Page 1

Samsung Electronics 4-1

4. Maintenance & Troubleshooting

4-1 Preventative Maintenance

The cycle period outlined below is a general guideline for maintenance. The example list is for an average

usage of 50 transmitted and received documents per day. Environmental conditions and actual use will vary

these factors. The cycle period given below is for reference only.

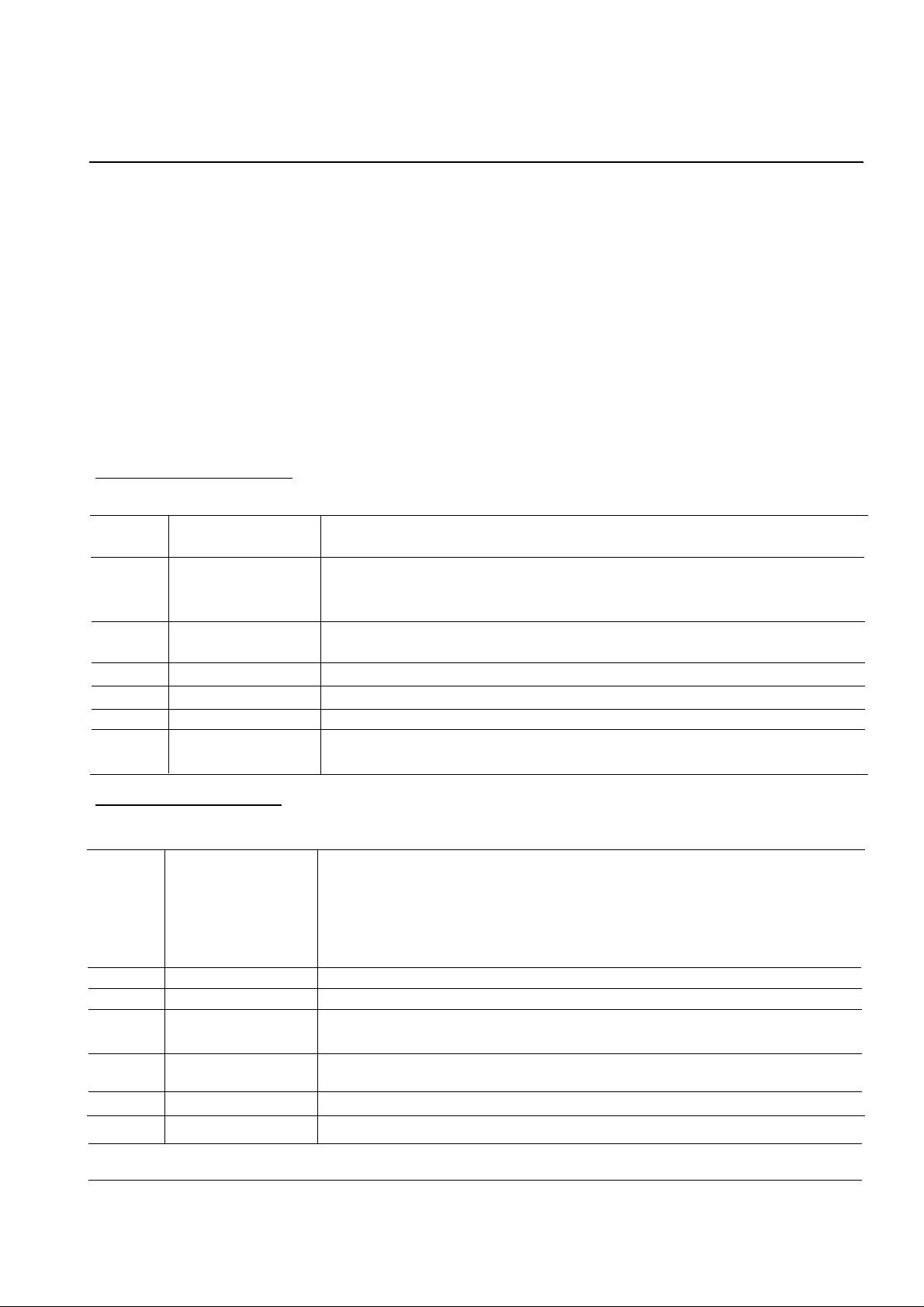

COMPONENT REPLACEMENT CYCLE

Cartridge

Pickup Roller

Feed Roller

Transfer Roller

Fuser

Driver

2,500 Pages

60,000 Pages

60,000 Pages

60,000 Pages

60,000 Pages

60,000 Pages

4-2 Print Quality

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 75.4mm

2 Charge Roller 37.7mm Black spot

3 Supply Roller 26.8mm Horizontal density band

4 Develope Roller 31.6mm Horizontal density band

5 Transfer Roller 47.1mm Black side contamination/transfer fault

6 Heat Roller 57.1mm Black spot, White spot

7 Pressure Roller 56.5mm Black side contamination

•White spot on black image

•Black spot

Page 2

4-2 Samsung Electronics

Troubleshooting

4-3 DCU Control

4-3-1 DCU Setup

DCU is used to diagnose the printer malfunctions. To use DCU, open and remove the Printer’s exit cover in

front, and remove the bottom cover from left. Connect the DCU harness wire (10 pin-to-4 pin) to CN9 (4 pins)

on the control board.

