Samsung SCX-4216, SCX-4116, SCX-4016 Service manual

SERVICE

DIGITAL LASER MFP

SCX-4216F

SCX-4116

SCX-4016

Manual

DIGITAL LASER MFP CONTENTS

1. Precautions

2. Reference Information

3. Specifications

4. Summary of product

5. Disassembly and Reassembly

6. Alignment and Adjustments

7. Troubleshooting

8. Exploded Views and Parts List

9. Block Diagram

10. Connection Diagram

© Samsung Electronics Co.,Ltd. March 2003

Printed in Korea.

VERSION NO. : 1.00 CODE : JC-0095A

This service manual is also provided on the web,

the ITSELF system f Samsung Electronics Co., Ltd.

“http://itself.sec.samsung.co.kr”

- This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law. -

Copyright(c) 2003.03

1

1

1-1

Samsung Electronics

Precautions

Service Manual

1. Precautions

The cautions in the below are items needed to keep in mind when maintaining and servicing.

Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent

that the machine gets damage.

1.1 Warning for safety.

(1) Request the service by qualified service person.

The service for this machine must be performed by a service person who took the additional education of

this field. It is dangerous if unqualified service person or user tries to fix the machine.

(2) Do not rebuild it discretionary.

Do not attach or change parts discretionary. Do not disassemble, fix, and rebuilt it. If you do, the printer will

not work and electric shock or a fire can occur.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J

for Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product conforming to the

requirements of IEC 825. Class I laser products are not considered to be hazardous. The laser system and

printer are designed so there is never any human access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The reflected

beam, although invisible, can damage your eyes. When using this product, these basic safety precautions should

always be followed to reduce risk of fire, electric shock, and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GE FFNET.

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE L ESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTRLNING VED BNING, NR

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STR LNING.

ADVARSEL. - USYNLIG LASERSTRLNING NR DEKSEL

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STR LEN.

VARNING - OSYNLIG LASERSTRLNING NR DENNA DEL

R PPNAD OCH SP RREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STR LEN R FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA N KYM TT M LLE LASERS TEILYLLE L KATSO S TEESEEN.

1-2

Precautions

Samsung Electronics

Service Manual

1.2 Caution for safety

1.2.1 Precaution related noxious material

It is possible to get harmed from noxious material if you ignore the below information.

(1) Do not touch the damaged LCD. This PRINTER has LCD in control panel. Noxious liquid to human body exists in the

LCD. If it is got into mouth, immediately see a doctor. If it is got into eyes or on skin, immediately wash off over 15

minutes with flowing water and see a doctor.

(2)

The toner in a printer cartridge contains a chemical material, which might harm human body if it is swallowed.

Please keep children out of the toner cartridge.

1.2.2 Precaution related electric shock or fire

It is possible to get electric shock or burn by fire if you don't follow the instructions of the manual.

(1) Use exact voltage. Please do use an exact voltage and wall socket. If not, a fire or an electric leakage

can be caused.

(2) Use authorized power code. Do use the power code supplied with PRINTER. Afire can be occurred

when over current flows in the power code.

(3) Do not insert many cords into a outlet. If do, a fire can occur due to a over flow of current in an outlet.

(4) Do not put water or extraneous matter in the PRINTER. Please do not put water, other liquid, pin, clip,

etc. It can cause a fire, electric shock, or malfunction. If it happens, turn off the power and remove the

power plug from outlet immediately.

(5) Do not touch the power plug with a wet hand. When servicing, remove the power plug from the outlet

and do not insert or remove it with a wet hand. Electric shock can occur.

(6) Use caution when inserting or taking off the power plug. The power plug has to be inserted completely.

If not, a fire will be caused due to poor contact. When taking off the power plug, grip the plug and

remove it.

(7) Management of power cord. Do not bend, twist, bind or place other materials on it. Do not use stales

around printer. If the power code gets damage, a fire or electric shock can occur. A damaged power

code must be replaced immediately. Do not repair the damaged part or reuse it. Repairing cord with

plastic tape can cause a fire or electric shock. Do not spread chemicals on the power code. Do not

spread insecticide on the power code. Afire or electric shock can occurred due to a thin(weak) cover on

the power code.

(8) Check whether the power outlet and the power plug are damaged, pressed or chopped. When such

inferiorities are found, repair it immediately. Do not press or chop the cord when moving the machine.

(9) Use caution during thunder or lightning storms. It may cause fire or electric shock. Take the power plug

off under these conditions. Do not touch cable and device duing thender or lightening storms.

(10) Avoid damp or dusty areas. Do not install the printer in dusty areas or around humidifiers. Afire can

occurr. Clean plug well with dried fabric to remove dust. Fire can occur if water is dropped into the unit

or if coverd with dust.

(11) Avoid direct sunlight. Do not install the printer near to a window where it directly contacts to the sun-

light. If the machine contacts sunlight for a long time, the machine will not work properly, because the

inner temperature of machine will get higher. A fire can beoccur.

(12) Turn off the power and take off the plug when smoke, a strange smell, or sound from the machine is

detected. Afire can occur if unit is used under these conditions.

(13) Do not insert steel or metal pieces inside/outside of the machine. Do not put steel or metal piece into

the ventila-tor. An electric shock can occur.

1-3

Samsung Electronics

Precautions

Service Manual

1.2.3 Precaution related to handling the machine.

If you ignore this information, you could get harm and machine could be damaged.

(1) Do not install unit on uneven surfaces or slanted floors.

Please confirm unit is correctly balanced after installation. Machine may fall ove when not balanced correctly.

(2) Be careful not to insert a finger or catch your hair in the rotating unit.

Be careful not to insert a finger or hair in the rotating unit (motor, fan, paper feeding part, etc) while the

machine is operation.

(3) Do not place any containers of water or chemical or small metals near the machine. If these objects get

into the inner side a fire or electric shock can be occurred.

(4) Do not install machine in areas where moisture or dust exists. For example, do not install machine near

open windows, damage may be caused by these conditions.

(5) Do not place candles, burning cigarettes, etc. on the machine. Do not install it near to a heater. A fire

may occur.

1.2.4 Precautions for when assembly/disassembly

Replace parts very carefully. Do remember the location of each cable before replacing parts, inorder to

reconnect it afterwards. Please perform the below steps before replacing or disassemblying any parts.

(1) Check the contents stored in the memory. All the information will be erased after the main board is

replaced. Write down and needed information.

(2) Disconnect power before servicing or replacing electrical parts.

(3) Remove printer cables and power cord.

(4) Do use formal parts and same standardized goods when replacing parts. Must check the product name,

part code, rated voltage, rated current, operating temperature, etc.

(5) Do not use excessive force when looening or tightening of plastic parts.

(6) Be careful not to drop small parts or objects in the machine.

1-4

Precautions

Samsung Electronics

Service Manual

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called “Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits,

some field effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused

by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface,

such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity

of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to

damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed,

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the

brushing together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to damage an ESD.

2

2

2-1

Samsung Electronics

REFERENCE INFORMATION

Service Manual

2. Reference Information

This chapter describes the reference information for applying this training manual, and it is consisted of the tool list, the abbreviation table, the outline of model, and so on.

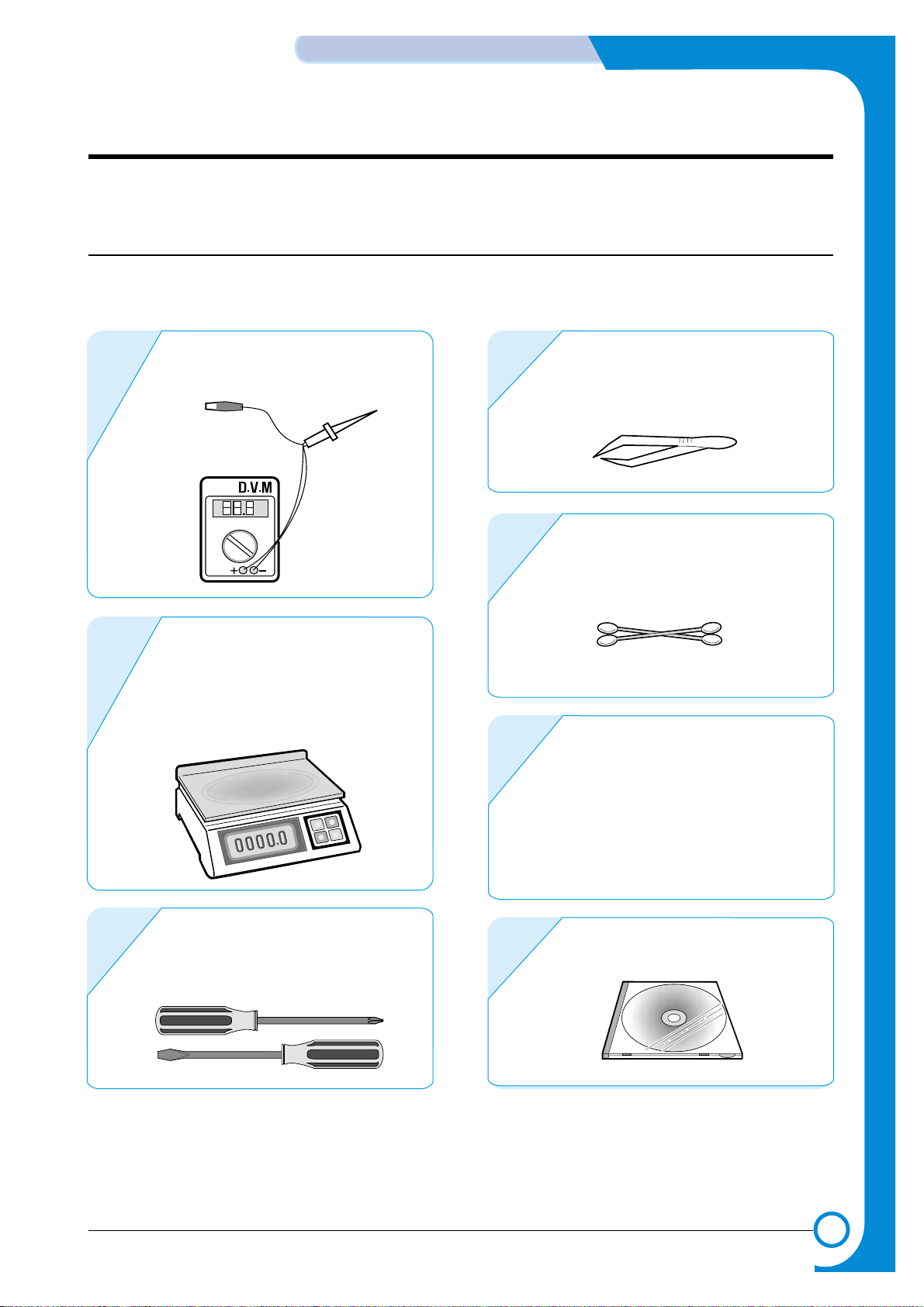

2.1 Tool for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DVM(Digital Volt Meter)

Standard: Indicates more than 3 digits.

