Samsung ltm295 service manual

LCD-TV

Chassis Model

AL29NO LTM295W

AL40NO LTM405W

Manual

SERVICE

LCD-TV CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Alignment & Adjustments

5. Troubleshooting

6. Exploded View & Parts List

7. Electrical Parts List

8. Block Diagram

9. Wiring Diagram

10. Schematic Diagrams

11. Panel Description

CONFIDENTIAL

1-1-1 Warnings

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power and DC Power Jack

before servicing.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor disconnect the

AC line cord from the AC outlet.

2. It is essential that service technicians have an

accurate voltage meter available at all times. Check

the calibration of this meter periodically.

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

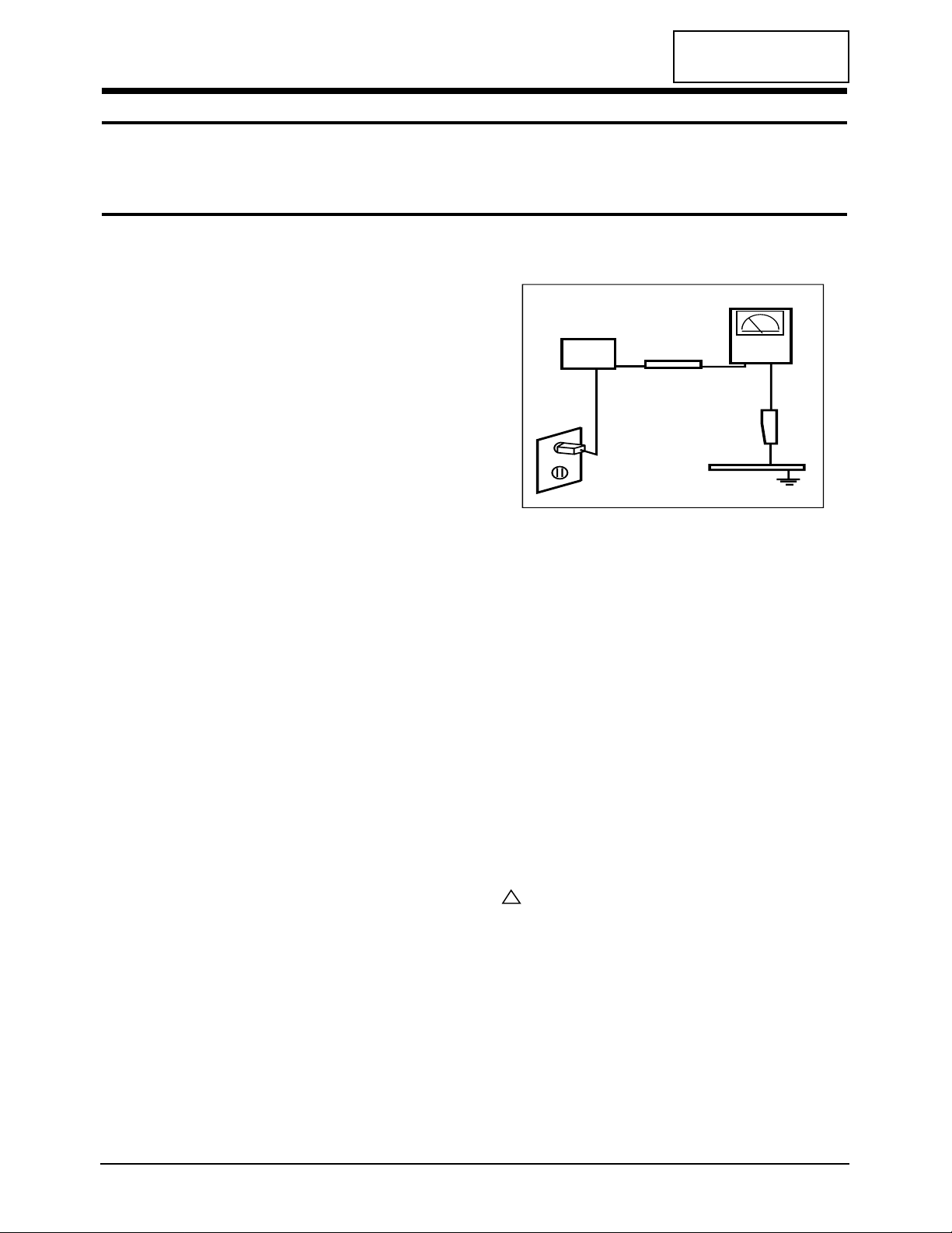

3. Leakage Current Hot Check (Figure 1-1):

WARNING:

Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

Figure 1-1. Leakage Current Test Circuit

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

LTM295W/LTM405W 1-1

CONFIDENTIAL

1 Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

!

1-2-1 General Servicing Precautions

1. Always unplug the unit’s AC power cord from the

AC power source and disconnect the DC Power

Jack before attempting to:

(a) remove or reinstall any component or assembly,

(b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic

capacitor.

2. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

3. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

4. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

5. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

6. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

1 Precautions

1-2 LTM295W/LTM405W

CONFIDENTIAL

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some field-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1-2 Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

CONFIDENTIAL

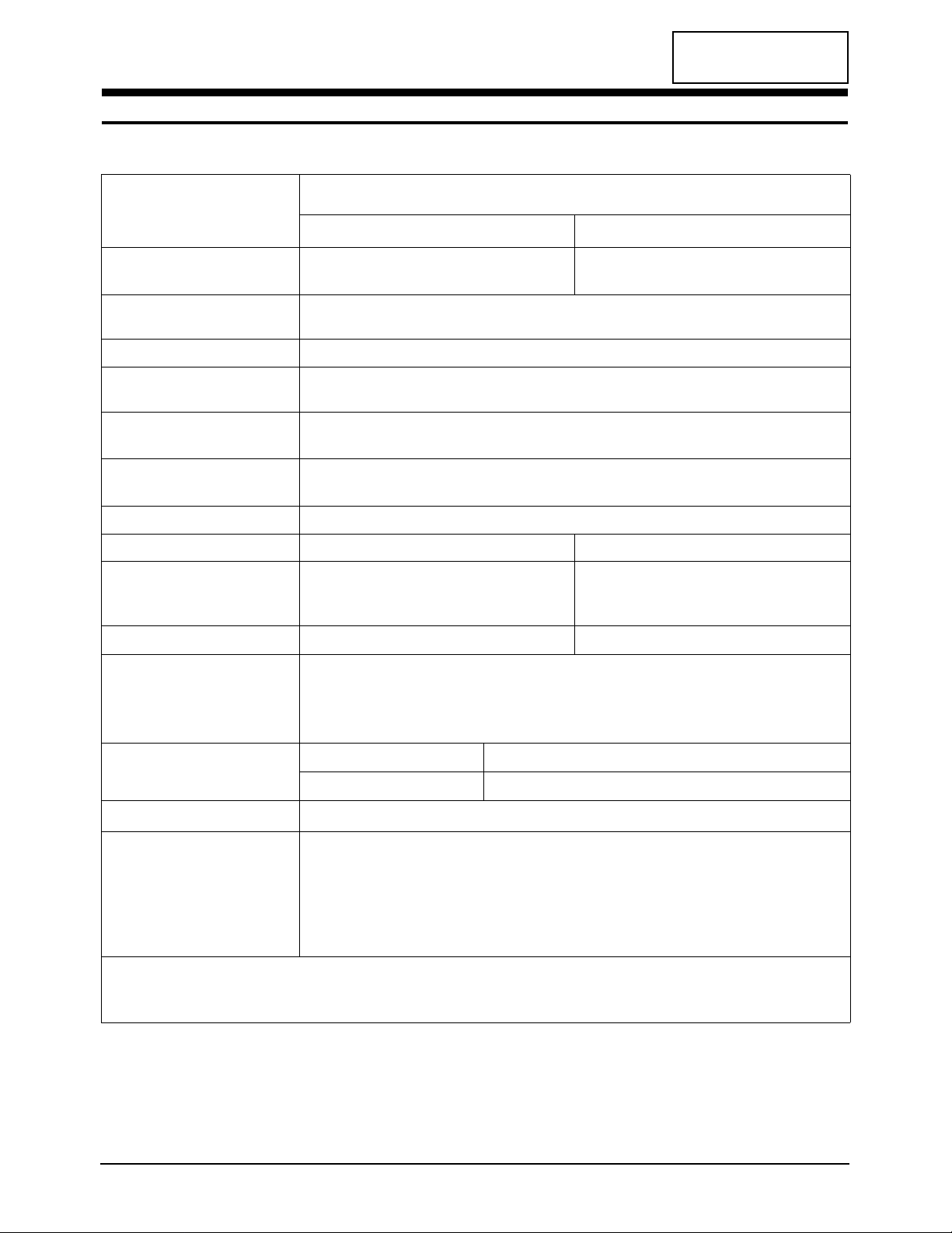

2 Product Specifications

2-1 Specifications

LCD Panel

TFT-LCD panel, RGB vertical stripe, normally black TFT-LCD panel, RGB vertical stripe, normally black

transmissive, (29 -Inch) viewable, 0.4935 mm pixel pitch

transmissive, (40-Inch) viewable, 0.6735 mm pixel pitch

Scanning Frequency Horizontal : 30 KHz ~ 60 KHz

Vertical : 56 Hz ~ 75 Hz

Display Colors 16,777,216 Million colors

Maximum Resolution Horizontal : 1280 Pixels

Vertical : 768 Pixels

Input Video Signal Analog, 0.7 Vp-p ± 5% positive at 75 Ω,

internally terminated

Input Sync Signal Type : Seperate H/V sync, Composite H/V, Sync-on-Green

Level : TTL level

AC power voltage & Frequency AC 90 ~ 240V 60 Hz/50 Hz ± 3 Hz, DC 28V / 8A

Power Consumption 160W (max) 220W (max)

Dimensions

Unit (W x D x H)

29.9 x 7.7 x 22.4 Inches (759.6 x 195.0 x 568.5 mm)

39.6 x 11.8 x 29.4 Inches (1006.0 x 300.0 x 746.5 mm)

Carton (W x D x H)

37.8 x 7.7 x 22.4 Inches (961.2 x 195.0 x 568.5 mm)

49.1 x 11.8 x 29.4 Inches (1247.6 x 300.0 x 746.5 mm)

Weight (Net / Gross)

Environmental Considerations Operating Temperature : 50°F ~ 104°F (10°C ~ 40°C)

Humidity : 10 % ~ 80 %

Storage Temperature : -4°F ~ 113°F (-20°C ~ 45°C)

Humidity : 5 % ~ 95 %

TV System

Sound Characteristics •Max Internal speaker Out : Right c 10 W / Leftc 10 W

•Bass control Range : -6 ± -12dB ~ +6 ± 12dB

•TREBLE control Range : -10 ± -12dB ~ +10 ± 12dB

•Output frequency : RFc 80 Hz~15 KHz /A/Vc 80 Hz~20 KHz

•Line out : RFc 80 Hz~15 KHz /A/Vc 80 Hz~20 KHz

•SyncMaster LTM295W/LTM405W comply with SWEDAC (MPRII) recommendations for reduced electromagnetic fields.

•Designs and specifications are subject to change without prior notice.

