Page 1

SERVICE AND OPERATING MANUAL

½ Filter/Regulator

½ Lubricator

Filter/Regulator

INSTALLATION: Before installing, blow out pipe line to remov e scale and other f oreign

matter. This unit has DRYSEAL pipe threads. Use pipe compound or tape sparingly to male

threads only . Install units in pipeline so that flow is with the arrows as indicated on faces of body .

Install as near as possible to equipment serviced.

MAINTENANCE: To maintain maximum filter ing efficiency and to avoid excessive

pressure drop, the filter must be kept clean. Bowl drainage is automatic in the Auto Drain

model, however, manual draining can also be done by removing the bowl. A visible coating of

dirt or condensate on the filter element surface or an excessive pressure drop is an indication

that cleaning is necessary.

FILTER CLEANING: To clean, it is not necessar y to remove filter from the line.

Disassembly is simple and does not require tools. Before disassembly, shut off air supply and

depressurize filter. Clean all par ts except plastic bowl with alcohol and blow out filter body

before reassembly. Wash filter element in alcohol and blow out from the inside. Plastic bowls

must be cleaned with household soap only.

AUTO DRAIN OPERA TION: A uto Drain filters are equipped with a float actuated

device which automatically ejects liquid contaminates.

REDUCED PRESSURE ADJUSTMENT: To adjust reduced pressure

setting, loosen lock screw in center of knob and turn knob clockwise to increase pressure

setting and counter-clockwise to lower setting. With relieving-type regulators the reduced

pressure follows adjustment of the screw.

REGULATOR CLEANING: Erratic regulator operation or loss of regulation is

generally due to dirt in the disc area. To clean, shut off and depressurize air line and disassemble

the regulator. Refer to drawing on reverse as a guide to disassembly and subsequent

reassembly. Clean parts with household soap and blow out body with compressed air. When

reassembling, make sure the disk assembly is firmly in place and that the disc stem fits into

center hole of diaphragm assembly. Tighten cage slightly more than hand tight (to 50 inch/

pounds, or 5.65 Newton meters torque).

W ARNING

The polycarbonate plastic material used

to manufacture the plastic bowls and the

sight dome on lubricators may be

attacked by certain chemicals. DO NOT

use these units on systems with air

supplied by a compressor lubricated with

synthetic oils or oils containing

phosphate esters or chlorinated

hydrocarbons. These oils carry over into

the air lines and will chemically attack or

possibly rupture the bowl and lubricator

sight dome. DO NOT expose these units

to materials such as carbon tetrachloride,

trichlorethylene, acetone, paint thinner,

cleaning fluids, or other harmful materials.

These will cause the plastic to craze and/

or rupture. For use in environments where

any of these chemicals may be present,

consult the factory for approval prior to

installation.

Filter/Regulator & Lubricator

BOWL MAX PRESS. MAX TEMP

PLASTIC 150 psi 120°F

10.3 bar 49°C

W ARNING

Clean metal bowl and sight glass only

with household soap. Do not use

denatured alcohol to clean.

Lubricator

LUBRICANT: For average conditions, the use of high quality SAE #10 (S.U.V. 150-200

SEC. @ 100°F/38°C) non-detergent oil is recommended.

FILLING: Depressurize system and slowly remove the fill plug. Fill to within ¼”(.635cm)

of top of bowl using correct oil. For best results use a long spout oil can. Lubricators may also

be filled by depressurizing the system and removing the bowl. After filling, replace the bowl,

making sure it has been tightened before repressurizing the system.

ADJUSTMENT: The adjustment knob is factory set, fully closed. When turned fully

clockwise, no oil is delivered to the venturi for atomization and equipment is not being lubricated.

T o adjust oil drip rate, turn on the air , start flow and set knob to obtain the desired drip rate. Drip

rate is visible through the sight dome. As a start, one or two drop per minute is suggested,

correct lubrication being a matter of experience and demand. Clockwise rotation of knob

decreases oil feed rate. To check lubrication, hold thumbnail or a mirror near the equipment

exhaust. A heavy film indicates over-lubrication and the drip rate should be reduced by turning

knob to a lower setting.

LUBRICATOR MAINTENANCE & CLEANING: If both air and oil are

kept clean and the oil level never allowed below end of tube in the bowl the lubricator should

provide long periods of unattended service. When no oil drips through the sight dome,

regardless of knob adjustment, cleaning is necessary. To clean, it is not necessar y to remove

lubricator from the line. Depressurize and disassemble. In most instances cleaning is needed

only in the oil metering area. Pull off adjusting knob and unscrew sight dome assembly,

remove inner drip spout and clean with household soap. PLASTIC BOWLS AND SIGHT DOME

MUST BE CLEANED WITH HOUSEHOLD SOAP ONLY.

©Copyright 1997 Warren Rupp, Inc. All rights reserved.

WARREN RUPP, INC. · A Unit of IDEX Corporation · P.O. Box 1568, Mansfield, Ohio 44901-1568 · (419) 524-8388 · Fax (419) 522-7867

520-190-000 10/97

A Note About Air Valve Lubrication

The SandPIPER pump’s pilot valve and

main air valve assemblies are designed

to operate WITHOUT lubrication. This is

the preferred mode of operation. There

may be instances of personal

preference, or poor quality air supplies

when lubrication of the compressed air

supply is required. The pump air system

will operate with properly lubricated

compressed air supplies.

It is important to remember to inspect

the sleeve and spool set routinely. It

should move back and forth freely. This

is most important when the air supply

is lubricated. If a lubricator is used, oil

accumulation will, over time, collect any

debris from the compressed air. This can

prevent the pump from operating

properly.