1

T weezers

Standard: For general home use, small

type.

4

Software(Driver) installation CD

ROM

7

Cotton Swab

Standard : For general home use, for

medical service.

5

Cleaning Equipments a IPA

(Isopropyl Alcohol)dry cloth or a

soft stuff neutral detergent.

6

Electronic Scale

Standard: Equipment to check the weight

of consumables supplied by

Samsung Electronics.

(The gram unit can be measured.)

2

Driver

Standard : "-" type, "+" type (M3 long, M3

short, M2 long, M2 short).

3

2-2

REFERENCE INFORMATION

Samsung Electronics

Service Manual

2.2 Acronyms and Abbreviations

The table in the below explains abbreviations used in this service manual.

The contents of this service manual are declared with abbreviations in many parts. Please refer to the

table.

AC Alternating Current

ADF Automatic Document Feeder

ASIC Application Specific Integrated Circuit

ASSY assembly

BIOS Basic Input Output System

CCD Charge Coupled Device

CMOS Complementary Metal Oxide Semiconductor

CN connector

CON connector

CPU Central Processing Unit

dB decibel

dbA decibelampere

dBM decibel milliwatt

DC direct current

DCU Diagnostic Control Unit

DPI Dot Per Inch

DRAM Dynamic Random Access Memory

DVM Digital Voltmeter

ECP Enhanced Capability Port

EEPROM Electronically Erasable Programmable Read

Only Memory

EMI Electro Magnetic Interference

EP electrophotographic

EPP Enhanced Parallel Port

F/W firmware

GDI graphics device interface

GND ground

HBP Host Based Printing

HDD Hard Disk Drive

HV high voltage

HVPS High Voltage Power Supply

I/F interface

I/O Input and Output

IC integrated circuit

IDE Intelligent Drive electronics or Imbedded

Drive Electronics

IEEE Institute of Electrical and Electronics

Engineers. Inc

IPA Isopropy Alcohol

IPM Images Per Minute

LAN local area network

lb pound(s)

LBP Laser Beam Printer

LCD Liquid Crystal Display

LED Light Emitting Diode

LSU Laser Scanning Unit

MB Megabyte

MHz Megahertz

NVRAM Nonvolatile random access memory

OPC Organic Photo Conductor

PBA Printed Board Assembly

PCL Printer Command Language , Printer Control

Language

PDL Page Discription Language

PPM Page Per Minute

PTL Pre-Transfer Lamp

Q’ty Quantity

RAM Random Access Memory

ROM Read Only Memory

SCF Second Cassette Feeder

SMPS Switching Mode Power Supply

SPGP Samsung Printer Graphic Processor

SPL Samsung Printer Language

Spool Simultaneous Peripheral Operation Online

SW Switch

Sync Synchronous or synchronization

USB Universal Serial Bus

2-3

Samsung Electronics

REFERENCE INFORMATION

Service Manual

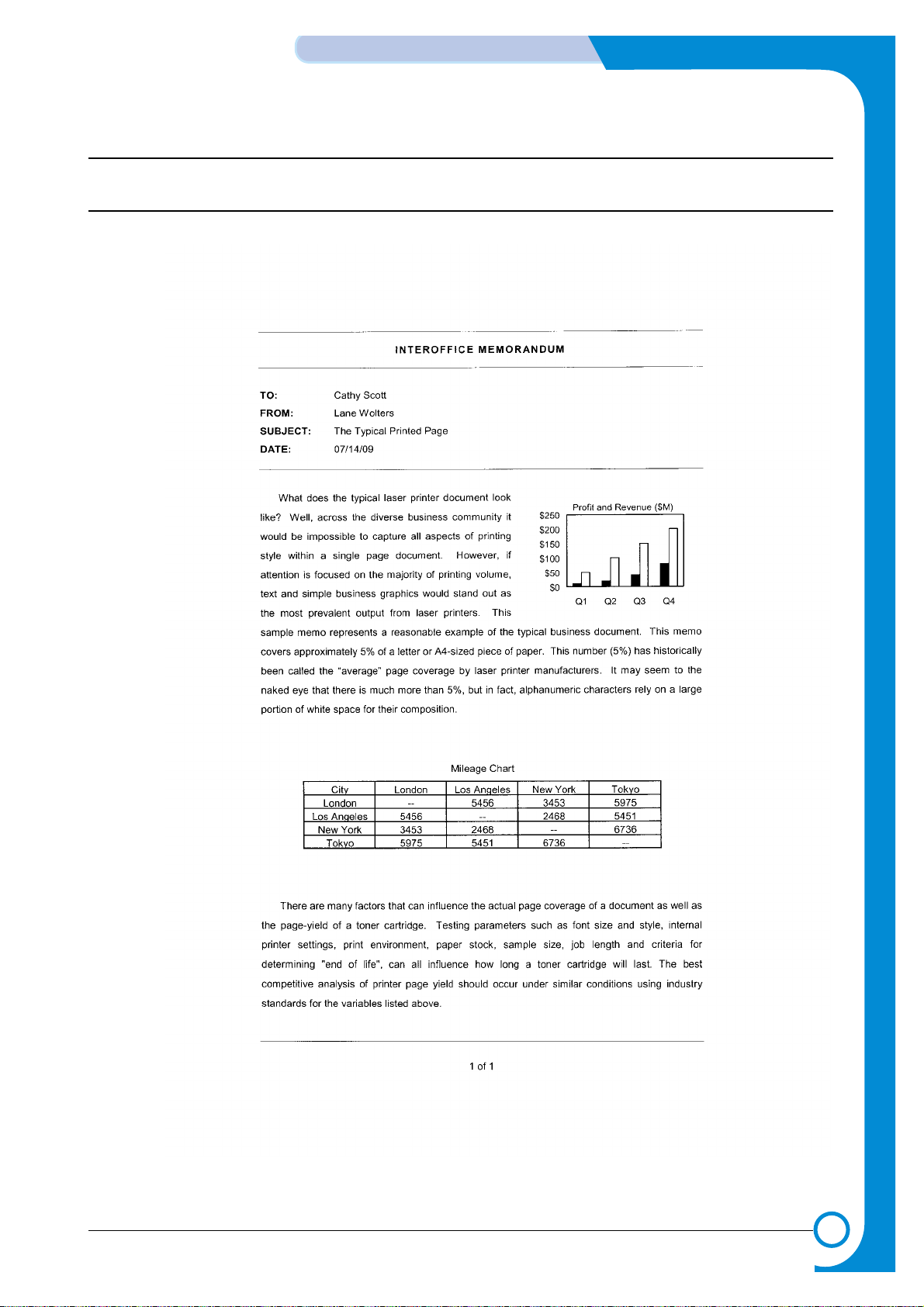

2.3 The Sample Pattern for the Test

The sample pattern shown in below is the standard pattern used in a factory.

The contents of the life span and the printing speed are measured with the pattern shown in below.

(The picture in the manual is 70% size of the actual A4 size.)