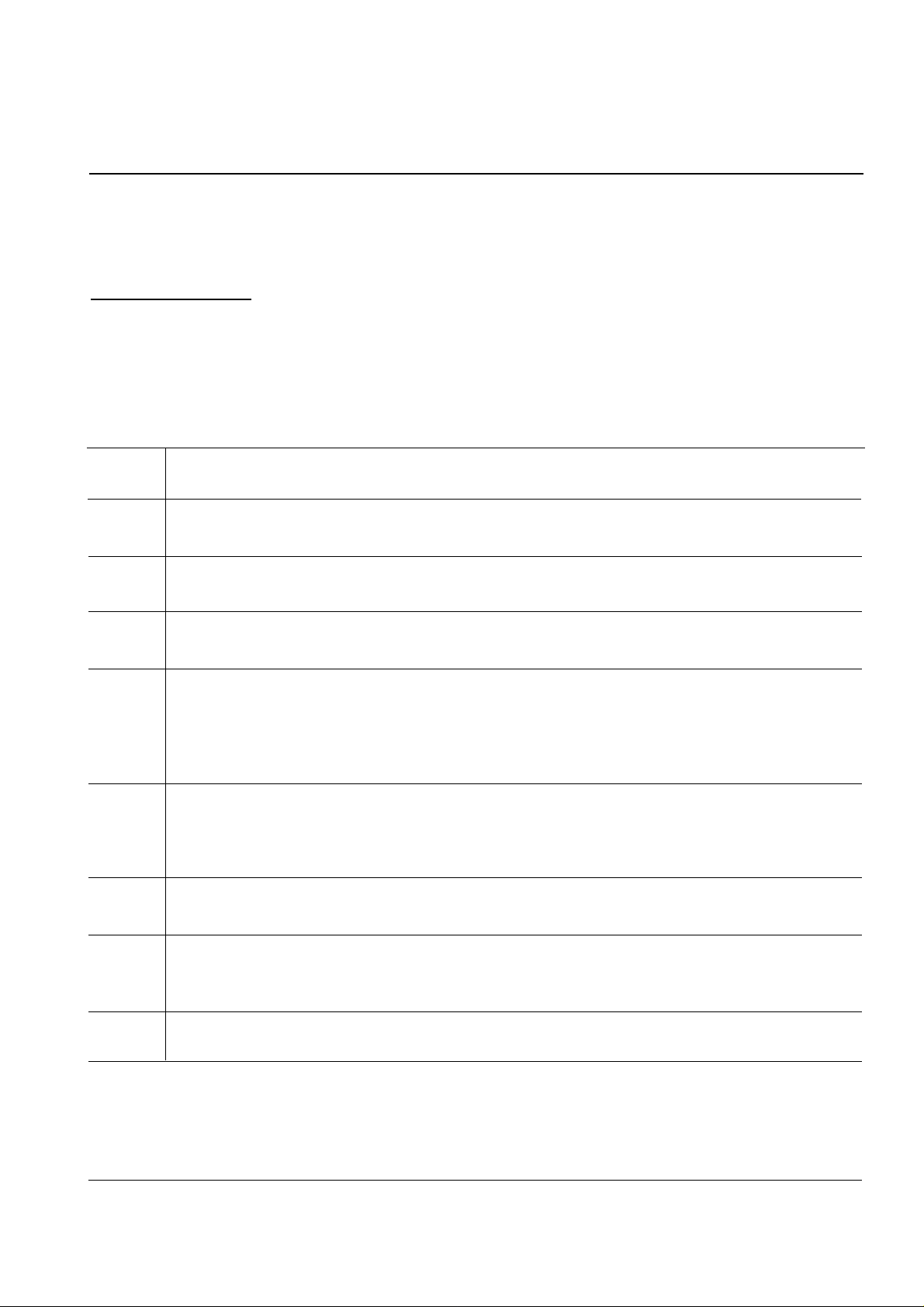

4-3-2 Status Code

Connect the DCU to the printer and turn power on. The DCU display Status Code in the 7 segment LEDs.

There are two kinds of Status Codes; Normal and Error. And their codes mean the printer operating status.

NORMAL STATUS CODE

These codes mean paper location on the paper path when the printer is printing, or warming up.

61 Warm up The printer warms up when the printer is turned on or the cover is closed, or

wake from sleep mode.

00~05 Ready(paper type) The printer is in printable state. The paper type is sensed after

one page printing.

00: Legal , 01: Letter , 02: A4 , 03: EXEC , 04: B5 , 05: Folio

20 Print Start The code is displayed when engine controller is received ‘PRINT’ command

from the video controller.

30 Feed Sensor On It means that paper is passing the feed sensor.

40 Feed Sensor Off It means that paper passed the feed sensor.

50 Paper out It means that paper passed the exit sensor.

69 Sleep Mode It means that the printer fuser is turned off, and the power consumption is

minimized.

ERROR STATUS CODE

If the printer stops printing by any malfunction, the DCU displays its error status code.

60,62,68 Fuser Error These codes mean the fuser error status. Heat lamp, thermistor, thermostat

open or thermistor short. The ‘Low Temperature Error’ is checked when the

printer is printing.

60: Open Fuser Error

62: Low Heat Error

68: Over Heat Error

64 Cover Open The printer cover open or no toner cartridge in the machine.

70 No Paper The paper is not loaded in the printer paper tray.

71 Paper Jam 0 Displays when the paper leading edge stops between the pick-up unit and

the feed sensor.

72 Paper Jam 1 Displays when the paper leading edge stops between the feed sensor and

the exit sensor.

73 Paper Jam 2 Displays when the paper leading edge stops after the exit sensor.

95 LSU Not Ready The LSU scanner motor is not ready or ‘Hsync’ signal is not output.

Page 3

Samsung Electronics 4-3

Troubleshooting

4-3-3 Diagnostic Mode

When the printer malfunction occurs and DCU displays Error Status Code, you can use the Diagnostic Mode to

find a problem and fix it.

DIAGNOSTIC CODE

When you fix the malfunction, you can make only a unit of machine operated in Diagnostic mode. To enter

Diagnostic mode, push three buttons ( [DOWN], [SHIFT], [STOP] ) simultaneously and turn the printer power

on. When the DCU displays ‘78’, release the keys in 2-3 seconds, then the DCU displays ‘00’. By using [UP] or

[SHIFT] and [DOWN] keys, select the desired Diagnostic Code, and push the [ENTER] key to perform the

operation. To stop its operation, push the [SHIFT] and [ENTER] buttons.

00 MAIN MOTOR OPERATING SYSTEM

Only main motor turns continuously.

01 MAIN HIGH VOLTAGE ON (THV)

There is output of -1550V to MHV terminal.

02 TRANSFER HIGH VOLTAGE (-) ON (THV - )

There is output of -1300V to THV terminal.

03 TRANSFER HIGH VOLTAGE (+) REFERENCE ON (THV + )

There is output of +1300V to THV terminal.

04 DEV/SUPPLY HIGH VOLTAGE

There is output DEV and SUPPLY high voltage to each HV terminals. At this time, the left one of

three LEDs (Diagnostic Mode Indicator) in the DCU lights, and DEV HV is -630V. To change this

voltage, push the [UP] button, and two (center and right) of three LEDs light, there are output

-530V to DEV HV terminal.

05 LSU OPERATING SYSTEM

The scanning motor in LSU turns and the right one of three LEDs lights. To check the LD (Laser

Diode) in the LSU at this state, push the [UP] button, the LD is driven, and the center LED lights. If

the LD is normal, all three LEDs light.

06 PICKUP CLUTCH ON

The solenoid in machine operate. To release the solenoid, push the [SHIFT] and [ENTER] buttons.

07 PEMPTY/PWIDTH/NEW CRU SENSOR TEST

When you make the actuator of PEMPTY/PWIDTH sensor operate, the left or right one of three

LEDs lights. If you set new CRU in the machine in this mode, the right LED lights.

08 FEED & EXIT SENSOR TEST

The feed & exit sensor also can be tested by the same method of the code ‘06’.

Page 4

4-4 Samsung Electronics

Troubleshooting

09 COVER OPEN SENSOR TEST

Same method of the code ‘06’.

10 FUSER TEST

When you push the [ENTER] button, the right LED lights, and the fuser temperature raises to

Ready. If you push the [UP] button, the center LED lights, and it raises to printing temperature.

When you push the [UP] button once more, the left LED lights, and it raises overheating temperature.

