Samsung SVR-171 Precautions

Samsung Electronics

2-1

2. Alignment and Adjustments

2-1 VCR Adjustment

1) X-Point (Tracking center) adjustment, “Head switching adjustment” and “NVRAM option setting” can be adjusted with remote control.

2) When replacing the Main PCB Micom (IC601) and NVRAM (IC605 ; EEPROM) be sure to adjust the “Head switching adjustment” and

“NVRAM option setting”.

3) When replacing the cylinder ass’y, be sure to adjust the “X-Point” and “Head switching adjustment”.

4) Among Samsung VCR remote control used for adjustment as a accessory, only the remote control that has figures buttons (0 ~ 9) and

“SPEED” button are available for all adjustment regardless of chassis.

5) How to adjust.

- Momently short-circuit the test point on Main PCB with pincers to set the adjustment mode.

- If the corresponding adjustment button is pressed, the adjustment is performed automatically.

- When the adjustment is completed, be sure to turn the power off.

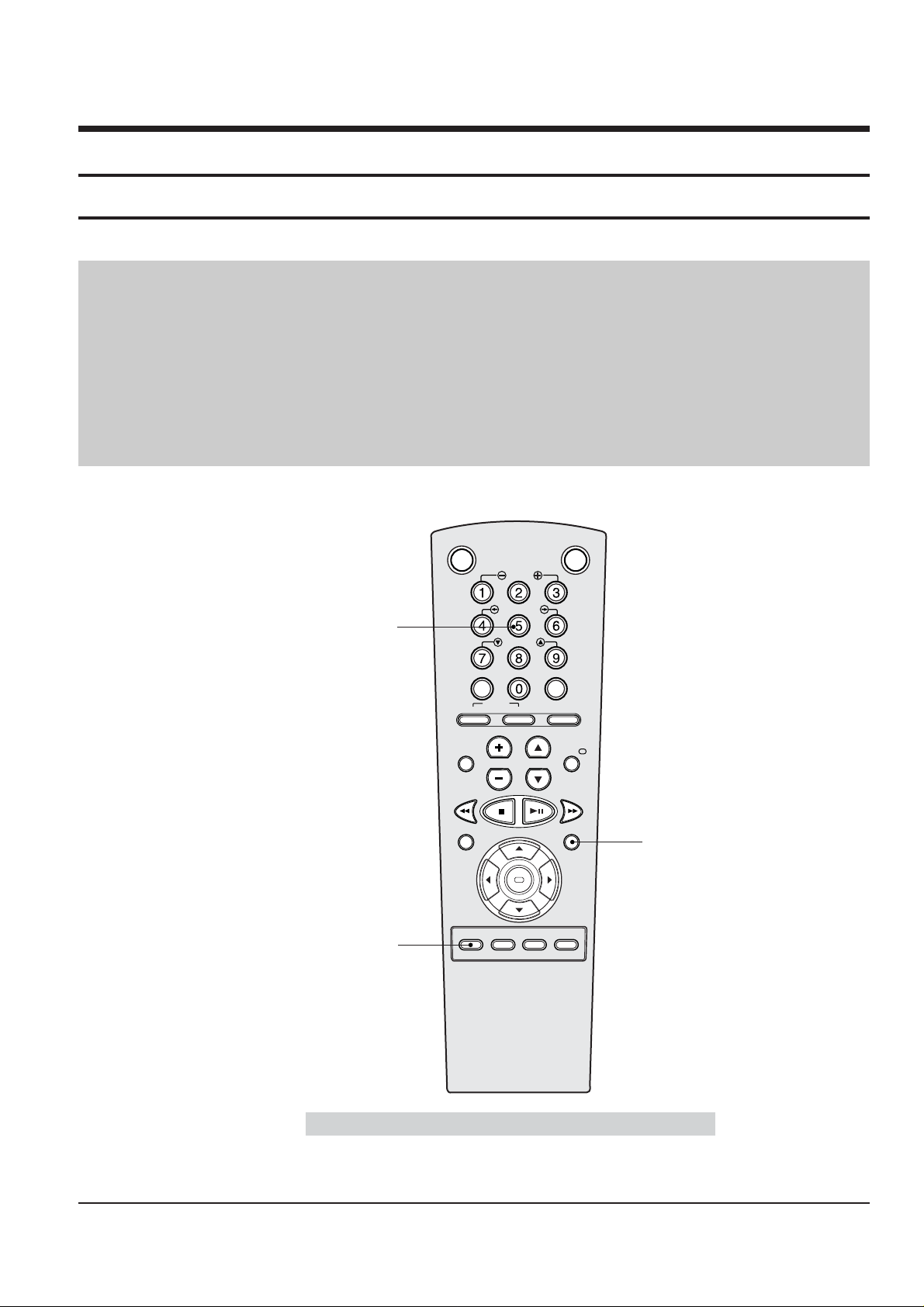

2-1-1(a) Location of adjustment button of remote control

Fig. 2-1

Remote Control for adjustment is not supplied as a Service Jig.

