SERVICE

LASER PRINTER

ML-4500/XEV

SAMSUNG

Manual

LASER PRINTER CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Electrical Parts List

7. Block Diagrams

8. Connection Diagrams

9. PCB Diagrams

10.Schematic Dagrams

ELECTRONICS

© Samsung Electronics Co.,Ltd. February 2001

Printed in Korea.

VERSION NO. : 1.00 P/N.: JC-0046A

1. Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

1. Be sure that all built-in protective devices are in

place. Restore any missing protective shields.

2. Make sure there are no cabinet openings through

which people- particularly children- might insert

fingers or objects and contact dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or electrical

design of this equipment, such as auxiliary

connectors, etc. Such alterations and

modifications will void the manufacturer’s

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-ofplace, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they provide could be

lost if a replacement component differs from the

original. This holds true, even though the

replacement may be rated for higher voltage,

wattage, etc.

Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. A replacement part that

does not have the same safety characteristics as

the original may create shock, fire, or other safety

hazards.

Samsung Electronics 1-1

1-2 Samsung Electronics

Precautions

1-2 ESD Precautions

Certain semiconductor devices can be easily

damaged by static electricity. Such components are

commonly called “Electrostatically Sensitive (ES)

Devices”, or ESDs. Examples of typical ESDs are:

integrated circuits, some field effect transistors, and

semiconductor “chip” components.

The techniques outlined below should be followed

to help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body

by touching a known earth ground. Alternatively,

employ a commercially available wrist strap

device, which should be removed for your personal

safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder

or desolder ESDs.

4. Use only an “anti-static” solder removal device.

Some solder removal devices not classified as

“anti-static” can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective

shorting material from the leads of a replacement

ESD, touch the protective material to the chassis

or circuit assembly into which the device will be

installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal motions,

such as the brushing together of clothing fabric

and lifting one’s foot from a carpeted floor, can

generate static electricity sufficient to damage an

ESD.

1. Exercise caution when replacing a super

capacitor or Lithium battery. There could be a

danger of explosion and subsequent operator

injury and/or equipment damage if incorrectly

installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Super capacitor or Lithium batteries contain toxic

substances and should not be opened, crushed,

or burned for disposal.

1-3 Super Capacitor or Lithium Battery Precautions

2. Specification

2-1 Printer

Print Speed 8 PPM (Letter Size, 5% Charcter Pattern) At Copy Mode

Resolution 600 X 600 DPI

Source of Light Laser Diode(LSU)

Print Method Non-impact Electrophotography, Laser Beam

Feed Method Multi-Purpose Feeder and Manual

Feed Reference Center Reference Loading

Paper Size Bin Type

Normal Paper : A4,Letter,Legal,B5,

Executive, A5

Envelope : Normal Envelope

Length : 149 ~ 365mm

Width : 100 ~ 216mm

Weight : For MPF, 60 ~ 90g/m

2

For Manual, 60 ~163g/m

2

Paper Capacity MPF : 150 Sheets (based on 75g/m2)

Manual Slot : 1 Sheet

Paper Stacker Capacity Face up : 100 Sheets (75g/m2,20 lb)

Warming up Time 30 Sec

First Printing Time Stand-By : 20Sec

Power Save Mode :Less than 5min

Power Rating AC 110V ~120V ± 15% 50/60Hz ± 3Hz,

AC 220V ~ 240V ± 15% 50/60Hz ± 3Hz

Power Consumption Avg. 180Wh

Power Saving Consumption Avg. 10Wh Sleep Mode

Certification & Compliance FCC, C-UL, CE, CB,TUV

Acoustic Noise Stand-by : Less than 35dB

Sleep Mode : Less than 29dB

Operating : Less than 50dB

Samsung Electronics 2-1

2-2 Samsung Electronics

Toner Cartridge One-Cartridge type

Expected Life Span 50,000 Sheets

Operating Environment Temperature : 10 ~ 32°C

Humidity : 20 ~ 85%

Storage Environment Temperature : -20 ~ 40°C

Humidity : 10 ~ 95%RH

Weight Net : Max.6.5kg(with Accessory)

Gross : Max. 9kg

External Dimension 329(W) X 343(D) x 224(H)mm

Developer . Life Span : 5% Pattern,Min. 2,500/1,000 Sheets

. Developing : Non-magnetic

Contact Developing

. Charging : Conductive Roller Charging

. Density Adjustment : Normal/Economic Mode selectable by the

PC driver (Only ML-4500)

. Toner Supply Method : Exchanging

Toner Cartridge

. New Developer Checkable

. Transfer System : Conductive Roller Transfer

. Fusing System : Temperature & Pressure

. OZONE Emission : Max. 0.1 PPM(8 Hours)

Specification

Samsung Electronics 2-3

Specification

2-2 Quality

Conditions

Paper Normal Paper 75g/m

2

Environment Temperature : 20 ~ 25°C

Humidity : 40 ~ 60%

Print Quality

Image Density Min. 1.3

Min. 1.0(Temperature : 10 ~ 15°C)

Background Max. 0.2

Uniformity Max. 0.2(Including Continuous Print)

Fusing Min. 80% (All Black) 75g/m

2

Start Position Top : x ± 4.23mm, Side : y ± 4mm From Left

Skew Top : Max. ± 1.5mm/117.9mm

Side : Max. ±1.8mm/241.3mm

Orthogonality ± 1.0mm

Horizontal Scan ± 0.6mm/208mm

(Bowed Line Skew : Pattern 1)

Special Paper Exception Image Density : Min 1.0 (Envelope)

Fusing : Min. 70% (All Black)

(Envelope/OHP/Postcard)

Paper Jam Less than 1/1,000(75g/m2Paper)

Paper Curl First : Less than 10mm (10 Sheets, 75g/m2Paper)

After Cooling : Less than 10mm (10 Sheets, 75g/m2Paper)

Reliability

Insulation Resistance Less than 10 MΩ (at DC 500V)

Dielectric Strength AC 1000V (DC 1420V), 10mA

Ground Continuity Less than 0.1Ω

Voltage DIP Rated Voltage ± 15%

AC Impulse Noise AC 1000V 10, 100, 200, 400, 1000ns Rated Power

Leakage Current Less than 3.5mA

Surge 6 KV, 500A/3 KV, 500A

OZONE Emission Less than 0.1 ppm (8 Hours)

Top Cover Open Isolating the input power of the LSU,

High Voltage Part, and Fuser

Overcurrent Protect Fuse inside the SMPS

Fusing System

Trouble Sensing .The temperature doesn’t rise to the specific

temperature in the specific time.

.The temperature is too high.

Overheat Sensing 240 ~ 250°C (The thermostat cuts off the Fuser

from the power.)

Thermistor Open Sensing : Without the initial

temperature change of the Fuser

Indicate the

Fuser error

2-4 Samsung Electronics

Specification

2-3 SMPS (Switching Mode Power Supply)

Input (AC)

AC Input Voltage Europe USA

Minimum 198V 90V

Typical 230V 120V

Maximum 264V 135V

Max. AC Input Current 2.5Amps 3Amps

Max. Inrush Current Ap-p (at 20°C)

Output (DC)

Line Regulation 24V ± 10%

5V ± 5%

Road Regulation 24V ± 10%

5V ± 5%,-5V ± 5%

Ripple Noise 24V : Peak 300mV

-5V : Peak 500mV

5V : Peak 500mV

Over Current Protect 24V : 2.7A ± 10% (by Circuit)

5V : A ± 10% (by Circuit)

Over Voltage Protect 24V : 33VDC

5V : 5.6VDC

3-1Samsung Electronics

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of

cables to moving parts makes proper routing a must. If components are removed, any cables disturbed by the

procedure must be restored as close as possible to their original positions. Before removing any component

from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Remove the print cartridge. Do not expose the cartridge to direct room light or sun light, and be careful not

to scratch the drum surface.

2. Turn the power switch off.

3. Unplug all the cables from the printer.

4. Replace with only an authorized component.

5. Do not force to open or fasten a plastic material component.

6. Be careful no obstacles are included when you reassemble components.

7. When you reassemble components, be careful small size components are located in place.

8. If you turn the machine over to replace some parts, toner or paper particles may contaminate the LSU window. Protect the LSU window with clean paper.

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them carefully. To remove such parts, press the hook end of

the latch away from the part to which it is latched.