LTM295W/LTM405W 2-1

Item

Description

LTM295W

LTM405W

18.0 kg (39.682 lbs) 28.0 kg ( 61.715 lbs)

Antena Input 75Ω, Coaxial Cable

Color NTSC-M

Sound BTSC, A2 STEREO, EIAJ

CONFIDENTIAL

2-2 Pin Assignments

Pin No.

30 Pin Signal Cable (DVI Analog)

Pin No.

30 Pin Signal Cable (DVI Analog)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

RX2+

RX2GND

RX1+

RX1GND

RX0+

RX0GND

RXC+

RXCGND

DDC (Clock)

DDC (Data)

GND

GND

Check • D-Sub

GND

DDC_5V

DDC_5V

GND

V/Sync

GND

H/Sync

GND

Blue

GND

Green

GND

Red

CONFIDENTIAL

2 Product Specifications

LTM295W/LTM405W 2-3

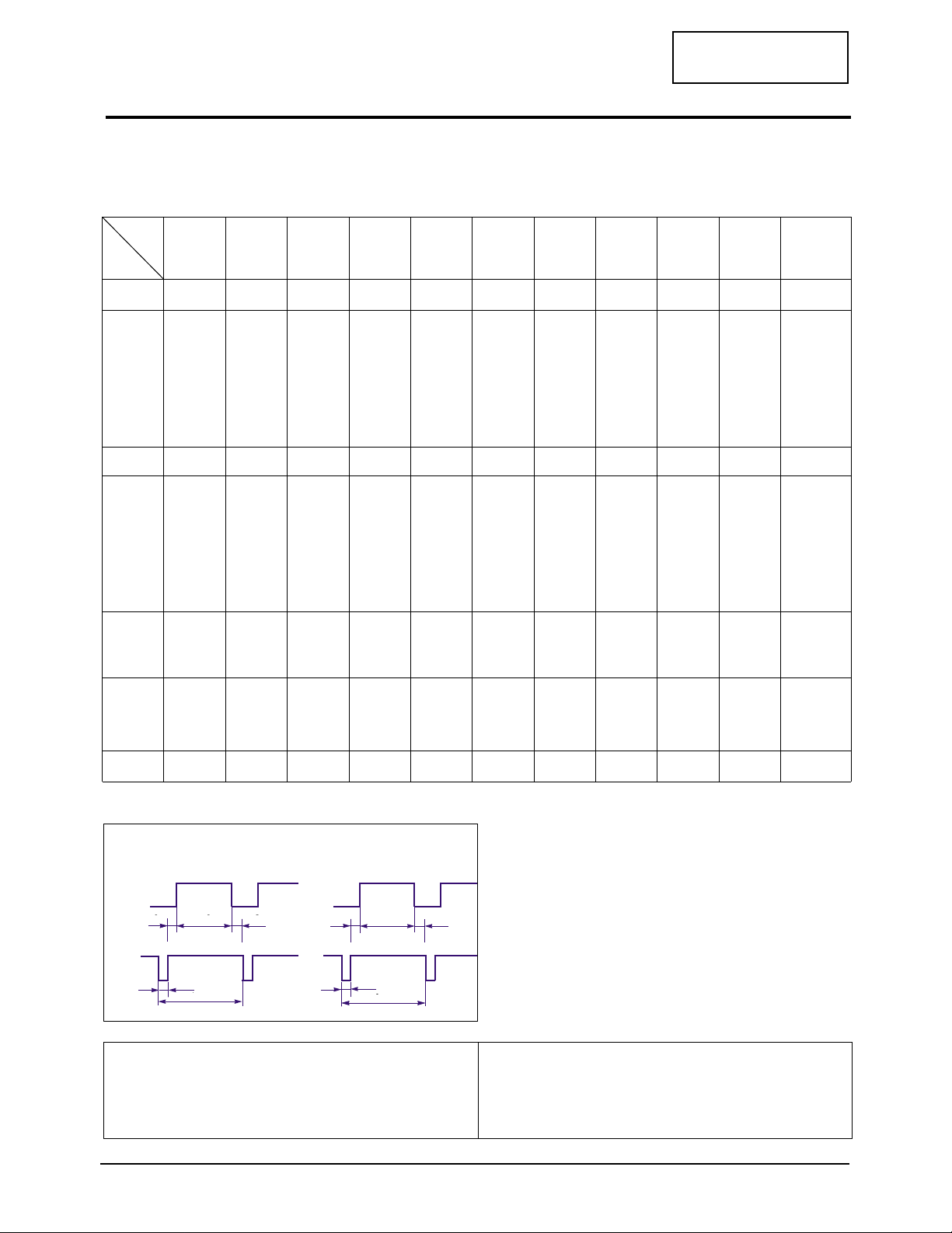

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

48.1

1040

120

64

800

56

72.2

666

6

23

600

37

50.000

Positive

Positive

Separate

37.9

1056

128

88

800

40

60.3

628

4

23

600

1

40.000

Positive

Positive

Separate

35.2

1024

72

128

800

24

56.3

625

2

22

600

1

36.000

–/+

–/+

Separate

SVGA/56 Hz

800 x 600

SVGA/60 Hz

800 x 600

SVGA/72 Hz

800 x 600

MAC/66 Hz

640 x 480

35.0

864

64

96

640

64

66.7

525

3

39

480

3

30.240

Negative

Negative

Separate

44.955

1650

40

70

1280

260

59.94

750

5

20

720

5

74.176

–/+

–/+

Separate

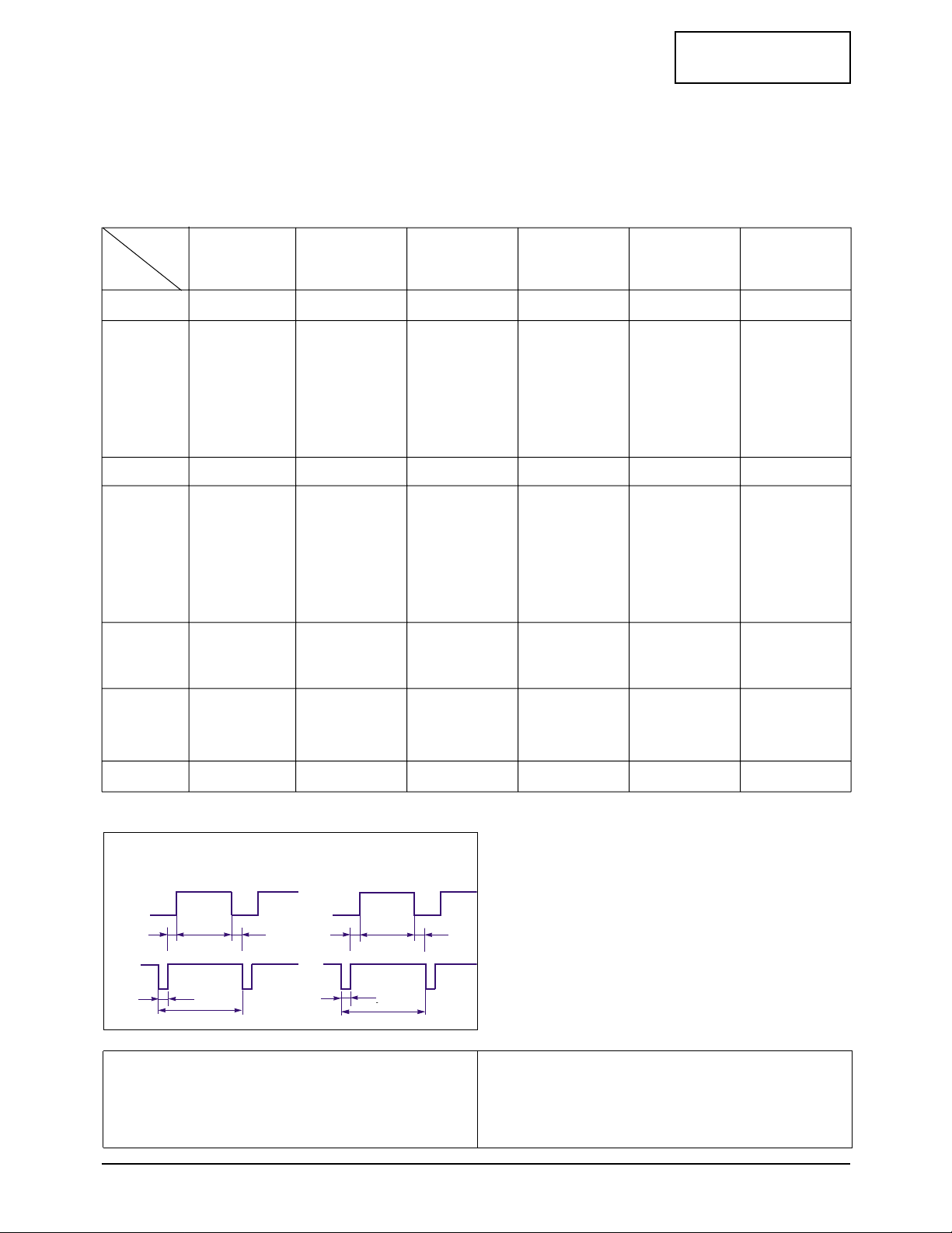

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Freq.

(MHz)

