Page 1

MonoLaserPrinter

ML-3750ND

MANUAL

SERVICE

MonoLaserPrinter

1.Precautions

2.ProductSpecications

3.DisassemblyandReassembly

4.AlignmentandTroubleshooting

5.SystemDiagram

6.ReferenceInformation

Contents

RefertotheservicemanualintheGSPN(seetherearcover)formoreinformation.

Page 2

Contents

Contents

1.Precautions......................................................................................................................................1−1

1.1.Safetywarning........................................................................................................................1−1

1.2.Cautionforsafety....................................................................................................................1−2

1.2.1.Toxicmaterial.............................................................................................................1−2

1.2.2.Electricshockandresafetyprecautions.........................................................................1−2

1.2.3.Handlingprecautions...................................................................................................1−3

1.2.4.AssemblyandDisassemblyprecautions...........................................................................1−3

1.2.5.Disregardingthiswarningmaycausebodilyinjury............................................................1−4

1.3.ESDprecautions......................................................................................................................1−5

2.ProductSpecications........................................................................................................................2−1

2.1.Specications..........................................................................................................................2−1

2.1.1.ProductOverview........................................................................................................2−1

2.1.2.Specications.............................................................................................................2−1

2.1.2.1.GeneralPrintEngine......................................................................................2−1

2.1.2.2.ControllerandSoftware..................................................................................2−2

2.1.2.3.PaperHandling.............................................................................................2−4

2.1.2.4.Consumables................................................................................................2−5

2.1.2.5.ReliabilityandService...................................................................................2−5

2.1.2.6.Maintenancepart...........................................................................................2−5

2.1.2.7.Environment................................................................................................2−5

2.1.3.ModelComparisonTable..............................................................................................2−7

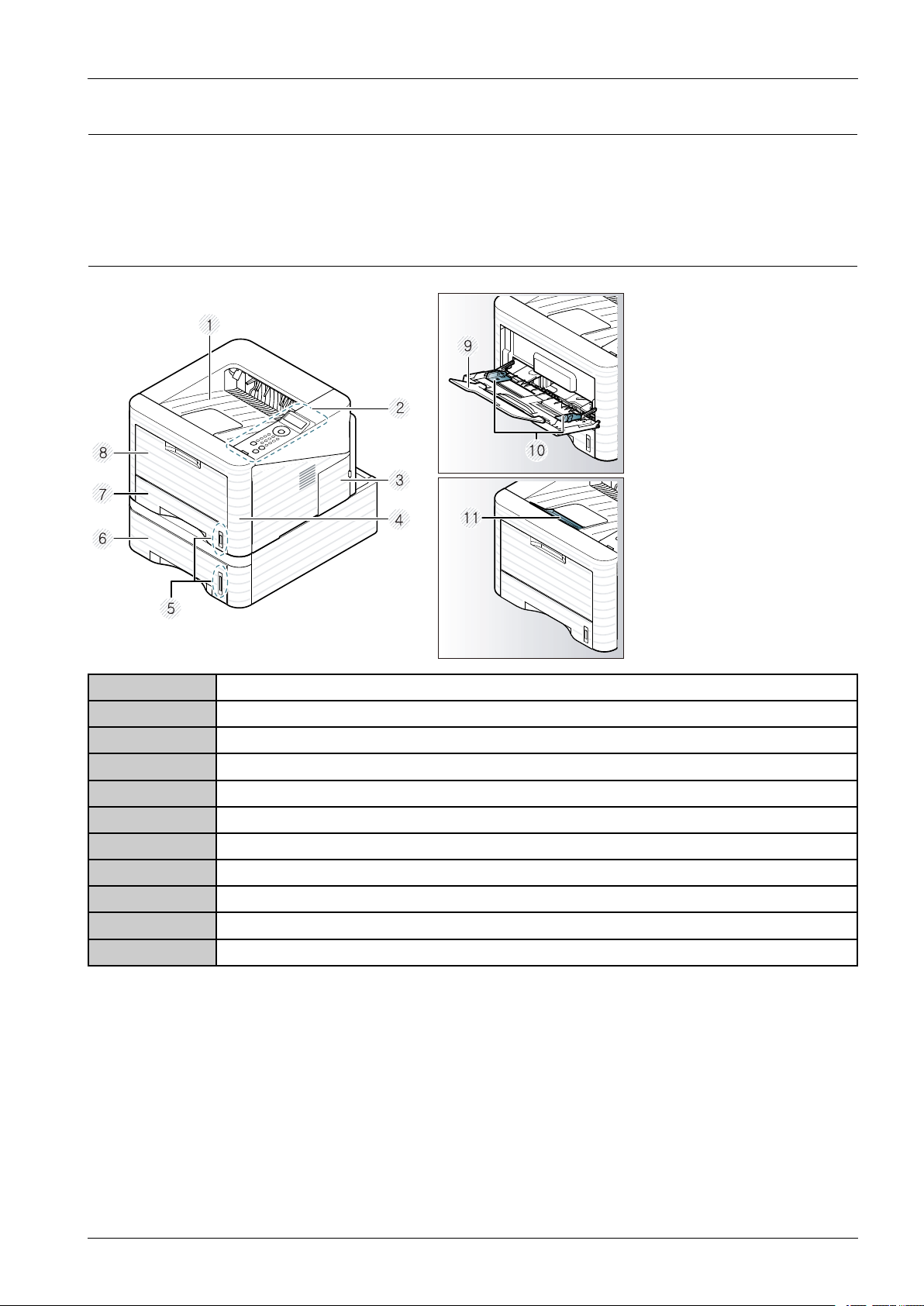

2.2.ProductDescription..................................................................................................................2−8

2.2.1.FrontView.................................................................................................................2−8

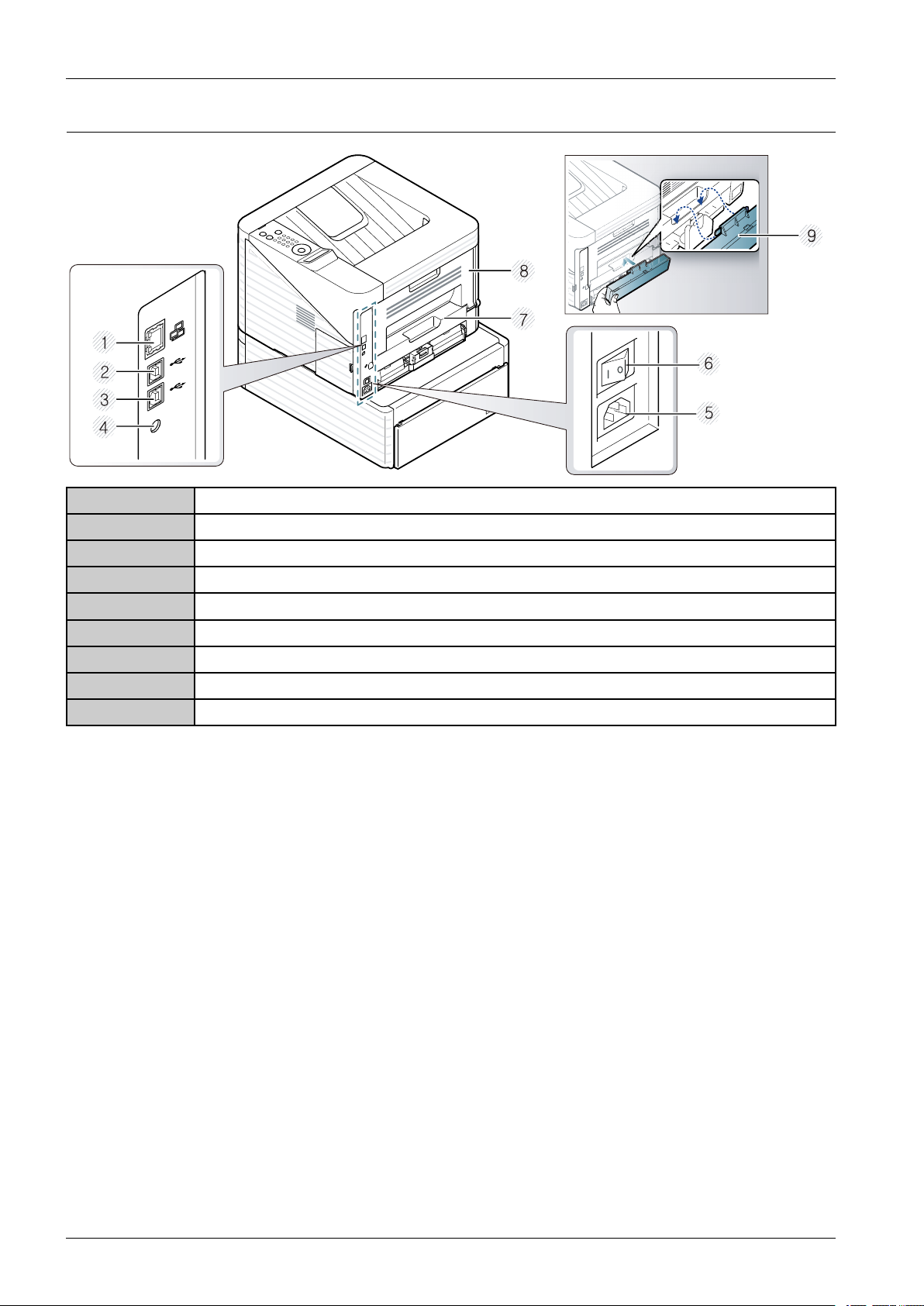

2.2.2.RearView..................................................................................................................2−9

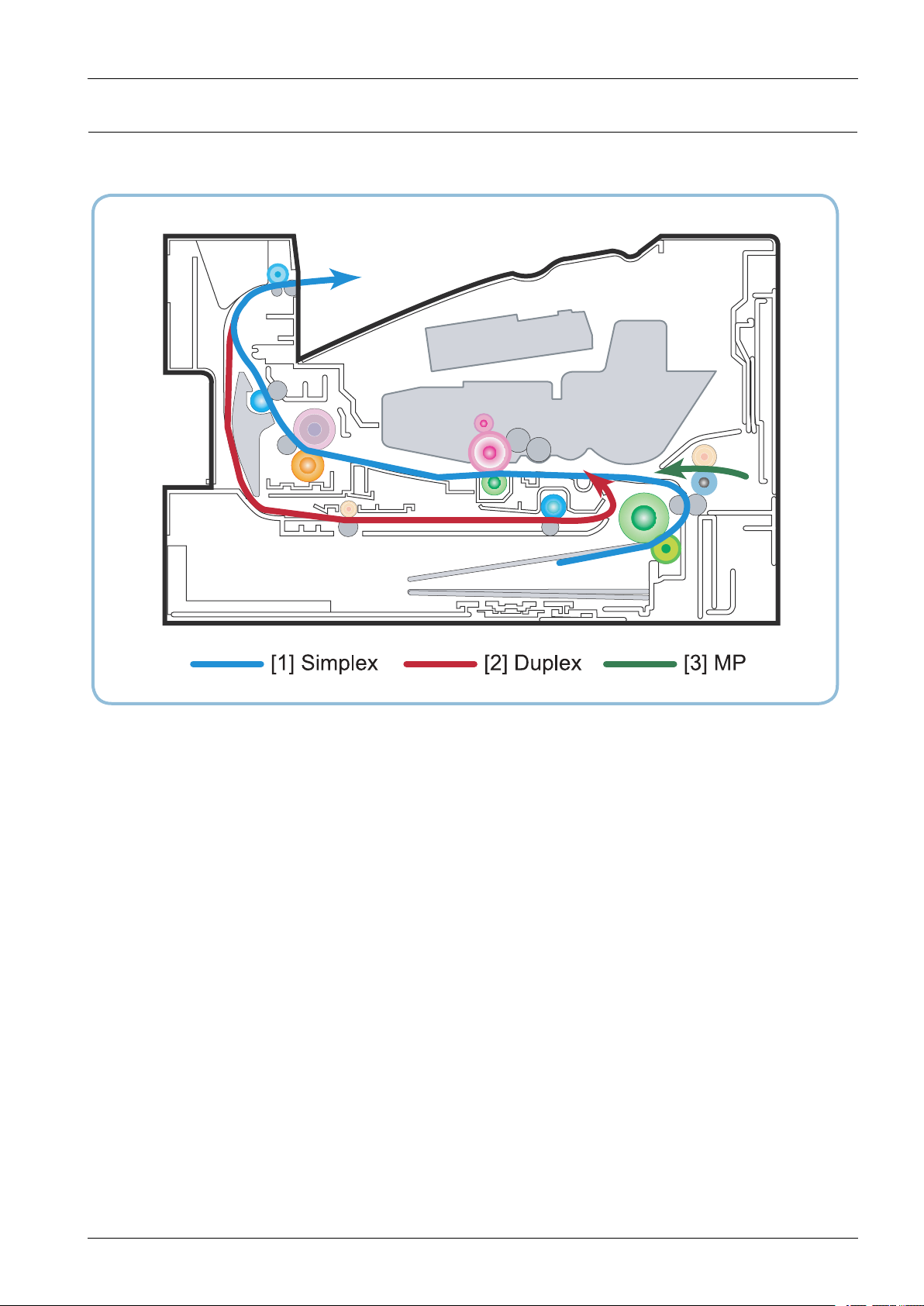

2.2.3.PaperPath..................................................................................................................2−10

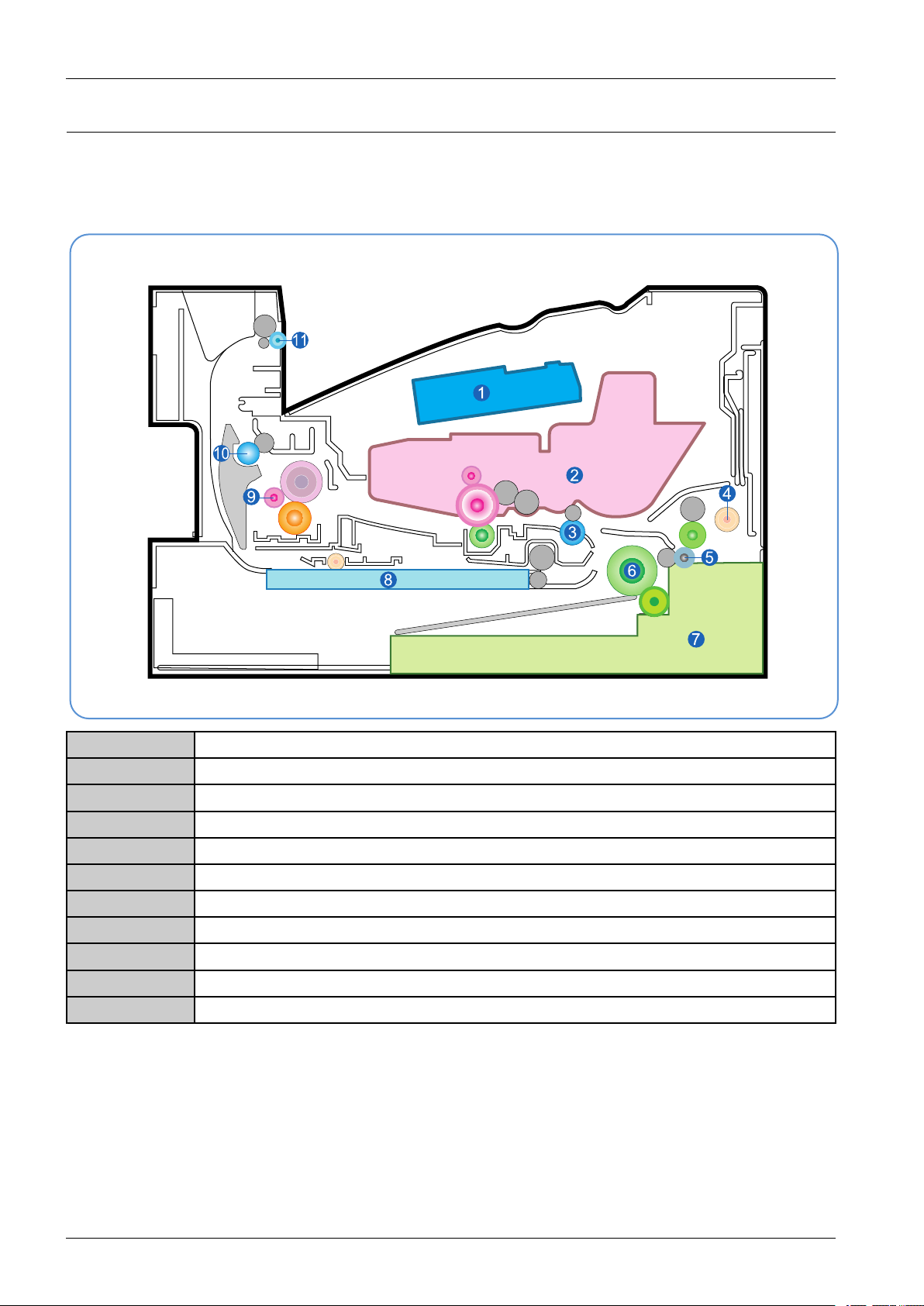

2.2.4.Systemlayout.............................................................................................................2−11

2.2.4.1.FeedingPart.................................................................................................2−12

2.2.4.2.Tonercartridge.............................................................................................2−14

2.2.4.3.Fuserunit....................................................................................................2−16

2.2.4.4.LSU(LaserScanningUnit).............................................................................2−17

2.2.5.HardwareConguration................................................................................................2−18

2.2.5.1.Mainboard..................................................................................................2−19

2.2.5.2.OPEboard...................................................................................................2−21

2.2.5.3.DIMMPBA-Optional...................................................................................2−22

2.2.5.4.SCFboard-Optional.....................................................................................2−22

2.2.5.5.SMPSboard.................................................................................................2−23

2.2.5.6.HVPSboard.................................................................................................2−24

2.2.6.EngineF/WControlAlgorithm......................................................................................2−25

iCopyright©1995-2011SAMSUNG.Allrightsreserved.

