Page 1

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges,or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

CMOS IC

4-bit Microcontroller

with Built-in EPROM and LCD Drivers

Ordering number:ENN3410C

LC58E68

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Overview

The LC58E68 is a 4-bit microcontroller with built-in 16

Kbytes of EPROM, 1 Kbit of RAM and LCD drivers. It

can perform most of the functions of the LC586X series

single-chip microcontroller, making it ideal for prototyping

systems based on these devices.

The LC58E68 features an additional 224 bytes of EPROM

containing the configuration option data. Configuration

options include input and output configurations and osillator

selection. Input configuration are LOW-level hold transistor, HIGH-level hold transistor and no hold transistor enabled, and pull-up and pull-down input transistors. Output

configuration options are LCD driver and CMOS, p-channel open-drain and n-channel open-drain general-purpose

outputs.The osillator options are ceramic filter, crystal, and

both ceramic filter and crystal.

The LC58E68’s UV-erasable EPROM can be reprogrammed using a general-purpose PROM programmer and

an adapter board.

The LC58E68 operates from a 3 or 5 V supply and is available in 80-pin QIPs.

Features

• Compatible with the LC586X series mask ROM devices

• 16-Kbyte program EPROM

• 224-byte configuration EPROM

• 1-Kbit RAM

• LCD drivers

• 3 or 5 V supply

• 80-pin QIP

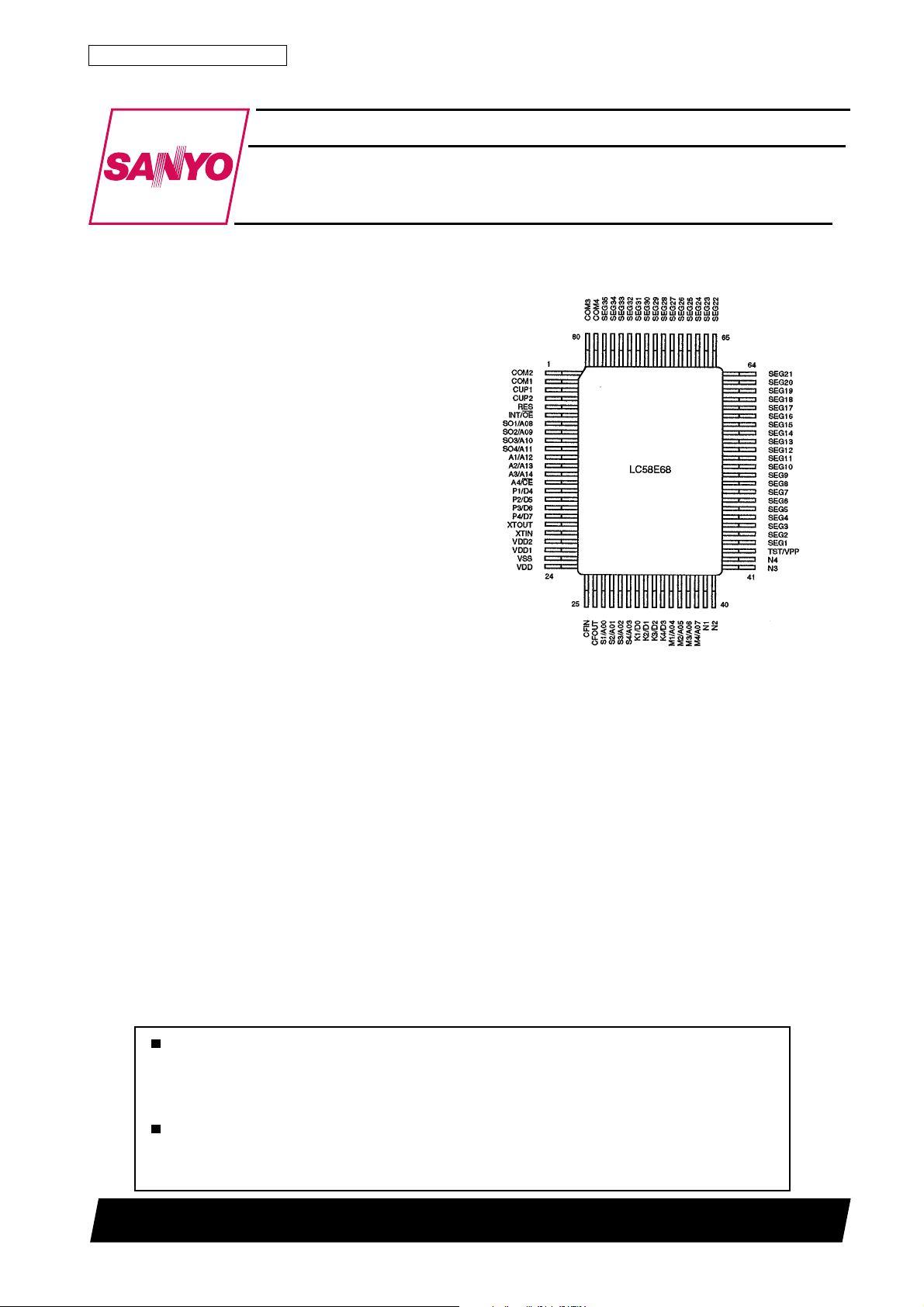

Pin Assignment

Top view

O2501TN(KT)/11795TH (ID)/7142JN No.3410–1/16

Page 2

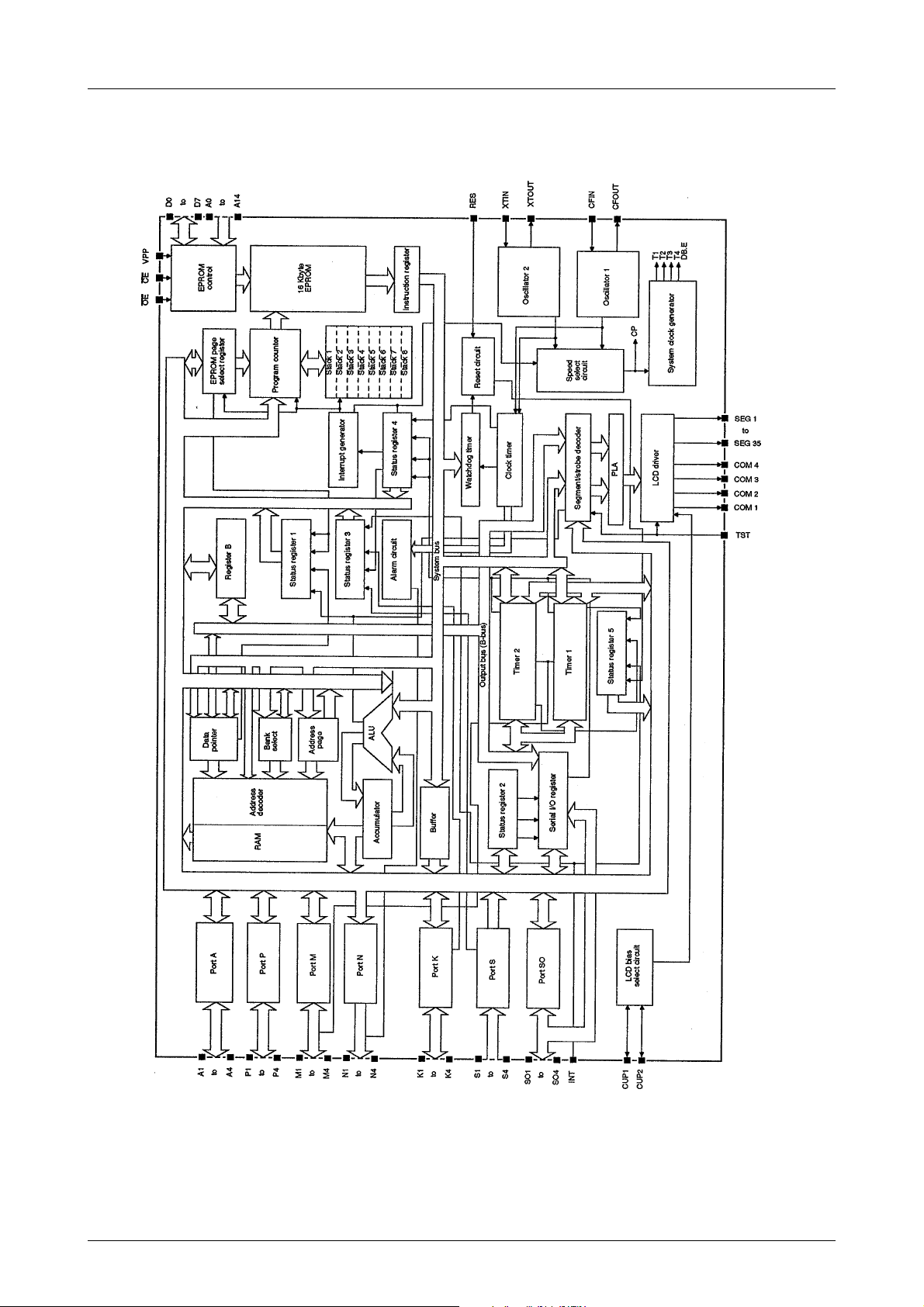

Block Diagram

LB58E68

No.3410–2/16

Page 3

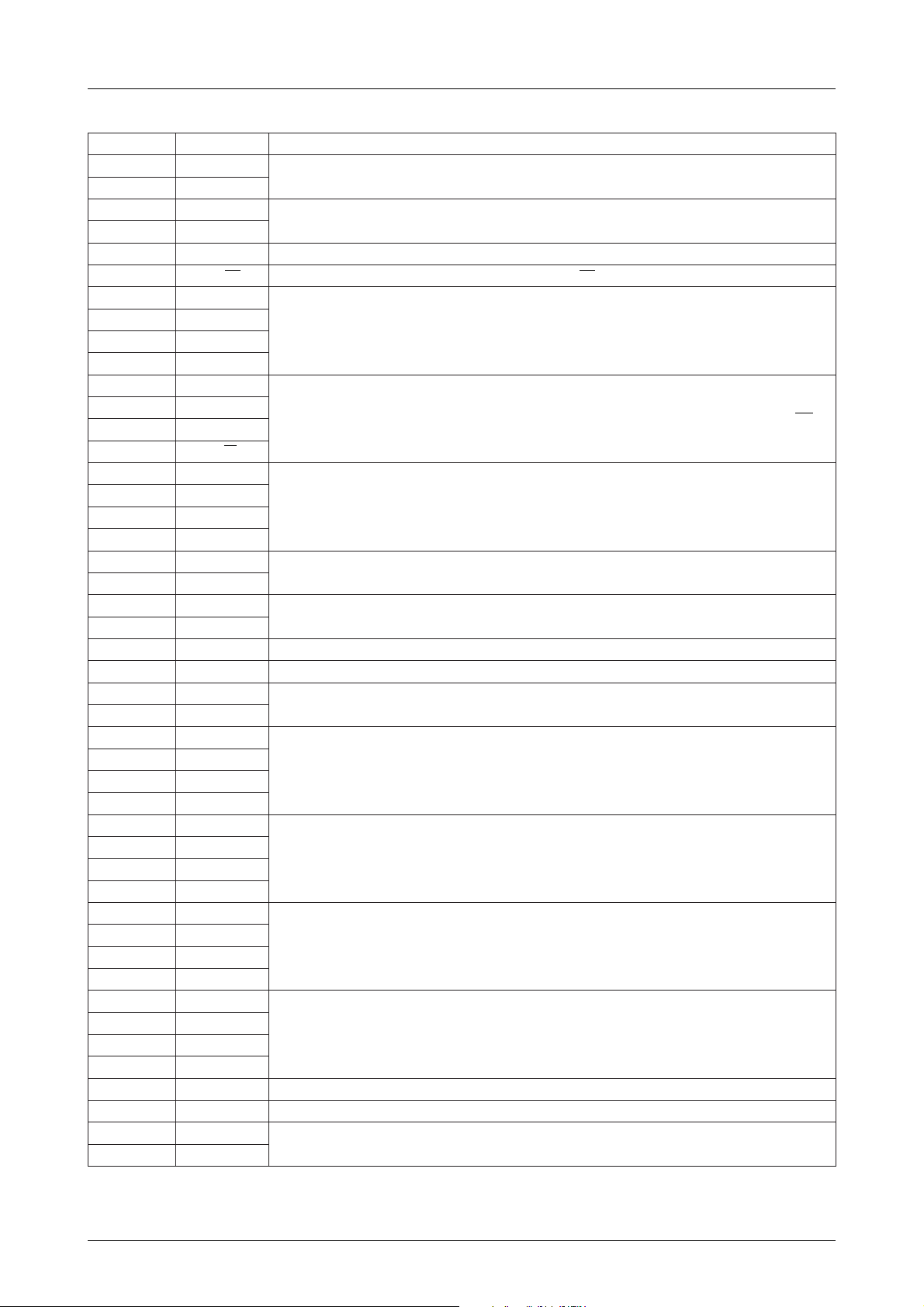

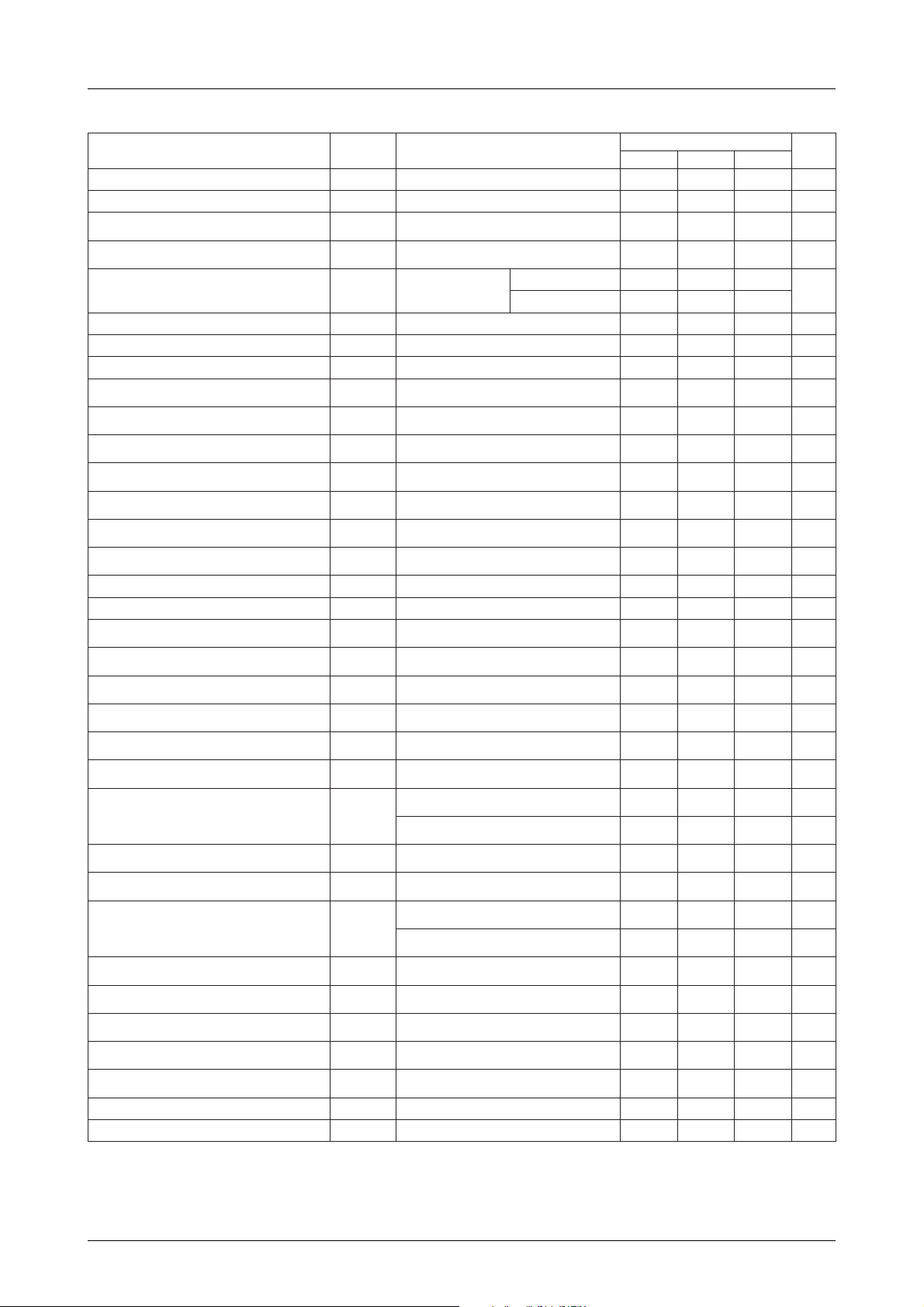

Pin Function

rebmuNemaN noitcnuF

12MOC

21MOC

31PUC

42PUC

5SERtupniteserHGIH-evitcA

6EO/TNI tupni)EO(elbanetuptuoMORPEdna)TNI(tseuqertpurretnidexelpitluM

780A/1OS

890A/2OS

901A/3OS

0111A/4OS

1121A/1A

2131A/2A

3141A/3A

41EC/4A

514D/1P

615D/2P

716D/3P

817D/4P

91TUOTX

02NITX

12V

22V

32VSSdnuorG

42V

52NIFC

62TUOFC

7200A/1S

8210A/2S

