Page 1

6

6

6-1

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6. Alignment and Adjustments

This chapter describes the main functions for service, such as the product maintenance method,

the test output related to maintenance and repair, DCU using method, Jam removing method, and

so on. It includes the contents of manual.

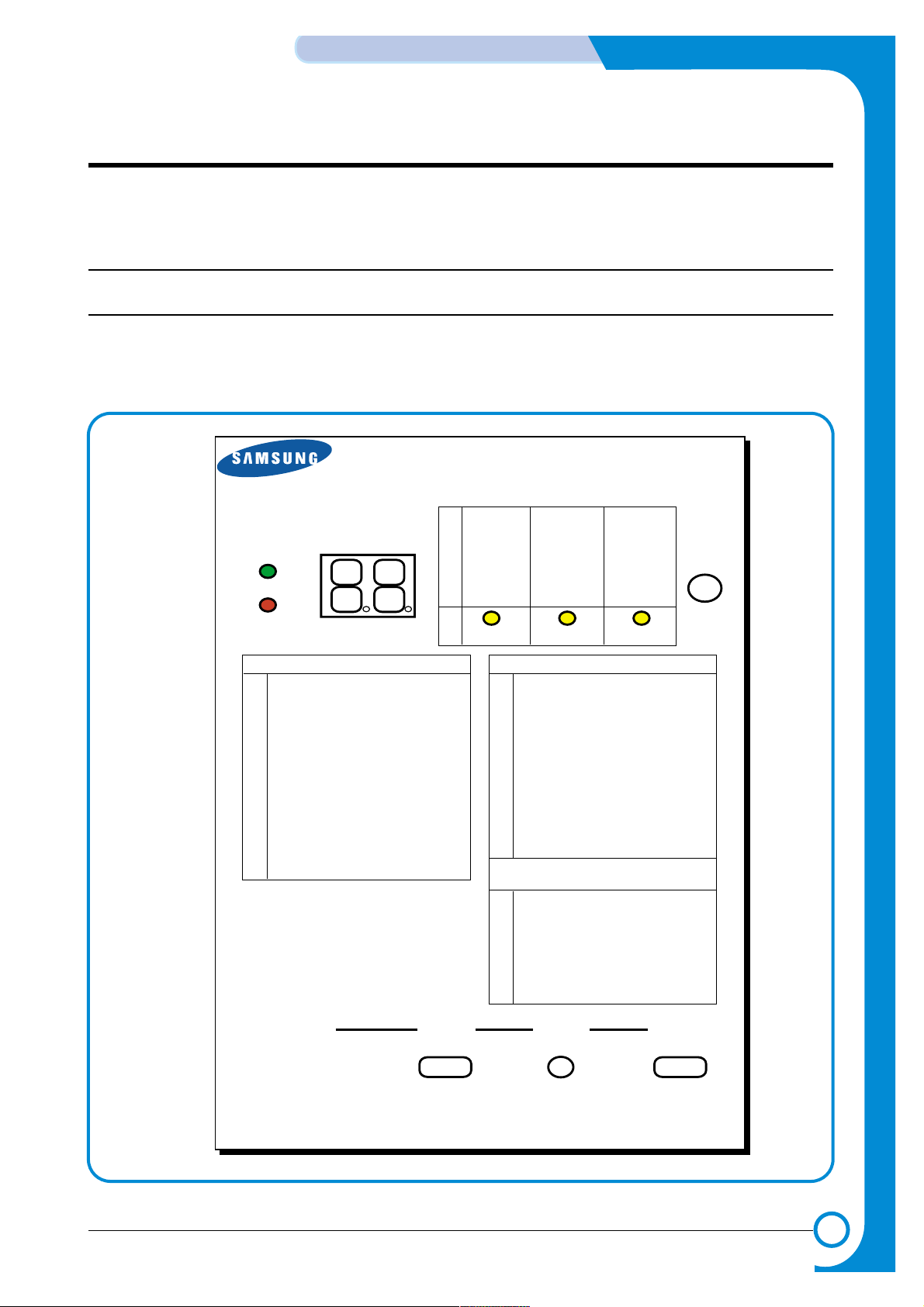

6.1 How to use DCU

6.1.1 DCU Setup

You can examine the malfunction of the printer. To perform DCU, open the front discharge cover and leave

the connect the harness wire(10 pin/4 pin) to the CN3(ML-1750) or CN2(ML-1710/1510) of the Main control

board.