Page 3

Contents

2.2.6.1.Feeding.......................................................................................................2−25

2.2.6.2.Transfer.......................................................................................................2−25

2.2.6.3.Fusing.........................................................................................................2−26

2.2.6.4.LSU............................................................................................................2−26

2.2.7.SoftwareDescriptions..................................................................................................2−27

2.2.7.1.Softwaresystemoverview..............................................................................2−27

2.2.7.2.Architecture.................................................................................................2−27

2.2.7.3.DataandControlFlow...................................................................................2−28

3.DisassemblyandReassembly..............................................................................................................3−1

3.1.Precautionswhenreplacingparts................................................................................................3−1

3.1.1.Precautionswhenassemblinganddisassembling...............................................................3−1

3.1.2.PreautionswhenhandlingPBA......................................................................................3−1

3.1.3.ReleasingPlasticLatches..............................................................................................3−2

3.2.Screwsusedintheprinter..........................................................................................................3−3

3.3.ReplacingtheMainSVCparts...................................................................................................3−4

3.3.1.Cover........................................................................................................................3−4

3.3.2.Mainboard.................................................................................................................3−6

3.3.3.HVPSboard...............................................................................................................3−6

3.3.4.SMPSboard...............................................................................................................3−7

3.3.5.LaserScanningUnit(LSU)...........................................................................................3−7

3.3.6.Fuserunit...................................................................................................................3−8

3.3.7.MainDriveunit...........................................................................................................3−9

3.3.8.Feeddriveunit............................................................................................................3−10

3.3.9.Pickup/Regi./MPClutch.............................................................................................3−11

3.3.10.Pickuproller..............................................................................................................3−11

3.3.11.TransferRoller............................................................................................................3−12

3.3.12.MPunit.....................................................................................................................3−12

3.3.13.OPEboard.................................................................................................................3−13

3.3.14.Bin-fullsensor............................................................................................................3−13

3.3.15.Regi_Feed_Emptysensor..............................................................................................3−14

3.3.16.Cassetteroller(Retardroller).........................................................................................3−15

4.AlignmentandTroubleshooting...........................................................................................................4−1

4.1.AlignmentandAdjustments.......................................................................................................4−1

4.1.1.ControlPanel..............................................................................................................4−1

4.1.2.UnderstandingTheStatusLED......................................................................................4−2

4.1.3.Clearingpaperjams.....................................................................................................4−3

4.1.4.Usefulmenuitemforservice.........................................................................................4−7

4.1.5.PeriodicDefectiveImage..............................................................................................4−9

4.1.6.Usefulmanagementtools..............................................................................................4−10

4.1.6.1.UsingSamsungEasyPrinterManager(Windowsonly)........................................4−10

Copyright©1995-2011SAMSUNG.Allrightsreserved.ii

Page 4

Contents

4.1.6.2.UsingSamsungPrinterStatus(Windowsonly)...................................................4−12

4.1.6.3.UsingSmartPanel(MacintoshandLinuxonly)..................................................4−13

4.1.6.4.UsingSyncThruWebService(SWS)................................................................4−14

4.1.7.UpdatingFirmware......................................................................................................4−16

4.1.7.1.UpdatethermwarebyusingtheUSBport........................................................4−16

4.1.7.2.Updatethermwarebyusingthenetwork..........................................................4−17

4.1.8.TechMode.................................................................................................................4−19

4.2.Troubleshooting......................................................................................................................4−22

4.2.1.Procedureofcheckingthesymptoms...............................................................................4−22

4.2.1.1.BasicCheckList...........................................................................................4−23

4.2.2.ErrorCodeandTroubleshooting.....................................................................................4−24

4.2.3.Imagequalityproblem..................................................................................................4−36

4.2.4.Othererrors................................................................................................................4−42

5.SystemDiagram................................................................................................................................5−1

5.1.BlockDiagram........................................................................................................................5−1

5.2.ConnectionDiagram.................................................................................................................5−2

6.ReferenceInformation........................................................................................................................6−1

6.1.ToolforTroubleshooting...........................................................................................................6−1

6.2.Glossary.................................................................................................................................6−2

6.3.TheSamplePatternfortheTest..................................................................................................6−8

6.4.Selectingalocation..................................................................................................................6−9

iiiCopyright©1995-2011SAMSUNG.Allrightsreserved.

Page 5

1.Precautions

Inordertopreventaccidentsandtopreventdamagetotheequipmentpleasereadtheprecautionslistedbelowcarefully

beforeservicingtheprinterandfollowthemclosely .

1.1.Safetywarning

1)Onlytobeservicedbyafactorytrainedservicetechnician.

Highvoltagesandlasersinsidethisproductaredangerous.Thisproductshouldonlybeservicedbyafactorytrained

servicetechnician.

2)UseonlySamsungreplacementparts.

Therearenouserserviceablepartsinsidetheproduct.Donotmakeanyunauthorizedchangesoradditionstothe

productasthesecouldcausetheproducttomalfunctionsandcreateanelectricshocksorrehazards.

3)LaserSafetyStatement

TheprinteriscertiedintheU.S.toconformtotherequirementsofDHHS21CFR,chapter1SubchapterJfor

ClassI(1)laserproducts,andelsewhereiscertiedasaClassIlaserproductconformingtotherequirementsofIEC

60825-1.ClassIlaserproductsarenotconsideredtobehazardous.Thelasersystemandprinteraredesignedso

thereisneveranyhumanaccesstolaserradiationaboveaClassIlevelduringnormaloperation,usermaintenance

orprescribedservicecondition.

1.Precautions

•Wavelength:800nm

•Beamdivergence

-Paraller:12degrees

-Perpendicular:35degrees

•Maximumpowerofenergyoutput:15mW

WARNING

NeveroperateorservicetheproductwiththeprotectivecoverremovedfromLaser/Scannerassembly .Thereected

beam,althoughinvisible,candamageyoureyes.

Whenusingthisproduct,thesebasicsafetyprecautionsshouldalwaysbefollowedtoreduceriskofre,electricshock,

andpersonalinjury .

Copyright©1995-2011SAMSUNG.Allrightsreserved.1-1

Page 6

1.Precautions

1.2.Cautionforsafety

1.2.1.Toxicmaterial

Thisproductcontainstoxicmaterialsthatcouldcauseillnessifingested.

1)Pleasekeepimagingunitandtonercartridgeawayfromchildren.Thetonerpowdercontainedintheimagingunitand

tonercartridgemaybeharmful,andifswallowed,youshouldcontactadoctor.

1.2.2.Electricshockandresafetyprecautions

Failuretofollowthefollowinginstructionscouldcauseelectricshockorpotentiallycauseare.

1)Useonlythecorrectvoltage,failuretodosocoulddamagetheproductandpotentiallycauseareorelectricshock.

2)Useonlythepowercablesuppliedwiththeproduct.Useofanincorrectlyspeciedcablecouldcausethecableto

overheatandpotentiallycauseare.

3)Donotoverloadthepowersocket,thiscouldleadtooverheatingofthecablesinsidethewallandcouldleadtoare.

4)Donotallowwaterorotherliquidstospillintotheproduct,thiscancauseelectricshock.Donotallowpaperclips,pins

orotherforeignobjectstofallintotheproduct,thesecouldcauseashortcircuitleadingtoanelectricshockorrehazard.

5)Nevertouchtheplugsoneitherendofthepowercablewithwethands,thiscancauseelectricshock.Whenservicing

theproduct,removethepowerplugfromthewallsocket.

6)Usecautionwheninsertingorremovingthepowercord.Whenremovingthepowercord,gripitrmlyandpull.The

powercordmustbeinsertedcompletely,otherwiseapoorcontactcouldcauseoverheatingleadingtoare.

7)Takecareofthepowercable.Donotallowittobecometwisted,bentsharplyaroundcornersorpowercablemaybe

damaged.Donotplaceobjectsontopofthepowercable.Ifthepowercableisdamageditcouldoverheatandcausea

re.Exposedcablescouldcauseanelectricshock.Replacethedamagedpowercableimmediately,donotreuseor

repairthedamagedcable.Somechemicalscanattackthecoatingonthepowercable,weakeningthecoverorexposing

cablescausingreandshockrisks.

8)Ensurethatthepowersocketsandplugsarenotcrackedorbrokeninanyway .Anysuchdefectsshouldberepaired

immediately.T akecarenottocutordamagethepowercableorplugswhenmovingthemachine.

9)Usecautionduringthunderorlightningstorms.Samsungrecommendsthatthismachinebedisconnectedfromthe

powersourcewhensuchweatherconditionsareexpected.Donottouchthemachineorthepowercordifitisstill

connectedtothewallsocketintheseweatherconditions.

10)A voiddampordustyareas,installtheproductinacleanwellventilatedlocation.Donotpositionthemachineneara

humidierorinfrontofanairconditioner.Moistureanddustbuiltupinsidethemachinecanleadtooverheatingand

causeareorcausepartstorust.

11)Donotpositiontheproductindirectsunlight.Thiswillcausethetemperatureinsidetheproducttorisepossiblyleading

totheproductfailingtoworkproperlyandinextremeconditionscouldleadtoare.

12)Donotinsertanymetalobjectsintothemachinethroughtheventilatorfanorotherpartofthecasing,itcouldmake

contactwithahighvoltageconductorinsidethemachineandcauseanelectricshock.

13)

cangetashockbytheelectricdischarge.

1-2Copyright©1995-2011SAMSUNG.Allrightsreserved.

WhenreplacingtheSMPSboard,pleasewait5minutesafterunpluggingthepowercord,thenreplaceit.Y ou

Page 7

1.Precautions

1.2.3.Handlingprecautions

Thefollowinginstructionsareforyourownpersonalsafetytoavoidinjuryandsoasnottodamagetheproduct.

1)Ensuretheproductisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodosocouldcause

theproducttotiporfall.

2)Theproductcontainsmanyrollers,gearsandfans.T akegreatcaretoensurethatyoudonotcatchyourngers,hairor

clothinginanyoftheserotatingdevices.

3)Donotplaceanysmallmetalobjects,containersofwater,chemicalsorotherliquidsclosetotheproductwhichifspilled

couldgetintothemachineandcausedamageorashockorrehazard.

4)Donotinstallthemachineinareaswithhighdustormoisturelevels,besideonopenwindoworclosetoahumidieror

heater.Damagecouldbecausedtotheproductinsuchareas.

5)Donotplacecandles,burningcigarettes,etcontheproduct,Thesecouldcauseare.

1.2.4.AssemblyandDisassemblyprecautions

1)ReplacepartscarefullyandalwaysuseSamsungparts.T akecaretonotetheexactlocationofpartsandalsocable

routingbeforedismantlinganypartofthemachine.Ensureallpartsandcablesarereplacedcorrectly.Pleasecarryout

thefollowingproceduresbeforedismantlingtheproductorreplacinganyparts.

2)Ensurethatpowerisdisconnectedbeforeservicingorreplacinganyelectricalparts.

3)Disconnectinterfacecablesandpowercables.

4)Onlyuseapprovedspareparts.Ensurethatpartnumber,productname,anyvoltage,currentortemperaturerating

arecorrect.

5)Whenremovingorre-ttinganypartsdonotuseexcessiveforce,especiallywhenttingscrewsintoplastic.

6)Takecarenottodropanysmallpartsintothemachine.

7)HandlingoftheOPCDrum

•TheOPCDrumcanbeirreparablydamagedifitexposedtolight.T akecarenottoexposetheOPCDrumeither

todirectsunlightortouorescentorincandescentroomlighting.Exposureforaslittleas5minutescandamage

thesurfaceofthephotoconductivepropertiesandwillresultinprintqualitydegradation.Takeextracarewhen

servicingtheproduct.RemovetheOPCDrumandstoreitinablackbagorotherlightproofcontainer.Take

carewhenworkingwiththeCovers(especiallythetopcover)openaslightisadmittedtotheOPCareaandcan

damagetheOPCDrum.

•TakecarenottoscratchthegreensurfaceofOPCDrumUnit.IfthegreensurfaceoftheDrumCartridgeis

scratchedortouchedtheprintqualitywillbecompromised.

Copyright©1995-2011SAMSUNG.Allrightsreserved.1-3

Page 8

1.Precautions

1.2.5.Disregardingthiswarningmaycausebodilyinjury

1)Becarefulwiththehightemperaturepart.

Thefuserunitworksatahightemperature.Usecautionwhenworkingontheprinter.Waitforthefuserunitto

cooldownbeforedisassembly.

2)Donotputngersorhairintotherotatingparts.

Whenoperatingaprinter,donotputhandorhairintotherotatingparts(Paperfeedingentrance,motor,fan,etc.).

Ifdo,youcangetharm.

3)Whenyoumovetheprinter,usesafeliftingandhandlingtechniques.

Thisprinterisheavy .Usetheliftinghandleslocatedoneachsideofthemachine.Backinjurycouldbecausedif

youdonotliftcarefully.

4)Ensuretheprinterisinstalledsafely.

Ensuretheprinterisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodosocouldcausethe

printertotiporfallpossiblycausingpersonalinjuryordamagingtheprinter.

5)Donotinstalltheprinteronaslopingorunstablesurface.Afterinstallation,doublecheckthattheprinterisstable.

1-4Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 9

1.Precautions

1.3.ESDprecautions

Certainsemiconductordevicescanbeeasilydamagedbystaticelectricity.Suchcomponentsarecommonlycalled

“ElectrostaticallySensitive(ES)Devices”orESDs.ExamplesoftypicalESDsare:integratedcircuits,someeldeffect

transistors,andsemiconductor“chip”components.Thetechniquesoutlinedbelowshouldbefollowedtohelpreducethe

incidenceofcomponentdamagecausedbystaticelectricity.

CAUTION

Besurenopowerisappliedtothechassisorcircuit,andobserveallothersafetyprecautions.

1)Immediatelybeforehandlingasemiconductorcomponentorsemiconductor-equippedassembly,drainoffany

electrostaticchargeonyourbodybytouchingaknownearthground.Alternatively ,employacommerciallyavailable

wriststrapdevice,whichshouldberemovedforyourpersonalsafetyreasonspriortoapplyingpowertotheunit

undertest.

2)AfterremovinganelectricalassemblyequippedwithESDs,placetheassemblyonaconductivesurface,suchas

aluminumorcopperfoil,orconductivefoam,topreventelectrostaticchargebuildupinthevicinityoftheassembly.

3)UseonlyagroundedtipsolderingirontosolderordesolderESDs.

4)Useonlyan“anti-static”solderremovaldevice.Somesolderremovaldevicesnotclassiedas“anti-static”can

generateelectricalchargessufcienttodamageESDs.

5)DonotuseFreon-propelledchemicals.Whensprayed,thesecangenerateelectricalchargessufcienttodamageESDs.

6)DonotremoveareplacementESDfromitsprotectivepackaginguntilimmediatelybeforeinstallingit.Most

replacementESDsarepackagedwithallleadsshortedtogetherbyconductivefoam,aluminumfoil,oracomparable

conductivematerial.

7)ImmediatelybeforeremovingtheprotectiveshortingmaterialfromtheleadsofareplacementESD,touchtheprotective

materialtothechassisorcircuitassemblyintowhichthedevicewillbeinstalled.

8)MaintaincontinuouselectricalcontactbetweentheESDandtheassemblyintowhichitwillbeinstalled,until

completelypluggedorsolderedintothecircuit.

9)MinimizebodilymotionswhenhandlingunpackagedreplacementESDs.Normalmotions,suchasthebrushingtogether

ofclothingfabricandliftingone’sfootfromacarpetedoor,cangeneratestaticelectricitysufcienttodamageanESD.

Copyright©1995-2011SAMSUNG.Allrightsreserved.1-5

Page 10

2.ProductSpecications

2.ProductSpecications

2.1.Specications

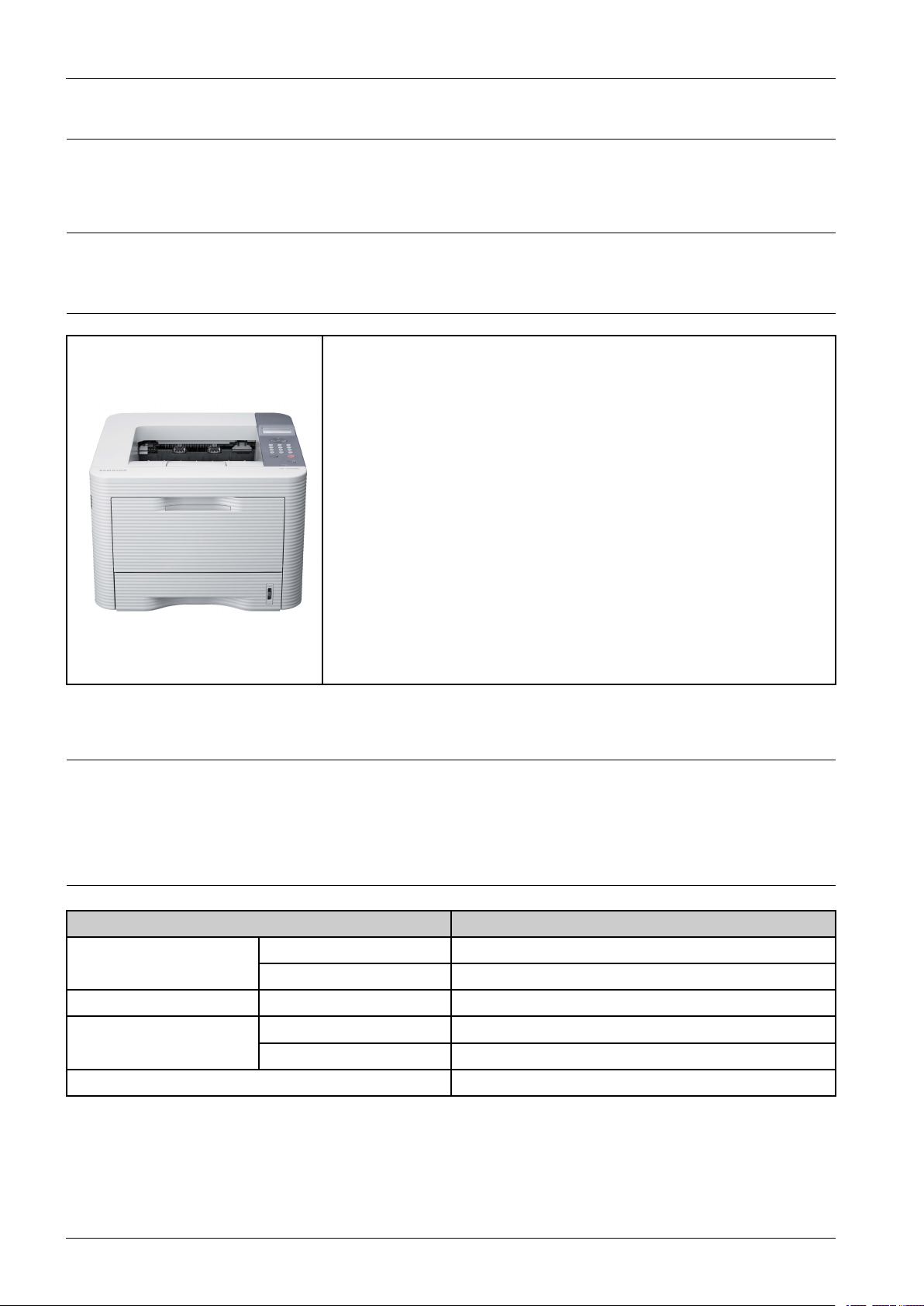

2.1.1.ProductOverview

1)Speed

•35ppminA4/37ppminLetter

2)Processor

•533MHz

3)PrinterLanguages

•PCL6/5e,PostsScript3,IBMProPrinter,EPSON

4)Memory(Std/Max)

•128MB/512MB

5)Interfaces

•HighSpeedUSB2.0

•10/100/1000BaseTXnetworkconnector

•IEEE1284Parallel(Optional)

6)Tonercartridge(Initial/Sales)

•7K/7K,15K

2.1.2.Specications

•ProductSpecicationsaresubjecttochangewithoutnotice.