2.3.1 A4 5% Pattern

2-4

REFERENCE INFORMATION

Samsung Electronics

Service Manual

2.3.2 A4 2% Pattern

2-5

Samsung Electronics

REFERENCE INFORMATION

Service Manual

2.3.3 A4 IDC 5% Patten

2-6

REFERENCE INFORMATION

Samsung Electronics

Service Manual

3

3

3-1

Samsung Electronics

Specifications

Service Manual

3. Specifications

Specfications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

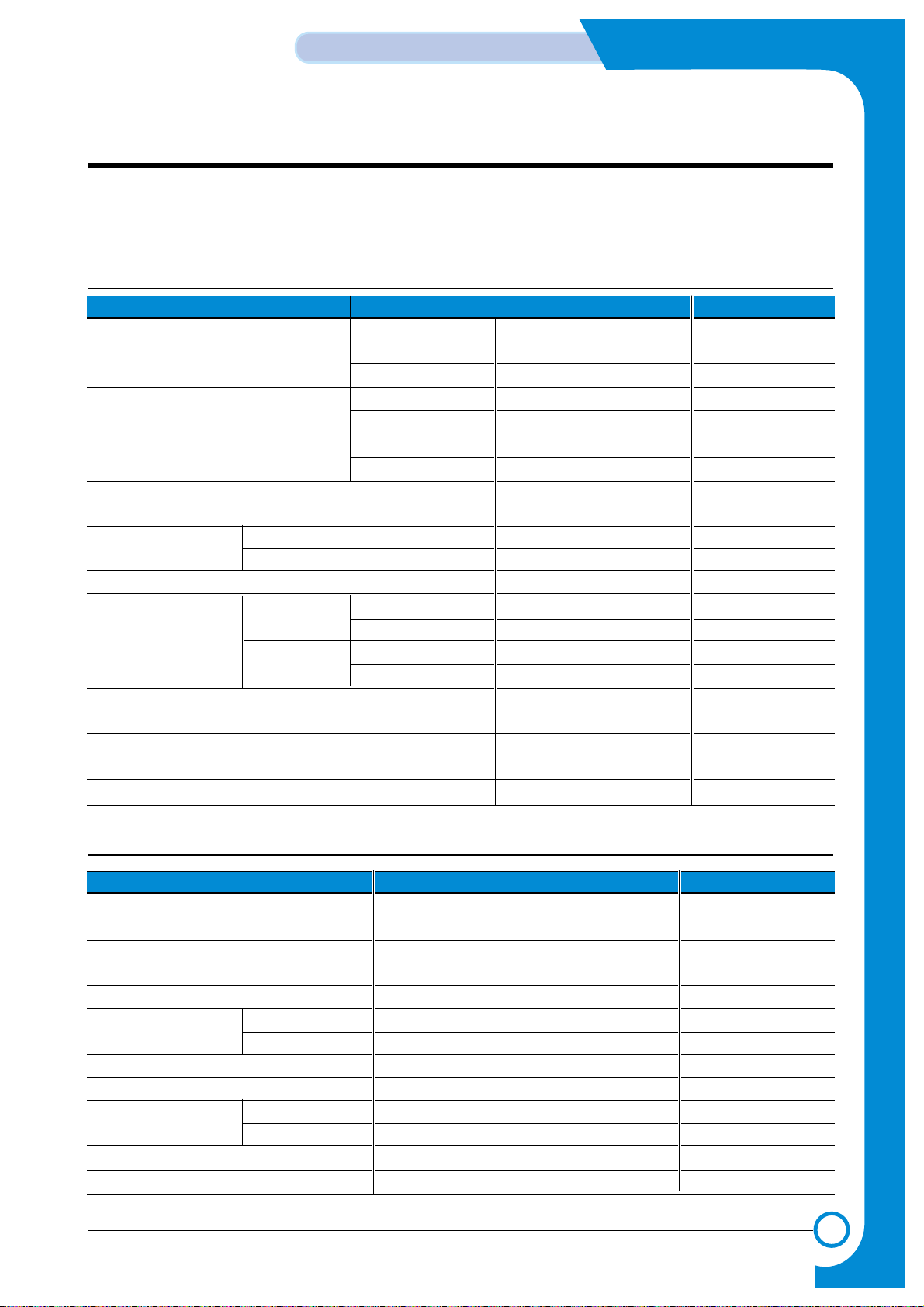

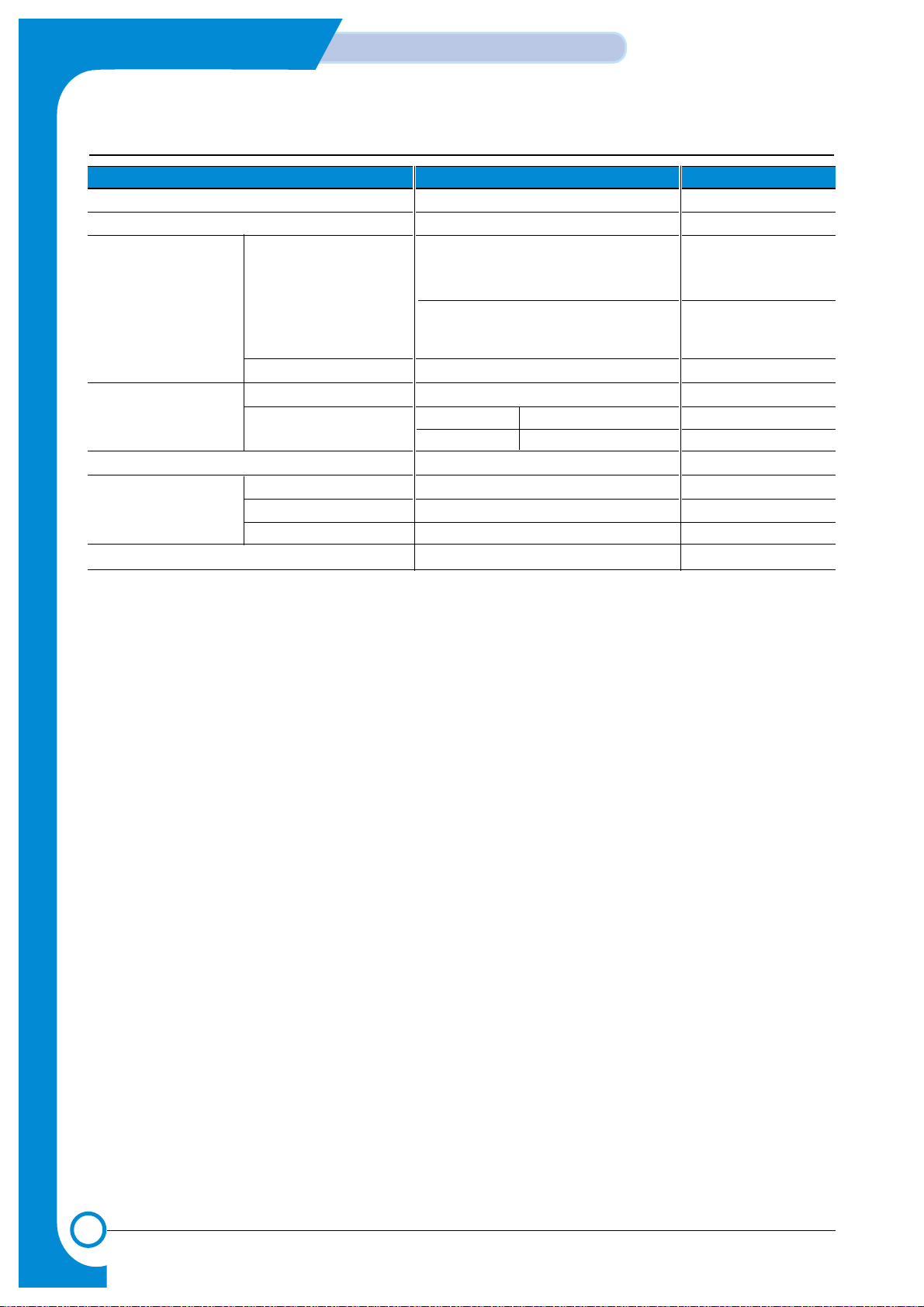

3.1 General Specifications

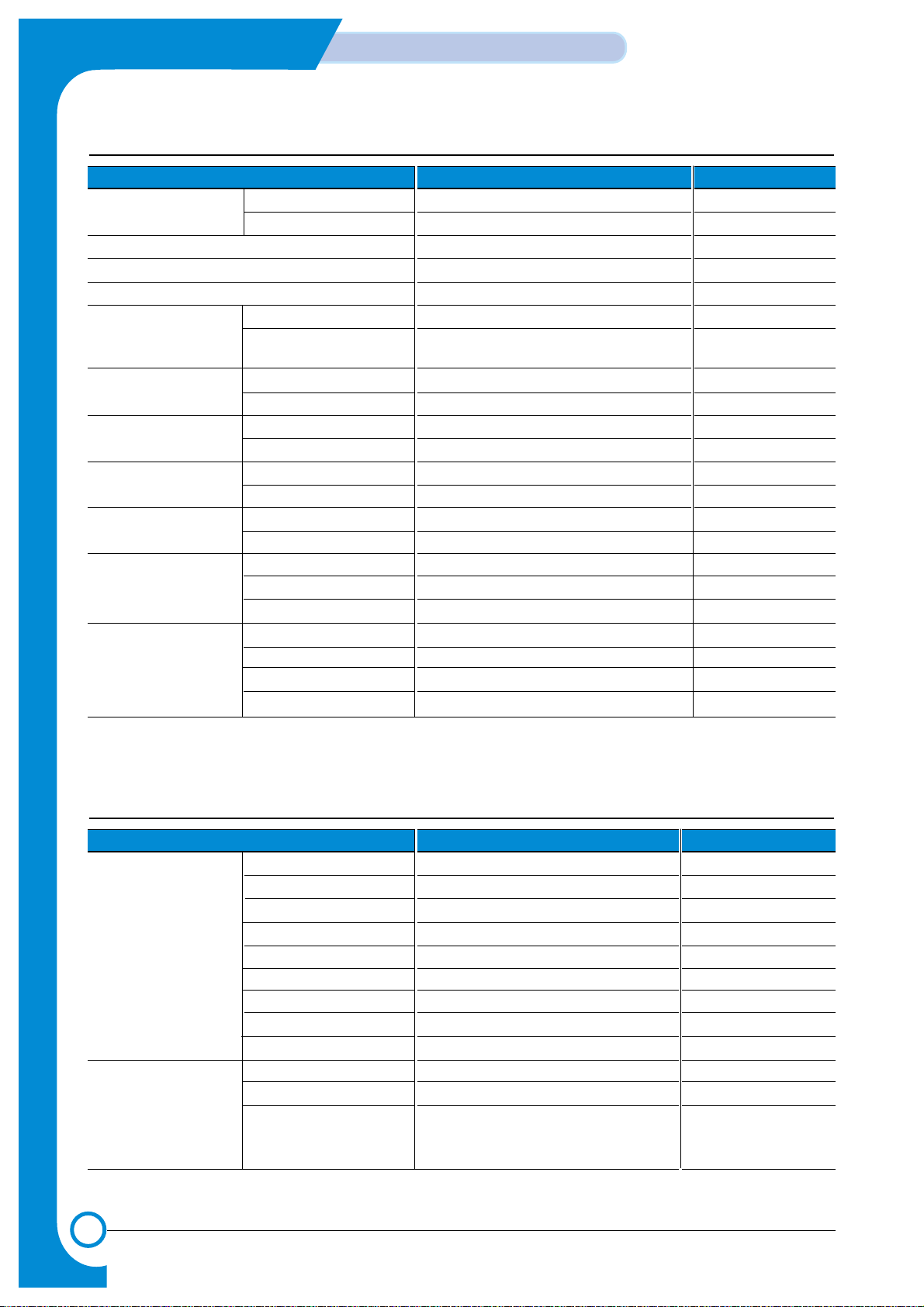

Items Descriptions Remarks

Major Features SCX-4016 Copier, Print, Scan Without ADF

SCX-4116 Copier, Print, Scan With ADF

SCX-4216F Copier, Print, Scan, Fax With ADF

Size (W*D*H) SCX-4016 474x436x353mm

SCX-4216F/41 16 474x436x417mm

Weight SCX-4016 11.7 Kg (25.8 lbs) With Toner Cartridge

SCX-4216F/4116 13 Kg (28.8 lbs) With Toner Cartridge

LCD 16*2 Char

I/O Interface USB1.1 & IEEE1284

Power Consumption Printing 350W

Sleep Mode 20W

Power Switch Yes

Noise Operating SCX-4016 52 dBA

SCX-4216F/4116 55 dBA

Standby SCX-4016 39 dBA

SCX-4216F/4116 39 dBA

Warm Up Less than 42 seconds

Approval Class B

Device Memory 16 MB

(Printer : 8M, Fax : 4M,

Scan : 2M, System : 2M)

Internal N/W Connectivity N/A

3.2 Print Specification

Items Descriptions Remarks

Print Speed 17ppm Letter size, 5%

Character Pattern

Print Method Laser Scanning Unit + Electro Photography

Print Language SPL

Power Save Yes(5/10/15/30/45min.)