11 HOT BURN TEST

When you push the [ENTER] button in this code, the machine prints endlessly without any sensing

operation. To stop this operation, turn the printer power off.

12 CLEANING MODE PRINT MODE

The machine prints one page to clean the OPC drum in CRU.

13 THV (+) TRIGGER, ALL HV

There is all output of high voltages to each HV terminal, and the LSU/FAN operate.

In this mode, the engine controller senses electric resistance of the transfer roller, and output

transfer high voltage corresponding to it. If there isn’t CRU in the machine, THV output is +199V ~

+2100V.

14 PTL TEST

This operation mean PTL LED status.

15 FAN TEST

This operation mean FAN status.

4-3-4 Self Test Button

When you push this button, the machine prints ‘vertical line’ pattern while it is pushed.

When you push this button and turn the Printer power on, the DCU displays code ‘89’, and the Printer warms

up. After warmed up, it is in ‘Ready’ state, and code ‘88’ is displayed in DCU. In this mode, the machine does

all printing operation (demo page printing and printing the data from PC) without all sensor operating. If you

diagnose the control board with malfunction printer engine, this mode is very useful.

Page 5

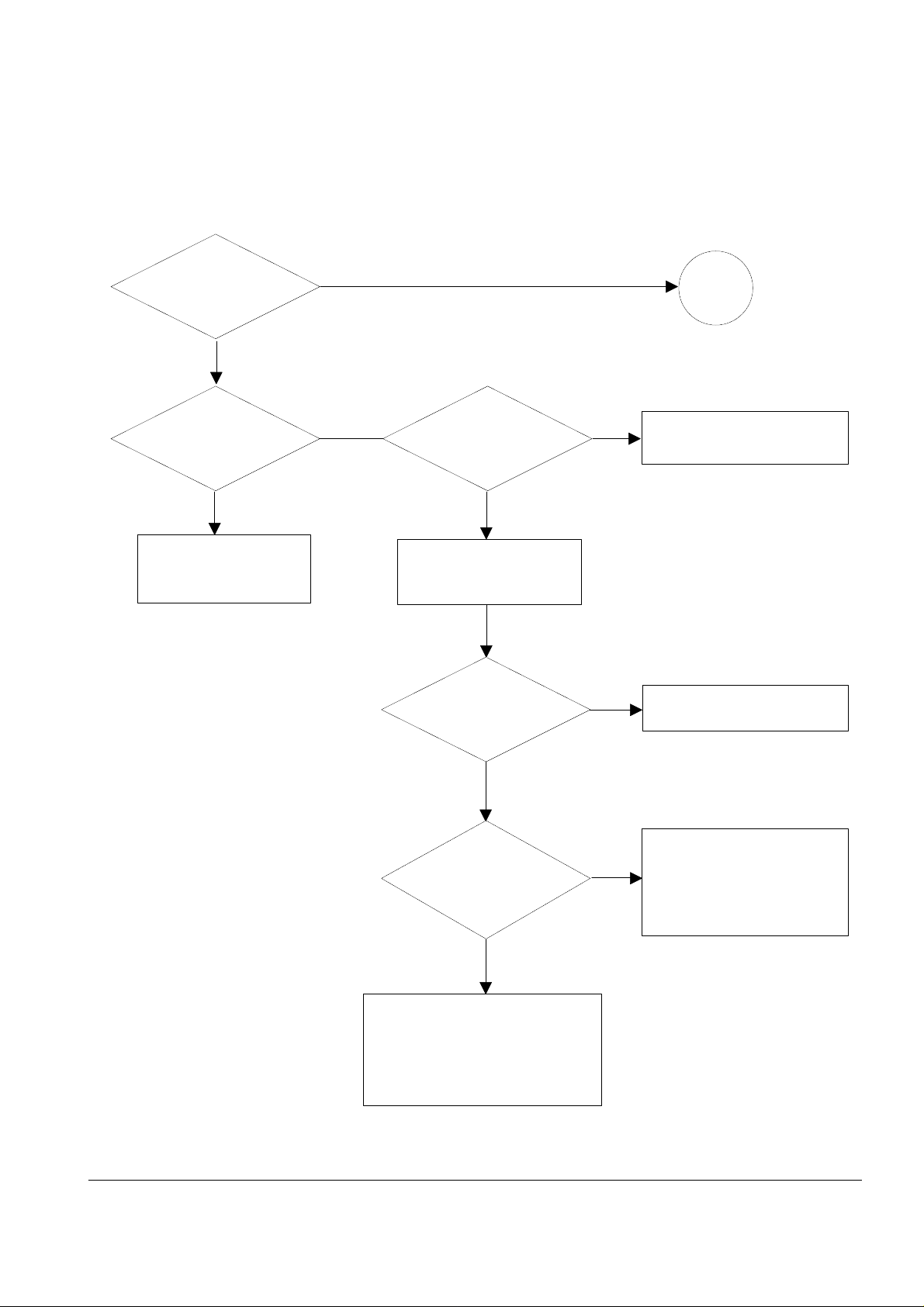

Samsung Electronics 4-5

Troubleshooting

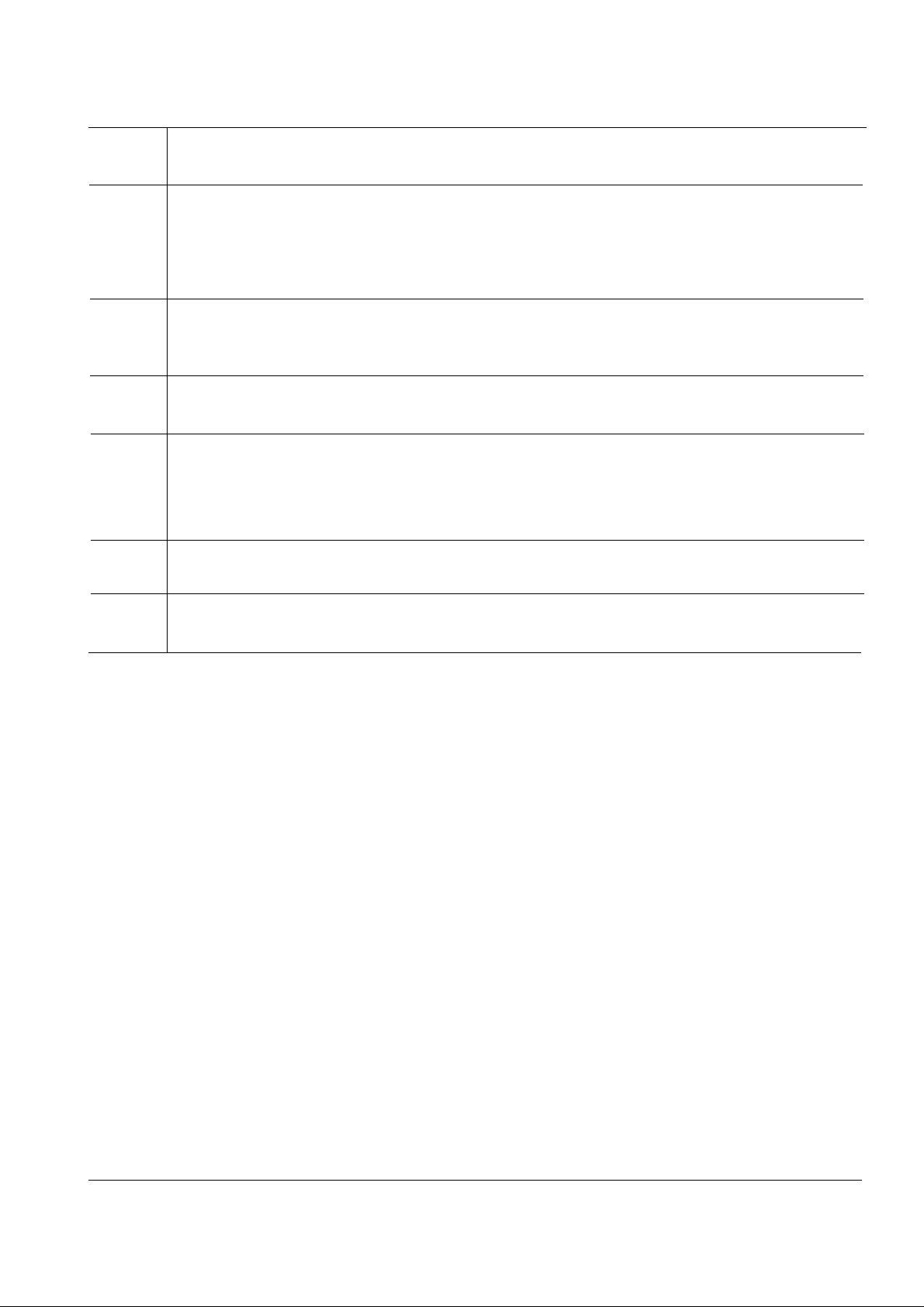

Vertical black line and band

YES

NO

YES

OK after

replacing the LSU?

Remove part on the paper

path causing the trouble

NO

OK after replacing

developer?

Any obstacles on

the developer blocking

the laser beam.

OK after

removing the

obstacles?

Any obstacles ON

mirror lens of LSU and

laser path?

Remove the obstacles.