2.1.2.1.GeneralPrintEngine

ItemSpecication

SimplexUpto35ppminA4(37ppminLetter) EngineSpeed

DuplexUpto17ipminA4(18ipminLetter)

Warm-uptimeFromSleep15sec

FromReadyAsfastas8sec FPOT

FromSleepAsfastas15.5sec

ResolutionUpto1,200x1,200dpieffectiveoutput

2-1Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 11

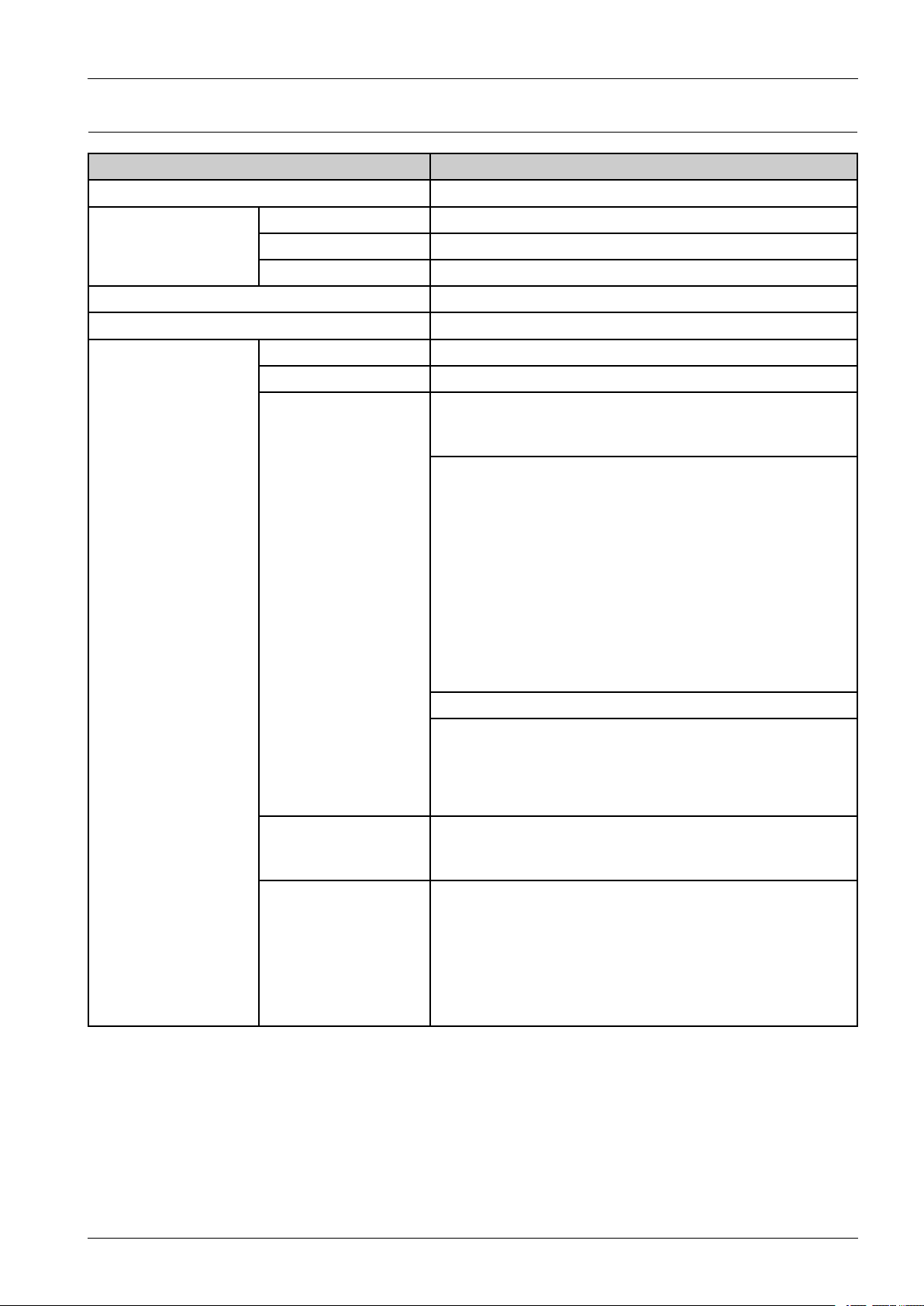

2.1.2.2.ControllerandSoftware

ItemSpecication

ProcessorSamsung533MHz

2.ProductSpecications

Memory

PrinterLanguagesPostScript3,PCL6/5e,IBMProPrinter,EPSON

Fonts93scalable,1bitmap,136PostScript3fonts

Driver

Std128MB

Max512MB

Flash16MB

DefaultDriverPCL

InstallPCL6/PS3

SupportingOS

Windows2000/XP(32/64bits)/Vista(32/64bits)/2003

Server(32/64bits)/2008Server(32/64bits)/7(32/64bits)/2008Server

R2(64bits)

VariousLinuxOS:

•RedHatEnterpriseLinuxWS4,5(32/64bit)

•Fedora4,5,6,7,8,9,10,11,12(32/64bit)

•SuSELinux10.0,10.1(32bit)

•OpenSuSE10.2,10.3,11.0,11.1,11.2(32/64bit)

•Mandriva2005,2006,2007,2008,2009,2009.1(32/64bit)

•Ubuntu5.04,5.10,6.06,6.10,7.04,7.10,8.04,8.10,9.04,

9.10(32/64bit)

•SuSELinuxEnterpriseDesktop10,11(32/64bit)

•Debian4.0,5.0(32/64bit)

MacOS10.3~10.6

UNIXOS:

•SunSolaris9,10(x86,SPARC)

•HP-UX11.0,11iv1,11iv2,11iv3(PA-RISC,Itanium)

•IBMAIX5.1,5.2,5.3,5.4

WHQLWindows2000/XP(32/64bits)/Vista(32/64bits)/2003

Server(32/64bits)/2008Server(32/64bits)/7(32/64bits)/2008Server

R2(64bits)

Compatibility•PCL6:Win2000/XP(32/64bits)/2003Server(32/64bits)/

Vista(32/64bits)/2008Server(32/64bits)/7(32/64bits)/2008

ServerR2(64bits)

•PS3:Win2000/XP(32/64bits)/Vista(32/64bits)/2003

server(32/64bits)/2008Server(32/64bits)/7(32/64bits)/2008

ServerR2(64bits)PPD,MacPPD,LinuxPPD(Withinthe

scopeofSupportingOS)

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-2

Page 12

2.ProductSpecications

ItemSpecication

WiredNetwork

Protocol•[TCP/IP]

TCP/IPv4/IPv6,HTTP ,SNMPv1/v2c/v3,SMTP ,IPSec,

DNS/WINS,DDNS,DHCP ,SSL/TLS,BOOTP ,AutoIP ,

StandardTCP/IPprinting,LPR,IPP ,UPnP(SSDP),Bonjour,

Telnet,WSD,SLP ,SetIP

•[Others]

HTTPs,IPPs,802.1x(EAP-MD5,EAP-MSCHAPv2,

PEAP,TLS),IPSec

SupportingOS•[Windows]

•MicrosoftWindows2000/XP(32/64bits)/

2003(32/64bits)/Vista(32/64bits)/2008(32/64bit)/

7(32/64bit)

•[Mac]

•MacOS10.3~10.6

•[Linux]

•RedHat8~9(32bit)/EnterpriseLinuxWS4,5(32/64bit)

•FedoraCore1~7(32/64bit)

•SuSE8.2~10.2/EnterpriseDesktop9~10(32/64bit)

•Madrake9.2~10.1(32/64bit)

•Mandriva2005~2007

•Ubuntu6.06~7.04

•Debian3.1~4.0[Novell]-Netware5.x,6.x(TCP/IPOnly)

•[Novell]

•Netware5.x,6.x(TCP/IPOnly)

•[Unix]

•SunSolaris8,9,10(SP ARC/x86)

•IBMAIX5.x(6.1)IBMLinux(SystemP)

•HP-UX11i(PA-RISC/IA-64)

(11.11/11.20/11.22/11.23/11.31)

ProtocolN/A WirelessNetwork

SupportingOSN/A

EasyPrinterManagerforWindows/Macintosh/LINUX Application

NetworkManagementSyncThruWebAdminService5.0

Interface

UserInterface

2-3Copyright©1995-2011SAMSUNG.Allrightsreserved.

ParallelOption

USBHi-SpeedUSB2.0

WiredNetworkGigabit(Internal)

WirelessNetworkN/A

LCD2-Line

LEDNavigation,ECO,Power,Status

KeyNavigationkeys,ECO,NumericKeypad,Power,Cancel

Page 13

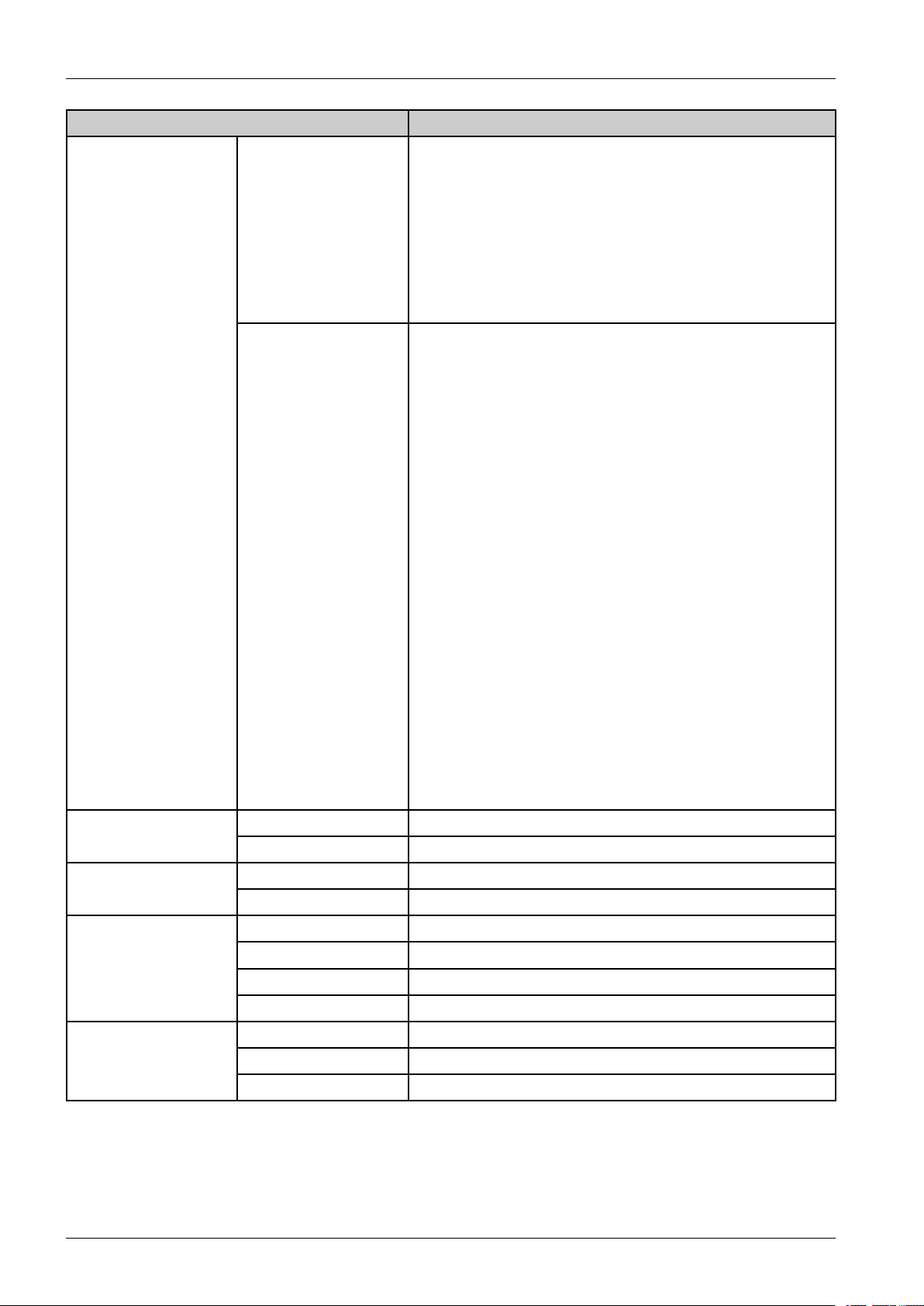

2.1.2.3.PaperHandling

ItemSpecication

StandardCapacity250-sheetCassetteTray,50-sheetMultiPurposeTray@80g/m²

Max.Capacity820sheets@80g/m²(850sheets@75g/m²)

2.ProductSpecications

Printing

Multi-purposetray

StandardCassetteTray

OptionalCassetteTray

•Max.Size:216x356mm(8.5"x14")

•Min.Size:76x127mm(3.0"x5.0")

Capacity

Mediasizes

Mediatype

Mediaweight16~58lb(60to220g/m²)

SensingPaperEmpty

Capacity250sheets@80g/m²(250sheets@75g/m²)

Mediasizes

MediatypesPlainPaper,Thin,Thick,Recycled,Bond,Cardstock,Archive

Mediaweight16~43lb(60to163g/m²)

SensingPaperEmpty

Capacity520sheets@80g/m²(550sheets@75g/m²)

MediasizesA4,A5,A6,Letter,Legal,Folio,Ocio,Executive,ISOB5,JISB5

MediatypesPlainPaper,Thin,Thick,Recycled,Bond,Cardstock,Archive

•PlainPaper:50sheets@80g/m²(50sheets@75g/m²)

•Envelop:5sheets

A4,A5,A6,Letter,Legal,Folio,Ocio,Executive,ISOB5,JISB5,

3"x5",Envelope(Monarch,No.10,DL,C5,C6),Custom

Plain,Thin,Thick,Thicker,Cotton,Colored,Envelope,Transparency ,

Pre-Printed,Recycled,Labels,Bond,Cardstock,Archive

A4,A5,A6,Letter,Legal,Folio,Ocio,Executive,ISOB5,JISB5,

Custom

Mediaweight16~43lb(60to163g/m²)

SensingCSTOpen,PaperEmpty

Capacity

OutputStacking

OutputFullsensingYes

SupportingBuilt-in

MediasizesA4,Letter,Ocio,Folio,Legal

Duplex

MediatypesPlainPaper,Thin,Thick,Recycled,Bond

Mediaweight16~32lb(60to120g/m²)

PrintableAreaNon-PrintableArea

•Face-Down:150sheets@80g/m²

•Face-Up:1sheet

•Envelop:10mm(0.4")fromedge(Top,Bottom,Left,Right)

•OtherMedia:4mm(0.16")fromedge(Top,Bottom,Left,

Right)

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-4

Page 14

2.ProductSpecications

2.1.2.4.Consumables

ItemSpecication

Toner

DrumYieldN/A

Black•Standard:AverageCartridgeYield7Kstandardpages.

KeyElectronickey(CRUM)Only

LifedetectTonergaugesensorbydotcount

2.1.2.5.ReliabilityandService

ItemSpecication

RecommandedAMPV1500sheets/month

MaxAMPV3500sheets/month

Max.MonthlyDuty80,000sheets/month

MPBF45,000sheets

MTBF35months

MTTR30min.

•HighYield:A veragecartridgeYield15Kstandardpages.

(Shipswith7,000pagesStarterTonerCartridge)

DeclaredcartridgeyieldinaccordancewithISO/IEC19752.

2.1.2.6.Maintenancepart

ItemPartCodeLife

TransferrollerJC66-02842AApprox.100,000Pages

FuserUnit•JC91-01023A(110V)

•JC91-01024A(220V)

Pick-upRollerJC73-00340AApprox.90,000Pages

ReverseRollerJC90-01032AApprox.60,000Pages

Approx.90,000Pages

2.1.2.7.Environment

ItemSpecication

Temperature10Cto32C OperatingEnvironment

Humidity20%to80%

AcousticNoiseLevel

(SoundPower/Pressure)

Printing52dBA

StandbyBackGroundLevel(Lessthan26dBA)

SleepBackGroundLevel

2-5Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 15

ItemSpecication

2.ProductSpecications

PowerConsumption

ReadyLessthan60W

AverageLessthan550W

Powersave/PowerOffLessthan1.5W/Lessthan0.1W

Dimension(WxDxH)Set366x368x272.9mm(14.40x14.48x10.74inches)withoutoptional

tray

WeightSet(Includetoner

10.24kg(22.58lbs)

cartridge)

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-6

Page 16

2.ProductSpecications

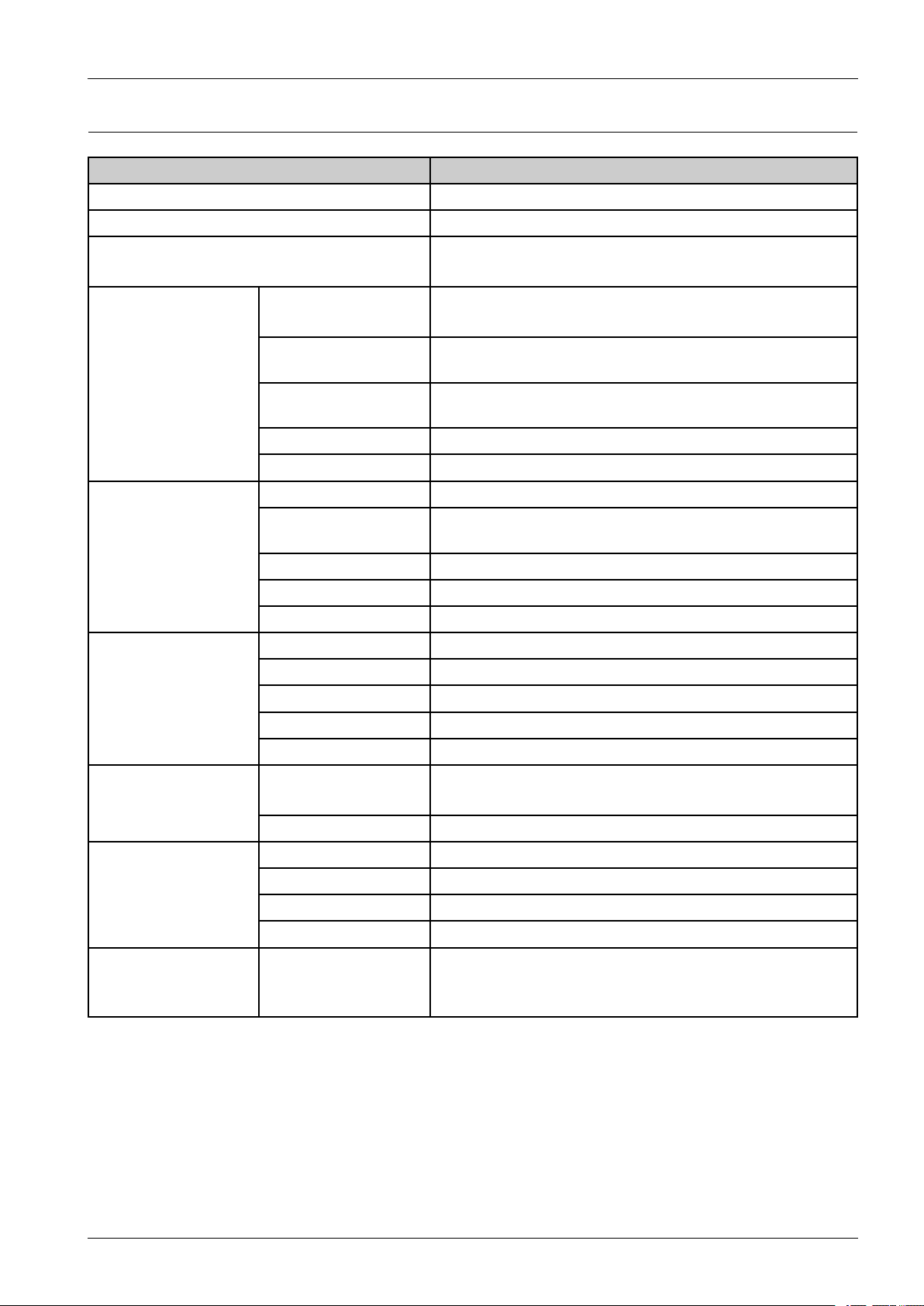

2.1.3.ModelComparisonTable

Samsung

ML-3750ND

Image

Speed35ppm(A4)/37ppm

(Letter)

Processor533MHz600MHz600MHz400MHz

Memory

(Std/Max)

EmulationPCL6/5e,PS3PCL6/5e,PS3PCL6PCL6/PS3

MP/Cassette50/25050/25050/25050/250

SCF520sheets520sheets500sheets550sheets

DuplexStd.Std.Std.Std.