ML SERIES DIAGNOSTIC CONTROL UNIT

04

05

07

08

09

10

DEV 300

LSU READY

PAPER EMPTY

COVER OPEN

COER HEATING

DEV 350

LSU MT & LD

PAPER WIDTH

EXIT SENSOR

PRINTING TEMP

DEV 350

LSU MOTOR

NEW CRU

FEED SENSOR

READY HEAT

ON

OFF

STATUS

SELF

TEST

DIAGNOSTIC

DIAGNOSTIC CODE

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

61

00

01

02

03

04

20

30

40

50

69

60

62

68

64

70

71

72

73

95

MAIN MOTOR OPERATING SYSTEM

MAIN HIGH-VOLTAGE ON

TRNSFER HIGH-VOLTAGE (-)ON

THV(+) REFERANCE VOLTAGE

DEV/SUPPLY HIGH-VOLTAGE ON/PTL ON

LSU OPERATING SYSTEM

PICKUP CLUTCH ON

PEEMPTY/PWITH/NEW CRU TEST

FEED & EXIT SENSOR TEST

COVER OPEN SENSOR TEST

FUSER TEST

HOT BURN TEST

CLEAN MODE PRINT

THV(+)TRIGGER, ALL HV & FAN ON

THV(+) REFERENCE ON

ERROR STATUS CODE

STATUS CODE

WARM UP

READY (REGAL)

READY (LETTER)

READY (A4)

READY (EXECUTIVE)

READY (B5)

PRINT START

FEED SENSOR ON

FEED SENSOR OFF

PAPER OUT

SLEEP MODE

OPEN FUSER ERROR

LOW TEMPERATURE ERROR

OVER HEATING ERROR

COVER OPEN ERROR

NO PAPERR

PAPER JAM 0

PAPER JAM 1

PAPER JAM 2

LSU NOT READY

DIAGNOSTIC

MODE

DOWN

UP ENTER

SHIFT STOP

TO ENTER DIAGNOSTIC MODE, PUSH THREE BUTTONS SIMUL ANEOUSL

AND TURN THE PRINTER POWER ON.

