Page 1

Samsung Electronics 1-1

1. Be sure that all of the built-in protective devices

are replaced. Restore any missing protective

shields.

2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices,

including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

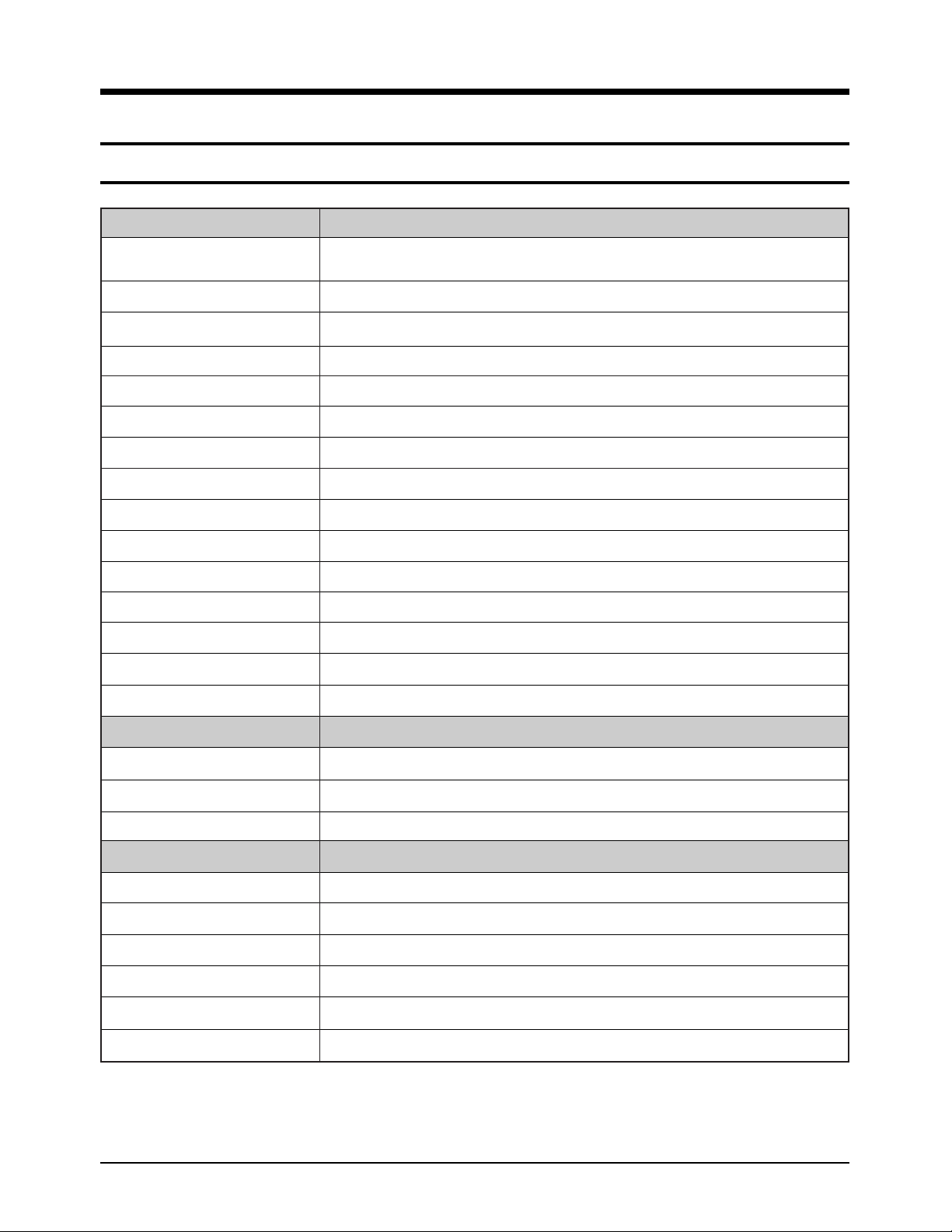

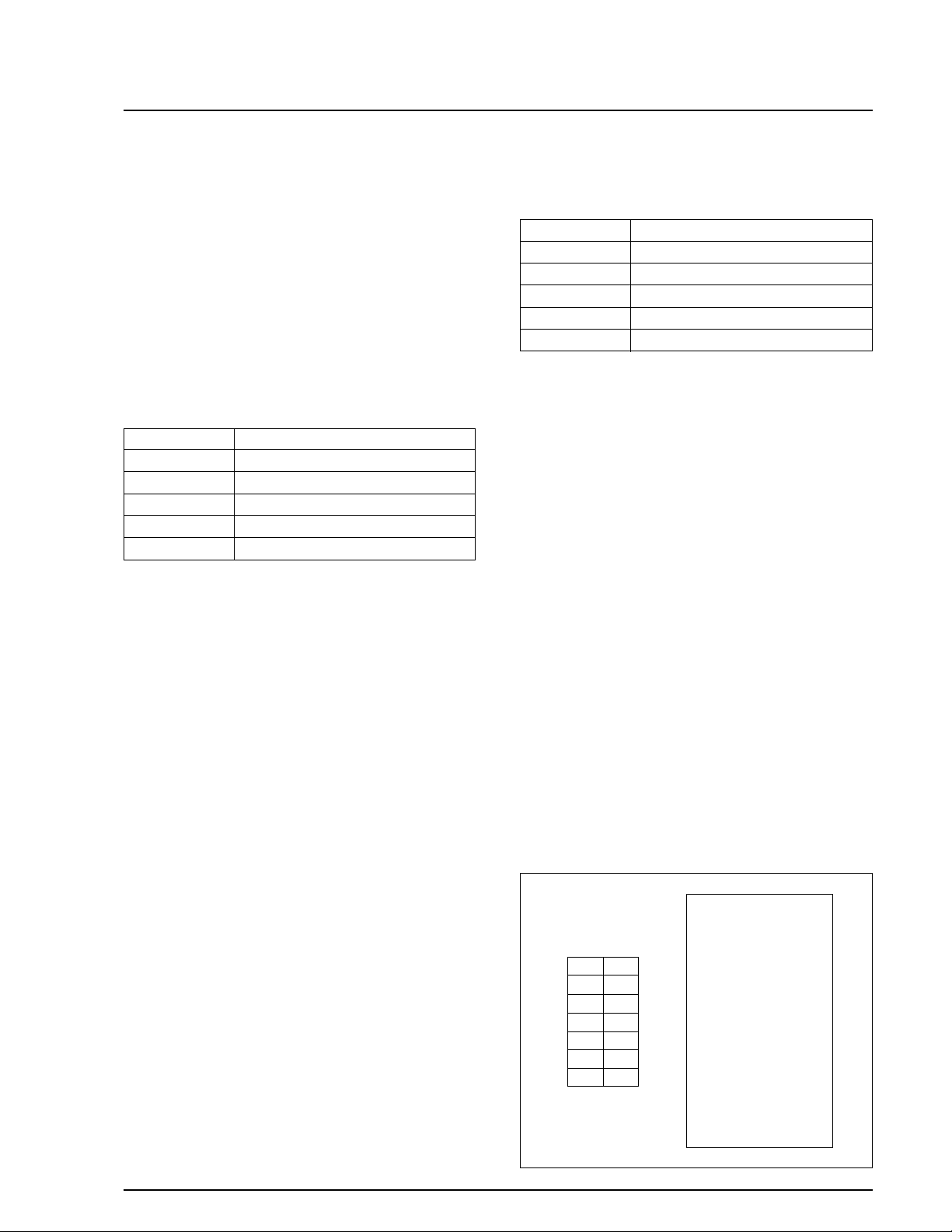

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or

a metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and

Underwriters Laboratories (UL Publication

UL1410, 59.7).

5. With the unit completely reassembled, plug the

AC line cord directly the power outlet. With the

unit’s AC switch first in the ON position and

then OFF, measure the current between a

known earth ground (metal water pipe, conduit, etc.) and all exposed metal parts, including : antennas, handle, brackets, metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection, replace the picture tube only with one that

is the same type as the original.

Fig. 1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by

static electricity.

10. Immediately before handling any semiconduc-

tor components or assemblies, drain the electrostatic charge from your body by touching a

known earth ground. Alternatively, wear a discharging Wrist-strap device. (Be sure to

remove it prior to applying power--this is an

electric shock precaution.)

1. Precautions

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Page 2

11. High voltage is maintained within specified

limits by close-tolerance, safety-related components and adjustments. If the high voltage

exceeds the specified limits, check each of the

special components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical design of this unit. Example : Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading is greater than 1.0V, remove the AC power

plug, reverse its polarity and reinsert. Re-measure the voltage between the chassis and

ground.

14. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation transformer inserted between the receiver and the

power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

16. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched,

out-of-place, or frayed wiring. Do not change

the spacing between components and the

printed circuit board. Check the AC power

cord for damage. Make sure that leads and

components do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

19. Do not remove, install or handle the picture

tube without first putting on shatterproof goggles equipped with side shields. Never handle

the picture tube by its neck. Some “in-line”

picture tubes are equipped with a permanently

attached deflection yoke; do not try to remove

such “permanently attached” yokes from the

picture tube.

20. Product Safety Notice :

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original--even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Samsung Electronics1-2

Precautions

Page 3

Samsung Electronics 2-1

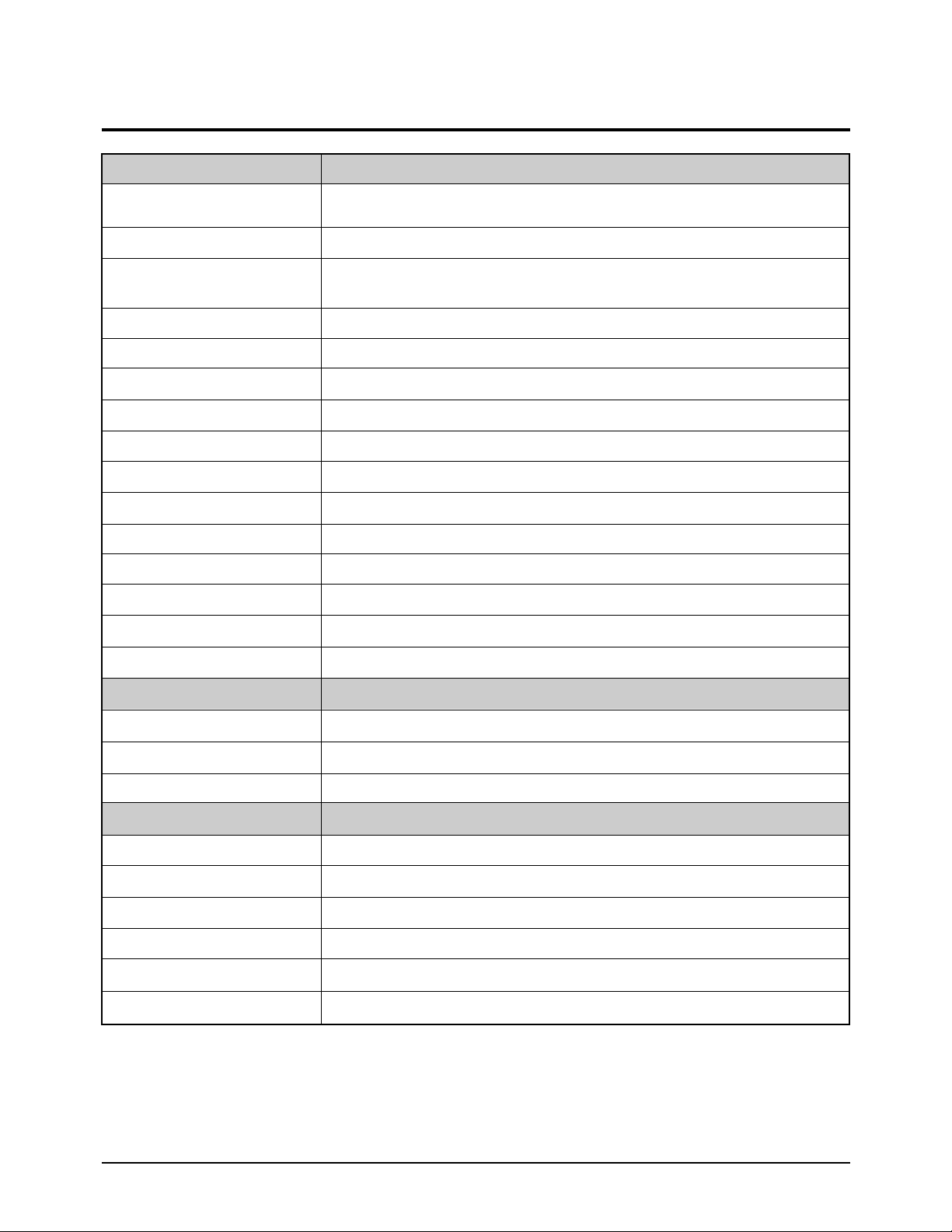

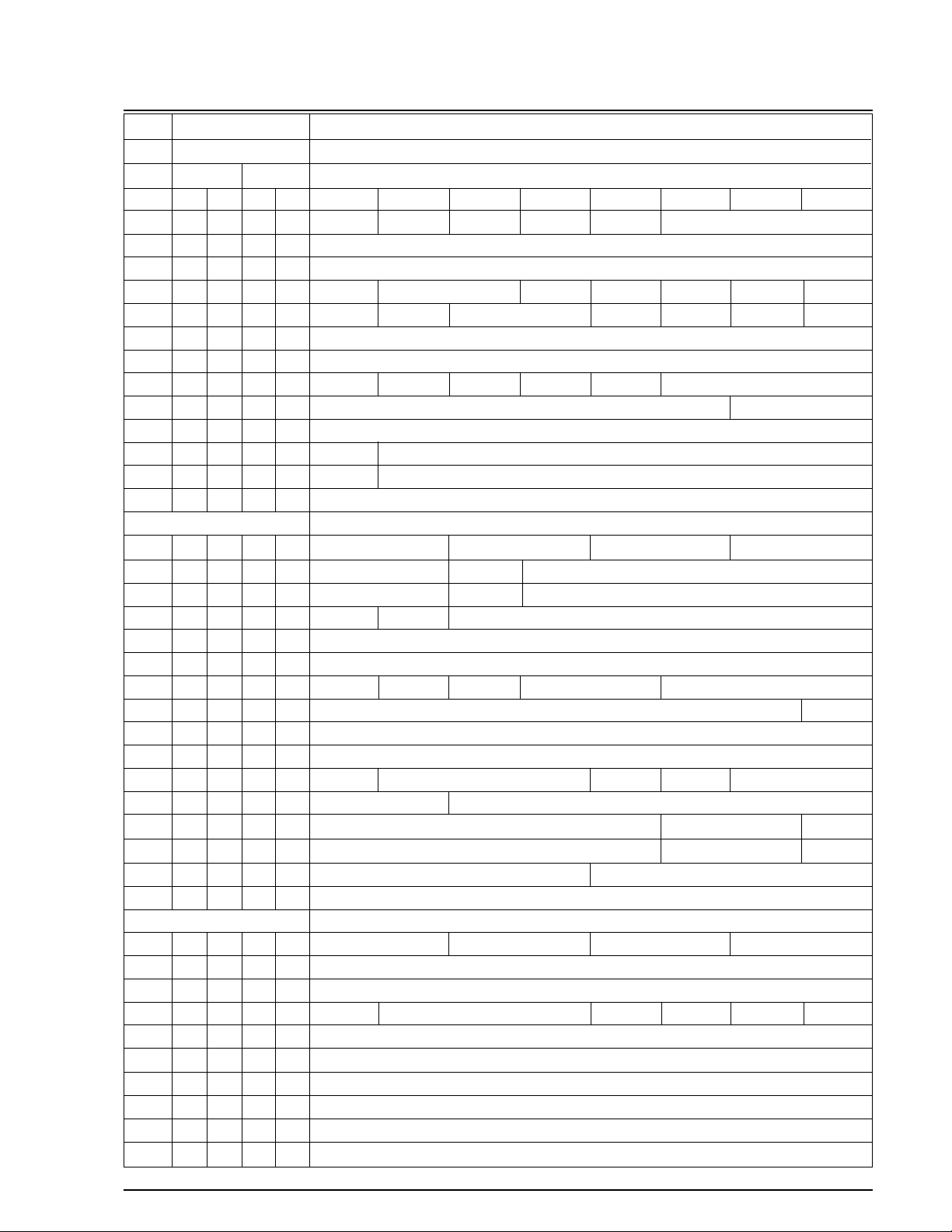

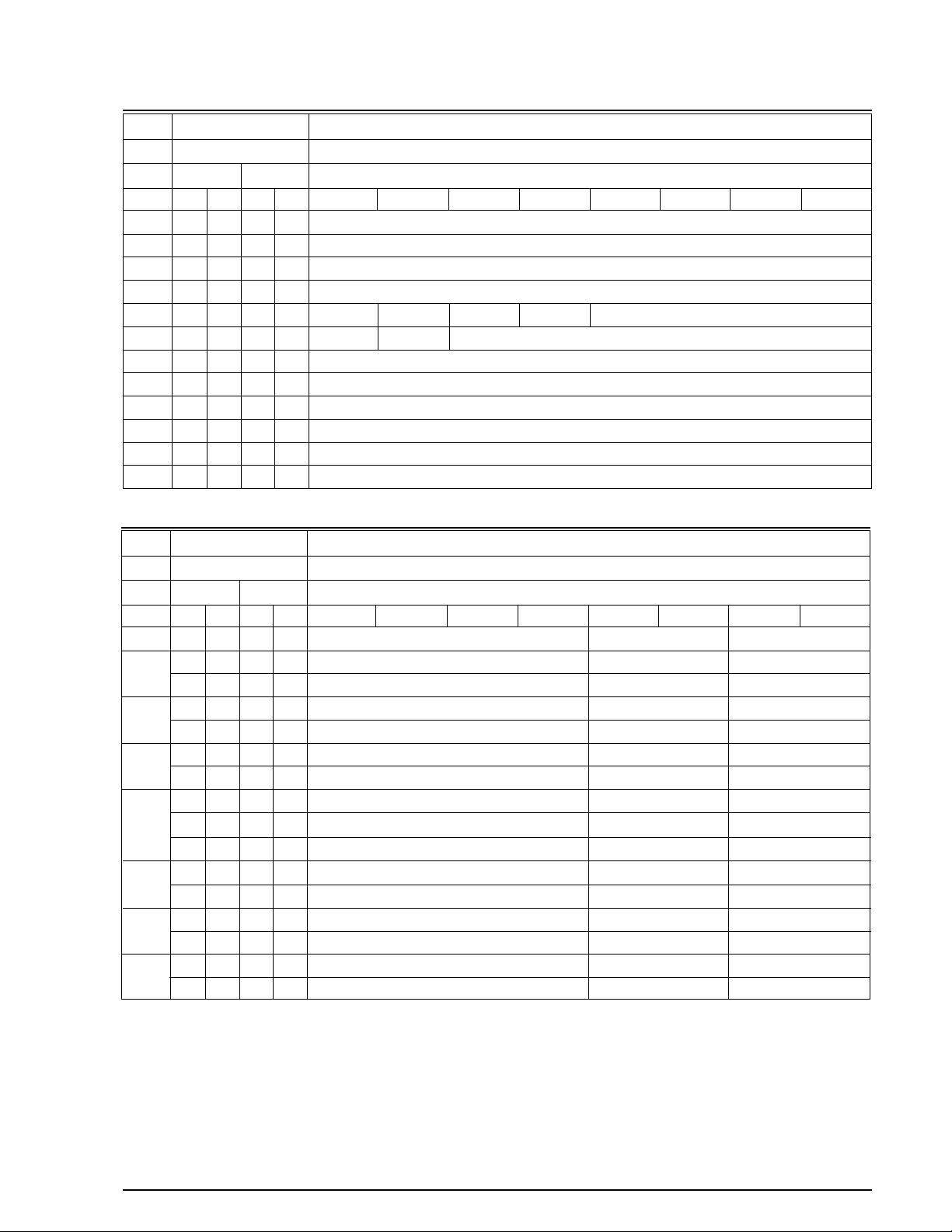

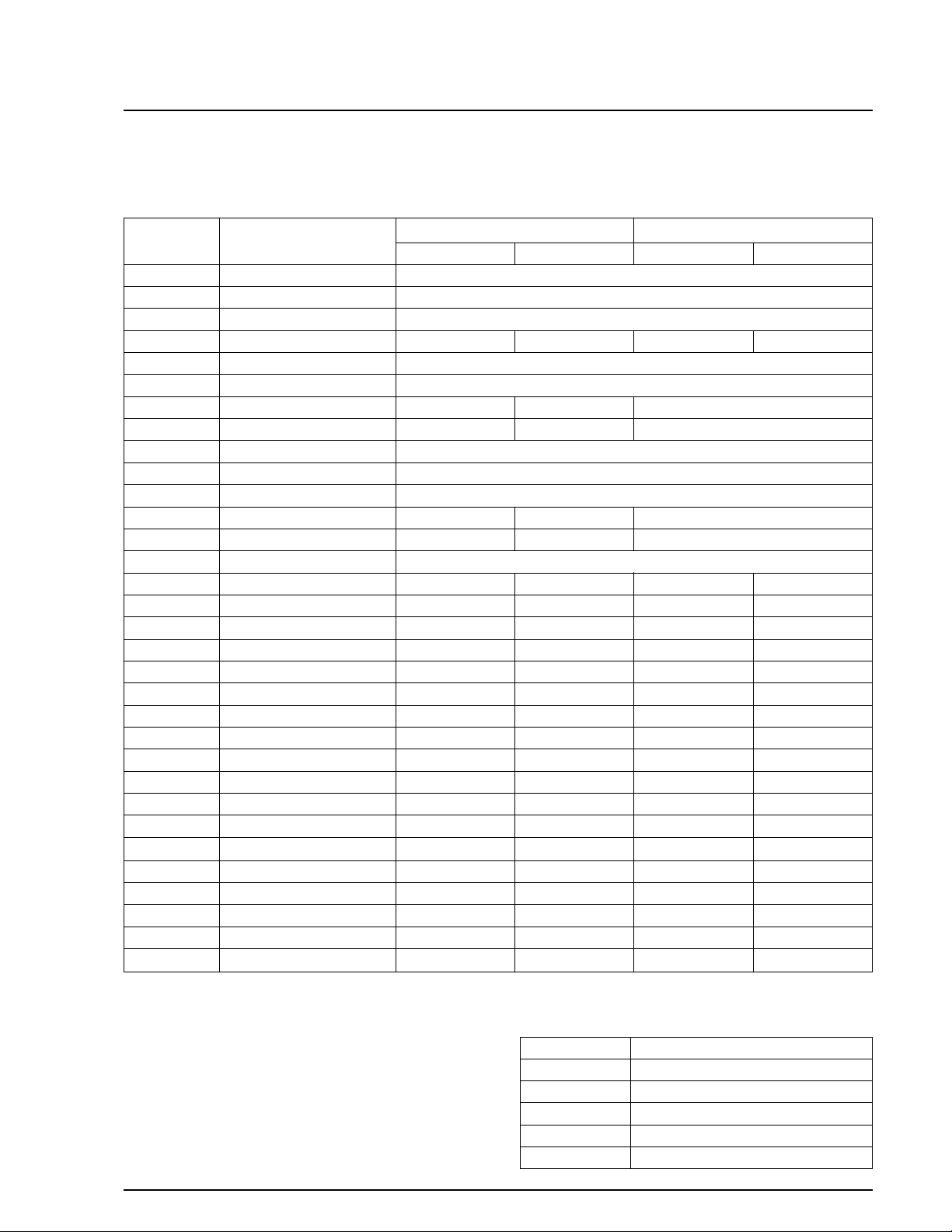

2. Product Specifications and Comparison Chart

2-1 NTSC Model (SCL500/L520/L530/L550)

Recording system

Video signal

Usable cassette

Tape speed

Speed mode

Recording time

FF or REW time

Image device

Optical zoom ratio

Focal lengh: f

F

Filter diameter

Focus system

Macro

Min. Illumination

Connectors

Video out

Audio out

External mic

General

Power requirement

Power consumption

Built-in mic

Operating temperature

Dimension (W x H x D)

Weight

System

SCL500/L520/L530/L550

Video: 2 rotary heads Helical scanning FM

Audio: FM monaural system

NTSC color, EIAstandard

SCL500/L520/L530 : 8mm SCL550 : Hi8 or 8mm

SP:14.345 mm/sec

Record: SP only, Playback: SP and LP

P6-120: 120 min.

P6-120: approx. 6.5 min.

CCD(Charge Coupled Device)

22X

3.6 ~ 79.2 mm

1.6

46 mm

Inner

Auto wide macro

0.3 lux (visible)

Mini jack, 1 Vp-p, 75 ohms, Unbalanced

Mini jack 7.7 dBs, imp.: less than 1.8 K ohms

Monaural,

Ø3.5

7.4 ~ 8.4 V DC

SCL500/L520: 4.3W, SCL530: 4.7W, SCL550: 5.3W

Condenser mic, omni-directional

0°C to 40°C (32°F to 104°F)

101 x 104 x 176 (mm) ; 3.98 x 4.09 x 6.93 (inch)

760g (1.675 lbs)

Page 4

Samsung Electronics2-2

Products Specifications and Comparison Chart

2-2 PAL Model (VP-L500/L520/L530/L530B/L550)

✤ The technical specifications and design may be changed without notice.