Page 2

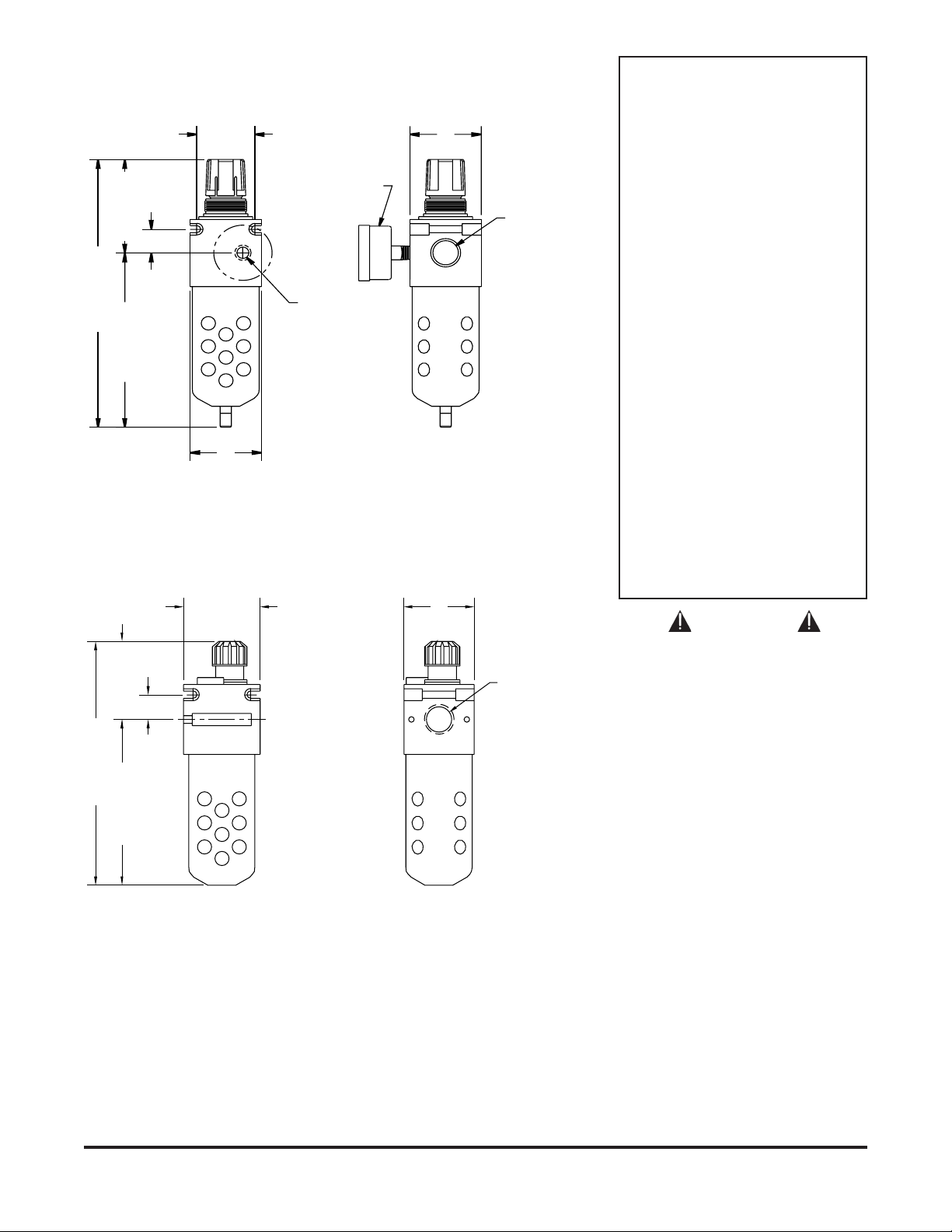

Filter/Regulator

(41.7)

1 41/

64

1 ½ PRESSURE

GAUGE (INCLUDED)

32 (70.6)

/

25

2

64

/

45

(17.8)

2

(50.8)

½ NPT PORT

BOTH SIDES

Part No. Description

020-050-000 ½” Filter/Regulator

Includes Mounting Bracket

Air requirements to

85 SCFM, 40.1 l/sec.

020-050-001 Lubricator

Optional

020-050-002 Shut Off Valve

020-050-004 Replacement Filter

for F/R 020-050-000

Includes 40 micron element

(202)

32

/

31

7

(132)

16

/

3

5

(50.8)

Lubricator

2 3/16

(55.5)

/32 (56)

7

2

020-050-005 Regulator Repair Kit

GAUGE PORT

1

/

8 NPT

020-049-006 Lubricator Repair Kit

2

2

(50.8)

020-050-007 Mounting Bracket

020-050-008 End Plate Kit

020-053-000 Pressure Gauge

for Regulator 020-050-000

Includes Diaphragm Assembly ,

Stem & Disc Assembly

for Lubricator 020-050-001

Includes Sight Dome

Sight Dome Retainer

Sight Dome O-Ring

Drip Spout

Drip Spout O-Ring

for F/R 020-050-000

for F/R 020-050-000,

Lubricator 020-050-001,

Shut Off Valve 020-050-002

for F/R 020-050-000

WARNING

Clean metal bowl and sight glass only

with household soap. Do not use

½ NPT PORT

denatured alcohol to clean.

TYPE 2 PLACES

/16 (176)

15

6

©Copyright 1997 Warren Rupp, Inc. All rights reserved.

WARREN RUPP, INC. · A Unit of IDEX Corporation · P.O. Box 1568, Mansfield, Ohio 44901-1568 · (419) 524-8388 · Fax (419) 522-7867

520-190-000 10/97

/32 (120)

23

4

/32 (18)

23

+-1/8” (3.2)

inches (millimeters)

Loading...

Loading...