Page 1

6

6

6-1

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6. Alignment and Adjustments

This chapter describes the main functions for service, such as the product maintenance method,

the test output related to maintenance and repair, DCU using method, Jam removing method, and

so on.

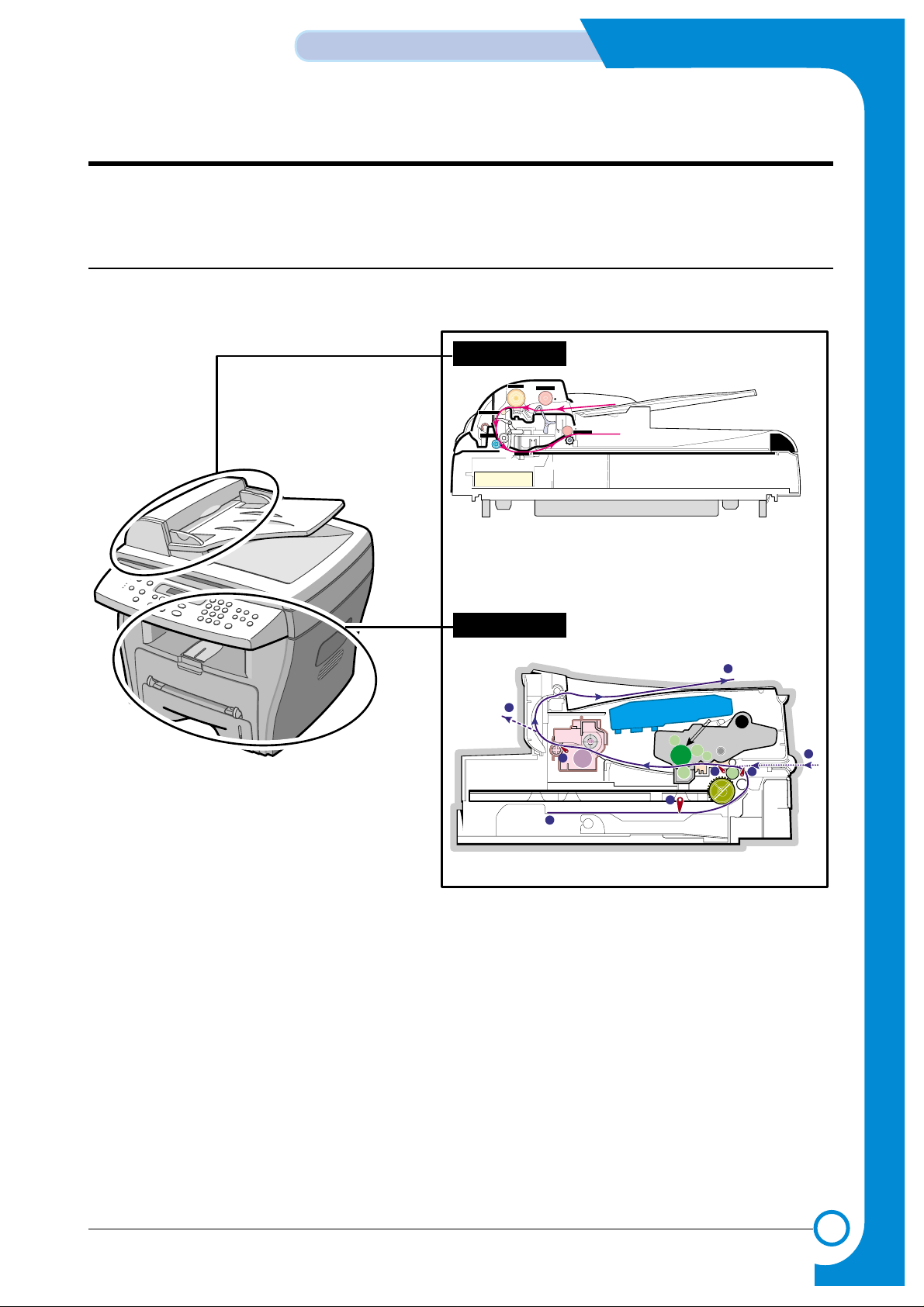

6.1 Paper path

Scanner Part

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

2

3

4

5

6

8

7

Sensor-DocSensor-Doc

ADF-Roller

Pickup-Roller

Exit-Roller

Doc-Paper(30Sheets)

