Page 1

SERVICE

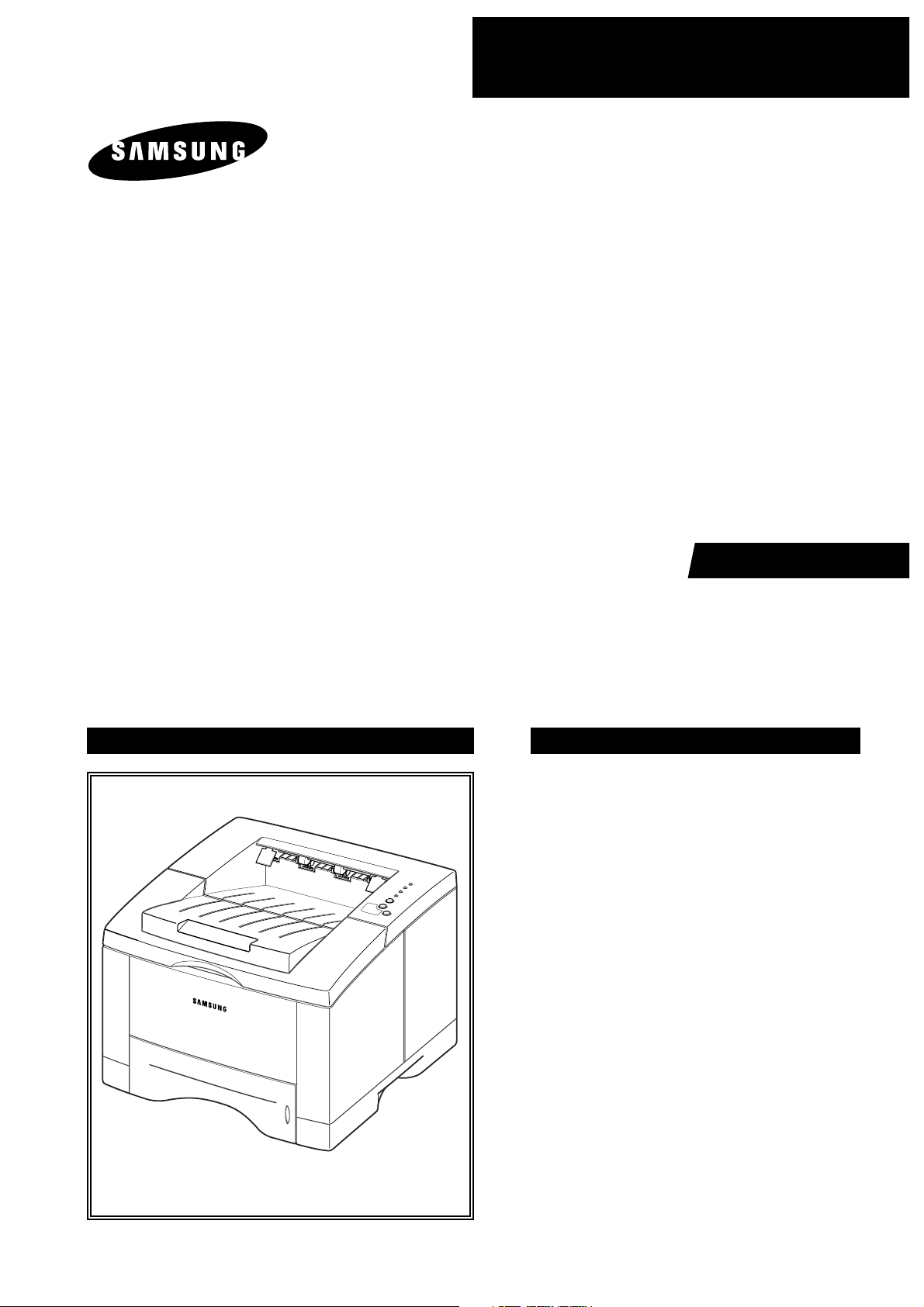

LASER PRINTER

ML-1650Series

ML-1650 / ML-1651N

Manual

LASER PRINTER CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

Page 2

© Samsung Electronics Co.,Ltd. September 2001

Printed in Korea.

VERSION NO. : 2.00 CODE : JC-0055A

This service manual is also provided on the web,

the ITSELF system f Samsung Electronics Co., Ltd.

“http://itself.sec.samsung.co.kr”

Page 3

This manual is stated and

provided for service description.

All rights reserved. Any parts of the

information in this manual are prohibited

from free duplication, use or translation

without prior written approval except in

cases allowed by the Copyright Act.

Specifications are subject to change without

prior notice.

Copyright (c) 2001. 6.

Samsung Electronics Digital Printing CS Group

Page 4

Read each caution carefully:

1. Do not use this printer near water or when exposed to

inclement weather.

2. Do not place this printer on an unstable cart, stand or

table; the product may fall, causing serious damage

to the product.

3. Slots and openings in the cabinet are provided for

ventilation. To ensure reliable operation and to protect

the printer from ever heating, do not block or cover

any of these openings. Do not place the printer in an

enclosure unless the enclosure provides adequate

ventilation.

4. Never push objects of any kind into the printer through

the cabinet ventilation slots as they may touch dangerous high voltage points, create short circuits,

cause a fire, or produce an electrical shock. Never

spill liquid of any kind on the printer.

5. Do not place the printer in a location where someone

may trip on the cords.

6. Select a work surface that is large enough to hold the

printer.

7. Position the printer within six feet of the computer and

within five feet of an electrical outlet.

8. Operate this printer using the power source (110V,

220V, etc) indicated on the marking label. If you are

not sure of the type of power source available, consult

your dealer or local power company.

9. If you need to use an extension power cord with this

printer, make sure that it uses a three-wire grounded

cord and that the total ampere ratings for all of the

products using the extension do not exceed the

extension cord ampere rating. Also, make sure that

the total of all products plugged into the wall outlet

does not exceed 15 amperes.

10. Do not allow anything to rest on the power cord or

data communications cable.

11. Unplug this printer from the wall outlet before clean-

ing. Do not use liquid cleaners or aerosol sprays. Use

a damp cloth for cleaning.

12. Do not touch the surface of the photo-sensitive drum

as marks or scratches may impair print quality.

13. Do not expose the drum unit to direct light for pro-

longed periods.

14. Use only standard papers, OHP films, and approved

envelopes. Feed OHP films though the manual feed

slot only . See specifications for approved papers and

envelopes.

15. Other than replacing consumables such as paper

and toner, refer all questions to qualified service personnel.

Precautions

1-1

Samsung Electronics

1. Precautions

1-1 Safety Precautions

Please read the following carefully to prevent any accidents and not to damage the unit during service.

Especially mind the safety on the part with

this mark.

You must use regular parts described in specifications for the parts inflammable and where the

current can be flown. Otherwise any hazard

such as an electric shock or a fire could occur.

LASER STATEMENT (LASERTURVALLISUUS)

WARNING : NEVER OPERATE AND SERVICE THE PRINTER

WITH THE PROTECTIVE COVER REMOVED

FROM LASER/SCANNER ASSEMBLY. THE

REFLECTIVE BEAM, ALTHOUGH INVISIBLE, CAN

DAMAGE YOUR EYES.

Class 1 laser product

Luokan 1 laserlaite

Klass 1 laser apparat

Allonpituus 770-795nm

Teho 0.3mW±0.03mW

CAUTION

VORSICHT

ATTENTION

ATTENZIONE

PRECAUCION

CAUTION : Avoid exposure to invisible laser radiation when the

development unit is not installed.

INVISIBLE LASER RADIATION WHEN

THIS COVER OPEN. DO NOT OPEN

THIS COVER.

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEOFFNET.

NIGHT DEM STRAHLAUSSETZEN.

REYONNEMENT LASER INVISIBLE EN CAS

D’OUVERTURE. EXPOSITION DANGERUSE AU

FAISCEAU.

RADIAZIONE LASER INVISIBLE IN CASO DI

APERTURA. EVITARE L’ESPOSIZONE LAFASCIO.

REDIACION LASER INVISIBLE CUANDO SE

ABRE. EVITAR EXPONERSE AL RAYO.

Page 5

Precautions

1-2

Samsung Electronics

1-2 Precautions on Disassembly and Reassembly

Very careful precautions should be taken when replacing

parts. Before replacing, please check cables because

you cannot put the cables that you removed for replacing

parts into the proper place if you would not make sure of

where they were connected and in which condition.

Please do the following before disassembling for a repair

or replacement of parts.

1. Pull out paper cassette, printer cartridge installed.

Especially careful not to be scratched by the surface of

developer or not to expose them to light.

2. Turn the power switch off.

3. Take out the power plug, printer cable from the printer.

4. Use only the same type of part as original when replacing parts.

5. Do not force to open or fasten plastic material compo-

nents.

6. Be careful that small parts such as screws should not

get in the printer.

7. When disassembling, assembling, also observe small

components are located in place.

8. If you uncover and turn the machine over to replace

some parts, toner or paper particles may contaminate

the LSU window. Protect the LSU window with clean

paper.

Releasing Plastic Latches

Many of parts are held in

place with plastic latches.

The latches break easily :

release them carefully.

To remove such parts,

press the hook end of the

latch away from the part to

which it is latched.

Page 6

Precautions

1-3

Samsung Electronics

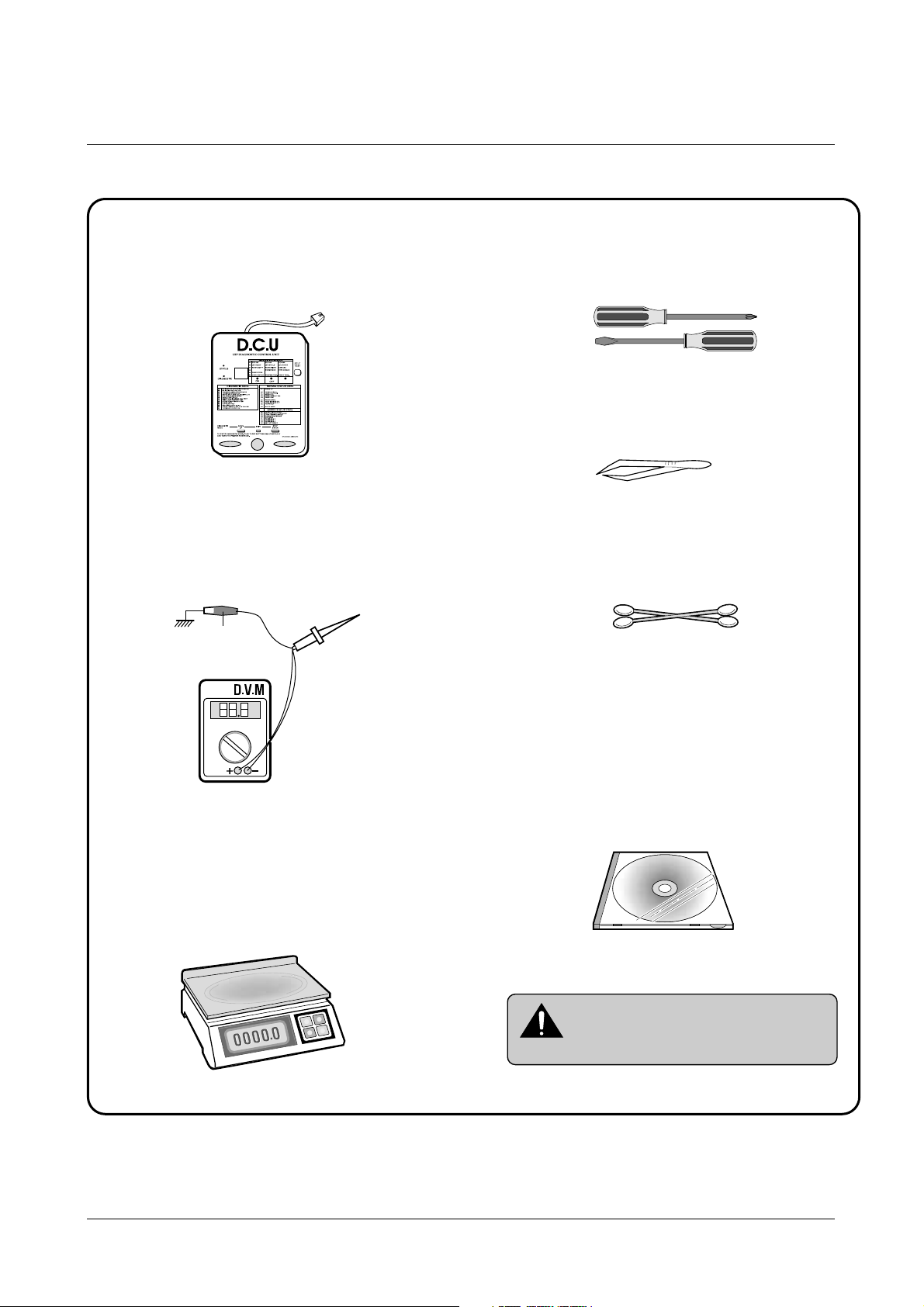

1-3 Tools for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DCU(Diagnostic Control Unit)

Standard: Test equipment to diagnose the Laser

printer supplied by Samsung Electronics.

DVM(Digital Volt Meter)

Standard: Indicates more than 3 digits.

Electronic Scale

Standard: Equipment to check the weight of consumables(toner cartridge) supplied by Samsung

Electronics. (The gram unit can be measured.)

Driver

Standard: "-" type, "+" type (M3 long, M3 short,

M2 long, M2 short).

Pinset

Standard: For general home use, small type.

Cotton Swab

Standard: For general home use, for medical ser-

vice.

Cleaning Equipments a IPA(Isopropyl

Alcohol)dry cloth or a soft stuff neutral

detergent.

Software(Driver) installation CD ROM

Mind your hands not to be touched when

you disassemble and reassemble PBAASS'Y ,

such as the main board, SMPS, HVPS.

Note

Ground

1

2

3

4

5

6

7

8

Page 7

17 PPM(Letter) , 16PPM(A4)

1200 * 1200

Tray 1 : Less than 14 seconds

Tray 2 : Less than 17 seconds

Less than 40 seconds

Print : 300 W, Sleep mode : Less than 20 W

361 x 409 x 294.5 mm

12.4 Kg/27.3lb (SET)

Stand by : Less than 35 dB, Operating : Less than 49dB

AC 100~127V , 50 Hz

AC 220~240V , 60 Hz

Power PC (166 MHz)

Standard : 16Mbyte

Option DIMM Module ; 16, 32,64,128M byte

4 Mbyte (16M bit x 2 : Program) Flash Memory

512 bytes

PCL6, PS 3(Option)

IEEE1284, USB, Network

Windows 95/98/2000/Me/NT,

Linux(Radhat 6.0 ↑), iMac(Mac OS 8.0 ↑)

Option Default

550 sheets (75g/m2)

100 sheets (75g/m2)

20 sheets (OHP)

10 sheets (Letter, card)

25 sheets (Label)

250 sheets

100 sheets

A4, Letter. Legal, Executive, B5, A5, Folio, 7 3/4(Monarch),

#10, DL, C5, C6, B5

Single Cartridge

8,000 sheets (Set : 4,000 sheets)

8,000 sheets (Set : 4,000 sheets)

60,000 sheets

60,000 sheets

125,000 sheets

40,000 sheets

3Key, 4LEDs

No

YES

YES(Button)

Specifications

2-1

Samsung Electronics

2. Specifications

Speed

Resolution

First Print Time

Warm-Up T ime

Power Consump.