Replace the LSU

Replace the developer

END

YES

YES

YES

NO

NO

NO

4-4 Troubleshooting Flow Chart

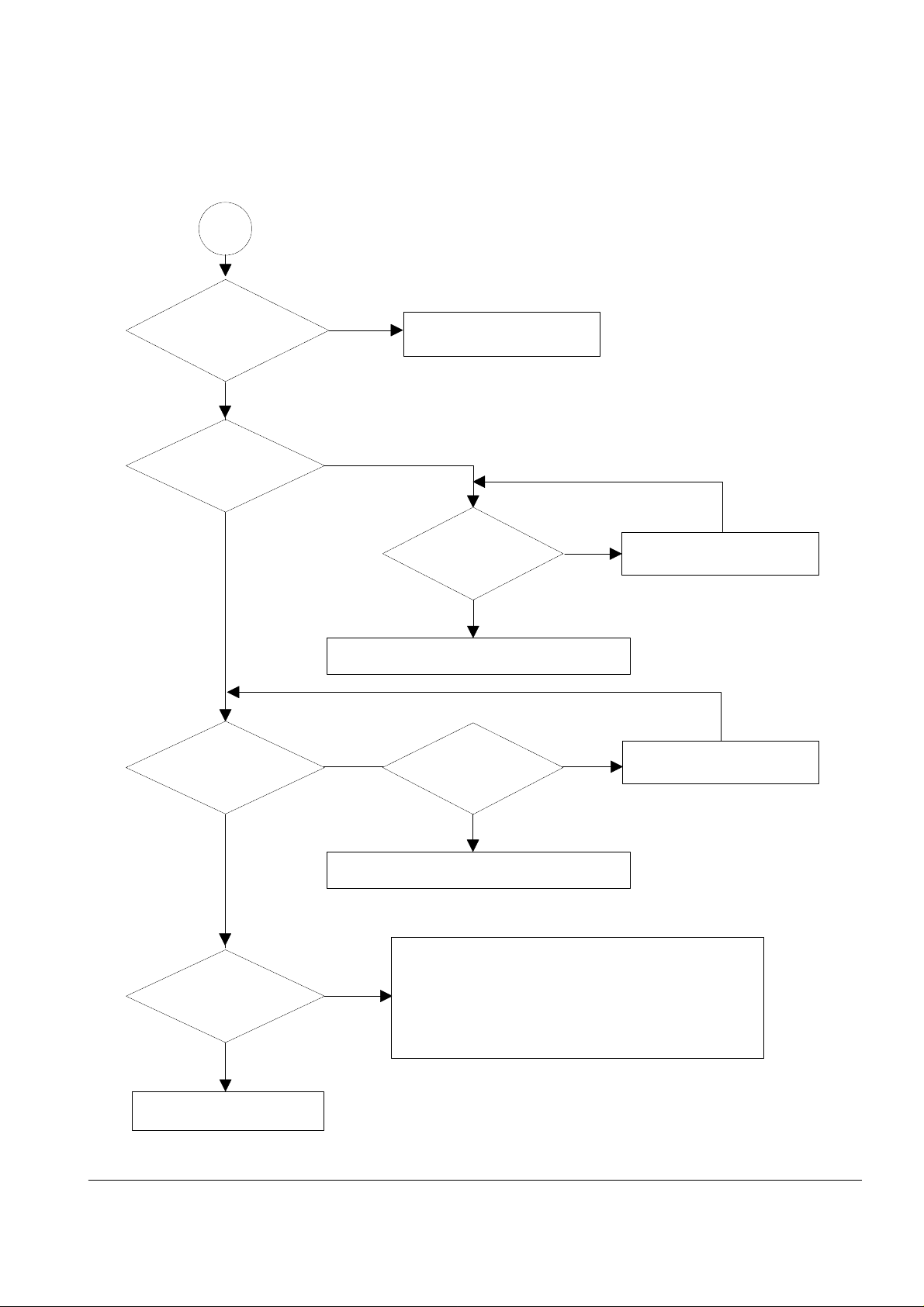

Page 6

4-6 Samsung Electronics

Troubleshooting

Check connection to

computer or replace

controller

Take out the cartridge

and prepare the tester

for electronic connection

Repair or replace the GND

terminal

Check the path between

video controller, engine board

and HVPS. Repair or replace

the defective component

or board

The mirror in LSU might be

misplaced so the light path to the

OPC deviates ->Repair or replace

LSU or remove any deffective

matters in the machine

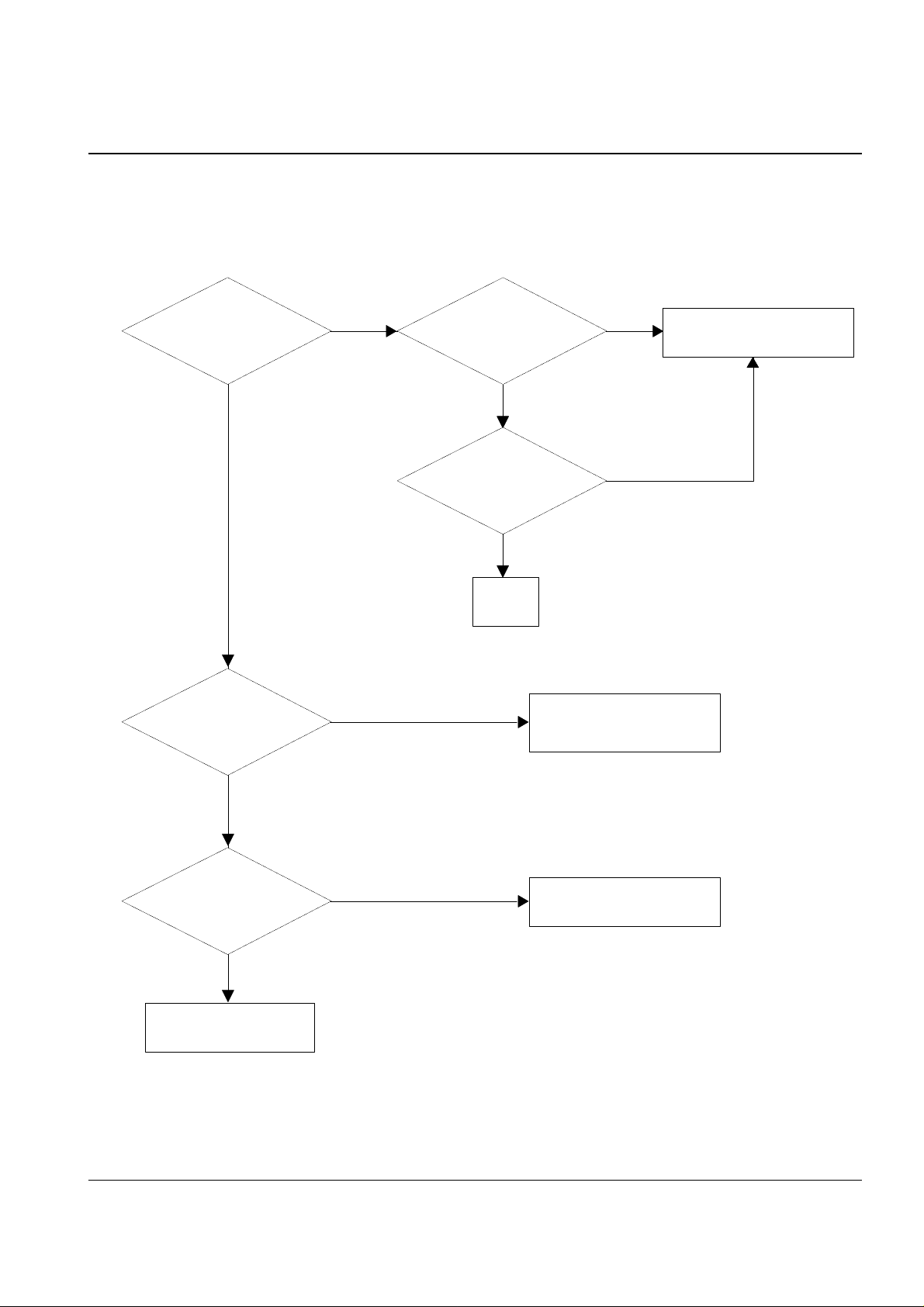

Self test

pattern prints?

No image?

Self testing

is possible via

Tech Mode?

Is the OPC

terminal of machine

is well-connected

to Frame?

Does the

video data line to

LSU transit to High/Low

when printing?

Re-test after replacing the

conector or Main board

A on

next page

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

No Image

Page 7

Samsung Electronics 4-7

Troubleshooting

Transfer roller might be out of its location

-> Locate the roller into its place

This could occurrs when he power of LSU is low or

the density is low due to the obstacles on the window

-> Replace LSU or clean the window

A

Trnasfer High

voltage OK? (on the

transfer roller

shaft)

Is the

connection of

OPC GND and Frame Ground

correct? (less than

10 ‰)

Are the

connection terminal

and connection

correct?

Repair or replace terminal

Replace HVPS or repair defective component

Is the connection

terminal OK?

Check the connection of

frame Ground and OPC GND

Replace HVPS or repair defective component

Repair or replace terminal

Developing

(-350V) and supplying

(-550V) voltage

are OK?