Disassembly and Reassembly

3-2 Samsung Electronics

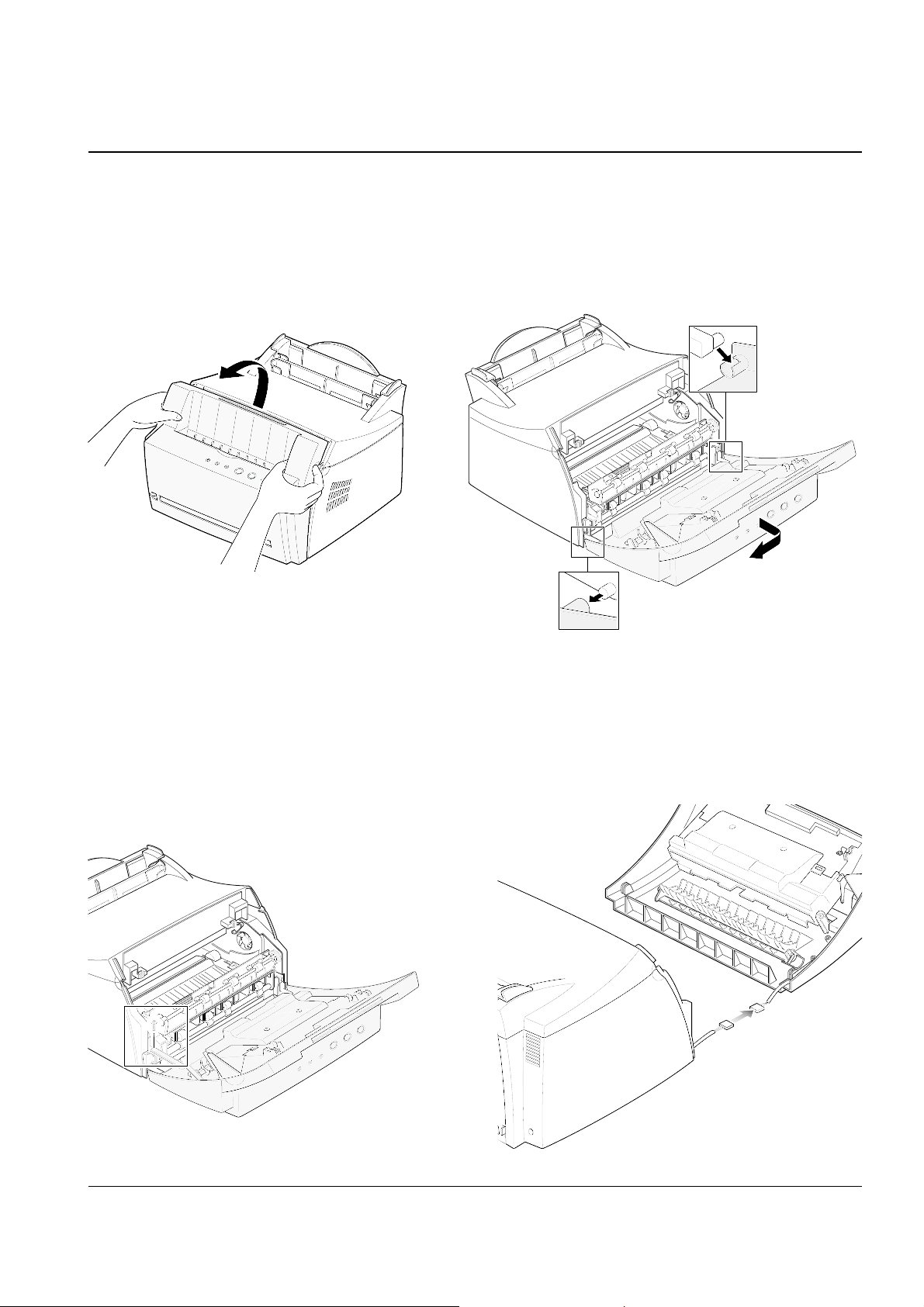

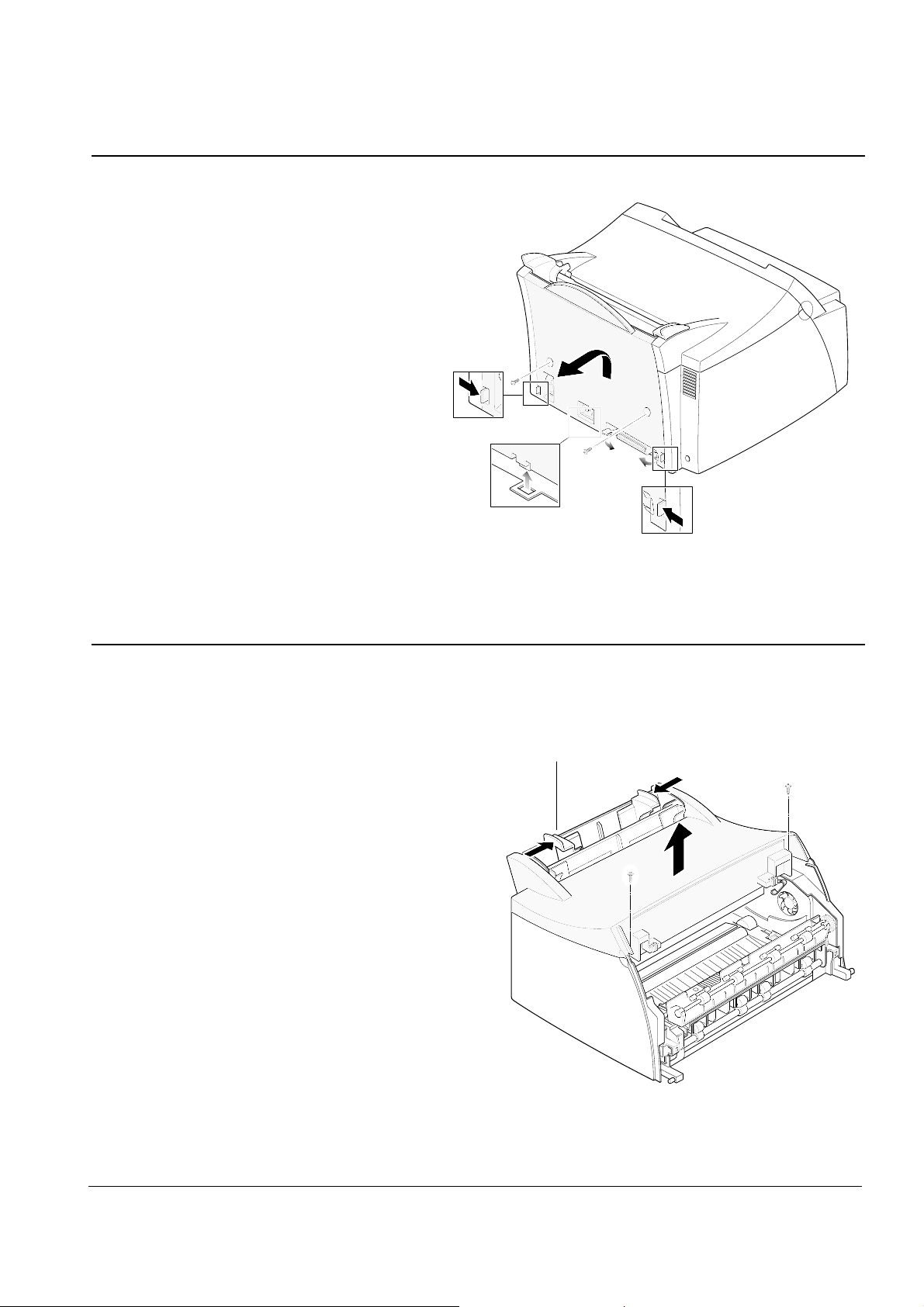

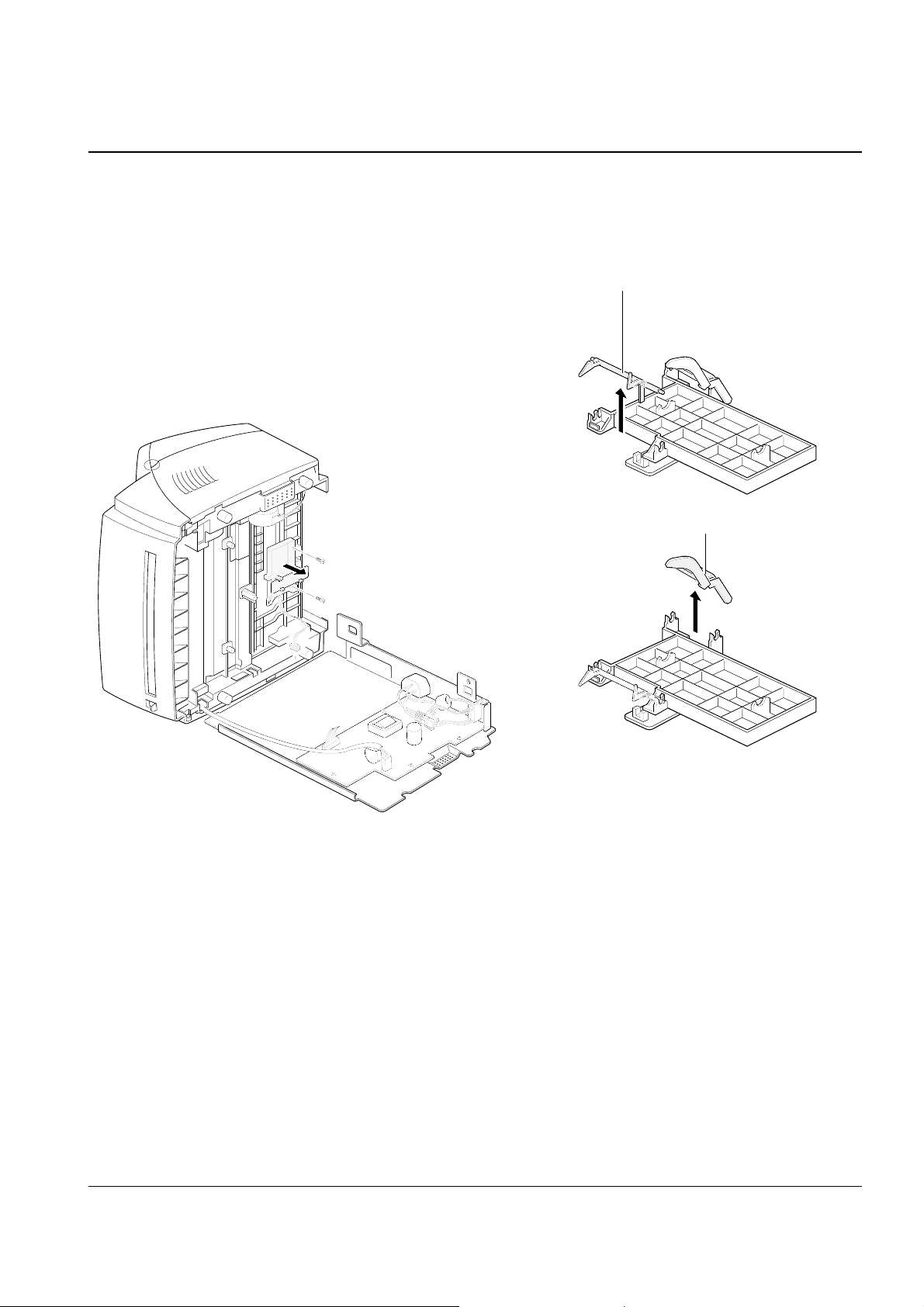

3-2 OPE Cover

1. Hold both sides of the cover and pull it towards

you.

3. Release the right-bottom of the cover, then pull it

in the direction of arrow to release the other end.

2. Remove the one screw to release the stopper

securing the cover to the main body.

4. Unplug the connector connecting the OPE cover

to the main body and remove the cover.

Disassembly and Reassembly

3-3Samsung Electronics

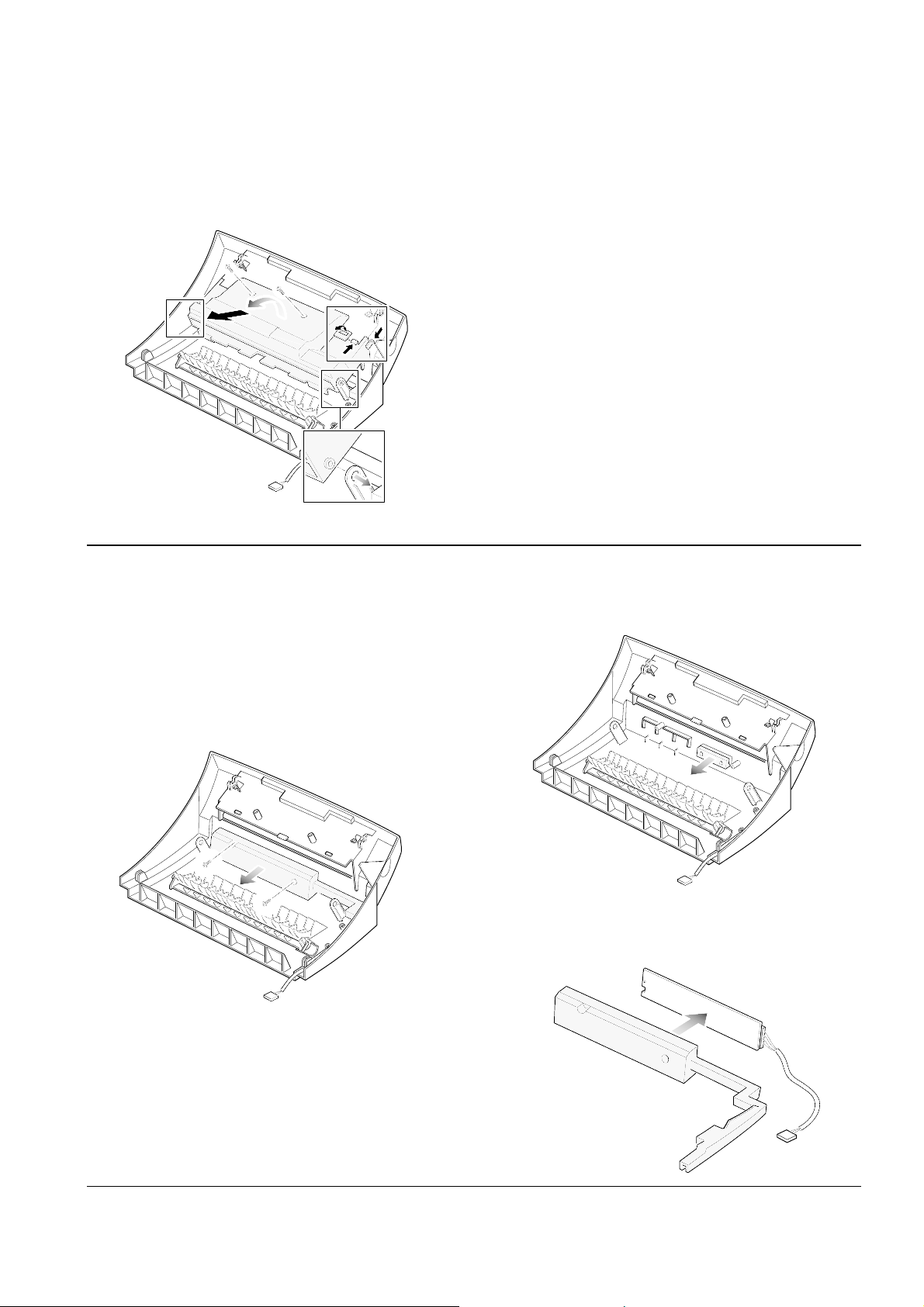

5. Remove the two screws and pull the guide stacker in the direction of arrow. Then Spread out the

parts securing the guide stacker on both sides to

release the cover.