TonerYield7K/15K2K/5K/10K2.3K/6.5K3.5K/9K

Interface•HighspeedUSB

128/512MB128/384MBP2055dn(128/384MB)

2.0

•Ethernet

10/100/1000Base

TX

Samsung

ML-3710ND

35ppm(A4)/37ppm

(Letter)

•HighspeedUSB

2.0

•Ethernet

10/100/1000Base

TX

HP

P2050series

33ppm(A4)38ppm(A4)

P2055d(64/320MB)

•HighspeedUSB

Lexmark

E360dn

32/288MB

•HighspeedUSB

2.0

•Ethernet

•Ethernet10/100

10/100/1000Base

TX(P2055dn)

2.0

BaseTX

Noise52dB52dB55dB53dB

2-7Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 17

2.2.ProductDescription

v

v

}

}

|

|

{

{

x

x

y

y

z

z

ee

ww

0

0

~

~

v

v

uu

0

v

v

vv

Thischapterdescribesthefunctionsandoperatingprincipalofthemaincomponent.

2.2.1.FrontView

2.ProductSpecications

1Outputtray

2Controlpanel

3Controlboardcover

4Frontcover

5Paperlevelindicator

6Optionaltray

7Tray1

8Multi-purposetray

9Multi-purposetraypaperextension

10Paperwidthguidesonamulti-purposetray

11Outputsupport

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-8

Page 18

2.ProductSpecications

|

|

{

{

v

v

x

x

ee

ww

yy

z

z

}

}

~

~

2.2.2.RearView

1NetworkPort

2USBport

3USBport2*(ML-3753NDonly)

4IEEE1284parallelconnectorpowersupplyjack

5Power-switch

6Powerreceptacle

7Duplexunit

8Rearcover

9Traybackcover

*TwoUSBportsallowyoutoconnectaprintertotwoseparatecomputers.Printerdriversneedtobeinstalledonboth

computersforthisoperation.DoubleconnectionsfromaprintertoasinglecomputerthroughtheUSBportscanresultin

seriousdamagetotheprinterandcomputer.

2-9Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 19

2.2.3.PaperPath

[1]

S implex [2] Duplex [3] MP

Thefollowingdiagramdisplaysthepaththepaperfollowsduringtheprintingprocess.

2.ProductSpecications

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-10

Page 20

2.ProductSpecications

1

2

3

4

7

6

8

5

11

10

9

2.2.4.Systemlayout

ThismodelconsistsoftheEngineparts,HardwareandFirmware.Theenginepartsconsistsofthemechanicalparts

comprisingFrame,Duplex,Tonercartridge,Driveunit,Transferroller,Fuser,Cassette.TheHardwarepartconsistsofthe

maincontrolboard,powerboard,operationpanel,PCInterface.

1LSU(LaserScanningUnit)

2TonerCartridge

3Regi.Roller

4MP

5FeedRoller

6Pick-UpRoller

7Cassette

8DuplexUnit

9Fuser

10ExitRoller1

11ExitRoller2

2-11Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 21

2.ProductSpecications

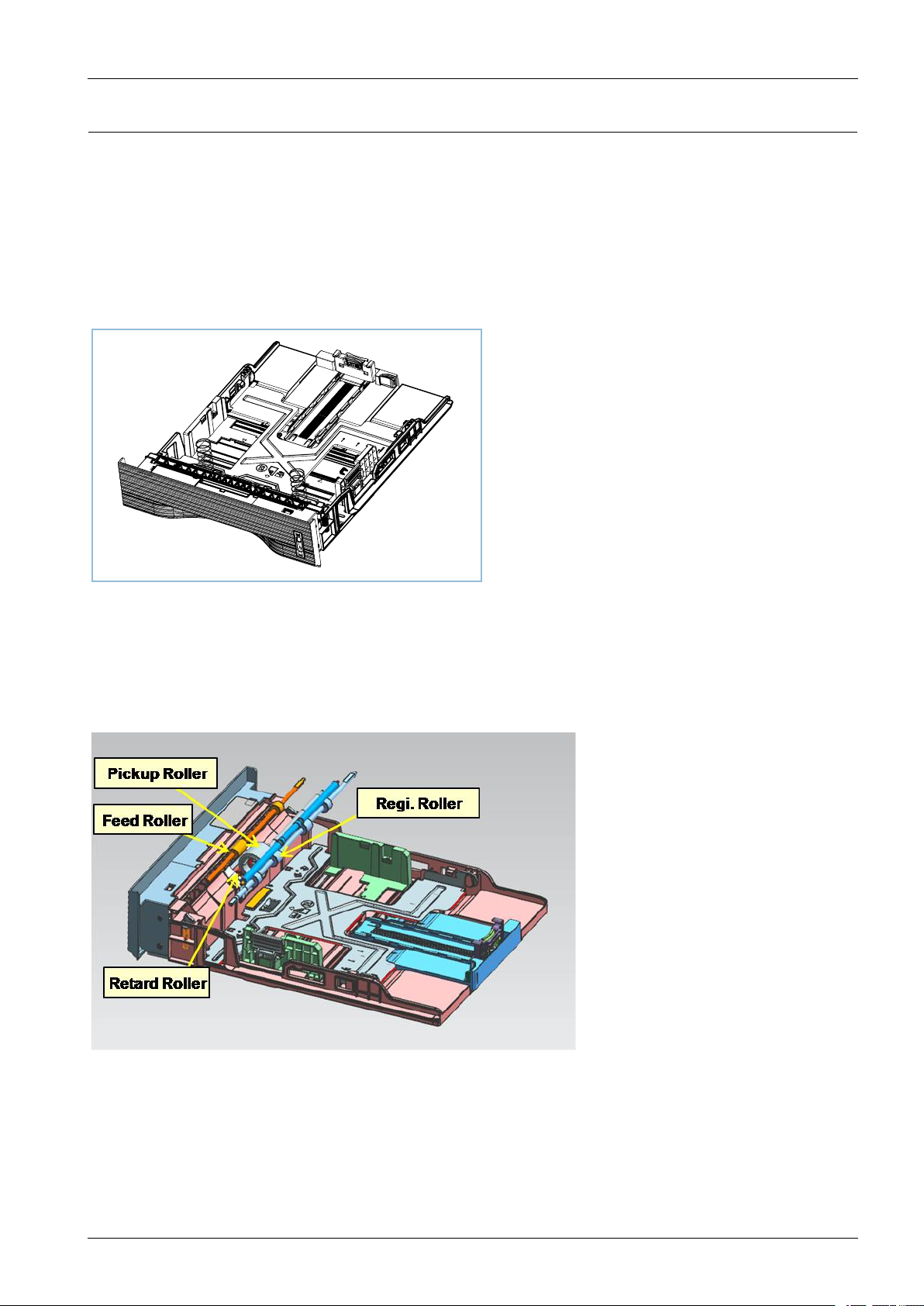

2.2.4.1.FeedingPart

Itconsistsofacassette,anMPtrayforsupplyingdifferenttypesofmedia(envelope,label,specialpaper)andparts

relatedtopaperfeedinitialization.

1)Cassette

ThepapertraysconsistoftheMaintrays,Optionaltrays(SCF),andoneMulti-Purpose(MP)tray .Thebasiccassetteis

locatedonfrontsideofthemachineandallowsfeedingofcommonpaper.PapersizeissetusingtheSizeGuidesineach

tray.AdjustthePaperlength/widthguidestomatchthepapersize.

2)Pickup/Retard(Reverse)roller

Whenpickuptakesplace,thepickuprollerrotatestoseparateandtransportthepaper.Thepickuprollerrotateswhenthe

pickupclutchisactivated.Thereverserollerservetomakesurethatasinglesheetofpaperismovedtothepaperpath,

andthepaperismovedasfarastheregistrationrollerbytheworkofthefeedroller.Thefollowingisadiagramofthe

pickupsection:

3)Registrationroller

Itisusedasanantiskewdevice,andtosetupproperregistrationtimingwiththatofthetonedimageonthedrum.Italsois

usedforjamdetectiontoensurepaperhasleftthepapertray.

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-12

Page 22

2.ProductSpecications

4)MPTray

Themulti-purposetraycanholdspecialsizesandtypesofprintmaterial,suchaspostcards,notecards,andenvelopes.

Itisusefulforsinglepageprintingonletterheadorcoloredpaper.Ituses3rollersfeedingmethodtofeed50sheets

ofgeneralpapers.

5)DuplexUnit

Ithaspapertransferringfunction,paperguidefunction,jamremovingfunction.Itisdesignedforbasicattachment,andthe

duplexfeedingtakesasidefeedingmethod.UsablepapersareA4,letter,andlegalsizepaper.Forremovingajamoccurred

inafrontpart,itisdesignedtoopenacassetteandaguide.Itisdesignedtoopenarearcovertoremoveajaminarearpart.

Ifafaceuptrayisopen,theduplexoptioncannotbeused.

6)OptionCassette

Itisthesamemethodwiththemaincassette,andthecapacityis520sheets.Ithasaseparatedrivingmechanism.Itis

designedforacommonusewithamaincassette.

2-13Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 23

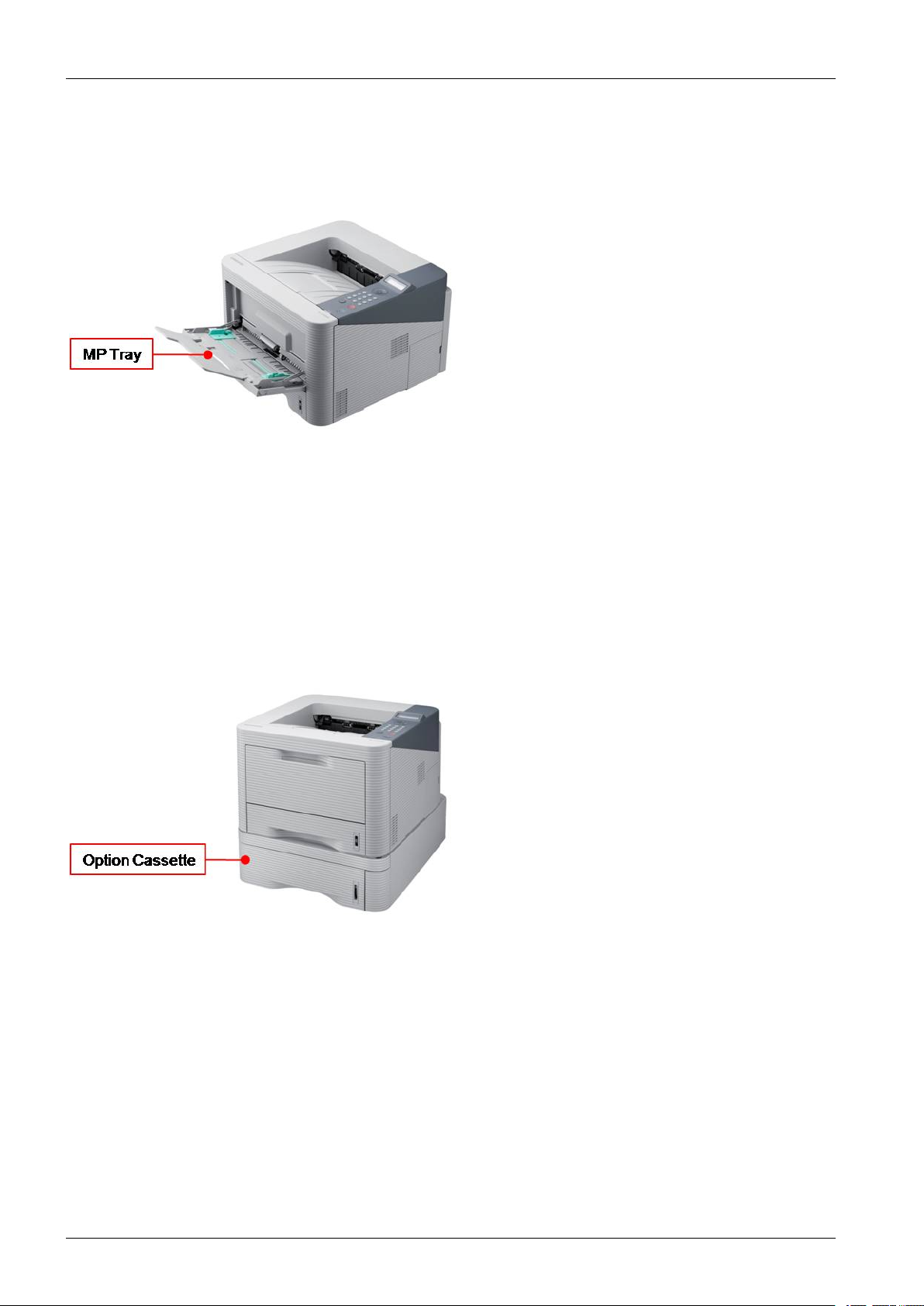

2.2.4.2.Tonercartridge

1)Printingprocessoverview

2.ProductSpecications

ThismonoprintingsystemincludestheLSUwithalaserbeams,atonercartridgeandtransferroller .

Thismachineusessingletonercartridgeandduallaserbeamsformonoprinting.ThetonercartridgeconsistsofDrum

unitandDevelopmentunit.TheDrumunithasanOPCdrum,cleaningblade.

TheOPCdrumischargedwithanegativevoltagebythescorotronandisexposedbythelightfromtheLSU(Laser

Scanningunit).ThelightproducedbyalasercreatesalatentimagebydischargingonthesurfaceoftheOPCdrum.The

negativelychargedtonersareattractedtothelatentimageduetoandelectriceld.Thetoners(realimage)ontheOPCdrum

aremovedtothetransfermediabythepositivebiasappliedtothetransferroller.

1)ChargingtheOPCdrum:Thescorotrongivesthedrumnegativecharges.

2)Laserexposure:LightproducedbyalaserdiodeirradiatesthechargedOPCthroughthelensandmirrors.

3)Development:Thismachineusesadual-componentdevelopmentsystem.Themagneticrollercarriesnegatively

chargedtonertothelatentimageonthedrumsurface.

4)Transfer:ThetransferrollersoppositetheOPCdrumstransfertonerfromthedrumstothetransfermedia(e.g.paper,

OHPlm,etc).

5)CleaningforOPCdrum:Thecleaningbladeremovesremainingtonersonthedrumsurfaceafterimagetransfer

tothepaper.

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-14

Page 24

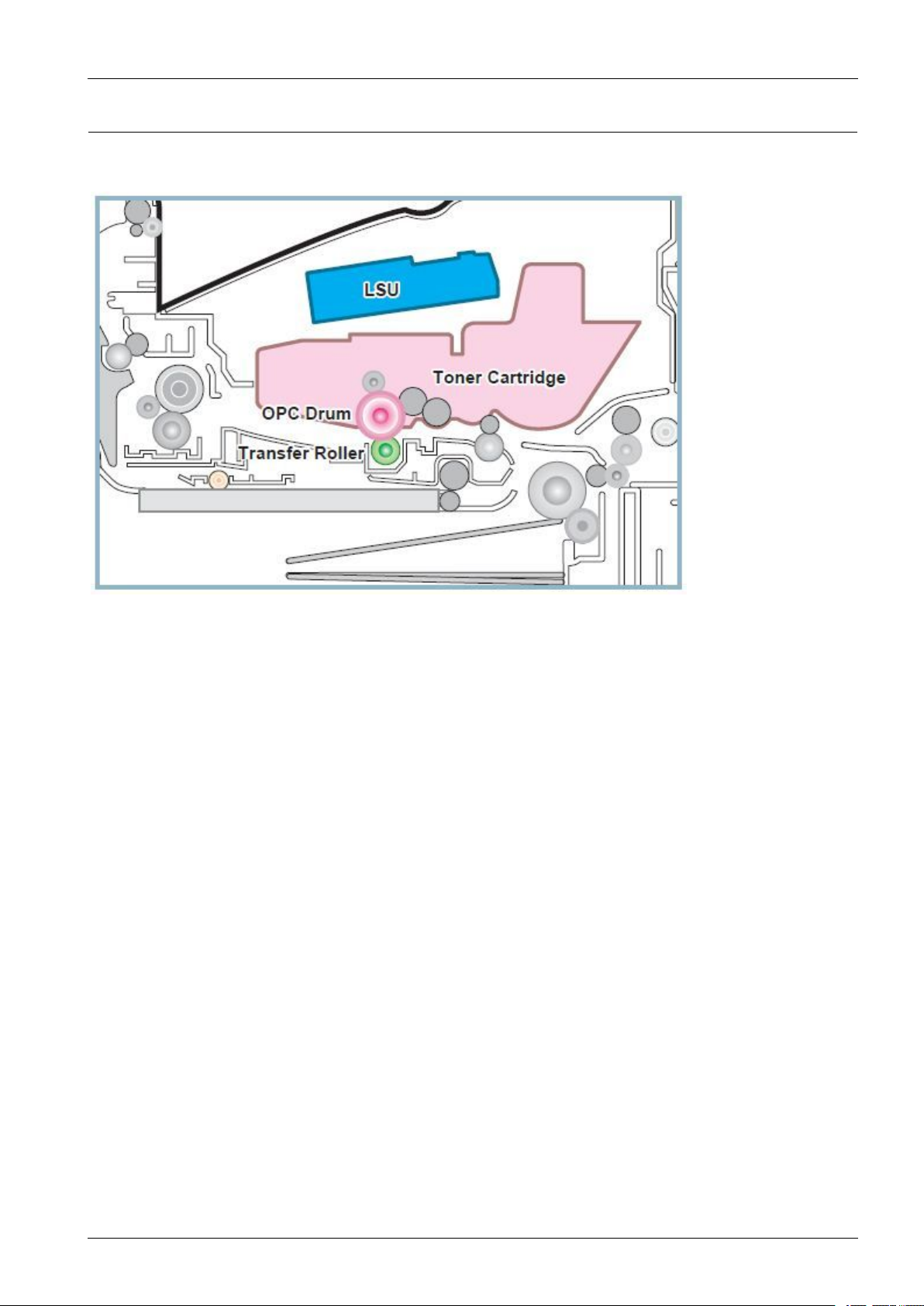

2.ProductSpecications

2)TonerCartridge

Byusingtheelectronicphotoprocess,itcreatesavisualimage.Inthetonercartridge,theOPCunitandthedeveloping

unitareinabody.TheOPCunithasOPCdrumandchargingroller,andthetonercartridgeunithastoner,supplyroller,

developingroller,andblade(Doctorblade).