Resolution Normal 600 *600dpi

RET No

Toner Save Yes

Memory 8 MB

FPOT Stand by Approx. 12 seconds

Power Save Less than 54 seconds

Printable Area 207.6 X 270.6 mm (Letter)

Toner Save Yes

3-2

Specifications

Samsung Electronics

Service Manual

3.3 Scan Specification

Items Descriptions Remarks

Halftone(Gray Scale) 256 level

Scan Method Color CCD ITU-T #1 Chart

Scan Speed ADF 25 sec Text/Mixed Mode :

(seconds/scan) (SCX-4216F/4116) B/W Letter & 300dpi.

(USB)

72 sec Photo Mode : Gray

Letter & 300dpi.

(USB)

Platen 23 sec

Resolution Optical 600 x 600 dpi

Enhanced USB 4800 x 4800 dpi

Parallel 2400 x 2400 dpi

Halftone 256 level

Scan Width Width Max.216mm (8.5")

Length(Adf) Max. 356mm (14.0")

Length(Platen) Max. 297mm (11.7")

Scan-to E-mail, Image, OCR, FAX, WEB

3-3

Samsung Electronics

Specifications

Service Manual

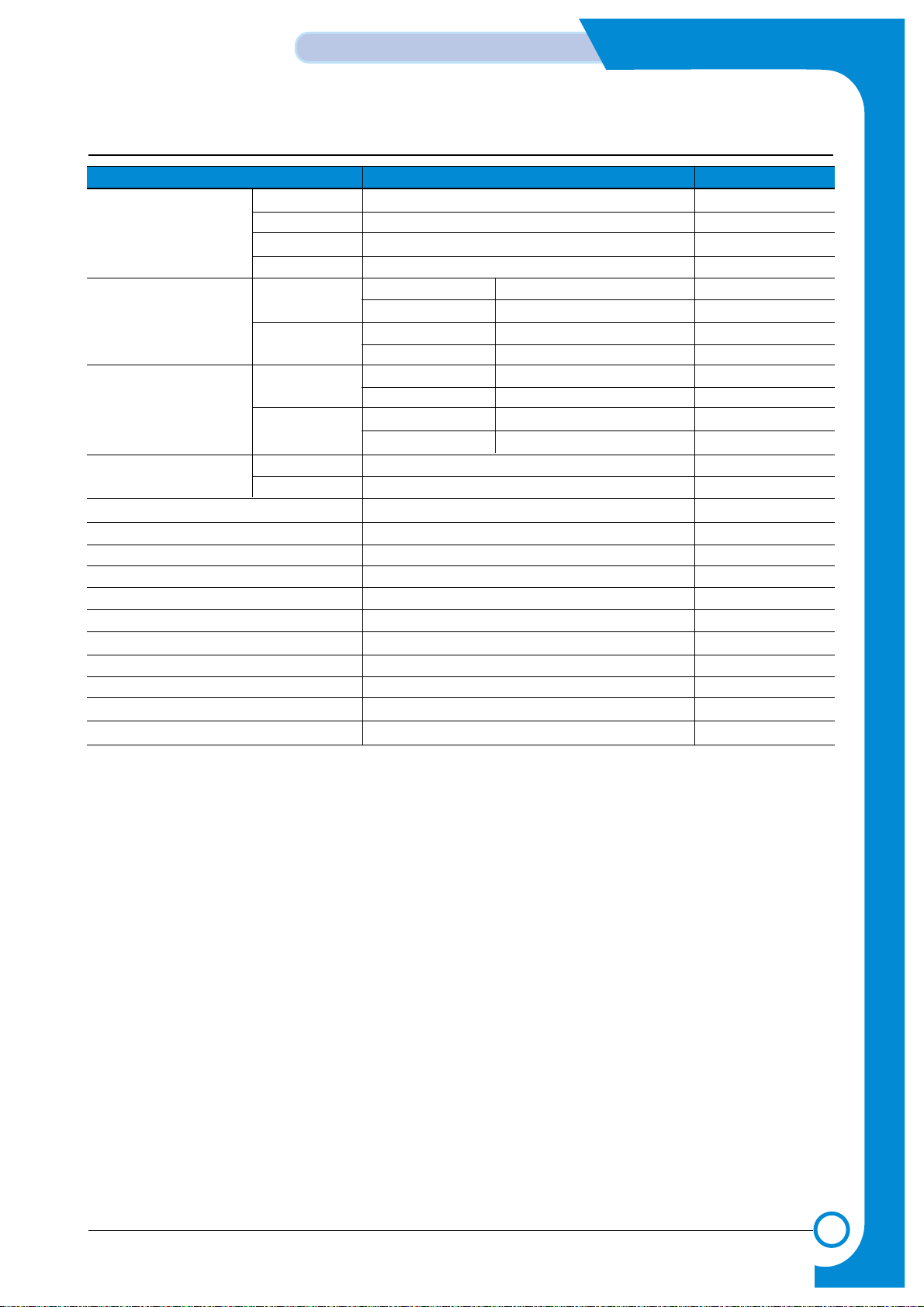

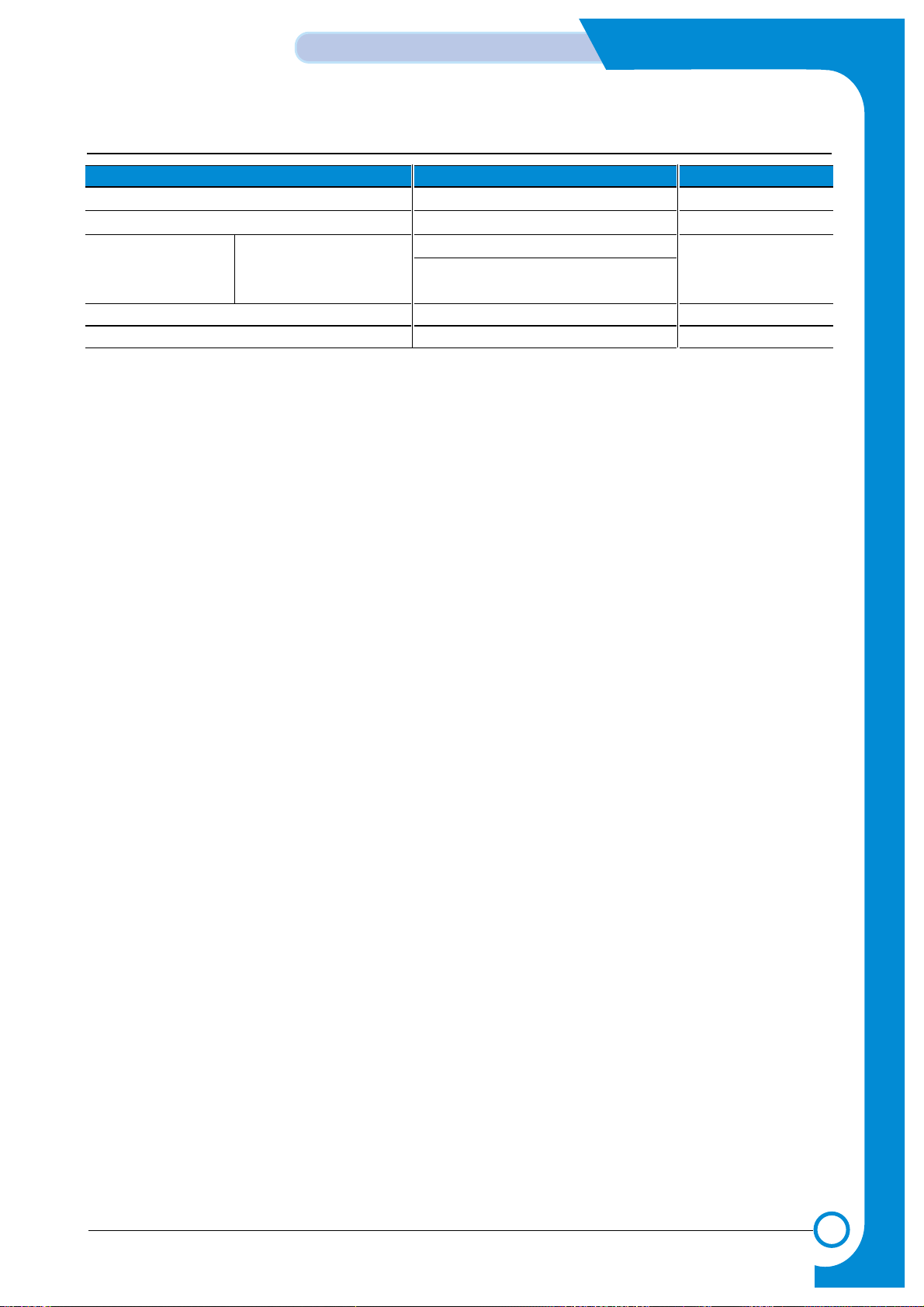

3.4 Copy Specification

Items Descriptions Remarks

Copy Quality Selection Text 600x300dpi

or Original Image type Auto 600x300dpi

selection Mode Photo 600x600dpi for Platen / 600x300dpi for ADF

Other -

FCOT Platen Power Save Approx. 54 seconds

Stand by Approx. 12 seconds

ADF Power Save Approx. 54 seconds

Stand by Approx. 17 seonds

Copy Speed Text Mixed SDMC 16 cpm/A4, 17 cpm/LTR

/ Letter MDMC 7 cpm/A4, 17 cpm/LTR

Photo SDMC 16 cpm

MDMC 4 cpm

Resolution Scan 600*600dpi

Print 600*600dpi

Zoom Range 25% to 400 %

Multi Copy 1~99

Preset Yes

Contrast Control 3 level(by LED)