Page 2

6-2

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

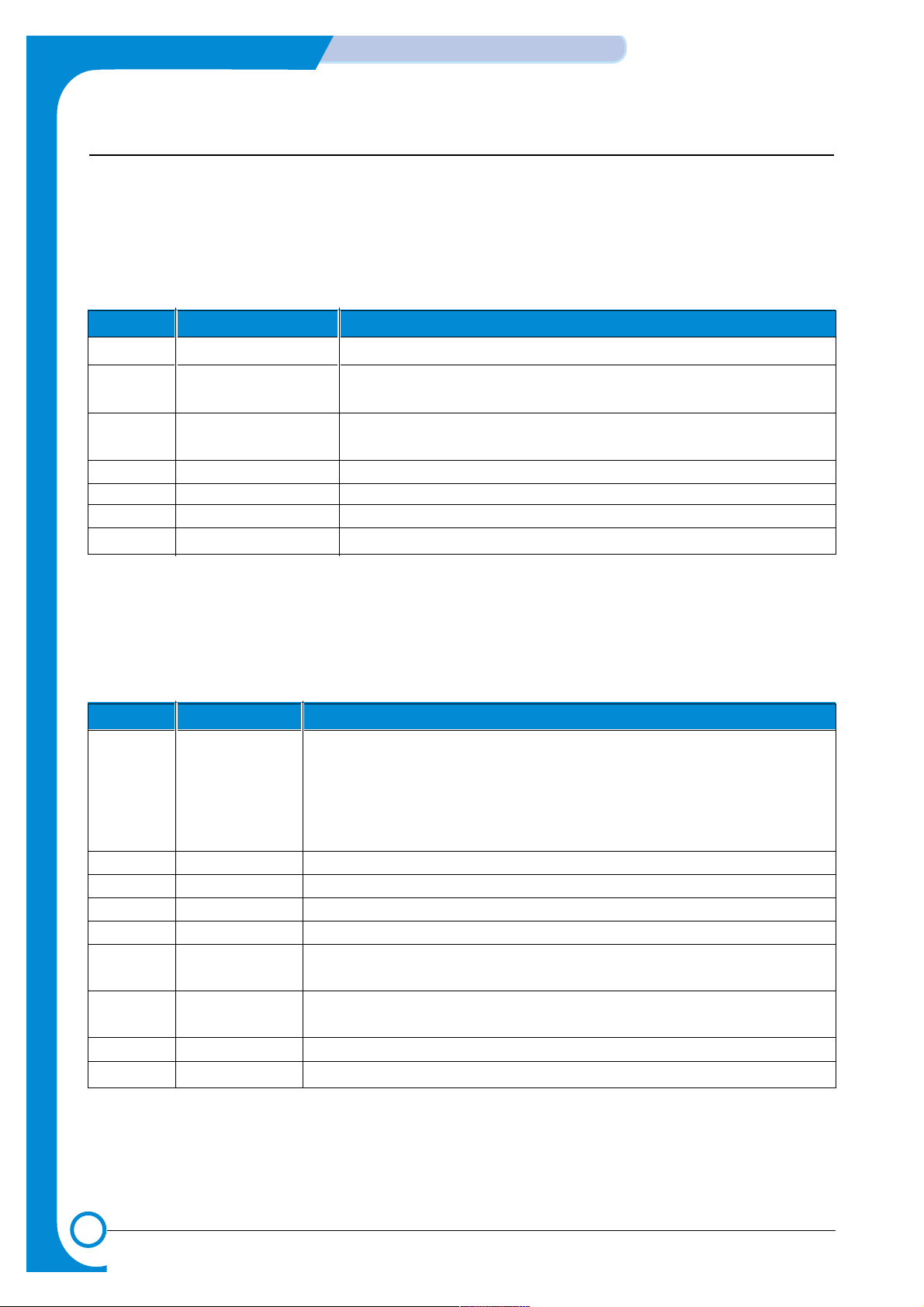

6.1.2 Code

Connect DCU to the printer and turn the power on. It show 7 Segment FND on the panel and each code

tells the function of the printer.

1) Normal Code

While printing or warming up, it indicate the position of the paper

2) Error Code

When detecting the malfunction, the printing is stopped to indicate error code.

Code State Description

61 Warm up The printer is on, the cover is open or close.

00~05 Ready(kind of paper) The printer is ready, the paper is detected when the first paper is printed.

00: Legal ,01: Letter ,02: A4 ,03: EXEC ,04: B5 ,05: Folio, 06: A5/A6

20, 21, 22 Print Start The engine controller received the print order from the video controller.

20: 1st, 21: MP, 22: SCF

30 Feed Sensor On The paper is passing out of the Feed Sensor.

40 Feed Sensor off The paper has passed out of the Feed Sensor.

50 Paper Out The paper has passed out of Exit Sensor.

69 Sleep Mode The fuser power turned off to minimize the power consumption.

Code State Description

60, 62, 68 Fuser Error The error in the fuser occurred. There is a short circuit in the thermistor

and the thermostat while printing, Low Temperature Error occurs.

• 60: Open Fuser Error

• 62: Low Heat Error

• 68: Over Heat Error

64 Cover Open The Printer Cover is open.

65 CRU Error The Toner Cartridge not installed,

70 No Paper No paper in the paper cassette.

71 Paper Jam 0 The front part of paper is jammed between pickup unit and Feed sensor.

72 Paper Jam 1 The front part of paper is jammed between the Discharge sensor and

Feed sensor.