ADF-Idle Roller

Sensor-Regi

Feed-Roller

CCD-Module

White-SheetWhite-Sheet

Sensor-Regi

Sensor-ScanSensor-Scan

Engine Part

Page 2

6-2

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

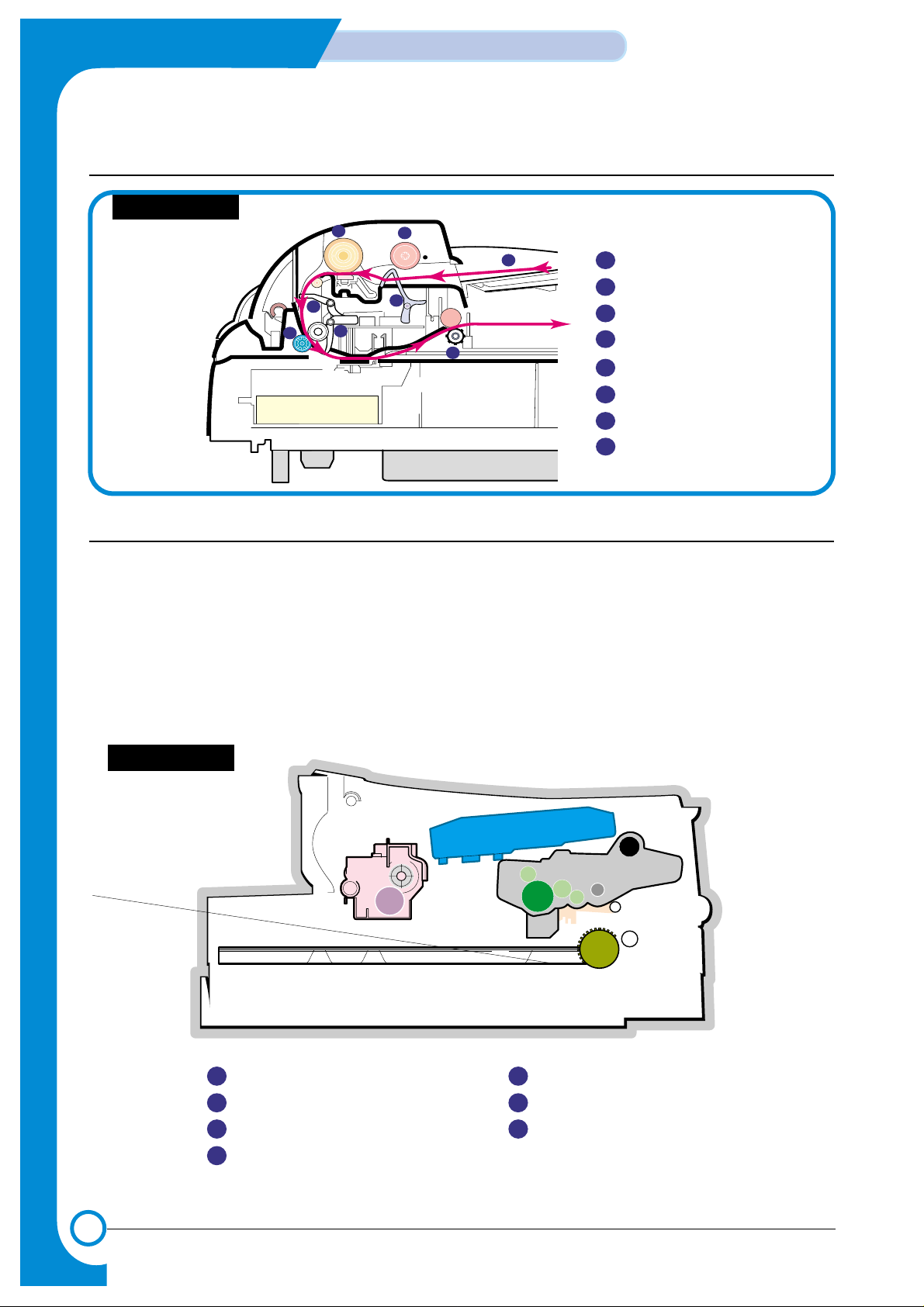

6.1.1 Copy & Scan Document Path

6.1.2 Printer Paper Path

1) After receiving print job, the printer feeds the printing paper from the cassette or manual feeder.

2) The fed paper passes the paper feeding sensor. (Jam 0 occurs if the sensor is not operated after certain

time passes)

3) The paper passes the paper feeding sensor moving to the paper exit sensor via printing process. (Jam

1 occurs if the sensor is not operated after a certain time passes)

4) The paper passed the paper exit sensor moving out from the set. (Jam 2 occurs if the sensor is still

operated after a certain time passes.)

Scanner Part

CCD-Module

White-SheetWhite-Sheet

1

2

3

4

8

5

6

7

5

6

7

Sensor - Scan

Sensor - Regi

Feed Roller

8

Exit Roller

1

2

3

4

Doc. Paper (30 Sheets)

Pickup Roller

ADF Roller

Sensor - Doc.

Engine Part

1

2

3

4

Paper Input (Cassette)

Paper Input (Manual Feeder)

Paper Out (Face Down)

5

6

7

Paper Empty Sensor (Cassette)

Paper Feeding Sensor

Paper Exit Sensor

Paper Empty Sensor (Manual)