9220A/3S

0330A/4S

130D/1K

231D/2K

332D/3K

433D/4K

5340A/1M

6350A/2M

7360A/3M

8370A/4M

931N

042N

143N

244N

34PPV/TSTVMORPEdna)TST(tupnitsetdexelpitluM

87ot4453GESot1GESstuptuoesorup-larenegrosrevirdtnemgesDCL

974MOC

083MOC

LB58E68

stuptuonommocDCL

snoitcennocroticapactiucricsaibevirdDCL

)11A

)7Dot4D(senilsubatadMORPEdna)4Pot1P(Ptroptuptuo/tupnitib-4dexelpitluM

snoitcennocrotallicsolatsyrC

2

DD

1

DD

DD

ylppusegatloV

)4Mdna3M(stupnikcolc

stuptuonommocDCL

noitcennocroticapacylppussaibevirdDCL

snoitcennocrotallicsoretlifcimareC

)30Aot00A(stupnisserddaMORPEdna)4Sot1S(Stroptupnitib-4dexelpitluM

)3Dot0D(senilsubatadMORPEdna)4Kot1K(Ktroptuptuo/tupnitib-4dexelpitluM

)4N(tuptuolangismraladna)4Not1N(Ntroptuptuoniardnepo,tib-4dexelpitluM

PP

)PPV(ylppus

ot8OA(stupnisserddaMORPEdna)3OSotOS(troplaires,)4OSot1OS(OStroptuptuo/tupnitib-4dexelpitluM

)EC(tupnielbanepihcdna)41Aot21A(stupnisserddaMORPE,)4Aot1A(Atroptuptuo/tupnitib-4dexelpitluM

lanretxe2dna1remitdna)70Aot40A(stupnisserddaMORPE,)4Mot1M(Mtroptuptuo/tupnitib-4dexelpitluM