Recording system

Video signal

Usable cassette

Tape speed

Speed mode

Recording time

FF or REW time

Image device

Optical zoom ratio

Focal lengh: f

F

Filter diameter

Focus system

Macro

Min. Illumination

Connectors

Video out

Audio out

External mic

General

Power requirement

Power consumption

Built-in mic

Operating temperature

Dimension (W x H x D)

Weight

System

VP-L500/L520/L530/L530B/L550

Video: 2 rotary heads Helical scanning FM

Audio: FM monaural system

PAL color, CCIR standard

VP-L500/L520/L530/L530B: 8mm

VP-L550: Hi8 or 8mm

SP: 20.051 mm/sec

Record: SP only, Playback: SP and LP

P5-120: 120 min.

P5-120: approx. 8 min.

CCD(Charge Coupled Device)

22X

3.6 ~ 79.2 mm

1.6

46 mm

Inner

Auto wide macro

0.3 lux (visible)

Mini jack, 1 Vp-p, 75 ohms, Unbalanced

Mini jack 7.7 dBs, imp.: less than 1.8 K ohms

Monaural,

Ø3.5

7.4 ~ 8.4 V DC

VP-L500/L520: 4.3W, VP-L530/L530B: 4.7W, VP-L550: 5.3W

Condenser mic, omni-directional

0°C to 40°C

101 x 104 x 176 (mm)

760g

Page 5

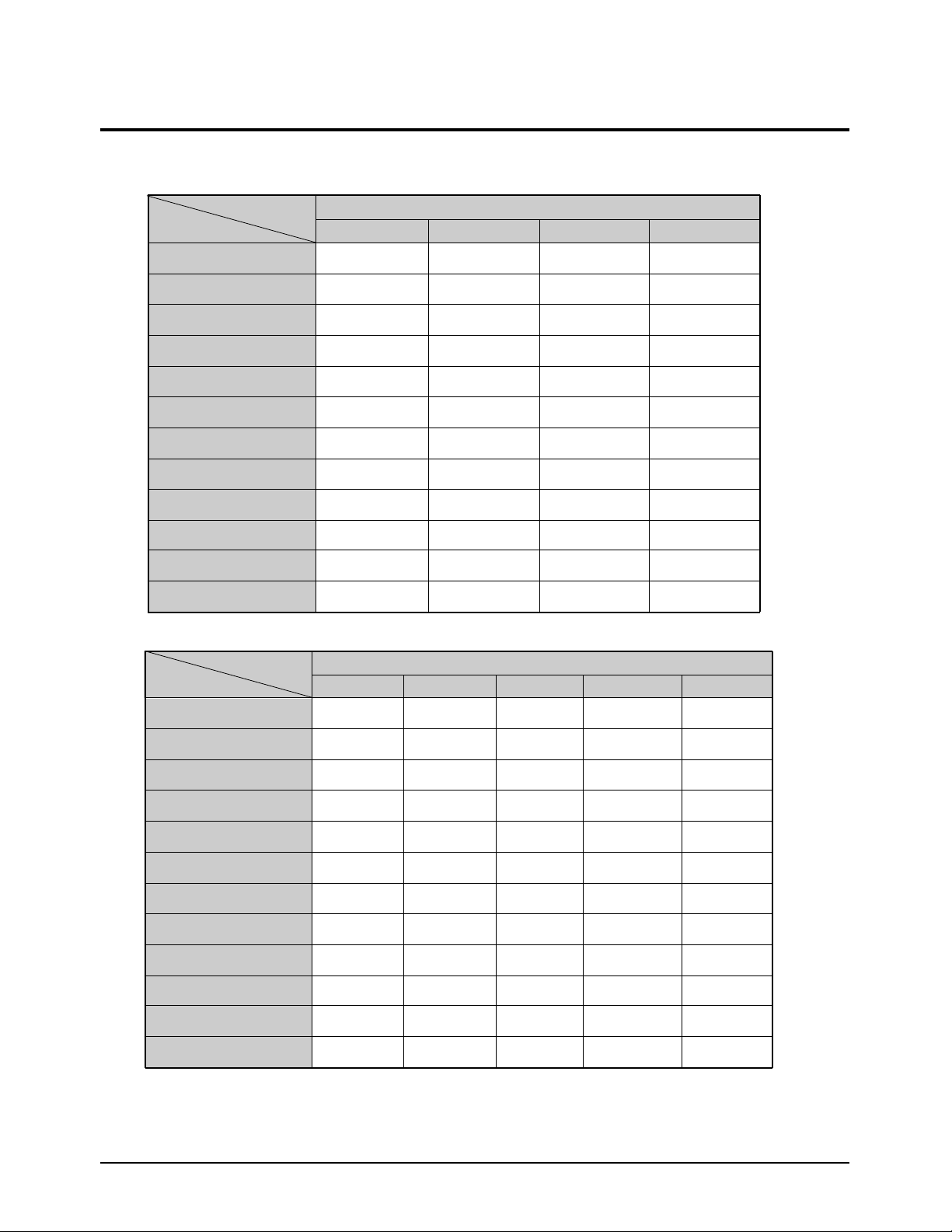

Samsung Electronics 2-3

Products Specifications and Comparison Chart

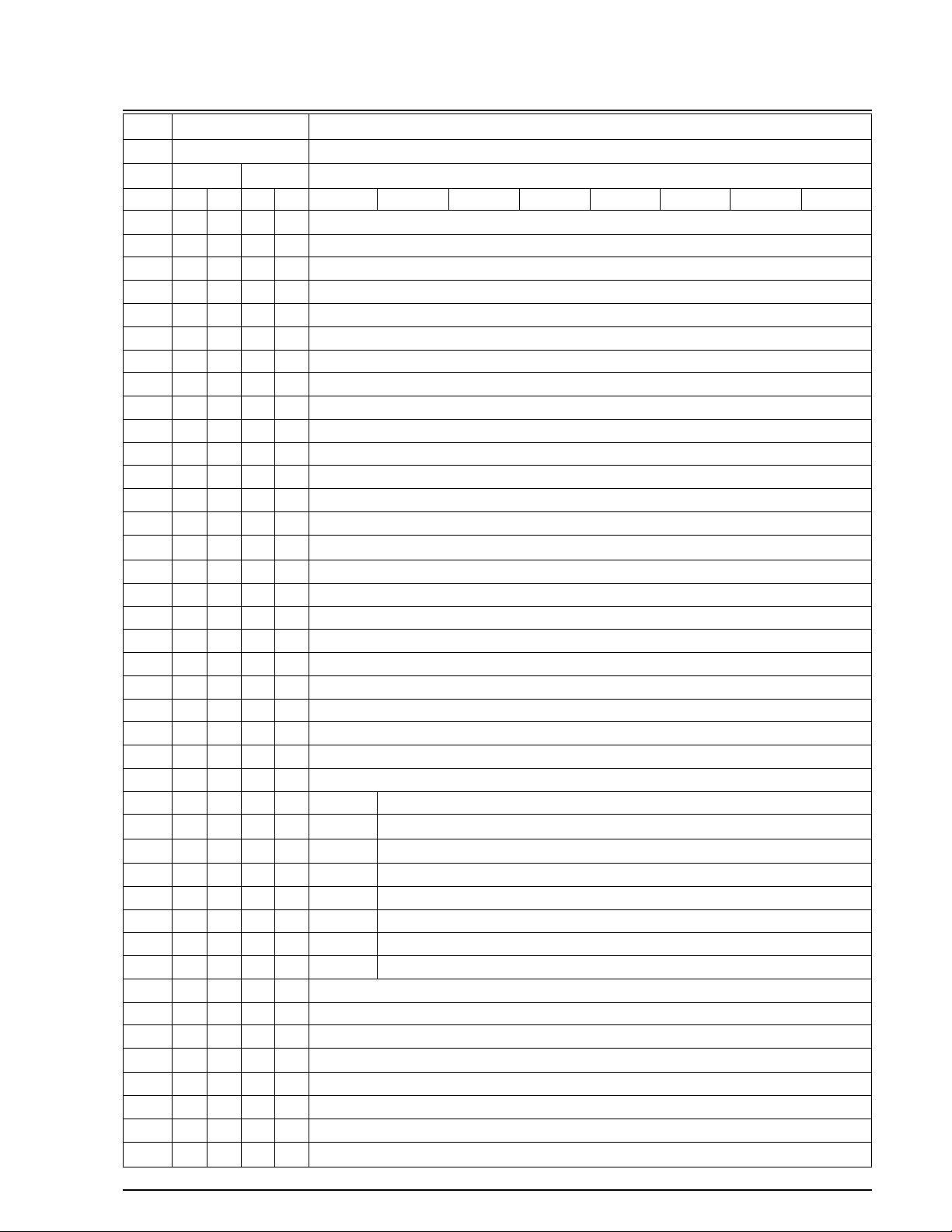

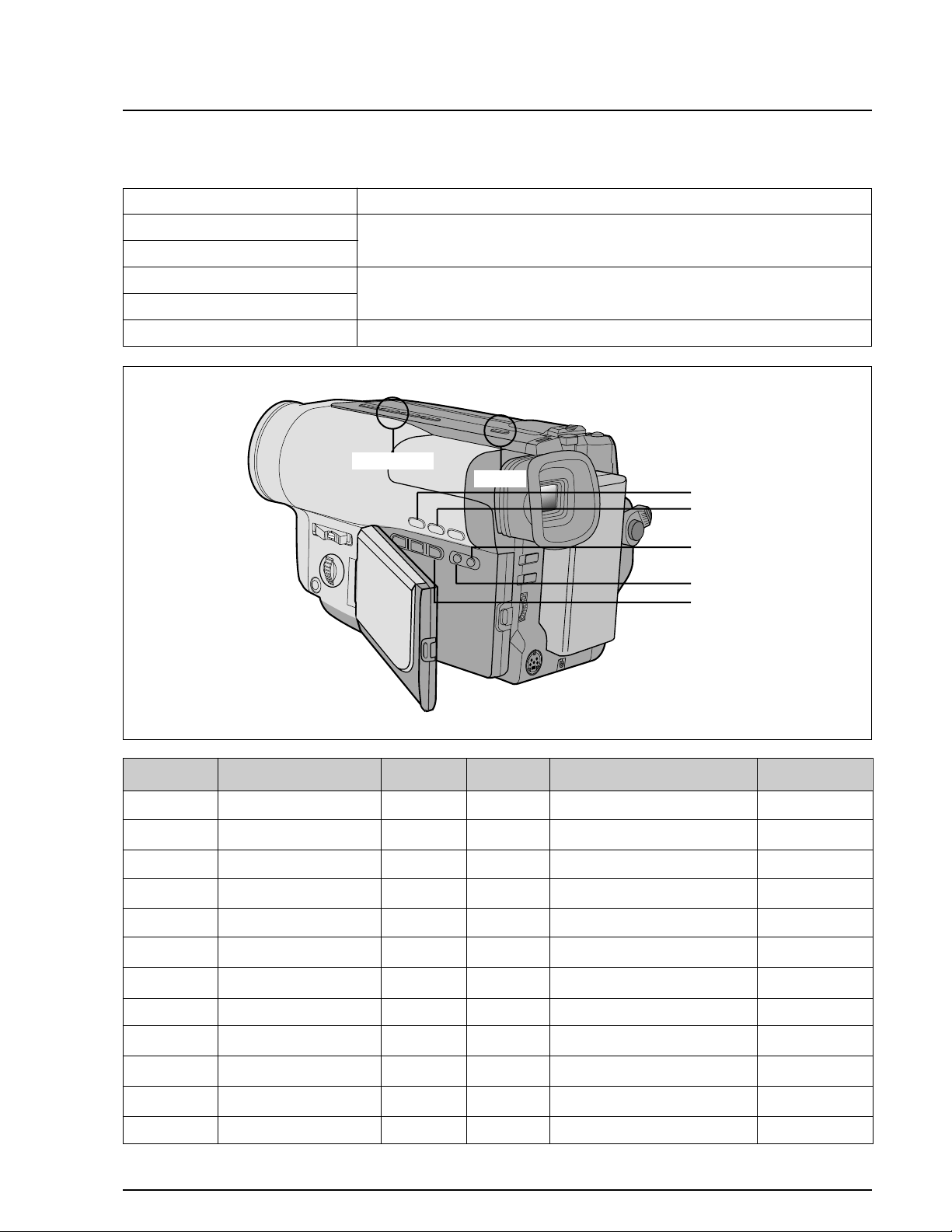

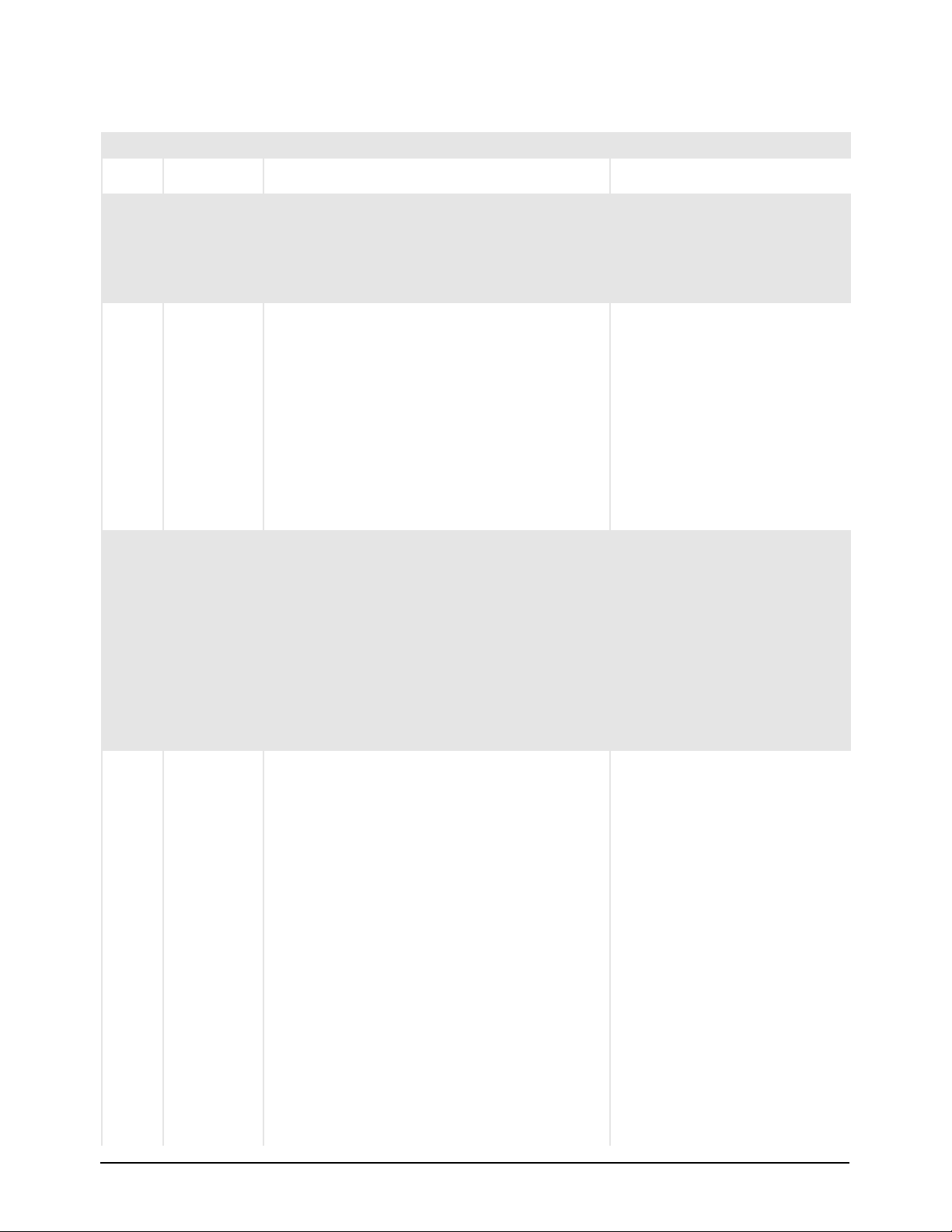

2-3 Comparison Chart

Features

Model

Format

SCL520

8mm

SCL530

8mm

SCL550

X

Li-ion

O

X

X

EVF

X

Video Light

Battery

BLC

Remote Control

XDR

Viewfinder

DIS

X

X

SNAP/SHOT

PIP

NTSC

X

Li-ion

O

O

X

EVF

O

O

O

Hi8

X

Li-ion

O

O

X

EVF

O

O

O

270K

CCD

270K

410K

SCL500

8mm

X

Li-ion

O

X

X

EVF

X

X

X

270K

220X 440X 440X 440XDigital Zoom Ratio

Features

Model

Format

VP-L500 VP-L520 VP-L530 VP-L530B

Video Light

Battery

BLC

Remote Control

XDR

Viewfinder

DIS

SNAP/SHOT

PIP

PAL

CCD

8mm

X

Li-ion

O

X

X

EVF

X

X

X

320K

440X

8mm

X

Li-ion

O

O

X

EVF

X

X

X

320K

440X

8mm

X

Li-ion

O

O

X

EVF

X

X

X

320K

440X

8mm

X

Li-ion

O

O

X

EVF

O

O

O

320K

440X

Hi8

X

Li-ion

O

O

O

EVF

O

O

O

470K

440X

Digital Zoom Ratio

VP-L550

Page 6

MEMO

MEMO

Products Specifications and Comparison Chart

Samsung Electronics2-4

Page 7

Samsung Electronics 3-1

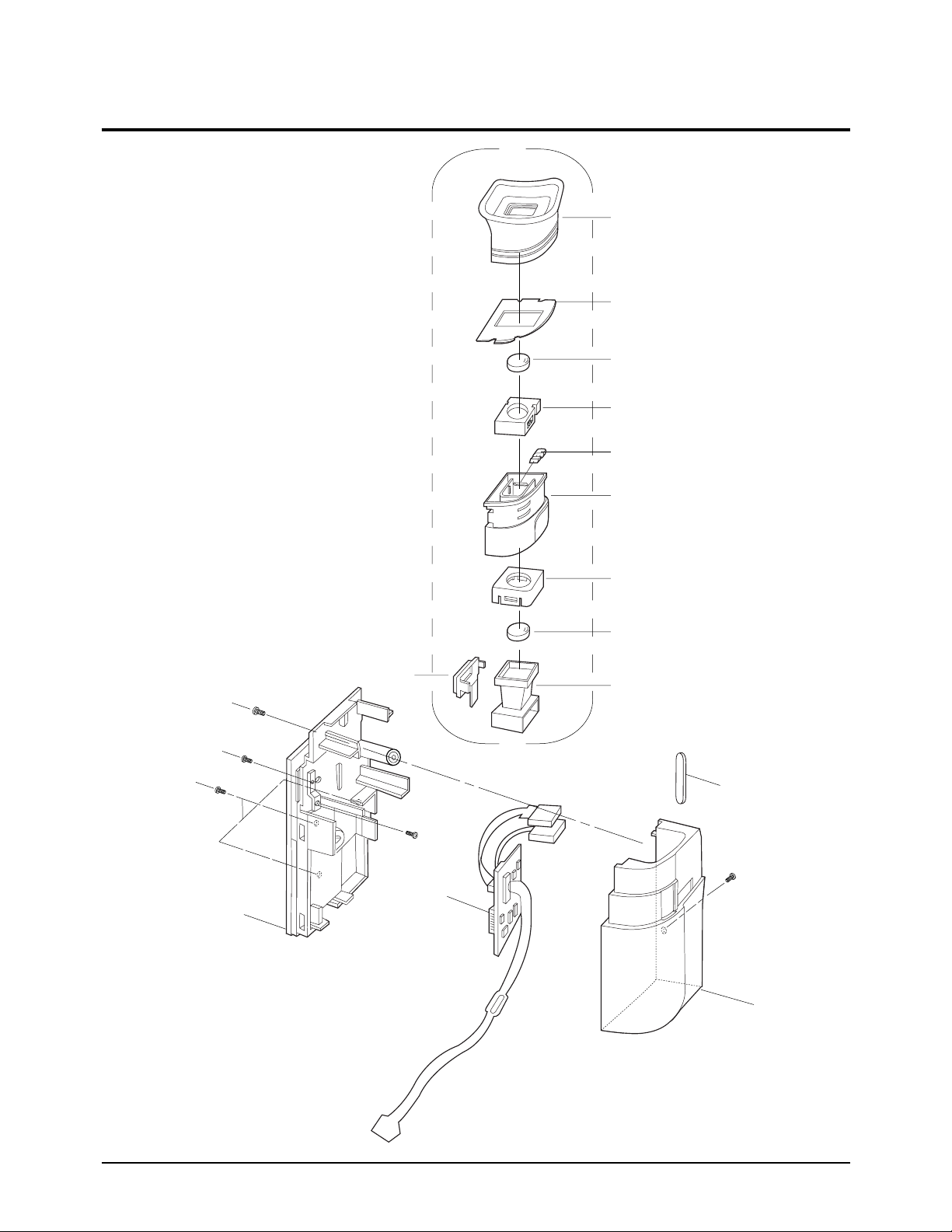

3. Disassembly and Reassembly

3-1. Cabinet and PCB

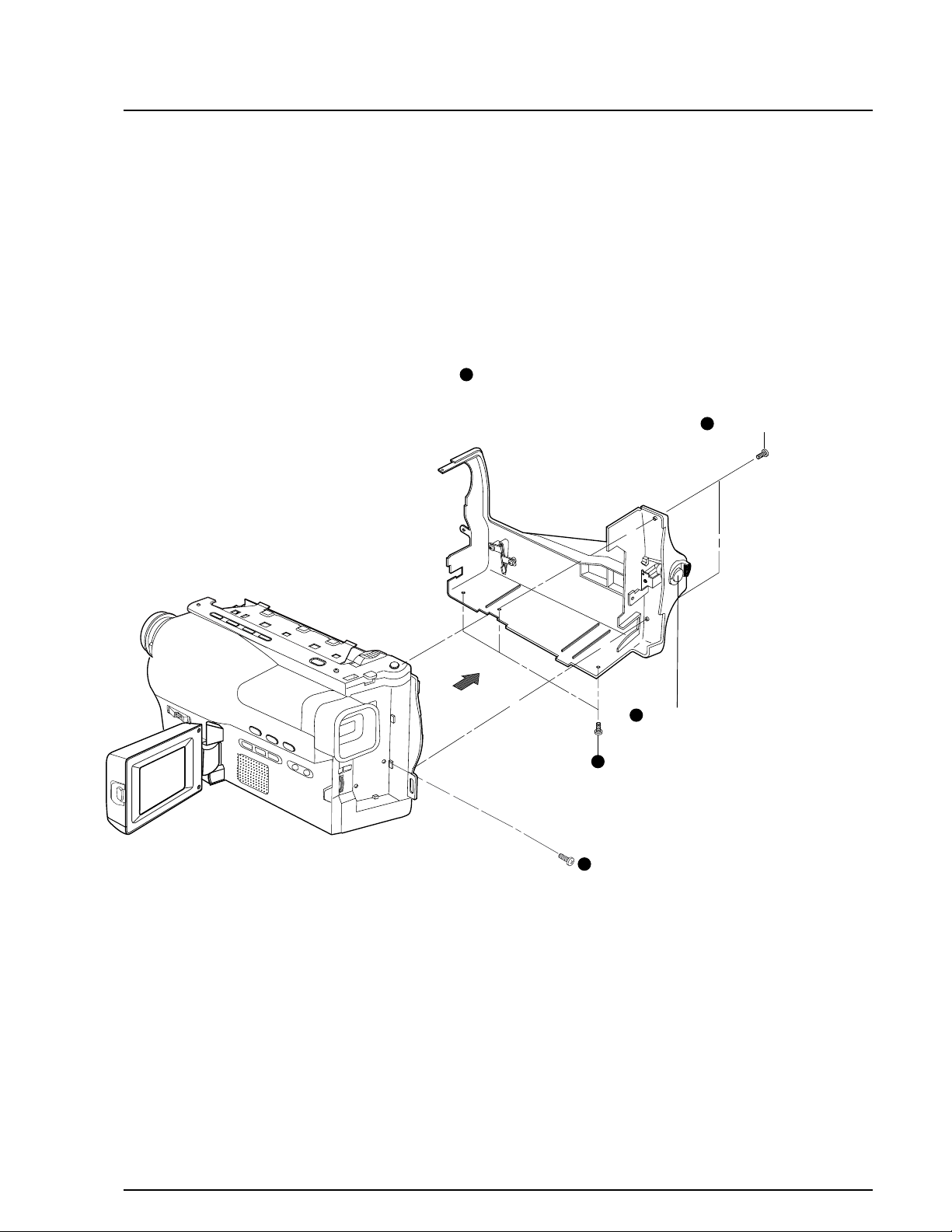

3-1-1 Ass’y Cover Housing Removal

2

Remove the ass’y cover

housing in the direction

of arrow .

"A"

A

1

REMOVE 2 SCREWS.