PTL

Page 3

6-3

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

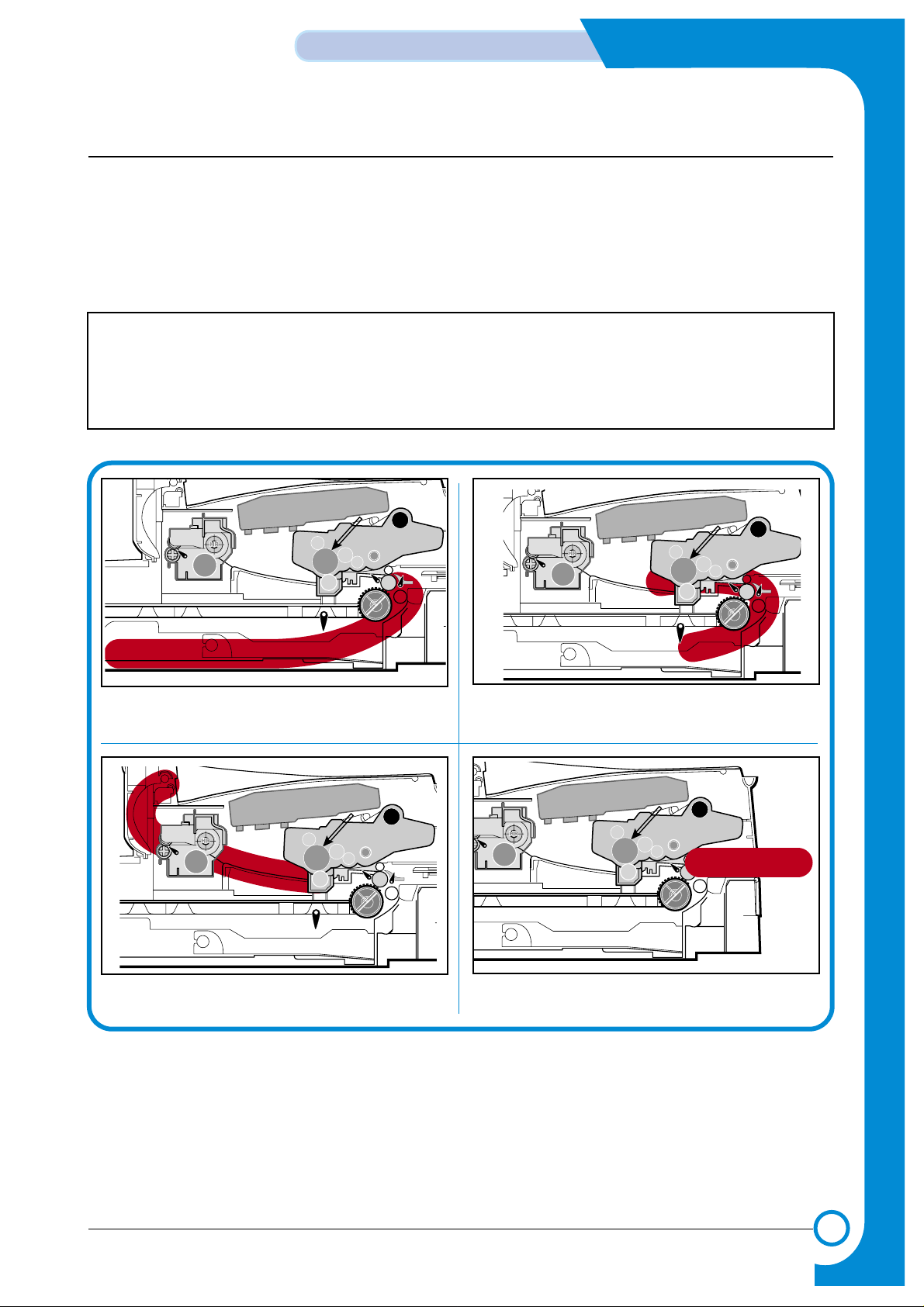

6.2 Clearing Paper Jams

Occasionally, paper can be jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specifications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs, the On Line/Error LED on the control panel lights red. Find and remove the

jammed paper. If you don’t see the paper, open the covers.

Do not use a tweezers or a sharp metal tool when removing a jam.

The covering of a metal part can be removed which can cause an electric leakage.