No.3410–3/16

Page 4

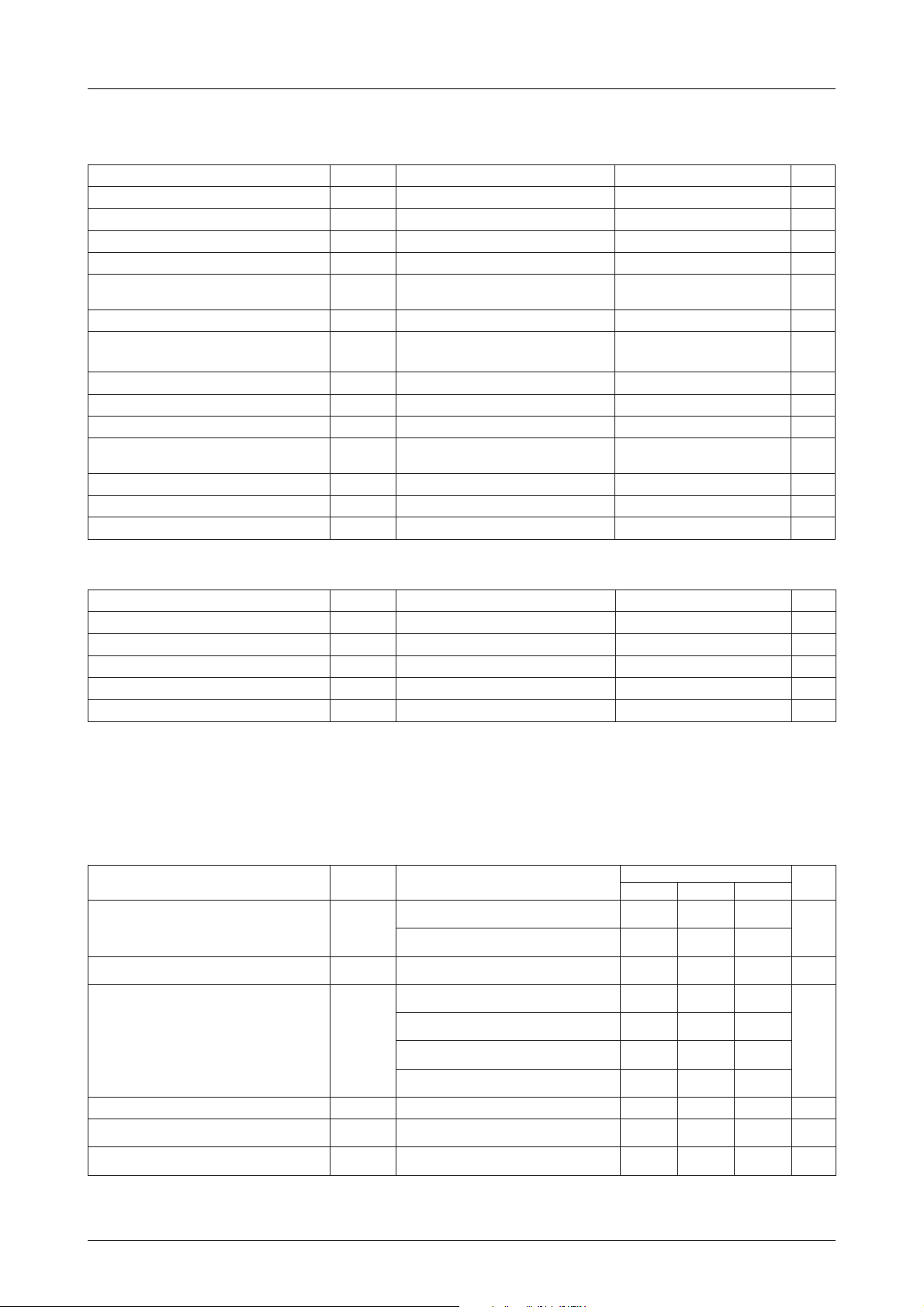

Specifications

Absolute Maximum Ratings

retemaraPlobmySsnoitidnoCsgnitaRtinU

egatlovylppuSV

1egatlovylppusDCLV

2egatlovylppusDCLV

egnaregatlovtupniNIFCdnaNITXV

egnaregatlovtupniTST

egnar

egnartnerructuptuoNstroPI

egnartnerructuptuolatot53

noitapissidrewopelbawollAxamdP 005Wm

erutarepmetgnitarepOrpoT 04ot01°C

erutarepmetegarotSgtsT 521+ot55–°C

LB58E68

xam 0.6+ot3.0–V

DD

1DD

2DD

1I

dnaTNI,SERdna,AdnaOS,P,K,SstroP

egnaregatlovtuptuoTUOFCdnaTUOTXV

egnaregatlovtuptuoniard-nepoNstroPV

egnartnerructuptuoAdnaOS,M,P,KstroPI

V

2I

1O

1GES,2PUC,1PUCdna,AdnaOS,P,KstroP

egatlovtuptuo4MOCot1MOCdna53GESot

V

2O

3O

1O

2O

GESot1GESdna,NdnaA,OS,M,P,KstroP

∑I

O

Vot3.0–

V

DD

Vot3.0–

V

DD

egatlovdetarenegmumixamot0V

Vot3.0–

3.0+V

DD

egatlovdetarenegmumixamot0V

Vot3.0–

3.0+V

DD

31+ot3.0–V

51+ot01–Am

5+ot5–Am

07+ot07–Am

Allowable Operating Ratings at Ta = 25˚C

retemaraPlobmySsnoitidnoCsgnitaRtinU

delbasidDCLhtiwegnaregatlovylppuSV

saibcitatshtiwegnaregatlovylppuSV

saib-2/1htiwegnaregatlovylppuSV

saib-3/1htiwegnaregatlovylppuSV

egatlovnoitneteratadmuminiMV

DD

DD

DD

DD

RD

1etoneeS 5.5ot8.2V

1etoneeS 5.5ot8.2V

2etoneeS 5.5ot8.2V

3etoneeS 5.5ot8.2V

4etoneeSot8.2VDDV

Notes

1. V

DD1=VDD2=VDD

2. V

DD1=VDD2

3. V

DD1

≈1/2×V

≈2/3×VDD, V

DD

DD2

≈1/3×V

DD

4. Oscillator and all internal circuits halted

Electrical Characteristics at Ta = 25˚C, VDD=2.8 to 3.2V

retemaraPlobmySsnoitidnoC

V

DD

f

1egatlovylppusDCLV

2egatlovylppusDCLV

tnerrucylppuSI

tnerrucegakaelylppuSI

-woltupniTNIdna,AdnaOS,M,P,K,SstroP

egatlovlevel

egatlovlevel

DD

DD

V

1LI

-hgihtupniTNIdna,AdnaOS,M,P,K,SstroP

V

1HI

1DD

2DD

latx

V

DD

f

latx

V

DD

f

latx

V

DD

V

DD

Zck52= Ω .4erugifeeS.saib-3/1,edomtlah,

V

DD

V

DD

V

DD

f,V3=

f,V3=

f,V3=

f,V3=

sgnitaR

nimpytxam

,saib-2/1,Fµ1.0=2C=1C,V3=

.2erugifeeS.zHk867.23=

,saib-3/1,Fµ1.0=2C=1C,V3=

.3erugifeeS.zHk867.23=

,saib-3/1,Fµ1.0=2C=1C,V3=

.3erugifeeS.zHk867.23=

C,zHk23=

latx

latx

rec

rec

C,zHk004=

.5erugifeeS.edomtlah

C,zHM1=

.6erugifeeS.edomtlah

g

gcC=dc

gcC=dc

Z,Fp02=

k52= Ω,

c

.4erugifeeS.saib-3/1,edomtlah

C,zHk56ro83=

,Fp01=

g

,Fp033=

,Fp001=

.1erugifeeS.edomybdnats,V3=1Aµ

03.0VDDV

V7.0

DD

5.1

0.1

0.2V

5

01

051

002

V

DD

tinU

V

Aµ

V

Continued on next page

No.3410–4/16

Page 5

Continued from preceding page

retemaraPlobmySsnoitidnoC

egatlov

egatlov

tnerruc

egatlovlevel-woltuptuoNtroPV

tnerrucegakaeltuptuoNtroPI

egatlov

egatlov

tnerruc

egatlov

tnerruc