3. Remove the LED.

4. Remove the PCB from the cover PCB.

3-3 OPE Board

1. Before you remove the board, you should

remove the OPE cover (see page 3-2).

2. Remove the three screws, then remove the cover

PCB.

Disassembly and Reassembly

3-4 Samsung Electronics

3-4 Rear Cover

1. Remove the two screws on the back of the

machine.

2. Pull the handles on both sides in the direction of

the arrows then lift the rear cover to unlatch it

from the bottom, then remove the cover.

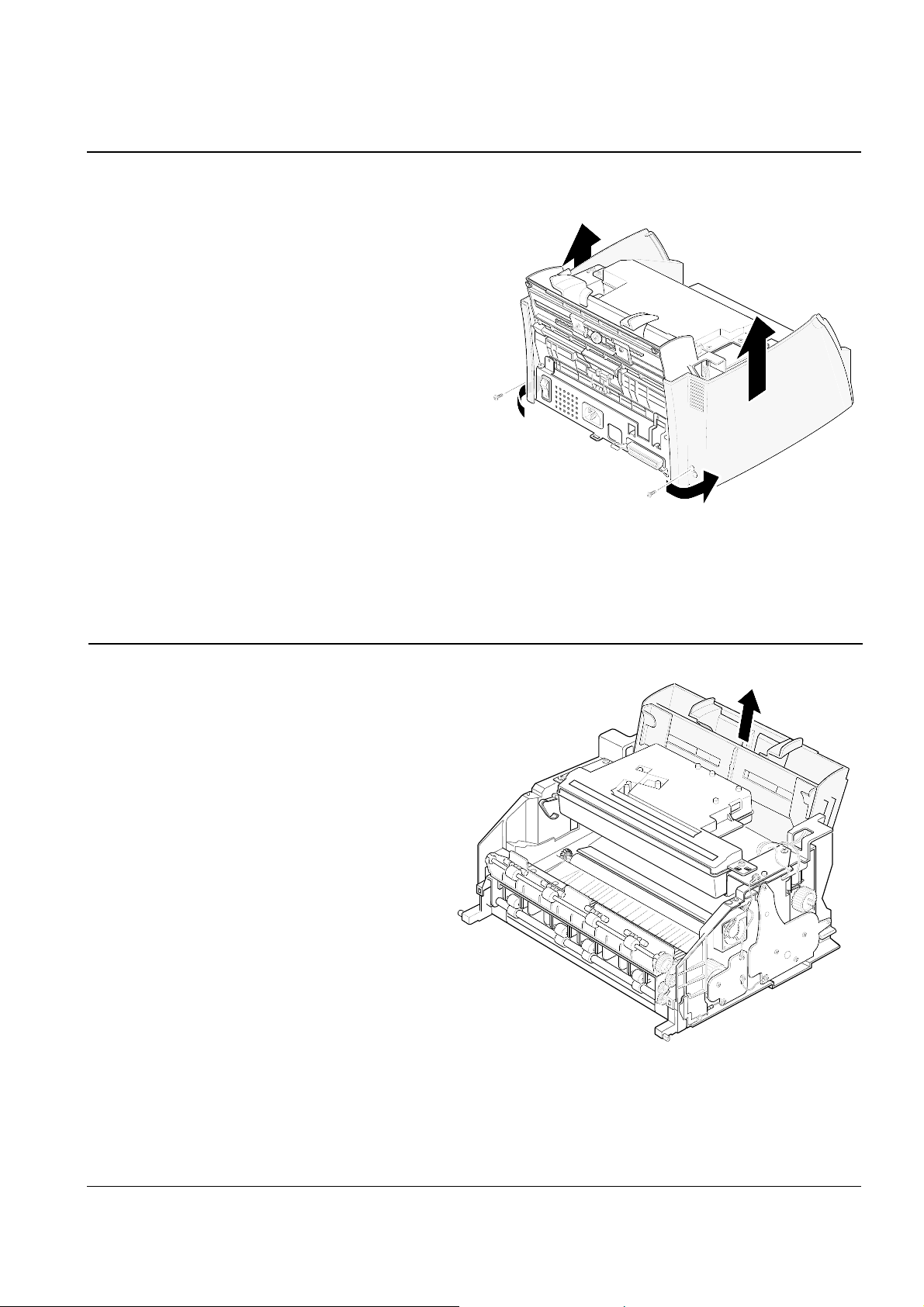

3-5 Top Cover

1. Before you remove the top cover, you should

remove:

– OPE cover (see page 3-2)

– Rear cover (see above)

2. Slide the paper guide on the paper tray inwards.

Remove the two screws on the top cover, then

remove the cover.

Paper guides

Disassembly and Reassembly

3-5Samsung Electronics

3-7 Paper Tray

1. Before you remove the paper tray, you should

remove:

– OPE cover (see page 3-2)

– Rear cover (see page 3-4)

– Top cover (see page 3-4)

– Side covers (see above)

2. Take out the tray from the main frame.

3-6 Side covers (R, L)

1. Before you remove the top cover, you

should remove:

– OPE cover (see page 3-2)

– Rear cover (see page 3-4)

– Top cover (see page 3-4).

2. Remove the two screws and pull the left and right side

covers in the direction of arrow.