Polarity

H.Sync

V.Sync

Remark

VGA3/60 Hz

640 x 480

VGA/72 Hz

640 x 480

VGA/75 Hz

640 x 480

VGA/85 Hz

640 x 480

MAC/60 Hz

640 x 480

DTV/

59.94 Hz

1280 x 720

DTV/

59.94 Hz

1920 x 1080

Table 2-1 Timing Chart

33.716

2200

44

44

1920

192

59.94

1125

15

2

1080

5

74.176

–/+

–/+

Separate

31.5

800

96

40

640

8

60.0

525

2

25

480

2

25.175

Negative

Negative

Separate

37.9

832

40

120

640

16

72.8

520

3

20

480

1

31.500

Negative

Negative

Separate

37.5

840

64

120

640

16

75.0

500

3

16

480

1

31.500

Negative

Negative

Separate

43.3

832

56

80

640

56

85.0

509

3

25

480

1

36.000

Negative

Negative

Separate

31.5

800

96

48

640

16

60.0

525

2

33

480

10

25.175

Negative

Negative

Separate

Mode

Timing

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

CONFIDENTIAL

2 Product Specifications

2-4 LTM295W/LTM405W

68.7

1456

128

144

1152

32

75.1

915

3

39

870

3

100.000

Negative

Negative

Separate

67.5

1600

128

256

1152

64

75.0

900

3

32

864

1

108.000

Positive

Positive

Separate

60.2

1328

96

176

1024

32

74.9

804

3

30

768

3

80.000

Negative

Negative

Separate

MAC/74 Hz

1024 x 768

VESA/75 Hz

1152 x 864

MAC/75 Hz

1152 x 870

MAC/60 Hz

1024 x 768

48.8

1312

96

128

1024

64

60.0

813

6

33

768

6

64.000

Negative

Negative

Separate

46.9

1056

80

160

800

16

75.0

625

3

21

600

1

49.500

Positive

Positive

Separate

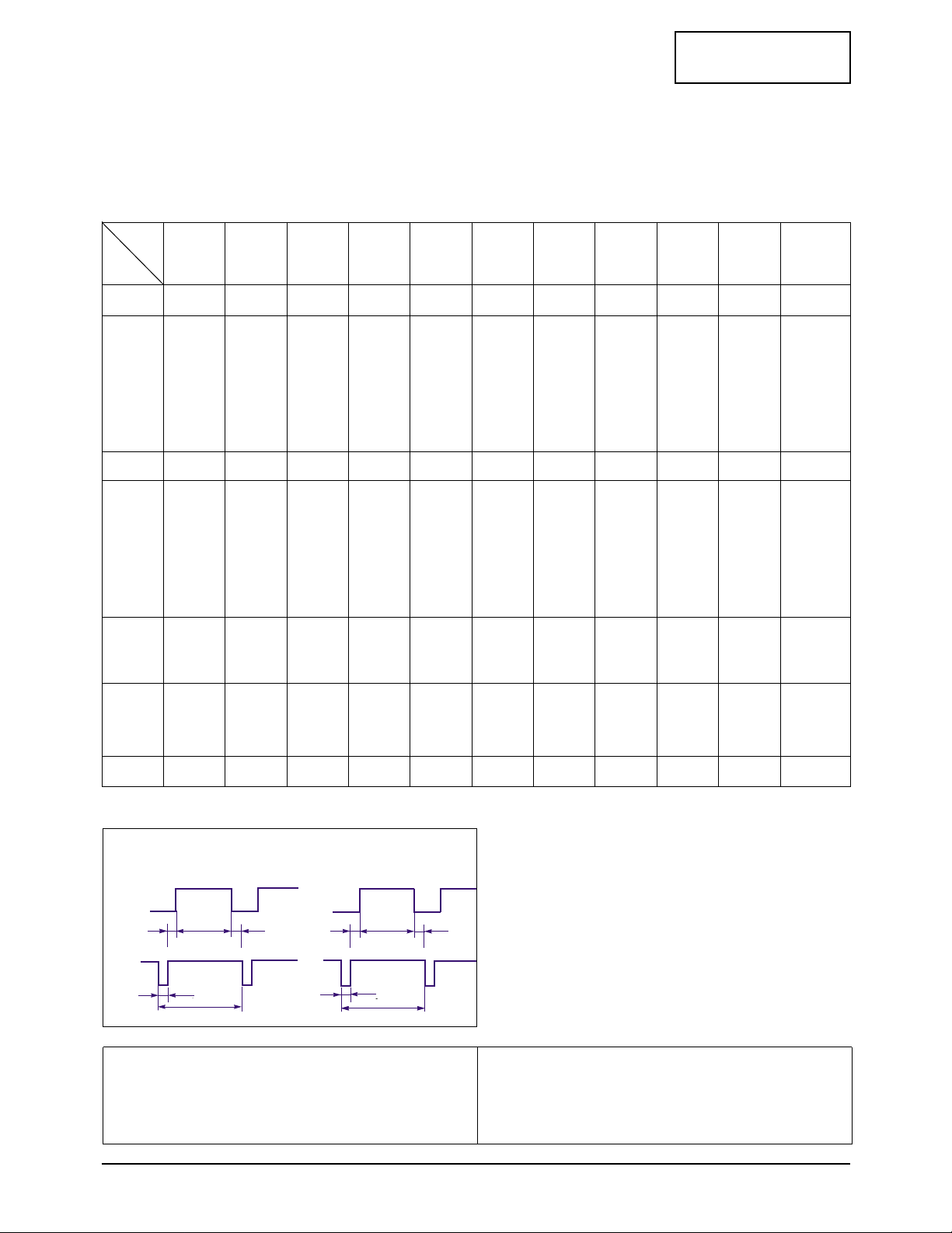

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Freq.

(MHz)

Polarity

H.Sync

V.Sync

Remark

MAC/74 Hz

832 x 624

XGA/60 Hz

1024 x 768

XGA/70 Hz

1024 x 768

XGA/75 Hz

1024 x 768

XGA/85 Hz

1024 x 768

SVGA/75 Hz

800 x 600

SVGA/85 Hz

800 x 600

Table 2-2 Timing Chart (continued)