•Operationcondition:T emp10~30℃,Humidity20~85%RH

•DevelopingMethod:Nonmagnetic1elementcontactingmethod

•Toner:Nonmagnetic1elementshattertypetoner

•Thelifespanoftoner(ISO19752pattern/A4standard)

-Initialtoner:7K

-Salestoner:7K/15K

•TonerResidualSensor:DotcountwithCRUM

•OPCCleaning:Collectthetonerbyusingcleaningblade

•Handlingofwastedtoner:Collectthewastedtonerinthecleaningframebyusingcleaningblade

•OPCDrumProtectingShutter:None

•Classifyingdevicefortonercartridge:IDisclassiedbyCRUM.

aChargeRoller

bDrumOPC

cCleaningBlade

fSupplyRoller

gChargeCleaningRoller

hAgitator1

dDoctorBlade

eDeveloperRoller

2-15Copyright©1995-2011SAMSUNG.Allrightsreserved.

iAgitator2

Page 25

2.ProductSpecications

Pressure Roller

Pressure Roller2

Halogen Lamp

Heat Roller

Thermistor

Thermostat

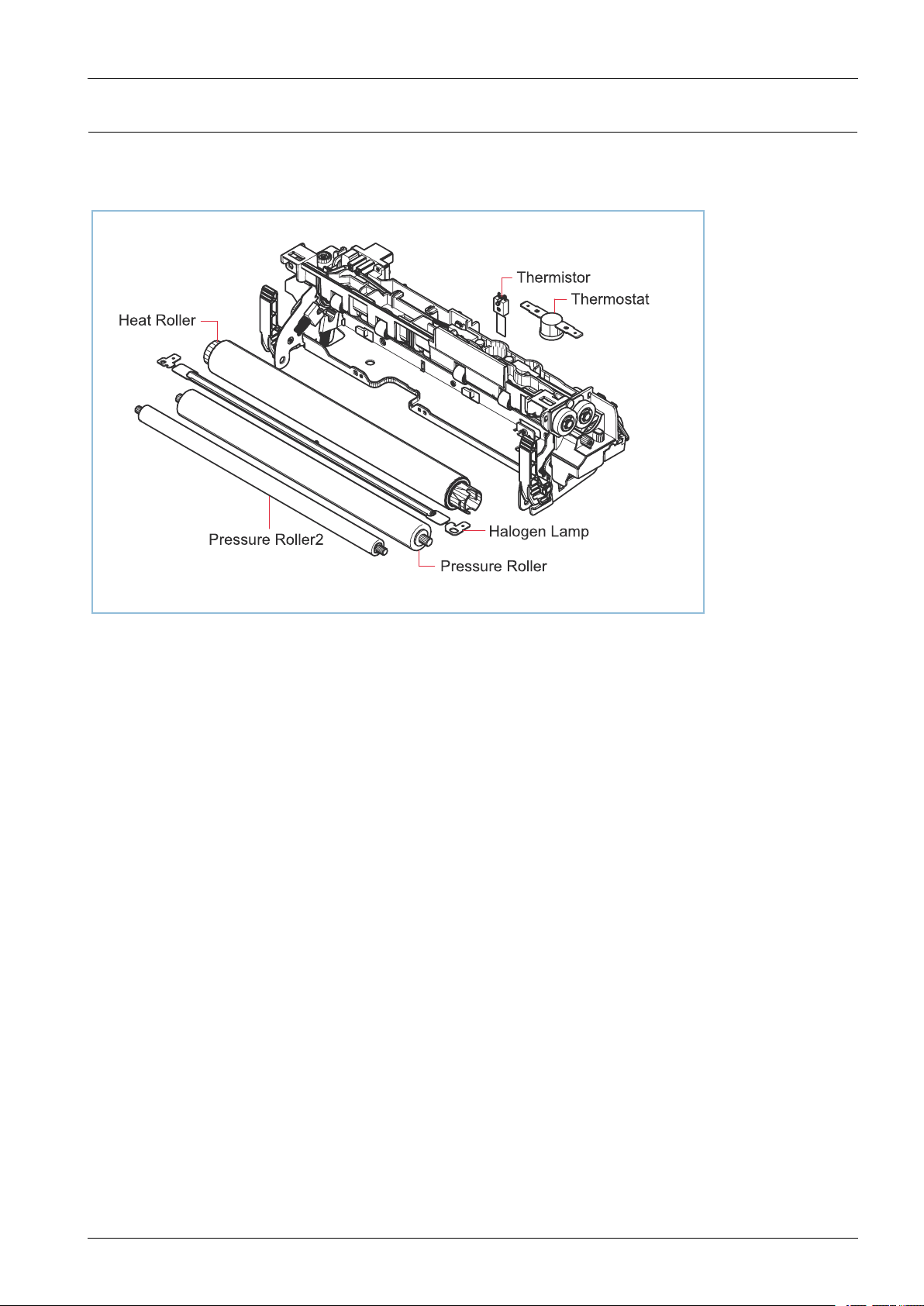

2.2.4.3.Fuserunit

Itisconsistedofahalogenlamp,heatroller,pressureroller,thermistorandthermostat.Itsticksthetoneronapaperby

heatandpressuretocompletetheprintingjob.

1)Thermostat

Whenaheatlampisoverheated,aThermostatcutsoffthemainpowertopreventover-heating.

•ThermostatType:Non-Contacttype

•ControlTemperature:170℃±5℃

2)Thermistor

Itisatemperaturedetectingsensor .

•TemperatureResistance:7(180℃)

3)Heatroller

Theheatrollertransferstheheatfromthelamptoapplyaheatonthepaper.

ThesurfaceofaheatrolleriscoatedwithTeon,sotonerdoesnotsticktothesurface.

4)Pressureroller

Apressurerollermountedunderaheatrollerismadeofasiliconresin,andthesurfacealsoiscoatedwithT eon.When

apaperpassesbetweenaheatrollerandapressureroller,toneradherestothesurfaceofapaperpermanently.

5)HalogenLamp

•V oltage:120V,115±5%/220V ,230±5%

•Capacity:850Watt±25W

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-16

Page 26

2.ProductSpecications

OPC Drum

Photo Diode

LD Driver circit

Protector panel

LD(Laser Diode)

Polygon Mirror

Polygon Motor

Motor Driver

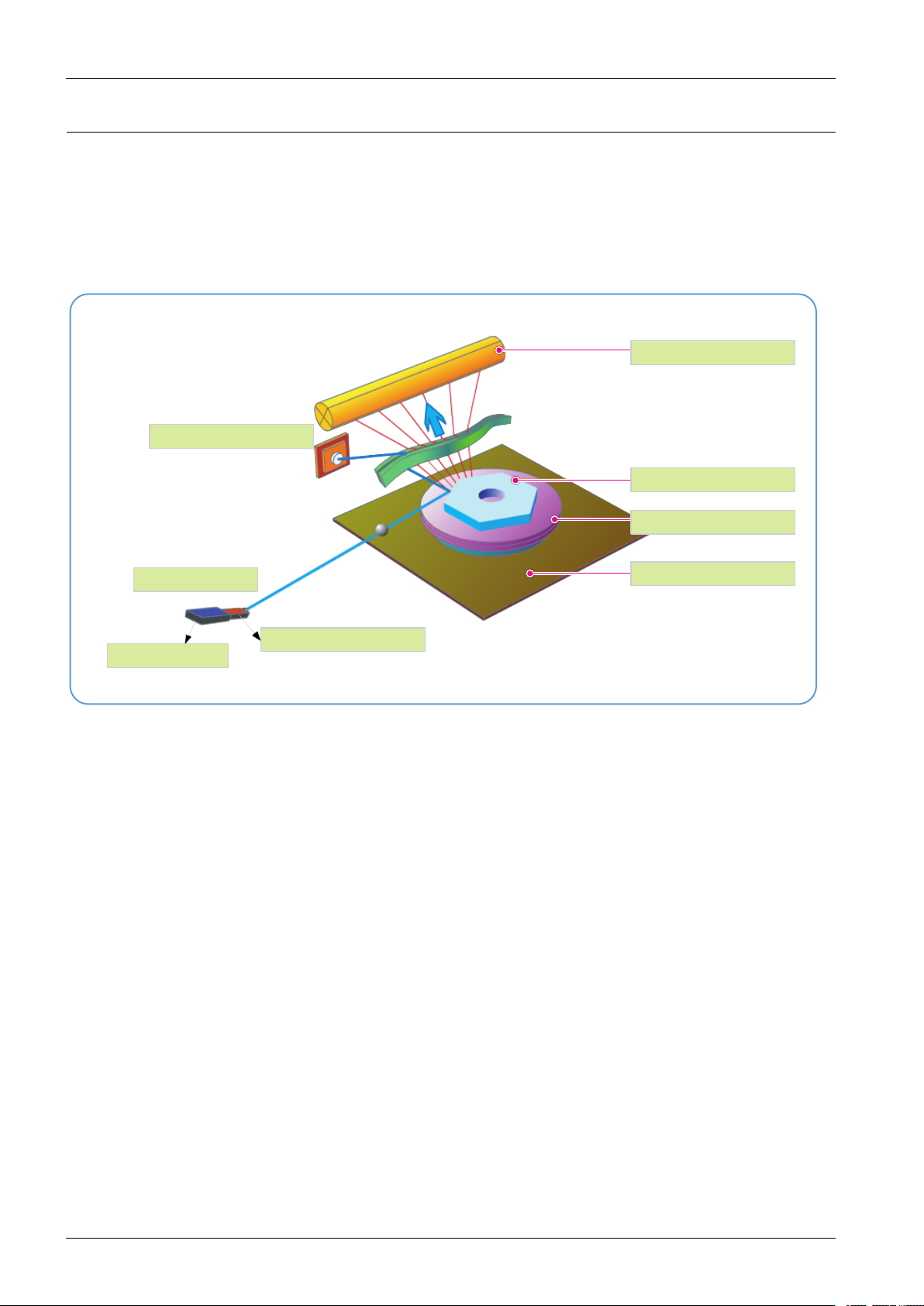

2.2.4.4.LSU(LaserScanningUnit)

ItisthecorepartoftheLBPwhichswitchesfromthevideodatareceivedtothecontrollertotheelectrostaticlatentimage

ontheOPCdrumbycontrollinglaserbeam,exposingOPCdrum,andturningprincipleofpolygonmirror.TheOPCdrumis

turnedwiththepaperfeedingspeed.The/HSYNCsignaliscreatedwhenthelaserbeamfromLSUreachestheendofthe

polygonmirror,andthesignalissenttothecontroller.Thecontrollerdetectsthe/HSYNCsignaltoadjusttheverticallineof

theimageonpaper.Inotherwords,afterthe/HSYNCsignalisdetected,theimagedataissenttotheLSUtoadjusttheleft

marginonpaper.Theonesideofthepolygonmirrorisonelineforscanning.

2-17Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 27

2.2.5.HardwareConguration

MAIN

C3N

533 MHz

FUSER Unit

ThermoS tat

Thermisto r1

Exit

Sen sor

Regi

Clutch

Pickup

Clutch

Front

Cover

Micro

Switch

24V

5V_SMP S

FUSER ON

Relay

24VS

3.3V

3.3V_Co ver_Op en1

3.3V_Co ver_Op en3.3V

DEVELOPER Unit

FAN

MAIN

FAN

SMPS

OPC MHV

DEV

Supp ly

THV

Varistor

T

D

S

DRUM

M

Main

Motor

MT

BLDC

Se rial Flas h

16MB

DDR3 1 DIMMP BA

Defa ult x1 6 128 MB(1Gb 1e a)

Opt ion x16 5 12MB(2Gb*2e a)

EEP ROM(I2C CH0 )

EEP ROM

24C51 2(Sys +NW)

SP I

000

000

00

000

00

00

00

00

00

00

00

00

000

000

000

00

00

SOL

C

R

U

M

0000

0000

RTL8211 E

Giga_ PHY

25MHz

FUSER

BIAS

INLET

MP

Clutch

Pap er

Size/Binful

Sen sor

Clock

Gene rato r

ASM3P28 63A

12MHz

MAINCLK

USB CLK

REF

0

0

USB 2 .0

Device

INLET

FUSER

SOL

HVPS

SMPS

24VS

EMPTY

Sen sor

REGI

Sen sor

MP

Sen sor

FEED

Sen sor

LSU MOTOR

Lase r Diod(Dua l Beam )

UART

Option

SCF

ECO

Canc el

Powe r

Statu s_LED

EC

O

C

ance

l

Na

vi

_K

E

Y

LCD

Relay

SYS TEM RAM

SO _DIMMCo n.

204 pin

Eras er

LED

SOL

5V

Usb

USB/P ara llel

0

DC-DC 3 CH

5V to 3 .3V,1.5V,1 .2V

2 Lin e LCD

I2C

3.3V/1.2 V

1.5V

Rea r Cove r

Micro Switch

PANEL

LSU

uart

Option

PARALLEL

(Parallel to US B)

DIMM_P BA

00

LDO

5V to 1 .8V

1.8V

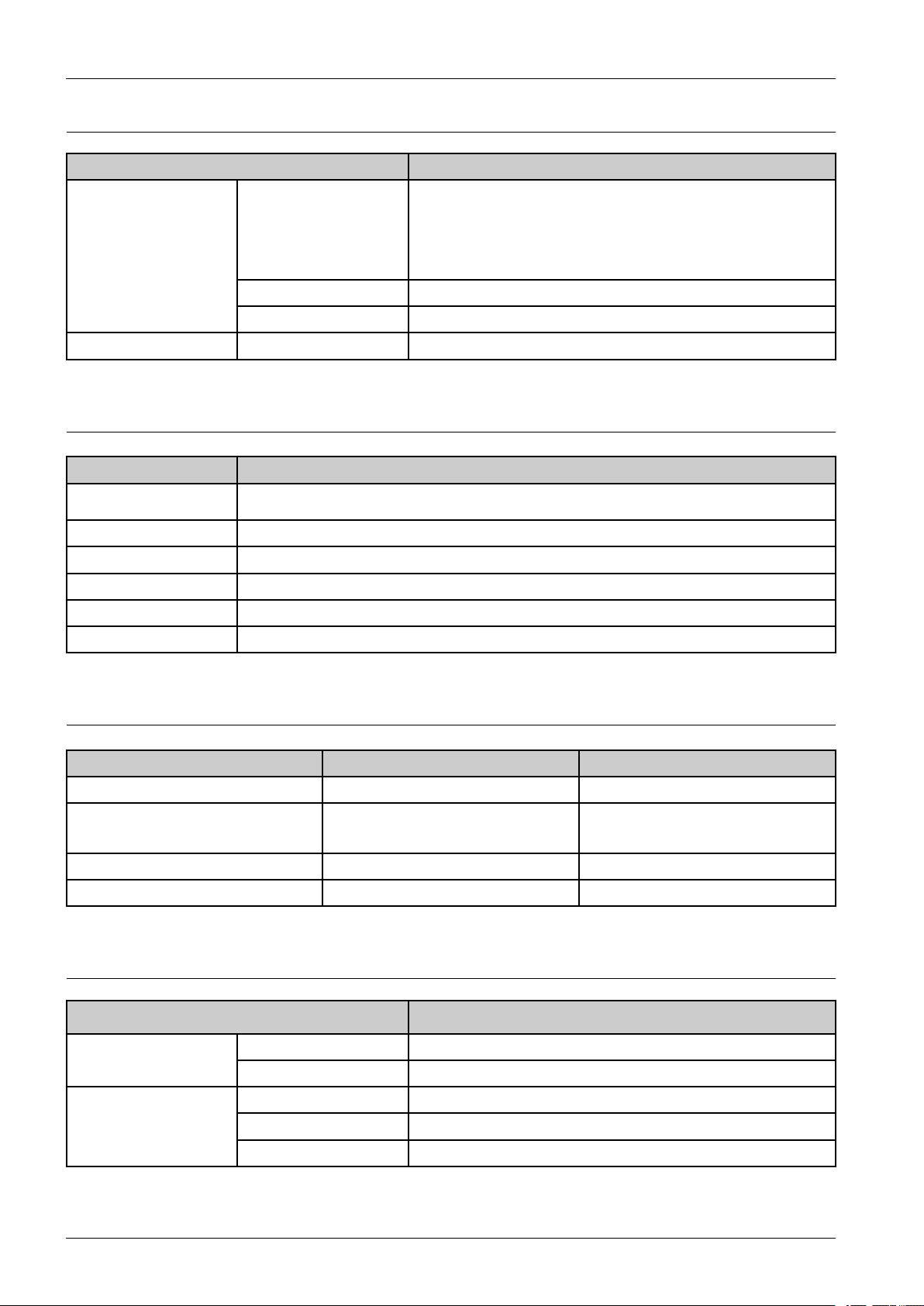

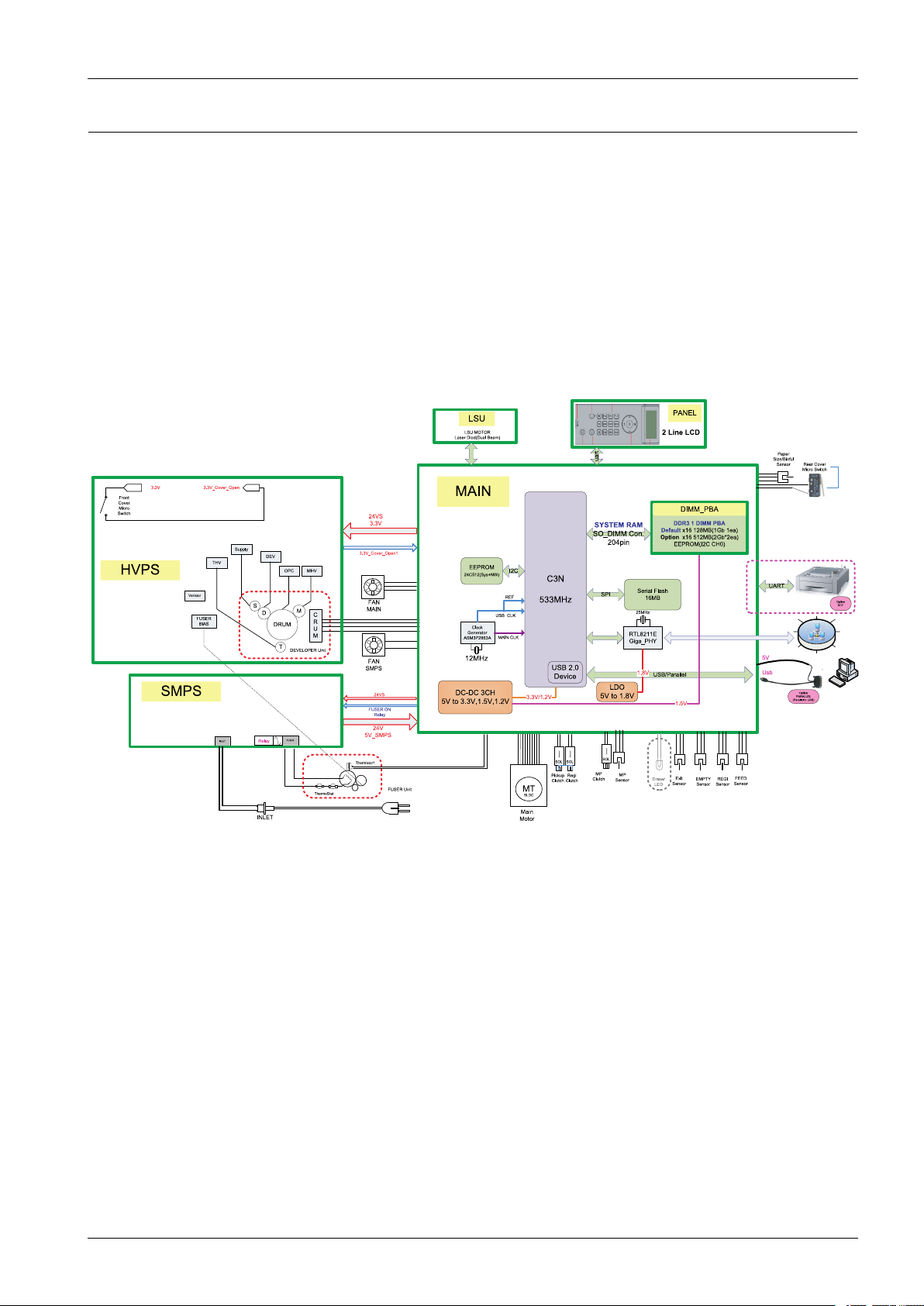

TheML-3750seriesElectricalCircuitSystemconsistsofthefollowing:

•Mainboard

•OPEboard

•SMPSboard

•HVPSboard

•SCFboard(Optional)

DiagramoftheML-3750SeriesElectricalCircuit

2.ProductSpecications

TheMainControllercontrolsallmodulesrequiredtoprint,thatis,LSU,HVPS,SMPS,FAN,Fuser,etc.

TheMainControllerreceivesprintdatafromthehostthroughnetworkorUSBPort.Ittakesthisinformationandgenerates

printablevideobitmapdata.EngineandVideoControllerarenotseparated.

TheMainControlleradoptstheChorus3N(533MHz)CPU,onboardDDR3memorytoperformprintingjobssuccessfully.

TheOPEControllerdisplaysthestatusofthesystemusing16x2lineLCDinresponsetouseractionsortheMaincontroller.

TheHVPSsupplieshighvoltagefordevelopingProcess.HighVoltagecontrolledbyPWMsignalfromCPU.