73 Paper Jam 2 The front part of paper is jammed just after passing through the discharge

sensor.

76 Out Bin Full The Out bin is filled with paper.

95 LSU Not Ready LSU Scanner Motor not ready or Hsync signal not output.

Page 3

6-3

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

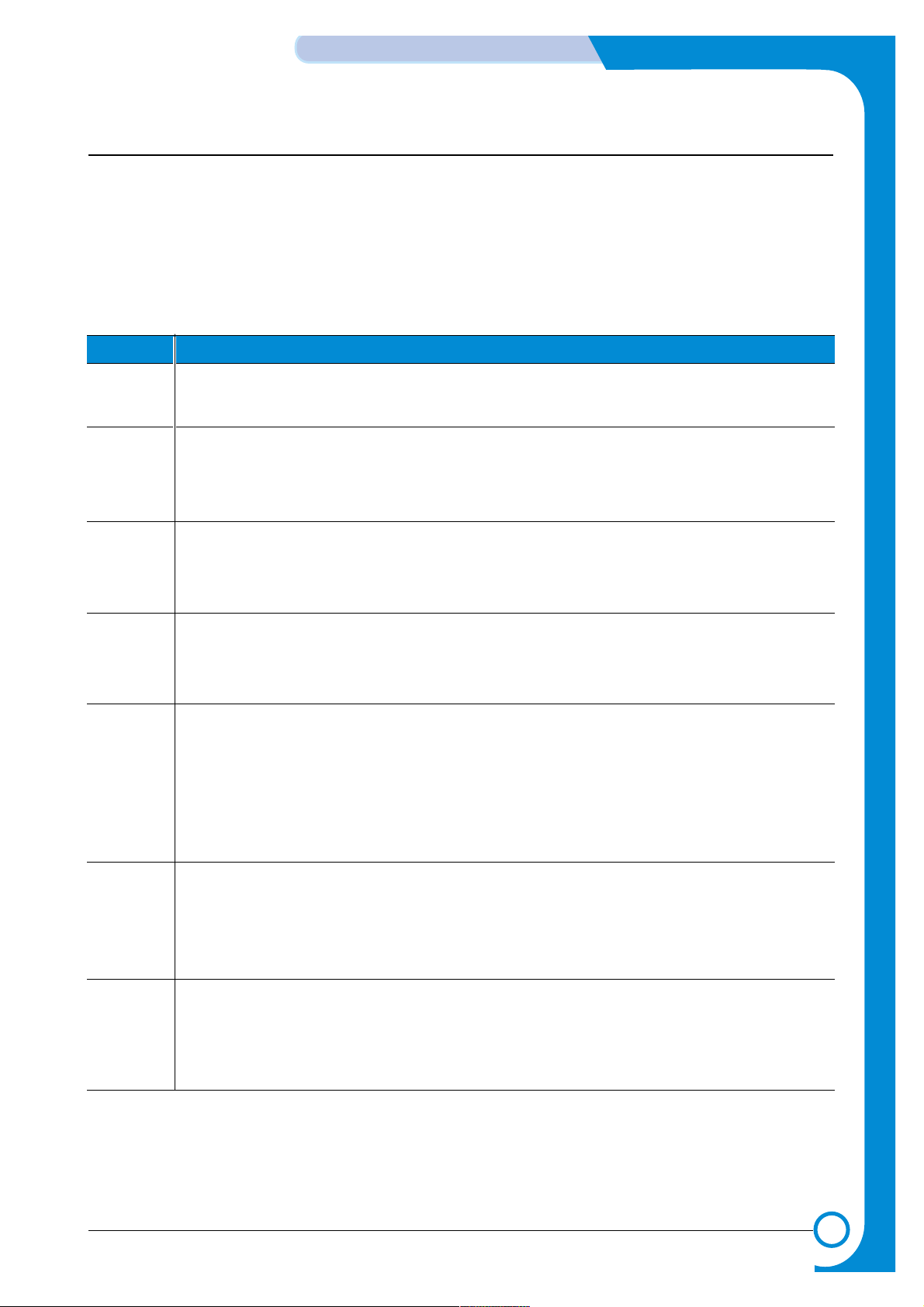

6.1.3 Self Diagnostic Mode

If Error code occurs due to malfunction of the printer, perform Self Diagnostic Mode to solve the problem.