Fig. 3-1 Ass’y Cover Housing Removal

Page 8

3-1-2 Ass’y Case Top Removal

Samsung Electronics3-2

Disassembly and Reassembly

1

REMOVE CASE TOP BY GENTLELY RELEASING

1 LOCKING TABS WITH A SMALL SCREW DRIVER.

(SEE DETAIL "A")

REASSEMBLY : PUT THE 4 TABS INTO THE SLOT,

WHILE SLIDING IT AS SHOWN IN DETAIL "B".

1 LOCKING TAB

PRECISION

SCREW DRIVER

< DETAIL "A" >

"B"

< DETAIL "B" >

Fig. 3-2 Ass’y Case Top Removal

Page 9

Samsung Electronics 3-3

Disassembly and Reassembly

3-1-3 Ass’y Front Removal

1

REMOVE 2 SCREWS.

1

2

REMOVE THE ASS’Y FRONT IN

THE DIRECTION OF ARROW "A".

3

PISCOANECT THE CONNECTOR

FROM THE MAIN PCB.

"A"

Fig.3-3 Ass’y Front Removal

Page 10

3-1-4 Ass’y Case Left Removal

Samsung Electronics3-4

Disassembly and Reassembly

2

REMOVE THE ASS’Y CASE Right

IN THE DIRECTION OF ARROW "A".

5

3

4

REMOVE 2 SCREWS.

DISASSEMBLE AFTER TURNING

KNOB to be "LOCK".

REMOVE 3 SCREWS.

1

REMOVE 1 SCREWS.

"A"

Fig. 3-4 Ass’y Case Left Removal

Page 11

Samsung Electronics 3-5

Disassembly and Reassembly

3-1-5 Ass’y Case Right Removal

2

PULL OUT THE CASE LEFT

ASSEMBLY IN THE DIRECTION

OF ARROW "A" .

DISCONNECT FPC FROM THE

CONNECTOR OF THE MAIN PCB.

REMOVE 1 SCREWS.

1

REMOVE 4 SCREWS.

1

"A"

1

1

1

Fig. 3-5 Ass’y Case Right Removal

Page 12

Samsung Electronics3-6

Disassembly and Reassembly

3-1-6 Ass’y LCD Removal

REMOVE THE LCD ASS’Y

IN THE DIRECTION OF ARROW.

REMOVE 3 SCREWS.

REMOVE THE COVER BOTTOM ASS’Y

IN THE DIRECTION OF ARROW "A".

REMOVE 3 SCREWS.

1

2

3

4

"A"

Fig. 3-6 Ass’y LCD Removal

Page 13

Samsung Electronics 3-7

Disassembly and Reassembly

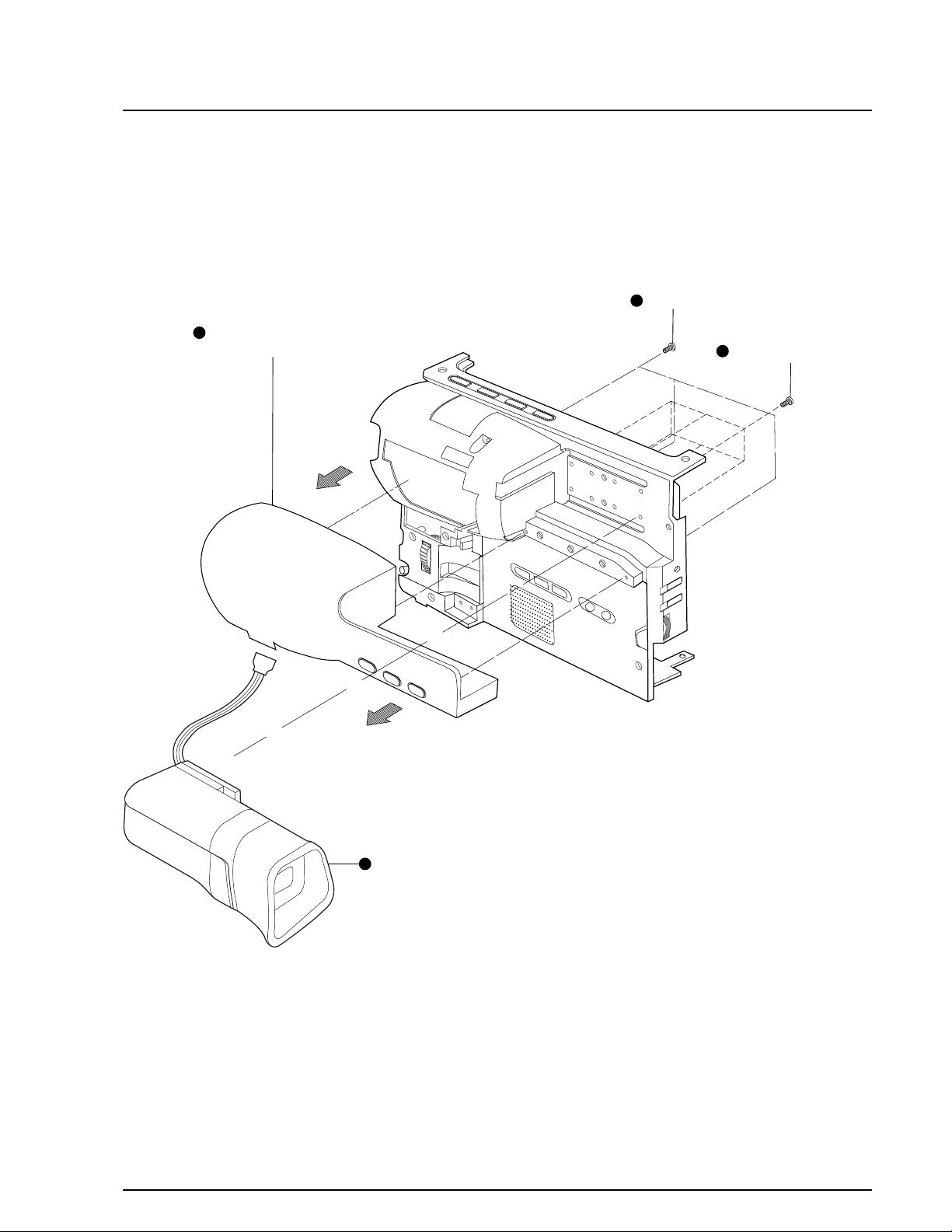

3-1-7 Ass’y EVF Removal

4

REMOVE THE EVF ASS’Y

IN THE DIRECTION OF ARROW.

1

REMOVE 3 SCREW.

2

REMOVE THE COVER LEFT TOP ASS’Y

IN THE DIRECTION OF ARROW.

3

REMOVE 6 SCREWS.

Fig. 3-7 Ass’y EVF Removal

Page 14

Samsung Electronics3-8

Disassembly and Reassembly

3-1-8 Ass’y Rear Board Removal

2

REMOVE THE ASS’Y FUNCTION

BOARD IN THE DIRECTION OF

ARROW "A".

1

REMOVE 2 SCREWS.

"A"

Fig. 3-8 Ass’y Rear Board Removal

Page 15

Samsung Electronics 3-9

Disassembly and Reassembly

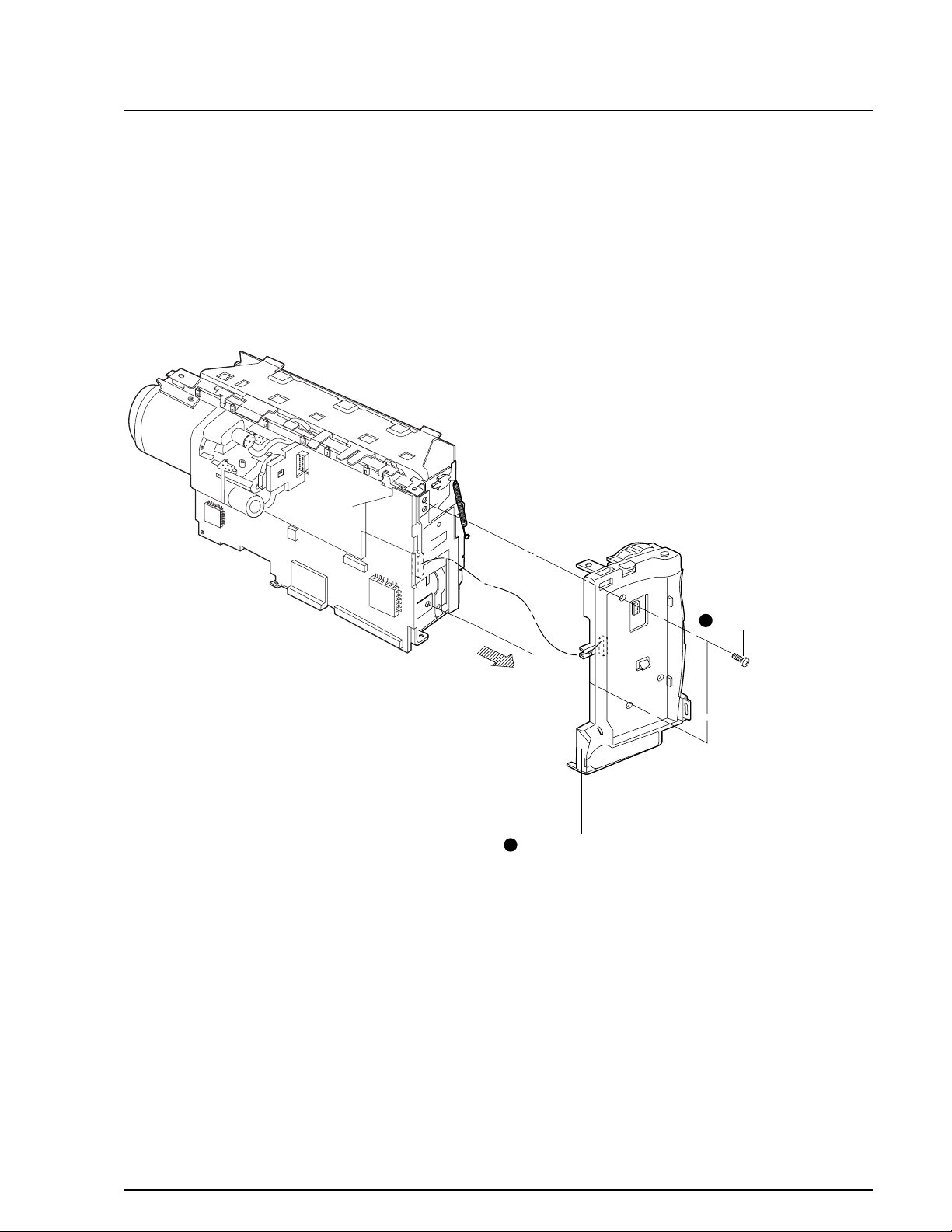

3-1-9 Ass’y Deck and Main PCB Removal

DISCONNECTOR THE FPC

FROM THE MAIN PCB.

REMOVE THE 2 SCREWS.

DISCONNECT CONNECTOR

FROM THE HEAD-DRUM.

1

PULL OUT THE MAIN POB FROM THE

ASS’Y DECK IN THE DIRATION OF

ARROW "A".

2

"A"

Fig. 3-9 Ass’y Deck and Main PCB Removal

Page 16

Samsung Electronics3-10

Disassembly and Reassembly

3-1-10 Ass’y Camera Removal

1

REMOVE 2 SCREWS.

3

DISCONNECT FPC FROM THE

CONNECTOR OF THE MAIN PCB.

2

REMOVESDLDER WITH

AN IRON TO ISOPATE

SHIELD-CASE AND LENS.

DISCONNECTOR CONNECTOR AND PULL OUT THE

ASS’Y LENS IN THE DIRECTION OF ARROW "A".

"A"

Fig. 3-10 Ass’y Camera Removal

Page 17

Samsung Electronics 3-11

Disassembly and Reassembly

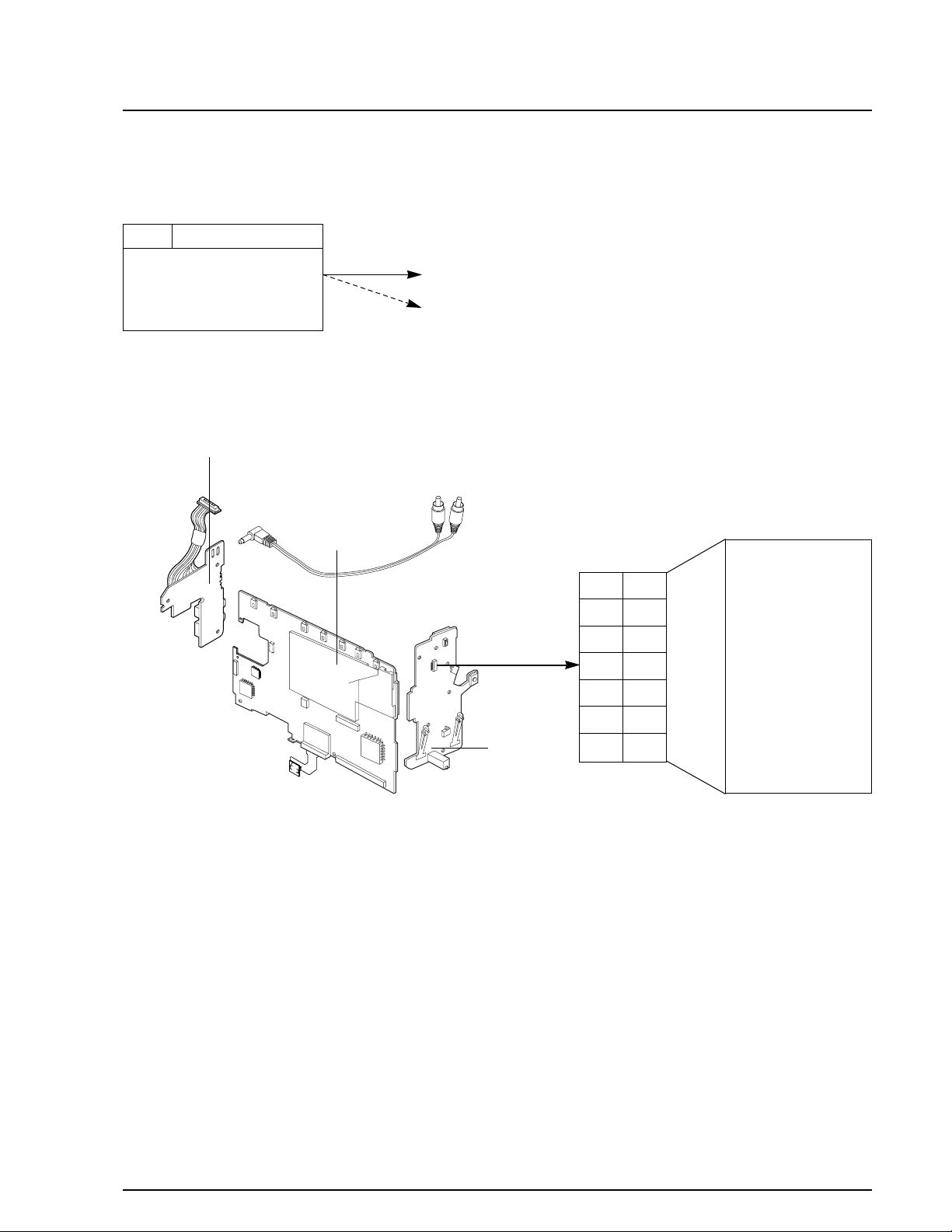

3-2. Circuit Boards Location

Fig. 3-11 Circuit Boards Location

ASS’Y MAIN BOARD

ASS’Y FRONT BOARD

ASS’Y FUNCTION BOARD

ASS’Y REAR BOARD

Page 18

Samsung Electronics3-12

Disassembly and Reassembly

3-3. Connector Diagram

Fig. 3-12 Connector Diagrams

NO. NO.CONNECTOR

CONNECTOR

DIRECTION

DECK FPC CN501

DECK MAIN PCB

DRUM HEAD FPC CN52

CN601 CN451

CNP02

CNP01 CNC01

CN701 CN801

CN602

CN802 MIC CONNECTOR

CN473

EVF FPC

CN471

DECK MAIN PCB

MAIN PCB REAR PCB

MAIN PCB ASS’Y LENS PCB

MAIN PCB CCD PCB

MAIN PCB FRONT PCB

MAIN PCB FUNCTION PCB

FRONT PCB ASS’Y MIC

FUNCTION PCB ASS’Y EVF

LENS FPC

SPEAKER CONNECTOR

CN475

LCD CONNECTOR

CN474

SPEAKER ASS’Y FUNCTION PCB

LCD ASS’Y FUNCTION PCB

Page 19

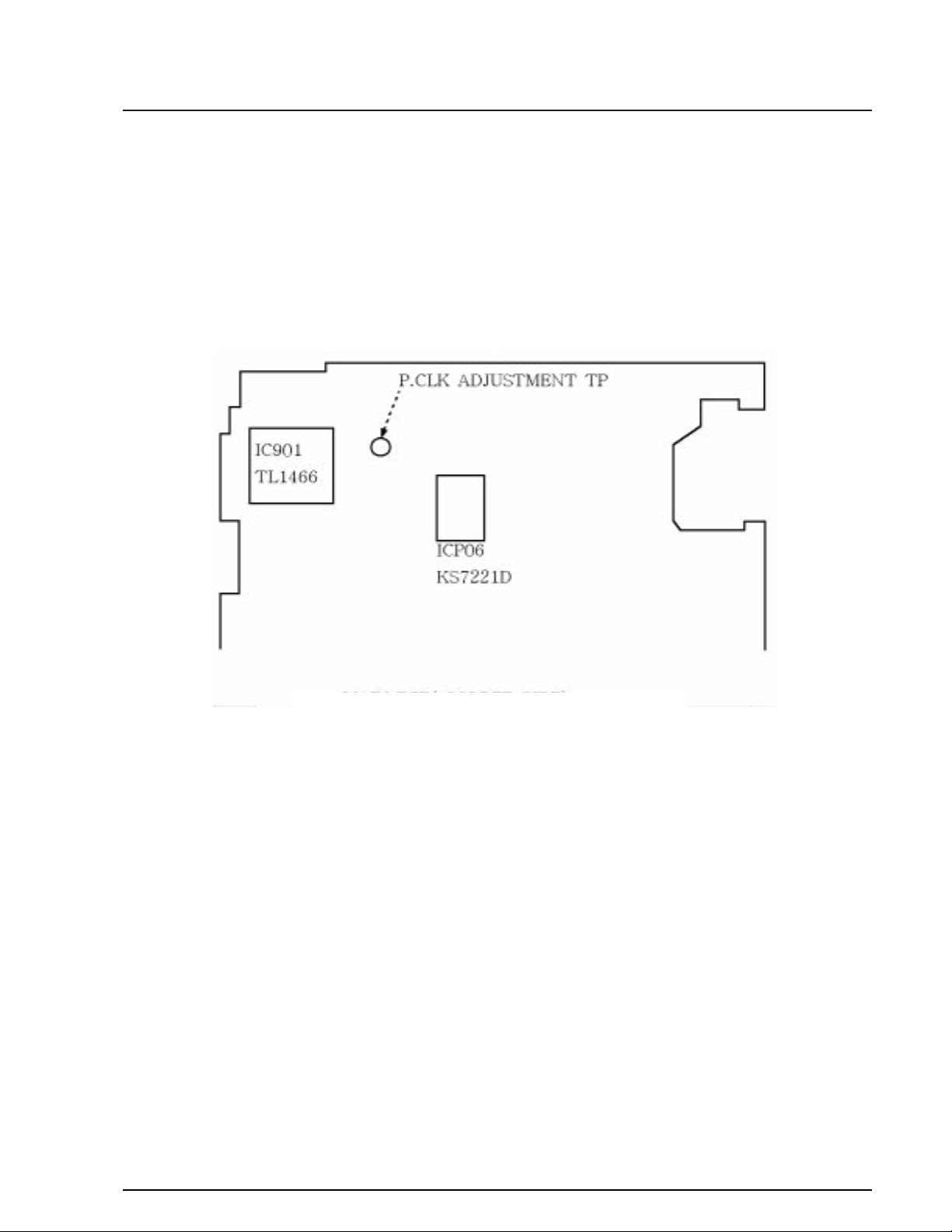

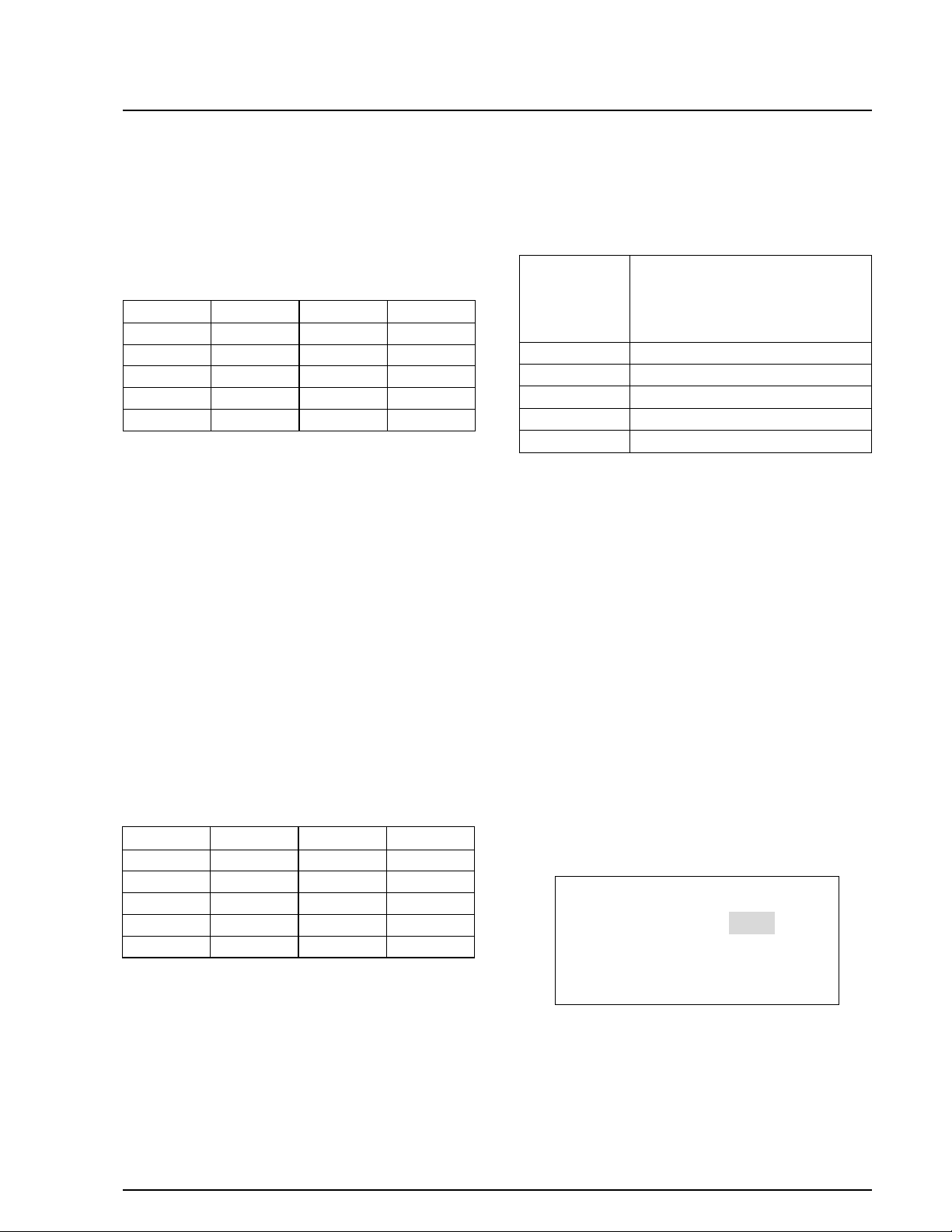

• Refer to mechanical manual “DE-6 (AD68-30200A)”for the adjustment and checks of mechanism section.