Dimension(W * D * H)

Weight

Acoustic Noice

Power Rating

Processor

Memory

Emulation

Interface

OS Support

N/W

Input

Output

Media Type

Type

Life

Cartridge

Pick up Roller

Feed Roller

Transfer Roller

Fuser

Key & LED

LCD

Toner Save

Reprint

RAM

ROM

EEPROM

Cassette

MP Tray

Face down

Face up

Engine

Controller

Paper

T oner

User interface

ML-1650 ML-1651N

Page 8

Specifications

2-2

Samsung Electronics

10 ~32˚c (50˚F ~ 90˚F)

20 ~ 80 % RH

-200 ~40˚c (4˚F ~ 104˚F)

10 ~90 % RH

Windows 95/98 and Windows NT (3.51, 4.x )

Netware (3.x, 4.x), NDS and Bindery Mode /RPRINT,

PSERVER Mode

UNIX and Apple Talk

TCP/IP : Windows 95/98, Windows NT, UNIX

IPX/SPX : Windows 95/98, Novell Netware

DLC/LLC : Windows 95/98, Windows NT

Ethertalk : Apple Talk

SNMP : for Network Printer Administration

Ethernet 10/100 BaseTX (Auto Negotiation)

Samsung’s Admin. Software Utility (SyncThru)

SNMP and MIB-II Support,

GUI based utility for Windows Systems and Test based

utility for UNIX Systems

HTTP server for web browser based network management (can manage NPC and printer options on Web

Browser)

Operation Environment

Storage Environment

Network Operating Systems

Network Protocols Supported

Network Card Interface

Network Management S/W

Temperature

Humidity

Temperature

Humidity

Environment

Network

ML-1650 ML-1651N

Page 9

Disassembly and Reassembly

3-1

Samsung Electronics

When you disassemble and reassemble components, you must use extreme caution. The close proximity of

cables to moving parts makes proper routing a must. If components are removed, any cables disturbed by

the procedure must be restored as close as possible to their original positions. Before removing any

component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Remove the paper cassette(s), and the print cartridge. Do not expose the cartridge to direct room light or

sun light, and be careful not to scratch the drum surface.

2. Turn the power switch off.

3. Unplug all the cables from the printer.

4. Replace with only an authorized component.

5. Do not force to open or fasten a plastic material component.

6. Be careful no obstacles are included when you reassemble components.

7. When you reassemble components, be careful small size components are located in place.

8. If you turn the machine over to replace some parts, toner or paper particles may contaminate the LSU

window. Protect the LSU window with clean paper.

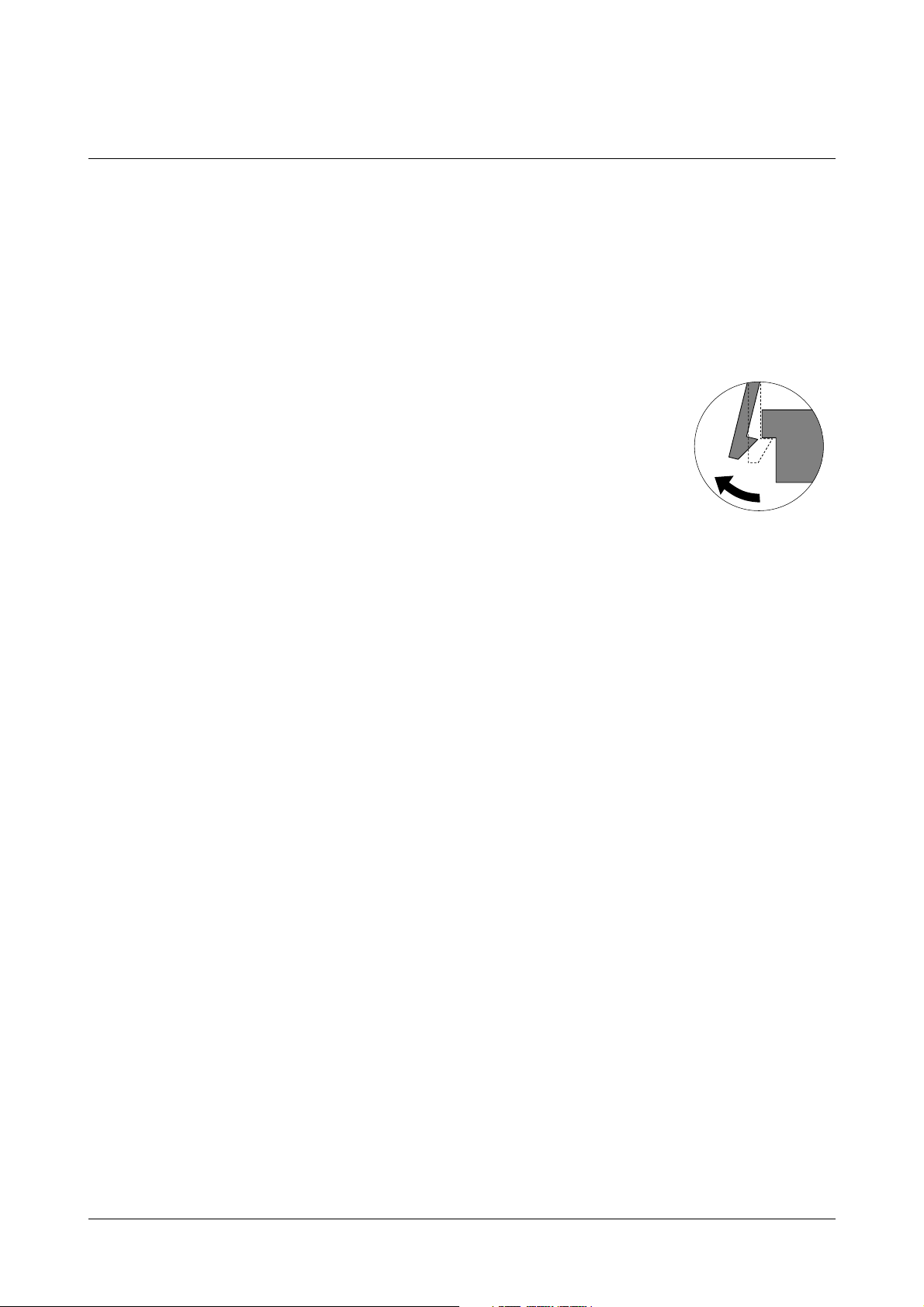

Releasing Plastic Latches

Many of the parts are held in place with plastic latches.

The latches break easily; release them carefully.

To remove such parts, press the hook end of the latch away from

the part to which it is latched.

3-1 General Precautions on Disassembly

3. Disassembly and Reassembly

Page 10

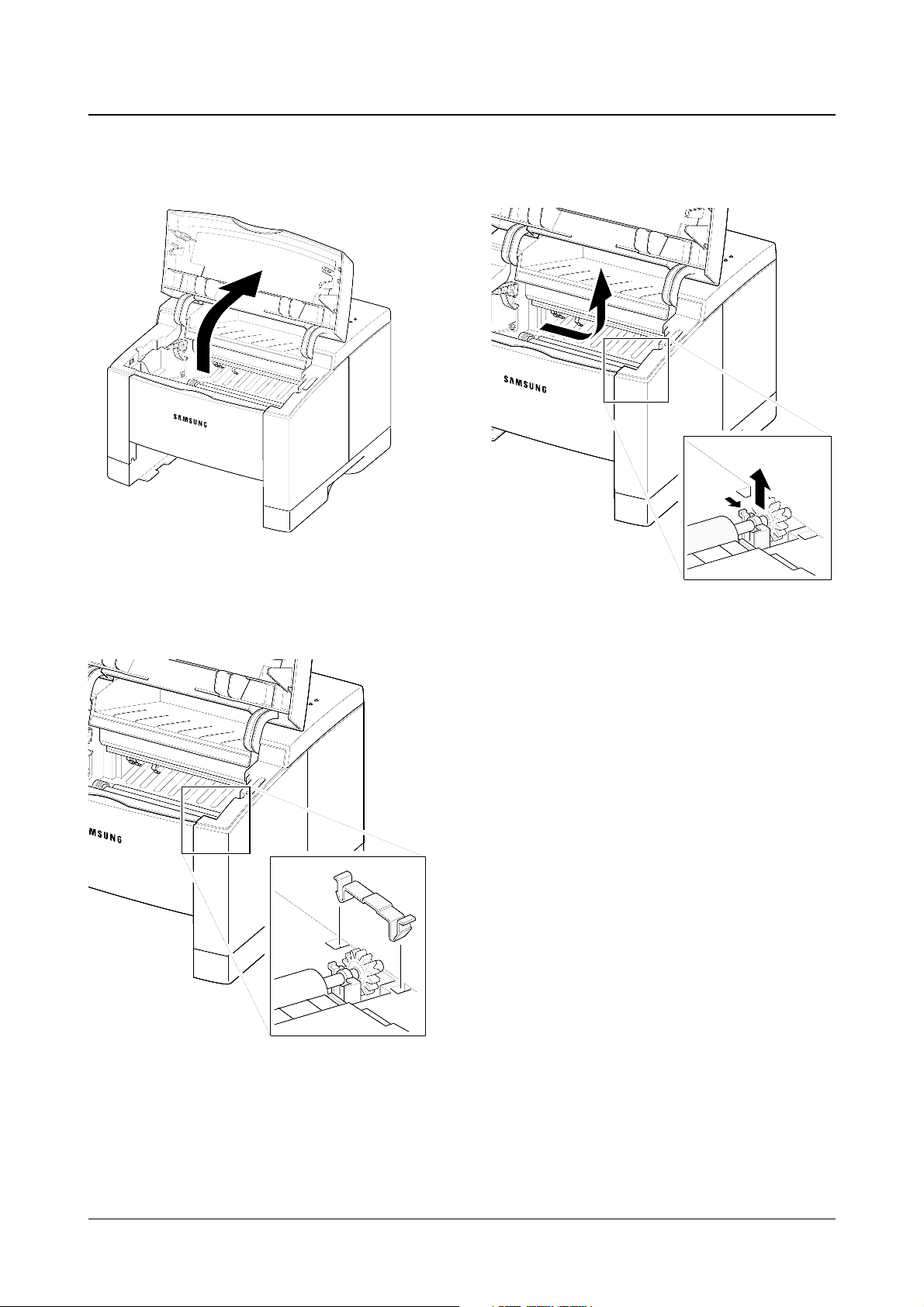

1. Open the printer cover.

2. Remove the cap.

3. Hold the cap at the both end of the roller, then

remove the roller.

Disassembly and Reassembly

3-2

Samsung Electronics

3-2 Transfer Roller

Page 11

Disassembly and Reassembly

3-3

Samsung Electronics

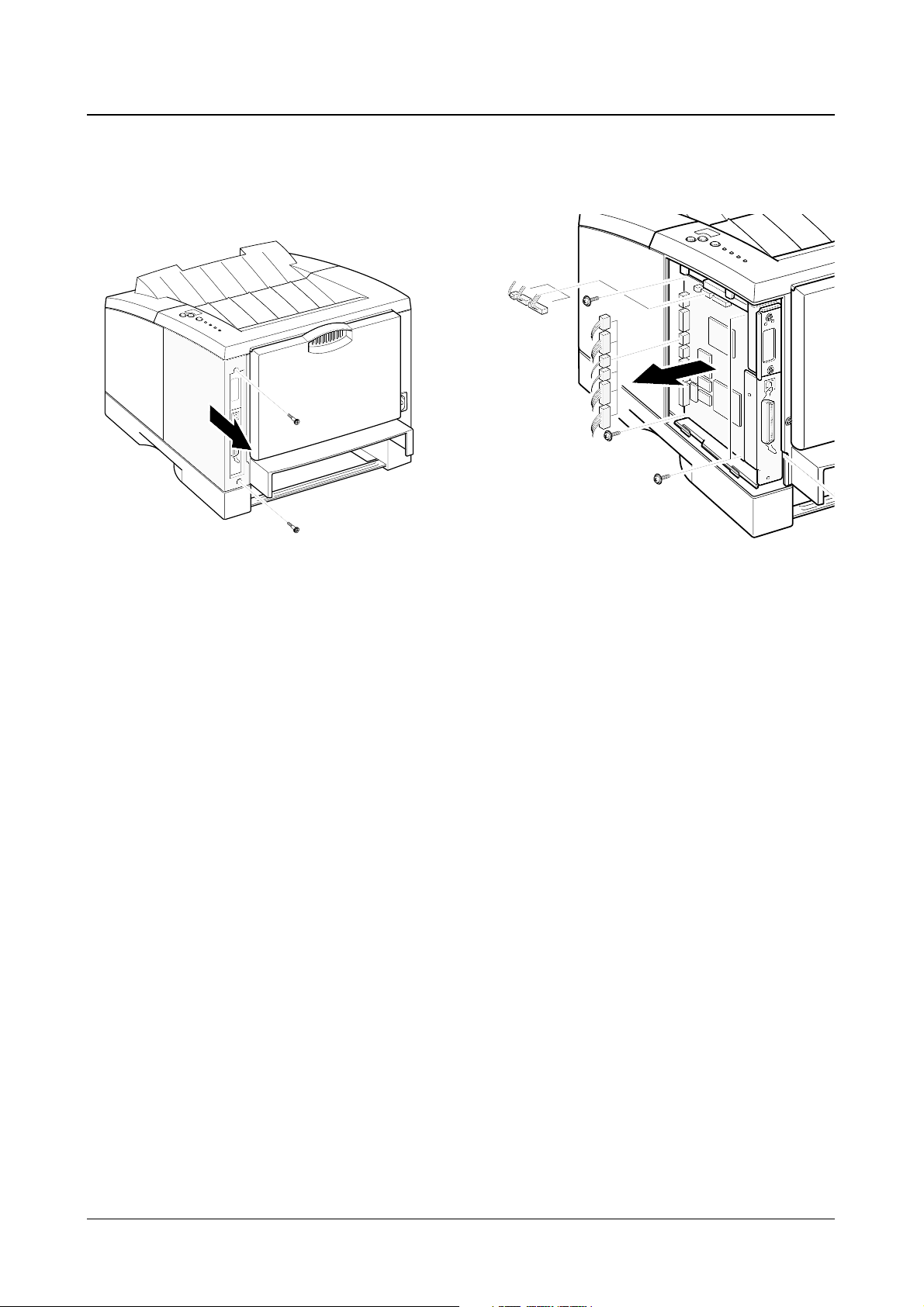

1. Remove two screws and remove the

controller cover.

2. Remove five screws securing the board and

unplug all connectors, and then take the

controller board out of the printer.

