SARGENT 2900 User Manual

Wiring Instructions for the 2900 Series FIREGUARD

®

Combination Door Closer-Holder and Releasing Device

with Integral Smoke Detector

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE.

For assistance, contact SARGENT at 800-810-WIRE (9473) or www.sargentlock.com

CAUTION

INSTALLER: LEAVE INSTRUCTION with building owner.

• Wire 12- smoke detector unit to appropriate

power supply and fire alarm

• Refer to data sticker for proper input voltage

and current specifications

• 9- Companion units are designed to work with

12- smoke detector units (12-2960, 12-2990,

12-2980) only

• Wire companion unit to 12- smoke detector

unit as shown on wiring diagram if required

• Do not disconnect any existing wires on

smoke detector unit’s terminal strip

• Energize power supply. Current draw

.1 AMP per 12- unit.

• Open door(s) to hold-open point.

Door(s) should hold open

• Depress On/Off test switch on circuit

board. Doors should close and latch

• Adjustment of spring power may be

necessary to ensure proper latching

• Depress On/Off test switch to

reactivate hold open latch

assembly(s)

A7408B

1

1. DISCONNECT ALL POWER BEFORE BEGINNING

INSTALLATION TO PREVENT ELECTRICAL SHOCK AND

EQUIPMENT DAMAGE.

2. INSTALLER MUST BE A TRAINED, EXPERIENCED

SERVICE PERSON.

3. ALL WIRING MUST COMPLY WITH APPLICABLE LOCAL

ELECTRICAL CODES, ORDINANCES AND REGULATIONS.