Does the

counter indicate over

the toner’s guarranty

life

Replace the toner cartridge

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

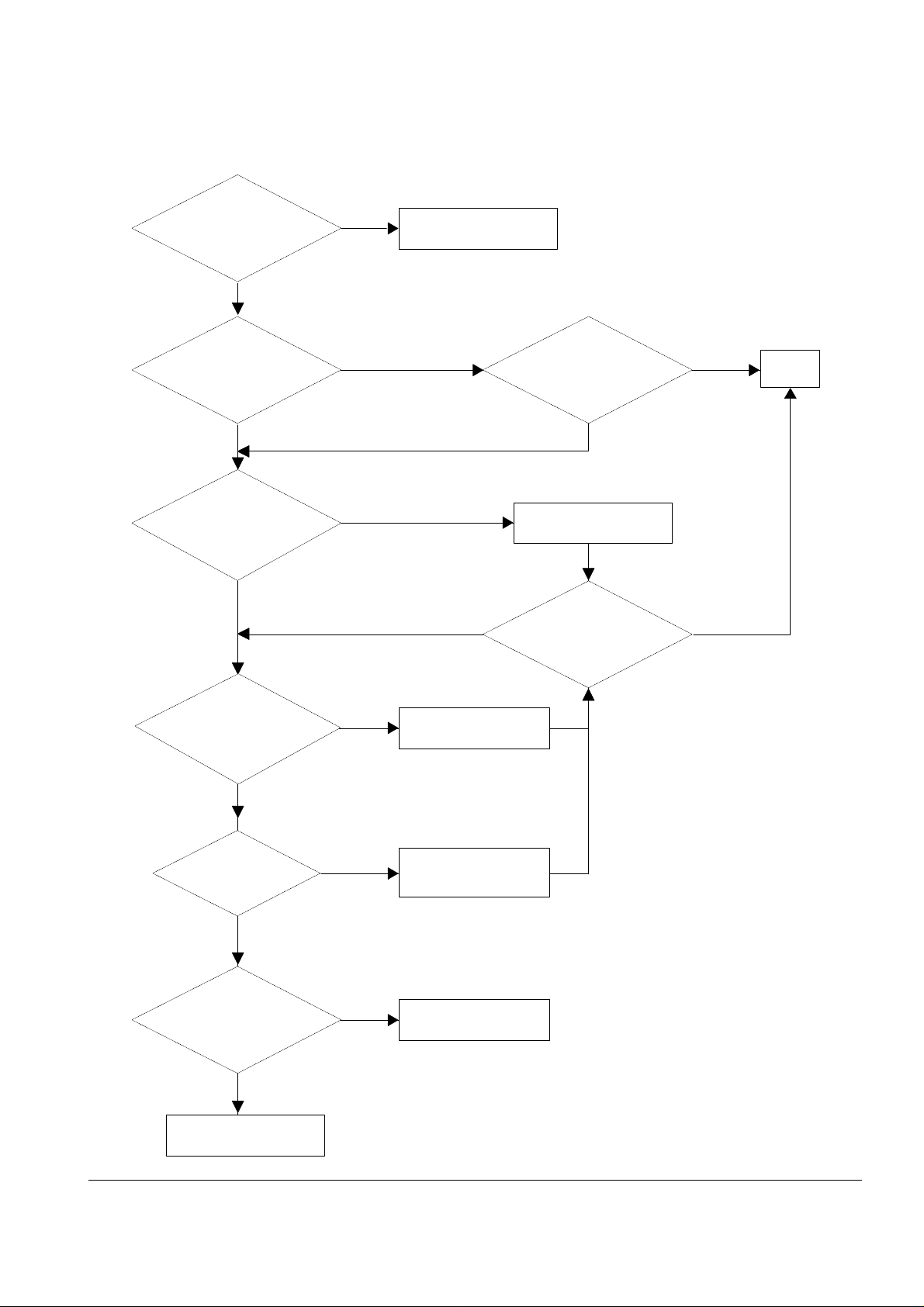

Page 8

4-8 Samsung Electronics

Troubleshooting

Replace the developer

NO

YES

YES

END

YESYES

NO

NO

NO

YES

YES

NO

Replace the HVPS

Ok after setting to the

normal mode?

YES

NO

Remove the obstacles

NO

YES

Clean transfer roller

and gear holder

YES

NO

Replace the LSU

Replace the developer

Is it not over

the guaranty life of dot

counter?

Is the toner save

mode or the light mode

is selected?

Is the high voltage

normal? (charging,

developing,

transfer)

Any obstacles on the

gab between high voltage

terminal and

developer?

Transfer roller

works OK?

OK after replacing

LSU?

HVPS works OK?

Light image

Page 9

Samsung Electronics 4-9

Troubleshooting

All black in

printing area?

Is transfer

voltage supplied

(-1.55 KV)?

Is the

Hsync/ signal received

in LSU?

Transfer part’s contact

is bad -> Repair or

replace toner cartridge

Does the

video data line to LSU

transit to High/Low when

printing?

Replace LSU

Check the path among video

controller, engine board,

HVPS, LSU for the shortage

or open -> Repair or replace

the boards

Repair or replace HVPS

Replace LSU

NO

NO

NO

NO

YES

YES

YES

YES

All Black

Page 10

4-10 Samsung Electronics

Troubleshooting

White line

missing definitely?

Dirt of dust stuck onto the window of internal

lens of LSU

-> Clean it or replace LSU

Preventive obstacles through the path between

OPC of developer and LSU prevent the path

-> Remove the obstacles

Check if the

printout is still has the

same problem even right after

passed through the

transfer roller

Toner material might be stuck to blade in the developer

inside and it prevents toner supply

-> Replace the toner cartridge

Check both if the toner cartridge’s counter is over its

guaranty and amount of the toner material

-> Replace the toner cartridge

The ribs in fuser or toner on the roller may invoke

the image problem

-> Replace the fuser cover or the defective part

The image is originally black or the black part is

far close to the top

-> Use the pattern which has the image below bigger

than 10mm from the top

NO

NO

END

NO

YES

Does the problem

persist?

YES

YES

Vertical White Line (Band)

Page 11

Samsung Electronics 4-11

Troubleshooting

Works cor

with -350V of Bias

voltage?

Works

correctly after

replaced LSU?

Repair or replace the defective

component

The power of LSU is set

high or internal problem

-> Replace LSU or adjust

voluem

NO

Toner over supply due to the

adjustment fault of metering

blade in developer

-> Replace developer

NO

YES

YES

Dark Image

Page 12

4-12 Samsung Electronics

Troubleshooting

Recommended

paper used?

Is pressure of

transfer roller too high?

Does the operation of

TR work properly?

Transfer,

charge and developing

voltage are OK?

Operating/

storage atmosphere is

too high temperature

/humidity?

Solve the problem under

the recommended condition

Dirt or

dust around the

charge roller?

Clean the charge roller

or replace step-up device

/terminal after check

Work OK?

Internal blade or suppying

part of the developer is

defective

-> Replace the toner cartridge

Check Terminals or contacts and ’Guide-Deve Spring’

are misplaced

-> Repair or replace transfer roller etc.

Print 20 to 30 pages using

the recommended paper

Same problem

occurs?

- Adjust voltage or replace HVPS

- Repair or replace after checking the

terminals’ contacts

Replace transfer

roller’s holder

END

Replace the

toner cartridge

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Background

Page 13

Samsung Electronics 4-13

Troubleshooting

Is it regular

interval of 75.4mm?

Irregularity of NIP

between rollers in

developer

-> Replace developer

Clean heat roller

or replace it

Clean transfer roller’s holder and

TR drive gearor replace TR holder ass’y

Clean TR drive

and OPC gear

END

A specific part of the transfer roller has

ruined or its resistance value is changed

-> Replace transfer roller

Transfer roller cannot force regularly due

to the gears eccentricity of transfer roller

-> Replace the defective component

Adjust the Bias

voltage or replace HVPS

There may be a problem in toner

layer control in toner cartridge

-> Replace the developer

Use the machine with

recommended paper and

at condition

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

YES

YES

YES

Check HVPS

contacts and

HVPS’s self-output

-> If failed, repair/

replace HVPS

- Repair or replace HVPS

- Check and Repair or

replace the terminal

contacts

NO

NO

Is it regular

interval of 31.6mm?

Is it regular

interval of 47mm?

(as transfer roller

interval)

Is it regular interval of

50.4 mm?

Does

the operation

of TR work properly?

Transfer

voltage is set to

standard?

Does the same

problem persist?

Developing

/suppying voltage

normal? (-350V/

-550V)

Bias voltage

is OK? (-350V)

Operating/storage

temperature is too low or

not recommended

paper used?