53.7

1048

64

152

800

32

85.1

631

3

27

600

1

56.250

Positive

Positive

Separate

49.7

1152

64

224

832

32

74.6

667

3

39

624

1

57.284

Negative

Negative

Separate

48.4

1344

136

160

1024

24

60.0

806

6

29

768

3

65.000

Negative

Negative

Separate

56.5

1328

136

144

1024

24

70.1

806

6

29

768

3

75.000

Negative

Negative

Separate

60.0

1312

96

176

1024

16

75.0

800

3

28

768

1

78.750

Positive

Positive

Separate

68.7

1376

96

208

1024

48

85.0

808

3

36

768

1

94.500

Positive

Positive

Separate

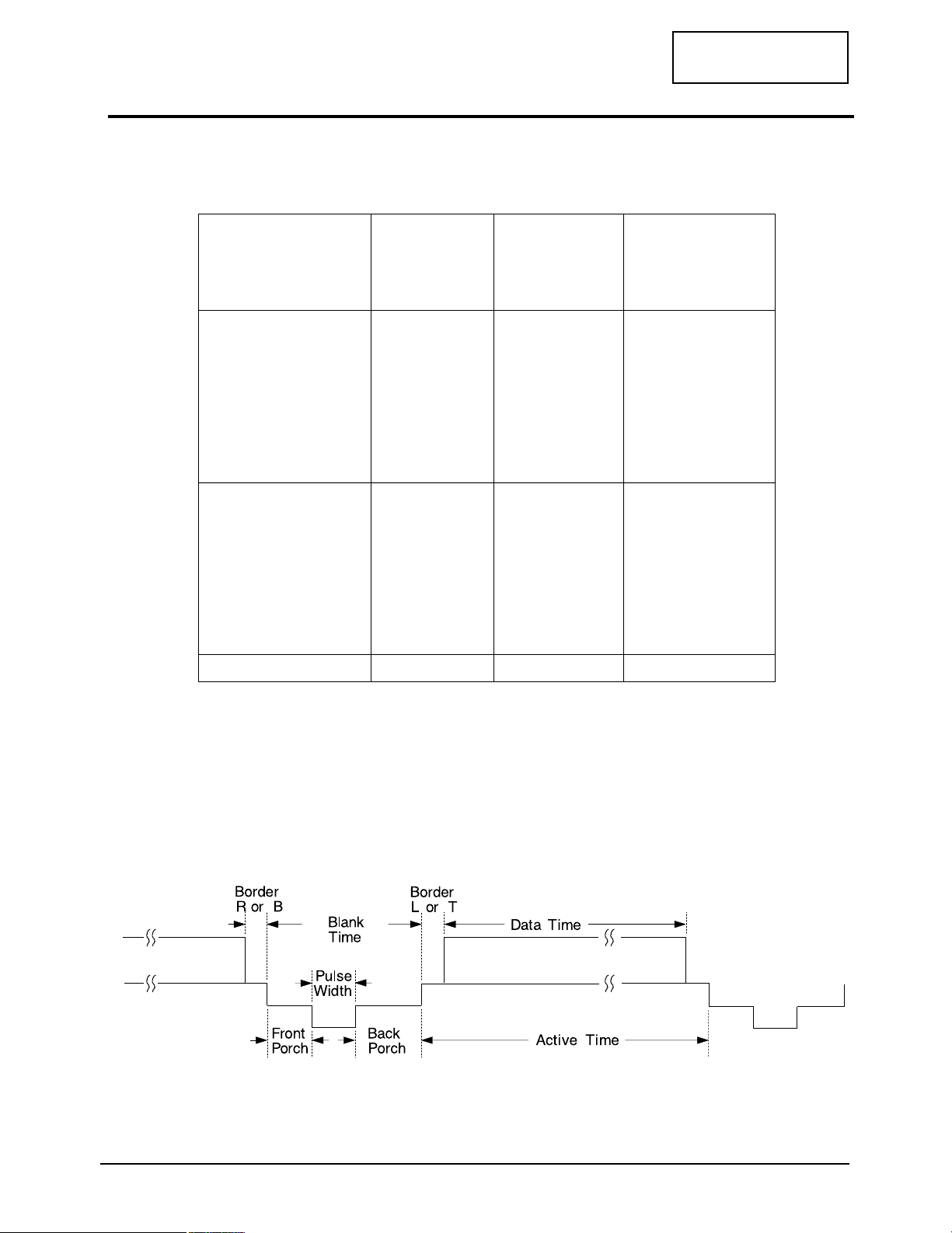

Mode

Timing

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

CONFIDENTIAL

2 Product Specifications

LTM295W/LTM405W 2-5

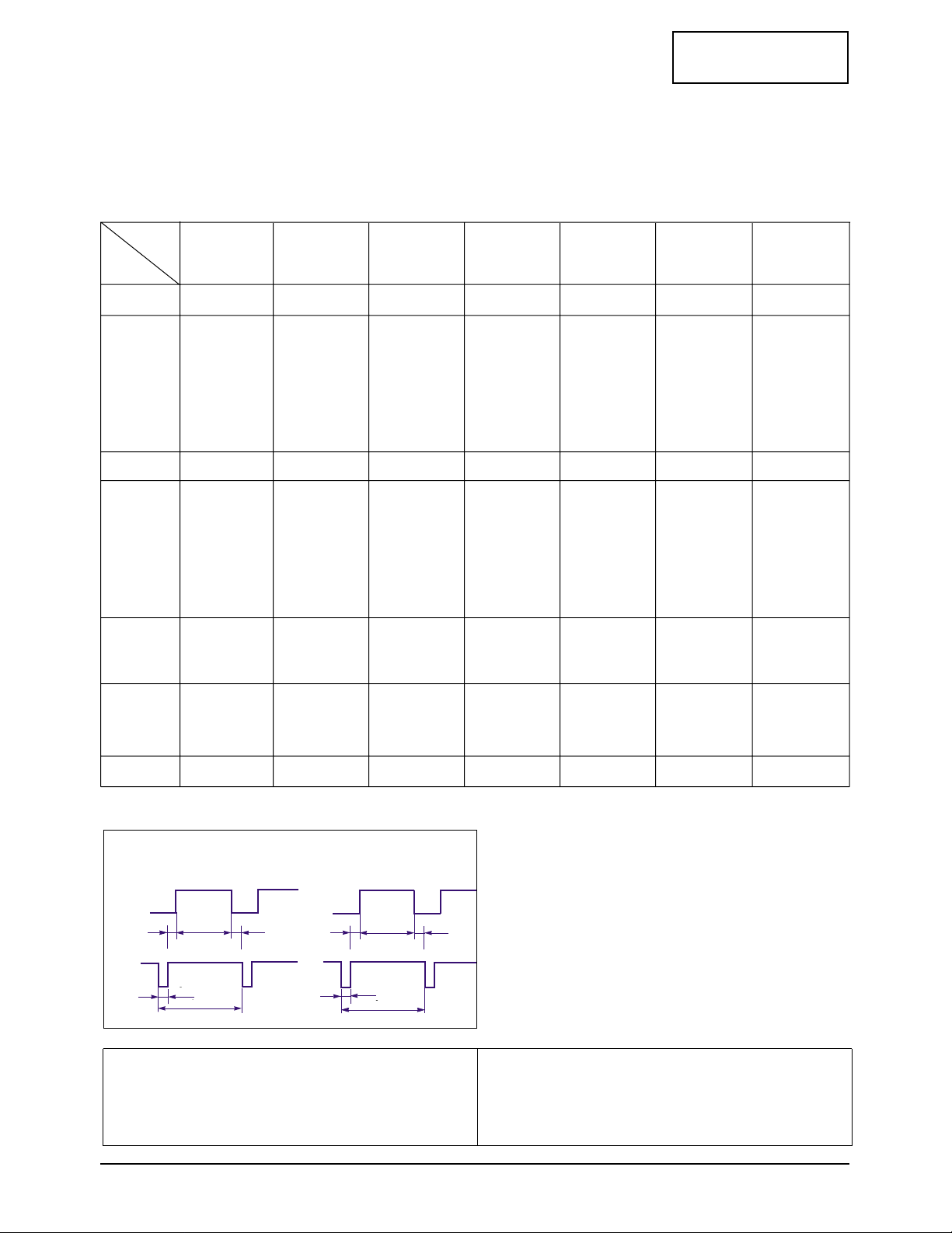

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Polarity

H.Sync

V.Sync

Remark

SUN/76 Hz

1280 x 1024

SXGA/60 Hz

1280 x 1024

SUN/76 Hz

1152 x 900

71.7

1472

96

208

1152

16

76.0

943

8

33

900

2

105.561

Negative

Negative

Separate

SUN/66 Hz

1152 x 900

61.8

1528

128

208

1152

40

66.0

937

4

31

900

2

94.500

–/+

–/+

Separate

64.0

1688

112

248

1280

48

60.0

1066

3

38

1024

1

108.000

Positive

Positive

Separate

74.4

1680

160

208

1280

32

70.0

1063

3

36

1024

0

125.000

Negative

Negative

Separate

80.0

1688

144

248

1280

16

75.0

1066

3

38

1024

1

135.000

Positive

Positive

Separate

81.1

1664

64

288

1280

32

76.1

1066

8

32

1024

2

135.000

Negative

Negative

Separate

SXGA/75 Hz

1280 x 1024

78.1

1728

192

192

1280

64

72.0

1085

3

55

1024

3

135.000

Negative

Negative

Separate

HP/72 Hz

1280 x 1024

NCD/70 Hz

1280 x 1024

Table 2-3 Timing Chart (continued)

Mode

Timing

CONFIDENTIAL

2 Product Specifications

2-6 LTM295W/LTM405W

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

Table 2-4 Timing Chart (continued)

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Polarity

H.Sync

V.Sync

Remark

UXGA/70Hz

1600 x 1200

UXGA/65Hz

1600 x 1200

81.25

2160

192

304

1600

64

65

1250

3

46

1200

1

175.500

–/+

–/+

Separate

UXGA/60Hz

1600 x 1200

75

2160

192

304

1600

64

60

1250

3

46

1200

1

162.000

–/+

–/+

Separate

87.5

2160

192

304

1600

64

70

1250

3

46

1200

1

189.000

–/+

–/+

Separate

80.038

2124

160

308

1600

56

64.443

1242

3

38

1200

1

170.000

–/+

–/+

Separate

74.52

2592

208

336

1920

128

60

1242

3

38

1200

1

193.156

Negative

Positive

Separate

WUXGA2/60 Hz

1920 x 1200

89.286

2240

256

368

1600

16

66.931

1334

10

44

1200

80

200.000

–/+

–/+

Separate

SUN/66 Hz

1600 x 1200

NCD/64Hz

1600 x 1200

Mode

Timing

CONFIDENTIAL

2 Product Specifications

LTM295W/LTM405W 2-7

Table 2-5 DTV Timing chart

Timing No.

Originator

Mode Name

Resolution (HxV)

1

274M

1080i/60iHz

1920x1080

2

296M

720p/60Hz

1280x720

3

293M

480p/60Hz

720x483

HORIZONTAL

Frequency

Total time

Border (L / R)

Data time

Front porch

Sync. width

Back porch

Sync. polarity

33.750kHz

29.630

µs

0.000

µs

25.859

µs

0.593

µs

0.593

µs

2.586

µs

-

-

45.000kHz

22.222

µs

0.000

µs

17.239

µs

0.943

µs

0.539

µs

3.502

µs

-

31.469kHz

31.778

µs

0.000

µs

26.667

µs

0.593

µs

2.333

µs

2.185

µs

-

VERTICAL

Frequency

Total time

Border (T / B)

Data time

Front porch

Sync. width

Back porch

Sync. polarity

30Hz

33.333ms

0.000ms

0.059ms

0.148ms

0.444ms

-

60Hz

16.667ms

0.000ms

16.000ms

0.111ms

0.111ms

0.444ms

-

60Hz

16.683ms

0.000ms

15.349ms

0.191ms

0.191ms

0.953ms

-

Dot Clock 75MHz 75MHz 27MHz

2-4 DTV Timing Chart

Memo

2 Product Specifications

2-8 LTM295W/LTM405W

CONFIDENTIAL

LTM295W/LTM405W 3-1

CONFIDENTIAL

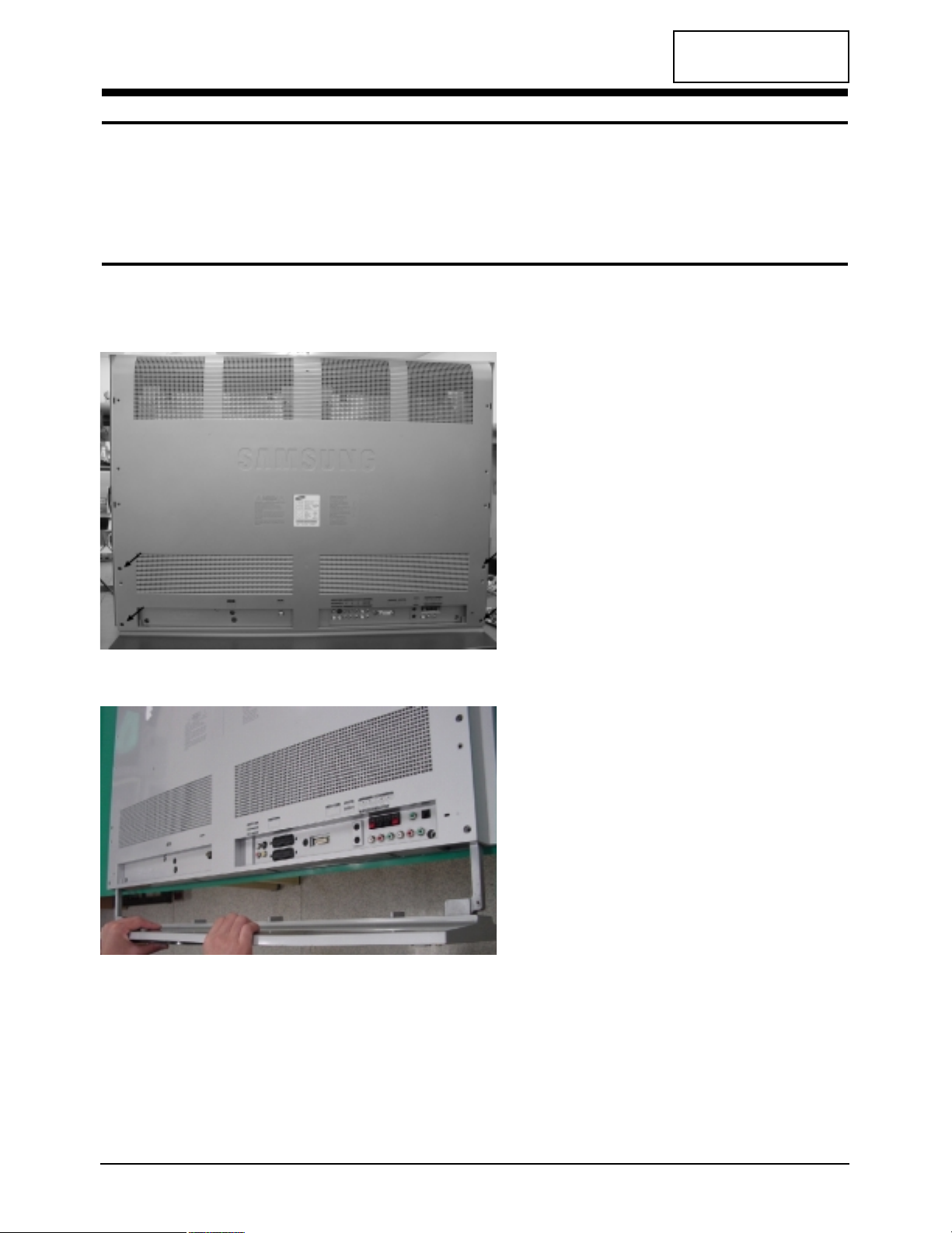

3 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

LTM295W/LTM405W monitor.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

3-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

1. Remove 4 screws of the cover rear.

2. Remove the stand from LCD-TV.

3 Disassembly and Reassembly

3-2 LTM295W/LTM405W

CONFIDENTIAL

3. Remove 4 screws of the cover rear.

4. Pull the cover rear.

3-2 Reassembly

Reassembly procedures are in the reverse order of Disassembly procedures.

CONFIDENTIAL

LTM295W/LTM405W 4-1

4 Alignments and Adjustments

This section of the service manual explains how to use the DDC JIG to adjust the black, red, green, and blue

levels of the FPD when you replace the AD Board, and how to update the microprocessor when you

change the Panel or Lamp(s).

4-1 General Alignment Instuction

1. Usually, a color TV-VCR needs only slight touch-up adjustment upon installation.

Check the basic characteristics such as height, horizontal and vertical sync.

2. Use the specified test equipment or its equivalent.

3. Correct impedance matching is essential.

4. Avoid overload. Excessive signal from a sweep generator might overload the front-end

of the TV. When inserting signal markers,do not allow the marker generator to distort

test result.

5. Connect the TV only to an DC power source with voltage and frequency as specified on

the backcover nameplate.

6. Do not attempt to connect or disconnect any wire while the TV is turned on. Make sure

that the power cord is disconnected before replacing any parts.