OK

VCR STANDBY/ON TV STANDBY/ON

SLOW

SHUTTLE

V-LOCK

CLR/RST F.ADV INDEX

TV VCR INPUT

REPEAT

VOL PROG/TRK

AUDIO

REC MENU

SPEED DUB TV/VCR TIMER

DISP./

SELECT

-/--

X-Point (Tracking Center) Adjustment

("5" Button)

Head Switching Adjustment

("SPEED" Button)

NVRAM Option Setting

("MENU" Button)

2-1-1 Reference

2-2

Alignment and Adjustments

Samsung Electronics

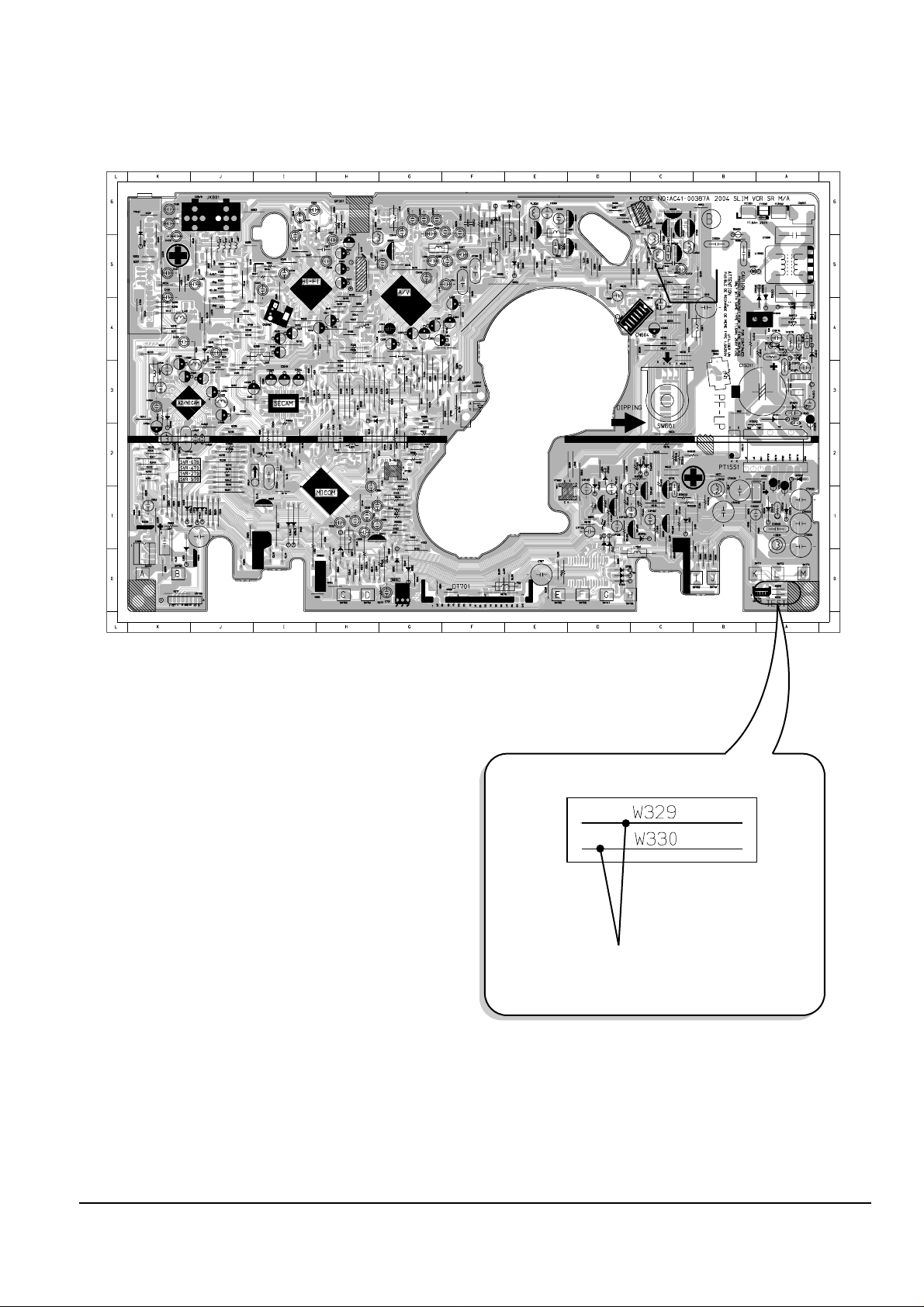

2-1-1(b) location for adjustment mode setting

Fig. 2-2 Main PCB (Top View)

Short-Circuit for few seconds and release.

(Just one time)

Alignment and Adjustments

2-3

Samsung Electronics

2-1-2 Head Switching Point Adjustment

1) Playback the alignment tape.

2) Momently short-circuit the test point on Main PCB with pincers to set the adjustment mode. (See Fig. 2-2)

3) Press the “SPEED” buttons; remote control adjustment operates automatically. (See Fig. 2-1)

4) Turn the Power off.