Paper Jam0

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam1

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam2

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Bypass Jam

L S U

Fuser

EXIT

PR

Sensor

Empty Sensor

CR

DR

OPC

SR

PTL

TR FR

Toner Cartridge

MP Sensor

Feed

Sensor

R

/

K

C

I

P

Page 4

6-4

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

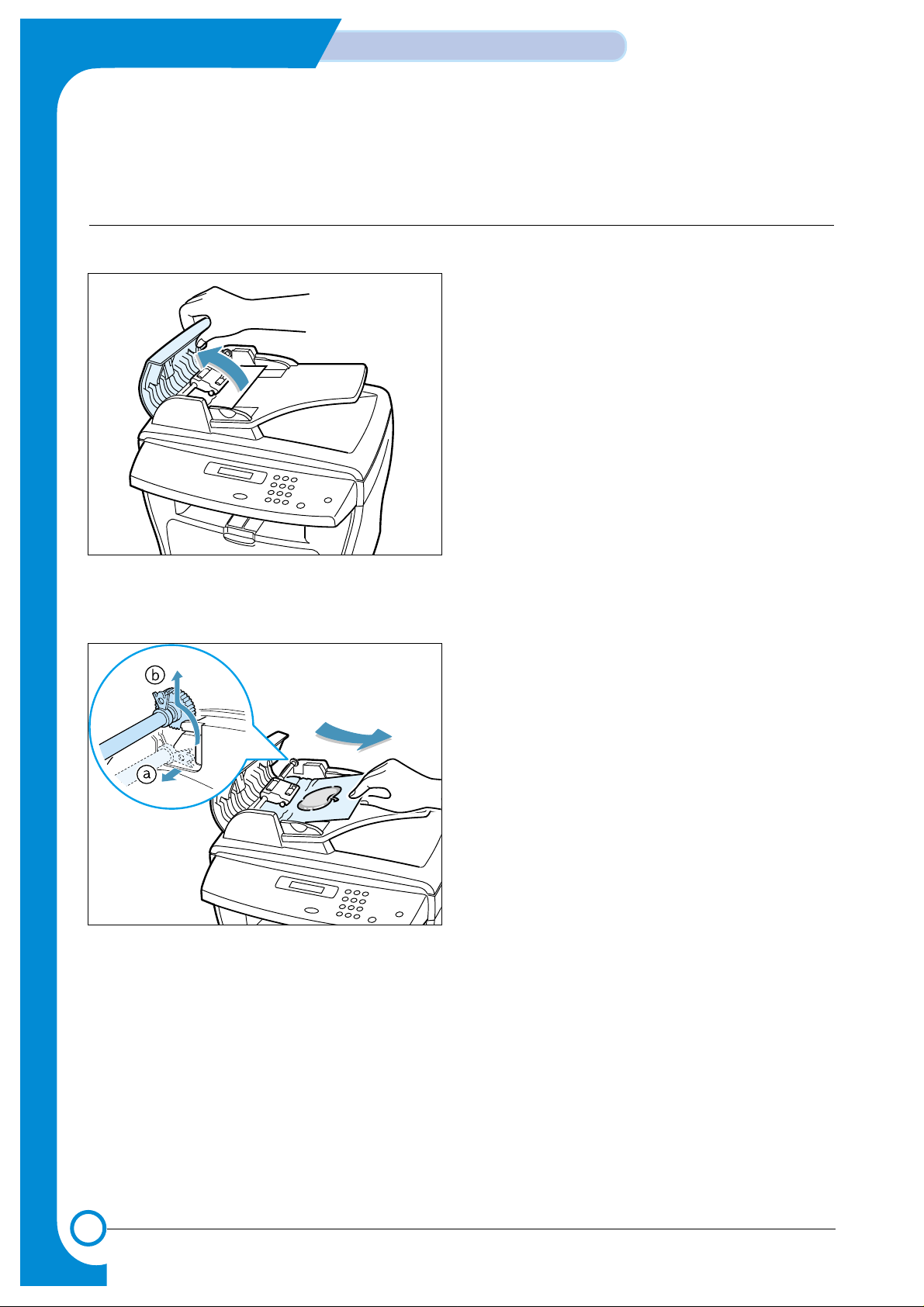

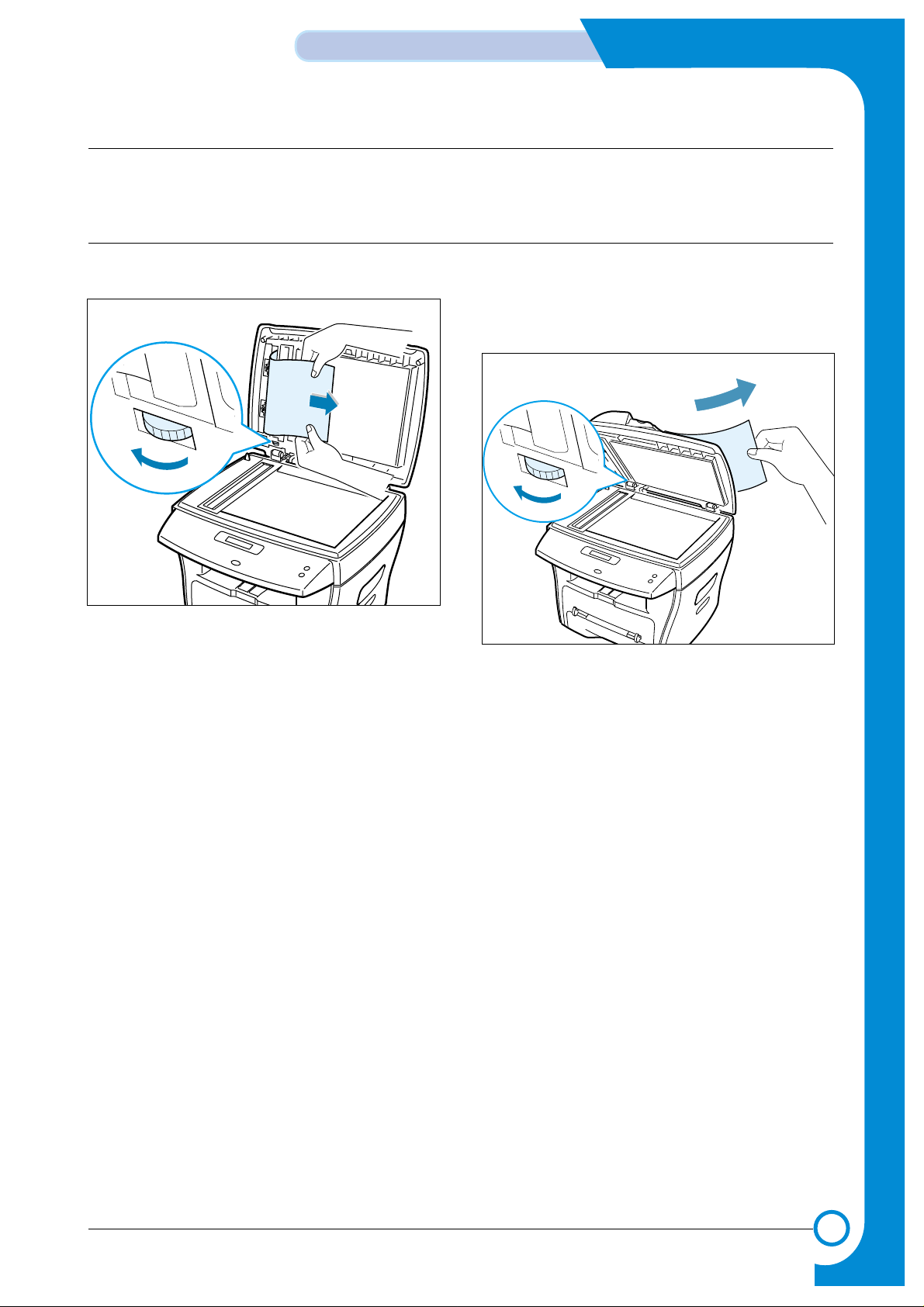

6.2.1 Clearing Document Jams

If a document jams while it is feeding through the ADF (Automatic Document Feeder),“DOCUMENT JAM ” appears on

the display.

6.2.1.1 Input Misfeed

1) Open the ADF top cover.

2) Pull the document gently to the right and out of the

ADF.

3) Close the ADF top cover.Then load the documents

back into the ADF.

NOTE : To prevent document jams,use the document

glass for the thick,thin or mixed documents.

Page 5

1) Open the document cover. 2) Turn the release knob so that you can easily remove

the misfed document,and remove the document from

the ADF or the feed area by carefully pulling it

towards the right by using both hands.

3) Close the document cover.Then load the documents

back into the ADF.

6-5

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.2.1.2 Exit Misfeed

1) Open the document cover and turn the release knob to remove the misfed documents from the exit area.

2) Close the document cover.Then load the documents back into the ADF.