7. To protect aganist shock hazard,use an isolation transform.

Memo

4 Alignments and Adjustments

4-2 LTM295W/LTM405W

CONFIDENTIAL

CONFIDENTIAL

LTM295W/LTM405W 5-1

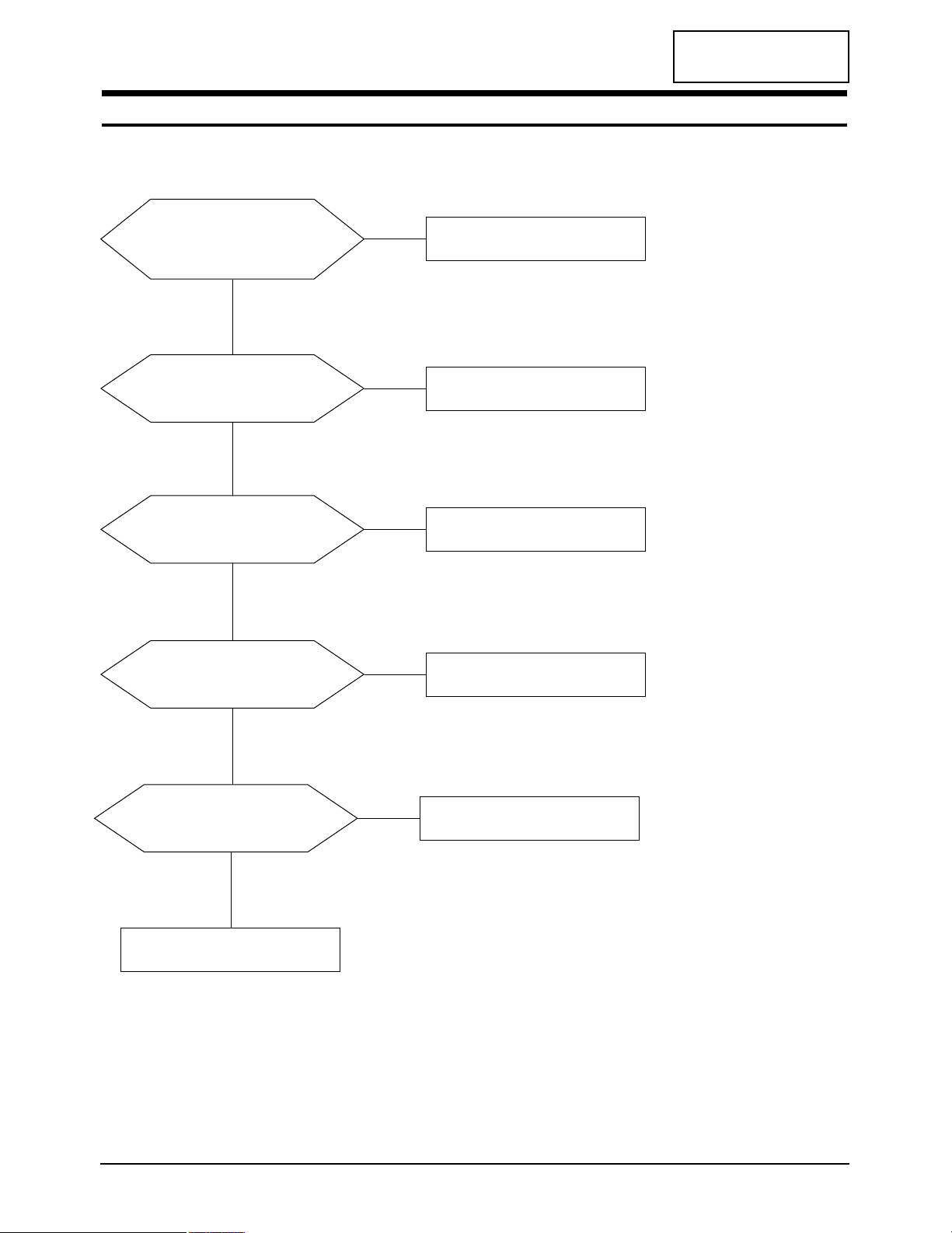

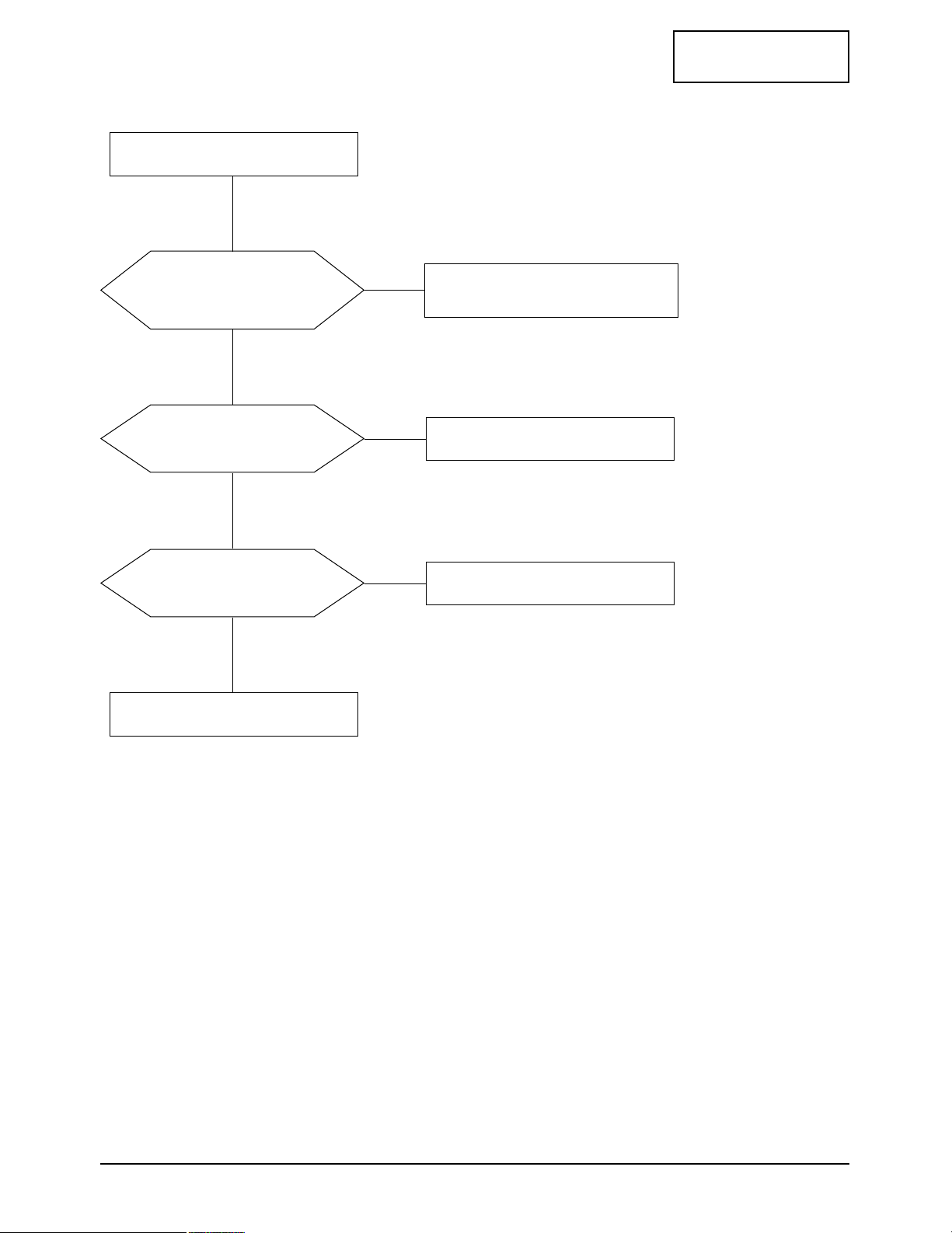

5 Troubleshooting

29”:Does proper DC 28 V appear

at DC jack connected to CN28?

40”:Does proper DC 28 V appear

at DC jack connected to CN29?

Check SMPS PCB and Adapter.

Yes

No

Does proper DC 5 V appear at

Pin 17 of CN201?

Check CN201 and related circuit.

Check IC963, IC906 and IC905.

Yes

No

Does proper DC 3.3 V

appear at Pin 2 of IC953,

IC954, IC956 and IC957?

Check IC953, IC954, IC956 and IC957

.

Yes

No

Does proper DC 2.5 V appear at

Pin 2 of IC961 and IC964?

Check IC961 and IC964.

Yes

No

Does proper DC 5 V appear at

Pin 2 of

IC952, IC955 and IC 958

?

Check IC952, IC955 and IC 958.

Yes

No

5-1 No Power

CONFIDENTIAL

5 Troubleshooting

5-2 LTM295W/LTM405W

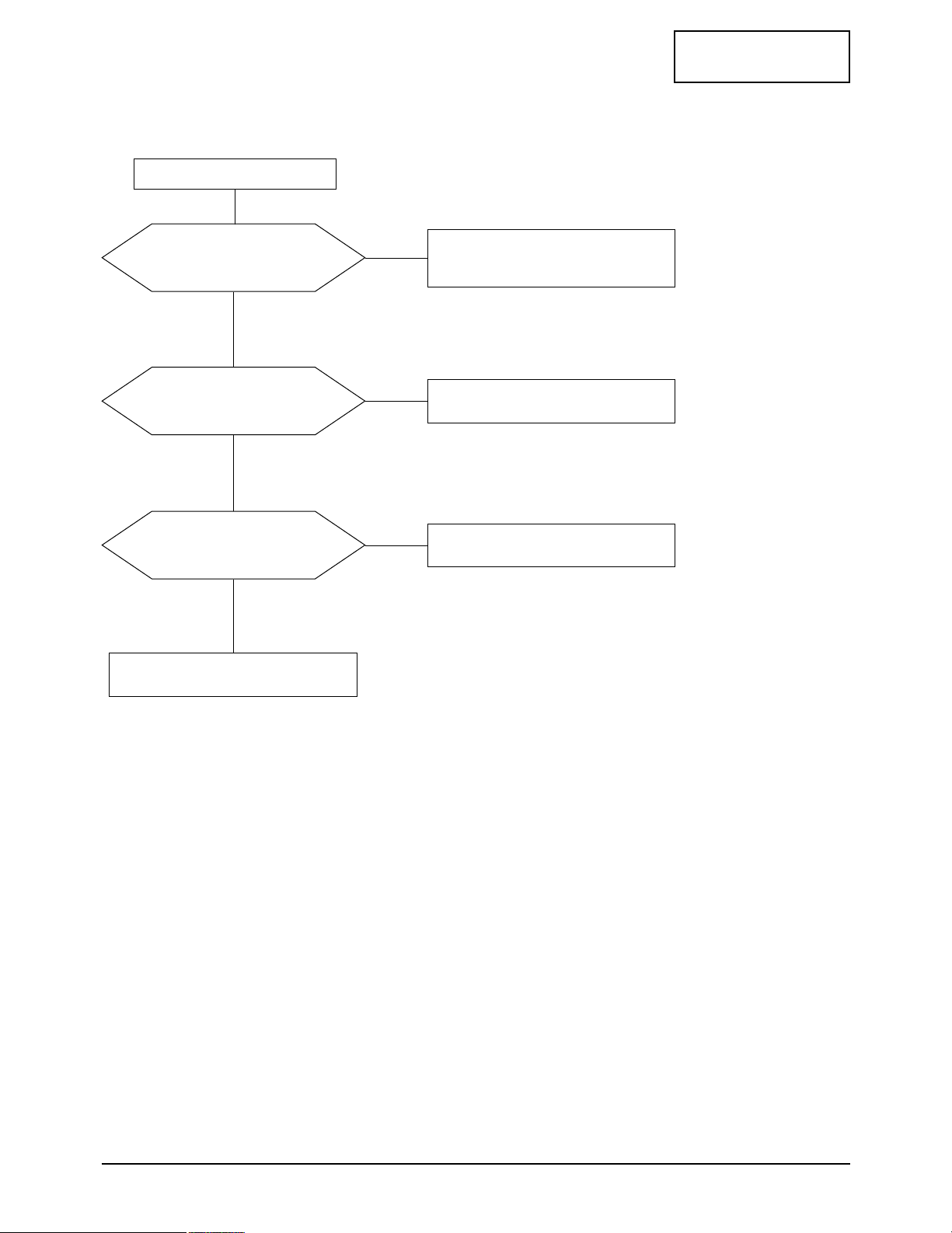

5-2 No Video (CVBS, S-Video)

Power indicator is green

Does the signal appear at

Pin 5, 9, 11 and 36 of IC1?