3-3 Controller Board

Page 12

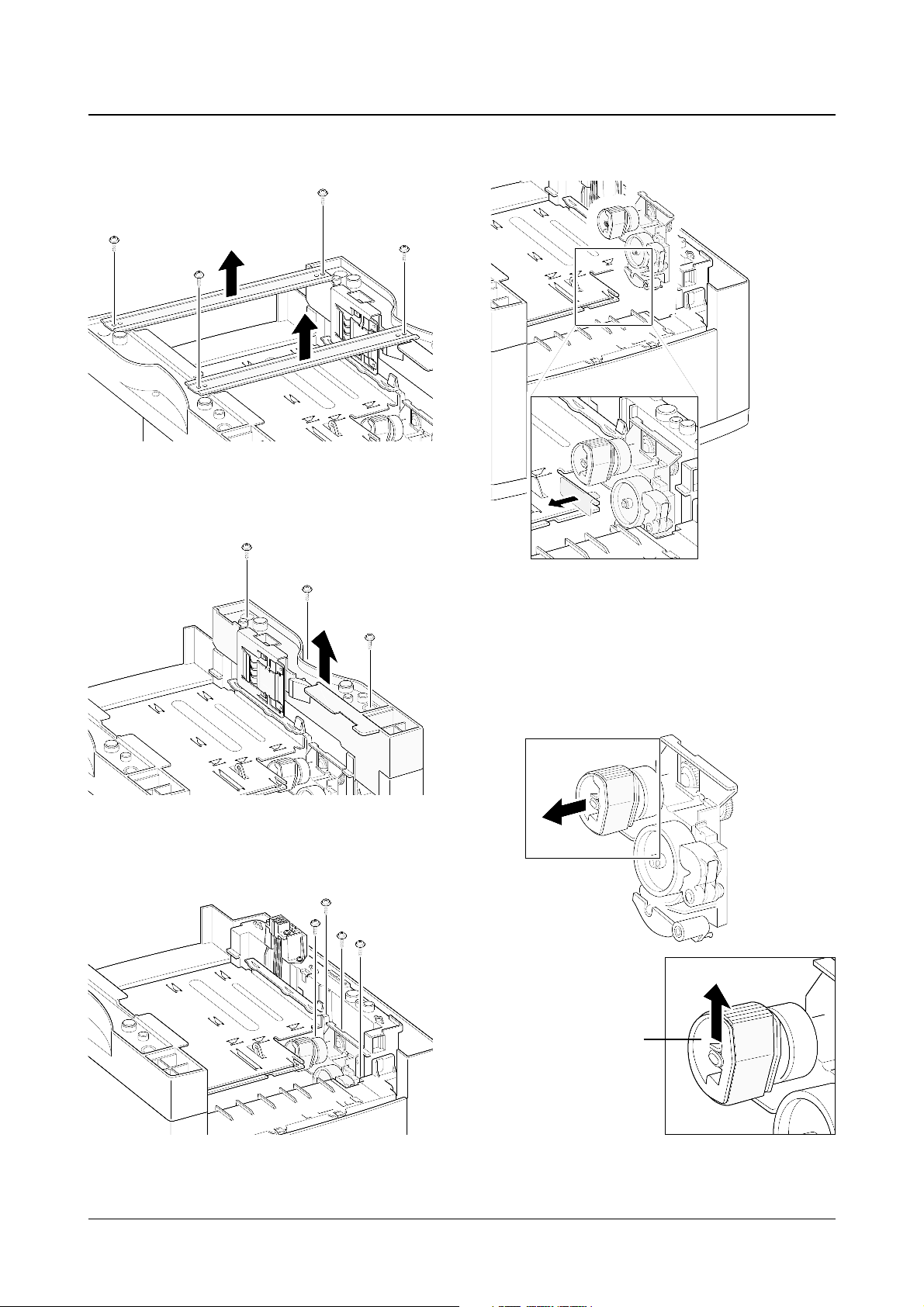

1. Turn the printer upside down. Remove four

screws, then remove the bar cross bottom.

2. Remove three screws from the left base

bracket, and take the bracket out.

3. Remove four screws securing the pickup

assembly.

4. Take the assembly out.

5. Check the pickup rubber wear. If the rubber is

heavily worn, replace it with a new one.

Disassembly and Reassembly

3-4

Samsung Electronics

Squeeze this tab to

remove the rubber.

3-4 Pickup Assembly

Push the solenoid if

you have difficulty to

remove the pickup

assembly.

Page 13

Disassembly and Reassembly

3-5

Samsung Electronics

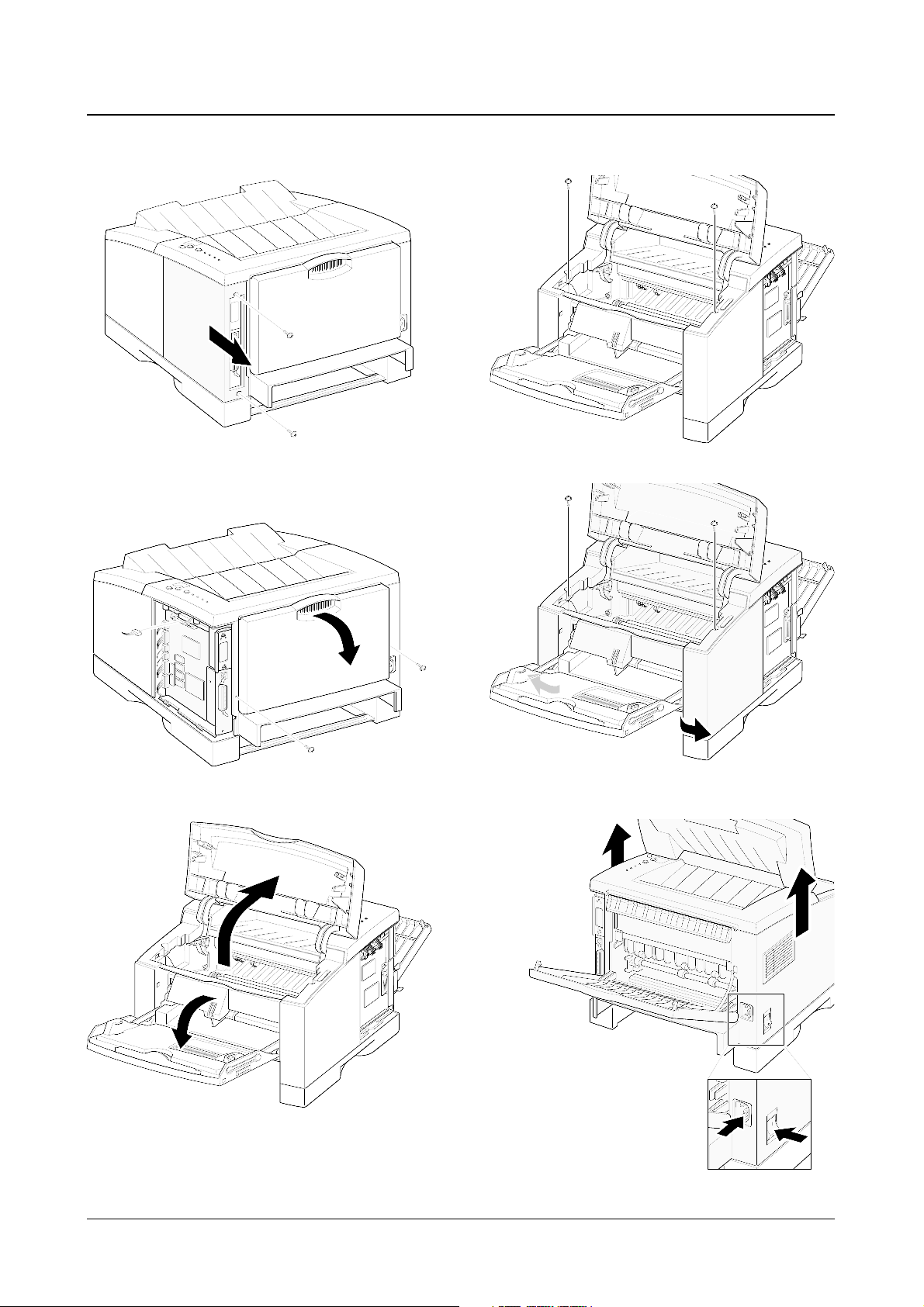

1. Remove two screws and remove the controller

cover.

2. Remove two screws at the back of the printer and

unplug one connector from the board, then open

the rear cover.

3. Open the printer cover, and open the MP tray.

4. Remove two screws securing the main cover.

5. Unlatch the front ends of the cover.

|6. Slide the main cover upward, out of the printer.

3-5 Main Cover

Note that the power

switch and the power

connecter are properly

released when you

remove the cover.

Page 14

1. Before you remove the exit assembly, you

should remove:

-Main Cover (see page 3-5)

2. Remove the exit tray in the direction of arrow.

3. If you want to remove the roller shaft, unlatch

both ends of the shaft and take it out.

4. If you want to remove the exit roller, squeeze

the bottom of the roller and take it out.

Disassembly and Reassembly

3-6

Samsung Electronics

1. Before you remove the MP tray, you should

remove:

-Main Cover (see page 3-5)

2. Remove the stoppers securing the MP tray.

3-6 MP (Multi-Purpose) Tray

3-7 Exit Assembly

Page 15

Disassembly and Reassembly

3-7

Samsung Electronics

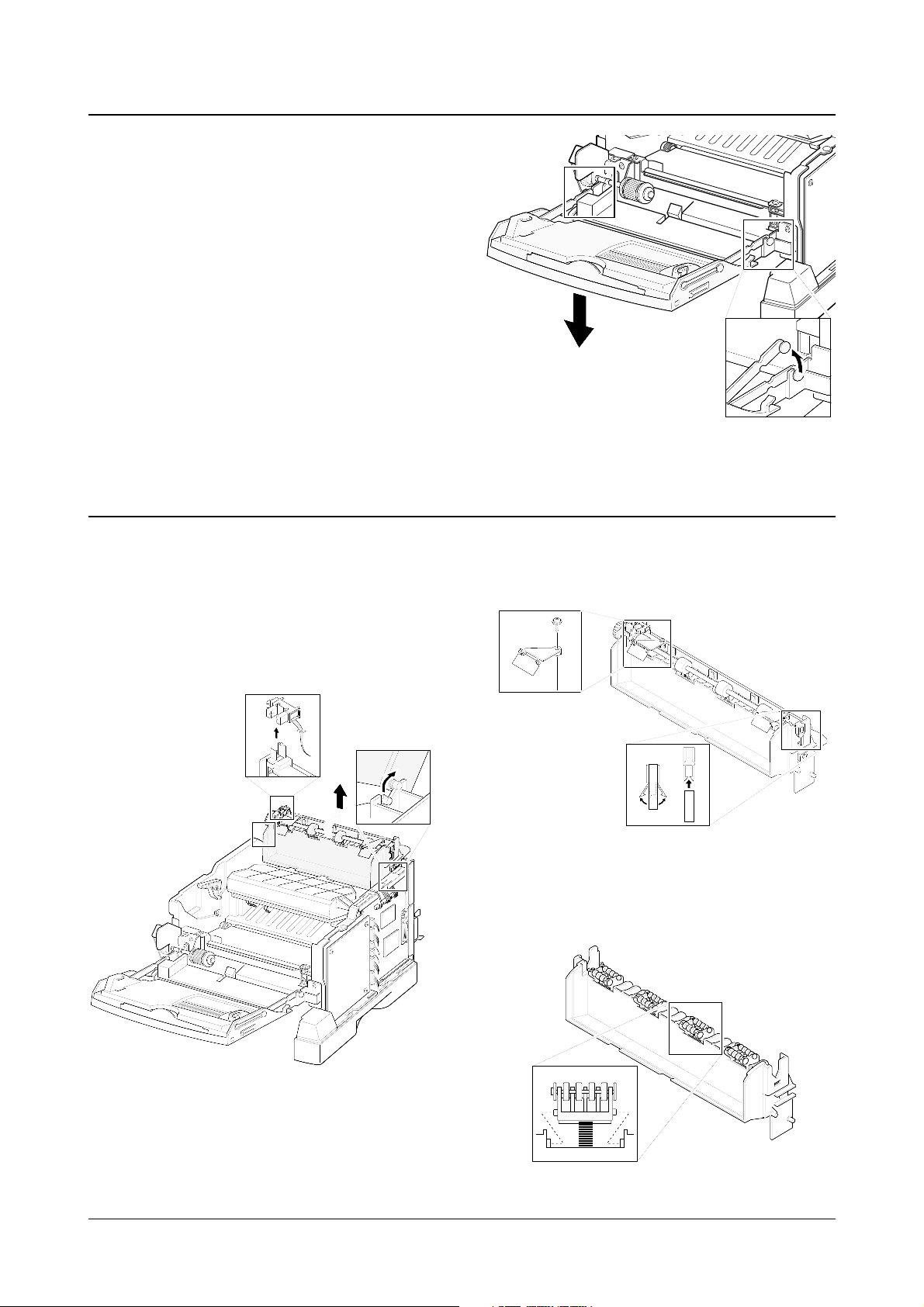

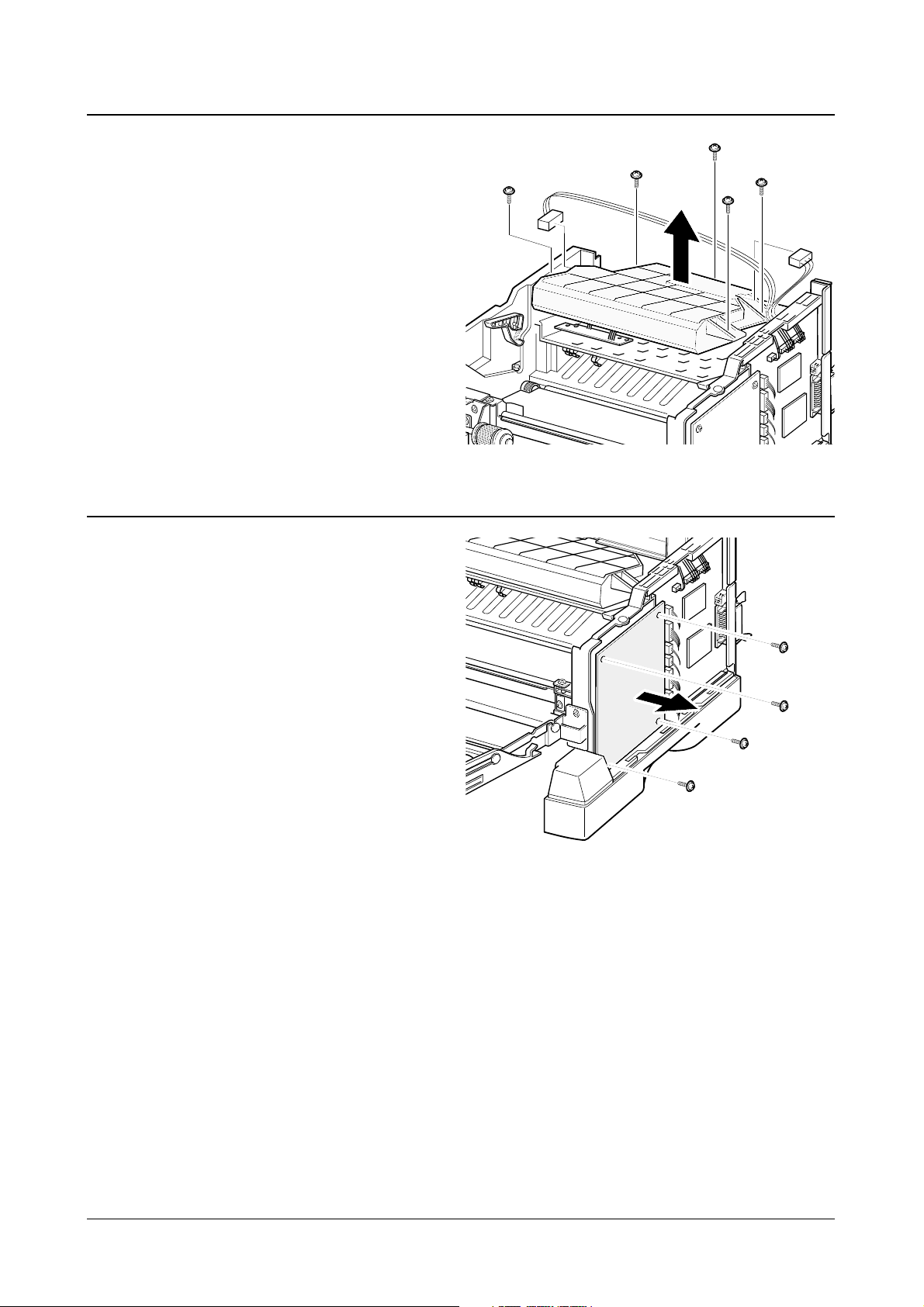

1. Before you remove the LSU, you should remove:

-Main Cover (see page 3-5)

-Exit assembly (see page 3-7)

2. Remove five screws, and remove the LSU. Then

unplug two connectors from the LSU.