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

ecnatsisertupnirotsisnart

ecnatsisertupnirotsisnart

ecnatsisertupni

ecnatsisertupni

LB58E68

egatlovlevel-woltupniNIFCdnaSERV

egatlovlevel-hgihtupniNIFCdnaSERV

level-woltuptuoAdnaOS,M,P,KstroP

level-hgihtuptuoAdnaOS,M,P,KstroP

egakaeltupniTNIdna,AdnaOS,M,K,SstroP

egatlovlevel-woltuptuoSOMC53GESot1GESV

level-hgihtuptuoSOMC53GESot1GES

level-hgihtuptuolennahc-p53GESot1GES

egakaeltuptuolennahc-p53GESot1GES

level-woltuptuolennahc-n53GESot1GES

egakaeltuptuolennahc-n53GESot1GES

level-woltuptuo53GESot1GESsaib-citatS

level-hgihtuptuo53GESot1GESsaib-citatS

egatlovlevel-woltuptuo1MOCsaib-citatSV

egatlovlevel-hgihtuptuo1MOCsaib-citatSV

level-woltuptuo53GESot1GESsaib-2/1

level-hgihtuptuo53GESot1GESsaib-2/1

level-woltuptuo4MOCot1MOCsaib-2/1

level-dimtuptuo4MOCot1MOCsaib-2/1

level-hgihtuptuo4MOCot1MOCsaib-2/1

level-woltuptuo53GESot1GESsaib-3/1

level-dimtuptuo53GESot1GESsaib-3/1

level-hgihtuptuo53GESot1GESsaib-3/1

level-woltuptuo4MOCot1MOCsaib-3/1

level-dimtuptuo4MOCot1MOCsaib-3/1

level-hgihtuptuo4MOCot1MOCsaib-3/1

dlohlevel-wolAdnaOS,M,P,K,SstroP

dlohlevel-hgihAdnaOS,M,P,K,SstroP

rotsisnartpu-llupAdnaOS,M,P,K,SstroP

rotsisnartnwod-llupAdnaOS,M,P,K,SstroP

ecnatsisertupnirotsisnartdlohlevel-wolTNIR

ecnatsisertupnirotsisnartdlohlevel-hgihTNIR

2LI

2HI

V

V

I

V

V

I

V

I

V

V

V

V

V

V

V

V

V

V

V

V

V

R

R

R

R

I

2LO

I

1HO

VDDV3=

1kael

I

1LO

V

2kael

I

3LO

I

2HO

I

3HO

VLOV0= 1Aµ

3kael

I

4LO

VHOV=

4kael

I

5LO

I

4HO

I

6LO

I

5HO

I

7LO

I

6HO

I

8LO

I

1MO

I

7HO

I

9LO

I

2MO

I

I

8HO

I

01LO

I

3MO

I

I

9HO

VIV2.0=

1LI

VIV8.0=

1HI

VIV=

1UP

VIV=

1DP

VIV2.0=

2LI

VIV8.0=

2HI

Aµ004=2.05.0V

LO

Aµ004–=V

HO

VIV=

SS

VIV=

DD

Am01= 5.0V

LO

V5.01= 1Aµ

HO

Aµ001= 5.0V

LO

Aµ001–=V

HO

Aµ001–=V

HO

Aµ001= 5.0V

LO

DD

Aµ02= 2.0V

LO

Aµ02–=V

HO

Aµ001= 2.0V

LO

Aµ001–=V

HO

Aµ02= 2.0V

LO

Aµ02–=V

HO

Aµ001= 2.0V

LO

LO

HO

LO

LO

LO

HO

LO

LO

LO

HO

IroAµ001=

Aµ001–=V

Aµ02= 2.0V

IroAµ02=

HO

IroAµ02=

HO

Aµ02–=V

Aµ001= 2.0V

IroAµ001=

IroAµ001=

Aµ001–=V

DD

DD

SS

DD

DD

DD

Aµ001–=

HO

Aµ02–=

Aµ02–=

Aµ001–=

HO

Aµ001–=

HO

sgnitaR

nimpytxam

052.0VDDV

V57.0

DD

5.0–VDD2.0–V

DD

1–

5.0–V

DD

5.0–V

DD

2.0–V

DD

2.0–V

DD

2.0–V

DD

V(

)2/

DD

2.0–

2.0–V

DD

V(

)3/

DD

2.0–

V3/2(

)

DD

2.0–

2.0–V

DD

V(

)3/

DD

2.0–

V3/2(

)

DD

2.0–

2.0–V

DD

060030021kΩ

060030021kΩ

03051005kΩ

03051005kΩ

060030021kΩ

060030021kΩ

V

DD

V(

DD

V(

DD

V3/2(

V(

DD

V3/2(

1

1Aµ

)2/

2.0+

)3/

2.0+

)

DD

2.0+

)3/

2.0+

)