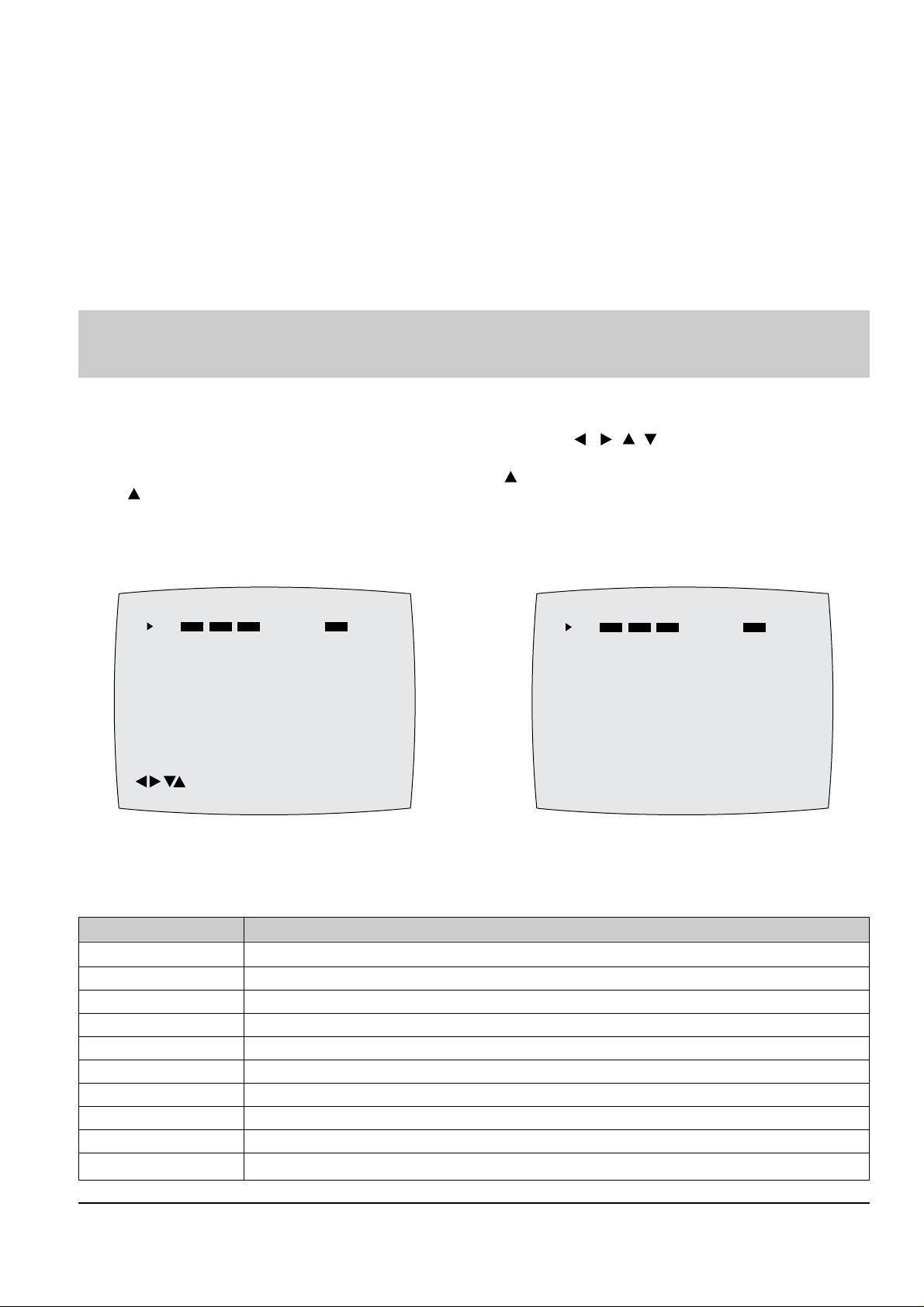

2-1-3 NVRAM Option Setting

1) Momently short-circuit the test point on Main PCB with pincers to set the adjustment mode. (See Fig. 2-2)

2)

Press the “MENU” button on the remote control. The option setting appears. (See Fig. 2-3)

3)

Select the option number (See table 2-1) of corresponding model with “ , , , ” buttons on the

remote control.

4) After selecting the option number is completed, press the “ ” button of remote control.

(If “ ” button is pressed, the selected number is changescolor. ; See Fig. 2-4)

5) Press the “ENTER” button of remote control again to store the option number.

6) Turn the Power off.

1) NVRAM Option is adjusted in the factory.

2) In case Main PCB Micom (IC601) and NVRAM (IC605 ; EEPROM) are replaced, be sure to set the corresponding option number of the

required model. (If the option is not set, the unit will not operate.)