The printer works only in the self-test mode to solve the malfunction problem.

To enter the self-test mode, turn the power on pressing the buttons of [Down], [Shift] and [Stop] at the same

time.

Release the button within 2 or 3 seconds if 78 shows in the DCU. If 00 shows in the DCU, press the button

[Up] or [Shift] to select the self+test , and press the button of [Enter] to operate. To stop, press the button of

[shift] and [Enter] together.

Code Description

00 Main Motor Operating System

Only the main motor is in operation.

01 Main High Voltage On(THV-)

-1400 voltage output by MHV terminal.

Caution : High voltage probe should be used.

02 Transfer High Voltage(-)On(THV-)

-1000 voltage output by MHV terminal.

Caution : High voltage probe should be used.

03 Transfer High Voltage (+)Reference on (THV +)

+800 voltage output by MHV terminal.

Caution : High voltage probe should be used.

04 DEV/supply High Voltage : DEV/Supply High Voltage Test.

The left one of the three LEDs in the self-test panel is on when DEV high voltage Supply

high voltage output by each HV terminal(-500V). Press the [Up] button to switch the voltage. The middle and right one of the three LEDs are on and -650 voltage output by DEV

HV terminal.

Caution : High voltage probe should be used.

05 LSU Operating System

The scanning motor of LSU is in operation, the right LED of the three buttons on. Press

the [Up] button to Check LD. LD is functioning and the middle button is on. If the LD is

normal, all LEDs are on.

06 Pickup clutch on

The Solenoid in the printer is in operation. To stop the operation, Press the button [shift]

and [Enter] together.

Page 4

6-4

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

Code Description

07 Paper Empty Sensor Test :

If activate the Actuator of the PEMPTY Sensor, the left and right of the three LEDs are

on.

Paper Empty Sensor ON/OFF 1st LED ON/OFF

08 Feed & Exit Sensor Test

Test the Feed sensor and Discharge sensor in the same way as '07'.

Feed Sensor ON/OFF 2nd LED ON/OFF

Exit Sensor ON/OFF 3rd LED ON/OFF

09 Cover Open Sensor Test

Test the Cover Open Sensor in th same way as code '07’

Cover Open Sensor ON/OFF 1st LED ON/OFF

10 Fuser Test

If the [Enter] button pressed, the right LED is on and temperature of the fuser is up to

READY Mode. If the [Up] button pressed, the middle LED is on and temperature of the

fuser is up to Printing Mode.

If you press the button once more, the left LED is on and temperature of the fuser is up

to overheat Mode.

11 Hot Burn Test

If the [enter] button pressed, the printer is continuously printing without detection.

Turn the power off to stop operation.

12 Cleaning Mode Print Mode

Print the paper to clean the OPC Drum in the Cartridge.

13 THV(+) TRIGGER. ALL HV :

All high voltage output by each HV terminal and LSU and the fan is in operation. In this

mode, electronic resistance of transfer roller and high voltage is detected.

14 PTL Test :

Indicates the function of the PTL, same method of the code ‘07’.

15 Fan Test :

Indicates the function of the Fan, same method of the code ‘07’.

16 Manual Pickup Test :

Indicates the function of th Manual Pickup, same method of the code ‘07’.

17 Manual Sensor Test :

Indicates the function of the Manual Sensor, same method of the code ‘07’.

Page 5

6-5

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6.1.4 Self Test Button

If the Self-Test button pressed, vertical lines are printed.

Turn the power on while pressing this button, '89' shows in the DCU and the printer is warming up. After

warming-up the printer is in READY Mode, and '88' shows in the DCU. In this mode, without any detection,

the printer begins printing(trial printing and data from the PC). It is convenient to use this mode when the

engine malfunction is detected in the control board.