DD

2.0+

tinU

V

Aµ

V

V

V

V

V

Continued on next page

No.3410–5/16

Page 6

LB58E68

Continued from preceding page

retemaraPlobmySsnoitidnoC

ecnatsiserrotsisnartpu-llupTNIR

ecnatsiserrotsisnartnwod-llupTNIR

ecnatsiserrotsisnartnwod-llupTSTR

ecnaticapacgnitasnepmocnoitallicsoTUOTXC

ycneuqerfgnitareporotallicsolatsyrCf

ycneuqerfgnitareporotallicsoretlifcimareCf

ycneuqerfkcolcecafretnilaireSf

Electrical Characteristics at Ta = 25˚C, VDD=4.5 to 5.5V

retemaraPlobmySsnoitidnoC

1egatlovylppusDCLV

2egatlovylppusDCLV

tnerrucylppuSI

tnerrucegakaelylppuSI

egatlovlevel-woltupni

egatlovlevel-hgihtupni

egatlov

egatlov

tnerruc

egatlov

egatlov

tnerruc

egatlov

tnerruc

TNIdna,AdnaOS,M,P,K,SstroP

TNIdna,AdnaOS,M,P,K,SstroP

egatlovlevel-woltupniNIFCdnaSERV

egatlovlevel-hgihtupniNIFCdnaSERV

level-woltuptuoAdnaOS,M,P,KstroP

level-hgihtuptuoAdnaOS,M,P,KstroP

egatlovtuptuolevel-WOLNtroPV

tnerrucegakaeltuptuoNtroPI

level-hgihtuptuoSOMC53GESot1GES

level-hgihtuptuolennahc-p53GESot1GES

egakaeltuptuolennahc-p53GESot1GES

level-woltuptuolennahc-n53GESot1GES

egakaeltuptuolennahc-n53GESot1GES

V

V

V

V

egakaeltupniTNIdna,AdnaOS,M,K,SstroP

I

egatlovlevel-woltuptuoSOMC53GESot1GESV

V

V

I

V

I

VIV=

2UP

2DP

3DP

d

latx

rec

res

1DD

2DD

DD

DD

1LI

1HI

2LI

2HI

2LO

1HO

1kael

1LO

2kael

3LO

2HO

3HO

3kael

4LO

4kael

SS

VIV=

DD

VIV=

DD

VDDV3=02Fp

egnarzHk232333

egnarzHk560607

emitllaf/esiR ≤ sµ010002zHk

V

DD

f

latx

V

DD

f

latx

V

DD

f

latx

V

V

Zck52= Ω .4erugifeeS.saib-3/1,edomtlah,

V

V

V

V

V

I

I

V

I

V

I

I

I

VLOV0= 1Aµ

I

VHOV=

f,V5=

DD

f,V5=

DD

f,V5=

DD

f,V5=

DD

f,V5=

DD

f,V5=

DD

DD

Am2=2.05.0V

LO

Am1–=V

HO

V5.5=

DD

Am01= 5.0V

LO

V5.01= 1Aµ

HO

Aµ052= 5.0V

LO

Aµ052–=V

HO

Aµ052–=V

HO

Aµ052= 5.0V

LO

DD

sgnitaR

nimpytxam

00300510005kΩ

00300510005kΩ

0207003kΩ

0910021zHk

sgnitaR

nimpytxam

,saib-2/1,Fµ1.0=2C=1C,V5=

.2erugifeeS.zHk867.23=

,saib-3/1,Fµ1.0=2C=1C,V5=

.3erugifeeS.zHk867.23=

,saib-3/1,Fµ1.0=2C=1C,V5=

.3erugifeeS.zHk867.23=

C,zHk23=

latx

latx

rec

rec

rec

rec

C,zHk004=

.5erugifeeS.edomtlah

C,zHM1=

.6erugifeeS.edomtlah

C,zHM2=

.6erugifeeS.edomtlah

C,zHM4=

.6erugifeeS.edomtlah

VIV=

VIV=

g

gcC=dc

gcC=dc

gcC=dc

gcC=dc

Z,Fp02=

k52= Ω,

c

.4erugifeeS.saib-3/1,edomtlah

C,zHk56ro83=

,Fp01=

g

,Fp033=

,Fp001=

,Fp33=

,Fp33=

.1erugifeeS.edomybdnats,V5.5=1Aµ

03.0VDDV

V7.0

DD

052.0VDDV

V57.0

DD

5.0–VDD2.0–V

DD

SS

DD

1–

5.0–V

DD

5.0–V

DD

5.2

76.1

33.3V

02

03

004

054

005

007

V

DD

V

DD

1

1Aµ

tinU

zHkegnarzHk837393

tinU

V

Aµ

V

V

Aµ

Continued on next page

No.3410–6/16

Page 7

Continued from preceding page

retemaraPlobmySsnoitidnoC

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

egatlov

ecnatsisertupnirotsisnart

ecnatsisertupnirotsisnart

ecnatsisertupni

ecnatsisertupni

LB58E68

level-wol-tuptuo53GESot1GESsaib-citatS

V

level-hgihtuptuo53GESot1GESsaib-citatS

V

egatlovlevel-woltuptuo1MOCsaib-citatSV

egatlovlevel-hgihtuptuo1MOCsaib-citatSV

level-woltuptuo53GESot1GESsaib-2/1

level-hgihtuptuo53GESot1GESsaib-2/1

level-woltuptuo4MOCot1MOCsaib-2/1

level-dimtuptuo4MOCot1MOCsaib-2/1

level-hgihtuptuo4MOCot1MOCsaib-2/1

level-woltuptuo53GESot1GESsaib-3/1

level-dimtuptuo53GESot1GESsaib-3/1

level-hgihtuptuo53GESot1GESsaib-3/1

level-woltuptuo4MOCot1MOCsaib-3/1

level-dimtuptuo4MOCot1MOCsaib-3/1

level-hgihtuptuo4MOCot1MOCsaib-3/1

dlohlevel-wolAdnaOS,M,P,K,SstroP

dlohlevel-hgihAdnaOS,M,P,K,SstroP

ecnatsisertupnirotsisnartdlohlevel-wolTNIR

ecnatsiserrotsisnartpu-llupTNIR

ecnatsiserrotsisnartnwod-llupTNIR

ecnatsiserrotsisnartnwod-llupTSTR

ycneuqerfgnitareporotallicsolatsyrCf

ycneuqerfgnitareporotallicsoretlifcimareCf

ycneuqerfkcolcecafretnilaireSf

V

V

V

V

V

V

V

V

V

V

V

R

R

rotsisnartpu-llupAdnaOS,M,P,K,SstroP

R

rotsisnartnwod-llupAdnaOS,M,P,K,SstroP

R

ecnatsisertupnirotsisnartdlohlevel-hgihTNIR

ecnaticapacgnitasnepmocnoitallicsoTUOTXC

I

5LO

4HO

6LO

5HO

7LO

6HO

8LO

1MO

7HO

9LO

2MO

8HO

01LO

3MO

9HO

1LI

1HI

1UP

1DP

2LI

2HI

2UP

2DP

3DP

d

latx

rec

res

Aµ02= 2.0V

LO

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

VIV2.0=

VIV8.0=

VIV=

VIV=

VIV2.0=

VIV8.0=

VIV=

VIV=

VIV=

VDDV5=02Fp

Aµ02–=V

HO

Aµ002= 2.0V

LO

Aµ002–=V

HO

Aµ02= 2.0V

LO

Aµ02–=V

HO

Aµ002= 2.0V

LO

LO

HO

LO

LO

LO

HO

LO

LO

LO

HO

IroAµ002=

Aµ002–=V

Aµ02= 2.0V

IroAµ02=

HO

IroAµ02=

HO

Aµ02–=V

Aµ002= 2.0V

IroAµ002=

IroAµ002=

Aµ002–=V

DD

DD

SS

DD

DD

DD

SS

DD

DD

egnarzHk232333

egnarzHk560607

emitllaf/esiR ≤ sµ010002zHk

Aµ002–=

HO

Aµ02–=

Aµ02–=

Aµ002–=

HO

Aµ002–=

HO

sgnitaR

nimpytxam

2.0–V

DD

2.0–V

DD

2.0–V

DD

V(

)2/

DD

2.0–

2.0–V

DD

V(

)3/

DD

2.0–

V3/2(

)

DD

2.0–

2.0–V

DD

V(

)3/

DD

2.0–

V3/2(

)

DD

2.0–

2.0–V

DD

03021005kΩ

03021005kΩ

0105002kΩ

0105002kΩ

03021005kΩ

03021005kΩ

0010050002kΩ

0010050002kΩ

0207003kΩ

0910021zHk

V(

DD

V(

DD

V3/2(

V(

DD

V3/2(

tinU

)2/

V

2.0+

)3/

V

2.0+

)

DD

V

2.0+

)3/

V

2.0+

)

DD

V

2.0+

zHkegnarzHk837393

No.3410–7/16

Page 8

Measurement Circuits

The following conditions apply to figure 1.

• Standby mode

• Port S input resistors enable

• I/O ports in output mode, all outputs HIGH

• INT open and internal input transistors enabled

• External pull-down resistor connected to RES.

• Current flow through components connected to LCD

ports is not included.

• f

= 32 to 65 kHz

xtal

• f

= 200 kHz to 4 MHz

cer

The flowing conditions apply to figures 2 and 3.

• f

= 32 kHz

xtal

• C1 = C2 = C3 = 0.1µF

• LCD ports are open.