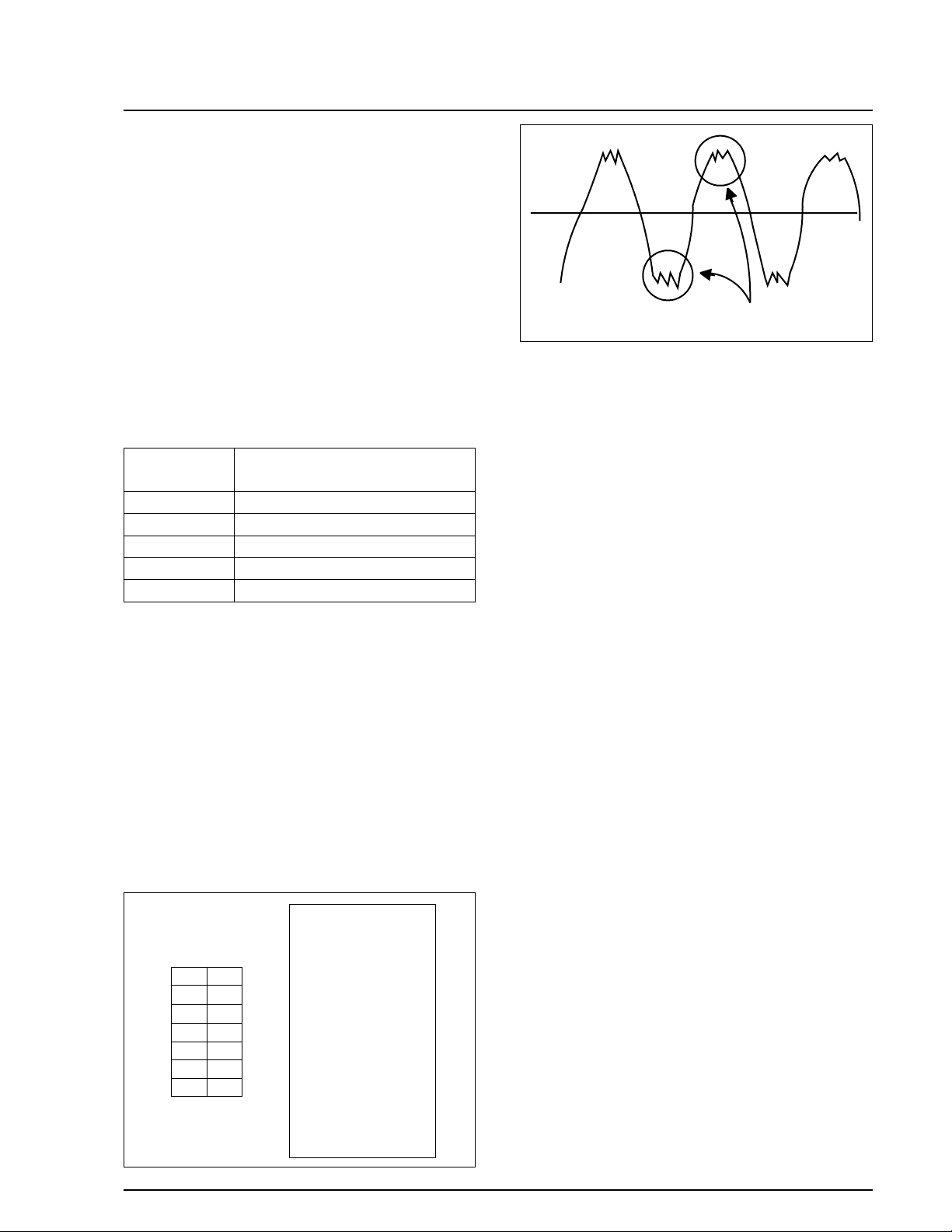

• The location of test point (See Fig.1)

Samsung Electronics 4-1

Alignment and Adjustment

4. Alignment and Adjustment

4-1. Mechanism Alignment

Test Point:

PB RF - Pin 11 of CN452

Head Switching Trigger - Pin 9 of CN452

Fig. 2 Test location of test point (Rear Board)

CN452

PB RF

Head Switching - Trigger

CN452

Fig. 1 Test point

SW471

J451

DC-JACK

BAT-TERMINAL

(+)

BAT-TERMINAL

(-)

14 13

12 11

10 9

87

65

43

21

Page 20

Samsung Electronics4-2

Alignment and Adjustment

POSITION

IC601 IC601 IC601

ACTION MODE

28PIN 27PIN 26PIN

L H H EJECT

L L H UNLOADING STOP

H L L LOADING STOP

H H L PLAY, FF, REW, STILL....

EJECT

UNLOADING STOP

LOADING STOP

PB

IC601

27PIN

GROUND

IC601

26PIN

COMMON

IC601

28PIN

OPEN

EJECT

PLAY

LOADING

STOP

UNLOADING

STOP

LOADING

UNLOADING

Page 21

Samsung Electronics 4-3

Alignment and Adjustment

Note :

1. This system has :

1) EEPROM to store the confirmed adjustment data.

2) DSP (Digital Signal Process ; ICP01 - Main board) chip to process the signal of camera parts.

3) One test point for the frequency adjustment of DSP main clock (P. CLK).

4) The special mode for camera adjustment using the function keys on the left case.

2. Keep in mind :

1) All adjustment steps should performed using the function keys on the left case.

4-2-1 Preparations

4. The Function keys on the left case :

The following is a chart explaining the use of each button :

4-2. Camera Section Adjustment

1. Equipment to be used :

1) DC Power supply

2) Oscilloscope

3) Frequency counter

4) Vectorscope

5) Waveform monitor

6) Color monitor or TV

7) Various charts

- Color bar chart

- Gray-scale chart, etc...

2. Composition of camera P.C.Boards :

1) Main PCB 2) CCD PCB

3) CVF PCB 4) EVF PCB 5) LCD PCB

3. Adjustment preparations :

1) The function keys on the left case is used as a

camera adjust tool.

2) Press the confirm button when each manual

adjustment step is completed to write the

adjustment data to the EEPROM.

3) After each adjustment step is completed, OSD

shows “OK!”.

4) To cancel the adjustment mode, remove the

power source.

Using Button

PROGRAM AE (CONFIRM)

TITLE (DATA DOWN)

DSE (DATA UP)

FADE (MODE UP)

BLC (MODE DOWN)

MANUAL FOCUS RING (NEAR/FAR)

ZOOM TELE

ZOOM WIDE

Adjustment

Data store after finishing adjustment by DATA UP/DOWN button.

When change data value of adjust state.

Mode change.

Manual focus adjustment.

1) Move the zoom position of lens.

2) Semi-Auto lens adjustment.

Page 22

Samsung Electronics4-4

Alignment and Adjustment

The function keys left case is required to adjust the camera section.

Note : In service adjustment mode, button names are different from those in customer camera function

control mode. EX) PROGRAM AE button is the same as confirm.

5. How to get into service “ADJUST” mode

1. Remove the lithium battery from the

camcorder.

2. Connect the power source (battery/

DC cable).

3. Eject the tape if it is in the unit.

4. Set the power switch of the

camcorder to “CAMERA” position.

5. Set OSD on state.

STEP 1

1. Press and hold the “EJECT” button and

“DATE/TIME” button on the camcorder at the

same time for more than 5 seconds.

Then unit goes into service mode.

STEP 2

On screen display show “0DF. T.INI XX XX”

CAMERAADJUSTMENT mode has successfully been activated.

STEP 3

Note : When “XX XX” is shown in service adjustment procedures, this indicates variable values.

EJECT

MODE DOWN

MODE UP

Confirm

DATA UP

DATA DOWN

FAR

NEAR

MANUAL

FOCUS

DATE/TIME

Page 23

Samsung Electronics 4-5

Alignment and Adjustment

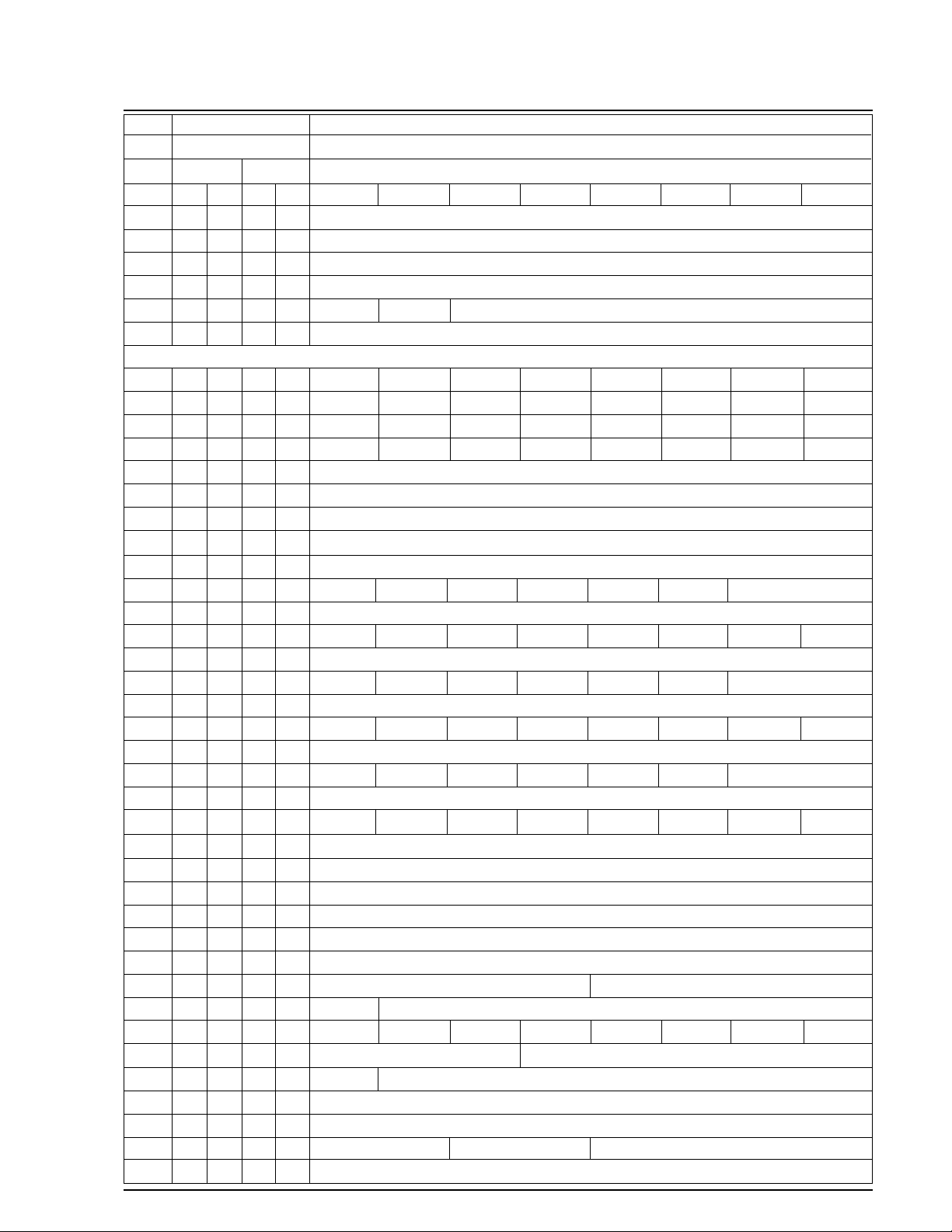

001 40 50 40 50 CDS-K=1 AGC TARGET photo/E,ODD WDR/NO WDR_AE_O KEY/RING CAN/SECREM ZOOM_STOP

002 00 00 00 00 @IRIS CONTROL-LOW

003 06 06 06 06 @IRIS CONTROL-HIGH

004 60 60 60 60 @P.CLK PWM-HIGH

005 08 08 08 08 @UPD16835 INIT 4th

006 55 55 55 55 @UPD16835 INIT 6th

007 33 33 33 33 @UPD16835 INIT 7th

008 03 03 03 03 @CDS F-REG(f1,f0) CAM : BIT0:f0,BIT1:f1

009 A0 A0 A0 A0 @CDS F-REG(f9,f2) CAM ;PGA GAIN -HIGH(0.00dB~ 30.0dB)

00A 60 60 60 60 changeb by AUTO HALL ADJ (0CD) ;HALL REFERENCE

00B 3A 3A 3A 3A changeb by AUTO HALL ADJ (0CD) ;HALL GAIN

00C 87 87 87 87 @CDS E-R(e1,e0),J-R(j0),M-R;D0:e0,D1:e1,D2:j0(CAM),D4:e0,D5:e1,D6:j0(VCR),D7:cds-rev='1'

00D 80 7B 77 77 @CDS F-REG(f9,f2) VCR ;PGA GAIN -HIGH(0.00dB~ 10.0dB)

00E 00 00 00 00 @WDR REGISTER[7,0] *AEINSEL=D7,AELPFSEL=D6,X[5:0]

00F 80 80 80 80 @WDR REGISTER[15,8] *AECLIP_TH[7:0]

010 00 00 00 00 @WDR REGISTER[23,16] *AEL_TH[7:0]

011 FF FF FF FF @WDR REGISTER[31,24] *AEH_TH[7:0]

012 76 76 8B 8B @WDR REGISTER[39,32] *AEW2VE[7:0]

013 24 24 24 24 @WDR REGISTER[47,40] *AEW2VS[7:0]

014 F1 F1 ED ED @WDR REGISTER[55,48] *AEW2HE[7:0]

015 13 13 07 07 @WDR REGISTER[63,56] *AEW2HS[7:0]

016 6E 6E 81 81 @WDR REGISTER[71,64] *AEW1VE[7:0]

017 20 20 26 26 @WDR REGISTER[79,72] *AEW1VS[7:0]

018 C1 C1 B4 B4 @WDR REGISTER[87,80] *AEW1HE[7:0]

019 43 43 32 32 @WDR REGISTER[95,88] *AEW1HS[7:0]

01A 30 30 30 30 @WDR REGISTER[103,96] *ALPF_THP[7:0]

01B 7F 7F 7F 7F @WDR REGISTER[111,104] *HLOG_ON[7],SAT_ON[6],ALPF_WTSTF[5:3],SHPF_SFT[2:0]

01C 80 80 80 80 @WDR REGISTER[119,112] *BOUND256[7:0]

01D 80 80 80 80 @WDR REGISTER[127,120] *BOUND128[7:0]

01E 80 80 80 80 @WDR REGISTER[135,128] *BOUND64[7:0]

01F 80 80 80 80 @WDR REGISTER[143,136] *BOUND32[7:0]

ADDR OSD-DISPLAY CONTENT

0DF T.INI TABLE INITIAL

0CD HALL HALL AUTO ADJUST

0CE IRIS IRIS AUTO ADJUST

0CF AWB AWB AUTO ADJUST

0D0 LENS LENS AUTO ADJUST( WARNING! DON’T USE WITHOUT AN INFINITE COLLIMATOR)

0D6 ZVR.C ZOOM LEVER CENTER DATA CHECKING

0DB AGCM AGC AUTO ADJUST (NORMALLY NO USED)

0DE 3MLENS 3M LENS AUTO ADJUST AT SERVICE FIELD (DISTANCE: 3M +/- 1Cm)

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

“CAMERA ADJUST MODE, EEPROM ADDRESS SEQUENCE & DATA OF PAGE 0”

Page 24

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics4-6

Alignment and Adjustment

020 60 60 60 60 @WDR REGISTER[151,144] *BOUND0[7:0]

021 3F 3F 3F 3F @WDR REGISTER[159,152] *LTIC[3:0],CH_SEL[3:0]

022 C7 C7 C7 C7 @WDR REGISTER[167,160] *LTI_ON[7],LSI_ON[6],LUT_TAB[5:3],LUT_HPF_SFT[2:0]

023 1E 1A 1E 1A @WDR REGISTER[175,168] *LUT_GAIN[7:0]

024 04 04 04 04 @WDR REGISTER[183,176] *BACK_WT[7:4],HIST_WT[3:0]

025 30 30 30 30 @WDR REGISTER[191,184] *EDGE_AMP[7:4],BACK_SP[3:0]

026 D0 D0 D0 D0 @WDR REGISTER[199,192] *LP_V[7:0] ACTIVE AREAVERTICAL LENGTH

027 24 24 24 24 @WDR REGISTER[207,200] *SP_V[7:0] ACTIVE AREA VERTICAL START

028 B0 B0 B0 B0 @WDR REGISTER[215,208] *LP_H[7:0] ACTIVE AREAHORIZENTAL LENGTH

029 30 30 30 30 @WDR REGISTER[223,216] *SP_H[7:0] ACTIVE AREAHORIZENTAL START

02A 00 00 00 00 @WDR REGISTER[231,224] *POFFSET[7:0]

02B 00 00 00 00 @WDR REGISTER[239,232] *CMP_ADJ[7:4],SP_ADJ[3:0]

02C 57 57 57 57 @WDR REGISTER[247,240] *CLPEN[7],SORSL[6],V1_EXIST[5],GR_MODE[4:3],GRB_MODE[2:0]

02D 01 01 01 01 @WDR REGISTER[255,248] *OUT_MODE[7:5],DLY_MODE[4:0]

02E 50 50 50 50 @WDR ON BLACK BALANCE MAX-DATA(MIN DATA+31)

02F 04 04 08 08 @WDR ON Y,C GAMMA 1

030 07 07 0D 0D @WDR ON Y,C GAMMA2

031 15 15 1B 1B @WDR ON Y,C GAMMA3

032 2C 2C 32 32 @WDR ON Y,C GAMMA4

033 4D 4D 57 57 @WDR ON Y,C GAMMA5

034 70 70 82 82 @WDR ON Y,C GAMMA 6

035 B4 B4 C0 C0 @WDR ON Y,C GAMMA 7

036 F8 F8 F0 F0 @WDR ON Y,C GAMMA8

037 99 99 99 99 @WDR ON ADDR#12C ;YVBKT,YVBK,HBLK,YHBK

038 03 08 03 08 @WDR ON ADDR#123;YHPSC,YAPC

039 E0 E0 E0 E0 @WDR ON ADDR#126;YLPFSEL

03A 10 10 10 10 @WDR ON ADDR#134;RED DARK SLICE

03B F8 F8 F8 F8 @WDR ON ADDR#135;BLUE DARK SLICE

03C 00 00 00 00 @WDR ON ADDR#136;GREEN DARK SLICE

03D D0 D0 D0 D0 @WDR ON, AE A-READ(SMALL)DATACUTTING -HIGH

03E 01 01 01 01 @WDR ON, AE A-READ(SMALL)DATACUTTING -LOW

03F 80 80 80 80 @WDR ON, AE DATA CUTTING -LOW

040 02 02 02 02 @WDR ON, AE DATACUTTING -HIGH

041 D0 D0 D0 E0 @AE TARGET-LOW BYTE

042 00 00 00 00 @AE TARGET-HIGH BYTE

043 48 48 48 48 @AETAR L(FLEX-ZONE)

044 00 00 00 00 @AETAR H (FLEX-ZONE)

045 00 00 00 00 @BLC/WDR , AE TARTGET 'L'

046 02 02 02 02 @BLC /WDR, AE TARTGET 'H'

047 00 00 00 00 @SAND&SNOW MODE AE TARGET 'L'

048 02 02 02 02 @SAND&SNOW MODE AE TARGET 'H'

Page 25

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics 4-7

Alignment and Adjustment

049 50 50 50 50 @NEGA BLC TARGET-'L'

04A 00 00 00 00 @NEGA BLC TARGET-'H'

04B 5E 5E 5E 5E @SPOTLIGHT AE-TARGET 'L'

04C 00 00 00 00 @SPOTLIGHT AE-TARGET 'H'

04D B0 B0 B0 B0 WDR AE TARGET -LOW

04E 00 00 00 00 WDR AE TARGET -HIGH

04F 04 04 04 04 @AE A-WINDOW WEIGHT VALUE '05'=50%

050 E0 E0 E0 E0 SHUTTER START POINT OF IRIS CONTROL PERCENT(FF=100% IRIS MAX)

051 50 30 50 50 AGC TARGETDOWN VALUE AT 001H D6='1' OPTION

052 00 00 00 00 AGC MAX, DARK SLICE-B CONTROL

053 90 90 90 90 @DIGITALCLAMP CONTROL STARTAGC

054 A0 A0 A0 A0 @ CHROMA SUPPRESS PERCENT

055 48 48 48 48 @ CHROMA SUPPRESS STARTAGC VALUE

056 48 48 48 48 @ NOISE SLICE STARTAGC VALUE

057 10 0B 10 15 @ Y_H_POSI_GAIN(DSP #121 D4:D0) MIN ATAGC MAX (MAX=1F)

058 18 0B 00 18 @ Y_V_POSI_GAIN(DSP #122 D4:D0) MIN ATAGC MAX (MAX=1F)

059 30 18 3F 18 @ NOISE SLICE(DSP #123 D5:D0) MIN AT AGC MAX (MAX=3F)

05A 08 00 0C 00 @AGC MAX, DIGITAL CLAMP CONTROL(ADDR,#118-#05A)

05B 05 00 00 15 @ Y_H_NEGATIVE_GAIN(DSP #12C D7:D3) MIN ATAGC MAX (MAX=1F)

05C 08 00 00 16 @ Y_V_NEGATIVE_GAIN(DSP #12D D7:D3) MIN AT AGC MAX (MAX=1F)

05D 25 25 25 25 @ Y_H_NEGATIVE_GAIN(DSP #12C D7:D3) MIN ATAGC MAX (MAX=1F)

05E 40 40 40 40 * AE SPOTLIGHT MODE CONTROL SPEED DOWN RANGE

05F 04 04 04 04 * AE AUTO MODE CONTROL SPEED DOWN REFERENCE

060 24 24 24 24 * AE OFFSET BORDER

061 0C 0C 0C 0C * AE SPPED OFFSET COUNTER

062 50 47 60 53 *AWB; @R-GAIN POSITIVE OUTDOOR

063 4A 45 50 50 *AWB; @R-GAIN NEGATIVE OUTDOOR

064 28 19 2C 1F *AWB; @R-HUE POSITIVE OUTDOOR

065 35 30 3B 28 *AWB; @R-HUE NEGATIVE OUTDOOR

066 31 2D 39 33 *AWB; @B-GAIN POSITIVE OUTDOOR

067 2C 22 30 29 *AWB; @B-GAIN NEGATIVE OUTDOOR

068 26 1E 1A 26 *AWB; @B-HUE POSITIVE OUTDOOR

069 1C 11 20 0E *AWB; @B-HUE NEGATIVE OUTDOOR

06A C0 C0 C0 C0 @WB AGC% , STOP POINT ( 80=50%, C0=75%)

06B B4 B4 B4 B4 WB;AT OUTDOOR, INDOOR DATA INPUT CONDITION TRACKING VALUE ,B4=70%,FF=0%(NO TRACKING)

06C 02 02 02 02 WB;Y AREA SELECTION NUMBER

06D 05 05 05 05 WB;AWB RATIO 1/3 CENTER TRACKING

06E 03 03 03 03 AWB RATIO HIGH , CENTER AXIALOF OVER 5100K COLOR TEMPERATURE

06F 04 04 04 04 AWB RATIO LOW ,CENTER AXIALOF BELOW 3100K COLOR TEMPERATURE

070 00 03 01 03 W/B R-CTRL COMPENSATION (D7='1' ;DECREASE ,'0'= INCREASE FROM W/B TARGET)

071 82 82 80 83 W/B R-CTRL COMPENSATION (D7='1' ;DECREASE ,'0'= INCREASE FROM W/B TARGET)

Page 26

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics4-8

Alignment and Adjustment

072 80 8A 80 8A OUTDOOR DECISION BY HALLVALUE

073 70 60 70 60 AWB;AWB TRACKING HALL2( WB TRACKING AVAILABLE BETWEEN #072~#072-#073)

074 04 07 06 04 W/B TRACKING AREA SELECT

075 0C 0C 0C 0C WB STABLE MODE THRESHOLD

076 10 10 10 10 |---- AWB CUTTING THRESHOLD1 Y LEVEL INTERVAL ----|

077 10 10 10 10 |---- AWB CUTTING THRESHOLD2 TOP LEVEL INTERVAL ----|

078 40 40 40 40 |---- AWB CUTTING THRESHOLD3 R CONTROL LOW MARGIN ----|

079 40 40 40 40 |---- AWB CUTTING THRESHOLD4 DATA CUT LOW ----|

07A 00 00 00 00 |---- AWB CUTTING THRESHOLD1 DATA CUT HIGH ----|

07B 60 6A 60 6A * AWB HALL STOP ATSPOLTLIGHT MODE

07C 80 8A 80 8A * AWB HALLAT EIS MODE

07D F0 F0 F0 F0 * AWB HALLSTOP AT SPORTS/PORTRAIT/SAND&SNOW/HSS MODE

07E F4 F4 F4 F4 @D/ZOOM RATIO MAX DATA( 80:2 TIMES, CO:4 TIMES, F4:20 TIMES)

07F 17 17 1B 1B ZOOM MAX SPEED ;22X LENS PAL:1BH ,NTSC:17H )

080 07 07 09 09 REMCON ZOOM SPEED X22 PAL:09 NTSC:07 )

081 0A 00 09 F8 @CCD H-PIXEL NUMBER -LOW BYTE

082 02 03 02 02 @CCD H-PIXEL NUMBER -HIGH BYTE

083 F7 F7 23 23 @CCD V LINE NUMBER -LOW BYTE 1/2

084 00 00 01 01 @CCD V LINE NUMBER -HIGH BYTE 1/2

085 09 09 0C 0C @V SKIP LINE NUMBER

086 00 11 00 00 DIS;VMX,VMY MAX-#086 (11:NTSC HI-8, 00:ETC)