Copy Mode TEXT/MIXED/PHOTO

Collation Copy Yes(300dpi only) SCX-4216F/4116

Auto return to default mode Yes(after 1 minute)

N-up copy 2-up, 4-up SCX-4216F/4116

AutoFit Copy Yes Platen Only

Clone Yes Platen Only

Poster Yes Platen Only

3-4

Specifications

Samsung Electronics

Service Manual

3.5 Telephone Specification (SCX-4216F Only)

Items Descriptions Remarks

Handset No

On hook Dial Yes

Search Yes (Phone Book)

1-Touch Dial 10EA(3*4 Numeric Key)

Auto dial 100 locations (Using 3*4 buttons)

TAD I/F No

Tone/Pulse Selectable in Tech Mode

Pause No

Auto Redial Yes

Last Number Redial Yes

Distinctive Ring No

Caller ID No

External Phone Interface No

Report & List Print out Tx/Rx Journal Yes

Confirmation 2 types available

(with Image TCR, w/o image TCR)

Help List No

Auto Dial List Yes

System Data List List all user setting

Sound Control Ring Volume Yes(Off,Low,MED,HIGH)

Key Volume Yes(On,Off)

Speaker Yes(On,Off)

3-5

Samsung Electronics

Specifications

Service Manual

3.6 Fax Specification (SCX-4216F Only)

Items Descriptions Remarks

Compatibility ITU-T G3

Communication System PSTN/PABX

Modem Speed 33.6 Kbps

TX Speed Approx. 3 sec

Compression MH/MR/MMR/JPEG

ECM Y es

Resolution Std 203 x 98 dpi

Fine 203 x 196 dpi

S.Fine 300 x 300 dpi

Scan Speed(ADF) Std Approx. 5sec/LTR

Fine Approx.7.5sec/LTR

S.Fine Approx.7.5sec/LTR

Rx fax duplex print out No

Multiple page scan speed Approx. 7 ppm/LTR

Receive Mode Fax, TEL

Memory Capacity 4 MB (320 pages)

Optional Memory No

Max locations to 99 locations

store to 1 Group Dial

Fax Forward Yes (On/Off)

Broadcasting Up to 59 locations

Forced Memory TX

No

Cover page No

Delayed fax Yes

Memory RX Yes

Functions Voice Request No

TTI Yes

RTI Y es

Polling No

Earth/Recall No

Auto Reduction Yes

RDC No

Junk Fax barrier Yes

Security Mode Yes

Battery Backup Yes (Min. 15 minutes) Back up Fax memory

and Real Time data

3-6

Specifications

Samsung Electronics

Service Manual

3.7 Paper Handling

3.8 Software

Items Descriptions Remarks

Capacity Main Tray 250sheets

(20lbs) Bypass Single Sheet

Optional Cassette No

Output Capacity 150Sheets/20lb, 1Sheet/Face up

Output Control Face down

Paper Size Main Tray

CST : A4,Letter,Legal, Folio,Executive,B5

Bypass Bypass : Envelope6 3/4,7 3/4, #9, #10,

DL,C5,B5

Paper Weight Main Tray 16~24 lb.

Bypass 16~32 lb.

Paper Path Standard output Bottom to Middle Front (FIFO)

Straight Through Face up, Single Sheet

Paper Size Max 216 x 356mm(8.5"x14")

Min 76 x 127mm(3"x5")

Output Stacker Paper Extension

Document Fixed

Input Guide Bypass Tray Adjustable

Main Tray Universal

Document Adjustable

ADF Paper Weight 12.5~28lb

Capacity 30 sheets(20lb)

Document Size Widtth 148mm - 216mm(5.8" - 8.5")

Document Size Length 127 mm - 356mm(5" - 14.0")

