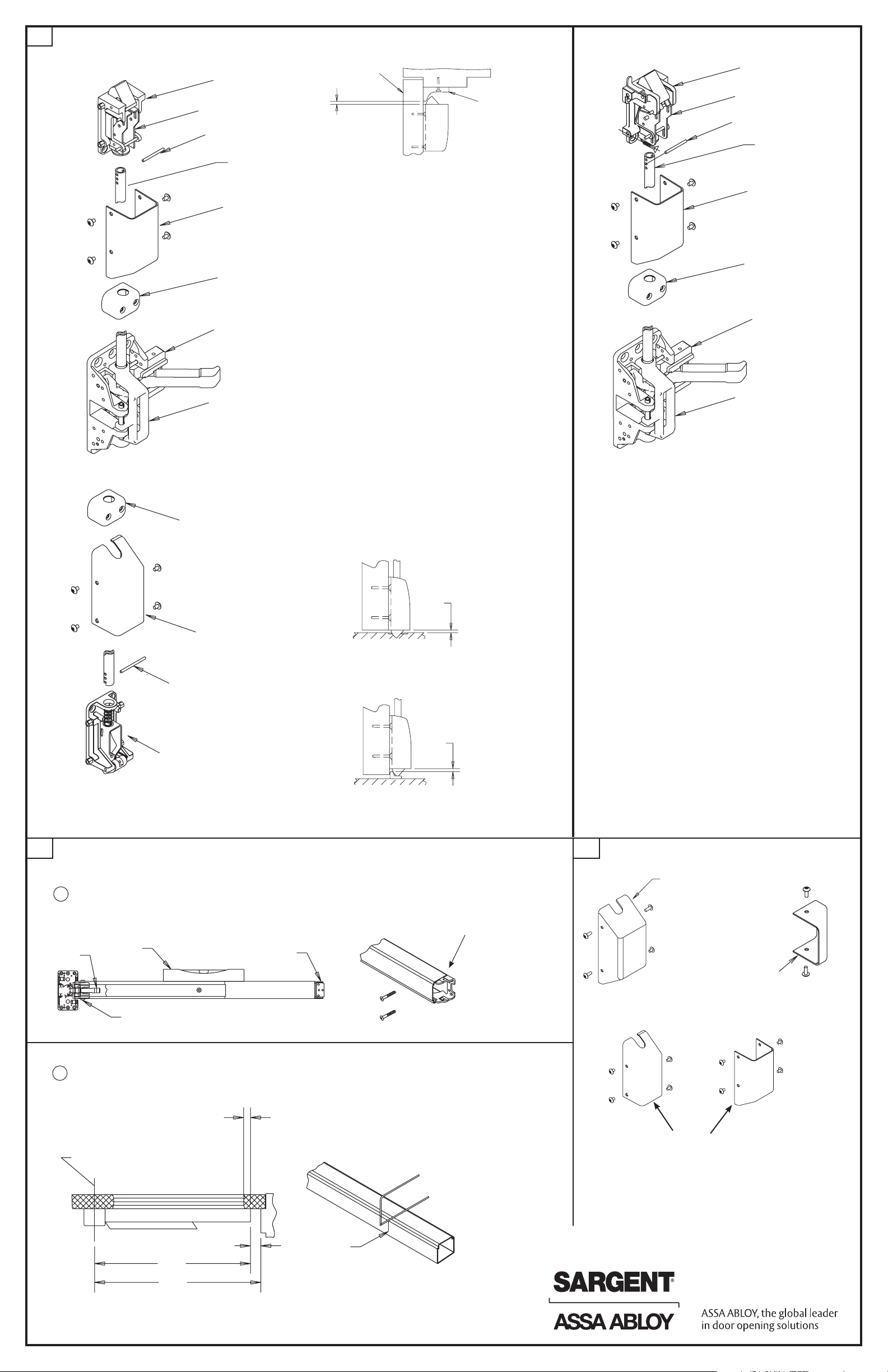

4.