3-8 LSU

1. Before you remove the HVPS board, you

should remove:

-Main Cover (see page 3-5)

2. Remove four screws and take the HVPS

board out.

3-9 HVPS board

Page 16

Disassembly and Reassembly

3-8

Samsung Electronics

1. Before you remove the fan, you should remove:

-Main Cover (see page 3-5)

2. Remove two screws securing the connector

cover and harness bracket from the gear

bracket.

3. Remove one screw, and remove the fan.

Then unplug one connector.

3-10 Fan

1. Before you remove the solenoid, you should

remove:

-Main Cover (see page 3-5)

2. Remove two screws, and remove the

solenoid. Then unplug one connector.

3-11 Solenoid

Page 17

Disassembly and Reassembly

3-9

Samsung Electronics

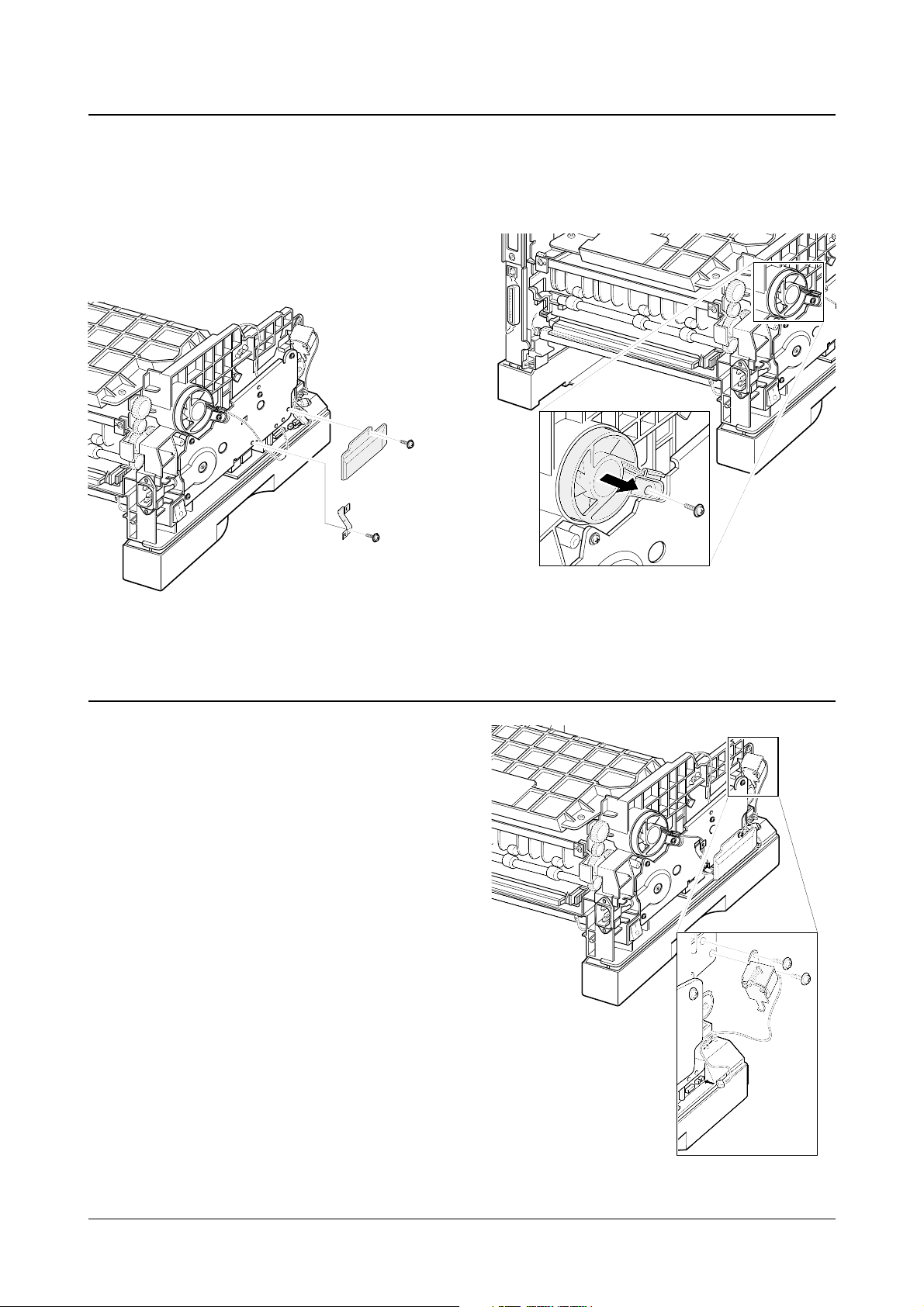

1. Before you remove the drive assembly, you

should remove:

-Main Cover (see page 3-5)

-Fan (see page 3-9)

2. Remove four screws securing the drive

assembly from the gear bracket and unplug

one connector from the motor, and then take

the drive assembly out.

3. If you want to remove the motor assembly from

the drive assembly, remove five screws

securing the motor assembly to the gear

bracket.

4. If you want to remove the step motor, remove

four screws securing the step motor from the

motor bracket and unplug two connector from

the motor.

5. If you want to remove the motor joint PCB,

remove two screws securing the motor joint

PCB from the gear bracket and unplug one

connector from the motor joint PCB.

3-12 Drive Assembly

Page 18

Disassembly and Reassembly

3-10

Samsung Electronics

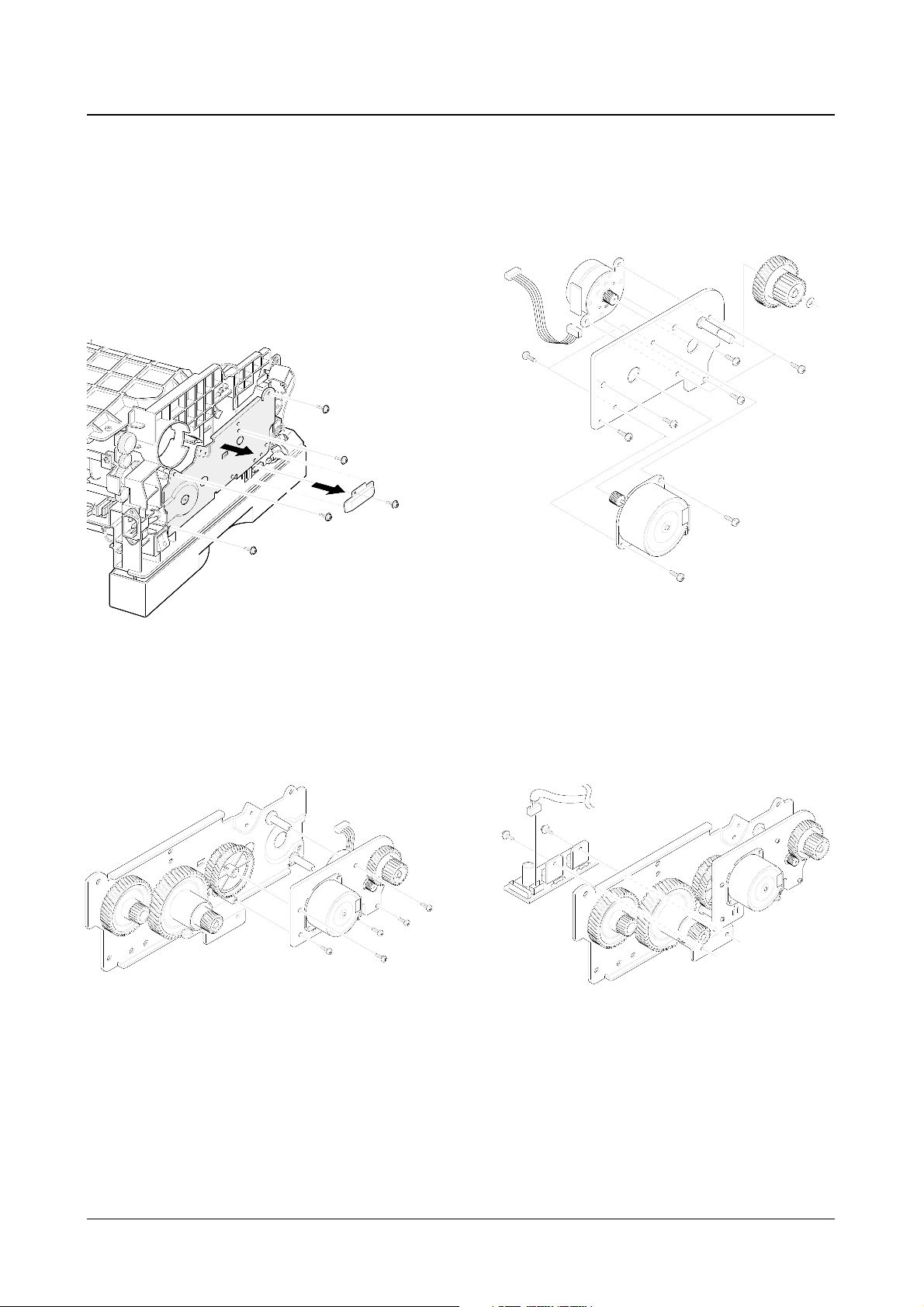

1. Before you remove the fuser, you should remov

e:

-Main Cover (see page 3-5)

2. Remove four screws and unplug one connector, and then remove the fuser assembly.

♦ To remove the thermostat from the fuser

assembly

Remove two screws and take the thermostat out.

♦ To remove the thermistor from the fuser

assembly :

Remove one screw, and release the wire from the

three holders, and then take the thermistor out.

♦ To remove the halogen lamp from the fuser

assembly :

Remove two screws and take the halogen lamp

out of the fuser assembly.

Note When you reassemble the halogen

lamp, make sure that it is inserted into

the slot properly.