• f

= 200 kHz to 4 MHz

cer

LB58E68

Figure 1. Supply leakage measurement Figure 4. Supply current measurement 1

Notes

1. Ceramic filter oscillator stopped

2. f

= 32, 38 or 65kHz

xtal

Figure 2. Supply voltage measurement 1

Figure 5. Supply current measurement 2

Figure 3. Output voltage measurement 2

Figure 6. Supply current measurement 3

Note

Crystal oscillator stopped

No.3410–8/16

Page 9

Pin Functions

emaN noitcnuF

1MOC

2MOC

3MOC

4MOC

1PUC

2PUC

SER .rotsisertupnilanretxenaseriuqerSER.rellortnocorcimehttesersµ002nahtretaergshtdiweslupSER

EO/TNI .desserddasiMORPEehtnehwtupnielbanetuptuoehtsasnoitcnufTNI

80A/1OS

90A/2OS

01A/3OS

11A/4OS

21A/1A

31A/2A

41A/3A

EC/4A

4D/1P

5D/2P

6D/3P

7D/4P

NITX

TUOTX

V

1DD

LB58E68

.wolebelbatehtninwohsera

ylcycytuD1MOC2MOC3MOC4MOC

citatS–––23

2/1––23

3/1 –7.24

4/1 23

etoN

φ

0

V

DD

zHk867.23=

.nepomehtevaelesiwrehto,snipesehtneewteb

.erawtfos

.desserddasiMORPEehtnehwtupnielbanepihcehtdnastupnisubsserddasasnoitcnufAtroP

.desserddasiMORPEehtnehwsenilsubatadsasnoitcnufPtroP

.nepotfelerayehtesiwrehto,snoitcennocrotallicsolatsyrcehtsanoitcufTUOTXdnaNITX

.noitcurtsniDLOHaretfastlahrotallicsoehT.noitponoitarugifnocsiycneuqerflatsyrcehT

Vdna1

DD

.wolebnwohssasnipesehttcennoc

saibcitatSsaib-2/1saib-3/1

,evirdsaibhcaeroF.snoitcennocroticapactiucricsaibevirdDCLsanoitcnuf2

elcycytudhcaerofycneuqrfemarfdnastuptuoevitcaehT.stuptuorevirdnommocDCLsanoitcnuf4MOCot1MOC

emarF

ycneuqerF

)zH(

roticapacralopibatcennoc,saib-3/1ro-2/1gnisunehW.tiucricredividegatlovevird-DCLehtfostrapera2PUCdna1PUC

2OS,tupniatadlairesehtsasnoitcnufosla1OS.desserddasiMORPEehtnehwstupnisubsserddasasnoitcnufOStroP

ybdenimetederaytiralopdnanoitceridkcolC.tuptuorotupnikcolcatadlairesehtsa3OSdnatuptuoatadlairesehtsa

V

2DD

NIFC

TUOFC

00A/1S

10A/2S

20A/3S

30A/4S

0D/1K

1D/2K

2D/3K

3D/4K

.noitcurtsniWOLSro

ta(sm8.7ro59.1 φ

0

.yaledecnuobedStropehtsaemasehtsidoirepyaledehT

.erawtfosybdetcelessidoirepyaledecnuobed)zHk867.23=

DLOHaretfastlahrotallicsoehT.nepotfelerayehtesiwrehto,snoitcennocretlifcimarecehtsanoitcnufTUOFCdnaNIFC

ehT.stiucricecnuobed-yeklanretnievahsnipStrop.desserddasiMORPEehtnehwstupnisubsserddasasnoitcnufStroP

.stiucricecnuobed-yektupnilanretnievahsnipKtroP.desserddasiMORPEehtnehwsenilsubatadsasnoitcnufKtroP

Continued on next page

No.3410–9/16

Page 10

Continued from preceding page

emaN noitcnuF

40A/1M

50A/2M

60A/3M

70A/4M

1N

2N

3N

4N

PPV/TST .dnuorgotdetcennocyllamronsitI.desserddasiMORPEehtnehwtupniPPVehtsasnoitcnufTST

53GESot1GES

.snoitponoitarugifnoc

ta(zHk4ro,2,1ehtsasnoitcnuf4N φ

0

Configuration Options

Oscillator

The oscillator options are ceramic filter, crystal, and

both ceramic filter and crystal. When the crystal oscillator is used, the oscillator frequency options are 32,

38 or 65 kHz. The ceramic filter and crystal oscillator

options are shown in figures 7 and 8, respectively.

LB58E68

2remitsa4Mdna,1remitsasnoitcnufosla3M.desserddasiMORPEehtnehwstupnisubsserddasasnoitcnufMtroP

.emitelcycehtelbuodsidoirepkcolclanretxemuminimehT.3edomnierasremitehtnehwstupnikcolclanretxe

.)WOLsihctaltuptuo4Nehtnehw(tuptuolangismrala)zHk867.23=

sateserastuptuolaudividnifonoitcnufehT.stuptuoesoprup-larenegrosrevirdtnemgesDCLsanoitcnuf53GESot1GES

Figure 8. Crystal oscillatorFigure 7. Ceramic filter oscillator

No.3410–10/16

Page 11

Input Ports

Ports S, K, P, SO and A input options are hold transistor and input transistor configurations as shown in f igure 9. The hold transistor options are LOW-level hold

transistor, HIGH-lev el hold transistor and no hold transistor enabled, The input options are pull-up and pulldown transistors enabled.

Figure 9. Ports S, K, P, SO and A input circuit

Note : Cofiguration data determines switch settings.

LB58E68

Figure 11. n-channel output

The output latch state of all LCD drivers and generalpurpose outputs can be reset in standby mode. The options are reset and no change.

Port N

Port N outputs are n-channel open-drain as shown in figure 12.

Outputs

SEG1 to SEG35

The SEG1 to SEG35 options are LCD driver or generalpurpose outputs, LCD driver bias and duty configiration,

general-purpose output configuration and output latch

state in STOP mode. The LCD driver and general-purpose output function selection is hard coded in the PLA

and, therefore, cannot be selected by software.

The LCD driver bias and duty configuration is set for all

LCD drivers. The configuration options are follows.

• Static

• 1/2-bias and 1/2-duty

• 1/2-bias and 1/3-duty

• 1/2-bias and 1/4-duty

• 1/3-bias and 1/3-duty

• 1/3-bias and 1/4-duty

The general-purpose output configuration is set for individual outputs. The options are CMOS, p-channel opendrain and n-channel open-drain. The p-channel and nchannel output equivalent circuits are shown in figures

10 and 11, respectively.

Figure 12. Ports N open-drain outputs

Serial Data Clock

The SO3 clock divider ratio options are 1/1, 1/2 and 1/4.

Interrupt Request

The interrupt request input options are hold transistor,

input transistor and interrupt request trigger configurations. The input hold transistor and input transistor options are the same as for the port inputs. The interrupt

request trigger options are rising-edge and falling-edge

triggering.

Figure 10. p-channel output

No.3410–11/16

Page 12

Design Information

Development Process

The LC5860 series software development tools,

EC5868.EXE software and a general-purpose PROM

programmer with a W58E68Q adapter board are re-

LB58E68

quired for LC58E68 program development. The de velopment flowchart is shown in figure 13.

Figure 13. Development flowchart

No.3410–12/16

Page 13

LC586X series software development tools

These tools are used on an MS-DOS computer to create programs and option data. See the LC586X series

development tools manual for further infomation.

EC5868.EXE

This program combines an LC586X series program with

the configuration option data generated by the option

LC5862H, 63H, 64H LC5866H, 68H

LB58E68

data software and converts the result to LC58E68 EPR OM

downloading format as shown in figure 14.