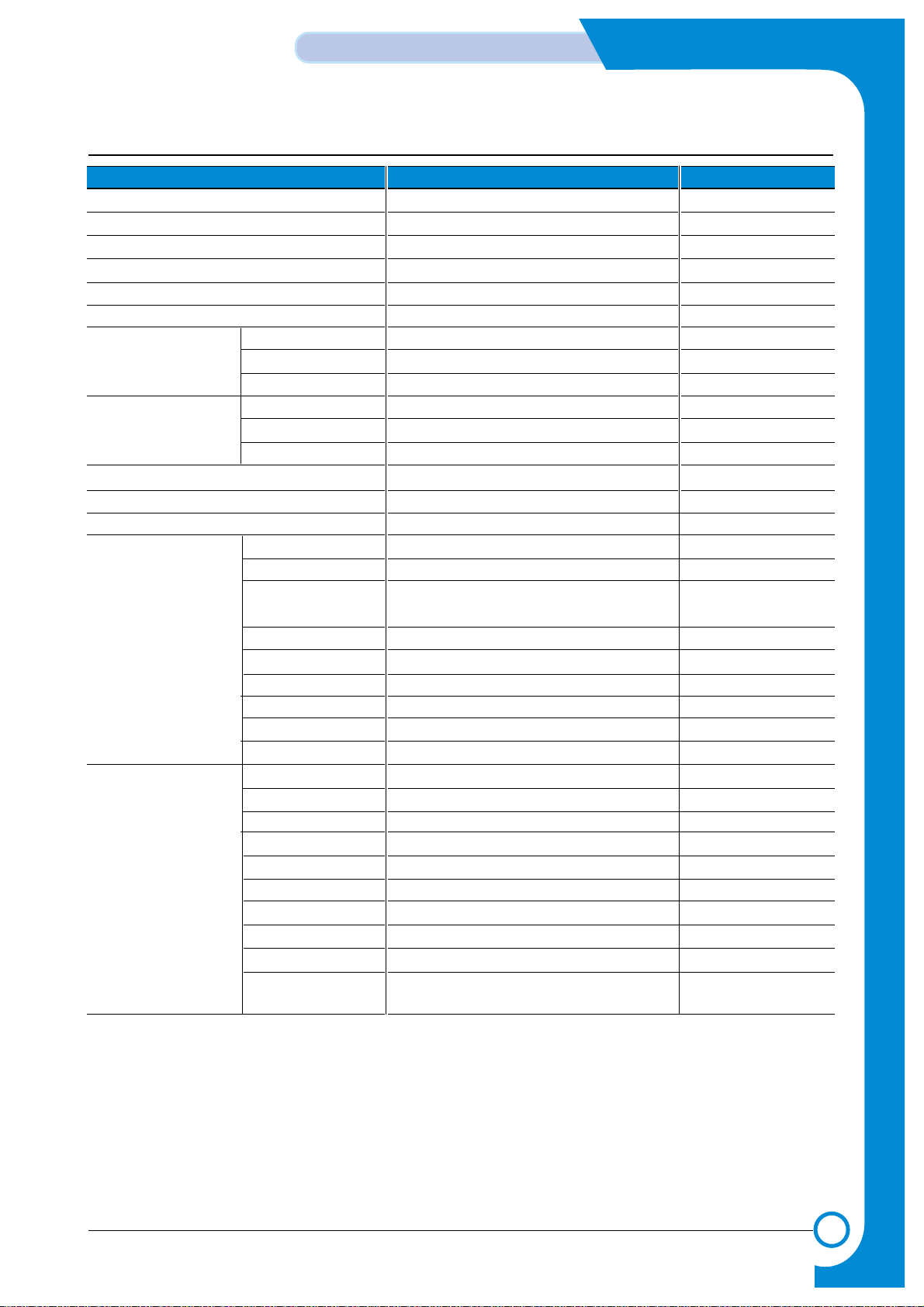

Items Descriptions Remarks

Compatibility DOS No

Win 3.x No

Win 95 Yes

Win 98&WinME Yes

Win NT 4.0 Yes

Win 2000 Yes

Win XP Yes WHQLfor Printer Only

Mac Yes Mac Printer Only

Linux No

Driver Printer SPL

TWAIN Yes

PC-FAX No PC Fax is only avail-

able through PC

Modem

3-7

Samsung Electronics

Specifications

Service Manual

3.9 Consumables

Items Descriptions Remarks

Type Single Cartridge

How to install Front door open and front loading

Toner Life Initial 1,000 sheets Initial toner life could

running 3,000 sheets be different accroding

to country

Level Sensor No

Toner Count Yes

3-8

Specifications

Samsung Electronics

Service Manual

4

4

4-1

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

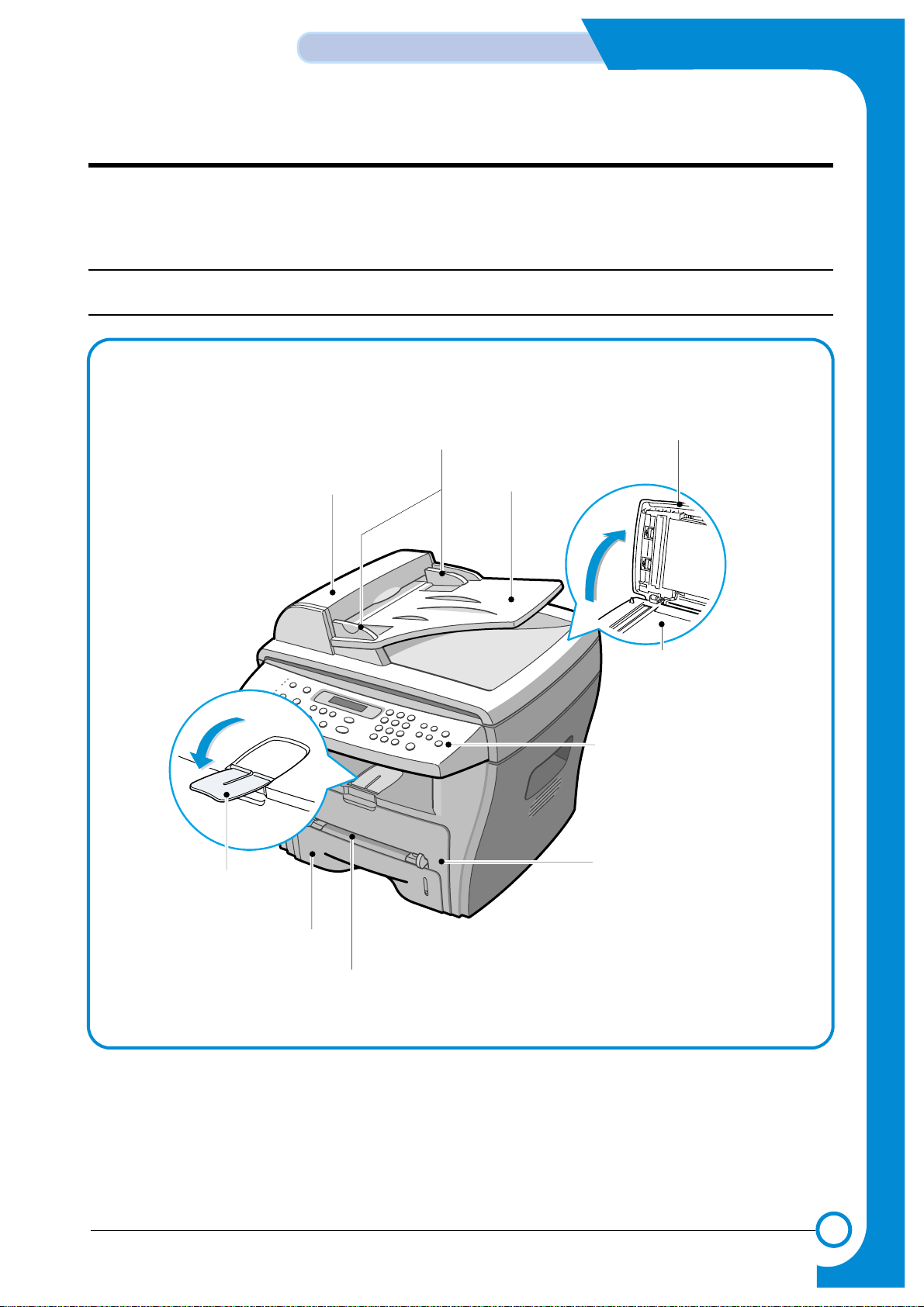

4. Summary of Product

This chapter describes the functions and operating principal of the main component.

4.1 Printer Components

4.1.1 Front View

Document

Guides

Document

Input Tray

Document

Output Tray

Control Panel

Paper Tray

Front Cover

Paper Level

Indicator

Bypass Tray

Paper Output

Extension

Automatic

Document Feeder

(for SCX-4116/4216F)

Document

Cover

Document Glass

4-2

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

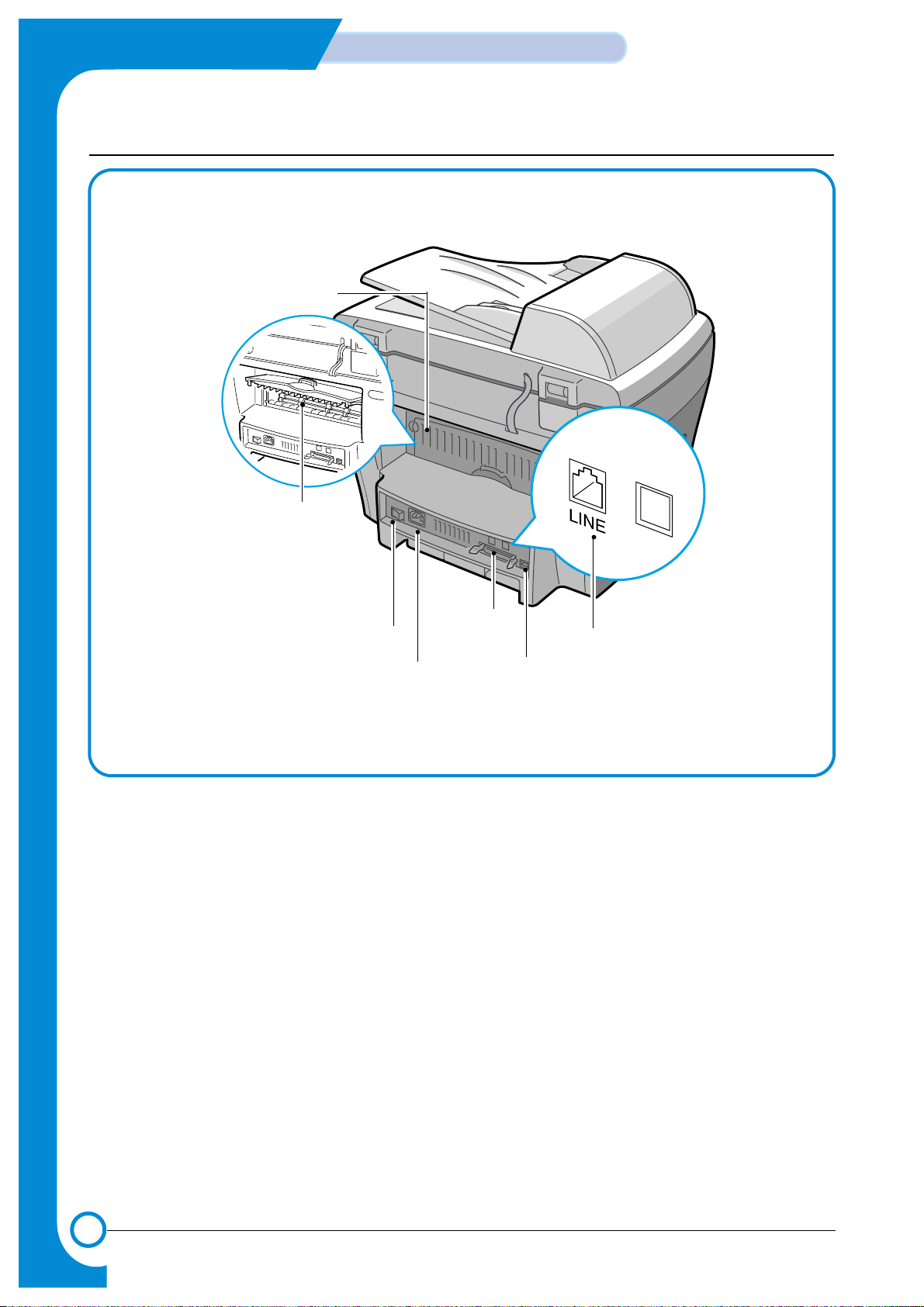

4.1.2 Rear View

AC Power Cord

Connector

Parallel

Connector

Power Switch

USB

Connector

Telephone Line

Connector

(for SCX-4216F)

Rear Output Slot

(Face up)

Rear Cover

4-3

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

1 2

4 653

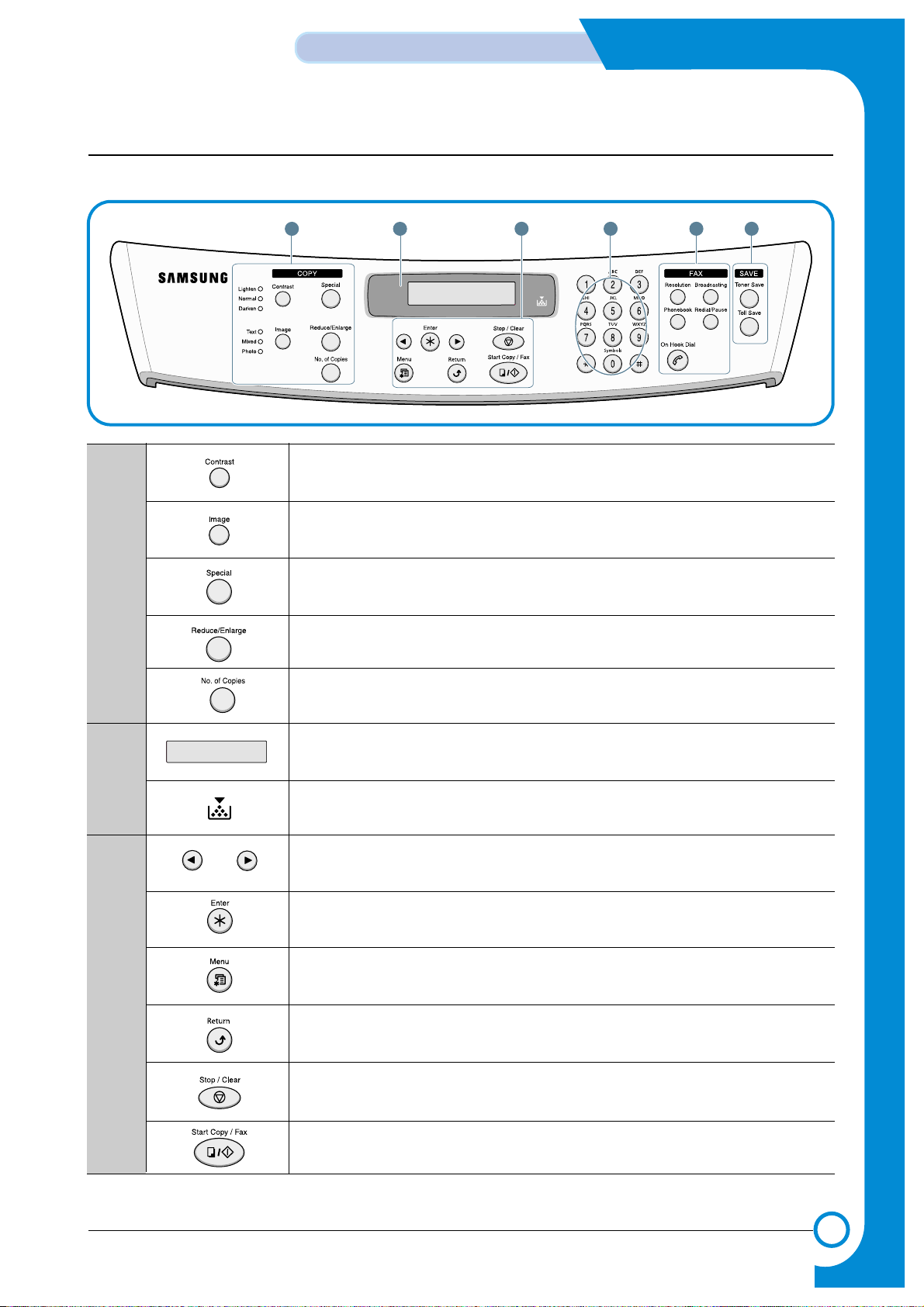

4.1.3 Control Panel

< SCX-4216F >

1

C

O

P

Y

2

3

Adjusts the brightness of the documents for the current copy job.