TheSMPSmakes+5Vand+24VDCfrom220Vor110AC.

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-18

Page 28

2.ProductSpecications

MAIN

C3 N

53 3 MHz

S e rial F las h

16 MB

DDR3 1 DIMM PBA

De fa u lt x16 1 28 MB(1 Gb 1 e a )

Op tion x16 512 MB(2Gb *2e a)

EE P RO M(I2C C H0)

EE P RO M

24C 512(S ys+NW)

S P I

RTL82 11 E

Giga _PHY

25MHz

Clock

Ge nera tor

ASM3P 2863 A

12 MHz

MAIN CLK

USB C LK

REF

US B 2 .0

De vice

S YSTEM R AM

S O_DIMM Con.

20 4pin

US B/P a ra llel

DC-DC 3 CH

5V to 3.3V,1.5 V,1.2V

I2C

3.3 V/1.2 V

1.5 V

DIMM_PBA

LDO

5V to 1.8V

1.8 V

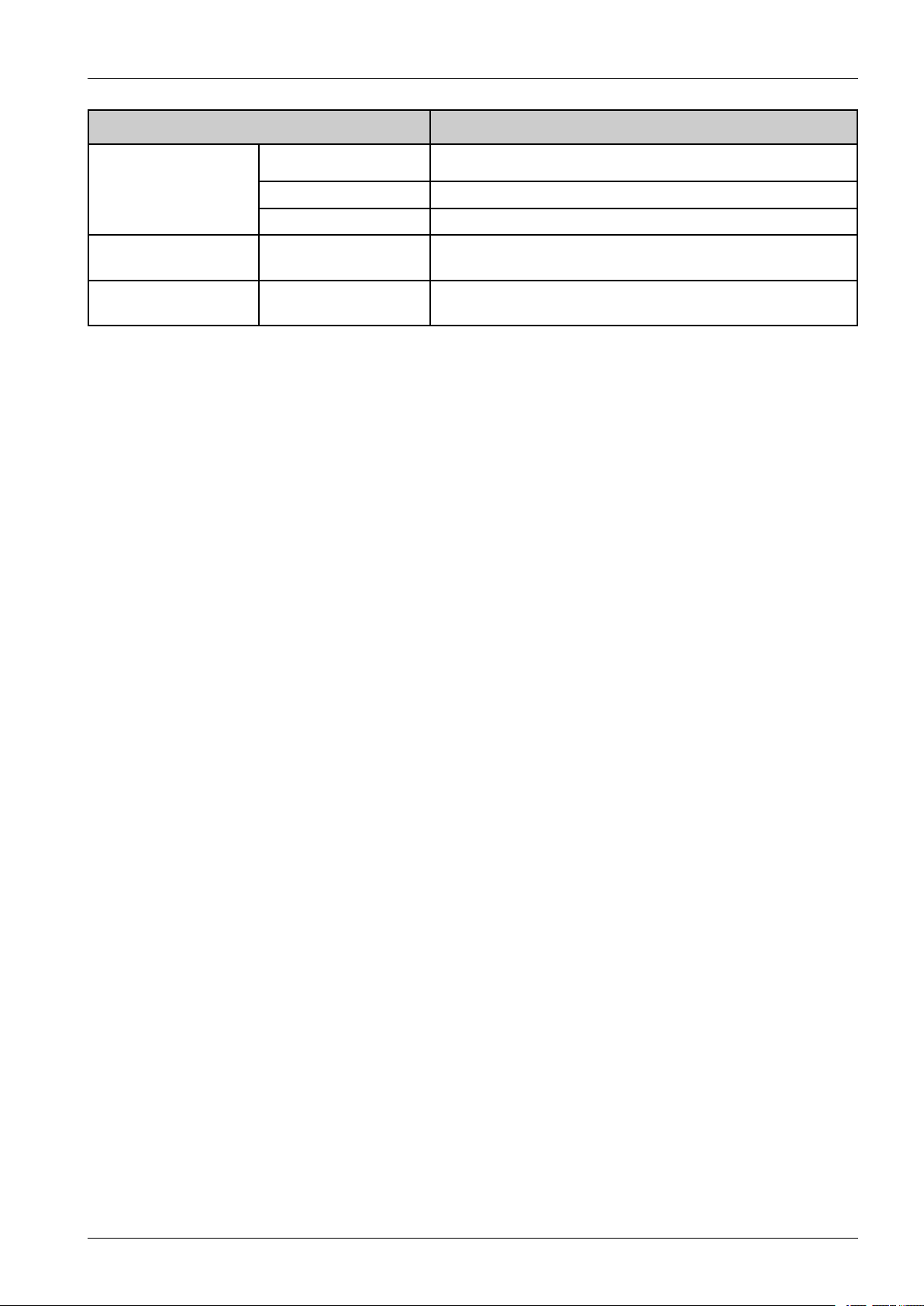

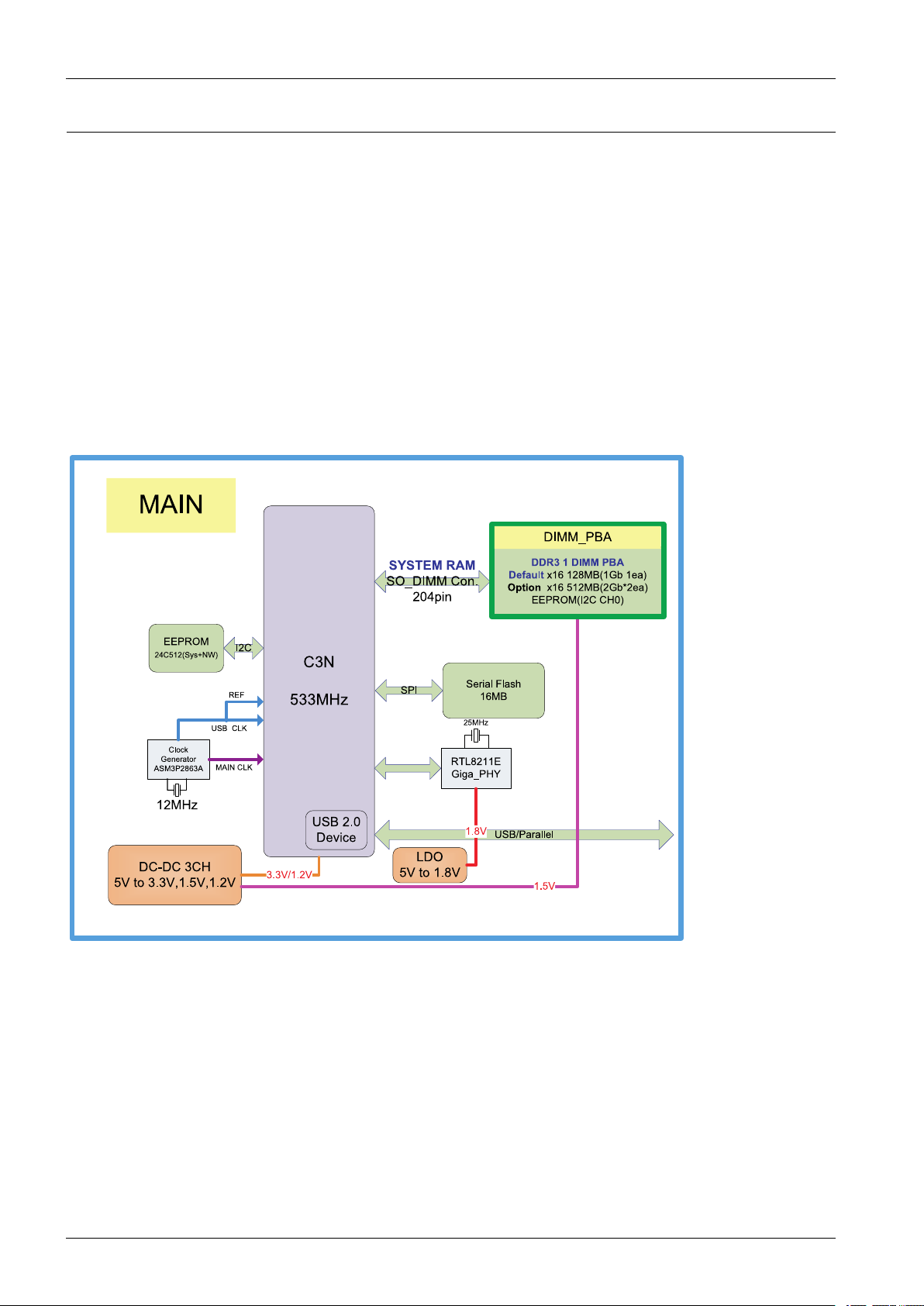

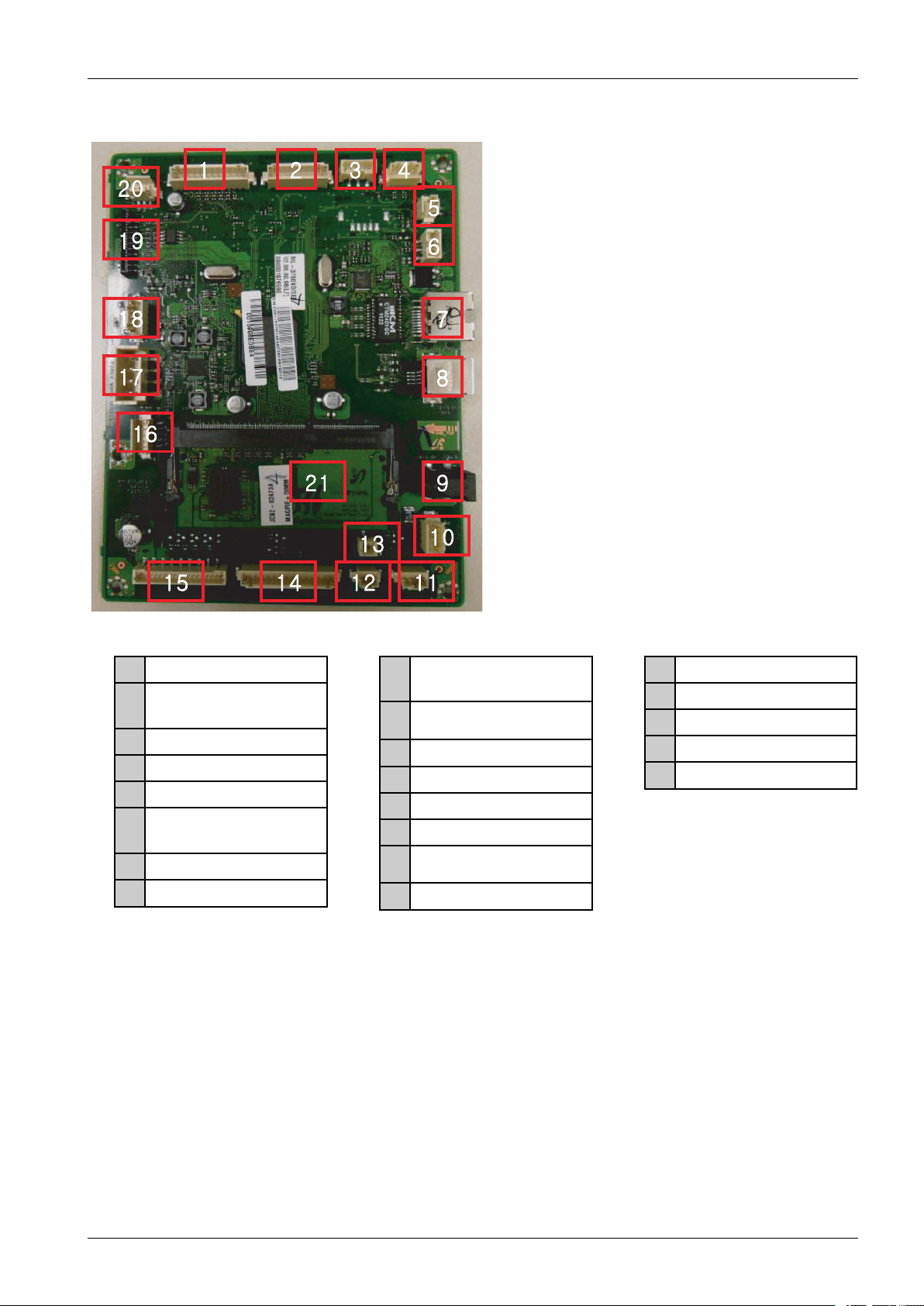

2.2.5.1.Mainboard

ML-3750seriesMainboardiscomposedwithbelowcomponents.

•Chorus3N:T ogeneratetheprintablevideodataandcontrolengineEmbeddedUSB2.0device,Hostchannel

•Systemmemory-1CHDIMMPBADDR3128MB(Default)

•GigaEthernetPHY:Networkprinting

•SerialFlash(16MB):Programmemory

TheMainControllermanagesanElectro-photographysystem,controlstheVideoDataofprintingimagesfromMainBoard

toLSU,provideshigh-voltagesandPWMs,adjuststemperatureinthefusingsystem,readssensorsignalsandcontrols

SCFoption.

TheMaincontrolleralsocontrolsOPEandGigaN/WPHY ,USBDevice.

[Mainboarddiagram]

2-19Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 29

[Mainboardimage]

v

v

e

e

w

w

e

e

x

x

e

e

y

y

e

e

z

z

e

e

{

{

e

e

|

|

e

e

}

}

e

e

~

~

e

e

v

v

uue

e

v

v

vve

e

v

v

wwe

e

v

v

xxe

e

v

v

yye

e

v

v

zze

e

v

v

{{e

e

v

v

||e

e

v

v

}}e

e

v

v

~~e

e

w

w

uue

e

w

w

vve

e

2.ProductSpecications

•Connection

1HVPS

2PaperEmpty,Regi,Feed

sensor

3OPE

4CRUM

5THERMISTOR

6OutbinFullSensor&Rear

Cover

7N/W

8USBDevice

•Information

-PartCode:JC92-02469A

-PBAName:PBA-MAIN

9ParallelOptionDCsupply

10Debug

11ExitSensor

12F ANSMPS

13Airtemperature

14MainMotor&Clutch

15SCF

16SMPSSignal

17SMPSPower

jack

18MP

19LSU

20F ANMAIN

21DDR3SODIMM

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-20

Page 30

2.ProductSpecications

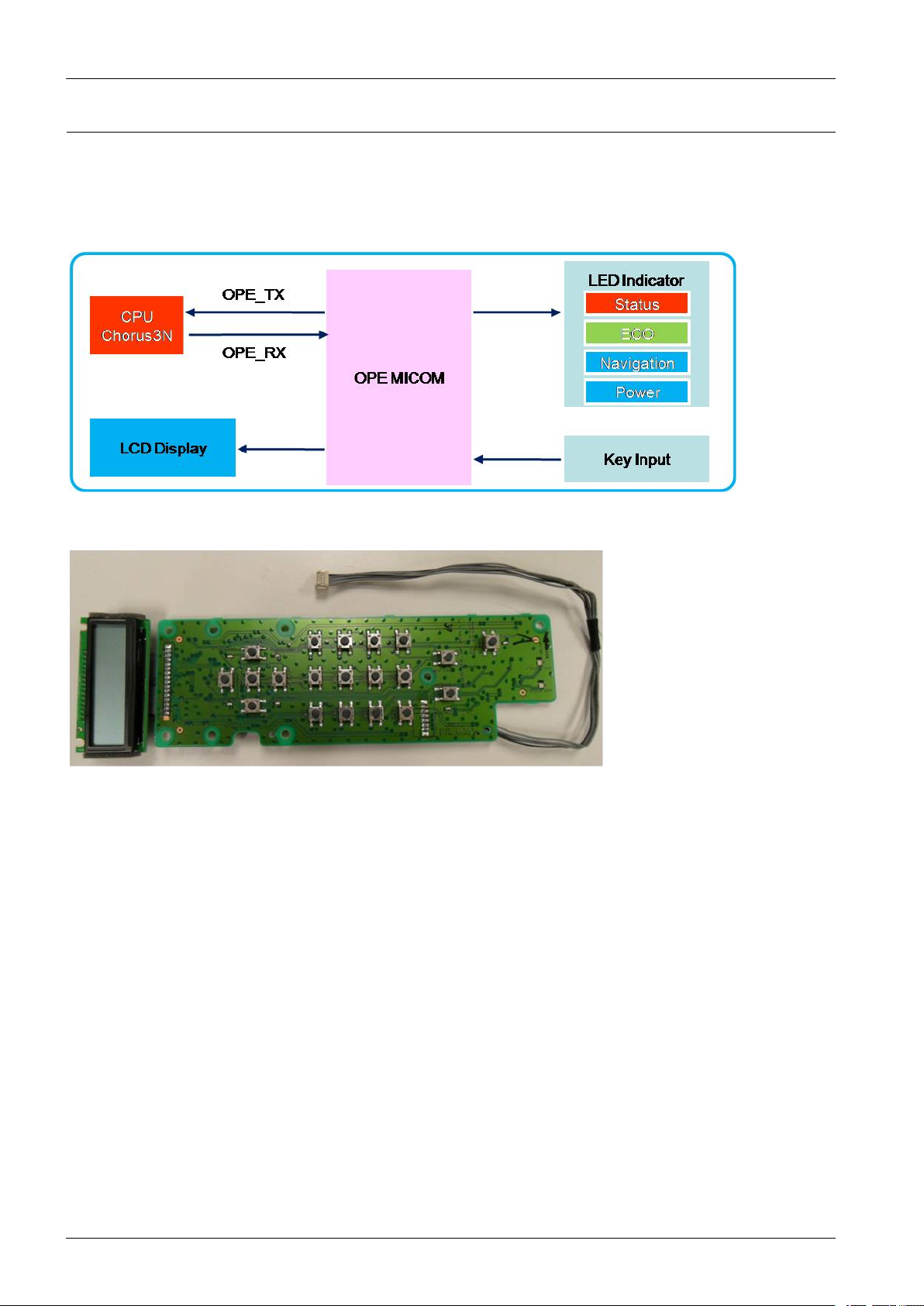

2.2.5.2.OPEboard

TheOPEboardiscomposedofanOPEMICOM(STM8SP103K3MAFTR),twostatusLED,ECOLED,powerLED,four

navigationLED,16x2lineLCDandsomekeys.OPEcommunicateswithmaincontrollerviaUART .

[OPEboarddiagram]

[OPEboardimage]

•Information

-PartCode:JC92-02468A

-PBAName:OPE-LCD

2-21Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 31

2.ProductSpecications

2.2.5.3.DIMMPBA-Optional

TheDIMMPBAisasystemmemorymoduleofthemainboard.Itisusedfortheoperatingsystem,somesystemapplication

programs,anditstoressomeprintdatafromtheUSBandNetworkport.TherearetwokindsofDIMMPBA.Oneis128

MB(default),theotheris512MB(optional).Toinstallthe512MBmemory,youhavetoremovethe128MBmemory.

•Information

-JC92–02473A:128MB(Default)

-CLP-MEM370:512MB(Optional)

2.2.5.4.SCFboard-Optional

TheSCFPBAistheSCFcontrolboard.ItuseUARTcommunicationwithmaincontroller.S3F443FXisusedasa

microcontroller.

•Information

-PartCode:JC82–00192A

-PBAName:A/SASSY -PBASCFMAIN

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-22

Page 32

2.ProductSpecications

2.2.5.5.SMPSboard

TheSMPS(SwitchingModePowerSupply)BoardsupplieselectricpowertotheMainBoardandotherboardsthrougha

MainController.Thevoltageprovidedincludes+5V ,and+24Vfroma110V/220Vpowerinput.