Disassembly and Reassembly

3-6 Samsung Electronics

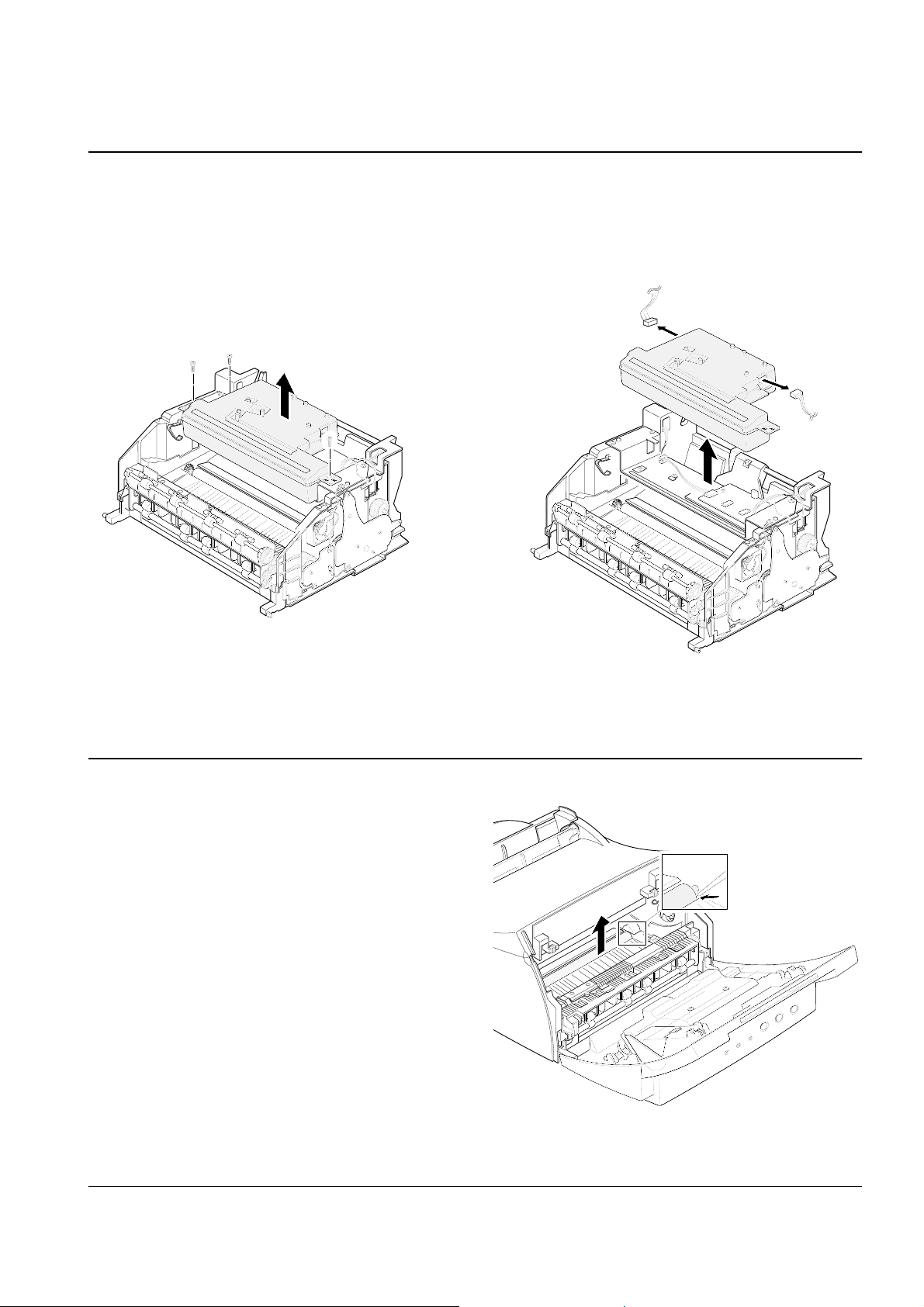

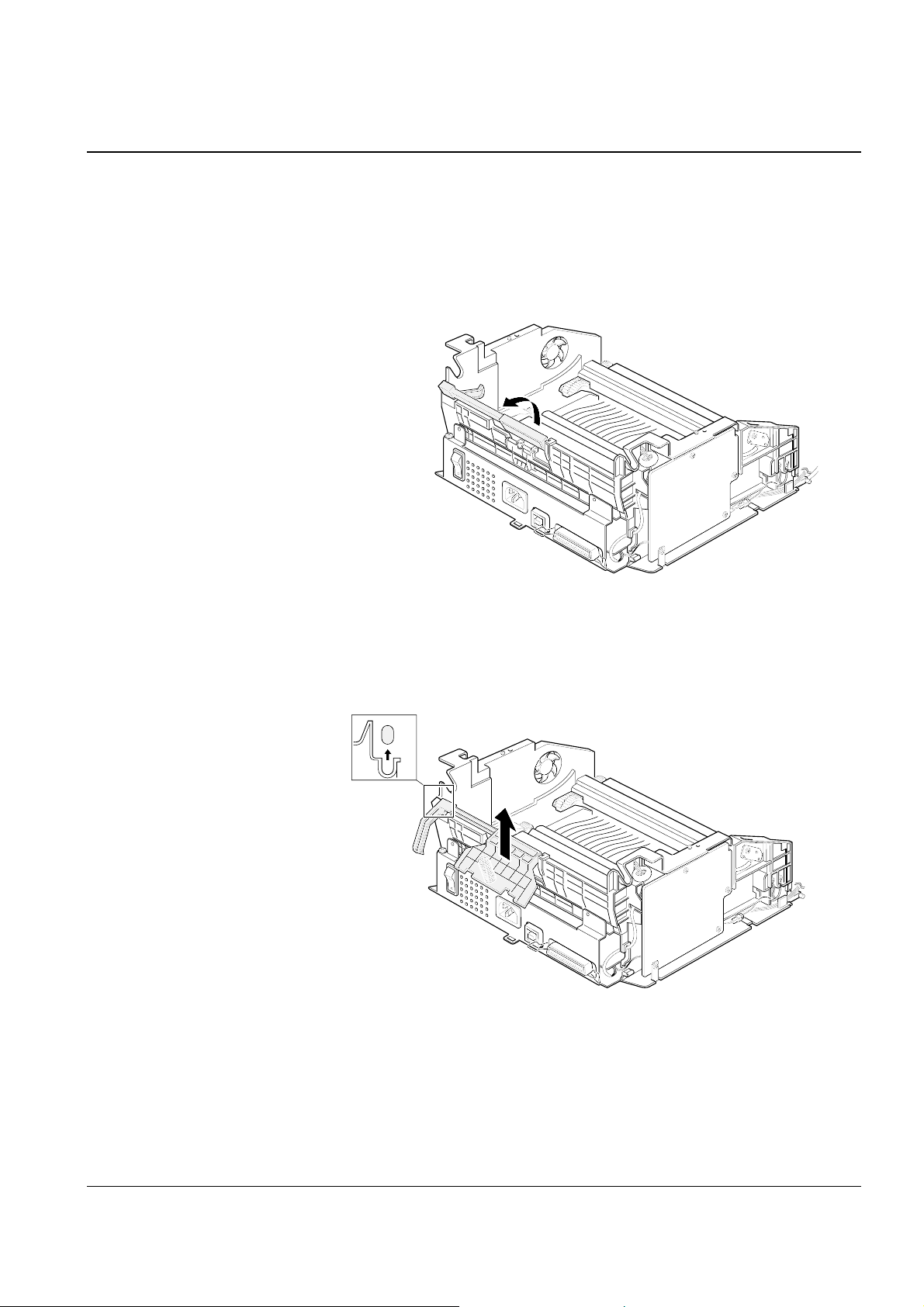

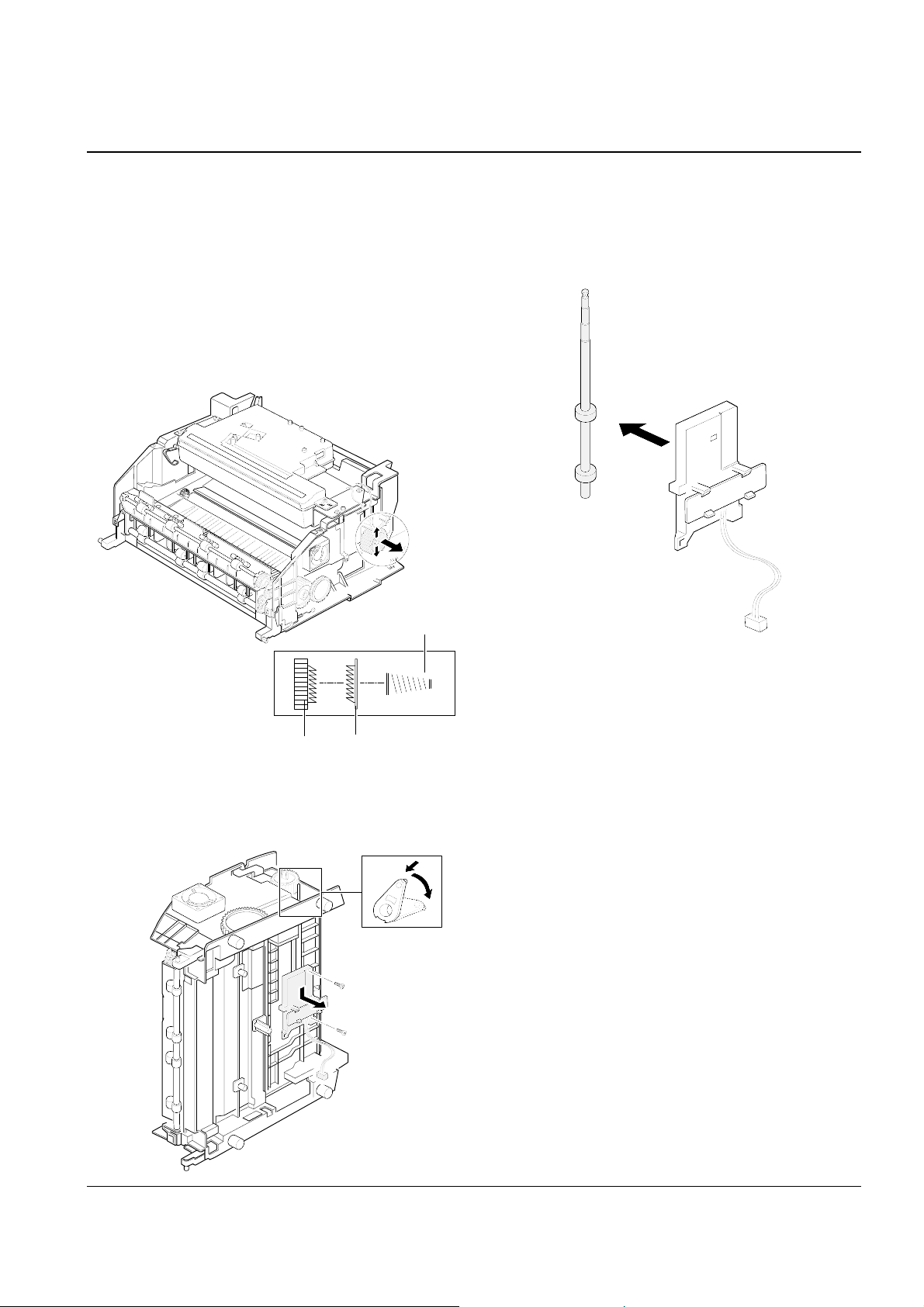

3-8 LSU

1. Before you remove the LSU, you should remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Remove the three screws securing the LSU.

3-9 Transfer Roller

1. Open the front cover.

2. Lift the transfer roller using a proper tool as

shown in the figure and take out the roller.

3. Unplug two connectors from the LSU and

remove the LSU.

Disassembly and Reassembly

3-7Samsung Electronics

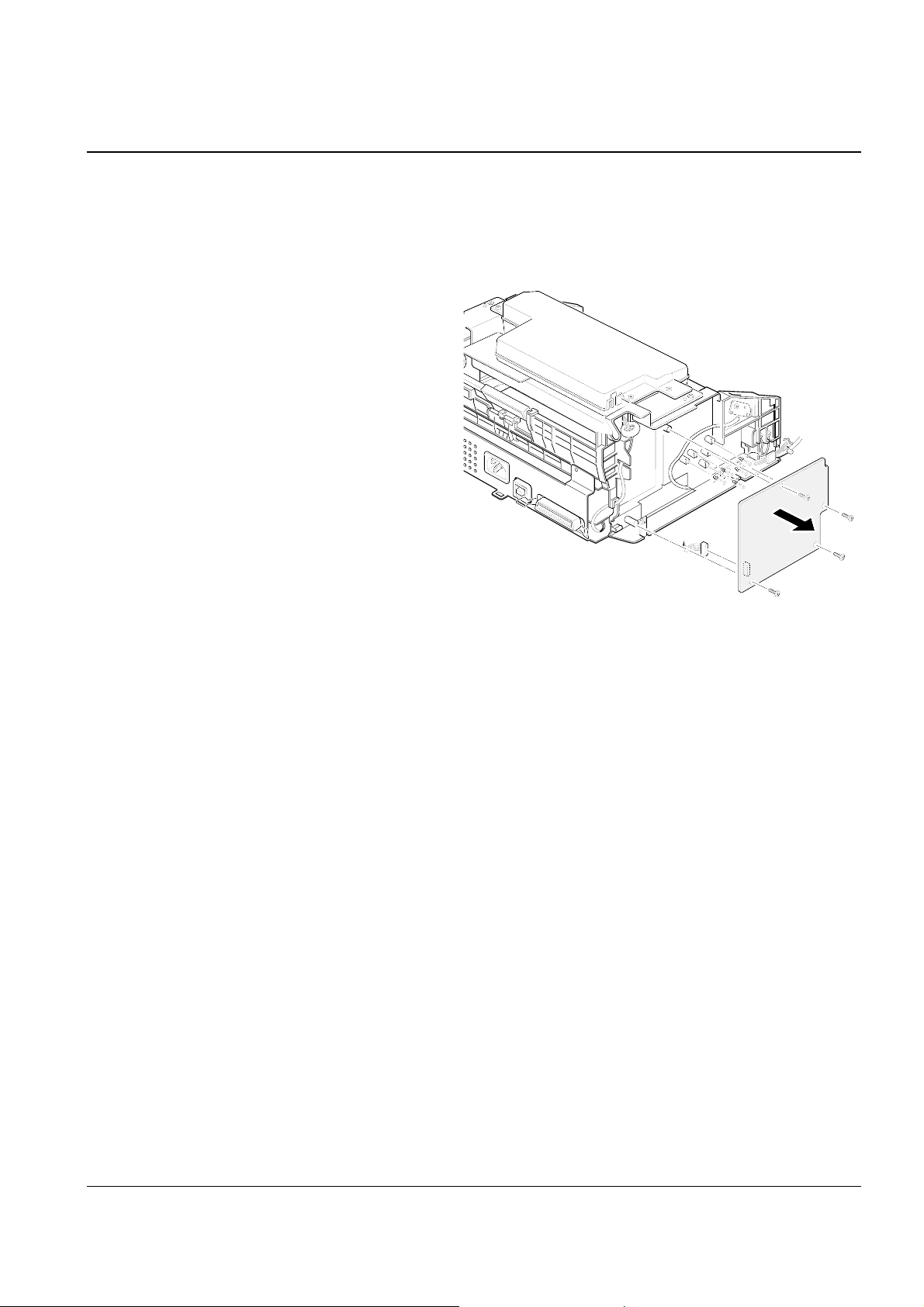

3-10 Engine Board

1. Before you remove the engine board, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– LSU (see page 3-6)

2. Unplug the four connectors and remove the two

screws from the engine board, then pull the

board in the direction of arrow.

3. Remove the Insulator which was under the

engine board.