3-13 Fuser Assembly

Page 19

Disassembly and Reassembly

3-11

Samsung Electronics

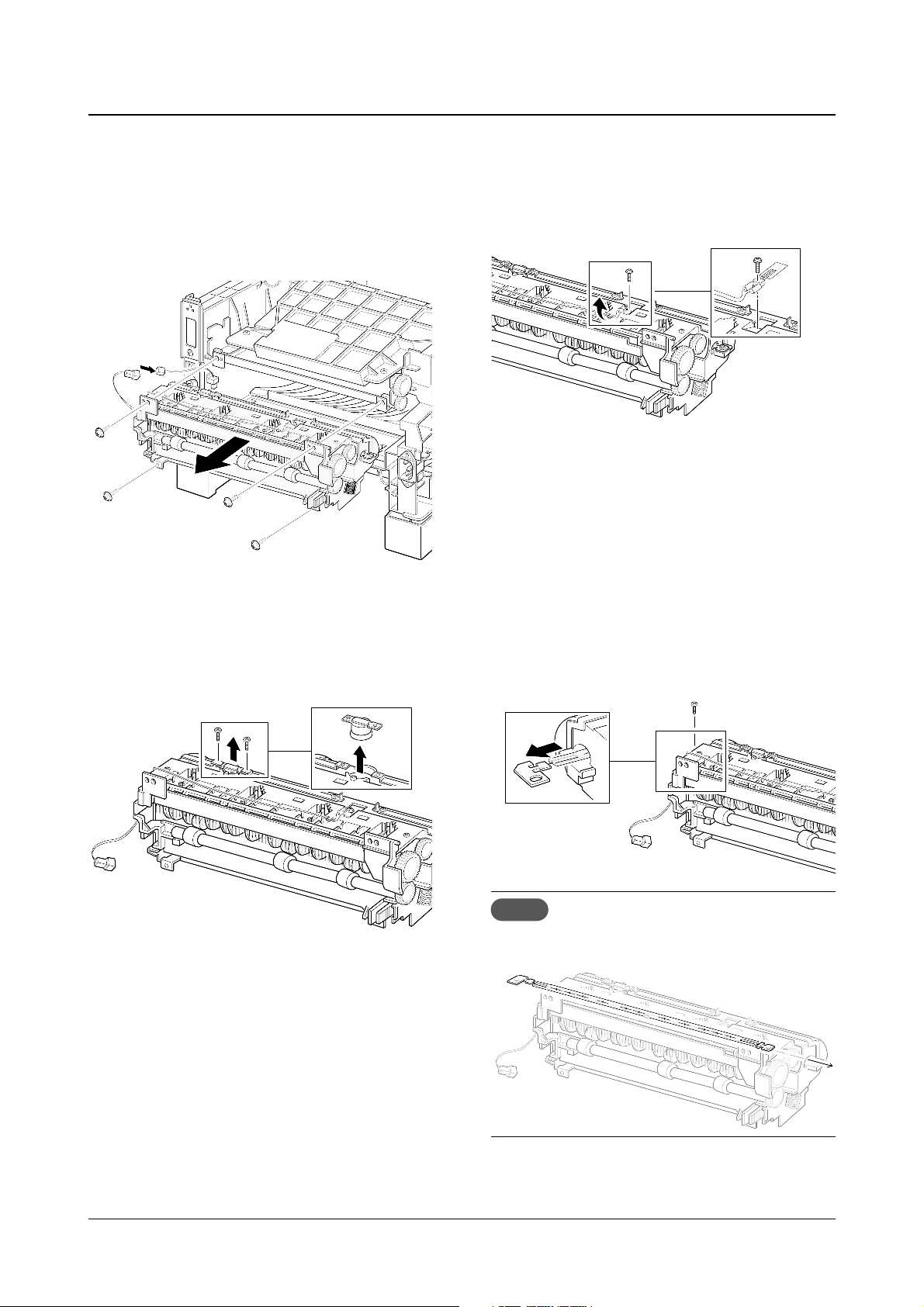

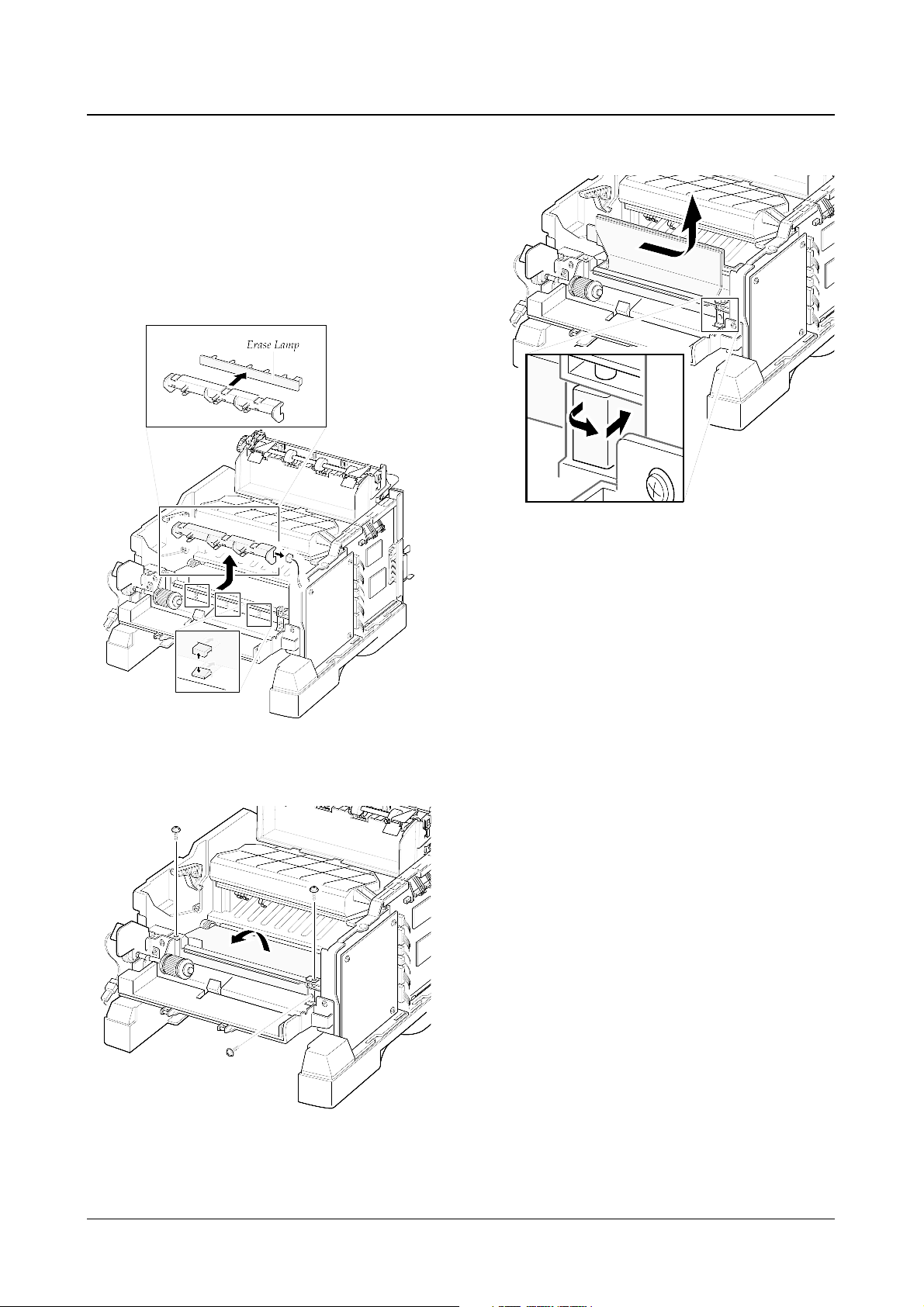

1. Before you remove the guide feed & PTL, you

should remove:

-Main Cover (see page 3-5)

2. Release the latches on the erase lamp from the MPF

ASS’Y and unplug one connector, then remove the

PTL.

3. Remove three screws and raise the guide feed in the

direction of arrow.

4. Remove the guide feed& erase PTL.

3-14 Guide Feed & Erase Lamp

Page 20

Disassembly and Reassembly

3-12

Samsung Electronics

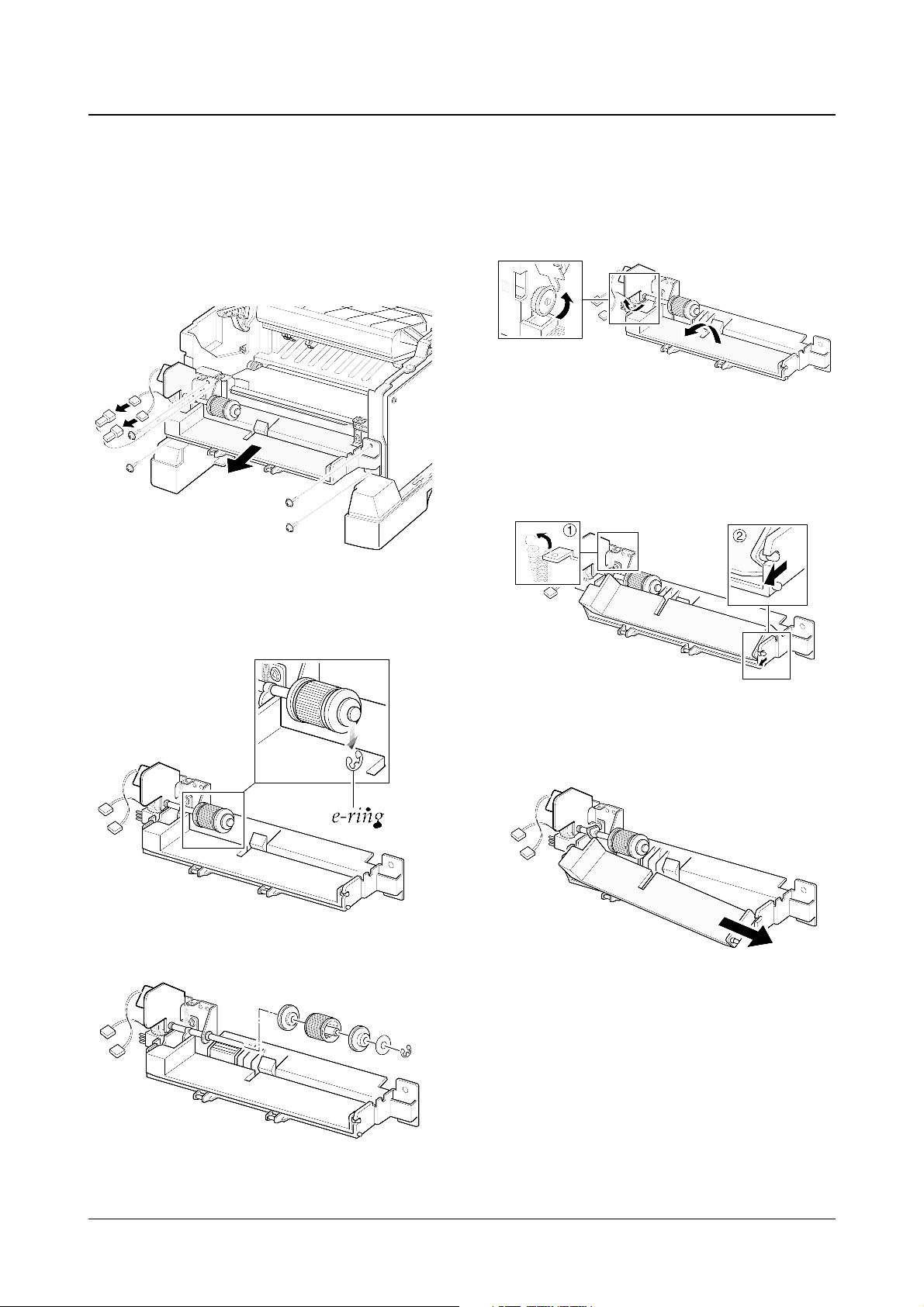

1. Before you remove the MPF assembly, you

should remove:

-Main Cover (see page 3-5)

2. Unplug two connectors and remove five

screws, and then take the MPF assembly out.

♦ To replace the pickup roller :

1. Remove the e-ring.

2. Remove the roller.

♦ To replace the nockup plate :

1. Turn the gear shown in the square in the

direction of arrow to release the nockup plate.

2. Remove the spring , then release the right end

of the plate.

3. Remove the nockup plate.

3-15 MPF Assembly and Miscellaneous on MPF Assembly

Page 21

Disassembly and Reassembly

3-13

Samsung Electronics

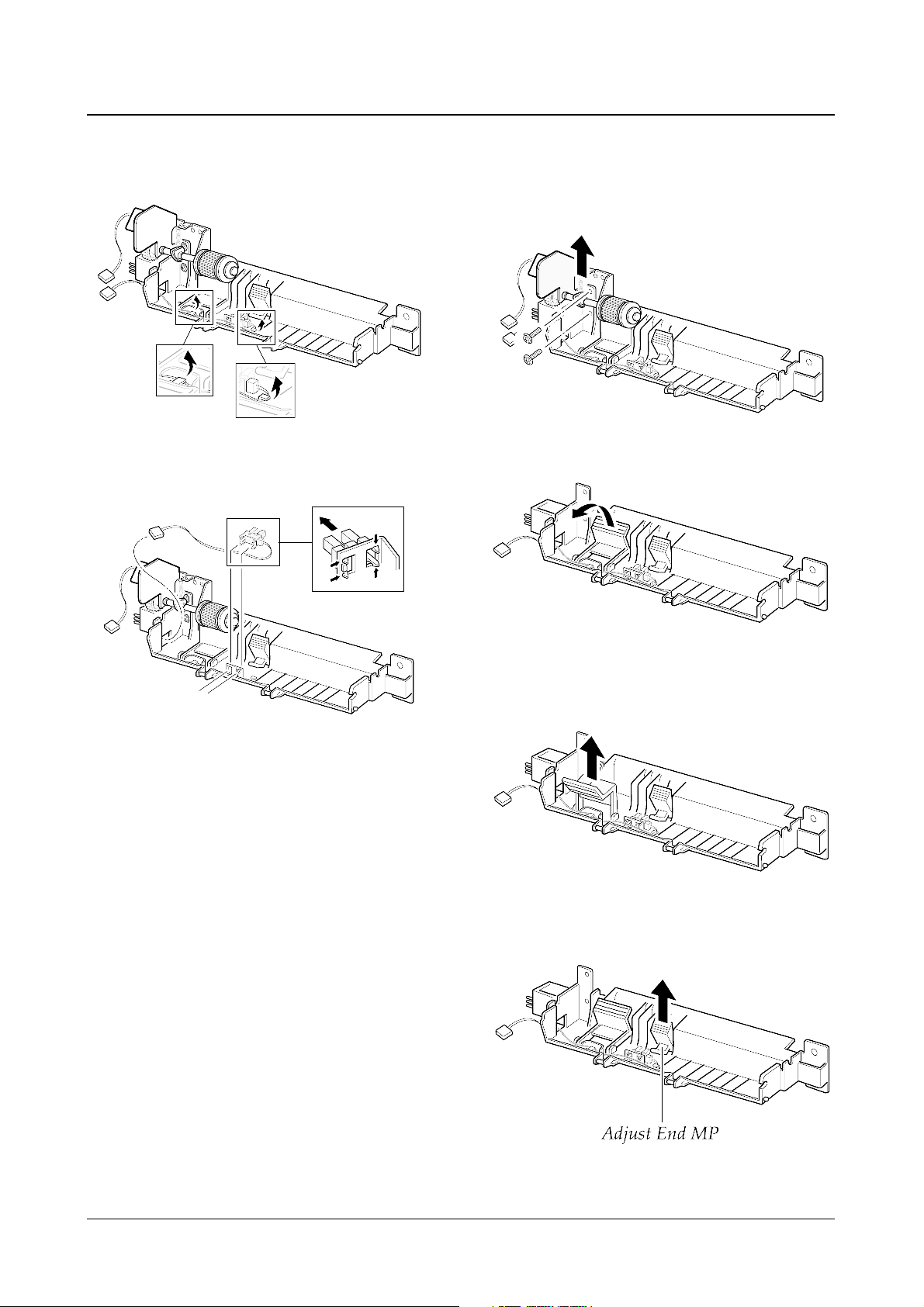

♦ To replace the Paper Empty (PE) sensor :

1. Release the wire from the two holders.

2. Raise the pickup holder in the direction of

arrow.

♦ To replace the pickup holder and the Adjust

End MP:

1. Remove two screws and remove the MPT

bracket.

2. Unlatch the PE sensor, then take it out.

3. Remove the pickup holder.

4. Remove the Adjust End MP

Page 22

Disassembly and Reassembly

3-14

Samsung Electronics

1. Before you remove the engine board, you should

remove:

-Main Cover (see page 3-5)

2. Remove six screws from the left and the right base

bracket and take them out.

3. Remove eight screws securing the PCU shield and

remove two screws securing the SCF connector , and

then take the PCU shield out of the printer.

4. While you push the latch to release the PCU shield,

take the PCU shield out of the printer.

5. Unplug all connectors from the PCU shield, and

remove the shield.

3-16 Engine Board and Miscellaneous

Page 23

Disassembly and Reassembly

3-15

Samsung Electronics

♦ To replace the exit board :

Unplug one connector from the controller board

and remove one screw securing the board.

Then release the wire from two holders and

take the board out.

♦ To replace the fuser sensor :

Remove two screws and take it out.

♦ To replace the Cap sensor :

Remove two screws and take it out.

♦ To replace the actuator empty :

Take the sensor out while you squeeze the both

ends of the sensor.

Page 24

Disassembly and Reassembly

3-16

Samsung Electronics

♦ To replace the actuator feed

1. Turn the mechanism back and push down the

points as shown to unlatch the actuator feed.

2. Turn the unit over again, and remove the

actuator feed.

♦ To remove the transfer guide :

Remove three screws and take the guide out.