CNG : OK SAVE : RETURN

01 02 03 04 05 06 07 08

09 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

Fig. 2-3

PLEASE WAIT

01 02 03 04 05 06 07 08

09 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

Fig. 2-4

<Table 2-1 NVRAM Option Table>

MODEL OPTION NUMBERS

SVR-679 6, 7, 8, 9, 10, 12, 20, 26, 27, 32, 33, 34, 36, 38, 42, 47, 54, 57, 60, 61, 64, 65

SVR-673 6, 7, 8, 9, 10, 12, 20, 26, 27, 32, 33, 34, 36, 38, 42, 47, 54, 57, 60, 61, 64, 65

SVR-670 6, 7, 8, 9, 10, 12, 20, 26, 27, 32, 33, 34, 36, 38, 42, 47, 49, 54, 57, 60, 61, 64, 65

SVR-473 9, 10, 12, 20, 26, 27, 32, 33, 34, 36, 38, 42, 47, 54, 57, 60, 61, 64, 65

SVR-273 10, 12, 20, 26, 27, 32, 33, 34, 36, 37, 42, 47, 54, 57, 60, 61, 64, 65

SVR-2701 10, 12, 20, 26, 27, 33, 34, 36, 37, 42, 47, 54, 57, 60, 61, 64, 65

SVR-2701B 10, 12, 20, 26, 27, 33, 34, 36, 37, 42, 47, 54, 57, 60, 61, 64, 65

SVR-170 10, 12, 20, 33, 34, 35, 36, 37, 40, 47, 49, 54, 57, 60, 61, 64, 65 68, 70

SVR-171 10, 12, 20, 33, 34, 35, 36, 37, 40, 47, 54, 57, 60, 61, 64, 65 68, 70

SVR-171B 10, 12, 20, 33, 34, 35, 36, 37, 40, 47, 54, 57, 60, 61, 64, 65 68, 70

2-4