4. MAXIMUM WIRE SIZE IS 18AWG.

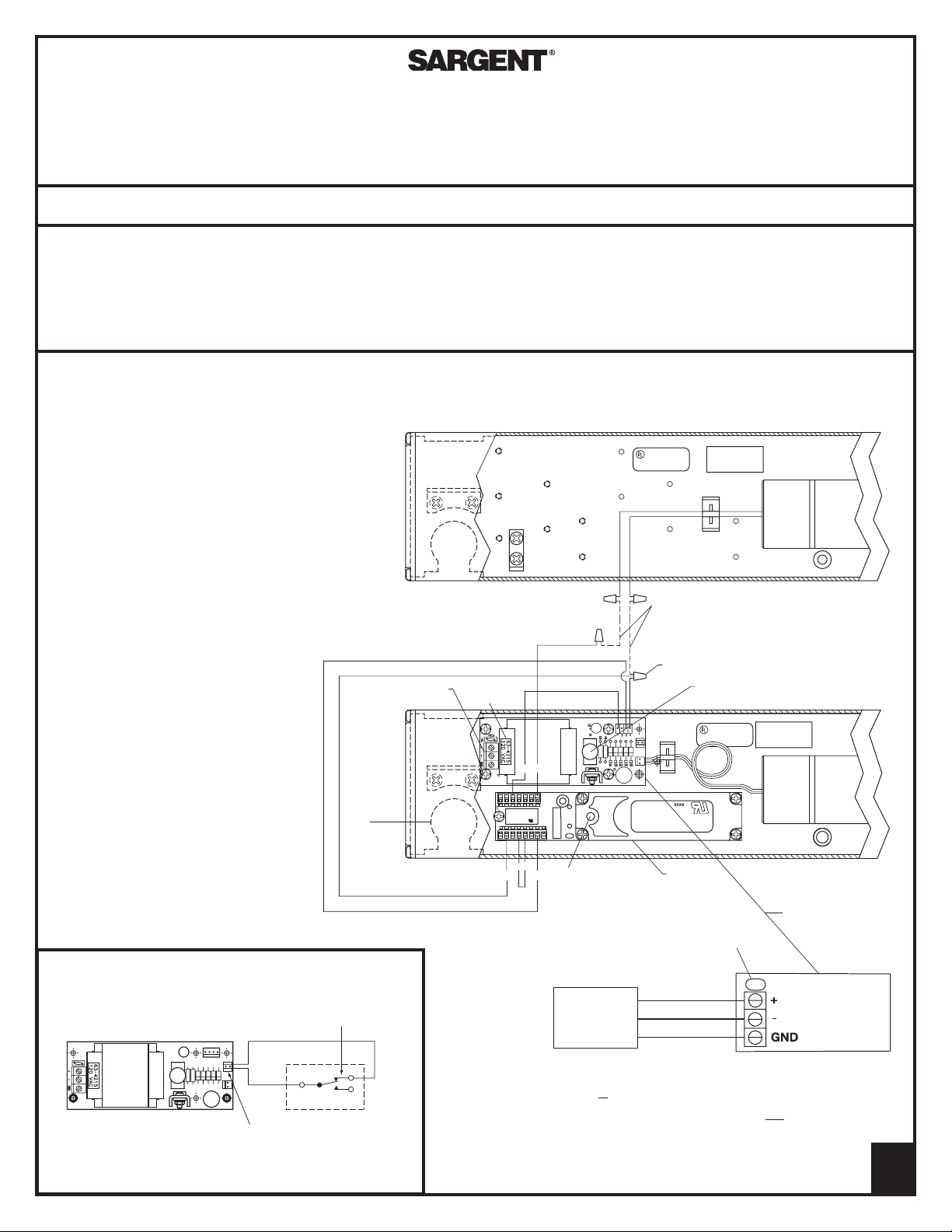

Wiring 12- Units with and without 9- Companion Unit

Wiring Optional Remote Push Button

Terminal strip for

power input wiring

Opening

for

surface

or

concealed

wiring

9- Companion Unit

(If required)

Black

Black

Field wiring by others

Yellow

Data

Sticker

Red

Yellow

Black

3

7

Wire nut

On/Off Test switch

12- Smoke Detector Unit

User supplied normally

closed momentary switch

Remove jumper and install

output connector assembly

(Part No. 63-2868) required

for this option

Yellow

Red

1112

9

RED LED/

14

Reset Switch

Earth ground connection is required

when 120VDC power is used

120VAC

Power

Supply

Wire the appropriate Power Supply

to circuit board. Power is either

120VAC or 24VDC/VAC depending

on circuit board supplied.

When 24VDC/VAC board is supplied,

wire 24VDC/VAC power supply to

+ and - terminals on circuit board.

Line

Neutral

Earth Ground

Smoke

detector

unit

*120VAC

wiring shown

Circuit board 120VAC

or 24VAC/DC

Self

resetting

fuse

(120VAC shown)

*120VAC

Circuit Board

shown

*CAUTION: Refer to data

sticker on circuit board for

proper input voltage required.

Do NOT wire 120VAC power

to 24VDC/VAC circuit board.