Check IC1.

Yes

No

Does the clock pulse appear at

Pin 6, 13 and Pin 69, 70 of IC302?

Check IC302 and related circuit.

Yes

No

Does the colck pluse

appear at R812, R813 and

H/V Sync pulse of IC801?

Check related circuit of IC801.

Yes

No

Replace LCD Panel.

CONFIDENTIAL

5 Troubleshooting

LTM295W/LTM405W 5-3

5-3 No Picture (PC Signal [Analog])

Check Pin 22 and 24 of CN201.

Check CN201 and related circuit.

Yes

No

Check Pin 66 and 67 of CN203.

Check IC203 and related circuit.

Yes

No

Does the colck pluse

appear at R619, R621 and

H/V Sync pulse of IC603?

Check IC603 and related circuit.

Yes

No

IC901 and IC903 and replace it.

CONFIDENTIAL

5 Troubleshooting

5-4 LTM295W/LTM405W

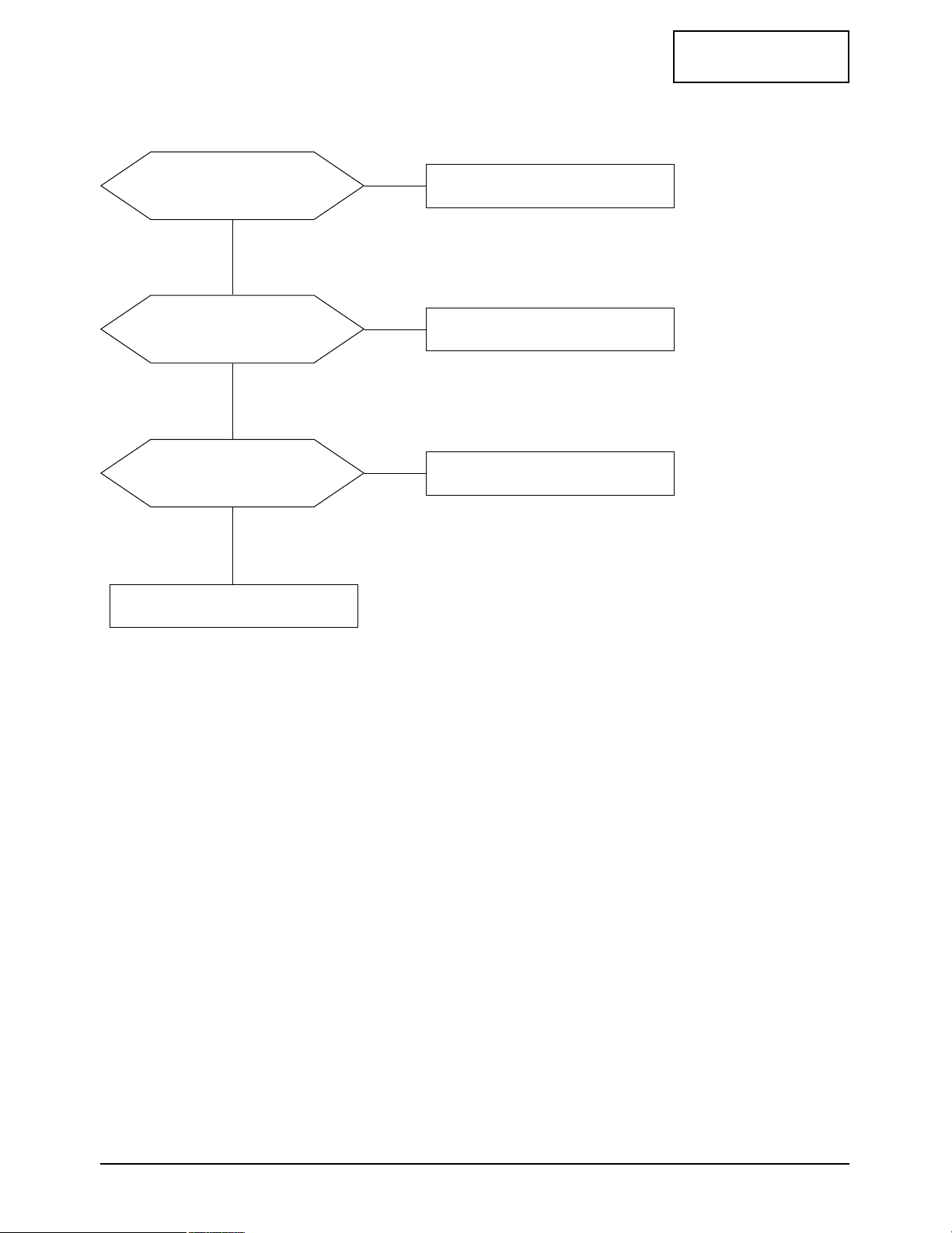

Does the signal appear at

Pin 47, 48, 50, 51, 53, 54, 56,

57 and 67 of IC503?

Check IC503 and related circuit.

Yes

No

Check Pin 10 and 13 of IC504?

Check IC504 and related circuit Q501.

Yes

No

Does the signal appear at

L502, L503, L504 and L505?

Replace L502, L503, L504 and L505.

Yes

No

29”:Check Speaker and CN2.

40”:Check Speaker and CN2.

5-4 No Sound (RF, PC, Video, Component)

CONFIDENTIAL

5 Troubleshooting

LTM295W/LTM405W 5-5

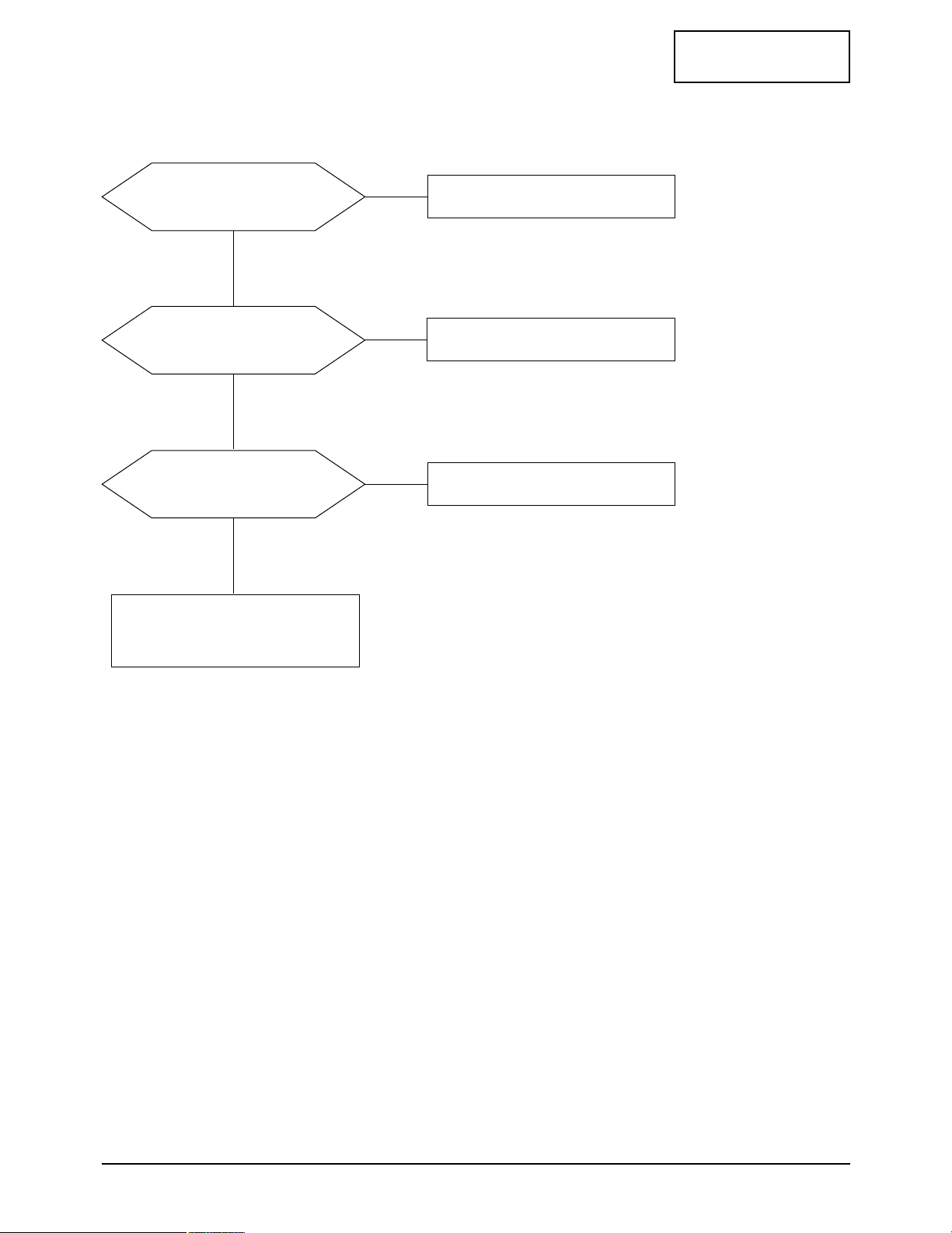

5-5 No Picture (DTV)

29”:Does the signal appear at

Pin 16, 18 and 20 of CN103?

40”:Does the signal appear at

Pin 16, 18 and 20 of CN3?

Check related circuit and

input signal of connector.

Yes

Yes

No

Dose the signal appear at

Pin 43, 48 and 54 of IC404?

Check IC404 and related circuit.

Yes

No

Dose the signal appear at

Pin 15, 19 and 21 of IC403?

Check IC403 and related circuit.

Yes

No

Check IC801 and related circuit.

Power inductor is green.