087 00 00 00 00 @CCD V LINE NUMBER HIGH BYTE

088 1D 1D 1D 1D @DSP IC ADDR #39H ;MOSAIC SIZE :VTR

089 98 98 98 98 @DSP IC ADDR #41H ;ART DSE LEVEL :VTR

08A B8 B8 B8 B8 @DSP IC ADDR #1CH ;NEGA MODE WHITE CLIP LEVEL :VTR

08B 75 75 75 75 @SEPIA CDS-R

08C 3A 3A 3A 3A @SEPIA CDS-G

08D 10 10 11 11 @CINEMA F-ZONE LIMIT UP

08E 68 68 7D 7D @CINEMA F-ZONE LIMIT UP

08F 01 01 01 01 @DSP IC ADDR #00H ;EMODE,CINEMA :VTR

090 88 88 88 88 @DSP IC ADDR #07H ;ADCLDEL. DSCKDEL,FWCKDLY :VTR

091 2E 2E 1B 1B @DSP IC ADDR #08H ;HCNTSET :VTR

092 00 00 00 00 @DSP IC ADDR #0AH ;DCKSEL,VCNTSET :VTR

093 4A 4C 4B 4A @DSP IC ADDR #10H ;C-SYNC :VTR

094 CE CE DB D8 @DSP IC ADDR #14H ;EUSC(B-Y) BURST :VTR

095 00 00 24 28 @DSP IC ADDR #15H ;EVSC(R-Y)BURST :VTR

096 77 77 77 77 @DSP IC ADDR #20H ;YVBTH,YVBKG,YHBKTH,YHBKG :VTR

097 B8 B8 B8 B8 @DSP IC ADDR #28H ;VCR_ADJ,WHITE LEVEL :VTR

098 7F 7F 7F 7F @DSP IC ADDR #47H ;CRYGP :VTR

099 7F 7F 7F 7F @DSP IC ADDR #48H ;CRYGN :VTR

09A 7F 7F 7F 7F @DSP IC ADDR #4BH ;CRYGP :VTR

Page 27

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics 4-9

Alignment and Adjustment

09B 7F 7F 7F 7F @DSP IC ADDR #4CH ;CRYGN :VTR

09C 80 80 80 80 @DSP IC ADDR #4FH ;C-GAIN VCR-PLAY MODE :VTR

09D 80 80 80 80 @DSP IC ADDR #4FH ;C-GAIN at color bar generation :VTR

09E 00 00 00 00 @DSP IC ADDR #13H ;VTR MOD EYDEL,UV-CTL,EBURST_H :VTR

09F 50 50 50 50 @DSP IC ADDR #32H ;VTR MODE EMBOO/PASTEL Y-LEVEL :VTR

0A0 00 00 1E 1E @DSP IC ADDR #1DAH ;RPS MODE HEAD SWITCHING POINT :VTR

0A1 0A 0A 0A 0A @DSP IC ADDR #121,122[D4:D0],12C,12D[D7:D3];H,V POSI/NEGA GAIN :VTR

0A2 05 05 7B 05 @DSP IC ADDR #10A, RFSΩ√ CONTROL :VTR

0A3 0B 0B 0B 0B @DSP IC ADDR #18FH ;RPS/FPS MODE :VTR

0A4 E0 E0 E1 E1 @DSP IC ADDR #1DEH ;RPS/FPS MODE :VTR

0A5 47 47 47 47 @DSP IC ADDR #1F0H ;RPS/FPS MODE :VTR

0A6 FC FC FC FC changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS TELE MARGIN LOW BYTE(CANON X22 LENS)

0A7 FF FF FF FF changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS TELE MARGIN HIGH BYTE(CANON X22 LENS)

0A8 05 05 05 05 changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS WIDE MARGIN LOW BYTE(CANON X22 LENS)

0A9 00 00 00 00 changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS WIDE MARGIN HIGH BYTE(CANON X22 LENS)

0AA BD BD BD BD changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS RESET LOW(16X,22X LENS)

0AB 81 81 81 81 changed by AUTO LENS ADJ(0D0, 0DE) @FOCUS RESET HIGH(16X,22X LENS)

0AC 26 26 26 26 changed by AUTO LENS ADJ(0D0, 0DE) @ZOOM RESET LOW(16X, 22X LENS)

0AD 87 87 87 87 changed by AUTO LENS ADJ(0D0, 0DE) @ZOOM RESET HIGH(16X, 22X LENS)

0AE 07 07 07 07 @LENS CHECK WIDE 1 END DIFFERENCE

0AF 0E 0E 0E 0E @LENS CHECK WIDE 2 DIFFERENCE

0B0 0E 0E 0E 0E @LENS CHECK MIDDEL 1 DIFFERENCE

0B1 20 20 20 20 @LENS CHECK MIDDLE 2 DIFFERENCE

0B2 30 30 30 30 @LENS CHECK TELE 1 DIFFERENCE

0B3 40 40 40 40 @HALL CLOSE TARGET

0B4 65 65 65 65 @IRIS CONTROL ATADJUSTMENT ;UPPER 8 BIT

0B5 B0 B0 B0 B0 changed by AUTO IRIS ADJ(0CE) @IRIS CONTROL MIN LOW BYTE

0B6 09 09 09 09 changed by AUTO IRIS ADJ(0CE) @IRIS CONTROL MIN HIGH BYTE

0B7 80 80 80 80 changed by ZOOM VR CENTER (0D6) @ZOOM VR CENTER VALUE

0B8 20 20 20 20 @ZOOM VR CENTER MARGEIN

0B9 60 5B 58 68 @0DB; AGC MIN ADJ SHUTTER CONTROLVALUE (UPPER BIT='0'FIX)

0BA 01 08 2B 2A @0DB; AGC MAX ADJ SHUTTER CONTROL VALUE (UPPER BIT='1'FIX )

0BB A0 A0 68 68 AGC ADJ. SHUTTER CONTROL VALUE FOR FIND FIRST TARGET

0BC 30 34 30 34 changed by AUTO AGC ADJ(0DB) @AGC MIN

0BD A8 A8 A8 A8 changed by AUTO AGC ADJ(0DB) @AGC MAX

0BE 89 89 89 89 @HALL WIDTH

0BF 3A 3A 3A 3A @HALL REF. START

0C0 4C 4C 4C 4C @HALL GAIN. START

0C1 40 40 40 40 changed by AUTO HALL ADJ(0CD) @HALL MIN

0C2 C0 C0 C0 C0 changed by AUTO HALLADJ(0CD) @HALL MAX

0C3 94 94 94 94 @FOCUS LOW

Page 28

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics4-10

Alignment and Adjustment

0C4 83 83 83 83 @FOCUS HIGH

0C5 FD FD FD FD @ZOOM LOW

0C6 87 87 87 87 @ZOOM HIGH

0C7 00 00 00 00 changed by AUTO IRIS ADJ(0CE) @ IRIS CONTROL MAX LOW BYTE

0C8 05 05 05 05 changed by AUTO IRIS ADJ(0CE) @ IRIS CONTROL MAX HIGH BYTE

0C9 32 3B 3F 31 changed by AUTO WB ADJ(0CF) R-COLTROL3100K :INDOOR

0CA 9B 87 93 A0 changed by AUTO WB ADJ(0CF) B-COLTROL 3100K :INDOOR

0CB 60 6B 71 5F changed by AUTO WB ADJ(0CF) R-COLTROL 5100K : OUTDOOR

0CC 5A 58 55 5A changed by AUTO WB ADJ(0CF) B-COLTROL 5100K : OUTDOOR

0CD FF FF FF FF @@HALL AUTO ADJUST

0CE FF FF FF FF @@IRIS AUTO

0CF FF FF FF FF @@W/B AUTO

0D0 FF FF FF FF @@LENS AUTO

0D1 FF FF FF FF

0D2 FF FF FF FF @@ AGC CHECK PAL:68H,NTSC:80H

0D3 FF FF FF FF @@LENS CHECK

0D4 FF FF FF FF @ WIDE END ZOOM POSITION & ONE AF MODE

0D5 FF FF FF FF @@GYRO SENSOR CHK2

0D6 FF FF FF FF @@ZOOM VR CENTER ADJT

0D7 01 01 01 01 @@ZOOM/FOCUS CHK=ONE AF ENABLE BIT 00~03

0D8 FF FF FF FF

0D9 FF FF FF FF @@COLOR ADJUST

0DA FF FF FF FF @@SETUP AUTO

0DB FF FF FF FF @AGC AUTO

0DC FF FF FF FF @LENS ZOOMTRACK CHECK

0DD FF FF FF FF

0DE FF FF FF FF @LENS 3M ZOOMTRACK ADJ. = SERVICE MODE

0DF A0 A0 A0 A0 @EEPROM -TABLE -INITIAL('99'+CONFIRM =EXCEPT(#0E0~0FF), 'AA'=ALL DATA INITIAL)

0E0 3B 7F 33 77 V.LIGHT XDR DIS PIP CVF/EVF HI8 PBDSE S/SHOT

@MODEL DATA : FIXED BY MODEL

0E1 C4 C4 C4 C4 --------VCR DATA[1] @SPECIAL MODEL-DATA

0E2 85 85 85 85 --------VCR DATA[2] @HD SW PULSE

0E3 8B 8B 8B 8B --------VCR DATA[3] COLOR BAR PATTERN GENERATION Y LEVEL

0E4 BB BC B6 BC --------VCR DATA[4] @Y-EMPHASIS(NOR)

0E5 94 70 9B 70 --------VCR DATA[5] @PB Y LEVEL(NOR)

0E6 BF CE BF CE --------VCR DATA[6] @Y-EMPHASIS(HI8)

0E7 60 60 60 60 --------VCR DATA[7] @PB Y LEVEL(HI8)

0E8 80 80 80 80 --------VCR DATA[8] *.@DSP IC ADDR #29H ;YGAIN VCR-PLAY MODE

0E9 7F 7F 87 7F --------VCR DATA[9] @Y FM CARRIER(NOR)

0EA 83 83 81 81 --------VCR DATA[10] @Y FM DEVIATION(NOR)

0EB 73 73 73 73 --------VCR DATA[11] @Y FM CARRIER(HI8)

Page 29

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

Samsung Electronics 4-11

Alignment and Adjustment

0EC 93 93 93 93 --------VCR DATA[12] @Y-FM DEVIATION(HI8)

0ED 65 65 65 65 --------VCR DATA[13] @BPF ADJ

0EE CD A9 CD CD --------VCR DATA[14] @C-EMPHASIS

0EF 80 80 80 80 --------VCR DATA[15] @WHITE CLIP(NOR)

0F0 B0 C0 99 D0 --------VCR DATA[16] @REC C LEVEL

0F1 C9 A8 C9 A8 --------VCR DATA[17] @REC Y FM LEVEL

0F2 65 85 65 85 --------VCR DATA[18] @PB DELAY ADJUST

0F3 65 65 65 65 --------VCR DATA[19] @D CLIP(NOR)

0F4 85 85 85 85 --------VCR DATA[20] @DEL ADJ

0F5 99 90 99 90 --------VCR DATA[21] @SMEAR CONT

0F6 D0 D0 D0 D0 --------VCR DATA[22] @MTG(PB)

0F7 7A 7A 7A 7A --------VCR DATA[23] @MTFO(NOR)

0F8 65 60 55 55 --------VCR DATA[24] @WHITE CLIP (HI8)

0F9 9A 9A 9A 9A --------VCR DATA[25] @MTFO(HI8)

0FA 8E 8E 8E 8E --------VCR DATA[26] @D-CLIP(HI8)

0FB 00 00 00 00 --------VCR DATA[27] @TITLE LANGUAGE

0FC 02 02 02 02 --------VCR DATA[28] @CUSTOM - 1 :MODE BACKUP DSE='00', D/Z&EIS='01' ..

0FD 0C 0C 0C 0C --------VCR DATA[29] @HEAD SWITCHING POINT(SUB DATA)

0FE 91 91 91 91 --------VCR DATA[30] @BATTERY END LEVEL

0FF FF FF FF FF --------VCR DATA[31] @ATF REFERENCE

“CAMERA ADJUST MODE, EEPROM ADDRESS SEQUENCE & DATA OF PAGE 1”

CLUSTER 0 (HEADER[3:0] = 4'b0000) TG/SHUTTER

100 00 00 00 00 EMODE(2:0)='000'internal reset VSKIP='0' CINEMA ='0' NDTEST DSYNC JITNSYNC

101 80 80 80 80 ADCK FWCK SCK LALT HSP DOSEL CLP='0' X

102 C0 C0 C0 C0 SHTR='11' HSS H2DEL(3:0) 0~15nSEC DELAY ADJUST PBLK_SEL HSSC(8)

103 00 00 00 00 |---- HIGH SHUTTER SPEED CONTROL (7:0) ----|

104 07 0C 07 0C |---- GHDLY(7:0) -128 ~+ 127 ----|

105 02 00 00 00 |---- H1DLY[3:0] 0~+15nS ----| |---- RGDLY[3:0] -8~+7nS ----|

106 2C 4E 19 68 |---- SHP_DLY[3:0] -8~+7nS |---- SHD_DLY[3:0] -8~+7nS ----|

107 40 60 50 60 FLALTSEL ADCKDLY[2:0] 0~+7nS DSCKSEL FWCKDLY[2:0] 0~+7nS

108 0D 0D 0D 0D |---- HCNTSET[7:0] '00' PROHIBIT ----|

109 00 00 00 00 |---- LSSC[7:0] low speed shutter ----|

10A 00 00 00 00 DCKSEL |---- VCNTSET[6:0] ----|

10B 00 00 00 30 CLP1-ADJ(2:0): -2~+2CK CLP1 ADJ X X X X X

10C 03 05 05 05 X X X X PSEUDO EBFDLY[2:0] BURST FLAG DELAY

10D 1B 1B 1F 1F |---- FHCNTSET[7:0]; INTERNAL JITER FREE SYNC SIGNAL DELAY DAJUST(AFTER TBC) ----|

10E 00 00 00 14 PBLK X SHP PULSE WIDTH[2:0] SHD PULSE WIDTH[2:0]

10F 00 00 00 00 |---- ONEH_P [3:0] ----| |---- ONEH_N [3:0] ----|

CLUSTER 1 (HEADER[3:0] = 4'b0001) ENCODER/ DEFECT ADJUST

110 4A 4C 4B 4A |---- C-SYNC[7:0] c.sync level 0~255 *EEPROM EMPTY ? ----|

111 00 01 01 03 |---- SETUP[7:0] setup level 0~255 ----|

112 00 00 00 00 |---- EBURST[7:0] burst phase ADJ:360deg./2047 control :NTSC only ----|

Page 30

Samsung Electronics4-12

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

113 00 40 00 20 ROM TEST E UV_CTRL |---- EBURST_H[2:0] ----|

114 CC C8 D8 D8 |---- EUSC[7:0] -128~+127 of B-Y(U) BURST VALUE ----|

115 00 00 28 28 |---- EVSC[7:0] -128~+127 of R-Y(V) BURST VALUE ----|

116 02 0 2 0 2 02 X EZBRT[1:0];BIGHT OF WINDOW EZONE X A/D-DIRECT EXTDAC PD1

117 03 03 03 03 X X AD[1:0] AD CLK DLY D-CLP S2:GISS COMP. S1 S0

118 08 00 0D 00 |----- CLAMP_OFFSET[7:0] ----|

119 30 30 30 30 |----- DEFECT_THRESHOLD[7:0] 0~255 ----|

11A 00 00 00 00 X X X X RAM-OUT |---- RAM-OUT[8:6]

11B 00 00 00 00 |---- RAM-OUT[5:0] ----| RAM-OUT[9:8]

11C 00 00 00 00 |---- RAM-OUT[7:0] ----|

11D 00 00 00 00 X |---- PFINDCNT[6:0] ----|

11E 0A 0A 0A 0E DUMMY W/B;INTERVALOF AREA(SECTOR) FROM CENTER CENTER

11F F0 F0 F0 F0 *DIS;WIGHT WHEN DATAINCREASE

CLUSTER 2 (HEADER[3:0] = 4'b0010) LUMINANCE

120 66 76 66 66 YVBKTH[1:0] YVBKG[1:0] YHBKTH[1:0] YHBKG[1:0]

121 10 D9 10 D9 Y_H_GAIN[1:0] X |---- Y_H_POSI_GAIN[4:0] ----|

122 58 94 58 D8 Y_L_GAIN[1:0] YOLD-GAMMA |---- Y_V_POSI_GAIN[4:0] ----|

123 02 02 03 03 X X |---- YA_NOISE_SLICE[5:0] ----|

124 B0 A0 B0 C0 |---- YHL_SC[7:0] ----|

125 FF 37 FF FF |---- YEDGE_SC[7:0] ----|

126 E0 E0 E0 E0 YVAPPSEL YEGCS YHLCS'1'=ON YLPFSEL[1:0];00,01,10 |---- YSCDLY[2;0] ----|

127 30 0A 30 0A |---- YHINS[6:0] aperture noise slice level after GAMMA. ----| YNEGA/POSI

128 D0 DE D8 E0 |---- YWC[7:0] *EEPROM EMPTY ? ----|

129 8A 8A 8E 90 |---- YGAIN[7:0] X0~X2 ----|

12A 00 00 00 00 X YENHANTH[2:0] X X YENHANG[1:0]

12B 00 00 06 00 |---- YART[2:0] ----| |---- YHI-A-GAIN[4:0] ----|

12C 57 AF 61 AF |---- HAPGN[4:0] ----| YHCLIP[3:2] H_C_SUP[4]

12D A1 81 B1 C8 |---- VAPGN[4:0] ----| YHCLIP[1:0] E_C_SUP[4]

12E 80 88 80 80 H_C_SUPP_GAIN[3:0]high light color suppress slope F_FALL[3:0] edge color suppress

12F 58 50 58 50 |---- Y_APERTUTR_CLIP[7:0] ----|

CLUSTER 3 (HEADER[3:0] = 4'b0011) LUMINANCE & CHROMA

130 20 20 20 20 YHPEG[1:0] YVPEG[1:0] YHEMBSEL[1:0] YVEMBSEL[1:0]

131 30 30 30 30 |---- YPST[7:0] pastel level ----|

132 30 30 30 30 |---- YEMB[7:0] embossing level ----|

133 00 00 00 00 X GYDLY[2:0];LINE-INPUT MODE YEMBOSS YPASTEL YIN-OUT YWINDOW

134 0A 05 04 09 |---- CRDS[7:0] r-dark-slice ----|

135 FA FE 07 00 |---- CBDS[7:0] b-dark-slice

136 FE 00 00 00 |---- CGDS[7:0] g-dark-slice

137 36 3A 34 31 |---- CRWB[7:0] R-white-balance-control

138 8F 8F 8C 90 |---- CBWB[7:0] B-white-balance-control

139 24 24 24 24 |---- CGWB[7:0] G-white-balance-control

Page 31

Samsung Electronics 4-13

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

13A 07 07 07 07 |---- CSLOPE1[7:0]COLOR_KEY_SLOPE_1;-64~+64

13B E6 E6 E6 E6 |---- CSLOPE2[7:0]COLOR_KEY_SLOPE_2;-64~+64

13C 29 29 29 29 COLOR KEY DEL:0(RED)~4;13A,3B,3C ADDR CSLOPE1 H[9] CSLOPE1 H[8] CSLOPE2 H[9] CSLOPE2 H[9]

13D 00 00 00 00 X X BLUE-SCREEN CNEGA CBAR CMONO CKEY CKEY-NEGA

13E 00 00 00 00 DUMMY X X X CRWB[9:8] #137 CBWB[9:8] #138

13F 13 13 13 13 DUMMY WDR; GRMODE(#02D) CONTROL DATAOF WDR OFF

CLUSTER 4 (HEADER[3:0] = 4'b0100) CHROMA

140 37 17 07 17 X CDEC-INSEL CHCON(S1/S2) CVCON(cr/cb) CYLSEL CRMS CBMS C-GAMMA-SEL

141 42 42 42 42 |---- CRCOEF[7:0] cr-matrix-coefficient ----|

142 66 66 66 66 |---- CBCOEF[7:0] cr-matrix-coefficient ----|

143 59 59 59 59 |---- CRRG[7:0] R-G SIGNAL COEFFECIENT FOR R-Y SIGNAL ----|

144 D9 D9 D9 D9 |---- CBRG[7:0] R-G SIGNAL COEFFECIENT FOR B-Y SIGNAL ----|

145 F2 F2 F2 F2 |---- CRBG[7:0] B-G SIGNAL COEFFECIENT FOR R-Y SIGNAL ----|

146 72 72 72 72 |---- CBBG[7:0] B-G SIGNAL COEFFECIENT FOR B-Y SIGNAL ----|

147 4F 5A 76 6B |---- CRYGP[7:0] R-Y GAIN CONTROL + ----|

148 5E 5F 7E 70 |---- CRYGN[7:0] R-Y GAIN CONTROL - ----|

149 0B 16 1D 15 |---- CRYHP[7:0] R-Y HUE CONTROL + ----|

14A 20 13 29 0F |---- CRYHN[7:0] R-Y HUE CONTROL - ----|

14B 35 36 3E 3D |---- CBYGP[7:0] B-Y GAIN CONTROL + ----|

14C 2C 26 35 29 |---- CBYGN[7:0] B-Y GAIN CONTROL - ----|

14D 2A 2D 3C 40 |---- CBYHP[7:0] B-Y HUE CONTROL + ----|

14E 18 06 05 01 |---- CBYHN[7:0] B-Y HUE CONTROL - ----|

14F 80 80 80 80 |---- CGAIN[7:0] x0~ x2 ----|

CLUSTER 5 (HEADER[3:0] = 4'b0101) GAMMA

150 04 04 04 04 |---- YG1[7:0] @Y GAMMA POINT 1 ----|

151 07 07 08 08 |---- YG2[7:0] @Y GAMMA POINT 2 ----|

152 15 15 1B 18 |---- YG3[7:0] @Y GAMMA POINT 3 ----|

153 2C 2C 30 2E |---- YG4[7:0] @Y GAMMA POINT 4 ----|

154 4D 4D 4D 4E |---- YG5[7:0] @Y GAMMA POINT 5 ----|

155 70 70 78 73 |---- YG6[7:0] @Y GAMMA POINT 6 ----|

156 AA B4 B8 AB |---- YG7[7:0] @Y GAMMA POINT 7 ----|

157 D8 F8 D0 E0 |---- YG8[7:0] @Y GAMMA POINT 8 ----|

158 04 04 04 06 |---- CGAMMA1[7:0] @C GAMMA POINT 1 ----|

159 07 07 0A 0C |---- CGAMMA2[7:0] @C GAMMA POINT 2 ----|

15A 18 18 18 1A |---- CGAMMA3[7:0] @C GAMMA POINT 3 ----|

15B 30 30 2B 2C |---- CGAMMA4[7:0] @C GAMMAPOINT 4 ----|

15C 50 50 4C 4C |---- CGAMMA5[7:0] @C GAMMA POINT 5 ----|

15D 78 78 78 78 |---- CGAMMA6[7:0] @C GAMMA POINT 6 ----|

15E B8 B8 B6 B6 |---- CGAMMA7[7:0] @C GAMMA POINT 7 ----|

15F F8 F8 F0 F0 |---- CGAMMA8[7:0] @C GAMMA POINT 8 ----|

CLUSTER 6 (HEADER[3:0] = 4'b0110) D.ZOOM & EIS

Page 32

Samsung Electronics4-14

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

160 AE AE AE AE D.ZOOM ZOOM-BYPASS D.EFFECT VADJ[1:0] HADJ[1:0] Z_DELAY

161 00 00 00 00 |---- VZOOM[7:0] ----|

162 09 09 0C |---- VZSKIP[7:0] ----|

163 00 00 00 00 |---- VZOFFE[7:0] EVEN FIELD LINE OFFSET ----|

164 00 00 00 00 |---- VZOFFO[7:0] ODD FIELD LINE OFFSET ----|

165 00 00 00 00 |---- HZOOM[7:0] ----|

166 80 80 80 80 MOSAIC H-ADJ[1:0] X X X X X HZSTR[8]

167 00 00 00 00 |---- HZSTR[7:0] ----|

168 00 00 00 00 |---- HZOFS[7:0] ----|

169 00 00 00 00 |---- MOSAIC[5:0] 4d=8x8,5d=10x10,63d=126x126 ----| MOSAIC V-ADJ[1:0]

16A 02 03 02 02 FEMODE[1:0] 01=F,10=H.M X X X X FCM[9:8]

16B 0A 00 09 F8 |---- FCM[7:0] ----|

16C 01 01 01 01 |---- V-MOSAIC[5:0] VERTICALMOSAIC SIZE HMIRROR[9:8]