Disassembly and Reassembly

3-8 Samsung Electronics

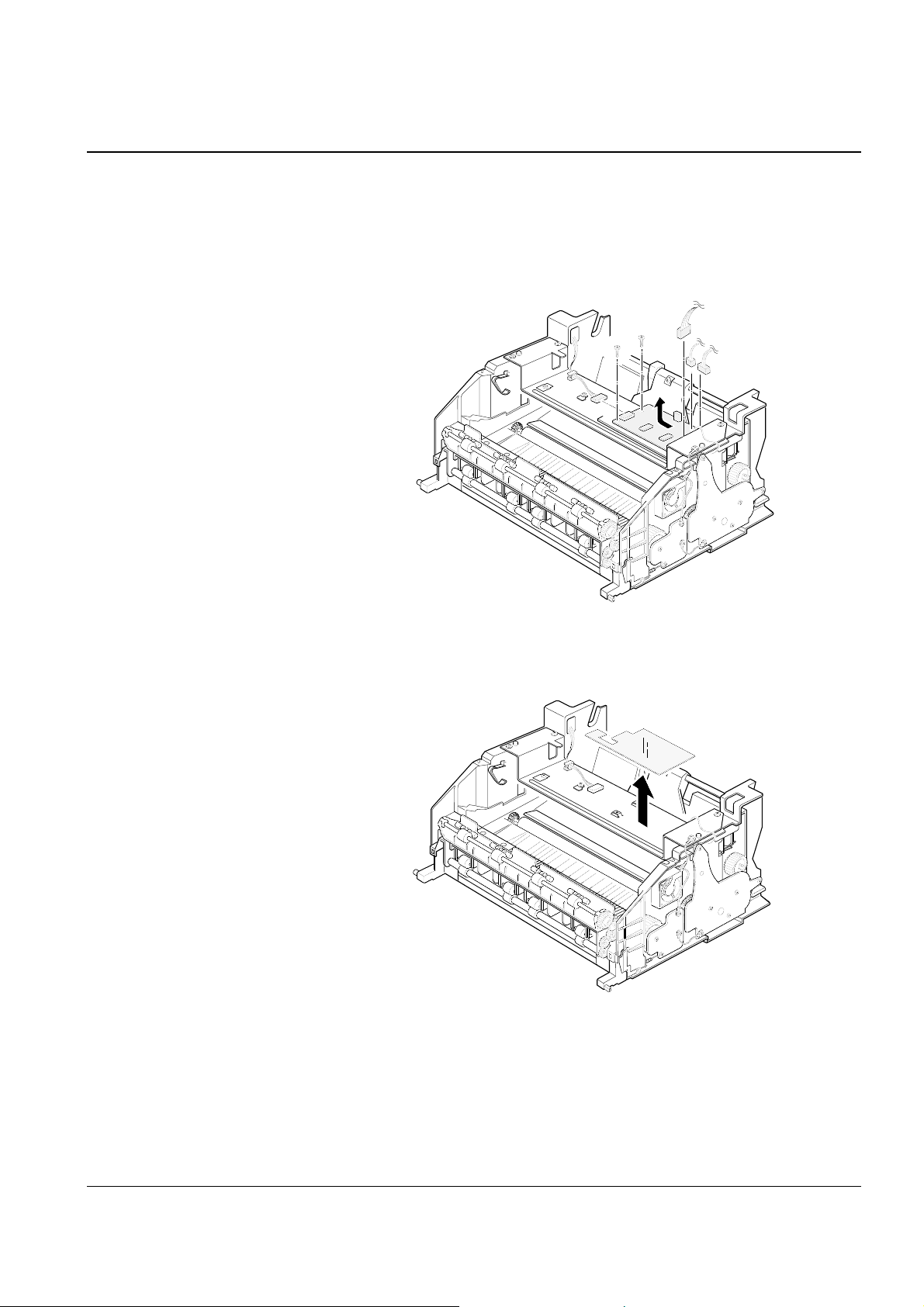

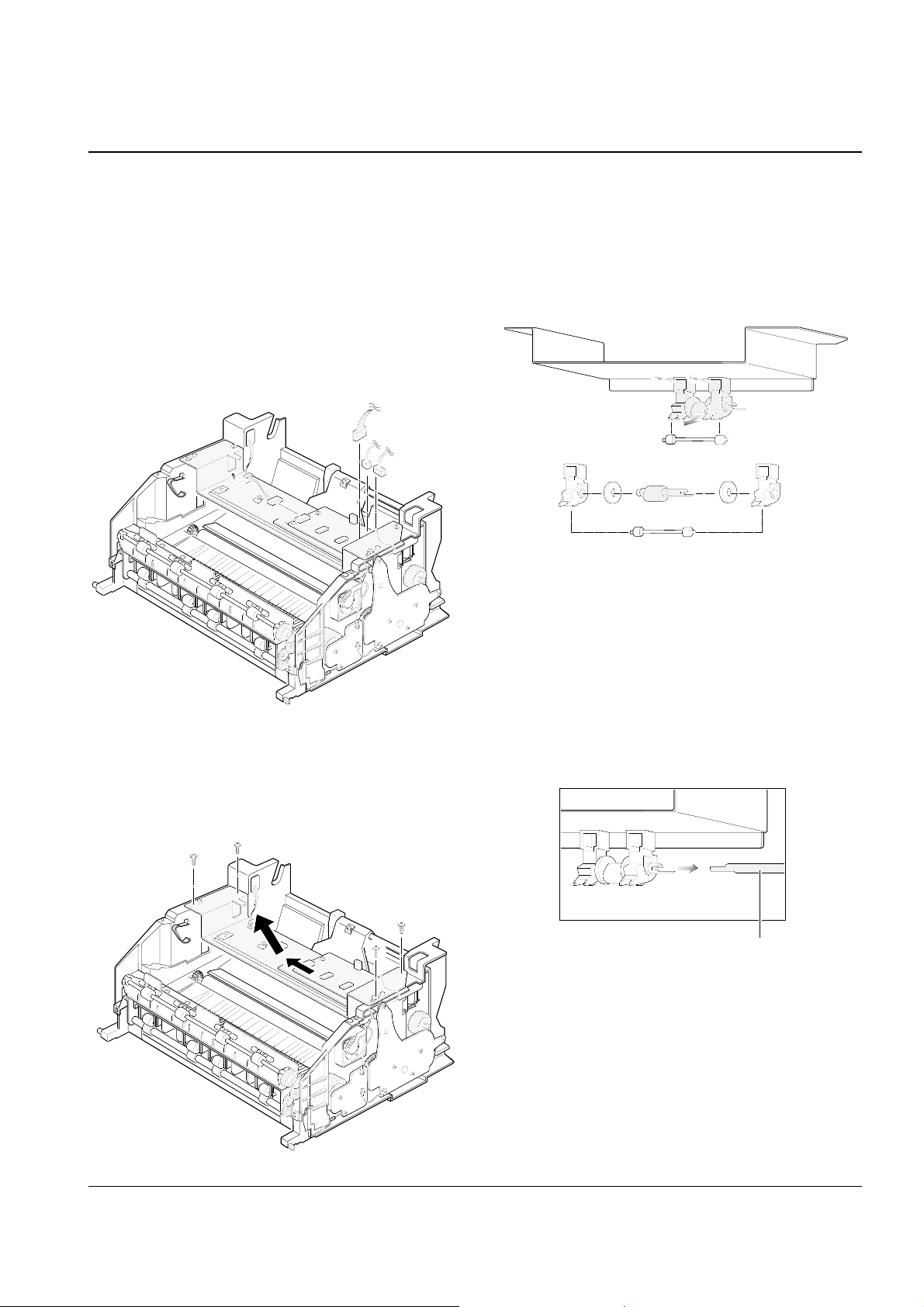

3-11 Pick-up Roller ass’y

1. Before you remove the pick-up roller ass’y,

you should remove:

– All covers (see page 3-2, 3-4, 3-5)

– LSU (see page 3-6)

2. Unplug all the connectors from the engine board.

3. Remove the four screws securing the plate and

remove the plate as shown below.

4. Remove the two screws and remove the roller

from the plate.

Note: When you reassemble the pick-up roller,

make sure that the right end of the pick-up

roller fits into the pick-up gear shaft.

Pick-up gear

shaft

Disassembly and Reassembly

3-9Samsung Electronics

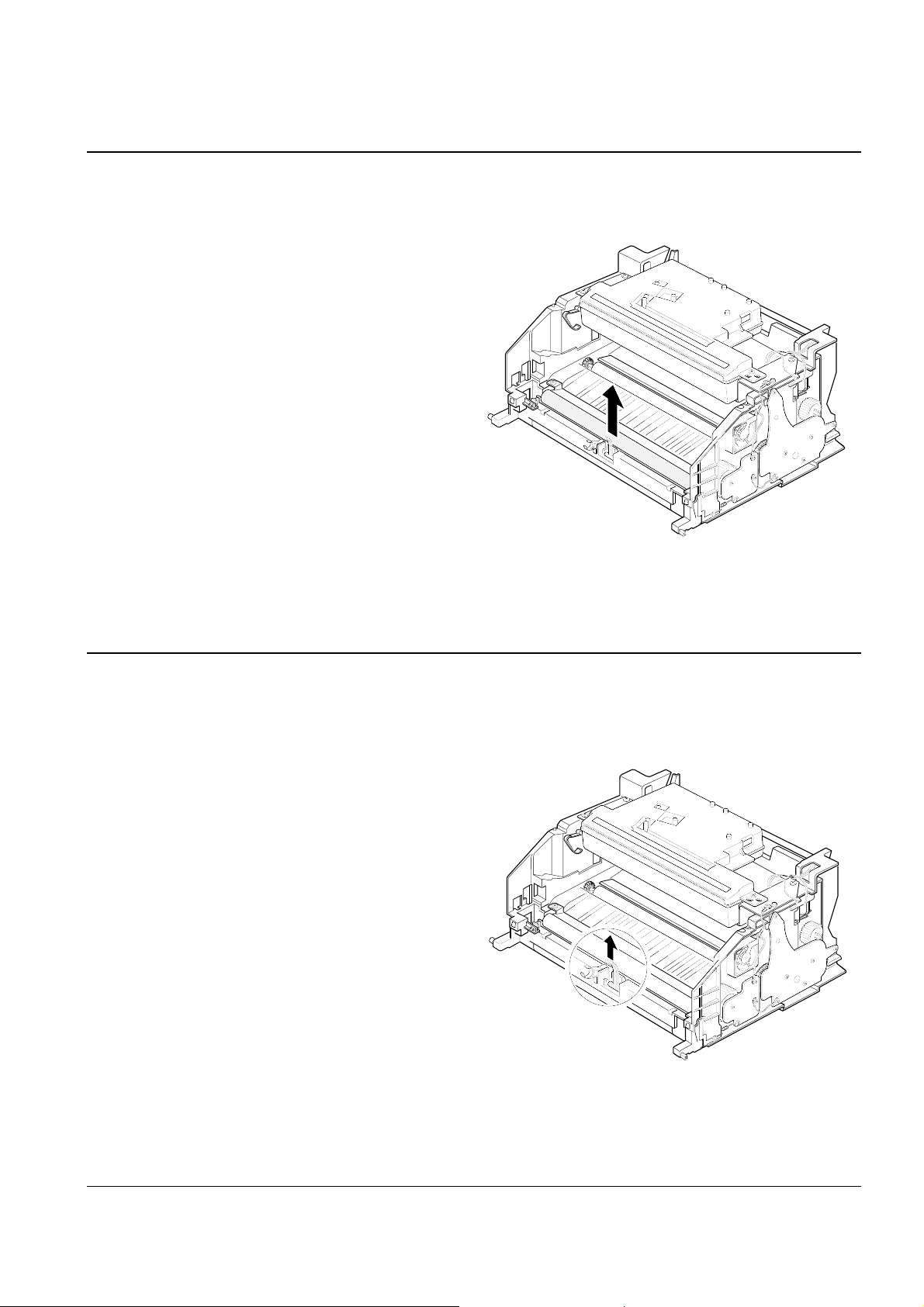

3-12 Knock-up ass’y

1. Before you remove the knock-up ass’y, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– LSU (see page 3-6)

– Plate in the pick-up roller ass’y (see page 3-8)

2. Pull the knock-up ass’y fully backward.

3. Remove the knock-up ass’y from the main frame.

Make sure it is properly unlatched.