Ghost

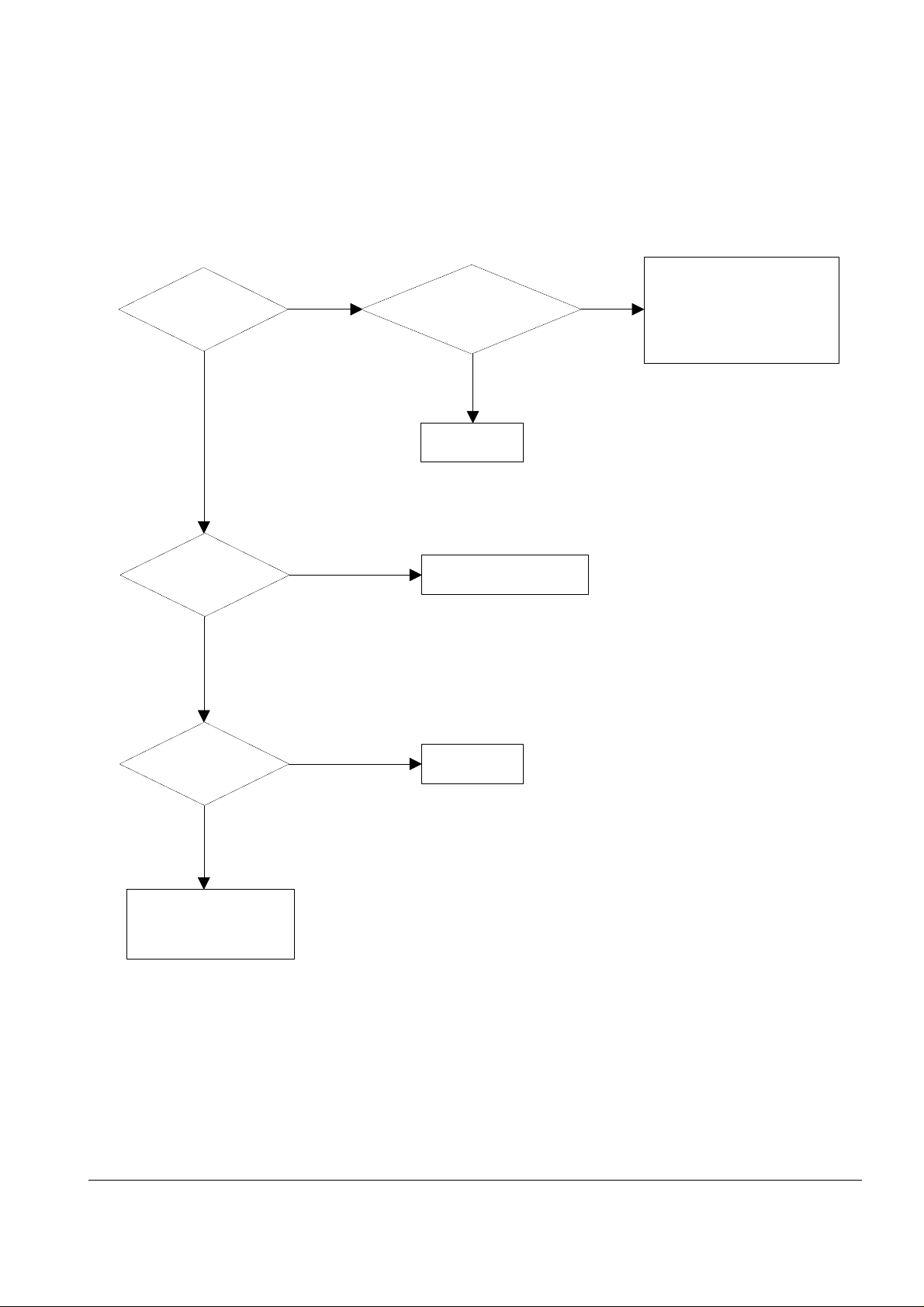

Page 14

4-14 Samsung Electronics

Troubleshooting

The problem occured

since the obstacles

stuck to charge roller

-> Replace toner cartridge

When taking

out the cartridge,

toner leaks?

Toner leaks and toner

material dropped onto

the paper -> Replace the

developer

Bad image

removes by

scratching?

Check toner is stuck onto

the P/R or H/R in fuser

-> Clean it or replace

The problem

randomly occured

due to the toner

fallen -> Clean the

machine

Remove obstacles

stuck on OPC

drum’s surface

Perform the OPC

cleaning using

the control panel

buttons.

END

NO

YES

NO

NO

YES

NO

YES

Does the same

problesm

persist?

Is it regular

interval of 37.7mm?

Is it regular

interval of 75.4 mm?

NO

YES

YES

Black Spot

Page 15

Samsung Electronics 4-15

Troubleshooting

NO

Black band?

The black

band has regular

interval?

Black band

is far about 10mm from

white band?

Problem of internal

contacts in OPC

-> Replace developer

The OPC is damaged under the

direct sunlight for around 5

minutes -> If the same problem

persists in 10 hours, replace

the developer

This occurs when no

Hsync/ at LSU

-> Replace LSU

75.4 mm interval?

Heat roller is ruined

-> Replace the roller

The OPC is damaged due to

the irregular transfer voltage

of HVPS

-> Repair/replace HVPS

-> If the same problem persists,

replace the developer

Does it appear

at every 56.1mm at

specific place?

Problems of terminal contact,

transfer voltage supplying,

and transfer roller’s due to the

charge roller is ruined (37.7mm)

-> Repair/replace HVPS,

developer

NO

NO NO

NO

YES

YES

YES

YES

Horizontal Band

Page 16

4-16 Samsung Electronics

Troubleshooting

Transfer roller

is clear ?

Clean the transfer roller

NO

YES

Paper path is

clear ?

Clean the paper path

Clean the pressure roller

NO

YES

Toner Contaminations on Back of Paper

Page 17

Samsung Electronics 4-17

Troubleshooting

Is it not over

the guaranty life of dot

counter?

Replace the toner cartridge

NO

YES

YES

YES

Is toner cartridge

installed correctly?

Install the toner cartridge correctly

NO

Transfer roller

works properly?

Clean the TR holder, the TR gear,

OPC roller gear and the transfer roller

NO

- Clean the contact point of transfer roller

- Check the output of high voltage terminal

and adjust or replace if required

Partial Blank Image (not Periodic)

Page 18

4-18 Samsung Electronics

Troubleshooting

Is it not over

the guaranty life of dot

counter?

Replace the toner cartridge

NO

YES

YES

NO

NO

Is toner

cartridge installed

correctly?

Install the toner cartridge

correctly

NO

Is it regular

interval of 47.1mm?

Transfer roller

works properly?

OK after

replacing the transfer

roller?

Is it regular

interval of 75.4mm, 31.6mm

or 37.7mm?

Replace the fuser

(50.2mm, 45.2mm or exit roller

- Clean the contact point of

transfer roller.

- Check the output of high

voltage terminal and adjust or

replace if required.