6.2.1.3 Roller Misfeed

Page 6

6-6

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

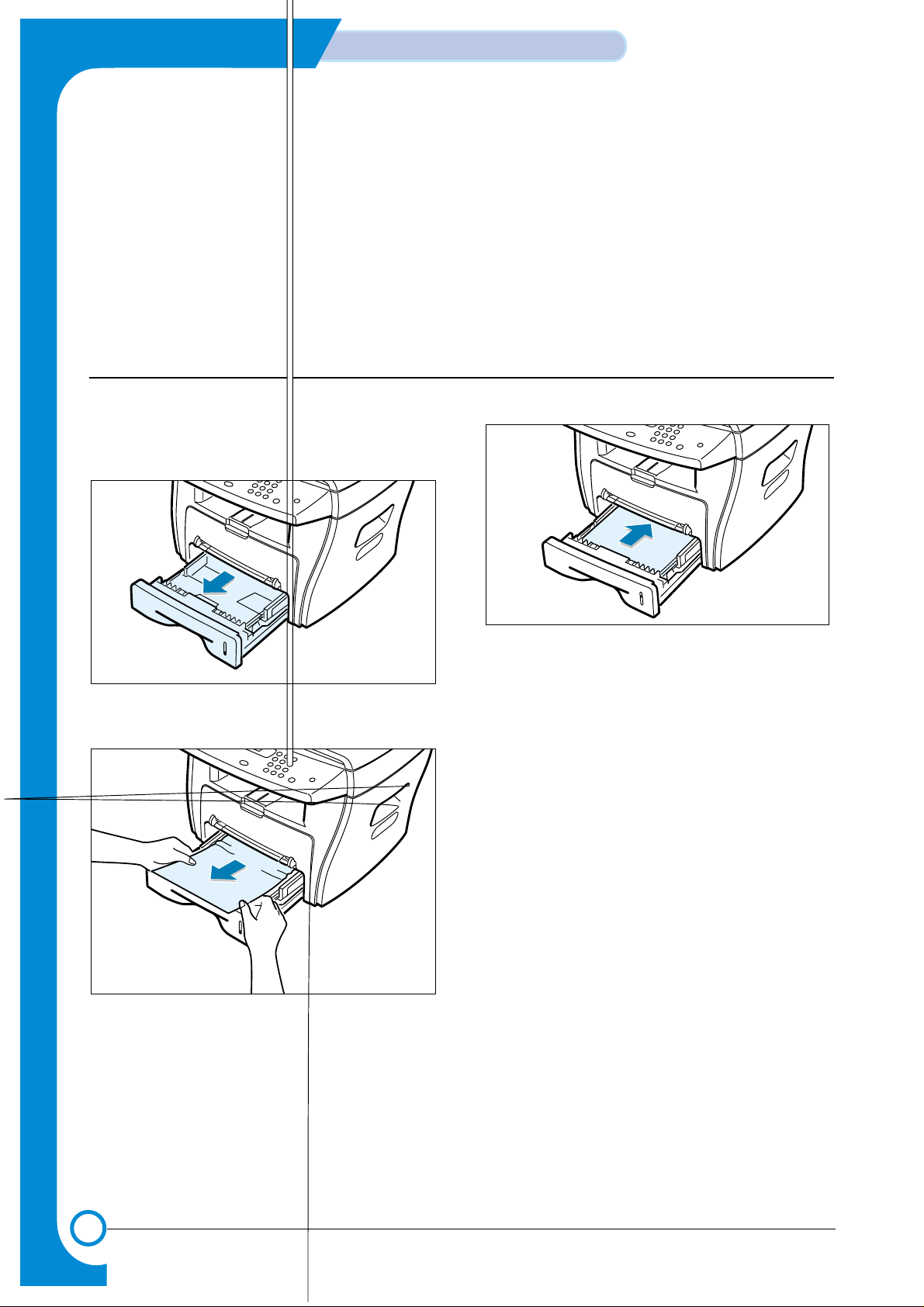

6.2.2 Clearing Paper Jams

If paper jams occur,“PAPER JAM ” appears on the display. Refer to the table below to locate and clear the paper jam.

PAPER JAM 0 : In the paper feed area

PAPER JAM 2 : In the paper exit area

PAPER JAM 1 : In the fuser area or around the toner cartridge

BYPASS JAM : In the Bypass tray

Follow the steps below to clear a jam.To avoid tearing the paper, pull the jammed paper out gently and slowly.

6.2.2.1 JAM0 (In the Paper Feed Area)

1) Open and close the front cover.The jammed paper

automatically exits the machine.

If the paper does not exit,continue to Step 2.

2 Pull the paper tray open.

3) Remove the jammed paper by gently pulling it

straight out.

If there is any resistance when you pull the

paper or the paper is not seen in this area,skip

to the fuser area around the toner cartridge

4) Insert the paper tray into the machine until it snaps

into place.

5) Open and close the front cover to resume printing.