3727 INSTALL TOP & BOTTOM CASES

NB 3727 INSTALL TOP CASE

Top case

Retractor

Adjustment pin

Center chassis

assembly

Main slide

Guide

Bottom

cover

Adjustment Pin

Top rod

Top cover

Guide

TOP STRIKE

1/8" GAP REQUIRED

SHIM TOP STRIKE

WHEN NECESSARY

TO OBTAIN 1/8" GAP

3727 / NB3727

3727

1. MOUNT TOP STRIKE ACCORDING TO LOCATION

MARKED IN SECOND STEP. USE #10 STEEL

SCREWS PROVIDED

2. SCREW TOP ROD INTO MAIN SLIDE.

3. SLIDE GUIDE AND COVER ONTO TOP ROD

AND ASSEMBLE TO TOP CASE BY INSERTING

ADJUSTING PIN THRU RETRACTOR AND

MIDDLE HOLE IN ROD (SEE ILLUSTRATION AT

LEFT). ADJUST SO THAT TOP CASE MOUNTING

HOLES LINE UP WITH LOCATION MARKED IN

SECOND STEP.

4. MOUNT BOTTOM CASE IN SAME MANNER AS

TOP CASE (SEE ILLUSTRATION AT LEFT). REFER

TO ILLUSTRATIONS BELOW FOR MORTISE OR

SURFACE APPLIED STRIKE APPLICATIONS.

5. SECURE ROD GUIDES

NOTE: IF SHORTER RODS ARE REQUIRED,

CUT TO LENGTH AND DRILL Ø1/8"

HOLE THROUGH.

1/4"

MORTISE TYPE BOTTOM STRIKE

Top case

Retractor

Adjustment pin

Top rod

Top cover

Guide

Center chassis

assembly

Main slide

NB 3727

1. MOUNT TOP STRIKE ACCORDING TO LOCATION

MARKED IN SECOND STEP. USE FOUR (4) #10

STEEL SCREWS AND MORTISE NUTS IN THE

FOUR CORNER MOUNTING HOLES

ILLUSTRATED IN THE TOP CASE.

2. SCREW TOP ROD INTO MAIN SLIDE

3. SLIDE ROD GUIDE AND COVER ONTO TOP ROD

AND ASSEMBLE TO TOP CASE BY INSERTING

ADJUSTING PIN THRU RETRACTOR AND MIDDLE

HOLE IN ROD (SEE ILLUSTRATION AT RIGHT).

ADJUST SO THAT TOP CASE MOUNTING HOLES

LINE UP WITH LOCATION MARKED IN SECOND

STEP.

NOTE: IF SHORTER RODS ARE REQUIRED, CUT

TO LENGTH AND DRILL .125 / 1/8" DIA

THROUGH HOLES

Bottom case

5.

INSTALL RAIL ASSEMBLY

• CHECK BOX LABEL.

A

DEPRESS ARM INTO RAIL OPENING AND SLIDE RAIL ONTO

CHASSIS. LEVEL RAIL AND FASTEN MOUNTING PLATE

Level

Attach rail assembly to the chassis with two

#8 Truss head machine screws

RAIL CUTTING INSTRUCTIONS

DETERMINE CUT OFF DIMENSION “X” BY SUBTRACTING 2" FROM

B

DIMENSION “Y”

Mounting plate

1/8"

SURFACE APPLIED BOTTOM STRIKE

PLACE MOUNTING PLATE TIGHT

AGAINST RAIL AND ATTACH IT

TO THE DOOR WITH#10 ROUND

HEAD SCREWS

6.

APPLY COVERS

ATTACH COVER TO

CHASSIS WITH (4) #8 TRUSS

HEAD MACHINE SCREWS

ATTACH RAIL END CAP TO

MOUNTING PLATE WITH (2)

COVER SCREWS

A7425F

VERTICAL REFERENCE LINE

(C CHASSIS)

L

“X”

“Y”

Copyright © 2003, 2008, 2012, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

2" MIN.

FOR DOORS WITH STILE,

RAIL MUST OVERLAP STILE

BY 1/2" MIN.

ATTACH COVERS TO TOP

AND BOTTOM CASES WITH

(4) COVER SCREWS EACH

CUT OFF ON MARK

AND DEBURR

Loading...

Loading...