[SMPSboardimage]

•Specication

GeneralInput/OutputV oltage

-AC110V(90V~135V)

-AC220V(180V~270V)

-OutputCurrent

▪+5V:1.6A

▪+24V:1.8A

-OutputPower

▪+5V:8.16W

▪+24V:43.2W

-HeatLampCapacity:850W

•Information

110V220V

PartCodeJC44-00095DJC44-00096D

PBANameSMPSV1SMPSV2

•Connection

1INPUT_AC

2Fuser_ACOutput

3SMPSControlSignal(fromEnginePBA)

4OUTPUT_5V&24V(toDCPOWERPBA)

2-23Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 33

2.ProductSpecications

2.2.5.6.HVPSboard

HighV oltagePowerSupply(HVPS)boardgenerateshigh-voltagechannelswhichincludesMHV,DEV ,BLADE,SUPPL Y,

OPC,THVandFUSERBIAS.

•Connection

•Information

-PartCode:JC44-00197A

-PBAName:HVPS

1MainInterface

2MHV(-1240V)

3DEV(-338V)

4BLADE(-389V)

5SUPPLY(-489V)

6OPC(-51V)

7THV(+1315V,-1000V)

8FUSERBIAS(240V)

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-24

Page 34

2.ProductSpecications

2.2.6.EngineF/WControlAlgorithm

2.2.6.1.Feeding

Iffeedingfromacassette,thedriveofthepickuprolleriscontrolledbycontrollingtheclutch.Theon/offoftheclutchis

controlledbycontrollingthegeneraloutputportortheexternaloutputport.Whilepapermoves,occurrenceofJam

isjudgedasbelow.

ItemDescription

JAM0•Afterpickingup,paperdoesnotreachtheFeedSensorwithinapredeterminedtime.

•Afterpickingup,ifthefeedsensorisnoton,re-pickupwillbeinitiated..Afterre-pickingup,ifthe

feedsensorisnotonaftercertaintime,itisJAM0.

•Eventhoughthepaperreachestothefeedsensor,thefeedsensordoesnotdetecttheleadedgeof

thepaper.

JAM1•Aftertheleadingedgeofthepaperpassesthefeedsensor,thetrailingedgeofthepaperdoesnotclear

thesensorafterpredeterminedperiodoftime.

•Aftertheleadingedgeofthepaperpassesthefeedsensor,thepapercannotreachtheexitsensor

afterpredeterminedperiodoftime.

*Thepaperexistsbetweenthefeedsensorandtheexitsensor.

JAM2•Thetrailingedgeofthepaperdoesnotcleartheexitsensorwithinapredetermined.

2.2.6.2.Transfer

Thechargingvoltage,developingvoltageandthetransfervoltagearecontrolledbyPWM(PulseWidthModulation).The

eachoutputvoltageischangeableduetothePWMduty.Thetransfervoltageadmittedwhenthepaperpassesthetransfer

rollerisdecidedbyenvironmentconditions.Theresistancevalueofthetransferrollerischangedduetothesurrounding

environmentortheenvironmentoftheset,andthevoltagevalue,whichchangesduetotheenvironment,ischangedthrough

theADconverter.Thevoltagevalueforimpressingtothetransferrollerisdecidedbythechangedvalue.

2-25Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 35

2.ProductSpecications

2.2.6.3.Fusing

Thetemperaturechangeoftheheatroller’ssurfaceischangedtotheresistancevaluethroughtheuseofathermistor.

TheMainBoardusestheresistancevalueoftheThermistorandconvertsittoavoltagevaluethroughtheuseofanAD

converter,thetemperatureisdecidedbasedonthevoltagevalueread.TheACpoweriscontrolledbycomparingthetarget

temperaturetothevaluefromthethermistor.Ifthevaluefromthethermistorisoutofcontrollingrangewhilecontrollingthe

fusing,theerrorstatedinthebelowtableoccurs.

•OpenHeatError

Whentheengineoperatesthewarm-upprocess,ifthetemperatureofthexingunitisnothigherthanaspecied

temperaturewithinapredeterminedtime,theenginedenesOpenHeatError.Whenthiserrorisdetected,theengine

stopsallfunctionsandkeepstheerrorstate.Also,theengineinformstheerrorstatusofthemainsystem,soitcantake

appropriateaction;andthentheerrormessageisdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.

•LowHeatError

Whentheengineisatstand-by,printingorwarm-upmode,ifthetemperatureofthexingunitislowerthanthe

speciedtemperatureateachstateandthelowertemperaturestateismaintainedduringthespeciedtime,theengine

denesLowHeatError.Whenthiserrorisdetected,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,

theengineinformstheerrorstatusofthemainsystem,soitcantakeappropriateaction;andthentheerrormessage

isdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.

•OverHeatError

Foroverallenginestate,ifthetemperatureofthexingunitishigherthanthespeciedtemperatureandthetemperature

stateisdetectedforaspecicduration,thentheenginedenesOverHeatError.Whenthiserrorisdetected,theengine

stopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthemainsystem,soit

cantakeappropriateaction;andthentheerrormessageisdisplayedatLCDwindoworLEDinformingtheerror

statusoftheuser.

2.2.6.4.LSU

LSUreceivestheimagedatafromPVCorHPVCandmakethelatentimageonOPCsurface.Itusesthedualbeam,

LD.TheerrorsrelatedtoLSUareasfollows:

•ByLready

Whentheprintingisstarted,theenginedrivesthepolygonmotorofLSU.Afterthespeciedtimeiselapsed,ifthe

motorisnotinareadystatus,theenginedetectstheerrorthatthepolygonmotorisnotinareadystatus.Ifthiserror

happens,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthe

mainsystemandtheerrormessageisdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.

•ByHsync

Whenthepolygonmotorisready,theLSUsendsoutthesignalcalledHsyncandusedtosynchronizewitheachimage

line.So,iftheenginedoesnotdetectconsecutivelythesignalforaxedtime,itdenestheHsyncError.Ifthiserror

happens,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthe

mainsystemandthentheerrormessageisdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.LSU

ErrorRecovery:IftheLReadyorHsyncerrorhappens,thepaperisexitedbeforetheerrorcodeisinitiated.Theengine

modeischangedtorecoverymodeandtheengineinformsthemainsystemoftheenginemode.Theenginerechecks

theLSUerror,iftheerrordoesnotreoccurprintingisresumed.

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-26

Page 36

2.ProductSpecications

P r in te r /MFP

HOS T

S o ftwa re

Driv e r

Web -b a s ed

App lic atio n

S ta n d -a lo n e

App lic atio n

Fi rm wa r e

App lic atio n

(Em ula tio n)

Ker n e l

2.2.7.SoftwareDescriptions

2.2.7.1.Softwaresystemoverview

Thesoftwaresystemofthismodelisconstructedwith

•HostSoftwarepartthattheapplicationsoftwareoperatedinWindowandWebEnvironment

•FirmwarepartsthatisaEmbeddedsoftwarecontrolsprintingjob.

2.2.7.2.Architecture

HostSoftwareismadeupof

1)GraphicUserInterfaceoffersthevariouseditingfunctionstouserinHost.

2)DrivertranslatesthereceiveddocumenttoaPrintingCommandlanguagewhichprintercanunderstandandtransfers

datatospooler.

3)Stand-aloneApplicationoffersthevariousprintingapplicationsuchasEasyPrinterManager,PrinterStatusinWindow

system.

4)Web-based-ApplicationoffersthesamefunctionsasStand-aloneApplicationinWebenvironment.

Firmwareismadeupof

1)Application(Emulation)thatisainterpretertranslatesdatareceivedfromHosttoaprintinglanguage(PCL,PS,GDI,

etc.)tobeabletomaketheusertotakesameoutputasoriginallyonewhatcomposedinHost.

2)KernelcontrolsandmanagethewholeprocedureincludingControlowandPrintingJobbeforetransferringtoEngine

system.

2-27Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 37

2.2.7.3.DataandControlFlow

Drive r

- PCL3, PS 3

Web -b as e d

- Do c ument Manag e m e nt

S ys te m

- Netwo rk Ad m inis tration

- S ta tus Monito r

- Re m o te Co ntrol Pa ne l

S t a n d -a lo n e

- P rinter S etting Utility

- Netwo rk Ad m inis tration

- S ta tus Monito r

Q

Q

p

p

s

s

uu

N

N

p

p

o

o

jj

u

u

p

p

s

s

Netwo r k

Interfa c e

App lic a tio n

KERNEL

App lic a tio n

(Em ulatio n )

- P CL

- P S 3

En g in e

US B

Ho s t Firm w a re

2.ProductSpecications

TheaboveBlockDiagramisexplainedthat:

HostSideismadeupof

1)DriverthatisWindowsapplicationsoftwaretranslateprinteddatatooneofprinterlanguageandcreatespoolerle.

2)Web-basedApplicationthatofferavariousprinteradditionalfunctions,managementofprintingjob,printer

administration,StatusmonitortomonitoringtheprinterstatusbyrealtimeinW eb,independentenvironmentonOS.

3)Stand-aloneApplicationthatisasimilarWindowsoftwareassameasabove2.

4)PortMonitorthatmanagesthenetworkcommunicationbetweenspoolerandNetworkInterfaceCard,orvarious

additionalapplicationandNetworkInterfaceCard,(thisis,atrst,makecommunicationlogicalport,managethedata,

transferthemfromspoolertonetworkport,andoffertheresultofprinting).

FirmwareSideismadeupof

1)NetworkInterfaceCardisthatrelaythecommunicationbetweenHostandkernelusingvariousnetworkprotocol.

2)Kernelisthatmanagestheowcontrolofemulationprocedure,receivingdatafromHostorNetworkcardandprinting

withengine&renderingjob.

Copyright©1995-2011SAMSUNG.Allrightsreserved.2-28

Page 38

2.ProductSpecications

3)Emulationisthatinterpretsthevariousoutputdatafromselectedemulation.

4)Engineisthatprintsrenderedbit-mapdatatopaperwithrequiredsizeandtypebyKernel.

Andthen,forJobSpoolingfunctionforMulti-User,Multi-PrintingthatisoccurredinNetworkprintingandvarious

additionalprintingfunctions,thisKernelusemax.10Queuingsystemsinamemory.

InPrinting,thetwoproceduresare

1)CaseofusingUSBPort

•AfteruserstarttoprintthewanteddocumenttoPCLstringorcompressedGDIbit-mapdata,theDrivertranslates

theallgraphicdataoftheclientPCandsenddatatohostspooler.Andthenthespoolersendsthedatastreamto

theprinterviaUSBport.

•KernelreceivesthisdatafromHost,andthenselectemulationttodataandstartselectedone.Afteremulationjob

end,Kernelsendstheoutputbit-mapdatatoEngineusingPrinterVideoController(byclocktypeforLSU).

•Engineprintthereceiveddatatorequiredpaperwiththesequentialdevelopingprocess.

2)CaseofusingNetworkInterfaceCard

•AfteruserstarttoprintthewanteddocumenttoPCLstringorcompressedGDIbit-mapdata,Drivertranslatethe

allgraphicdataofitandsenddatatohostspooler.

•Ifso,PortmonitormanagingnetworkportreceivesdatafromspoolerandsendsadatastreamtotheNetwork

InterfaceCard.

•NetworkinterfacecardreceivesitandsendtoKernelpart.

•KernelreceivesthisdatafromHost,andthenselectemulationttodataandstartselectedone.Afteremulationjob

end,Kernelsendstheoutputbit-mapdatatoEngineusingPrinterVideoController(byclocktypeforLSU).

•Engineprintthereceiveddatatorequiredpaperwiththesequentialdevelopingprocess.

2-29Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 39

3.DisassemblyandReassembly

3.DisassemblyandReassembly

3.1.Precautionswhenreplacingparts

3.1.1.Precautionswhenassemblinganddisassembling

•UseonlyapprovedSamsungspareparts.Ensurethatpartnumber,productname,anyvoltage,currentortemperature

ratingarecorrect.Failuretodosocouldresultindamagetothemachine,circuitoverload,reorelectricshock.

•Donotmakeanyunauthorizedchangesoradditionstotheprinter,thesecouldcausetheprintertomalfunctionand

createelectricshockorrehazards.

•Takecarewhendismantlingtheunittonotewhereeachscrewgoes.Thereare19differentscrews.Useofthewrong

screwcouldleadtosystemfailure,shortcircuitorelectricshock.

•DonotdisassembletheLSUunit.Onceitisdisassembleddustisadmittedtothemirrorchamberandwillseriously

degradeprintquality .Therearenoserviceablepartsinside.

•Regularlychecktheconditionofthepowercord,plugandsocket.Badcontactscouldleadtooverheatingandrfe.

Damagedcablescouldleadtoelectricshockorunitmalfunction.

3.1.2.PreautionswhenhandlingPBA

StaticelectricitycandamageaPBA,alwaysusedapprovedanti-staticprecautionswhenhandlingorstoringaPBA.

•PrecautionswhenmovingandstoringPBA

1)PleasekeepPBAinaconductivecase,anti-staticbag,orwrappedinaluminumfoil.

2)DonotstoreaPBAwhereitisexposedtodirectsunlight.

•PrecautionswhenreplacingPBA

1)Disconnectpowerconnectorsrst,beforedisconnectingothercables.

2)Donottouchanysolderedconnections,connectorterminalsorotherelectronicpartswhenhandlinginsulatedparts.

•PrecautionswhencheckingPBA

1)BeforetouchingaPBA,pleasetouchothergroundedareasofthechassistodischargeanystaticelectricalcharge

onthebody.

2)TakecarenottotouchthePBAwithyourbarehandsormetalobjectsasyoucouldcreateashortcircuitorgetan

electricshock.TakeextracarewhenhandlingPBAswithmovingpartsttedsuchassensors,motorsorlampsas

theymaygethot.

3)Takecarewhentting,orremoving,screws.Lookoutforhiddenscrews.Alwaysensurethatthecorrectscrewis

usedandalwaysensurethatwhentoothedwashersareremovedtheyarerettedintheiroriginalpositions.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-1

Page 40

3.DisassemblyandReassembly

3.1.3.ReleasingPlasticLatches

Manyofthepartsareheldinplacewithplasticlatches.Thelatchesbreakeasily;releasethemcarefully.

Toremovesuchparts,pressthehookendofthelatchawayfromtheparttowhichitislatched.

3-2Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 41

3.DisassemblyandReassembly

3.2.Screwsusedintheprinter

Thescrewslistedinthetablebelowareusedinthisprinter.Pleaseensurethat,whenyoudisassembletheprinter,youkeep

anoteofwhichscrewisusedforwhichpartandthat,whenreassemblingtheprinter,thecorrectscrewsareusedinthe

appropriateplaces.

PartCodeLocationDescriptionQty

6002-000440DUPLEXSCREW-T APPING;PWH,+,2,M3,L8,ZPC(BLK),SWRCH18A5

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPLT ,SWRCH18A20

6003-000261SCREW-T APTYPE;BH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,-2

6003-000269

6003-000196MPSCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A2

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPLT ,SWRCH18A5

6003-000269SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-3

6003-000282

6003-000269DRIVESCREW-TAPTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-6

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPLT ,SWRCH18A38

6003-000261SCREW-T APTYPE;BH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,-3

6003-000301

6006-001078FRAME-ETCSCREW-T APTYPE;PH,+,WSP ,B,M3,L10,ZPC(WHT),SWRCH18A1

6003-000282LSUSCREW-TAPTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-5

6003-000196COVER-TOPSCREW-TAPTYPE;PWH,+,B,M3,L10,NIPL T ,SWRCH18A3

6003-000196COVER-FRONTSCREW-TAPTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A2

6003-000264MPGUIDE-TRAYSCREW-T APTYPE;PWH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,-1

6003-000282CARTRIDGE-TONERSCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-5

6003-000196OPESCREW-TAPTYPE;PWH,+,B,M3,L10,NIPLT,SWRCH18A5

FRAMEMAIN

SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-3

FUSER

SCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-4

FRAME-ETC

SCREW-T APTYPE;BH,+,S,M4,L6,ZPC(WHT),SWRCH18A1

6003-000196MAINLINESCREW-TAPTYPE;PWH,+,B,M3,L10,NIPL T ,SWRCH18A9

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-3

Page 42

3.DisassemblyandReassembly

3.3.ReplacingtheMainSVCparts

3.3.1.Cover

1.Removethecassette.

2.Openthefrontcover.Removethetonercartridge.

4.Toremovethetopcover,rst,remove2screws.

5.Opentherearcover.Remove2screws.

3.Removethefrontcoverbyreleasingbothhooks.

3-4Copyright©1995-2011SAMSUNG.Allrightsreserved.

6.Unplugaconnectoronthemainboard.

Page 43

3.DisassemblyandReassembly

7.Liftupandreleasethetopcover.

8.Closetherearcover.Removetheduplexunit.

10.Removetheleftcoverbyreleasinghooks.

11.Removetherightcoverbyreleasinghooks.

9.Removetherearcoverbyreleasingbothhooks.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-5

Page 44

3.DisassemblyandReassembly

3.3.2.Mainboard

1.Removetherightcover.(Referto3.3.1Cover)

2.Unplugallconnectorsonthemainboard.

3.Remove4screws.

3.3.3.HVPSboard

1.Removetherightcover.(Referto3.3.1Cover)

2.Remove5screws.

3.UnplugallconnectorsontheHVPSboard.

4.Releasethemainboard.

4.ReleasetheHVPSboard.

3-6Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 45

3.3.4.SMPSboard

3.DisassemblyandReassembly

1.Removetherightcover.(Referto3.3.1Cover)

2.UnplugallconnectorsontheSMPSboard.

3.Remove4screws.

3.3.5.LaserScanningUnit(LSU)

1.Removethetopcover.(Referto3.3.1Cover)

2.Unplug2atcablesfromtheLSU.

3.Remove3screws.

4.ReleasetheSMPSboard.

4.ReleasetheLSU.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-7

Page 46

3.DisassemblyandReassembly

3.3.6.Fuserunit

CAUTION

Thetemperaturegetshighinthevicinityofthefuserunit.

Whenreplacingit,youmaygetburned.Beforereplacing

it,makesurethatfuserunithascooled.

1.OpentheFrame-Rearbypushingbothgreenpoints.

2.RemovetheFrame-Rearbyreleasingbothhooks.

3.Removetheexitsensorholderafterremoving2screws.

4.Remove4screws.

CAUTION

Whenreassemblingthefuserunit,donotforgetto

tightenthesescrews.

5.Releasethefuserunit.

3-8Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 47

3.3.7.MainDriveunit

1.Removetheleftcover.(Referto3.3.1Cover)

2.RemovetheBarcoupler.

3.Removethemaindriveunitafterremoving6screws.

3.DisassemblyandReassembly

NOTE

Whenreassemblingthemaindriveunit,tighten6screws

inorderasshownabove.

4.Unplugtheconnectorfromthemainmotor.

5.Releasethemaindriveunit.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-9

Page 48

3.DisassemblyandReassembly

3.3.8.Feeddriveunit

1.Removethemaindriveunit.(Referto3.3.7)

2.Releasethefeeddriveunitafterremoving2screwsand

1E-ring.

3-10Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 49

3.DisassemblyandReassembly

3.3.9.Pickup/Regi./MPClutch

1.Removethefeeddriveunit.2.Fortheclutchtorequirereplacement,unplugthe

connectorthenreplaceit.

3.3.10.Pickuproller

1.Removethecassetteandduplexunit.

2.Pullthesmalltapdown,thenreleasethepickuproller.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-11

Page 50

3.DisassemblyandReassembly

3.3.11.TransferRoller

1.Removethetopcover.(Referto3.3.1Cover)

2.ReleasetheLSUbracketafterremoving4screws.

3.Pushthetransferrollerholdertothecenterandrelease

it.

3.3.12.MPunit

4.Removethetransferroller.

1.Removethefront/top/rightcover.

2.Remove4screws.