Replace the toner cartidge

END

YES

YES

NO

YES

NO

YES

Clean the TR holder, the TR

gear OPC roller gear and the

transfer roller

Partial Blank Image (Periodic)

Page 19

Samsung Electronics 4-19

Troubleshooting

It is over the guaranty

life of toner cartridge

(Check the counter

and replace it)

Defective agitator in

the toner supplying part

of developer

->Replace the developer

Check if the ’guide deve

spring’ works OK and

repair/repalce

Check high voltage

output and repair/

replace terminals, HVPS

Irregualrity of toner

suppy from developer

-> Repalce developer

Light distortion due to

the mirror ruined or

LSU’s diffused reflection

-> Replace LSU

NO

NO

YES YES

YES

YES

NO NO

OK after

taking out and

rocking the toner

cartridge?

When gray

pattern printing,

irregular density

persists?

transfer/

charge/developing

voltage drops while

printing?

Bad images

aroung the no image

area?

Irregular Density

Page 20

4-20 Samsung Electronics

Troubleshooting

Is it regular

interval of 75.4mm?

Obstacles stuck on OPC’s

surface

-> Clean the OPC and

machine or replace

developer

When putting in/out the

developer, scratch is made

-> Replace the developer

Transfer

voltage is normal?

D/R in developing unit has

the defect

-> Replace the developer

Too high voltage supplied

due to the setting error of

transfer voltage

-> Adjust/replace HVPS

NO

NO

YES

YES

White Spot

Page 21

Samsung Electronics 4-21

Troubleshooting

When multi-page OHP printng,

less than 10 films are

guranteed.

Use the recommended film

When OHP

printing, does the fan

temporarily stops

and revolves?

Use the recommended film

Other parts are touching the

fan and prevents it from

revolution

-> Check and repair

NO

NO NO

YES

Set to OHP mode

NO

YES

YES YES

Is the OPC

mode selected using

the software

application?

Recommended

OHP film used?

Inserted over

than 10 films into

the MPF?

Trembling at the End When OHP Printing

Page 22

4-22 Samsung Electronics

Troubleshooting

After printing

completed, any error

related fuser?

Both ends

of thermostat

open?

Replace thermostat

and re-test

Replace the contol

component on engine

board

Check any contact

problem in thermistor

and repair

The machine

placed under the

severe low tempera

ture for a long

time?

Place the machine

at normal

temperature and

re-test

While printing,

the voltage of pin 208

of U5 (CPU) on Main

board is 2.0V

~2.3V?

Thermistor’s

contact is OK?

Open the top

cover. When black

printing, is the fuser NIP

width is 1.2~

3.0mm?

The paper used is too

thick or contains too

much cotton in it

-> Re-test with the

recommended paper

Check if the hardness of

P/R, and spring force is OK?

(spring’s force: 2.5 Kg)

Re-assemble

thermistor

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Poor Fusing Grade

Page 23

Samsung Electronics 4-23

Troubleshooting

Plug in the

power cord?

The power

voltage supplying is

the same as

rating?

The fan

revolves when

powered on?

LEDs blink

once when

powered on?

The On-Line

key is being pressed

or shortage on

the panel

board?

Repair/replace the

board

Check the voltage first and plug

the power cord

Supply the power as the rating

Connections

on board are OK?

Re-connect firmly

and re-test

The connection

error between

controller board

and panel board

or malfunction

of boards.

-> Replace the

boards

Fuse of SMPS

if open?

Shortage

between 5V and

GND, or between

24V and

GND?

Replace the fuse

Toner cartridge

is in the set?

Detect failure due to the

board which detects top

cover open or switch error

-> Replace the board or switch

Put in the

cartridge

Remove the shortage

or replace the board

NO

NO

NO

NO

NO

NO

NO NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

No Power (LED Off)

Page 24

4-24 Samsung Electronics

Troubleshooting

Less than 10W?

AC is being supplied?

The voltage

of pin #208 of U5

(CPU) on the Main board

is about 2.3V when

printing?

END

Thermostat is open due to the heat etc.

-> Replace the thermostat

Check the PCI and fusing

control part and CN502

on the SMPS

-> Replace the component

or replace the SMPS

Measure the resistance

at the both ends of AC

Line with covers open

Remove the covers

Re-assemble the top

cover and close it

Thermistor, connecting point or engine

board defect -> Repair/replace the

component/board

NO

NO

NO

YES

YES

YES

Fuser Error

Page 25

Samsung Electronics 4-25

Troubleshooting

Sounds the

solenoid on when starts

print?

Does the

paper move?

Does the

paper move more than

100mm?

The Engine board defected

-> Replace boards

The solenoid defected

-> Replace it

The pick-up unit is

assembled wrong

-> Re-assemble or replace

the unit

Feeder

sensor and paper

width detect sensor

are assembled

reverse?

Switch them

The Sensor board

defected

-> Repair/replace

Too many

papers in the

feeder?

Paper guides

fit the paper width?

Paper end curled?

Does the

extender pulled out?

<Recommendation>

Use the MPF for the thick

paper such as envelope

and cardstock

Reduce the amount

and re-test

Take out the paper

and re-insert

Use the recommended

and quality paper

Pull out the

extender

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES YES

Paper Jam (Mis-feeding)

Page 26

4-26 Samsung Electronics

Troubleshooting

Paper

stopped before

the OPC?

Check the LSU and

if it has the defect

replace it

Paper

stopped before

the fuser?

Severe skew

when feeding?

Adjust the paper guides to fit the

paper width

The force of springs pressing the

developer is weak

-> Check guide-DEVE

The paper

came out through

between fuser and

developer?

Too thin

or sensitive paper to

static electricity?

Use the recommended

paper

Check guide transfer

is grounded Check

the shutter prevents

feeding

Check the input path

to the fuser (such as

mis-assembly)

The

actuator of

paper exit sensor

works OK?

Check the actuator exists and its

operation and around the engine board

-> Replace

Is the paper

rolled around the

presseure

roller?

Remove the fuser, remove

the paper and replace the

pressure roller, if necessary

Feeds

multiple pages?

Remove any factors

Check the roller

and ribs of fuser

are in place, and

remove burrs, if

any

-> Remove the

factors of jam

NO NO NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

Paper Jam (Jam1)

Page 27

Samsung Electronics 4-27

Troubleshooting

Try again to connector

or

Replace connector

END

NO

Check

CBF Harness28P

(MAIN B’D to ENGINE

B’D)

YES

Check

MAIN B’D CN9-6,

HSYNC Signal

( )

Replace LSU

NO

YES

Check

MAIN B’D CN9-3,

P_MOTOR Signal

( )

Replace MAIN B’D

NO

YES

Check

MAIN B’D CN9-4,

LREDADY Signal

( )

Replace LSU

NO

YES

Check

MAIN B’D CN9-9,

LDON Signal

( )

Replace MAIN B’D

NO

YES

LSU Error

Page 28

4-28 Samsung Electronics

Troubleshooting

Memo

Loading...

Loading...