2

A7408B

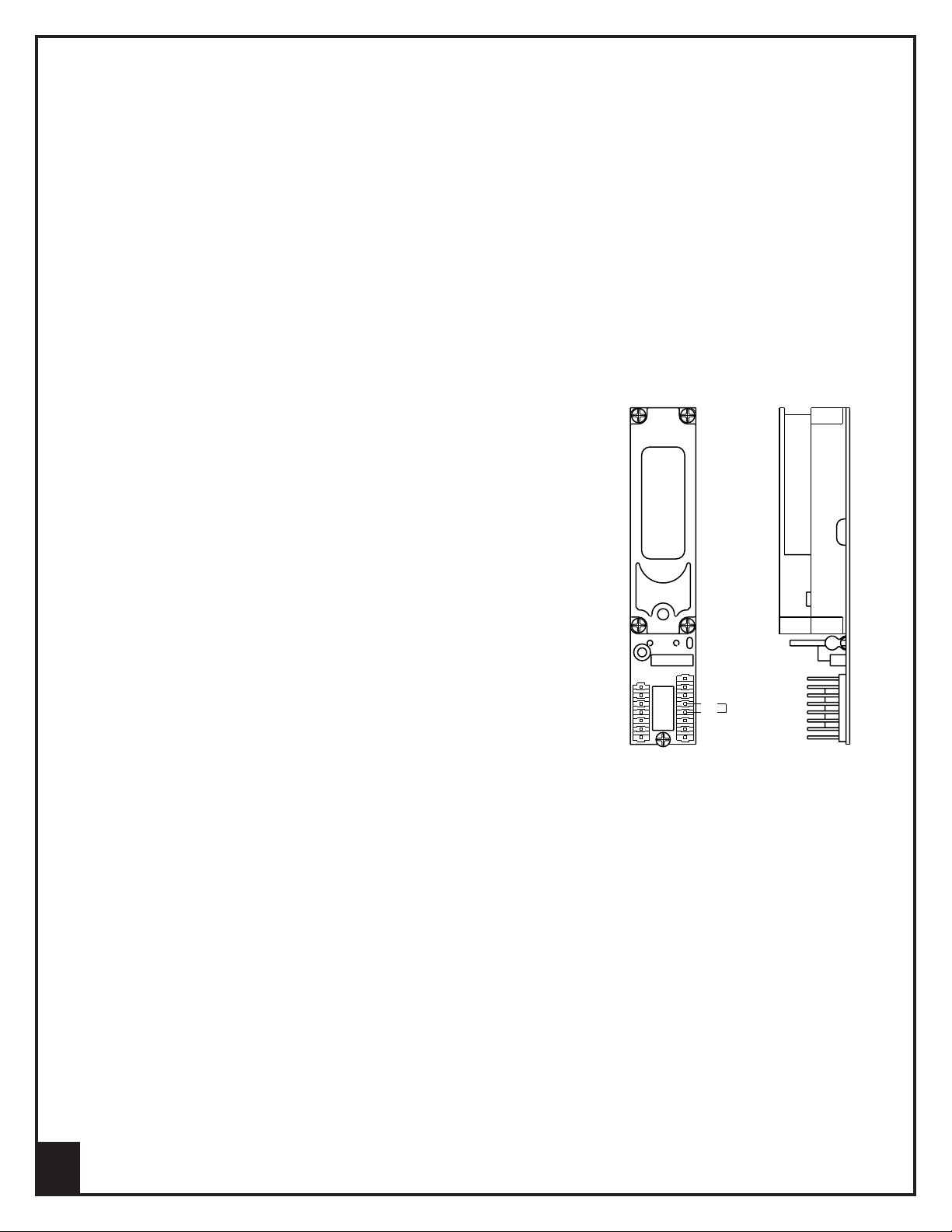

Smoke Detector Operation and Application

The closer/holder unit includes a 4-wire, photoelectric type smoke

detector. It provides: smoke detection, door holder solenoid control,

N.O. alarm contact, N.C. supervisory contact and interconnection to

other smoke detectors. Field option: one form C auxiliary contact (cut

jumper wire between 11 and 12).

Terminal Inputs and Outputs

• 24VDC input power is applied to terminals 3 (-) and 14 (+) by the

adjacent circuit board. Red LED flashes every 8 seconds

• Terminals 1 and 2 provide a normally open (alarm) contact. This

contact closes when smoke is detected. Red LED illuminates

continuously

• Terminals 5 and 13 provide a normally closed supervisory (trouble)

contact. This contact opens when power is lost to the detector

circuity. Red LED stops flashing

• Terminals 9 and 6 provide rectified, unfiltered 24VDC to the door

holder solenoid. This power is cut in alarm and the door closes

• Terminals 7 and 8 provide rectified, unfiltered 24VDC to auxiliary

devices when the detector alarms

• Terminal 10 is rail + output. It is a continuous, rectified, unfiltered

24VDC used for remote detector interconnect applications

• Terminals 8, 9 and 10 may be field configured to a dry form contact

by cutting jumper between terminal 11 and 12. Terminal 10 is

Common, 9 is N.C. and 8 is N.O. If this is done, Aux.+ is lost;

solenoid power must be supplied by a separate source.

• Terminals 15 and 4 provide interconnections to other detectors (See

diagram Pg. 4). Up to five smoke detectors may be interconnected.