Page 7

6-7

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

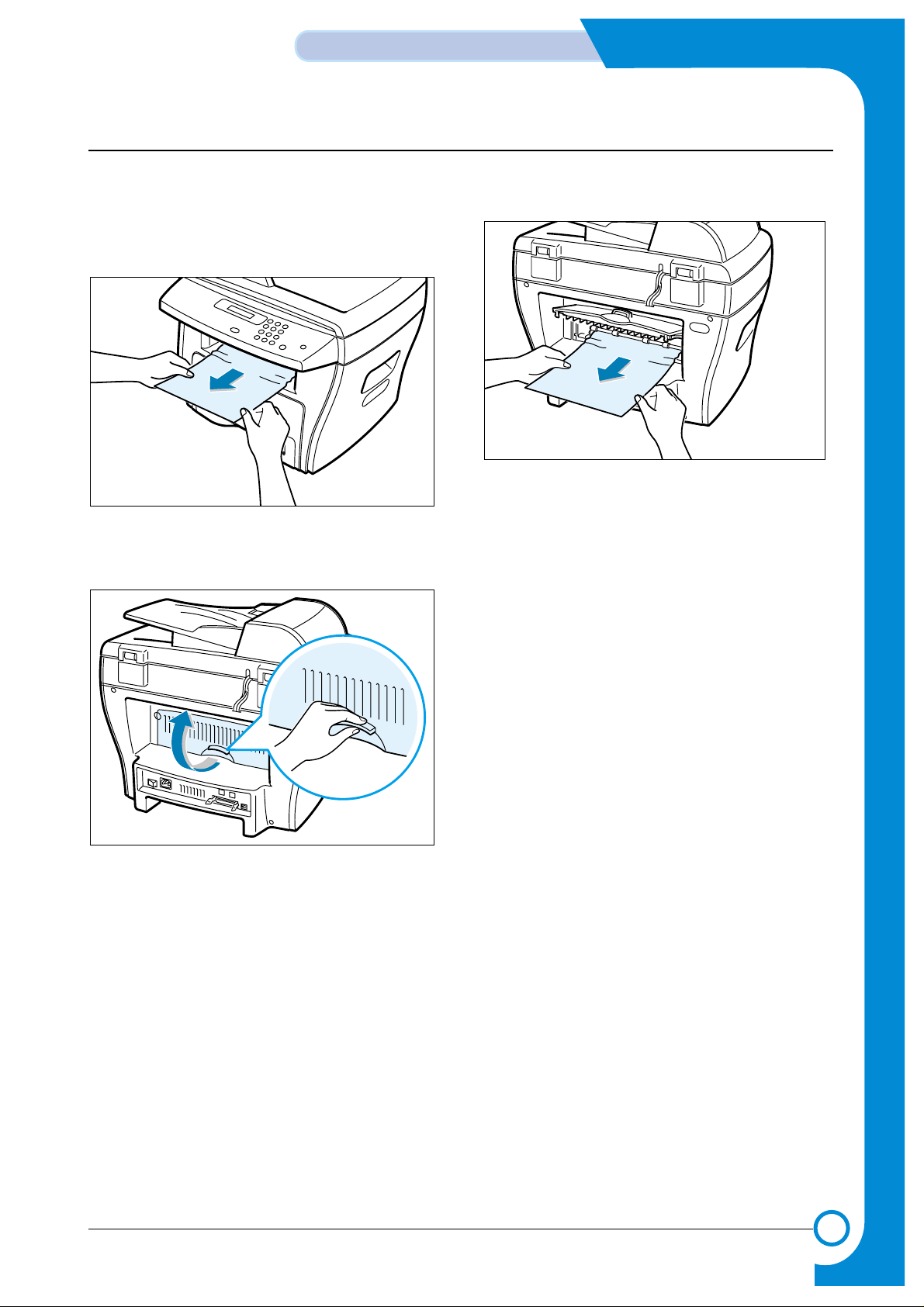

6.2.2.2 JAM 2 (In the Paper Exit Area)

1) Open and close the front cover.The jammed paper

automatically exits the machine.

If the paper does not exit,continue to Step 2.

2) Gently pull the paper out of the front output tray.

3) If there is any resistance when you pull the paper or

the paper is not seen in the front output tray,open the

rear cover.

4) Remove the jammed paper by gently pulling it

straight out.

5) Close the rear cover.

6) Open and close the front cover to resume printing.

Page 8

6-8

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

6.2.2.3 JAM1 (In the Fuser Area of Around the Toner Cartridge Area)

NOTE : The fuser area is hot.Be careful when removing paper from the machine.

1) Open the front cover and remove the toner cartridge.

2) Remove the jammed paper by gently pulling it

straight out.

3) Replace the toner cartridge and close the front cover.

Printing automatically resumes.

Page 9

6-9

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.2.2.4 BYPASS JAM (In the Bypass Tray)

“BYPASS JAM ” appears on the display when the machine does not detect paper in the Bypass tray due to no paper or

improper paper loading when you try to print using the Bypass tray.

“BYPASS JAM ” also may occur when the paper is not properly fed into the machine through the Bypass tray.In that

case,pull the paper out of the machine.

6.2.2.5 Tips for Avoiding Paper Jams

By selecting the correct paper types,most paper jams can be avoided. If a paper jam occurs, follow the steps outlined in

“Clearing Paper Jams ”

• Follow the procedures in “Loading Paper ” .Ensure that the adjustable guides are positioned correctly.

• Do not overload the paper tray.Ensure that the paper is below the paper capacity mark on the inside wall of

the paper tray.

• Do not remove the paper from the tray while printing.

• Flex, fan and straighten the paper before loading.

• Do not use creased, damp or highly curled paper.

• Do not mix paper types in the paper tray.

• Use only recommended print materials. See “Paper Specifications ”

• Ensure that the recommended print side is facing down when loading paper in the paper tray and facing up in

the Bypass tray.

Page 10

6-10

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

1.Paper Setting

Paper Tray

Paper Size

2.Copy Setup

Change Default

Timeout

6.Reports

System Data

8.Machine Setup

Language

Power Save

CCD Power Save

USB Mode

9.Maintenance

Clean Drum

Clear Memory

6.3 User Mode(SCX-4116 & SCX-4016)

The table in the bellow explains the possible setting functions by user. The details about the ways to use

are explained in the user manual.

In the service manual, the items are about the possible set-up by user.

Page 11

6-10

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

1.Paper Setting

Paper Tray

Paper Size

2.Copy Setup

Change Default

Timeout

3.Fax Setup

Receive Mode

Ring to Answer

Contrast

Redial Term

Redials

MSG Confirm.

Auto Report

Auto Reduction

Discard Size

4.Fax Feature

Delay Fax

Priority Fax

Add / Cancel

5.Advanced Fax

Send Forward

RCV Forward

Toll Save

Junk Fax Setup

Secure Receive

Prefix Dial No

Stamp RCV Name

ECM Mode

6.Reports

Phone Book

Send Report

RCV Report

System Data

Scheduled Jobs

Tx Confirm.

Junk Fax List

7.Sound/Volume

Speaker

Ringer

Key Sound

Alarm sound

8.Machine Setup

Machine ID

Date&Time

Clock Mode

Language

Power Save

CCD Power Save

USB Mode

9.Maintenance

Clean Drum

Notify toner

Clear Memory

6.3 User Mode

The table in the bellow explains the possible setting functions by user. The details about the ways to use

are explained in the user manual.

In the service manual, the items are about the possible set-up by user.

Page 12

6-11

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.4 Tech Mode

6.4.1 How to Enter Tech Mode

In service (tech) mode, the technician can check the machine and perform various test to isolate the cause

of a malfunction.

While in Tech mode, the machine still performs all normal operations.

To enter the Tech mode

To enter the Tech mode, press in sequence, and the LCD

briefly displays ‘TECH’, the machine has entered service (tech) mode.

6.4.2 Setting-up System in Tech Mode

WorkCentre PE16

Page 13

6-12

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

6.4.3 Data Setup

SEND LEVEL

You can set the level of the transmission signal. Typically, the Tx level should be under -12 dBm.

Caution : The Send Fax Level is set at the best condition in the shipment from factory. Never change settings

arbitrarily .

DIAL MODE

This function can choose dial method.

*Default : Dial(Tone/Pulse)

MODEM SPEED

You can set the maximum modem speed.

Communication is done with modem speed automatically set at lower speed when communicating with a slower speed modem since communication is done on the standard of the side where modem speed is low for

transmission/reception. It is best set 33.6Kbps as default setting.

ERROR RATE

When the error rate is about exceed the set value, the Baud rate automatically adjusts to 2400 bps.

This ensures that the error rate remains below the set value.

You can select the rate between 5% and 10%.

CLEAR ALL MEMORY

The function resets the system to factory default settings.

This function is used to reset the system to the initial value when the product is functioning abnormally . All the values are returned to the default values, and all the information, which was set by

the user, will be erased.

< Method >

1. Select the [MEMORY CLEAR] at the TECH MODE.

2. Push the ENTER button.

3. Select you country. (There are four country groups. Refer to the table below.)

4. Push the ENTER button then it will clear all memory.

NOTICE : Always perform a memory clear after replacing the main board. Otherwise, the system

may not operate properly.