16D 05 84 07 7C |---- HMIRROR[7:0] ----|

16E 00 00 00 00 |---- CBLK-ADJ[3:0] ----| CCIR-Y CCIR-C X SCKIV

16F 01 01 01 01 DUMMY #16C:MIRROR WHEN EIS ON/OFF '0'=OFF,'1'=ON

CLUSTER 7 (HEADER[3:0] = 4'b0111) AF/AE

170 05 05 06 06 |---- OAFHS-W1 @AF WINDOW 1 H-START POINT;3~252 ----|

171 F3 F3 EC EC |---- OAFHE-W1 @AF WINDOW 1 H-END POINT;5~254 ----|

172 03 03 04 04 |---- OAFVS-W1 @AF WINDOW 1 V-START POINT;3~152 ----|

173 76 76 8D 8D |---- OAFVE-W1 @AF WINDOW 1 V-END POINT;5~154 ----|

174 52 52 4D 4D |---- OAFHS-W2 @AF WINDOW 2 H-START POINT;1~254 ----|

175 AC AC A8 A8 |---- OAFHE-W2 @AF WINDOW 2 H-END POINT;3~256 ----|

176 25 25 29 29 |---- OAFVS-W2 @AF WINDOW 2 V-START POINT;1~154 ----|

177 5F 5F 71 71 |---- OAFVE-W2 @AF WINDOW 2 V-END POINT;3~156 ----|

178 43 43 37 37 |---- OAEHS-WA @ AE WINDOW A H-ST ARTPOINT;1~254 ----|

179 C1 C1 B8 B8 |---- OAEHE-WA @ AE WINDOW AH-END POINT;3~256 ----|

17A 20 20 26 26 |---- OAEVS-WA @ AE WINDOW A V-START POINT ;1~155 ----|

17B 6E 6E 81 81 |---- OAEVE-WA @ AE WINDOW A V-END POINT;3~156 ----|

17C 0A 0A 07 07 |---- OAEHS-WB @ AE WINDOW B H-START POINT;1~254 ----|

17D EE EE ED ED |---- OAEHE-WB @ AE WINDOW B H-END POINT;3~256 ----|

17E 1E 1E 24 24 |---- OAEVS-WB @ AE WINDOW B V-STARTPOINT;1~155 ----|

17F 73 73 8B 8B |---- OAEVE-WB @ AE WINDOW B V-END POINT;3~156 ----|

CLUSTER 8 (HEADER[3:0] = 4'b1000) AWB

180 0A 0A 0A 07 |---- OAWBHS @ AWB WINDOW H-STARTPOINT;1~254 ----|

181 EE EE ED ED |---- OAWBHE @ AWB WINDOW H-END POINT;3~256 ----|

182 1E 1E 24 24 |---- OAWBVS @ AWB WINDOW V-STARTPOINT;1~155 ----|

183 73 73 8B 8B |---- OAWBVE @ AWB WINDOW V-END POINT;1~156 ----|

184 FF FF FF FF |---- OYH-AE @Y-HIGH-THRESHOLD FOR AE;0~255 ----|

185 00 00 00 00 |---- OYL-AE @Y-LOW -THRESHOLD FOR AE ----|

186 90 90 90 90 |---- OYH-AWB @Y-HIGH-THRESHOLD FOR AWB ----|

Page 33

Samsung Electronics 4-15

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

187 30 30 30 30 |---- OYL-AWB @Y-LOW -THRESHOLD FOR AWB ----|

188 C0 C0 C0 C0 |---- OAF_CLIP_TH[7:0] THRESHOLD VALUE FOR AF CLIP COUNTER ----|

189 C0 C0 C0 C0 |---- OAE_CLIP_TH[7:0] THRESHOLD VALUE FOR AE CLIP COUNTER ----|

18A 02 02 02 02 OVAF OLPFSEL OFILPASS OYISEL OAWBSEL |---- OZNSEL[2:0] ----|

18B 00 00 00 00 X X X X ODMTST OAWBC SEL ORBSEL OAWB AREA

18C 00 00 00 00 GAP_SEL [2:0] |---- GAP_TH [4:0] ----|

18D 00 00 00 00 Q1_H [3:0] AUTO FILTER SPEED CONTROL Q1_L [3:0] AUTO FILTER SPEED CONTROL

18E 00 00 00 00 Q2_H [3:0] FILTER INPUT LIMIT Q2_L [3:0] FILTER INPUT LIMIT

18F 00 00 00 00 L9_EN1 L9_EN2 L9_EN3 GAP_EN DOP_EN1 DOP_EN2 DOP_EN3 DOP_EN4

CLUSTER 9 (HEADER[3:0]=4'b1001 ,AWB

190 1F 1F 1F 1F X X X |---- ORYTH[4:0] ----|

191 1F 1F 1F 1F X X X |---- OBYTH[4:0] ----|

192 30 30 30 30 |---- OAWBSL 1[7:0]; 0~15, R-Y/B-Y CHART SLOPE 1 FOR AWB ----|

193 15 15 15 15 |---- OAWBSL 2[7:0]; 0~15, R-Y/B-Y CHART SLOPE 2 FOR AWB ----|

194 70 70 70 70 |---- OAWBSL 3[7:0]; 0~15, R-Y/B-Y CHART SLOPE 3 FOR AWB ----|

195 60 60 60 60 |---- OAWBSL 4[7:0]; 0~15, R-Y/B-Y CHART SLOPE 4 FOR AWB ----|

196 20 20 20 20 |---- OAWBSL 5[7:0]; 0~15, R-Y/B-Y CHART SLOPE 5 FOR AWB ----|

197 05 05 05 05 |---- OAWBSL 6[7:0]; 0~15, R-Y/B-Y CHART SLOPE 6 FOR AWB ----|

198 34 34 34 34 X X |---- OAWB_DETECT_R-Y_POINT A[5:0] ;0~63 ----|

199 1C 1C 1C 1C X X |---- OAWB_DETECT_R-Y_POINT B[5:0] ;0~63 ----|

19A 18 18 18 18 X X |---- OAWB_DETECT_R-Y_POINT C[5:0]; 0~63 ----|

19B 28 28 28 28 X X |---- OAWB_DETECT_R-Y_POINT D[5:0] ;0~63 ----|

19C 18 18 18 18 X X |---- OAWB_DETECT_B-Y_POINT A[5:0] ;0~63 ----|

19D 28 28 28 28 X X |---- OAWB_DETECT_B-Y_POINT B[5:0] ;0~63 ----|

19E 1E 1E 1E 1E X X |---- OAWB_DETECT_B-Y_POINT C[5:0]; 0~63 ----|

19F 16 16 16 16 X X |---- OAWB_DETECT_B-Y_POINT D[5:0] ;0~63 ----|

CLUSTER 10 (HEADER[3:0] = 4'b1010) AF DATA1

1A0 08 08 08 08 * VCR MODE NOISE SLICE(#123) ----|

1A1 02 02 02 02 * VCR MODE PB LPF(#126) ----|

1A2 10 10 10 10 * VCR MODE RPS/FPS LOCK SPEED(#1D7) ----|

1A3 07 09 07 09 * VCR MODE NORMAL DELAY(#1FC) ----|

1A4 00 00 00 00 * CDS IC A REG ATVCR MODE ----|

1A5 01 02 02 02 D.ZOOM ON, DSP #123 CONTROL DATA ----|

1A6 D9 DB 5E DB D.ZOOM ON, DSP #121 CONTROL DATA ----|

1A7 9A 99 5F D9 D.ZOOM ON, DSP #122 CONTROL DATA ----|

1A8 9F BF AF BF D.ZOOM ON, DSP #12C CONTROL DATA ----|

1A9 00 00 00 00 * STILLOFFSET AT PB MODE ----|

1AA 80 80 80 80 * D/ZOOM ON START POSITION-LOW BYTE OF WIDE IMAGE COMPENSATION ----|

1AB 87 87 87 87 * D/ZOOM ON START POSITION-HIGH BYTE OF WIDE IMAGE COMPENSATION ----|

1AC 00 00 00 00 * D/ZOOM ON END POSITION-LOW BYTE OF WIDE IMAGE COMPENSATION

1AD 85 85 85 85 * D/ZOOM ON END POSITION-HIGH BYTE OF WIDE IMAGE COMPENSATION

Page 34

Samsung Electronics4-16

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

1AE 1A 1A 1A 1A * D/ZOOM RATIO OF WIDE IMAGE COMPENSATION

1AF 12 04 04 04 ADDR. #228 FIELD-'H',EDGE CHROMA SUPP.ON(ADDR.#201 D4='1') ,ADDR.#223 DATA=10 B/B

CLUSTER 11 (HEADER[3:0] = 4'b1011) ,AF DATA2

1B0 04 10 10 10 ADDR.#229 FIELD-'H',EDGE CHROMA SUPP.ON(ADDR.#201 D4='1') ----|

1B1 12 00 00 00 ADDR.#228 FIELD-'L',EDGE CHROMA SUPP.ON(ADDR.#201 D4='1') ----|

1B2 04 14 14 14 ADDR.#229 FIELD-'L',EDGE CHROMA SUPP.ON(ADDR.#201 D4='1') ----|

1B3 80 80 20 80 ADDR.#21B DATAOF FIELD-'H' WHEN PHOTO ON ----|

1B4 80 80 2F 8F ADDR.#21B DATAOF FIELD-'L' WHEN PHOTO ON ----|

1B5 0A 0A 0B 0B #VTR PB DSE;MOASIC,MIRROR OF COLOR , RELATED ADDR.:#09E -->#113;D3 bit ----|

1B6 80 80 1F 8C ADDR. #21B DATA WHNE GHOST ON ----|

1B7 30 30 00 20 D/ZOOM SUB-PIXEL CONTROL(ADDR.#163) FIELD-'H' BY DSP; ----|

1B8 1B 1B 1B 1B DIS ON XMX,XMY SETTING BY ZOOM POSITION,ADDR.#1B9,#1AE ,at WIDE END #1B8-#1AA=01hex ----|

1B9 29 29 29 29 DIS ON, TELE POSISION D/ZOOM RATIO (29 HEX= X 1.19) ----|

1BA 01 01 01 01 * CCD DEFECT AE WINDOW B HORIZENTAL START VALUE (DSP#17C , DIS#261) ----|

1BB F4 F6 F2 F2 * CCD DEFECT AE WINDOW B HORIZENTALEND VALUE (DSP#17D , DIS#260) ----|

1BC 02 02 02 02 * CCD DEFECT AE WINDOW B VERTICAL STARTVALUE (DSP#17E , DIS#25F)

1BD 77 77 8E 8E * CCD DEFECT AE WINDOW B VERTICAL END VALUE (DSP#17F , DIS#25E)

1BE B1 B1 C1 B1 D.ZOOM ON, DSP #12D CONTROL DATA

1BF 10 10 10 10 D0 BIT='0' AF1,2 DATA FOR DIS BLOCKING PGM ON,D8 BIT RPS/FPS CVF PLL LOCKING SPPED 1=OLD

CLUSTER 12 (HEADER[3:0] = 4'b1100); AWB/AE

1C0 FC FC FB FA * FLEXZONE AF1 HORIZENTAL START VALUE (DSP#170 - DIS#261)

1C1 00 00 00 00 WIDE D.ZOOM X1.1 DECREASE ZOOM POSITION-'L' POINT (00 83)OR(08 80) ----|

1C2 83 83 83 83 WIDE D.ZOOM X1.1 DECREASE ZOOM POSITION-'H' POINT (00 83)OR(08 80) ----|

1C3 50 50 50 50 WIDE D.ZOOM OFF ZOOM POSITION-'L' POINT (50 81)OR(08 80) ----|

1C4 7C 7C 7C 7C WIDE D.ZOOM OFF ZOOM POSITION-'H' POINT (50 81)OR(08 80).7C=X1.06(0E hex) ----|

1C5 0C 0C 0C 0C DIS;CONTROL OF AF DATA ----|

1C6 02 02 02 02 DIS;STEP OF AF DAT A ----|

1C7 00 30 00 10 W/B ADJ, CENTER COMPENSATION VALUE, INDOOR R,B (EX, E4 ; R -2,B +4) ----|

1C8 F3 53 E4 21 W/B ADJ, CENTER COMPENSATION VALUE, OUT DOOR R,B (EX, E4 ; R -2,B +4) ----|

1C9 69 69 B6 B6 DIS ON, SHUTTER CONTROL VALUE ----|

1CA 30 30 00 1C D/ZOOM SUB-PIXEL CONTROL(ADDR.#164) FIELD-'H' BY DSP; ----|

1CB 30 30 00 18 D/ZOOM SUB-PIXEL CONTROL(ADDR.#163) FIELD-'L' BY DSP; ----|

1CC 30 30 00 14 D/ZOOM SUB-PIXEL CONTROL(ADDR.#164) FIELD-'L' BY DSP; ----|

1CD 02 02 02 02 @VTR ;VCNT DATA DSP ADDR.#10A FOR FPS ----|

1CE 50 50 50 50 DIS;LIMIT

1CF 18 18 18 18 DIS; FACTOR OF FREQUENCY

CLUSTER 13 (HEADER[3:0] = 4'b1101); DECODER 1

1D0 00 00 00 00 |----DVAS[7:0]; HORIZENTALACTIVE VIDEO START POINT ----|

1D1 00 26 00 00 |----DVAE[7:0]; HORIZENTALACTIVE VIDEO END POINT CONTROL ----|

1D2 00 00 00 00 |----VAVS[7:0]; VERTICAL ACTIVE VIDEO START POINT ----|

1D3 00 00 00 00 |----VAVE[7:0]; VERTICAL ACTIVE VIDEO END POINT CONTROL ----|

Page 35

Samsung Electronics 4-17

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

1D4 26 26 15 15 |---- H_SYNC_START_POINT[7:0]; -128~+0127 ----|

1D5 00 00 00 00 |---- H_SYNC_END_POINT[7:0]; -128~+0127 ----|

1D6 04 04 04 04 SIM COMP COPYEN LOCKER MANU PLAY FAET STILL

1D7 00 00 00 00 DLINE LOCKSPD[2:0] PD2 PD3 COPYLVL[1:0]00:LARGE

no-ad no-dop u-sign copy c-lock c-det h-lock no-video

1D8 00 00 00 00 |---- HSW-ADJ[7:0];HAED SWITHING POINTADJUDT VALUE ----|

1D9 26 26 26 26 |---- Y-OFFSET DATAREAD[7:0] ----|

1DA 0C 0C 0C 0C |---- VCOPY[3:0] VCO_RNGL[1:0] VCO_RNGH[1:0]

1DB 56 56 56 56 |---- DCSYNC_ADJ[7:0] DCSYNC HORIZONTAL STARTPOINT ----|

1DC 00 00 00 00 |---- C_PRO_GAIN[7:0] COPY PROTECT LEVEL CONTROL ----|

1DD 10 0E FA FB |---- PHSYNC_ADJ[7:0] PSEUDO HSYNC POINT ADJUST ----|

1DE E0 E0 E1 E1 FILSEL2 FILSEL3 X SUB DVC PAL

1DF 21 21 20 20 DCP[3:0] 0.5H:DCP*0.5H ANALOG[3:0] 0.5H:ANALOG*0.5H

CLUSTER 14 (HEADER[3:0] = 4'b1110) ; DECODER 2

1E0 80 80 80 80 OLD2 BETA[8] SEL_CON;U/V CDLY[1:0] CORE[2:0] ;CHROMA SIGNAL SLICE

1E1 00 00 04 04 FASTAPC CGAINH C.KILL[1:0] |---- FIL_SEL[2:0] ----| X

1E2 C3 C3 C3 C3 PAL_JOG ACCFR |----UOFF[5:0]; U(B-Y) SIGNAL OFFSET ----|

1E3 83 83 83 83 VCLPF GAINSEL |----VOFF[5:0]; V(R-Y) SIGNAL OFFSET ----|

1E4 37 37 37 37 |---- U(B-Y)_GAIN[7:0]; -X2~X2 ----|

1E5 51 51 51 51 |---- V(R-Y)_GAIN[7:0]; -X2~X2 ----|

1E6 75 80 80 80 |---- CGAIN-L[7:0]; ACCR='1'UNI-GAIN MODE ----|

1E7 00 00 00 00 |---- HUE[7:0] ;CHROMA HUE CONTROL VALUE FOR NTSC USED ONLY ----|

1E8 00 00 00 00 |---- CKILL_REF[7:0]; COLOR KILL REFERENCE VALUE ----|

1E9 80 80 80 80 |---- DYGAIN[7:0] ; DECODER Y GAIN CONTROL ,0~X2 ----|

1EA 00 00 00 00 X DPR_WR DPR_RD |---- HLPF[2:0]; Y LPF HPK[1:0]; PEAKING DEPTH

1EB 10 10 10 10 X X COMBY_DLY AUTO-OFF CTRAP YBWR HBW DECIMATION

1EC 00 00 00 00 |---- CORR[7:0] CTRAP CORRELATION ADDRESS ----|

1ED 53 53 53 53 |---- ATT[7:0] CORRELATED SIGNALATTENUATION LEVELY COMB(0 ~ X1) ----|

1EE 04 04 04 04 X X X X TRAP_LIM[3:0] TRAP LIMITTER Y COMB

1EF BD BD BD BD |---- BURSTG[7:0] BURST GAIN 0 ~ X2 ----|

CLUSTER 15 (HEADER[3:0] = 4'b1111) , DECODER 3

1F0 00 00 00 00 |---- YOFF[7:0] -128~+127 AUTO ----|

1F1 60 60 60 60 DCDLY MULTI VAV_ADJ[1:0] V-MOSAIC H-MOSAIC F-MIRROR H-MIRROR

1F2 04 04 04 04 |---- VMSIZE[7:0] VERTICAL MOSAIC SIZE ----|

1F3 04 04 04 04 |---- HMSIZE[7:0] HORIZONTALMOSAIC SIZE ----|

1F4 BD BD BA BA |---- HM_REF[7:0] HORIZONTAL MOSAIC REFERENCE ----|

1F5 08 08 08 08 |---- DNR_LIM[7:0] DNR LIMITATION VALUE ----|

1F6 71 71 71 71 |---- DNR_GAIN[3:0] ----| |---- DNR_LIM[3:0] ----|

1F7 00 00 00 00 |---- VS_DET[7:0] VERTICAL SYNC DETECTION DEFAULT ADD OR SUB FROM 244 ----|

1F8 00 00 00 00 |---- STILL_OFF[7:0] STILL MODE AD DATA, ADD OR SUB ----|

1F9 40 43 40 43 |---- ALPHA[7:0] VERTICALLOW PASS FILTER, DEEP at '00' ----|

Page 36

Samsung Electronics4-18

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 OPTION D6 D5 D4 D3 D2 D1 D0

1FA 80 70 80 70 |---- BETA[7:0] VERTICAL LOW PASS FILTER BETA=256-2*ALPHA ----|

1FB 05 05 16 16 |---- STP_TH[7:0] STEEP THRESHOLD:0~255 VERTICAL LPF, AD ACTIVE OPERATION THRESHOLD ----|

1FC 07 0B 07 0B |---- COFFSET[7:0] Y,C DELAY ----|

IFD 00 FC FC FC |---- DOP_DLY[7:0] DOP DELAY ----|

1FE 00 00 00 00 X X MEM_TH [5:0] MEMORY THRESHOLD CONTROL ----|

1FF xx CAMERA MICOM VERSION DISPLAY XX XX (Month-date)

“CAMERA ADJUST MODE, EEPROM ADDRESS SEQUENCE & DATA OF PAGE 2”

NOR HI8 NOR HI8 D7 D6 D5 D4 D3 D2 D1 D0

200 40 40 40 40 DIS_ON ZOOM_ON LSSC_ON MIRR_ON PIP_ON POWER PIP_MIRR BYPASS

201 8C 8C 8C 8C FRAME STILL1 STILL2 CEDGE_ON APT_ON OSD_ON TRA_ON GAMA_ON

202 00 20 40 60 DVC PAL HIGH FLD_SEL BIST PN_SEL CUR_HOLD CLEAR

203 F0 F0 F0 F0 |---- KX (7:0) HORIZONTAL ZOOM COEFFICENT VALUE ----|

204 F0 F0 F0 F0 |---- KY (7:0) VERTICAL ZOOM COEFFICENT VALUE ----|

205 64 8E 5D 98 |---- SP_H (7:0) HORIZONTAL START POINT FOR ZOOM ----|

206 14 13 19 19 |---- SP_V (7:0) VERTICAL START POINT FOR ZOOM ----|

207 00 00 00 00 |---- WIDTH (7:0) HORIZONTAL WIDTH LSB ----|

208 02 03 02 03 X X X X X X WIDTH (9:8) WIDTH MSB

209 F5 F5 22 22 |---- HEIGHT [7:0] VERTICAL HEIGHT LSB ----|

20A 00 00 01 01 X X X X X X X HEIGHT(8)

20B 98 8D 98 8E |---- PIP_HSP (7:0) PIP IMAGE HORIZONTAL START POINT LSB ----|

20C 01 02 01 02 X X X X X X PIP_HSP(9:8)

20D 88 87 AD AD |---- PIP_VSP (7:0) PIP IMAGE VERTICAL START POINT LSB ----|

20E 00 00 00 00 X X X X X X X PIP_VSP(8)

20F A4 A4 A3 A3 |---- PBOX_HSP (7:0) PIP BOX HORIZONTAL START POINT LSB ----|

210 01 01 02 02 X X X X X X PBOX_HSP(9:8)

211 B8 B8 B9 B8 |---- PBOX_VSP (7:0) PIP BOX VERTICAL START POINT LSB ----|

212 00 00 00 00 X X X X X X X PBOX_VSP(8)

213 07 07 07 07 |---- PIP_DSP_HADJ (7:0) PIP IMAGE WIDTH ADJUST ----|

214 03 03 03 03 |---- PIP_DSP_VADJ (7:0) PIP IMAGE HEIGHT ADJUST ----|

215 00 03 00 00 |---- PBOX_DSP_HADJ (7:0) PIP BOX WIDTH ADJUST ----|

216 00 00 00 00 |---- PBOX_DSP_VADJ (7:0) PIP BOX HEIGHT ADJUST ----|

217 45 6E 3C 78 |---- OUT_OFF (7:0) FIELD MEMORY1 HORIZONTALOUTPUT S/P ----|

218 44 6E 3C 78 |---- OUT_OFF1 (7:0) FIELD MEMORY1 HORIZONTALOUTPUT S/P ----|

219 08 08 08 08 GR_MODE (7:4) INTERNAL IMAGE SELECT MODE |---- OSD_VAL(3:0) ----|

21A 99 8E 99 8E CLK2_SEL |----CLK2_SEL (6:0) CLK DELAY ADJUST ----|

21B 80 80 1F 8C S1S2_SEL0 CRCB_SEL0 S1S2_SEL1 CRCB_SEL1 LINE_SEL0 LINE_SEL1 LINE_SEL2 LINE_SEL3

21C 12 0C 12 0B OSD_SEL (7:5) |---- HVD_ADJ ----|

21D 04 84 04 04 PIP_S1S2_SEL |----LS_CNT(6:0) LOW SHUTTER SPEED CONTROL REGISTER ----|

21E 4C 76 52 84 |---- DCLP_R (7:0) RISING EDGE TIME CONTROL FOR ODM ----|

21F 54 7E 5A 8C |---- DCLP_F (7:0) FALLING EDGE TIME CONTROL FOR ODM ----|

220 04 04 08 04 YHAFS YLPFS HAPG (3:0) HORIZONTAL APERTURE GAIN CONTROL

221 2A 2A 2A 2A |---- APCLP (7:0) HORIZONTALAPERTURE CLIP LEVEL ----|

Page 37

Samsung Electronics 4-19

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 D7 D6 D5 D4 D3 D2 D1 D0

222 02 02 02 02 |---- APSC (7:0) HORIZONTAL APERTURE SLICE LEVEL ----|

223 00 00 00 00 |---- ECST (7:0) COLOR EDGE SUPRESSION CLIP LEVEL ----|

224 44 44 44 44 ECSG (7:4) HORIZONTALCOLOR EDGE SUPRESSION ECSGV (3:0) VERTICAL COLOR EDGE SUPRESSION

225 83 83 83 83 G1 (7:4) COLOR HORIZONTALSPLINE GAIN CONTROL |---- G2 (3:0) ----|

226 0D 0D 0D 0D EDGE_SEL X X |---- G0 (4:0) ----|

227 00 00 00 00 |---- HUE1_OFF (7:4) ----| |---- HUE2_OFF (3:0) ----|

228 12 02 1F 1F |---- ECHUE1 (7:0) GAIN OF CR FOR BLACK BALANCE ----|

229 04 14 00 02 |---- ECHUE2 (7:0) GAIN OF CB FOR BLACK BALANCE ----|

22A 02 02 02 02 |---- APSCV (7:0) VERTICAL APERTURE SLICE LEVEL ----|

22B F0 F0 F0 F0 WV1 (7:4) VERTICAL SPLINE GAIN CONTROL1 WV2 (3:0) VERTICAL SPLINE GAIN CONTROL2

22C 70 70 70 70 WH1 (7:4) HORIZONTAL SPLINE GAIN CONTROL KT_DIV (3:0) SUB PIXEL COEFFICENT GAIN

22D 04 04 04 04 |---- OVERLAY(7:0) FEED BACK IMAGE BOUNDARY ADJUST ----|

22E 40 40 40 40 |---- TO (7:0) TIIR COEFFICENT VALUE ----|

22F 10 10 10 10 |---- MAN_TO (7:0) TIIR FILTER CLIPGAIN ----|

230 04 04 04 04 |---- TIIR_TH (7:0) TIIR FILTER SLICE LEVEL ----|

231 40 40 40 40 LINEAR FM2_FLD TIIR_INT DIR_CURX DIR_CURY X X X

232 04 04 08 08 |---- GA0 (7:0) IMAGE1 GAMMA GAIN ----|

233 07 07 0D 0D |---- GA1 (7:0) IMAGE1 GAMMA GAIN ----|

234 15 15 1B 1B |---- GA2 (7:0) IMAGE1 GAMMA GAIN ----|

235 2C 2C 32 32 |---- GA3 (7:0) IMAGE1 GAMMA GAIN ----|

236 4D 4D 57 57 |---- GA4 (7:0) IMAGE1 GAMMA GAIN ----|

237 70 70 82 82 |---- GA5 (7:0) IMAGE1 GAMMA GAIN ----|

238 B4 B4 C0 C0 |---- GA6 (7:0) IMAGE1 GAMMA GAIN ----|

239 F8 F8 F0 F0 |---- GA7 (7:0) IMAGE1 GAMMA GAIN ----|

23A F8 F8 F0 F0 |---- GA8 (7:0) IMAGE1 GAMMA GAIN ----|

23B 04 04 08 08 |---- GB0 (7:0) IMAGE1 GAMMA GAIN ----|

23C 07 07 0D 0D |---- GB1 (7:0) IMAGE1 GAMMA GAIN ----|

23D 15 15 1B 1B |---- GB2 (7:0) IMAGE1 GAMMA GAIN ----|

23E 2C 2C 32 32 |---- GB3 (7:0) IMAGE1 GAMMA GAIN ----|

23F 4D 4D 57 57 |---- GB4 (7:0) IMAGE1 GAMMA GAIN ----|

240 70 70 82 82 |---- GB5 (7:0) IMAGE1 GAMMA GAIN ----|

241 B4 B4 C0 C0 |---- GB6 (7:0) IMAGE1 GAMMA GAIN ----|

242 F8 F8 F0 F0 |---- GB7 (7:0) IMAGE1 GAMMA GAIN ----|

243 F8 F8 F0 F0 |---- GB8 (7:0) IMAGE1 GAMMA GAIN ----|

244 60 A5 60 C4 |---- SP_HM (7:0) HORIZONTAL START POINT FOR MOTION ----|

245 15 15 1E 1E |---- SP_VM (7:0) VERTICAL START POINT FOR MOTION ----|

246 F2 F2 16 16 |---- HEIGHTM (7:0) IMAGE HEIGHT FOR MOTION ----|

247 00 00 01 01 X X X X X X X HEIGHTM(8)