Disassembly and Reassembly

3-10 Samsung Electronics

3-13 Cap-pad

1. Before you remove the cap-pad, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– LSU (see page 3-6)

– Plate in the pick-up roller ass’y (see page 3-8)

– Knock-up ass’y (see page 3-10)

2. Take out the cap-pad from the main frame.

3-14 Holder-pad

1. Before you remove the holder-pad, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– LSU (see page 3-6)

– Plate in the pick-up roller ass’y (see page 3-8)

– Knock-up ass’y (see page 3-10)

2. Remove the holder-pad from the main frame.

Disassembly and Reassembly

3-11Samsung Electronics

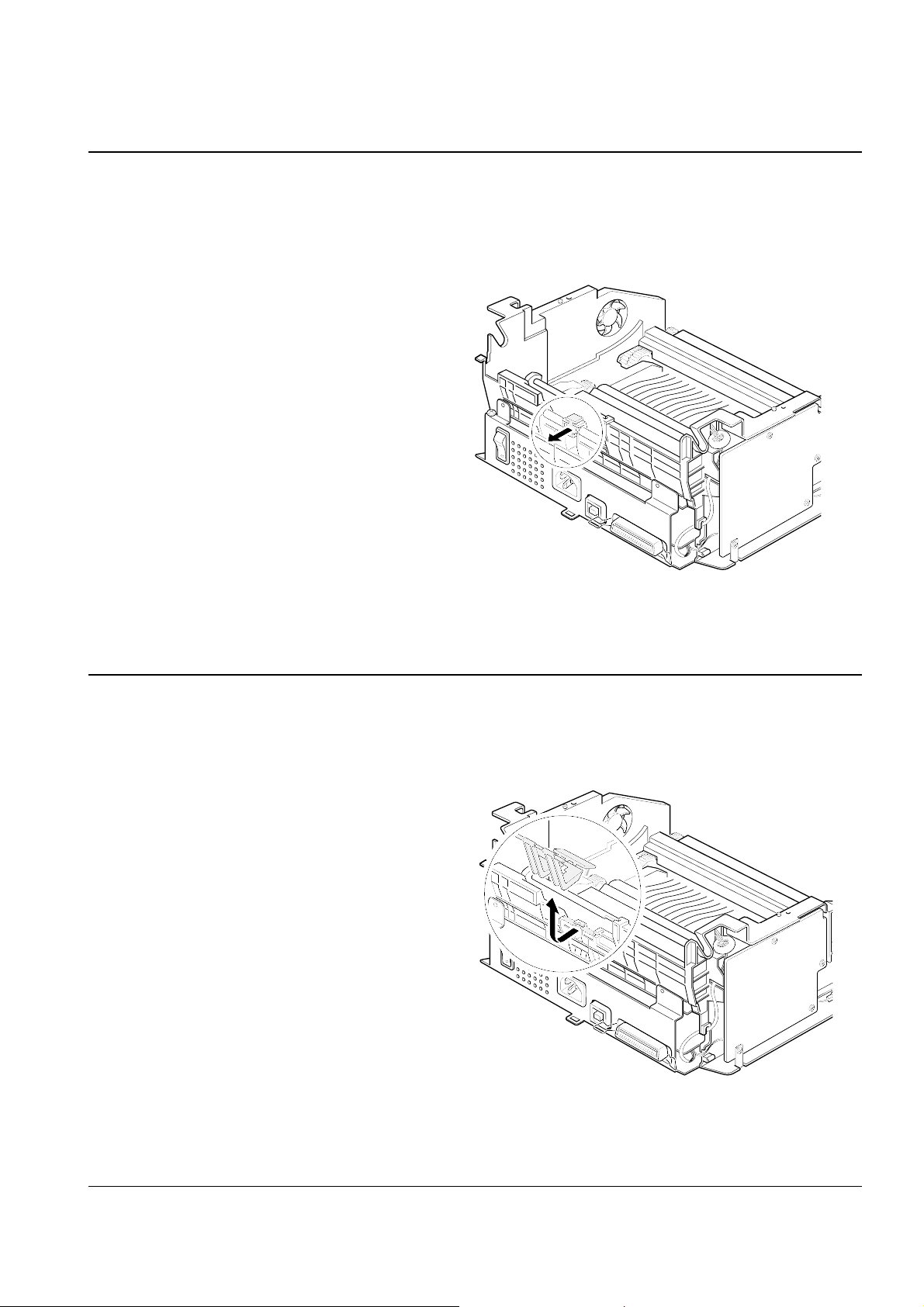

3-15 Motor ass’y

1. Before you remove the motor ass’y, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Remove the three screws securing the motor

ass’y and unplug one connector from the engine

board, then remove the motor ass’y.

3-16 Fan

1. Before you remove the fan, you should remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Unplug the one connector on the fan from the

engine board, remove the one screw, then

remove the fan.

Disassembly and Reassembly

3-12 Samsung Electronics

3-17 Gear Pick-up ass’y

1. Before you remove the gear pick-up ass’y, you

should remove:

– All covers (see page 3-2, 3-4, 3-5)

Note: When you reassemble the gear, make sure

that the direction of the gear is correct.

2. Spread out the two snap-fits on the gear to

release the gear, then remove the gear pick-up

ass’y from the main frame.

3-18 Solenoid

1. Before you remove the solenoid, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Unplug the connector on the solenoid from the

engine board, remove the one screw, then

remove the solenoid.

Disassembly and Reassembly

3-13Samsung Electronics

3-19 HVPS Board

1. Before you remove the HVPS board, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Remove three three screws and the connector

from the HVPS board, then remove the board.

Note: when you reassemble the board, make sure

that the five terminals are correctly inserted in

place.

Disassembly and Reassembly

3-14 Samsung Electronics

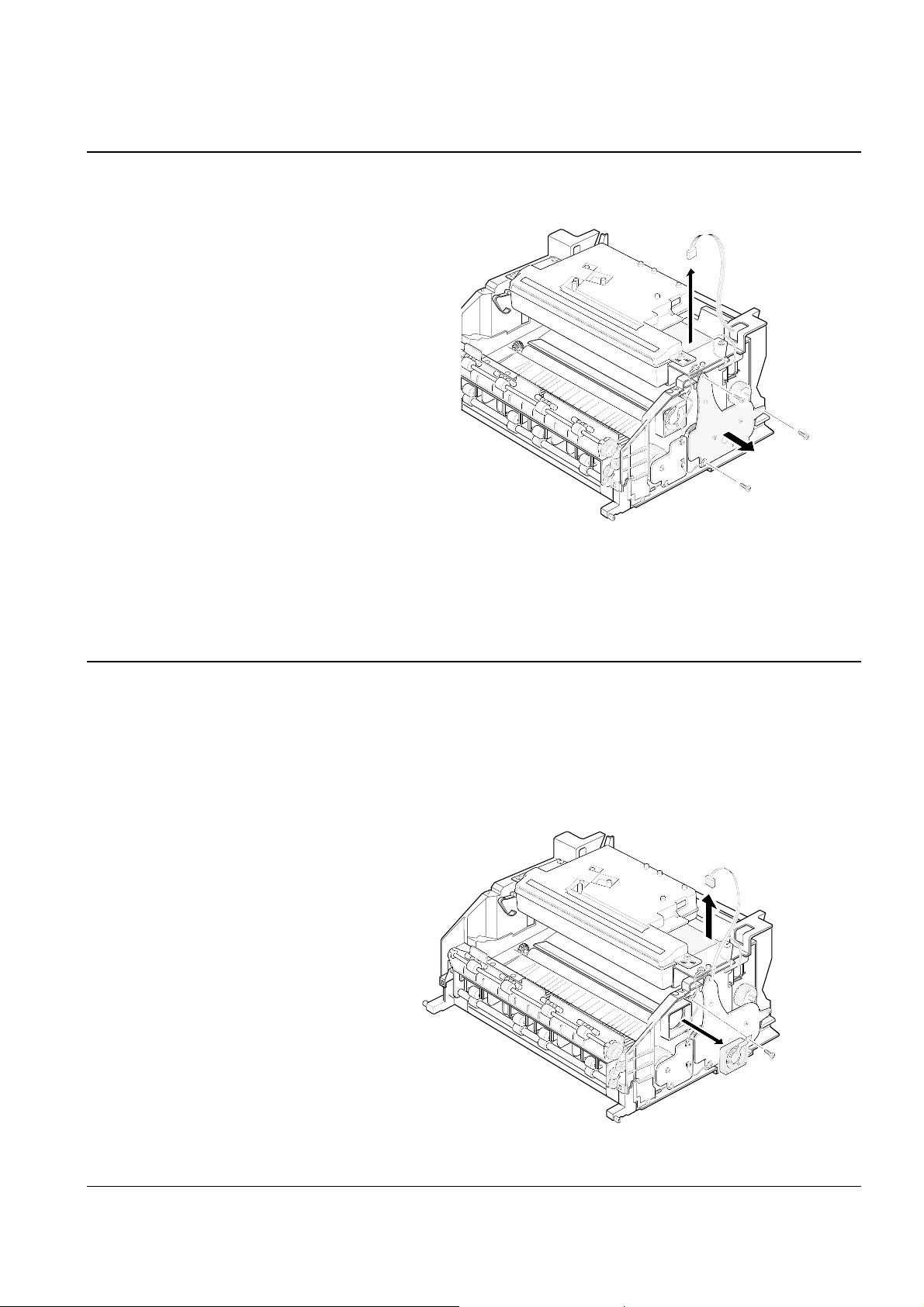

3-20 Fuser ass’y

1. Before you remove the fuser ass’y, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

2. Remove the two ground screws and unplug the

one connector as shown in the figure.

3. Remove the one screw and unlatch the fuser

ass’y using a proper tool as shown in the figure,

then remove the fuser ass’y.

Disassembly and Reassembly

3-15Samsung Electronics

3-21 Pressure Roller

1. Before you remove the pressure roller, you

should remove:

– All covers (see page 3-2, 3-4, 3-5)

– Fuser ass’y (see page 3-15)

2. Lift and remove the pressure roller from the

main frame.

3-22 Actuator-exit

1. Before you remove the actuator-exit, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– Fuser ass’y (see page 3-15)

2. Lift and remove the actuator-exit from the main

frame.

Disassembly and Reassembly

3-16 Samsung Electronics

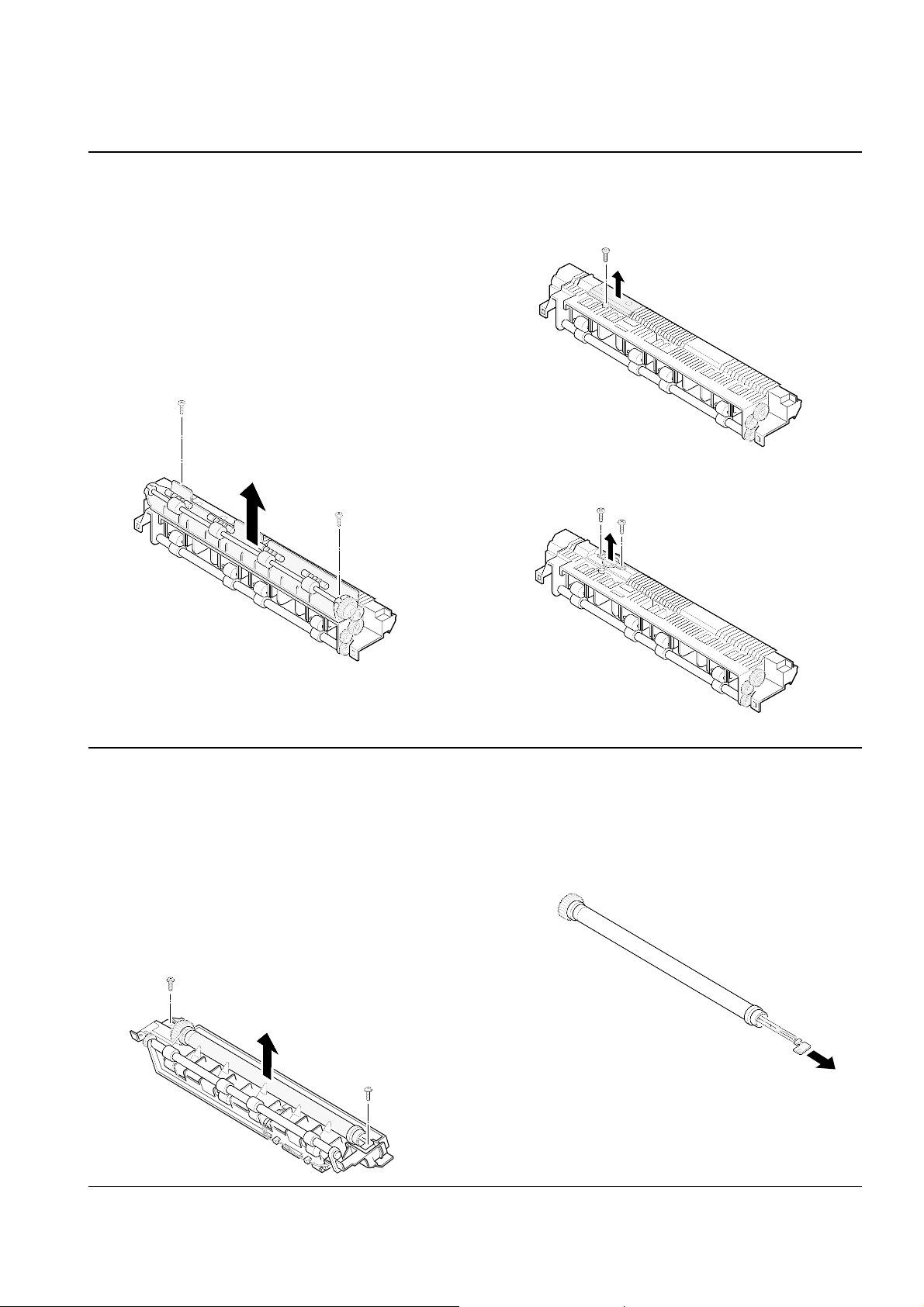

3-23 Thermostat

1. Before you remove the thermostat, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– Fuser ass’y (see page 3-15)

2. Remove the two screw securing the face up and

remove the face up.