Selects the document type for the current copy job.

Allows you to use special copy features, such as Clone, Collation, Auto fit, 2-side,

N-up (multiple pages on a sheet) and Poster copying.

Makes a copy smaller or larger than the original.

Selects the number of copies.

Displays the current status and prompts during an operation.

Turns on when the toner cartridge is empty.

Scrolls through the options available for the selected menu item.

Confirms the selection on the display.

Enters Menu Mode and scrolls through the menus available.

Sends you back to the upper menu level.

Stops an operation at any time.

In Standby Mode, clears/cancels the copy options, such as the contrast, the

image setting, the copy size and the number of copies.

Starts a job.

4-4

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4

5

F

A

X

6

S

A

V

E

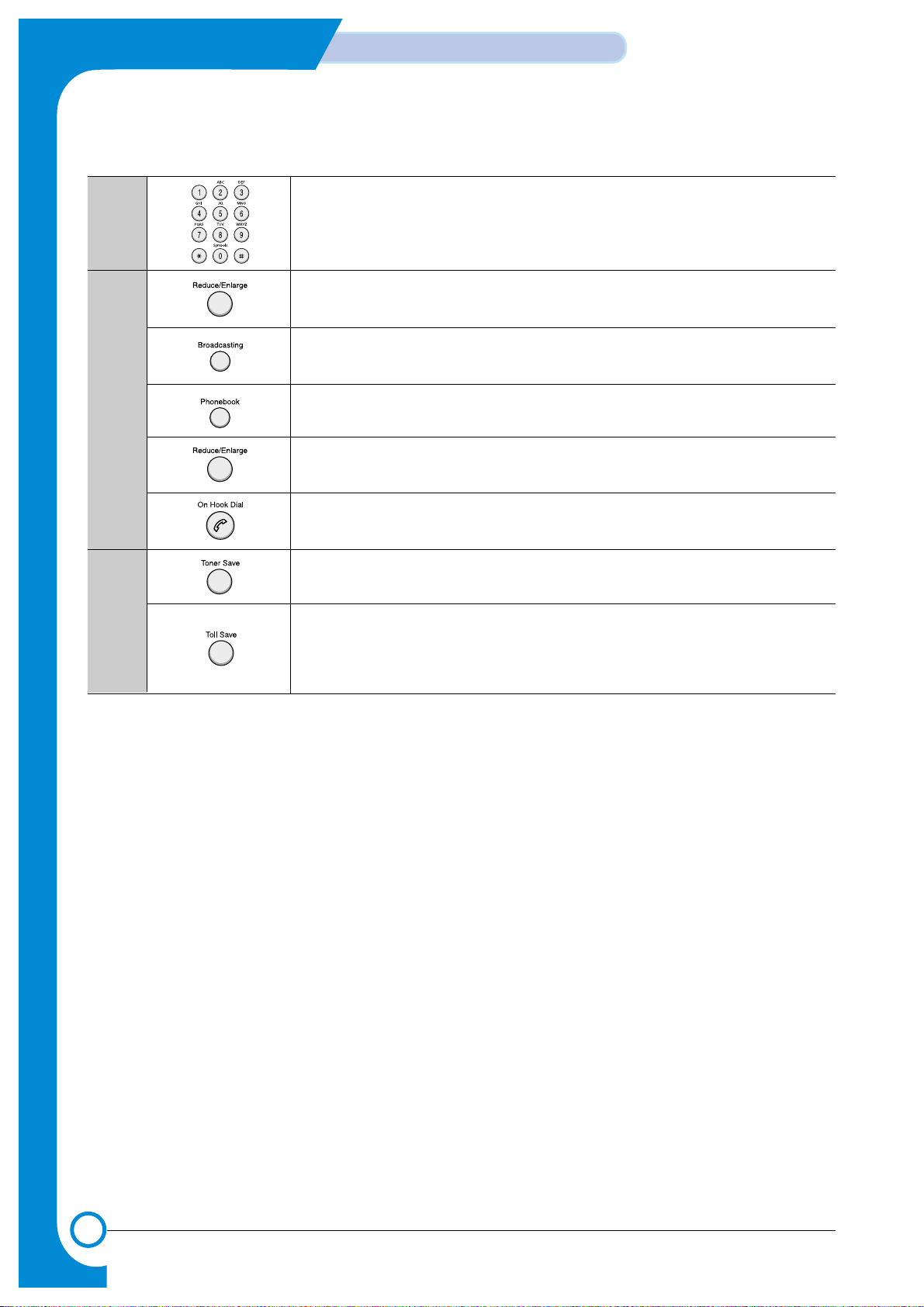

Dials a number or enters alphanumeric characters.

Adjusts the resolution of the documents for the current fax job.

Allows you to send a fax to multiple destinations.

• Allows you to store frequently-dialed fax numbers using a one or two-digit speed

dial or group number for automatic dialing and edit the stored numbers.

• Allows you to print a Phonebook list.Redials the last number in Standby Mode or

inserts a pause into a fax number in edit mode.

Engages the telephone line.

Allows you to save on toner by using less toner to print a document.

Allows you to save on call costs by sending a fax at a preset toll-saving time.

Using this feature, you can take advantage of lower long distance rates at night,

for example.

4-5

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

1 2

543

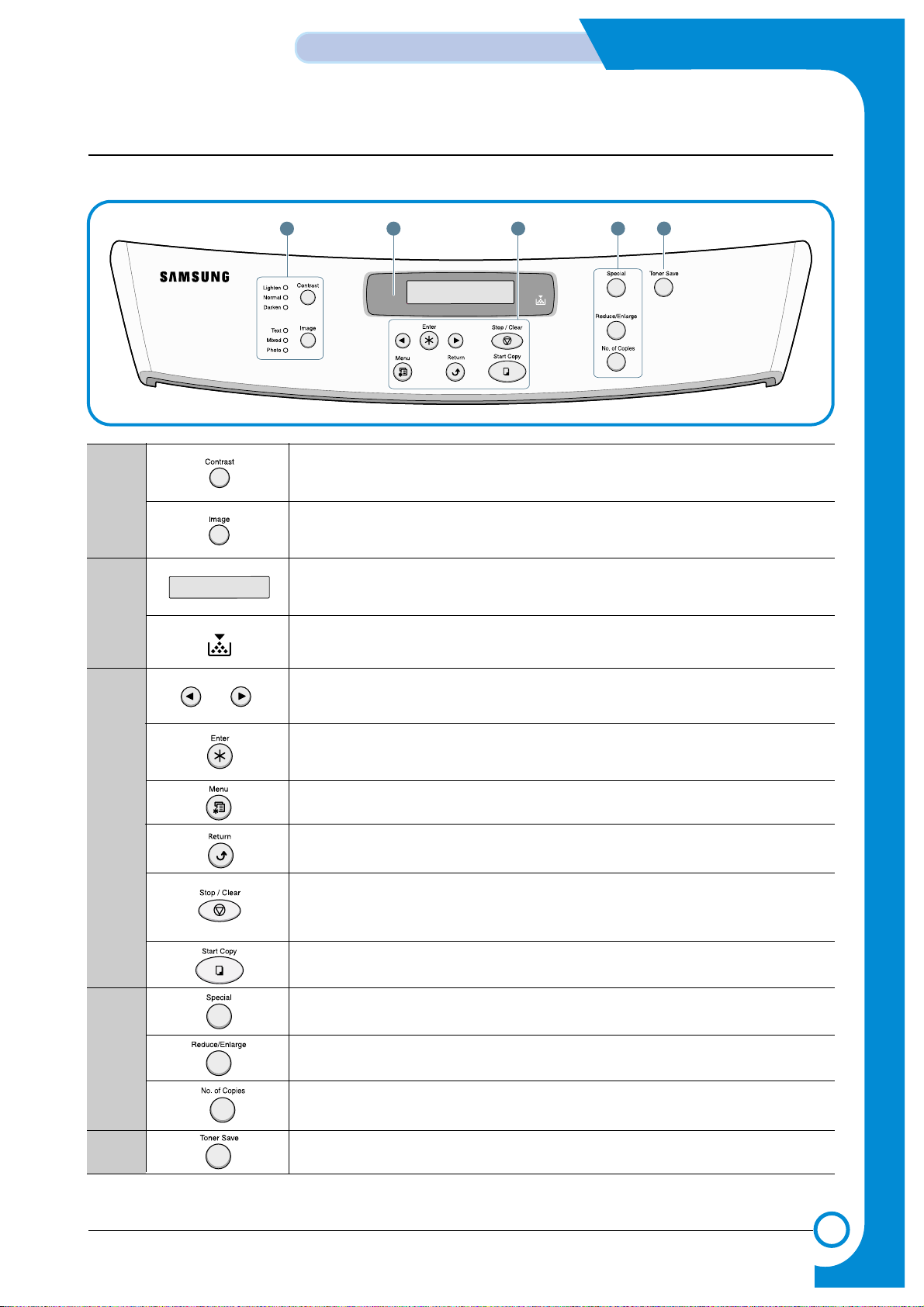

< SCX-4016/4116 >

1

2

3

35

4

Adjusts the brightness of the documents for the current copy job.