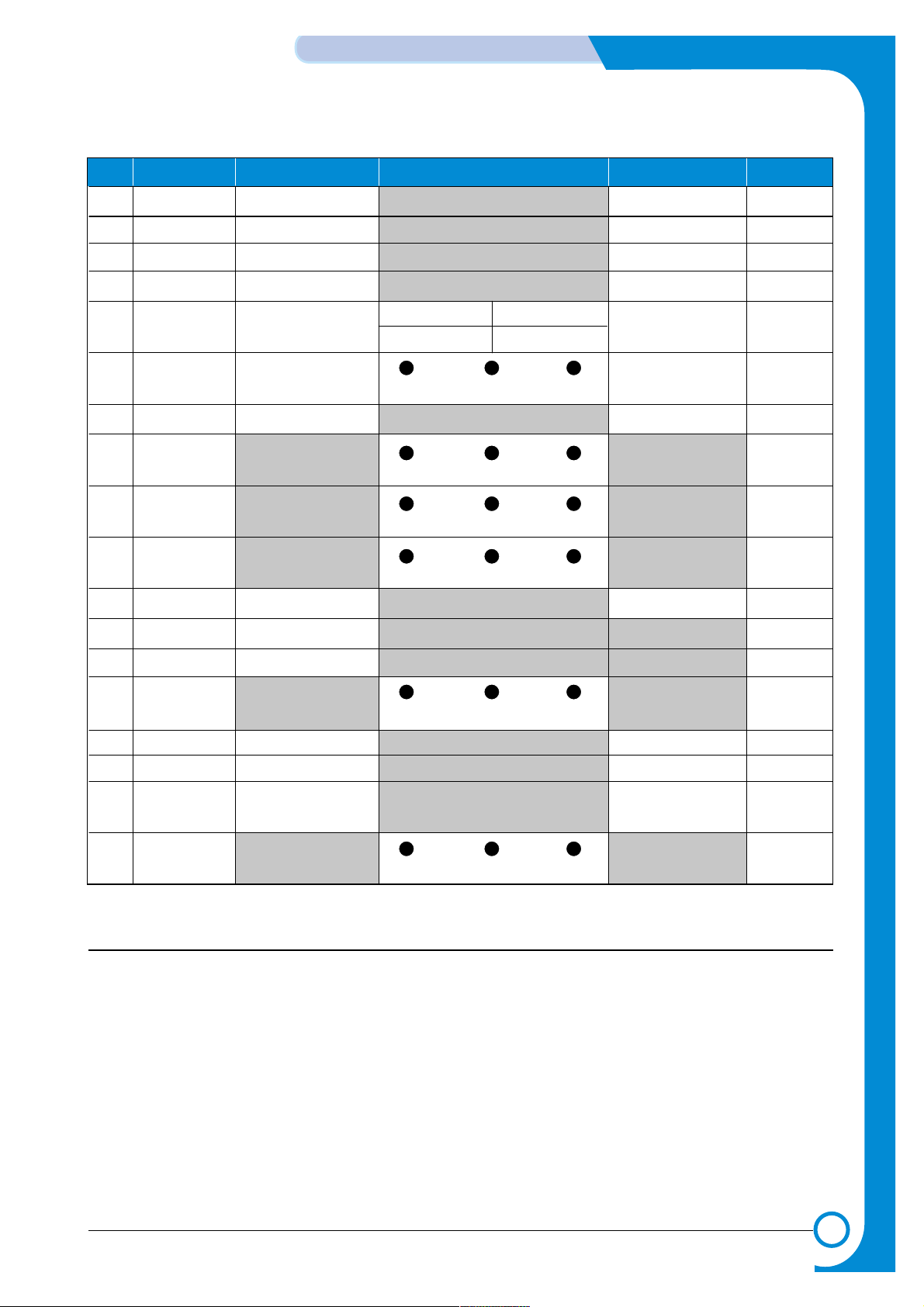

No. Function Enter Up/ Dow n Stop Remark

00

Motor

Motor Run Mo tor S top

01

MHV

Mhv On Mhv Off -1550V

02

THV(-)