4. Remove the two screws and take out thermostat

from the fuser ass’y.

3. Remove the halogen lamp from the heat roller.

3-24 Halogen Lamp

1. Before you remove the thermostat, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– Fuser ass’y (see page 3-15)

2. On the fuser ass’y, remove the two screws, then

remove the heat roller.

3. On the fuser ass’y, remove the one screw, then

remove the thermostat cover.

Disassembly and Reassembly

3-17Samsung Electronics

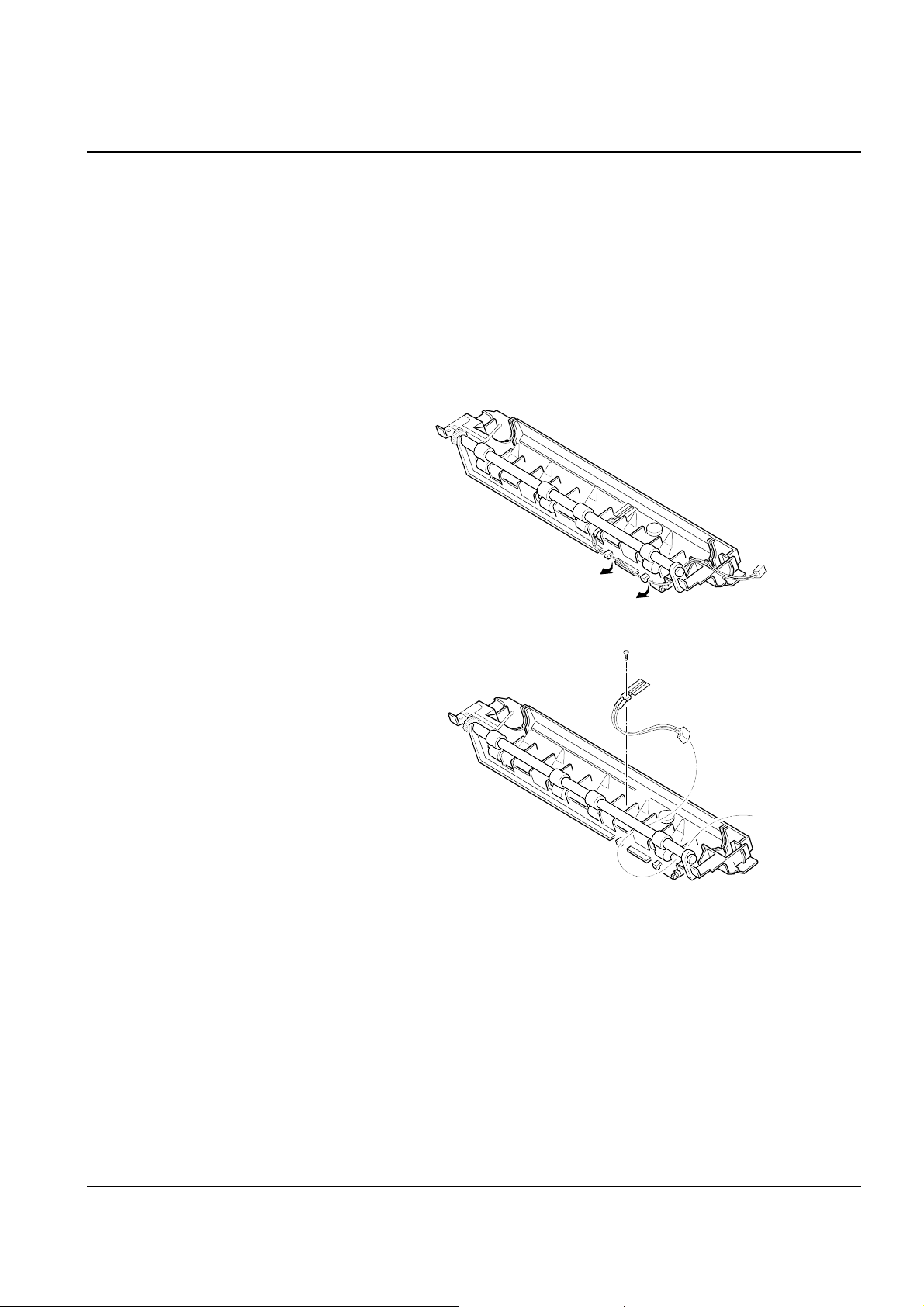

3-25 Thermistor

1. Before you remove the thermister, you should remove:

– All covers (see page 3-2, 3-4, 3-5)

– Fuser ass’y (see page 3-15)

2. On the fuser ass’y, remove the heat roller as described

on page 3-17.