248 FE E0 D0 94 |---- WIDTHM (7:0) IMAGE WIDTH FOR MOTION ----|

249 01 02 01 02 X X X X X X WIDTH(9:8)

24A DE DE DE DE |---- KX_MD (7:0) MOTION DETECTION ZOOM COEFFICIENT FOR HORIZONTAL ----|

Page 38

Samsung Electronics4-20

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 D7 D6 D5 D4 D3 D2 D1 D0

24B DE DE DE DE |---- KY_MD (7:0) MOTION DETECTION ZOOM COEFFICIENT FOR VERTICAL ----|

24C 00 00 00 00 |---- OSD_MODE (7:0) ----|

24D C1 C1 C1 C1 DIS_ENX DIS_DNY DIR_VX DIR_VY DXYSET F_PROJ HLF_SFT FRM_VY

24E 00 00 00 00 |---- OX (7:0) AREAOFFSET OF MOTION DETECTION AREAIN X DIRECTION ----|

24F 00 00 00 00 X X X X X X OX (9:8)

250 00 00 00 00 |---- OY (7:0) AREA OFFSET OF MOTION DETECTION AREA IN Y DIRECTION ----|

251 00 00 00 00 |---- CX (7:0) ASSIGNED MOTION VECTOR FOR X ---> MOTION CENTERING ----|

252 06 06 06 06 |---- CY (7:0) ASSIGNED MOTION VECTOR FOR Y ---> MOTION CENTERING ----|

253 00 00 00 00 AX (7:4) COMPENSATION MARGIN X AY (3:0) COMPENSATION MARGIN Y

254 33 33 33 33 |---- AUTO_CENT (7:0) AUTO CENTERING ----|

255 88 88 88 88 VGGAINX (7:4) MOTION GAIN X VGGAINY (3:0) MOTION GAIN Y

256 21 21 21 21 VGSTEP (7:4) MOTION GAIN RECOVERY STEP GSPEED (3:0) DISPLAY BAR GRAPH SPEED

257 48 48 48 48 |---- THR_SEL (7:0) THRESHOLD CONTROL ----|

258 11 11 11 11 |---- CXY_BIAS (7:0) SCENE CHANGE FILTER OFFSET FOR THRESHOLD ----|

259 A5 A5 A5 A5 MATCHX_EN MVX_FMIN QUART_X MVX_GAP(3:0) MISMATCH THRESHOLD

25A A5 A5 A5 A5 MATCHY_EN MVY_FMIN QUART_X MVX_GAP(3:0) MISMATCH THRESHOLD

25B 68 68 68 68 SHMFBC (7:4) SUM FILTER FEED BACK COEFFICIENT SHMITT (3:0) SUM FILTER THRESHOLD

25C E0 E0 E0 E0 MVIIR_EN SCENE_X SCENE_Y FRM_DIS F_SELECT HLD_HIST HIST_SFT

25D 00 00 00 00 OZNSEL (7:5) AF/AE DISPLAY WINDOW OYISEL OFILPASS OLPFSEL X X

25E 73 70 8B 8B |---- OAEVE_WB (7:0) AE WINDOW B, VERTICAL END POINT ----|

25F 1E 1B 24 24 |---- OAEVS_WB (7:0) AE WINDOW B, VERTICAL START POINT ----|

260 EA E2 E7 E8 |---- OAEHE_WB (7:0) AE WINDOW B, HORIZONTALEND POINT ----|

261 06 02 01 02 |---- OAEHE_WB (7:0) AE WINDOW B, HORIZONTALSTART POINT ----|

262 6A 6B 81 81 |---- OAEVE_WA (7:0) AE WINDOW A, VERTICAL END POINT ----|

263 20 1D 26 26 |---- OAEVS_WA (7:0) AE WINDOW A, VERTICAL START POINT ----|

264 BD B9 B2 B3 |---- OAEHE_WA (7:0) AE WINDOW A, HORIZONTAL END POINT ----|

265 3F 3B 31 32 |---- OAEHE_WA (7:0) AE WINDOW A, HORIZONTAL STAR TPOINT ----|

266 5F 5C 71 71 |---- OAFVE_W2 (7:0) AF WINDOW 2, VERTICAL END POINT ----|

267 25 22 29 29 |---- OAFVS_W2 (7:0) AF WINDOW 2, VERTICAL START POINT ----|

268 A8 A4 A2 A3 |---- OAFHE_W2 (7:0) AF WINDOW 2, HORIZONTALEND POINT ----|

269 4E 4A 47 48 |---- OAFHS_W2 (7:0) AF WINDOW 2, HORIZONTAL STARTPOINT ----|

26A 76 76 8D 8D |---- OAFVE_W1 (7:0) AF WINDOW 1, VERTICAL END POINT ----|

26B 03 03 04 04 |---- OAFVS_W1 (7:0) AF WINDOW 1, VERTICALSTART POINT ----|

26C E5 E5 DC DC |---- OAFHE_W1 (7:0) AF WINDOW 1, HORIZONTAL END POINT ----|

26D 03 03 06 06 |---- OAFHS_W1 (7:0) AF WINDOW 1, HORIZONTAL STARTPOINT ----|

26E 00 00 00 00 |---- OYL_TH (7:0) AE YSINGLE LOW THRESHOLD ----|

26F FF FF FF FF |---- OYH_TH (7:0) AE Y SINGLE HIGH THRESHOLD ----|

270 C0 C0 C0 C0 |---- OAECLIP_TH (7:0) AE CLIP COUNT THRESHOLD ----|

271 C0 C0 C0 C0 |---- OAFCLIP_TH (7:0) AF CLIP COUNT THRESHOLD ----|

272 00 00 00 00 |---- PFCNT_MI (7:0) DEFECT COUNT VALUE FROM MICOM ----|

273 28 28 28 28 |---- PTHRESH (7:0) DIGITAL CLAMP THRESHOLD VALUE FROM MICOM ----|

Page 39

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 D7 D6 D5 D4 D3 D2 D1 D0

PAL NTSC

001 40 - 40 - CAMERA OPTION ; NON I-BLC VP-L500,L520,L530 SCL500,L520

50 50 50 50 CAMERA OPTION ; I-BLC VP-M550(HI-8) SCL530,L550(HI8)

05A 08 - 0C - DIGITAL CLAMP ATAGC ON(#118-#05A); NON-DIS VP-L500,L520 SCL500,L520

00 00 00 00 DIGITAL CLAMPAT AGC ON(#118-#05A); DIS MODE VP-L530,L550(HI-8) SCL530,L550(HI8)

07E E7 - - - D.ZOOM RATIO MAX ; X220 - SCL500

F4 F4 F4 F4 D.ZOOM RATIO MAX ; X440 VP-L500,L520,L530,L550(HI8) SCL520,L530,L550(HI8)

104 07 - 08 - GLOVALDELAY : NON I-BLC, NON-DIS VP-L500,L520 SCL500,L520

- - 08 - GLOVAL DELAY ; NON I-BLC DIS VP-L530 -

18 0C - 0C GLOVAL DELAY ; I-BLC,DIS VP-L550(HI8) SCL530,L550(HI8)

118 08 - 0D - DIGITAL CLAMP ; NON-DIS VP-L500,L520 SCL500,L520

00 00 00 00 DIGITAL CLAMP ; DIS VP-L530,L550(HI8) SCL530,L550(HI8)

134 0A - 04 - R-DARK-SLICE ; NON-DIS VP-L500,L520 SCL500,L520

0A 05 09 09 R-DARK-SLICE ; DIS VP-L530,L550(HI8) SCL530,L550(HI8)

135 FA - 07 - B-DARK-SLICE ; NON-DIS VP-L500,L520 SCL500,L520

00 FE FD 00 B-DARK-SLICE ; DIS VP-L530,L550(HI8) SCL530,L550(HI8)

Samsung Electronics 4-21

Alignment and Adjustment

NO-OSD-DISPLAY DISTANCE

ADDR MODEL/DATA CONTENT

NTSC PAL

NOR HI8 NOR HI8 D7 D6 D5 D4 D3 D2 D1 D0

274 0C 0D 0D 0D |---- POFFSET (7:0) DIGITAL CLAMP OFFSET VALUE FROM MICOM ----|

275 03 03 03 03 |---- PCMD (7:0) PREPROCESS COMMAND FROM MICOM ----|

276 00 00 00 00 |---- PRAMIL (7:0) DEFECT POSITION VALUE(7:0) FROM MICOM ----|

277 00 00 00 00 |---- PRAMIM (16:8) DEFECT POSITION VALUE(15:8) FROM MICOM ----|

278 00 00 00 00 X X X X PRAMIM (19:16) DEFECTPOSITION FROM MICOM

279 00 00 00 00 X X |----PRAMA_MI (5:0) LINE MEMORY ADDRESS FROM MICOM ----|

27A 00 00 00 00 DIS;FACTOR AT BLC ON CONDTION

27B 00 00 00 00 DIS;FACTOR AT BLC ON CONDTION

27C 00 00 00 00 DIS;FACTOR AT WDR ON CONDTION

27D 00 00 00 00 DIS;FACTOR AT WDR ON CONDTION

27E F4 F4 F4 F4 DIS;WIGHT WHEN DECREASE

27F 00 00 00 00 DIS; STEP CONTROL '00~88'

“CHANGED BY MODEL”

Page 40

Samsung Electronics4-22

Alignment and Adjustment

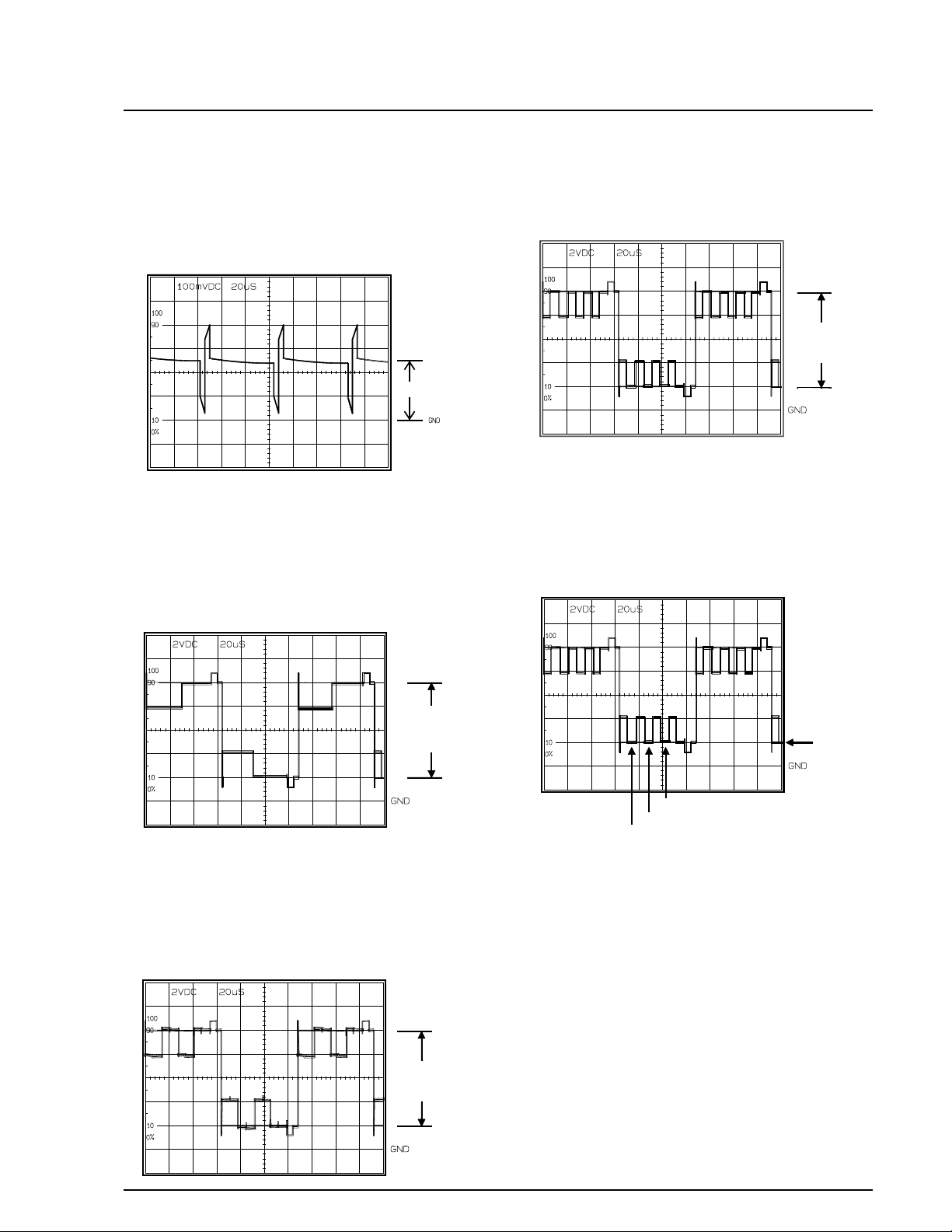

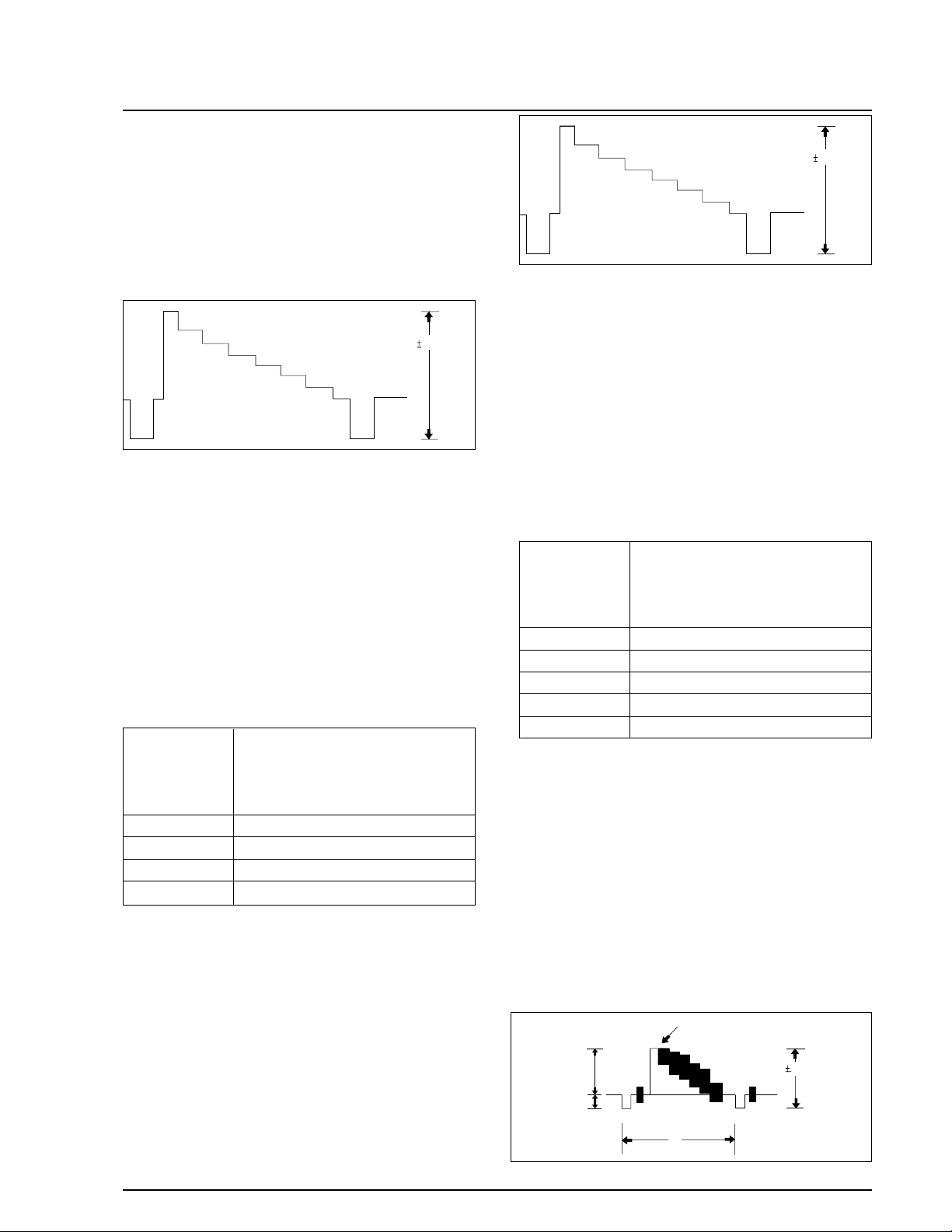

1. Focus to zoom tracking

Notes : To maintain proper focus throughout the zoom range, the focus lens position must be changed as

the zoom lens is moved.

During this adjustment the microprocessor will measure the focus positioning requirements at the

wide and telephoto position of the zoom lens.

1) Camera “E-E”.

2) Focus chart (Attached on the last page of this manual).

3) Aim the camera at the focus chart placed 3 meters away and perpendicular to the center of the lens.

The chart should be placed on the flat, gray or white wall.

4) Connect monitor TV jack to video output jack.

5) Press the “FADE(MODE UP)” and “BLC(MODE DOWN)” button, so that the OSD start is “0DE. 3M

LENS XX XX”.

6) Press “PROGRAM AE(CONFIRM)” button.

The camera will move both zoom and focus lens.

The adjustment is finished when the O.K! message appears on the TV screen.

Store the data to mode 0A6, 0A7, 0A8, 0A9, 0AA, 0AB, 0AC or 0AD.

4-2-2 Camera System Adjustment

(3M±1cm)

(Be sure to maintain the distance.)

LENS

CCD

Note : The on-screen display information.

“XX XX” means arbitrary value.

It can be different number depend on the conditions.

0DF T.INI XX XX

Page 41

Samsung Electronics 4-23

Alignment and Adjustment

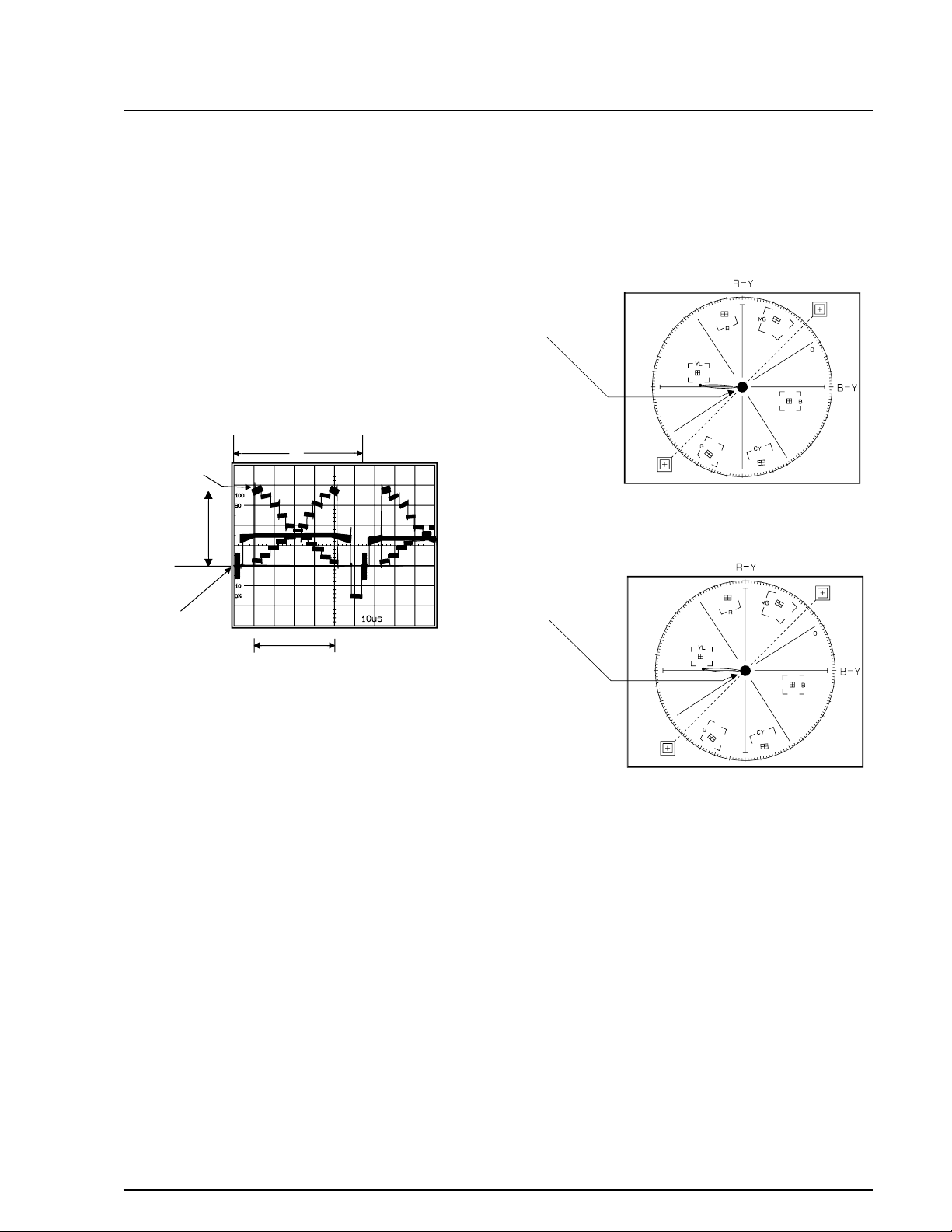

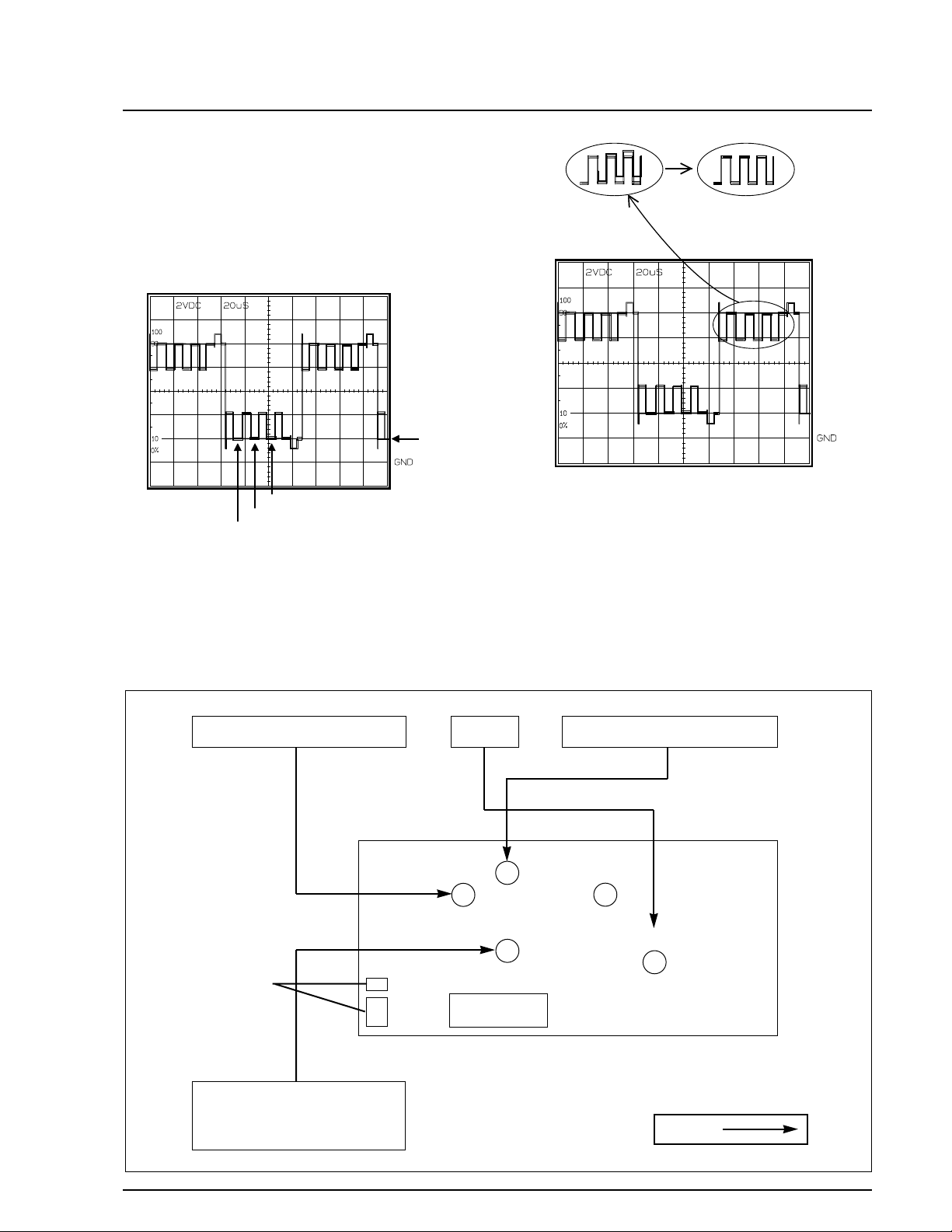

2. P. CLK Adjustment

1) “Camera”, no signal input.