When a single detector alarms, terminal 15 goes high and any

interconnected smoke detector will close its doors. The unit that

initiated the alarm will have its LED on. The other interconnected

units’ LEDs will flash as normal. Refer to interconnection wiring

diagram for connections.

Detector Specifications (Part# 63-3210, Revision D)

Type: Photo-Electric Smoke Detector

Complies with UL 228 and UL 268 standards

Power Requirements: 24VDC +/- 10%

Nominal Sensitivity: 2.325 +/- 1.055%/FT

Contact Ratings

Alarm and/or Accessory 2.0 AMPS Max. @ 24VDC

(Resistive load) 0.6 AMPS Max. @ 120 VAC

Trouble Contact 0.5 AMPS Max. @ 24VDC

(Resistive load)

Connection List

Function Terminal

24VDC input 3 (-), 14 (+)

Alarm contacts 1, 2

Solenoid + 9

Solenoid - 6

Aux + 8

Aux - 7

Interconnect + 15

Interconnect - 4

Trouble contacts 13, 5

+24VDC output (unfiltered) 10

NOTE: Terminals 4, 6 and 7 are same point.

15

7

6

5

4

3

2

1

14

13

12

11

10

9

8

3

A7408B

1. Turn the power to the unit “On”. Red LED pilot light should illuminate at 8 sec. intervals

2. Open door to the hold open point. The door should hold open. Manually pull door out of hold open and release. Door should close

3. Open door to the hold open position. Depress (maintained type) On/Off “test switch” button on the power supply board. Door should close

4. Depress On/Off test switch again. Open door to the hold open position. Inducing smoke into the smoke detector chamber assembly will bring the unit

into alarm. The red LED will be continuously illuminated and the door will close. After clearing the smoke chamber, reset unit as follows