Country Group USA/Canada UK Russia Southafrica

USA/Canada UK Russia Southafrica

Mexico Germany india

Brazil France Oman

Italy Poland

Spain Bangladesh

Austria Kuwait

Netherlands Moroco

Belgium Algeria

Country Portugal Pakistan

Sweden UAE

Norway Bahrain

Denmark Srilanka

Finland SaudiArabia

Switzerland Chile

Greece Peru

Ireland Argentina

Turkey Hungary

Romania

Bulgaria

Czech

Page 14

6-14

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

FLASH UPGRADE

The Firmware Upgrade function and has two methods, Local and Remote.

(1) Local Machine

• RCP(Remote Control Panel) mode

This method is for Parallel Port.or USB Port Connect to PC and activate RCP(Remote Control Panel) to

upgrade the Firmware.

< Method >

How to Update Firmware using RCP

1. Connect PC and Printer with Parallel Cable or USB Cable.

2. Execute RCP and select Firmware Update.

3. Search Firmware file to update with Browse Icon.

4. Click Update icon, firmware file is transmitted to Printer automatically and printer is initialized when it finished.

5. Click Refresh icon and check what is updated.

• DOS Command mode

This method is just for Parallel Port. Connect to PC with Parallel cable and enter DOS Command to upgrade

the Firmware.

< Method >

1. The first of all, need the files : down.bat, down_com.bin, fprt.exe, and Rom File: file name for

upgrade.Save the files in the same folder.

2. In the DOS, input as below and push the enter key. Then, it will be automatically upgraded.

3. There are two commands for the conditions of product.

* When the product is in idle condition down "rom file"

* When the product is in Ready condition (TECH MODE → MAINTENANCE→ FLASH UPGRADE→ LOCAL)

fprt "rom file"

4. Do not turn off the power while upgrading process.

(2) Remote FAX

This is a function that a fax with the latest firmware sends files to a fax in long distance through telephone line.

< Method >

1. Operate a fax with the latest firmware to prepare it being upgrade.

(TECH MODE →MAINTENANCE→FLASH UPGRADE→REMOTE)

2. Input the fax number, which needs to be upgraded.

(Several faxes can be upgrade at the same time. In this case, enter the each fax number.)

3. After push the enter button, send the firmware file by calling to the appointed number.

(Around 10~15 minutes needs to send the file.)

< Caution >

1. sending and receiving fax must be the same model.

2. Asending fax must be set up as ECM mode, and a receiving memory must be set up as 100%.

If not, the function operates abnormally.

Page 15

6-15

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.5.4 Machine Test

SWITCH TEST

Use this feature to test all keys on the operation control panel. The result is displayed on the LCD

window each time you press a key.

MODEM TEST

Use this feature to hear various transmission signals to the telephone line from the modem and to

check the modem. If no transmission signal sound is heard, it means the modem part of the main

board malfunctioned.

DRAM TEST

Use this feature to test the machine's DRAM. The result appears in the LCD display.

If all memory is working normally, the LCD shows << O K >>

ROM TEST

Use this feature to test the machine'S ROM. The result and the software version appear in the LCD

display.

• FLASH VER : 1.00 V

• ENGINE VER :1.00V

PATTERN TEST

Using this pattern printout, you can check if the printer mechanism is functioning properly.

It is needed in the production progress. Service person doesn't need to use it.

SHADING TEST

The function is to get the optimum scan quality by the specific character of the CCD(Charge

Coupled Device). If the copy image quality is poor, perform this function to check the condition

CCD unit.

< Method >

1. Select the [ADJUST SHADING] at the

TECH MODE.

2. Push the SET UP button then an image

will be scanned.

3. After the scan, CCD SHADING PROFILE will be print out.

4. If the printed image is different to the

image, the CCD is defect.

NOTICE : When you test CCD, make sure

that the cover is closed.

Page 16

6-16

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

6.5.5 Report

PROTOCOL LIST

This list shows the sequence of the CCITT group 3 T.30 protocol during the most recent sending or receiving

operation. Use this list to check for send and receive errors. If a communication error occurs while the machine

is in TECH mode, the protocol list will print automatically.

SYSTEM DATA

This list provides a list of the user system data settings and tech mode settings.

Page 17

6-17

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.6 Engine Test Mode

The Engine Tests Mode supplies useful functions to check the condition of the engine. It tests the condition

of each device and displays the result of the test on the LCD. It is classified into 5 functions )0~4), and are

shown below.

6.6.1 To enter the Engine Test Mode

To enter the Engine Test mode

Press in sequence, and the LCD briefly displays

‘Engine Test’, the machine has entered Engine Test Mode.

6.6.2 Diagnostic

NO. Sub No. Engine test Remark

0 1 Motor Test 1 : On, 2 : Off

2 PickUp Test 1 : On, 2 : Off

3 Fan Test 1 : On, 2 : Off

4 Manual Clt Test 1 : On, 2 : Off

5 PTL Test 1 : On, 2 : Off

1 1 LSU Motor Test 1 : On, 2 : Off

2 LSU Hsync Test 1 : On, 2 : Off

3 LD Test 1 : On, 2 : Off

2 1 Feed Sen Test Check : Check Start

Next : Next Sensor Check

2 Exit Sen Test Check : Check Start

Next : Next Sensor Check

3 Cover Sen Test Check : Check Start

Next : Next Sensor Check

4 Empty Sen Test Check : Check Start

Next : Next Sensor Check

5 Manual Sen Text Check : Check Start

Next : Next Sensor Check

3 1 Therm ADC 180 1 : On, 2 : Off (maintain the fusing temp. 80C)

2 Therm ADC 140 1 : On, 2 : Off (maintain the fusing temp. 135C)

3 Therm ADC 120 1 : On, 2 : Off (maintain the fusing temp. 160C)

4 Therm ADC 100 1 : On, 2 : Off (maintain the fusing temp. 191C)

4 1 MHV Test 1 : On, 2 : Off (-1550V ± 50V)

2 Dev Bias Test 1 : On, 2 : Off (-430V ± 20V)

3 THV EN/NEG Test 1 : On, 2 : Off (-1000V +300V/-150V)

4 THV ON (1300V) 1 : On, 2 : Off (+1300V ± 20V)

5 THV ADC 1300V 1 : On, 2 : Off (ADC Value : 101 ±5)

6 THV ADC 600V~3500V 1 : On, 2 : Off (Compare each ADC Value)

Page 18

6-18

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

6.7 Identify Sale Date

This function confirms the date that consumer bought product and used the product for the first time.