Thv Negative On Thv Negative Off

03

THV(+)

Thv On Thv Off +1300V

04

DEV

Dev On

Supp l y DEV

De v O f f

0:-630V 0:-430V

05

LSU

LSU R u n

On Off Ready

LSU Stop

06

Pic kUp

Picku p On Pickup Off

07

PEmpty

Pape r Empt y

08

Sen so r

Ex it Feed

09

Cover

Cover Open

10

Fus er

Fuser On Fuser Off

11

Hot Burn

Ho tB u rn O n

12

Clean Print

Cl e an Pr i nti n g

13

Thv

Refer ence

low adequate high

14

PTL

PTL On PTL Off

15

FAN

Fan On Fan Off

16

Ma nu al

Pic kUp

Manual Pickup On Manual Pickup O ff

17

Ma nu al

Sen so r

Manual Sensor

Page 6

6-6

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

6.2 Paper Path

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

1

2

2

3

3

4

4

Paper Input (Cassette)

Paper Input (Manual Feeder)

Paper Out(Face Down)

Paper Out(Face Up)

5

5

6

6

7

7

Paper Empty Sensor

Paper Feeding Sensor

Paper Exit Sensor

Feed

Sensor

MP Sensor

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

1) After taking order, the printer feeds the printing paper from the cassette or manual feeder.

2) The fad paper passes the paper feeding sensor. (Jam 0 occurs if the sensor is not operated after certain

time passes)

3) The paper passed the paper feeding sensor moves to the paper exit sensor via printing process. (Jam 1

occurs if the sensor is not operated after certain time passes)

4) The paper passed the paper exit sensor moves out from the set. (Jam 2 occurs sometime after if the tail-

ing edge of the paper is not coming out from the set after the leading edge of paper passes the paper

exit sensor.)

<Jam0> <Jam1> <Jam2>

Page 7

6-7

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6.3 Clearing Paper Jams

Occasionally, paper can be jammed during a print job. Some of causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper that does not meet paper specifications has been used.

• Paper that is outside of the supported size range has been used.

If a paper jam occurs, the On Line/Error LED on the control panel lights red. Find and remove the jammed

paper. If it is invisible, look inside the printer.

Do not use a pinset or a sharp metal tool when removing a jam.

The covering of a metal part can be removed which can cause an electric leakage.

6.3.1 In the Paper Exit Area (JAM2)

1) If the paper jams as it exits to the output tray and a

long portion of the paper is visible, pull the paper

straight out.

When you pull the jammed paper, if there is resistance and the paper does not move immediately, stop

pulling. Continue with the next step.

2) Open the rear output tray.

3) Loosen the paper if it is caught in the feed rollers.

Then pull the paper gently out.

Note: Please be careful when you open the rear cover.

The inside of the printer is still hot.

4) Close the rear output tray. Open and close the front

cover. Printing can be resumed.

Page 8

6-8

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

6.3.2 In the Paper Feed Area

1) Open the front cover and remove the toner cartridge 2) Gently pull the paper toward you.

3) Check that there is no other paper in the printer.

4) Reinstall the toner cartridge, and then close the cover.

Printing can be resumed.

1) Slide out the tray to expose the jammed paper. 2) Remove any missfeed paper by pulling it out by the visible edge from the tray. Make sure that all of the paper is

properly aligned in the tray.

3) Slide the tray back into the printer. Open and close the

front cover. Printing can be resumed.

6.3.2 In the Paper Feed Area (JAM0)

6.3.3 Around the Toner Cartridge (JAM1)

Page 9

6-9

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6.3.4 Tips for Avoiding Paper Jams

By selecting the correct paper types, most paper jams can be avoided. If a paper jam occurs, follow the

steps outlined in

• Ensure that the adjustable guides are positioned correctly.