Page 25

Troubleshooting

4-1

Samsung Electronics

4. Troubleshooting

4-1 How to use DCU

4-1-1 DCU Setup......................................Page(4-2)

4-1-2 Code ................................................Page(4-2)

4-1-3 Self Diagnostic Mode......................Page(4-3)

4-1-4 Self Test Button ................................Page(4-4)

4-1-5 Paper Path Layout...........................Page(4-4)

4-1-6 DCU Panel .......................................Page(4-5)

4-2 The cause and solution of Bad image

4-2-1 Vertical Black Line and Band..........Page(4-6)

4-2-2 Vertical White Line...........................Page(4-6)

4-2-3 Horizontal Black Band .....................Page(4-7)

4-2-4 Black/White Spot..............................Page(4-7)

4-2-5 Light Image.......................................Page(4-8)

4-2-6 Dark Image or a Black.....................Page(4-8)

4-2-7 Uneven Density................................Page(4-9)

4-2-8 Background ......................................Page(4-9)

4-2-9 Ghost (1)...........................................Page(4-10)

4-2-10 Ghost (2)..........................................Page(4-10)

4-2-11 Ghost (3)..........................................Page(4-11)

4-2-12 Ghost (4) .........................................Page(4-11)

4-2-13 Satins on the Face of Page............Page(4-11)

4-2-14 Satins on Back of Page..................Page(4-12)

4-2-15 Blank Page Print out (1) .................Page(4-12)

4-2-16 Blank Page Print out (2) .................Page(4-12)

4-3 The cause and solution of the bad discharge

4-3-1 Wrong Print Position.......................Page(4-13)

4-3-2 JAM 0...............................................Page(4-13)

4-3-3 JAM 1...............................................Page(4-14)

4-3-4 JAM 2...............................................Page(4-14)

4-3-5 Multi-Feeding...................................Page(4-15)

4-3-6 Paper rolled in the fuser .................Page(4-15)

4-3-7 OPC.................................................Page(4-16)

4-4 The cause and solution of the malfunction

4-4-1 All LEDs blinking (Fuser Error)........Page(4-17)

4-4-2 All LEDs blinking (SCAN ERROR).Page(4-17)

4-4-3 Not function of the gear of the fuser due to

melting away.....................................Page(4-18)

4-4-4 Paper Empty.....................................Page(4-18)

4-4-5 Paper Empty without indication.......Page(4-18)

4-4-6 Cover Open......................................Page(4-19)

4-4-7 No lamp on when the cover is open

...........................................................Page(4-19)

4-4-8 Defective motor operation ...............Page(4-20)

4-4-9 No Power..........................................Page(4-20)

4-4-10 Vertical Line Getting Curved.........Page(4-21)

4-5 Toner Cartridge Service

4-5-1 Precautions on Safe-keeping of Toner Cartridge

..........................................................Page(4-22)

4-5-2 Service for the Life of Toner Cartridge

..........................................................Page(4-22)

4-5-3 Service for Judgement of Inferior Expendables

and the Standard of Guarantee.....Page(4-22)

4-5-4 Signs and Measures at Poor toner cartridge

..........................................................Page(4-23)

4-6 The cause and solutions of bad environment

of the software

4-6-1 The printer is not working (1)...........Page(4-26)

4-6-2 The printer is not working (2) .........Page(4-27)

4-6-3 Abnormal Printing.............................Page(4-28)

4-6-4 SPOOL Error ...................................Page(4-29)

Page 26

Troubleshooting

4-2

Samsung Electronics

4-1 How to use DCU

4-1-1 DCU Setup

You can examine the malfunction of the printer. To perform DCU, open the front discharge cover and leave the connect

the harness wire(10 pin/4 pin) to the CN10(4 pin) of the Main control board.

4-1-2 Code

Connect DCU to the printer and turn the power on. It show 7 LED on the panel and each code tells the function of the

printer.

Normal Code

While printing or warming up, it indicate the position of the paper

61 Warm up The printer is on, the cover is open or close.

00-05 Ready(kind of paper) The printer is ready, the paper is detected when the first paper is printed.

00: Legal ,01: Letter ,02: A4 ,03: EXEC ,04: B5 ,05: Folio, 06: A5/A6

20, 21, 22 Print Start The engine controller received the print order from the video controller.

20: 1st, 21: MP, 22: SCF

30 Feed Sensor On The paper is passing out of the Feed Sensor.

40 Feed Sensor off The paper has passed out of the Feed Sensor.

50 Paper Out The paper has passed out of Exit Sensor.

69 Sleep Mode The fuser power turned off to minimize the power consumption.

Error Code

When detecting the malfunction, the printing is stopped to indicate error code.

60, 62, 68

Fuser Error The error in the fuser occurred. There is a short circuit in the thermistor and the

thermostat while printing, Low Temperature Error occurs.

• 60: Open Fuser Error

• 62: Low Heat Error

• 68: Over Heat Error

64 Cover Open The Printer Cover is open.

65 CRU Error The Toner Cartridge not installed,

70 No Paper No paper in the paper cassette.

71 Paper Jam 0 The front part of paper is jammed between pickup unit and Feed sensor.

72 Paper Jam 1 The front part of paper is jammed between the Discharge sensor and Feed sensor.

73 Paper Jam 2 The front part of paper is jammed just after passing through the discharge sensor.

76 Out Bin Full The Out bin is filled with paper.

95 LSU Not Ready LSU Scanner Motor not ready or Hsync signal not output.

Page 27

Troubleshooting

4-3

Samsung Electronics

4-1-3 Self Diagnostic Mode

If Error code occurs due to malfunction of the printer, perform Self Diagnostic Mode to solve the problem.

The printer works only in the self-test mode to solve the malfunction problem.

To enter the self-test mode, turn the power on pressing the buttons of [Down], [Shift] and [Stop] at the same time.

Release the button within 2 or 3 seconds if 78 shows in the DCU. If 00 shows in the DCU, press the button [Up] or [Shift]

to select the self+test , and press the button of [Enter] to operate. To stop, press the button of [shift] and [Enter] together.

00 Main Motor Operating System

Only the main motor is in operation.

01 Main High Voltage On(THV-)

-1400 voltage output by MHV terminal. Caution : High voltage probe should be

used.

02 Transfer High Voltage(-)On(THV-)

-1000 voltage output by MHV terminal. Caution

:

High voltage probe should be

used.

03 Transfer High Voltage (+)Reference on (THV +)

+800 voltage output by MHV terminal. Caution : High voltage probe should be used.

04 DEV/supply High Voltage : DEV/Supply High Voltage Test.

The left one of the three LEDs in the

self-test panel is on when DEV high voltage Supply high voltage output

by each HV terminal(-500V). Press the [Up] button to switch the voltage. The middle and right one of the three

LEDs are on and -650 voltage output by DEV HV terminal.

Caution : High voltage probe should be used.

05 LSU Operating System

The scanning motor of LSU is in operation, the right LED of the three buttons on. Press the [Up] button to

Check LD. LD is functioning and the middle button is on. If the LD is normal, all LEDs are on.

06 Pickup clutch on

The Solenoid in the printer is in operation. To stop the operation, Press the button [shift] and [Enter] together.

07 Paper Empty(1st, SCF, MF) Sensor Test :

If activate the Actuator of the PEMPTY/PWIDTH Sensor, the left and right of the three LEDs are on.

Paper Empty Sensor (1st) ON/OFF 1st LED ON/OFF

Paper Empty Sensor (SCF) ON/OFF 2nd LED ON/OFF

Paper Empty Sensor (MP) ON/OFF 3rd LED ON/OFF

Increment DCU Code No. (08, Sensor TEST)

08 Feed & Exit Sensor Test

Test the Feed sensor and Discharge sensor in the same way as '06'.

09 Cover Open Sensor Test

The same way as code '06'.

10 Fuser Test

If the [Enter] button pressed, the right LED is on and temperature of the fuser is up to READY Mode. If the

[Up] button pressed, the middle LED is on and temperature of the fuser is up to Printing Mode.

If you press the button once more, the left LED is on and temperature of the fuser is up to overheat Mode.

11 Hot Burn Test

If the [enter] button pressed, the printer is continuously printing without detection.

Turn the power off to stop operation.

12 Cleaning Mode Print Mode

Print the paper to clean the OPC Drum in the Cartridge.

Page 28

Troubleshooting

4-4

Samsung Electronics

13 THV(+) TRIGGER. ALL HV :

All high voltage output by each HV terminal and LSU and the fan is in operation. In this mode, electronic

resistance of transfer roller and high voltage is detected.

14 +7P Clutch Test :

Same method of the code ‘06’.

15 Fan Test :

Indicates the function of the fan, same method of the code ‘06’.

16 Paper size Sensor Test :

Cassette Sensor 1 ON/OFF 1st LED ON/OFF

Cassette Sensor 2 ON/OFF 2nd LED ON/OFF

Cassette Sensor 3 ON/OFF 3rd LED ON/OFF

Increment DCU Code No. (00,MAIN MOTOR TEST)

Decrement DCU Code No. (15, FAN TEST)

17 SMD Test :

This function is for a manufacturing process. You can test all diagnostic Codes(0~06).

When you push the ‘Enter’ button, the main motor runs (Diagnostic Code 00).

If you push the ‘up’ botton, the current diagnostic Code stops, and the next diagnostic Code starts.

4-1-4 Self Test Button

If the Self-Test button pressed, vertical lines are printed.

Turn the power on while pressing this button, '89' shows in the DCU and the printer is warming up. After warming-up the

printer is in READY Mode, and '88' shows in the DCU. In this mode, without any detection, the printer begins

printing(trial printing and data from the PC). It is convenient to use this mode when the engine malfunction is detected in

the control board.

4-1-5 Paper Path Layout

LSULSU

CARTRIDGECARTRIDGE

MPF

PICK UP

OPC

FEED

CR

IDLE

EMPTY SEN

FEED SENFEED SEN

DR

PTL

SR

TR

FUSERFUSER

FACE DOWN

FACE UPFACE UP

H/R

Pr/R

SCF

CASSETTE

EXIT SEN

EXIT1EXIT1

EXIT2

OUT BIN FULL SEN

Page 29

Troubleshooting

4-5

Samsung Electronics

4-1-6 DCU Panel

ML-1650 DIAGNOSTIC CONTROL UNIT

QUICK REFERANCE

04

05

07

08

09

10

BIAS 3

LSU READY

PAPER EMPTY

CRU

COVER OPEN

COER HEAT

BIAS 1

LSU MT&LD

SCF

EXIT SENSOR

COVER COVER

PRINT HEAT

BIAS 0

LSU MOTOR

MP

FEED SENSOR

OUT BIN

STANDBY HEAT

ON OFF

STATUS

SELF

TEST

DIAGNOSTIC

DIAGNOSTIC CODE

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

00

01

02

03

04

05

06

20

21

22

40

50

60

62

68

61

64

65

69

70

71

72

73

76

90

95

MAIN MOTOR OPERATION

MAIN HIGH VOLTAGE ON

TRNSFER HIGH VOLTAGE (-)ON

THV(+) REFERANCE VOLTAGE

DEV/SUPPLY VOLTAGE ON

LSU OPERATING TEST

PICKUP CLUTC ON

PAPER EMPTY SENSOR TEST

FEED & EXIT SENSOR TEST

COVER OPEN SENSOR TEST

FUSER TEST

HOT BURN TEST

CLEAN (MESSAGE)PRINT

THV(+)TRIGGER &THV ON

MP PICKUP ON

FAN TEST

PAPER SIZE SENSOR TEST

SMD TEST

GREEN STATUS CODE

88

99

STATUS CODE

READY (REGAL)

READY (LETTER)

READY (A4)

READY (EXECUTIVE)

READY (B5)

READY (FOLIO)

READY (A5,A6)

PRINT START (1'st CASSETTE)

PRINT START (MP)

PRINT START (2'nd CASSETTE)

FEED SENSOR 2'st ON

PAPER OUT

OPEN FUSER ERROR

LOW HEAT ERROR

OVERHEAT ERROR

WARM UP

COVER OPEN ERROR

CRU ERROR

SLEEP MODE

NO PAPERR or CASSETTE

PAPER JAM 0

PAPER JAM 1

PAPER JAM 2

OUTBIN FULL ERROR

MANUAL PRINT MODE

LSU NOT READY

DCU MODE!! DOWN!! SHIFT!! STOP

!!! UP!!!! ENTER

O ENTER DIAGNOSTIC MODE, PUSH THREE BUTTONS SIMUL ANEOUSL

THE PRINTER POWER ON.

Page 30

Troubleshooting

4-6

Samsung Electronics

4-2 The cause and solution of Bad image

4-2-1 Vertical Black Line and Band

• Description

1. Straight thin black vertical line occurs in the printing.

2. Dark black vertical band occur in the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Damaged develop roller in the Developer.

Deformed Doctor-blade or cleaningblade.

2. Scratched surface of the discharge roller

in the developer.

3. Partly depression or deformation on the

surface of the transfer roller.

1. If causes 1 and 2 occur in the developer

cartridge, replace the developer and try to

print out.

2. Replace the transfer roller if occurred as

No. 3.

4-2-2 Vertical White Line

• Description White vertical voids in the image.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Foreign matter stuck onto the window of

internal lenses of LSU mirror.

2. Foreign matter or toner particles between

the developer roller and blade.

(In case the life of the developer has

been expired, white lines or light image

occur in front of the image.)

3. It may occur when Burr and foreign substances are on the window of the developer frame.

4. If the fuser is defective, voids occur periodically at the top of a black image.

1. Foreign matter stuck onto the window :

Clean the LSU window with recommended cleaner(IPA) Clean the window with a

clean cotton swab.

2. Foreign matter in the LSU : Open the

cover of LSU and clean with a cotton

swab on the surface of the reflex mirror.

3. No 3. : Remove the foreign matter and

burr of the exposure window.

(Developer cartridge)

4. No. 4. : Open the front cover and check

ribs that corresponds to the position of

the voids. Remove if found.

5. If the problems are not solved, replace

the developer cartridge.

Page 31

Troubleshooting

4-7

Samsung Electronics

4-2-3 Horizontal Black Band

• Description

1. Dark or blurry horizontal stripes occur in the printing periodically.

(They may not occur periodically.)

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Bad contacts of the voltage terminals to

developer.

2. The rollers of developer may be stained.

Charge roller = 38.5mm

Supply roller = 51mm

Develop roller = 50mm

Transfer roller = 56.8mm

1. Clean each voltage terminal of the Charge,

Supply, Develop and Transfer roller.

(remove the toner particles and paper particles)

2. Clean the right Gear that has relatively

small gap of the teeth in the OPC.

3. If the malfunction persists, replace the

developer.

4-2-4 Black/White Spot

• Description

1. Dark or blurry black spots occur periodically in the printing.

2. White spots occur periodically in the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. If dark or blurry black spots occur periodically, the rollers in the Developer may be

contaminated with foreign matte or paper

particles.

( Charge roller : 38.5 mm interval

OPC drum : 96 mm interval)

2. If faded areas or voids occur in a black

image at intervals of 96 mm, or black

spots occur elsewhere, the OPC drum

surface is damaged.

3. If a black image is partially broken, the

transfer voltage is abnormal or the transfer roller's life has expired.

1. Run OPC cleaning Mode Print and run the

Self-test 2 or 3 times.

2. In case of 96 mm interval unremovable in 1,

cleanly remove foreign substances stuck on

the OPC location equivalent to black spots

and white spots with a dry duster.

3. The transfer roller guarantees 125,000

sheets printing. If the roller's life is expired,

replace it.

4. In case of 38.5 mm interval unremovable in

1, take measures as to replace the developer cartridge and try to print out.

5. Clean the inside of the set against the paper

particles and foreign matter in order not to

cause the trouble.

Page 32

Troubleshooting

4-8

Samsung Electronics

4-2-5 Light Image

• Description The printed image is light, with no ghost.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Develop roller is stained when the toner

of developer cartridge is almost consumed.

2. Ambient temperature is below than 10°C.

3. Bad contact caused by the toner stains

between the high voltage terminal in the

HVPS and the one in the set.

4. Abnormal output from the HVPS.

(Run self-test and check 1~4)

1. Check if the Toner Save mode is off.

2. No 1 : R

eplace the developer cartridge and

try to print out.

3. No 2 : Wait 30 minutes after printer is powered on before you start printing.

4. No3 : Clean up the contaminated area by

the toner.

5. Replace the HVPS if the problems are not

solved by the above four directions.

4-2-6 Dark Image or a Black

• Description The printed image is dark.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. No charge voltage in the engine board.

( Perform DCU diagnostic code 01)

2. Charge voltage is not turned on due to

the bad contacts between power supply

in the side of the Developer and charge

terminal of HVPS.

1. Clean the high voltage charge terminal.

2. Check the state of the connector which

connects the engine board and HVPS.

3. Replace the HVPS if not solved by the

above direction 1 and 2.