Figure 14. Conversion to EPROM format

No.3410–13/16

Page 14

LB58E68

For example, to con v ert the ROMSAMP.HXE program

file and the PLASAMP.HEX option data file into the

EP-SAMP.HEX download-format file, enter one of the

following commands at the command line:

A : >EC5868 ROMSAMP.HEX PLASAMP.HEX EP–SAMP.HEX ↵

or

A : >EC5868 B:ROMSAMP.HEX B:PLASAMP.HEX C:EP–SAMP.HEX ↵

or

A : >EC5868↵

****************************************************************

* LC58E68 PROGRAM & MASK OPTION CONVERSION Ver XXXX *

****************************************************************

A : ROM PROGRAM NAME : B:ROMSAMP.HEX ↵

A : PLA PROGRAM NAME : B:PLASAMP.HEX ↵

A : EP ROM WRITE NAME : B:EP-SAMP.HEX ↵

A program completion message is output at the end of

conversion.

If an error occurs, the program will issue one of the

following error messagees.

Note that the programmer provided with the EVA-520

and EVA-850 development tools cannot be used. Set the

programmer for a 256 Kbyte PROM, V

gram addresses 0000H to 40FFH.

The W58E68Q adapter board, shown in figure 15, is

• Error ON filename.HEX, FILE NOT FOUND

The file filename.HEX was not found or the f ile name

placed in the PROM programmer socket and the

LC58E68 to be programmed, in the W58E68Q adapter.

was incorrect.

• Error ON, MAKE LC5864H, 63H, 62H

The ROM data and option data are not consistent.The

cross assembler and option data software used should

be for the same device.

• Error ON filename.HEX, EOF NOT DETECTED

The file filename.HEX does not have a record end

marker or the file is corrupted.

• Error ON filename.HEX, ILLEGAL CHARACTER

The file filename.HEX contains a non-hexadecimal

character.

• Error ON filename.HEX, ADDRESS OVER

An address in the file filename.HEX exceeds the address limit.

• Error ON filename.HEX, ILLEGAL FILE HDR.

The file filename.HEX does not have the correct

LC586X series header or there is an error in the hex

Figure 15. W58E68Q adapter board

file.

• Error ON command line input, INVALID NUMBER

OF PARAMETERS

Affix an opaque seal to the window of the programmed

LC58E68 when not programming the EPROM.

The number of parameters entered on the command

line is incorrect.

• Error ON ILLEGAL, MASK OPTION DATA

The mask option data is incorrect.

Erasing the EPROM

The EPROM data can be erased with a standard UV

EPROM eraser.

=21V and pro-

P–P

PROM programmer and W58E68Q adapter

board

Programming the LC58E68 requires a general-purpose

PROM programmer and a W58E68Q adapter board.

Soldering

Do not use the solder-dip process for soldering the

LC58E68.

No.3410–14/16

Page 15

LB58E68

Reset Timing

The reset state is released following a HIGH-to-LOW

transition on RES. Configuration options and the segment output control PLA are initialized during the next

256 clock cycles. The program counter is then reset and

Ordering Information

T ypically, a mask ROM LC586X series de vice is ordered

after a system has been prototyped with the LC58E68.

However, a programmed LC58E68 or an LC58E68-format hex file cannot be used to specify the mask ROM

device.

When ordering, provide three EPROMs each containing

the mask ROM program generated using a standard as-

Table 1. Electrical characteristics comparison

retemaraPlobmySsnoitidnoC86E85CLseiresX685CLtinU

erutarepmetgnitarepOrpoT04ot0107ot03–°C

egatlovylppuSV

tnerrucylppusedom-tlahlacipyTI

DD

V

V

DD

V

V

V

program execution begins. Configuration options are invalid and segment outputs are held at VSS from when

RES goes HIGH until the options are initialized.

sembler and another three EPROMs each containing the

option data generated using the option specification tool.

A comparison of LC58E68 characteristics with those of

LC586X series mask ROM devices is shown in tables 1

and 2.

5.5ot8.20.6ot0.2V

f,V3=

DD

f,V5=

DD

f,V5=

DD

f,V5=

DD

f,V5=

DD

zHk23=54

latx

zHk23=0251

latx

zHk004=004004

rec

zHM2=005005

rec

zHM4=007007

rec

Aµ

Table 2. Configuration comparison

retemaraP86E85CLsecivedX685CL

tesergnirud

stuptuonommocdnatnemgesDCL

teserretfaetatstuptuotnemgeSdeyalpsidtoN deyalpsidtonrodeyalpsiD

epyttiucricrotallicsO latsyrcdnaretlifcimarecro,latsyrc,retlifcimareC

ycneuqerflatsyrC )tesergnirudzHk56(zHk56ro83,23zHk56ro83,23

tupniteserSERHGIH-evitcA

stuptuoNtroPniard-nepO SOMCroniard-nepO

epytevirdDCL

).1etoneeS(ytud-4/1dna

egnar'.oNebortS').2etoneeS(HE1otH00HE1otH00

VtadleheradnaSOMCerastuptuotnemgeS

.

SS

.niard-nepodnalennahc-nerastuptuonommoC

,ytud-3/1dnasaib-2/1,ytud-2/1dnasaib-2/1,citatS

saib-3/1roytud-3/1dnasaib-3/1,ytud-4/1dnasaib-2/1

noitarepocitatS

CR,latsyrcdnaretlifcimarec,latsyrc,retlifcimareC

rorotallicsolanretxe,latsyrcdnatiucricCR,tiucric

latsyrcdnarotallicsolanretxe

roHGIH-evitca,pu-lluphtiwWOL-evitca,WOL-evitcA

pu-lluphtiwHGIH-evitca

-2/1,ytud-3/1dnasaib-2/1,ytud-2/1dnasaib-2/1,citatS

dnasaib-3/1,ytud-3/1dnasaib-3/1,ytud-4/1dnasaib

desunuroytud-4/1

Notes

1. Configure as static drive if not used.

2. Strobe numbers 00 to 1EH can be used in applications that use a 2 MHz ceramic resonator. Strobe numbers 0E, 0F and

1EH cannot be used in applications that use a 4 MHz ceramic resonator.

No.3410–15/16

Page 16

LB1720

The LC586X series devices, including the LC58E68, are

shown in table 3.

Table 3. LC586X series devices

eciveD)setybk(yticapacMOR)stib(yticapacMARepytegakcaP

H2685CL4652 × 408PIQ

H3685CL6652 × 408PIQ

H4685CL8652 × 408PIQ

H6685CL21652 × 408PIQ

H8685CL61652 × 408PIQ

86E85CL)MORPE(61652 × 408CFQ

Table 4. Recommended ceramic resonators for LC5862H/63H/64H/66H/68H mask ROMs

rerutcafunaM

ycneuqerfrotanoseR

rebmuntraPC

zHk004P004BSC033033B004-RBK033033

zHk008J008BSC022022H008-RBK001001

zHM1J0001BSC022022H0001-RBK001001

zHM2

zHM4

GM00.2ASC

GM00.2TSC

GM00.4ASC

GM00.4TSC

ataruMarecoyK

)Fp(Cdc)Fp(rebmuntraPC

gc

3333SM0.2-RBK3333

3333SM0.4-RBK3333

gc

)Fp(Cdc)Fp(

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of October, 2001. Specifications and information herein are subject

to change without notice.

No.3410–16/16

Loading...

Loading...