3. Unwrap the thermister wire as shown in the figure.

4. Remove the one screw, then remove the thermister.

Disassembly and Reassembly

3-18 Samsung Electronics

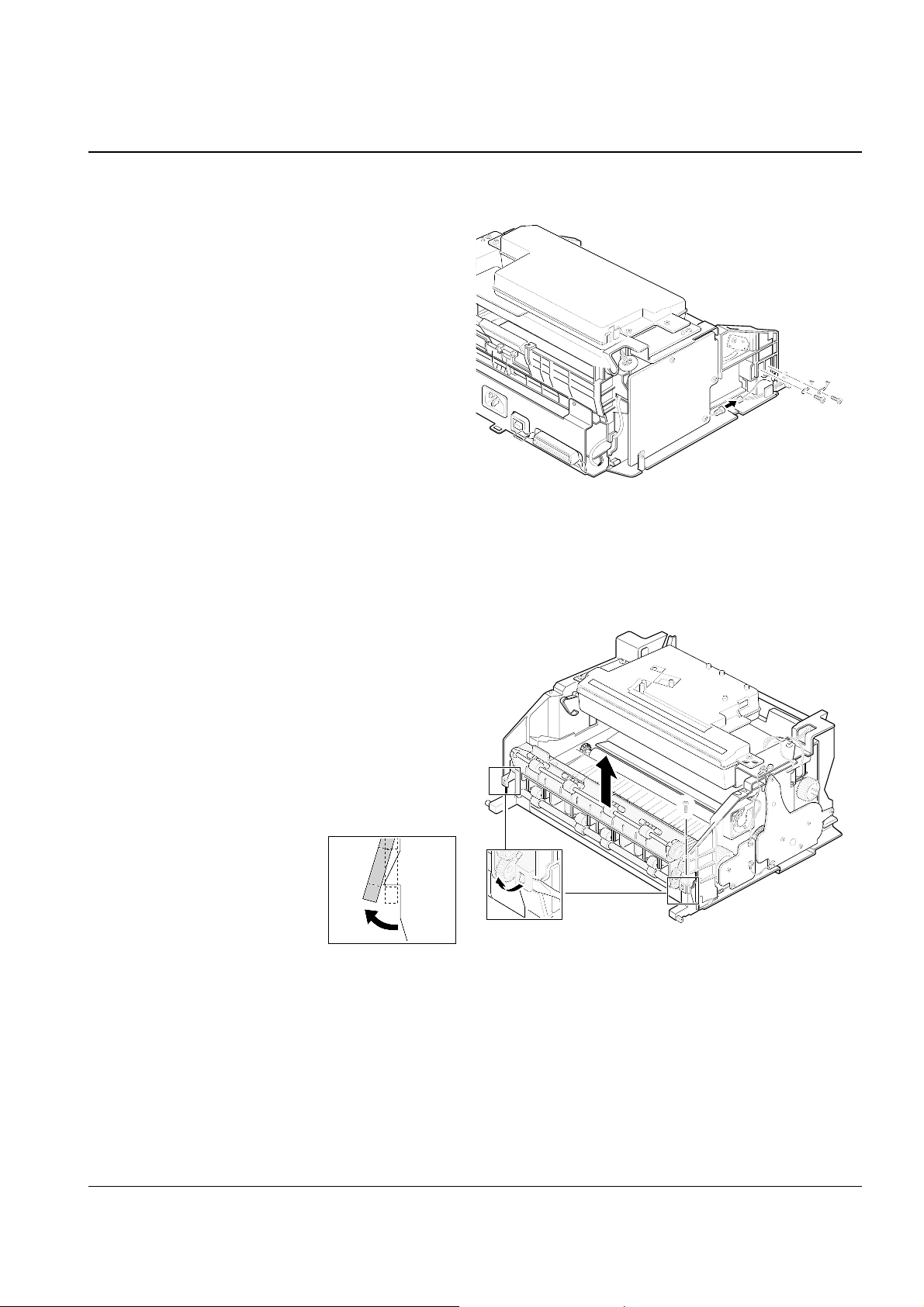

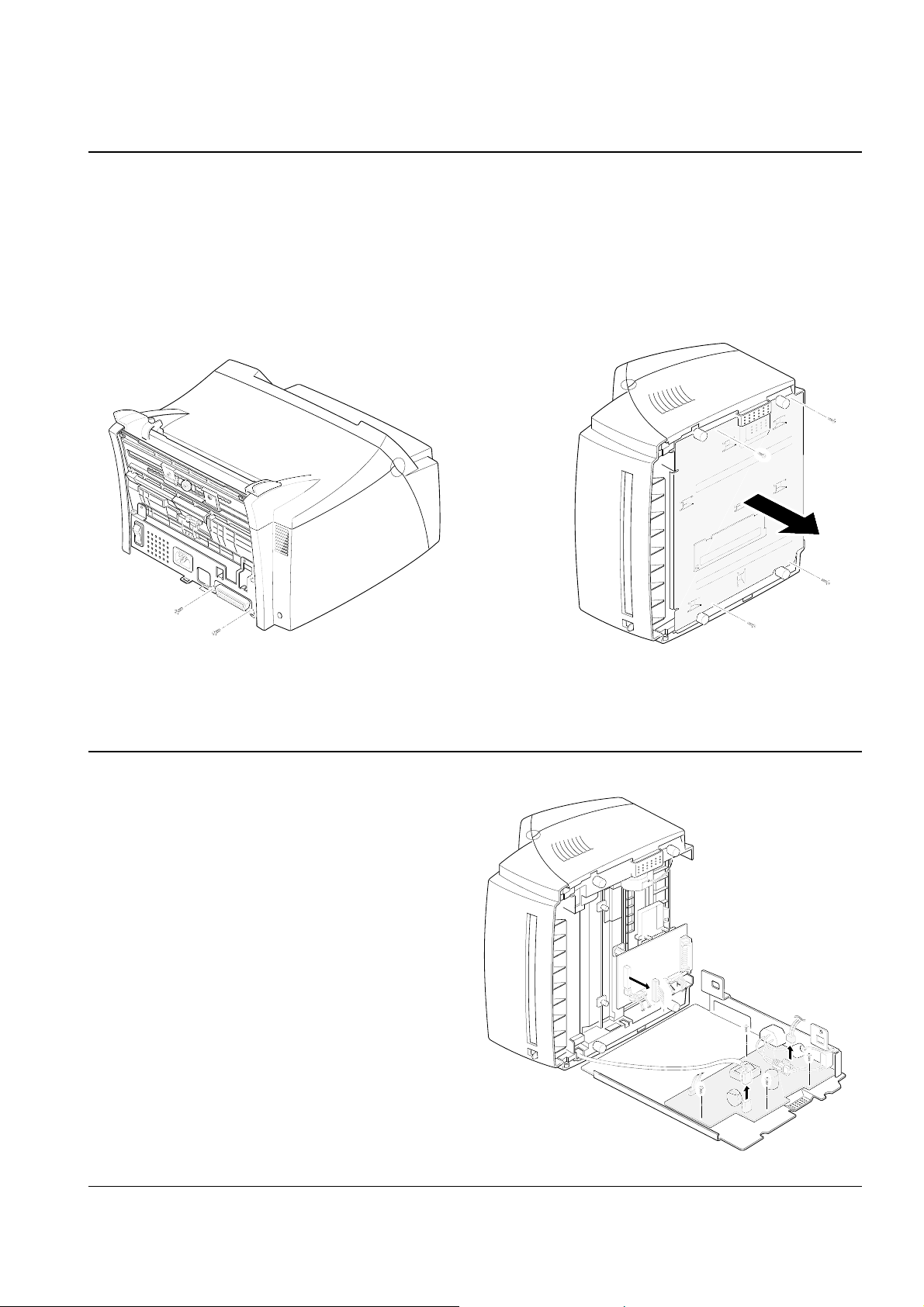

3-26 Shield Engine ass’y

1. Before you remove the shield engine ass’y, you

should remove:

– Rear cover (see page 3-4)

2. Remove the two screws.

3. Remove the four screws securing the shield

engine ass’y and remove the shield engine ass’y

from the main frame.

3-27 SMPS Board

1. Before you remove the SMPS board, you should

remove:

– Rear cover (see page 3-4)

– Shield engine ass’y (see above)

2. Remove the four screws and on the SMPS board,

unplug the two connectors from the SMPS board

and the one connector from the main board, then

remove the SMPS board.

Disassembly and Reassembly

3-19Samsung Electronics

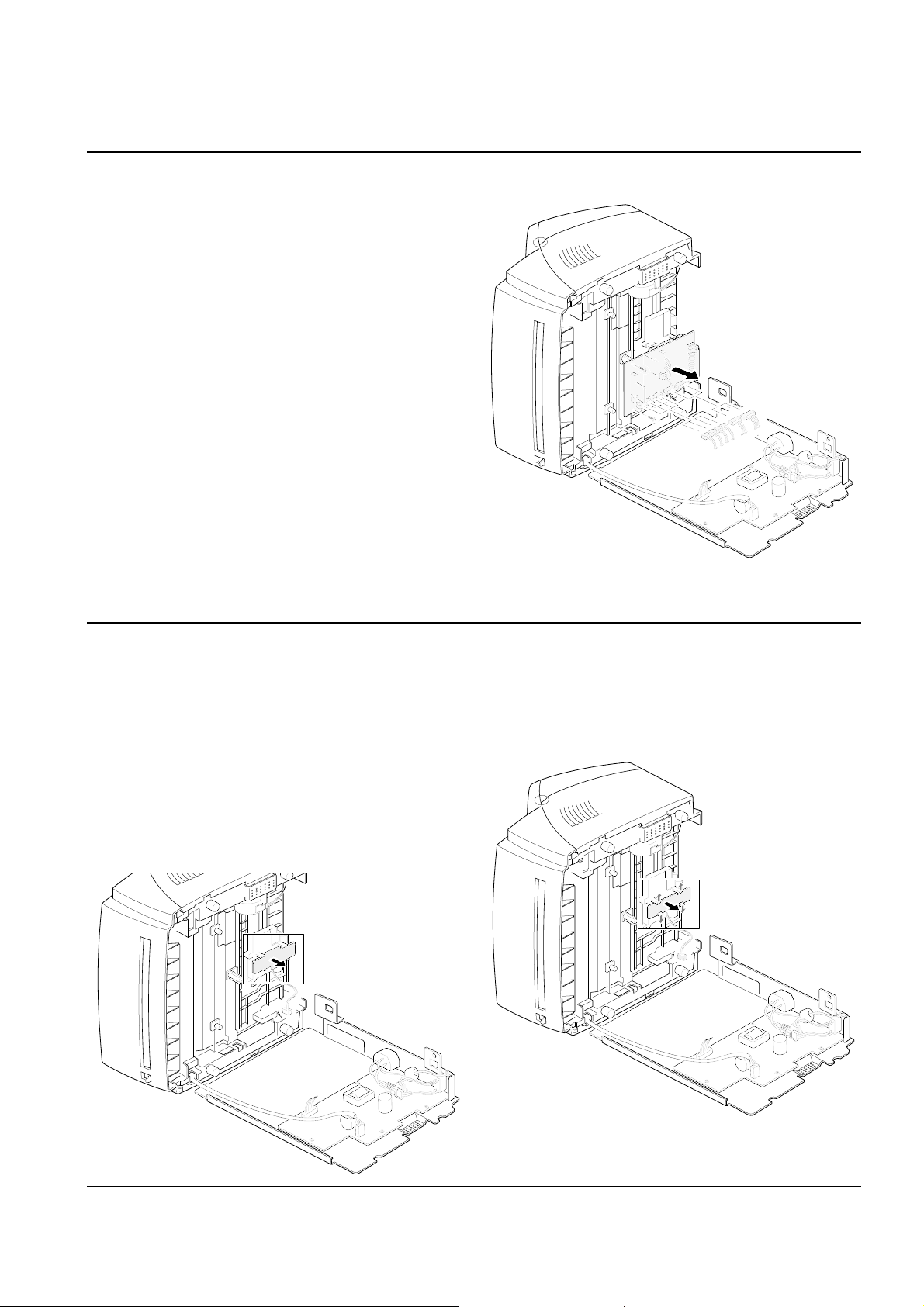

3-28 Main Board

1. Before you remove the main board, you should

remove:

– Rear cover (see page 3-4)

– Shield engine ass’y (see page 3-19)

2. Remove the two screws unplug and all the connectors from the main board, then remove the

board.

3-29 Sensor Board

1. Before you remove the sensor board, you should

remove:

– Rear cover (see page 3-4)

– Shield engine ass’y (see page 3-19)

2. Release four snap-fits securing the insulator

engine board and remove the insulator engine

board.

3. Release four snap-fits securing the sensor board,

then remove the sensor board.

Disassembly and Reassembly

3-20 Samsung Electronics

Feed sensor

Empty sensor

3-30 Feed Sensor and Empty Sensor

1. Before you remove these parts, you should

remove:

– Rear cover (see page 3-4)

– Shield engine ass’y (see page 3-19)

2. Unplug the one connector from the main board

and remove the two screws securing the holder

feed ass’y, then remove the holder feeder ass’y.

3. Remove the feed sensor and the empty sensor.

Disassembly and Reassembly

3-21Samsung Electronics

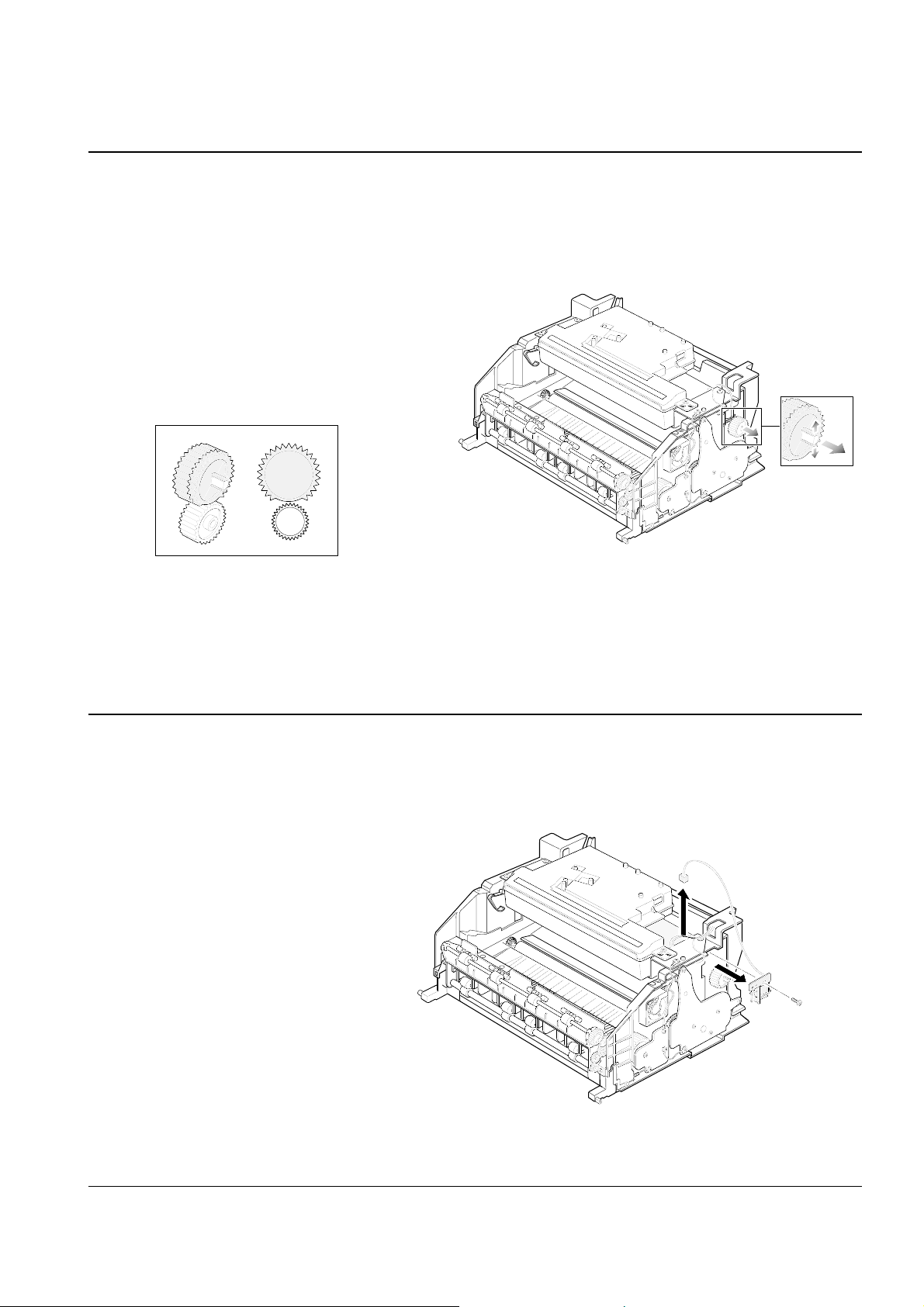

Gear-feed

Clutch-feed

Spring-clutch

3-31 Feed Roller

1. Before you remove the roller, you should

remove:

– All covers (see page 3-2, 3-4, 3-5)

– Motor ass’y (see page 3-12)

2. Spread out the two snap-fits on the gear to

release the gear, then remove gear-feed, springclutch and clutch-feed from the gear.

3. Remove the feed roller from the holder.

3. Rotate the pick-up bushing in the direction of

arrow, then remove the the feed roller ass’y.

Disassembly and Reassembly

3-22 Samsung Electronics

MEMO