Page 33

Troubleshooting

4-9

Samsung Electronics

4-2-7 Uneven Density

• Description Print density is uneven between left and right.

Check and Cause Solution

1. The pressure force on the left and right

springs of the transfer roller is not even,

the springs are damaged, the transfer

roller is improperly installed, or the transfer roller bushing or holder is damaged.

2. The life of the Developer has expired.

3. The toner level is not even on the developer roller due to the bad blade.

1. Replace both the left and right Spring

Holder.

2. Occur in the developer cartridge, replace

the developer and try to print out.

4-2-8 Background

• Description Light dark background appears in whole area of the printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Recycled recording paper has been

used.

2. The life of the Developer has expired.

3. The up-to-down movement of the transfer roller is swift?

4. The HVPS is normal?

(Perform DCU diagnostic code 01~04)

1. B/S is not guaranteed when using recycled

paper.

2. Replace the Developer that has expired.

3. Clean the busing part of the transfer roller.

4. Replace the Developer if not solved by the

above direction 1~3.

Page 34

Troubleshooting

4-10

Samsung Electronics

4-2-9 Ghost (1)

• Description Ghost occurs at 96 mm intervals of the OPC drum in the whole printing.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

96 mm

Check and Cause Solution

1. Bad contacts caused by contamination

from toner particles between high voltage

terminal in the main body and the electrode of the Developer.

2. Bad contacts caused by contamination

from toner particles between high voltage

terminal in the main body and the one in

the HVPS board.

3. The life of developer is expired.

4. Transfer roller lifetime(125,000 sheets)

has expired.

5. Abnormal low temperature(below 10°C).

6. Damaged cleaning blade in the developer .

1. Clean the terminals when contaminated by

toner particles.

2. Occur in the developer cartridge, replace

the developer and try to print out.

3. Replace the engine board if not solved by

the above directions 1-2.

4. If not solved by the direction 3, check the

transfer roller lifetime and replace it.

5. Wait about 1 hour after power on before

using printer.

6. Occur in the developer cartridge, replace

the developer and try to print out.

4-2-10 Ghost (2)

• Description

Ghost occurs at 96 mm intervals of the OPC drum in the whole printing.

(When printing on card stock or transparencies using manual feeder)

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

96 mm

Check and Cause Solution

When printing on card stock thicker than normal paper or transparencies such as OHP,

higher transfer voltage is required.

Select 'Thick Mode' on paper type menu from

the software application and after using returning to the original mode is recommended.

Page 35

Troubleshooting

4-11

Samsung Electronics

4-2-11 Ghost (3)

• Description White ghost occurs in the black image printing at 51mm intervals.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

47.1 mm

Check and Cause Solution

1. The life of the developer may be expired.

2. The abnormal voltage and bad contact of

the terminal of the supply roller

1. Occur in the developer cartridge, replace

the developer and try to print out.

2. Check the approved voltage of the supply

roller and contact of the terminal and adjust

if necessary.

4-2-12 Ghost (4)

• Description Ghost occurs at 70 mm intervals.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

56.1 mm

Check and Cause Solution

The temperature of the fuser is maintained

high.

1. Disassemble the fuser and remove the

contaminated toner particles on the roller

and clean the foreign matter between

Thermistor and Heat roller.

( Caution: can be deformed)

4-2-13 Satins on the Face of Page

• Description The background on the face of the printed page is stained.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

1. Toner leakage due to improperly sealed

developer.

2. If the transfer roller is contaminated, satins

on the face of page will occur.

1. Replace the developer cartridge.

2. If the transfer roller is contaminated, run PC

Cleaning Mode Print 2 or 3 times.

And perform Self-Test 2 or 3 times to

remove contamination.

Page 36

Troubleshooting

4-12

Samsung Electronics

4-2-14 Satins on Back of Page

• Description The back of the page is stained at 56.1 mm intervals.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

56.1 mm

Check and Cause Solution

1. Transfer roller is contaminated.

2. Pressure roller is contaminated.

1. Perform the OPC Cleaning Mode Print 2 or

3 times. Run Self-Test to remove the contamination of the transfer roller.

2. Replace the transfer roller if contaminated

severely .

3. Disassemble the fuser and clean the

H/R(Heat Roller) and P/R(Pressure roller).

And check the area between H/R and

Thermistor. If contaminated, clean the area

not to be deformed.

4-2-15 Blank Page Print out (1)

• Description Blank page is printed.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Check and Cause Solution

Bad ground contacts in OPC and/or developer.

Remove contamination of the terminals of the

developer and the unit.

4-2-16 Blank Page Print out (2)

• Description

1. Blank page is printed.

2. One or several blank pages are printed.

3. When the printer turns on, several blank pages print.

Check and Cause Solution

1. Bad ground contacts in OPC and/or

developer.

2. Abnormal solenoid.

1. Remove contamination of the terminals of

the developer.

2. Perform the engine self test using DCU to

check

if the Solenoid is normal.(refer to code 06)

3. If not solved by the above directions 1-2,

Replace the engine board.

4. Turn the power off, delete the data of PC

and try printing again.

Page 37

Troubleshooting

4-13

Samsung Electronics

4-3 The cause and solution of the bad discharge

4-3-1 Wrong Print Position

• Description Printing begins at wrong position on the paper.

Check and Cause Solution

Wrong sense time caused by defective feed sensor

actuator.

Replace the defective actuator

4-3-2 JAM 0

• Description

1. Paper is not exited from the cassette.

2. Jam-0 occurs if the paper feeds into the printer.

JAM 0

LSULSU

CARTRIDGECARTRIDGE

MPF

PICK UP

FEED

IDLE

EMPTY SEN

FEED SEN

TR

FUSERFUSER

FACE DOWN

FACE UPFACE UP

H/R

Pr/R

CASSETTE

EXIT SEN

EXIT1EXIT1

EXIT2

OUT BIN FULL SEN

Check and Cause Solution

1. Check the Solenoid by using DCU

diagnostic mode 06.

2. Check if the pad is loose due to bad

sealing of the side-pad.

3. Check the surface of the roller-pickup for foreign matter.

4. If continuous clusters occur, check

whether the assembly slot between

shaft-pickup and housing-pickup

become open or is broken away.

5. If the paper feeds into the printer

rand Jam 0 occurs, perform DCU to

check feed-sensor of the engine

board.

1. Replace the solenoid.

2. Replace the side-pad Assembly Lor

R, if necessary.

3. Clean with soft cloth dampened with

IPA(Isopropyl Alcohol) or water.

4. Replace the Housing-Pickup and/or

Shaft-Pickup.

Page 38

Troubleshooting

4-14

Samsung Electronics

4-3-4 JAM 2

• Description

1. Recording paper is jammed in front of or inside the fuser.

2. Recording paper is stuck in the discharge roller and in the fuser just after passing through the

Actuator-Feed.

JAM 2

LSULSU

CARTRIDGECARTRIDGE

MPF

PICK UP

FEED

IDLE

EMPTY SEN

TR

FUSERFUSER

FACE DOWN

FACE UPFACE UP

H/R

Pr/R

CASSETTE

EXIT1EXIT1

EXIT2

OUT BIN FULL SEN

EXIT SEN

EXIT SEN

Check and Cause Solution

1. If the paper is completely fed out of

the printer, but Jam 2 occurs : Exit

sensor is defective.

• After the paper is completely dis-

charged, actuator Exit should return

to the original position to shut the

photo-sensor. Sometimes it takes

longer hour than it should and does

not return.

2. If the paper is rolled in the Fuser Roller:

• This occurs when a Guide claw is

broken away or transformed.

• It occurs when the Spring of a Guide

claw is broken away or transformed.

• It occurs when the Heat-Roller or

Pressure-Roller is seriously contaminated with the toner.

3. Paper is accordion in the fuser.

1. Check if the exit sensor actuator is

defective.

• Check if the actuator exit is unformed

(Check if the lever part is unformed

in shape).

• Check whether burrs occur in the

assembly part of the actuator exit or

not and if the actuator is smoothly

operated.

• Check if foreign matters and wire get

caught in the actuator exit's operation.

2. If the paper is stuck in the fuser : dis-

assemble the fuser and remove the

jammed paper, and clean the surface

of the pressure roller with dry gauze.

3. Remove the jammed paper after disas-

sembling the fuser : Clean the surface

of the pressure roller with dry gauze.

• Remove the toner particles stained

on the rib.

• Check the assemblage and perfor-

mance of the exit.

4-3-3 JAM 1

• Description

1. Recording paper is jammed in front of or inside the fuser.

2. Recording paper is stuck in the discharge roller and in the fuser just after passing through the

Actuator-Feed.

JAM 1

LSULSU

CARTRIDGECARTRIDGE

MPF

PICK UP

FEED

IDLE

EMPTY SEN

TR

FUSERFUSER

FACE DOWN

FACE UPFACE UP

H/R

Pr/R

CASSETTE

EXIT1EXIT1

EXIT2

OUT BIN FULL SEN

EXIT SEN

EXIT SEN

Check and Cause Solution

1. If the recording paper is jammed in

front of or inside the fuser.

(Perform DCU diagnostic code of)

2. If the recording paper is stuck in the

discharge roller and the fuser just

after passing through the ActuatorFeed, Feed Actuator may be defective.

1. Replace the SMPS.

2. Reassemble the Actuator-Feed and

Spring-Actuator if the returning is bad.

Page 39

Troubleshooting

4-15

Samsung Electronics

4-3-5 Multi-Feeding

• Description Multiple sheets of paper are fed at once.

Check and Cause Solution

1. Solenoid malfunction(the solenoid does not work

properly): Perform DCU mode : solenoid check 06.

2. Pad-Friction is contaminated with foreign matter.(oil...)

3. The face of paper is blended.

1. Replace the solenoid if necessary.

2. Clean the pad friction with soft clothe dampened

with IPA(Isopropyl Alcohol).

3. Use the smooth paper.

4-3-6 Paper rolled in the fuser

• Description If contaminated at intervals of 57mm on the back of a paper.

Check and Cause Solution

1. Contamination of the pressure roller.

(Background, Hot off set)

1. Disassemble the fuser, clean the area between the

Heat-roller and Thermistor and remove the foreign

matter of the pressure roller.

2. If background appears badly in the printing, fix it by

referring to the solutions for background.

(See 4-2-8 Background)

Page 40

Troubleshooting

4-16

Samsung Electronics

4-3-7 OPC

• Description Paper is rolled up in the OPC.

Check and Cause Solution

1. Paper is too much thin.

2. The face of paper is curled.

1. Recommend to use normal paper.

2. How to remove the rolled paper in the OPC.

• Remove the paper while turning the OPC against

the ongoing direction.

• Clean fingerprints on the OPC softly with soft

cloth dampened with IPA(Isopropyl Alcohol) or tissue.

Page 41

Troubleshooting

4-17

Samsung Electronics

4-4 The cause and solution of the malfunction

4-4-1 All LEDs blinking (Fuser Error)

• Description

1. All the lamps on the operator panel blink.

2. Gear of the fuser does not work and breaks away melt away.

When printing, motor breaks away from its place due to defective fuser gear.

Check and Cause Solution

1. Check if the thermostat, AC wire and Heat Lamp is

open.

2. Check if the thermistor sensor is in place.

3. Check if the heat lamp works properly.

4. Check if the overheat circuit works properly.

5. The fuser gear is defective due to melting away.

1. If the thermostat is open replace the fuser and

check following items.

2. If the thermistor sensor device is located deep in the

sponge, replace the fuser.

3. Check if the circuit of overheat mode works properly.

4. Run DCU mode : Perform DCU diagnostic code 10.

4-4-2 All LEDs blinking (Scan Error)

• Description

1. All lamps on the operator panel blink.

Check and Cause Solution

DCU Mode : Perform DCU diagnostic code 05. If the DCU

error code 95 is displayed, replace LSU.

Replace LSU.

If you cannot solve the problem after you replace LSU,

replace the main board.

Page 42

Troubleshooting

4-18

Samsung Electronics

4-4-3 Not function of the gear of the fuser due to melting away

• Description

The motor breaks away from its place due to gear melting away.

Check and Cause Solution

DCU Mode : Check if the Error States '60' '62' '68' occur.

Check the operation of Fuser Erasing Lamp On/Off with

the Error Code Check -10-.

1. Replace the Fuser.

2. Replace the Main Control board.

4-4-4 Paper Empty

• Description

The paper lamp on the operator panel is on even when paper is loaded in the cassette.

Check and Cause Solution

1. Bending or deformation of the actuator of the paper sensor.

2. The function of the engine board is defective Perform

DCU mode: Perform DCU diagnostic code 8.

1. Replace the defective actuator.

2. Replace the engine board.

4-4-5 Paper Empty without indication

• Description

The paper lamp on the operator panel does not come on when the paper cassette is empty.

Check and Cause Solution

1. Bending or deformation of the actuator of the paper sensor.

2. The function of the engine board is defective Perform.

DCU mode : Perform DCU diagnostic code 8.

1. Replace the defective actuator.

2. Replace the engine board.

Page 43

Troubleshooting

4-19

Samsung Electronics

4-4-6 Cover Open

• Description

The ERROR lamp is on even when the print cover is closed.

Check and Cause Solution

1. The hook lever in the top cover may be defective.

2. Check the connector (CN1 : Engine B’d↔HVPS) and

circuit of the cover switch department in the Main Control

board. Perform DCU mode : If Error state '64' occurs,

Check the related codes of the Cover Open Error.

1. Replace the hook lever, if defective.

2. Check the insertion of the Cover Open S/W

Connect.

3. Replace the Main Control board or Cover Open

S/W.

4-4-7 No lamp on when the cover is open

• Description

The ERROR lamp does not come on even when the printer cover is open

Check and Cause Solution

1. Check the connector(CN8) and circuit of the cover switch

department in the Main Control board. Perform DCU

mode : If Error state '64' occurs, Check the related codes

of the Cover Open Error

1. Check the insertion of the Cover Open S/W

Connect.

2. Replace the Main Control board or Cover Open

S/W.

Hook Lever

Page 44

Troubleshooting

4-20

Samsung Electronics

4-4-8 Defective motor operation

• Description

Main motor is not driving when printing, and paper does not feed into the printer, resulting 'Jam 0'.

Check and Cause Solution

1. Motor harness or sub PCB may be defective.

2. Perform DCU diagnostic code 00 and Check the motor

operation.

1. Check the motor harness, replace it, if defective.

2. Replace the SMPS, if necessary.

4-4-9 No Power

• Description

When system power is turned on, all lamps on the operator panel do not come on.

Check and Cause Solution

1. Check if the power input and SMPS output are normal.

2. Check the inferiority of LED-Panel on the front-cover if

the LED of Panel does not appear after normal warmingup.

1. Replace the power supply cord or SMPS.

2. Replace the control board.

3. Replace the LED-panel.

Page 45

Troubleshooting

4-21

Samsung Electronics

4-4-10 Vertical Line Getting Curved

• Description

When printing, vertical line gets curved.

Check and Cause Solution

1. If the supply of +24v is unstable in the Main Control board

linking with LSU, check drive by DCU Mode: LSU Check

-05- LSU Motor on.

1. Replace LSU.

2. Replace the Main Control board.

Page 46

Troubleshooting

4-22

Samsung Electronics

4-5 Toner Cartridge Service

It is not guaranteed for the default caused by using other toner cartridge other than the cartridge supplied by the

Samsung Electronic or caused by non-licensed refill production.