Alignment and Adjustments

Samsung Electronics

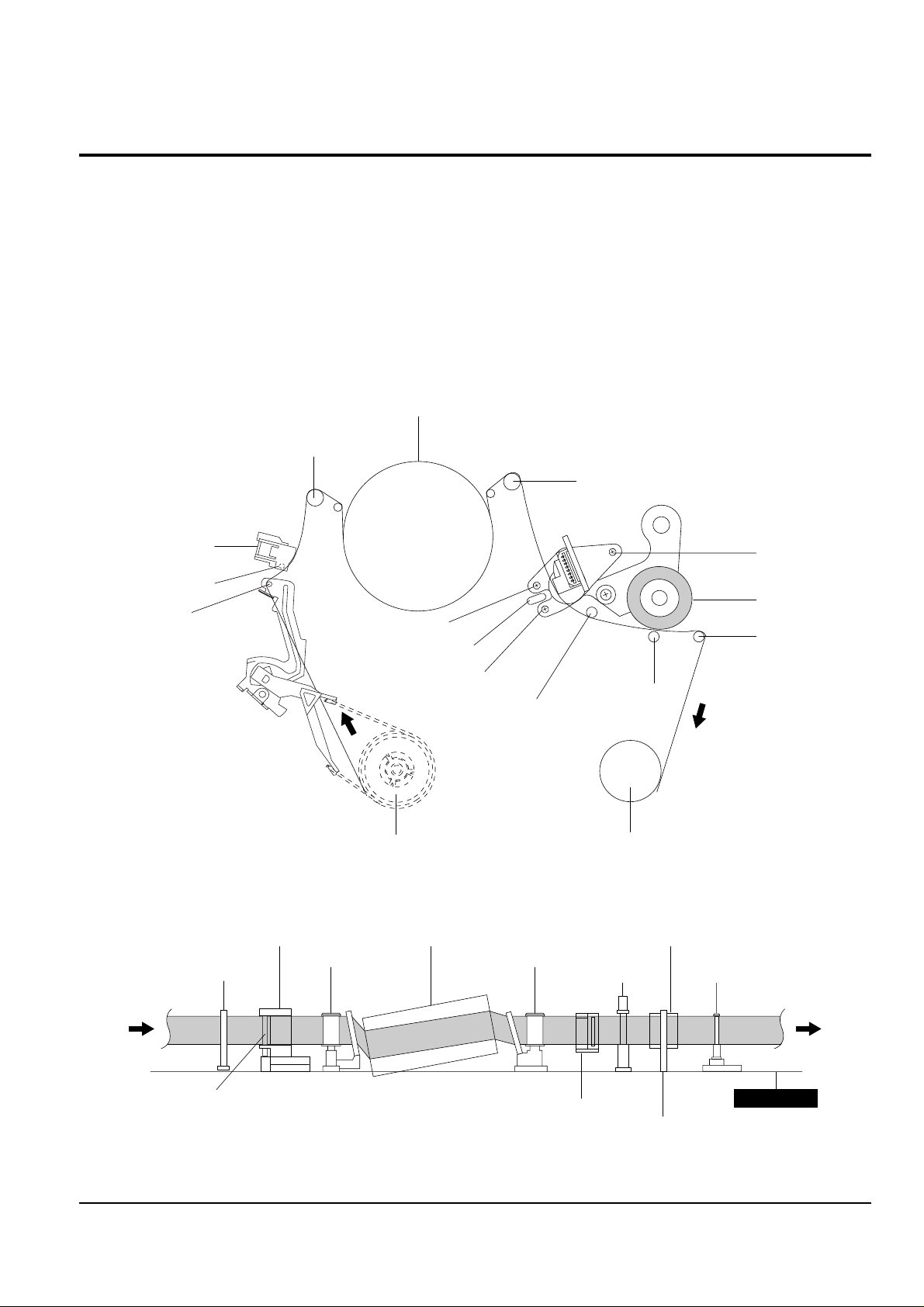

2-2 VCR Mechanical Adjustment

2-2-1 Tape Transport System and Adjustment Locations

The tape transport system has been adjusted precisely in the factory. Alignment is not necessary except for the

following :

1) Noise observed on the screen.

2) Tape damage.

3) Parts replacement in the tape transport system.

Lower flange height of tape guide is used as the reference for the transport adjustment.

To maintain the height of the tape guide and prevent damage, do not apply excessive force onto the main base.

Fig. 2-5 Location of Tape Transport Adjustment

Fig. 2-6 Tape Travel Diagram

CYLINDER ASS'Y

TAKE UP REEL DISK

#8 GUIDE POST

#9 GUIDE POST

SUPPLY REEL DISK

CAPSTAN

PINCH ROLLER

GUIDE ROLLER "T"

GUIDE ROLLER "S"

FULL ERASE HEAD

#3 GUIDE POST

TENSION POST

HEIGHT SCREW

TILT SCREW

X - POSITION

ADJUST SILT

AZIMUTH SCREW

POST TENSION

MAIN BASE

FE HEAD CYLINDER ASS'Y

PINCH ROLLER

GUIDE ROLLER "S" GUIDE ROLLER "T"

#8 GUIDE POST #9 GUIDE POST

CAPSTAN SHAFT

ACE HEAD

#3 GUIDE POST

Loading...

Loading...