Memo

5 Troubleshooting

5-6 LTM295W/LTM405W

CONFIDENTIAL

CONFIDENTIAL

LTM295W/LTM405W 6-1

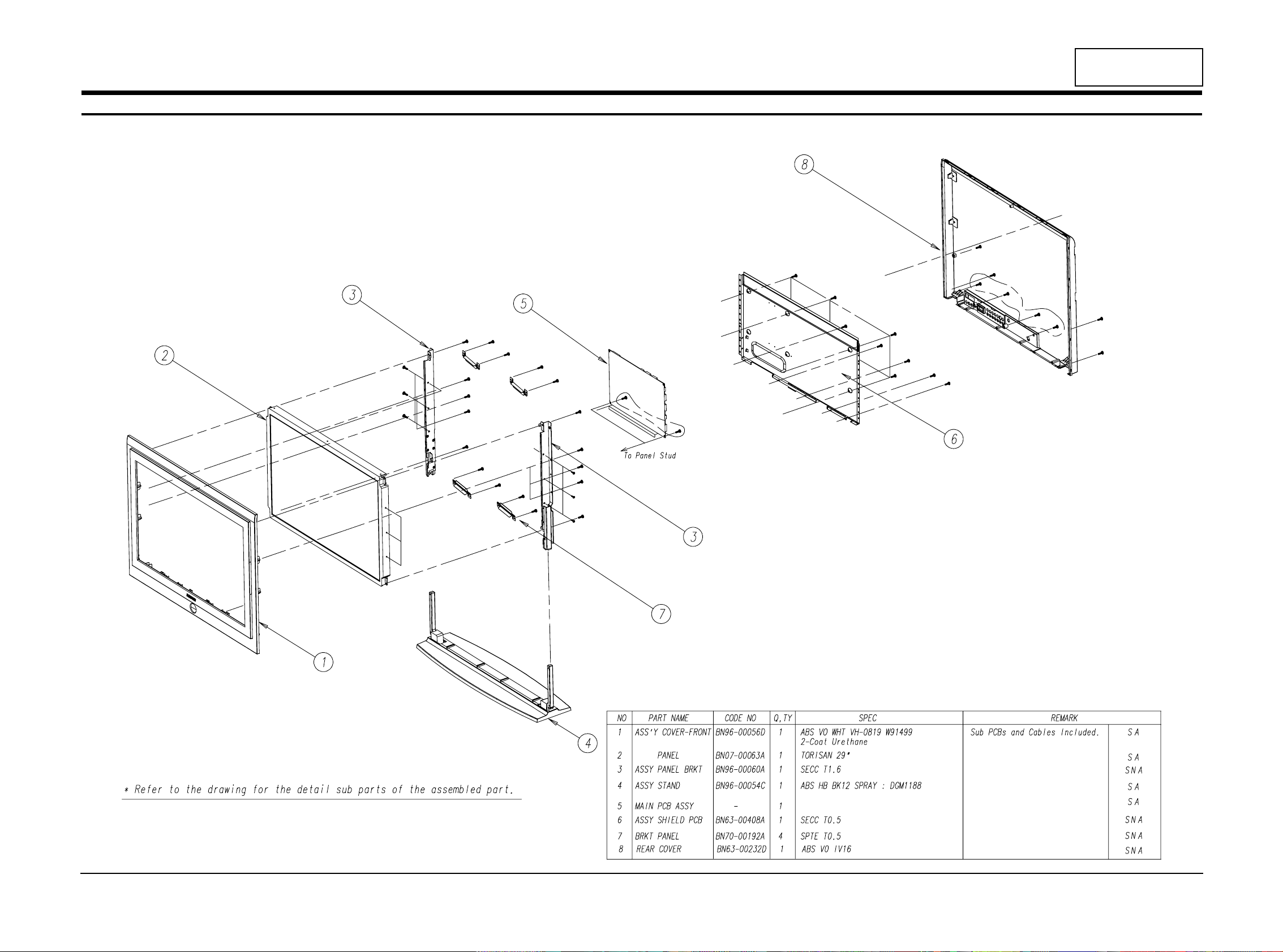

6 Exploded View and Parts List

6-1 LTM295W

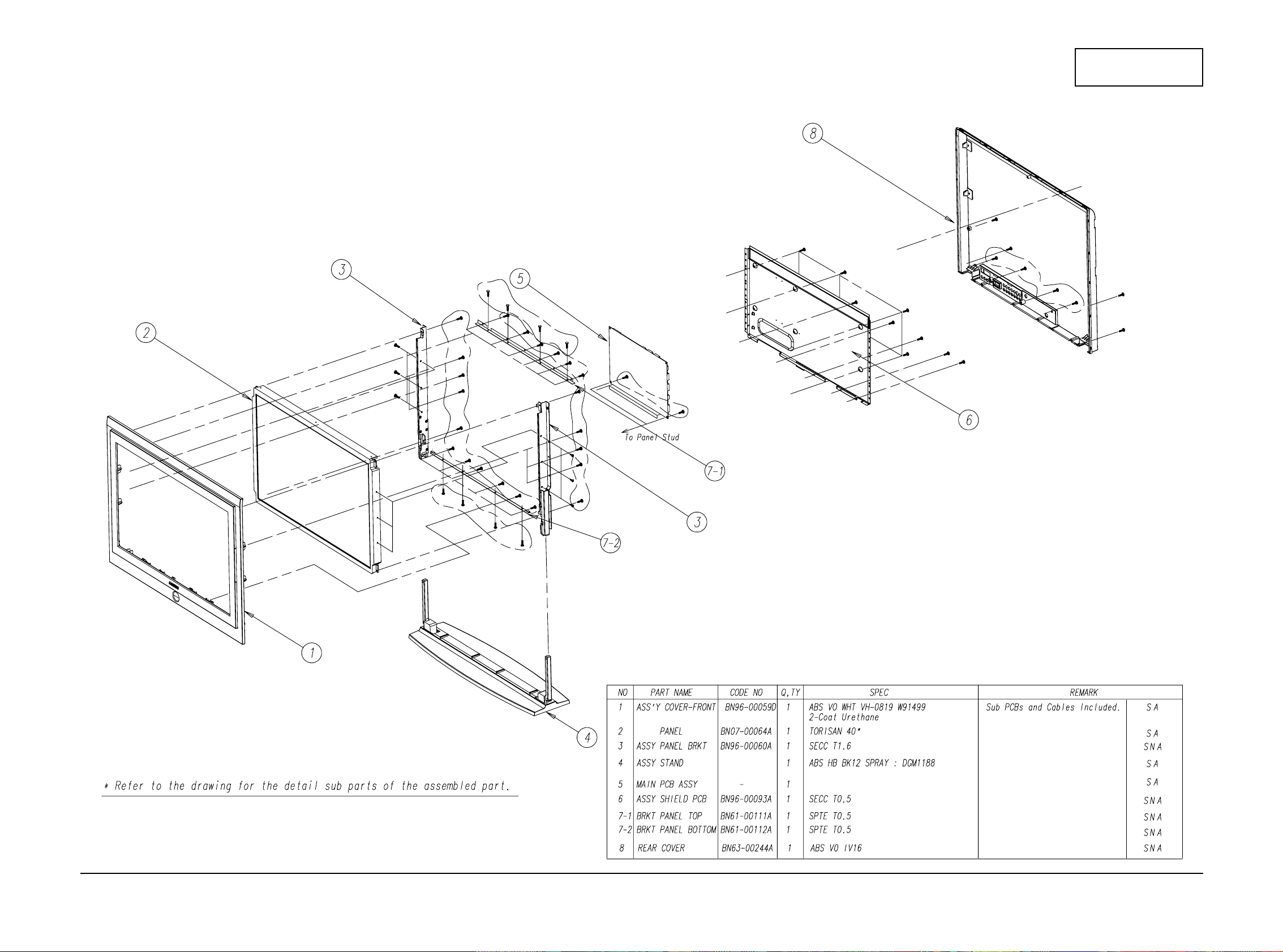

6-2 LTM405W

6 Exploded View & Parts List

6-2 LTM295W/LTM405W

CONFIDENTIAL

ItemNo DesignLOC 품명 Spec SERVICE

LTM295WX/XAA

RE-LTM295WX/XAA - 1 TORISAN,WX-71N31 BN90-00281A - ASSYSTAND AL29UO,U.S.A SNA

6003-001310 C/R+STAND SCREW-TAPTITE BH,+,B,M4,L16,ZPC(BLK),SWRCH18A SNA

BN96-00054C STD ASSYSTANDP APOLLO29,ABSVOGR81,DG-703P

BN90-00446A - ASSYCOVERFRONT AL29UO,U.S.A SNA

6003-000009 P/BRKT+C/F SCREW-TAPTITE BH,+,B,M4,L16,ZPC(YEL),SWRCH18 SNA

BN64-00101C C/F BADGE-BRAND AL29NO,AL,T1.5,11.5,65,DG-703P,SAMSUNG SNA

BN96-00056D C/F ASSYCOVERP-FRONT AL29UO,ABSVO,FORUSA

6003-001188 C/F SCREW-TAPTITE BH,+,B,M4,L10,YEL,SWRCH18A SNA

BN59-00290A C/F BOARD-FUNCTIONASS'Y AL29NO,CT5000-0600,FUNCTIONASS'Y

BN63-00230A C/F COVER-FRONT APOLLO29,ABS,V0,SILVER,SPRAY SNA

BN64-00061A C/F KNOB-RING APOLLO29,ABS,HB,CLEAR

BN64-00062A C/F KNOB-FUNCTION APOLLO29,ABS+PC,5V,SILVER

BN64-00101A C/F BADGE-BRAND APOLLO,AL,T1.5,11.5,65,SVM-2012,SAMSUNG SNA

BN67-00055A C/F LENS-LED APOLLO29,ACRYL,CLEAR SNA

BN67-00056A C/F LENS-MIRROR APOLLO29,ACRYL,CLEAR,ALCOATING

BN67-00070A C/F LENS-IR APOLLO29,ACRYL,CLEAR

BN90-00448A - ASSYCOVERREAR AL29UO,U.S.A SNA

6003-001003 C/F+C/R SCREW-TAPTITE BH,+,B,M4,L12,ZPC(BLK),SWRCH18

BN63-00232D C/R COVER-REAR AL29UO,ABS+PC,USA SNA

BN91-00388A - ASSYLCD AL29NO SNA

BN07-00063A CIS LCD TM290WX-71N31,RS24NS,6BITFRC,684.0*426.5*45.0,16.7M,40,0.4935*0.4935,040,5.0,T

BN91-00518A - ASSYMISC AL29/40UO,U.S.A SNA

BN44-00067C CIS ADAPTOR PSCV22101B,AMERICA,APPOLLO,100-240V,47-63HZ,28VDC,8ADC,224W,AMERICA,ULAREA

BN91-00552A - ASSYCHASSIS AL29UO,U.S.A

BN94-00403A - ASSYPCBMAIN AL29UO,U.S.A SNA

0202-001044 CIS01 SOLDER-WIRE. S63S-W3.0,S63S,D3,63Sn/37Pb,- SNA

0202-001172 CIS03 SOLDER-WIREFLUX RS-107,RS60,D1.2,SN60/PB40,- SNA

0204-001096 CIS04 ETHANOL ISO-PROPYLENE,C2H50H,99.8%,- SNA

0204-001527 CIS05 FLUX DF-201TVS,MIX,0.820,FLUX13%,14KG SNA

1001-001037 IC1 IC-RF/VI/AUDIOS/W TA8851CN,-,DIP,54P,600MIL,SING

2801-003224 X102 CRYSTAL-UNIT 32.768KHz,20ppm,28-AAY,12.5pF,

3711-003846 CN950 CONNECTOR-HEADER BOX,8P,1R,2mm,ANGLE,SN SNA

3711-004123 CN501 CONNECTOR-HEADER BOX,15P,1R,2mm,ANGLE,SN SNA

3711-004261 CN2 CONNECTOR-HEADER BOX,12P,1R,2MM,ANGLE,SN SNA

6001-000677 CIS06 SCREW-MACHINE RH,+,M3,L6,ZPC(YEL),SM20C,- SNA

BN27-00012A L901 COILCHOKE 5UH,APPOLO,5UH,10%,0.01OHMMAX,10A,PEI3210S,1T,40X70X25MM,BK,-10CTO+85C

BN73-00025A CIS07 RUBBERCUSHION AL29NO,CR,10*15,60,T4,BLACK,3M#9448 SNA

BN96-00093A CIS08 ASSYMISCP-SHIELD/D-SUB AL29NO,SPTET0.5 SNA

BN97-00164P CIS09 ASSYMICOM AL29UO,U.S.A

1102-001108 IC105 IC-EPROM 27C020,256Kx8Bit,PLCC,32P,495MIL,70nS,5V,10%,PLASTIC,0to+70C,100uA,CMOS,TR

BN82-00075U CIS A/SMICOM AL29UO,U.S.A SNA

BN97-00174A - ASSYSMD PD22EO,EUROPE SNA

Page1

0202-001162 CIS02 SOLDER-CREAM RMA-20-21L,S63,-,SN63/PB36.6/AG0.4,FLUX9.5% SNA

0401-001056 D1 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D2 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D3 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D401 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D402 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D403 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D404 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D405 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D406 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D501 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D502 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D503 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D504 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D505 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D506 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D507 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D508 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D6 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D7 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D8 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D9 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001116 D201 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D202 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D203 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D204 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D205 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D206 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D207 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0401-001116 D208 DIODE-SWITCHING BAV99DW,75V,150MA,SOT-363,TP