• Do not overload the tray. Ensure that the paper is below the paper capacity mark on the right inside of

the tray.

• Do not remove the paper from the tray while printing.

• Flex, fan and straighten the paper before loading.

• Do not use creased, damp or highly curled paper.

• Do not mix paper types in the input tray.

• Use only recommended print media.

• Ensure that the recommended print side is facing down when loading paper into the input tray.

Page 10

6-10

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

6.4 Sample Pattern

This product has the several sample patterns for maintenance. With the sample patterns, check the existence of the abnormality. The patterns help to regularly maintain the product.

6.4.1 Printing a Demo Page

Print a demo page or a configuration sheet to make sure that the printer is operating correctly.

1) Hold down the Cancel button for about 2 seconds to print a demo page.

Hold down the Cancel button for about 6 seconds to print a configuration sheet.

2) The Demo page or the configuration sheet shows the printer’s current configuration.

<Demo Page : ML-1710> <Demo Page : ML-1750>

Page 11

6-11

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6.4.2 Printing a cleaning sheet

If you are experiencing blurred, faded or smeared printouts. Printing a cleaning sheet cleans the drum

inside the toner cartridge. This process will produce a page with toner debris, which should be discarded.

1) Ensure that the printer is turned on and in the Ready mode with paper loaded in the tray.

2) Press and hold down the Cancel button on the control panel for about 10 seconds.

3) Your printer automatically picks up a sheet of paper from the tray and prints out a cleaning sheet with

dust or toner particles on it.

Note:The cartridge cleaning process takes some time. To stop printing, turn the power off.

<System Data List : PCL Model Only>

Page 12

6-12

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

COMPONENT REPLACEMENT CYCLE

Pick-up Roller 60,000 Pages

Paepr Feeding Roller(Friction Pad) 60,000 Pages

Transfer Roller 60,000 Pages

Fuser 60,000 Pages

Toner Cartridge 3,000 Pages

6.5 Consumables and Replacement Parts

The cycle period outlined below is a general guideline for maintenance.

The example list is for an average usage of 50 transmitted and received documents per day.

Environmental conditions and actual use will vary these factors.

The cycle period given below is for reference only.

6.6 The LED Status Display by Each Error

ERROR LED Status DCU CODE

Open Fuser Error The [Error] LED (red) and the [Toner Save] LED are simultaneously 60

flashing every one-second.

Over Heat Error The [Error] LED (orange) and the [Toner Save] LED are 68

simultaneously flashing every one-second.

Low Heat Error The [Error] LED (red) and the [Toner Save] LED are simultaneously 62

flashing every 4 seconds.

LSU not Ready Error The [Error] LED (green) and the [Toner Save] LED are 95

(Pmotor Error) simultaneously flashing every one-second.

LSU Not Ready Error The printing is stop in the fad status, and the [Error] LED (green) and 96

(HSYNC Error) the [Toner Save] LED are simultaneously flashing every 4 seconds.

Page 13

6-13

Samsung Electronics

ALIGNMENT & ADJUSTMENTS

Service

Manual

6.7 Periodic Defective Image

If the delinquent image regularly occurs in the printed-paper, it is due to delinquent or damaged roller.

Refer to the table in below and check the condition of the roller.

No Roller Defective image Typical defect

1 OPC Drum 75.5mm white spot on black image or black spot

2 Charge Roller 37.7mm black spot

3 Supply Roller 37.0mm light or dark horizontal image band

4 Developing Roller 35.3mm horizontal image band

5 Transfer Roller 45.3mm image ghost

6 Heat Roller 64.1mm Black spot and image ghost

7 Pressure Roller 75.5mm black spot on the backside

PTL

L S U

Fuser

Toner Cartridge

1

2

3

7

6

5

4

MP Sensor

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Tramsfer Roller

Heat Roller

Pressure Roller

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

MP Sensor

<Rollers Layout>

Page 14

6-14

ALIGNMENT & ADJUSTMENTS

Samsung Electronics

Service

Manual

Loading...

Loading...