4-5-1 Precautions on Safe-keeping of Toner Cartridge

Excessive exposure to direct light more than a few minutes may cause damage to the cartridge.

4-5-2 Service for the Life of Toner Cartridge

If the printed image is light due to the life of the toner, you can temporarily improve the print quality by redistributing the

toner(Shake the toner cartridge), however, you should replace the toner cartridge to solve the problem thoroughly.

4-5-3 Judgment of a genuine Toner Cartridge

Genuine Label :

The prevention of

disassembly

Capacity indication Label

One-way Screw

One-way Screw

Page 47

Troubleshooting

4-23

Samsung Electronics

4-5-4 Signs and Measures at Poor toner cartridge

Fault Signs Cause & Check Solution

Light image and

partially blank

image

(The life is ended.)

T oner

Contamination

• The printed image

is light or unclean

and untidy.

• Some part of the

image is not printed.

• Periodically a noise

as "tick tick" occurs.

• Toner is fallen on

the papers periodically .

• Contaminated with

toner on prints partly or over the whole

surface.

1. If the image is light or unclean

and untidy printed image Shake the developer and

then recheck.

(1)NG: Check the weight of the

developer

(2)OK: Lack of toner, so the life

is nearly closed.

2. Some part of image is not

printed - Shake the developer and then recheck.

(1)NG: Check the weight of the

developer and clean

the LSU window with a

cotton swab, then

recheck.

(2)OK: Lack of toner, so the life

is nearly closed.

3. Periodically a noise as "tick

tick" occurs - Measure the

cycle and the weight of the

developer.

4. White vertical stripes on the

whole screen or partly :

Check the weight of the

developer.

1. Toner is fallen on the paper

periodically .

(1)Check the cycle of the

falling of the toner.

(2)Check the appearance of

both ends of the developer

OPC drum.

2.The center of the printed mat-

ter is contaminated with toner.

(1)Check whether foreign sub-

stances or toner are stuck

to the terminal (contact

point) of the developer.

(2)Check whether the state of

the terminal assembly is

normal.

1. All of 1, 2, 3 aboveIf it become better by shaking,

replace with a new developer

after 50-100 sheets in the closing state of the life span.

2. In case of 2-

If it becomes better after cleaning the LSU window, then the

developer is normal.

(Because of foreign substance

on the LSU window, the image

has not been printed partly.)

3. In case of 3-

If the cycle of noise is about 2

seconds, the toner inside the

developer has been nearly

exhausted.( Purchase and

replace with a new developer

after using about 200 sheets at

the point of occurrence)

4. In case of 3This is a phenomenon caused

by lack of toner, so replace with

a new developer.

1. If both ends of the OPC drum

are contaminated with toner:

Check the life of the developer.

2. Check whether it could be recycled.

3. If it cannot be recycled:

Replace the developer.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 48

Troubleshooting

4-24

Samsung Electronics

Fault Signs Cause & Check Solution

White Black spot

Recycled product

• Light or dark black

dots on the image

occur periodically.

• White spots occur

in the image periodically .

• Poor appearance of

the developer.

• Unclean and rough

printouts.

• Bad background in

the image.

1. If light or dark periodical black

dots occur, this is because the

developer rollers are contaminated with foreign substance

or paper particles.

(1)38.5mm interval : Charged

roller

(2)96mm interval : OPC cycle

2. If white spots occur in a black

image at intervals of 96mm, or

black spots occur elsewhere,

the OPC drum is damaged or

foreign substance is stuck to

the surface.

3. If a black and white or graphic

image is partially broken at

irregular intervals, the transfer

roller's life has been expired or

the transfer voltage is abnormal.

1. Poor appearance of the developer.

(1)Check the damage to label

and whether different materials are used.

(2)Check the appearance of

parts of the developer, such

as frame, hopper.

2. Unclean and rough printouts.

(1)Check whether foreign sub-

stance or toner are stuck to

the terminal (contact point) of

the developer.

(2)Check whether the state of

the terminal assembly is normal.

1. In case of 1 above Run OPC Cleaning Mode Print

4-5 times repeatedly to remove.

Especially check foreign substance on the OPC surface, then

remove them with a clean gauze

moistened with IPA(Isopropyl

Alcohol) not to damage OPC if

necessary .

Never use usual alcohol.

2. In case of 2

If they are not disappeared by

running OPC Cleaning Mode

Print 4-5 times.

:

at intervals of 38.5mm

- Replace

the developer.

: at intervals of 96mm - Remove

foreign substance.

: Broken image - Replace the

developer according to carelessness.

3. In case of 3 - Exchange the

transfer roller because the life of

the transfer roller in use has been

expired. (Check the transfer voltage and readjust if different.)

1. In case of 1 -

(1)If there is an evidence of disas-

sembling the developer.

(2)If materials other than normal

parts of the developer are

added or substituted.

2. In case of 2 - If there are any

abnormals in connection with the

situation of 1.

(1)It occurs when the developer

is recycled over 2 times.

(2)If toner nearly being expired

are collected to use, it is

judged as the recycled developer.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 49

Troubleshooting

4-25

Samsung Electronics

Fault Signs Cause & Check Solution

Ghost & Image

Contamination

• The printed image

is too light or dark,

or partially contaminated black.

• Totally contaminatedblack.

(Black image printed out)

• The density of printouts is too dark and

ghost occurs.

1. The printed image is too light

or dark, or partially contaminated black.

(1)Check whether foreign sub-

stance or toner are stuck to

the terminal(point of contact)

of the developer.

(2)Check whether the terminal

assembly is normal.

2. Totally contaminated black.

(Black image printed out)

(1)Check whether foreign sub-

stances are stuck to the terminal(point of contact) of the

developer and the state of

assembly .

(Especially check the

charged roller terminal.)

3. The printed image is dark and

ghost occurs.

(1)Check foreign substance

attached to the terminal

(point of contact) of the

developer and the state of

assembly .

(Especially check the developing roller terminal.)

1. All of 1, 2, 3 above

(1)Remove toner and foreign sub-

stances adhered to the contact

point of the developer.

(2)The contact point of the unit

facing that of the developer

also must be cleaned.

(3)If the terminal assembly is

unsafe:

• Fully stick the terminal to or

reassemble it after disassembling.

• Disassemble the side plate and

push the terminal to be stuck,

then reassemble it.

2. In case of 2

It is a phenomenon when the

OPC drum of the developer is not

electrically charged. Clean the

terminals of the charged roller,

then recheck it.

3. In case of 3

It is a phenomenon as the developing bias voltage of the developer. Clean the terminals of the

developing roller, then recheck it.

Page 50

Troubleshooting

4-26

Samsung Electronics

4-6 The cause and solutions of bad environment of the software

4-6-1 The printer is not working (1)

• Description

While Power turned on, the printer is not working in the printing mode.

Check and Cause Solution

1. Run Self-Test Mode: Turn the power on while pressing

the test printing button for 2 or 3 seconds before printing

works.

2. Check if the PC and the printer is properly connected

and the toner cartridge installed.

3. Printing is nor working in the Windows.

4. Check if the printer cable is directly connected to peripheral devices

1.Check the power of the printer and perform the SelfTest. If the test printing works, that means no problems in the printer itself. If the test printing does not

work, that means bad functioning of the printer(not

because of software). Perform DCU to check the

Error Status.

2. Replace the printer cable. If the problems not solved

even after the cable replaced, check the amount of

the remaining tone.

(refer to Toner Cartridge Service 4-5)

3. Check if the connection between PC and printer port

is proper. If you use windows, check if the printer dri ver in the controller is set up. If the printer driver is

properly set up, check in which program the printing

is not working. The best way to find out is to open the

memo pad to check the function of printing. If it is not

working in a certain program, adjust the setup the

program requires. Sometimes, the printout is normal

within the Windows basic programs, but it's not working in a particular program. In such case, install the

new driver again. If not working in the Windows basic

program, Check the setup of the port of CMOS is on

ECP. And check the address of IRQ 7 and 378

4. If the scanner needs to be connected to the printer,

first the remove the scanner from the PC to see if the

printer is properly working alone.

Page 51

Troubleshooting

4-27

Samsung Electronics

4-6-2 The printer is not working (2)

• Description

After receiving the printing order, no response at all or the low speed of printing

occurs due to wrong setup of the environment rather than malfunction of the printer itself.

Check and Cause Solution

1. Secure more space of the hard disk.

2. Printing error occurs even if there is enough space in

the hard disk.

3. Check the parallel-port-related items in the CMOS

Setup.

4. Reboot the system to print.

1. Not working with the message 'insufficient printer

memory' means hard disk space problem rather than

the RAM problem. In this case, provide more space

for the hard disk. Secure more space using the disk

utilities program.

2. The connection of the cable and printer port is not

proper. Check if the connection is properly done and

if the parallel port in CMOS is rightly set up.

3. As a printer port, Select ECP or SPP among

SPP(Normal), ECP, and EPP modes(increase printing speed) SPP normal mode support 8-bit data

transfer, while ECPMode transfer the 12-bit data.

4. If the regular font is not printing, the cable or the

printer driver may be defective.

Turn the PC and printer off, and reboot the system

to print again. If not solved, double-click the printer in

my computer If the regular fonts are not printed this

time again. the cable must be defective so replace

the cable with new one.

Page 52

Troubleshooting

4-28

Samsung Electronics

4-6-3 Abnormal Printing

• Description

The printing is not working properly even when the cable has no problem.

(even after the cable is replaced)

If the printer won't work at all or the strange fonts are repeated, the printer driver may be defective or wrong setup in the CMOS Setup.

Check and Cause Solution

1. Set up the parallel port in the CMOS SETUP.

2. Printer Driver Error.

3. Error message from insufficient memory.

(The printing job sometimes stops or due to insufficient

virtual memory, but it actually comes from the insufficient space of the hard disk.)

1. Select SPP(Normal) or ECP LPT Port the among

ECP, EPP or SPP in the CMOS Setup.

2. Check the printer in My Computer.(to see if the

printer driver is compatible to the present driver or

delete

the old driver, if defective and reinstall the new

driver)

3. Delete the unnecessary files to secure enough

space of the hard disk and start printing job again.

Page 53

Troubleshooting

4-29

Samsung Electronics

4-6-4 SPOOL Error

• Description

To spool which stands for "simultaneous peripheral operations online" a computer document or

task list (or "job") is to read it in and store it, usually on a hard disk or larger storage medium so

that it can be printed or otherwise processed at a more convenient time (for example, when a

printer is finished printing its current document).

Check and Cause Solution

1. Insufficient space of the hard disk in the directory

assigned for the basic spool.

2. If the previous printing error not solved.

3. When expected to collide with other program.

4. When an application program or the printer driver is

damaged.

5. When some files related to OS are damaged or virus

infected.

6. Memory is less than suggested one.

1. Delete the unnecessary files to provide more space

to start printing job.

2. If there are some files with the extension name of

****.jnl, Delete them and Reboot the Windows to

restart printing job.

3. Shut down all other programs except the current

one, if possible.

4. Delete the printer driver completely and reinstall it.

5 After rebooting the computer, check for viruses,

restore the damaged files and reinstall the program

to do the printing job.

6. Add up enough memory to the PC.

How to delete the data in the spool manager.

In the spool manager, the installed drivers and the list of the documents waiting to be printed are shown.

Select the document to be deleted and check the delete menu.

If you intend to delete the current document being printed, the data being transferred to the printer will be put

out and then the document is removed. Before choosing the document, the menu is still inactive.

Or put the document out of the list and repeat the routine as in the above or finish the spool manager.

Page 54

Exploded Views and Parts List

5-1

Samsung Electronics

5. Exploded Views and Parts List

• Deal drawings and service parts are declared for the items with higher rate

of inferiority and replaceable in the level of service description only.

• If inferiority occurs, you can replace the parts by the unit declared in deal

drawings and service items.

DIVISION PART CODE DESCRIPTION

A/S Private **81-****** AS-*****

(JB81-00039A) (AS-USE)

ASS’Y Part **75-****** MEC-*****

(JB75-00068A) (MEC-CHUTE)

ASS’Y Part **92-****** PBA ******

(JB92-01131A) (PBA MAIN-CONTROLLER)

ASS’Y Part **97-****** MEA ******

(JB97-01089A) (MEA UNIT-PULLEY IDLE)

Part code and Description is quoted and controlled by determined standard. Refer to this determined

standard, it will help with ordering Part.

• There ar woo kinds of Part code inscription type.

Type 1 : Controlled by Company : It can be commonly used for all kinds of product SEC produce.

Mostly, electronics Parts.

Type 2 : Controlled by Division : It is used or one produce. Mostly, Mostly, mechanical Parts.

• A/S privately used part : It is only used for A/S .

• Ass’y part :

Assembled by more than 2 Parts. If necessary part is not A/S Part, Ass’y part including

necessary par can be used. It is shown in the diagram and drawing of SVC manual.

• Ass’y part and A/S privately used Part is distinguished by part Code and Description.

The are inscription type 2. It is recognized by Part character and front side of description.

Way to observe Part Code & Description

ex ) 2007-007961

ex ) JB96-01268A

R-CHIP

ELA UNIT-COVER TOP

Page 55

Exploded Views and Parts List

5-2

Samsung Electronics

O : Service available X : Service not available

5-1 Exploded Views and Parts List

NO. DESCRIPTION SEC CODE Q’TY SA REMARK

• Service Parts List

1 ELA HOU-HOUSING HAWK16 refer to the 1 O

table

1-1 PMO-COVER OPEN JC72-00628A 1 O

1-2 PMO-COVER MAIN refer to the 1 O

table

1-3 PMO-STOPPER HINGE OPEN JC72-00482A 2 O

1-4 PMO-LENS LED JC72-00365A 1 O

1-5 PMO-KEY BUTTON JC72-00499A 1 O

1-6 PBASUB-PANEL_SEC JC92-01208D 1 O

1-7 PMO-COVER REAR JC72-00355A 1 O

1-8 PMO-STACKER REAR JC72-00356A 1 O

1-9 PMO-COVER CONTROLLER JC72-00358A 1 O

1-10 MEA UNIT-MPTRAY JC97-01325A 1 O

1-10-1 PMO-COVER-MP JC72-00349A 1 O

1-10-2 PMO-TRAY LINK MP JC72-00350A 2 O

1-1 1

MEA UNIT-BRKT BOTTOM(L)

JC97-01315C 1 O

1-1 1-1 FOOT-RUBBER JC61-40001A 1 O

1-12

MEA UNIT-BRKT BOTTOM(R)

JC97-01316A 1 O

1-12-1

FOOT-RUBBER JC61-40001A 1 O

2 UNIT-LSU(M) JC59-00013A 1 O

3 ELA UNIT-MOTOR 16 JC96-02057A 1 O

3-1 MOTOR-STEP 7.5_DEG JC31-00002A 1 O

3-2 MOTOR-STEP JC31-00009A 1 O

4 ELA UNIT-DEVE * 1 X

5 ELA HOU-MPF JC96-01650A 1 O

5-1 PHOTO-INTERRUPTER 0604-001095 1 O

5-2 SOLENOID-HAWK JC33-00003A 1 O

5-3 RPR-RUBBER P/UP MP JC73-10907A 1 O