0402-000553 ZD901 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD950 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD951 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD952 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD953 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD954 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-000553 ZD955 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0403-000579 ZD1 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD2 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD201 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD202 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD203 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD204 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD205 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD206 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD207 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD208 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

Page2

0403-000579 ZD209 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD210 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD501 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 ZD505 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-001052 ZD502 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 ZD503 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 ZD504 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 ZD506 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 ZD507 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0404-001055 D902 DIODE-SCHOTTKY -,60V,3000MA,SMC,TP

0404-001055 D903 DIODE-SCHOTTKY -,60V,3000MA,SMC,TP

0404-001084 D901 DIODE-SCHOTTKY BAT54A,30V,200MA,SOT-23,TP

0501-000280 Q1 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q10 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q11 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q13 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q16 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q4 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q5 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q7 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-000280 Q8 TR-SMALLSIGNAL KSA1182,PNP,150mW,SOT-23,TP,70

0501-002080 Q101 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q12 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q14 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q15 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q2 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q3 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q301 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q501 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q6 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q901 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q906 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q950 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q951 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q952 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q953 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q954 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q955 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q956 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0505-000275 IC905 FET-SILICON SI4435DY,P,-30V,+-8.0A,0.014ohm,2.5W,SO-8

0505-001170 IC963 FET-SILICON SI9933ADY-T1,P,-20V,3.4A,0.06ohm,2W,SO-8

0505-001662 Q904 FET-SILICON FDB5645,N,60V,80A,0.0095OHM,125W,TO-263AB

0505-001662 Q905 FET-SILICON FDB5645,N,60V,80A,0.0095OHM,125W,TO-263AB

0505-001663 Q902 FET-SILICON FQB50N06L,N,60V,52.4,0.021OHM,3.75W,D-PAK

0505-001663 Q903 FET-SILICON FQB50N06L,N,60V,52.4,0.021OHM,3.75W,D-PAK

0801-002267 IC205 IC-CMOSLOGIC 74LCX14,-,SOIC,14P,150MIL,-,TP,-,-,-,3.6V,-40TO+85C,-,5.5V,-,-,24MA

0801-002267 IC604 IC-CMOSLOGIC 74LCX14,-,SOIC,14P,150MIL,-,TP,-,-,-,3.6V,-40TO+85C,-,5.5V,-,-,24MA

Page3

0801-002268 IC110 IC-CMOSLOGIC 74VHC139,DECODER,SOP,16P,150MI

0801-002394 IC107 IC-CMOSLOGIC 74LCX32,ORGATE,SOIC,14P,150MI

0801-002394 IC112 IC-CMOSLOGIC 74LCX32,ORGATE,SOIC,14P,150MI

0801-002559 IC104 IC-CMOSLOGIC 74LVX74,DFLIP-FLOP,TSSOP,14P,173MIL,DUAL,TP,PLASTIC,-,-,0.36V,-40to+85C,180mW,2

0801-002559 IC405 IC-CMOSLOGIC 74LVX74,DFLIP-FLOP,TSSOP,14P,173MIL,DUAL,TP,PLASTIC,-,-,0.36V,-40to+85C,180mW,2

0801-002574 IC106 IC-CMOSLOGIC 74LVX04,INVERTER,SOP,14P,150MIL,HEX,TP,PLASTIC,-,-,0.36V,-40to+85C,180mW,2.4V,20

0801-002576 IC109 IC-CMOSLOGIC 74LVX373,LATCH,SOP,20P,300MIL,OCTAL,TP,PLASTIC,3-STATE,-,0.36V,-40to+85C,180mW,2

0903-001202 IC103 IC-MICROCONTROLLER 80251G2,8Bit,PLCC,44P,653MIL,24MHz,TR,CMOS,PLASTIC,5V,1.5W,0to+70C,1KBYTE,-,24Bi SNA

0909-001037 IC111 IC-REALTIMECLOCK M41ST84YMQ6TR,64BIT,SO16,16P,21.21X14.22MM,400KHZ,TP,CMOS,PLASTIC,-,1W,-40TO+85C

1001-001082 IC306 IC-VIDEOSWITCH BA7657F,-,SOP,24P,300MIL,SINGL

1001-001082 IC403 IC-VIDEOSWITCH BA7657F,-,SOP,24P,300MIL,SINGL

1001-001146 IC304 IC-ANALOGSWITCH FST3257,BUSSWITCH&CMOS,SOP,16P,150MIL,QUAD,5.5V,-40to+85C,PLASTIC,-,15ohm,-,1001-001146 IC406 IC-ANALOGSWITCH FST3257,BUSSWITCH&CMOS,SOP,16P,150MIL,QUAD,5.5V,-40to+85C,PLASTIC,-,15ohm,-,1001-001146 IC701 IC-ANALOGSWITCH FST3257,BUSSWITCH&CMOS,SOP,16P,150MIL,QUAD,5.5V,-40to+85C,PLASTIC,-,15ohm,-,1001-001190 IC702 IC-ANALOGSWITCH FST16233MTD,BUSSWITCH,TSSOP,56P,240MIL,-,5.5V,-40TO+85C,PLASTIC,-,20OHM,8.5NS,7

1002-001292 IC203 IC-A/DCONVERTER AD9883AKST-110,8BITS,QFP,80P,551MIL,±0.5LSB,TR,CMOS,PLASTIC,3.3V,-25TO+85C,650M

1002-001292 IC404 IC-A/DCONVERTER AD9883AKST-110,8BITS,QFP,80P,551MIL,±0.5LSB,TR,CMOS,PLASTIC,3.3V,-25TO+85C,650M

1103-000129 IC207 IC-EEPROM 24C02,256x8BIT,SOP,8P,150MIL,1

1103-001223 IC102 IC-EEPROM 24C16,2048x8Bit,SOP,8P,150MIL,10mS,2.7V,-,PLASTIC,0to+70C,4uA,CMOS,TP

1105-001336 IC601 IC-DRAM 4S643232,512Kx32x4Bit,TSOP,86P,400MIL,60nS,3.3V,10%,PLASTIC,0to+70C,2mA,CMOS,TP

1105-001336 IC602 IC-DRAM 4S643232,512Kx32x4Bit,TSOP,86P,400MIL,60nS,3.3V,10%,PLASTIC,0to+70C,2mA,CMOS,TP

1105-001336 IC704 IC-DRAM 4S643232,512Kx32x4Bit,TSOP,86P,400MIL,60nS,3.3V,10%,PLASTIC,0to+70C,2mA,CMOS,TP

1105-001336 IC802 IC-DRAM 4S643232,512Kx32x4Bit,TSOP,86P,400MIL,60nS,3.3V,10%,PLASTIC,0to+70C,2mA,CMOS,TP

1105-001336 IC803 IC-DRAM 4S643232,512Kx32x4Bit,TSOP,86P,400MIL,60nS,3.3V,10%,PLASTIC,0to+70C,2mA,CMOS,TP

1201-001495 IC505 IC-AUDIOAMP 7050,SOP,8P,150MIL,DUAL,26DB,PLASTIC,6V,0.25W,-,40DB,-,-,20NA,1201-001681 IC504 IC-AUDIOAMP 1101,SOP,30P,433MIL,-,-,PLASTIC,13.2V,-,0to+70C,-,-,-,-,-,TP

1203-001432 IC904 IC-POSI.FIXEDREG. 78M12,DPAK,3P,-,PLASTIC,11.5/1

1203-001448 IC901 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001448 IC951 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001448 IC952 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001448 IC955 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001448 IC958 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001465 IC950 IC-POSI.ADJUSTREG. 317,TO-263,3P,-,PLASTIC,1.2/37

1203-001465 IC961 IC-POSI.ADJUSTREG. 317,TO-263,3P,-,PLASTIC,1.2/37

1203-001465 IC964 IC-POSI.ADJUSTREG. 317,TO-263,3P,-,PLASTIC,1.2/37

1203-001488 IC502 IC-POSI.FIXEDREG. 7805,T0-252,3P,-,PLASTIC,4.8/5

1203-001559 IC101 IC-RESET DS1834,SOIC,8P,150MIL,-,1.2/5V

1203-001815 IC959 IC-POSI.FIXEDREG. 78M09,TO-252,3P,-,PLASTIC,8.6/9.4V,1.0W,-40TO+85C,0.5A,-,TP

1203-001815 IC960 IC-POSI.FIXEDREG. 78M09,TO-252,3P,-,PLASTIC,8.6/9.4V,1.0W,-40TO+85C,0.5A,-,TP

1203-001816 IC501 IC-POSI.FIXEDREG. 78M08,TO-252,3P,-,PLASTIC,7.7/8.3V,1.0W,-40TO+85C,0.5A,-,TP

1203-002067 IC201 IC-POSI.FIXEDREG. 3330,SOT-23,6P,65MIL,PLASTIC,3.284/3.316V,-,-40to+125C,200mA,-,TP

1203-002067 IC202 IC-POSI.FIXEDREG. 3330,SOT-23,6P,65MIL,PLASTIC,3.284/3.316V,-,-40to+125C,200mA,-,TP

1203-002067 IC206 IC-POSI.FIXEDREG. 3330,SOT-23,6P,65MIL,PLASTIC,3.284/3.316V,-,-40to+125C,200mA,-,TP

1203-002067 IC401 IC-POSI.FIXEDREG. 3330,SOT-23,6P,65MIL,PLASTIC,3.284/3.316V,-,-40to+125C,200mA,-,TP

1203-002067 IC402 IC-POSI.FIXEDREG. 3330,SOT-23,6P,65MIL,PLASTIC,3.284/3.316V,-,-40to+125C,200mA,-,TP

1203-002191 IC906 IC-DC/DCCONVERTER LTC1778,SSOP,16P,153MIL,PLASTIC,-,-,125C,-,-,TP

1203-002199 IC962 IC-POSI.FIXEDREG. LM2596,TO-263,5P,340MIL,PALSTIC,-,-,-40TO+125C,-,-,ST

Page4

Loading...

Loading...