2) P.CLK and AF MICOM.

3) Connect a frequency counter to P.CLK.

4) Press the “FADE(MODE UP)/BLC(MODE DOWN)” button so that the OSD state is

“004 XX XX”.

5) Adjust the “DSE(DATA UP)/TITLE(DATA DOWN)” button so that frequency is

.

PAL: NORMAL --> 9.453125MHz ± 50Hz. Hi8 --> 14.18750MHz ± 50Hz.

.

NTSC: NORMAL --> 9.534964MHz ± 50Hz. Hi8 --> 14.318182MHz ± 50Hz.

NOTE : Frequency changes after the confirm button is pressed.

Main PCB (Solder side)

3. Zoom VR Center

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and EVR.

3) Connect monitor TV to video(output) jack.

4) Press the “FADE (MODE UP)/BLC

(MODE DOWN)” button so that the OSD state

is “OD6. ZVR.C XX XX”.

5) Press “PROGRAM AE(CONFIRM)” button.

6) Then, the microprocessor will work ;

- Find the Zoom VR Center position

- Store the data to mode 0B7.

4. Auto hall

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and EVR.

3) Connect monitor TV to video(output) jack.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “OCD.

HALL XX XX”.

5) Press “PROGRAM AE(CONFIRM)” button.

6) Then, the microprocessor will work ;

- IRIS open, HALL maximum value found,

- IRIS closed, HALL minimum value found,

- IRIS open, HALL maximum value found,

- Store the data to mode 00A and mode 00B.

- Store the HALL min./max. data to mode 0C1

and mode 0C2.

Page 42

Samsung Electronics4-24

Alignment and Adjustment

5. AUTO IRIS

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

3) Connect video(output) jack to waveform monitor input jack and monitor TV jack respectively.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “OCE.

IRIS XX XX”.

5) Press “PROGRAM AE(CONFIRM)” Button.

6) Then, the micro process will work;

- IRIS open, IRIS control minimum Value found.

- IRIS close, IRIS control minimum Value found.

- Store the data to mode 0B5, 0B6, 0C7 and 0C8.

7) The OSD shows “O.K”.

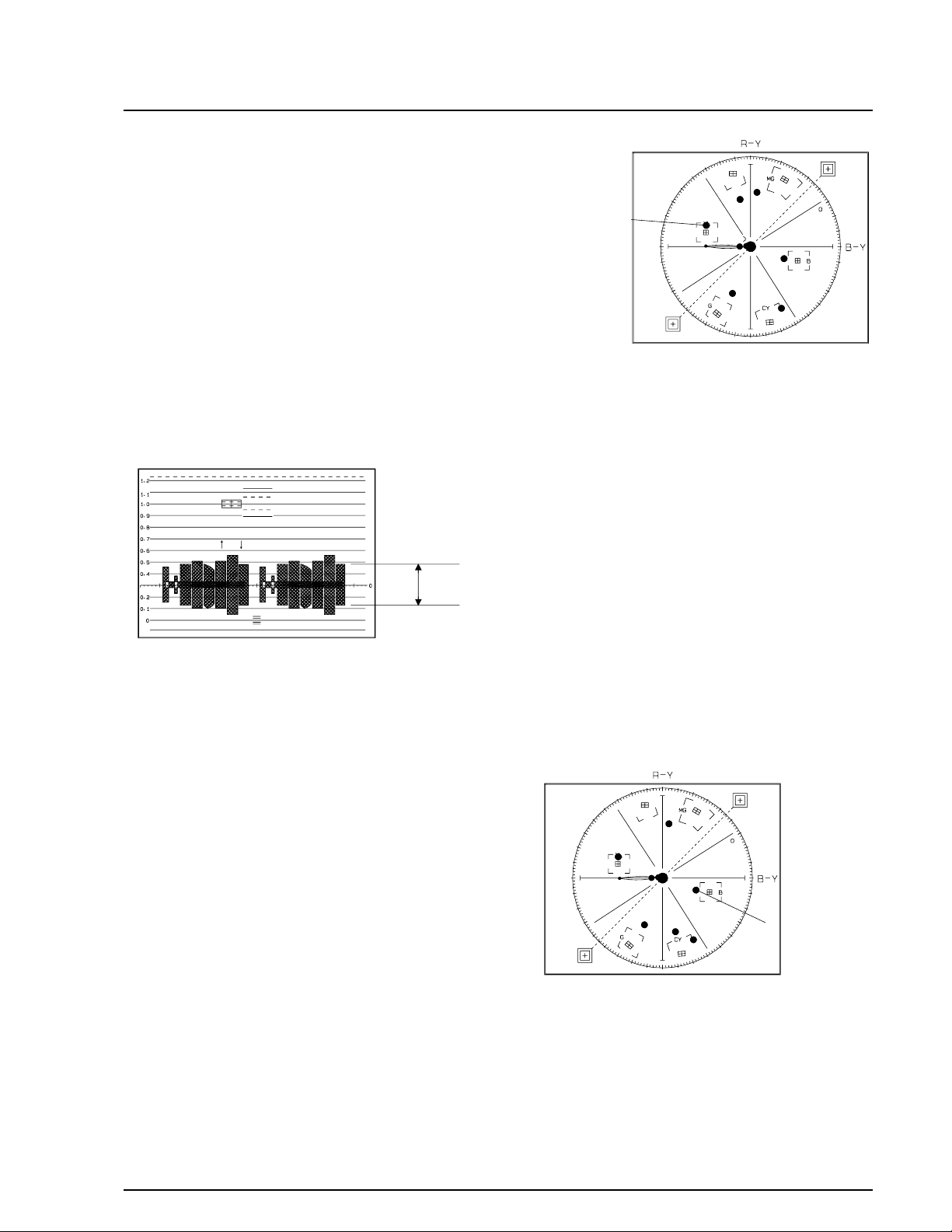

6. Auto white balance

1) Camera “E-E”, 3100°K/5100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

4) Connect vectorscope input jack to video(output) jack.

3) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “0CF.

AWB XX XX”.

a. W/B Indoor

a-1. Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx. (40us)

a-2. Press “PROGRAM AE(CONFIRM)” button so

that the white vector moves to the center

on screen of the vectorscope.

a-3. The OSD shows “OK!”.

b. W/B Outdoor

b-1. Aim the camera at a 5100°K gray-scale

(3100°K+CCB16) chart illuminated at 1500 to

2000 lx. (40us)

b-2. Press “PROGRAM AE(CONFIRM)” button

so that the white vector moves to the center

on screen of the vectorscope.

b-3. Store the data to mode 0C9, 0CA, 0CB and

0CC.

b-4. The OSD shows “OK!”.

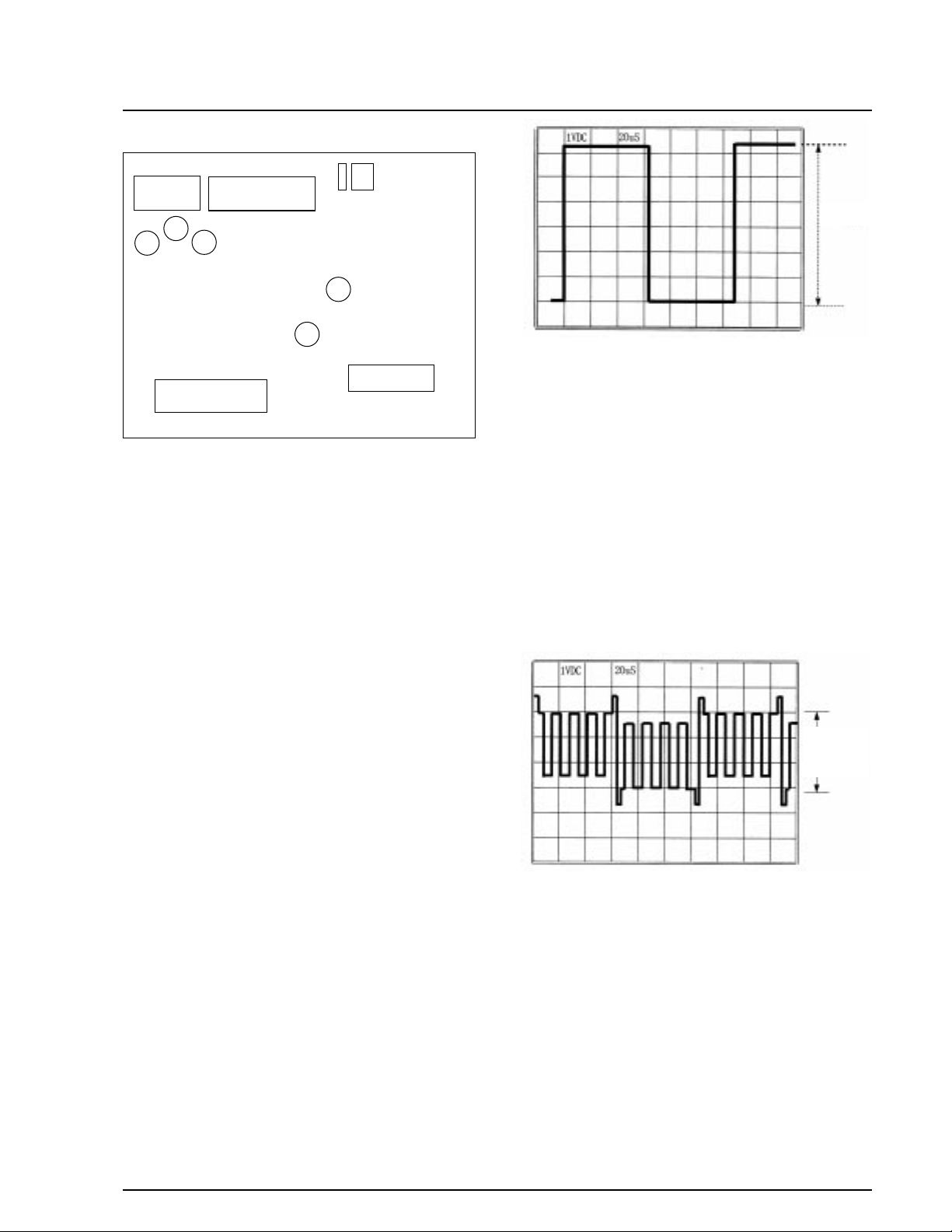

7. Pre white balance (I)

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

3) Connect vectorscope input jack to video(output) jack.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “137.

XX XX”.

5) Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx.

6) Adjust the “ DSE(DATA UP)/TITLE

(DATA DOWN)” button so that the white vector moves to the B-Y axial on screen of the

vectorscope.

Note : Bright dot shifts after the confirm button is

pressed.

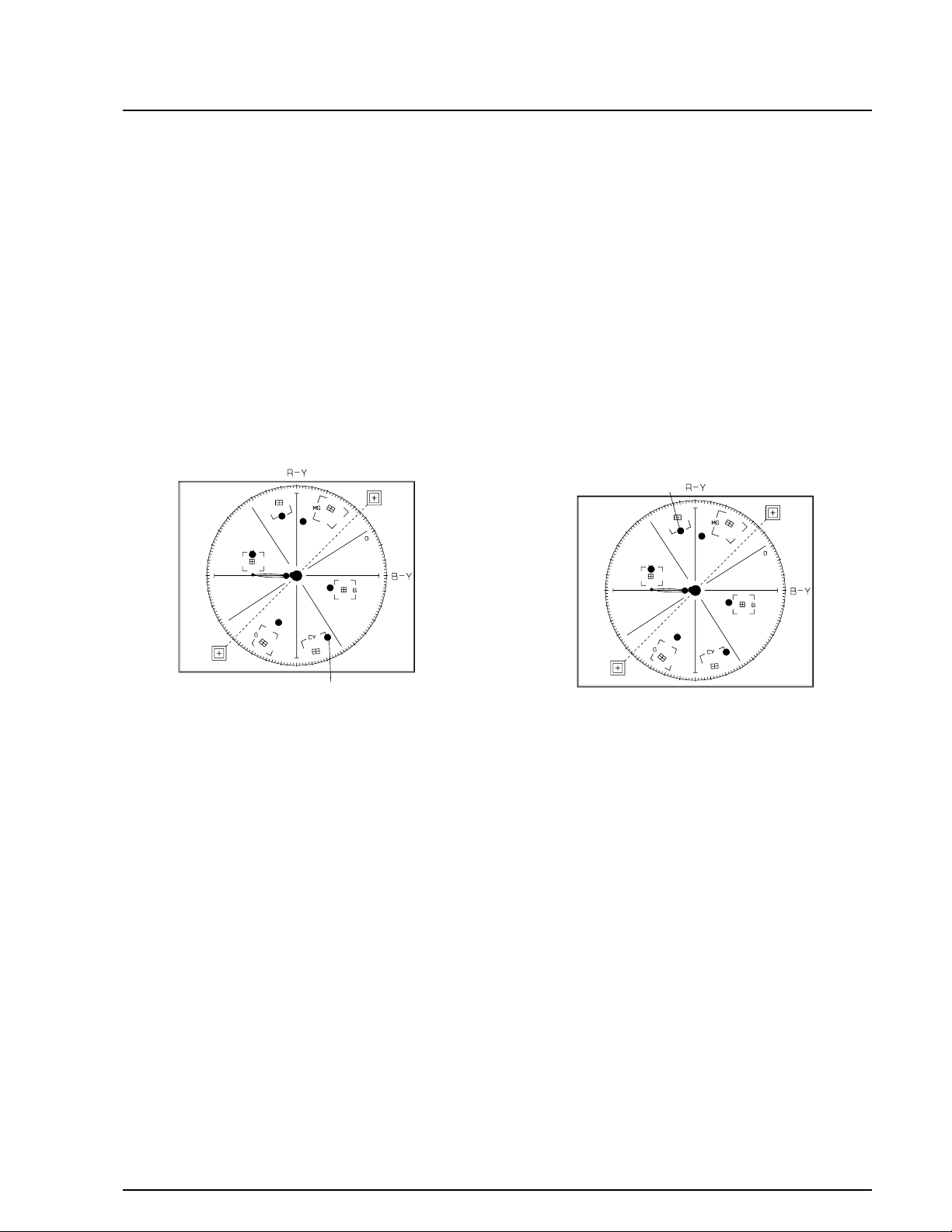

Center of

white level

100IRE

Optical

black level

H

40US

Match the white luminance

point with the

black luminance

point

Match the white luminance

point with the

black luminance

point

Page 43

Samsung Electronics 4-25

Alignment and Adjustment

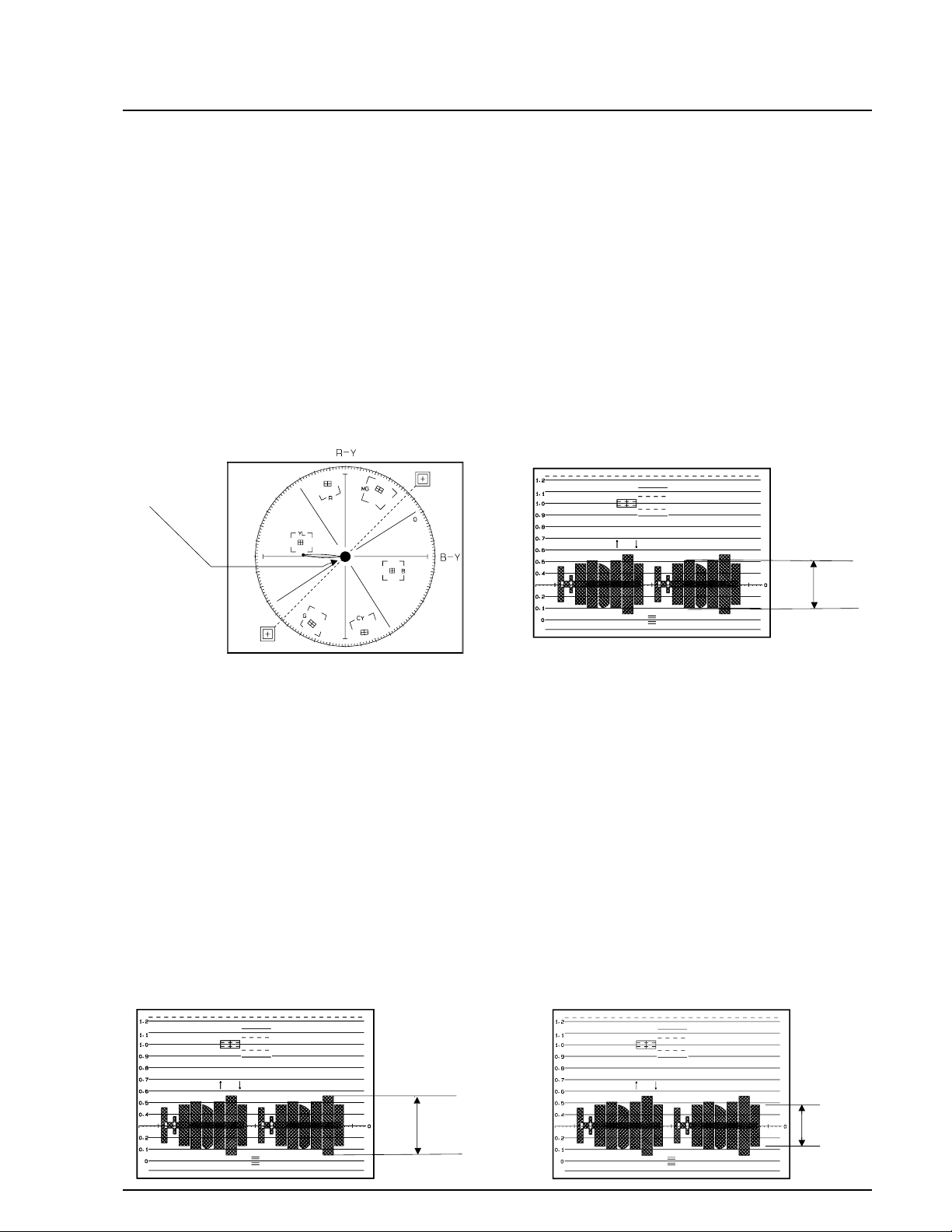

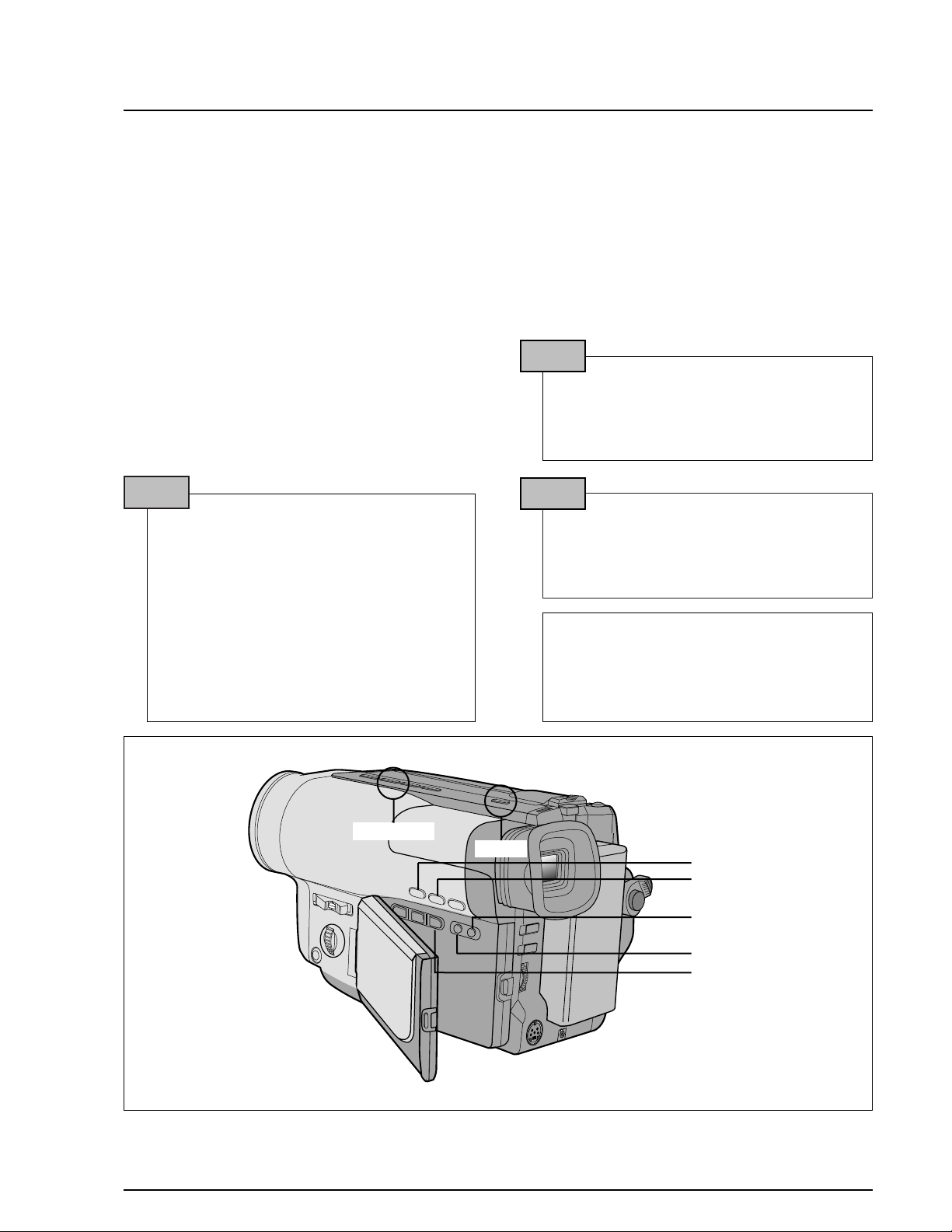

8. Pre white balance (II)

1) Camera “E-E”, 3100°K gray-scale chart.

2) Video(output) jack and AF MICOM.

4) Connect vectorscope input jack to video(output) jack.

3) Press the “FADE (MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “138.

XX XX”.

5) Aim the camera at a 3100°K gray-scale chart

illuminated at 1500 to 2000 lx.

6) Adjust the “DSE(DATA UP)/TITLE

(DATA DOWN)” button so that the white vector moves to the R-Y axial on screen of the vectorscope.

Note : Bright dot shifts after the confirm button is

pressed.

9 R-Y Positive Gain

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to waveform monitor input jack and monitor TV jack respectively.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “147.

XX XX”.

5) Aim the camera at a color bar chart illuminated

at 1500 to 2000 lx.

6) Adjust the “ DSE(DATAUP)/TITLE(DATA

DOWN)” button so that the red level is

70IRE(NTSC)/500mV(PAL) .

7) Be sure to press the “PROGRAM AE(CONFIRM)” button to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

10. R-Y Negative Gain

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to waveform monitor input jack and monitor TV jack respectively.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “148.

XX XX”.

5) Aim the camera at a color bar chart illuminated

at 1500 to 2000 lx.

6) Adjust the “ DSE(DATAUP) /TITLE(DA TA

DOWN)” button so that the cyan level is

65IRE(NTSC)/350mV(PAL).

7) Be sure to press the “PROGRAM AE(CONFIRM)” button to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

11. B-Y Positive Gain

1) Camera “E-E”, 3100°K color bar chart.

2) Video(output) jack and register of EEPROM.

3) Connect video(output) jack to waveform monitor input jack and monitor TV jack respectively.

4) Press the “FADE(MODE UP)/BLC(MODE

DOWN)” button so that the OSD state is “14B

XX XX”.

5) Aim the camera at a color bar chart illuminated

at 1500 to 2000 lx.

6) Adjust the “DSE(DATA UP)/TITLE (DATA

DOWN)” button so that the blue level is

50IRE(NTSC)/350mV(PAL).

7) Be sure to press the “PROGRAM AE(CONFIRM)” button to memorize setting.

Note : Bright dot shifts after the confirm button is

pressed.

Match the white luminance

point with the

black luminance

point

70IRE

65IRE