3.SeparatetheMPlowerfromtheMPupper.

3-12Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 51

3.3.13.OPEboard

1.Removethetopcover.(Referto3.3.1Cover)

2.ReleasetheOPEboardafterremoving4screws.

3.DisassemblyandReassembly

3.3.14.Bin-fullsensor

1.Removethetop/leftcover.(Referto3.3.1Cover)

2.Releasethebin-fullsensorafterunpluggingthe

connector.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-13

Page 52

3.DisassemblyandReassembly

3.3.15.Regi_Feed_Emptysensor

1.Removethecassetteandduplexunit.

2.RemovethePLATE-FRAMEBOTTOMafterremoving

4screws.

3.Removethesensorcoverafterremoving2screws.

5.Removethesensorcoverafterremoving2screws.

6.Unplugtheconnectorthenreleasetheemptysensor.

4.Forthesensortorequirereplacement,unplugthe

connectorthenreplaceit.

3-14Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 53

3.3.16.Cassetteroller(Retardroller)

3.DisassemblyandReassembly

1.Removethecassette.

2.OpentheCOVER-CASSETTE.

3.ReleasetheRetardroller.

Copyright©1995-2011SAMSUNG.Allrightsreserved.3-15

Page 54

4.AlignmentandTroubleshooting

vv

e

e

w

w

x

x

y

y

}

}

|

|

{

{

zz

~

~

v

v

u

u

4.AlignmentandTroubleshooting

4.1.AlignmentandAdjustments

Thischapterdescribesthemainfunctionsforservice,suchastheproductmaintenancemethod,thetestoutputrelatedto

maintenanceandrepair,Jamremovingmethod,andsoon.

4.1.1.ControlPanel

1DisplayShowsthecurrentstatusandpromptsduringanoperation.

2MenuEntersmenumodeandscrollsthroughtheavailablemenus.

3OKConrmstheselectiononthedisplay .

4BackSendsyoubacktotheuppermenulevel.

5NumerickeypadUsethekeypadtoenternumbersandcharacters.ItisusefulforenteringIP

6CancelStopsanoperationatanytime.

7PowerYoucanturnthepoweronandoffwiththisbutton.

8StatusLEDShowsthestatusofyourmachine.

9EcoEntersecomodetoreducetonerconsumptionandpaperusage.

10ArrowsNavigatesavailablevaluesbymovingtothenextorpreviousoptions.

4-1Copyright©1995-2011SAMSUNG.Allrightsreserved.

addresses.

Page 55

4.1.2.UnderstandingTheStatusLED

ThecoloroftheStatusindicatesthemachine’scurrentstatus.

StatusDescription

OffThemachineisoff-line.

BlinkingThemachineisreceivingdatafromthecomputerorthemachineisprintingdata. Green

OnThemachineison-lineandcanbeused.

4.AlignmentandTroubleshooting

Red

Blinking•Aminorerrorhasoccurredandthemachineiswaitingfortheerrortobe

cleared.Checkthedisplaymessage.Whentheproblemiscleared,the

machineresumes.

•Smallamountoftonerisleftinthecartridge.Theestimatedcartridge

lifeoftonerisclose.Prepareanewcartridgeforreplacement.Y oumay

temporarilyincreasetheprintingqualitybyredistributingthetoner.

On•Atonercartridgehasalmostreacheditsestimatedcartridgelife*.

•Thecoverisopened.Closethecover.

•Thereisnopaperinthetray .Loadpaperinthetray.

•Themachinehasstoppedduetoamajorerror.

•Apaperjamhasoccurred.

*Estimatedcartridgelifemeanstheexpectedorestimatedtonercartridgelife,whichindicatestheaveragecapacityof

print-outsandisdesignedpursuanttoISO/IEC19752.Thenumberofpagesmaybeaffectedbyoperatingenvironment,

printinginterval,graphics,mediatypeandmediasize.Someamountoftonermayremaininthecartridgeevenwhen

redLEDisonandtheprinterstopsprinting.

Copyright©1995-2011SAMSUNG.Allrightsreserved.4-2

Page 56

4.AlignmentandTroubleshooting

0

0

0

0

4.1.3.Clearingpaperjams

NOTE

Toavoidtearingthepaper,pullthejammedpaperoutslowly

andgently.

Intray1

1)Openandclosethefrontcover.Thejammedpaperis

automaticallyejectedfromthemachine.

Ifthepaperdoesnotexit,gotothenextstep.

2)Pullouttray1.

Inoptionaltray2

3)Removethejammedpaperbygentlypullingitstraight

out.

Ifthepaperdoesnotmovewhenyoupull,orifyou

donotseethepaperinthisarea,checkthefuserarea

aroundthetonercartridge.

4)Inserttray1backintothemachineuntilitsnapsinto

place.Printingautomaticallyresumes.

1)Pulloutoptionaltray2.

2)Removethejammedpaperfromthemachine.

Ifthepaperdoesnotmovewhenyoupullorifyoudo

notseethepaperinthisarea,stopandgotothenext

step.

3)Pulltray1half-wayout.

4)Pullthepaperstraightupandout.

5)Insertthetraysbackintothemachine.Printing

automaticallyresumes.

4-3Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 57

Inthemulti-purposetray

0

0

0

0

x

x

4.AlignmentandTroubleshooting

1)Ifthepaperisnotfeedingproperly ,pullthepaperout

ofthemachine.

Insidethemachine

NOTE

Thefuserareaishot.Takecarewhenremovingpaperfrom

themachine.

1)Openthefrontcoverandpullthetonercartridgeout.

2)Openandclosethefrontcovertoresumeprinting.

2)Removethejammedpaperbygentlypullingitstraight

out.

3)Replacethetonercartridgeandclosethefrontcover.

Printingautomaticallyresumes.

Copyright©1995-2011SAMSUNG.Allrightsreserved.4-4

Page 58

4.AlignmentandTroubleshooting

0

0

0

x

x

0

0

0

0

0

vv

v

v

e

e

ww

e

e

xx

Intheexitarea

1)Openandclosethefrontcover.Thejammedpaperis

automaticallyejectedfromthemachine.

Ifyoudonotseethejammedpaper,gotothenextstep.

2)Gentlypullthepaperoutoftheoutputtray.

Ifyoudonotseethejammedpaperorifthereisany

resistancewhenyoupull,stopandgotothenextstep.

3)Opentherearcover.

4)Removethejammedpaperasshowninthefollowing

gure.

5)Closetherearcover.Printingautomaticallyresumes.

4-5Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 59

Intheduplexunitarea

0

0

0

0

x

x

0

0

0

0

0

vv

v

v

e

e

ww

e

e

xx

4.AlignmentandTroubleshooting

1)Pulltheduplexunitoutofthemachine.

2)Removethejammedpaperfromtheduplexunit.

3)Inserttheduplexunitintothemachine.

4)Opentherearcover.

5)Removethejammedpaperasshowninthefollowing

gure.

Ifthepaperdoesnotcomeoutwiththeduplexunit,

removethepaperfromthebottomofthemachine.

6)Closetherearcover.Printingautomaticallyresumes.

Ifyoustilldonotseethepaper,gotothenextstep.

Copyright©1995-2011SAMSUNG.Allrightsreserved.4-6

Page 60

4.AlignmentandTroubleshooting

4.1.4.Usefulmenuitemforservice

a)Monitoringthesupplieslife.

Toviewthesupplylifeindicators,followthestepsbelow:

1)PressMenuonthecontrolpanel.

2)PressSystemSetup>OK>Maintenance>OK.

3)PressSuppliesInfo>OK.

4)PressOKtoselecttheoptionyouwant.

b)Printingareport

Thisproductprovidesseveralprintablereportsformaintenancepurposes.

Thesereportscanbeusedtoaidthediagnosisofprintqualityproblems.

•Demopage(Menu>Information>Demopage)

Youcanprintthedemopagetocheckwhetheryourmachineisprintingproperlyornot.

•Congurationreport(Menu>Information>Conguration)

Youcanprintareportonthemachine’soverallconguration.ItshowsvariousSWversionandcurrentmachine

settingstatus.

•SuppliesInformationreport(Menu>Information>SuppliesInfo.)

Youcanprintsupplies’informationpage.Itshowsconsumableunitlifestatusandtonerusingstatus.

•UsageCounter(Menu>Information>UsageCounter)

Youcanprintausagepage.Theusagepagecontainsthetotalnumberofpagesprinted.

c)Maintenancemenu

Thismenuallowsyoutomaintainyourmachine.(Menu>Systemsetup>Maintenance)

•CleanDrum:CleanstheOPCdrumofthecartridgebyprintingasheet.

•CleanFuser:Cleansthefuserbyprintingasheet.

•CLREmptyMsg.:Thisoptionappearsonlywhentonercartridgeisempty.

•SuppliesInfo.:Thisitemallowsyoutocheckhowmanypagesareprintedandhowmuchtonerareleftinthecartridge.

•TonerLowAlert:Iftonerinthecartridgehasrunout,amessageinformingusertochangethetonercartridgeappears.

Youcansettheoptionforthismessagetoappearornot.

•PaperStacking:Ifyouuseamachineinahumidarea,oryouareusingthedampprintmediacausedbyahigh

humidity,theprintoutsontheoutputtraymaybecurledandmaynotbestackedproperly .Inthiscase,youcansetthe

machinetousethisfunctiontoletprint-outsstackedrmly.But,usingthisfunctionwillmaketheprintspeedslow.

4-7Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 61

4.AlignmentandTroubleshooting

1 High 3

2 High 2

3 High 1

4 Nor m al

0

4,000 m

(13,123 ft)

3,000 m

(9,842 ft)

2,000 m

(6,561 ft)

1,000 m

(3,280 ft)

4

3

2

1

d)Altitudeadjustment

Printqualityisaffectedbyatmosphericpressure,whichisdeterminedbytheheightofthemachineabovesealevel.The

followinginformationwillguideyouonhowtosetyourmachineforthebestprintquality.

Beforeyousetthealtitudevalue,determinethealtitudewhereyouare.

1)EnsurethatyouhaveinstalledtheprinterdriverwiththeprovidedPrinterSoftwareCD.

2)Double-clicktheSmartPaneliconontheNoticationAreainLinux.Y oucanalsoclickSmartPanelonthestatus

barinMacOSX.ForWindowsuser,selectStart>ProgramsorAllPrograms>SamsungPrinters>SamsungEasy

PrinterManager.

3)ClickPrinterSetting.

NOTE

Ifyourmachineisconnectedtothenetwork,youcansetthealtitudeviaSyncThru™W ebService.

4)ClickSetting>AltitudeAdjustment.Selecttheappropriatevaluefromthedrop-downlist,andthenclickApply.

NOTE

YoucanalsosetthealtitudeinSystemSetup>AltitudeAdj.optiononthemachine’sdisplay.

Copyright©1995-2011SAMSUNG.Allrightsreserved.4-8

Page 62

4.AlignmentandTroubleshooting

1

3

8

2

7

4

6

5

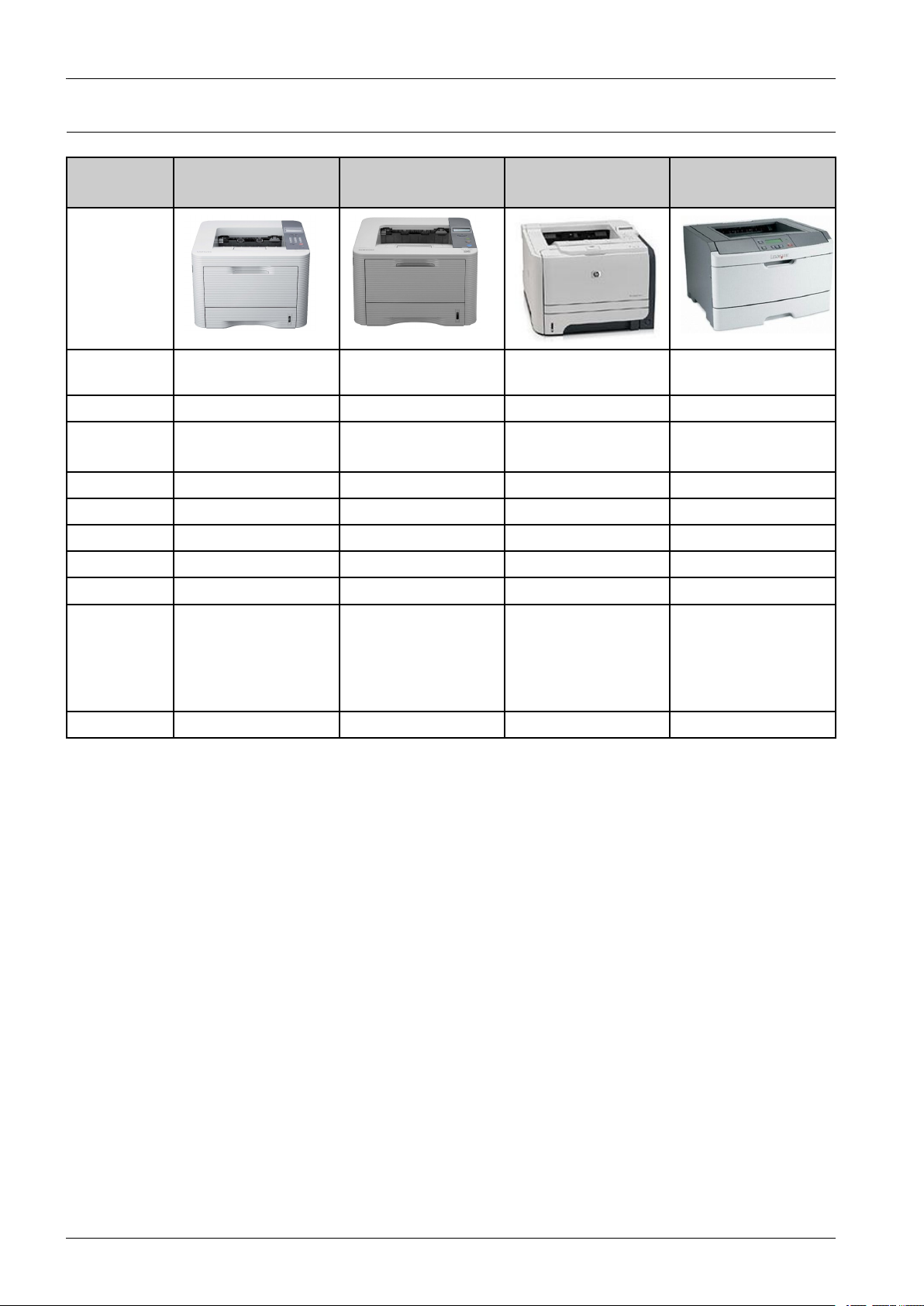

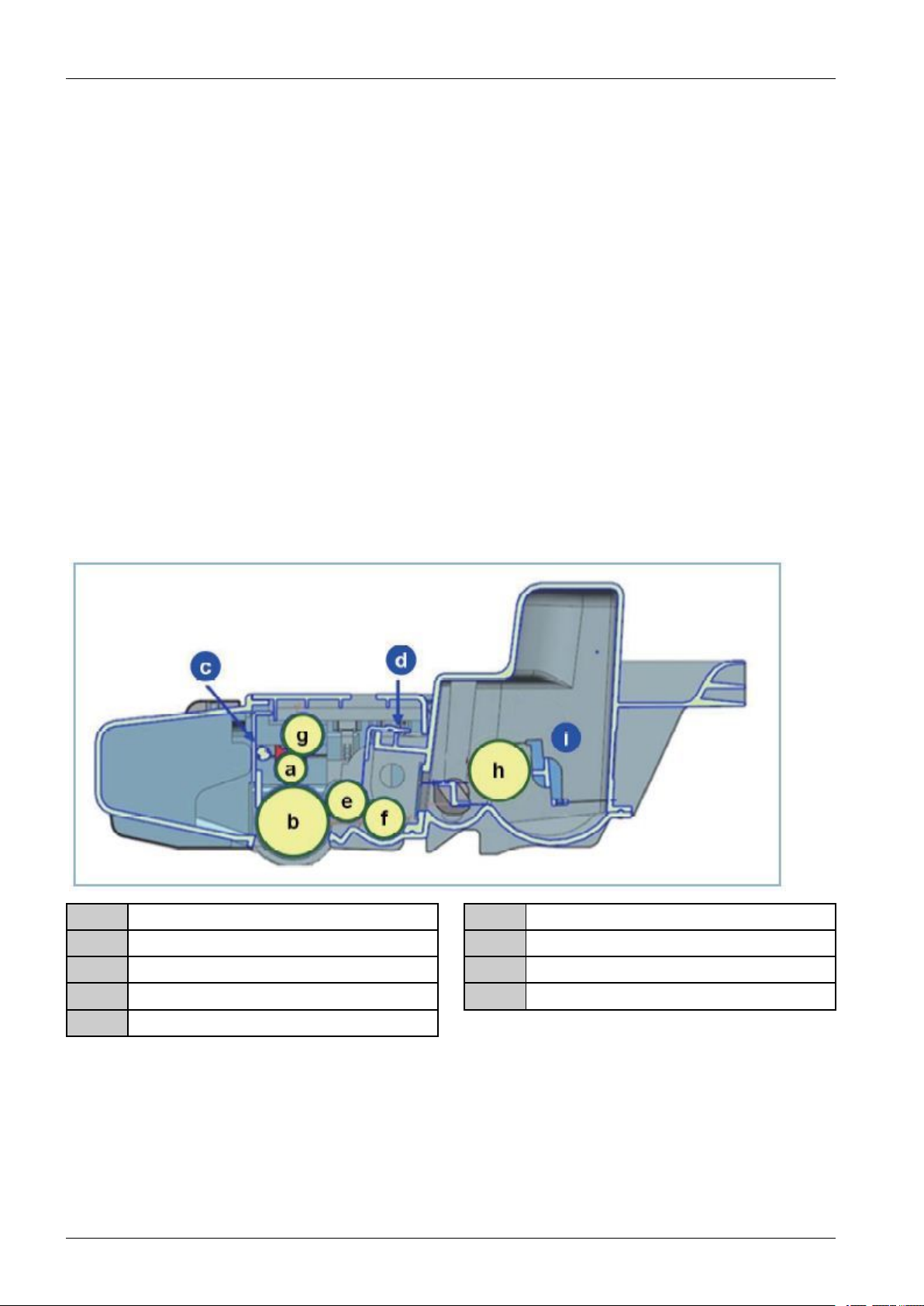

4.1.5.PeriodicDefectiveImage

Ifanimagedefectsappearsatregularintervalsontheprinted-paper,itisduetoafaultyordamagedroller.Refertothetable

belowandchecktheconditionoftheappropriateroller.

NoRollerDescription

11stPressurerollerBackground

22ndPressurerollerBackground

3HeatrollerBlackspotandfuserghost

4Chargeroller26.7mmBlackspot

5Developerroller36.78mmHorizontalband

6OPCdrum75.49mmWhiteandBlackspots

7Supplyroller69.57mmHorizontalband

8TransferrollerGhost,Damagedimage

BandPeriod

(mm)

PhenomenonDefectivepart

Fuserunit

Tonercartridge

4-9Copyright©1995-2011SAMSUNG.Allrightsreserved.

Page 63

4.AlignmentandTroubleshooting

4.1.6.Usefulmanagementtools

4.1.6.1.UsingSamsungEasyPrinterManager(Windowsonly)

NOTE

•ForWindows,InternetExplorer6.0orhigheristheminimumrequirementforSamsungEasyPrinterManager.

SamsungEasyPrinterManagerisanapplicationthatcombinesSamsungmachinesettingsintoonelocation.Samsung

EasyPrinterManagercombinesdevicesettingsaswellasprintingenvironments,settings/actionsandlaunching.Allof