When the consumer first operate the machine, it will start a scan and page count.

The time the machine was first used is remembered.

These settings are are remembered after memory delete (Clear All Memory).

< Method >

Press MENU, #, 1, 9, 3, # in sequence.Firmware version is displayed on LCD.

Press 1( in the number keypad) : The LCD display shows "Updated date"

Press 2( in the number keypad) : The LCD display shows "Product first use date"

Page 19

6-19

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.8 Consumables and Replacement Parts

The cycle period outlined below is a general guideline for maintenance.

The example list is for an average usage of 50 transmitted and received documents per day.

Environmental conditions and actual use will may vary.

The cycle period given below is for reference only.

COMPONENT REPLACEMENT CYCLE

ADF Rubber 20,000 Pages

ADF Roller 60,000 Pages

Pick-up Roller 60,000 Pages

Friction Pad 60,000 Pages

Transfer Roller 60,000 Pages

Fuser 60,000 Pages

Toner Cartridge 3,000 Pages (A4 IDC 5% Pattern)

Page 20

6-20

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

6.9 Abnormal Image Printing and Defective Roller

If abnormal image prints periodically, check the parts shown below.

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 75.5mm White spot, Block spot

2 Charge Roller 37.7mm Black spot

3 Supply Roller 37.0mm Horizontal density band

4 Develop Roller 35.2mm Horizontal density band

5 Transfer Roller 45.3mm Black side contamination/transfer fault

6 Heat Roller 66.3mm Black spot and fuser ghost

7 Pressure Roller 75.5mm Black side contamination

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Transfer Roller

Heat Roller

Pressure Roller

L S U

Fuser

PR

CR

OPC

TR FR

Toner Cartridge

DR

SR

PTL

MP Sensor

R

/

K

C

I

P

Page 21

6-21

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 June 2003

6.10 Error Messages

The display on the front panel shows the messages to indicate the printer ’s status or errors.Refer to the tables below to

understand the message ’s meaning and clear the problem if necessary.Messages and their meanings are listed in

alphabetical order,with numbered messages following.

BYPASS JAM

Meaning : When the machine detected the non-feeding from BYPASS Tray.

Solution : Open the side Cover and clear the jam.

COMM. ERROR

Meaning : A problem with the facsimile communications has occurred.

Solution : Try again.

DOCUMENT JAM

Meaning : Loaded document has Jammed in the feeder When Document Jam aeeurred at AD

Solution : Clear the document Jam.

DOOR OPEN

Meaning : The side cover is not securely latched.

Solution : Clear the cover until it clicks in place.

DRUM WARNING

Meaning : When the machine has encountered the drum life,14000 print pages.

Solution : Use little more change if “REPLACE DRUM” is marked in LCD window.

GROUP NOT A VAILABLE

Meaning : You have tried to select a group location where only a single location number can be used, such

as when adding locations for a multi-dial operation.

Solution : Try again, check location for group.

Heating Error

Meaning : During operation, Temperature does not go up.

Solution : Check thermister contact point & Heating Lamp.

LINE BUSY

Meaning : The remote FAX didn’t answer

Solution : Try again.

LINE ERROR

Meaning : Your unit cannot connect with the remote machine, or has lost contact because of a problem on

the phone line. When the machine has a problem in cause of fax data reception step

Solution : Try again. If failure persists, wait an hour or so for the line to clear then try again.

LOAD DOCUMENT

Meaning : You have attempted to set up a sending operation with no document loaded.

Load a document and try again.

Solution : Try again. Make sure the remote machine is OK.

MEMORY FULL

Meaning : The memory has become full.

Solution : Either delete unnecessary documents, or retransmit after more memory becomes available, or

split the transmission into more than one operation.

Page 22

6-22

ALIGNMENT & ADJUSTMENTS

Service

Manual

June 2003 WorkCentre PE16

NO ANSWER

Meaning : The remote machine was not answered after all the redial attempts.

Solution : Try again. Make sure the remote machine is OK.

NO CARTRIDGE

Meaning : When the machine detected the toner cartridge has not been installed.

Solution : Install the Cartridge.

NO. NOT ASSIGNED

Meaning : The speed dial location you tried to use has no number assigned to it.

Solution : Dial the number manually with the keypad, or assign the number.

NO PAPER [ADD PAPER]

Meaning : The recording paper has run out. The printer system stops.

Solution : Load the recording paper in the paper feeder.

OPEN HEAT ERROR

Meaning : Thermister does not connected to main board or contact point is not coupled tightly in power on.

Solution : Check thermister contact point, Heating Camp & Thermostat.

OVERHEA T

Meaning : The printer part has overheated.

Solution : Your unit will automatically return to the standby mode when it cools down to normal operating

temperature. If failure persists, call service.

PAPER JAM 0

OPEN/CLOSE DOOR

Meaning : Recording paper has jammed in paper feeding area. Recording paper is jammed in pick-up unit

Solution : Press STOP and clear the jam.

PAPER JAM 1/2

OPEN/CLOSE DOOR

Meaning : Recording paper has jammed inside the unit. Recording paper has jammed in paper exit unit.

Solution : Clear the jam.

RETRY REDIAL?

Meaning : The machine is waiting for the programmed interval to automatically redial.

Solution : You can press START to immediately redial, or STOP to cancel the redial operation.

TONER EMPTY

Meaning : When the machine has encountered the Toner Empty.

Solution : Replace the Toner Cartridge.

TONER LOW

Meaning : Toner may be low

Solution : Toner may be unevenly distributed. Remove the toner cartridge and shake it gently to evenly dis-

tribute the toner. Then replace the toner cartridge.

Scanner Locked

Meaning : Scanner is locked by locker.

Solution : Check locker. Connect the Flat-Cable.

Loading...

Loading...