Selects the document type for the current copy job.

Displays the current status and prompts during an operation.

Turns on when the toner cartridge is empty.

Scrolls through the options available for the selected menu item.

Confirms the selection on the display.

Enters Menu Mode and scrolls through the menus available.

Sends you back to the upper menu level.

Stops an operation at any time. In Standby Mode, clears/cancels the copy

options, such as the contrast, the image setting, copy size and the number of

copies.

Starts a job.

Allows you to use special copy features, such as Clone, Collation, Auto fit, 2-side,

N-up (multiple pages on a sheet) and Poster copying.

Makes a copy smaller or larger than the original.

Selects the number of copies.

Allows you to save on toner by using less toner to print a document.

4-6

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4.2 System Layout

4.2.1 Feeding section

There is the universal cassette, which automatically loads paper and the manual feeder, which supplies

paper one by one. The cassette has the friction pad which separates paper one by one, and it has a sensor, which functions to check the existence of loaded paper.

- Feeding Method: Universal Cassette Type

- Feeding Standard: Center Loading

- Feeding Capacity: Cassette-250 sheets (75g/m2, 20lb paper standard)

Manual 1 sheet (Paper, OHP, Envelop, etc.)

- Paper detecting sensor: Photo sensor

- Paper size sensor: None

4.2.2 Transfer Ass’y

It consists of the PTL (pre-transfer lamp) and the Transfer Roller. The PTL sends a light to the OPC drum,

drops the current on the drum surface and improves the transfer efficiency.

The transfer roller transfers toner from the OPC drum surface to the paper.

- The life span: Print over 60,000 sheets (in 15~30°C)

4.2.3 Driver Ass’y

- Gear driven power unit. By driving the motor, it supplies power to the feeding unit, the fusing unit, and the

distributing unit.

4.2.4 Fixing Part(Fuser)

- The fuser consists of the Heat Lamp, Heat Roller, Pressure Roller, Thermistor, and Thermostat. It adheres

toner to the paper with pressure and a heat to complete the printing job.

4.2.4.1 Temperature-Intercepting Device (Thermostat)

The thermostat is the temperature-intercepting device, which cuts off the power for preventing an overheating or a fire when the heat lamp or the heat coil of the heat roller is overheated.

4.2.4.2 Temperature Detecting Sensor (Thermistor)

The Thermistor detects the surface temperature of the heat roller, and it maintains the regular temperature

of the heat roller by responding to the information of the temperature.

4.2.4.3 Heat Roller

The heat roller transfers the temperature from the heat lamp to the surface to heat the paper which passes

the surface. The melted toner cannot stain the heat roller coated with Teflon.

4.2.4.4 Pressure roller

The pressure roller mounted right under the heat roller is made of the silicon resin, and the surface of the

roller is coated with Teflon to fuse the toner on the paper when paper passes between the heat roller and

the pressure roller.

4.2.4.5 Safety Relevant Facts

4-7

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

• Protecting device when overheating

- 1st protecting device: H/W cuts off when detecting an overheating

- 2nd protecting device: S/W cuts off when detecting an overheating

- 3rd protecting device: Thermostat cuts off the power

• Safety device

- The power of the fuser is cut off when the front cover is open.

- The overheating safety device for customer

- Maintains the surface temperature of the Fuser Cover under 80°C and has a caution label

attached inside of the rear cover where the customer can find it easily.

4.2.5 Scanner

It reads an image with a photosensitive sensor. In hardware aspect, it is consisted of CCD module,

Connection board, ADF board (4016 does not have ADF board), AFE (Analog Front End), and Image

Processor (Located in CPU), and mechanically, and ADF (Automatic Document Feeder-SCX-4016 does not

have ADF function)

• CCD Module Specification

1.Resolution: 600dpi/A4

2.Maximum scan wide: 8.5”

3.Color filter: Red, Green, Blue

4.Output channel: 3 channels (R, G, B)

5.Effective pixel: 5,400 pixel *3

6.Voltage: 24V & 5V

7.Pre-heating time: Maximum 30 seconds (70% of light reach to it)

8.The life span of a lamp: 30,000 hours (25oC)

• Image Processor Specification

1.Operating frequency: 66MHz

2.Image sensor interface: 200/300/600 dpi CIS or CCD

3.Line time: Copy, FAX, Binary (Lineart, Halftone) PC Scan: 1.5ms/Line Color PC Scan (Grey, 256

Color, True Color): 4.5ms/Line

4.A/D conversion: 10bit conversion

4-8

SUMMARY OF PRODUCT

Samsung Electronics

Service Manual

4.2.6 LSU (Laser Scanner Unit)

The LSU unit is controlled by the video controller. It scans the video data received from video controller

with laser beam by using the rotation principal of the polygon mirror to create the latent image on the OPC

drum. It is the core part of LBP.

The OPC drum rotates as the same speed as the paper feeding speed. It creates the /HS YNC signal and

sends it to the engine when the laser bean of the LSU reaches the end of the polygon mirror, and the

engine detects the /HS YNC signal to arrange the vertical line of the image on the paper. After detecting

the /HS YNC signal, the image data is sent to the LSU to arrange the its left margin on the paper.

The one side of the polygon mirror is one line for scanning.

4-9

Samsung Electronics

SUMMARY OF PRODUCT

Service Manual

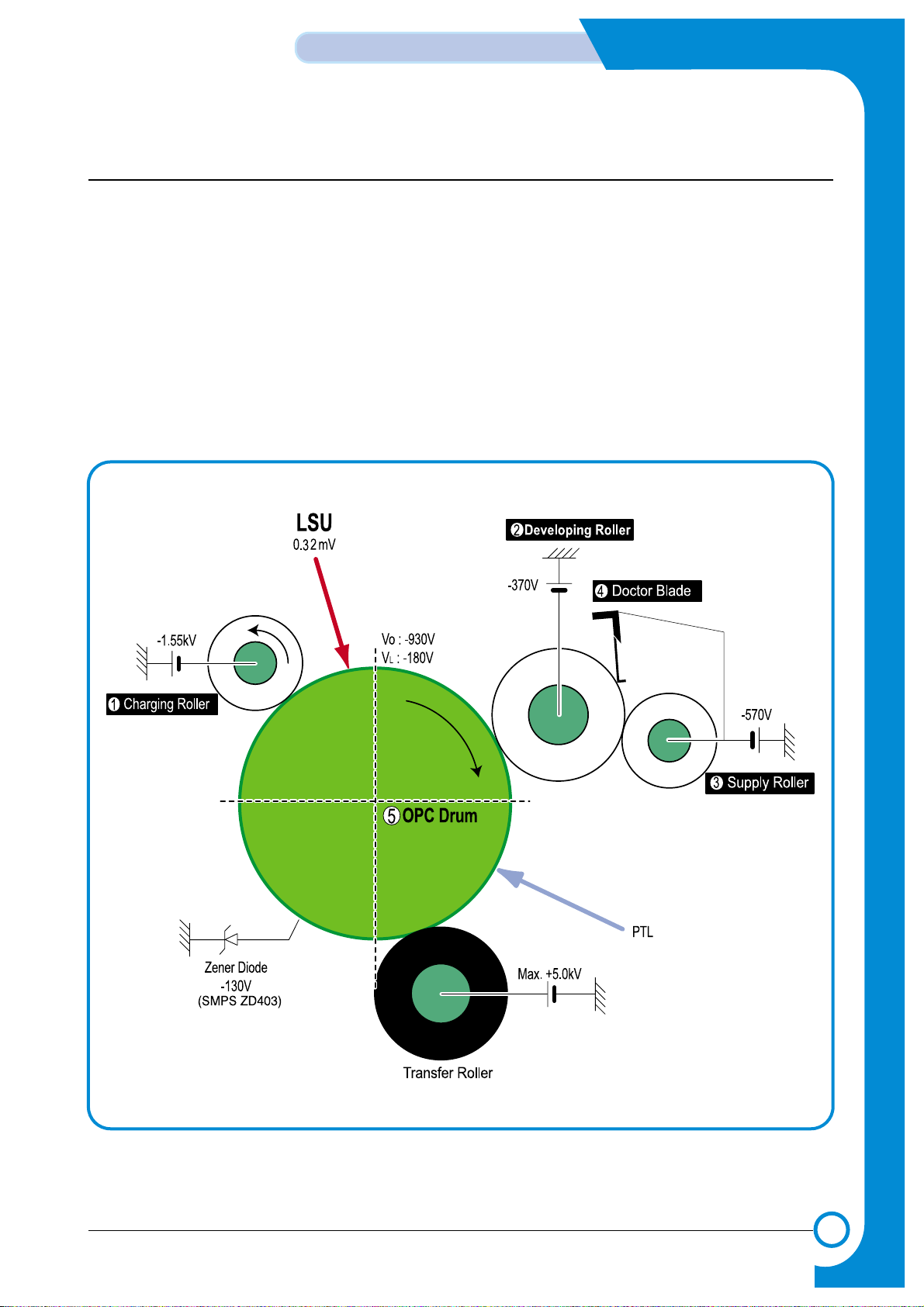

4.2.7 Toner Cartridge

By using the electronic photo process, it creates a visual image. In the toner cartridge, the OPC unit and

the developer unit are in a body. The OPC unit contains the OPC drum and charging roller. The developer

unit contains toner, toner cartridge, supply roller, developing roller, and blade (Doctor blade)

- Developing Method: Non magnetic 1 element contacting method

- Toner: Non magnetic 1 element shatter type toner

- The life span of toner: 3,000 sheets (IDC Pattern/A4 standard)

- Toner remaining amount detecting sensor: None

- OPC Cleaning: Collect the toner by using electric static + FILM OPC

- Management of disusable toner: Collect the toner by using electric static (Clenerless Type- No

disusable toner)

- OPC Drum protecting Shutter: None

- Classifying device for toner cartridge: ID is classified by interruption of the frame channel.

Loading...

Loading...