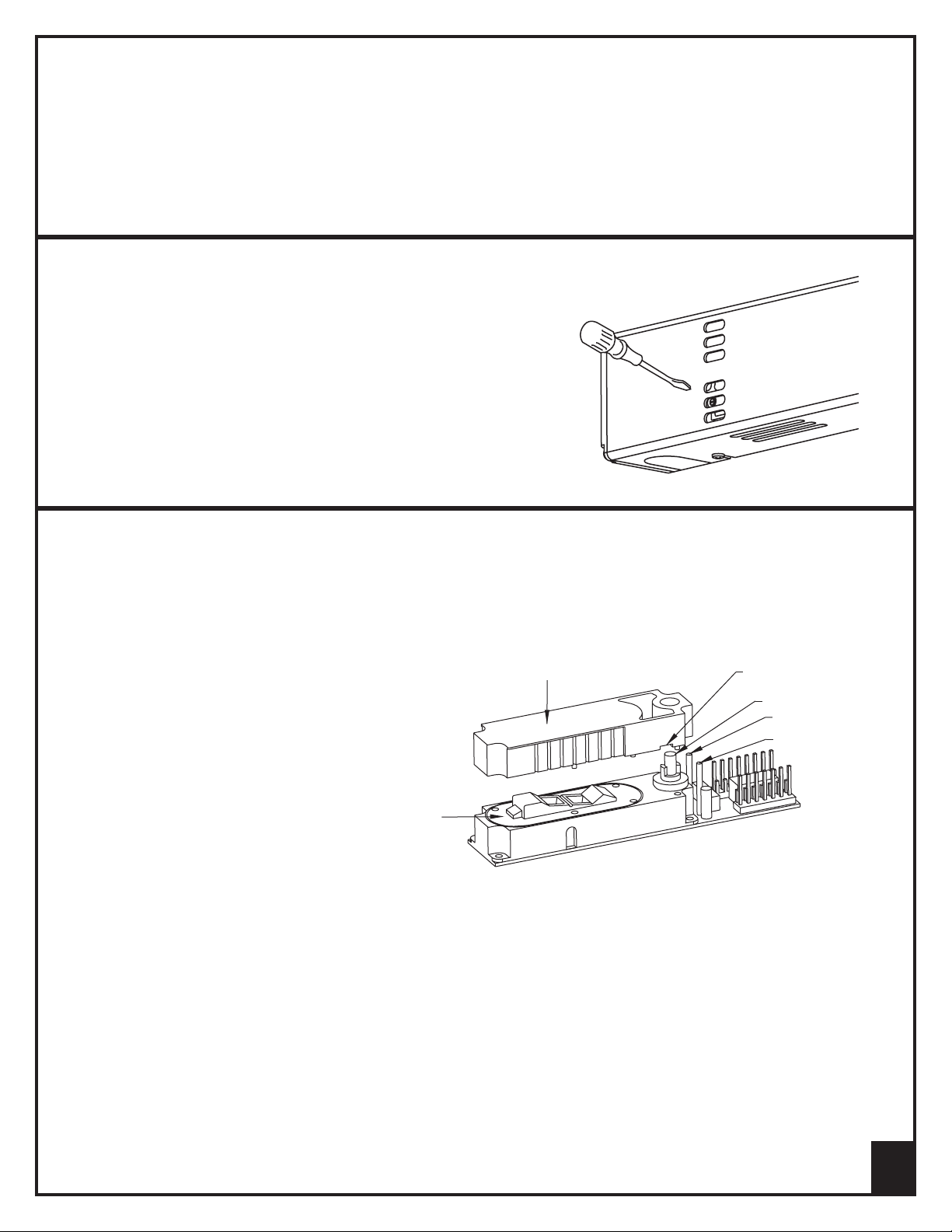

Checkout Procedure

1. Remote Reset: Cycle main power by turning the facility main power supply OFF then ON.

NOTE: If there are other units connected to the same power supply those doors will close.

They will have to be reopened returning them to the hold open position

2. Local Reset: Insert a small flat head screwdriver through the cover and into the slotted

light tube on the smoke detector as shown. Turn screwdriver slightly (about 1/8 turn)

clockwise until hitting stop and hold for 2 seconds until the Red LED turns OFF.

WARNING: Do not force past the stop. Doing so may damage the smoke detector

Once the detector is reset and the smoke has cleared, the detector’s Red LED should flash

once every 8 seconds. The door(s) should hold open now

Resetting Instructions

SARGENT recommends cleaning smoke detectors at least every six months. The frequency of cleaning will depend upon local ambient conditions

The smoke detector in this door closer-holder has been enhanced with a feature that detects when a smoke-sensing chamber requires cleaning

due to dirt and dust. The need for cleaning is indicated by the flashing of the Red LED light once per second

• Normal Supervisory Operation — Red LED flashes once every 8 seconds

• Dirty Chamber, needs cleaning — Red LED flashes once every second

• Smoke Detection — Red LED is continuously illuminated

To clean the smoke detector assembly, follow the instructions below:

NOTE: Before servicing the system, notify the proper authorities

that the smoke detector system is undergoing maintenance

and will be temporarily out of service. Disable the zone undergoing

maintenance to prevent unwanted alarms

Smoke Detector Maintenance

• Remove detector cover and screen assembly using a standard screwdriver. Turn the screwdriver in the cover slot to loosen the cover and carefully

rock the cover back and forth until it snaps out of place. See slot location above

• Inspect chamber for particles and dust. Vacuum the screen, cover, and photo chamber. Then use clean, compressed air to loosen and blow out

any remaining debris

• Before reassembling the detector, be sure all parts are free of dust and debris

• Replace cover and screen, aligning cover snaps, press cover onto chamber until it snaps into place

• Measure and record the test voltage at test points RP1 and RP2 (see above). If the smoke detector is operating normally and was cleaned

effectively, the test voltage will be greater than .90VDC and less than 1.58VDC. The test voltage will increase with dust accumulation in the

smoke sensing chamber. A difference in test voltages over time will provide an indication of dust accumulation

• Enable system and inform proper authorities system is operational

RP2 test point

RP1 test point

Slot for screwdriver

To remove cover

Cover and

screen

Chamber

Slotted light tube (Red LED)

Loading...

Loading...